Page 1

For proportional temperature control of pneumatic valves and

actuators to maintain discharge temperature of reheat

systems and sampling chamber or return air temperature of

terminal units and as a proportional low limit thermostat.

GENERAL INFORMATION

Proportional control type of pneumatic instrument, using

balanced lever system actuated by a liquid-filled thermal

copper element with a 3’ (914 mm) capillary.

Maximum Safe Air Pressure: 30 psig (207 kPa).

Maximum Sale Case Temperature: 140°F (60°C).

Mounting: Directly by means of top mounting holes or with

a right angle mounting bracket included with thermostat.

Air Connections: Post with barb for 1/4" O.D. plastic tubing.

Air Consumption for Sizing Air Compressor: .016 scfm

(8 ml/s) @ 15 psig (103 kPa), .024 scfm (11 ml/s) @ 20 psig

(138 kPa).

Air Capacity for Sizing Air Mains: 36 scim (10 ml/s) @ 15

psig (103 kPa), 50 scim (14 ml/s) @ 20 psig (138 kPa).

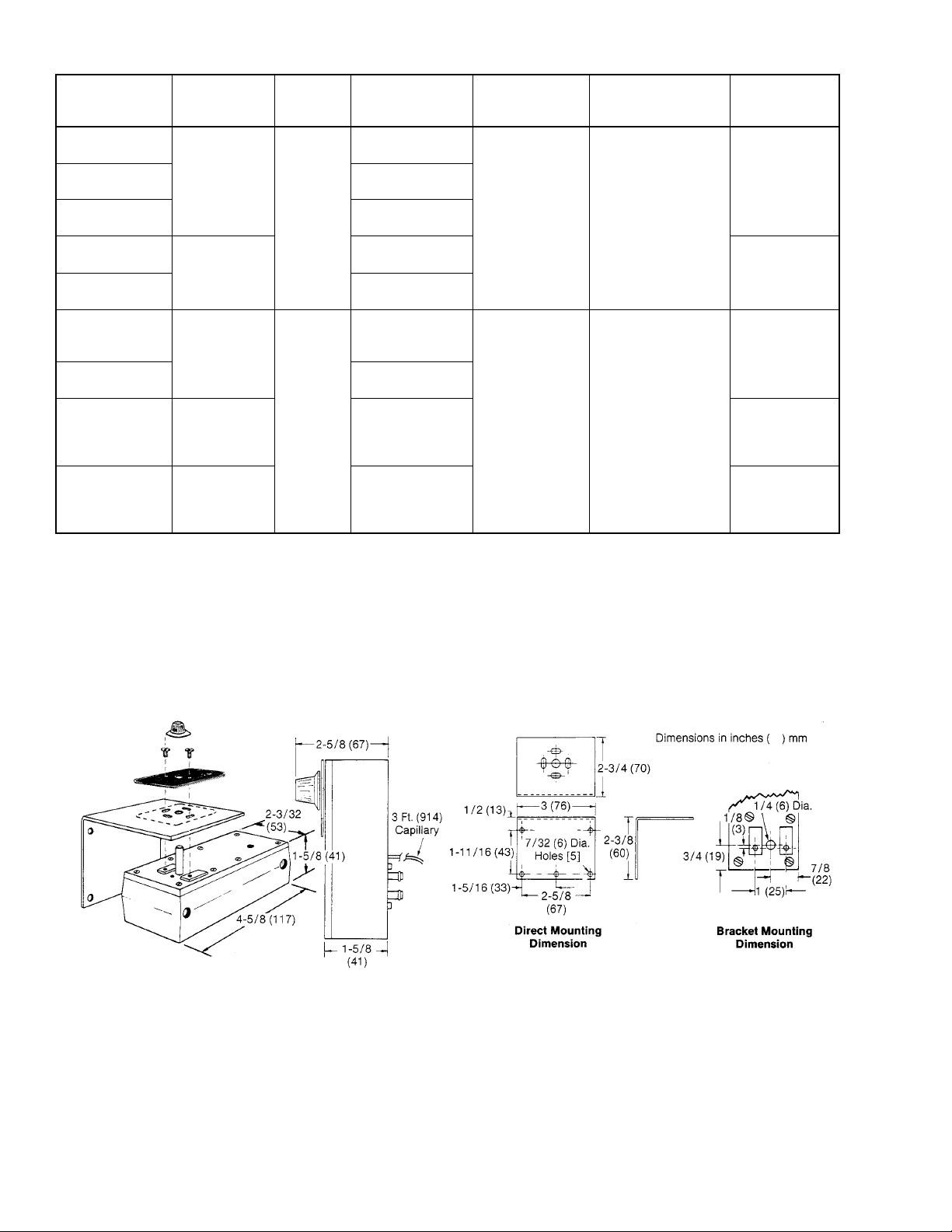

Dimensions: 4-5/8" (117 mm) high x 2-1/8" (54 mm) wide x

1-5/8" (41 mm) deep.

TK-2001, TK-2012, TK-2201,

TK-3001, TK-3201, TK-4001,

TK-4012, TK-4212 TK-4212-201

Pneumatic Bulb Thermostats

General Instructions

Options

None

ACCESSORIES

AT-208 Duct mounting kit

Tool-95 Pneumatic calibration tool kit

Printed in U.S.A. 12/09 © Copyright 2009 Schneider Electric All Rights Reserved. F-12585-8

Page 2

Table-1 Model Chart.

Bulb Style

Dimensions in

inches (mm)

Straight

7/32 x 14 (6 x 356)

Coiled

