Page 1

Application

Spring Return

Non-Spring

Return

The Erie™ Modulating PopT op™ Series valve actuator

assemblies are designed for closed hydronic heating

and cooling systems. The Modulating PopTop is used

to control fluid flow in fan coil units, VAV reheat, unit

ventilators, AHUs and radiant applications.

The Modulating PopTop Proportional (P) type is

compatible with any 0 to 10 Vdc or 4 to 20 mA signal

with jumper selectable operating range and action

resulting in precise positioning. The floating (T) type is

compatible with any 24 Vac three-wire signal when

three minute time-out logic resides in the valve actuator

or system controller.

The Modulating PopTop valve assemblies allow the

actuator to be snapped onto, or off from, the valve

body. The actuator can be mounted after the valve

body has been installed into the system without the

need for linkages or calibration.

Available in standard (non-spring return) and spring

return modulating actuators. The two-way spring return

modulating actuators are provided in either normally

open or normally closed operation. The three-way

valves are available in normally closed operation only.

Valve body reversal provides normally open flow for

three-way valve bodies.

Erie VM PopTop Series

Modulating Valves

Floating "T" & Proportional "P"

Standard and Spring Return Modulating Valves

General Instructions

Features

• Magnetic clutch to maxi mize the life of the motor and

gear train

• Manual operating lever/position indicator facilitates

field setup

• Easy to use lever terminal blocks

• Actuator can be installed after the valve body

• Three wire floating and 0 to 10 Vdc or 4 to 20 mA

proportional available

• Spring return will return actuator to normal position

when the power is lost for more than two minutes.

Printed in U.S.A. 2-13 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Applicable Literature

