Page 1

v.G1.5

Profile

& LK Exit Device

Installation Instructions

A7856C

10/16

Copyright 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Page 2

Page 3

Table of Contents

1

Warning ............................................................................3

2

General Description

3

Specifications

4

Features

5

Parts Breakdown

............................................................................ 4

................................................................... 4

.......................................................... 4

8877/8878 x ET x Profile Series Rim Exit Device

8977/8978 x ET x Profile Series Mortise Exit Device

Installation Instructions: Rim 8877/8878

6

Installation Instructions: Mortise 8977/8978

7

8

RF Technology Lock

9

Wiring Options

10

Operational Check

................................................................ 22

........................................................ 21

.......................................................... 27

........................ 9

............. 5

....... 7

................ 15

Warning

1

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received, including

interference that may cause undesired operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

the interference will not occur in a particular installation. If this equipment does cause harmful interference to radio

or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna

• Increase the separation between the equipment and receiver

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected

• Consult the dealer or an experienced TV technician for help

This Class B digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe B est conforme avec la norme NMB-003 du Canada.

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

1-800-810-WIRE • www.sargentlock.com • A7856C

To comply with “Fire Listed” doors, the batteries must be replaced with alkaline batteries only.

!

Do not install batteries if controller is powered by external power supply.

Warning SARGENT Mfg. Co. locksets utilizing a door position switch (DPS)

!

are not rated for, or intended for use in life safety applications.

Changes or modifications to this unit not expressly approved by the party

responsible for compliance could void the user’s authority to operate the equipment.

Page 4

Profile Series v.G1.5 Rim Exit Device

General Description

2

The SARGENT Profile v.G1.5 Rim and Mortise Exit Devices are designed for areas which require stand-alone

authorized entry. They consist of a self-contained microprocessor-controlled keypad with non-volatile memory.

The keypad holds a total of 100(LK)/2000 (G1-LU, G1-PK, G1-PA, G1-TU, G1-TP, G1-TA) different user codes.

User codes 01 and 02 are utilized for Master and Supervisory Codes, respectively. SARGENT mortise locks are

designed with quality components to provide high security, performance and durability.

• The Profile v.G1.5 Series provides enhanced software and hardware features.

• New v.G1.5 controllers replace v.G1 controllers. Product is still ordered as “G1-” prefix.

Controllers are labeled “G1.5”.

• This product is operated by six (6) “AA” alkaline batteries.

Specifications

3

Profile Series Rim Exit

• Latch – 3/4” throw, stainless steel

• Outside motor driven Exit Trim (“ET”) lever

controlled by keypad

• Push bar retracts latch from inside

• Fire stop provided on all lever handle designs

• Profile Series exit devices furnished for 1-3/4”

doors

• UL Listed

• Accepts all SARGENT rim cylinders (8877 only)

• Key retracts latch (8877 only)

• Available in ET lever handle designs only

4

Features

• Non-volatile memory

• Motor driven, battery operated

• Battery operated with 6 “AA” Alkaline

• Low battery alert–4 chirps after code entry

• External remote “request to enter”

• Master, Emergency or Supervisory code will

unlock door when low battery has expired

• 100 (LK) or 2000 (G1-LU, G1-PK, G1-PA,

G1-TU, G1-TP, G1-TA) users

• Programming done at keypad or with a DTD

(Data Transfer Device) using SoloPlus™

software and a Laptop /PC (G1-TA and

G1-TP require software)

SoloPlus™ works with PalmPilot; SofLink™

Plus software not supported with DTD.

Profile Series Mortise Exit

• Latch – 3/4” throw, anti-friction, brass

• Outside motor driven Exit Trim (“ET”) lever

controlled by keypad

• Push bar retracts latch from inside

• Fire stop provided on all lever handle designs

• Profile Series exit devices furnished for

1-3/4” doors

• UL Listed

• Accepts all SARGENT mortise cylinders (8977 only)

• Key retracts latch (8977 only)

• Available in ET lever handle designs only

• RF Fob and Proximity Card, Tag, and

Fob are optional

• Operates utilizing any one to six digit code.