1 x 5 (25 x 127)

Averaging

1/8 x 48 (3 x 1.2 m)

Straight

7/32 x 14 (6 x 356)

Coiled

1 x 5 (25 x 127)

Straight

3/16 x 11-1/4 (5 x

286)

Averaging

3/32 x 54 (2 x 1.4 m)

Averaging

3/32 x 54 (2 x 1.4 m)

Averaging

3/32 x 54 (2 x 1.4 m)

Part

Number

Description and

Action

a

Max. Safe

Bulb Temp.

°F (°C)

TK-2001

Heating

b

DA

TK-4001

TK-2201

Heating-Cooling

140 (60)

20 (138) DA

TK-3201

TK-2012

15 (103) RA

Heating

b

DA

TK-4012

TK-4212

Heating-Cooling

20 (138) DA

230 (110)

15 (103) RA

TK-4212-201

Heating-Cooling

Low Limit

20 (138) DA Full

c

Output 15 (103)

a

Direct Acting (DA) - Increase output pressure on temp. rise.

Reverse Acting (RA) - Decrease output pressure on temp. rise.

b

Field changeable to reverse acting.

c

AT 20 psi (138 kPa) unit can bleed down a branch line from a controlling thermostat.

At 15 psi (103 kPa) unit is inoperative, i.e. passes controlling thermostat signal.

Control Dial

Range

°F (°C)

Dial Marked

Cooler-Warmer

60-90

(15-32)

Dial Marked

Cooler-Warmer

30-90 (-1 to 32)

Throttling Range

Adjustable 2-10°F

(1-6

°C)/10 psi (69 kPa)

Factory Set

4°F (2°C)/

10 psi (69 kPa)

Adjustable 5-25°F

(3-14

°C)/

10 psi (69 kPa) Factory

Set

10°F (6°C)/

10 psi (69 kPa)

Supply Air

Pressure psig

(kPa)

15 (103)TK-3001

15 (103) RA

Cooling

20 (138) DA

a

a

Heating

15 (103)

15 (103) RA

Cooling

20 (138) DA

a

a

Heating

15 (103

Full Output

20 (138) DA

a

Heating

DIMENSIONS

Figure-1 Mounting Dimensions.

