Page 1

HT200e

Direct Thermal Printer

OPERATOR MANUAL

PN 9001103B

Page 2

SATO America, Inc.

10350A Nations Ford Road

Charlotte, NC 28273

Main Phone: (704) 644-1650

Technical Support Hotline: (704) 644-1660

Technical Support Fax: (704) 644-1661

E-Mail: satosales@satoamerica.com

www.satoamerica.com

© Copyright 2003

SATO America, Inc.

All rights reserved. No part of this document may be reproduced or issued to third parties in any form

whatsoever without the express permission of SATO America, Inc. The materials in this document is

provided for general information and is subject to change without notice. SATO America, Inc. assumes no

responsibilities for any errors that may appear.

Warning: This equipment complies with the requirements in Part 15 of FCC rules for a Class B computing

device. Operation of this equipment in a residential area may cause unacceptable interference to radio

and TV reception requiring the operator to take whatever steps are necessary to correct the interference.

Page 3

TABLE OF CONTENTS

INTRODUCTION

About This Manual 1-2

General Description 1-3

Primary Components 1-3

Connection Ports 1-3

Control Features 1-5

Keypad Buttons 1-5

TECHNICAL DATA

Physical Characteristics 2-2

Power 2-2

Processing 2-2

Enviromental 2-2

Print 2-2

Media 2-3

Sensing 2-3

Interface Modules 2-3

Character Font Capabilities 2-3

Charcater Control 2-3

Symbologies 2-4

Other Features 2-4

Accessories 2-4

Regulatory Approvals 2-4

INSTALLATION

Unpacking & Parts Identification 3-2

Printer Installation 3-3

Site Location 3-3

Media Selection 3-3

Media Loading 3-3

Interface Selection 3-5

RS232 Serial Interface Specifications 3-5

RS232 Interface Signals 3-5

RS232 Cable Requirements 3-5

Accessories Installation 3-6

Battery Power Module 3-6

PCMCIA Memory Card 3-7

Scanner Connection 3-7

PN 9001103B

Page 4

OPERATION

Printer Configuration

Entering Alphanumerics & Symbols 4-2

Initial Setup Mode 4-3

User Mode 4-4

Data Maintenance Mode 4-5

Copy Print Parameters Mode 4-6

Send/Receive Preset Data Mode 4-7

Copy Preset Data Mode 4-8

Copy Font Mode 4-9

Copy Table Data Mode 4-10

Copy All Parameters Mode 4-11

Country Code Mode 4-12

Memory Card Clear Mode 4-13

Select Currency Mode 4-14

Fixed Formats 4-15

PLU Barcodes 4-15

Non PLU Bracodes 4-15

Price Reductions 4-17

Simple Data and Price 4-18

VAT Calculation 4-18

Shelf Edge Label 4-18

Unit Pricing 4-19

Euro Pricing 4-19

Customizing Label Formats 4-20

Configuration Breakdown 4-20

Programming Process 4-21

Beginning A Customized Label 4-22

Normal Field Configuration 4-23

Table Field Configuration 4-25

Sequential Number Field Configuration 4-27

Price Field Configuration 4-29

Calendar Field Configuration 4-31

Barcode Field Configuration 4-33

Copy Configuration 4-35

Print Quantity Configuration 4-36

Discount Rate Configuration 4-37

Tax Rate Configuration 4-38

Operational Modes 4-39

Online Mode 4-39

Table Data Mode 4-40

Preset Data Mode 4-41

Preset Data Storage 4-42

Suspending A Print Job 4-43

Reprinting A Label 4-44

Data Entry Edit 4-45

Operational Adjustments 4-46

Eye-Mark Adjustment 4-46

Dispenser Sensor Adjustment 4-47

Pitch Adjustment 4-48

Dispense Stop Position 4-49

LCD Brightness Adjustment 4-49

PN 9001103B

Page 5

TROUBLESHOOTING

LCD Error Signals 5-2

Troubleshooting Table 5-3

RS232 Serial Interface Troubleshooting 5-4

Hex Dump Printing 5-5

ASCII Dump Mode 5-6

Check Online Connection 5-7

Check Scanner Operation 5-8

Test Module Usage 5-9

Test Module Dial 5-10

MAINTENANCE

Cleaning Procedures 6-2

Replacement Procedures 6-3

Print Head 6-3

Power Switch 6-4

Memory Backup Battery 6-4

Adjustment Procedures 6-5

Print Head Alignment 6-5

Print Head Balance 6-5

Belt Tension 6-6

Eye-Mark Sensor 6-7

Dispenser Sensor 6-8

Pitch 6-9

Dispenser Stop Position 6-10

LCD Brightness 6-10

Service Modes 6-11

Service Mode 6-11

Hex Dump Mode 6-12

ASCII Dump Mode 6-13

Print Head & Life Counter Clear 6-14

Test Print Mode 6-15

SRAM Clear Mode 6-16

PN 9001103B

Page 6

PN 9001103B

Page 7

INTRODUCTION

• About This Manual

• General Description

• Primary Components

• Control Features

SATO HT200e Operator Manual PN 9001103B Page 1-1

Page 8

Unit 1: Introduction

ABOUT THIS MANUAL

This manual is laid out consistent with the product discussed and provides all of the information

required for general printer installation, configuration, troubleshooting, and maintenance. For

specialized programming, refer to the Programming Manual provided with the product.

Step-by-step maintenance instructions are provided with typical problems and solutions. Become

familiar with each section before installing and maintaining the printer.

This manual also incorporates the use of special information boxes. Examples of these boxes

and the type of information provided in each, are below.

WARNING: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN PRESONAL INJURY.

CAUTION: PROVIDES INFORMATION THAT, IF UNHEEDED, MAY

RESULT IN EQUIPMENT DAMAGE.

NOTE: Provides helpful hints to assist in performing the tasks at hand.

LCD DISPLAY: Provides the specific display that should be visible on

the LCD at that point.

A comprehensive Table Of Contents provided at the front of this manual facilitates rapid

movement within. The contents identify the different Units, Chapters, and Sections. Each

references the page number of their commencement.

The pages of this manual have embedded headers and footers to assist the user in identifying

his or her exact position within the manual. The header provides the section number followed by

its name. The footer identifies the product on the left, the manual’s part number in the center, and

the page number to the right side of the page.

Page enumeration is two-part with each separated by a hyphen. The first character set

references the Unit and the second identifies the page number. Page numbers begin with the

numeral (1) one at the commencement of a new unit and ascends sequentially.

SATO HT200e Operator Manual PN 9001103B Page 1-2

Page 9

Unit 1: Introduction

GENERAL DESCRIPTION

The HT200e is a small, compact printer designed specifically for point-of-usage labeling

applications. It can be used as a stand alone printer with predefined formats or connected to a

PC using an RS232C communications for variable labeling applications.

