Page 1

APPLICATION

TS-8201-105

TS-8201-110

TS-8501

TS-8241

TS-9201-106

TS-9400 Series

Electronic sensing of temperature at remote room locations, ducts, plenum chambers, liquid lines, tanks, outdoor air, and similar applications.

TS-8000 Series

TS-9000 Series

Electronic Remote Temperature Sensors

General Instructions

TS-8204

TS-8131

SPECIFICATIONS

TS-8261

TS-9201

Sensing Element: Balco resistance, 1000 ohms ±0.1% at 70oF (21oC); TS-9405, TS-9422: ±

1% at 70°F (21°C). Changes 2.2 ohms per 1 F°(0.5 C°) at 70°F (21°C). TS-8204 only: 1657 ohms

±0.1% at 300°F (149°C); changes 2.5 ohms per 1 F°(0.5 C°) at 300°F (149°C).

Note: TS-8204 is not compatible with internal setpoints of controllers (except for differential

control), TSP-8101 or TSP-8111 temperature transmitters. Order AT-8435, 200 to 400°F (93 to

204°C) when setpoint is required.

See Tables 1 and 2 for additional specifications.

ACCESSORIES

AT-208 Duct mounting kit for TS-8201-105 (included with TS-8204).

AT-211 Outdoor bulb shield.

AT-215 Stainless steel bulb well for TS-9201, TS-8201-105 or TS-8204.

AT-225 Stainless steel bulb well for TS-9201-106.

AT-226 High pressure brass well.

AT-8435 Remote setpoint adjuster, dual scale 200 to 400

required for all TS-8204 applications except differential control.

°F (93 to 204°C):

Printed in U.S.A. 11/10 Copyright 2010 Schneider Electric All Rights Reserved. F-22668-7

