Application

The AV-352 valve linkage is used to field-install gear

train actuators on specified 2-1/2" to 6" valve bodies.

Features

• Compatible with Schneider Electric

2-1/2" to 6" valves

AV-352

Gear Train Actuator Valve Linkage

General Instructions

• Provides increased close-off pressure on

2-1/2" to 4" valves

• Required for rated close-off pressure on

5" and 6" valves

Applicable Literature

• Environmental Controls Cross-Reference Guide,

F-

23638

• Environmental Controls Reference Manual,

F-

21683

• Environmental Controls Application Manual,

F-

21335

• Environmental Controls Catalog, F-16650

Printed in U.S.A. 6-10 © Copyright 2010 Schneider Electric All Rights Reserved. F-19070-7

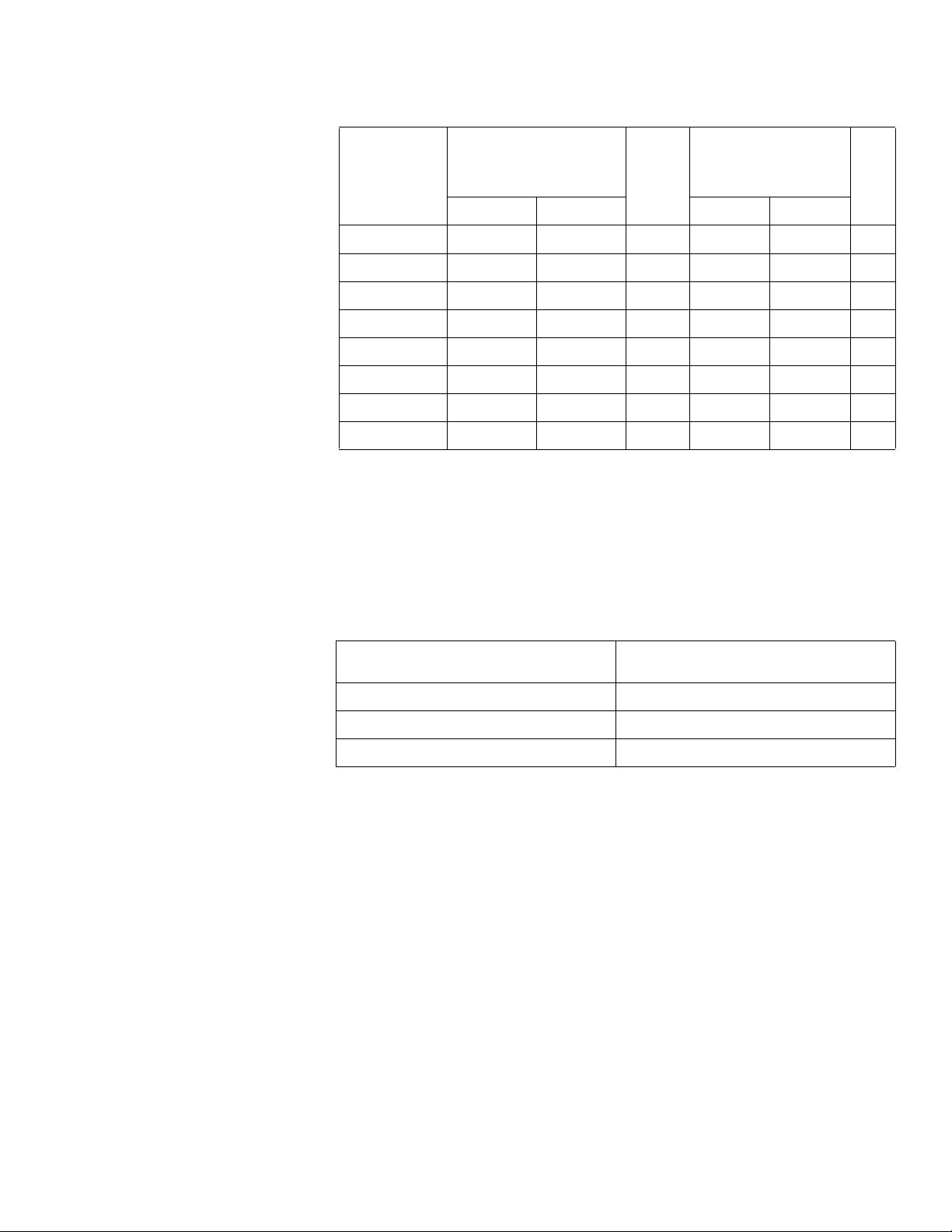

SPECIFICATIONS Close-Off Pressure Rating

Refer to Table-1 and Table-2 to make sure the valve, valve linkage, and actuator are

compatible with each other, and that the close-off rating is adequate.

Table-1 Valve Close-Off Ratings, Pivot Pin Position, and Crank Arm Pivot Radius.