• Digits may be repeated and codes may start

with zero

• Cylinder override

• Entry of three wrong User Codes disables all

codes for ten seconds. Yellow LED on solid

• Piezo horn can be heard with each keystroke or

turned off by Master or Supervisory Code

• Last 15 transactions can be output to portable

print via infrared link (LK Only)

• Last 2000 (Except LK) transactions can be

output to PC via SofLink™ Plus Software

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

4 1-800-810-WIRE • www.sargentlock.com • A7856C

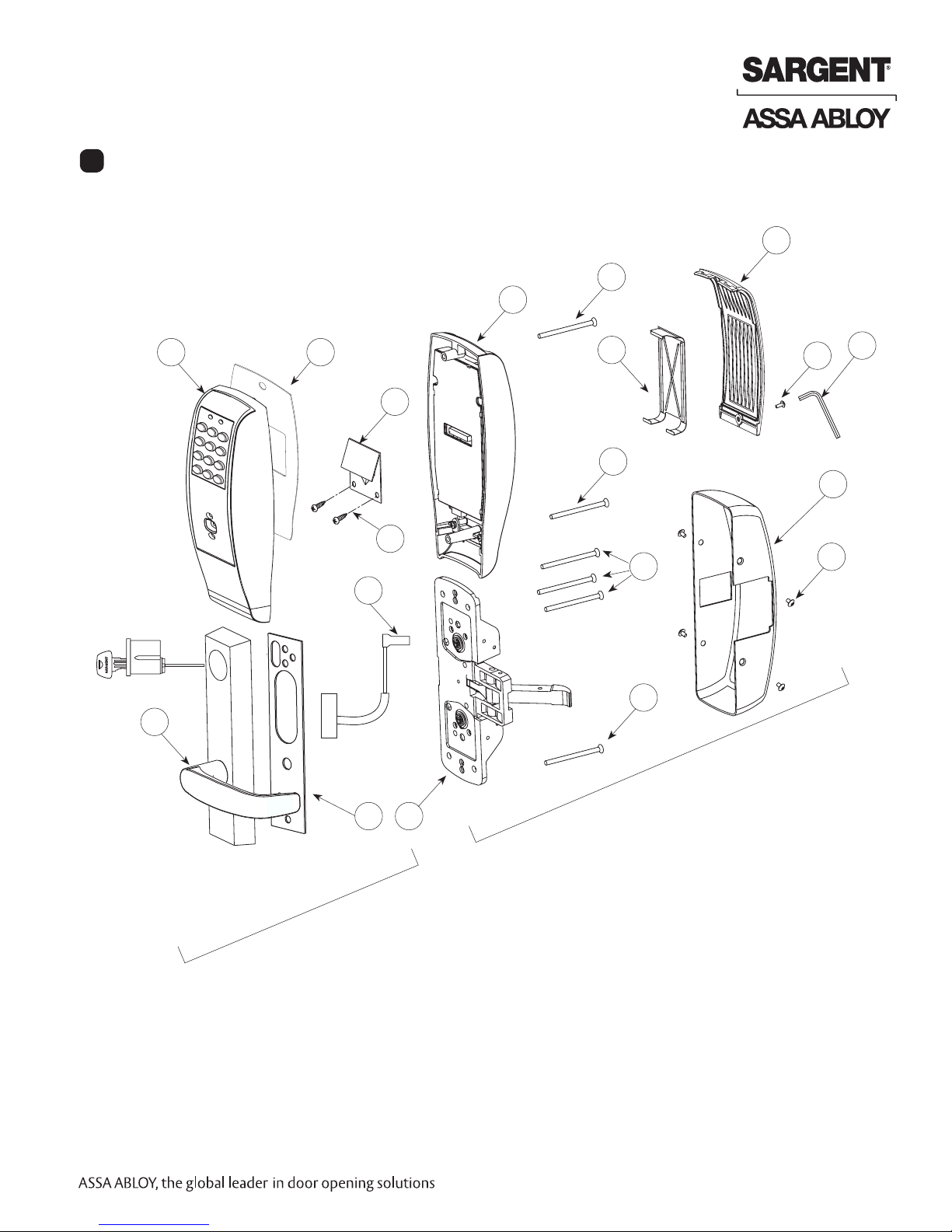

Page 5

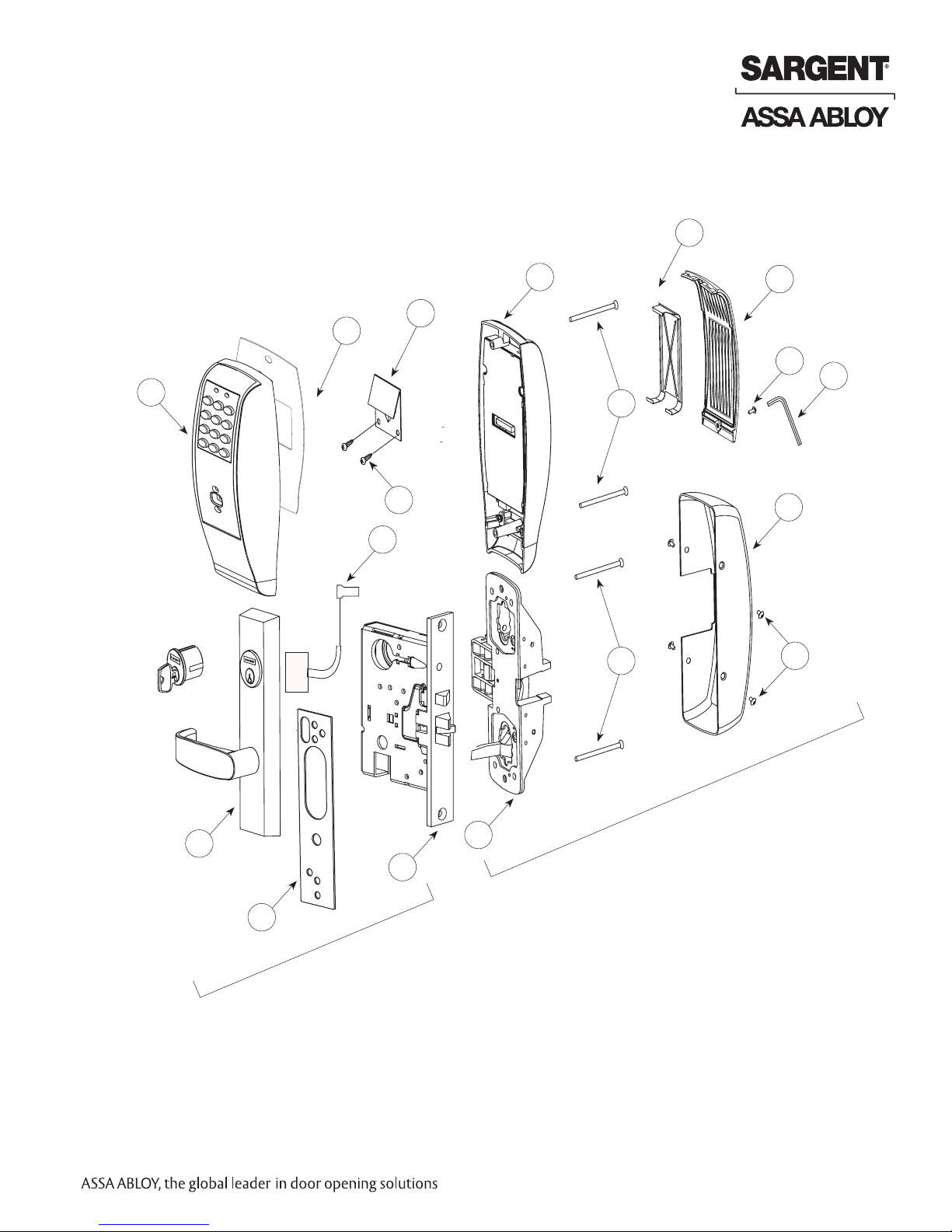

Profile Series v.G1.5 Rim Exit Device

Parts Breakdown

5

8877/8878 x ET x Profile Series Rim Exit Device

3

12

2

1

9

17

6

7

10

8

12

11

11

Inside

5

4

14

15

Outside

16

13

Items included with 8877 and 8878 Rim Exit Device:

• Outside Escutcheon with Keypad

• Outside motorized ET Trim Assembly

• Exit Device (Chassis & Rail Assembly)

• Rim cylinder for 8877

