Page 1

Schaerer Barista

Operating instructions

V01 / 04.2017

Page 2

Schaerer AG

P.O.Box 336

Allmendweg 8

CH-4528 Zuchwil,

Switzerland

info@schaerer.com

www.schaerer.com

Original operating instructions

Schaerer Barista OE, EN

N° 021046

Page 3

Schaerer Barista

Operating instructions

Publisher

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

Edition

Version 01 | 4/2017

Software

V 1.3.2

Concept and editing:

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

Copyright ©

Schaerer AG, P.O.Box 336, Allmendweg 8, CH-4528 Zuchwil

This document is protected by copyright. All rights are reserved. The reproduction, distribution or transmission of this document, as well as the transmission via electronic systems or

translation into another language, are not permitted without the written consent of Schaerer AG. This applies to both the entire document and individual excerpts thereof. The contents of the document are based on the most current data available at the time of printing.

Schaerer AG reserves the right to make changes at any time without further notice. All im-

ages, gures and display notications in this manual are only shown by way of example.

Due to the wide variety of possible options, each individual machine may differ from the

devices depicted herein. Schaerer AG is only liable for the contents of the original German

document.

Page 4

Introduction and general information

|

Congratulations on the purchase of your

Schaerer Barista coffee machine!

The Schaerer Barista coffee machine is a portalter

coffee machine with automatic grinders for

espresso, coffee and hot water.

Follow the operating instructions

> Read the operating instructions before use.

> Always follow the operating instructions

exactly, especially the safety notes and the

Safety chapter.

> Keep the operating instructions accessible

to the staff and all users.

Risk of death due to electrocution!

• There risk of death due to the mains

voltage inside the coffee machine.

> Never open the housing.

> Never loosen the screws and do not

remove housing parts.

Conditions for use and installation

• If the maintenance specications are not

observed, no liability is assumed for any

damages.

> Follow the operating instructions.

CAUTION

Note the signs and symbols in

the operating instructions

page 20

Observe the Safety chapter

wfrom page 8

WARNING

Observe the Safety chapter

wfrom page 8

IMPORTANT

Technical data

wfrom page 79

Maintenance

wfrom page 68

4

Schaerer Barista operating instructions

Page 5

1 Safety ...................................................................................8

1.1 General safety notes ......................................................................8

1.2 Intended use ..................................................................................15

1.3 Conditions for use and installation .............................................17

2 Introduction .......................................................................18

2.1 Labelling of coffee machine parts ...............................................18

Display .....................................................18

Glossary ....................................................21

3 Operation ...........................................................................22

3.1 Operation safety notes .................................................................22

3.2 Switching on the coffee machine ................................................23

3.3 Portalter .......................................................................................23

3.3.1 Portalter status displays .......................................24

3.4 Beverage dispensing ....................................................................25

Beverage interruption ..........................................25

3.5 Manually adding coffee grounds ................................................26

3.6 Brewing sieve rinsing ...................................................................26

3.7 Hot water dispensing ...................................................................26

3.8 Steam options ...............................................................................27

3.8.1 Autosteam. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Powersteam .................................................29

3.9 Cup platform .................................................................................30

3.10 SteamJet (steam cup warmer) .....................................................30

3.11 Bean hoppers ................................................................................31

3.12 Cup storage (heatable) .................................................................32

3.13 Switching off the coffee machine ................................................33

4 Setting the grind level ...................................................... 33

5 Software ............................................................................35

5.1 Overview ........................................................................................35

Readiness for use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Status line elds ..............................................35

Main menu functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Menu control elds ............................................36

Notications on the display ......................................36

5.2 Readiness for use .........................................................................37

Ready for operation display .....................................37

5.3 Readyforoperationdisplayelds ..............................................37

Beverage buttons .............................................37

Function key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Barista - coffee strength ........................................37

Schaerer Barista operating instructions

5

Page 6

5.4 Care ................................................................................................38

Brewing group cleaning ........................................38

CleanLock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cleaning the coffee grounds slide ................................38

Replacing seal ...............................................38

5.5 Beverages ......................................................................................39

Changing recipes .............................................39

Loading recipes ..............................................40

Text 41

Test output ..................................................41

Saving recipes ...............................................41

5.6 Info .................................................................................................42

Last brewing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Service .....................................................42

Care .......................................................42

Filter and descaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Log 42

5.7 Accounting ....................................................................................43

Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.8 PIN rights .......................................................................................44

Cleaning PIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Setting PIN ..................................................44

Accounting PIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.9 System ...........................................................................................45

Language ......................................................................................................45

Operating option ..........................................................................................45

SteamJet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Barista eld ..................................................45

Target contact time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Display text ..................................................46

Bean type ...................................................46

Milk foam selection (Autosteam). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Brewing end signal tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Auto start ...................................................48

Left external grinding ..........................................48

Right external grinding .........................................48

Settings 49

Cup lighting ..................................................49

Rear wall lighting .............................................49

Display brightness ............................................49

Cup heating .................................................50

Touch display calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Water lter ..................................................50

Eco Mode ...................................................50

Automatic switch-off ...........................................51

Date/Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.10 USB ................................................................................................52

Loading recipes ..............................................52

Saving recipes ...............................................52

Exporting counter .............................................52

HACCP export ...............................................52

Data backup .................................................52

6

Schaerer Barista operating instructions

Page 7

Loading data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Loading language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Firmware update ..............................................52

6 Care ....................................................................................53

6.1 Care safety notes ..........................................................................53

6.2 Overview of cleaning intervals ....................................................54

6.3 Cleaning programmes ..................................................................55

6.3.1 Brewing group cleaning ........................................55

6.3.2 Brewing sieve rinsing ..........................................56

6.4 Manual cleaning ............................................................................57

6.4.1 Cleaning the cup storage .......................................57

6.4.2 Cleaning the coffee grounds slide ................................57

6.4.3 Manually cleaning the brewing group ..............................58

6.4.4 Cleaning the portalter .........................................58

6.4.5 Cleaning the drip tray ..........................................59

6.4.6 Cleaning the touch display (CleanLock) . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6.4.7 Cleaning the housing ..........................................60

6.4.8 Cleaning steam wands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.4.9 Cleaning the bean hoppers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

6.5 Replacing seal ...............................................................................64

7 HACCP cleaning concept ................................................66

8 Maintenance and descaling ............................................. 68

8.1 Maintenance ..................................................................................68

8.2 Schaerer Support ..........................................................................68

9 Noticationsandnotes .................................................... 69

9.1 Operationnotications ................................................................69

9.2 Error messages and faults ...........................................................70

9.3 Troubleshooting ............................................................................71

10 Safety and warranty .........................................................74

10.1 Hazards for the coffee machine ..................................................74

10.2 Directives .......................................................................................76

10.3 Operator responsibilities .............................................................77

10.4 Warranty claims ............................................................................78

Appendix: Technical data ................................................................... 79

Technical data of the coffee machine ........................................................79

Power requirements ....................................................................................80

Appendix: Accessories and spare parts ..........................................83

Schaerer Barista operating instructions

7

Page 8

Safety

1 Safety

Incorrect use

> Non-compliance with the safety

notes can result in serious

injuries.

> Observe all safety notes.

1.1 General safety notes

Dangers for the operator

Maximum safety is one of the most

important features of Schaerer products.

The effectiveness of the safety devices is

only ensured as long as the following is

observed:

> Read the operating instructions

before use.

> Do not touch any hot machine

parts.

> Be careful with the portalters

and never drop them.

> Do not use the coffee machine

if it is not working properly or is

damaged.

WARNING

CAUTION

8

Schaerer Barista operating instructions

Page 9

Safety

> Only use the coffee machine if

it is completely installed.

> Under no circumstances may

the installed safety devices be

modied.

> Under continuous supervision

this device can be used by

children aged 8 and up and by

persons with limited physical,

sensory or mental capabilities

or a lack of experience and/

or knowledge, provided they

have been instructed about

the safe use of the device

and understand the potential

hazards resulting from said

use.

> Children must not play with the

device.

> Children must also not be

allowed to perform cleaning

procedures or user service.