Figure 1-1a, Primary Components

Figure 1-1b, Primary Features & Components

SATO HT200e Operator Manual PN 9001103B Page 1-3

Page 10

Unit 1: Introduction

Figure 1-1b, Primary Components

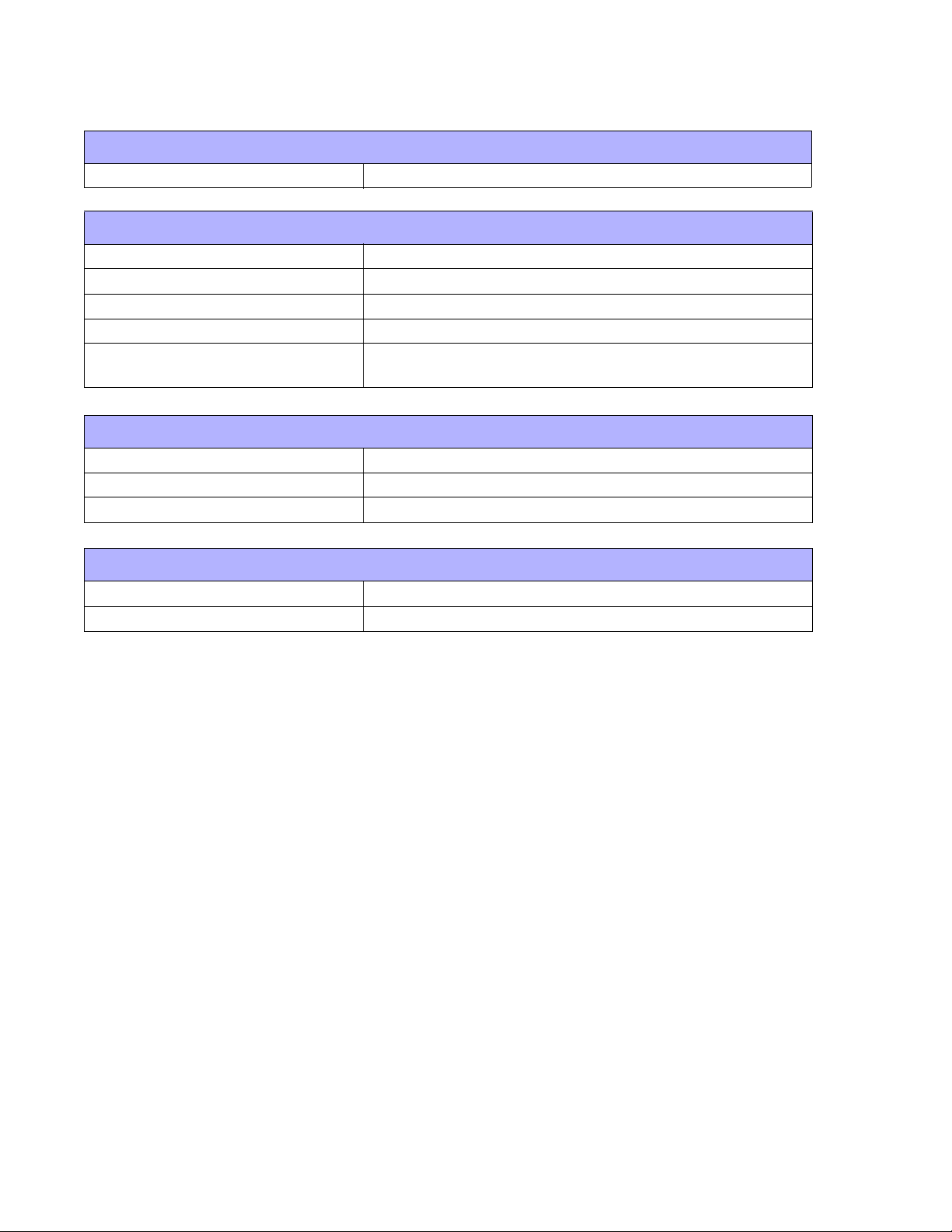

CONNECTION PORTS

TYPE FUNCTION

Power

Serial Port

Scanner Port

Tes t Te rm in al

SATO HT200e Operator Manual PN 9001103B Page 1-4

Electrical cord provided with the product. Permits source electrical supply

to the printer for operation.

Permits an RS232C cable to be connected for host computer interface. Is

used for remote configuration and operation.

Allows a barcode scanner to be connected and used in conjunction with

the printer.

Permits a SATO Test Module and/or multimeter to be connected to

troubleshoot electrical circuitry and to measure electrical values when

adjusting potentiometers.

Page 11

Unit 1: Introduction

CONTROL FEATURES

KEYPAD BUTTONS

KEY NAME FULL NAME FUNCTION

0 TO 9 Numeric Keys

Cursor Keys For scrolling through screen options and moving the cursor.

FNC1 Function1

FNC2 Function2

SET Set Switches between input of numeric and alphabetical characters.

FEED Paper Feed Feeds media forward one label at a time.

FMT Format Allows selection of label format.

RCL Recall

DATE Date

S/S Start/Stop Allows user to start and stop printing.

PGUP Page Up Returns user to the previous screen.

SHIFT Shift

DEL Delete Deletes data entered one character at a time.

AC All Clear Clears all input data on the screen.

ENTR Enter Confirms current action and proceeds to the next step.

For entry of numerals, alphabets, and symbols. Keys [1] and [.] are used

for input of symbols.

Sets usage of British Pound (GMP) and unit volume. During input of print

format number, displays menu for managing table data management. In

the print density menu, allows user to change black and red density.

Sets discount rate, exchange rate, and consumption tax. In the print

format input menu, displays name for label and format.

Calls up the preset menu for management of presets. During input of

alphabetical code data, calls up the code-entry menu for inserting special

symbols. During input of a table item number, allows user to preview the

item’s contents to check for accuracy.

Displays calendar information. Allows adjustment of the calendar when

pressed during Power On.

Switches between upper and lower case input. Selects the other functions

of a dual-function key.

SATO HT200e Operator Manual PN 9001103B Page 1-5

Page 12

Unit 1: Introduction

SATO HT200e Operator Manual PN 9001103B Page 1-6

Page 13

TECHNICAL DATA

• Physical Characteristics

•Power

• Processing

• Enviromental

•Print

•Media

• Sensing

• Interface Modules

• Processing

• Character Font Capabilities

•Character Control

• Symbologies

• Other Features

• Accessories

• Regulatory Approvals

SATO HT200e Operator Manual PN 9001103B Page 2-1

Page 14

Unit 2: Technical Data

TECHNICAL DATA

All technical data deemed pertinent has been tabulated below for quick reference. Find the

relative section header and then locate the specific type of technical data in the left column.

PHYSICAL CHARACTERISTICS

Width 5.2 Inches (132 mm)

Height 5.94 Inches (151 mm)

Depth 9.06 Inches (230 mm)

Weight 5.5 Pounds (2.5 Kg)

POWER

Adapter Voltage Autoswitching 100-120/200-240 VAC, 50-60 Hz

Battery Supply NiMH, 8.4VDC 2.4 AH

PROCESSING

CPU 32 Bit RISC

FLash ROM 512K Bytes

SRAM 2 Mega-Bytes

ENVIRONMENTAL

Operating Temperature 41° to 104°Fahrenheit (5° to 40°C)

Storage Temperature -4° to 104°Fahrenheit (-5° to 45°C)

Storage Humidity Maximum 90% RH, Non-Condensing

Operating Humidity 15 to 80% RH, Non-Condensing

PRINT

Type Direct Thermal Only

Speed

Resolution 203 Dots Per Inch (8 d/mm)

Print Module (Dot Size) 0.0049 Inches (0.125 mm)

Maximum Print Width 1.89 Inches (48 mm)

Maximum Print Length 3.78 Inches (96 mm)

2.4 Inches Per Second (60 mm/s) Battery Operated

Up to 3 Inches Per Second (80 mm/s) AC Adapter

SATO HT200e Operator Manual PN 9001103B Page 2-2

Page 15

Unit 2: Technical Data

MEDIA

Type Die-Cut & Fan-Fold Labels, Tags (Face Up Stack), Continuous

Minimum Width 1.1 Inches (28 mm)

Minimum Length 0.63 Inches (16 mm)

Maximum Width 2.0 Inches (51 mm)

Maximum Length 4.0 Inches (103 mm)

Maximum Caliper 0.007 Inches (0.18 mm)

Maximum Roll Diameter 2.95 Inches (75 mm) Wound Face-In

Minimum Core Diameter 1.0 Inches (25.4 mm)

SENSING

Reflective Eye-Mark

Continuous Form Sensor not used.

INTERFACE MODULES

RS232C, 4800 to 19.2K BPS

Serial Port

Scanner Input RS232C or TTL

Hardware Ready/Busy Flow Control

Sftware X-On/X-Off Flow Control

CHARACTER FONT CAPABILITIES

MATRIX FONTS

X1 20 dots W x 50 dots H

X2 8 dots W x 20 dots H

X3 13 dots W x 21 dots H

OCR-B 20 dots W x 24 dots H

Price 16 dots W x 24 dots H (Numeric Only)

Outline 1 28 dots W x 48 dots H (Numeric Only)

Outline 2 48 dots W x 68 dots H (Numeric Only)

Outline 3 26 dots W x 56 dots H (Numeric Only)

CHARACTER CONTROL

Expansion Up to 4X in either the X or Y coordinates

Rotation 0, 90, 180, or 270 Degrees

Pitch 0 to 90 dots

SATO HT200e Operator Manual PN 9001103B Page 2-3

Page 16

Unit 2: Technical Data

SYMBOLOGIES

Linear UPC-A/E, EAN-8/13, Code 39, I 2/5, Codabar, Code 128B/C

OTHER FEATURES

Sequential Numbering Sequential numbering of both numerics and bar codes.

Custom Characters Up to 24 Currency Marks

Graphics BW Graphic files in BMP format

Real-Time Clock Day, Month, Year

Formats

6 User defined (30 fields/format std, 200 fields/format w/2M)

29 Fixed Formats

ACCESSORIES

Battery Pack NiMH Battery Pack and Charger

Wand Scanner For scanning input fields

CCD Scanner For scanning input fields

REGULATORY APPROVALS

Safety UL, CE, TUV

RFI/EMI FCC Class B

SATO HT200e Operator Manual PN 9001103B Page 2-4

Page 17

INSTALLATION

• Unpacking

• Parts Identification

• Printer Installation

• Interface Selection

• Accessories Installation

SATO HT200e Operator Manual PN 9001103B Page 3-1

Page 18

Unit 3: Installation

UNPACKING & PARTS IDENTIFICATION

Unpack the printer as directed in the following procedure.

1 Place the shipping container (box) upright on a solid, flat surface.

2 Open the box, remove any loose items and the first layer of packing material.

3 Carefully lift the printer and accessories from the box and place them on a solid flat surface.

4 Remove the plastic covers from the packed items and visually inspect for physical damage.

5 Ensure the following components are present:

6 Report damaged property.

PACKED COMPONENTS

Printer (Figure 3-1a)

Power Cord (Figure 3-1b)

Media Spool (Figure 3-1c)

Operator Manual

Programming Manual

(Figure 3-1d)

Software Disk (Figure 3-1e)

SATO HT200e Operator Manual PN 9001103B Page 3-2

Page 19

Unit 3: Installation

PRINTER INSTALLATION

SITE LOCATION

• Stationed on a solid flat surface

• Stationed away from hazardous conditions

• Stationed within operational distance of the host based on interface specificaitons

POWER SUPPLY

Figure 3-2a Figure 3-2b Figure 3-2c

MEDIA SELECTION

The size and type of the labels or tags to be printed should have been taken into consideration

before printer purchase. Ideally, the media width will be equal to, or just narrower than, the print

head. Using media that does not cover the print head, will allow the platen roller to tread on it and

wear it out. The media edge will also wear a groove in the platen roller effecting print quality.