Page 2

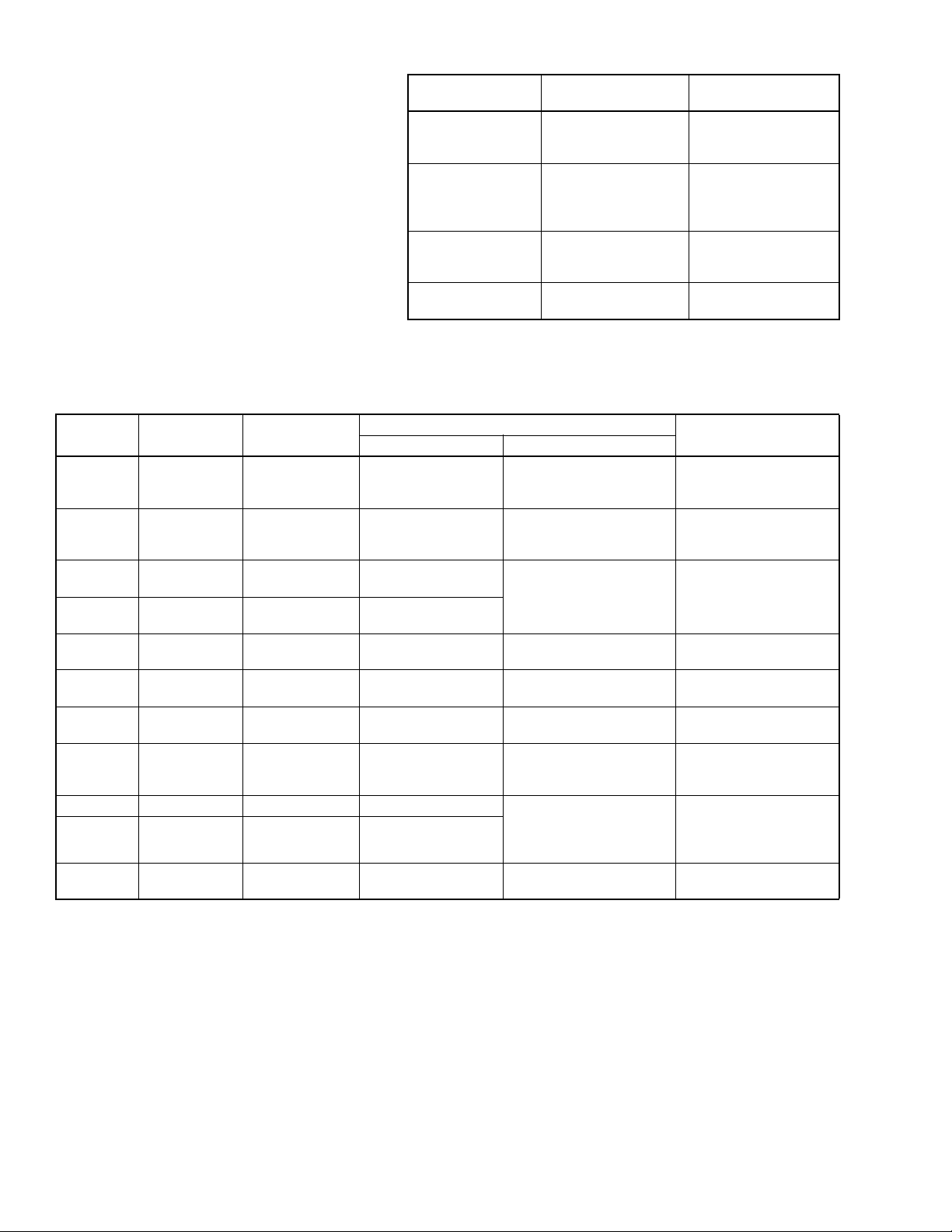

Table-1 AMBIENT TEMPERATURE LIMITS.

Part Number

TS-8131

TS-8241

TS-8261

a

a

a

Shipping & Storage

TS-9201

TS-8201-105

TS-9201-106

(-40 to 121)

TS-8201-110

TS-9405

TS-9422

TS-8501

TS-8204

a

Humidity, 5 to 95% RH, non-condensing.

(-40 to 104)

(-40 to 204)

°F (°C)

-40 to 160

(-40 to 71)

-40 to 250

-40 to 220

-40 to 400

Operating

°F (°C)

-40 to 140

(-40 to 60)

-40 to 250

(-40 to 121)

-40 to 220

(-40 to 104)

200 to 400

(93 to 204)

Table-2 SPECIFICATIONS.

Part

Number

TS-8131 Unitary

Description

a

TS-8201-105 Duct/Immersion

TS-9201 Duct/Immersion

TS-9201-106 Immersion

c

TS-8201-110 Strap-on Nylon Wire Tie

TS-8204 Duct/Immersion

TS-8241 Ceiling Diffuser

Combination

TS-8261

Light Fixtures &

Ceiling Diffuser

Mounting

Connection

7/32" (13.5 mm)

dia.

Mounting Hole

b

1/4" NPT Nut

b

Flange, 1/4” NPT

1/4" NPT Nut

1/4" NPT Nut

b

AT-208 included

7/16" (11.1 mm)

Mounting Hole

None

3/4 dia. x 1-1/4 long

b

c

d

e

1/4 dia. x 8 long

1/4 dia. x 6 long

b

1/4 dia. x 4 long

1/4 dia. x 2-1/4 long

1/4 dia. x 8 long

1-5/8 dia. x 1-3/4 long

1/4 dia. x 8-1/8 long

Element Wiring Enclosure

(19 x 32)

(6 x 203)

(6 x 152)

(6 x 102)

(6 x 57)

(6 x 203)

(41 x 44)

(6 x 206)

TS-9405 Averaging (Duct) Flange 5 ft(1.5 m) long 2-7/8 H x 2-3/8 W x 1-1/2 D

TS-9422 Averaging (Duct) Flange 22 ft(6.7 m) long

TS-8501 Outdoor 1/2" Conduit

a

For mounting through fan coil of unit ventilator cabinet or similar application.

b

Immersion requires AT-215 or AT-226 bulb well.

c

Immersion requires AT-225 bulb well.

d

Factory supplied 2-1/2 x 2 in. (64 x 51 mm) foam insulation tape and 30 in. (762 mm) nylon wire tie for 1-1/2 thru 8 in. (38 thru 203 mm) diameter pipes.

e

AT-255 bulb well included.

