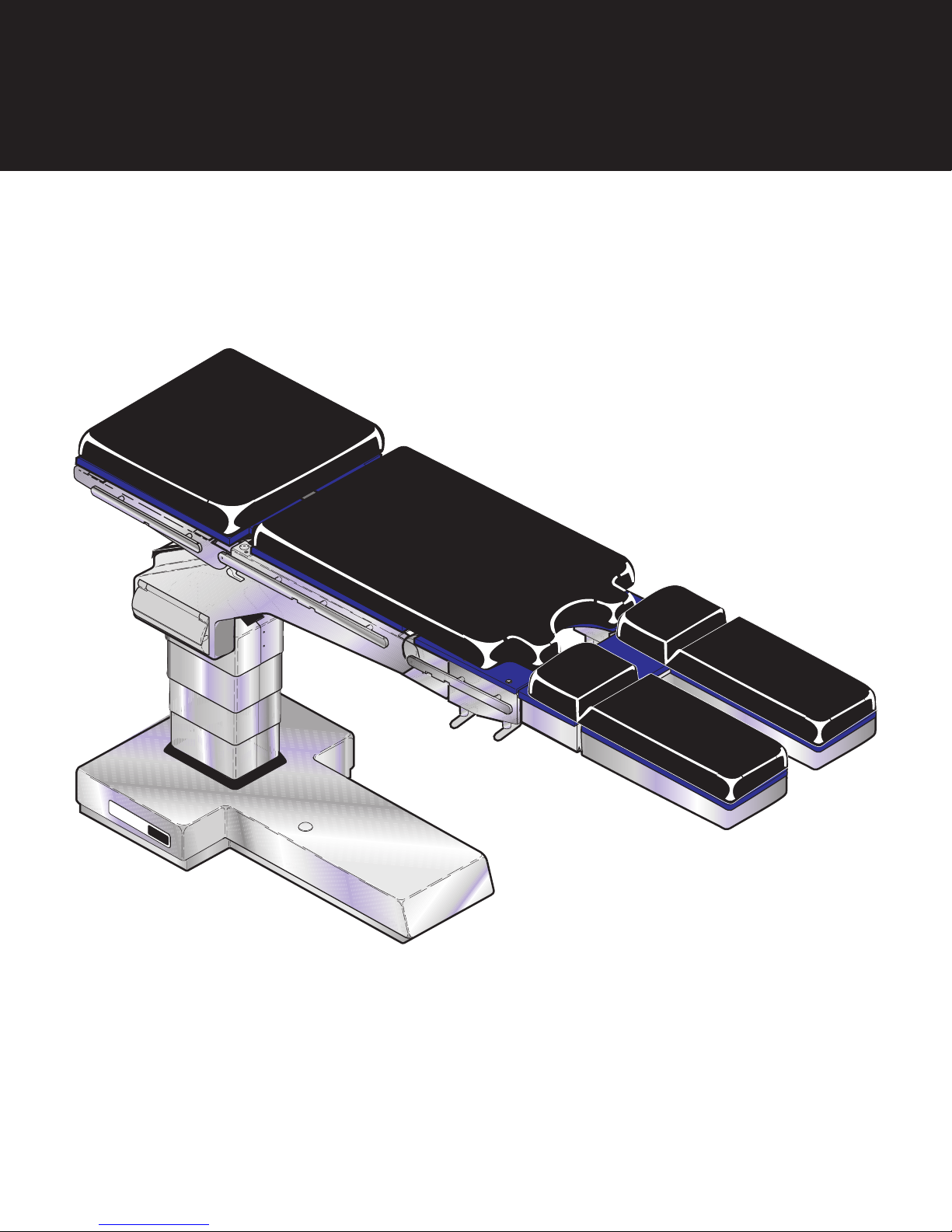

Page 1

Schaerer Mayfield USA, Inc.

7300

Modular Surgery

Table

Service and

Parts Manual

SMI

7300

SF-1586 Part No. 504-0023-00 Rev. E (5/04)

CA802000

FOR USE BY SMI

TRAINED TECHNICIANS

ONLY

Page 2

Page 3

TABLE OF CONTENTS

Section/Paragraph Page Section/Paragraph Page

IMPORTANT INSTRUCTIONS

General Safety Instructions........................................ iv

Warnings.................................................................... iv

Warranty Instructions ................................................. iv

SECTION I GENERAL INFORMATION

1.1 Scope of Manual ......................................... 1-1

1.2 How to Use Manual ..................................... 1-1

1.3 Description of 7300 Modular Surgery

Table ....................................................... 1-1

1.4 Specifications ............................................. 1-7

1.5 Parts Replacement Ordering ....................... 1-8

1.6 Special Tools .............................................. 1-9

SECTION II TESTING AND TROUBLESHOOTING

2.1 Operational Test.......................................... 2-1

2.2 Troubleshooting Procedures ........................ 2-6

SECTION III SCHEDULED MAINTENANCE

3.1 Scheduled Maintenance .............................. 3-1

SECTION IV MAINTENANCE/SERVICE

INSTRUCTIONS

4.1 Introduction ................................................. 4-1

4.2 Checking Oil Level / Adding Oil To

Reservoir .................................................. 4- 1

4.3 Calibration Of Return To Level / Neutral

Position .................................................... 4- 2

4.4 Hand Control Button Board

Removal / Installation ............................... 4-4

4.5 Hand Control Board

Removal / Installation ............................... 4-4

4.6 Seat Cylinders Synchronization

Procedure ................................................. 4- 5

4.7 Column Cylinder Slave Line Volume

Adjustment ............................................... 4- 7

4.8 Trendelenburg Cylinder

Removal / Installation ............................... 4-9

4.9 Trendelenburg Pilot Operated Check Valve

Removal / Installation ............................. 4-11

4.10 Trendelenburg Cylinder Orifice(s)

Removal / Installation ............................. 4-13

4.11 Trendelenburg Position Sensor

Removal / Installation ............................. 4-14

4.12 Lateral Tilt Cylinder

Removal / Installation ............................. 4-15

4.13 Lateral Tilt Orifice(s)

Removal / Installation ............................. 4-16

4.14 Lateral Tilt Pilot Operated Check Valve

Removal / Installation ............................. 4-18

4.15 Lateral Tilt Position Sensor

Removal / Installation ............................. 4-20

4.16 Seat Cylinder

Removal / Installation ............................. 4-21

4.17 Seat Cylinder Orifice(s)

Removal / Installation ............................. 4-26

4.18 Seat Cylinder Pilot Operated Check Valve

Removal / Installation ............................. 4-27

4.19 Seat Position Sensor

Removal / Installation ............................. 4-28

4.20 Column Cylinder

Removal / Installation ............................. 4-31

4.21 Column Pilot Operated Check Valve

Removal / Installation ............................. 4-34

4.22 Typical L.H. and R.H. Control Valve Solenoids

Removal / Installation ............................. 4-35

4.23 Typical Base Mounted Control Valve Solenoids

Removal / Installation ............................. 4-37

4.24 Discharge Filter Replacement .................... 4-39

4.25 Main Floor Lock or Outrigger

Floor Lock Cylinder

Removal / Installation ............................. 4-41

4.26 Motor Or Motor Pump

Removal / Installation ............................. 4-42

4.27 Pump Unit

Removal / Installation ............................. 4-44

4.28 Motor Pump Output Check Valve

Removal / Installation ............................. 4-47

4.29 Motor Pump Pressure Relief Valve

Removal / Installation ............................. 4-48

4.30 Outrigger Pressure Relief Valve

Removal / Installation ............................. 4-50

4.31 Main Controller Board

Removal / Installation ............................. 4-53

4.32 Charging / Power Driver Board

Removal / Installation ............................. 4-55

4.33 Emergency Override Panel

Removal / Installation ............................. 4-57

4.34 Distribution Board

Removal / Installation ............................. 4-58

4.35 RFI Filter

Removal / Installation ............................. 4-59

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Schaerer Mayfield USA, Inc. 2004 Page iPrinted in U.S.A.

Page 4

TABLE OF CONTENTS - CONTINUED

Section/Paragraph Page Section/Paragraph Page

4.36 Transformer

Removal / Installation ............................. 4-61

4.37 Line Power Pilot Lamp

Removal / Installation ............................. 4-63

4.38 Plug Receptacle

Removal / Installation ............................. 4-63

4.39 Batteries

Removal / Installation ............................. 4-64

4.40 Primary Thermostat

Removal / Installation ............................. 4-65

4.41 Secondary Thermostat

Removal / Installation ............................. 4-66

4.42 Floor Lock Status Switch

Removal / Installation ............................. 4-66

4.43 Head Section Gas Spring

Removal / Installation / Adjustment ........ 4-68

4.44 Foot Control Interface Board

Removal / Installation ............................. 4-69

4.45 Typical Latch Mechanism

Removal / Installation ............................. 4-70

4.46 Typical Floor Lock Check Valve

Removal / Installation ............................. 4-71

4.47 Articulating Leg Transfer Board

Adjustments............................................ 4-73

4.48 Bell Footpiece Traction Crank Assembly

Disassembly / Assembly ........................ 4-75

SECTION V SCHEMATICS AND DIAGRAMS

5.1 Electrical Schematics / Wiring Diagrams..... 5-1

5.2 Hydraulic Flow Diagram................................ 5-4

5.3 Hand Control Messages ............................... 5- 5

5.4 Error Code Chart .......................................... 5- 6

SECTION VI PARTS LIST

6.1 Introduction ................................................. 6-1

6.2 Description of Columns ............................... 6-1

6.3 Torque Specifications And Important

Assembly Notes ....................................... 6-1

Pictorial Index ............................................. 6-2

Accessories ................................................. 6- 3

Labels And Decals ....................................... 6-4

Cushions and Table Tops............................. 6- 5

Covers and Shields ...................................... 6-6

Head Section Assembly............................... 6-7

Bridge Components...................................... 6-8

Lateral Tilt Cylinder Assembly...................... 6- 9

Upper Hose Connections............................ 6-10

L.H. Side Components ............................... 6-11

L.H. Control Valve Assembly ..................... 6-12

L.H. Seat Cylinder Assembly ..................... 6-13

R.H. Side Components............................... 6-14

Emergency Override Panel Assembly ........ 6-15

R.H. Control Valve Assembly..................... 6-16

R.H. Seat Cylinder Assembly..................... 6-17

Column Assembly Components ................. 6-18

Column Assembly ...................................... 6-19

Trendelenburg Cylinder Assembly ............. 6-20

Column Cylinder Assembly ........................ 6-21

Hand Control Assembly.............................. 6-22

Base Cover Components ........................... 6-23

Base Hydraulic / Electrical

Components............................................ 6-24

Electrical Control Box Components ............ 6-25

Base Hydraulic Plumbing ........................... 6-26

Base Control Valve Assembly.................... 6-27

Hydraulic Pump / Motor Components ......... 6-28

Hydraulic Motor Components ..................... 6-29

Hydraulic Pump Components ..................... 6-30

Floor Lock Components ............................. 6-31

Main Floor Lock Cylinder Components ....... 6-32

Outrigger Floor Lock Cylinder

Components............................................ 6-33

Caster Components ................................... 6-34

Power Driver Board Components................ 6-35

Battery Components .................................. 6-36

10210 Perineal Post Assembly .................. 6-37

10322 Cross Arm Support Assembly ......... 6-38

10360 Safety Strap .................................... 6-39

10395 Lottes Anklet ................................... 6-40

10508 Well Leg Support Assembly............. 6-41

10509 Equipment Cart................................ 6-42

10620 Drape Stand Assembly .................... 6-43

10821 Removable Siderail.......................... 6-44

10823 Leg Transfer Board .......................... 6-45

10824 Horizontal Perneal Post ................... 6-46

10825 Tibia Extender ................................. 6-47

10830 Well Leg Support (Siderail Mount).... 6-48

10836 Offset Adapter Mount ...................... 6-49

13100 / 13200 Montreal Lateral

Position Device....................................... 6-50

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

© Schaerer Mayfield USA, Inc. 2004

Page iiPrinted in U.S.A.