2 © Copyright 2009 Schneider Electric All Rights Reserved. F-12585-8

Page 3

INSTALLATION

Locating

The thermostat can be mounted in any position. However, it is

most common to mount the thermostat with the setpoint

adjusting shaft on top. The adjusting mechanism is in the

thermostat on the side opposite from the setpoint knob shaft.

This area should be readily accessible so that the thermostat

can be serviced easily. Locate the bulb in the return air intake

in a position where it will sense representative air

temperatures.

Mounting

If the thermostat is mounted directly to the unit air conditioner,

drill three holes corresponding to the location of the mounting

holes and setpoint shaft in the thermostat. T o use bracket, drill

three holes to match any three of the five bracket mounting

holes selected (Figure 1).

Mount the thermostat using the two #10-32 screws, and the

scale plate which indicates the temperature setting. Attach the

knob, positioned so that the pointer indicates the cooler

(CCW) position on the scale. Rotate setpoint to midscale.

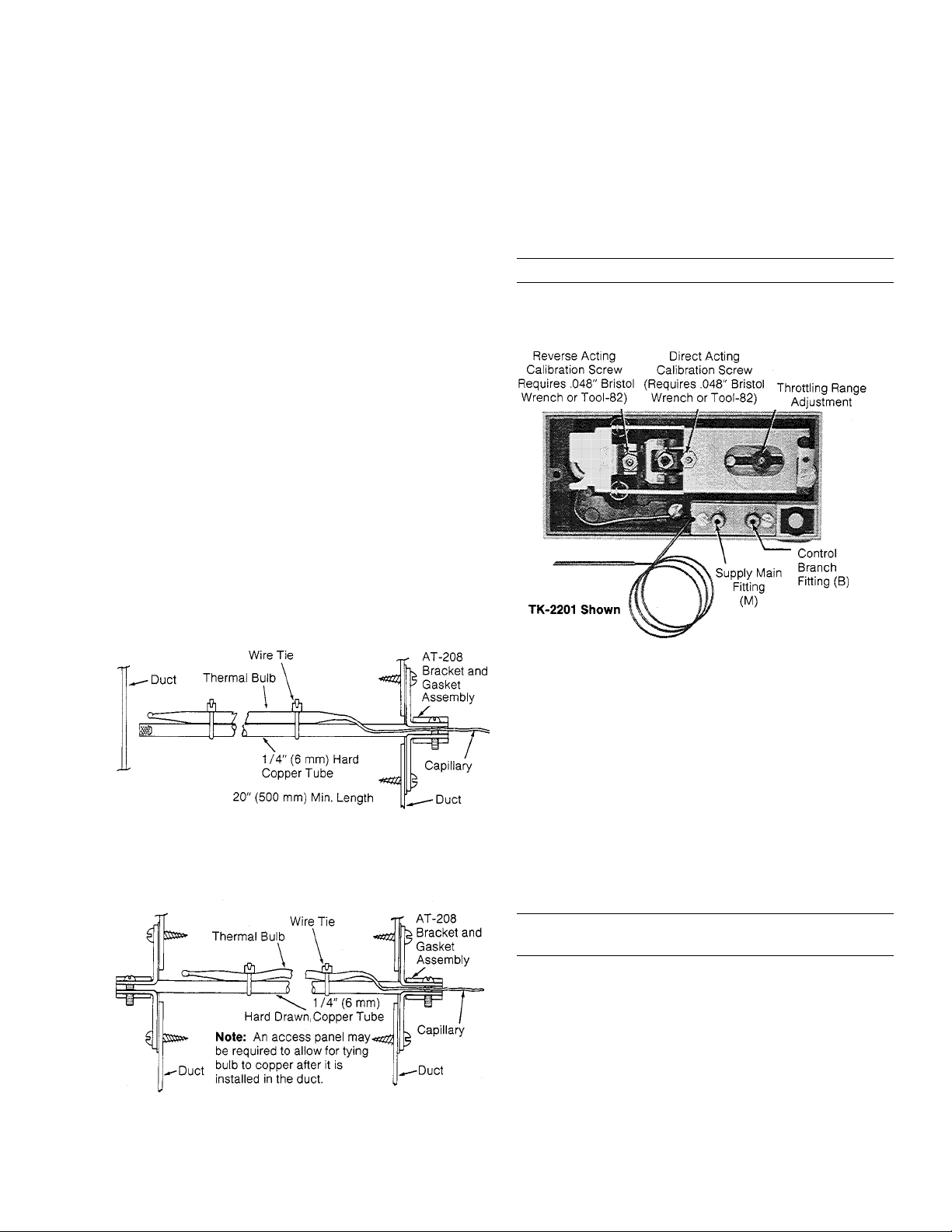

Uncoil the capillary tubing and fasten the bulb in the air stream

being controlled as shown in Figures 2 and 3 below. (See

Figures 7 and 8 for duct mounting template and assembly).

Attach 1/4" O.D. plastic tube to “m” (main) and “B” (branch)

fittings by slightly rotating the tubes back and forth and

pushing firmly onto the fitting (see Figure 4).

CONVERSION OF DIRECT ACTING THERMOSTAT TO REVERSE ACTING

1. Remove direct acting calibration screw complete with tension nut (Figure 4).

