Page 1

Page 2

M. Schaerer Ltd. Telephone: +41 31 858 51 11 User manual

Gewerbestrasse 15 Fax: +41 31 858 51 40 BASCC BC - 02

3302 Moosseedorf E-Mail: info@schaerer.com

Switzerland Internet: www.schaerer.com Order number: 021'221

Page 3

Introduction

Schaerer Coffee

Celebration BC

User manual

Published by: M. Schaerer Ltd., CH-3302 Moosseedorf

Version: Version 01a / April 2004

Software: V 1.26

Designed and edited by: M. Schaerer Ltd., CH-3302 Moosseedorf

© Copyright by: M. Schaerer Ltd., CH-3302 Moosseedorf

All rights reserved, including translation into other languages. This manual may not be

copied, photocopied or distributed, in whole or in part, by any means, nor transmitted

electronically, without the publisher’s written consent.

All information, illustrations, and specifications in this manual are based on the latest

product information available at the time of publication approval. M. Schaerer Ltd.

reserves the right to change the content at any time without any prior notice.

BASCC BC - 02.01 - V01a Page1-1

Page 4

Introduction

Page 1-2 BASCC BC - 02.01 - V01a

Page 5

Introduction

1 INTRODUCTION

1.1 Welcome

D e a r C u s t o m e r,

With Schaerer Coffee Celebration, we have developed the next generation of fully automated coffee

machines. Core competence as well as decades of experience from our company went into the

design of this machine.

The large control panel makes operation extremely easy for you. Cleaning is done very quickly with

just a few steps.

Total: A machine and coffee products which you will like!

This operating manual will give you information on the product, usage and cleaning of the Schaerer

Coffee Celebration.

Important!

Prior to commissioning the machine, carefully read the chapter "Safety instructions". The

manufacturer rejects any liability for damages that are caused by improper use of the

machine.

The performance of the machine depends on proper usage and service. We therefore recommend

that you read the operating manual carefully before commissioning the machine and that you keep it

handy for future reference.

We hope you enjoy Schaerer Coffee Celebration!

BASCC BC - 02.01 - V01a Page1-3

Page 6

Introduction

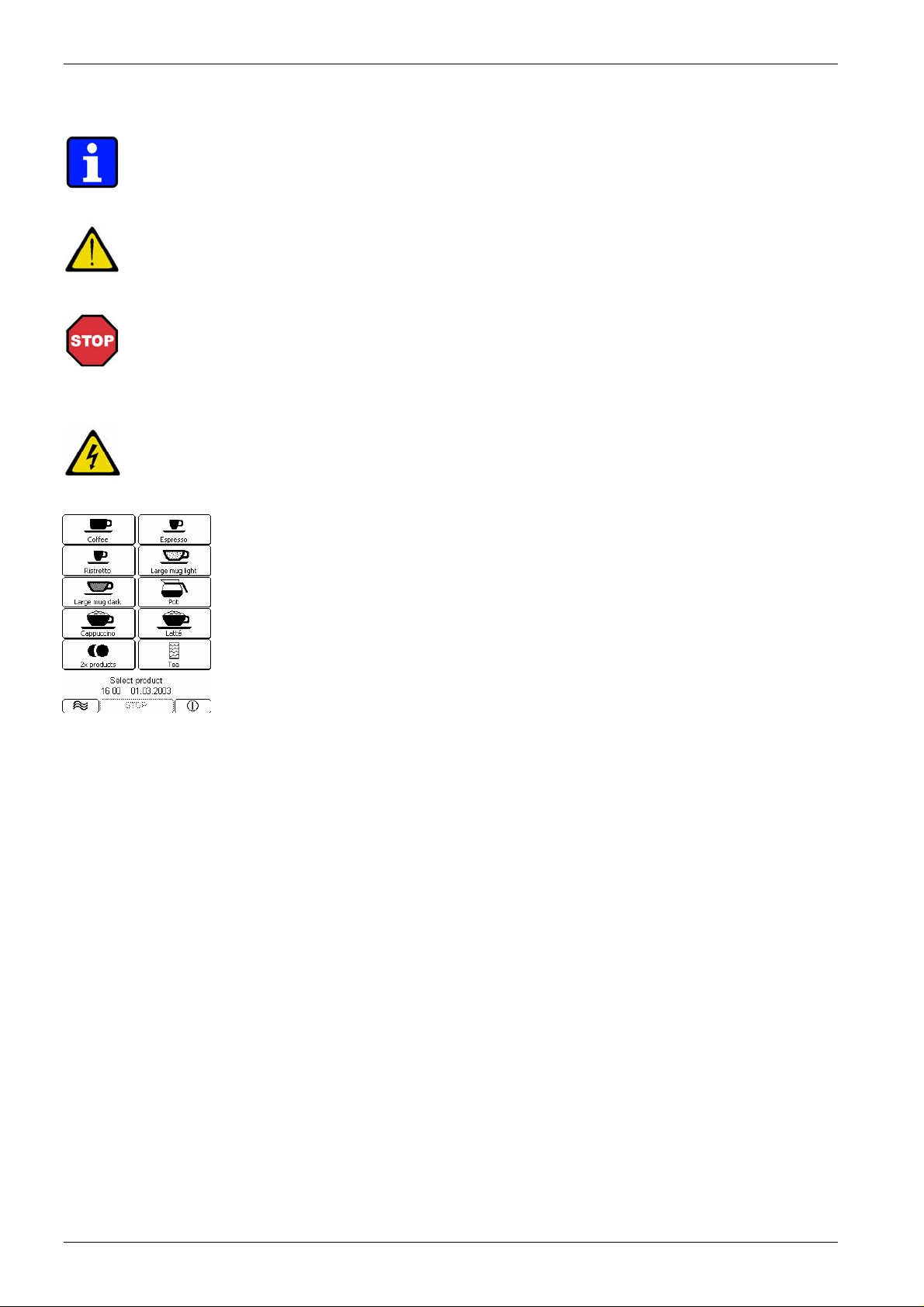

1.2 Symbols and Pictograms

Note:

This section provides you with important notes and information.

Important!

This note indicates possible damage to property as well as possible financial and

statutory penalties (e.g. loss of rights to claim under guarantee, liability suits, etc.).

Danger!

This note indicates a risk of severe and/or fatal injury if specific procedural

rules are violated.

Whenever you see this symbol in the operating manual, take all necessary

safety precautions.

Electric shock!

Risk of severe and/or fatal injury due to electric shock!

Illustrations

An example is shown to illustrate the individual descriptions.

Status line

The status line displays the current operating state (e.g. Select product).

Messages in the control panel

Situations which require your attention or an action by you are displayed in the

information window in the control panel (e.g. Grinder Front Add Beans).

Page 1-4 BASCC BC - 02.01 - V01a

Page 7

Introduction

1.3 Table of contents overview

Chapter Page

Copyright .............................................................................................................................................1-1

1 Introduction .........................................................................................................................................1-3

1.1 Welcome ...............................................................................................................................................1-3

1.2 Symbols and Pictograms ......................................................................................................................1-4

1.3 Table of Contents Overview..................................................................................................................1-5

2 Safety instructions..............................................................................................................................2-1

2.1 General..................................................................................................................................................2-2

2.2 Safety Symbols .....................................................................................................................................2-2

2.3 Accident Prevention / Operational Safety.............................................................................................2-3

2.4 Hygiene.................................................................................................................................................2-5

2.5 Designated Use.....................................................................................................................................2-5

2.6 Liability ..................................................................................................................................................2-6

3 Product description ............................................................................................................................3-1

3.1 Coffee Machine Specifications..............................................................................................................3-2

3.2 Operating Information for the Coffee Machine......................................................................................3-7

3.3 Design of the Coffee Machine...............................................................................................................3-9

3.4 Commissioning....................................................................................................................................3-10

4 Operation .............................................................................................................................................4-1

4.1 Introduction............................................................................................................................................4-2

4.2 Daily Operation......................................................................................................................................4-3

4.3 Making the Coffee Machine Ready for Operation.................................................................................4-3

4.4 Setting Coffee Outlet Height .................................................................................................................4-4

4.5 Beverage Output...................................................................................................................................4-5

4.6 End of Operation.................................................................................................................................4-10

4.7 Programming Using Standard Chip Cards..........................................................................................4-11

5 Cleaning .....................................................................................................................