• Inside Escutcheon with Circuit Board and Battery Pack

• 6 “AA” alkaline batteries

• Screw Packs

1-800-810-WIRE • www.sargentlock.com • A7856C 5

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 6

Profile Series v.G1.5 Rim Exit Device

Parts Breakdown 8877/8878 x ET x Profile Series Rim Exit Device (Continued)

ITEM PART NO.

1 52-2839 Outside Escutcheon (Prox Only) Assembly (G1-PA, G1-TA) 1

52-2474 Outside Escutcheon (Key Pad Only) Assembly (LK)

52-2838 Outside Escutcheon (Key Pad/Prox) Assembly (G1-LU, G1-PK, G1-TU, G1-TP)

52-2704 Key Pad and Proximity Assembly (G1-LU, G1-PK, G1-TU, G1-TP) 1

52-2432 Key Pad/Proximity Bezel Assembly w/ Harness (LK)

52-2706 Proximity Only Assembly (G1-PA, G1-TA) 1

68-1397 Outside Escutcheon Housing Only 1

52-0176 Outside Escutcheon End Cap 1

2 52-2460 Inside Escutcheon Assembly with 100 User Controller (LK) 1

52-2833 Inside Escutcheon Assembly with 2000 User Controller (G1-LU)

52-2834 Inside Escutcheon Assembly with Prox/Key Pad Controller (G1-PA, G1-PK)