•

EN-205 Water and S team System Gu idelines, F-26080

Page 2

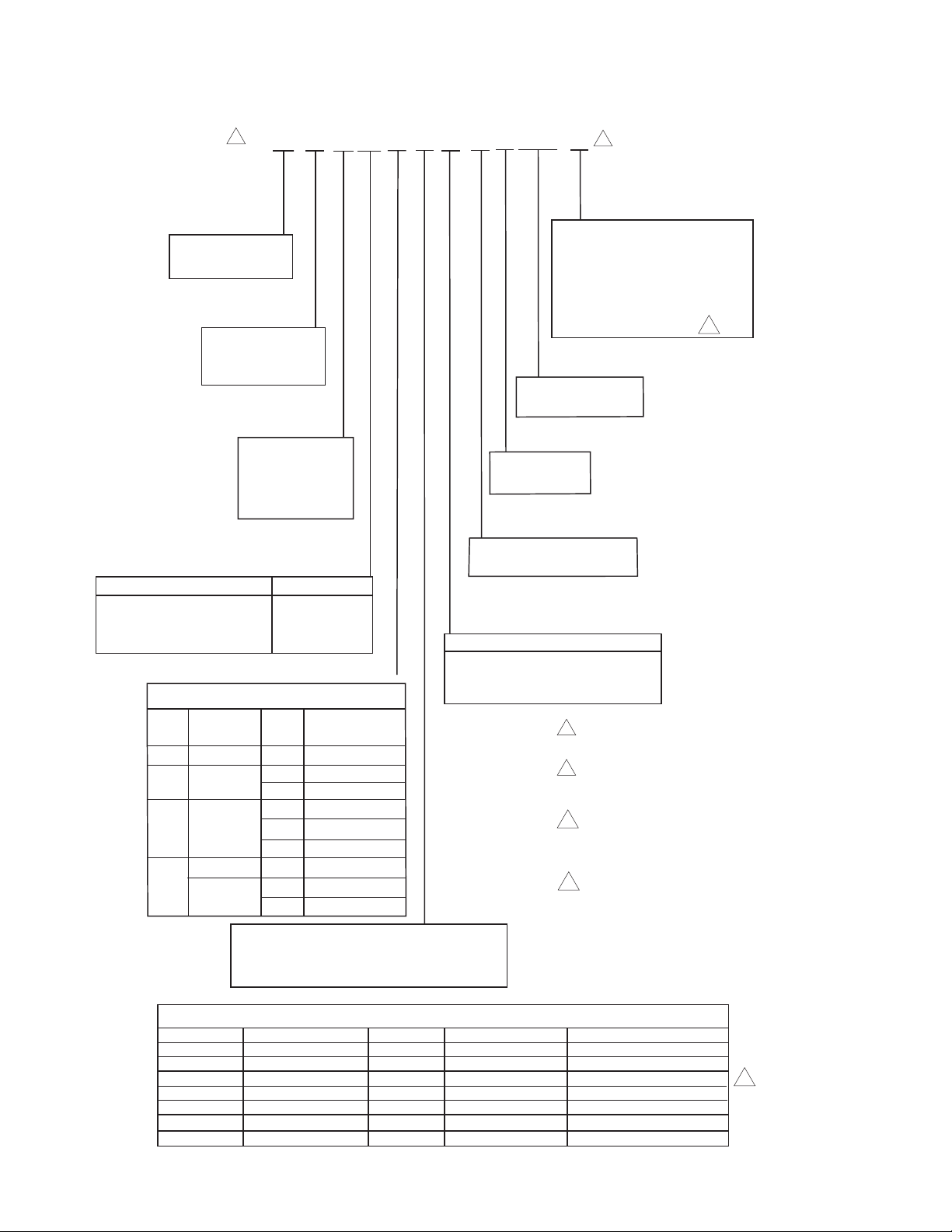

Part Numbering System

Modulating Spring and Non-Spring Return Zone Valves

1

V M X X X X X X 3 A 00 X

Body Type

M = Modulating

Configuration

2 = 2-Way

3 = 3-Way

2 = 1/2"

3 = 3/4"

4 = 1"

5= 1-1/4"

Connection Type Availability

1 = Sweat 1/2", 3/4", 1", 1-1/4"

2 = Threaded NPT 1/2", 3/4", 1"

3 = Threaded Rp (Metric) 1/2", 3/4", 1"

5 = SAE Flare 1/2"

CV Size

1/2" 1, 2, 3, 5

1 = 1.0

1/2" 1, 2, 3, 5

2 = 2.0

3/4" 1, 2, 3

1/2" 1, 2, 3, 5

3 = 4.0

3/4" 1, 2, 3

1" 1

3/4" 1, 2, 3

7 =

1" 1, 2, 3

1-1/4" 1

7.5

8.0

T = Three-wire Floating

P = Proportional, 0-10 Vdc, 0-5 Vdc,

5-10 Vdc or 4-20 mA, Jumper Selectable

Valve Size

Size Connection Type

Actuator Type

2

Options

Non-Spring Return Actuators

0 = No Options

T = Three-Wire Signal Time-Out

Spring Return Actuators

T = Time-Out

Electrical Leads

00 = No leads

Voltage

A = 24 Vac Only

Temperature Ratings

3 = General Temperature

Action

1 = Spring Return Normally closed

2 = Spring Return Normally opened

3 = Non-Spring Return

1

When ordering valve body only: use the first

six positions to configure the valve.

2

When ordering actuator only: use the last

seven positions to configure the actuator.

Prefex with the letter "A."

3

This feature is standard

for spring return actuators.

It must be included in the

part number.

4

Should not be used with thermostats/

controllers unless they have a

timeout feature.

3

Available Actuators

Part Number

AT13A00T

AT23A00T

AT33A000

AT33A00T

AP13A000

AP23A000

AP33A000

2 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Action

Spring Return

Spring Return

Non-Spring Return

Non-Spring Return

Spring Return

Spring Return

Non-Spring Return

Position

N.C.

N.O.

N.C.

N.O.