5.1 Important General Notes on Cleaning ..................................................................................................5-2

5.2 Daily Cleaning.......................................................................................................................................5-3

5.3 Cleaning As Required ...........................................................................................................................5-4

6 Error Messages and Malfunctions ....................................................................................................6-1

6.1 Error Messages With Display on the Control Panel..............................................................................6-2

6.2 Malfunctions Without Display on the Control Panel..............................................................................6-4

7 Optional Features................................................................................................................................7-1

7.1 Payment Systems .................................................................................................................................7-2

7.2 Water Softener (Filados/Brita)...............................................................................................................7-2

7.3 Cup Warmer..........................................................................................................................................7-2

7.4 Coffee Grounds Disposal to Container.................................................................................................7-2

7.5 Brew Accelerator...................................................................................................................................7-2

7.6 Wastewater and Fresh Water Container...............................................................................................7-2

7.7 Grinders and Funnel for Ground Coffee...............................................................................................7-3

7.8 Base Material ........................................................................................................................................7-3

7.9 Cup Plate Frames Illuminated...............................................................................................................7-3

8 Appendix..............................................................................................................................................8-1

8.1 CE Declaration of Conformity................................................................................................................8-2

8.2 Cleaning agent......................................................................................................................................8-3

8.3 Serials Plates of Steam Generator and Instant Heater.........................................................................8-4

8.4 Environmental Aspects .........................................................................................................................8-4

9 Index.....................................................................................................................................................9-1

..........................5-1

BASCC BC - 02.01 - V01a Page1-5

Page 8

Introduction

Page 1-6 BASCC BC - 02.01 - V01a

Page 9

Safety instructions

2. Contents

Chapter Text Page

2

2.1

2.2

2.3

2.4

2.5

2.6

General ..............................................................................................................................................2-2

Safety Symbols.................................................................................................................................2-2

Accident Prevention / Operational Safety......................................................................................2-3

Hygiene..............................................................................................................................................2-5

Designated Use.................................................................................................................................2-5

Liability ..............................................................................................................................................2-6

Safety instructions............................................................................2-2

BASCC BC - 02.02 - V01 Page 2-1

Page 10

Safety instructions

2 SAFETY INSTRUCTIONS

This chapter warns you about possible dangers when operating the machine. The

information contained herein on how to recognize hazardous situations allows safe

and proper operation.

2.1 General

The coffee machine will be handed over by a service technician authorised by the

manufacturer. However, you should read the operating instructions carefully and

ensure that you fully understand them prior to commissioning the machine.

Always comply with your local safety regulations and hygienic guidelines.

Be sure that only authorised and trained personnel work on the machine!

Always keep this manual in a handy place near the machine.

2.2 Safety Symbols

You will see the following symbols with all safety instructions.

Follow the instructions to the letter and proceed with particular care in the cases

described.

Danger!

This note indicates a risk of severe and/or fatal injury if specific procedural

rules are violated.

Whenever you see this symbol in the operating manual, take all necessary

safety precautions.

Electric shock!

Risk of severe and/or fatal injury due to electric shock!

Important!

This note indicates possible damage to property as well as possible financial and

statutory penalties (e.g. loss of rights to claim under guarantee, liability suits, etc.).

Page 2-2 BASCC BC - 02.02 - V01

Page 11

Safety instructions

2.3 Accident Prevention / Operational Safety

In the event of incorrect operation or misuse, one or more of the following might occur:

• Risk of severe and/or fatal injury of the operator, third persons or animals that are

in close proximity to the machine,

• Risk of damage to machine and other property of the operator or of third parties,

• Inefficient performance of the machine.

Danger!

People who are not familiar with these operating instructions, as well as

children or people under the influence of alcohol, drugs or medication may not

operate the machine. On self-service units, danger zones such as the steam

pipe and the hot water outlet must be labelled in such a manner that the

warning is clearly visible to the customer.

Important!

The installation, programming, maintenance and repair of the coffee machine must be

carried out only by an authorised service technician.

Important!

The machine must be connected to the power supply system and fresh water lines in

compliance with the regulations of your local service providers.

Electric shock!

Work on electric systems may be carried out only by qualified engineers or

technicians.

The machine must be connected to a fuse-protected circuit.

Appropriate EU directives on low voltage systems and/or the country's or local

safety rules and regulations apply.

We recommend connection through a residual current operated circuit-breaker.

The connection must be grounded and protected against spark-over in

compliance with regulations.

The voltage must comply with the information given on the machine's serial

plate.

Important!

To prevent water damage caused by hose breakage, it is recommended to run the

water line via a water stop valve (mains-side).

Electric shock!

Never insert the power plug into the socket when wet and do not touch the plug

with wet hands.

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

BASCC BC - 02.02 - V01 Page 2-3

Page 12

Safety instructions

Danger!

Parts of the product outlets, the hot water pipe and the steam pipe become very

hot during the machine's cleaning cycle and when coffee, milk, hot water or

steam are delivered. Always touch all outlets only at the specially designed

protective elements.

Important!

Pressing the Stand-by button will only switch off the machine, but not physically

separate it from the mains.

Important!

The machine may not be operated if the fresh water supply is disabled.

Important!

Never disconnect the water line while the machine is switched on or in stand-by mode.

Electric shock!

Never touch live parts!

Always switch off the main switch or disconnect the machine from the mains

before carrying out any maintenance work.

Important!

Malfunctions may be repaired only by manufacturer-authorised and qualified

personnel.

Important!

Only use original spare parts.

Electric shock!

Immediately report damaged cables and plugs to an authorised and qualified

technician and have them repaired or replaced.

If the mains cable is damaged, it may be replaced only by a service technician

authorised by the manufacturer.

Important!

Immediately report visible damages and leakages to an authorised and qualified

technician and have them repaired or replaced.

Environmental protection!

Use cleaning agents recommended by the manufacturer.

Page 2-4 BASCC BC - 02.02 - V01

Page 13

Safety instructions

2.4 Hygiene

Note:

Prior to commissioning, run the cleaning program (see chapter "Cleaning").

Important!

• Observe the general hygiene regulations according to HACCP!

• For daily and weekly cleaning, proceed as described in chapter "Cleaning".

• Never spray the machine with water or other liquids.

• For cleaning, never immerse the machine in water or any other liquid.

Danger!

During cleaning and usage of cleaning tools or products, there is a risk of

injury.

2.5 Designated Use

Designated use of the machine and the included accessories and optional features

are subject to the agreement on use, any other existing additional agreements and the

general terms and conditions of the M. Schaerer Ltd.. The operating manual is an

integral part of the above agreement of use. Any usage other than within the limits

specified herein shall be regarded as not in accordance with the designated use. The

manufacturer shall not be liable for any resulting damage.

BASCC BC - 02.02 - V01 Page 2-5

Page 14

Safety instructions

2.6 Liability

Guarantee and liability claims in the event of injury to people and damage to property

cannot be entertained if they are due to one or more of the following causes:

• Any use other than the designated one

• Improper assembly, commissioning, operation and maintenance of the machine

and its optional features.

• Non-compliance with specified maintenance intervals

• Operating the machine with defect safety devices or with safety devices that are

either not in place or not functioning properly

• Non-compliance with safety instructions in this manual with special regard to

storage, installation, commissioning, operation and maintenance of the machine,

• Operating the machine in other than perfect condition

• Repairs not carried out by a qualified technician

• Catastrophic damage due to the influence of foreign bodies, accidents, vandalism

and force majeure

• Intrusion into the machine with objects and opening of the housing

Important!

The manufacturer's warranty exclusively covers machines that have been properly

maintained at the intervals specified and where original spare parts are used that were

directly supplied by the manufacturer or one of the manufacturer's authorised

suppliers.

Maintenance of the machine has to be carried out either after 12 months or after

70,000 coffee products have been dispensed.

Safety-relevant parts, such as safety valves, safety thermostats, boiler, etc., must be

replaced and may not to be repaired under any circumstances. These parts

always have to be replaced.