52-2836 Inside Escutcheon Assembly (Key Pad Only) with RF Technology Controller (G1-TU)

52-2835 Inside Escutcheon Assembly (Key Pad/Prox or Prox Only) with RF Technology Controller

(G1-TA, G1-TP)

68-1396 Inside Escutcheon Housing Only 1

52-0175 Inside Escutcheon End Cap Only 1

52-2441 100 User Controller Assembly (LK) 1

52-2783 2000 User Controller Assembly (G1-LU)

52-2784 2000 User Controller Assembly (G1-PA, G1-PK)

52-2786

52-2785 2000 User (Key Pad Only) Controller Assembly w/ RF Technology (G1-TU)

3 52-0170 Battery Cover 1

52-2309 Battery Cover – RF Technology (G1-TU,G1-TP, G1-TA)

4 01-1212 Security Screw 1

5 01-0297 Security Tool 1

6 52-0033 Fire Stop Plate 1

7 01-1500 Fire Stop Screws #8 x 1/2” Type “AB” Phillips Pan Head Self Tap 2

8 52-0253 Battery Keeper 1

52-0344 Battery Keeper – RF Technology (G1-TU, G1-TP, G1-TA)

Consult Factory

9

Consult Factory

10

11 01-4451 ET Through-bolts 2

12 77-0685 Escutcheon Through-bolts 2

13 68-4261 Center Case Assembly LHRB & RHRB (Std.)