Page 5

TABLE OF CONTENTS - CONTINUED

Section/Paragraph PageSection/Paragraph Page

22111 Pin and Wire Holder ......................... 6-51

22119 Traction Bow Assembly ................... 6-52

22314 Traction Cuff Assembly ................... 6-53

70542 Bierhoff Leg Holder .......................... 6-54

70556 Siderail Extension Set ..................... 6-55

71070 Siderail Socket ................................ 6-56

71071 I.V. Arm Board Assembly ................ 6-57

71073 Siderail Clamp ................................. 6-58

71074 Conventional Ether Screen .............. 6-59

71075 Foot Rest......................................... 6-60

71077 Siderail Extender Set ....................... 6-61

71078 A/P Cassette Holder ........................ 6-62

71079 Lithotomy Leg Holder ....................... 6-63

71080 Universal Ether Screen .................... 6-64

71082 Lateral Cassette Holder ................... 6-65

71083 Cross Arm Support .......................... 6-66

71084 / 71085 / 71093 I.V. Arm Board

Cushion .................................................. 6-67

71088 Neuro Headrest Adapter................... 6-68

71090 Lateral Support Set.......................... 6-69

71092 Infant Arm & Hand Table ................. 6-70

71094 Table Side Extenders ...................... 6-71

71097 Tri Clamp 2 ...................................... 6-72

71098 Flexguard Stirrup Set ....................... 6-73

71099 Guardian Stirrup Set ........................ 6-74

71100 Leg Prep Stand................................ 6-75

71101 Snaplock Arm Board........................ 6-76

71102 / 71103 Snaplock Arm

Board Cushion ........................................ 6-77

71104 Shoulder Brace Set.......................... 6-78

71105 Universal Patient Brace /

71113 Circular Head Cushion ..................... 6-79

71106 / 71107 Uro Catch Bags................... 6-80

71108 Winged Anesthesia Screen.............. 6-81

71110 Footswitch ....................................... 6-82

71111 Split Leg Set - 71118 / 71119 Split

Leg Pad Set............................................ 6-83

71112 Foot Extension Assembly /

71114 Foot Extension Cushion................... 6-84

71116 Conductive Safety Strap /

20715 Nonconductive Safety Strap ............ 6-85

71120 Side Extender Shelf......................... 6-86

71125 Image Amplification Extension ....... 6-87

71129 X-Ray Arm Board............................. 6-88

71130 I.A. Board (36-inch).......................... 6-89

73001 Pelvic Base w/ Cushion ................... 6-90

73002 Leg Transfer Board w/ Cushion ........ 6-91

73003 Drain Pan......................................... 6-92

73004 I.A. Extention w/ Cushion (55-inch).. 6-93

73005 X-Ray Top Set................................. 6-94

73006 Back Section ................................... 6-95

73007 Ortho Pelvic Base /

73023 / 73024 Board w/ Cushion............ 6-96

73008 Abductor Bar ................................... 6-97

73009 Abductor Bar Clamp ........................ 6-98

73010 Traction Unit .................................... 6-99

73011 Traction Unit Extention .................. 6-100

73012 Popliteal Support ........................... 6-101

73013 Lateral Well Leg Holder .................. 6-102

73014 Shoulder Arthroscopic Attachment. 6-103

Shoulder Arthroscopic Lumbar

Support Assembly ................................ 6-104

Shoulder Arthroscopic Head Rest............. 6-105

73015 Articulating Bracket ....................... 6-106

73016 Drapery Kit .................................... 6-107

73019 Back Section X-Ray Top ............... 6-108

73020 Leg Transfer Frame ....................... 6-109

73021 Yellofin Leg Holder System.... Not Shown

73022 Clear Vision Drapes ............... Not Shown

10531 Bell Footpiece Traction Assy......... 6-110

73025 Orthopedic Cart ............................. 6-111

73026 General Surgery Cart ..................... 6-112

COMMENTS ............................................................ 7-1

(*) Indicates that there has been a serial number break for the illustration

and that there are additional point page(s) following the original page.

Page iiiPrinted in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 6

IMPORTANT INSTRUCTIONS

General Safety Instructions

Safety First: The primary concern of

Schaerer Mayfield USA is that this surgery table is

maintained with the safety of the patient and staff in

mind. Toassure that services and repairs are completed

safely and correctly, proceed as follows:

(1 ) Read this entire manual before performing any

services or repairs on this surgery table.

(2 ) Be sure you understand the instructions con-

tained in this manual before attempting to

service or repair this surgery table.

Warnings

Throughout this manual are Note, Caution, and Danger

paragraphs that call attention to particular procedures.

These items are used as follows:

NOTE

A note is used to amplify an operating procedure,

practice or condition.

Warranty Instructions

Refer to the SMI “Limited Warranty” printed on the

back cover of the Installation and Operation Manual for

warranty information. Failure to follow the guidelines

listed below will void the warranty and / or render the

7300 Modular Surgery Table unsafe for operation.

• In the event of a malfunction, do not attempt to

operate the surgery table until necessary repairs have

been made.

• Do not attempt to disassemble surgery table, replace

malfunctioning or damaged components, or perform

adjustments unless you are one of SMI’s

authorized service technicians.

• Do not substitute parts of another manufacturer when

replacing inoperative or damaged components. Use

only SMI replacement parts.

CAUTION

A CAUTION is used for an operating

procedure, practice, or condition which, if

not correctly followed, could result in equipment

damage.

DANGER

A DANGER is used for an operating

procedure, practice, or condition

which, if not correctly followed, could result in

loss of life or serious personal injury.

© Schaerer Mayfield USA, Inc. 2004

Page ivPrinted in U.S.A.

Page 7

SECTION I

GENERAL INFORMATION

SECTION I

GENERAL INFORMATION

1.1 Scope of Manual

This manual contains detailed troubleshooting, scheduled maintenance, maintenance, and service instructions for 7300 Modular Surgery Table. This manual is

intended to be used by SMI’s authorized service

technicians.

1.2 How to Use Manual

A. Manual Use When Performing Scheduled Mainte-

nance.

(1) Perform inspections and services listed in

Scheduled Maintenance Chart (Refer to

para 3.1).

(2) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance/service instructions (Refer to para 4.1).

B. Manual Use When Unit Is Malfunctioning And

Cause Is Unknown.

(1) Perform an operational test on unit (Refer to

para 2.1).

(2) Perform troubleshooting procedures listed in

Troubleshooting Guide (Refer to para 2.2).

(3) If a component is discovered to be faulty or out

of adjustment, replace or adjust component in

accordance with maintenance/service instructions (Refer to para 4.1).

C. Manual Use When Damaged Component Is Known.

(1) Replace or adjust component in accordance

with maintenance/service instructions (Refer to

para 4.1).

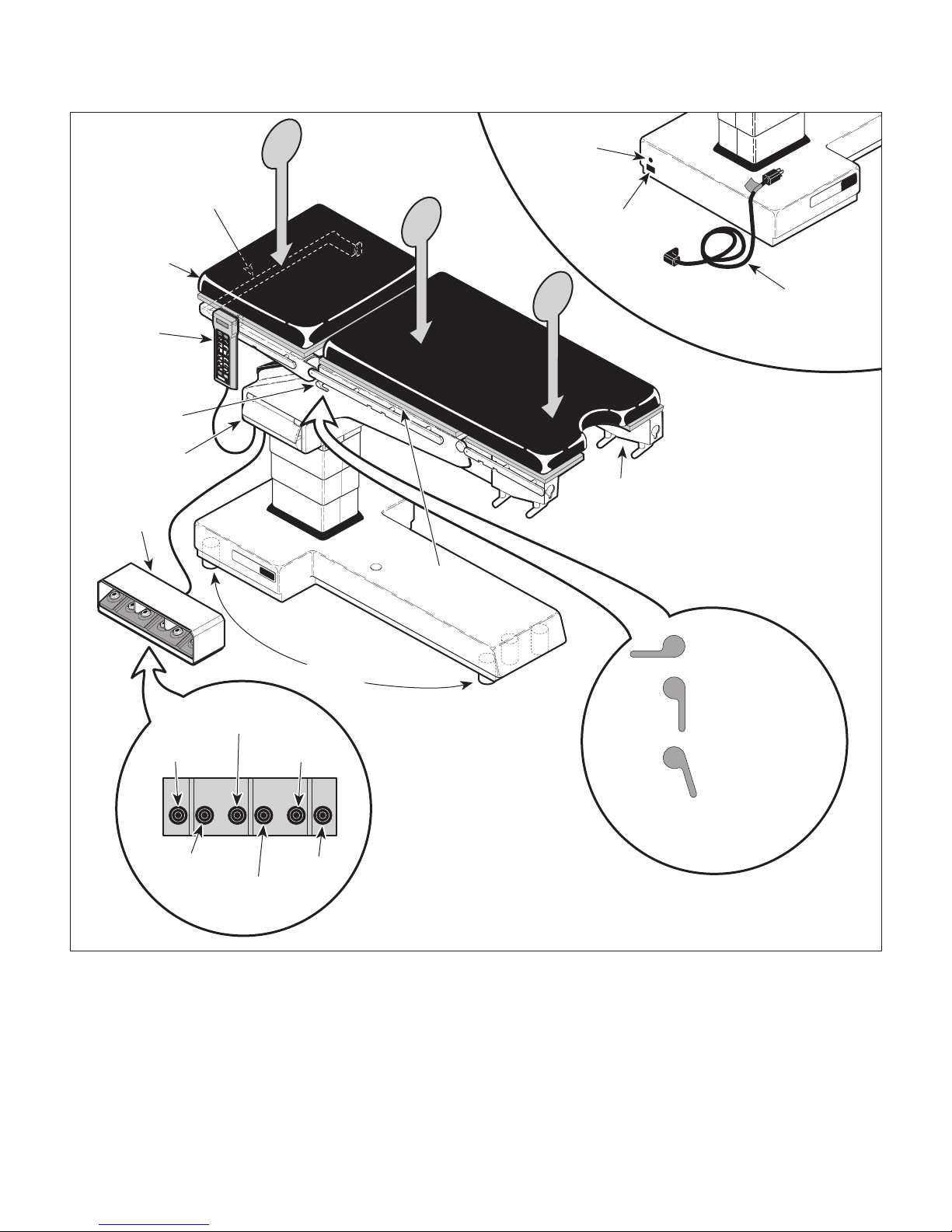

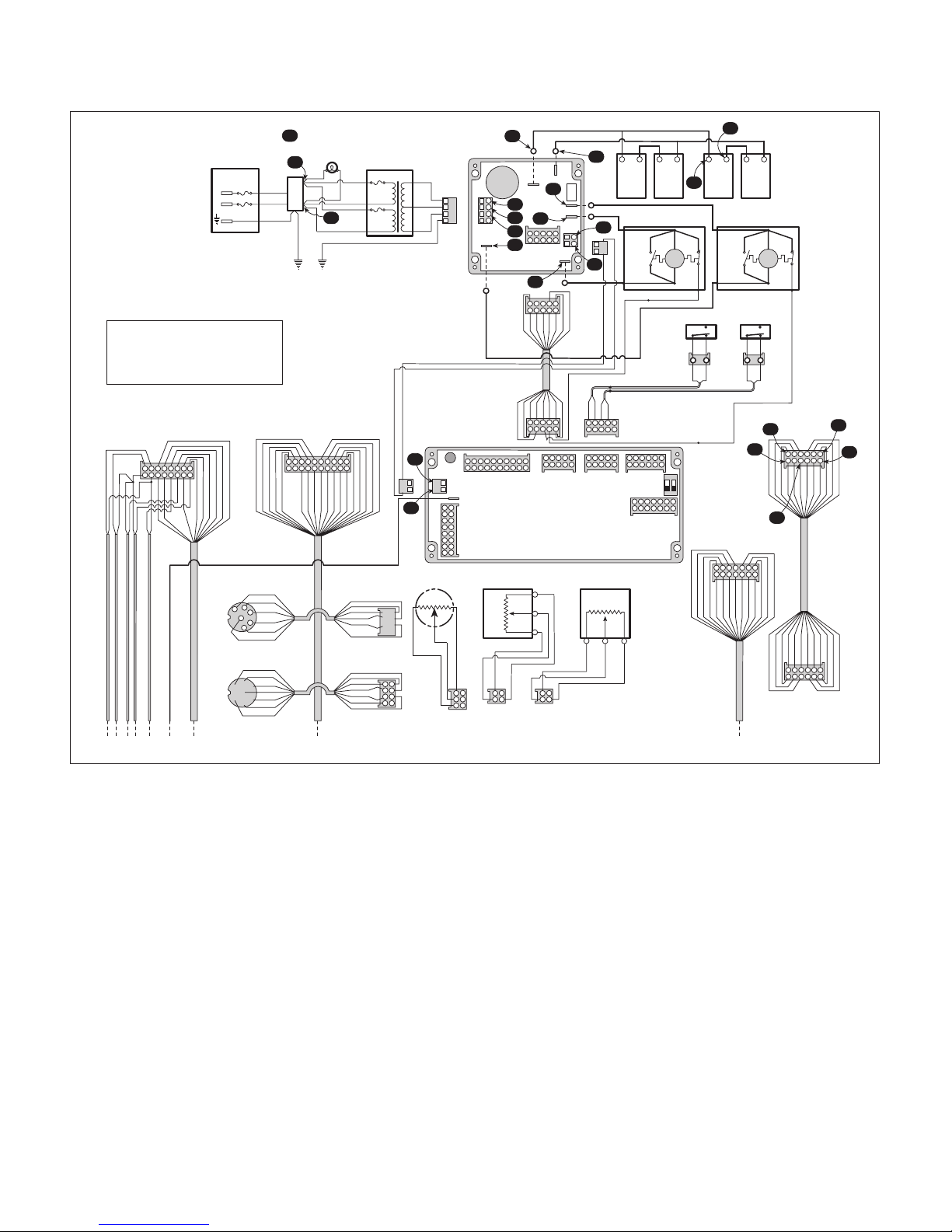

1.3 Description Of 7300 Modular Surgery

Table

A. General Description (See Figure 1-1, Sheets 1

and 2).

The 7300 Modular Surgery Table is designed for use as

a general surgery table on which virtually any surgical

procedure can be accomplished. 7300 was designed

for maximum C-arm access and X-ray visibility.

Major serviceable components of the surgery table are:

1. Motor pump which includes two motors, two pump

units, two motor pump pressure relief valves, two

primary thermostats, two secondary thermostats, and a

motor pump output check valve, and a discharge filter,

2. Trendelenburg (UP and DOWN) solenoid valves,

Trendelenburg cylinder pilot operated check valves,

and Trendelenburg cylinder, trendelenburg position

sensor.

3. Seat (UP and DOWN) solenoid valves, seat cylinder

pilot operated check valves, seat cylinders and, seat

position sensor.

4. Lateral tilt (LEFT and RIGHT) solenoid valves,

lateral tilt cylinder pilot operated check valves, lateral tilt

cylinder, and lateral tilt position sensor.

5. Column (UP and DOWN) solenoid valves, column

cylinder pilot operated check valve, column cylinder,

and column assembly which includes slides.

6. Main and Outrigger Floor Lock solenoid valves,

three main floor lock cylinders, two outrigger floor lock

cylinders, outrigger pressure relief valve, main and

outrigger floor lock status switches.

7. Head section with two gas cylinders.

8. Main Controller Board which includes a 10 amp

fuse.

9. Charging / Power Driver Board which includes a 40

amp fuse.

10. RFI filter.

11. Transformer.

12. Four batteries.

13. Hand control which includes button board and

hand control board.

14. Foot control which includes foot switch pad and

foot control interface board.

15. Emergency override board.

16. Distribution board.

17. Plug Receptacle which includes two 5 amp fuses,

and line power pilot lamp.

© Schaerer Mayfield USA, Inc. 2004

Page 1-1Printed in U.S.A.