1-1/8 dia. x 5 long

(29 x 127)

Dimensions in. (mm)

2-7/8 H x 2-3/8 W x 1-1/2 D

(73 x 60 x 38) wi

e

xtension to element; 1/2"

knockout (top)

(73 x 60 x 38) wi

e

xtension to element; 1/2"

knockout (top)

Wiring Connections

None 1/4 in. Spade Connections

10 ft (3 m) Armored

None

Capillary with additional

6"(152 mm) leads

th 2-1/2 (64)

12 in. (305 mm) Black

Pigtail Leads

None

None

ne

No

None

th 2-1/2 (64)

12 in. (305 mm) Black

Pigtail Leads

16 in. (401 mm) Yellow

Pigtail Leads

20 ft (6.1 m) Black Pigtail

Leads

6 ft (1.8 m) Black Pigtail

Leads

12 in. (305 mm) Black

Pigtail Leads

None

3 ft (0.9 m) Black Pigtail

Leads

2 Copyright 2010 Schneider Electric All Rights Reserved F-22668-7

Page 3

INSTALLATION

1-3/16 (30)

Dimensions shown

are in inches (mm).

5/32 (4.0)

1/4 (6)

1/2

(12)

13/16

(21)

1/2

(12)

3/64 x 3/16

(1.2 x 4.8)

Tabs (2)

Requires

17/32 (13.5) Dia.

Mounting Hole

Inspection

Visually inspect the carton for damage. If damaged, notify the appropriate carrier

immediately. If undamaged, open the carton and visually inspect the device for obvious

defects. Return damaged or defective products.

Required Installation Items

• Wiring diagrams

• Tools (not provided):

– DVM (digital volt/ohm meter)

– Appropriate screwdriver for mounting screws and terminal connections

– Appropriate drill and drill bit for mounting screws

• Appropriate accessories

• Mounting screws, (2) #10 x 3/4" sheet metal, provided for TS-9201, TS-9405 and

TS-9422 (TS-8204 contains mounting screws in AT-208 kit)

Caution: Installer must be a qualified, experienced technician. Make all connections in

accordance with the wiring diagram, and in accordance with national and local electrical

codes. Do not exceed the ratings of the device.

Mounting

Caution: Avoid locations where excessive vibration, moisture, corrosive fumes or vapors

are present.

TS-8131 Unitary Sensor

TS-9201 Duct/Immersion Sensor

1. Determine the sensor mounting location (Figure-1).

2. Drill 17/32" (13.5 mm) diameter mounting hole.

3. Insert gasket to base of sensor “button”.

4. Insert sensor with gasket into mounting hole.

5. Secure sensor to mounting flange or surface by inserting Tinnerman nut over back of sensor.

6. Two crimp wire receptacles are provided for spade terminal connection to field wiring.

Figure-1 TS-8131 Mounting Dimensions.

Duct

Note: Hand tighten only - do not overtighten.

1. Determine the sensor mounting location on the duct (predetermine the knockout hole

F-22668-7 Copyright 2010 Schneider Electric All Rights Reserved 3

location for routing of conduit). The sensing element is located within 1 inch of the end of

the sensing probe, and it should be in the air stream at a location that is typical of the

temperature requiring sensing. Approximately 3" of length adjustment is available.

