Page 1

TAC Vista

TAC Xenta® 102-VF

VAV Controller with Valve Reheat

TAC Xenta 102-VF is a zone controller for VAV heating and cooling applications that use fan on/off control and modulating valve

reheat.

The con trol ler keeps a constant temperature by controlling the air flow with the aid of a Belimo® VAV Compact; a valve reheat coil

is used for the hea t ing stage. Through a carbon dioxide sensor, the air quality can be controlled in the zone.

The controller is a LonMark compliant device that communicates on a LonTalk TP/FT-10 network via a twisted-pair, unpolarized

cable. It is able to operate both as a stand-alone unit and as part of a system. All network variables can be monitored and configured

via the TAC Xenta OP, if the OP version is 3.11 or higher.

STR 100 is a range of wall modules intended to be used together with TAC Xenta 102.

There are plug-in terminal blocks available for the TAC Xenta 100 series that can be attached to the existing terminals.

TECHNICAL DATA

Supply voltage............ 24 V AC –10% +20%, 50–60 Hz

Power consumption:

Controller with TAC Xenta OP ....................4 VA

Actuator supply ..........................max. 12 VA

Digital output............................max. 19 VA

Total...................................max. 35 VA

Ambient Temperature

Storage ................–20 °C to +50 °C (– 4 °F to 122 °F)

Operation ................0 °C to +50 °C (32 °F to 122 °F)

Humidity

Mechanical

Enclosure

Enclosure rating

Flammability class, materials

Dimensions

Weight

Inputs/Outputs

Inputs for occupancy sensor and window contact, X2–X3:

Output for fan on/off control, V1:

Maximum load................................0.8 A

Input for bypass button on wall module, X1:

Input for temperature sensor, B1:

Inputs for air flow and carbon dioxide sensor, Z1–Z2:

..................max. 90% RH non-condensing

....................................ABS/PC

.................................IP 30

...................UL 94 5VB

................................ see Fig. 1

...............................0.4 kg (0.88 lb.)

Voltage across open contact............23 V DC ±1 V DC

Current through closed contact ...................4 mA

Minimum pulse input duration X2/X3 .....250 ms / 15 sec.

Minimum output voltage ...........supply voltage – 1.5 V

Minimum pulse input duration .................. 250 ms

Maximum current, LED ...........2 mA, for ZS 100 series

Thermistor type ............NTC, 1800 W at 25 °C (77 °F)

Measuring range ........ –10 °C to 50 °C (14 °F to 122 °F)

Accuracy ..........................±0.2 °C (±0.36 °F)

Measuring range ......................... 0–10 V DC

Accuracy ..................................±0.05 V

Input setpoint adjustment on wall module, R1:

Type.......................10 kW linear potentiometer

Adjustment range........................±5 °C (±9 °F)

Accuracy ..........................±0.1 °C (±0.18 °F)

Outputs for air flow controller and reheat actuator, Y1–Y2:

Output range............................ 0–10 V DC

Maximum current .............................2 mA

Accuracy ...................................±0.2 V

Application Program

Cycle time ....................................15 sec.

Indication LED Colors

Power On .....................................green

..........................................red

Service

LonMark Standard

................... LonMark Interoperability Guidelines

..............LonMark Functional Profile: VAV Controller

Communication protocol

Physical channel

Neuron type

Agency Compliances

Emission:

CE ..................EN 61000-6-3, C-Tick, FCC Part 15

Immunity:

