Altivar 32

Variable Speed Drives

Safety Functions Manual

08/2014

S1A45606.03

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technica l characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical,

including photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2013 Schneider Electric. All rights reserved.

2 S1A45606 08/2014

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chapter 1 Generalities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standards and Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safety Function STO (Safe Torque Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Function SS1 (Safe Stop 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Function SLS (Safely-Limited Speed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Calculation of Safety Related Parameters . . . . . . . . . . . . . . . . . . . . . . . . 29

SLS Type 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SLS Type 2, Type 3, Type 4, Type 5, and Type 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Behavior of Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Detected Fault Inhibition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priority Between Safety Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Priority Between Safety Functions and No Safety-Related Functions. . . . . . . . . . . . . . . . . .

Chapter 5 Safety Functions Visualization by HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Status of Safety Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dedicated HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Code Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting and Operating the Safety Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Function Capability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Debounce Time and Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7 Certified Architectures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-drive with the Safety Module Type Preventa XPS AF - Case 1 . . . . . . . . . . . . . . . . . .

Multi-drive with the Safety Module Type Preventa XPS AF - Case 2 . . . . . . . . . . . . . . . . . .

Multi-drive Without the Safety Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Drive with the Safety Module Type Preventa XPS AV - Case 1. . . . . . . . . . . . . . . . .

Single Drive with the Safety Module Type Preventa XPS AV - Case 2. . . . . . . . . . . . . . . . .

Single Drive with the Safety Module Type Preventa XPS AF - Case 1. . . . . . . . . . . . . . . . .

Single Drive with the Safety Module Type Preventa XPS AF - Case 2. . . . . . . . . . . . . . . . .

Single Drive According to IEC 61508 and IEC 60204-1 - Case 1 . . . . . . . . . . . . . . . . . . . . .

Single Drive According to IEC 61508 and IEC 60204-1 - Case 2 . . . . . . . . . . . . . . . . . . . . .

Chapter 8 Commissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Safety Functions Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure Safety Functions Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Visualization and Status of Safety Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Safety Related Configuration from Device to PC and from PC to Device. . . . . . . .

Machine Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9 Services and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power and MCU Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Machine Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

13

14

18

20

22

30

32

35

38

39

40

41

42

43

48

49

50

58

59

60

62

64

65

66

67

68

69

70

71

72

73

76

77

81

82

85

90

91

92

S1A45606 08/2014 3

4 S1A45606 08/2014

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, or maintain it. The following special messages may appear throug hout this

documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

S1A45606 08/2014 5

6 S1A45606 08/2014

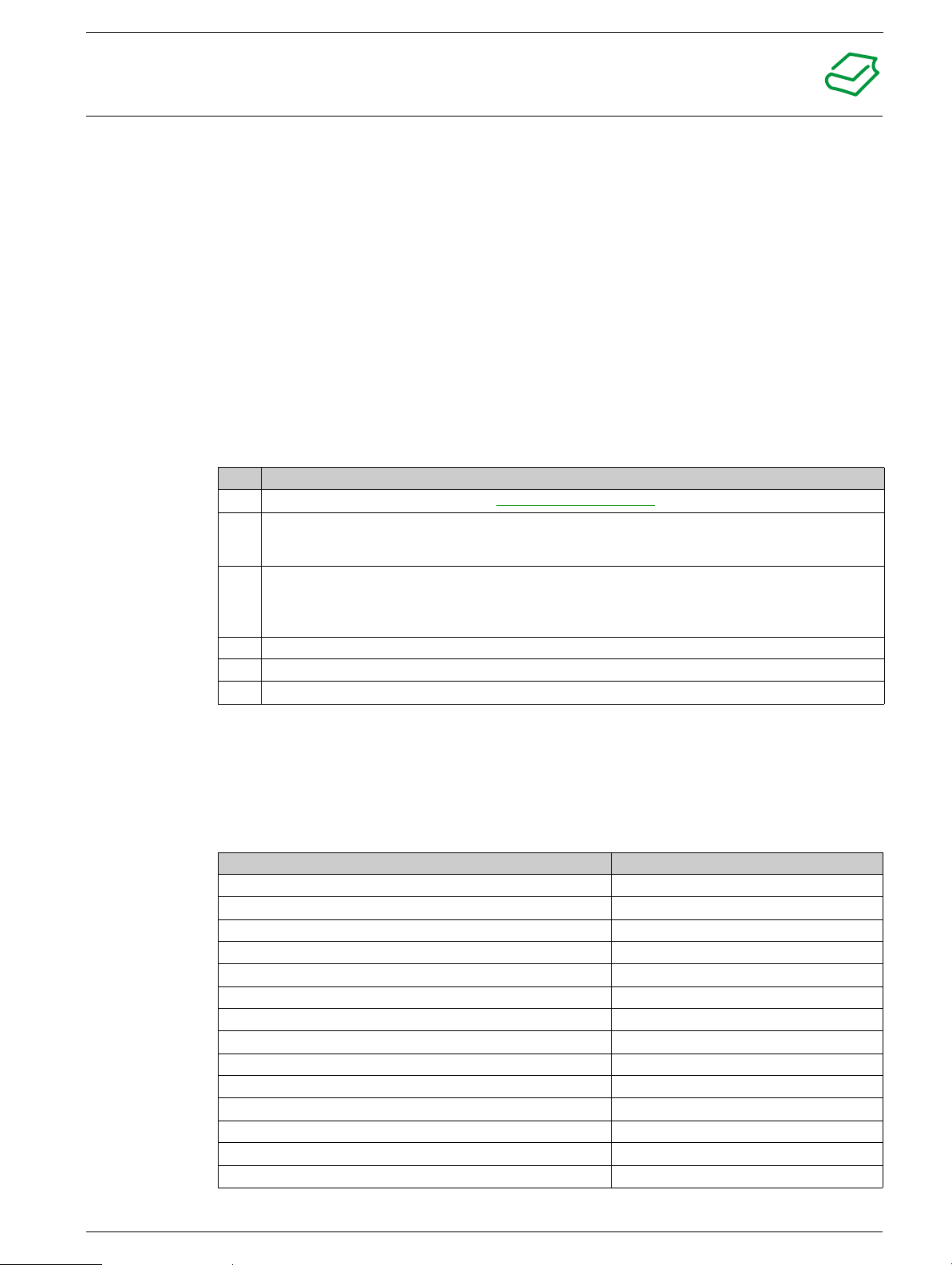

At a Glance

Document Scope

Validity Note

About the Book

The purpose of this document is to provide information about safety functions incorporated in Altivar 32.

These functions allow you to develop applications oriented in the protection of man and machine.

FDT/DTM (field device tool / device type manager) is a new technology chosen by several companies in

automation.

To install the Altivar 32 DTM, you can download and install our FDT: SoMove lite on www.schneiderelectric.com. It is including the Altivar 32 DTM.

The content of this manual is also accessible through the ATV32 DTM online help.

This documentation is valid for the Altivar 32 drive.

The technical characteristics of the devices described in this document also appear online. To access this

information online:

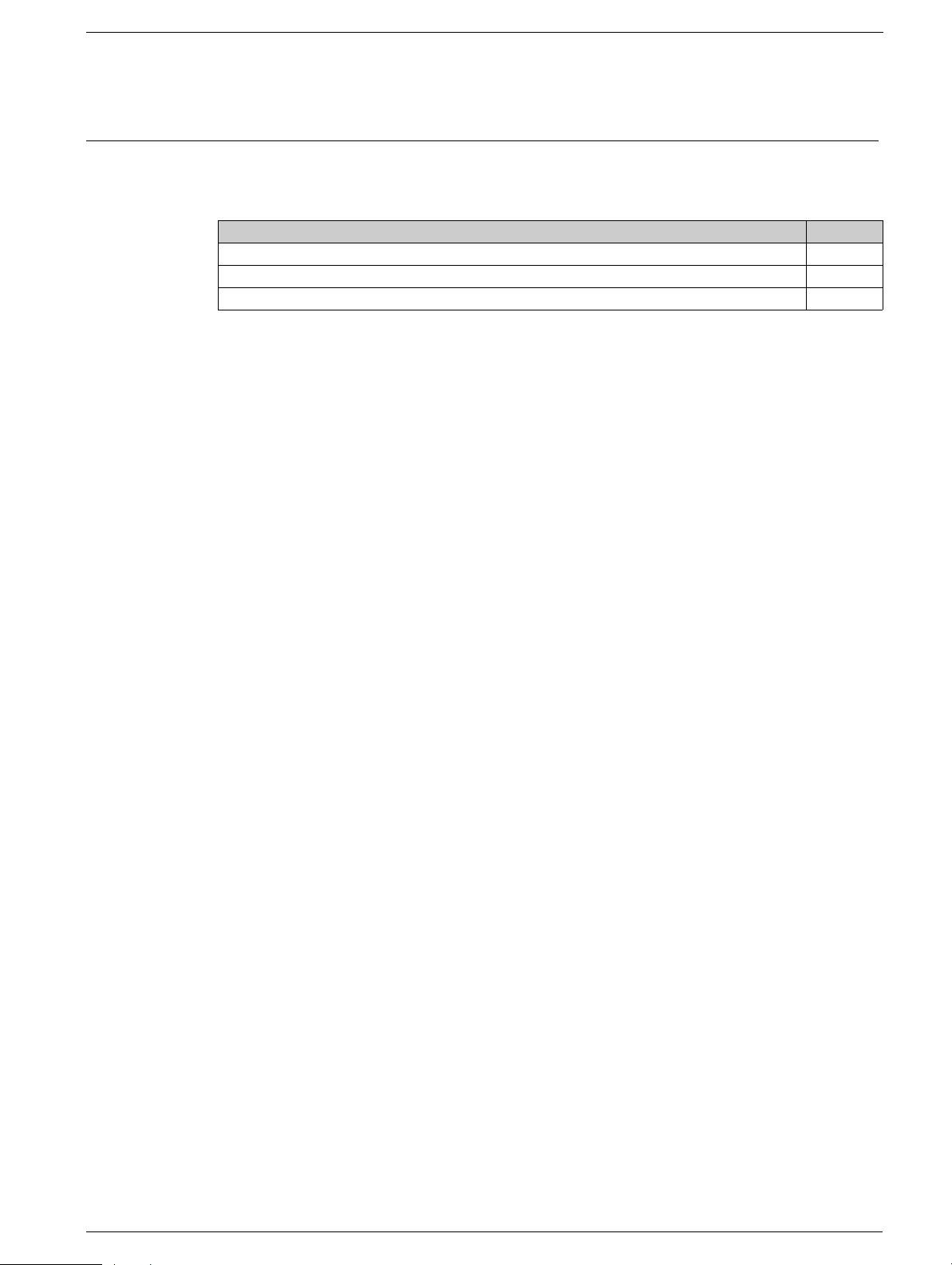

Step Action

1 Go to the Schneider Electric home page www.schneider-electric.com

2 In the Search box type the reference of a product or the name of a product range.

z Do not include blank spaces in the model number/product range.

z To get information on grouping similar modules, use asterisks (*).

3 If you entered a reference, go to the Product Datasheets search results and click on the reference that

interests you.

If you entered the name of a product range, go to the Product Ranges search results and click on the product

range that interests you.

4 If more than one reference appears in the Products search results, click on the reference that interests you.

5 Depending on the size of your screen, you may need to scroll down to see the data sheet.

6 To save or print a data sheet as a .pdf file, click Download XXX product datasheet.

.

Related Documents

The characteristics that are presented in this manual should be the same as those characteristics that

appear online. In line with our policy of constant improvement, we may revise content over time to improve

clarity and accuracy. If you see a difference between the manual and online information, use the online

information as your reference.

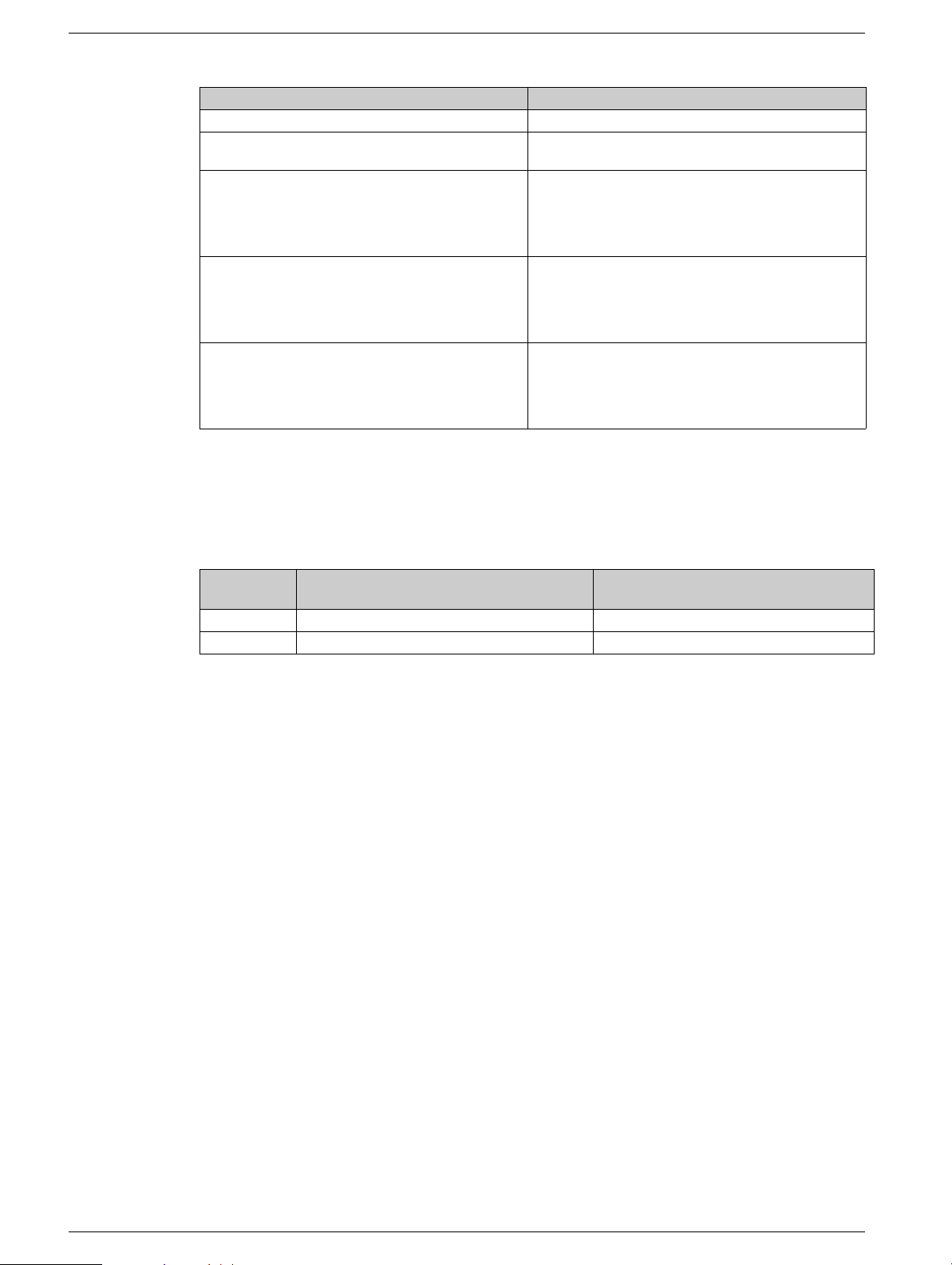

Title of Documentation Reference Number

ATV32 Quick Start Guide S1A41715

ATV32 Quick Start Annex S1B39941

ATV32 Installation Manual S1A28686

ATV32 Programming Manual S1A28692

ATV32 Atex Manual S1A45605

ATV32 Safety Integrated Functions Manual S1A45606

ATV32 Modbus Manual S1A28698

ATV32 CANopen Manual S1A28699

ATV32 PROFIBUS DP Manual S1A28700

ATV32 Modbus TCP - EtherNet/IP Manual S1A28701

ATV32 DeviceNet Manual S1A28702

ATV32 EtherCAT Manual S1A28703

ATV32 PROFINET Manual HRB25668

ATV32 Communication Parameters Manual S1A44568

S1A45606 08/2014 7

Title of Documentation Reference Number

BMP Synchronous Motor Manual 0198441113981

ATV32 Certificates, See www.schneider-electric.com NA

You can download these technical publications and other technical information from our website at

www.schneider-electric.com.