Page 8

SECTION I

GENERAL INFORMATION

Figure 1-1. Major Components (Sheet 1 of 2)

Page 1-2Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 9

SECTION I

GENERAL INFORMATION

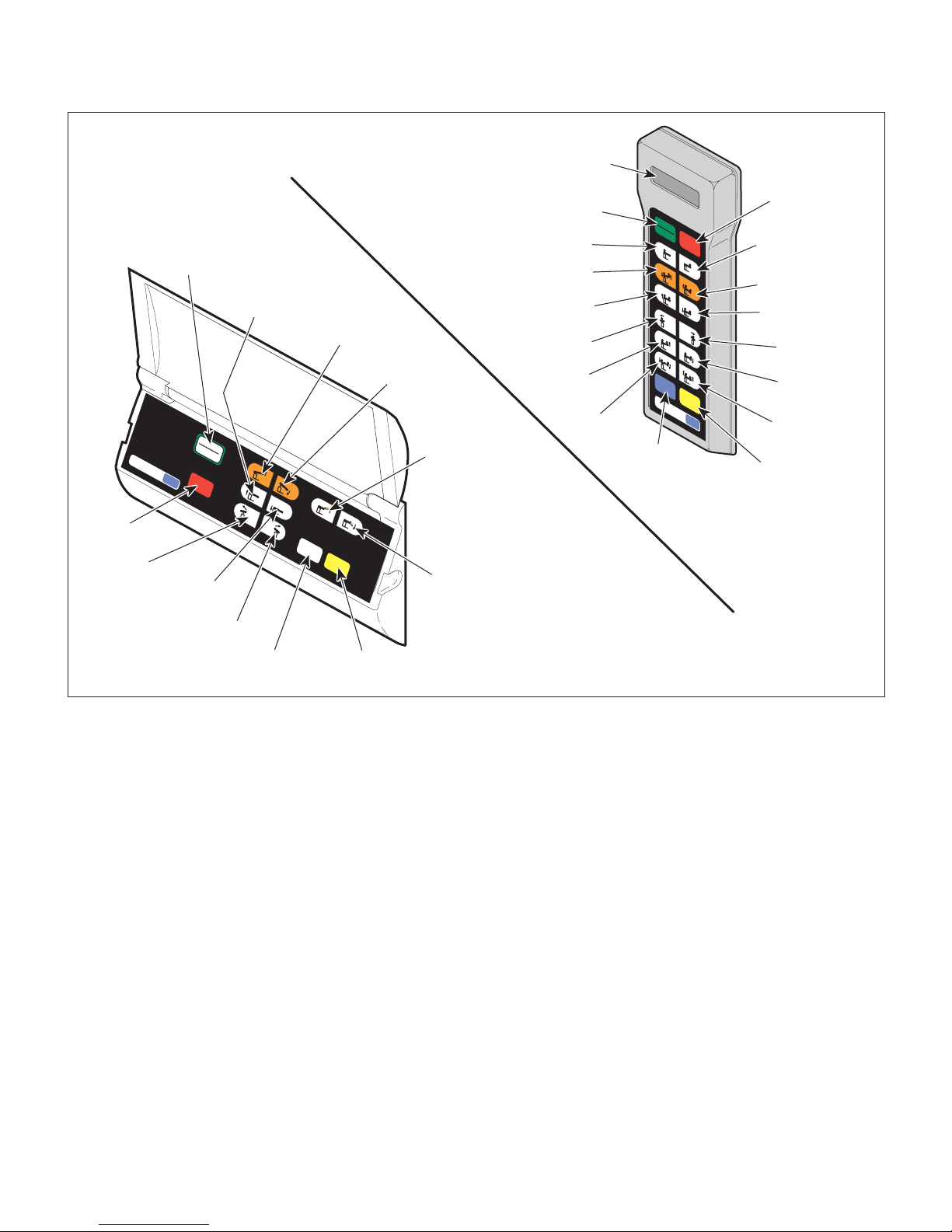

Figure 1-1. Major Components (Sheet 2 of 2)

Page 1-3Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 10

SECTION I

GENERAL INFORMATION

B. Theory of Operation. See Figures 5-1, Sheets 1

and 2, and Figure 5-2 for electrical schematic /

wiring diagram. See Figure 5-3 for hydraulic

schematic.

Electrical Theory Of Operation

When power cord is plugged into power cord receptacle, line voltage (approximately 115 VAC) is supplied

to table. Line voltage is applied across an RFI filter.

RFI filter reduces line conducted RFI / EMI that is

present on incoming power line. Across RFI filter

output is a line power pilot lamp which illuminates to

indicate power is present at output of RFI filter.

Transformer primary lines are also connected across

RFI filter output. Transformer steps line voltage down

to 32.5 VAC ± 2 VAC. The 32.5 VAC from output of

transformer is applied to charging / power driver board.

Charging / power driver board uses a DC rectifying

circuit to convert 32.5 VAC to approximately 27.8 VDC.

Charging / power driver board regulates charging rate

of four batteries by regulating rate at which 27.8 VDC is

applied to batteries. Charging / power driver board also

supplies 27.5 VDC to main controller board to power it.

Transformer has thermal fuses connected in each

primary winding and they are embedded between the

primary and secondary windings. If transformer overheats, normally closed (N.C.) thermal fuses open,

disconnecting power to transformer.

Transformer is primarily used to supply power to

charging / power driver board, so board can charge

batteries and supply power to rest of table.

Charging / power driver board regulates charge rate

of batteries when batteries are being charged. This

means that a full load is not continuously being placed

on transformer, which is important because transformer

is not sized to draw a full current load continuously. If

batteries are low and a function is selected, power to

drive motor pump(s) is drawn from batteries first and

then from transformer as necessary. If batteries are too

low or a function is selected for too long, continuous

current draw thru transformer will overheat transformer

very quickly, causing thermal fuses to blow.

CAUTION

It is important that a table with a low battery charge be operated only in case of

emergency and for a very short time period (less

than a minute).

Logic Theory Of Operation

When ENABLE button is pressed, a 5 VDC signal is

sent to main controller board, activating it. Main

controller board performs a self diagnostic check on

itself. If self diagnostic check fails, error code E11

(Internal RAM / Register Failure) is displayed on hand

control.

Main controller board and charging / power driver board

uses status circuits to check functionality of following

electrical components: motors, charging / power driver

board, valve spool solenoids, main controller board,

position sensors, foot control switch pad, and hand

control button board.

A status circuit, on charging / power driver board,

monitors amount of current draw thru motor pump

windings, when a function has been selected. If current

draw exceeds a predetermined value, main controller

board stops all functions and displays error code E02

(Overcurrent - Motor Pump #1) or E03 (Overcurrent Motor Pump #2), which indicates a failure of a motor

pump.

If current draw falls below a predetermined value, main

controller board stops all functions and displays error

code E04, which indicates failure of charging / power

driver board.

A status circuit, on main controller board, monitors

enable circuitry for each valve spool solenoid and

detects if a valve spool solenoid or enable circuitry of

main controller board is functioning correctly. If not,

main controller board stops all functions and displays

error code E05 (Valve Drive Failure), which indicates

failure of either a valve spool solenoid or main controller

board.

Another status circuit, on main controller board, monitors voltage input from position sensors. If voltage

value exceeds or falls below a predetermined range,

main controller board stops all functions and displays

appropriate error code: E07 (Trendelenburg Position

Sensor Failure), E08 (Tilt Position Sensor Failure), E09

(Seat Position Sensor Failure). An error code indicates

failure of either a position sensor, main controller board,

or wiring.

Main controller board also monitors main floor lock

status switch, outrigger floor lock status switch, motor

pump #1 primary thermostat, and motor pump # 2

primary thermostat. When hand control is ENABLED,

main controller board checks if normally open (N.C.)

main floor lock status switch and outrigger floor lock

status switch is untripped. If main controller does not

detect that

energizes main floor lock valve spool and motor pump,

causing main floor locks to extend. After eight seconds,

main controller de-energizes main floor lock valve spool

both

status switches are untripped, it

Page 1-4Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 11

SECTION I

GENERAL INFORMATION

and motor pump, and then energizes outrigger floor

lock valve spool and motor pump, causing outrigger

floor locks to extend. After six seconds, main controller

de-energizes outrigger floor lock valve spool and motor

pump. At this time main controller checks status of

status switches again. If main controller does not

detect that

all functions and displays E01 (Floor Lock Status

Switch Is Not Responding).

Also, when hand control is ENABLED, main controller

board checks if normally closed (N.C.) motor pump

primary thermostats are closed. If main controller

board detects an open circuit, it stops all functions and

displays error code E13 (Overheat - Motor Pump #1) or

E14 (Overheat - Motor Pump #2), which indicates that

motor pump has overheated, opening its primary

thermostat.

Also, when hand control is ENABLED, main controller

board checks status of each set of switches in hand

control; there are two normally open (N.O.) switches for

each function, one for solenoid valve and one for motor.

If only one of the set of two switches is detected as

being pressed, main controller board detects this and

displays error code E15 (Hand Control Switch Failure).

This indicates that one switch is stuck in closed position. Also, if a function button is pressed and then error

code E15 displays, this indicates that only one of two

switches is working properly. This safety feature

prevents unintended table movement due to a switch

malfunction.

Also, when a function is selected using foot control,

main controller board checks status of each set of

switches in the foot control pad; there are two normally

open (N.O.) switches for each function. If there is a set

of switches for which only one of two switches is

detected as being pressed, the main controller board

detects this and displays error code E06 (Foot Switch

Failure) on hand control. This indicates that one of two

switches is stuck in closed position or not working

properly. This safety feature prevents unintended table

movement due to a switch malfunction.

Motor pumps also have secondary thermostats which

provide backup protection if primary thermostats fail. If

a motor pump overheats and its primary thermostat

does not shut off motor pump, normally open (N.O.)

secondary thermostat closes, directly shorting current

past motor windings to ground, causing 40 amp fuse on

charging / power driver board to blow, which stops

motor pump.

both

status switches are untripped, it stops

Hydraulic System Theory Of Operation

When a function is selected using hand control or foot

control, motor pump(s) begins to run and selected

function's valve spool shifts.

Hydraulic oil flows thru a strainer in reservoir and into

pump chamber. Pump pumps oil thru an internal check

valve, and a discharge filter. Oil is now in supply line,

ready to power selected function's cylinder(s). Motor

pump internal check valve allows oil to flow thru to the

supply line, but closes when motor pump stops running,

preventing oil from back flowing into motor pump, which

prevents gravity drain out of supply line and back into

motor pump. Discharge filter removes any contaminants from oil before oil reaches any hydraulic components. This prevents reduced life expectancy of

hydraulic components such as seals and o-rings and

prevents clogging of valves and check valves.

There is a 250 BAR (3625 PSI) pressure relief valve on

each motor pump. If pressure reaches or exceeds this

pressure, valve opens dumping oil back into reservoir.

Oil is now in supply line, ready to power selected

function's cylinder(s).

Trendelenburg and Lateral Tilt

If

Trendelenburg

control was selected (in normal table orientation), motor

pump is energized and valve spool for that function

moves to an up function position (oil will now flow in

new oil flow path that has been created; this path is

shown by straight flow symbols on hydraulic schematic)

and oil flows thru a check valve (A) and into the base of

cylinder, extending cylinder. Check valve (A) prevents

oil from escaping from cylinder after valve spool is deenergized, keeping cylinder from drifting. Oil also flows

thru a pilot line (represented by a dashed line on

hydraulic schematic) and extends a pilot piston. Pilot

piston forces open check valve (B) on retracting side of

cylinder, allowing oil to escape from top side of cylinder, thru valve spool and into the oil return line.

If

Reverse Trendelenburg

hand control was selected (in normal table orientation),

motor pump is energized and valve spool for that

function moves to a down function position (oil will now

flow in new oil flow path that has been created; this path

is shown by crossed flow symbols on the hydraulic

schematic) and oil flows thru a check valve (B) and into

top of cylinder, retracting cylinder. Check valve (B)

prevents oil from escaping from cylinder after valve

spool is de-energized, keeping cylinder from drifting.

Oil also flows thru a pilot line (represented by a dashed

line on hydraulic schematic) and extends a pilot piston.

or

Lateral Tilt Left

or

button on hand

Lateral Tilt Right

button on

Page 1-5Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 12

SECTION I

GENERAL INFORMATION

Pilot piston forces open check valve (A) on base of

cylinder, allowing oil to flow from base of cylinder, thru

valve spool, and into oil return line.

Seat Functions

If

SEAT UP

normal table orientation), motor pump is energized and

valve spool for that function moves to an up function

position (oil will now flow in new oil flow path that has

been created; this path is shown by straight flow

symbols on hydraulic schematic) and oil flows thru a

check valve (A) and into base of left cylinder (master

cylinder), extending cylinder. Check valve (A) prevents

oil from escaping from cylinder after valve spool is deenergized, keeping cylinder from drifting. Oil also flows

thru two pilot lines (represented by dashed lines on

hydraulic schematic) and extends two pilot pistons (B

and D). One pilot piston forces open a check valve (B)

which allows oil to flow out of top side of left cylinder

thru another check valve (C) and into base of right

cylinder (slave cylinder), extending cylinder. Other pilot

piston forces open check valve (D) on top side of right

cylinder (slave cylinder), allowing oil to flow from top

side of cylinder, flow thru valve spool and into oil return

line.

If

SEAT DOWN

normal table orientation), motor pump is energized and

valve spool for that function moves to a down function

position (oil will now flow in new oil flow path that has

been created; this path is shown by crossed flow

symbols on hydraulic schematic) and oil flows thru a

check valve (D) and into top of right cylinder (slave

cylinder), retracting cylinder. Check valve (D) prevents

oil from escaping from right cylinder after valve spool is

de-energized, keeping cylinder from drifting. Oil also

flows thru two pilot lines (represented by dashed lines

on hydraulic schematic) and extends two pilot pistons.