Valve Body Information

Valve Body

Part Number

VB-202-0-2-12

VB-202-0-2-13 85 3 77 (531) 1 2 (50.8)

VB-202-0-2-14 145 4 42 (290) 1 2 (50.8)

VB-202-0-2-15 235 5 20 (138) 2 2-1/2 (63.5)

VB-202-0-2-16 350 6 14 (97) 2 2-1/2 (63.5)

VB-804-0-2-12

VB-804-0-2-13 101 3 77 (531) 1 2 (50.8)

VB-804-0-2-14 170 4 42 (290) 1 2 (50.8)

VB-804-0-2-15 290 5 20 (138) 1 2-3/4 (69.8)

VB-804-0-2-16 390 6 14 (97) 2 2-1/8 (53.9)

VB-817-0-2-14

VB-817-0-2-15 "U" = 195, "L" = 220 5 125 (862) 1 2-1/2 (63.5)

VB-817-0-2-16 "U" = 250, "L" = 275 6 125 (862) 2 2-1/8 (53.9)

VB-9213-0-4-12 2-Way

VB-9213-0-4-13 85 3 77 (531) 1 2 (50.8)

Description C

2-Way

(Obsolete)

125 psig

Flanged

3-Way Mixing

(Obsolete)

125 psig

Flanged

3-Way Diverting

(Obsolete)

125 psig

Flanged

(Current)

250 psig

Screwed

"U" = 160, "L" = 180 4 125 (862) 1 2-1/4 (57.1)

v

56 2-1/2 112 (773) 1 2 (50.8)

74 2-1/2 112 (773) 1 2 (50.8)

56 2-1/2 112 (773) 1 2 (50.8)

Size

in.

Close-Off

Pressure*

psi (k Pa)

Pivot Pin

Position

Approximate

Crank Arm

Pivot Radius

in. (mm)

VB-9213-0-5-12

VB-9213-0-5-13 85 3 77 (531) 1 2 (50.8)

VB-9213-0-5-14 145 4 42 (290) 1 2 (50.8)

VB-9213-0-5-15 235 5 20 (138) 2 2-1/2 (63.5)

VB-9213-0-5-16 350 6 14 (97) 2 2-1/2 (63.5)

VB-9313-0-4-12 3-Way Mixing

VB-9313-0-4-13 101 3 77 (531) 1 2 (50.8)

VB-9313-0-5-12

VB-9313-0-5-13 101 3 77 (531) 1 2 (50.8)

VB-9313-0-5-14 170 4 42 (290) 1 2 (50.8)

VB-9313-0-5-15 290 5 20 (138) 2 2-1/2 (63.5)

VB-9313-0-5-16 390 6 14 (97) 2 2-1/2 (63.5)

VB-9323-0-5-14

VB-9323-0-5-15 "U" = 195, "L" = 220 5 125 (862) 1 2-1/2 (63.5)

VB-9323-0-5-16 "U" = 250, "L" = 275 6 125 (862) 2 2-1/8 (53.9)

*The actuator used must have a 180° travel and a minimum torque of 175 lb-in.

Typical Actuators: MC-351, MC-421, MC-431, MC-4311, MC5-4311, MP-381, MP-382, MP-451, MP-452,

MP-481-600, MP-485, MP-486, MP-4851, and MP5-4851

2-Way

(Current)

125 psig

Flanged

(Current)

250 psig

Screwed

3-Way Mixing

(Current)

125 psig

Flanged

3-Way Diverting

(Current)

125 psig

Flanged

56 2-1/2 112 (773) 1 2 (50.8)

74 2-1/2 112 (773) 1 2 (50.8)

74 2-1/2 112 (773) 1 2 (50.8)

"U" = 160, "L" = 180 4 125 (862) 1 2-1/4 (57.1)

2 © Copyright 2010 Schneider Electric All Rights Reserved. F-19070-7

Table-2 Pivot Pin Position and Crank Arm Pivot Radius

for Valves Not Included in Table-1.

Temperature Restrictions

Valve Stroke

(For Rated Flow)

Stem Up to

Stem Down

in. (mm)

1 (25.4) 1-1/16 (26.9) 1-1/8 (28.5) 1 2-1/8 (53.9) 2-1/4 (57.1) 0.252

1-1/8 (28.5) 1-3/16 (30.1) 1-1/4 (31.7) 1 2-3/8 (60.3) 2-1/2 (63.5) 0.252

1-1/4 (31.7) 1-5/16 (33.3) 1-3/8 (34.9) 1 2-5/8 (66.6) 2-3/4 (69.8) 0.252

1-3/8 (34.9) 1-7/16 (36.5) 1-1/2 (38.1) 1 2-7/8 (73) 3 (76.2) 0.252

1-1/2 (38.1) 1-9/16 (39.6) 1-5/8 (41.2) 2 2 (50.8) 2-1/8 (53.9) 0.385

1-3/4 (44.4) 1-13/16 (46) 1-7/8 (47.6) 2 2-3/8 (60.3) 2-1/2 (63.5) 0.385

2 (50.8) 2-1/16 (52.3) 2-1/8 (53.9) 2 2-5/8 (66.6) 2-3/4 (69.8) 0.385

2-1/4 (57.1) 2-5/16 (58.7) 2-3/8 (60.3) 2 3 (76.2) 3-3/32 (78.5) 0.385

For a 180° actuator: crank arm pivot radius = (required lift/2)(lever ratio).