68-4263 Center Case Assembly LHRB (12-) & RHRB (12-) 2

14 68-0406 Chassis Cover 1

15 97-0052 Chassis Cover Screws 4

52-2425 Screw Pack (Includes item numbers 5,6,7,15) 1

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

16 52-0263 Gasket, ET 1

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

17 68-1400 Gasket, Escutcheon 1

10/31/16

6 1-800-810-WIRE • www.sargentlock.com • A7856C

01-0803 Battery Alkaline (“AA” Cell) (Not Shown) 6

2000 User (Key Pad/Prox or Prox Only) Controller Assembly w/ RF Technology (G1-TA, G1-TP)

Motorized ET Lever Trim (with Key and Cylinder) 1

Motor and Harness Assembly 1

DESCRIPTION REQ’D

Page 7

Profile Series v.G1.5 Mortise Exit Device

Parts Breakdown (continued)

8977/8978 x ET x Profile Series Mortise Exit Device

8

2

6

3

19

4

5

1

7

11

13

12

16

17

10

18

Outside

15

Inside

14

Items included with 8977 and 8978 Mortise Exit Device:

• Outside Escutcheon with Keypad

• Outside Motorized ET Trim Assembly

• Exit Device (Chassis, Rail Assembly and Mortise Lock)

• Mortise Cylinder for 8977

• Inside Escutcheon with Circuit Board and Battery Pack

• 6 “AA” alkaline batteries

• Screw Packs

1-800-810-WIRE • www.sargentlock.com • A7856C 7

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 8

Profile Series v.G1.5 Mortise Exit Device

Parts Breakdown 8977/8978 x ET x Profile Series Mortise Exit Device (Continued)

ITEM PART NO.

1 52-2839 Outside Escutcheon (Prox Only) Assembly (G1-PA, G1-TA) 1

52-2838 Outside Escutcheon (Key Pad/Prox) Assembly (G1-LU, G1-PK, G1-TU, G1-TP)

52-2704 Key Pad and Proximity Assembly (G1-LU, G1-PK, G1-TU, G1-TP) 1

52-2432 Key Pad/Proximity Bezel Assembly w/ Harness (LK)

52-2706 Proximity Assembly (G1-PA, G1-TA) 1

68-1397 Outside Escutcheon Housing Only 1

52-0176 Outside Escutcheon End Cap Only 1

2 52-2460 Inside Escutcheon Assembly with 100 User Controller (LK) 1

52-2833 Inside Escutcheon Assembly with 2000 User Controller (G1-LU)

52-2834 Inside Escutcheon Assembly with Prox/Key Pad Controller (G1-PA, G1-PK)

52-2836 Inside Escutcheon Assembly (Key Pad Only) with RF Technology Controller (G1-TU)

52-2835 Inside Escutcheon Assembly (Key Pad/Prox or Prox Only) with RF Technology Controller

(G1-TA, G1-TP)

68-1396 Inside Escutcheon Housing Only 1

52-0175 Inside Escutcheon End Cap Only 1

52-2441 Enclosure Assembly (LK) 1

52-2783 Enclosure Assembly (G1-LU) 1

52-2784 Key Pad/Prox or Prox Only Controller Assembly (G1-PA, G1-PK) 1

52-2786

52-2785 2000 User (Key Pad Only) Controller Assembly w/ RF Technology (G1-TU) 1

3 52-0170 Battery Cover 1

52-2309 Battery Cover – RF Technology (G1-TU,G1-TP, G1-TA) 1

4 01-1212 Security Screw 1

5 01-0297 Security Tool 1

6 52-0033 Fire Stop Plate 1

7 01-1500 Fire Stop Screws #8 x 1/2” Type “AB” Phillips Pan Head Self Tap 2

8 52-0253 Battery Keeper 1

52-0344 Battery Keeper – RF Technology (G1-TU, G1-TP, G1-TA)