Product Related Information

The information provided in this manual supplements the product manuals.

Carefully read the product manuals before using the product.

Read and understand these instructions before performing any procedure with this drive.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

z Only appropriately trained persons who are familiar with and understand the contents of this manual

and all other pertinent product documentation and who have received safety training to recognize and

avoid hazards involved are authorized to work on and with this drive system. Installation, adjustment,

repair, and maintenance must be performed by qualified personnel.

z The system integrator is responsible for compliance with all local and national electrical code

requirements as well as all other applicable regulations with respect to grounding of all equipment.

z Many components of the product, including the printed circuit boards, operate with mains voltage. Do

not touch. Use only electrically insulated tools.

z Do not touch unshielded components or terminals with voltage present.

z Motors can generate voltage when the shaft is rotated. Before performing any type of work on the drive

system, block the motor shaft to prevent rotation.

z AC voltage can couple voltage to unused conductors in the motor cable. Insulate both ends of unused

conductors of the motor cable.

z Do not short across the DC bus terminals or the DC bus capacitors or the braking resistor terminals.

z Before performing work on the drive system:

z Disconnect all power, including external control power that may be present.

z Place a "Do Not Turn On" label on all power switches.

z Lock all power switches in the open position.

z Wait 15minutes to allow the DC bus capacitors to discharge. The DC bus LED is not an indicator

of the absence of DC bus voltage that can exceed 800 Vdc.

z Measure the voltage on the DC bus between the DC bus terminals using a properly rated voltmeter

to verify that the voltage is < 42Vdc.

z If the DC bus capacitors do not discharge properly, contact your local Schneider Electric

representative.

z Install and close all covers before applying voltage.

Failure to follow these instructions will result in death or serious injury.

DANGER

DANGER

UNINTENDED EQUIPMENT OPERATION

z Read and understand this manual before installing or operating the drive.

z Any changes made to the parameter settings must be performed by qualified personne l.

Failure to follow these instructions will result in death or serious injury.

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

8 S1A45606 08/2014

WARNING

LOSS OF CONTROL

z The designer of any control scheme must consider the potential failure modes of control paths and,

for critical control functions, provide a means to achieve a safe state during and after a path failure.

Examples of critical control functions are emergency stop, overtravel stop, power outage, and restart.

z Separate or redundant control paths must be provided for critical control functions.System control

paths may include communication links. Consideration must be given to the implications of

unanticipated transmission delays or failures of the link.

z System control paths may include communication links. Consideration must be given to the

implications of unanticipated transmission delays or failures of the link.

z Observe all accident prevention regulations and local safety guidelines.(1)

z Each implementation of the product must be individually and thoroughly tested for proper operation

before being placed into service.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

1. For USA: Additional information, refer to NEMA ICS 1.1 (latest edition), “Safety guidelines for the

application, installation, and maintenance of solid-State control” and to NEMA ICS 7.1 (latest edition),

“Safety standards for construction and guide for selection, installation, and operation of adjustable

speed drive systems.”

CAUTION

INCOMPATIBLE LINE VOLTAGE

Before turning on and configuring the drive, ensure that the line voltage is compatible with the supply

voltage range shown on the drive nameplate. The drive may be damaged if the line voltage is not

compatible.

Failure to follow these instructions can result in injury or equipment damage.

NOTICE

RISK OF DERATED PERFORMANCE DUE TO CAPACITOR AGING

The product capacitor performances after a long time storage above 2 years can be degraded. In that

case, before using the product, apply the following procedure:

z Use a variable AC supply connected between L1 and L2 (even for ATVpppppN4 references).

z Increase AC supply voltage to have:

z 80% of rated voltage during 30 min

z 100% of rated voltage for another 30 min

Failure to follow these instructions can result in equipment damage.

S1A45606 08/2014 9

Qualification of personnel

Only appropriately trained persons who are familiar with and understand the contents of this manual and

all other pertinent product documentation are authorized to work on and with this product. In addition, these

persons must have received safety training to recognize and avoid hazards involved. These persons must

have sufficient technical training, knowledge and experience and be able to foresee and detect potential

hazards that may be caused by using the product, by changing the settings and by the mechanical,

electrical and electronic equipment of the entire system in which the product is used.

All persons working on and with the product must be fully familiar with all applicable standards, directives,

and accident prevention regulations when performing such work.

Intended use

The functions described in this manual are only intended for use with the basic product; you must read and

understand the appropriate product manual.The product may only be used in compliance with all

applicable safety regulations and directives, the specified requirements and the technical data.Prior to

using the product, you must perform a risk assessment in view of the planned application. Based on the

results, the appropriate safety measures must be implemented.Since the product is used as a component

in an entire system, you must ensure the safety of persons by means of the design of this entire system

(for example, machine design).

Operate the product only with the specified cables and accessories. Use only genuine accessories and

spare parts.Any use other than the use explicitly permitted is prohibited and can result in hazards.Electrical

equipment should be installed, operated, serviced, and maintained only by qualified personnel.The product

must NEVER be operated in explosive atmospheres (hazardous locations, Ex areas).

10 S1A45606 08/2014

Generalities

Chapter 1

Generalities

What Is in This Chapter?

This chapter contains the following topics:

Introduction 12

Standards and Terminology 13

Basics 14

Topic Page

S1A45606 08/2014 11

Introduction

Overview

The safety functions incorporated in Altivar 32 are intended to maintain the safe condition of the installation

or prevent hazardous conditions arising at the installation. In some cases, further safety-related systems

external to the drive (for example a mechanical brake) may be necessary to maintain the safe condition

when electrical power is removed.

The safety functions are configured with SoMove software.

Integrated safety functions provide the following benefits:

z Additional standards-compliant safety functions

z No need for external safety-related devices

z Reduced wiring effort and space requirements

z Reduced costs

The Altivar 32 drives are compliant with the requirements of the standards in terms of imp lementation of

safety functions.

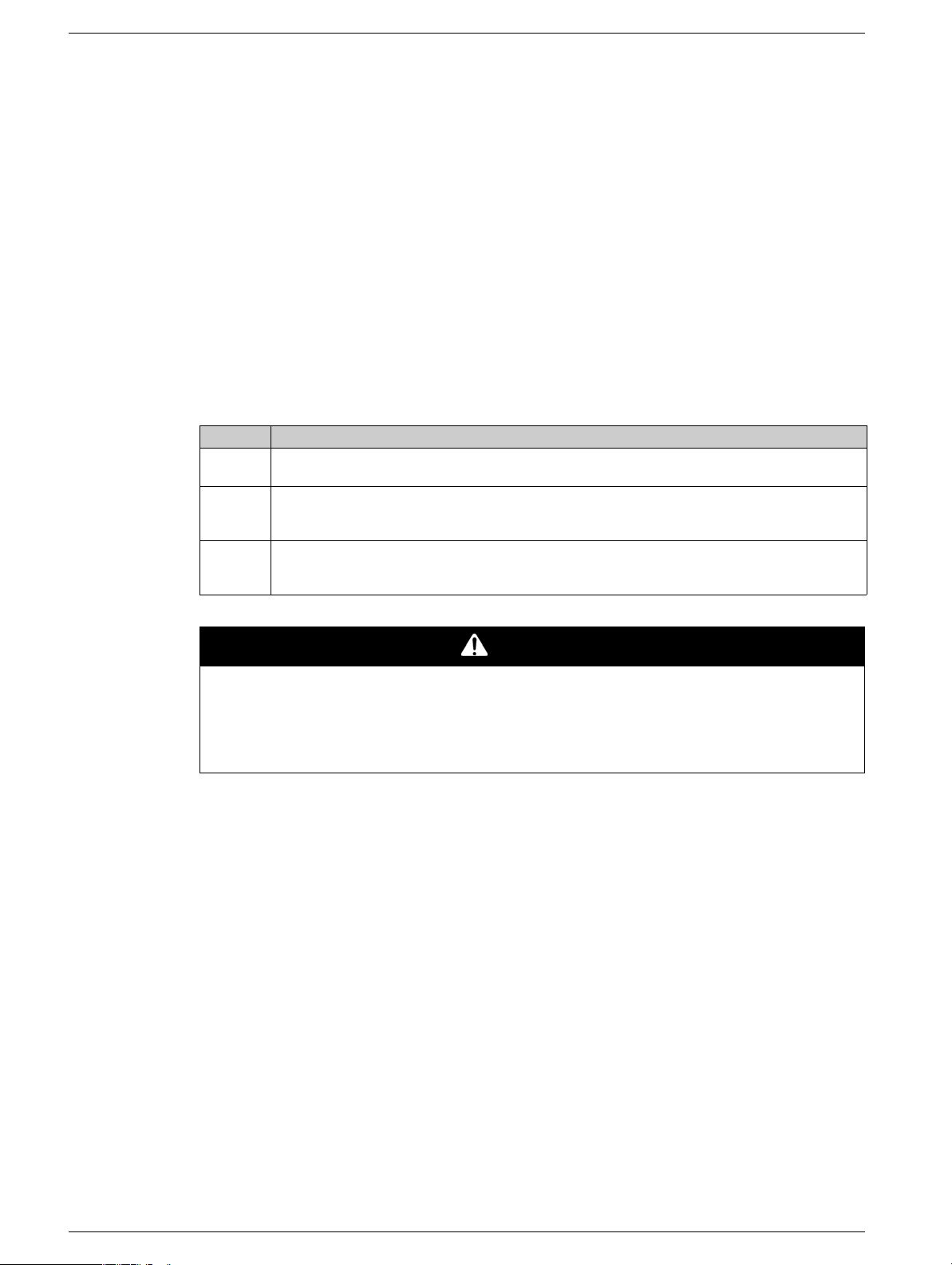

Safety Functions as Defined by IEC 61800-5-2

Definitions

Acronym Description

STO Safe Torque Off

No power that could cause torque or force is supplied to the motor.

SLS Safely-Limited Speed

The SLS function prevents the motor from exceeding the specified speed limit. If the motor speed exceeds

the specified speed limit value, safety function STO is triggered.

SS1 Safe Stop 1

z initiates and monitors the motor deceleration rate within set limits to stop the motor

z initiates the Safe Operating Stop function when the motor speed is below the specified limit

Notation

DANGER

ELECTRIC SHOCK CAUSED BY INCORRECT USE

The safety function STO ([Safe Torque Off]) does not cause electric isolation. The DC bus voltage is

still present.

z Turn off the main voltage using an appropriate switch to achieve a voltage-free condition.

Failure to follow these instructions will result in death or serious injury.

The graphic display terminal (to be ordered separately - reference VW3A1101) menus are shown in square

brackets.

The integrated 7-segment display terminal menus are shown in ro und brackets.

Parameter names are displayed on the graphic display terminal in square brackets.

Parameter codes are displayed on the integrated 7-segment display terminal in round brackets.

12 S1A45606 08/2014

Standards and Terminology

Overview

The technical terms, terminology, and the corresponding descriptions in this manual normally use the

terms or definitions in the relevant standards.

In the area of drive systems this includes, but is not limited to, terms such as safety function, safe state,

fault, fault reset, failure, error, error message, warning, warning message, and so on.

Among others, these standards include:

z IEC 61800 series: Adjustable speed electrical power drive systems

z IEC 61508 Ed.2 series: Functional safety of electrical/electronic/programmable electronic safety-related

systems

z EN 954-1 Safety of machinery - Safety related parts of control systems

z EN ISO 13849-1 & 2 Safety of machinery - Safety related parts of control systems

z IEC 61158 series: Industrial communication networks - Fie ldbus specifications

z IEC 61784 series: Industrial communication networks - Pro files

z IEC 60204-1: Safety of machinery - Electrical equipment of machines – Part 1: General requirements

EC Declaration of Conformity

The EC Declaration of Conformity for the EMC Directive can be obtained on www.schneider-electric.com.

ATEX Certification

The ATEX certificate can be obtained on www.schneider-electric.com.

Functional Safety Certification

The integrated safety functions are compatible and certified according to IEC 61800-5-2 Ed.1 Adjustable

speed electrical power drive systems - Part 5-2: Safety requirements - Functional.

IEC 61800-5-2, as a product standard, sets out safety-related considerations of Power Drive System

Safety Related PDS (SR)s in terms of the framework of the IEC 61508 Ed.2 series of standards.

Compliance with the IEC 61800-5-2 standard, for the safety functions described below, will facilitate

incorporation of a PDS (SR) (Power Drive System suitable for use in safety-related applications) into a

safety-related control system using the principles of IEC 61508, or ISO 13849, as well as IEC 62 061 for

process systems and machinery.

The defined safety functions are:

z SIL2 and SIL3 capability in compliance with IEC 61800-5-2 and the IEC 61508 Ed.2 series.

z Performance Level d and e in compliance with ISO 13849-1.

z Compliant with Category 3 and 4 of European standard ISO 13849-1 (EN 954-1).

Also refer to safety function Capability.

The safety demand operating mode is considered to be high demand or continuous mode of operation

according to the IEC 61800-5-2 standard.

The functional safety certificate is accessible on www.schneider-electric.com.

S1A45606 08/2014 13

Basics

Functional Safety

Automation and safety engineering are two areas that were completely separate in the past but have

recently become more and more integrated.

The engineering and installation of complex automation solutions are greatly simplified by integrated safety

functions.

Usually, the safety engineering requirements depend on the application.

The level of requirements results from the risk and the hazard potential arising from the specific application.

IEC 61508 Standard

The standard IEC 61508 Functional safety of electrical/electronic/programmable electronic safety-related

systems covers the safety-related function.

Instead of a single component, an entire function chain (for example, from a sensor through the logical

processing units to the actuator) is considered as a unit.

This function chain must meet the requirements of the specific safety integrity level as a whole.

Systems and components that can be used in various applications for safety tasks with comparable risk

levels can be developed on this basis.

SIL - Safety Integrity Level

The standard IEC 61508 defines 4 safety integrity levels (SIL) for safety functions.

SIL1 is the lowest level and SIL4 is the highest level.

A hazard and risk analysis serves as a basis for determining the required safety integrity level.

This is used to decide whether the relevant function chain is to be considered as a safety function and

which hazard potential it must cover.