MEDIA LOADING

1 Unlatch top housing cover (Figure 3-2a).

2 Lift top housing cover into a vertical position (Figure 3-2b).

3 Apply media to the printer’s media spool (Figure 3-2c).

4 Place the media spool onto the printer’s holder (Figure 3-2d).

5 Unwind approximately one (1) foot of media from the roll (Figure 3-2e).

6 Adjust the media guides loosely against each side of the media (Figure 3-2f).

7 Close the printer and begin operation (Figure 3-2g).

With Dispenser Function

8 Remove approximately 6 inches of labels from backing (Figure 3-2h).

9 Open dispenser cover (Figure 3-2i).

10 Feed media through slot beneath cover (Figure 3-2j).

11 Close top housing cover (Figure 3-2k).

12 Close dispenser cover and begin operation (Figure 3-2l).

SATO HT200e Operator Manual PN 9001103B Page 3-3

Page 20

Unit 3: Installation

Figure 3-3a Figure 3-3b Figure 3-3c

Figure 3-3d Figure 3-3e Figure 3-3f

Figure 3-3g Figure 3-3h Figure 3-3i

Figure 3-3j Figure 3-3k Figure 3-3l

SATO HT200e Operator Manual PN 9001103B Page 3-4

Page 21

Unit 3: Installation

INTERFACE SELECTION

The HT200e has two integrated interface connectors accessible on the printer’s left front side.

One is a RS232C serial used for interfacing with a host computer and the other is for use with an

optional scanner to input variable data by reading barcode symbols from a menu sheet.

RS232C SERIAL INTERFACE SPECIFICATIONS

Asynchronous ASCII Half-duplex communication

Ready/Busy Hardware Flow Control

Pin 9, DTR Control

Pin 4, RTS Error Condition

X-On/X-Off Software Flow Control

Bi-Directional Communication

Data Transmission Rate 4800, 9600, 19200 bps

Data Length 8 bit (selectable)

Stop Bit 1 or 2 bits (selectable)

Parity Bit ODD, EVEN, NONE (selectable)

Character Format 1 Start Bit (fixed), 7 or 8 bits (selectable)

Connector DB9S (female)

Cable DB-9P (male), 50 feet maximum length.

Signal Levels High = +5V to +12V, Low = -5V to -12V

RS232 INTERFACE SIGNALS

PIN DIRECTION SIGNAL DEFINITION

1 Reference FG (Frame Ground)

2 To Host TD (Trnasmit Data) - Data from the printer to the host computer. X-On/X-Off.

3 To Printer RD (Receive Data) - Data to the printer from the host computer.

4 To Host RTS (Request To Send) - Always high.

6 To Printer DSR (Data Set Ready) Always high.

7 Reference SG (Signal Ground)

9 To Host DTR (Data Terminal Ready) - This signal applies to Ready/Busy flow control.

The printer is ready to receive data when this pin is high. It goes low when the

printer is Busy or off line due to an error condition.

RS232 CABLE REQUIREMENTS

DB9 DB25 HOST CONNECTION DB9 PRINTER

1 FG (Frame Ground) Bi-Directional 1 FG (Frame Ground)

2 3 RD (Receive Data) To Host 2 TD (Transmit Data)

3 2 TD (Transmit Data) To Printer 3 RD (Receive Data)

8 5 CTS Clear To Send) To Printer DB9 - 6 4 RTS (Request to Send)

4 20 DTR (Data Terminal Ready) To Printer DB9 - 4 6 DSR (Data Set Ready)

6 6 DSR (Data Set Ready) To host 9 DTR (Data Terminal Ready)

5 7 SG (Signal Ground) Bi-Directional 7 SG (Signal Ground)

SATO HT200e Operator Manual PN 9001103B Page 3-5

Page 22

Unit 3: Installation

ACCESSORIES INSTALLATION

There are several optional accessories that are available to make the HT200e printer more

useful in certain applications.

• Battery Power Module

• PCMCIA Memory Card

• Scanner

BATTERY POWER MODULE

The optional Battery Power Module attaches to bottom of the printer the same as the included

AC Power Module. To charge the battery pack, simply power off the printer and withdraw it from

the underside.

1 Remove AC Power Module (Figure 3-4a).

2 Insert Battery Power Module in its place (Figure 3-4b).

3 Power on printer to operate. Power off to remove battery pack for charging (Figure 3-4c).

To Charge Battery Pack

4 Connect charger to power receptacle (Figure 3-4d).

5 Insert battery pack into the charger base (Figure 3-4e).

6 Charge until LED indicates charging is complete (Figure 3-4f).

Figure 3-4a Figure 3-4b Figure 3-4c

Figure 3-4d Figure 3-4e Figure 3-4f

SATO HT200e Operator Manual PN 9001103B Page 3-6

Page 23

Unit 3: Installation

PCMCIA MEMORY CARD

This purchase option provides memory expansion up to 2MB. Perform the procedure below to for

memory card installation.

1 Lift memory card cover (Figure 3-5a).

2 Insert memory card into slot (Figure 3-5b).

3 Press button to eject memory card as necessary (Figure 3-5c).

Figure 3-5a Figure 3-5b Figure 3-5c

SCANNER CONNECTION

The scanner option can be used to input variable data by reading barcode symbols from a menu

sheet.

1 Open the interface cover (Figure 3-6a).

2 Connect the scanner to the scanner connector (Figure 3-6b).

Figure 3-6a Figure 3-6b

SATO HT200e Operator Manual PN 9001103B Page 3-7

Page 24

Unit 3: Installation

SATO HT200e Operator Manual PN 9001103B Page 3-8

Page 25

OPERATION

• Printer Configuration

• Configuration Modes

• Fixed Formats

• Customizing Label Formats

• Operational Modes

• Operational Adjustments

SATO HT200e Operator Manual PN 9001103B Page 4-1

Page 26

Unit 4: Operation

PRINTER CONFIGURATION

The printer may be configured for specific jobs via the operator panel located on the top surface

of the printer. The operator panel is comprised of a keypad and a LCD panel.

Once the printer has been configured, the settings are retained in the battery backup memory.

For additional information regarding the operator panel, refer to Unit 1: Introduction.

ENTERING ALPHANUMERICS & SYMBOLS

Each numeric key of the keypad can also input

alphabets when the SET or SHFT key has been

pressed.

For example, pressing the SET key and then

pressing 2 once yields an A. Pressing 2 again

yields a B.

Refer to the table below.

FNC1

PG UPFMT

87

9

FNC2

SET

FEED

SHFTRCL

DELDATE

Figure 5-1, Operator Panel

54

21

.ACS/S ENTR

0

6

3

KEY DEFAULT WITH SET KEY PRESSED WITH SHFT KEY PRESSED

. . ( ) < > , - : ; ‘ ( ) < > , - : ; ‘

0 0 Y Z space ½ ¼ y z space ½ ¼

1 1 £ * + ! & % $ = / ° £ * + ! & % $ = / °

2 2 ABC Ä Å Æ Ç abc ä å æ ç

3 3 DEF Ë É def ë é

4 4 GHI ghi

55JKL jkl

6 6 MNO Ñ Ö Ø mno ñ ö ø

7 7 PQR pqr

8 8 STU ß Ü stu ü

99VWX vwx

SATO HT200e Operator Manual PN 9001103B Page 4-2

Page 27

Unit 4: Operation

INITIAL SETUP MODE

Is the first menu in the printer configuration process. Typically, these values will not change

following initial printer setup.

POWER ON

FORMAT NO.

[ . . ]

HT200e

00

Use arrow keys to

cursor. Press

ENTR to advance.

CHECK LABEL

YES NO

STR/RCL PRESET

INT/RAM OPT CARD

PRINT

NORMAL DEMAND

PRICE POSITION

UPPER LOWER

Power = Off

REAL-TIME PRINT

ON OFF

PRE-EDITED PRINT

ON OFF

GUARD BAR

NORMAL LONG

CALENDAR PRINT

NO PRINT PRINT

CALENDAR EXP

DDMMYY MMDDYY

PRICE FONT SIZE

NORMAL BIG

PRINT PRESET NO.

PRINT NO PRINT

PRICE FORMAT

UK EUROPE

Figure 4-2, Initial Setup Mode

SATO HT200e Operator Manual PN 9001103B Page 4-3

Page 28

Unit 4: Operation

USER MODE

This menu, like the Initial Setup Mode, allows certain values to be set based on the user/

operator’s needs that typically will not change.

3 + POWER

DATA BIT SETTING

7 BITS 8 BITS

PRINT DARKNESS

L 1 2 3 4 5 D

PRINT SPEED

600 MM/SEC

800 MM/SEC

AUTO POWER OFF

ON OFF

STARTUP DISPLAY

MANUAL ONLINE

I/F SETTING

4800 BPS 9600 BPS

800 BPS

Use arrow keys to

cursor. Press

ENTR to advance.