Page 4

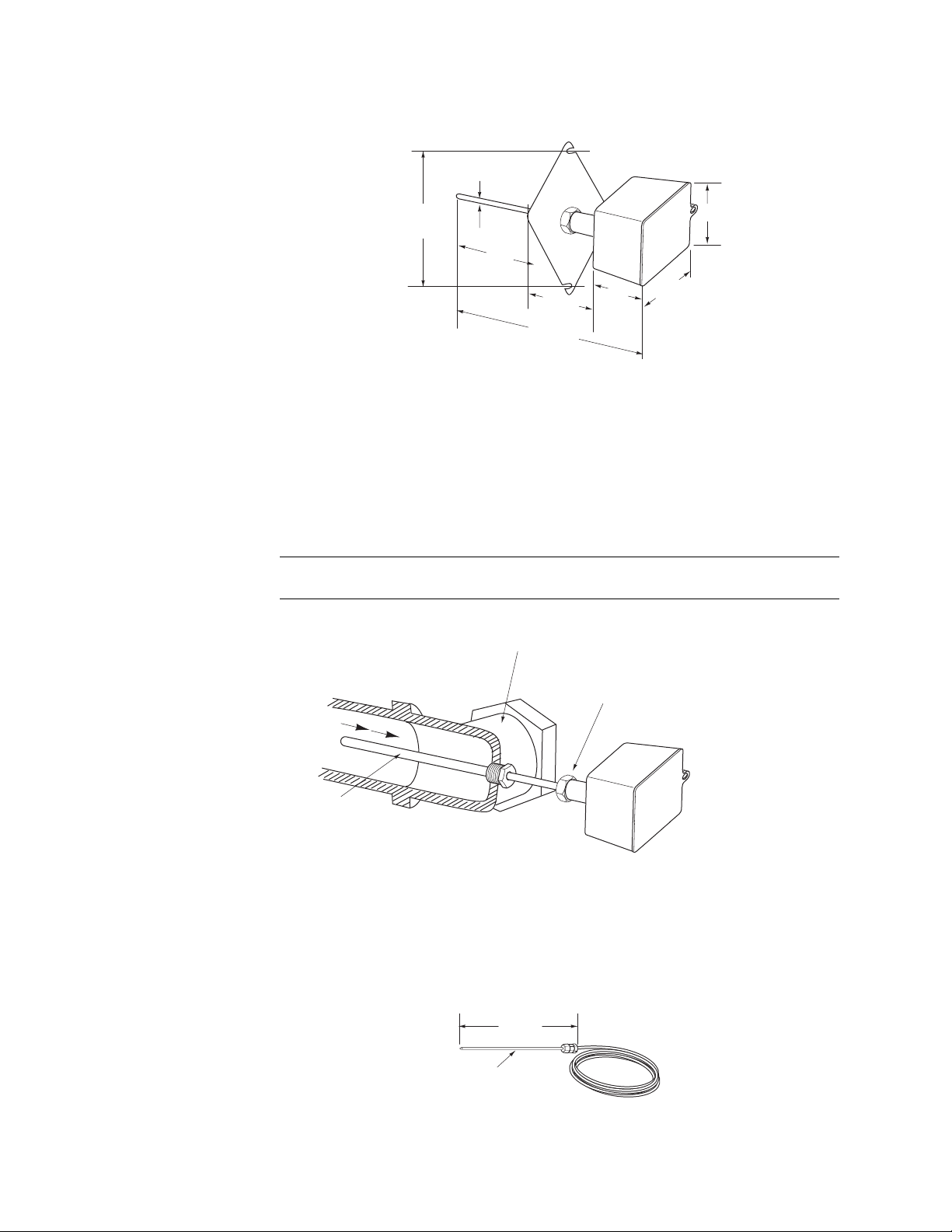

2. Use the mounting flange supplied as a template (or refer to Figure-2 for duct mounting

3-25/64

(86)

Dimensions shown

are in inches (mm).

13 (330)

1-5/8

(41)

2-5/16 (59)

1/4 (6) O.D.

8

(203)

2-1/2

(64)

2-1/2

(64)

Enclosure

Sensor Mounting Nut

Tee or Elbow for Mounting Well

Flow

Well

AT-225

8"

(203 mm)

1/4" (6 mm) dia.

dimensions) for mounting hole location.

3. Mount the sensor to the duct using the two #10 x 3/4” sheet metal screws provided.

Figure-2 TS-9201 Mounting Dimensions.