Example: If the required lift is 1-1/8", the crank arm pivot radius = (1.125/2)(0. 252) = 2.232", or approximately 2- 1/4".

Required Linkage Lift

Including 1/16"

Compression on Valve Seats

in. (mm)

2-Way Valve 3-Way Valve 2-Way Valve 3-W ay Valve

Required

Pivot Pin

Position

Approximate Crank Arm

Pivot Radius

in. (mm)

Lever

Ratio

Verify that the fluid temperature of the media in the valve and the ambient temperature at

the actuator do not exceed the values shown in

Table-3.

Required Components

Table-3 Restrictions on the Maximum Ambient Temperature for the Actuators.

Maximum Temperature of Media in the Valve

(Check Ratings of Valve)

260°F (126°C) 136°F (57°C)

281°F (138°C) 125°F (52°C)

300°F (149°C) 100°F (37°C)

Maximum Ambient Temperature

for Actuator

The actuators and the valves (see Table-1 and Table-2) must be purchased separately.

F-19070-7 © Copyright 2010 Schneider Electric All Rights Reserved. 3

INSTALLATION

C A U T I O N

N O T E

W A R N I N G

Inspection

Requirements

Mounting

Inspect the package for damage. If damaged, notify the appropriate carrier immediately.

If undamaged, open the package and inspect the device for obvious damage.

Return damaged products.

• Tools (not provided):

– Appropriate wrenches for stem extensions, locknuts, packing nuts, and bracket nuts

– Appropriate screw driver for actuator mounting screws

• Training: Installer must be a qualified, experienced technician

1. Install all two-way valves so that they close against the flow. An arrow on the valve body or a tag indicates the proper flow direction.

2. Install all three-way mixing valves with two inlets and one outlet.

3. Install all three-way diverting valves with one inlet and two outlets.

4. Actuators can be mounted in any upright position above the centerline of a valve body.

5. When selecting a location, allow sufficient room for accessories and for service of the product.

Avoid locations where excessive moisture, corrosive fumes, or vibration is present.

ASSEMBLY PROCEDURE

• Refer to Figure-1 during the assembly procedure for clarification, and for part s identification

and layout. The item designators used in Figure-1 are referenced in parentheses throughout the assembly procedure.

• Refer to Figure-3 for mounting dimensions of the linkage assembly.

1. If the packing nut must be removed from the valve, first isolate the valve body , using shutoff valves, or reduce the system pressure on the valve to zero (0) psig. Then, drain all the

fluid from the isolated or depressurized part of the system. Remove the packing nut from

the valve.

Reduce the system pressure in the valve to zero (0) psig and drain all the fluid from the i solated

or depressurized part of the system before removing the p acking nut. R emo ving the p acking

nut while pressure exsists in the valve may cause the packing part s to bl ow out of the valve,

causing bodily injury or water damage.

2. Remove the bracket nut from the valve body.

3. If the valve bonnet is 1" (25.4 mm) in diameter, place the bonnet collar around it.

4. Position the mounting base (D) onto the valve body and secure it in place with the bracket nut. Replace the packing nut if it was removed.

5. Install the actuator (A) onto the mounting base (D), using the actuator mounting

(B).

screws

6. Assemble the two stem links (G) to the main arm (E), using the stem link studs (N) and the stem link nuts (P).

7. Screw the stem locknut (L) and the stem extension (K) well down onto the valve stem.

8. Determine the correct pivot pin location and the approximate crank arm pivot radius.

Refer to

valves not listed in Table-1, refer to Table-2.

Table-1 for applications using Schneider Electric valves. For applications using

4 © Copyright 2010 Schneider Electric All Rights Reserved. F-19070-7

H

P

N

G

E

Enlarged View

A

C

D

E

F

Valve Stem

(Part of Valve Assembly)

Packing Nut and Bracket Nut

(Part of Valve Assembly)

Hidden from View by

Plunger Assembly in the

"Valve Closed" Position

Set Crank Arm at this

Position with Actuator at

Clockwise (180°) End

of Stroke

P

R

H

J

R

R

H

K

L

N

39°

Approx.