CAUTION

Schaerer Barista operating instructions

9

Page 10

Safety

In spite of the safety devices, every

coffee machine carries some potential

risk if used improperly. Please comply

with the following instructions when

handling the coffee maker in order to

prevent injuries or health hazards:

Risk of death due to electrocution!

• There risk of death due to the

mains voltage inside the coffee

machine.

> Never open the housing.

> Never loosen the screws and

do not remove housing parts.

> Never use a damaged mains

cable.

> Avoid damages to the mains

cable. Do not kink or crush.

WARNING

10

Schaerer Barista operating instructions

Page 11

Safety

Risk of burns/

Danger of scalding

• Hot liquid comes out of the

outlets during beverage

and steam dispensing. The

adjacent surfaces and outlets

get hot as well.

• The portalter is very hot during

dispensing.

• Hot steam is output through the

SteamJet (steam cup warmer).

At the same time, the cups and

the adjacent surfaces get hot.

> Do not touch the area under

the outlets during beverage and

steam dispensing.

> Do not touch the outlets shortly

after dispensing.

> Always touch the portalter by

its handle only after dispensing.

> Always put a suitable container

under the outlet before

beverage dispensing.

CAUTION

Schaerer Barista operating instructions

11

Page 12

Safety

Risk of injury

• Very long hair could get stuck

in the grinder head and get

pulled into the coffee machine.

• If you're not careful, the

portalter could fall out of your

hand or the holder and injure

your feet.

> Always protect hair with a

hairnet before you remove the

bean hopper.

> Make sure that the portalter

does not fall.

Risk of trapping/Risk of injury

• The coffee machine contains

moving parts which could injure

ngers or hands.

• Crushing hazard when closing

the cup storage.

> Always switch off the coffee

machine and pull out the power

plug before reaching into the

grinder or into the opening of

the brewing unit.

> Close the cup storage carefully.

CAUTION

CAUTION

12

Schaerer Barista operating instructions

Page 13

Safety

Health risk

• Only make products which are

suitable for consumption and

the use of the coffee machine.

> The bean hoppers may only

be lled with the materials

intended for use.

Health risk

• Cleaning products are irritants.

> Follow the protective measures

on the packaging of the

cleaning products.

> Do not add the cleaning tablets

into the machine until the

notication appears on the

display.

CAUTION

CAUTION

Schaerer Barista operating instructions

13

Page 14

Safety

Health risk/

Risk of irritation and burns

• During cleaning, hot cleaning

liquid and hot water ows out of

the portalter and the hot water

outlet.

• The hot liquids could irritate the

skin and the heat creates a risk

of burns.

> Never reach under the outlets

during cleaning.

> Ensure that no one ever drinks

cleaning liquid.

> Carefully move the drip tray.

Risk of slipping

• Liquids can escape from the

machine if it is used incorrectly

or if errors are made. These

liquids can cause a slipping

hazard.

> Regularly check whether the

coffee machine is leak-free and

that no water can escape.

CAUTION

CAUTION

14

Schaerer Barista operating instructions

Page 15

1.2 Intended use

Safety

Incorrect use

• If the machine is not used

correctly, it could cause an

injury hazard.

> The coffee machine must only

be used in the correct manner.

The Schaerer Barista is designed to

dispense variations of coffee and milk

beverages. This professional device is

intended for industrial and commercial

use in hotels and restaurants.

It is only intended for use by specialists

or trained users.

WARNING

Schaerer Barista operating instructions

15

Page 16

Safety

Use of this equipment is subject these

operating instructions. In legal terms,

any other use is not an intended use.

The manufacturer accepts no liability for

damage resulting from unintended use.

The Schaerer Coffee Barista must not

be used for heating and dispensing

any liquids other than coffee, hot

water (beverages, cleaning) or milk

(cooled, pasteurised, homogenised,

UHT).

16

Schaerer Barista operating instructions

Page 17

1.3 Conditions for use and installation

Safety

Risk of burning/Risk of injury

> The conditions for installation

and use must be observed.

> The conditions for installation

and use specied in the

Technical data chapter must be

observed.

Preparatory structural work for the

electrical connection, the water

connection and the waste water

connection must be commissioned by

the operator of the machine. It must

be carried out by licensed installers

observing all general, national as well as

locally applicable regulations. Schaerer

Service may only connect the coffee

machine to the prepared connections.

They are neither authorised to carry

out structural installation, nor are they

responsible for its implementation.

WARNING

Technical data

w page 79

Schaerer Barista operating instructions

17

Page 18

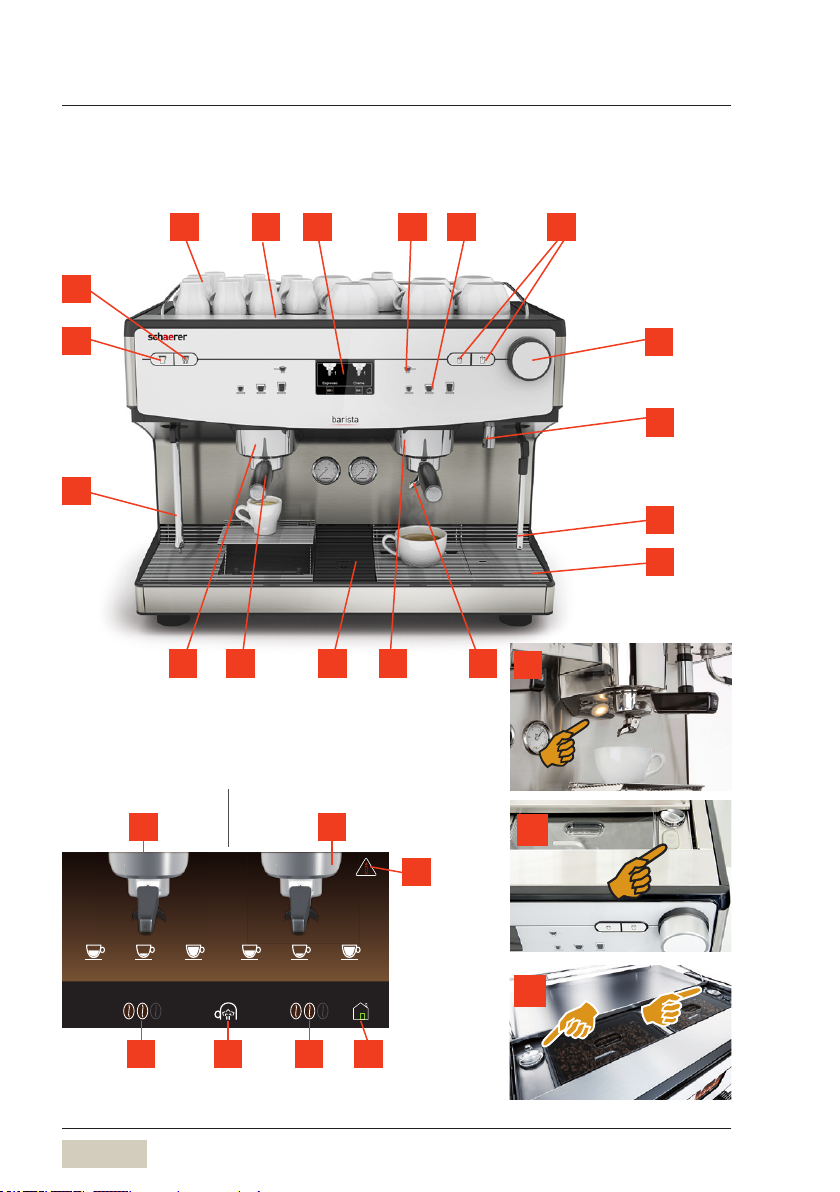

Introduction | Labelling of coffee machine parts

2 Introduction

2.1 Labelling of coffee machine parts

17 16 15 13141

2

3

4

765

8 6

Display

Left brewing group Right brewing group

2526

12

11

10

9

18

19

24

2 1

2 Espresso Espresso Lungo 2 Espresso Espresso Lungo

21 2123

18

Status bar

20

22

Schaerer Barista operating instructions

Page 19

1

Bean hopper (under the cup storage)

2

Milk foam button

3

Milk button

4

Autosteam outlet

5

Left brewing group with portalter

6

Outlet

7

SteamJet (steam cup warmer)

8

Right brewing group with portalter

9

Cup grid

10

Powersteam outlet

11

Hot water outlet

12

Powersteam knob

13

Hot water buttons

14

Beverage buttons

15

Function key

16

Touch display

17

Cup storage

18

Cup lighting

19

On/off button

20

Left/right grind level adjustment

Introduction | Labelling of coffee machine parts

Ready for operation display

21

Barista eld

22

Menu eld (opens the main menu)

23

SteamJet eld (steam cup warmer)

24

Notication eld

Right brewing group display

25

(In the example, right brewing group beverage dispensing status display)

Left brewing group display

26

(In the example, readiness for use of left brewing group)

Schaerer Barista operating instructions

19

Page 20

Introduction | Labelling of coffee machine parts

Signs and symbols in the operating instructions

Personal injury safety notes

If the safety notes are not observed, mild

to serious injury could occur in the event of

incorrect operation.