Immersion (Requires AT-215 Bulb Well)

1. Remove lock nut and duct mounting flange from sensor (Figure-3).

2. Thread the sensor into AT-215 bulb well that has been installed in a liquid line or tank.

TS-8201-105 Duct/ Immersion Sensor

4 Copyright 2010 Schneider Electric All Rights Reserved F-22668-7

Note: The AT-215 bulb well should be filled with a temperature conductive grease (TAC part

number M-500) prior to element insertion, for optimum medium temperature sensing.

Figure-3 TS-9201 Immersion Mounting.

Duct (Requires AT-208 Duct Kit)

1. Determine the sensor mounting location on the duct. The sensing element is located within 1 inch of the end of the sensing probe and it should be located in the air stream typical of the temperature requiring sensing (see Figure-4).

Figure-4 TS-8201-105 Mounting Dimensions.

2. Drill insertion and mounting holes for AT-208 in the duct wall (see Figure-5).

Page 5

3. Mount the sensor the duct using the AT-208 kit.

AT-208 Bracket, Gasket and Mounting Screws

1/2 (13) Dia.

1/8 (3.2) Dia.

TS-8201-110 Strap-on Sensor

1/8 (3.2)

1 (25)

Full Scale - May be used as a template.

1 (25)

Dimensions shown

are in inches (mm).

Figure-5 AT-208 Mounting Dimensions.

Immersion (Requires AT-215 Bulb Well)

Thread the sensor into AT-215 bulb well that has been installed in a liquid line or tank.

Note: The AT-215 bulb well should be filled with a temperature conductive grease (TAC part

number M-500) prior to element insertion, for optimum medium temperature sensing.

1. Foam insulation tape should be placed over the sensor (Figure-6). Extend insulation beyond the ends of the sensor.

2. Secure sensor and foam insulation tape to pipe with wire tie (factory supplied) or metal hose clamp (not included).

Caution: Do not tighten clamp or nylon tie (or metal hose clamp) to the point of distorting

the sensor. Overtightening fasteners will cause a shift in sensed temperature.

Sensor Leads

TS-8201-110

Pipe

Foam Insulation Tape

Wire Tie (factory supplied) or

Metal Hose Clamp (field supplied)

Figure-6 TS-8201-110 Strap-On Sensor Installation.

TS-9201-106 Immersion Sensor

Thread the sensor into AT-225 bulb well that has been installed in a liquid line or tank (see

Figure-7).

Note: The AT-225 bulb well should be filled with a temperature conductive grease (TAC part

number M-500) prior to element insertion, for optimum medium temperature sensing.

F-22668-7 Copyright 2010 Schneider Electric All Rights Reserved 5

Page 6

Figure-7 TS-9201-106 Immersion Mounting.

Enclosure

Sensor Mounting Nut

Tee or Elbow for Mounting Well

Flow

Well

AT-225

Sensor Mounting Nut

Tee or Elbow for Mounting Well

Flow

Well

AT-225

TS-8204 Duct/Immersion Sensor

Duct (Requires AT-208 Duct Kit)

1. Determine the sensor mounting location on the duct. The sensing element is located within 1" of the end of the sensing probe and it should be located in the air stream typical of the temperature requiring sensing (see Figure-8).

2. Drill insertion and mounting holes for AT-208 in the duct wall (see Figure-5).

3. Mount the sensor to the duct using the AT-208 kit.

Immersion (Requires AT-215 Bulb Well)

Thread the sensor into AT-215 bulb well that has been installed in a liquid line tank.

Note: The AT-215 bulb well should be filled with a temperature conductive grease (TAC part

number M-500) prior to element insertion, for optimum medium temperature sensing.

1/4

(6)

Figure-8 TS-8204 Mounting Dimensions.

8

(203)

Dimensions shown

are in inches (mm).

TS-8241 Duffuser The sensor should be mounted to the face of the ceiling diffuser so that it projects downward

into the room (see Figure-10).

1. Drill a 7/16" (11.1 mm) diameter mounting hole in the diffuser face.

Figure-9 TS-8204 Immersion Mounting.