Actuator Type

Three Wire Floating

Three Wire Floating

Three Wire Floating

Three Wire Floating

Proportional

Proportional

Proportional

Option

With Time-Out

With Time-Out

None

With Time-Out

None

None

None

4

Page 3

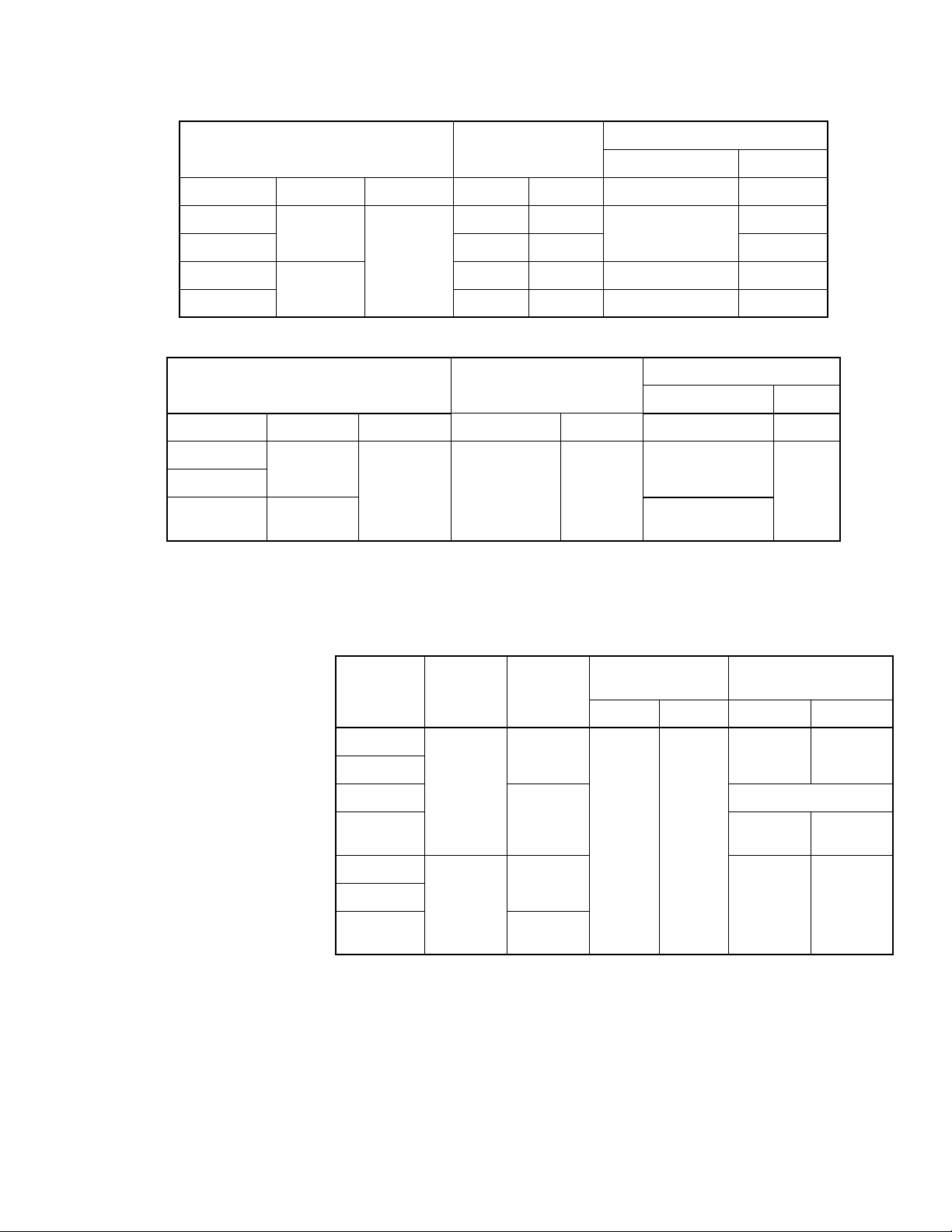

SPECIFICATIONS

Inputs

Floating Actuator Control Circuit, Max.

Powerup Inrush

a

Running

Series Action Vac mA VA VA VA

Total Actuator, Max.

AT13A00T

AT23A00T 24 0.6 1.9

Spring

Return

24 Vac

24 0.6

10

1.9

+25%/-15%

A T33A000

AT33A00T – – 1.2 1.2

a Transformer must be sized for Powerup Inrush

Non- Spring

Return

50/60 Hz

–– 1.0 1.0

To tal Actuator, Max.

Proportional Actuator Control Circuit, Max.

Powerup Inrush

a

Running

Series Action VAC Range Rin VA VA

AP13A000

AP23A000

AP33A000

a Transformer must be sized for Powerup Inrush

b Factory supplied. Actual range is 1-9 Vdc.