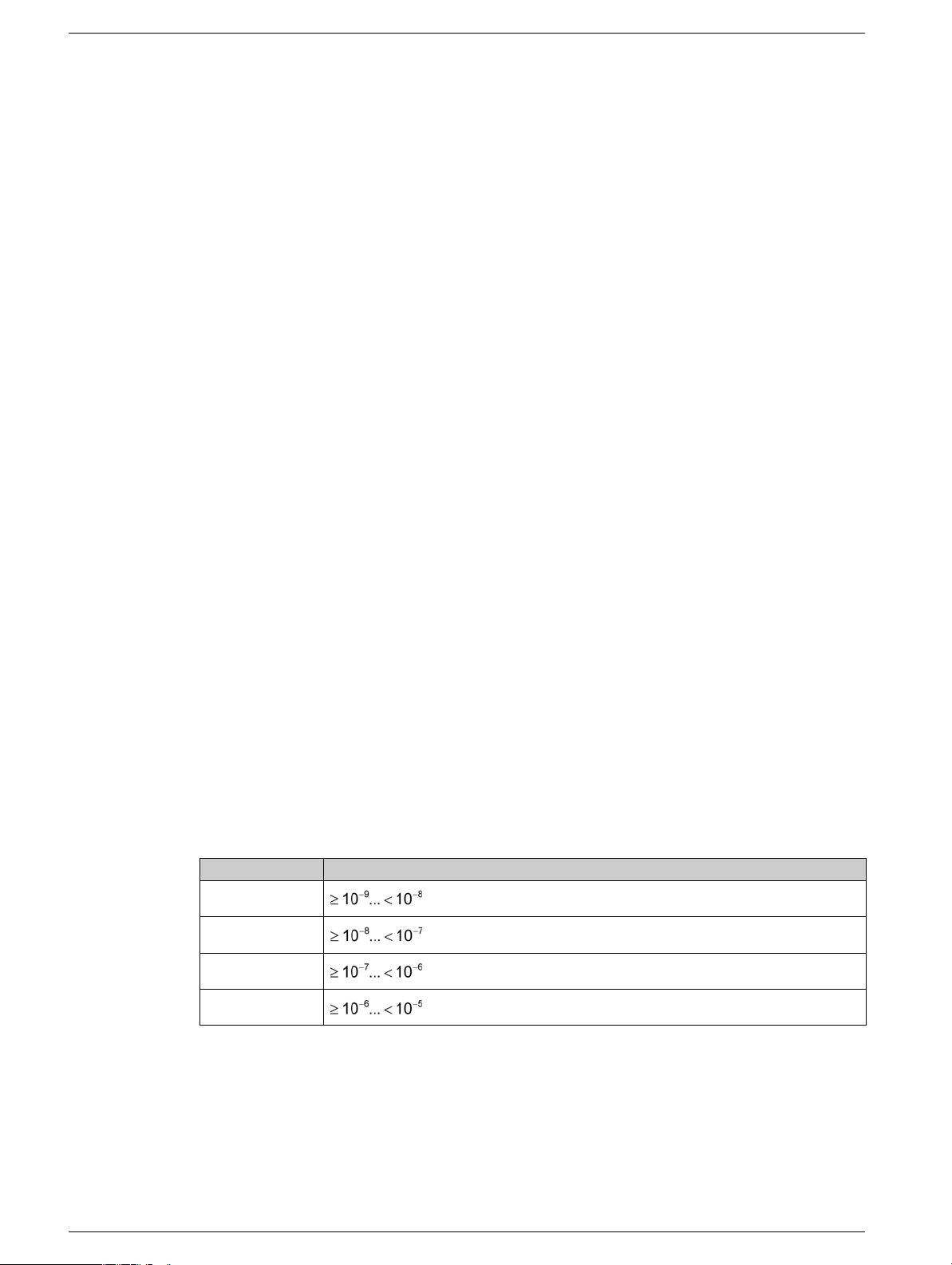

PFH - Probability of a Dangerous Hardware Failure Per Hour

To maintain the safety function, the IEC 61508 standard requires various levels of measures for avoiding

and controlling detected faults, depending on the required SIL.

All components of a safety function must be subjected to a probability assessment to evaluate the

effectiveness of the measures implemented for controlling detected faults.

This assessment determined the PFH (Probability of a dangerous Failure per Hour) for a safety system.

This is the probability per hour that a safety system fails in a hazardous manner and the safety function

cannot be correctly executed.

Depending on the SIL, the PFH must not exceed certain values for the entire safety system.

The individual PFH values of a function chain are added. The result must not exceed the maximum value

specified in the standard.

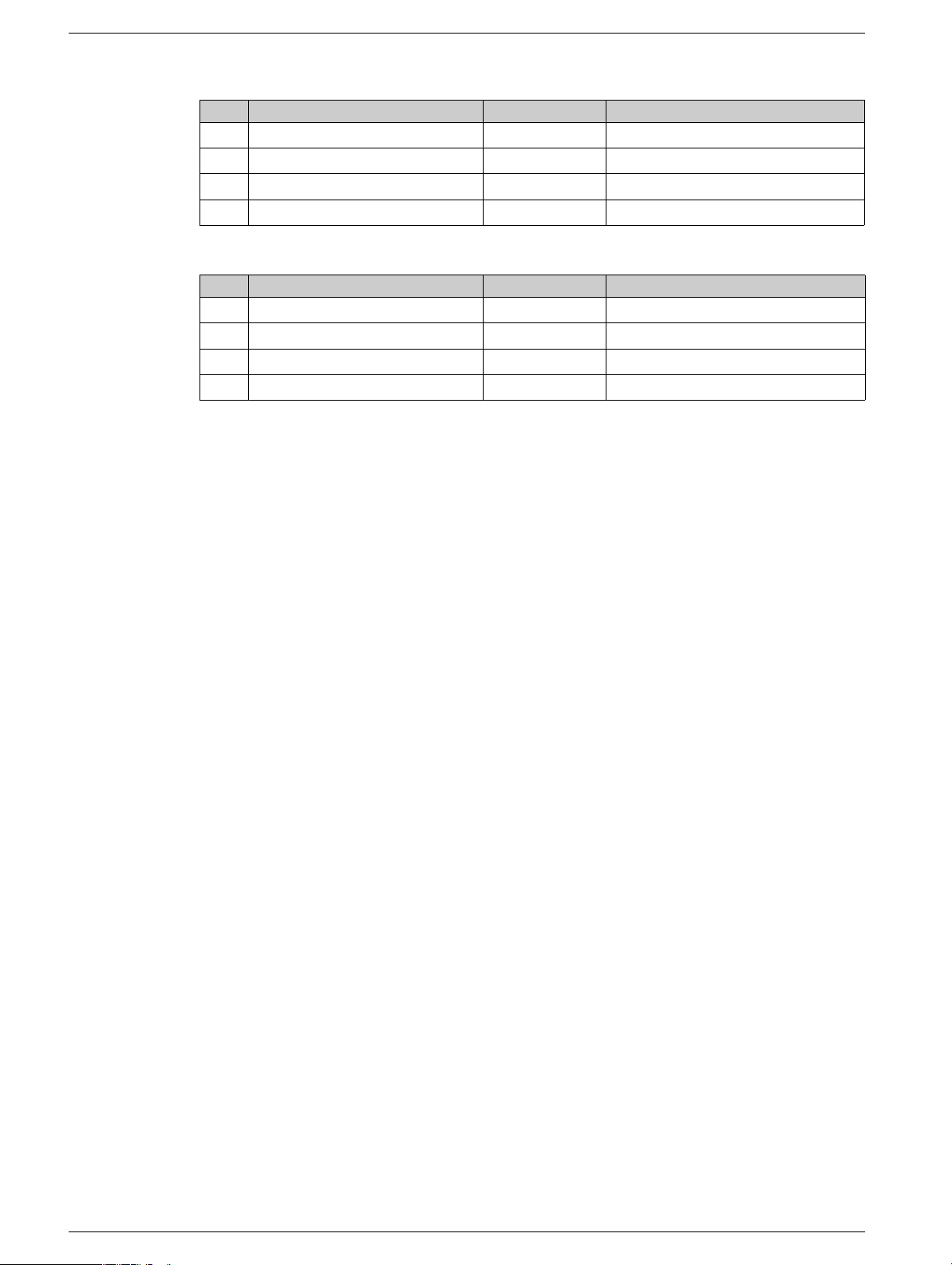

Performance level Probability of a dangerous Failure per Hour (PFH) at high demand or continuous demand

4

3

2

1

14 S1A45606 08/2014

PL - Performance Level

The standard IEC 13849-1 defines 5 Performance levels (PL) for safety functions.

a is the lowest level and e is the highest level.

Five levels (a, b, c, d, and e) correspond to different values of average probability of dangerous failure per

hour.

Performance level Probability of a dangerous Hardware Failure per Hour

e

d

c

b

a

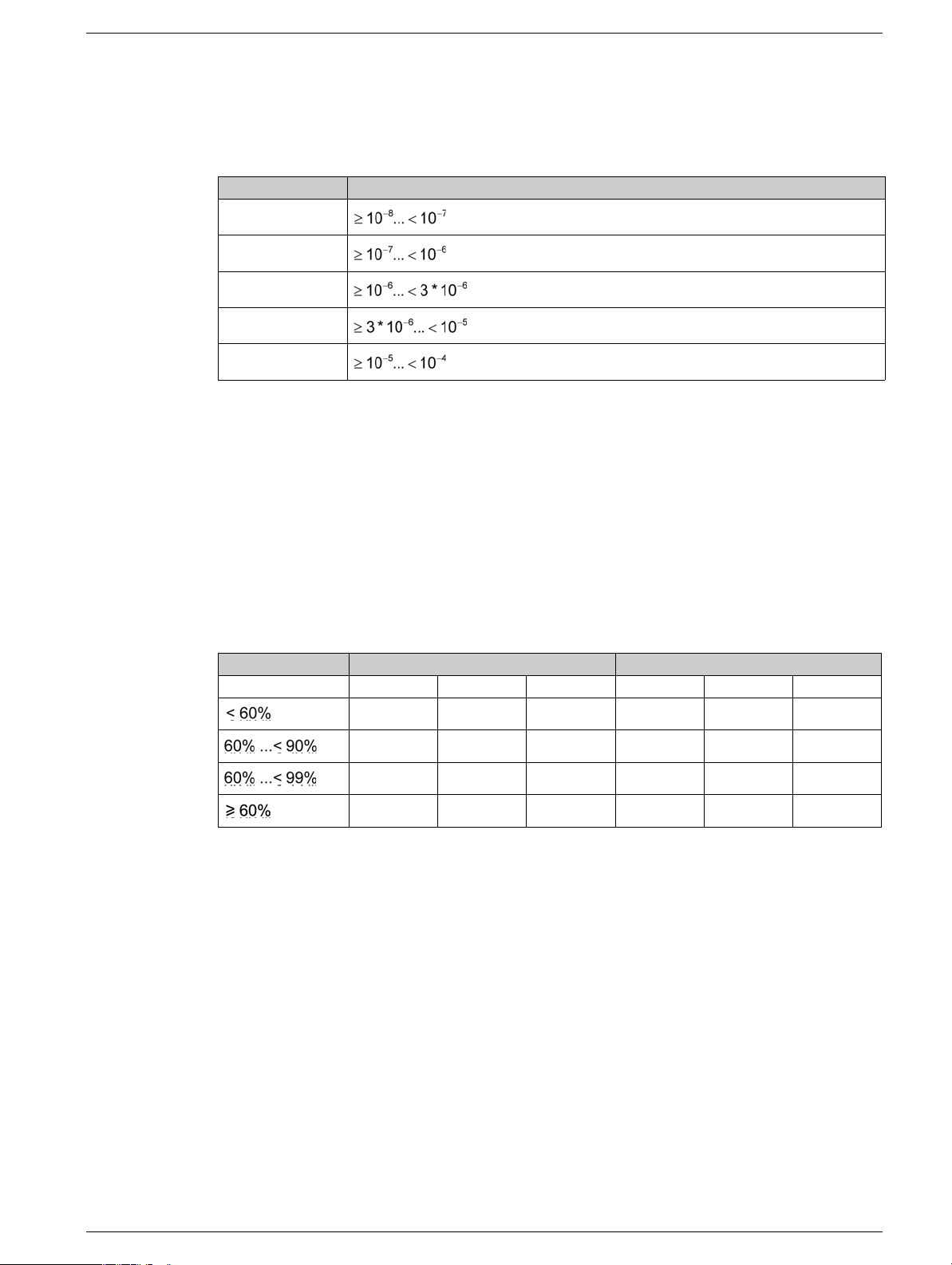

HFT - Hardware Fault Tolerance and SFF - Safe Failure Fraction

Depending on the SIL for the safety system, the IEC 61508 standard requires a specific hardware fault

tolerance HFT in connection with a specific proportion of safe failures SFF (Safe Failure Fraction).

The hardware fault tolerance is the ability of a system to execute the required safety function in spite of the

presence of one or more hardware faults.

The SFF of a system is defined as the ratio of the rate of safe failures to the total failure rate of the system.

According to IEC 61508, the maximum achievable SIL of a system is partly determined by the hardware

fault tolerance HFT and the safe failure fraction SFF of the system.

IEC 61508 distinguishes two types of subsystem (type A subsystem, type B subsystem).

These types are specified on the basis of criteria which the standard defines for the safety-relevant

components.

SFF HFT type A subsystem HFT type B subsystem

PFD - Probability of Failure on Demand

The standard IEC 61508 defines SIL using requirements grouped into two broad categories: hardware

safety integrity and systematic safety integrity. A device or system must meet the requirements for both

categories to achieve a given SIL.

The SIL requirements for hard ware s af ety i ntegri ty are based on a probabilistic analysis of the device. To

achieve a given SIL, the device must meet targets for the maximum probability of dangerous failure and a

minimum Safe Failure Fraction. The concept of ’dangerous failure’ must be rigorously defined for the

system in question, normally in the form of requirement constraints whose integrity is verified throughout

system development. The actual targets required vary depending on the likelihood of a demand, the

complexity of the device(s), and types of redundancy used.

012012

SIL1 SIL2 SIL3 ---- SIL1 SIL2

SIL2 SIL3 SIL4 SIL1 SIL2 SIL3

SIL3 SIL4 SIL4 SIL2 SIL3 SIL4

SIL3 SIL4 SIL4 SIL3 SIL4 SIL4

S1A45606 08/2014 15

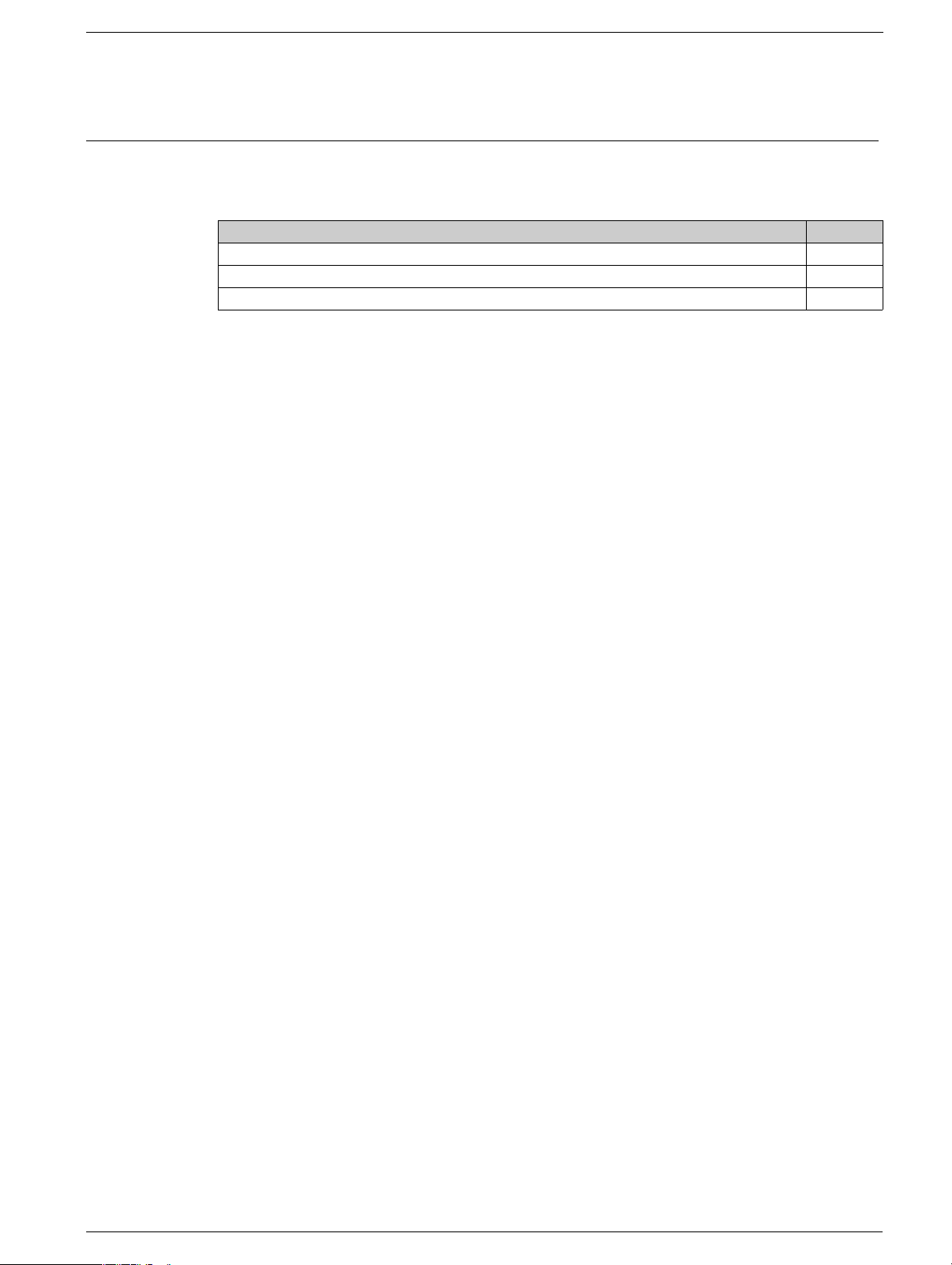

The PFD (Probability of Failure on Demand) and RRF (Risk Reduction Factor) of low demand operation

for different SILs are defined in IEC 61508 are as follows:

SIL PFD PFD (power RRF

1 0.1 - 0.01

2 0.01 - 0.001

3 0.001 - 0.0001

4 0.0001 - 0.00001

In continuous operation, these changes to the following:

SIL PFD PFD (power RRF

1 0.00001 - 0.000001

2 0.000001 - 0.0000001

3 0.0000001 - 0.00000001

4 0.00000001 - 0.000000001

The hazards of a control system must be identified then analyzed in a risk analysis. These risks are

gradually mitigated until their overall contribution to the hazard is deemed to be acceptable. The tolerable

level of these risks is specified as a safety requirement in the form of a target probability of a dangerous

failure over a given period, stated as a discrete SIL level.