Power = Off

HEAD CHECK

NORMAL BARCODE

PARITY SETTING

ODD EVEN NONE

PROTOCOL

READY/BUSY

XON/OFF

FIXED FORMAT

NO [ . . ]

99: CLEAR

CALENDER SETTING

DDMMYY XX:XX

HEAD CHECK

ON OFF

CODE PAGE SET

858 852

EURO CALC

CM=E E=CM

REPRINT FUNC

YES NO

CALENDAR DISP

NO YES

BEEP SETTING

ON OFF

PROTO CODE

STANDARD

NON-STANDARD

NON-STANDARD

DEFAULT USER SET

Figure 4-3, User Mode

NON-STANDARD

STX: 02 HEX

NON-STANDARD

ETX: 03 HEX

NON-STANDARD

ESC: 1B HEX

NON-STANDARD

EOT: 04 HEX

NON-STANDARD

SOH: 01 HEX

SATO HT200e Operator Manual PN 9001103B Page 4-4

Page 29

Unit 4: Operation

DATA MAINTENANCE MODE

Is the primary menu for the maintenance of print data. This chart provides the route to more

specific menus for the transfer and storage of data.

6 + POWER

PARAMETER COPY

PRINTER CARD

Refer to

Enter Country

Code Mode

CARD CLEAR

Press

ENTR

Refer to

Memory Card

Clear

Mode

Refer to

Copy All

Parameters

Mode

Press

Press Press

Press

ENTR

EAN COUNTRY CODE

50

Press

To go back.

To go back.

Press Press

Press

ENTR

Refer to

Copy Print

Parameters

Mode

Press

ENTR

Refer to

Send/Receive

Preset Data

Mode

Press

ENTR

Refer to

Copy Preset

Data

Mode

DATA STORE / RCALL

PRINTER HOST

To go back.

PRESET STR / RCALL

To go back.

PRESET COPY

PRINTER CARD

To go back.

FONT STORE / RCALL

PRINTER HOST

Press Press

Press Press

Press Press

Press Press

Press Press

Refer to

Select

Currency

Mode

Press

ENTR

Press

To go back.

Press

Refer to

Copy Font

Mode

Refer to

Copy Table

Data Mode

Press

ENTR

Press

ENTR

To go back.

TABLE STR / RCALL

PRINTER HOST

To go back.

CURRENCY SELECT

Figure 4-4a, Data Maintenance Mode

SATO HT200e Operator Manual PN 9001103B Page 4-5

Page 30

Unit 4: Operation

COPY PRINT PARAMETERS MODE

This menu provides the flow sequence of copying print parameters from the host and sending

them to the printer or copying from the printer and sending them to the host.

This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

DATA SEND / REC

HT HOST HOST HT

HT HOST SEND OK?

Press

to scroll options.

Yes / No

Press ENTR Press ENTR

RECEIVING

ITEM: 0000

Y / N

Returns to

Maintenance

Mode

Data

Determine direction and

press to scroll.

Press ENTR.

RECEIVING

ITEM: 0000

HOST HT REC OK?

Y / N

Press

to scroll options.

Yes / No

Press ENTR Press ENTR

Returns to

Data

Maintenance

Mode

Figure 4-4b, Copy Print Parameters Mode

SATO HT200e Operator Manual PN 9001103B Page 4-6

Page 31

Unit 4: Operation

SEND/RECEIVE PRESET DATA MODE

This menu provides the flow sequence of sending or receiving preset data from the host or

printer. This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

SEND / REC DATA

SEND RECEIVE

Determine direction and

press to scroll.

STR / RCL DATA

INT RAM OPT CARD

Determine direction and

press to scroll.

Int Ram / Opt Card

Press ENTR

HT HOST

SEND OK?

Y / N

Confirm action and

press to scroll.

Yes / No

Press ENTR

Send / ReceivePress ENTR

Press ENTR Press ENTR

Press ENTR

Press ENTR

STR / RCL DATA

INT RAM OPT CARD

Determine direction and

press to scroll.

Int Ram / Opt Card

Press ENTR

HOST HT

REC OK?

Y / N

Confirm action and

press to scroll.

Yes / No

SENDING

ITEM: 0000

Returns to

Data

Maintenance

Mode

RECEIVING

ITEM: 0000

Figure 4-4c, Send/Receive Preset Data Mode

SATO HT200e Operator Manual PN 9001103B Page 4-7

Page 32

Unit 4: Operation

COPY PRESET DATA MODE

This menu provides the flow sequence of copying preset data from the host to the printer or vice

versa. This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

SEND / REC DATA

SEND RECEIVE

Determine direction and

press to scroll.

STR / RCL DATA

INT RAM OPT CARD

Determine direction and

press to scroll.

Int Ram / Opt Card

Press ENTR

HT HOST

SEND OK?

Y / N

Confirm action and

press to scroll.

Yes / No

Press ENTR

Send / ReceivePress ENTR

Press ENTR Press ENTR

Press ENTR

Press ENTR

STR / RCL DATA

INT RAM OPT CARD

Determine direction and

press to scroll.

Int Ram / Opt Card

Press ENTR

HOST HT

REC OK?

Y / N

Confirm action and

press to scroll.

Yes / No

SENDING

ITEM: 0000

Returns to

Data

Maintenance

Mode

RECEIVING

ITEM: 0000

Figure 4-4d, Copy Preset Data Mode

SATO HT200e Operator Manual PN 9001103B Page 4-8

Page 33

Unit 4: Operation

COPY FONT MODE

This menu provides the flow sequence of copying font types from the host to the printer and vice

versa. This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

FONT SEND / REC

HT HOST HOST HT

HT HOST

SEND OK?

Y / N

Press to scroll.

Press ENTR

SENDING

ITEM: 0000

Yes / No

Determine direction and

press to scroll.

HT Host / Host HTPress ENTR

Press ENTR Press ENTR

Returns to

Data

Maintenance

Mode

Press ENTR

RECEIVING

ITEM: 0000

Press ENTR

HOST HT

REC OK?

Y / N

Press to scroll.

Yes / No

Figure 4-4e, Copy Font Mode

SATO HT200e Operator Manual PN 9001103B Page 4-9

Page 34

Unit 4: Operation

COPY TABLE DATA MODE

This menu provides the flow sequence of copying table data from the host to the printer or vice

versa. This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

DATA SEND / REC

HT HOST HOST HT

Determine direction and

press to scroll.

HT HOST SEND OK?

Y / N

Press to scroll.

Press ENTR

SENDING

ITEM: 0000

Yes / No

HT Host / Host HTPress ENTR

Press ENTR Press ENTR

Returns to

Data

Maintenance

Mode

Press ENTR

RECEIVING

ITEM: 0000

Press ENTR

HOST HT REC OK?

Y / N

Press to scroll.

Yes / No

Figure 4-4f, Copy Table Data Mode

SATO HT200e Operator Manual PN 9001103B Page 4-10

Page 35

Unit 4: Operation

COPY ALL PARAMETERS MODE

This menu provides the flow sequence of copying print parameters from the host to the printer or

vice versa. This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

PARAMETER COPY

HT CARD CARD HT

Press

to scroll options.

Press ENTR

HT CARD COPY OK?

Y / N

COPYING

Complete when the

PARAMETER COPY

PRINTER CARD

CARD HT COPY OK?

Y / N

Press

to scroll options.

Press ENTR

Copying

while the screen

above is displayed.

screen below is

displayed.

Refer to

Data

Maintenance

Mode

Figure 4-4g, Copy All Parameters Mode

SATO HT200e Operator Manual PN 9001103B Page 4-11

Page 36

Unit 4: Operation

SELECT COUNTRY CODE MODE

This menu provides theflow sequence for selecting the applicable Country of use. By selecting

the applicable Country; specific symbols, features, and calculations are automatically initiated as

part of the operational function. Each Country is assigned a two-digit code for this selection

process.

This menu is accessed through the Data Maintenance Mode.

Refer to

Data

Maintenance

Mode

EAN COUNTRY CODE

50

Determine which country is applicable

and enter its code from this table.

01 Holland

02 Euro

03 USA

04 France

05 Swiss

06 Spain

07 Italy

08 Germany

09 Austria

10 Poland

11 Czech

12 Romania

13 Slovenia

14 Slovakia

15 Russia

16 Hungary

17 Finland

18 Greece

19 Belgium

20 Scandinavia

Press ENTR

Figure 4-4h, Country Code Mode

SATO HT200e Operator Manual PN 9001103B Page 4-12

Page 37

Unit 4: Operation

MEMORY CARD CLEAR MODE

Allows the selected values stored on the memory card to be cleared from its memory. This menu

is accessed through the Data Maintnenance Mode.

Refer to

Data

Maintenance

Mode

CARD TYPE

PRESET

BACKUP

Press to scroll.

Select Presets if card

has presets.

Select Backup if card

contains fonts, table

data, firmware, etc.

Press ENTR

CURRENCY CR 1

HOLLAND [ f ]

Press to scroll.