- Safety valves every 12 months

- Boilers (steam generators, instant heaters) every 60 months

Page 2-6 BASCC BC - 02.02 - V01

Page 15

Product description

3. Contents

Chapter Text Page

3

3.1

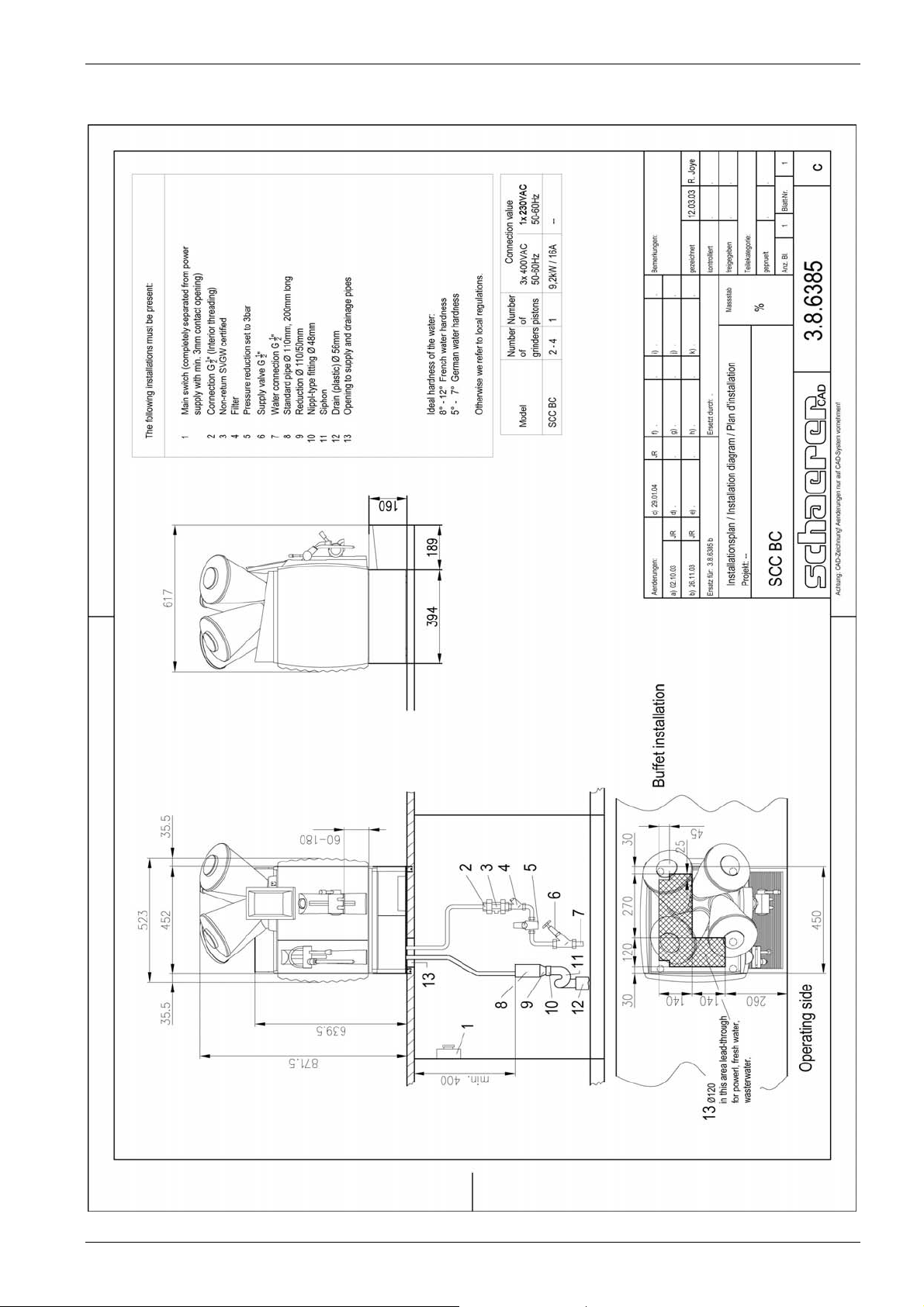

3.1.1 Exterior View..........................................................................................................................................2

3.1.2 Interior View...........................................................................................................................................3

3.1.3 Control Panel of the Coffee Machine ....................................................................................................4

3.1.4 Installation Layout..................................................................................................................................5

3.1.5 Purpose of Coffee Machine...................................................................................................................6

3.1.6 Serial Plate on the Coffee Machine.......................................................................................................6

3.2

3.2.1 Performance Characteristics.................................................................................................................7

3.2.2 Dimensions and Weight.........................................................................................................................7

3.2.3 Power Supply.........................................................................................................................................8

3.2.4 Water Supply/Drain................................................................................................................................8

3.2.5 Volumes.................................................................................................................................................9

3.3

3.3.1 Model Variations....................................................................................................................................9

3.3.2 Included in Shipment.............................................................................................................................9

3.3.3 Optional Features..................................................................................................................................9

3.4

3.4.1 Initial Commissioning of the Coffee Machine......................................................................................10

3.4.2 Set-Up Conditions................................................................................................................................10

3.4.2.1 Location...............................................................................................................................................10

3.4.2.2 Installation of the Coffee Machine.......................................................................................................10

3.4.3 Counter Lead-Throughs ......................................................................................................................10

Product description ............................................................................. 2

Coffee Machine Specifications...........................................................................................................2

Operating Information for the Coffee Machine.................................................................................7

Design of the Coffee Machine............................................................................................................9

Commissioning..................................................................................................................................10

BASCC BC - 02.03 - V01a Page 3-1

Page 16

Product description

3 PRODUCT DESCRIPTION

3.1 Coffee Machine Specifications

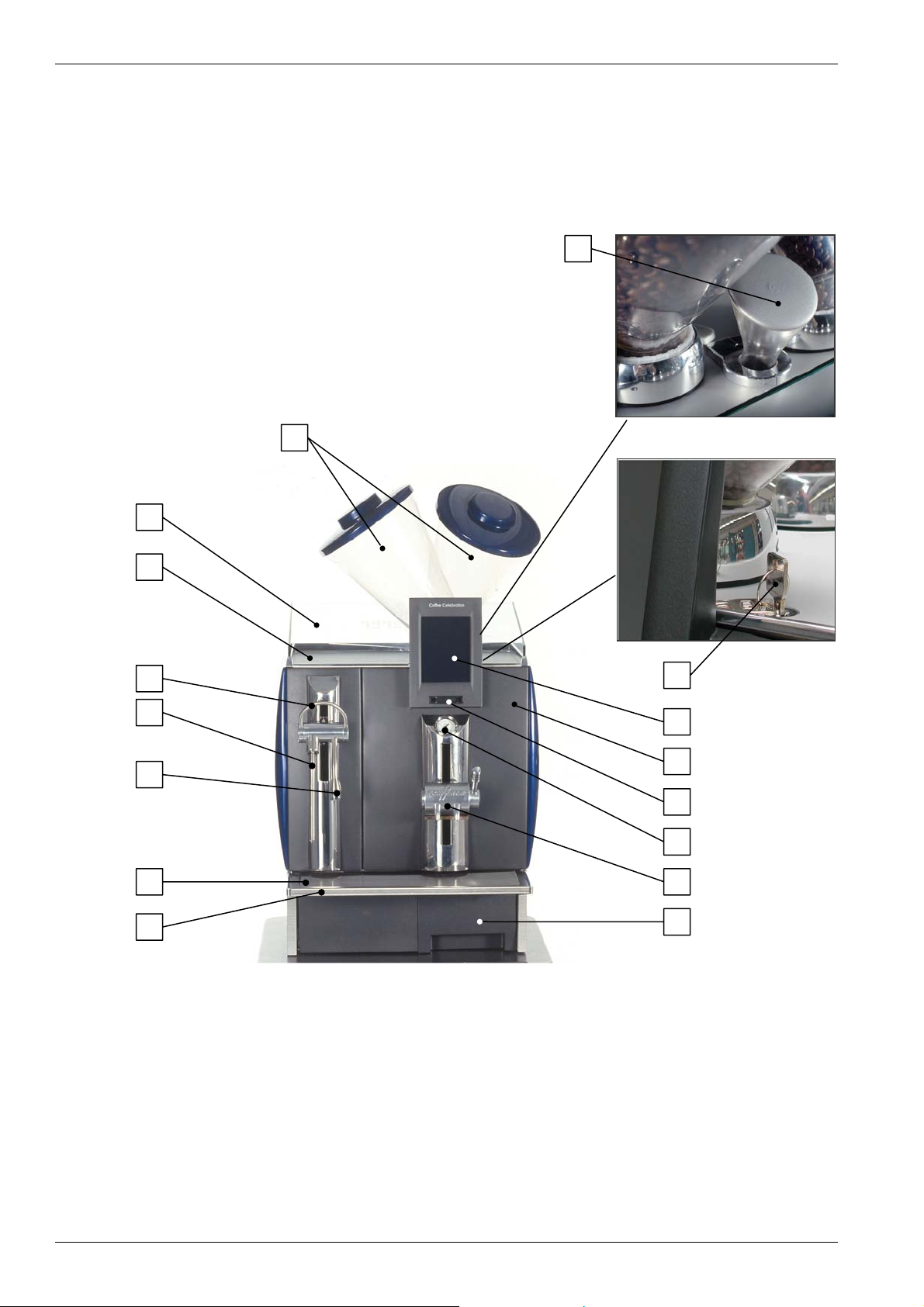

3.1.1 Exterior View

2

3

4

5

6

7

8

Fig. 001

Legend:

1 Coffee beans container

2 Cup plate frame

3 Heated cup plate

4 Valve bow steam

5 Steam pipe

6 Hot water outlet

7 Drip grid

8 Drip tray with drain

1

9

Fig. 002

Fig. 003

10

11

12

13

14

15

16

9 Funnel for ground coffee

(e.g. decaffeinated)