One pilot piston forces open a check valve (C) which

allows oil to flow out of base of right cylinder thru

another check valve (B) and into top side of left cylinder

(master cylinder), retracting cylinder. Other pilot piston

forces open check valve (A) on base of left cylinder

(master cylinder), allowing oil to flow out of base of

cylinder, thru valve spool, and into oil return line.

Column Functions

If

TABLE UP

pump energizes and valve spool for that function moves

to an up function position (oil will now flow in new oil

flow path that has been created; this path is shown by

straight flow symbols on hydraulic schematic) and oil

flows thru a check valve (A) and into base of column

button on hand control is selected (in

button on hand control is selected (in

button on hand control is selected, motor

cylinder, extending cylinder. Check valve (A) prevents

oil from escaping from column cylinder after valve spool

is de-energized, keeping cylinder from drifting. Oil flows

out of top side of column cylinder as necessary, thru

valve spool, and into return line.

If

TABLE DOWN

motor pump energizes and valve spool for that function

moves to a down function position (oil will now flow in

new oil flow path that has been created; this path is

shown by crossed flow symbols on hydraulic schematic) and oil flows to top side of base cylinder, retracting cylinder. Oil also flows thru a pilot line (represented

by a dashed line on hydraulic schematic) and extends a

pilot piston. Pilot piston forces open check valve (A) on

base of cylinder, allowing oil to flow out of base of

cylinder, thru valve spool, and into oil return line.

Floor Lock Functions

If

ENABLE / LOCK

motor pump energizes and valve spool for main floor

lock cylinders moves to an up function position (oil will

now flow in new oil flow path that has been created; this

path is shown by straight flow symbols on hydraulic

schematic) and oil flows thru a check valve (A) and into

base of three main floor lock cylinders, extending

cylinders. Check valve (A) prevents oil from escaping

from three main floor lock cylinders after valve spool is

de-energized, keeping cylinders from drifting.

After approximately 10 seconds, main controller board

de-energizes motor pump and main floor lock spool and

then reenergizes motor pump and energizes outrigger

floor lock valve spool to an up function position (oil will

now flow in new oil flow path that has been created; this

path is shown by straight flow symbols on hydraulic

schematic) and oil flows thru two check valves (B and

C) and into the base of two outrigger floor lock cylinders, extending cylinders. As soon as pressure in

outrigger floor lock cylinders reaches 10 BARS (145

PSI), outrigger pressure relief valve opens, dumping oil

back to return line. Outrigger cylinders were designed

to add stability to table on an uneven floor.

Three main floor lock cylinders lift table off of casters;

then the two outrigger floor lock cylinders extend with

enough power to stabilize table

further.

Check valves (B and C) prevent oil from escaping from

two outrigger floor lock cylinders after valve spool is deenergized, keeping cylinders from drifting.

If

UNLOCK & ENABLE

selected for three seconds, motor pump energizes and

main floor lock valve spool moves to a down function

position (oil will now flow in new oil flow path that has

been created; this path is shown by crossed flow

button on hand control is selected,

button on hand control is selected,

without lifting

buttons on hand control is

table

Page 1-6Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 13

SECTION I

GENERAL INFORMATION

symbols on hydraulic schematic). Oil flows thru three

pilot lines (represented by dashed lines on hydraulic

schematic) and extends three pilot pistons, which

forces open three check valves; check valves A, B, and

C. With all three check valves open, oil flows out of

base of three main floor lock cylinders and two outrigger

floor lock cylinders, causing them to retract. There is a

strong spring in each floor lock cylinder which helps

retract cylinder.

Seat Slave Line Valve

On the seat functions, there is a manually operated two

way-valve (slave line valve) which is used to add or

remove oil from closed loop (slave line) to synchronize

stroke of left (master) and right (slave) cylinders.

Column Slave Line Valve

There is a manually operated two-way valve (slave line

valve) on column function, which is used to add or

remove oil from middle stage of column cylinder (if

there is too much oil in second stage, column cylinder

will "jump" downward and make a noise when column

down function is selected. If there is not enough oil in

second stage, full height potential of column cylinder

will not be reached).

Orifices

Orifices are internal to Trendelenburg, Lateral Tilt, and

Seat, cylinders to meter flow of oil into cylinders,

thereby regulating speed of cylinders.

1.4 SPECIFICATIONS

Factual data for the 7300 Modular Surgery Table is

provided in Table 1-1.

Table 1-1. Specifications

Description Data

Weight

Normal (w/ head & pelvic sections & upholstery) ...........

........................................................... 660 lb. (299 kg)

With Shipping Carton.......................... 764 lb. (347 kg)

Shipping Carton........ 58 in. "L" x 30 in. "W" x 40 in. "H"

(147 cm x 76 cm x 102 cm)

Dimensions: (w/ Head, Back, Pelvic & Leg Transfer

Board.)

Table Top Length ............................. 75.6 in. (192 cm)

Table Top Width ...................................... 20.5 (52 cm)

Overall Width......................................... 24 in. (61 cm)

Overall Length..................................... 78 in. (198 cm)

Table Positioning:

Table Top Height (Adjustable) .......... 27.7 (± 0.2) in. to

43.9 (± 0.2) in.

(70 to 112 cm)

Trendelenburg ......................................0° to 28° (±1°)

Reverse Trendelenburg....................... 0° to -28° (±1°)

Lateral Tilt................ 0° to -18° (±1°) in either direction

Seat Section .......... + 75° (±1°) to -40° (±1°) in relation

to back section

Coordinating Flex (Normal Position):

Trendelenburg ................+20° (±5°) above horizontal

Seat Section ......-40° (±5°) in relation to back section

Coordinating Reflex (Normal Position):

Trendelenburg ................. -28° (±5°) below horizontal

Seat Section ..... +60° (±5°) in relation to back section

Head Section:

Mounted on Head End...........+30° (±3°) to -30° (±3°)

Mounted on Foot End ............+30° (±3°) to -75° (±5°)

Page 1-7Printed in U.S.A.© Schaerer Mayfield USA, Inc. 2004

Page 14

SECTION I

MODEL

NUMBER

SERIAL

NUMBER

SMI

7100-001

115 VAC

2 AMP 60 HZ

TDWXXXXX

MODEL

INPUT

RATING

SERIAL NO.

GENERAL INFORMATION

Table Speed (Table in normal orientation, full battery

charge, ambient oil temp.):

Extend Column Fully .................. 16.0 to 21.0 seconds

Retract Column Fully.................. 16.0 to 21.0 seconds

Reverse Trend. to Trend. ........... 20.5 to 24.5 seconds

Trend. to Reverse Trend. ........... 16.0 to 20.0 seconds

Lat. Tilt R to Lat. Tilt L .................. 9.5 to 12.5 seconds

Lat. Tilt L to Lat. Tilt R ................ 10.0 to 13.0 seconds

Seat Down to Seat Up ................ 18.0 to 21.0 seconds

Seat Up to Seat Down ................ 18.5 to 21.5 seconds

Weight Capacity (maximum):

Normal Table Orientation ..................500 lbs. (227 kg)

Reverse Table Orientation..............400 lbs. (181.4 kg)

Head Section.........................................40 lbs. (18 kg)

Overweight Operation ................ Patient Positioning is

restricted. To learn of limita-

tions, contact the Surgical

Table Product Manager at

1-800-643-6275

Hydraulic System Oil ................ ISO Viscosity Grade 32

Premium Hydraulic Fluid

Reservoir Capacity ..................... 2.1 Quarts (2.0 Liters)

(2) Refer to the Parts List to determine the item

numbers of the parts, part numbers of the

parts, descriptions of the parts, and quantities

of parts needed and record this data (Refer to

para 6.1).

NOTE

Ask the Purchasing Department of the company that

owns the unit for this information. Otherwise, this

information may be obtained from the dealer that

sold the unit.

(3) Determine the installation date of the unit and

record this data.

Serial Number when contacting SMI

(4)Call SMI with recorded information and ask

for Technical Services Department. Use phone

number 1-800 643-6275

Please have the Model and

System Capacity ........................ 3.7 Quarts (3.5 Liters)

Battery Charging Time.............................. 8 to 12 hours

Motor Pump Pressure

Relief Valve ...............Opens At 250 BARS (3625 PSI)

Outrigger Pressure

Relief Valve ...................Opens At 10 BARS (145 PSI)

Electrical Requirements:

115 VAC Unit........................... 110 - 120 VAC, 60 HZ,

2 amp, single phase

Battery Power Output............ 24 VDC, 18 amp-hours

1.5 Parts Replacement Ordering

If a part replacement is required, order the part directly

from the factory as follows:

(1) Refer to Figure 1-2 to determine the location of

the model number and serial number of the unit

and record this data.

SMI

7100

CA7681

Figure 1-2. Model Number / Serial

Number Location

© Schaerer Mayfield USA, Inc. 2004

Page 1-8Printed in U.S.A.

Page 15

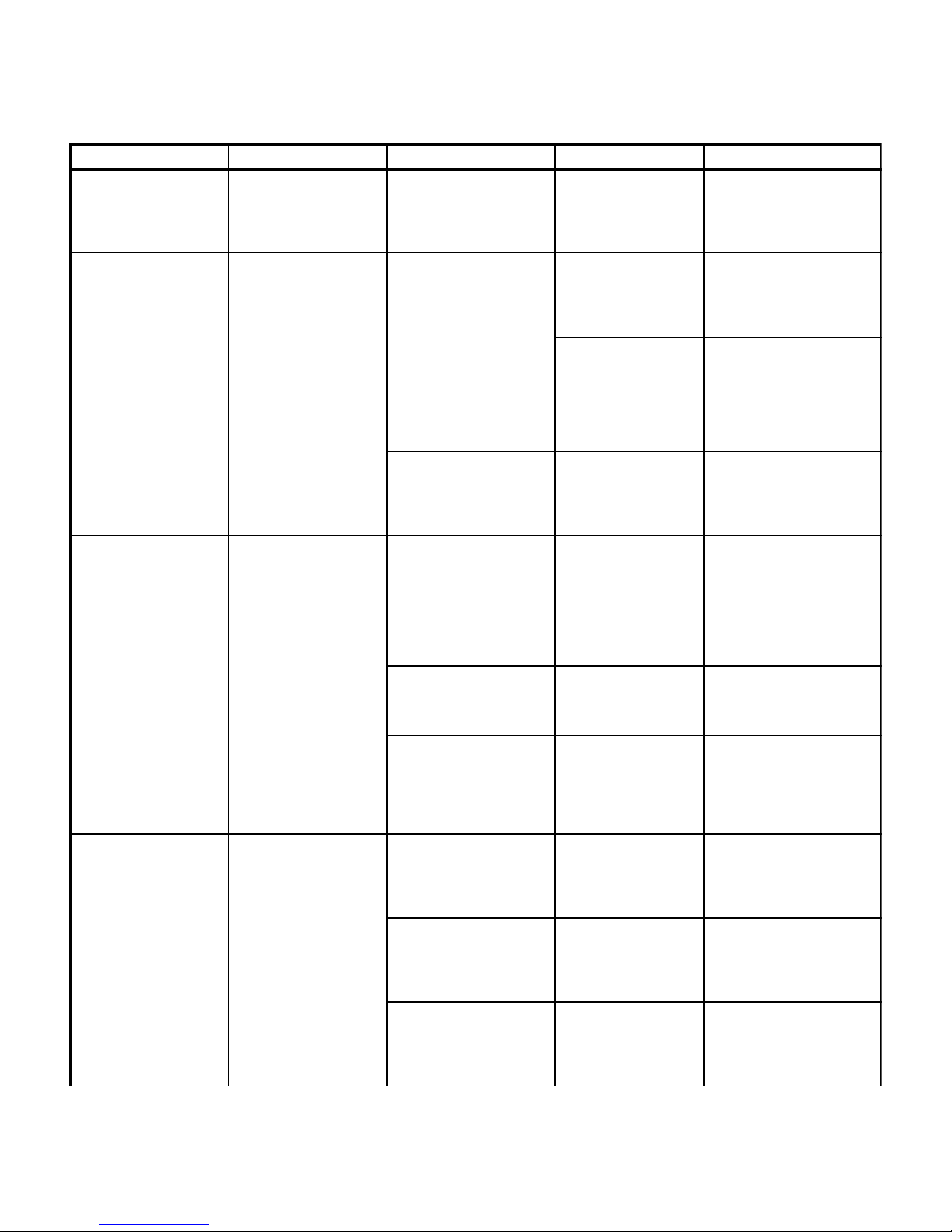

1.6 Special Tools

Table 1-2 lists all of the special tools needed to repair

the unit, how to obtain the special tools, and the purpose of each special tool.

Table 1-2 is on the following page.