Personal injury safety notes

If the safety notes are not observed, mild

injury could occur in the event of incorrect

operation.

Risk of

electrocution

Risk of trapping

ngers

Hot steam

Hot surfaces

Risk of slipping

Property damage notes

• For the coffee machines

• For the installation location

> Always follow the operating instructions

exactly.

WARNING

Safety notes

Observe the Safety chapter

wfrom page 8

CAUTION

Operation safety notes

wpage 22

Care safety notes

wpage 53

Observe the Safety chapter

wfrom page 8

IMPORTANT

Observe the Warranty chapter

wfrom page 78

Technical data

wfrom page 79

Notes/Tip

• Notes for safe handling and tips for easier

operation.

20

NOTE

TIP

Schaerer Barista operating instructions

Page 21

Introduction | Labelling of coffee machine parts

Calling up main menu

* Tap the on the "Main menu" eld

The main menu is displayed.

There are other display options

w Main menu.

Glossary

Term Explanation

• • Counting, selection options

* * Individual work steps

Cursive text Description of condition of the coffee machine and/or

explanations of automatic steps.

Barista Personal coffee maker

Blind sieve Cleaning sieve

Beverage

dispensing

Main water valve Stopcock, angle valve

Carbonate

hardness

Preinfusion The coffee is briey pre-brewed before the brewing

Service life For example: Litre capacity of the water lter

Pounding Automatic pressing of the ground coffee before brewing

Test preparation Trials

Brewing sieve

rinsing

Extras Components of a recipe for a beverage, for example

SteamJet Integrated steam cup warmer in the drip tray

Powersteam Simple steam dispensing without monitoring

Autosteam Steam dispensing with monitored temperature

Coffee and hot water dispensing

Given in °dKH Water hardness is a measure of the

limescale dissolved in drinking water.

process to bring out a more intense aroma.

Intermediate rinsing of the brewing group (ushing)

coffee and water

Schaerer Barista operating instructions

21

Page 22

Operation | Operation safety notes

3 Operation

3.1 Operation safety notes

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage and steam dispensing. The

adjacent surfaces and outlets get hot as

well.

• The portalter is very hot during

dispensing.

• Hot steam is output through the SteamJet

(steam cup warmer). At the same time, the

cups and the adjacent surfaces get hot.

• If the drip tray does not correctly engage,

there is a risk of burns from hot uids.

• Damaged portalters, brewing sieves

or overlled brewing sieves can cause

serious scalding injuries.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets shortly after

dispensing.

> Always touch the portalter by its handle

only after dispensing.

> Always put a suitable container under the

outlet before beverage dispensing.

> Always make sure the drip tray is

positioned correctly.

> Only use portalters or brewing sieves that

are in perfect condition.

> Only ll the portalters with ground coffee

up to the specied maximum level.

CAUTION

Observe the Safety chapter

wfrom page 8

22

Schaerer Barista operating instructions

Page 23

Operation | Switching on the coffee machine

Health risk

• Only make products which are suitable

for consumption and the use of the coffee

machine.

> The bean hoppers may only be lled with

the materials intended for use.

3.2 Switching on the coffee machine

* Open the cover.

* Press on the on/off button.

The coffee machine switches on and heats up.

Automatic rinsing starts.

When the coffee machine is ready to dispense

beverages, the display will show "Ready for use".

3.3 Portalter

There are two sizes of portalter.

Portalter type 1 = 8 to 11 g

Portalter type 2 = 10 to 16 g

• An empty portalter must be inserted before

beverage dispensing.

• The display shows which portalter is currently

inserted in which brewing group. The number

indicates the portalter type. Single portalter (1)

or double portalter (2).

CAUTION

Observe the Safety chapter

wfrom page 8

Schaerer Barista operating instructions

23

Page 24

Operation | Portalter

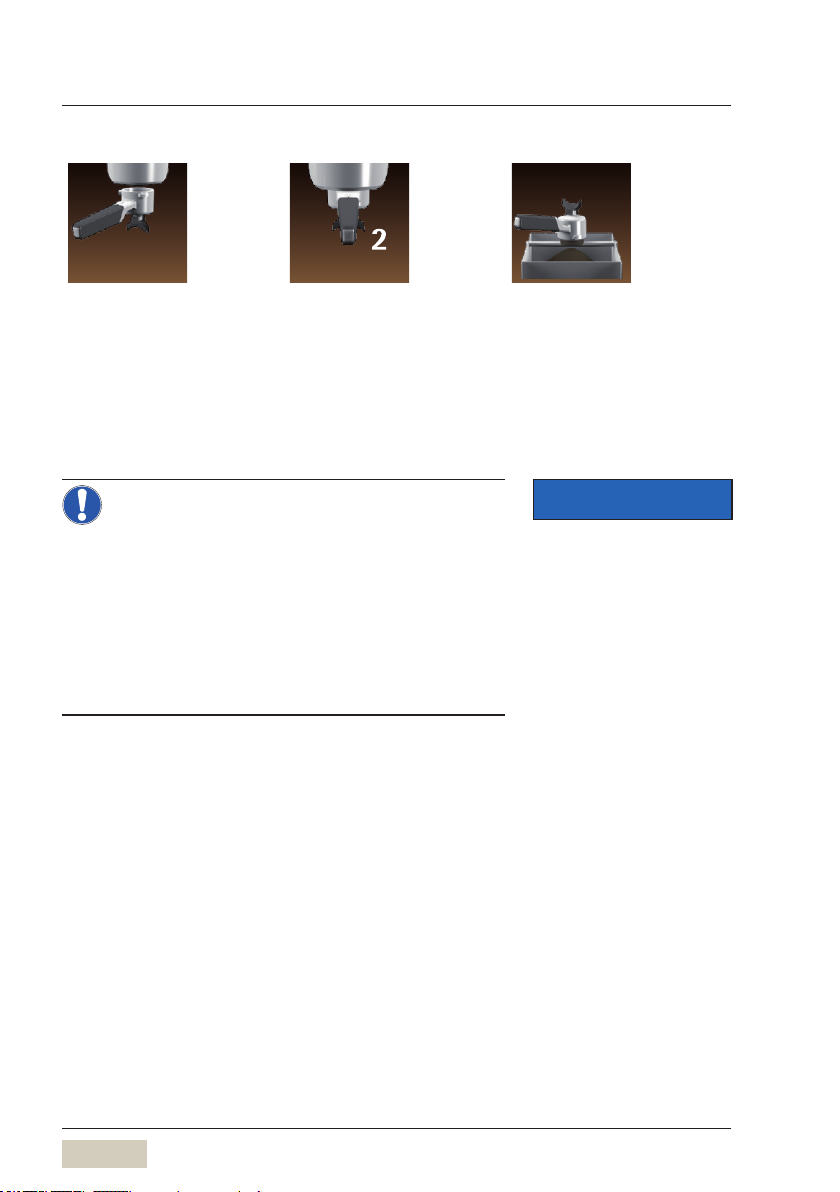

3.3.1 Portalterstatusdisplays

Portaltermissing Portalterinserted Emptying the

portalter

A portalter must be

inserted.

Which portalter type is

inserted is shown.

The beverages set

for the portalter are

available for selection.

The portalter must be

emptied.

• If the portalter is removed before the

current brewing is complete, the brewing

unit can get damaged.

> Do not remove the portalter until the

brewing process is complete. A notication

appears on the display.

> The portalter is locked during brewing

and cannot be removed.