2. Insert the threaded end of the sensor into the mounting hole.

3. Secure the sensor to the diffuser face using the mounting nut and lock washer provided.

6 Copyright 2010 Schneider Electric All Rights Reserved F-22668-7

Page 7

If the diffuser has an adjustable pattern, the discharge air direction must be adjusted to a

Induced Room Air

Discharge Air

TS-8241

horizontal pattern. This horizontal pattern will insure a representative sample of room air

over the element (see Figure-11). The sensor will not perform satisfactorily if the discharge

is adjusted to a vertical pattern.

Figure-10 TS-8241 Sensor Mounted in Perforated Face Ceiling Diffuser.

TS-8261 Light Fixture or Ceiling Diffuser Sensor

Figure-11 Room Air Induced over Sensor by Discharged Air.

The sensor may be mounted in the return air grill of a light fixture or to the face of a ceiling

diffuser using field supplied fasteners (see Figure-12 and Figure-13).

Combination Light-Air

Diffuser Unit

Sensing Element

Room Air Entering Light Fixture through Return Grill

Access Door

Exhaust Air from

Light Fixture

Ceiling

Figure-12 TS-8261 Sensor Mounted in Light-Air Diffuser Unit.

Figure-13 TS-8261 Sensor Mounted in Perforated Ceiling Diffuser.

F-22668-7 Copyright 2010 Schneider Electric All Rights Reserved 7

Page 8

TS-9405, TS-9422

3-25/64

(86)

4-3/4

1-5/8

(41)

2-5/16 (59)

2-1/2

(64)

Dimensions shown

are in inches (mm).

Part Element

Number Length

TS-9405 5 ft.

TS-9422 22 ft.

Averaging Sensors

Note: Hand tighten only - do not overtighten.

1. Determine the sensor enclosure mounting location on the duct (see Figure 16)

(predetermine the knockout hole location for routing of conduit). The sensor should be

serpentined through the duct in a pattern that will expose it to all areas where variations

of temperature may occur. If duct can not be entered, wrap the element around a section

of conduit and place the conduit diagonally in the duct. Consider using part number

M-648 mounting clips when the inside of the duct can be accessed.

Caution: Do not make sharp bends in the element.

2. Use the mounting flange supplied as a template (or refer to Figure 14 for duct mounting dimensions) for mounting hole location.

3. Mount the sensor enclosure to the duct using the two #10 x 3/4” sheet metal screws provided.

TS-8501 Outdoor Air Sensor

Figure-14 TS-9405/9422 Mounting Dimensions.

Figure-15 TS-9405/9422 Typical Mounting.

Mount sensor to waterproof conduit box using the 1/2" conduit connection (see Figures 17

and 18).

Use optional shield if required by application (see Figure 19).

8 Copyright 2010 Schneider Electric All Rights Reserved F-22668-7

Page 9

Figure-16 TS-8501 Mounting Dimensions.

3/4

(19)

5

(127)

Fitting included for 1/2 in. Conduit

2 Leads

3 ft. (0.9 m) length

Dimensions shown

are in inches (mm).

TS-8501 Sensor

Outside Wall

Waterproof Conduit Box

(outside)

Knockouts

Figure-17 TS-8501 Typical Mounting.

TS-8501 Sensor

Figure-18 TS-8501 Mounted with Shield.

Mounting Duct Sensor Using Existing Mounting Plate

F-22668-7 Copyright 2010 Schneider Electric All Rights Reserved 9

Table-3 APPLICABLE MODELS.

New Part Number Old Part Number

TS-9201

TS-9201-106

TS-9405

TS-9422

TS-8201

TS-8201-106

TS-8405

TS-8422

When a duct sensor is being replaced at a location where an existing mounting hole size

exceeds the coverage of the adaptor flange, use the existing mounting plate as follows:

1. Remove the existing unit from the duct. Note location of the unit’s conduit hole.

2. Remove (and set aside for later use) the conduit nut securing the mounting plate to the sensor.

3. Remove the mounting plate from the old sensor.

4. Place the mounting plate on the new sensor and secure with the conduit nut removed from the old sensor. Do not include the plastic adaptor flange.