9 52-2425 Screw Pack (Includes item numbers 5, 6, 7, 12, 13) (not shown) 1

Consult Factory

10

Consult Factory

11

12 01-4451 ET Through-bolts 2

13 77-0685 Escutcheon Through-bolts 2

14 68-2172 Center Case Assembly LHRB (Standard and 12-) 1

68-2173 Center Case Assembly RHRB (Standard and 12-) 1

15 99-2401 Mortise Lock LHRB 1

99-2402 Mortise Lock RHRB 1

16 68-0407 Chassis Cover 1

17 97-0052 Chassis Cover Screws 4

18 68-1400 Chassis Gasket 1

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

19 52-0263 ET gasket 1

10/31/16

01-0803 Batteries - Alkaline (“AA” Cell) (not shown) 6

8 1-800-810-WIRE • www.sargentlock.com • A7856C

2000 User (Key Pad/Prox or Prox Only) Controller Assembly w/ RF Technology (G1-TA, G1-TP)

Motorized ET Lever Trim 1

Motor and Harness Assembly 1

DESCRIPTION REQ’D

1

Page 9

Profile Series v.G1.5 Rim Exit Device

Installation Instructions: 8877/8878 Rim Type Exit Device

6

Step #1 – Prepare Door

A. Verify Hand and Bevel of Door

• This device is non-handed.

• Door should be fitted and hung.

• Verify box label for size of exit device and function.

B. Door Preparation

If using a mullion, install prior to installing hardware.

Doors should be pre-prepped.

Prepare door according to appropriate template:

• Exit installation instructions A6770

• Door Manufacturer’s Template 4640 (Metal and Wood)

Note: Wood door has additional cutout if installation includes a cylinder.

Step #2 – Position Exit Trim (ET)

For exterior applications, use ET gasket (P/N 52-0263)

to seal between ET escutcheon and outside door surface.

1A. For wood doors: Route ET wire harness through the cylinder

hole, out the other side, and through the wire run channel to

the controller cutout.

1B. For metal doors: Route ET wire harness

through the cylinder hole and door

and out the controller cutout.

2. Position and hold ET trim on the door.

3. Connector from ET harness connects

to connector from chassis (Fig. 2)

Exit trim Gasket

(Exterior Applications)

Left Hand

Reverse Bevel

LHRB

Inside

Outside

Fig. 1

Right Hand

Reverse Bevel

RHRB

ET Wire Harness

(from motor)

Outside of Door

Exit trim

Fig. 2

1-800-810-WIRE • www.sargentlock.com • A7856C 9

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 10

Profile Series v.G1.5 Rim Exit Device

Outside of Door

Inside of Door

Fig. 4B

Step #3 – Mount Exit Device Chassis (Inside Trim)

1. Route ET harness along track cutout for wood doors and

through access hole for metal doors.

2. Position exit chassis carefully.

Do not pinch the wire harness.

3. Engage ET spindle in hub of exit device chassis.

4. Secure the exit chassis with through-bolts

to the ET trim using (2) 1/4 -20 x 2-3/8”

flat head machine screws.

Inside of Door

(2) 1/4 x 2-3/8” Flathead

Machine Screws

ET Motor

Harness

Step #4 – Install Cylinder and Secure Chassis

For devices without cylinder, skip this step.

1. Insert cylinder into ET control (Fig. 4A).

2. Mate cylinder tailpiece into hub of exit device chassis.

3. Make sure ET harness is clear of cylinder and cylinder tailpiece.

4. Secure cylinder to exit chassis using (2) #12-24 x 1-7/8”

connecting screws (Fig 4B).

5. Fasten exit chassis to door using:

• (4) #10 wood screws for wood doors (or)

• (4) #10-24 machine screws for metal doors.

6. Position cylinder so that the SARGENT

logo is right-side up (Fig. 4C).

Exit Chassis

Fig. 3

Inside of Door

(4) #10 Wood or

#10-24 Machine

Screws

(2) #12-24 x 1-7/8”

Flat Head Screws

(Connecting Cylinder)

Fig. 4C

Incorrect

Fig. 4A

Correct

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

10 1-800-810-WIRE • www.sargentlock.com • A7856C

Fig. 4B

Page 11

Profile Series v.G1.5 Rim Exit Device

Step #5 – Exterior Door Options

A. Fire Stop Plate (P/N 52-0033)

Fire-rated doors require a fire stop plate on the

outside of the door (Fig.5A).