> Brewing can be interrupted by pressing the

beverage button again.

IMPORTANT

24

Schaerer Barista operating instructions

Page 25

Operation | Beverage dispensing

Café Crème

3.4 Beverage dispensing

Pressing on the beverage buttons starts dispensing

of the set beverages.

A suitable portalter must be inserted.

The portalter must be empty.

The previous beverage dispensing process must

be completely nished. This can be reported with a

signal tone. The signal tone can be deactivated.

• Illuminated eld = Ready for dispensing

• Non-illuminated eld = Not ready for dispensing/

eld locked

• Flashing eld = Beverage is dispensed

* Adjust the cup grid to the correct height

* Set a beverage container of a suitable size below

the inserted portalter

* Press on the desired beverage button.

The coffee beans will be ground directly into the

portalter. The coffee grounds will be automatically

tempered with the brewing piston.

Beverage dispensing starts.

Button functions

w Software

w Change recipes

page 39

2

2 Espresso Espresso Lungo

Beverage interruption

* Tap on the ashing beverage button again

Schaerer Barista operating instructions

25

Page 26

Operation | Manually adding coffee grounds

3.5 Manually adding coffee grounds

* Briey press on the function button.

The internal grinder will be deactivated.

* Add the desired ground coffee to the portalter.

* Insert the desired portalter.

* Press on the desired beverage button.

The coffee grounds will be automatically tempered

with the brewing piston. Beverage dispensing starts.

3.6 Brewing sieve rinsing

Function key

Activating function

Individual recipes

w System

w External grinding

page 48

* Remove the portalter

* Press on the portalter gure on the display

* Conrm with and continue

A hot water rinse starts.

The water warms up the system and ensures that

the brewed coffee is at an optimum temperature.

The brewing sieve is cleaned at the same time.

> During brewing sieve rinsing, remove the

coffee ground remains on the brewing

sieve with the brewing group brush.

> At the same time, check whether the

water still runs through the brewing sieve

unimpeded.

> Do not use the brewing sieve rinsing

process to rinse portalters.

3.7 Hot water dispensing

* Set a beverage container of a suitable size below

the hot water outlet.

* Press on the desired water button.

The beverage is dispensed.

1

Espresso

NOTE

26

Schaerer Barista operating instructions

Page 27

3.8 Steam options

Operation | Steam options

Risk of burns/

Danger of scalding

• When using the Autosteam, Powersteam

and SteamJet, hot steam runs out of the

steam openings. The adjacent surfaces

and outlets get hot as well.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets shortly after

dispensing.

> Always put a suitable container under the

outlet before beverage dispensing.

Risk of burns/

Danger of scalding

• When the temperature is set to 90 °C, milk

and foam can overcook.

> Fill the container no more than halfway.

> Do not overheat the milk, or the amount of

milk foam will decrease

The basic coffee machine equipment includes the

Autosteam, Powersteam and SteamJet.

Dispensing Autosteam and Basic Steam at the same

time is not possible.

CAUTION

CAUTION

TIP

Schaerer Barista operating instructions

27

Page 28

Operation | Steam options

3.8.1 Autosteam

Milk is heated or foamed with the Autosteam option.

Foam button

Milk can be foamed with the set foam quality using

the foam button.

A milk foam quality is available as a standard

setting.

After activating milk foam selection, 3 individually

adjustable foam qualities are available. The

selection is shown on the display after pressing the

foam button.

Possible foam qualities are:

• Standard

• Fine

• Very ne

Milk button

Milk is heated using the Milk button.

Heating up or foaming milk

* Use a tall and narrow container with a handle

* Fill the container no more than halfway so that

milk does not overow during foaming

* Place the container in the centre below the steam

wand

The steam wand must dip into the milk.

* Briey press on the desired Autosteam button

Steam is dispensed according to the Autosteam

button functions.

Steam dispensing will end when the programmed

temperature is reached or when the Autosteam

button is pressed again.

* Put away the container and press the Autosteam

button again briey

The remainders in the steam wand are rinsed out.

* Clean the steam wand externally with a clean,

damp cloth after use

Foam button Milk button

Milk foam selection

w System

page 47

Button functions

w Software

w Change recipes

page 39

28

Schaerer Barista operating instructions

Page 29

Powersteam

Operation | Steam options

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage and steam dispensing. The

adjacent surfaces and outlets get hot as

well.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets shortly after

dispensing.

> Always put a suitable container under the

outlet before beverage dispensing.

* Turn the Powersteam knob

Steam is dispensed until the Basic Steam knob is

turned off.

The quantity of steam dispensed depends on how

far the Powersteam knob is turned.

• Steam warms up beverages

• Steam manually foams milk

Heating up beverages

* Use a tall and narrow container with a handle

* Fill the container no more than halfway

* Immerse the steam wand deep into the container

* Turn the Powersteam knob and warm up

the beverage with steam until the desired

temperature has been reached

* Turn off the Powersteam knob

* Swivel the steam wand to the drip tray

* Put away the container and turn the Basic Steam

knob again briey

The remainders in the steam wand are rinsed out.

* Clean the steam wand externally with a clean,

damp cloth after use

CAUTION

Observe the Safety chapter

wfrom page 8

Schaerer Barista operating instructions

29

Page 30

Operation | Cup platform

3.9 Cup platform

Raise

* Grab the opening of the cup grid with one nger

and pull it up until the hinges latch in the frame

Lowering

* Lift front of the cup grid slightly until the hinges

unlatch

* Lower the cup grid

Height adjustments when the cup grid is up

Single outlet: 82 mm

Double outlet: 77 mm

Lifting cup platform

3.10 SteamJet (steam cup warmer)

Risk of burns/

Danger of scalding

• Hot steam is output through the SteamJet.

At the same time, the cups and the

adjacent surfaces get hot.

> Use heat-resistant drink containers.

> Always put a cup with the opening at the

bottom over the cup warmer before steam

is dispensed.

> Do not touch the adjacent surfaces shortly

after dispensing.

> Do not touch the outlets shortly after

dispensing.

> Never use the SteamJet function without

using a drip grid or the cup warmer insert.

30

Lowering cup platform

CAUTION

Observe the Safety chapter

wfrom page 8

Clean the drip tray daily

Care

w from page 53

Schaerer Barista operating instructions

Page 31

Operation | Bean hoppers

Health risk/Hygiene

• The SteamJet function is intended for

warming up drink containers and is not

suitable for cleaning.

> Instead, use a freshly-rinsed drink

container to warm the cups.

The SteamJet warms up to 2 cups simultaneously

with hot steam.

* Place a cup into the steam cup warmer with the

opening facing down.

* Tap the on the "SteamJet" eld.

Hot steam slowly ows into the cup from below.

The steam ow is output as long as is specied in

the settings.

1 to 10 seconds can be set. The SteamJet function

is deactivated when 0 seconds is entered.

* Tap on the SteamJet eld again.

The steam ow immediately stops.

3.11 Bean hoppers

Top off the containers as soon as possible to the

time of use.

Fill the containers with no more than is needed for a

day to ensure the products remain fresh.

Each container has a capacity of 550 g.

The beans are protected by a lid.

CAUTION

Observe the Safety chapter

wfrom page 8

This description corresponds

with the standard setting.

Dosing type = dosed.

Activating SteamJet

w System

page 45

• Foreign particles may damage the grinder.

These damages are excluded from the

warranty.

> Ensure that no foreign particles enter the

bean hopper.

Schaerer Barista operating instructions

IMPORTANT

Observe the Warranty chapter

wfrom page 78

31

Page 32

Operation | Cup storage (heatable)

3.12 Cup storage (heatable)

Risk of burns

• The cup storage and the cups stored on it

can get hot.

> Only touch the heated cups and surface

with caution.

• Since the cup storage is movable, the

cups can fall.

> Do not overll the cup storage and do not

stack the cups on top of each other.

The upper cover of the coffee machine is a heatable

cup storage area.

The cup storage can be moved backwards to

access the interior of the coffee machine.

The cup heater can be activated and deactivated

using the software.

CAUTION

Observe the Safety chapter

wfrom page 8

Clean the drip tray daily

Care

w from page 53

IMPORTANT

Observe the Warranty chapter

wfrom page 78

32

Schaerer Barista operating instructions

Page 33

3.13 Switching off the coffee machine

Setting the grind level

Follow hygiene standards

• Hazardous bacteria can grown in the

coffee machine.