Fault Avoidance Measures

Systematic errors in the specifications, in the hardware and the software, usage faults and maintenance

faults in the safety system must be avoided to the maximum degree possible. To meet these requirements,

IEC 61508 specifies a number of measures for fault avoidance that must be implemented depending on

the required SIL. These measures for fault avoidance must cover the entire life cycle of the safety system,

i.e. from design to decommissioning of the system.

10

10

10

10

10

10

10

10

-1

-2

-3

-4

-5

-6

-7

-8

- 10

- 10

- 10

- 10

- 10

- 10

- 10

- 10

-2

-3

-4

-5

-6

-7

-8

-9

10 - 100

100 - 1000

1000 - 10,000

10,000 - 100,000

100,000 - 1,000,000

1,000,000 - 10,000,000

1000 - 10,000

100,000,000 - 1,000,0000,000

16 S1A45606 08/2014

Description

Chapter 2

Description

What Is in This Chapter?

This chapter contains the following topics:

Safety Function STO (Safe Torque Off) 18

Safety Function SS1 (Safe Stop 1) 20

Safety Function SLS (Safely-Limited Speed) 22

Topic Page

S1A45606 08/2014 17

Safety Function STO (Safe Torque Off)

Overview

ELECTRIC SHOCK CAUSED BY INCORRECT USE

The safety function STO (Safe Torque Off) does not cause electric isolation. The DC bus voltage is still

present.

z Turn off the mains voltage using an appropriate switch to achieve a voltage-free condition.

Failure to follow these instructions will result in death or serious injury.

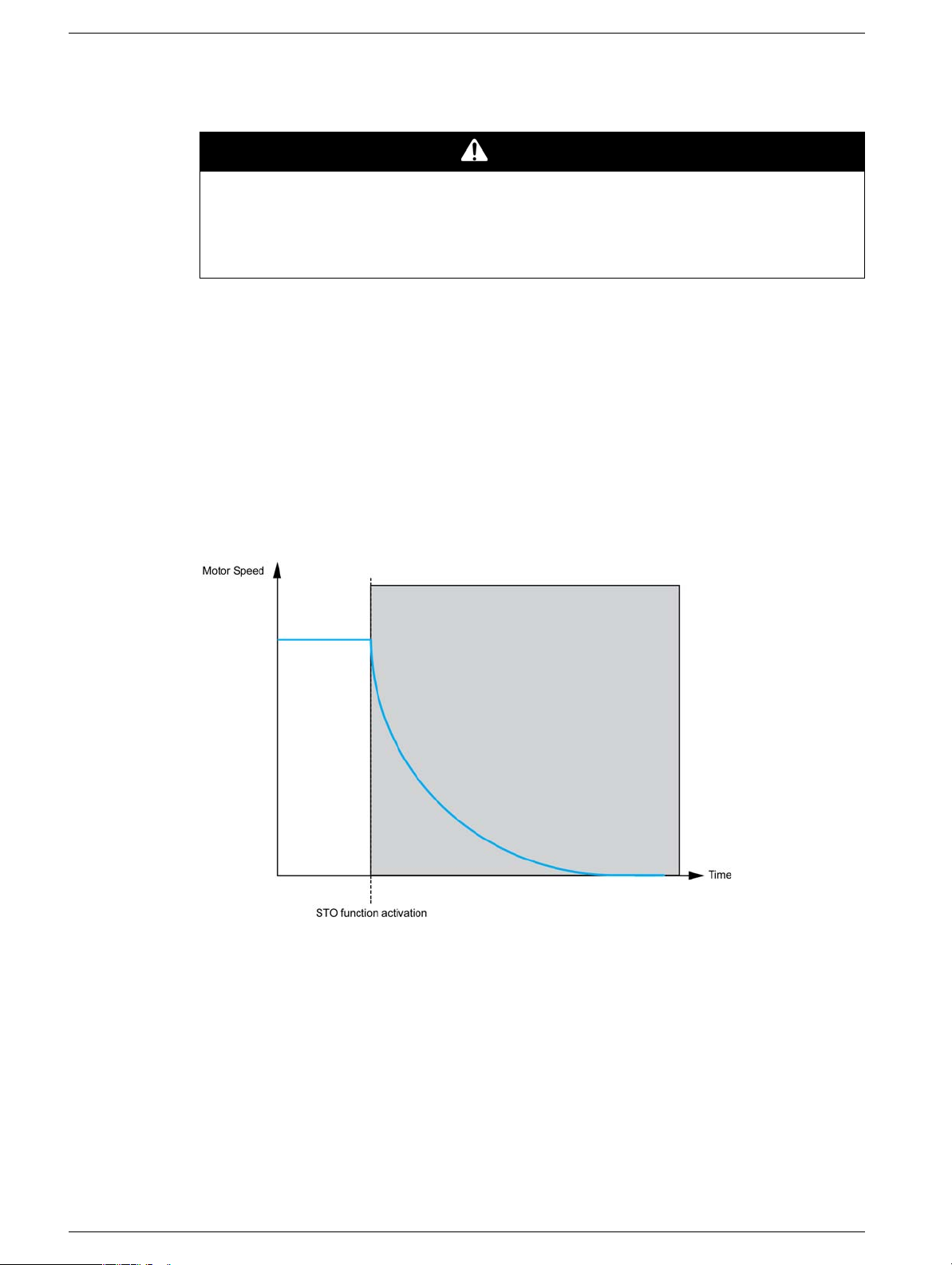

This function brings the machine safely into a no-torque state and / or prevents it from starting accidentally.

The safe torque-off (safety function STO) function can be used to effectively implement the prevention of

unexpected start-up functionality, thus making stops safe by preventing the power only to the motor, while

still maintaining power to the main drive control circuits.

The principles and requirements of the prevention of unexpected start-up are described in the standard EN

1037:1995+A1.

The logic input STO is assigned to this safety function and cannot be modified.

If a paired terminal line in 2 channels is required to trigger safety function STO, the function can also be

enabled by the safety-related logic inputs.

The safety function STO is configured with the commissioning software.

The safety function STO status can be displayed using the HMI of the drive or using the commissioning

software.

DANGER

18 S1A45606 08/2014

Safety Function STO Standard Reference

The safety function STO is defined in section 4.2.2.2 of standard IEC 61800-5-2 (edition 1.0 2007.07):

Power, that can cause rotation (or motion in the case of a linear motor), is not applied to the motor.The

PDS(SR) (power drive system suitable for use in safety-related applications) will not provide energy to the

motor which can generate torque (or force in the case of a linear motor).

z NOTE 1: This safety function corresponds to an uncontrolled stop in accordance with stop category 0

of IEC 60204-1.

z NOTE 2: This safety function may be used where power removal is required to prevent an unexpected

start-up.

z NOTE 3: In circumstances where external influences (for example, falling of suspended loads) are

present, additional measures (for example, mechanical brakes) may be necessary to prevent any

hazard.

z NOTE 4: Electronic equipment and contactors do not provide adequate protection against electric

shock, and additional insulation measures may be necessary.

Safety Function (SF) Level Capability for Safety Function STO

Configuration SIL

STO with or without safety module SIL 2 PL d

STO & LI3 with or without safety module SIL 3 PL e

LI3 and LI4 SIL 2 PL d

LI5 and LI6 SIL 2 PL d

Emergency Operations

Standard IEC 60204-1 introduces 2 emergency operations:

z Emergency switching-off:

z Emergency stop:

PL

Safety Integrity Level according

to IEC 61-508

Performance Level according

to ISO-13849

This function requires external switching components, and cannot be accomplished with drive based

functions such as safe torque-off (STO).

An emergency stop must operate in such a way that, when it is activated, the hazardous movement of

the machinery is stopped and the machine is unable to start under any circumstances, even after the

emergency stop is released.

An emergency stop shall function either as a stop category 0 or as a stop category 1.

Stop category 0 means that the power to the motor is turned off immediately. Stop category 0 is

equivalent to the safe torque-off (STO) function, as defined by standard EN 61800-5-2.

In addition to the requirements for stop (see 9.2.5.3 of IEC 60204-1), the emergency stop function has

the following requirements:

z it shall override all other functions and operations in all modes.

z This reset shall be possible only by a manual action at that location where the command has been

initiated. The reset of the command shall not restart the machinery but only permit restarting.

z For the machine environment (IEC 60204-1 and machinery directive), when safety function STO is

used to manage an emergency stop category 0, the motor must not restart automatically when safety

function STO has been triggered and deactivated (with or without a power cycle). This is the reason

why an additional safety module is required if the machine restarts automatically after the safety

function STO has been deactivated.

S1A45606 08/2014 19

Safety Function SS1 (Safe Stop 1)

Overview

The safety function SS1 (Safe Stop 1) monitors the deceleration according to a dedicated deceleration

ramp and safely shuts off the torque once standstill has been achieved.

When the safety function SS1 is triggered, it overrides all othe r fu nctions (except STO function that has

priority) and operations in all modes.

The unit of the SS1 deceleration ramp is in Hz/s. The setting of the ramp is done with two parameters:

[SS1 ramp unit] SSrU (Hz/s) to give the unit of the ramp in 1 Hz/s, 10 Hz/s, and 100 Hz/s

[SS1RampValue] SSrt (0.1) to set the value of the ramp

Ramp calculation:

Ramp = SSrU*SSrt

Example: If SSrU = 10 Hz/s and SSrt = 5.0 the deceleration ramp is 50 Hz/s.

The safety function SS1 is configured with the commissioning software, for more information see

Commissioning (see page 75).

The safety function SS1 status can be displayed using the HMI of the drive or using the commissioning

software.

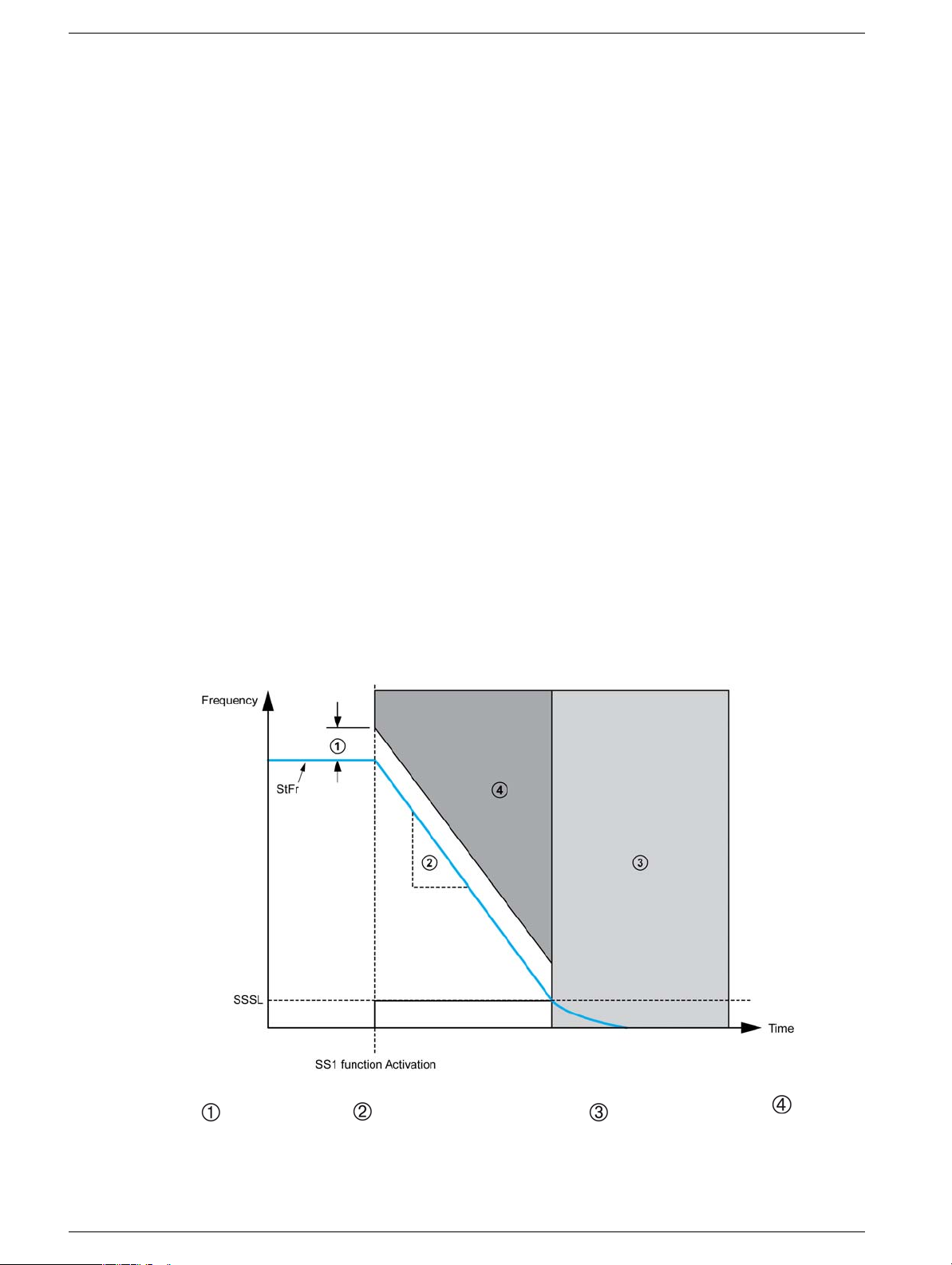

Behavior on Activation of the SS1 Function

When SS1 function is triggered, it monitors the deceleration of the motor according to the specified

monitoring ramp until standstill is reached and verifies if the motor speed is not above a monitored limit

value depending on the specified monitoring ramp and the parameter [SS1 trip threshold] SStt.

If the monitored limit value is exceeded:

z An error is triggered and the error code [Safety function fault] SAFF is displayed.

z Safety function STO is triggered.

After the [Standstill level] SSSL has been reached, the safety function STO is triggered.

SS1 function continues to be active if the request has been removed before the standstill has been

reached.

NOTE: The error detection depends on [Stator Frequency] StFr.

: SS1 trip threshold, : SS1 deceleration ramp (dV/dT), : STO function triggered, : Error and

STO function triggered

20 S1A45606 08/2014

Behavior on Deactivation of the SS1 Function

After an SS1 stop, send a new run command (even if the run command is set on level command).

SS1 Standard Reference

The SS1 function is defined in section 4.2.2.2 of standard IEC 61800-5-2:

The PDS(SR) (Power drive system suitable for use in safety-related applications) either:

z Initiates and controls the motor deceleration rate within set limits to stop the motor and initiates the STO

function (see 4.2.2.2) when the motor speed is below a specified limit; or

z Initiates and monitors the motor deceleration rate within set limits to stop the motor and initiates the STO

function when the motor speed is below a specified limit; or

z Initiates the motor deceleration and initiates the STO function after an application-specific time delay.