Press ENTR

Returns to

Data

Maintenance

Mode

Figure 4-4i, Memory Card Clear Mode

SATO HT200e Operator Manual PN 9001103B Page 4-13

Page 38

Unit 4: Operation

SELECT CURRENCY MODE

Allows the desired currency to be selected independently of the Country previously selected.

Typically, the currency selected will be representative of the Country selected.

Refer to

Data

Maintenance

Mode

CURRENCY SELECT

DEFAULT USER

Determine direction and

press to scroll.

Default / UserPress ENTR

Returns to

Data

Maintenance

Mode

Press ENTR

CURRENCY CR 1

HOLLAND [ f ]

Press to scroll.

Press ENTR

Figure 4-4j, Select Currency Mode

SATO HT200e Operator Manual PN 9001103B Page 4-14

Page 39

Unit 4: Operation

FIXED FORMATS

This unit identifies and defines the 29 pre-programmed label designs that are part of the HT200e

printer package. These fixed formats are suitable for a wide variety of general uses.

NOTE: The folowing text references PLU. PLU (Price Lookup) is the

process by which a bar coded item number is decoded and seached

for in a database so the price information can be sent back to the

scanning location.

PLU BARCODES

Format 01 Format 02 Format 03 Format 04

EAN 8 Barcode. Has

price and three-digit

human readable code.

EAN 8 Barcode. Flag

50 is fixed. Includes

price and three-digit

human readable code.

EAN 13 barcode. Has

price and three-digit

human readable code.

EAN 13 barcode. Flag

50 is fixed. Includes

price and three-digit

human readable code.

NON PLU BARCODES

Format 05 Format 06 Format 07 Format 08

EAN 8 Barcode. Needs

a Non PLU flag. Has

price and three-digit

human readable code.

EAN 13 Barcode.

Needs a Non PLU flag.

Has price and threedigit human readable

code.

EAN 13 barcode.

Needs a Non PLU flag.

Has price and threedigit human readable

code.

EAN 13 barcode.

Needs a Non PLU flag.

Has price and threedigit human readable

code.

SATO HT200e Operator Manual PN 9001103B Page 4-15

Page 40

Unit 4: Operation

NON PLU BARCODES

Format 09 Format 11 Format 12

EAN 13 Barcode. Needs a Non

PLU flag. Has four-digit item

code and six-digit price. Also

has human readable code.

EAN 13 Barcode. Needs a Non

PLU flag. Has five-digit item

code and five-digit price. Human

readable code not included.

EAN 13 barcode. Needs a Non

PLU flag. Has four-digit item

code and six-digit price. Human

readable code not included.

Format 14 Format 15

Two EAN 8 barcodes. Not normally PLU. Includes

price and three-digit human readable code.

Two EAN 13 barcodes. Not normally PLU. Has

price and three-digit human readable code.

SATO HT200e Operator Manual PN 9001103B Page 4-16

Page 41

Unit 4: Operation

PRICE REDUCTIONS

Format 16 Format 17 Format 18

Enter the non-discounted (WAS)

price. The printer calculates the

discounted (NOW) price.

Enter the EAN 13 Barcode and

non-discounted (WAS) price.

The discounted (NOW) price is

calculated automatically.

The EAN 13 and the “NOW”

price are added into the new

barcode (Code128). A prefix

“10” is added to act as an

application identifier.

Enter the EAN 13 Barcode and

non-discounted (WAS) price.

The discounted (NOW) price is

calculated automatically.

The EAN 13 and the “NOW”

price are added into the new

barcode (Code128). A prefix

“10” is added to act as an

application identifier.

Format 19 Format 25

Enter the non-discounted (WAS) price. The printer

calculates the discounted (NOW) price.

SATO HT200e Operator Manual PN 9001103B Page 4-17

Enter the non-discounted (WAS) price. The printer

calculates the discounted (NOW) price. The

discounted rate is also printed on the label.

Page 42

Unit 4: Operation

SIMPLE DATA AND PRICE

Format 10 Format 13

Contains 15 alphanumeric characters and the

price.

VAT CALCULATION

Contains two lines of 15 alphanumeric charcters

and the price.

Format 23 Format 24

Enter the pre-tax amount. The printer automatically calculates the VAT and payable amount.

SHELF EDGE LABEL

Format 22

Contains one line of 20 alphanumeric characters,

plus tow of ten digits, a price, and the EAN 13

barcode.

Enter the pre-tax amount and the EAN 13 barcode

data. The printer automatically calculates the VAT

and payable amount., and creates or copies the

barcode.

SATO HT200e Operator Manual PN 9001103B Page 4-18

Page 43

Unit 4: Operation

UNIT PRICING

Format 26 Format 27

When promted to enter “Unit Voles”, press [FNC1]

to select the number of units. Press Enter.

At the “Pack Size” screen, enter a numeric value,

the pack price, two line of sixteen-digit alphanumeric code, and the symbol of the weight/volume

unit (Kg, g). To complete the label, enter the number of days to add the current date.

When promted to enter “Unit Voles”, press [FNC1]

to select the number of units. Press Enter.

At the “Pack Size” screen, enter a numeric value,

the pack price, two line of sixteen-digit

alphanumeric code, and the symbol of the weight/

volume unit (Kg, g).

EURO PRICING

Format 20 Format 21

Enter the local currency. The printer calculates the

Euro value. Data is needed for the EAN 13

barcode.

Similar to Format 20 but excludes the barcode.

SATO HT200e Operator Manual PN 9001103B Page 4-19

Page 44

Unit 4: Operation

CUSTOMIZING LABEL FORMATS

Customized Label Formats allow label layout and format to be customized by the user. A label

format consists of a single or multiple printable areas called fields. For each field and field type,

predetermined configuaration attributes must be programmed. Regardless of the field type, to

customize a label format, a total of 46 numerical programming entries must be made for each

established field. These numerical programming entries are refered to as parameters.

Before beginning to create a customized label, determine the label size, the number of

fields within the label, and their contents. It is recommended that a sample label be

drawn on a piece of paper displaying the location of each field and its field type before

commencing. Figure 7-1 displays a sample label.

Since all programming is numerical, the format name, the label name, and all

configuration entries will be made by using the printer’s keypad. The following procedure

generalizes the programming sequence when prompted by the LCD:

1 Enter a format number for the label.

2 Enter a label name.

3 Configure label size.

4 Create and configure each field one at a time.

• Field number

• Field type

• Parameters

Figure 7-2 is a visual image of how programming entries are broken down into three primary

categories: Field Designation & Font Type (1-3), Field Configuration (4-21), and Copy

Configuration (22-46). Each time a parameter is configured, its configuration numeral replaces a

“0”, or series of ”0” ‘s, in the bottom row of the LCD.

BOTTOM ROW OF LCD WHEN CONFIGURING LABEL

000 000000000000000000 0000000000000000000000000

1 to 3

4 to 21

46 Data Entry Characters Required (Replace the Zeroes with the Required Numerals)

Figure 4-6, Configuration Breakdown

22 to 46

SATO HT200e Operator Manual PN 9001103B Page 4-20

Page 45

Unit 4: Operation

Figure 7-3 is an example of a LCD display. Notice that the field parameter to be configured on

that LCD is FONT TYPE and that the configuration entry 03 is displayed to its left. Whichever

option is chosen (0, 1, 2) will replace the third character from the left on the bottom row.

Field Parameter

01 03: FONT TYPE

0: X1 1: X2 2: X3

1000000000000000000

Configuration Options

Configuration Entry will Display

here.

Figure 4-7, Sample LCD Display

Figure 7-4 displays the programming process for creating a customized label.

Create Label Format

&

Field Names

Chart 7-5

Normal Field

Configuration

Entries 1-21

Normal Field

Configuration

Table & Chart

7-6

Normal/Table

/Seq. No.

Table Field

Configuration

Entries 1-21

Field

Type

Seq. Number

Configuration

Entries 1-21

Price Field

Configuration

Table & Chart

7-9

Price Field

Configuration

Entries 1-21

Calendar Field

Configuration

Table & Chart

7-10

Calendar Field

Configuration

Entries 1-21

Barcode Field

Configuration

Table & Chart

7-11

Barcode Field

Configuration

Entries 1-21

Entries 22-46

Leave as 0

Print Configuration

Table & Chart

7-13

Entries 22-46

Leave as 0

Print?

Yes / No

Entries 22-46

Leave as 0

Copy Configuration

Entries 22-46

Table & Chart

7-12

Entries 22-46

Leave as 0

Copy?

Yes / No

Figure 4-8, Programming Process

NOTE: A calendar field cannot be copied. For Normal/Table data, a

copy cannot be received.

SATO HT200e Operator Manual PN 9001103B Page 4-21

Page 46

Unit 4: Operation

Figure 7-5 provides visual sequential instructions for beginning to create a customized label.

After completing those instructions, refer to the relative flow chart for Normal, Price, Calendar,

or Barcode fields configuration. Use those flow charts in conjunction with the tables that follow to

create a customized label.

POWER ON

FORMAT NO.