CE ..................................EN 61000-6-1

Safety

CE ....................................EN 61010-1

UL 916, C-UL US, Open Energy Management Equipment

Approved for plenum installations

RoHS directive............................ 2002/95/EG

Part Numbers

Controller ................................007305350

..................................0-004-7516

Manual

Plug-in Terminal Blocks TAC Xenta 100

......................TP/FT-10, 78 kbps

............................3150, 10 MHz

........................LonTalk

..........007309140

03-00130-02-en

Page 2

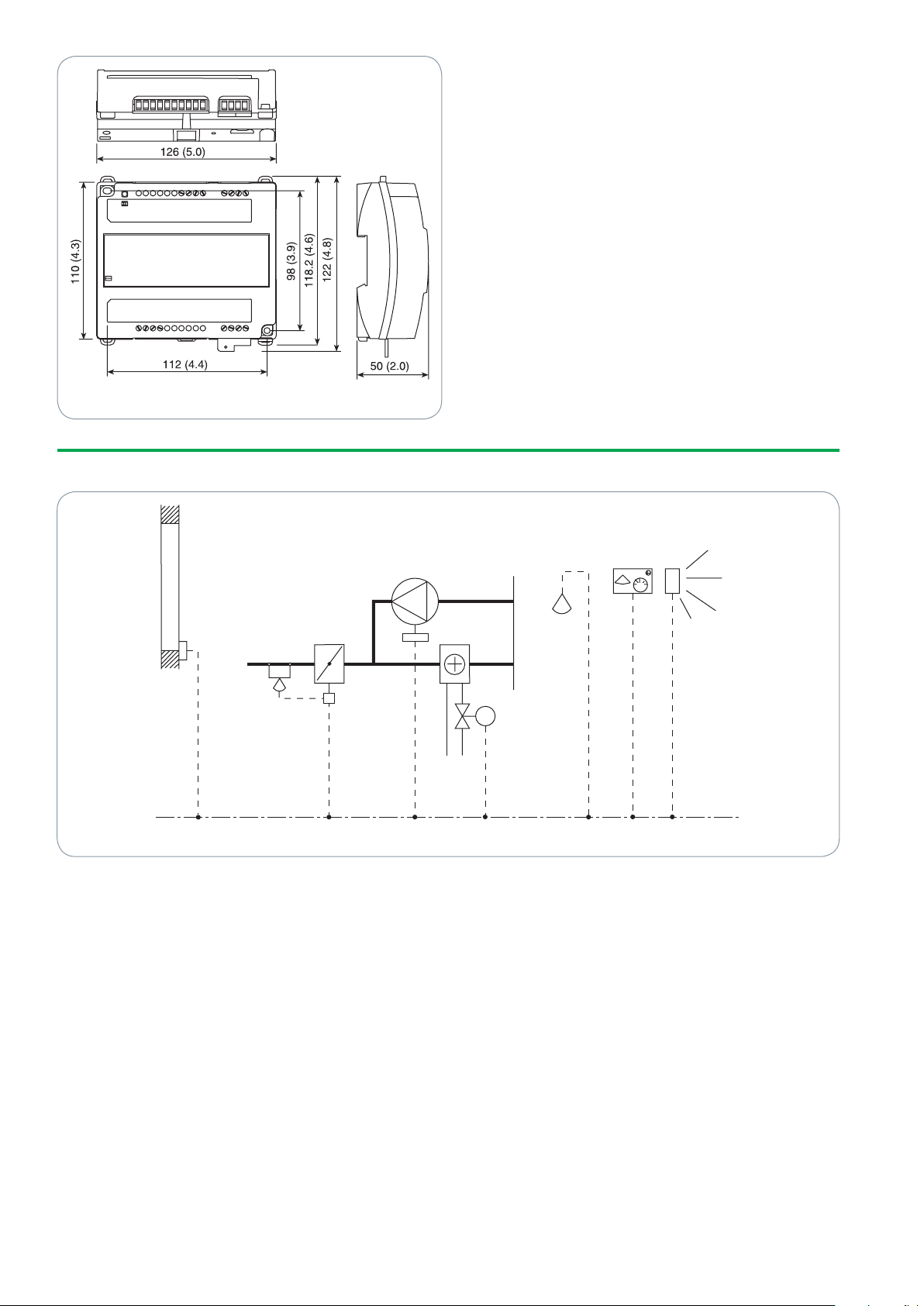

Figure 1

Window

contact

Fan

Damper and

air flow sensor

Valve reheat

Carbon

dioxide

sensor

Wall

module

Occupancy

sensor

2

03-00130-02-en

APPLICATION EXAMPLE

Figure 2

Page 3

0%

100%

HeatingCooling HeatingCooling

Neutral

zone

Neutral

zone

Cooling demandCooling demand

Fan disabled Fan enabled

0%

100%

100%

0%

Air flow

min

max

“low” limit“high” limit

CO

2

level

(ppm)

MAIN FUNCTIONS

3

03-00130-02-en

The function of TAC Xenta 102-VF is

determined by the occupancy mode, the

application mode, the emergency mode,

the manual mode and the node state.

The airflow and a valve reheat coil are

controlled to maintain the zone temperature in sequence. The airflow in crea ses

when the cooling demand in crea ses. If

the cooling demand in the zone decreases, the valve reheat is started, and the fan

runs (if a fan is enabled). Furthermore,

the airflow is set to its minimum value

with a fan, and the minimum heat value

without a fan.

Air Quality Control

In order to maintain the air quality, the

controller selects the highest of three possible air flow values: the air flow or dered

from the cooling sequence, the air quality

control or the set minimum air flow.

When carbon dioxide con centration is

high, the airflow is set from the air quality

control (see fig. 3); at other times, it is

set by the temperature con trol sequence.

The air quality control is enabled in the

occupied and bypass modes.