NOTE: This safety function corresponds to a controlled stop in accordance with stop category 1 of IEC

60204-1.

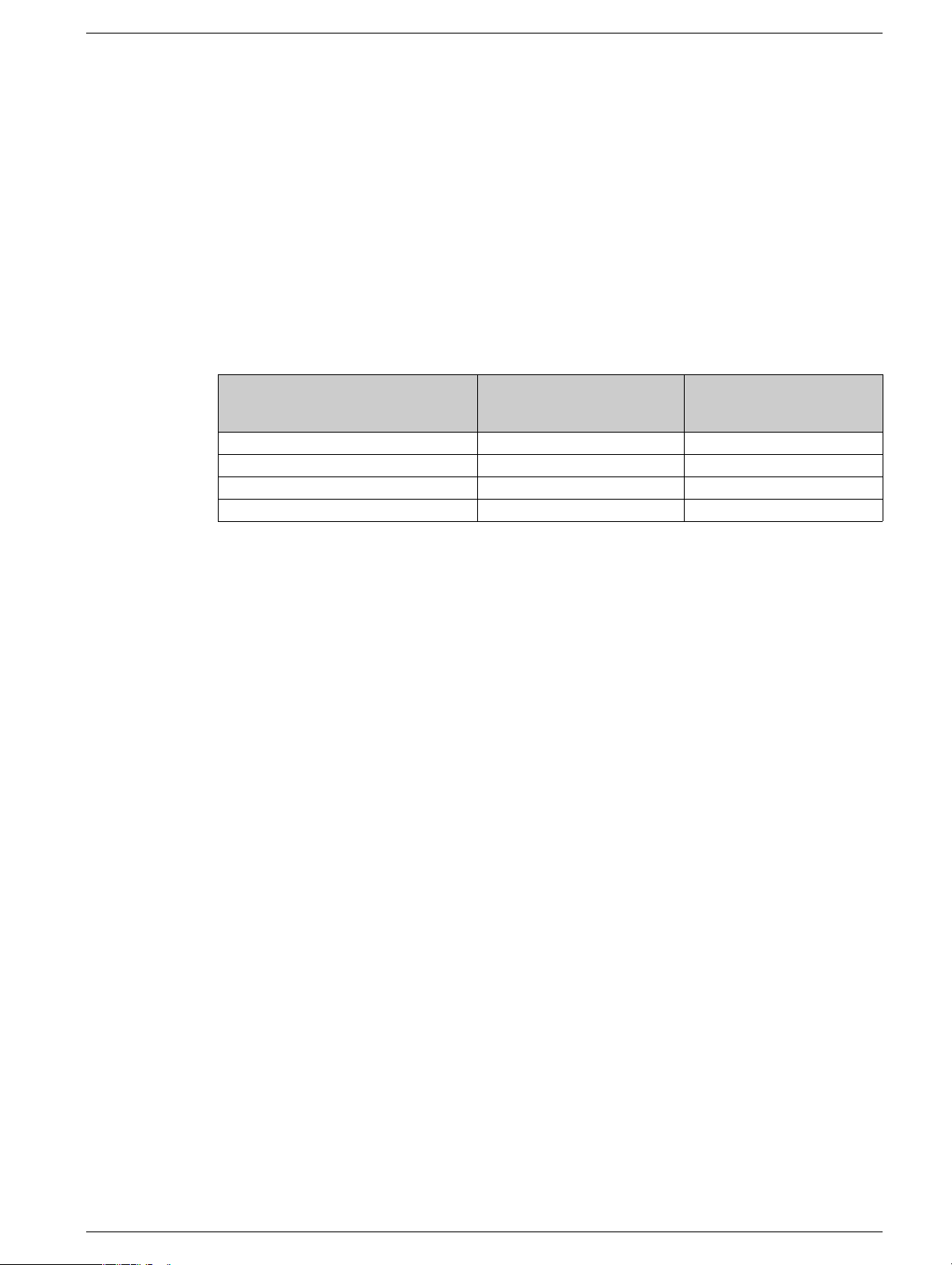

Safety Function (SF) Level Capability for Safety Function SS1

Function Configuration SIL

SS1 type C STO with Preventa module SIL2 PL d

SS1 type B LI3 and LI4 SIL 2 PL d

Emergency Stop Category 1

An emergency stop must operate in such a way that, when it is activated, the hazardous movement of the

machinery is stopped and the machine is unable to start under any circumstances, even after the

emergency stop is released.

An emergency stop shall function either as a stop category 0 or as a stop category 1.

Stop category 1 is a controlled shut-down, whereby the energy supply to the motor is maintained to perform

the shut-down, and the energy supply is only interrupted when the shut-down has been completed.

Stop category 1 is equivalent to the [Safe Stop 1] SS1 function, as defined by standard EN 61800-5-2.

In addition to the requirements for stop (see 9.2.5.3 of IEC 60204-1), the emergency stop function has the

following requirements:

z it shall override all other functions and operations in all modes.

z This reset shall be possible only by a manual action at that location where the command has been

initiated. The reset of the command shall not restart the machinery but only permit restarting.

For the machine environment (IEC 60204-1 and machinery directive), when safety function SS1 is used to

manage an emergency stop category 1, the motor must not restart automatically when safety function SS1

has been triggered and deactivated (with or without a power cycle). This is the reason why an addition al

safety module is required if the machine restarts automatically after the safety function SS1 has been

deactivated.

PL

Safety Integrity Level

According to IEC 61-508

STO and LI3 with Preventa module SIL 3 PL e

LI5 and LI6 SIL 2 PL d

Performance Level

According to ISO-13849

S1A45606 08/2014 21

Safety Function SLS (Safely-Limited Speed)

Overview

This function is used to limit the speed of a motor.

There are 6 types of SLS function:

z SLS type 1: Limits the motor speed to the actual motor speed.

z SLS type 2: Limits the motor speed to a value set using a parameter.

z SLS type 3: Same as type 2 with specific behavior if the motor speed is above threshold value set using

a parameter.

z SLS type 4: Limits the motor speed to a value set using a parameter. The direction of rotation can be

changed while the safety function is active.

z SLS type 5: Same as type 4 with the specific behavior if the motor speed is above threshold value set

using a parameter.

z SLS type 6: Same as type 4 with specific behavior if the motor speed is above threshold value set using

a parameter.

NOTE: SLS types 2 and 3 use (SLwt) [SLS Wait time] parameter to allow the motor to run under the

[standstill level ] SSSL for a given time after the safety function SLS has been activated.

The safety function SLS is configured with the commissioning software, for more information see

commissioning (see page 75).

The status of the safety function SLS can be displayed using the HMI of the drive or using the

commissioning software.

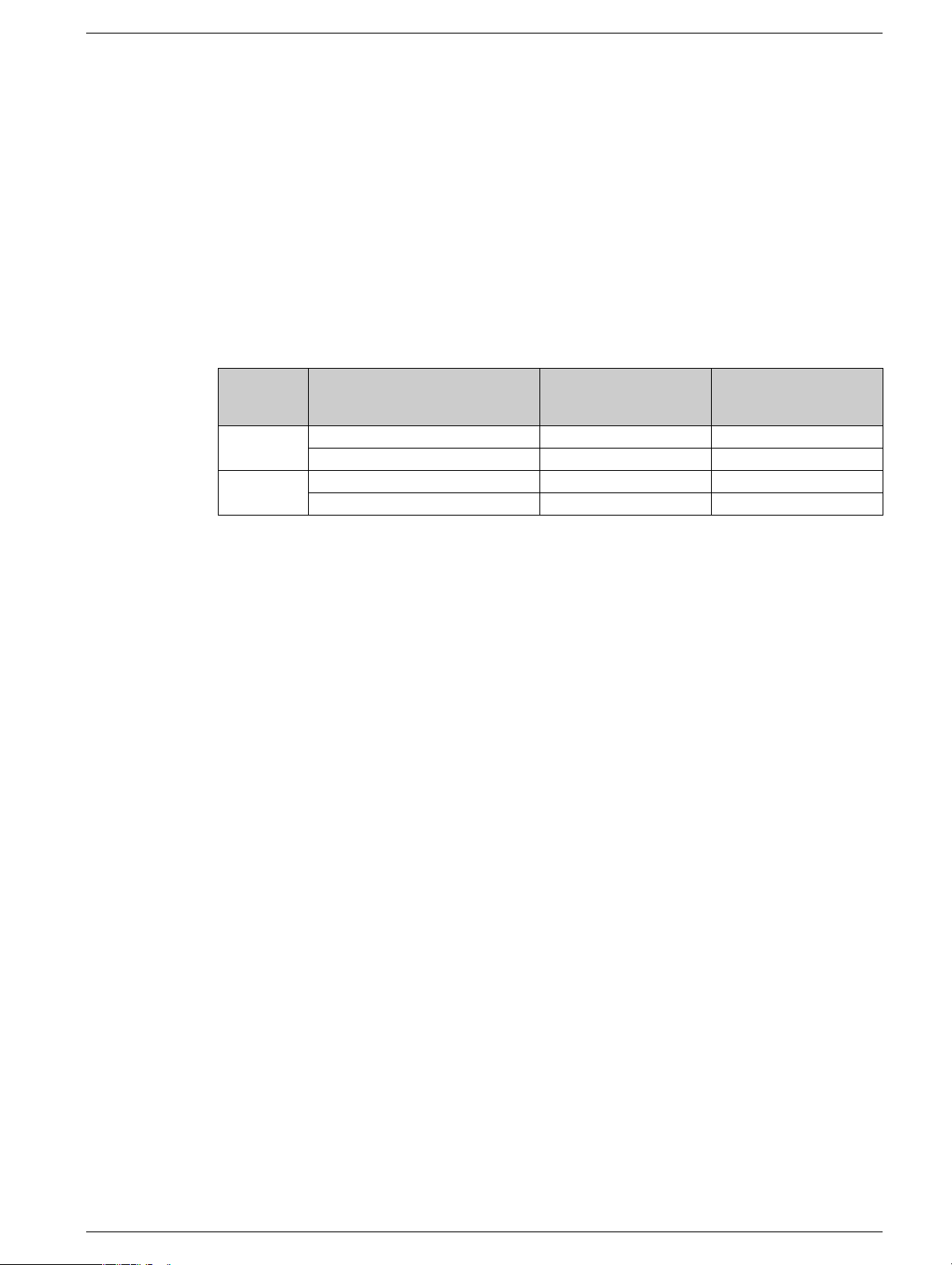

Behavior on Activation of the Safety Function SLS Type 1

: Error and STO function triggered, : Reference upper limit, : STO function triggered

When the safety function is activated:

z If the [Stator Frequency] StFr is above the [SLS tolerance threshold] SLtt, the safety function

STO is triggered and an error is triggered with the error code [Safety function fault] SAFF.

z If the [Stator Frequency] StFr is under the [SLS tolerance threshold] SLtt, the stator

frequency is limited to the actual stator frequency. The reference frequency will only vary between this

value and the standstill level SSSL.

While the function is activated:

z If the[Stator Frequency] StFr decreases and reaches the [Standstill level] SSSL frequency, the

safety function STO is triggered.

z If the [Stator Frequency] StFr increases and reaches [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