> Before switching off the coffee machine,

perform the daily rinsing.

Follow the operating instructions

• No liability is assumed for damage

resulting from the failure to do so

* Briey press on the On/Off button

(approx. 1 second)

The coffee machine switches off.

* Pull the power plug

* Close the main water valve of the water supply

line

4 Setting the grind level

Risk of trapping/Risk of injury

• The coffee grinder contains moving parts

which could injure ngers.

> Never reach into the grinders while the

coffee machine is running and the product

hoppers have been removed.

CAUTION

Observe the Safety chapter

wfrom page 8

Clean the coffee machine as

specied in the instructions.

Care

w from page 53

IMPORTANT

Observe the Warranty chapter

wfrom page 78

CAUTION

Observe the Safety chapter

wfrom page 8

Schaerer Barista operating instructions

33

Page 34

Setting the grind level | Switching off the coffee machine

Finer setting of grind level

• Making a big change to a ner grind level

can block the coffee grinder.

Important! Only adjust the grind level

when the grinder is running.

> Onlysetthegrindlevelnerbyone

scale line at a time using the knobs.

> Then dispense a coffee beverage using

the ner grinder setting.

> Repeat this step until the desired grind

level is set.

Coarser setting of grind level

A change to a coarser grind level can only be

set once.

* Push the cup storage to the back.

The arrow points to the set grind level on the grind

level knob.

* Initiate coffee dispensing and wait until the mill

starts up.

* Change the grind level as desired; to do so, push

the grind level knob downwards and turn

Grind level 1 g ne

Grind level

10 g coarse

IMPORTANT

Observe the Warranty chapter

wfrom page 78

Grind level knob

Dispensing is not done with the new values

until the second brewing after the new

setting was made.

34

IMPORTANT

Observe the Warranty chapter

wfrom page 78

Schaerer Barista operating instructions

Page 35

5 Software

Software | Overview

• When setting beverages, the same safety

notes apply as for the operation of the

coffee machine.

> Observe all operating safety notes.

5.1 Overview

Readiness for use

2 1

2 Espresso Espresso Lungo 2 Espresso Espresso Lungo

Statuslineelds

Barista (coffee strength)

Page 37

CAUTION

Operation safety notes

wpage 22

Page 37

The elds and buttons on

the display are available

depending on the setting

and machine version.

Page 37

Notications

Page 69

SteamJet

Page 45

Schaerer Barista operating instructions

35

Page 36

Software | Overview

Main menu functions

Care

Page 38

Accounting

system

Page 43

Beverages

Page 39

PIN rights

Page 44

Menucontrolelds

To the main menu Conrm the value/setting

Return to the previous menu Delete the value/setting

PIN entry Test preparation (trials)

Next, previous, start Back

System

Page 45

USB

Page 52

from page 38

Info

Page 42

Service

Call up help text Calling up temperature

Saving settings Loading settings

Noticationsonthedisplay

Error message

36

Schaerer Barista operating instructions

Page 37

5.2 Readiness for use

Café Crème

Software | Readiness for use

Ready for operation display

The display shown when the machine is ready for

use depends on the options of the coffee machine

and individual settings.

5.3 Ready for operation display

elds

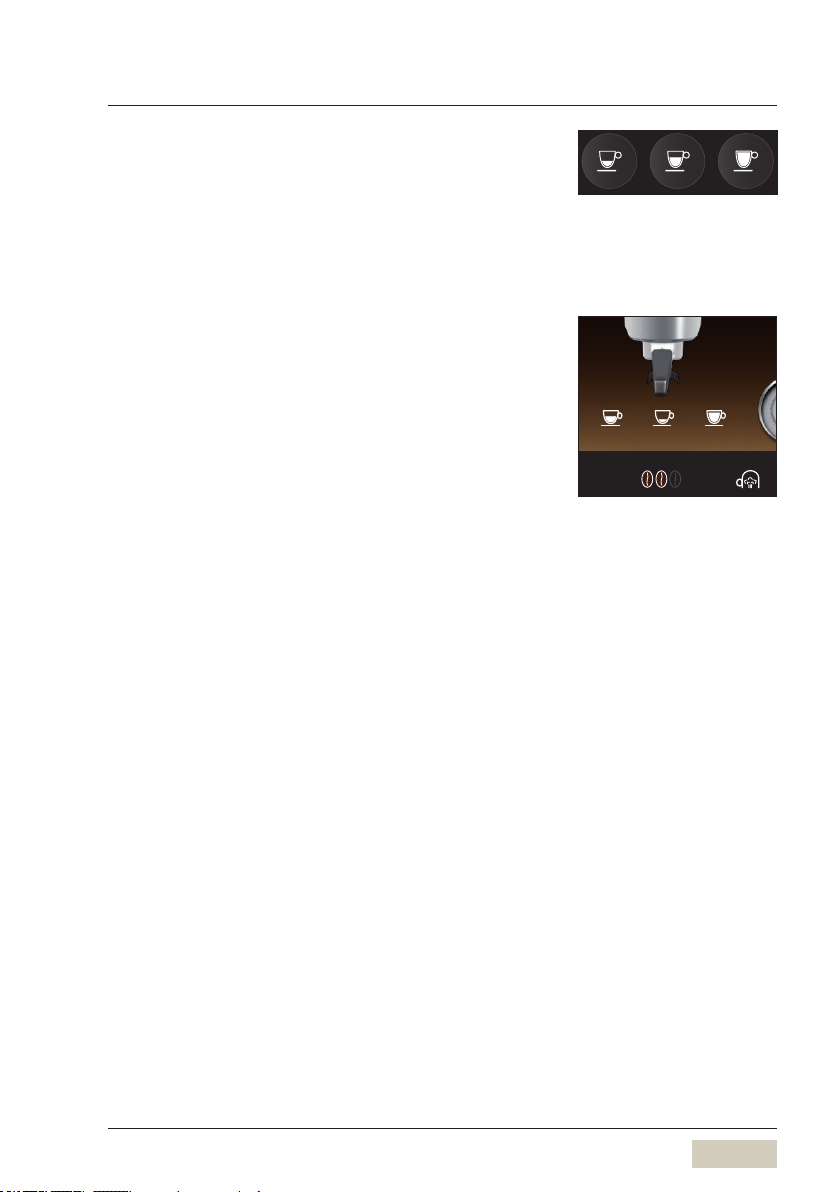

Beverage buttons

All output-ready beverage buttons are illuminated.

Up to 3 different beverage recipes can be congured

per brewing group for each portalter type; these

recipes can be selected using the beverage buttons.

The portalter type is automatically detected after

insertion.

Depending on the setting, the beverage names or

the bean types can also be displayed now.

Function key

Manually adding coffee grounds

w Operation, page 26

External grinding

w System, page 48

Barista - coffee strength

2

2 Espresso Espresso Lungo

Display texts

w System

page 46

Function key

The coffee strength is changed one time for the next

brew. This function is available for both brewing

groups.

Display Coffee strength

Standard 2 beans Normal, as set

Tap 1 x 3 beans 15% stronger than set*

Tap 2 x 1 bean 15% weaker than set*

* Maximum coffee ground

quantity per brew

Schaerer Barista operating instructions

Portalter holder 11 g

Double portalter 16 g

Barista eld active/inactive

wSystem

page 45

37

Page 38

Software | Care

CleanLock

Cleaning ground coffee chute

Changing the seal

Filter change

5.4 Care

Brewing group cleaning

CleanLock

Cleaning ground coffee chute

...

...

Care

carried out last

-

Menu control elds

wOverview

page 36

Care

w from page 53

HACCP cleaning concept

w from page 66

Brewing group cleaning

• The two brewing groups are cleaned at the same

time.

CleanLock

* Tap on CleanLock

A 15-second countdown starts.

The touch display can now be cleaned.

The touch display is reactivated 15 seconds after

the last time it is touched.

Cleaning the coffee grounds slide

The display-guided cleaning of the coffee grounds

slide starts.

Replacing seal

The display-guided brewing sieve seal change is

started here.