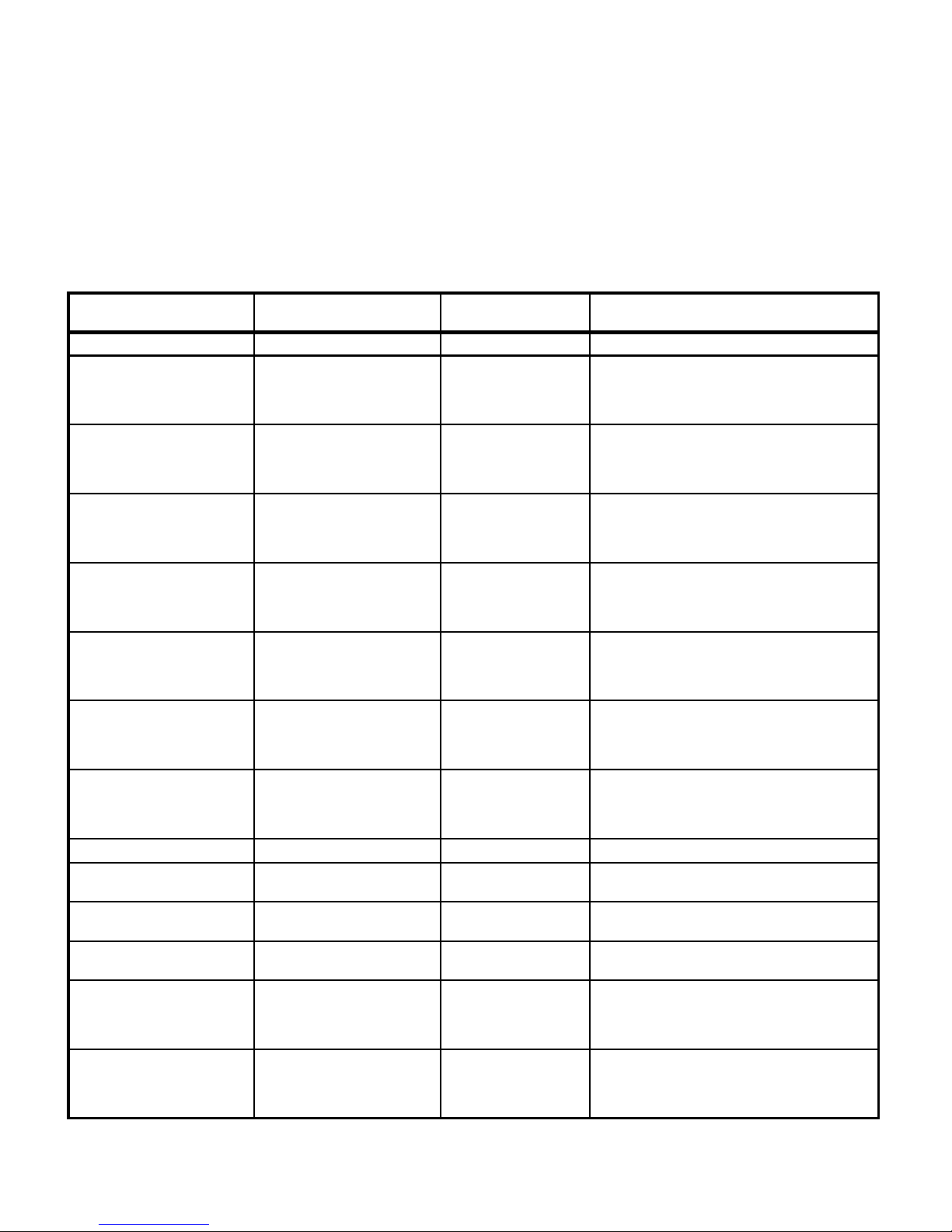

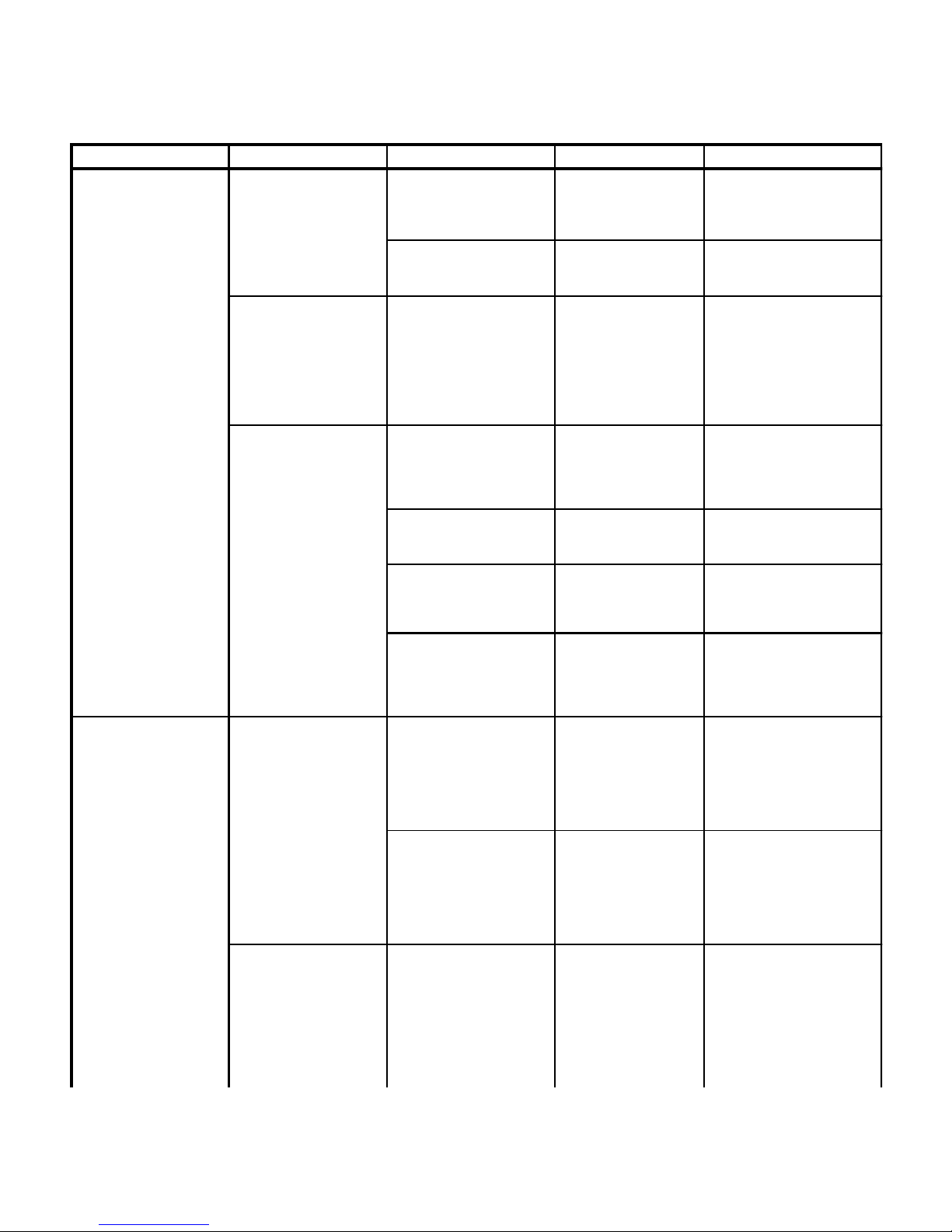

Table 1-2. Special Tools List

SECTION I

GENERAL INFORMATION

Description of Special Tool

Multimeter Commercially Available Any Type Used to perform continuity and voltage checks.

Pin Extractor (has

interchangable bits - M3x0.5,

M4x0.7, M5x0.8, M6x1.0,

1/4-20, 10-24, and 5/16-18)

Spanner Wrench - locking nut Schaerer Mayfield USA

Spanner Wrench - brass pivot

puck

Retaining Bolt Schaerer Mayfield USA

Spanner Wrench - retainer cap Schaerer Mayfield USA

Pressure Relief Valve Test

Harness

Blanking Plug Kit Schaerer Mayfield USA

Soldering Iron Commercially Available Any Type Used to connect wires to terminals with solder.

60 / 40 Solder Commercially Available Any Type Type of solder which should be used when

Internal retaining ring pliers Commercially Available Any Type Used to remove snap rings which secure bearings

Torque Wrench Commercially Available Any Type Used to tighten hardware to specified torque

Transport Tool Schaerer Mayfield USA

Tipping Tool Schaerer Mayfield USA

Manufacturer's

Name / Address / Phone

Schaerer Mayfield USA

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

Schaerer Mayfield USA

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

Schaerer Mayfield USA

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

4900 Charlemar

Drive Cincinnati, Ohio 45227

(800) 755-6381

Manufacturer's

Part Number

M05390 Used to pull pins which secure cylinders, handles,

etc. in place. Can also be used to remove caster

fork.

M07235 Used to remove locking nut which secures top of

column cylinder in column.

M07236 Used to remove brass pivot puck which secures

top of column cylinder in column.

M07407 Used to hold rod of column cylinder stationary,

while special tools, M07235 and M07236 are

used.

M07161 Used to remove retainer cap which secures

latching mechansim in place.

M07443 Used to adjust crack settings of motor pump

pressure relief valves and outrigger pressure relief

valve.

502-0176-00 Used to cap the end of hydraulic lines to allow

pressure checks to be made.

soldering wires on surgery table.

in base of cylinders.

values.

502-0169-00 A dolly type tool which is used to transport Model

7100 or 7300 surgical tables around.

502-0168-00 Used to tip over Model 7100 or 7300 surgical

tables to access base of table for servicing.

Purpose of Special Tool

© Schaerer Mayfield USA, Inc. 2004

Page 1-9Printed in U.S.A.

Page 16

SECTION I

GENERAL INFORMATION

© Schaerer Mayfield USA, Inc. 2004

Page 1-10Printed in U.S.A.

Page 17

TESTING AND TROUBLESHOOTING

SECTION II

TESTING AND TROUBLESHOO TING

SECTION II

2.1 Operational Test

In order to effectively diagnose malfunctions of the 7300

Modular Surgical Table, it may be necessary to perform

an operational test as follows:

DANGER

Refer to the Operator Manual for

complete instructions on operating the

surgical table. Failure to do so could result in

personal injury.

Power must be supplied to the unit to measure

the voltage at the Test Points. Do not touch any

bare wires or terminals while making these

voltage checks. Failure to do so may result in

electrical shock which could result in serious

personal injury or death.

NOTE

The Operational Test, for the most part, only describes what should happen when the surgical table is

operated. If the surgical table does something other

than described, a problem has been discovered.

Refer to the Troubleshooting Guide to determine the

cause of the problem and its correction.

(1 ) Plug power cord into table's plug receptacle.

See Figure 2-1, Sheets 1 and 2.

(8 ) Move the surgery table around.

(9) Observe. The casters should swivel freely and

the table should roll easily on the casters. The

table should not wobble.

(10) Press ENABLE button on hand control.

(11) Observe. The motor pump should run and the

main floor lock cylinders should extend. After

eight seconds, the motor pump should stop

running. Then the motor pump should begin

running again and the outrigger floor lock

cylinders should extend. After six seconds, the

motor pump should stop running. The hand

control display should read LOCKING FLOOR

while the floor lock cylinders are extending.

(12) Insert pins of Head Section into sockets on

column end of table. Rotate latch handles to

locked position (to move latch handles to locked

position, rotate them away from you) and then

pull and push on head sections.

(13) Observe. When the latch handles are rotated to

the locked position, the section being installed

should now be held securely in place. No side-

to-side or in-and-out movement should be

possible.

(2) Observe. The line power pilot lamp should

illuminate.

(3 ) Unplug the power cord.

(4 ) Press ENABLE button on hand control.

(5) Observe. The hand control display should

illuminate and display the current table position

and battery charge level (XX POSITION and

BATT LEVEL XX. After 10 seconds, the hand

control display should extinguish.

(6 ) Press and hold UNLOCK & ENABLE buttons on

hand control for three seconds.

(7) Observe. The motor pump should run and the

table should lower (floor lock cylinders should

retract) until table is on its casters. The hand

control display should read UNLOCKING

FLOOR and then ON WHEELS.

© Schaerer Mayfield USA, Inc. 2004

(14) Press the ENABLE and REVERSE POSITION

buttons on hand control.

(15) Observe. The hand control display should read

REVERSE POSITION.

(16) Press the FLEX button and then REFLEX

button.

(17) Observe. Hand control display should indicate

these positions are "disabled" and cannot be

used when table is in REVERSE POSITION.

(18) Press the ENABLE and NORMAL POSITION

buttons on hand control.

(19) Observe. The hand control display should read

NORMAL POSITION.

Page 2-1 Printed in U.S.A.

Page 18

SECTION II

TESTING AND TROUBLESHOOTING

C

LINE POWER

PILOT LAMP

HEAD

SECTION

HAND

CONTROL

LATCH

HANDLE

EMERGENCY

OVERRIDE

PANEL

FOOT

CONTROL

RELEASE

HANDLE

ENABLE

LOCK

LEVEL

SMI

7300

SMI

PLUG

B

DISABLE

UNLOCK

7100

SMI

7300

BACK

SECTION

RECEPTACLE

A

SEAT SECTION

(PELVIC BASE)

POWER

CORD

TRENDEL-

ENBURG

REVERSE

TRENDEL-

ENBURG

TABLE

UP

TABLE

DOWN

FLOOR

LOCK

CYLINDERS

LATERAL

TILT

LEFT

LATERAL

TILT

RIGHT

Figure 2-1. Operational Test (Sheet 1 of 2)

LOCKED

POSITION

AUTO

CAPTURE

POSITION

UNLOCKED

POSITION

LATCH HANDLE

POSITIONS

(TYP. 2 PLACES)

CA819700

© Schaerer Mayfield USA, Inc. 2004

Page 2-2Printed in U.S.A.

Page 19

SECTION II

TESTING AND TROUBLESHOOTING

BUTTONS

SMI

DISABLE

LATERAL

TILT LEFT

SYSTEM

OVERRIDE

SYSTEM

OVERRIDE

7300

DISABLE

TABLE

DOWN

TABLE

UP

TRENDELENBURG

REVERSE

TRENDELENBURG

UNLOCKLOCK

SEAT

UP

SEAT

DOWN

HAND

CONTROL

DISPLAY

ENABLE

NORMAL

POSITION

TRENDELENBURG

TABLE

UP

LATERAL

TILT LEFT

SEAT

UP

FLEX

ENABLE

LOCK

DISABLE

NORMAL

REVERSE

POSITION

TREND

POSITION

REV TREND

HEIGHT UP

HEIGHT DOWN

TILT L

TILT R

SEAT UP SEAT DOWN

FLEX

UNLOCKLEVEL

SMI

LEVEL

(RETURN TO)

DISABLE

REVERSE

POSITION

REVERSE

TRENDELENBURG

TABLE

DOWN

LATERAL

REFLEX

TILT RIGHT

SEAT

DOWN

7300

REFLEX

UNLOCK

LATERAL

TILT RIGHT

LEVEL

UNLOCK

(RETURN TO)

Figure 2-1. Operational Test (Sheet 2 of 2)

(20) Press the ENABLE button and then press the

TABLE UP, TABLE DOWN,

TRENDELENBURG, REVERSE

TRENDELENBURG, LATERAL TILT LEFT,

LATERAL TILT RIGHT, SEAT UP, SEAT

DOWN, FLEX, and REFLEX buttons, running

each function thru its full range of motion, and

checking its speed and range of motion performance.