10 Lock with key

11 Control panel (Touch Screen)

12 Front door

13 Chip card reader

14 Manometer

15 Coffee outlet (height adjustable)

16 Grounds container

Page 3-2 BASCC BC - 02.03 - V01a

Page 17

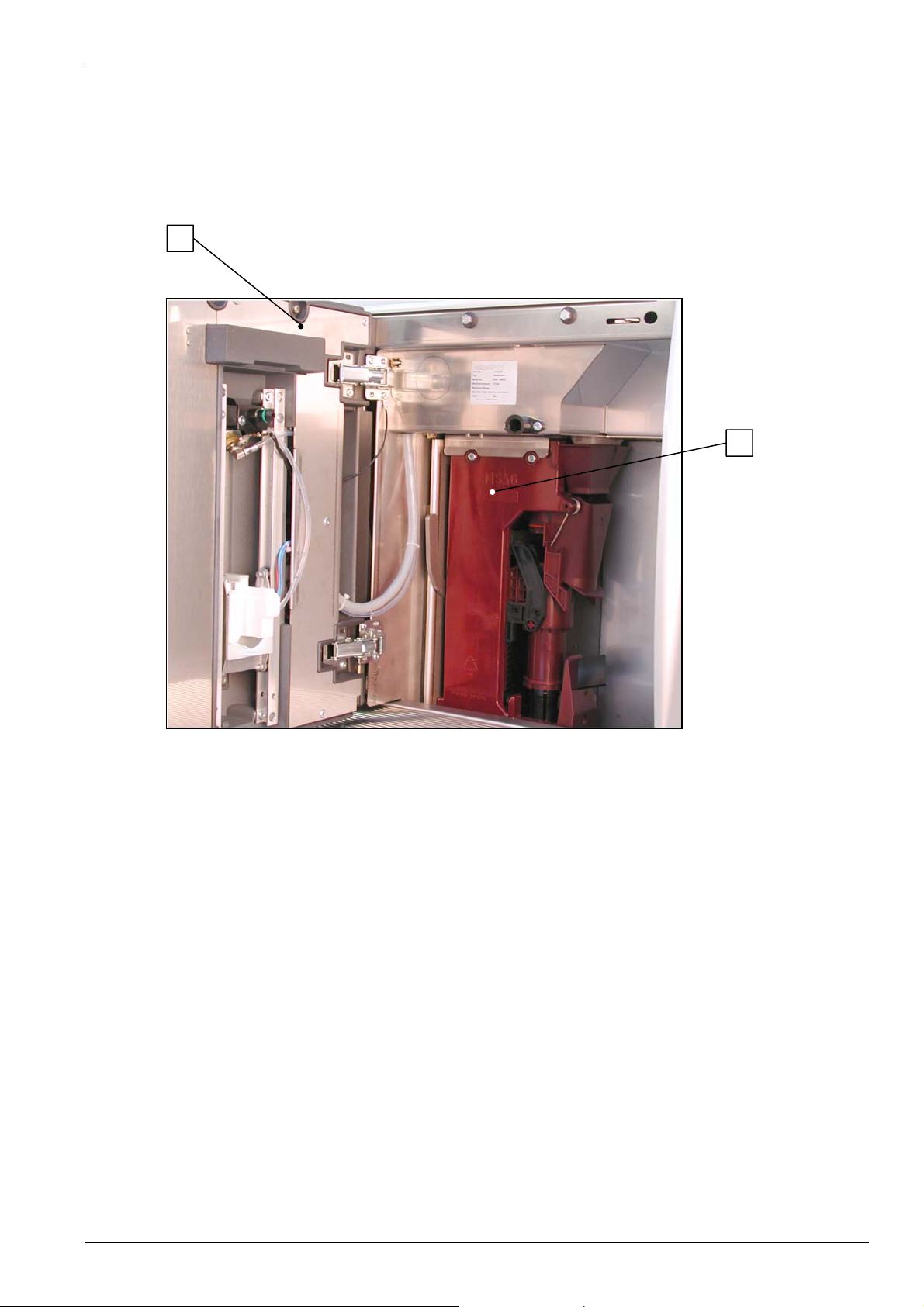

3.1.2 Interior View

1

Product description

2

Fig. 004

Legend:

1 Front door

2 Brewing unit

BASCC BC - 02.03 - V01a Page 3-3

Page 18

Product description

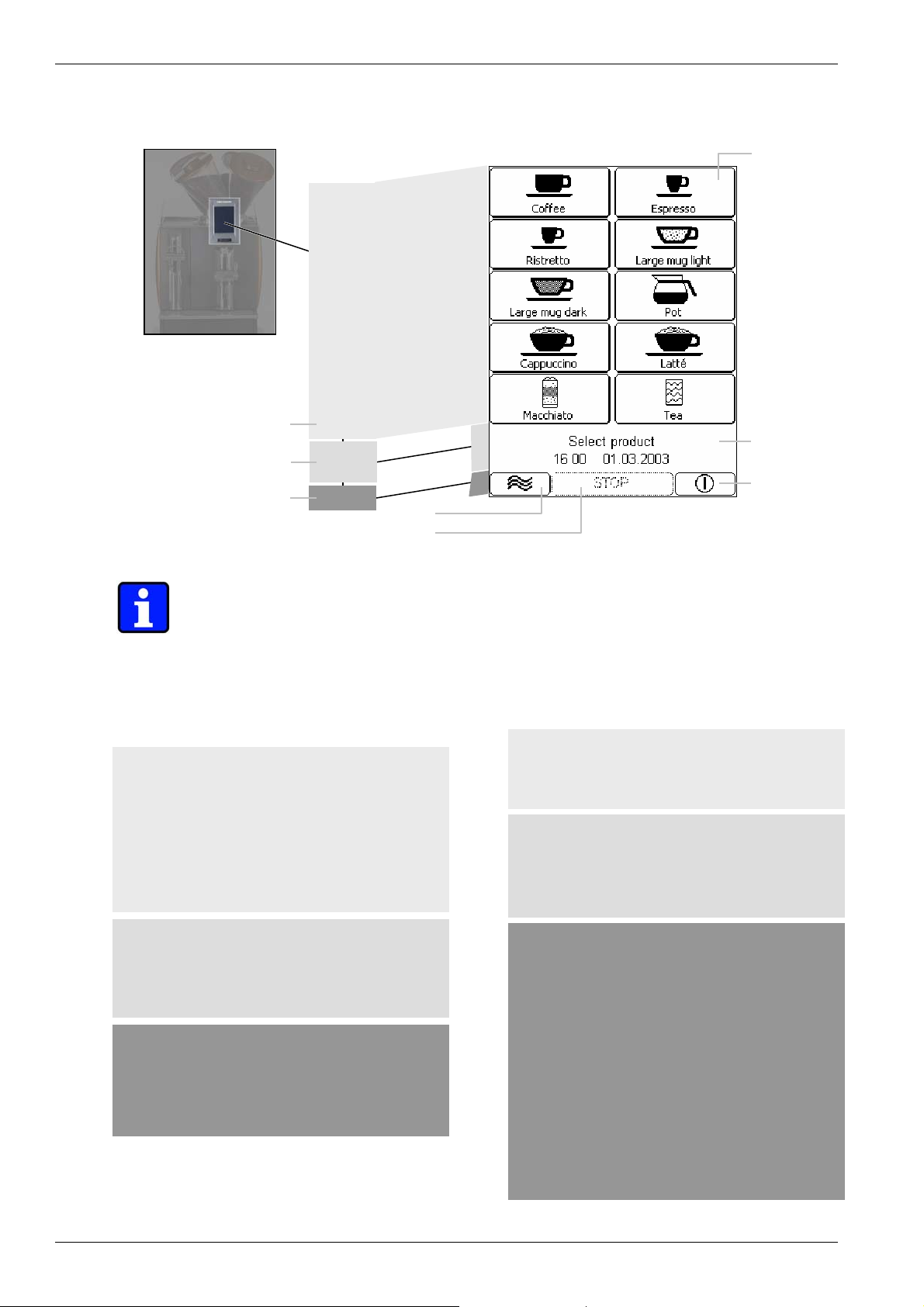

3.1.3 Control Panel of the Coffee Machine

Fig. 005

1

2

3

Note:

The control panel can have different buttons depending on the configuration.

Here only an example is shown.

Legend:

Basic configuration of control panel:

1 Field for freely selectable buttons

z Product fields

z Freely-selectable configuration

z Instructions and information during the

cleaning process

z Malfunction messages

z Error messages

2 Field for messages and information in

normal mode

z Status line

z Information

3 Field with function buttons:

z Cleaning button

z STOP button

z Stand-by button

4

5

6

8

Fig. 006

7

Example:

4 Product field on the control panel

z Programmable buttons to dispense

coffee and hot water

5 Status line:

z Displays activities

z Time and date

z Problems

6 Stand-by button

z From stand-by mode:

Switch on machine

z From normal mode:

Switch to stand-by mode

7 STOP button:

z Cancel beverage output in process

z Cancellation of pre-selected products

8 Cleaning button:

z Starting cleaning

Page 3-4 BASCC BC - 02.03 - V01a

Page 19

Product description

3.1.4 Installation Layout

Installation Plan 3.8.6076 ---

BASCC BC - 02.03 - V01a Page 3-5

Page 20

Product description

3.1.5 Purpose of Coffee Machine

The coffee machine can prepare the following beverages:

• Espresso

• Coffee

• Ristretto (short espresso)

• Coffee pot

• Decaffeinated coffee

• Hot water for tea, punch etc.

• Steam to foam up milk (e.g. hot milk, milk foam, cappuccino, macchiato etc.)

3.1.6 Serial Plate on the Coffee Machine

For warranty purposes, and in case of failure, please copy the machine’s serial plate

data in the field on this page!

Fig. 007

If you have opened the front door, the

serial plate is located on the brewing unit.

Inst. No. 4.6.9450

Type Celebration

Serial No. 0000 000000

Nominal pressure 12 bar

Electrical Ratings

380-415V 3NAC 50/60Hz 9300-9800W

Fuse: 16A

Installation No.: .............................................

Type: Celebration...........................

Serial No.: .............................................

Nominal pressure:

................................... ..........

Electrical ratings:

.....................V ......NAC ……...Hz ………….W

Fuse: ……….A

Page 3-6 BASCC BC - 02.03 - V01a

Page 21

Product description

3.2 Operating Information for the Coffee Machine

3.2.1 Performance Characteristics

The output per hour depends on the product type.

Output per hour: 240 cups

3.2.2 Dimensions and Weight

Width : 521 mm

Height : 871.5 mm

Depth : 617 mm

Coffee outlet height : 60 -180 mm

Outlet height hot water : 180 mm

Net weight : approx. 50 kg

Subject to changes without notice!

BASCC BC - 02.03 - V01a Page 3-7

Page 22

Product description

3.2.3 Power Supply

Model Connected load

SCC BC 9,3 kW / 16 A 3 x 400 VAC 50/60 Hz

SCC BC Self 9.3 kW / 16 A 3 x 400 VAC 50/60 Hz

The voltage on the serial plate must correspond to the local mains voltage.

For special voltages ask the manufacturer or one of your authorised after sales

service people.

Electric shock!

• An authorised specialist must install or inspect the installation!

• The phase must be protected with 16 A fuse.

• The machine must be fully disconnected from the power supply.