Crank Arm

Pivot Radius

1/16" Plunger

Compression

Pivot

Position "1"

3-7/8"

Approx.

Pivot

Position "2"

ABC DEF

GHJKLN

P

R

Act.

Act.

Mtg

Screw

Act.

Crank

Arm

Mtg

Base

Main

Arm

Plunger

Assy.

Stem

Link

Stem

Link

Pin

Main

Arm

Shaft

Stem

Exten.

Stem

Locknut

Stem

Link

Stud

Stem

Link

Nut

"E" Ring

ITEM DESCRIPTIONS

B

F-19070-7 © Copyright 2010 Schneider Electric All Rights Reserved. 5

Figure-1 AV-352 Valve Linkage Assembly.

9. Install the main arm (E) onto the mounting base (D) at the pivot position determined in

N O T E

Full CW Position

Full CCW Position

Short Tooth on

Actuator Shaft

at 9:00

Short Tooth on

Actuator Shaft

at 3:00

the previous step, using the main arm shaft (J) and two "E" rings (R). Make sure that

the innermost hole of the mounting base is used for pivot position "1" and the outermost

hole is used for pivot position "2".

10. Operate the actuator to the full clockwise position (the short tooth on the actuator shaft

is at the 9:00 position). See

Figure-2.

Figure-2 Actuator Shaft Position (Front View).

11. With the actuator at the full clockwise position, position the actuator crank arm (C) on the actuator output shaft at approximately 45°. Tap the actuator crank arm into place, and secure it with the locknut.

12. Install the plunger (F) onto the main arm (E), using the stem link pin (H) and two "E" rings (R).

13. Install the plunger (F) onto the actuator crank arm (C) at the pivot radius determined earlier.

14. With the valve stem fully down against the valve’s bottom seat, turn the stem extension (K) until the hole in the stem extension aligns with the holes in the stem links (G). Then turn the stem extension CCW (upward), one full turn.

15. Operate the actuator (A), as necessary, to realign the holes in the stem extension (K) and stem links (G). Insert the stem link pin (H) into the holes, and secure it in place with two "E" rings (R).

6 © Copyright 2010 Schneider Electric All Rights Reserved. F-19070-7

For MC actuators, remove the power from the actuator once the holes in the stem extension and stem links are realigned.

16. Adjust the plunger compression (see Figure-1) at the stem down position as follows: a. Operate the actuator (A) to its full clockwise position (the short tooth on the actuator

shaft is at the 9:00 position). See Figure-2. The valve stem should be fully down.

b. Check that the plunger compression is approximately 1/16" (1.6 mm).

c. If the plunger compression is less than required, increase it by turning the stem

extension (K) counterclockwise.

d. If the plunger compression is more than required, decrease it by turning the stem

extension (K) clockwise.

MAINTENANCE

9"

(228.6 mm)

12"

(304.8 mm)

1-17/64" (32.1 mm)

Diameter

FIELD REPAIR

17. If the valve is a th ree-way type , adjust the plunger compression at the stem up position as follows:

a. Operate the actuator (A) to its full counterclockwise position (the short tooth on

the actuator shaft is at the 3:00 position). See Figure-2. The valve stem should

be fully up.

b. Check that the plunger compression is approximately 1/16" (1.6 mm).

c. If the plunger compression is less than required, increase it by increasing the crank

arm pivot radius.

d. If the plunger compression is more than required, decrease it by decreasing the

crank arm pivot radius.

e. If the crank arm pivot radius is changed, the stem extension must be readjusted to

provide proper plunger compression on the valve’s bottom seat. If readjustment is

required, repeat the plunger compression adjustment procedure at the stem down

position. This will ensure proper plunger compression in both the stem up and stem

down positions.

18. When adjustment of the plunger compression is completed, tighten the stem locknut (L) against the stem extension (K) to secure the stem extension in position.

The actuator linkage requires no maintenance.

Regular maintenance of the total system is recommended to assure sustained, optimum

performance.

Individual parts of the actuator linkage are not repairable. Replace an inoperative actuator

linkage with a functional unit.

DIMENSIONAL DATA

Figure-3 Mounting Dimensions of Valve Linkage Assembly.

F-19070-7 © Copyright 2010 Schneider Electric All Rights Reserved. 7

On October 1s t, 2009, TA C became the Buildings business of its parent company Schneider Electric. This document r eflects the visual identity of Schneider Electric,

however there remains r eferences to TAC as a cor porate brand in the body copy. As each doc um ent is updated, the body copy wi ll be changed to r eflect appropriate

corporate brand changes.

Copyright 2010, Schneider Electric

All brand names, trademarks and registered

trademarks are the property of their respective

owners. Information contained within this

document is subject to change without notice.

F-19070-7

Loading...

Loading...