Spring

Return

Non-Spring

Return

24 Vac

+25%/-15%

50/60 Hz

b

0-10 VDC

or

0-5 VDC or

5-10 VDC or

4-20 mA

>200K

>200K

>200K

300

10

1.7

1.7

Outputs

Timing:

Nominal Stroke

Series Mode Action

Time

60 Hz 50 Hz 60 Hz 50 Hz

AT13A00T

AT23A00T

AT33A000

Floating

Spring

Return

3 min.

Non-Spring

AT33A00T

AP13A000

AP23A000

AP33A000

Modulating

Return

Spring

Return

Non-Spring

Return

2 min. 30

sec.

3 min.

3 min.

± 30 sec.

2 min.

45 sec.

Mechanical:

Action, T series: Direct acting.

P series: Direct acting (valve opens port B with increase in signal.) Field

selectable reverse acting.

Manual Override, Allows manual positioning.

Operating Pressure Limits, 400 psi (2758 kPa) static pressure.

Material,

Actuator: High temperature plastic.

Valve: Body: Forged brass; stem: nickel- plated/chrome-plated brass; seat:

brass, plug/paddle: high temperature thermoplastic/rubber.

Flow Characteristic, 1.0 to 4.0 Cv: equal percentage. 7.0/8.0 Cv: linear.

Total Run Time

3 min.

36 sec.

no delay

na

3 min.

18 sec.

F-27013-8 © Copyright 2013 Schneider Electric All Rights Reserved. 3

Page 4

Environment

Ambient Temperature Limits:

Shipping & Storage, -40 to 158°F (-40 to 70°C)

Operating, 35 to 125°F (2 to 52°C).

Fluid, 32 to 200× F (0× to 93× C) (not steam rated).

Humidity: 5 to 95% RH, non-condensing.

Seat Leakage: ANSI class IV (0.01%)

Shipping Weight: 1.9 lbs (860 g), actuator and valve body.

Location: NEMA Type 1.

Agency Listings (Actuator Only):

UL873: Underwriters Laboratories (File #E9429 Category Tempera tu re Indicating and

Regulating Equipment) Class 2.

CUL: UL Listed for use in Canada by Underwriters Laboratory. Canadian Standards C22.2

No. 24.

European Community: CE Approved.

Australia: This product meets the requirements to bear the C-Tick Mark according to the

terms specified by the Communications Authority under the Radio Communications Act of

1992.