[ . . ]

Press ENTR

FORMAT No

[ . . ] [ . . . . . . . . . . ]

[ . . . . . . . . . . ]

NORMAL OPTION

FMT

Enter number,

SETTING MODE

PARAMETER

SET LABEL SIZE

PARAMETER,

Press ENTR

xx = FIELD No LABEL TYPE

HT200e

Press

ENTR

Enter number,

Press SHFT

SET LABEL SIZE,

Press ENTR

Press SHFT,

then SET

PARAMETER

SETTING MODE

FORMAT NAME

[ . . ] [ . . . . . . . . . . ]

[ . . . . . . . . . . ]

Enter number,

Press SHFT

LABEL NAME

[ . . ] [ . . . . . . . . . . ]

[ . . . . . . . . . . ]

Enter number,

Press ENTR

Enter number,

Press SHFT

Enter field number,

Press ENTR

xx = ITEM NAME

[ . . . . . . . . . . ]

SHFT to scroll

options, Press ENTR

Refer to

relative table

& chart to

continue.

NORMAL

Press ENTR

PRINT POS OFFSET

V [ 00] dot

H [ 00] dot

Enter a value less

than 41 for each.

Press ENTR

OPTION

Press ENTR

LABEL PITCH

16 MM 20 MM

25 MM 8 MM

Select option,

Press ENTR

Figure 4-9a, Beginning a Customized Label

SATO HT200e Operator Manual PN 9001103B Page 4-22

Page 47

Unit 4: Operation

NORMAL FIELD CONFIGURATION

Normal fields may easily be defined as any that does not possess the characteristics of any of

the other field types. Typically, it will contain text or graphic that is stable or unchanging.

XX XX: FLD TYPE

X: ***********

000000000000000000000

Enter numeral/s at

each screen to

configure.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Numeral

will display on

bottom row of

LCD.

XX 01: FLD TYPE

1: NORMAL

X00000000000000000000

XX 02: DATA TYPE

1: NORMAL

XX000000000000000000

XX 03: FONT TYPE

0: X1 1: X2 2: X3

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

XXXXXXXXXX000000000

XX 15: H - EXPANSE

XXXXXXXXXXXXXXX0

XX 16: INPUTCHECK

0: NO CHECK

XXXXXXXXXXXXXXXX

XX 17: SET TITLE

X00000000000000000000

XX 18: 0 RESERVED

XX000000000000000000

XX 19: AUTO-INS

XXX0000000000000000

XX 20: PRESET

XXXX000000000000000

XX 21: COLOR

0: BLACK 3: RED

XXXXX0000000000000

Press SHFT to

scroll options.

Press SHFT to

scroll options.

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 14: V - EXPANSE

XXXXXXXXXXXXXX00

Copy?

Yes / No

Refer to the

relative table

& chart to

continue.

Press

FMT

Figure 4-9b, Normal Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-23

Page 48

Unit 4: Operation

NORMAL FIELD CONFIGURATION

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Normal 10: Normal

3 Font Type 0: X1

1: X2

2: X3

4: OCR-B

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 32: Number of characters in the field.

14 Vertical Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

15 Horizontal Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

16 Input Check 0: No check

2: Mandatory entry.

5: Numeric only.

6: Numeric in all digits.

7: Non-zero numeric only; entry is manditory.

17 Title Setup 0: Not displayed in a title in printing preset.

2: Initially displayed as a title in printing preset

(for a format, one field set only).

18 Reserved 0: Determined

19 0 Insertion (specifies

whether a leading or trailing

zeroes are inserted)

20 Preset 0: No entry in printing preset (no display).

21 Font Color 0: Black

0: No 0 insertion.

1: 0 insertion in right aligned when copy is

required (i.e. 1=001).

1: Entry in printing preset (displayed).

3: Red

4: Black and White reversal.

Table 4-9b, Normal Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-24

Page 49

Unit 4: Operation

TABLE FIELD CONFIGURATION

Fields of tabulated data may be stored in the printer’s memory and linked to another field type to

be displayed when scanned.

XX XX: FLD TYPE

X: ***********

000000000000000000000

Enter numeral/s at

each screen to

configure.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Numeral

will display on

bottom row of

LCD.

XX 01: FLD TYPE

1: NORMAL

X00000000000000000000

XX 02: DATA TYPE

1: TABLE 2: SEQ

XX000000000000000000

XX 03: FONT TYPE

0: X1 1: X2 2: X3

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

XXXXXXXXXX000000000

XX 15: H - EXPANSE

XXXXXXXXXXXXXXX0

XX 16: INPUTCHECK

0: NO CHECK

XXXXXXXXXXXXXXXX

XX 17: SET TITLE

X00000000000000000000

XX 18: TABLE No

1: TABLE 1

XX000000000000000000

XX 19: 0 AUTO-INS

XXX0000000000000000

XX 20: PRESET

0: OFF 1: OM

XXXX000000000000000

XX 21: COLOR

0: BLACK 3: RED

XXXXX0000000000000

Press SHFT to

scroll options.

Press SHFT to

scroll options.

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 14: V - EXPANSE

XXXXXXXXXXXXXX00

Copy?

Yes / No

Refer to the

relative table &

chart to

continue.

Press

FMT

Figure 4-9c, Table Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-25

Page 50

Unit 4: Operation

TABLE FIELD CONFIGURATION

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Tab le 11: Table

3 Font Type 0: X1

1: X2

2: X3

4: OCR-B

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 32: Number of characters in the field.

14 Vertical Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

15 Horizontal Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

16 Input Check 0: No check

2: Mandatory entry

17 Title setup 0: No display as a title in printing preset.

1: Initially display as a title in printing preset for a

format, one field set only).

18 Table number setup 1: Table 1 data

2: Teble 2 data

3: Table 2 data

19 0 Insertion 0: No 0 insertion.

1: 0 insertion in right aligned when copy is

required (i.e. 1=001).

20 Preset 0: No entry in printing preset (no display).

1: Entry in printing preset (displayed)

21 Font Color 0: Black

3: Red

4: Black and White reversal.

Table 4-9c, Table Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-26

Page 51

Unit 4: Operation

SEQUENTIAL NUMBER FIELD CONFIGURATION

This field type allows numerals to be sequentially printed onto a label in the designated location.

The make-up of the sequential number may be configured to incorporate other characters in

addition to the sequential digits.

XX XX: FIELD TYPE

X: ***********

000000000000000000000

Enter numeral to

designate field

number & field

type.

XX 15: H - EXPANSE

XXXXXXXXXXXXXXX0

Numeral

is displayed

on bottom

row of LCD.

XX 01: FIELD TYPE

1: NORMAL

X00000000000000000000

XX 02: DATA TYPE

1: TABLE 2: SEQ

XX000000000000000000

XX 03: FONT TYPE

0: X1 1: X2 2: X3

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

0: 0 1: 90

XXXXXXXXXX000000000

XX 16: INPUTCHECK

6: FULL NUMERIC

XXXXXXXXXXXXXXXX

XX 17: SEQ

0: SEQUENCE NONE

X00000000000000000000

XX 18: 0 RESERVED

XXXX000000000000000

XX 19: 0 AUTO - INS

XXXXX0000000000000

XX 20: PRESET

0: OFF 1: ON

XXXXX0000000000000

XX 21: 0 RESERVED

XXXXX0000000000000

Copy?

Yes / No

Press

FMT

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 14: V - EXPANSE

XXXXXXXXXXXXXX00

Refer to the

relative table

& chart to

continue.

Figure 4-9d, Sequential Number Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-27

Page 52

Unit 4: Operation

SEQUENTIAL NUMBER FIELD CONFIGURATION

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Normal 12: Normal

3 Font Type 0: X1

1: X2

2: X3

4: OCR-B

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 32: Number of characters in the field.

14 Vertical Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

15 Horizontal Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

16 Input Check 0: No check

2: Mandatory entry.

5: Numeric only.

6: Numeric in all digits.

7: Non-zero numeric only; entry is manditory.

17 Title Setup 0: Not displayed in a title in printing preset.

2: Initially displayed as a title in printing preset

(for a format, one field set only).

18 Reserved 0: Determined

19 0 Insertion (specifies

whether a leading or trailing

zeroes are inserted)

20 Preset 0: No entry in printing preset (no display).

21 Font Color 0: Black

0: No 0 insertion.

1: 0 insertion in right aligned when copy is

required (i.e. 1=001).

1: Entry in printing preset (displayed).

3: Red

4: Black and White reversal.

Table 4-9d, Sequential Number Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-28

Page 53

Unit 4: Operation

PRICE FIELD CONFIGURATION

This field type allows for a price to be printed onto a label in the designated location and

orientation. The price printed will be represented in the currency type selected.

XX XX: FIELD TYPE

X: ***********

000000000000000000000

Enter numeral/s at

each screen to

configure.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Numeral

will display on

bottom row of

LCD.

XX 01: FIELD TYPE

2: PRICE

X00000000000000000000

XX 02: DATA TYPE

0: STANDARD 1: POP

XX000000000000000000

XX 03: FONT TYPE

0: X1 1: X2 2: X3

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

XXXXXXXXXX000000000

XX 15: H - EXPANSE

XXXXXXXXXXXXXXX0

XX 16: INPUTCHECK

5: NUM ONLY

XXXXXXXXXXXXXXXX

XX 17: INP METHOD

0: LEFT 1: RIGHT

X00000000000000000000

XX 18: INSERTION

0: NON 1: CM 2: CM&.