(21) Observe. The table performance should meet

the following specifications:

Range Of Motion:

Table Top Height (Adjustable) ........... 27.7 (± 0.2) in. to

43.9 (± 0.2) in.

(70 to 112 cm)

Trendelenburg ....................................... 0° to 28° (±1°)

Reverse Trendelenburg ......................... 0° to -28° (±1°)

Lateral Tilt................. 0° to -18° (±1°) in either direction

CA819800

Seat Section ........... + 25° (±1°) to -40° (±1°) in relation

to back section

Coordinating Flex (Normal Position):

Trendelenburg .................. +20° (±5°) above horizontal

Coordinating Reflex (Normal Position):

Trendelenburg ................... -12° (±5°) below horizontal

Table Speed (Table in normal orientation, full battery

charge, ambient oil temp.):

Extend Column Fully................... 16.0 to 21.0 seconds

Retract Column Fully .................. 16.0 to 21.0 seconds

Reverse Trend. to Trend. ............ 20.5 to 24.5 seconds

Trend. to Reverse Trend. ............ 16.0 to 20.0 seconds

Lat. Tilt R to Lat. Tilt L .................. 9.5 to 12.5 seconds

Lat. Tilt L to Lat. Tilt R ................ 10.0 to 13.0 seconds

Seat Down to Seat Up ................ 18.0 to 21.0 seconds

Seat Up to Seat Down ................ 18.5 to 21.5 seconds

© Schaerer Mayfield USA, Inc. 2004

Page 2-3Printed in U.S.A.

Page 20

SECTION II

TESTING AND TROUBLESHOOTING

(22) Press the ENABLE button and then press the

LEVEL button until the table reaches its level

position. Using a protractor, check the table top

to ensure it is level within ±2°.

(23) Observe. The table top should move to a level

position within ±2° as follows: The lateral tilt

function should level out first; then a sequence

of the Seat, and Trendelenburg functions should

move, with each function moving no more than

10° at a time.

(24) Squeeze the release handle on the head section

and move the head section thru its full range of

motion.

(25) The head section should move smoothly and

should not take excessive force. The head

section should meet the following range of

motion specifications:

Head Section:

Mounted on Head End ........... +30° (±3°) to -30° (±3°)

Mounted on Foot End ............ +30° (±3°) to -75° (±5°)

(26) Move head section to level position and then

place approximately 40 lbs. (18 kgs) at Point C

(head section). Observe head section for two to

three minutes.

(27) Observe. The head section should not drift.

(28) Place approximately 400 lbs. (181.4 kg) of

weight on table top as follows: 28 lbs. (12.7 kg)

at Point C (head section), 152 lbs. (69 kg) at

Point B (back section), and 168 lbs. (76.2 kg) at

Point A (seat section).

(33) Observe. Each function should move as

depicted by the illustration on its button.

(34) Press each function button on the foot control.

Then place the table top in REVERSE position.

Then press each function button on the foot

control again.

(35) Each function should move as depicted when

table top is in NORMAL position. The table

should not operate, using the foot control, when

the table top is in REVERSE position.

(36) Plug power cord into table's power receptacle.

DANGER

Electrical power must be connected to

perform the following steps. Do not

touch any bare wires or terminals. Failure to do

so could cause an electrical shock which could

result in serious personal injury or death.

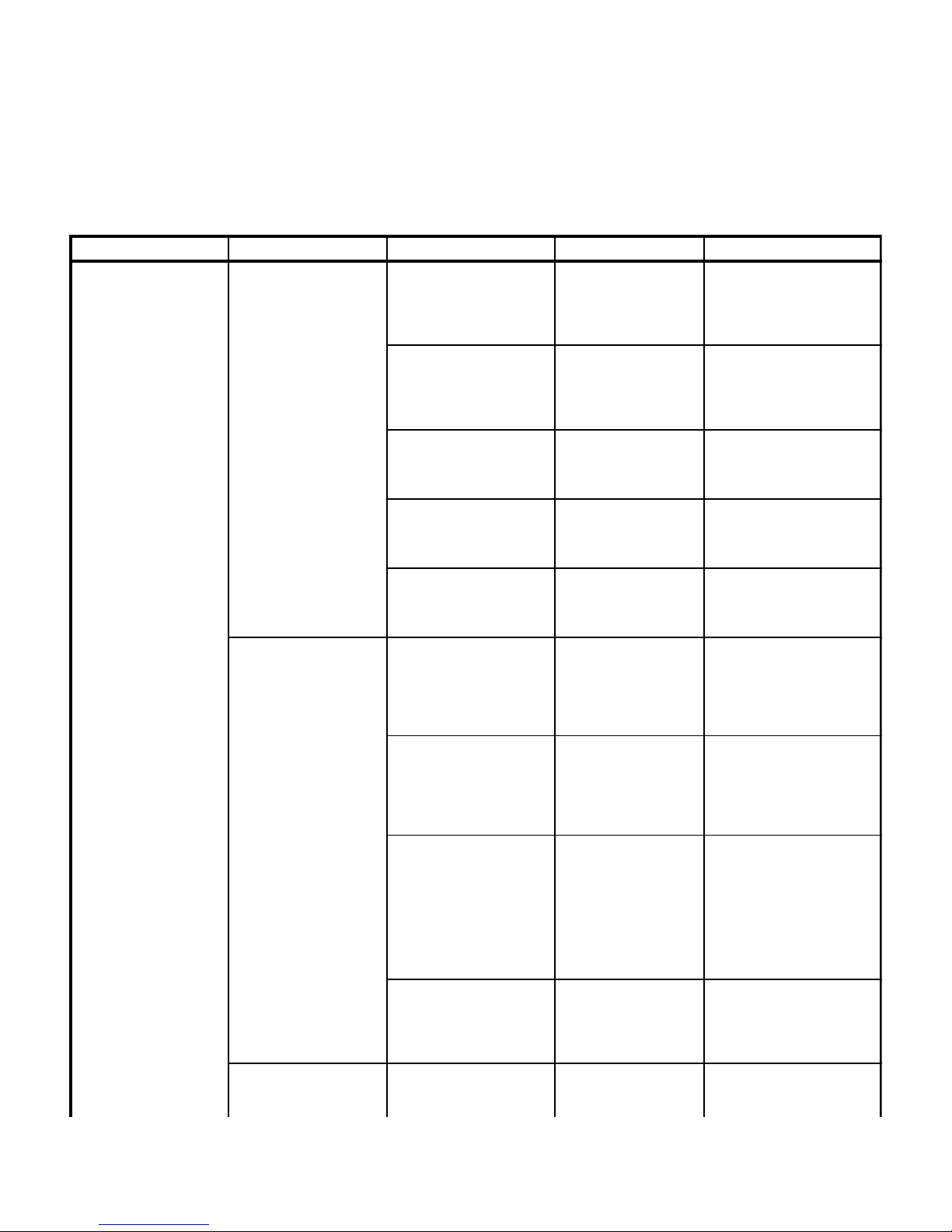

(37) See Figure 2-2 for this step. Check for 32.5

VAC ± 2 VAC across Test Points C and D and

across Test Points D and E.

(38) Observe. There should be 32.5 VAC ±2 VAC

across

(39) See Figure 2-2 for this step. Check for 27.7

VAC ± 2 VAC across Test Points F and G and

across Test Points H and J. Check for 27.8

VAC ±2 VAC across Test Points K and L.

(40) Observe. The proper voltages should be

present across

both

sets of test points.

each

set of test points.

(29) Press ENABLE button and then press TABLE

UP and TABLE DOWN buttons to run column

function up and down several times.

(30) Observe. Column function should move up and

down steadily and smoothly. No binding

condition should be evident, especially when

column is lowering. There should be no exces-

sive side-to-side play in column assembly.

(31) Remove weight from table top.

(32) Press and hold the SYSTEM OVERRIDE button

while pressing the function buttons, one at a

time, on the emergency override panel.

© Schaerer Mayfield USA, Inc. 2004

Page 2-4Printed in U.S.A.

Page 21

SECTION II

TESTING AND TROUBLESHOOTING

POWER CORD

RECEPTACLE

5 amp.

FUSE

L

115

N

VAC

5 amp.

FUSE

Note

Wire colors may change

without notification

ST5b

3

1

11

9

15

5

7

8

6

10

2

12

141316

4

RED

RED

RED

RED

RED

BLACK

BLACK

BROWN

BLUE

BLACK

BLACK

BLACK

BLACK

WHITE

VIOLET

GREEN

YELLOW

ORANGE

RED

4

5

FOOT

CONTROL

6

PORT

1

NOTE: FOOT AND HAND CONTROL

PLUGS ARE POSITIONED TO VIEW

TERMINAL (BACK) END.

5

6

HAND

CONTROL

7

PORT

1

2

GREEN

3

2

4

3

= DENOTES "TEST POINTS"

!!

LINE POWER

PILOT LAMP

A

BROWN

BROWN

RFI

FILTER

BLUE

YELLOW / GREEN

YELLOW / GREEN

ST6

12

GREY / PINK

GREY / WHITE

BROWN / GREY

WHITE / GREEN

BROWN / GREEN

YELLOW / WHITE

BROWN / YELLOW

BLUE

GREEN

YELLOW

RED

BROWN

GREY

GREY

BLUE

GREEN

WHITE

YELLOW

RED

BROWN

9111413161518172019

10

RED / BLUE

B

7

8

WHITE

BLUE

YELLOW / GREEN

3

5

6

4

GREY

VIOLET

WHITE

YELLOW

1

2

BLUE

M

N.C.

80° c

(176° F)

FUSE

OUTRIGGER

FLOOR LOCK

STATUS SWITCH

BLACK

2

WHITE

GREY

WHITE

N

100° c

MOTOR

(212° F)

PUMP

SECONDARY

L2

#2

THERMAL

RED

1

BROWN

N.O.

N.O.

N.C.C.

(SWITCHES

SHOWN IN

UNTRIPPED

POSITION)

BROWN

FUSE

MAIN FLOOR

LOCK STATUS

SWITCH

BLACK

2

WHITE

Q

RED

1

BROWN

N.C.

P2

80° c

(176° F)

L1

PRIMARY

THERMAL

FUSE

N.O.

N.C.C.

4

BROWN

X

ST3

W

8

6

10

12

7

9 11

PINK

WHITE

GREEN

YELLOW

RED / BLUE

GREY / PINK

RED

R

2

1 3 5

BLUE

GREY

VIOLET

BLACK

P

ST10

8

10 12 14

6

4

2

7

1 3 5

13

9

11

RED

PINK

BLUE

BLACK

BROWN

VIOLET

GREEN

YELLOW

RED / BLUE

GREY / PINK

WHITE / GREEN

BROWN / GREEN

RED

PINK

BLUE

GREY

RED / BLUE

BLACK

GREEN

VIOLET

BROWN

YELLOW

GREY / PINK

3

911

5

7

1

2

12

10

6

8

4

St23

WHITE

K

ST3a

ST2a

TRANSFORMER

THERMAL

FUSE

BLACK

RED

THERMAL

FUSE

YELLOW

BLACK

RED

2

2

ST1

ST1

3

3

4

4

ST8

(P2)

1

1

CHARGING / POWER

ST8

BLACK

RED

BLACK

C5

ST3a

(BATT. -)

C

D

E

9

10

V

DRIVER BOARD

T

9

10

RED

YELLOW

BLUE

BLACK

BROWN

2

1 3 5

7

8

7

8

WHITE

VIOLET

4

S

ST5a

ST5a

ST2a

(BATT. +)

5

6

5

6

GREY

GREY

6

3

4

3

4

VIOLET

WHITE

8

7

ST2b

2

3

1

9111413161518172019

5

7

1 3 5

8

6

10

2

4

MAIN CONTROLLER BOARD

1

2

3

WHITE

GREEN

BROWN

2

4

2

1

3

4

St35

BLACK

GREEN

BROWN

YELLOW

GREEN

BROWN

YELLOW

H

10 amp.

FUSE

1

1

St1

2 2

RED

PINK

BROWN

YELLOW

RED

RED

2

1

3

4

BLUE

St37

5

6

7

8

GREY

RED

2

1

3

4

BLUE

St36

5

6

WHITE

7

8

GREY

J

SEAT POSITION

YELLOW

SENSOR

16

14 13

12

10

8

6

4

2

RED

12

ST6

St1

St4

15

11

9

7

St5b

5

3

1

LATERAL TILT

POSITION SENSOR

GREEN

2

1

1

3

3

4

5

6

St33

St32

U

ST7a

4

(PUMPS +)

1

2

1

2

BLUE

RED

10

9

6

ST2b

ST9 a & b

ST7

(P1)

BLACK

YELLOW

8

7

WHITE

FUSE

40 amp.

ST4

2

1

BLACK

BROWN

10

9

GREEN

BROWN

L

- +- +- +-

+

BATTERY BATTERY BATTERY BATTERY

ST9a

RED

ST9b

RED

F

2

1

G

RED

GREY

WHITE

BLACK

BROWN

8

6

4

2

7

1 3 5

ST7

8

6

4

2

7

1 3 5

ST7

TRENDELENBURG

POSITION SENSOR

2

3

100° c

MOTOR

(212° F)

PUMP

SECONDARY

L2

#1

THERMAL

N.O.

ST4

FUSE

PI

L1

PRIMARY

THERMAL

WHITE

BLACK

BLACK

GREEN

10

9

10

9

YELLOW

8

10

6

4

2

12

7

9 11

1 3 5

ST3

ON ON

12

8

10 12 14

6

4

2

7

1 3 5

13

9

11

ST10

1

Figure 2-2. Voltage Checks

© Schaerer Mayfield USA, Inc. 2004

CA819900

Page 2-5Printed in U.S.A.

