Page 1

Smart Sensor Series

SensorsField Devices

Installation Guide

1

Installation

Installation consists of mounting the module to the

wall then wiring power and data connections to a

controller.

The sensor can be mounted directly on drywall, or on

any electrical outlet box with no adapters required.

This sensor is for indoor use only and is not suitable

for use where condensation may occur.

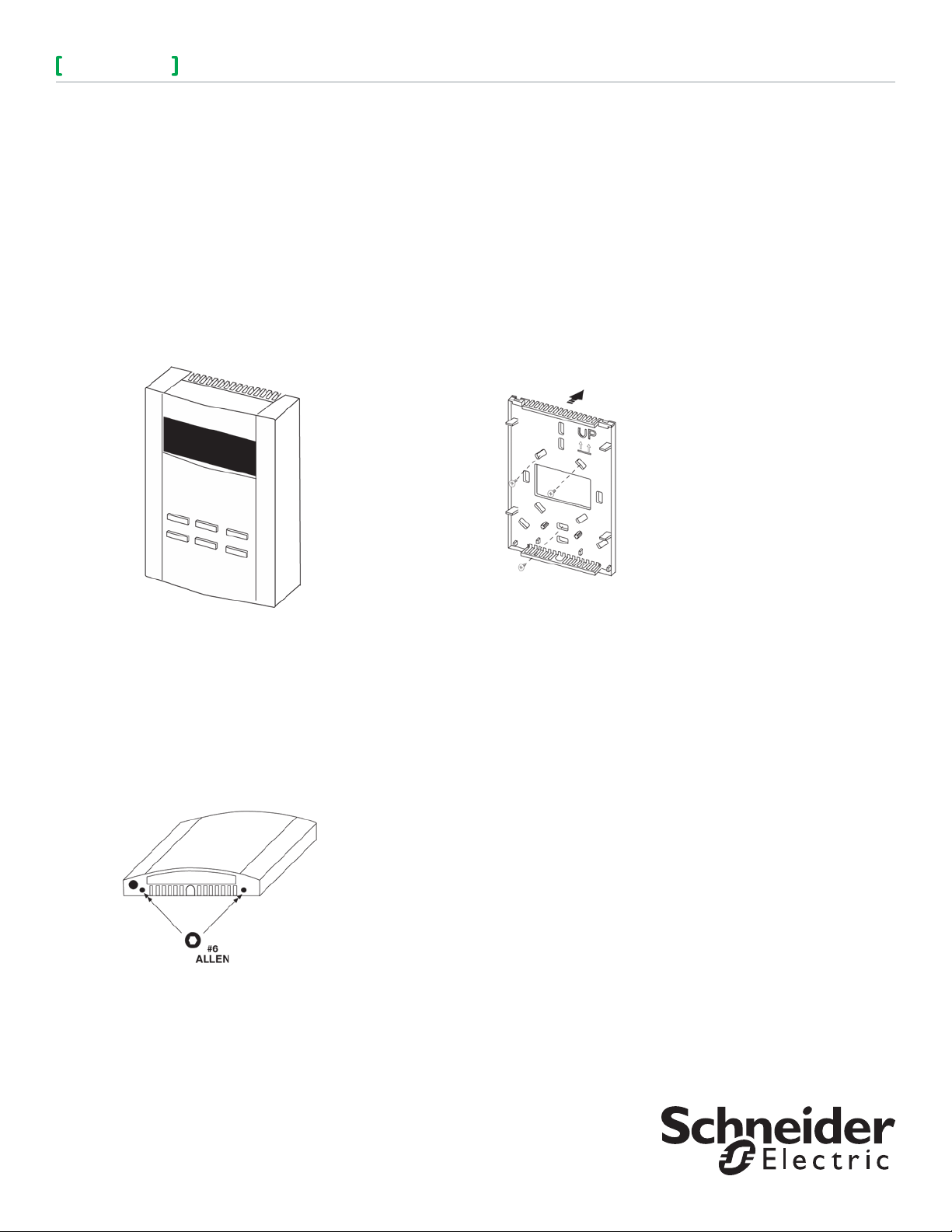

INSTALLING THE SENSOR AND BASE

To remove the sensor

The sensor is fastened to the base using Allen

screws.

1. Using a #6 Allen tool, turn the two Allen screws

located in the bottom of the sensor cover

clockwise (inward) until the sensor lifts off easily.

To install the base

Note: If you are mounting the sensor to an

existing electrical box, skip steps 1, 2 and

3. To prevent drafts from affecting the

Sensor reading, cover the openings in the

back of the base.