22 S1A45606 08/2014

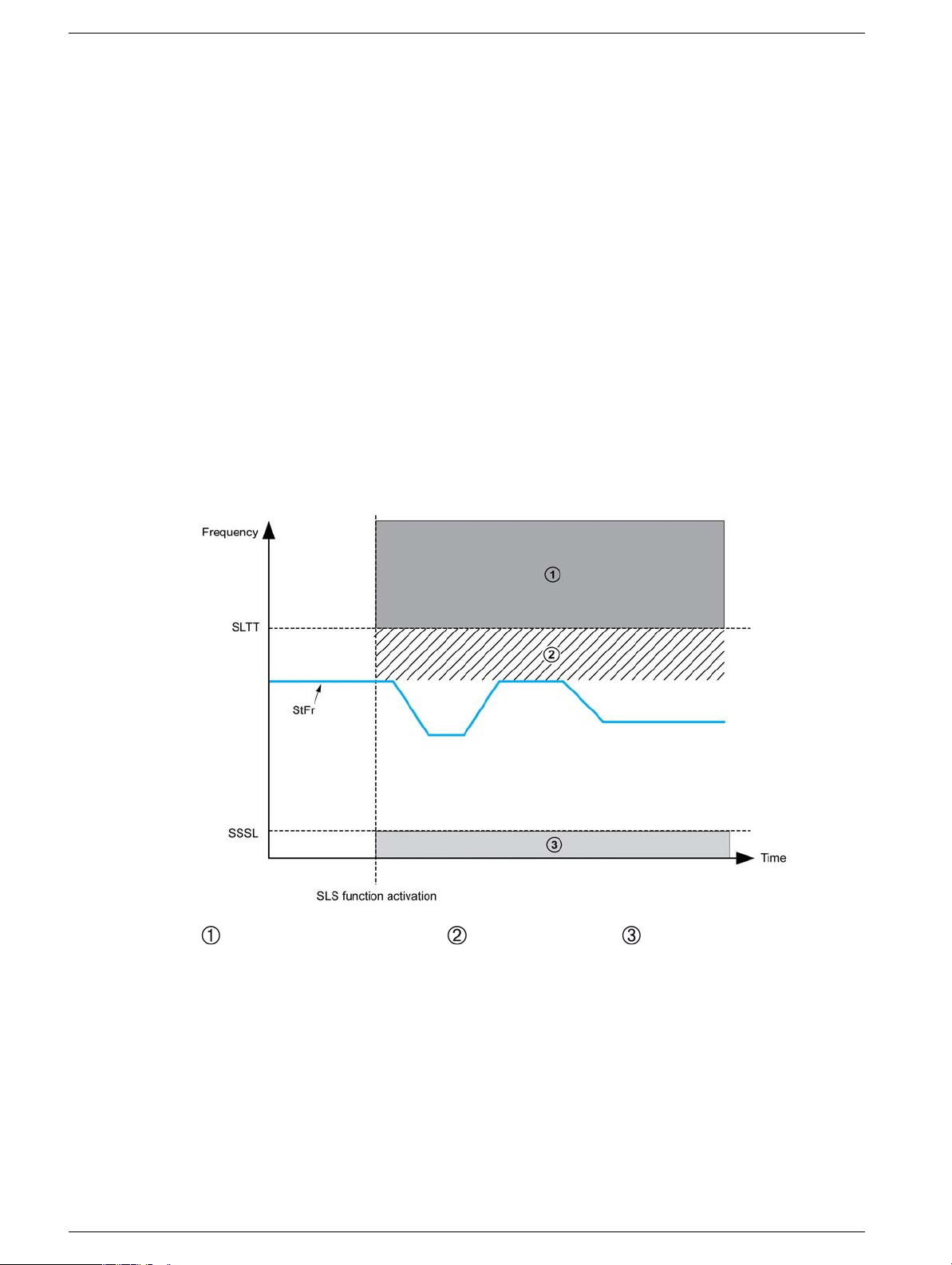

Behavior on Activation of the Safety Function SLS Type 2

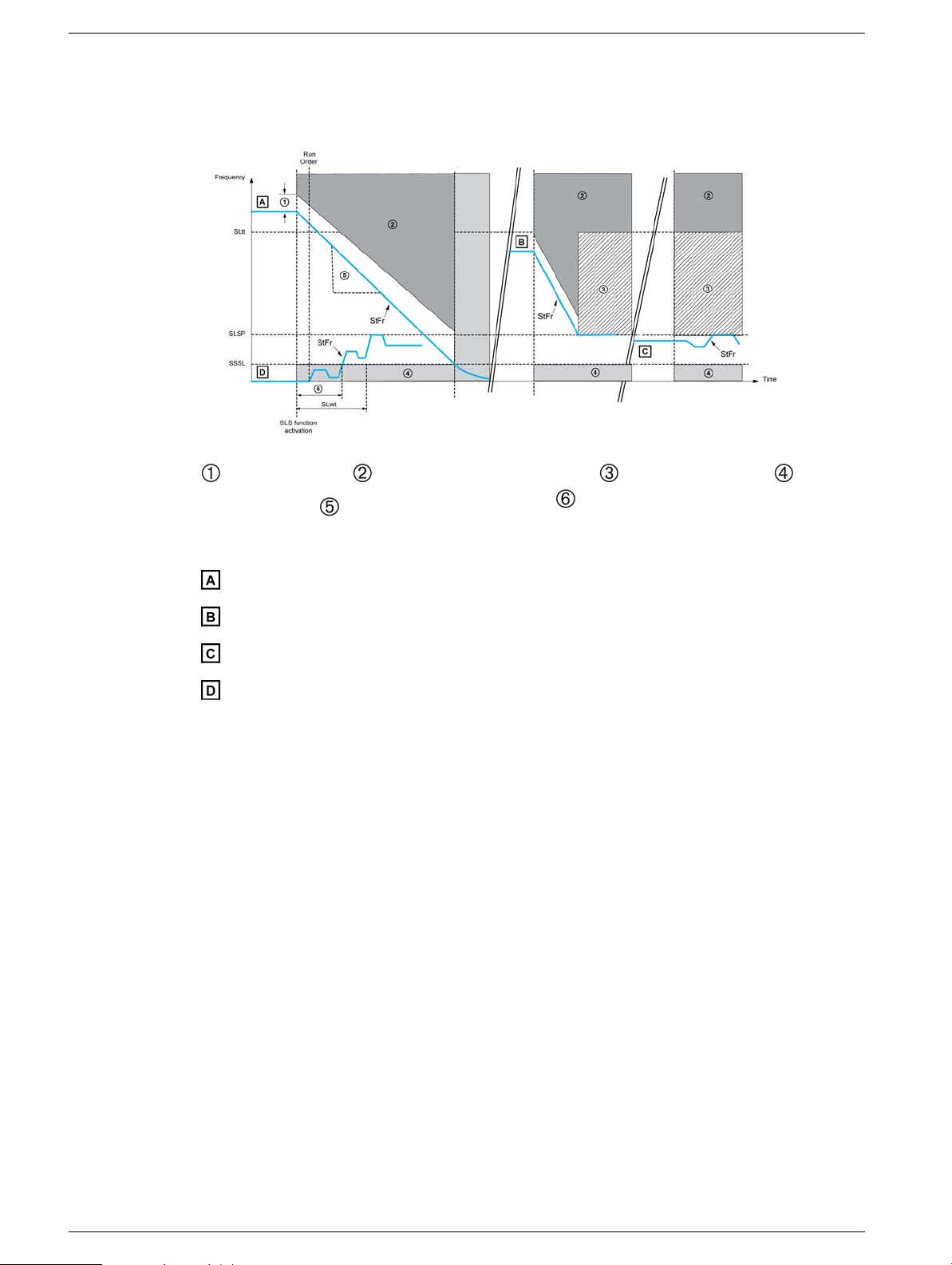

: SS1 trip threshold, : Error and STO function triggered, : Reference upper limit, : STO

function triggered, : SS1 deceleration ramp (dV/dT), : Time taken fo r the [Stator Frequency ]

StFr to become greater than SSSL

: [Stator Frequency] StFr is above [Set Point] SLSP

: [Stator Frequency] StFr is between [Standstill level] SSSL and [Set Point] SLSP

: [Stator Frequency] StFr is below [Standstill level] SSSL and [SLS wait time] (SLwt) ≠ 0

When the function is activated :

z If the [Stator Frequency ] StFr is above the [Set point] SLSP, the drive decelerates according

to SS1 deceleration ramp until the [Set point] SLSP is reached.(see case A)

z If the [Stator Frequency] StFr is below the SLSP the current reference is not changed but limited

to the [Set point] SLSP.(see case B)

z If the [Stator Frequency] StFr is still below the [Standstill level] SSSL frequency after [SLS

wait time] (SLwt ) has elapsed, the safety function STO will be triggered.(see case C)

While the function is activated:

z The reference frequency can only vary between the [Set point] SLSP and the standstill level SSSL.

z If the [Stator Frequency ] StFr decreases and reaches the [Standstill level] SSSL frequency,

safety function STO is triggered.

z If the [Stator Frequency ] StFr increases and reaches the [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

S1A45606 08/2014 23

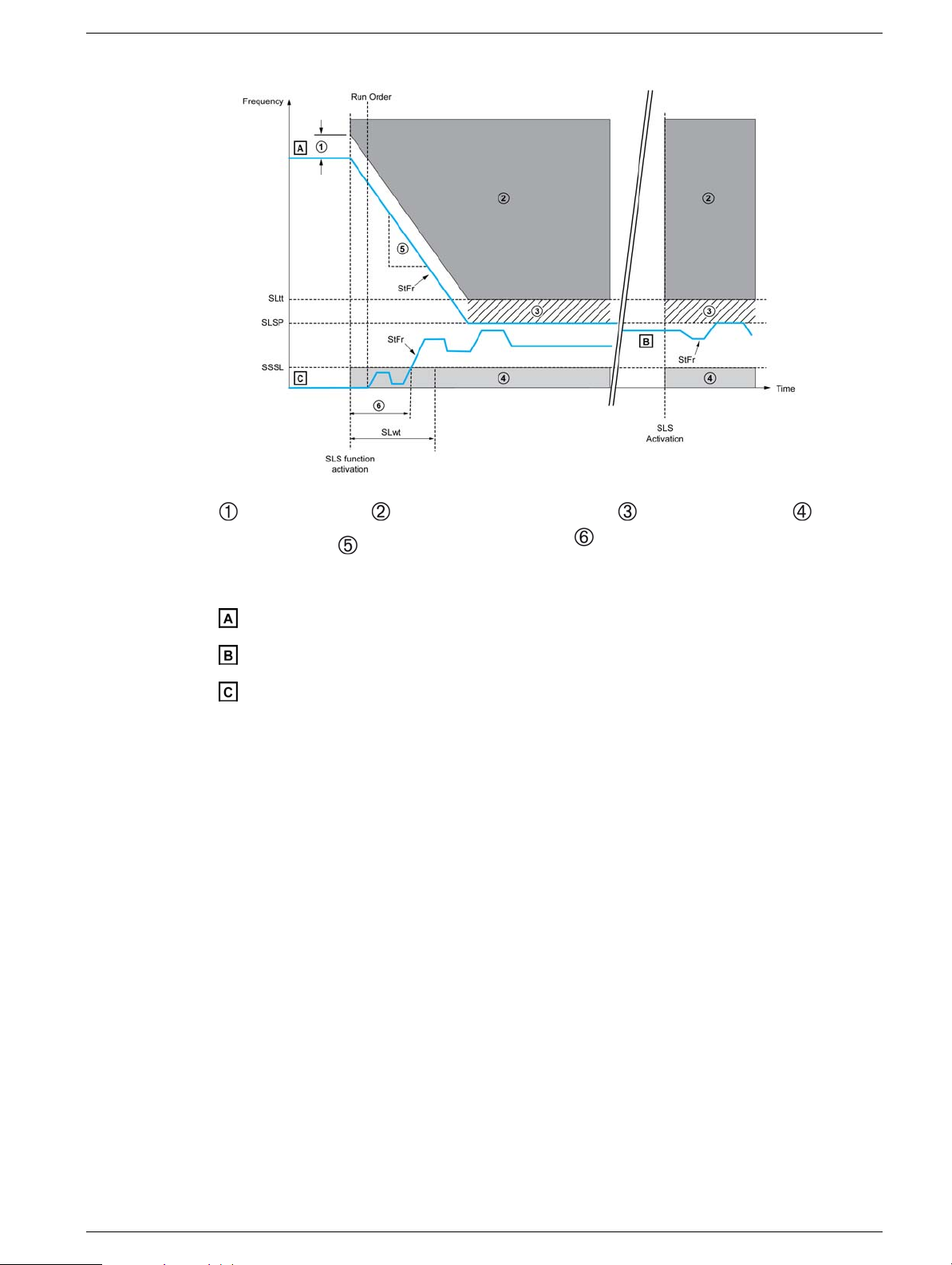

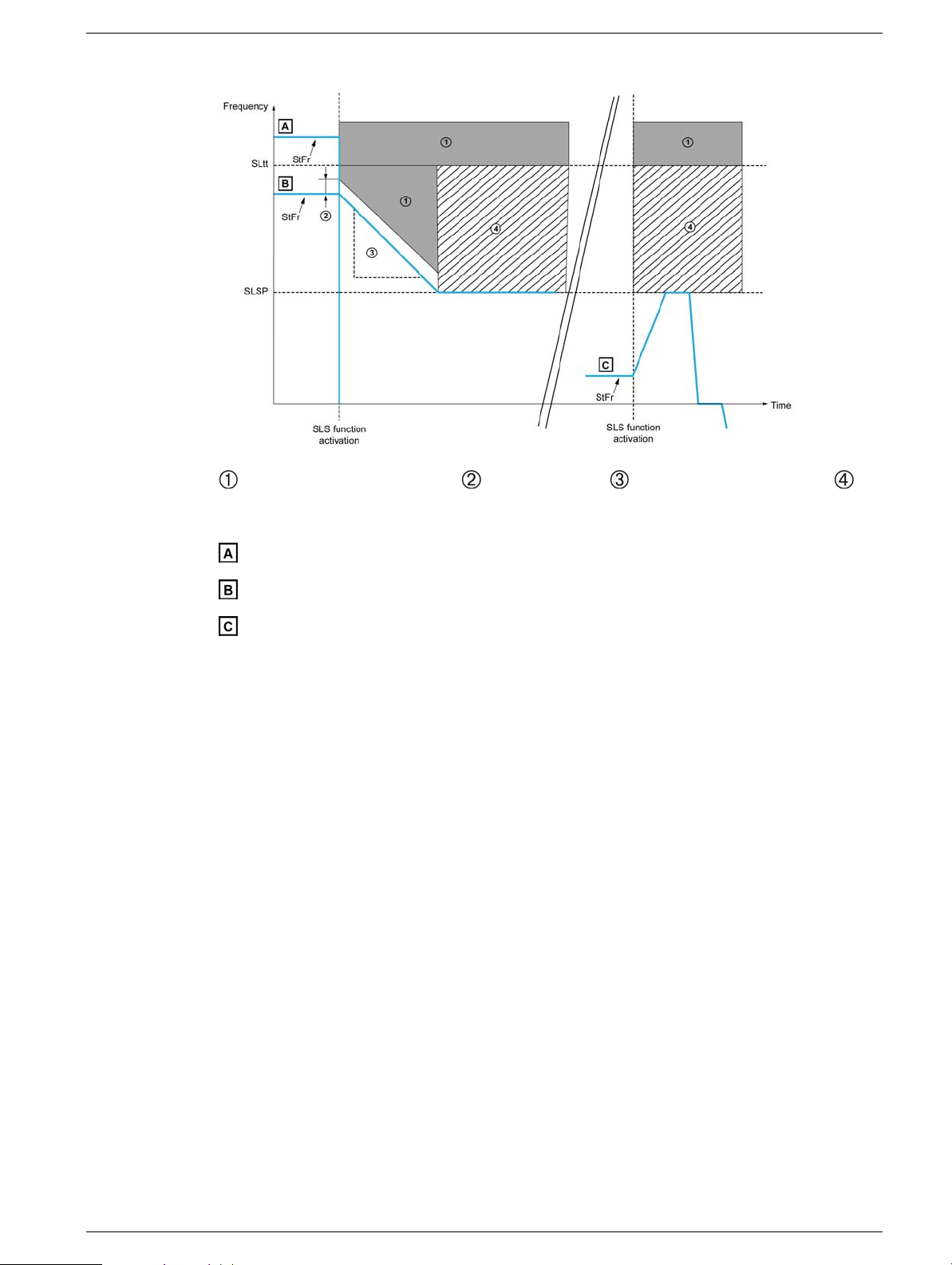

Behavior on Activation of the Safety Function SLS Type 3

SLS type 3 has the same behavior as SLS type 2 except that If the [Stator Frequency] StFr is above

the [SLS tolerance threshold] SLtt, the safety function SS1 is triggered instead of decelerating to the

[Set point] SLSP (see case A)

: SS1 trip threshold, : Error and STO function triggered, : Reference upper limit, : STO

function triggered, : SS1 deceleration ramp (dV/dT), : Time taken for the [Stator Frequency]

StFr to become greater than SSSL

: [Stator Frequency] StFr is above [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is between [Set Point] SLSP and [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is between [Standstill level] SSSL and [Set Point] SLSP

:[Stator Frequency] StFr is below [Standstill level] SSSL and [SLS wait time] (SLwt) ≠ 0

When the function is activated :

z If the [Stator Frequency] StFr is above the [SLS tolerance threshold] SLtt, the safety function

SS1 is triggered. (see case A).

z If the [Stator Frequency] StFr is between the [SLS tolerance threshold] SLtt and the [Set

point] SLSP, the drive decelerates according to SS1 deceleration ramp until the [Set point] SLSP

has been reached.(see case B).

z If the [Stator Frequency] StFr is below the [Set point] SLSP the current reference is not changed

but limited to the [Set point] SLSP.(see case C)

z If the [Stator Frequency] StFr is still below the [Standstill level] SSSL frequency after [SLS wait

time] SLwt has elapsed, the safety function STO will be triggered.(see case D)

While the function is activated:

z The reference frequency can only vary between the [Set point] SLSP and the [Standstill level]

SSSL.

z If the [Stator Frequency ] StFr decreases and reaches the [Standstill level] SSSL frequency,

the safety function STO is triggered.

z If the [Stator Frequency ] StFr increases and reaches the [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

24 S1A45606 08/2014

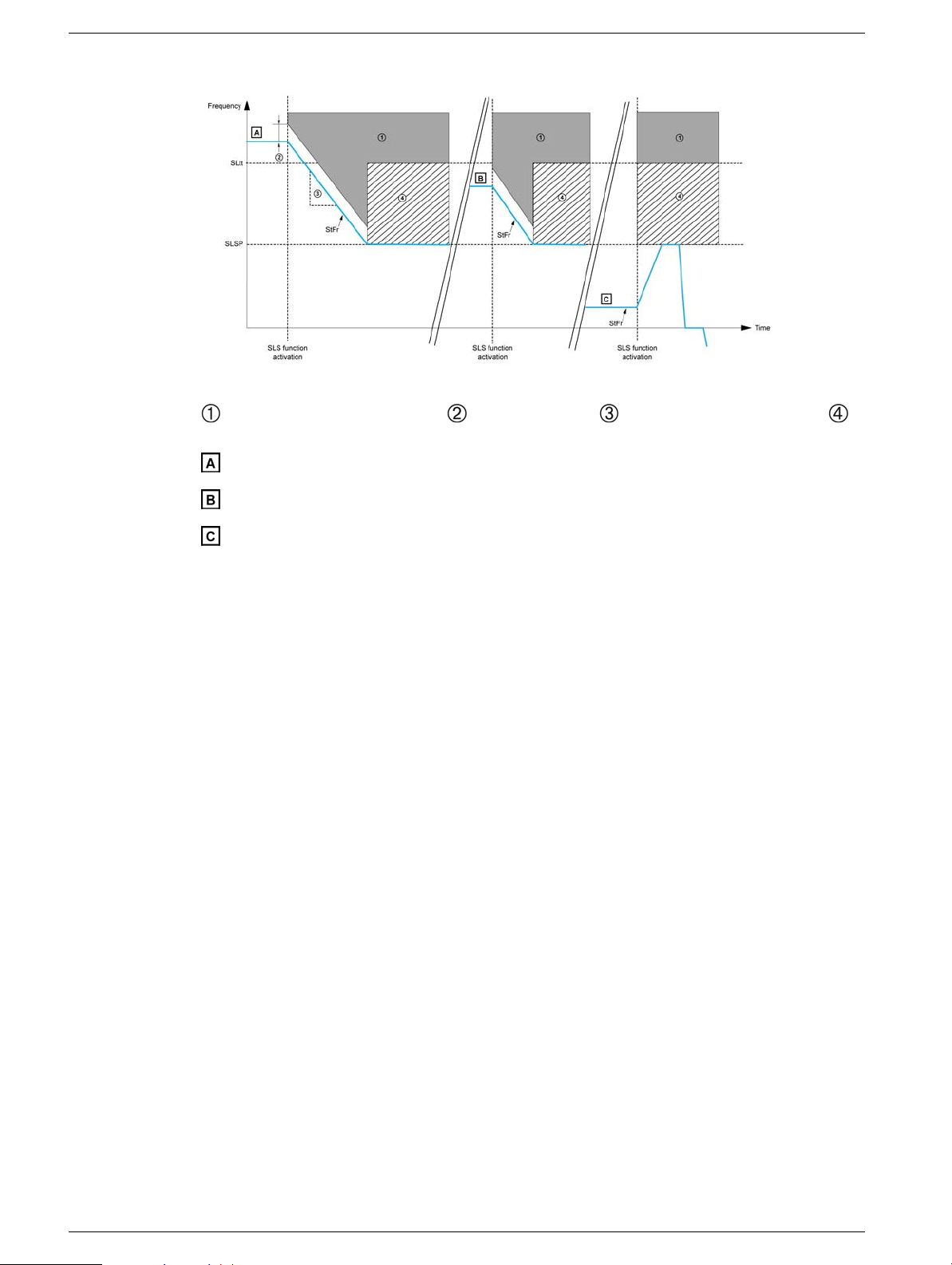

Behavior on Activation of the Safety Function SLS Type 4

Error and STO function triggered, SS1 trip threshold, SS1 deceleration ramp (dv/dt),

reference upper limit

: [Stator Frequency] StFr is above [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is between [Set Point] SLSP and [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is below [Set Point] SLSP

NOTE: If the SLTT ≤ SLSP for SLS type 4, SAFF fault is triggered.