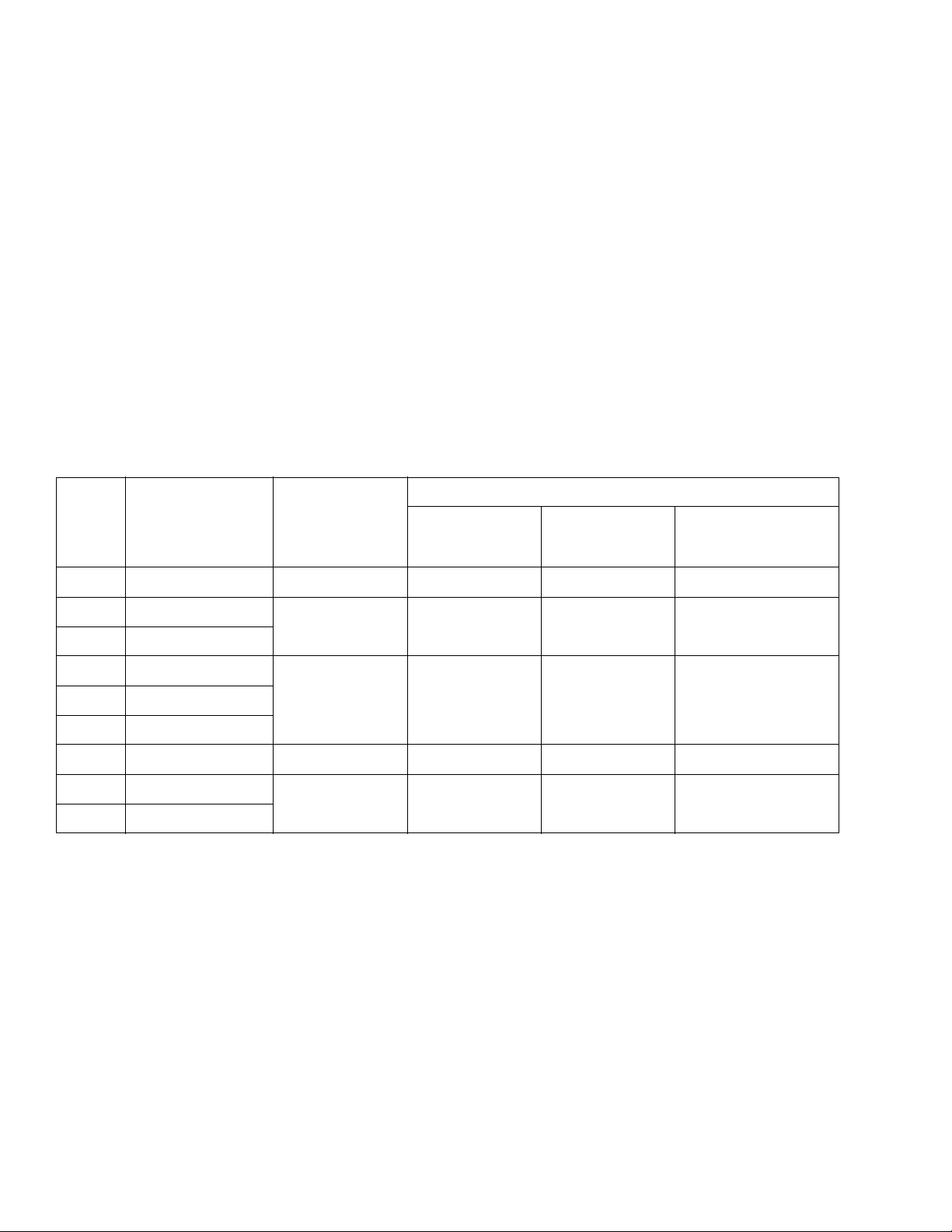

T ab le-1 Flow Coefficients & Maximum Close-Off Differential Pressu r e.

Valve

Size in.

Connection Type

Flow Coefficient

Cv (kv)

Non-Spring

Operating Mode

(Driven Close)

Maximum Close-Off DP, PSI (kPa)

Spring Return

Operating Mode

(Driven Closed)

Spring Return

Power Failure Mode*

(Spring Close) PSID

1/2 NPT, SW, SAE, Rp 1.0 (0.9) 50 (344) 50 (344) 50 (344)

1/2 NPT, SW, SAE, R p

2.0 (1.8) 50 (344) 50 (344) 20 (138)

3/4 NPT, SW, Rp

1/2 NPT, SW, SAE, R p

4.0 (3.5) 35 (241) 35 (241) 20 (138)3/4 NPT, SW, SAE, R p

1SW

3/4 NPT, SW, Rp 7.5 (6.5) 35 (241) 35 (241) 15 (103)

1SW, Rp

8.0 (6.9) 35 (241) 35 (241) 15 (103)

1-1/4 SW

*If valve is driven closed before a power failure, the "operating mode" close- off pressures apply.

Valve Body Legend

NPT — Threaded

SW — Sweat

SAE — Society Automotive Engineers.

Rp—"Metric" Threaded

4 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Page 5

TYPICAL APPLICATION (wiring diagram)

Close

COM

Open

J2

100-315

14-28 AWG

J1

C1

Figure-1 Typical Wiring of Three-Wire

Floating Non-Spring Return Valves.

Figure-2 Typical Wiring of Three-Wire Floating

Non-Spring Return Valves with Time-Out.

Figure-3 Typical Wiring of Three-Wire Floating Spring Return Valves with Time-Out.

Figure-4 Typical Wiring of Three-Wire

Proportional Non-Spring Return Valves.

24 Vac

COM

DC In

18-22 AWG

DA

RA

J2

J3

0-10 V

0-5V

5-10V

4-20mA

J4

100-317

J1

Figure-5 Typical Wiring of Three-Wire Proportional

Spring Return Valves.

1

2

1

2

24 Vac

Closed

COM

Open

J2

Close

COM

Open

J1

18-22 AWG

J2

100-316

J1

J3

1

The 24 Vac/COM supply must be

maintained continuously for valve operation.

The valve returns to its normal position

whenever this supply is interrupted.