2. Insert screw into threaded hole where reverse acting screw is shown in Figure 4.

3. Tighten tension nut carefully until it is snug.

Caution: DO NOT overtighten as this will ruin nut.

4. Calibrate per instructions shown below.

Figure-2 Mounting TK-2000 Series Bulb.

Figure-3 Mounting TK-4000 Series Bulb.

Figure-4

THROTTLING RANGE ADJUSTMENT

The throttling range should be set at the lowest value which

will allow the thermostat to control the system without cycling

under normal load conditions. The most satisfactory setting

will vary with the type of control system.

The throttling range is changed by sliding the throttling range

adjustment pivot in the flapper to its proper position (see

Figure 4). Calibration of the thermostat should be checked

after the throttling range has been changed. When making the

throttling range adjustment, care should be taken to prevent

excessive side forces on the flapper lever (see Figure 6).

Caution: In no case should the pivot point be rais ed when

the adjustment is made (see Figure 6).

CALIBRATION

After the throttling range adjustment is made, the thermostat

should be checked for calibration. As a nominal calibration,

the controlled branch pressure should be 8 psig (55 kPa)

when the setpoint is equal to the bulb temperature, indicated

by a thermometer located near the bulb. In some applications,

a value other than 8 psig (55 kPa) will be required to get the

desired control results. Change the 8 psig (55 kPa)

designation as used in the calibration procedure, should this

be the case.