Filter change (optional)

Only available if authorisation is given to trained

staff by Schaerer Service.

Brewing group cleaning

Brewing group cleaning

w Care w page 55

Cleaning coffee grounds slide

w Care w page 57

Seal change

w Care w page 64

38

Schaerer Barista operating instructions

Page 39

5.5 Beverages

Software | Beverages

Changing recipes

Ristretto – Change recipes type of portalter 1

Pre-infusion

g ml °C sec sec

90

22

service /

factory

8.8

8.9

9.0

9.1

9.2

9.0 26 92 2.0 20 Yes

0.0 / 9.0 0 / 26 0 / 92 0.0 / 2.0 0 / 20 No / Yes

91

24

92

26

93

28

94

30

The recipe name and the portalter type are shown

in the title.

The recipe is connected to the respective portalter

type. The desired portalter must therefore be

inserted to change the recipe.

* Insert the desired portalter.

* Press on the desired beverage button.

* The beverage name along with the portalter

specication appears.

* Set the recipe.

* If desired, dispense a test brewing.

* When the recipe is set as desired, save the

recipe.

Pause

1.8

1.9

2.0

2.1

2.2

Target

Brewing time

18

19

20

21

22

Reference

Beverage

Menu control elds

wOverview

page 36

Saving recipes

wpage 41

External grinding recipes

You can set your own recipes for external grinding.

* Briey press on the function button.

* Press on the desired beverage button.

* Proceed as described above.

Schaerer Barista operating instructions

Recipes for the manual addition

of ground coffee

w External grinding

page 48

w Function key

page 37

39

Page 40

Software | Beverages

Ground coffee quantity

Given in grams (g)

Water volume

Given in millilitres (ml)

Brewing temperature

Specication in degree Celsius (°C)

Preinfusion

Break between pre-brewing and brewing in seconds

Target contact time

Specication in seconds (sec) for the target brewing

time

Reference beverage

The reference beverage is set by Service during

commissioning. A reference beverage is can be set

for every brewing group. All other beverage settings

relate to the values of this reference.

The reference beverage can be changed by Service.

At the factory, espresso or coffee is set as the

reference beverage. Follow the notes on the display.

Yes/No specication

Loading recipes

A saved recipe is loaded here on a beverage button

* Insert the desired portalter.

* Tap on a beverage button

* Tap the on the "Load recipes" eld

A sub-menu opens.

* Mark the desired recipe

* Tap the on the "Save recipes" eld

The beverage button is assigned with the

newly-selected recipe.

40

Schaerer Barista operating instructions

Page 41

Text

Software | Beverages

Ristretto - Change type of portalter text: 1

Recipe number 3 Factory: 3

Text

Note

Ristretto

Text

The beverage name is adjusted here.

Activate the keyboard with the keyboard eld.

Remarks

A note on the beverage can be stored here.

Test output

For many beverage settings, is it possible to start a

test output with the new settings before the recipe is

saved.

* Change the settings as desired

* Tap the on the "Test output" eld

The beverage is dispensed with newly-set values.

* If the beverage is as desired, tap on the Save

symbol

The recipe is saved.

Menu control elds

w Overview

page 36

Saving recipes

The changed recipe is saved here

Schaerer Barista operating instructions

41

Page 42

Software | Info

Service

Filter and descaling

5.6 Info

The Info menu offers the selection options described

in the following.

Last brewing

Information on the last brewing.

Service

Contact information for Schaerer Service.

Serial number of the coffee machine.

Care

The last cleaning processes and care measures

which run via coffee machine programmes are

shown here.

Filter and descaling

Information on the remaining lter time and duration

until the next descaling.

Log

Log of the events and errors during operation and

cleaning of the coffee machine.

Last brewing cycle

Care

Journal

42

Schaerer Barista operating instructions

Page 43

5.7 Accounting

Software | Accounting

Counters

The counters of the dispensed individual beverages

and the sum of the beverages are shown here.

A log can be read out using the USB connection.

Accounting

Counter

Beverage Counter 1 Counter 2 Counter 3 Counter 4 Total

2 Espresso M... 2 2 2 2 2

Espresso 1 1 1 1 1

Espresso M... 1 1 1 1 1

Standard setting

Counter 1 = daily counter

Counter 2 = weekly counter

Counter 3 = monthly counter

Counter 4 = annual counter

All counters can be reset.

Counter

PIN rights

wAccounting PIN

page 44

TIP

Schaerer Barista operating instructions

43

Page 44

Software | PIN rights

Cleaning

Setting

Accounting

5.8 PIN rights

A PIN can be assigned for all of the areas listed

below.

• Cleaning

• Settings

• Accounting

The PINs are hierarchically structured.

That means, for example: The setting PIN

simultaneously releases all rights for the cleaning

PIN, but not all the rights for the accounting PIN.

If no PIN is assigned, the area is accessible without

a PIN.

If a PIN is assigned to an area, no access is granted

without that PIN.

Cleaning PIN

After the valid PIN is entered, access to:

Care

Setting PIN

After the valid PIN is entered, access to:

Care System

Beverages

Accounting (without

"deletion")

Accounting PIN

Language

Operating option

Settings

USB

After the valid PIN is entered, access to:

Care

Beverages

Accounting (with

"deletion")

PIN rights USB

44

System

Language

Operating option

Settings

Schaerer Barista operating instructions

Page 45

5.9 System

Operating options

Software | System

Language

The display language is set here.

The available languages are displayed in English.

Operating option

SteamJet

The SteamJet (steam cup warmer) is switched on or

off here.

The maximum duration of steam dispensing via the

SteamJet is set here.

Options: Off, 1 to 10 seconds

Standard

value:

6 seconds

Baristaeld

Options: • Active

Standard

value:

Active

• Inactive

Language

Schaerer Barista operating instructions

45

Page 46

Software | System

Target contact time

When the "target contact time" (brewing time) is

actively regulated, the coffee machine reports

when the grind level has to be readjusted. This

happens as soon as the current brewing duration of

a reference beverage deviates from the set target

brewing duration.

The reference beverage can be changed, but a

recommended target brewing duration must be set

in the recipe.

Options: • Active

Standard

value:

Inactive

• Inactive

Display text

Which information is shown on the display can be

selected here.

Options: No display

Bean type

Beverage name

Standard

value:

Beverage name

Setting the grind level

w page 33

Reference beverage

wBeverages

page 40

Bean type

If the bean type has been selected in the display

text menu item, the name of the bean type can be

entered in the bean hopper.

To call up the entry, tap on the desired bean hopper

using the display keypad.

46

Schaerer Barista operating instructions

Page 47

Milk foam selection (Autosteam)

3 individually-adjustable foam qualities can be saved

for Autosteam. The foam qualities are set using

recipes.

If milk foam selection is active, this selection

appears when the Milk foam button is pushed.

Options: • Active

Standard

value:

Inactive

• Inactive

Brewing end signal tone

The signal tone informs that brewing is done and

thereby the time at which the portalter can be

removed.

Options: • Active

Standard

value:

Active

• Inactive

Software | System

Autosteam

w Operation

page 28

Schaerer Barista operating instructions

47

Page 48

Software | System

Auto start

If the Auto start function is active, the coffee

machine starts as soon as a portalter is inserted,

with beverage preparation.

One recipe for Auto start can be dened per

portalter type.

Only one recipe per brewing group can be

available for the start function. The two remaining

buttons must be assigned in Change recipes with

the !Locked recipe.

Options: • Active

Standard

value:

Inactive

• Inactive

Left external grinding

The "Manual addition of ground coffee" function

can be activated or deactivated here, or individual

recipes can be saved for this function.

If the "Left external grinding" function is activated,

recipes as saved in the standard are used. If

changed recipes are to be used, "Individual recipes"

must be set here.

Options: Inactive, active, individual recipes

Standard

value:

Active

Setting recipes

w Changing recipes

page 39

Manually adding ground coffee

w Operation

page 37

Right external grinding

w "Left external grinding"

48

Schaerer Barista operating instructions

Page 49

Settings

Settings

Cup lighting

The cup lighting is set here.

Options: Off/ 20 % / 40 % / 60 % / 80 % / 100 %

Software | System

Standard

value:

80%

Rear wall lighting

The lighting colour is set here.