1. Drill (2) 1/8" x 1-1/4" deep holes in the door if not

already present.

Refer to template for fire-stop prep locations.

2. Attach with flap up and out using (2) #8 x 1/2”

self-tapping screws for wood

and metal doors.

B. Weather Conduit (P/N 52-2847)

Ribbon Cable Hole

Install weather conduit on NON FIRE-RATED

exterior doors only.

1. Carefully insert the weather conduit

into the ribbon cable hole on

the inside of the door (Fig 5B).

2. Place the O-ring around the

weather conduit on the outside

and up against the door (Fig. 5C).

Outside of Door

O-Ring

Fig.5C

Step #6 – Gasket Installation (for Exterior Doors)

For exterior applications, use a gasket between

escutcheon and outside door surface:

1. Carefully remove the backing from the gasket.

2. Apply gasket to escutcheon carefully.

a. Starting in one place, press the adhesive side

of the gasket firmly against the escutcheon.

b. Work around the escutcheon, pressing the sticky side

of the gasket firmly against the escutcheon edge.

c. The gasket should be aligned so that all edges

of the escutcheon are covered.

4. Attach escutcheon to the door.

Fig.5B

Fig. 5A

Outside of Door

Fig. 6A

Fig. 6B

1-800-810-WIRE • www.sargentlock.com • A7856C 11

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 12

Profile Series v.G1.5 Rim Exit Device

Step #7 – Install Outside Escutcheon

For 12- fire rated exit devices, feed keypad

ribbon cable/connector from outside of door

through the gasket then

Fire

Stop

Plate

Weatherseal

Gasket

Ribbon

Cable

fire stop plate (Fig. 7).

For non-fire 12- exit devices, feed keypad

ribbon cable/connector through gasket then

through the conduit hole in door.

Outside of Door

Fig. 7

Step #8 – Connect and Position Outside Escutcheon Wires

Images shown represent installation without gasket. If gasket is necessary, refer to Step #6.

Before the controller is attached to the door:

1. Attach the reader assembly ribbon cable to the inside face of the controller assembly (side that

faces towards the door when mounted (Fig. 8B).

Note: Install ribbon cable with side marked TOP facing up. (Fig. 8A).

2. Attach the ground wire to the bottom of the controller assembly (E1, Fig. 8A).

3. Connect the exit connector to the bottom of the controller (TB1, Fig. 8B).

If Hardwiring is required, go to “Hardwire Wiring Options” on page 14.

4. Place extra wire inside door hole and/or outside escutcheon,

being careful not to pinch wires.

Connectors go on only one way.

Do not offset connectors,

and make sure they are

completely seated.

Outside

escutcheon

Reader Cable

1

2

Ground Wire

Outside Escutcheon

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Fig. 8A

12 1-800-810-WIRE • www.sargentlock.com • A7856C

3

Reader Cable

Ground

Wire

1

P1

1

2

TB1

Motor

Connector

TB1

3

Power/Data

E3

Connector

2

TB2

RedBlack

3

Fig. 8B

Page 13

Profile Series v.G1.5 Rim Exit Device

Step 9 – Install and Secure Inside Escutcheon

1. Secure the inside escutcheon using two #8-32

screws through top and bottom of the

escutcheon (Fig. 9).

Thread into outside escutcheon.

2. Straighten escutcheons and tighten securely,

being careful to avoid pinching wires.

Battery Cover

Step #10 – Install and Remove Batteries*

Battery Keeper

Security

Screw

Security Tool

(P/N 01-0297, Included

Fig. 9

A. Install Batteries and Keeper

1. Place (6) “AA” batteries into the compartment, being careful to properly align polarity (Fig. 10A).

2. To install battery keeper, insert the tabs on the bottom of the keeper into the battery compartment slots

and press the keeper tightly against batteries and inserting tabs into bottom slots.

• For RF technology, use RF Technology lock information 20.

IMPORTANT: * Do not install batteries if controller is powered by external power supply.