• Never operate the coffee machine if the mains cable is defective. A defective

mains cable or plug must immediately be replaced by a service technician

authorised by the manufacturer.

• Use extension cords only when you are sure that they are in perfect condition.

The extension cord must have a minimum cross section of 1.5 mm² for each core

and a permitted 5 pole plug (PNE) for 16 A.

• Power cable and/or extension cords must be placed so that they pose no safety or

health hazard. Do not pinch the cords or pull them around sharp corners and over

sharp edges; do not let them hang exposed in the room. Do not place the cords

on hot surfaces and protect them from oil and harsh cleaning agents.

• Never lift or pull the appliance by the mains cable. Never pull the plug out of the

socket by gripping the mains cable or extension cord. Never touch cord and plug

with wet hands. Never insert a wet plug into the socket.

3.2.4 Water Supply/Drain

The machine must be connected as shown in the installation diagram to a G 1/2"

drinking water line (section 3.1.4, page 3-5).

If the coffee machine is to be connected to a newly installed water line, the line and

the pressure hose must be properly rinsed to ensure that no dirt particles are fed into

the machine.

If the machine is to be connected to a water drain, the supplied drainage hose should

be connected to the drip tray and the siphon and fastened securely. The hose should

point downwards so that water can easily flow out of the drip tray.

Note:

The coffee machine is specifically designed for a water hardness of between 5° - 7° dH

(German hardness) or 8° - 12° fH (French hardness). Chlorine content should not

exceed 100 mg per litre. The ideal pH value is 7. For all other values, local

regulations apply.

Page 3-8 BASCC BC - 02.03 - V01a

Page 23

Product description

Water pressure:

Minimum pressure: 1 bar

Maximum pressure: 3 bar

Note:

We recommend setting the decompression valve to 3 bar.

Feed water temperature:

Min. 10 °C

Max 30 °C

3.2.5 Volumes

2 hot water boilers

1.2 l hot water

0.8 l coffee water

1 steam boiler

0.8 l, of which 0.4 l are steam

2 coffee grounds containers

1 kg each coffee grounds container

1 funnel for ground coffee (e.g. decaffeinated)

1 to 2 portions

3.3 Design of the Coffee Machine

3.3.1 Model Variations

SCC BC Coffee, hot water, steam

SCC BC Self Coffee, hot water

3.3.2 Included in Shipment

Item Order. no.

- 1 User manual *

- 1 Daily cleaning short cleaning instructions *

- 1 Measuring spoon for ground coffee (e.g. decaffeinated) 067’111

- 1 Cleaning tab 065’221

- 1 Cleaning brush 067’409

- 1 CHEF chip card 063’930

- 1 SAVE DATA chip card 063’929

- 1 Case for chip cards 065’278

- 2.0 m Drainage hose 063'345

- 1 Bride to drainage hose Ø 29 mm 063'119

- 1 Flat packing 064'249

- 1 Screw fittings 068'179

- 2 O-rings coffee outlet 070’195

- 1 O-ring coffee outlet 070’408

- 1 Turning handle grinder adjustment 061’977

* Customized items!

Subject to changes without notice!

3.3.3 Optional Features

See Chapter 7 “Options“.

BASCC BC - 02.03 - V01a Page 3-9

Page 24

Product description

3.4 Commissioning

3.4.1 Initial Commissioning of the Coffee Machine

The coffee machine must be installed and commissioned by a service technician

authorised by the manufacturer.

3.4.2 Set-Up Conditions

3.4.2.1 Location

Danger!

- Prior to installing, ensure that the coffee machine will not be positioned on a

hot surface or near an oven.

- Not suitable for outdoor use. Never expose the coffee machine to external

conditions such as rain, snow, frost, etc.

- Do not place the coffee machine on a surface cleaned with a hose.

- Only place the appliance where it can be supervised by trained personnel.

- The support surface for the unit must be stable and level and may not be

deformed by the weight of the coffee machine.

Important!

The location must comply with the following climatic conditions:

- Ambient temperature from 10 °C to 35 °C

- Relative humidity max. 80 % rF

- The machine is designed exclusively for interior use.

- Protect the coffee machine from frost. If the coffee machine has been exposed to

temperatures below freezing point, contact an authorised customer service

representative before you start the unit.

3.4.2.2 Installation of the Coffee Machine

Installation of the coffee machine should be done under the following conditions:

- Install the supply lines as shown in the mains-side installation diagrams to within one

meter of the place of installation.

- Conform to the technical data.

- - Provide and maintain sufficient clearance for maintenance work and operation:

- above for filling coffee beans

- Keep approx. 35 cm clear on left side

- A minimum of 15 cm between machine back panel to wall (air circulation)

- Comply with the respective local statutory regulations regarding catering premises.

Note:

- The dimensions of the installed coffee machine are given in the corresponding

installation plan (section 3.1.4, page 3-5).

3.4.3 Counter Lead-Throughs

Note:

You can find the counter lead-through specifications on the corresponding installation

plan (Section 3.1.4, Page 3-5).

Page 3-10 BASCC BC - 02.03 - V01a

Page 25

Operation

4. Contents

Chapter Text Page

4

4.1

4.2

4.2.1 Refilling Coffee Beans...........................................................................................................................4-3

4.3

4.3.1 Pre-Checks............................................................................................................................................4-3

4.3.2 Switching on the Coffee Machine .........................................................................................................4-3

4.4

4.4.1 Setting Coffee Outlet Height.................................................................................................................4-4

4.5

4.5.1 Output of Coffee Beverages..................................................................................................................4-5

4.5.2 Pre-Selecting Beverage Type...............................................................................................................4-5

4.5.3 Double Button........................................................................................................................................4-6

4.5.4 Dispensing Coffee With Previously Ground Coffee..............................................................................4-6

4.5.5 Dispensing Hot Water........................................................................................................... ................4-7

4.5.6 Generating Steam.................................................................................................................................4-8

4.6

4.6.1 Shutting Off the Coffee Machine...........................................................................................................4-9

4.6.2 Extended Idle Time...............................................................................................................................4-9

4.6.2.1 Disassembly..........................................................................................................................................4-9

4.7

4.7.1 Navigation on Programming Level......................................................................................................4-10

4.7.2 Inserting the Chip Card into the Chip Card Reader............................................................................4-11

4.7.3 CHEF Chip Card.................................................................................................................................4-11

4.7.3.1 Menu Overview CHEF chip card.........................................................................................................4-11

4.7.3.2 Introduction to the CHEF Programming Level....................................................................................4-12

4.7.3.3 Reading the Counter...........................................................................................................................4-12

4.7.3.4 Configuring Products...........................................................................................................................4-14

4.7.3.5 Configuring the Display.......................................................................................................................4-15

4.7.3.6 Time / Date..........................................................................................................................................4-16

4.7.3.7 Automatic Timer..................................................................................................................................4-16

4.7.3.8 Language ............................................................................................................................................4-16

4.7.3.9 Changing PIN code.............................................................................................................................4-17

4.7.4 SAVE-DATA PLUS Chip Card............................................................................................................4-17

4.7.4.1 Saving Coffee Machine Data to Chip Card.........................................................................................4-17

4.7.4.2 Saving Data from the Chip Card to the Coffee Machine.....................................................................4-17

OPERATION 4-2

Introduction .........................................................................................................................................4-2

Daily Operation....................................................................................................................................4-3

Making the Coffee Machine Ready for Operation............................................................................4-3

Setting Outlet Height ..........................................................................................................................4-4

Beverage Output .................................................................................................................................4-5

End of Operation.................................................................................................................................4-9

Programming Using Standard Chip Cards.....................................................................................4-10

BASCC BC - 02.04 - V01 Page 4-1

Page 26

Operation

4 OPERATION

4.1 Introduction

This chapter describes the basic functions of the coffee machine. Read them carefully

to ensure easy and problem-free routine operation.

Note:

Proper installation and programming of the coffee machine by an authorised service

technician are crucial for a smooth operation and good product quality.

Danger!

- During product release, never move cups or other objects positioned below

the beverage outlet, the hot water outlet or the steam pipe! The beverages

delivered by the machine are hot!

After having pressed the selection button, keep hands and other body parts

away from the outlets to prevent scalding!

- Never aim steam or hot water jets against persons!

- Do not touch the hot cup plate or the beverage outlets. Touch the hot water

outlet and the steam pipe only at the insulated handles.

- The coffee machine does not stop when a cup is removed from underneath an

outlet during serving. Delivery (including pre-selected delivery) can only be

terminated by pressing the [STOP] button.

Danger!

Switch off the coffee machine if you accidentally pour liquid over the cup plate

(risk of short-circuit)!

Contact a customer service representative immediately.

Environmental protection!

Noise emission levels can be up to 70 dB (A), particularly when heating up beverages.

Page 4-2 BASCC BC - 02.04 - V01

Page 27

Operation

4.2 Daily Operation

4.2.1 Refilling Coffee Beans

Note:

Only pour roasted coffee beans into the coffee bean container(s)!

Danger!

Never reach with your hands into the coffee bean container(s) when the machine is

switched on. When refilling the bean container(s), do not reach into the grinder and do not

press any of the product fields!

1. Remove the cover (1) from the coffee bean container (2)

1

(see Fig. 008).

2. Refill with coffee beans (max. 1 kg). Close the cover again.

Note:

A well closed cover prevents the loss of aroma.