The desired colour for the User-dened option is

set here using the triangle in the colour wheel. The

colour can also be dened and set using the RGB

values.

These options also exist:

• Colour change slow

• Colour change normal

• Colour change quick

• Off

• Amber

• Blue

The current setting is displayed immediately.

Display brightness

The display brightness is set here.

Options: 0 to 100 %, in 5 % steps

Standard

value:

80%

Schaerer Barista operating instructions

49

Page 50

Software | System

Cup heating

The cup heating is switched on and off here.

Options: • Active

Standard

value:

Active

• Inactive

Touch display calibration

The touch display can be recalibrated here.

After selection, a query appears asking whether

calibration should be started.

Waterlter

Options: • Active

Standard

value:

If active

Inactive

A water lter is present. Service life

• Inactive

and water hardness can be queried.

Filter service life

The lter service life in litres is entered here.

Measured water hardness

The measured water hardness in °dKH is entered

here.

Eco Mode

If Eco mode is set to "active", the steam boiler

temperature is decreased 10 minutes after the last

beverage dispensing process.

The optional cup grid and rear wall lighting is

switched off.

If a beverage is to be dispensed when the

temperature is lowered, the coffee machine needs

up to 15 seconds to heat up.

Beverages cannot be dispensed again until after it

heats up.

Display of remaining lter

service life

w Info

page 42

50

Schaerer Barista operating instructions

Page 51

Eco Mode

Eco Mode can be activated here.

Options: • Active

Standard

value:

Inactive

• Inactive

Automatic switch-off

The menu item is only available if Eco mode is

active.

The time the last beverage is dispensed is set

here. If this time is exceeded, the coffee machine

automatically switches off.

The time can be set in 30-minute steps.

Options: (never /after 30 min. / 60 min. / 90

min./ 120 min. / 150 min. / 180 min.)

Standard

value:

Never

Date/Time

The current time and data are set here.

Software | System

Schaerer Barista operating instructions

51

Page 52

Software | USB

Load recipes

Export counters

HACCP export

Data back-up

Load data

Firmware update

5.10 USB

Data exchange is possible using the USB

connection.

The USB connection is at the top left, on the rear

side of the control panel, directly under the cup

storage.

Loading recipes

Load saved recipes here.

Saving recipes

Export recipes onto a USB stick.

Exporting counter

The counters are exported to a CSV le here.

HACCP export

The cleaning processes performed are logged and

are exported here for the HACCP certicate.

Data backup

Set data such as machine data, beverage data, etc.

is saved here.

Loading data

Saved data such as machine data, beverage data,

etc. is loaded here.

Loading language

If available, an additional display language can be

loaded using the USB connection.

Firmware update

Save recipes

Load language

Only for Service.

52

Schaerer Barista operating instructions

Page 53

6 Care

6.1 Care safety notes

Regular cleaning is a requirement for fault-free

operation of the coffee machine and for optimal

coffee quality.

Care | Care safety notes

Health risk/Hygiene

• Milk is very sensitive. Hazardous bacteria

can grown in the milk system.

> All parts which come into contact with milk

must be cleaned immediately.

> Observe all hygiene notes.

> Observe the HACCP cleaning concept.

Health risk/Hygiene

• Bacteria can spread in a coffee machine

which is not in use.

> Carry out all cleaning processes before

and after operating breaks of several

days.

Health risk/Hygiene

• All cleaning products are perfectly

matched to the cleaning programmes.

> Use only Schaerer cleaning and descaling

agents.

CAUTION

Observe the Safety chapter

wfrom page 8

CAUTION

Observe the Safety chapter

wfrom page 8

CAUTION

Observe the Safety chapter

wfrom page 8

Schaerer Barista operating instructions

53

Page 54

Care | Overview of cleaning intervals

6.2 Overview of cleaning intervals

Care

Daily

Weekly

Regular

Automatically

As needed

Cleaning programmes

x x Brewing sieve rinsing

x Clean brewing group

Manual cleaning

x Clean the cup storage

x x Clean the coffee grounds slide

x Manually clean the brewing group

x x Clean the portalters

x Clean the drip tray

x Clean the touch display (CleanLock)

x x Clean housing

x x Clean the Autosteam steam wand

x x Clean the Powersteam steam wand

x Clean the bean hoppers

x Clean the drip tray below the bean hopper

x Replace seal

w Page 26

w Page 55

w Page 57

w Page 57

w Page 58

w Page 58

w Page 59

w Page 60

w Page 60

w Page 61

w Page 62

w Page 63

w Page 64

w Page 64

Daily = at least once daily and as needed

Weekly = weekly cleaning

Regular = regularly as needed

Automatically= automatic drain

54

Schaerer Barista operating instructions

Page 55

6.3 Cleaning programmes

6.3.1 Brewing group cleaning

Brewing group cleaning is an automatic cleaning

programme which cleans the coffee system of the

coffee machine with Schaerer cleaning tablets.

Total time required: about 10 minutes

Health risk/

Risk of irritation and burns

• During cleaning, hot cleaning liquid and

hot water ows out of the portalter and

the hot water outlet. The portalter and

the hot water outlet get hot.

• The hot liquids could irritate the skin and

the heat creates a risk of burns.

> The black drip tray must remain inserted

during cleaning.

> Always touch the portalter by its handle

only after dispensing.

> Never reach under the outlets during

cleaning.

> Ensure that no one ever drinks cleaning

liquid.

Care | Cleaning programmes

Animated instructions

wCoffee machine

wMain menu

wCare

wInstructions

CAUTION

Observe the Safety chapter

wfrom page 8

The cleaning programme proceeds

step-by-step through the system cleaning via

the display.

Follow the notications.

* Tap on .

The care programme is called up.

* Tap on Brewing group cleaning

* Tap on Yes

Schaerer Barista operating instructions

TIP

55

Page 56

Care | Cleaning programmes

When switching OFF after cleaning

* Tap on Yes

Without switching OFF after cleaning

* Tap on No

* Remove the portalter

* Remove the brewing sieves from the portalters

* Insert the blind sieves into the portalters

* Insert one 1.3 g Schaerer special cleaning tablet

into each portalter

Note: Do not add water.

* Insert the portalter.

The question of whether cleaning should be

continued appears.

* Conrm with

and continue

The question of whether cleaning tablets are

inserted appears.

* Conrm with

and continue

The cleaning process starts. A bar graph and the

remaining time are displayed.

After about 9 minutes, an animation plays,

instructing the portalter to be removed and the

sieve changed.

* Remove the portalter

* Remove the blind sieve

Do not yet insert the portalter. The brewing sieve is

rinsed.

* Conrm with

and continue

An instruction to manually clean the portalters and

the sieve appears.

* Conrm with

and continue

If Yes is selected for cleaning with switch off, the

machine switches off now.

If No is selected for cleaning without switch off,

the coffee machine heats back up.

The coffee machine is now ready for use.

The programme always

cleans both brewing groups

together, even if only one

was in operation. If a brewing

group was not used, it is not

necessary to insert cleaning

tablets into this portalter. The

blind sieve must be inserted in

both portalters.

8:03

Manually clean the portalter

and sieve.

w Cleaning the portalter

page 58

6.3.2 Brewing sieve rinsing

w Operation w Rinsing brewing sieve, page 26

56

Manually cleaning the brewing

sieve

wCleaning portalter

page 58

Schaerer Barista operating instructions

Page 57

Care | Manual cleaning

6.4 Manual cleaning

Danger of scalding

• If a beverage is accidentally initiated,

there is a risk of injury.

> Always lock the touch display using the

CleanLock before cleaning.

• There is a risk that scratches or dents will

occur during cleaning.

> Do not clean with abrasive agents or

similar.

> Do not use aggressive cleaning agents.

> Only use soft cloths for cleaning.

6.4.1 Cleaning the cup storage

* Thoroughly clean the cup storage daily with a

damp cloth.

6.4.2 Cleaning the coffee grounds slide

• Cleaning the coffee grounds slide could

damage the grinder.

> Always clean the coffee grounds slide only

with the brush provided for this purpose.

Check the coffee grounds slide regularly and clean

with the provided brush if needed.