When the function is activated :

z If the [Stator Frequency] StFr is above the [SLS tolerance threshold] SLtt, the safety function

STO is triggered with the error code [Safety function fault] SAFF.(see case A)

z If the [Stator Frequency] StFr is between the [SLS tolerance threshold] SLtt and the [Set

point] SLSP, the drive decelerates according to SS1 deceleration ramp until the [Set point] SLSP

has been reached.(see case B)

z If the [Stator Frequency] StFr is below the [Set point] SLSP, the current reference is not

changed but limited to the [Set point] SLSP.(see case C).

While the function is activated:

z The reference frequency can vary between the [Set point] SLSP in both forward and reverse

directions.

z If the [Stator Frequency] StFr increases and reaches [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

S1A45606 08/2014 25

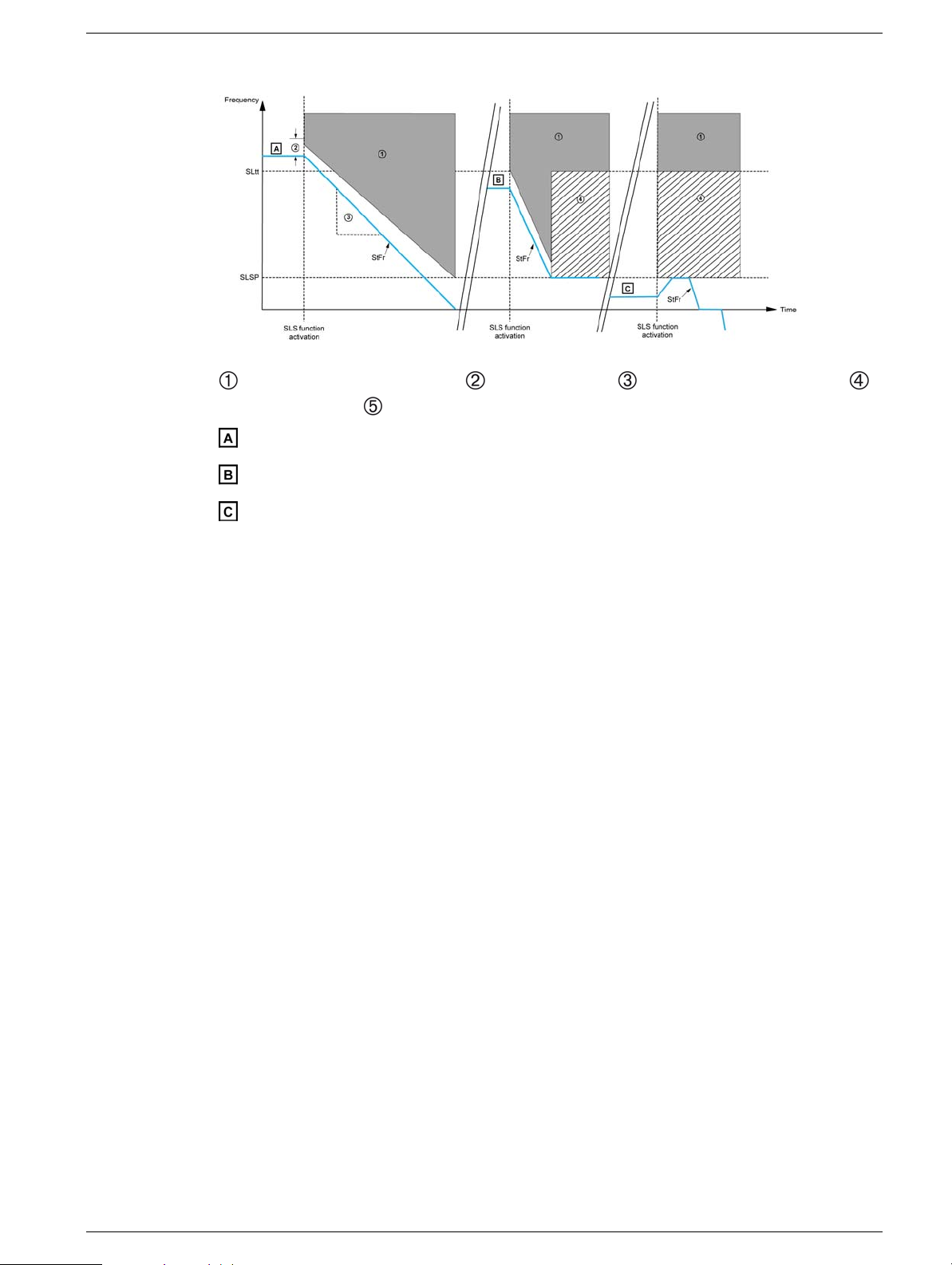

Behavior on Activation of the Safety Function SLS Type 5

: Error and STO function triggered, : SS1 trip threshold, : SS1 deceleration ramp (dv/dt), :

Reference upper limit

: [Stator Frequency] StFr is above [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is between [Set Point] SLSP and [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is below [Set Point] SLSP

When the function is activated :

z If the [Stator Frequency] StFr is above the [SLS tolerance threshold] SLtt, the drive

decelerates according to SS1 deceleration ramp until the [Set point] SLSP has been reached. (see

case A)

z If the [Stator Frequency] StFr is between the [SLS tolerance threshold] SLtt and the [Set

point] SLSP, the drive decelerates according to SS1 deceleration ramp until the [Set point] SLSP

has been reached.(see case B)

z If the [Stator Frequency] StFr is below the [Set point] SLSP, the current reference is not

changed but limited to the [Set point] SLSP.(see case C).

While the function is activated:

z The reference frequency can vary between the [Set point] SLSP in both forward and reverse

directions.

z If the [Stator Frequency] StFr increases and reaches [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

26 S1A45606 08/2014

Behavior on Activation of the Safety Function SLS Type 6

: Error and STO function triggered, : SS1 trip threshold, : SS1 deceleration ramp (dV/dT) :

Reference upper limit, : STO function triggered.

: [Stator Frequency] StFr is above [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is between [Set Point] SLSP and [SLS tolerance threshold] SLtt

: [Stator Frequency] StFr is below [Set Point] SLSP

When the function is activated :

z If the [Stator Frequency] StFr is above the [SLS tolerance threshold] SLtt, the drive

decelerates according to SS1 deceleration ramp until 0 Hz has been reached (see case A).

z If the [Stator Frequency] StFr is between the [SLS tolerance threshold] SLtt and the [Set

point] SLSP, the drive decelerates according to SS1 deceleration ramp until the [Set point] SLSP

has been reached.(see case B)

z If the [Stator Frequency] StFr is below the [Set point] SLSP, the current reference is not

changed but limited to the [Set point] SLSP.(see case C).

While the function is activated:

z The reference frequency can vary between the [Set point] SLSP in both forward and reverse

directions.

z If the [Stator Frequency] StFr increases and reaches [SLS tolerance threshold] SLtt, the

safety function STO is triggered and an error is triggered with the error code [Safety function fault]

SAFF.

S1A45606 08/2014 27

Behavior on Deactivation of the Safety Function SLS for All SLS Types

If... Then ...

The drive is still running when the function is deactivated The reference frequency of the active channel is applied.

Safety function STO has been triggered and the drive is

not in fault state.

The safety function SLS type 2, 3, 4 is deactivated while

the drive decelerates to the [Set point] SLSP

according to SS1 deceleration ramp.

The safety function SLS type 3 is deactivated while the

safety function SS1 has been triggered

a stop command is applied The safety function SLS remains active and the drive

an error is detected The safety function SLS remains active and the drive stops

A new run command must be applied.

The safety function SLS remains activated until the [Set

point] SLSP has been reached.

STO is triggered when [Standstill level] SSSL is

reached and a new run command must be applied.

decelerates until standstill is reached.

For SLS type 1, 2, or 3 STO function is triggered when the

[Stator Frequency] StFr decreases and reaches the

[Standstill level] SSSL frequency.

according to the configured error response.

For SLS type 1, 2, or 3 STO function will be triggered after

the [Standstill level] SSSL frequency has been

reached.The drive can be reset after the cause is cleared.

SLS Standards References

The safety function SLS is defined in section 4.2.3.4 of standard IEC 61800-5-2 The SLS function helps to

prevent the motor from exceeding the specified speed limit.

Safety Function (SF) Level for Safety Function SLS

Configuration SIL

Safety Integrity Level According to IEC 61-508PLPerformance level According to ISO-13849

LI3 and LI4 SIL 2 PL d

LI5 and LI6 SIL 2 PL d

28 S1A45606 08/2014

Calculation of Safety Related Parameters

Chapter 3

Calculation of Safety Related Parameters

What Is in This Chapter?

This chapter contains the following topics:

SLS Type 1 30

SLS Type 2, Type 3, Type 4, Type 5, and Type 6 32

SS1 35

Topic Page

S1A45606 08/2014 29

SLS Type 1

Collect Application Data

Before starting to configure the SLS function, you must collect the following data:

Code Description Unit Comment

FrS [Rated motor freq.] Hz See motor nameplate

nSp [Rated motorspeed] rpm See motor nameplate

ppn Motor pole pair number – See motor nameplate

Max Frequency Maximum motor frequency for normal

Calculate the rated motor slip frequency Fslip (Hz).:

To Configure the Function

Overview of diagram

operation

Hz This value is equal to [High speed]

HSP or lower

: Error and STO function triggered, : Reference upper limit, : STO function triggered

Standstill Level

The recommended standstill level is: SSSL = Fslip

If the application requires a different standstill level, it can be set accordingly with the SSSL parameter.

Motor Frequency Limit Threshold

The recommended value of the parameter is SLtt = 1.2 x Max Frequency + Fslip

30 S1A45606 08/2014

Testing and Adjusting the Configuration

When configuration is complete, test the SLS function to verify it behaves as expected.

If an error is triggered with the error code [Safety function fault] SAFF apply the following

troubleshooting rules

Context Drive Status Adjustment

SLS activated and motor

running at the fixed setpoint

frequency

Example

Code Description Unit

FrS [Rated motor freq.] 50 Hz

nSp [Rated motorspeed] 1350 rpm

ppn Motor pole pair number 2

Max Frequency Maximum motor frequency on normal operation. This value is generally

With these numerical values, the configuration of SLS type 1 is:

z SAFF error code

z SFFE.7 = 1

equal to [High speed] HSP or lower

Motor frequency has reached the motor frequency limit

threshold.

The cause of the detected error can be due to frequency

instability. Investigate and correct the cause. The value of

SLtt can be modifed to increase the tolerance threshold to

the instability of the drive system.

50 Hz

SSSL = Fslip = 5 Hz

SLtt = 1.2 x Max Frequency + Fslip = 1.2 x 50 + 5 = 65 Hz

S1A45606 08/2014 31

SLS Type 2, Type 3, Type 4, Type 5, and Type 6

Collect Application Data

Before starting to configure the SLS function, you must collect the following data:

Code Description Unit Comment

FrS [Rated motor freq.] Hz See motor nameplate

nSp [Rated motor speed] rpm See motor nameplate

ppn Motor pole pair number – See motor nameplate

Max Frequency Maximum motor frequency

on normal operation

SS1 deceleration

ramp

Calculate the rated motor slip frequency Fslip (Hz).

Deceleration ramp to apply

when SS1 ramp is triggered

Hz This value is equal to [High speed] HSP or lower.

Hz –

Fslip = FrS -

To Configure the Function

Overview of diagram

Nsp x ppn

60

: SS1 trip threshold, : Error and STO function triggered, : Reference upper limit, : STO

function triggered, : SS1 deceleration ramp (dV/dT), : Time taken for the [Stator Frequency ]

StFr to become greater than SSSL

: [Stator Frequency] StFr is above [Set Point] SLSP

: [Stator Frequency] StFr is between [Standstill level] SSSL and [Set Point] SLSP

: [Stator Frequency] StFr is below [Standstill level] SSSL and [SLS wait time] (SLwt) ≠ 0

Standstill Level

The recommended standstill level is: SSSL = Fslip

If the application requires a different standstill level, it can be set accordingly with the SSSL parameter.

Ramp Value and Ramp Unit

32 S1A45606 08/2014

Set SSrt (ramp value) and SSrU (ramp unit) parameters according to the deceleration ramp to apply when

the safety function SS1 is triggered.

Ramp calculation: Ramp = SSrU*SSrt

Example 1: If SSrU = 1 Hz/s and SSrt = 500.0 the deceleration ramp is 500.0 Hz/s and the accuracy is

0.1 Hz

Example 2: If SSrU = 10 Hz/s and SS rt = 50.0 the deceleration ramp is 500 Hz/s and the accuracy is 1 Hz

Use the table to set the correct accuracy according to the deceleration ramp to apply when the safety

function SS1 is triggered:

Min Max Accuracy SSrt SSrU

0.1 Hz/s 599 Hz/s 0.1 Hz/s 1 Hz/s SS1 deceleration ramp

599 Hz/s 5990 Hz/s 1 Hz/s 10 Hz/s SS1 deceleration ramp/10

5990 Hz/s 59900 Hz/s 10 Hz/s 100 Hz/s SS1 deceleration ramp/100

SLS Setpoint

Set the SLS setpoint parameter (SLSP) to: SLSP= Fsetpoint (SLS)

Motor Frequency and ramp Limit Threshol d

The recommended motor frequency limit threshold is SLtt = 1.2 x SLSP + Fslip and the recommended SS1

ramp limit threshold is: SStt = 0.2 x Max Frequency

SLS Wait time

Set the [SLS wait time] (SLwt) greater than 0 ms to to allow the motor to run under the [standstill level]

SSSL for a given time after the safety function SLS has been activated.

NOTE: When SLS Type 4 is configured, [SLS wait time] (SLwt) must be set to 0 otherwise an error is

triggered and the error code [Safety function fault] SAFF is displayed

Testing and Adjusting the Configuration

When configuration is complete, test the SLS function to verify that it behaves as expected.

If an error is triggered with the error code [Safety function fault] SAFF, apply the following

troubleshooting rules

Context Drive Status Adjustment

SLS activated and

deceleration ramp in

progress

z SAFF error code

z SFFE.3 = 1

Motor frequency has reached the motor frequency limit threshold.