2

The CLOSE and OPEN control signals

share the COM terminal with the 24 Vac

supply.

100-516

J4

J3

4-20 mA

5-10V

0-5V

0-10V

24 Vac

J1

COM

DC In

J2

RA

DA

J5

100-517

F-27013-8 © Copyright 2013 Schneider Electric All Rights Reserved. 5

Page 6

INSTALLATION

N O T E

N O T E

Inspection

Requirements

Precautions

Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage.

Return damaged products.

• Tools (not provided):

— Wrench 1 to 1-5/8" (if threaded valve)

— Pipe wrench according to pipe size (if threaded valve)

— Soldering equipment (if sweat fit)

— #1 Phillips head screw driver

— Volt-ohm multimeter

• Training: Installer must be a qualified, experienced technician

• Other accessories as appropriate

General

WARNING:

• Electrical shock hazard! Disconnect power before installation to prevent electrical shock

or equipment damage.

• Make all connections in accordance with the electrical wiring diagram and in accordance

with national and local electrical codes. Use copper conductors only.

CAUTION:

• Avoid locations where excessive moisture, corrosive fumes, explosive vapors, or vibra-

tion are present.

• Avoid electrical noise interference. Do not install near large conductors, electrical

machinery, or welding equipment.

Federal Communications Commission (FCC)

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in residential installations. This equipment generates, uses, and can radiate radio frequency energy and may cause harmful interference if

not installed and used in accordance with the instructions. Even when instructions are followed, there is no guarantee that interference will not occur in a particular installation. If this

equipment causes harmful interference to radio and television reception—which can be

determined by turning the equipment off and on—the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment to an outlet on a circuit different from that to which the receiver

is connected.

• Consult the dealer or an experienced radio/television technician for help.

Canadian Department of Communications (DOC)

This class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

European Standard EN 55022

WARNING:

This is a class B (European Classification) product. In a domestic

environment this product may cause radio interference in which case the

user may be required to take adequate measures.

6 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Page 7

Mounting

360

Figure-6 Mounting.

Figure-7 Two-Way Spring Return Valves.

The Modulating PopT op Series valves can be mounted in horizontal or vertical piping. When

installed in horizontal piping, the actuator must be above the valve body. Refer to Figure-6.

85

Piping

Refer to the piping diagrams in Figure-7 fo r two-way valves. For three-way valves refer to

Figure-8.

• The 3-way is only configured as normally closed. For normally open configuration to the

coil turn valve around. For proportional valves, set the control action (direct or reverse

accordingly).

WARNING:

• The valve should be used in a closed loop system.

• All valves must be piped so that the plug closes against the direction of flow. For two-way

valves, flow is from port B to port A. For normally closed three-way valves, B is the service

port and A is the bypass port. For normally open three-way valves. A is the service port

and B is the bypass port.

• Three-way VM valves must be piped in a mixing configuration, not diverting.

B

COIL

Normally Open

A

Normally Closed

B

COIL

A

F-27013-8 © Copyright 2013 Schneider Electric All Rights Reserved. 7

Page 8

Spring Return

Figure-8 Three-Way Spring Return Val v es.

Figure-9 Three-Way Spring Return Valves.

Normally Closed

Spring Return

Normally Open

B

COIL

A

A B

COIL

Sweat End Valves

1. Slowly position the actuator’s manual operating lever (on the front of the actuator) to the

middle position, to manually open the valve so that the plug is not in contact with the

valve body.

CAUTION:

• The plug inside the valve is made of a plastic material. It may be damaged by heat con-

ducted through the valve body if it remains seated against its port during soldering. Be

sure to manually open the valve before soldering to prevent damage.

• If the manual operating lever does not move freely for manual positioning, the solenoid

may have latched during shipping. Do not force the lever. Instead, first unlatch the solenoid by placing the red manual solenoid latch lever (on the side of the actuato r ) in the

"Up" position, then placing the manual o perating lever in the middle position.

2. With the valve in the mid-position, latch the solenoid by placing the manual solenoid

latch lever in the "Up" position. Then, detach the actuator by depressing the release button and pulling it away from the valve body (Figure-9).

CAUTION:

• Be sure to remove the actuator from the valve body before soldering, to avoid damage to

the actuator and to ease the soldering process.