5. When mounting the sensor to the duct, be sure the conduit hole is located appropriately.

Page 10

WIRING

Conduit Nut

Mounting Plate

Adaptor Flange

Figure-19 Mounting Duct Sensor Using Existing Mounting Plate.

Two separate twisted pair wires (six turns per foot). Class II, low voltage, are suitable for the

sensor leads except as stated below.

Caution: Shielded cable must be used when it is necessary to install the sensor lead in the

same conduit with power wiring, or when it is known that high RFI/EMI generating devices

are near. System ground the shield at the controller only on the COM (-) terminal or blue (-)

lead. Do not use an earth ground. Do not use the enclosure as a junction box for other

control circuits.

It is generally advisable to use flexible conduit to connect enclosure to rigid conduit.

To Energy Management

System Sensor Input

1/4" Spades

(TS-8131)

Two Leads

Figure-20 Sensor Connections.

Restrict element lead to shortest length practical (see Table-4).

Table-4 SENSOR WIRING LENGTHS.

Length of Run - ft. (m)

Wire Gauge

22 - 125 (38)

18 1000 (305) 300 (91)

16 2250 (686) -

14 4000 (1219) -

TS-8xxx and TS-9xxx

Sensor to Controller

(except TP-810x)

TS-8xxx and TS-9xxx

Sensor to TP-810x

Table-5 TS-8000 & TS-9000 SERIES BALCO TEMPERATURE SENSORS.

T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms

-50 760.8 0 854.8 50 956.9 100 1067.0 150 1185.2 200 1311.4

10 Copyright 2010 Schneider Electric All Rights Reserved F-22668-7

Page 11

Table-5 TS-8000 & TS-9000 SERIES BALCO TEMPERATURE SENSORS.