XX000000000000000000

XX 19: 0 AUTO-INS

XXX0000000000000000

XX 20: PRESET

0: OFF 1: ON

XXXX000000000000000

XX 21: RESERVED

XXXXX0000000000000

Press SHFT to

scroll options.

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 14: V - EXPANSE

XXXXXXXXXXXXXX00

Copy?

Yes / No

Refer to the

relative table

& chart to

continue.

Press

FMT

Figure 4-9e, Price Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-29

Page 54

Unit 4: Operation

PRICE FIELD CONFIGURATION

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Price 20: Normal 21: POP

3 Font Type Normal:

0: X1

1: X2

2: X3

5: Price character

POP:

0: POP1

1: POP2

2: POP3

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 10: Number of characters in the field.

(excludes curency marks, commas, decimals)

14 Vertical Expansion 1 to 4: Magnification of horizontal/vertical

direction to character (1 to 3 for POP fonts).

15 Horizontal Expansion 1 to 4: Magnification of horizontal/vertical

direction to character (1 to 3 for POP fonts).

16 Input Check 5: Numeric Only.

6: Numeric in all digits.

7: Numeric is accepted, but no currency mark. 0

and non-entry are not allowed.

17 Input Method 0: Left aligned format.

2: Right aligned format.

18 Insertion 0: None

1: Currency mark.

2: Currency mark and decimal point.

5: Currency mark and comma.

6: Currency mark, comma, and decimal point.

7: Comma and decimal point.

19 0 Insertion 0: No 0 insertion.

1: With 0 insertion, right aligned (i.e. 1=001).

20 Preset for general/Euro

currency mark.

21 Reserved 0: Determined

Table 4-9e, Price Field Configuration

0: General currency mark is not shown.

1: Entry required. Show general currency mark.

8: Euro currency mark is not shown.

9: Entry required. Euro currency mark is shown.

SATO HT200e Operator Manual PN 9001103B Page 4-30

Page 55

Unit 4: Operation

CALENDAR FIELD CONFIGURATION

This field type permits a date and/ot time to be printed in the designated location and orientation

of a label. Typical applications of this feature is to identify the date of manufacture, inspection, or

expiration.

XX XX: FIELD TYPE

X: ***********

000000000000000000000

Enter numeral/s at

each screen to

configure.

Numeral

is displayed

Press SHFT to

scroll options.

Press SHFT to

scroll options.

on bottom

row of LCD.

XX 01: FIELD TYPE

3: CALENDAR

X00000000000000000000

XX 02: DATA TYPE

0: DATE 1: TIME

XX000000000000000000

XX 03: FONT TYPE

1: X2 2: X3

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

0: 0 1: 90

XXXXXXXXXX000000000

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 15: H - EXPANSE

XXXXXXXXXXXXXXX0

XX 16: INPUTCHECK

6: NUMBER ONLY

XXXXXXXXXXXXXXXX

XX 17: INCREMENT

X00000000000000000000

XX 18: DISP METHD

0: ddmmyy

XX000000000000000000

XX 19: SEPARATOR

0: NONE 1: /

XXX0000000000000000

XX 20: PRESET

0: OFF 1: ON

XXXX000000000000000

XX 21: 0 RESERVED

XXXXX0000000000000

Copy?

Yes / No

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press

FMT

XX 14: V - EXPANSE

XXXXXXXXXXXXXX00

Refer to the

relative table

& chart to

continue.

Figure 4-9f, Calendar Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-31

Page 56

Unit 4: Operation

CALENDAR FIELD SETUP

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Calendar 30: Date

31: Time

3 Font Type 1: X2

2: X3

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 32: Number of characters in the field.

14 Vertical Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

15 Horizontal Expansion 1 to 4: Magnification of horizontal/vertical

direction to character.

16 Input Check 6: Numeric in all digits.

7: Numeric is accepted, but no currency mark. 0

and non-entry are not allowed.

17 Addition 0: No addition.

1: Addition

Date and time should be arranged separately in

each field per format.

18 Presentation Format 0: ddmmyy

1: mmddyy

2: yymmdd

3: ddmmyyyy

4: mmddyyyy

5: yyyymmdd

0: 24 hour format

1: AM/PM before time

2: AM/PM after time

19 Symbol for separating

calendarr data

20 Preset 0: No entry in printing preset (not displayed).

21 Reserved 0: Determined

0: None

1: “/”

2: “-”

3: ”.”

1: Entry in printing preset (displayed).

Table 4-9f, Calendar Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-32

Page 57

Unit 4: Operation

BARCODE FIELD CONFIGURATION

Allows a barcode to be printed onto a label in the specified location and orientation. This menu

permits all barcode values and variables to be configured.

XX XX: FIELD TYPE

X: ***********

000000000000000000000

Enter numeral/s at

each screen to

configure.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Press SHFT to

scroll options.

Numeral

will display on

bottom row of

LCD.

XX 01: FLD TYPE

7: BARCODE

X00000000000000000000

XX 02: DATA TYPE

0: HUMAN FONT OFF

XX000000000000000000

XX 03: SYMBOLOGY

0: NW7 1: CODE39

XXX00000000000000000

XX 04: V - POSITION

XXXX0000000000000000

XX 07: H - POSITION

XXXXXXX000000000000

XX 10: ROTATION

0: 0 2: 180

XXXXXXXXXX000000000

XX 15: BAR EXPANS

XXXXXXXXXXXXXXX0

XX 16: BAR HEIGHT

XXXXXXXXXXXXXXXX

XX 19: CHECK DGT

0: OFF 1: ON

X00000000000000000000

XX 20: PRESET

0: OFF 1: ON

XXXX000000000000000

XX 21: 0 RESERVED

XXXXX0000000000000

Copy?

Yes / No

Press SHFT to

scroll options.

Press

FMT

Press SHFT to

scroll options.

XX 11: CHAR PITCH

XXXXXXXXXXX00000000

XX 12: CHAR COUNT

XXXXXXXXXXX00000000

XX 14: BAR RATIO

0: FIXED 1: 1-2

XXXXXXXXXXXXXX00

Refer to the

relative table

& chart to

continue.

Figure 4-9g, Barcode Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-33

Page 58

Unit 4: Operation

BARCODE FIELD SETUP

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Barcode 70: Readable>

71: Not readable.

3 Font Type 0: NW-7

1: CODE39

2: INT2of5

3: EAN13

4: EAN8

5: UPC-E

6: CODE128 (C Set)

7: CODE129 (B Set)

4, 5, 6 Vertical Position 001 to 784 dots: Vertical print position.

000: Entry only, where print is not required.

7, 8, 9 Horizontal Position 001 to 384 dots: Horizontal print position.

10 Rotation 0: 0 degrees

1: 90 degrees

2: 180 degrees

3: 270 degrees

11 Character Pitch 0 to 9 dots

12, 13 Character Count 01 to 22: Number of digits in the barcode.

14 Bar Ratio 0: Invalid (EAN, UPC-A, UPC-E)

1: 1:2

2: 1:2.5

3: 1:3

15 Bar Expansion 2 to 4: For bar ratio of 1: 2.5, enlargement is

restricted to 2x and 4x only.

16, 17, 18 Bar Height 001 to 240 dots.

19 Check digit (when Code

128 is being set, specify

“1”).

20 Preset 0: No entry in printing preset (not displayed).

21 Reserved 0: Determined

0: No CD

1: CD creation (computing)

2: CD Check (with input data)

3: Price CD (only for EAN13)

1: Entry in printing preset (displayed).

Table 4-9g, Barcode Field Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-34

Page 59

Unit 4: Operation

Scroll through all

of the screens of

the established

field and begin

entering Copy data

with number 22.

Configuration

numeral

is displayed on

bottom row of

LCD.

XX 22: V - COPY

0: NONE

XXXXXX000000000000

XX 23: COPY 1 - 1

XXXXXXX00000000000

XX 25: COPY 1 - 2

XXXXXXXXX00000000

XX 27: COPY 1 - 3

XXXXXXXXXXX000000

XX 29: COPY 1 - 4

XXXXXXXXXXXXX00000

XX 31: COPY 2 - 1

XXXXXXXXXXXXXX0000

XX 33: COPY 2 - 2

X0000000000000000000

XX 35: COPY 2 - 3

XXX0000000000000000

XX 37: COPY 2 - 4

XXXXX00000000000000

XX 39: COPY 3 - 1

XXXXXXX0000000000

XX 41: COPY 3 - 2

XXXXXXXXX0000000

XX 43: COPY 3 - 3

XXXXXXXXXXX0000

XX 45: COPY 3 - 4

XXXXXXXXXXXXX0

Press

ENTR

Refer to the

relative table &

chart to

continue.

Figure 4-9h, Copy Configuration

COPY SETUP

DIGIT DESIGNATION DESCRIPTION

22 Copy action 0: No copy.

1: Copy.

2: Receive a copy.

23, 24 Copy 1 01-32: Specify starting position to begin copying.

25, 26 01-32: Specify number of characters to copy.

27, 28 01-29: Specify where to send the characters.

29, 30 01-32: Starting postion to paste copied characters.

31, 32 Copy 2 01-32: Specify starting position to begin copying.