• Use only lead or tin based solder with a melting point below 600×F (315×C).

Solenoid Latch

Lever

Release

Button

Pin Mating Hole

Stem

Pin

3. Thoroughly clean the ends of the water supply tubing for a minimum distance of 1 inch

(25 mm) from the end, so that a good joint can be made in the shortest time and without

an excessively large flame.

8 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Manual Opening

Lever

Stem Mating Hole

Page 9

4. Solder the valve body in place, directing the flame tip away from the valve and taking

N O T E

N O T E

N O T E

N O T E

care not to overheat the joint area. When finished, cool the valve quickly with a wet

cloth.

The valve body may be submerged in water, or pressurized, for leak testing before

reattaching the actuator.

5. Reinstall the actuator according to "Reattaching the Actuator to the Valve Body."

NPT and Rp Threaded Valves

When installing threaded valves, the actuator should be detached from the valve body to

ease installation. To do so, first slowly move the actuator’s manual operating lever (on the

front of the actuator) to the middle position. Then latch the solenoid by placing the red

manual solenoid latch lever on the side of the actuator to the "Up" position. Finally detach

the actuator by depressing the release button and pulling the actuator away from the valve

body (Figure-9).

1. Apply teflon tape to all but the last two threads on the end of a properly threaded,

reamed, and cleaned pipe. Make sure that pipe chips, scale, etc. do not get into the pipe

since this material may lodge in the valve seat and prevent proper closing and opening

of the valve.

2. Start the joint by hand-screwing the pipe to the valve. If the thread engages normally,

turn the pipe by hand as far as it will go.

3. Use a wrench to fully tighten the valve to the pipe using the flats located on the valve

body ports. Take care not to over-tighten or strip the threads.

4. Reinstall the actuator according to "Reattaching the Actuator to the Valve Body."

Reattaching the Actuator to the Valve Body

1. Before reinstalling the actuator, be sure that its manual operating lever is in the midposition, and that the solenoid is latched. The solenoid is latched when the manual

solenoid latch lever is in its "Up" po si ti on (Figure-9).

2. Depress the release button.

3. Align the valve body with the actuator to ensure the stem is inserted into the large mating hole on the bottom side of the actuator (Figure-9).

4. Engage the actuator on the body and release the button.

Wiring

• Multiple actuators may be connected to a single controller, up to the current rating of the

controller and transformer. Do not exceed the maximum current draw of the controller.

• Use of a properly sized, inherently limited, Class 2 transformer is recommended.

• Use only 18 to 24 AWG copper wire for all connections.

• The return spring feature is primarily a safety feature. It is recommended that the spring

return feature is not used for routine, normal operation.

Three-wire Floating

• The three-wire floating spring return valve includes a time-out feature that automatically

turns off the control signal to the valve after a pre-determined period of continuous operation. This time period is three minutes at 60 Hz and 3.6 minutes at 50 Hz.

• Spring return valves feature a two second time delay upon power loss, to prevent the loss

of valve position during brief outages. There is a three second delay at power-up.

1. Remove the cover from the actuator, then connect the power and control wiring to the

terminal block (Figure-1 and Figure-3).

2. Reinstall the cover onto the actuator.

F-27013-8 © Copyright 2013 Schneider Electric All Rights Reserved. 9

Page 10

N O T E

N O T E

INITIAL SETUP

Application Notes

Proportional

If multiple proportional valves are used on a single 4 to 20 mA loop, each valve must have

its own isolation transformer.

1. Remove the cover from the actuator, then connect the power and control wiring to the

terminal block (Figure-4 and Figure-5).

All units are shipped with the actuator in the direct-acting, 0 to 10 Vdc mode, which means

that the valve opens the B port upon receiving an increasing Vdc control signal. To change

the action to reverse-action (valve closes with an increase in control signal), simply remove

the action jumper J2 and relocate it to the reverse-acting pins. See Figure-4 and Figure-5.

2. Reinstall the cover onto the actuator.

These valves are designed for application to closed hydronic heating and cooling systems.

Use in systems which have substantial make-up water (open systems) is not recommended.

High levels of dissolved oxygen, chlorine, and debris that may be found in open systems can

attack the valve materials and result in premature failure.