2

2

Fig. 008

4.3 Making the Coffee Machine Ready for Operation

4.3.1 Pre-Checks

Prior to switching on the machine, check the following:

- The fresh water supply is open

- The coffee bean containers are filled (see section 4.2.1 “Refilling Coffee Beans”, page 4-3).

- The grounds container is empty

- The coffee machine is connected to the power supply.

- Check whether the coffee sliding hatches are open.

4.3.2 Switching on the Coffee Machine

1. Switch the coffee machine on by touching the control panel

at any point for approx. 3 seconds.

2. Wait for product output until the message Select Product

appears on the status line.

Fig. 009

BASCC BC - 02.04 - V01 Page 4-3

Page 28

Operation

4.4 Setting Outlet Height

4.4.1 Setting Coffee Outlet Height

Danger!

Set the correct outlet height before selecting the coffee product!!

Fig. 010

1

Fig. 011

Note:

There are two possibilities for setting the outlet height

to the optimal height:

(Max. cup height: 180 mm)

1. Rough setting:

Press in the fixing button on the right side of the

coffee outlet body. Push the coffee outlet to the

desired position (see Fig. 010).

2. Fine setting:

You can do the fine setting by moving the handle

(1) on the coffee outlet upward or downward (see

Fig. 011).

Page 4-4 BASCC BC - 02.04 - V01

Page 29

Operation

4.5 Beverage Output

Danger!

The beverages delivered by the coffee machine are hot! To protect yourself

against scalding, keep hands and other body parts away from the outlet area

during the preparation and delivery of beverages.

Set the correct outlet height before selecting the coffee product!!

4.5.1 Output of Coffee Beverages

1. Place one or two empty cup(s) under the beverage outlet

(see Fig. 012).

2. Push the coffee outlet to the correct position.

3. Select the desired beverage on the control panel.

Your Product is Being Prepared appears in the status line.

4. Only remove the cup(s) if the text in the current product field

no longer blinks and Select Product appears on the status

line.

Fig. 012

4.5.2 Pre-Selecting Beverage Type

When configured in this way, you can select several products in succession. The

coffee machine will dispense the selected beverages in this order.

Display example:

Fig. 013

The control panel in Fig. 013 displays the selected products in each product field:

1 Espresso was selected

1 Ristretto was selected

1 white coffee was selected

The first selected product is served first. The text blinks during preparation. Æ Product

name blinks

The product dispensed next is displayed by the blinking number (number of preselected products) in the corresponding product field. Æ Number blinks

The pre-selected amount for each product is displayed at the top right in each product

field. Æ The number does not blink yet

Deleting pre-selected beverage types and cancelling and beverage output:

Select the STOP button again and the originally saved pre-selection of the coffee

output is deleted. The current beverage continues to be dispensed and can be

cancelled by selecting the STOP button again.

BASCC BC - 02.04 - V01 Page 4-5

Page 30

Operation

4.5.3 Double Button

The beverage type on the product button, if configured in this way, is dispensed twice.

Perform the following procedure:

Fig. 014

1. Place one or two empty cup(s) under the coffee outlet.

If two cups on the coffee output are to be filled simultaneously, ensure that

the cups are positioned exactly under the outlet openings.

2. Press the button programmed for double beverage output

(see Fig. 014).

3. The displayed buttons for products change to "double beverage output" (see

Fig. 015).

4. Select the desired beverage on the control panel.

Fig. 015

5. Only remove the cup(s) if the text in each product field no longer blinks and

Select Product appears on the status line.

4.5.4 Dispensing Coffee With Previously Ground Coffee

- The coffee machine can be configured for coffee preparation with previously ground

coffee beans.

- Beverages prepared with previously ground coffee beans cannot be pre-selected.

- Only use ground coffee (e.g. decaffeinated)

1. Place the empty cup(s) under the coffee outlet

Fig. 016

2. Press the button Decaffeinated

3. All of the displayed buttons for possible

4. Pour ground coffee for one or two cups into the

Fig. 017

5. Press the button for the desired beverage.

6. Only remove the cup(s) if the text in the

1

Fig. 018

(see Fig. 012).

(see Fig. 016).

decaffeinated products change to

"decaffeinated beverage output" (see Fig. 017).

The following appears in the status line: Pour

in the coffee powder and select the product.

funnel for ground coffee (1) (see Fig. 018)

corresponding product field no longer blinks

and Select Product appears on the status line.

Fig. 018

Page 4-6 BASCC BC - 02.04 - V01

Page 31

Operation

4.5.5 Dispensing Hot Water

Press the Tea product field on the control panel

to dispense hot water (see Fig. 019).

Depending on the configuration, the output is either dosed or manual (Start / Stop)

via the hot water pipe located to the left next to the coffee outlet (see Fig. 020).

In self-service mode, products are selected via an external button directly above the

hot water pipe.

Fig. 019

- Hot water cannot be pre-selected.

- Coffee and hot water can be dispensed simultaneously.

Danger!

Risk of injury by scalding! Keep hands and other body parts away from the

outlet!

If portioned delivery is programmed:

1. Place an empty cup under the hot water outlet

(see Fig. 020).

2. Touch the Tea product field (Fig. 019).

3. To cancel the current output:

Press the STOP button.

Note:

If, after output of an appropriately large amount of hot

Fig. 020

water, the message "Under-Temperature Tea"

appears, it means that the boiler is being heated up to

the set temperature.

If start / stop mode is programmed:

1. Place an empty cup under the hot water outlet

(see Fig. 020).

2. Touch the Tea button (Fig. 019).

The hot water is delivered continuously.

3. Press the Tea button again or the STOP button

to end the hot water output or to cancel.

BASCC BC - 02.04 - V01 Page 4-7

Page 32

Operation

4.5.6 Generating Steam

Note:

To output steam, press the steam valve bow. Output is through the steam pipe located

to the left of the hot water pipe (Fig. 021).

Steam is used for heating beverages such as milk or cocoa.

Danger!

Keep away from underneath the steam pipe while steam is delivered! Hold the

cup in such a way that no liquid is spilled onto your hands or other body parts

during heating!

1

Fig. 021

Danger!

When the boiling point is reached, the beverage may start to spill over. During

steam output, ensure that the steam pipe remains immersed in the liquid.

1. Point the steam pipe towards the drip grid.

Remove the condensation water from the pipe

system by briefly folding down the steam valve

bow to open it. If steam escapes from the

steam pipe, turn the bow upward again.

2. Immerse the steam pipe into the container of

the beverage to be heated until it reaches the

bottom.

3. Press the steam valve bow.

Steam is released. No message is displayed on

the control panel during the steam output.

4. Heat the content to the desired temperature.

Ensure that the steam pipe is always immersed

in the liquid.

Tip: The deeper the sound, the higher the

temperature of the heated liquid.

5. To end or cancel steam output:

Close the steam valve by moving the bow

upward.

6. Put the cup aside.

7. Clean the outside of the steam pipe with a wet

and clean paper tissue.

8. Point the steam pipe towards the drip grid. To

clean the steam pipe on the inside, open it

briefly, twice in succession.

Page 4-8 BASCC BC - 02.04 - V01

Page 33

Operation

4.6 End of Operation

4.6.1 Shutting Off the Coffee Machine

If the coffee machine is not used for longer periods, e.g. nights, it can be switched to stand-by. In

this mode, the boilers are not heated and no beverages are available.

1. Touch the Stand-by button in the control panel until the background lighting of

the control panel goes out.

4.6.2 Extended Idle Time

1. Do the daily cleaning:

(See section 5.2 “Daily Cleaning“, page 5-3)

2. Pull the mains plug from the socket, respectively cut off the power supply with the

master switch.

3. Close the stop valve on the fresh water line if the machine has a fixed installation.

4. To empty the boiler, ask a customer service representative authorised by the

manufacturer for assistance or advice.

5. Store the coffee machine in a dry and dust-free location. On premises where the

temperature can drop below zero, the boilers have to be emptied. For this you

should call in a service technician authorised by the manufacturer.

4.6.2.1 Disassembly

1. Contact a manufacturer-authorised customer service representative.

BASCC BC - 02.04 - V01 Page 4-9

Page 34

Operation

4.7 Programming Using Standard Chip Cards

For all the functions described in this chapter, it is assumed that the coffee

machine is ready for routine.

The CHEF and SAVE DATA cards are part of the standard delivery package and

provide a simple means of changing settings or retrieving information from the

coffee machine.

Note:

- Keep the chip cards in a safe place where only authorised persons have access

to them.

- When a chip card is in the card reader, product selection is disabled.

4.7.1 Navigation on Programming Level

With the following control elements, you are at the right place at the

programming level and can change settings.

You exit a menu or sub-menu with an upward arrow (see Fig. 022)

Fig. 022

Fig. 023

Display example:

Fig. 024

Fig. 025

Fig. 026

and return to the next highest level.

You can navigate to the next page with the right arrow (see Fig. 023)

to read information or change settings.

If values can be changed/ set, a key block appears after the

selection of the desired function (see display example, Fig. 024).

Confirm your entry with the button (see Fig. 025) (e. g. “Enter

PIN Code“).

You can adjustment values which were entered incorrectly with the

adjustment button (see Fig. 026).

Page 4-10 BASCC BC - 02.04 - V01

Page 35

Operation

4.7.2 Inserting the Chip Card into the Chip Card Reader

1. Insert the desired chip cared with the print

image facing upward into the chip card reader

(1) Fig. 027.

1

2. Follow the instructions presented in the

individual chapters.