Figure 3

Figure 4

OPERATING MODES

Occupied Mode

Occupied mode is used when the zone

is occupied. This mode is also the de fault

mode after a reset or a power up. The fan

is on if it is enabled and the heating stage

is active.

Standby Mode

The standby mode is enabled. The neutral

In slave mode, both the slave and mas ter

controllers must be equipped with identical actuators and valves.

Night Purge Mode

In night purge mode, the air flow is set

to its maximum value in order to cool the

zone with outdoor air. If the controller is

used in a heating app lication, the heating

is off.

zone is larger than in occupied mode, and

the air flow is diminished from “minimum

occupied air flow” to “minimum standby

air flow”.

Bypass Mode

To bypass the centrally set standby mode,

press the by pass button on the wall module. The controller switches to oc cupied

mode. When two hours have passed, the

controller reverts to standby mode.

Unoccupied Mode

This mode is used when the building is

EMERGENCY MODE

Emergency mode is forced and has two

different settings:

• Shutdownmode–Thedamperisfully

closed.

• Purgemode–Theairflowissettoits

nominal value, which equals a fully

open damper.

When emergency mode is not needed,

the network variable is set to normal

control.

unoccupied for a longer pe riod. In this

mode, the neutral zone is even larger

than that of the standby mode. The fan is

con trolled in standby mode.

Off Mode

The controller stops running when off

mode is centrally ordered, when a window is opened or slave mode is enab led

in the controller.

Slave Mode

When the network variable nciAppOptions is set so that slave mode is enab led,

the following happens:

The slave controller goes into off mode

and receives copies of output signals from

the master controller.

INSTALLATION

The controller may be mounted on a DIN

rail or fastened onto a ceiling or a wall.

Two sockets are included to allow for this

type of installation.

CABLES

Communication cables: refer to the TAC

Xenta Network Guide, part number

0-004-7460.

Other cables: maximum length 30 m

(100 ft), minimum wire size of 0.7 mm²

(18 AWG) applies to all other cables and

all other equipment. The cables are to be

twisted, but not shielded.

CONFIGURATIONS OPTIONS

By changing the network variable nciAppOptions (see figure 6), it is possible

to achieve different options in TAC Xen ta

102-EF.

The factory setting of the controller is

that all auxi liary units are disabled. Below

is a list of the different options:

• Occupancysensorenabled/disabled

• Windowcontactenabled/disabled

• Fanenabled/disabled

• Airqualitycontrollerenabled/disabled

• Slavemodeenabled/disabled

• Occupancysensornormallyopen/nor-

mally closed

Page 4

Figure 5: LonMark Objects and Network Variables

4

03-00130-02-en

Page 5

HARDWARE INTERFACE

5

03-00130-02-en

Term.

No.

Term.

Name

Description

1 C1 TP/FT-10 communication channel

2 C2 TP/FT-10 communication channel

3 X3 Input, window contact

4 M Measurement neutral

5 X2 Input, occupancy sensor

6 Z2 Input, carbon dioxide sensor

7 M Measurement neutral

8 Z1 Input, air flow

9 D1 Output, indication on wall module

10 M Measurement neutral

11 X1 Input, bypass button on wall module

12 R1 Input, setpoint offset dial on wall module

13 M Measurement neutral

14 B1 Input, temperature sensor

15 G 24 V AC (G) input

16 G0 24 V AC (G0) input

17 OP 24 V AC supply for TAC Xenta OP

18 G 24 V AC supply for TAC Xenta OP

19 V1 Fan on-off control

20 G 24 V AC (G) output

21 G0 24 V AC (G0) output

22 Y2 Reheat valve actuator

23 M Measurement neutral

24 Y1 Air flow controller setpoint

25 – Not used

26 – Not used

27 – Not used

28 – Not used

ROOM UNITS

The STR is a series of wall modules optimized for public facilities such as office buildings, hotels, hospitals, schools, and shopping malls.

The following room units can be configured with the TAC Xenta 102-VF.

Model Temp.

Sensor

Mode

Indicator

Setpoint

Offset

Bypass

Button

Back

Light

SNVT

Binding

Required

STR100 X

STR101 X X

STR102 X X X

STR103 X X X

STR104 X X X X

STR350 X X X X X

STR351 X X X X X X

PART NUMBERS

STR100 .................004600100

STR100-W (White) ........004600110

STR101 .................004600200

STR102 .................004600300

STR103 .................004600700

STR104 .................004600400

LON Modules

STR350 .................004605000

STR351 .................004605100

Page 6

Copyright © 2008-2010, Schneider Electric

All brand names, trademarks and registered trademarks are

the property of their respective owners. Information contained

within this document is subject to change

without notice. All rights reserved.

03-00130-02-en Mar 2010

Loading...

Loading...