3-Wire Floating "T" Type

The controller or thermostat used to operate the "T" type must be configured to turn off the

control signal after being on continuously for three minutes.

3-Wire Floating Time Out "T" Option

If the control system used does not have the ability to limit the running time, then the time

out option must be utilized, which automatically cuts off the control signal to the valve after

three minutes of continuous operation. This is standard on the spring return, and is an option

on the non-spring return.

Proportional "P" Type

Multiple "P" valves may be connected to a single controlle r, up to the current rating of the

controller and transformer. For 4-20 mA control, a separate isolation transformer must be

used with each valve. The actuator is also provided with a jumper to allow the action to be

reversed. All units are shipped with the actuator in the DA (direct acting) mode, which means

that the valve opens the B port upon receiving an increasing control signal. To change the

action to reverse action (valve closes upon receiving an increasing control signal), simply

remove the action jumper and relocate it to the RA (reverse acting) pins.

CHECKOUT

1. Make sure the valve operates freely before installing the valve.

2. If the stem does not operate freely it may indicate that the stem was damaged and may

require that the valve be repaired or replaced.

3. After the piping is under pressure check the valve body and the connections for leaks.

4. After the valve and actuators are installed power the actuator and check the operation.

a. For two-way model:

Power the valve to the close position (per label), and the "B" port should be closed.

b. For three-way model:

Power the valve to the open position (per label), and the "A" port should be closed.

c. For Spring Return model:

Removing power should return the actuator to its normal position.

10 © Copyright 2013 Schneider Electric All Rights Reserved. F-27013-8

Page 11

THEORY OF OPERATION

Figure-10 Modulating Non-Spring Return Valve.

3-3/16

(81)

MAINTENANCE

FIELD REPAIR

DIMENSIONAL DATA

The PopT op Series floating or proportional modulation valves are modulating valve actuator

assemblies. The modulating valves are designed to control the flow in the circuit by making

incremental adjustments to the flow path with-in the valve.

The Spring Return PopT op Series modulating valves, when powered, the actuator moves to

the desired position, at the same time tensing the spring return system. When power is

removed for more than two minutes the spring returns the actuator to the normal position.

The Modulating PopTop Series valves require no maintenance. Replace defective modules

Regular maintenance of the total system is recomended to assure sustained, optimum

performance.

Replace any damaged or failed components with complete bodies or actuator replacements.

4-1/4

(107)

3-13/16

(98)

3/16

(4)

1/8

(2)

Ta ble-2 Dimensions - inches (mm).

Valve Body Size A B C

1/2" Sweat 1-5/16 (33) 15/16 (23) 1-5/16 (33)

3/4" Sweat 1-3/8 (35) 15/16 (23) 1-11/16 (43)

1-1/4" Sweat 1-7/8 (47) 1 (25) 1-13/16 (46)

1/2" NPT, Rp 1-3/8 (35) 15/16 (23) 1-5/16 (33)

3/4" NPT, Rp 1-11/16 (43) 15/16 (23) 1-7/16 (37)

1" NPT, Rp 1-7/8 (47) 1 (25) 1-11/16 (43)

1/2" SAE Flare See Figure-12

2-1/4

(57)

3-3/16

(81)

1-5/8

(41)

B

C

2-Way

3-Way

A

2

(51)

1-9/16

(39)

1-3/16

(31)

A

1" Sweat 1-11/16 (43) 15/16 (23) 1-11/16 (43)

F-27013-8 © Copyright 2013 Schneider Electric All Rights Reserved. 11

Page 12

3-7/8

Figure-11 Modulating Spring Return Valve.

4-3/4

(121)

4-1/4

(108)

15/16 (24)

2-Way

1-5/16

(33)

3-Way

3-7/8

(98)

1-1/4

(33)

4-9/16

(116)

2-5/16

(58)

3-11/16

(94)

4-3/4

(121)

1-9/16

(40)

1-3/16

(30)

1-9/16

(40)

Figure-12 1/2" SAE.

(98)

4-1/4

(107)

3-11/16

B

2-Way

(93)

4-3/4

(121)

C

3-Way

1/16

(1)

1-9/16

(40)

AA

2

(51)

1-9/16

(39)

1-3/16

(31)

© Copyright 2013, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-27013-8

Loading...

Loading...