The cause of the detected error can be due to frequency instability.

Investigate and correct the cause. The value of SLtt can be modified to

increase the tolerance threshold to the instability of the drive system.

S1A45606 08/2014 33

Context Drive Status Adjustment

SLS activated and end

of ramp at SLSP

frequency

z SAFF error code

z SFFE.3 = 1

or

z SFFE.7 = 1

Motor frequency stabilization at SLSP takes too long and has reached

the safety function error detection condition.

: Safety function error detection, Tosc: T oscillation, F: Frequency

The oscillations must be lower than SLtt before the time T(oscillation)

elapses.

If the condition is not followed, an error is triggered and the error code

[Safety function fault] SAFF is displayed

The relationship between SStt and T(oscillation) is:

Motor frequency has reached the motor frequency limit threshold.

The cause of the detected error can be due to frequency instability.

Investigate and correct the cause. The value of SStt can be modified to

increase the tolerance threshold to the oscillations of the drive system.

SLS activated and

motor running at SLSP

frequency

z SAFF error code

z SFFE.7 = 1

Motor frequency has reached the motor frequency limit threshold.

The cause of the detected error can be due to frequency instability.

Investigate and correct the cause. The value of SLtt can be modified to

increase the tolerance threshold to the instability of the drive system.

Example

Code Description Unit

FrS Rated motor frequency 50 Hz

nSp Rated motor speed 1350 rpm

ppn Motor pole pair number 2

Max Frequency Maximum motor frequency on normal operation. This value is equal to

50 Hz

[High speed] HSP or lower

Fsetpoint(SLS) Motor frequency setpoint 15 Hz

SS1 deceleration ramp Deceleration ramp to apply when SS1 is triggered 20 Hz/s

With these numerical values, the configuration of SLS type 2, 3, and 4 is:

Fslip = 50 -=5 Hz

1350 x 2

60

SSSL = Fslip = 5Hz

SSrU = 1 Hz/s and SSrt = 20.0 for SS1 deceleration ramp = 20 Hz/s (accuracy is 0.1 Hz)

SLSP = Fsetpoint(SLS) = 15 Hz

SLtt = 1.2 x SLSP + Fslip = 1.2 x 15 + 5 = 23 Hz

SStt = 0.2 x Max Frequency = 0.2 * 50 = 10 Hz

In this example, the frequency oscillations are allowed to be higher than SLtt for 350 ms.

34 S1A45606 08/2014

SS1

Collect Application Data

Before configuring the SS1 function, you must collect the following data:

Code Description Unit Comment

FrS Rated motor frequency Hz From motor

nSp Rated motor speed rpm From motor

ppn Motor pole pair number – From motor

Max Frequency Maximum motor

Calculate the rated motor slip frequency Fslip (Hz).

To Configure the Function

Overview of diagram

Hz This value is equal to [High speed] HSP or lower

frequency on normal

operation

: SS1 trip threshold, : SS1 deceleration ramp (dV/dT), : STO function triggered, : Error and

STO function triggered

Standstill Level

The recommended standstill level is: SSSL = Fslip

If the application requires a different standstill level, it can be set accordingly with the SSSL parameter.

Ramp Value and Ramp Unit

Set SSrt (ramp value) and SSrU (ramp unit) parameters according to the deceleration ramp to apply when

the safety function SS1 is triggered.

Ramp Calculation: Ramp = SSrU*SSrt

Example 1: If SSrU = 1 Hz/s and SSrt = 500.0 the deceleration ramp is 500.0 Hz/s and the accuracy is

0.1 Hz

Example 2: If SSrU = 10 Hz/s and SS rt = 50.0 the deceleration ramp is 500 Hz/s and the accuracy is 1 Hz

S1A45606 08/2014 35

Use the table to set the correct accuracy according to the deceleration ramp to apply when the safety

function SS1 is triggered:

Min Max Accuracy SSrU SSrt

0.1 Hz/s 599 Hz/s 0.1 Hz/s 1 Hz/s SS1 deceleration ramp

599 Hz/s 5990 Hz/s 1 Hz/s 10 Hz/s SS1 deceleration ramp/10

5990 Hz/s 59900 Hz/s 10 Hz/s 100 Hz/s SS1 deceleration ramp/100

Ramp Limit Threshold

The SS1 ramp trip threshold is calculated by: SStt = 0.2 x Max Frequency

This value is equal to [High speed] HSP or lower

Testing and Adjusting the Configuration

When configuration is complete, test the safety function SS1 to verify that it behaves as expected.

If an error is triggered with the error code [Safety function fault] SAFF, apply the following

troubleshooting rules

Context Drive Status Adjustment

SS1 activated and the

[Standstill level] SSSL

has not yet been reached

z SAFF error code

z SFFE.3 = 1

Motor frequency has reached the motor frequency limit

threshold.

The cause of the detected error can be due to frequency

instability. Investigate and correct the cause. The value of

SStt can be modified to increase the tolerance threshold

to the instability of the drive system.

Example

Code Description Unit

FrS Rated motor frequency 50 Hz

nSp Rated motor speed 1350 rpm

ppn Motor pole pair number 2

Max Frequency Maximum motor frequency on normal operation 50 Hz

SS1 deceleration ramp Deceleration ramp to apply when SS1 is triggered 20 Hz/s

With these numerical values, the configuration of SS1 is:

SSSL = Fslip = 5Hz

SSrU = 1 Hz/s and SSrt = 20.0 for SS1 deceleration ramp = 20 Hz/s (accuracy is 0.1 Hz)

SStt = 0.2 x Max Frequency =0.2x50=10Hz

36 S1A45606 08/2014

Behavior of Safety Functions

Chapter 4

Behavior of Safety Functions

What Is in This Chapter?

This chapter contains the following topics:

Limitations 38

Detected Fault Inhibition 39

Priority Between Safety Functions 40

Factory Settings 41

Configuration Download 42

Priority Between Safety Functions and No Safety-Related Functions 43

Topic Page

S1A45606 08/2014 37

Limitations

Type Of Motor

The safety functions SLS and SS1 on ATV32 are only applicable for asynchronous motors with openloop control profile.

The safety function STO can be used with synchronous and asynchronous motors.

Prerequisites for Using Safety Functions

Following conditions have to be fulfilled for correct operation:

z The motor size is adequate for the application and is not at the limit of its capacity.

z The drive size has been correctly chosen for the line supply, sequence, motor, and application and is

not at the limit of their capacities as stated in the catalog.

z If required, the appropriate options are used.

Example: dynamic braking resistor or motor choke.

z The drive is correctly set up with the correct speed loop and torque characteristics for the application;

the reference frequency profile applied to the drive control loop is followed.

Requirements on Logical Inputs

z Sink mode must not been used with the safety function. If you use the safety function, you need to wire

the logic inputs in source mode.

z PTC on LI6 is incompatible with the safety function set on this input. If you are using the safety function

on LI6, do not set the PTC switch to PTC

z If you are using the pulse input, you cannot set the safety function on LI5 at the same time.

38 S1A45606 08/2014

Detected Fault Inhibition

When a safety function has been configured, the error [Safety Function Fault] SAFF cannot be

inhibited by the function [Fault Inhibit assign.] InH

S1A45606 08/2014 39

Priority Between Safety Functions

1. The safety function STO has the highest priority. If the safety function STO is triggered, a Safe Torque

Off is performed regardless of which other functions are active.

2. The safety function SS1 has medium priority in relation to the other safety functions.

3. The safety function SLS has the lowest priority.

40 S1A45606 08/2014

Factory Settings

If the safety functions are configured and you restore the factory settings, only the parameters which are

not safety-related will be reset to the factory setting. The settings of safety-related parameters can only be

reset using the commissioning software, for more information see Commissioning (see page 75).

S1A45606 08/2014 41

Configuration Download

You can transfer a configuration in all situations. If a safety function has been configured, the functions

using these same logic inputs will not be configured.

For example: If the downloaded configuration has functions (Preset speed,...) on LI3-4-5-6 and if the drive

has a safety function configured on these logic inputs, safety function will not be erased. It is the functions

that have the same logic input as safety functions that are not transferred. Multiconfiguration/multimotor

and macro configuration obey the same rules.

42 S1A45606 08/2014

Priority Between Safety Functions and No Safety-Related Functions

Priority Table

o: Compatible functions

x: Incompatible functions

: The function indicated by the arrow has priority over the other.

Drive Function SLS SS1 STO

[HIGH SPEED HOISTING] HSH-

[+/- SPEED] UPd-

[Skip Frequency] JPF oo

[Low speed time out] tLS

[MULTIMOTORS] MMC- Configuration must be consistent with the 3 motors o

[PRESET SPEEDS] PSS-

[PID REGULATOR] PId- oo

[RAMP] rPt-

[Freewheel stop ass. ]nSt

[Fast stop assign.] FSt

[TRAVERSE CONTROL] tr0- o: both function configurations

[EXTERNAL FAULT] EtF- B: NST

[AUTOMATIC RESTART] Atr-

[FAULT RESET] rSt-

[JOG] JOG-

[STOP CONFIGURATION] Stt-

[Ramp stop] rMP

[Fast stop] FSt

[DC injection] dCI xx

[Freewheel] nSt

[+/-SPEED AROUND REF.]

SrE-

[POSITIONING BY SENSORS]

LPO-

[RP input] PFrC o: if the safety function is not

[Underload Detection] ULF

should not overlap

o: motor frequency can exceed

SLS set-point (but not the motor

frequency limit threshold)

x: DCI

: fast, ramp, fallback, maintain

: SLS ramp

: SLS steady

: SLS ramp

: SLS steady

: SLS ramp

& position is not respected

assigned to LI5

B: NST

x: DCI

: fast, ramp,

fallback, maintain

: Position is not

respected

o: if the safety

function is not

assigned to LI5

B: NST

: DCI

: fast, ramp,

fallback, maintain

o: if the safety

function is not

assigned to LI5

[Overload Detection] OLC

[Rope slack config.] rSd xxx

S1A45606 08/2014 43

Drive Function SLS SS1 STO

[UnderV. prevention] StP xx

[AUTO DC INJECTION] AdC- xx

[DC injection assign.] dCI xx

[Load sharing] LbA o: If the [Stator Frequency]

[Motor control type] Ctt

[Standard] Std xxo

[SVC V] UUC ooo

[V/F Quad.] UFq xxo

[Energy Sav.] nLd xxo

[Sync. mot.] SYn xxo

[V/F 5pts] UF5 xxo

[OUTPUT PHASE LOSS] OPL x: Motor output phase loss is

[Output cut] OAC xxx

[Dec ramp adapt.] brA o :If the [Stator Frequency]

[REF. OPERATIONS] OAI- o

[2 wire] 2C o: Run command on transition

[PTC MANAGEMENT] PtC- o: inactive if the safety function

[FORCED LOCAL] LCF- o

StFr is above the frequency

limit threshold, the error SAFF is

triggered.

detected by the safety function

StFr is above the Frequency

limit threshold, the error SAFF is

triggered.

Run command on level is not

compatible

is not assigned to LI6

x: Motor output

phase loss is

detected by the

safety function

o :If the [Stator

Frequency] StFr

is above the

Frequency limit

threshold, the error

SAFF is triggered.

o: Run command on

transition

Run command on

level is not

compatible

o: inactive if the

safety function is not

assigned to LI6

o

o: Run command on

transition

Run command on

level is not

compatible

o: inactive if the

safety function is not

assigned to LI6

[LI CONFIGURATION] o: inactive if the safety function

[MULTIMOTORS/CONFIG].

MMC-

[FAULT INHIBITION] InH xxx

[Profile] CHCF Logic input used by safety

[Macro configuration] CFG

[RAMP] rPt-

[Motor short circuit] SCF1 o

44 S1A45606 08/2014

is assigned to logic input

o: except safety-related

parameters

function cannot be switched

: Macro configuration could be

overlapped if safety function use

a logical input requested by the

macro configuration

: SLS ramp

B : SLS steady

o: inactive if the

safety function is

assigned to logic

input

o: except safetyrelated parameters

Logic input used by

safety function

cannot be switched

: Macro

configuration could

be overlapped if

safety function use a

logical input

requested by the

macro configuration

o:inactive if the

safety function is

assigned to logic

input

o: except safetyrelated parameters

Logic input used by

safety function

cannot be switched

: Macro

configuration could

be overlapped if

safety function use a

logical input

requested by the

macro configuration

o

Drive Function SLS SS1 STO

[Ground short circuit] SCF3 o

[Overspeed] SOF o

[Sync. mot.] SYn xxo

[Configuration Transfer] o: except safety-related

parameters

o: except safetyrelated parameters

o: except safetyrelated parameters

[Energy Sav.] nLd xxo

For more information about these functions, see ATV32 Programming manual.

S1A45606 08/2014 45

46 S1A45606 08/2014

Safety Functions Visualization by HMI

Chapter 5

Safety Functions Visualization by HMI

What Is in This Chapter?

This chapter contains the following topics:

Status of Safety Functions 48

Dedicated HMI 49

Error Code Description 50

Topic Page

S1A45606 08/2014 47

Status of Safety Functions

Description

The status of the safety functions can be displayed using the HMI of the drive or using the commissioning

software. HMI of the drive can be the local HMI on the product or the graphic display terminal or the remote

display terminal. There is one register for each safety function. See introduction (see page 12) for more

information about the safety functions.

To access these registers with an HMI: [2 MONITORING] MOn- --> [MONIT. SAFETY] SAF-

z [STO status] StOS: Status of the safety function STO (Safe Torque Off)

z [SLS status] SLSS: Status of the safety function SLS (Safely-Limited Speed)

z [SS1 status] SS1S: Status of the safety function SS1 (Safe Stop 1)

The status registers are not approved for any type of safety-related use.

For more information about these registers, see ATV32 Visualization and Status of Safety Functions

(see page 81) on www.schneider-electric.com.

48 S1A45606 08/2014

Dedicated HMI

Description

When a safety function has been triggered, some information is displayed.

Example with the local HMI of the product when the safety function SS1 has been triggered:

: Display alternately the name of the safety function SS1 and the current display parameter as long as

the motor decelerates according to the specified monitoring ramp until standstill is reached, After the

[Standstill level] SSSL has been reached, the safety function STO is triggered and displayed

S1A45606 08/2014 49

Error Code Description

Description

When an error is detected by the safety function, the drive displays [Safety function fault] (SAFF). This

detected error can only be reset after powering the drive OFF/ON.

for more information, you can access to the registers to find out the possible reasons for triggeri ng.

These registers can be displayed using the graphic display terminal or the commissioning software:

[DRIVE MENU] --> [MONITORING] --> [DIAGNOSTICS] --> [MORE FAULT INFO]

SFFE [Safety Function Error Register]

Bit Description

Bit0=1 Logic inputs debounce time-out (verify value of debounce time LIDT according to the application)

Bit1 Reserved

Bit2=1 Motor speed sign has changed during SS1 ramp

Bit3=1 Motor speed has reached the frequency limit threshold during SS1 ramp.

Bit4 Reserved

Bit5 Reserved

Bit6=1 Motor speed sign has changed during SLS limitation

Bit7=1 Motor speed has reached the frequency limit threshold during SS1 ramp.

Bit8 Reserved

Bit9 Reserved

Bit10 Reserved

Bit11 Reserved

Bit12 Reserved

Bit13=1 Not possible to measure the motor speed (verify the motor wiring connection)

Bit14=1 Motor ground short-circuit detected (verify the motor wiring connection)

Bit15=1 Motor phase to phase short-circuit detected (verify the motor wiring connection)

This register is reset after powering OFF/ON.

This register can also be accessed from [DRIVE MENU] --> [MONITORING] --> [MONIT. SAFETY]

SAF1 [Safety Fault Register 1]

This is an application control error register.

Bit Description

Bit0=1 PWRM consistency detected error

Bit1=1 Safety functions parameters detected error

Bit2=1 Application auto test has detected an error

Bit3=1 Diagnostic verification of safety function has detected an error

Bit4=1 Logical input diagnostic has detected an error

Bit5=1 Application hardware watchdog active