1. Place the base on the surface of the wall area

where the sensor is to be mounted and mark the

location of at least three mounting holes.

Figure 2. Placement of the base.

2. Drill the marked holes and insert wall anchors into

the surface.

3. Mount the base using at least three screws.

4. Guide your facility wiring into the large opening

of the base.

5. Connect your wires to the probe wires that are

part of the cover assembly using wire nuts.

6. Collect any slack wire, fold and tuck into the

base.

7. Place the cover on the mounted base.

8. Secure the cover by turning the Allen screws

counterclockwise (outward) until the cover is

locked in place. Refer to Figure 1.

Figure 1. Turn two Allen screws clockwise.

2. Remove the sensor by lifting the front bottom

outward.

Page 2

SensorsField Devices

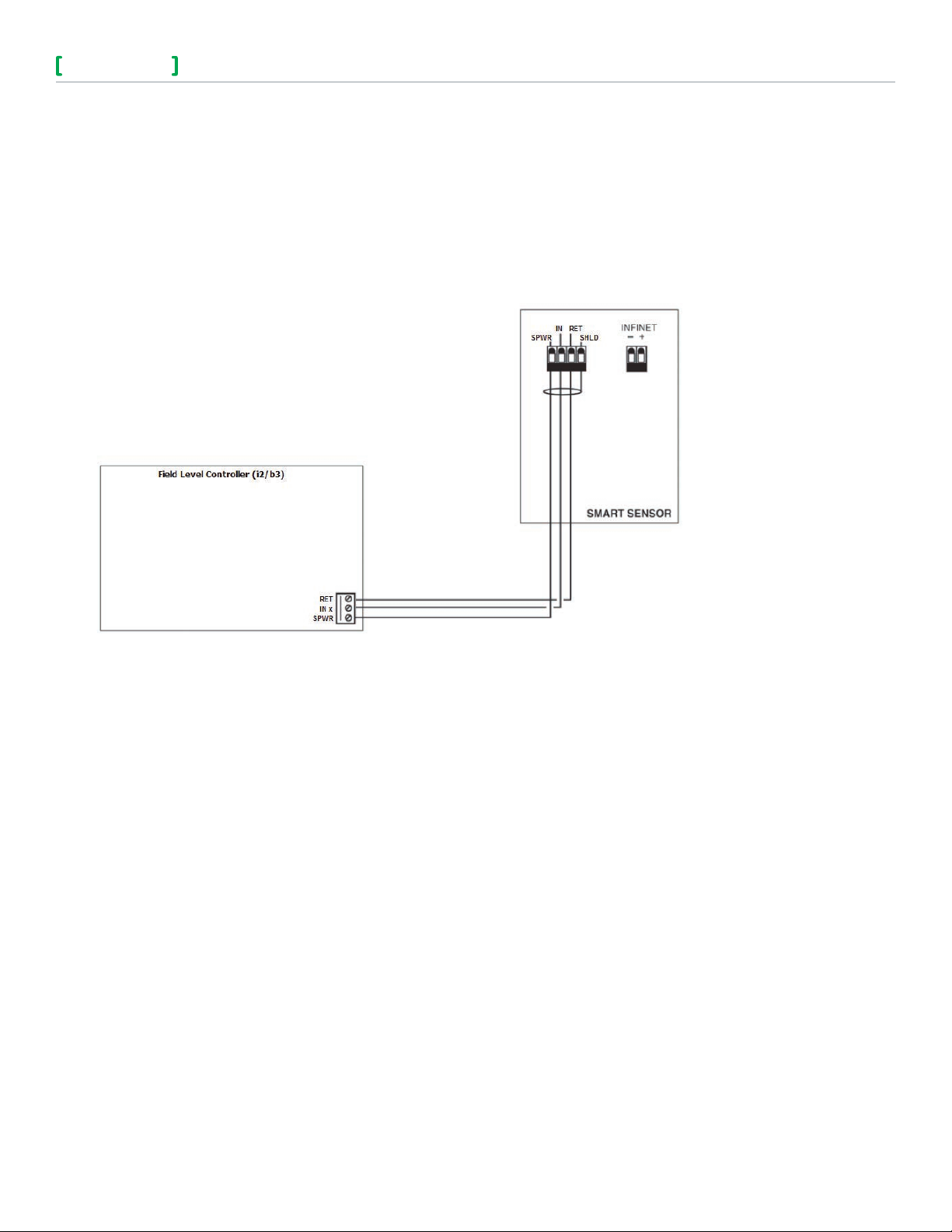

SMART SENSOR CONNECTION

The Smart Sensor bus consists of a three wire connection between the sensor and the controller, using the

dedicated three-terminal connector on the field level controller.