T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms T=F R=Ohms

-49 762.6 1 856.8 51 959.0 101 1069.3 151 1187.7 201 1314

-48 764.4 2 858.8 52 961.2 102 1071.6 152 1190.1 202 1316.7

-47 766.2 3 860.7 53 963.3 103 1073.9 153 1192.6 203 1319.3

-46 768.0 4 862.7 54 965.4 104 1076.2 154 1195.0 204 1321.9

-45 769.9 5 864.7 55 967.6 105 1078.5 155 1197.5 205 1324.5

-44 771.7 6 866.7 56 969.7 106 1080.8 156 1199.9 206 1327.1

-43 773.5 7 868.6 57 971.8 107 1083.1 157 1202.4 207 1329.1

-42 775.3 8 870.6 58 974.0 108 1085.4 158 1204.9 208 1332.4

-41 777.1 9 872.6 59 976.1 109 1087.7 159 1207.3 209 1335.0

-40 779.0 10 874.6 60 978.3 110 1090.0 160 1209.5 210 1337.7

-39 780.8 11 876.6 61 980.5 111 1092.3 161 1212.3 211 1340.3

-38 782.6 12 878.6 62 982.6 112 1094.7 162 1214.8 212 1342.9

-37 784.5 13 880.6 63 984.8 113 1097.0 163 1217.3 213 1345.6

-36 786.3 14 882.6 64 986.9 114 1099.3 164 1219.7 214 1348.2

-35 788.2 15 884.6 65 989.1 115 1101.6 165 1222.2 215 1350.9

-34 790.0 16 886.6 66 991.3 116 1104.0 166 1224.7 216 1353.5

-33 791.9 17 888.6 67 993.5 117 1106.3 167 1227.2 217 1356.2

-32 793.7 18 890.7 68 995.6 118 1108.7 168 1229.7 218 1358.9

-31 795.6 19 892.7 69 997.8 119 1111.0 169 1232.2 219 1361.5

-30 797.5 20 894.7 70 1000.0 120 1113.3 170 1234.7 220 1364.2

-29 799.3 21 896.7 71 1002.2 121 1115.7 171 1237.2 221 1366.9

-28 801.2 22 898.8 72 1004.4 122 1118.0 172 1239.3 222 1369.5

-27 803.1 23 900.8 73 1006.6 123 1120.4 173 1242.3 223 1372.2

-26 804.9 24 902.8 74 1008.8 124 1122.5 174 1244.8 224 1374.9

-25 806.8 25 904.9 75 1011.0 125 1125.1 175 1247.3 225 1377.6

-24 808.7 26 906.9 76 1013.2 126 1127.5 176 1249.8 226 1380.3

-23 810.6 27 909.0 77 1015.4 127 1129.9 177 1252.4 227 1382.9

-22 812.5 28 911.0 78 1017.6 128 1132.2 178 1254.9 228 1385.6

-21 814.4 29 913.1 79 1019.8 129 1134.6 179 1257.4 229 1388.3

-20 816.3 30 915.1 80 1022.0 130 1137.0 180 1260.0 230 1391.0

-19 818.2 31 917.2 81 1024.2 131 1139.4 181 1262.5 231 1393.7

-18 820.1 32 919.2 82 1026.5 132 1141.7 182 1265.1 232 1396.4

-17 822.0 33 921.3 83 1028.7 133 1144.1 183 1267.6 233 1399.2

-16 823.9 34 923.4 84 1030.9 134 1146.5 184 1270.2 234 1401.9

-15 825.8 35 925.4 85 1033.2 135 1148.9 185 1272.7 235 1404.6

-14 827.7 36 927.5 86 1035.4 136 1151.3 186 1275.3 236 1407.3

-13 829.6 37 929.6 87 1037.6 137 1153.7 187 1277.8 237 1410.0

-12 831.5 38 931.7 88 1039.9 138 1156.1 188 1280.4 238 1412.8

-11 833.5 39 933.8 89 1042.1 139 1158.5 189 1283.0 239 1415.5

-10 835.4 40 935.9 90 1044.4 140 1160.9 190 1285.6 240 1418.2

-9 837.3 41 937.9 91 1046.6 141 1163.4 191 1288.1 241 1421.0

-8 839.3 42 940.0 92 1048.9 142 1165.8 192 1290.7 242 1423.7

-7 841.2 43 942.1 93 1051.1 143 1168.2 193 1293.3 243 1426.4

-6 843.1 44 944.2 94 1053.4 144 1170.6 194 1295.9 244 1429.2

-5 845.1 45 946.3 95 1055.7 145 1173.0 195 1298.5 245 1431.9

-4 847.0 46 948.5 96 1057.9 146 1175.5 196 1301.0 246 1434.7

-3 849.0 47 950.6 97 1060.2 147 1177.9 197 1303.6 247 1437.4

-2 850.9 48 952.7 98 1062.5 148 1180.3 198 1306.2 248 1440.2

-1 852.9 49 954.8 99 1064.8 149 1182.8 199 1308.8 249 1443.0

0 854.8 50 956.9 100 1067.0 150 1185.2 200 1311.4 250 1445.7

Ta b l e D at a :

1. Material: Balco wire calibrated for 1000 ohms ± 1% at 70 °F.

2. Temperature coefficient: 4300 (± 150) ppm °C between 25 and 100°C.

3. Relationships: R (resistance)= 0.00161T2 + 1.961T + 854.841 Temperature = (SQRT ((.00644 x R) - 1.6597) - 1.961) / .00322

F-22668-7 Copyright 2010 Schneider Electric All Rights Reserved 11

Page 12

MAINTENANCE

FIELD REPAIR

4. Storage Temperature Specification: Minimum = -40 °F Maximum = 160 °F

5. Operation Temperature Specification: Minimum = -40 °F Maximum = 240 °F

Ta b l e N ot e s:

1. Temperature (T) in °F

2. Resistance (R) in ohms

3. Temperature coefficient is positive

Regular maintenance of the total system is needed to assure sustained optimum

performance. Sensors should be periodically inspected for dirt or blockage of air over the

elements.

These sensors are not field repairable.

On October 1st, 2009, TAC became the Buildings business of its p arent company Schneide r Electric. This document reflects the visual identity of Schnei der Electric,

however there remains references to T AC a s a corporate bran d in the body copy. As each document is updated, the body copy will be changed to ref lect appropriate

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-22668-7

Loading...

Loading...