Page 22

SECTION II

TESTING AND TROUBLESHOOTING

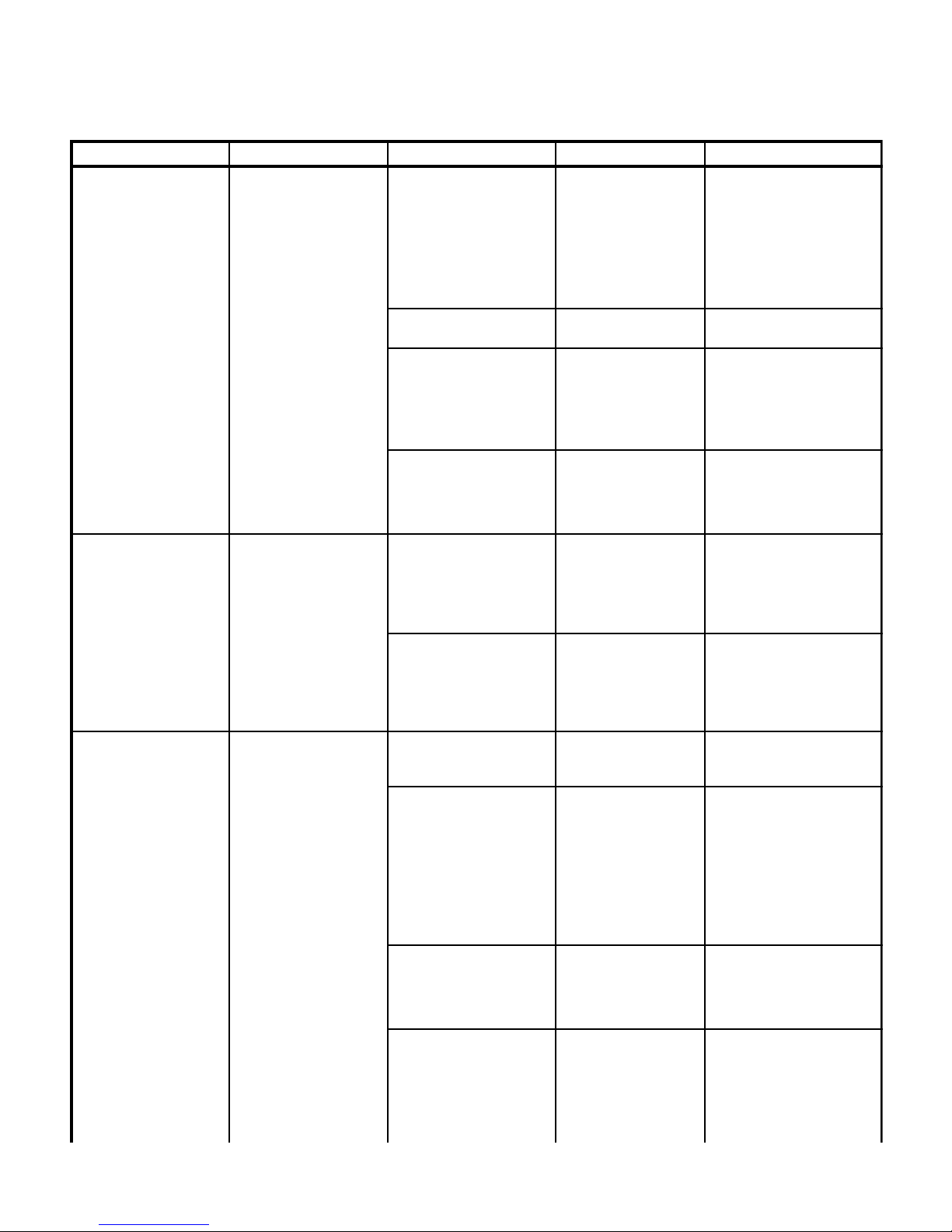

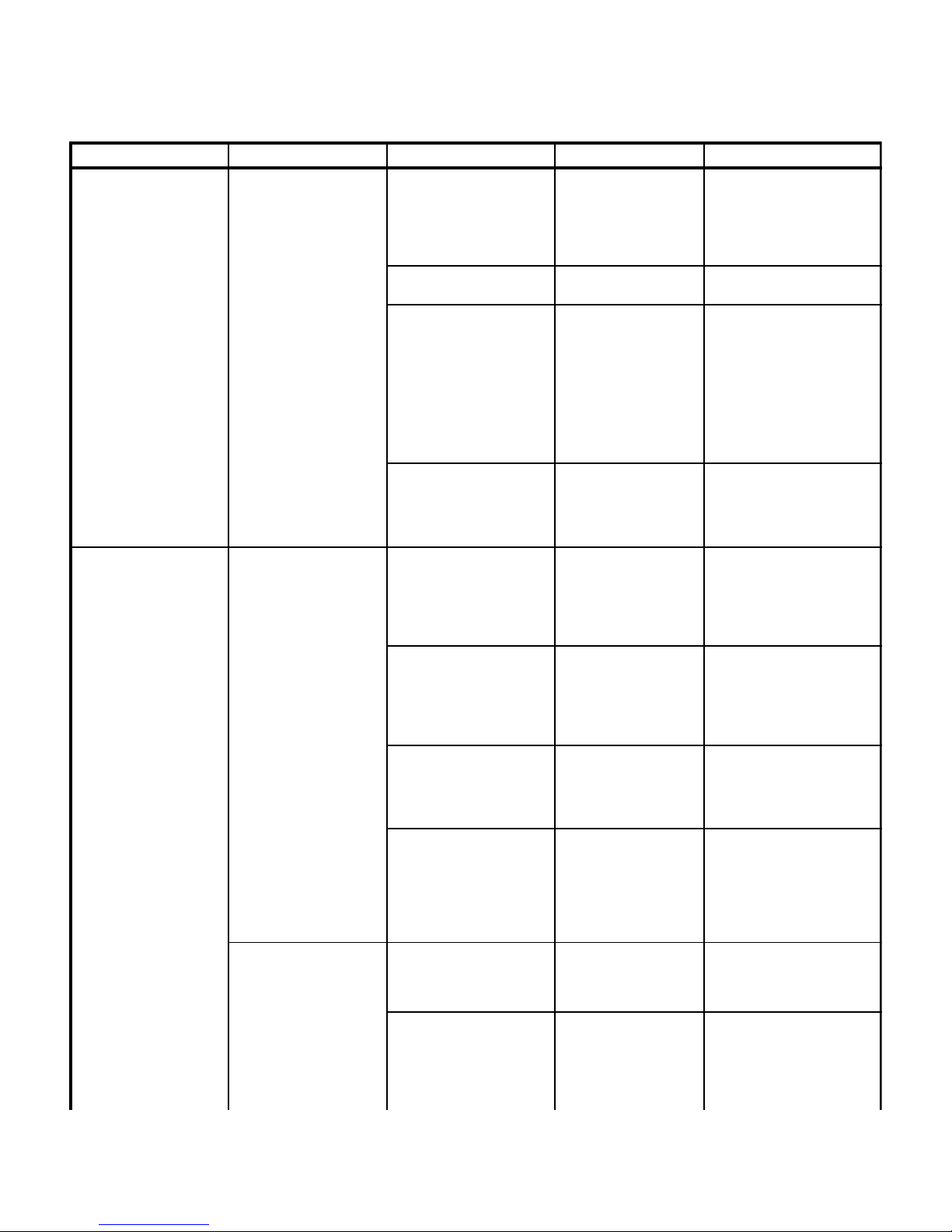

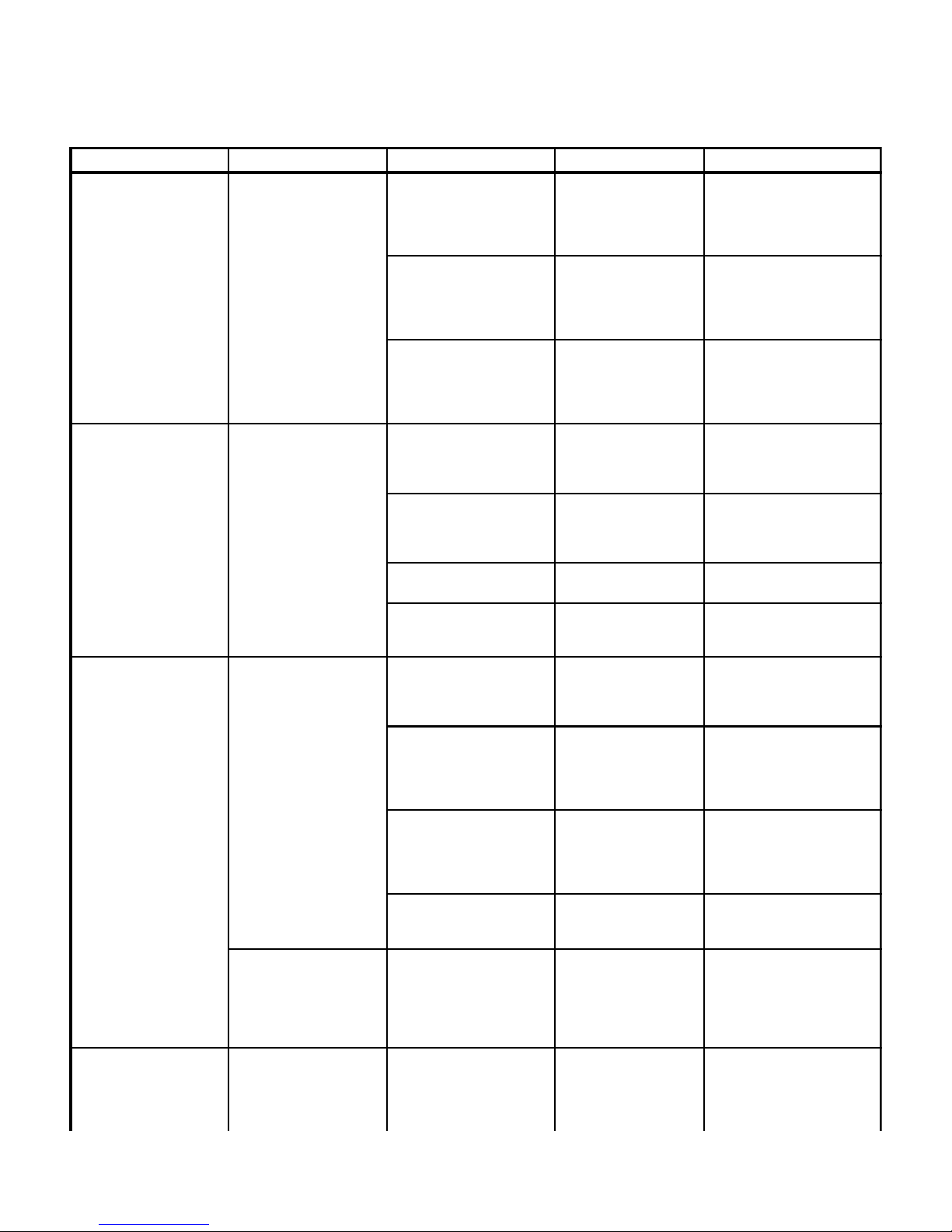

2.2 Troubleshooting Procedures

Table 2-1 is a Troubleshooting Guide which is used to

determine the cause of the malfunction.

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

Table seems powerless

even when plugged into a

wall outlet.

Line Power Pilot Lamp

does not illuminate (with

power cord plugged in).

Line Power Pilot Lamp

illuminates, but batteries

do not recharge and table

is powerless (with power

cord plugged in).

Line Power Pilot Lamp

illuminates, but table is

powerless.

Facility circuit breaker

providing power to table is

tripped.

One of two 5 amp fuses in

the power cord receptacle is

blown.

RFI filter is blown. See Figure 5-1 for this

Line power pilot lamp is

burned out.

Wires or wire connections

between power cord

receptacle and transformer

are broken, loose or dirty.

Thermal fuse(s) in

transformer are blown.

Transformer is blown. See Figure 5-1 for this

Charging / power driver

board is malfunctioning.

Wires or wire connections

between transformer and

charging / power driver

board are broken, loose, or

dirty.

10 amp fuse on main

controller board is blown.

Check to see if facility

circuit breaker is tripped.

Remove both 5 amp

fuses from power cord

receptacle and perform a

continuity check on the

fuses.

check. Check for 115

VAC ± 5.0 VAC across

Test Points A and B.

Replace suspect line

power pilot lamp with

known working line

power pilot lamp.

Perform a continuity

check on all suspect

wires or connections.

See Figure 5-1 for this

check. Check for 32.5 ±

2.0 VAC across Test

Points C and D and

across Test Points D

and E.

check. Check for 32.5 ±

2.0 VAC across Test

Points C and D and

across Test Points D

and E.

See Figure 5-1 for this

check. Check for 27.7

+/- 0.3 VDC across Test

Points F and G. Check

for 27.7 +/- 0.3 VDC

across Test Points H and

J. Check for 27.8 +/- 0.3

VDC across Test Points

K and L.

Perform a continuity

check on all suspect

wires or connections.

Perform continuity check

on 10 amp fuse.

If circuit breaker is tripped,

determine what caused the

circuit breaker to trip, correct

the problem, and then reset /

replace circuit breaker.

Replace any blown 5 amp

fuses.

If 115 VAC ± 5.0 VAC is not

present across Test Points A

and B, replace RFI filter.

Refer to para 4.35.

Replace line power pilot lamp.

Refer to para 4.37.

Clean any dirty connections.

Tighten any loose

connections. Replace any

broken connectors or wires.

If 32.5 VAC ± 2.0 VAC is not

present across one or both of

the Test Point groups, replace

the transformer. Refer to

para 4.36.

If 32.5 VAC ± 2.0 VAC is not

present across one or both of

the Test Point groups, replace

the transformer. Refer to

para 4.36.

If proper voltage is not

present at Test Points,

replace charging / power

driver board. Refer to para

4.38.

Clean any dirty connections.

Tighten any loose

connections. Replace any

broken connectors or wires.

Replace 10 amp fuse. See

Figure 5-1 for fuse location.