• RET

• IN x

• SPWR

The following illustrates the connection between the two units.

2

Figure 3. Smart Sensor wiring diagram.

TEMPERATURE INPUT TROUBLESHOOTING

1. Disconnect the wiring to the input and connect an ohm meter directly across the input wires at the

controller. Verify the measurement against the resistance to temperature chart found below.

2. Measure the resistance directly at the probe. If there is a significant difference between the resistance

measured at the probe and at the controller, then there is a resistance problem in the wiring, which will

affect the reading.

Note: When the controller no longer considers an input reading to be valid, it sets the ElecValue to

999.9. Each controller has two additional internal inputs. One is hard-wired to the reference

channel and the other is connected to ground. These two inputs are used for continuous software

calibration of the input circuit. If at any time either of these two inputs reads out of a predened

range, then the input routine will set the ElecValue of all inputs to 999.9.

chneider Electric | Buildings

S

F-27637-3

© 2014 Schneider Electric. All rights reserved.

May 2014 tl

Page 3

SensorsField Devices

Table-1. Resistance versus Temperature for Smart Sensor

R Ohms °F (°C) R Ohms °F (°C) R Ohms °F (°C) R Ohms °F (°C)

29481.1 32 (0.0) 18331.5 51 (10.6) 11716.6 70 (21.1) 7680.64 89 (31.7)

28732.2 33 (0.6) 17892.8 52 (11.1) 11452.0 71 (21.7) 7516.78 90 (32.2)

28004.6 34 (1.1) 17465.9 53 (11.7) 11194.2 72 (22.2) 7356.9 91 (32.8)

27297.7 35 (1.7) 17050.4 54 (12.2) 10943.0 73 (22.8) 7200.88 92 (33.3)

26610.8 36 (2.2) 16646.1 55 (12.8) 10698.1 74 (23.3) 7048.62 93 (33.9)

25943.4 37 (2.8) 16252.6 56 (13.3) 10459.4 75 (23.9) 6900.01 94 (34.4)

25294.7 38 (3.3) 15869.6 57 (13.9) 10226.8 76 (24.4) 6754.96 95 (35.0)

24664.2 39 (3.9) 15496.8 58 (14.4) 10000.0 77 (25.0) 6613.38 96 (35.6)

24051.4 40 (4.4) 15133.8 59 (15.0) 9778.91 78 (25.6) 6475.18 97 (36.1)

23455.6 41 (5.0) 14780.4 60 (15.6) 9563.35 79 (26.1) 6340.25 98 (36.7)

22876.5 42 (5.6) 14436.4 61 (16.1) 9353.18 80 (26.7) 6208.53 99 (37.2)

22313.4 43 (6.1) 14101.3 62 (16.7) 9148.24 81 (27.2) 6079.91 100 (37.8)

21765.9 44 (6.7) 13775.1 63 (17.2) 8948.38 82 (27.8) 5954.33 101 (38.3)

21233.5 45 (7.2) 13457.3 64 (17.8) 8753.48 83 (28.3) 5831.7 102 (38.9)

20715.7 46 (7.8) 13147.9 65 (18.3) 8563.39 84 (28.9) 5711.95 103 (39.4)

20212.2 47 (8.3) 12846.4 66 (18.9) 8377.98 85 (29.4) 5594.99 104 (40.0)

19722.4 48 (8.9) 12552.8 67 (19.4) 8197.12 86 (30.0) 5480.76 105 (40.6)

19245.9 49 (9.4) 12266.8 68 (20.0) 8020.69 87 (30.6) — —

18782.4 50 (10.0) 11988.1 69 (20.6) 7848.56 88 (31.1) — —

3

LAPTOP SERVICE TOOL CONNECTION

The connector located on the bottom of the sensor provides access to the Infinet for the Laptop Service Tool.

Connect the Laptop Service Tool cable as shown below.

Figure 4. Service connector on the bottom of the sensor.

chneider Electric | Buildings

S

F-27637-3

© 2014 Schneider Electric. All rights reserved.

May 2014 tl

Page 4

44

SensorsField Devices

F-27637-3 May 2014 tl

© 2014 Schneider Electric. All rights reserved.

Loading...

Loading...