33, 34 01-32: Specify number of characters to copy.

35, 36 01-29: Specify where to send the characters.

37, 38 01-32: Starting postion to paste copied characters.

39, 40 Copy 3 01-32: Specify starting position to begin copying.

41, 42 01-32: Specify number of characters to copy.

43, 44 01-29: Specify where to send the characters.

45, 46 01-32: Starting postion to paste copied characters.

Table 4-9h, Copy Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-35

Page 60

Unit 4: Operation

PRINT CONFIGURATION

Print Configuration is treated as a field. Thusly, print configuration should always be the last field

for that label.

XX XX: FIELD TYPE

X: ***********

000000000000000000000

Enter numeral to

designate field

number & field

type.

Numeral

is displayed

on bottom

row of LCD.

XX 01: FIELD TYPE

0: QTY

X00000000000000000000

XX 03: FIXED QTY

XX000000000000000000

Press 0 until the

following screen is

displayed.

XX 16: DISP COUNT

XXX00000000000000000

Press 0 until

through screen 46.

Press ENTR

Refer

to the relative

table & chart

to continue.

Figure 4-9i, Print Quantity Configuration

PRINT QUANTITY CONFIGURATION

DIGIT POSITIONS DESIGNATED ITEM DESCRIPTION

1, 2 Print Quantity 00: Quantity.

3 Quantity 0: Not fixed. (default)

1: Fixed quantity

4 to 15 Reserved All remains at 0

16 Count 0: Prints the quantity entered.

Other than 0: Prints freely.

Figure 4-9i, Print Quantity Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-36

Page 61

Unit 4: Operation

DISCOUNT RATE CONFIGURATION

Where applicable, this menu allows the discount rate to be configured.

POWER

FORMAT NO.

[ . . ]

HT200e

Refer to relative

Fixed Formats

16, 17, 18, 19, 25.

Press ENTR.

[WAS 25%] *

$ . . . . . .

Press

FNC2

DISCOUNT RATE

[ . . ] %

Enter

discount rate.

Press

ENTR

Press AC

if incorrect

entry.

Figure 4-10, Discount Rate Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-37

Page 62

Unit 4: Operation

TAX RATE CONFIGURATION

Where applicable, this menu allows the tax rate to be configured.

POWER

FORMAT NO.

[ . . ]

HT200e

Refer to relative

Fixed Formats.

Enter 23 or 24.

Press ENTR.

[VAT 15.00%] *

$ . . . . . . .

Press

FNC2

VAT

[ 17.55 ] %

Enter four

digit tax rate.

Press

ENTR

Press AC

if incorrect

entry.

Figure 4-11, Tax Rate Configuration

SATO HT200e Operator Manual PN 9001103B Page 4-38

Page 63

Unit 4: Operation

OPERATIONAL MODES

This unit provides instruction on the various modes used in operation.

ONLINE MODE

This operational mode permits printing activity when the print data is received from the host.

POWER

FORMAT NO.

[ . . ]

HT200e

70

[ONLINE MODE]

Printer

awaits data from the

host. Starts printing

when data is

received.

PRINTING

Printing

completed.

Power = Off

Figure 4-12, Online Mode

SATO HT200e Operator Manual PN 9001103B Page 4-39

Page 64

Unit 4: Operation

TABLE DATA MODE

This operational mode permits the configuration, data entry, modification, and deletion of table

data.

POWER ON

FORMAT NO.

[ . . ]

HT200e

FNC1

Use arrow keys to

cursor. Press

ENTR to advance.

TABLE 1

STR MODIFY DEL

STR TABLE NO.

[ . . ]

COPY FROM [ . . . ]

TABLE 1

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

MODIFY TABLE NO.

[ . . . ]

DELETE TABLE NO.

[ . . . ]

TABLE STORING

TABLE 1 TABLE 2

TABLE 3

TABLE 2

STR MODIFY DEL

STR TABLE NO.

[ . . ]

COPY FROM [ . . . ]

TABLE 1

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

MODIFY TABLE NO.

[ . . . ]

DELETE TABLE NO.

[ . . . ]

Power = Off

TABLE 3

STR MODIFY DEL

STR TABLE NO.

[ . . ]

COPY FROM [ . . . ]

TABLE 1

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

MODIFY TABLE NO.

[ . . . ]

DELETE TABLE NO.

[ . . . ]

TABLE DATA DEL

YES NO

XXX

TABLE DATA DEL

YES NO

XXX

TABLE DATA DEL

YES NO

XXX

Figure 4-13, Table Data Mode

SATO HT200e Operator Manual PN 9001103B Page 4-40

Page 65

Unit 4: Operation

PRESET DATA MODE

This operational mode permits the configuration, modification, and deletion of preset data.

RCL + POWER

[PRESET]

PRINT STR MODIFY

DEL DUMP MODIFIER

Press

to scroll options.

Press ENTR

PRESET NO. INPUT

. . . . <PRINT>

PRESET F-NO. [ . . ]

PRESET NO. INPUT

. . . . <MODIFY>

PRESET NO. INPUT

. . . . <DELETE>

DUMP FROM

INT RAM OPT CARD

PRESET NO. INPUT

…… - ...… MASTER

Enter preset

number.

Press ENTR

Enter preset

number.

Press ENTR

Enter preset

number.

Press ENTR

Enter preset

number.

Press ENTR

PRESET NO. INPUT

…… - ...… <DUMP>

Enter preset

number.

Press ENTR

PRESET NO. INPUT

. . . . <PRINT>

Refer to

Preset Data

Storage

[ ITEM ]

. . . . . . . . .

PRESET DELETE OK

. . - . . . . Y / N

Enter preset

number.

Press ENTR

Enter preset

number.

Press ENTR

Change data.

Press ENTR

PRESET DELETED

PRINTING

[ ITEM ]

. . . . . . . . .

Enter preset

number.

Press ENTR

[ PRICE ]

S . . . . . . . . .

Enter preset

number.

Press ENTR

[ QTY ]

. . . .

Enter preset

number.

Press ENTR

Figure 4-14, Preset Data Mode

SATO HT200e Operator Manual PN 9001103B Page 4-41

Page 66

Unit 4: Operation

PRESET DATA STORAGE

This operational mode permits the storage of preset data.

POWER

FORMAT NO.

[ . . ]

HT200e

Press

RCL

[ PRESET ]

PRINT STR MODIFY

DEL DUMP MASTER

Press

to scroll options.

Press ENTR

PRESET F-NO.

[ . . ]

Enter a label

format number.

Press ENTR

PRESET NO. INPUT *

. . . . < STORE >

Enter data as

required. Press

ENTR

Prompted

to enter various

label format

data.

[ ITEM ]

. . . . . . . . .

Enter a number to

assign to the

following preset.

Press ENTR

Figure 4-15, Preset Data Storage

SATO HT200e Operator Manual PN 9001103B Page 4-42

Page 67

Unit 4: Operation

SUSPENDING A PRINT JOB

This operational mode provides instruction on how to suspend a print job once initiated.

PRINTING

Continue?

Yes / No

Press

S/S

Press

S/S

S/S PRINT

REMAIN QTY: 0001

Printing

ceases.

Begin again?

Yes / No

Continue to

wait.

Figure 4-16, Suspending A Print Job

SATO HT200e Operator Manual PN 9001103B Page 4-43

Page 68

Unit 4: Operation

REPRINTING A LABEL

This operational mode provides instruction on how to print a duplicate of a previously printed

label.

A

Format has

printed.

[ITEMSQ] *

. . . . . . . . . . . . . C

Reprints

the last label

with the sequential

variable incremented

or decremented

accordingly.

Reprint?

Yes / No

Press

S/S

REPRINT W/ SEQNUM

ON OFF

On / Off

PRINTING

Completes

printing the

label.

Determine

what next. Refer

to charts to

execute.

Reprints

the last label

with exactly the

same sequential

variable.

Figure 4-17, Reprinting A Label

SATO HT200e Operator Manual PN 9001103B Page 4-44

Page 69

Unit 4: Operation

DATA ENTRY EDIT

The black blinking cursor indicates where the next typed character will appear. Use the arrow

keys on the printer keypad to move the cursor in the direction desired for entry or edit.

If an additional character was accidentally typed, move the cursor to the right of the accidental

character and press DEL once. The accidental character wil be replaced when the text moves

one space to the left.

If an incorrect character is typed, move the cursor onto that character and enter the desired one.

The incorrect character will be replaced by the one entered. Any additional charcters entered will

replace those to the right.

Use of the AC key of the keypad will replace will clear the entire set of characters entered.

Press the ENTR key to set the entries. Once the ENTR key has been pressed, data entry or edit

is not possible.

SATO HT200e Operator Manual PN 9001103B Page 4-45

Page 70

Unit 4: Operation

OPERATIONAL ADJUSTMENTS

This unit covers adjustment of printer features and components to ensure proper function and

performance.

EYE-MARK SENSOR ADJUSTMENT

The penetrating sensitivity of the eye-mark sensor may be electrically adjusted through a

potentiometer integrated into the main circuit board. This potentiometer is externally accessible,

thusly dismantling of the printer is not required.

For proper performance, the sensor must have a voltage reading greater than 0.9V. If the