Fig. 027

4.7.3 CHEF Chip Card

The CHEF card allows the principal settings or modifications to be made for routine

operation.

- Read product counter for coffee and tea per button

- Reset counter

- Read monthly counter

- Read machine counter

- Change grinding quantity.

- Change coffee water volume

- Change water dosing time and steam

- Change time and date display

- Change on/off time (automatic timer)

- Change display language

- Change PIN code

4.7.3.1 Menu Overview CHEF chip card

Æ See section 4.7.3.3, Page 4-12

Æ See section 4.7.3.4, Page 4-14

Æ See section 4.7.3.5, Page 4-15

Æ See section 4.7.3.6, Page 4-16

Æ See section 4.7.3.7, Page 4-16

Æ See section 4.7.3.8, Page 4-16

Æ See section 4.7.3.9, Page 4-17

Fig. 028

BASCC BC - 02.04 - V01 Page 4-11

Page 36

Operation

4.7.3.2 Introduction to the CHEF Programming Level

1. Insert the CHEF chip card into the card reader (see section 4.7.2,

page 4-11).

2. Enter the PIN code and confirm it.

Fig. 029

3. Select one of the buttons listed to move to the desired sub-menu.

Fig. 030

4.7.3.3 Reading the Counter

Æ Section 4.7.3.3.1, Page 13

Æ Section 4.7.3.3.2, Page 13

Æ Section 4.7.3.3.3, Page 13

Fig. 031

1. Perform steps 1…3, as described in section

“4.7.3.2 Introduction to the Programming

Level“, page 4-12.

2. Select one of the displayed sub-menus.

Page 4-12 BASCC BC - 02.04 - V01

Page 37

Operation

4.7.3.3.1 Reading Daily Counter

Fig. 032

Fig. 033 Fig. 034

4.7.3.3.2 Reading Monthly Counter

Fig. 035

Fig. 036 Fig. 037 Fig. 038

4.7.3.3.3 Reading Machine Counter

Fig. 041 Fig. 040 Fig. 039

Fig. 042

BASCC BC - 02.04 - V01 Page 4-13

Page 38

Operation

4.7.3.3.4 Clearing the Daily Counter

In this function, the count of the daily counter is cleared.

1. Proceed as in section “4.7.3.3 Read Counter“, page 4-12, steps 1…2.

2. Press the Daily Counter button (see Fig. 043).

3. Now press the button Clear Statistics (see Fig. 044).

Fig. 043 Fig. 044

4.7.3.4 Configuring Products

1. Proceed as described in section “4.7.3.2 Introduction to the Programming

2. Press the Configure Products button.

3. Select one of the displayed sub-menus.

Fig. 045

Level“, page 4-12.

Æ See next page!

Page 4-14 BASCC BC - 02.04 - V01

Page 39

Operation

Fig. 046 Fig. 047 Fig. 048 Fig. 049

1. Select the product field for which you would

like to change the settings.

Possible settings:

- Adjust Product Name through a key block.

- Set water quantity through a key block.

- Set powder quantity through a key block.

- Set powder quantity for a Double Product.

Other settings:

- The desired mixture can be adjusted through

a key block.

You can enter the grinding quantity per

grinder in percentages.

Note:

While adjusting values, you can also

prepare a test product (see Fig. 49).

Press the button with the name of the

currently programmed products.

4.7.3.5 Configuring the Display

Set contrast:

darker

lighter

Fig. 050

Fig. 051

Fig. 052

BASCC BC - 02.04 - V01 Page 4-15

Page 40

Operation

4.7.3.6 Time / Date

Fig. 053 Fig. 054

4.7.3.7 Automatic Timer

Fig. 055 Fig. 056

4.7.3.8 Language

Select the desired function to adjust or set the values.

With this function, you

can specify the time of

the day when the

machine is to be shut on

or off.

Fig. 057

Select the button with the desired language.

Fig. 059 Fig. 058

Page 4-16 BASCC BC - 02.04 - V01

Page 41

Operation

4.7.3.9 Changing PIN code

By pressing on the PIN Code button, you can change the PIN code you are

currently using to another one.

Fig. 060

4.7.4 SAVE-DATA PLUS Chip Card

The SAVE DATA PLUS card is a backup card to which all the coffee machine

data can be saved.

The SAVE DATA PLUS chip card should be stored in a safe place where it can be

found easily.

You can:

- transfer data from the coffee machine to the chip card

- transfer data from the chip card to the coffee machine

4.7.4.1 Saving Coffee Machine Data to Chip Card

1. Insert the SAVE DATA PLUS chip card into the card reader (see

section 4.7.2, page 4-11).

2. Select the button Save in the dialogue window.

The following message appears: Please wait: Data are being

saved.

3. Then remove the chip card if the following appears in the control

panel on the dialogue field: Data were successfully saved.

Press the Ok button.

4.7.4.2 Saving Data from the Chip Card to the Coffee Machine

1. Insert the SAVE DATA PLUS chip card into the card reader (see

section 4.7.2, page 4-11).

2. Select the button Load in the dialogue window.

The following message appears: Please wait: Data are being

saved.

3. Then remove the chip card if the following appears in the control

panel on the dialogue field: Data were successfully saved.

Press the Ok button.

BASCC BC - 02.04 - V01 Page 4-17

Page 42

Operation

Page 4-18 BASCC BC - 02.04 - V01

Page 43

Cleaning

5. Contents

Chapter Text Page

5

5.1

5.2

5.3

5.3.1 Drip Tray Coffee Coupling..................................................................................................................5-4

5.3.2 Control Panel (Touch Screen)............................................................................................................5-5

5.3.3 Longer Idle Time.................................................................................................................................5-5

5.3.4 Disassembly .......................................................................................................................................5-5

Cleaning.............................................................................................5-2

Important General Notes on Cleaning............................................................................................5-2

Daily Cleaning...................................................................................................................................5-3

Cleaning As Required ......................................................................................................................5-4

BASCC BC - 02.05 - V01 Page 5-1

Page 44

Cleaning

5 CLEANING

5.1 Important General Notes on Cleaning

Danger!

Never reach into the machine during automatic cleaning and keep clear of the

beverage outlets.

Danger!

Never clean the machine with a hose or a high pressure cleaner. Do not use

steam cleaning devices.

Never immerse the machine in water!

Important!

• Wash and disinfect your hands tho rou ghly before cleaning the machine!

• Follow the dosing instructions, safety notes and warnings included with the cleaning

products! Also read the information on cleaning agents in section 8.2 on page 8-3.

• Never use abrasives, scrubbers or cleaning tools made of metal!

• Only use cleaning agents approved by the manufacturer.

• Ask the manufacturer o r a cu stomer service, authorised by the manufacturer, for

advice on the cleaning tools you should use.

Note:

• Please note that some compone nts in the following illustrations may differ from those

in your machine.

• All the machine’s product outlets will be disabled duri ng the cleaning cycle.

• The machine cleaning p rog ram consists of an automatic self-cleaning cycle and a

manual cleaning cycle. Together they form one operation cycle.

• To ensure that all products are avail able in best quality, careful daily and weekly

cleaning is imperative

• The cleaning steps are displayed on the control panel. Follow the instructions.

Page 5-2 BASCC BC - 02.05 - V01

Page 45

5.2 Daily Cleaning

1

z Hold down the cleaning button

the control panel for approx. 4 seconds.

4

z Open the front door.

7

The cleaning program is running

(5 minutes).

on

2

z Remove and clean the coffee grounds

container.

If you have accidentally activated

the cleaning mode, press Cancel.

5

z Clean the brewing unit with the included

brush.

8

z Remove the drip grid and clean it.

z Clean the coffee machine from the

outside.

z Clean the drip tray with clean water.

z Confirm by clicking on Ok on the control

panel.

Cleaning

3

z Insert the coffee grounds container.

z Follow the instructions on the control

panel.

6

z Add the cleaning tablet to the brewing

chamber.

z Close the front door (turn the key)

z Move the coffee outlet to the lowest

position.

z Confirm that you have inserted the

cleaning tablet by clicking on Ok on the

control panel.

9

Daily cleaning is completed.

BASCC BC - 02.05 - V01 Page 5-3

Page 46

Cleaning

5.3 Cleaning As Required

5.3.1 Drip Tray Coffee Coupling

Note:

If necessary, the drip tray of the coupling in the front door can be removed and

cleaned.

Fig. 060

1. Unlock the front door by turning the key to the left

until it stops (see Fig. 060).

2. Pull the drip tray by the handle from the holder

(see Fig. 061).

3. Clean the drip tray under clean water.

4. Dry the drip tray off and re-insert it.

Fig. 061

Page 5-4 BASCC BC - 02.05 - V01

Page 47

5.3.2 Control Panel (Touch Screen)

Note:

The control panel interface (touch screen) should always be kept clean. A dirty touch

screen no longer functions properly.

Fig. 062

5.3.3 Longer Idle Time

See section 4.6.2 on page 4-12.

5.3.4 Disassembly

Contact a manufacturer-authorised customer service representative.

Cleaning

Important!

Use a commercial window cleaner. Do not use any

other cleaning agents! Do not use any cleaners with

abrasive effects.

Do not apply the cleaner directly to the control panel

but always onto a piece of cloth!

You can use cleaning clothes for PC screens for

heavy contamination.

If necessary, clean the control panel as follows:

1. Take a clean piece of cloth.

2. The piece of cloth may only be damp, not

wet.