F-12585-8 © Copyright 2009 Schneider Electric All Rights Reserved. 3

Page 4

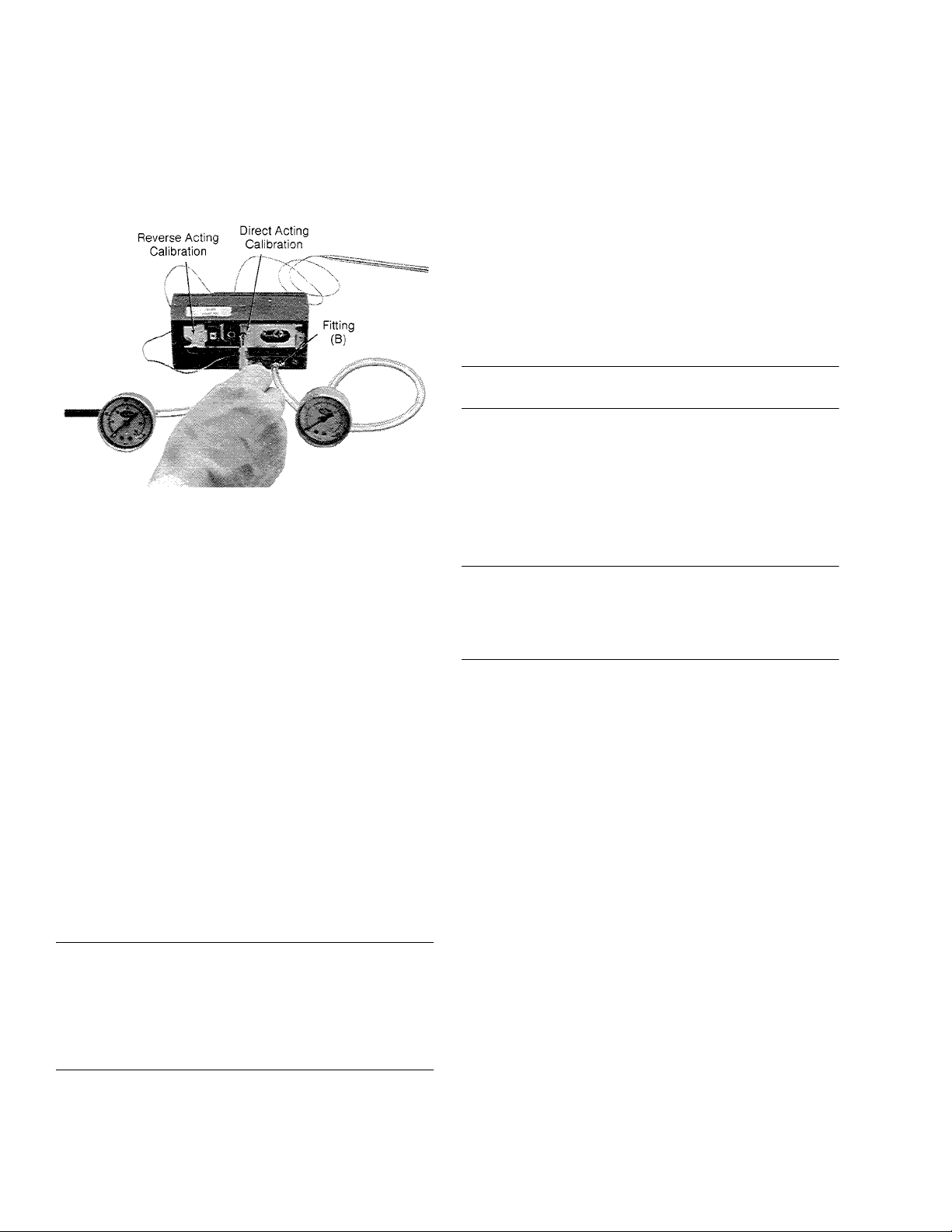

Calibrate the thermostat as follows (See Figure 5):

Disconnect the branch line at the thermostat and attach a test

gauge to the fitting (B). Push the tubing on as far as it will go,

approximately 1/4" (6 mm). The tubing for this test gauge

should be approximately 6" (150 mm) long to permit bringing

the gauge out from the test point to a place where it can be

easily read. The supply pressure to the thermostat should be

15 psig (103 kPa).

Figure-5

One Temperature Thermostats

These thermostats are factory adjusted to operate at the

midpoint of the dial span, when the adjusting dial is in its

mid-position. Whenever the throttling range is changed, the

thermostat calibration should be checked and adjusted if

necessary as follows:

1. The scale on the thermostat represents 30°F (17°C) or 60°F (33°C) span (see page 1) with the desired control point in the center. Each divi sion is equal to 5 °F (3°C) for 30°F (17°C) span units and 10°F (6°C) for 60°F (33°C) span units.

2. Observe the temperature of the bulb using a test thermometer. T urn the knob of the thermostat to the point on the scale which would correspond to the bulb temperature. Read the branch line pressure. It should be 8 psig ±1 psig (55 kPa ±7 kPa).

3. If the pressure is not 8 psig (55 kPa) use a .048" Bristol

wrench (TOOL-82) in the calibrating screw and adjust the

screw to obtain 8 psig (55 kPa). The proper screw holes

for the reverse acting or direct acting calibration are

labeled on the main lever (Figure 5).