© Schaerer Mayfield USA, Inc. 2004

Page 2-6Printed in U.S.A.

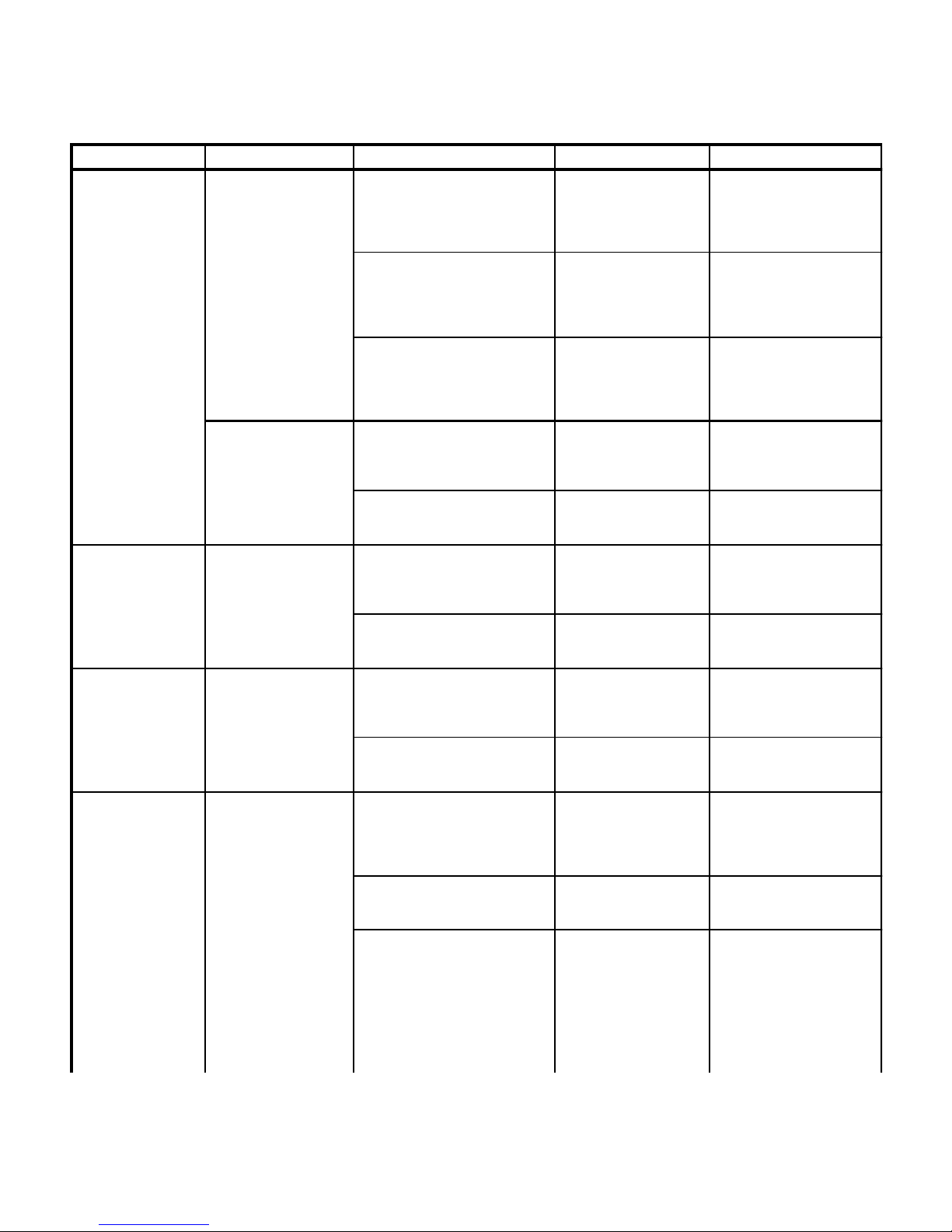

Page 23

Problem Symptom Probable Cause Check Correction

Table operates when

power cord is plugged in,

but will not operate when

power cord is unplugged.

Table 2-1. Troubleshooting Guide

When ENABLE button on

hand control is pressed, its

display does not illuminate

(with power cord

unplugged).

TESTING AND TROUBLESHOOTING

40 amp fuse on charging /

power driver board is blown.

10 amp fuse on main

controller board is blown.

Batteries are dead and are

not supplying charging /

power driver board with

enough power to operate.

See Figure 5-1 for this

check. Check fuse

visually or perform

continuity check on fuse

(may need to check

secondary thermal fuse

of motor pump. If blown,

thermal fuse will cause

40 amp fuse to blow).

Perform continuity check

on 10 amp fuse.

See Figure 5-1 for this

check. Check individual

batteries by checking for

13.2 +/- 0.4 VDC across

terminals of each battery

(Test Points M and N).

SECTION II

Replace 40 amp fuse. See

Figure 5-1 for fuse location.

Replace 10 amp fuse. See

Figure 5-1 for fuse location.

If 13.2 +/- 0.4 VDC is not

present across Test Points,

replace batteries. Refer to

para 4.39.

Batteries do not recharge

in 6 to 8 hours from low

charge.

Hand control does not

work.

Batteries do not recharge

very quickly.

When ENABLE button on

hand control is pressed, its

display does not illuminate.

Charging / power driver

board is malfunctioning.

One of thermal fuses in

transformer is blown.

Batteries are dead. See Figure 5-1 for this

10 amp fuse on main

controller board is blown.

Main controller board or

hand control board is

malfunctioning.

Wires or wire connections

between main controller

board, distribution board,

and hand control port are

broken, loose or dirty.

Motor pump secondary

thermostat is closed creating

a direct short to ground,

causing 40 amp fuse on

charging / power driver

board to blow.

See Figure 5-1 for this

check. Check for 27.7

+/- 0.3 VDC across Test

Points F and G.

See Figure 5-1 for this

check. Check for 32.5

+/- 2.0 VAC across Test

Points C and D, and

across Test Points D

and E.

check. Check individual

batteries by checking for

13.2 +/- 0.4 VDC across

terminals of each battery

(Test Points M and N).

Perform continuity check

on 10 amp fuse.

See Figure 5-1 for this

check. Check for 5.0

VDC across Test Points

P and Q. If 5 VDC is

present, check for 5.0

VDC across Test Points

Q and R within 10

seconds of pressing

ENABLE button on hand

control.

See Figure 5-1 for this

check. Perform a

continuity check on all

suspect wires or

connections.

See Figure 5-1 for this

check. Check for a

resistance value of 0

ohms between Test

Points S and T for motor

# 1 or Test Points U and

V for motor # 2.

If proper voltage is not

present at Test Points,

replace charging / power

driver board. Refer to

para 4.32.

If 32.5 +/- 2.0 VAC is not

present across one or both of

the Test Point groups, replace

the transformer. Refer to

para 4.36.

If 13.2 +/- 0.4 VDC is not

present across Test Points,

replace batteries. Refer to

para 4.39.

Replace 10 amp fuse. See

Figure 5-1 for fuse location.

If 5.0 VDC is not present

across Test Points P and Q,

the main controller board is

malfunctioning. If 5.0 VDC is

not present across Test Points

Q and R during check, then

main controller board or hand

control board is

malfunctioning. Refer to para

4.31 or 4.5.

Clean any dirty connections.

Tighten any loose

connections. Replace any

broken connectors or wires.

Replace malfunctioning motor,

secondary thermostat, and 40

amp fuse. Refer to para 4.26

and 4.41.

© Schaerer Mayfield USA, Inc. 2004

Page 2-7Printed in U.S.A.

Page 24

SECTION II

TESTING AND TROUBLESHOOTING

Table 2-1. Troubleshooting Guide

Problem Symptom Probable Cause Check Correction

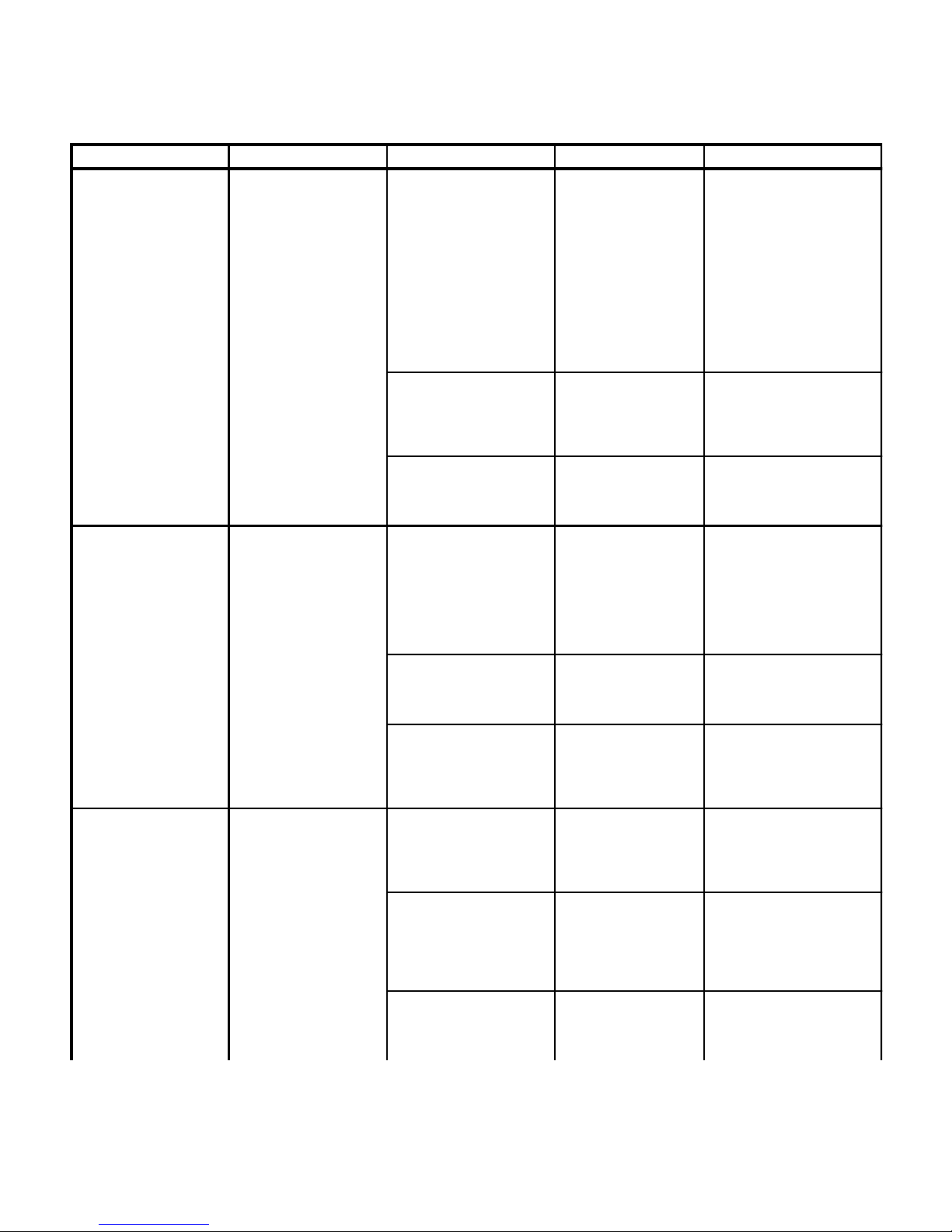

Hand control does not

work - Continued.

When ENABLE button on

hand control is pressed, its

display does not illuminate

- Continued.

Display of hand control

board is malfunctioning.

Replace suspect hand

control board with known

working hand control

board.

Replace hand control board.

Refer to para 4.5.

Foot control does not

work.

When a button on hand

control is pressed, error

code E15 displays.

When a function button on

hand control is pressed,

the motor pump does not

run and no error codes

display.

Foot control operates fine

sometimes, but not every

time.

When foot switch on foot

control is pressed, nothing

happens (hand control

display should illuminate

when foot switch is

depressed).

Button board is

malfunctioning.

Button board is

malfunctioning. One of two

button switches for a

function is stuck in closed

position or will not close.

Hand control board is

malfunctioning.

Button board is

malfunctioning.

Main controller board is

malfunctioning.

Wires or wire connections

between main controller

board, distribution board,

and hand control port are

broken, loose or dirty.

Table is in reverse

orientation.

The hand control or

emergency override panel is

being used (hand control

and / or emergency override

panel takes priority over foot

control).

One of two foot switches for

a function is stuck in closed

position or will not close.

Replace suspect button

board with known

working button board.

Perform a continuity

check on both button

switches of suspect

function (when a button

switch is pressed, there

should be continuity

between its two

terminals).

Replace suspect hand

control board with known

working hand control

board.

Replace suspect button

board with known

working button board.

Replace suspect main

controller board with

known working main

controller board.

See Figure 5-1 for this

check. Perform a

continuity check on all

suspect wires or

connections.

Foot control is locked out

from being used when

table top is in reverse

orientation - foot control

may only be used when

table top is in normal

orientation.

Check if problem occurrs

only when hand control

or emergency override

panel is being used.

See Figure 5-1 for this

check. Perform a

continuity check on both

foot switches of suspect

function (when foot

switch is pressed, there

should be continuity

between its two

terminals).

Replace button board. Refer

to para 4.4.

If check fails, replace button

board. Refer to para 4.4.

Replace hand control board.

Refer to para 4.5.

Replace button board. Refer

to para 4.4.

Replace main controller

board. Refer to para 4.31.

Clean any dirty connections.

Tighten any loose

connections. Replace any

broken connectors or wires.

Use hand control or set up

table top in normal orientation.

Inform operator that Foot

Control cannot be used when

table is in reverse orientation.

Do not use foot control

simultaneously with hand

control or emergency override

panel. Inform operator of

Emergency Override Panel,

Hand Control, and Foot

Control priorities.

If check fails, replace foot

switch pad.

© Schaerer Mayfield USA, Inc. 2004

Page 2-8Printed in U.S.A.

Page 25

Problem Symptom Probable Cause Check Correction