3. Carefully wipe the piece of cloth over the

control panel.

4. Re-rub the area with a dry piece of material.

BASCC BC - 02.05 - V01 Page 5-5

Page 48

Cleaning

Page 5-6 BASCC BC - 02.05 - V01

Page 49

Error messages and malfunctions

6. Contents

Chapter Text Page

6

6.1

6.1.1 Error Messages - Coffee Machine.........................................................................................................2

6.2

Error messages and malfunctions ..................................................... 2

Error Messages with Display on the Control Panel.........................................................................2

Malfunctions Without Display on the Control Panel........................................................................4

BASCC BC - 02.06 - V01 Page 6-1

Page 50

Error messages and malfunctions

6 ERROR MESSAGES AND MALFUNCTIONS

6.1 Error Messages with Display on the Control Panel

6.1.1 Error Messages - Coffee Machine

Danger!

Inform your authorised customer service representative immediately if

you cannot rectify a malfunction!

Do not attempt to repair the coffee machine yourself!

Control panel display Cause Remedy

"Under-temperature steam"

"Under-temperature coffee"

"Under-temperature tea"

"Flowmeter timeout"

"Front door open"

"Grinder L./B. motor driver

error"

"Grinder R./F. motor driver

error"

"Brewing piston motor driver

error"

- Excessive steam outputs.

- Phase fuse defective.

- Safety fuse has opened.

Steam discharge is blocked.

Other products can be dispensed.

- More coffee servings than normal.

- Phase fuse defective.

- Safety fuse has opened.

No coffee can be dispensed.

Steam and hot water can be dispensed.

- More hot water servings than normal.

- Phase fuse defective.

- Safety fuse has opened.

Hot water dispensing is disabled.

Other products can be dispensed.

- Fresh water supply is blocked or one of the

stop valves is defective.

- Brewing unit dirty.

Products can still be served.

- The front door is open or the lock bolt did

not engage.

- Limit switch is damaged.

The coffee machine is blocked.

Control defective.

The coffee machine is blocked.

Control defective.

The coffee machine is blocked.

Control defective.

The coffee machine is blocked.

Wait for approx. 3 minutes. If during this

time "Timeout Heating Steam" appears

on the display, check if phase fuse is

defective. If the fuse is in working order,

contact a manufacturer-authorised

customer service representative.

Wait for approx. 3 minutes. If during this

time "Timeout Heating Coffee" appears

on the display, check if phase fuse is

defective. If the fuse is in working order,

contact a manufacturer-authorised

customer service representative.

Wait for approx. 3 minutes. If during this

time "Timeout Heating Tea" appears on

the display, check if phase fuse is

defective. If the fuse is in working order,

contact a manufacturer-authorised

customer service representative.

- Open stop valve and press the desired

button again.

- Clean the brewing unit.

- If the message persists, contact a

manufacturer-authorised customer

service representative.

- Close the front door.

- Contact a manufacturer-authorised

customer service representative.

-

Contact a manufacturer-authorised

customer service representative.

-

Contact a manufacturer-authorised

customer service representative.

-

Contact a manufacturer-authorised

customer service representative.

Page 6-2 BASCC BC - 02.06 - V01

Page 51

Error messages and malfunctions

Control panel display Cause Remedy

"Grinder left no beans"

"Grinder right no beans"

"Grinder front no beans"

"Grinder back no beans"

"Grinder left blocked

"Grinder right blocked"

"Grinder front blocked"

"Grinder back blocked"

"Timeout level supply "

"Coffee grounds container is

missing"

”Clean the coffee grounds

container”

”Coffee grounds container

full”

"Temperature sensor - steam”

"Temperature sensor coffee”

"Temperature sensor tea”

One of the coffee bean containers is empty.

An object (e.g. a stone) is stuck in the

grinder.

The water level in the steam generator is

not correct.

Steam discharge is blocked.

Other products can be dispensed.

- The coffee grounds container is not in its

- The coffee grounds container is not in its

- Limit switch is damaged.

The coffee machine is blocked.

The coffee grounds container is full.

The coffee machine is blocked.

You can still serve 5 products before the

coffee machine gets blocked.

The temperature sensor in the steam

generator is defective.

Steam discharge is blocked.

Other products can be dispensed.

The temperature sensor in the instant

heater for coffee water and hot water is

defective:

No coffee can be dispensed.

Other products can be dispensed.

The temperature sensor in the instant water

heater is defective.

Hot water dispensing is disabled.

Other products can be dispensed.

compartment.

proper final position.

Pour in 1 kg of coffee beans and click

on Ok.

- If the message on the control panel

persists, disconnect the coffee machine

from the power mains. Vacuum the coffee

beans out of the grinder. Check the

grinder for stuck objects.

- If the problem still persists, contact an

authorised customer service

representative.

- Check whether the stop valve of the

water mains is open.

- Switch the machine off and on again.

- If the problem still persists, contact an

authorised customer service

representative.

- Push coffee grounds container fully into

coffee grounds container compartment.

- Check whether the coffee grounds

container is fully inserted into the coffee

grounds container slot. Always remove

the ground coffee residue from the back

panel of the coffee grounds compartment.

- If the message persists, contact a

manufacturer-authorised customer

service representative.

Empty the coffee grounds container.

Empty the coffee grounds container.

Contact a manufacturer-authorised

customer service representative.

Contact a manufacturer-authorised

customer service representative.

Contact a manufacturer-authorised

customer service representative.

BASCC BC - 02.06 - V01 Page 6-3

Page 52

Error messages and malfunctions

Control panel display Cause Remedy

“Timeout heating steam”

“Timeout heating coffee”

“Timeout heating tea”

The programmed target temperature was

not reached within the specified time.

Steam discharge is blocked.

Other products can be dispensed.

The programmed target temperature for the

coffee water was not reached within the

specified time.

No coffee can be dispensed.

Other products can be dispensed.

The programmed target temperature for the

hot water (hot water outlet) was not reached

within the specified time.

Hot water outlet is disabled.

Other products can be dispensed.

6.2 Malfunctions Without Display on the Control Panel

Note:

The following problems may occur without causing the coffee machine to

display an error message.

- Switch the machine off and on again.

- Check the phase fuse.

- If the message persists on the control

panel, contact a manufacturer-authorised

customer service representative.

See “Timeout heating steam”.

See “Timeout heating steam”.

Malfunction Cause Remedy

Dark display, no

message

Plug at power socket is disconnected or

main switch is OFF.

Control panel (Touch screen) defective.

Reconnect plug at power socket or switch

main switch to ON.

Contact a customer service representative

authorised by the manufacturer.

Page 6-4 BASCC BC - 02.06 - V01

Page 53

Options

7. Contents

Chapter Text Page

7

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

Payment Systems.............................................................................................................................7-2

Water Softener (Filados/Brita).........................................................................................................7-2

Cup Warmer ......................................................................................................................................7-2

Coffee Grounds Disposal to Container..........................................................................................7-2

Brew Accelerator..............................................................................................................................7-2

Wastewater and Fresh Water Container ........................................................................................7-2

Grinders / funnel for Ground Coffee...............................................................................................7-2

Base Material.....................................................................................................................................7-2

Cup Plate Frames Illuminated.........................................................................................................7-2

Optional Features..............................................................................7-2

BASCC BC - 02.07 - V01 Page 7-1

Page 54

Options

7 OPTIONAL FEATURES

Note:

You can obtain additional information on the optional features described in this chapter

form a manufacturer-authorised customer service agent.

7.1 Payment Systems

Your coffee machine can be connected to your cash register by means of a payment

system, for example. This facilitates daily, weekly and monthly accounting.

Your coffee machine has been prepared for connection to a payment system and it is

compatible with all conventional systems on the market.

7.2 Water Softener (Filados/Brita)

A water softener helps to reach a better water quality and softens it.

It allows the recommended value for the coffee machine to be achieved.

7.3 Cup Warmer

The cup warmer consists of an additional framing. Cups can be pre-heated in large

quantities.

7.4 Coffee Grounds Disposal to Container

If a large amount of coffee is served or if the coffee machine is used in a self-service

establishment, we recommend adding a coffee grounds container. the coffee grounds

container is attached under the counter.

7.5 Brew Accelerator

The brew accelerator can be used, for example, in self-service mode to achieve an even

higher output capacity.

7.6

7.7

7.8 Base Material

7.9

Wastewater and Fresh Water Container

If there is no fixed water supply present, the machine can be supplied with water via a

fresh water container.

Grinders / funnel for Ground Coffee

The following configurations are also possible with this model:

- 3 grinders and a funnel for ground coffee (e.g. decaffeinated)

- 4 grinders

Special base materials are available upon request:

- Wood base

- Concrete base

- Granite base

Cup Plate Frames Illuminated

The cup plate frames is also available in an illuminated version.

Page 7-2 BASCC BC - 02.07 - V01

Page 55

Appendix

8. Contents

Chapter Text Page

8

8.1

8.2

8.2.1 Cleaning Tablet for the Coffee Machine.............................................................................................8-3

8.3

8.4

APPENDIX..........................................................................................8-2

CE Declaration of Conformity .........................................................................................................8-2

Cleaning Agent .................................................................................................................................8-3

Serials Plates of Steam Generator and Instant Heater.................................................................8-4

Environmental Aspects....................................................................................................................8-4

BASCC BC - 02.08 - V01 Page 8-1

Page 56

Appendix

8 APPENDIX