Caution: Cae should be taken when adjusting the reverse

acting setpoint screw. Avoid unnecessary side motions and

particularly avoid lifting the lever to which the screw is

attached. Burrs on the Bristol wr ench could cause it to stick in

the screw. Note also, that the hex nuts on the adjusting

screws are used to provide tension only and should not be

loosened when making calibration adjustments.

4. When the calibration has been completed, turn the knob to the desired setpoint and remove the gauge, reconnect the branch line and replace the cover.

Heating-Cooling Thermostats

1. Adjust the supply line pressure for the system to 25 psig (172 kPa).

2. Connect a pressure regulator into the supply main between the main and the thermostat at the thermostat location.

3. Adjust the regulator to 20 psig (138 kPa); at this supply pressure the thermostat is direct acting.

4. Set the dial knob on the thermostat to the bulb temperature setting and observe the branch line control air pressure. This pressure should be 8 psig ±1 psi (55 kPa ±7 kPa).

5. If not, adjust the direct acting screw to obtain 8 psig (55 kPa) branch line control pressure using a .048" Bristol wrench (Tool-82).

Caution: Do not loosen the hex nut on the screw.This nut is

for friction purposes only; it does not lock the screw.

6. Adjust the regulator in the main line to 15 psig (103 kPa). At this supply pressure the temperature is reverse acting.

7. Observe the branch line control air pressure. If this pressure is not 8 psig (55 kPa), use a .048" Bristol wrench (TOOL-82) and adjust the reverse acting calibrating screw to obtain an 8 psig (55 kPa) branch line control pressure.

Caution: The lever to which this screw is attached contains

a spring hinge and is pivoted on the switch point adjusting

spring. Undue side motion or forces tending to lift the switch

lever off the main lever can damage the hinge or unseal the

lever.

8. Recheck calibration by switching the supply pressure between 15 and 20 psig (103 and 138 kPa) several times and observe the control pressure. If it varies from the desired pressure, repeat the calibration procedures.

9. Calibration is now complete. Turn the adjusting knob to the desired setpoint. Remove the test gauge and regulator, reconnect the main and branch lines and replace the cover.

Heating-Cooling Low Limit TK-4212-201

A special Heating-Cooling Thermostat is available for unitary

heating-cooling applications. This thermostat is very similar to

the TK-4212 except:

1. The restriction plate has been removed making the unit a one pipe thermostat. The air signal to the main connection actuates only the switchover parts.

2. The R.A. calibration screw has been removed. Therefore, when the main pressure is reduced to 15 psig (103 kPa). there is no calibration screw to contact the main lever and the flapper closes the nozzle completely and the thermostat is inoperative.

To calibrate apply 20 psig (138 kPa) to the main and full

branch pressure from the primary controller to the branch

connection of the TK-4212-201. Then calibrate as a single

temperature D.A. thermostat.

4 © Copyright 2009 Schneider Electric All Rights Reserved. F-12585-8

Page 5

MAINTENANCE

This is a quality product. Regular maintenance of the total

system is recommended to assure sustained optimum

performance.

FIELD REPAIR

Repair is not recommended except for replacement of

restrictor assembly. Use AT -529 restrictor kit (see Figure 6) if

restrictor replacement is required. Otherwise, replace

thermostats if system is not operating correctly and the cause

is traced to the thermostat.

Figure-7 AT-208 Duct Mounting Kit.

Figure-6

Figure-8 Bulb Mounting Hole Arrangement for Drilling

Ductwork.

F-12585-8 © Copyright 2009 Schneider Electric All Rights Reserved. 5

Page 6

On Oc tober 1st, 2009, TAC becam e the Buildings busin ess of its par ent company Schneider El ectric. This docum ent ref lects the visual i denti ty of Schneider Electric,

ho wever t he re remains refer ences to TAC as a corpor a te br an d in the body copy. As eac h document i s updated, the body copy will be changed to reflect appr op riate

corpor ate br a nd ch a nges.

Copyright 2009, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-12585-8

Loading...

Loading...