Order numbers for the

Schaerer care programme

wAccessories and spare parts

page 83

CAUTION

Observe the Safety chapter

wfrom page 8

IMPORTANT

Observe the Warranty chapter

wfrom page 78

IMPORTANT

Observe the Warranty chapter

wfrom page 78

* Always clean the coffee grounds slide only with

the brush provided for this purpose.

* Follow the step-by-step instructions on the

display.

Schaerer Barista operating instructions

Cleaning coffee grounds slide

w Software w Care

page 38

57

Page 58

Care | Manual cleaning

6.4.3 Manually cleaning the brewing group

* Remove the ground coffee remains and the seal

with the brewing group brush

* Start a brewing sieve rinsing process

6.4.4 Cleaningtheportalter

Rinsing brewing sieve

w Operation

page 26

Riskofburns

• The portalters and the brewing sieves

get very hot during beverage dispensing

and cleaning.

> Do not touch the portalters and the

brewing sieves directly after dispensing or

after "Brewing group cleaning".

All individual parts of theportalter (these are the

portalter itself, the portalter handle, the brewing

sieve, the sieve retaining ring and the insulation

insert) can be washed in a dishwasher.

Daily cleaning

* Remove the portalter and the sieves

* Rinse all parts with warm, pure drinking water

Weekly cleaning

Once a week, insert and clean the portalter in a

container

* Place a cleaning tablet into the container

* Fill the container with hot water and dissolve the

cleaning tablet in it

* Remove the brewing sieve and the sieve

retaining ring

CAUTION

58

Schaerer Barista operating instructions

Page 59

* Remove the insulation insert and remove and

rinse off deposits with a brush

* Place the portalter parts and the sieves

completely into the cleaning liquid for 30 minutes

* Remove the parts and clean with a brush if

necessary

* Rinse all parts with warm, pure drinking water

* Reassemble the portalter

6.4.5 Cleaning the drip tray

Care | Manual cleaning

Danger of scalding

• Hot liquids could be in the drip trays.

> Carefully move the drip trays.

> Reinstall it carefully so that no unintended

water leakage occurs.

> Always make sure the drip trays are

positioned correctly.

Important!

Do not kink the relief water hose [1].

* Remove the drip grid.

* Remove the drip trays.

* Thoroughly clean the drip trays.

* Thoroughly wipe out the surfaces under the drip

trays.

* Dry the drip trays and reinsert them.

CAUTION

Observe the Safety chapter

wfrom page 8

1

Schaerer Barista operating instructions

59

Page 60

Care | Manual cleaning

6.4.6 Cleaning the touch display (CleanLock)

Danger of scalding

• If a beverage is accidentally initiated,

there is a risk of injury.

> Always lock the touch display using the

CleanLock before cleaning.

• There is a risk that scratches or dents will

occur during cleaning.

> Do not clean with abrasive agents or

similar.

> Do not use aggressive cleaning agents.

> Only use soft cloths for cleaning.

* Tap on CleanLock

A 15-second countdown starts.

The touch display can now be cleaned.

The touch display is reactivated 15 seconds after

the last time it is touched.

6.4.7 Cleaning the housing

• There is a risk that scratches or dents will

occur during cleaning.

> Do not clean with abrasive agents or

similar.

> Do not use aggressive cleaning agents.

> Only use soft cloths for cleaning.

Clean the housing at regular intervals using suitable

materials.

CAUTION

Observe the Safety chapter

wfrom page 8

IMPORTANT

Observe the Warranty chapter

wfrom page 78

IMPORTANT

Observe the Warranty chapter

wfrom page 78

60

Schaerer Barista operating instructions

Page 61

6.4.8 Cleaning steam wands

Care | Manual cleaning

Risk of burns/

Danger of scalding

• Hot liquid comes out of the outlets during

beverage and steam dispensing. The

adjacent surfaces and outlets get hot as

well.

> Do not touch the area under the outlets

during beverage and steam dispensing.

> Do not touch the outlets shortly after

dispensing.

Cleaning the Autosteam steam outlet

Daily

* Mix 5 ml of cleaner into a tall container with 0.5 l

cold water

* Completely immerse the steam wand into the

cleaning liquid

* Briey tap on an Autosteam button

Exposure time: 30 minutes

* Clean with a brush

* Rinse thoroughly with water

* Tap on the foam button

The steam cleans the milk remains from the holes in

the steam wand and removes cleaning residues.

Weekly

* Unscrew steam wand

* Insert the steam wand completely into the

cleaning liquid for at least 5 hours

* Clean the steam openings with the brush

* Rinse thoroughly with clear water

* Screw the steam wand onto the Autosteam outlet

* Place the steam wand into a container with clear

water

* Briey tap on an Autosteam button

* Wipe the steam wand using a moist cloth

CAUTION

Schaerer Barista operating instructions

61

Page 62

Care | Manual cleaning

Cleaning the Powersteam steam outlet

Daily

* Mix 5 ml of cleaner into a tall container with 0.5 l

lukewarm water

* Completely immerse the steam wand into the

cleaning liquid

* Briey turn the Powersteam knob all the way

Exposure time: 30 minutes

* Clean with a brush

* Rinse thoroughly with water

* Briey turn the Powersteam knob all the way

The steam cleans the milk remains from the holes in

the steam wand and removes cleaning residues.

Weekly

* Unscrew steam wand

* Insert the steam wand completely into the

cleaning liquid for at least 5 hours

* Clean the steam openings with the brush

* Rinse thoroughly with clear water

* Screw the steam wand onto the Powersteam

outlet

* Place the steam wand into a container with clear

water

* Briey turn the Powersteam knob all the way

* Wipe the steam wand using a moist cloth

62

Schaerer Barista operating instructions

Page 63

6.4.9 Cleaning the bean hoppers

The bean hoppers can be cleaned at regular

intervals and as needed. Recommendation: monthly.

Care | Manual cleaning

Risk of injury

• Very long hair could get stuck in the

grinder head and get pulled into the coffee

machine.

> Always protect hair with a hairnet before

you remove the bean hopper.

Risk of trapping/Risk of injury

• The coffee machine contains moving parts

which could injure ngers or hands.

> Always switch off the coffee machine and

pull out the power plug before reaching

into the grinder or into the opening of the

brewing unit.

> Never clean the bean hoppers and their

lids in the dishwasher.

* Switch the coffee machine off.

* Pull the power plug.

* Push the cup storage to the back.

* Remove bean hopper lids.

* Turn the bean hopper locking mechanisms

clockwise and unlock.

* Remove the bean hoppers.

* Remove all beans under the bean hoppers,

vacuum up if necessary.

* Empty all coffee beans from the bean hopper.

CAUTION

CAUTION

IMPORTANT

Locked

Schaerer Barista operating instructions

Unlocked

63

Page 64

Care | Replacing seal

* Wipe out the bean hoppers thoroughly with a

moist cloth.

* Let the bean hopper dry fully.

* Clean the drip trays under the bean hoppers.

* Rell the bean hoppers and reinsert them.

* Close the locking mechanism anti-clockwise.

Cleaning the drip tray below the bean hopper

Regularly clean the drip trays under the bean

hoppers

* Unlock and remove the bean hopper

* Clean the drip tray under the bean hoppers

6.5 Replacing seal

Riskofburns

• The portalters and the brewing sieves

get very hot during beverage dispensing

and cleaning.

> Do not touch the portalters and the

brewing sieves directly after dispensing or

after "Brewing group cleaning".

If necessary, the customer can change the seal

him-/herself

* Call up the seal change for the desired brewing

group in the Care menu

The animation guides you through the task

step-by-step.

* Remove the portalter

* Take the sieve out of the portalter

* Insert the portalter without the sieve

* Conrm this with

The brewing piston moves into the seal change

position.

* Wait until the next notication

CAUTION

Software

w Care

w Seal change

page 38

64

Schaerer Barista operating instructions

Page 65

* Remove the portalter

The animation for changing the seal runs.

* Remove the old seal

* Insert the new seal

* Conrm this with

* Insert the portalter without the sieve

The brewing piston moves into the normal position.

* Wait until the next notication

* Remove the portalter

* Reinsert the sieve in the portalter

* Insert the portalter with the sieve

The coffee machine sensors detect that the

portalter is reinserted and the seal change is

completed.

Care

Schaerer Barista operating instructions

65

Page 66