• Test for proper operation before closing door.

B. Remove Battery Keeper

To remove the battery keeper, pull the keeper away from the batteries (Fig. 10B).

+

-

Battery Keeper

+

+

Tip Out

-

+

Bottom Tabs

(Battery Keeper)

Fig. 10A

Keeper Tabs

Fig. 10B

1-800-810-WIRE • www.sargentlock.com • A7856C 13

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 14

Step #11 – Install Inside Cover

1. Attach inside cover to escutcheon making

sure to line up tabs with retaining

slots in cover.

2. Secure with security screw using

provided security tool Fig. 11).

Profile Series v.G1.5 Rim Exit Device

Tabs

Retaining Slots

Fig. 11

For information about the RF Technology versions (G1-TU, G1-TP, G1-TA),

refer to “RF Technology Lock” on page 21.

For information about Wiring, refer to “Wiring Options” starting on page 22.

For information about the Testing,

refer to “Operational Check” on page 27.

Step #12 – Install Rail Assembly

Attach rail assembly according to Exit Installation Instructions A6770.

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

14 1-800-810-WIRE • www.sargentlock.com • A7856C

Page 15

Profile Series v.G1.5 Mortise Exit Device

7

Installation Instructions: 8977/8978 Mortise Exit Device

Step #1 – Prepare Door

A. Verify Hand and Bevel of Door

• This device is non-handed.

• Door should be fitted and hung.

• Verify box label for size of exit device and function.

B. Door Preparation

Prior to installation, all holes must be free of burrs, debris and sharp edges.

Prepare door according to appropriate template:

• Exit installation instructions A6770

• Wood door template A7457 ships with product.

• Door manufacturer’s template 4641 (metal and wood)

Left Hand

Reverse Bevel

“LHRB”

Inside of DoorOutside of Door

Inside

Outside

Fig. 1A

Right Hand

Reverse Bevel

“RHRB”

Hole for Ribbon Cable from

Controller to Keypad

Inside of Cylinder Hole

Thumb Turn Lever Hole

Lever Handle Hole

Mortised

Pocket

Pre-drilled and/or

Tapped Holes (2 places)

Through-bolt Hole

Outside Cylinder Hole

(76 and 78 Functions)

Lever Handle Hole

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1-800-810-WIRE • www.sargentlock.com • A7856C 15

10/31/16

Page 16

Profile Series v.G1.5 Mortise Exit Device

Step #2 - Install (ET) Exit Trim and Mortise Lock

1. For exterior applications, use ET gasket (52-0263)

to seal between ET escutcheon and outside

door surface (Fig. 2A).

2. Slide mortise lock into door and securely

fasten with (2) flat head screws (Fig. 2B).

3. Route ET harness through square wire

cutout and out other side of door.

4. Place ET control on door with spindle

inserted through mortise lock (Fig. 2A).

Outside of Door

Outside of Door

1

ET gasket

(part number

52-0263)

3

Fig. 2A

Showing Wood Door Template

Without Cylinder

4

Fig. 2B

Showing Wood Door Template

With Cylinder

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

16 1-800-810-WIRE • www.sargentlock.com • A7856C

2

Page 17

Profile Series v.G1.5 Mortise Exit Device

Outside of Door

Inside of Door

Fig. 4B

Step #3 - Install Exit Chassis

1. Route ET harness along track cutout for wood doors or through

access hole for metal doors (Fig. 3A).

2. Mount exit chassis carefully. Do not pinch harness wires.

3. Position exit chassis on door with lever arm under

rear section of mortise lock (Fig. 3B).

4. Secure chassis and ET with (2) 1/4-20 x

2-3/8” flat head machine screws (Fig. 3A).

4. Fasten exit chassis to door using:

• (4) #10 wood screws for wood doors (or)

• (4) #10-24 machine screws for metal doors.

Inside of Door

(4) #10 Wood or

#10-24 Machine

Screws

Latchbolt

Fig. 3A

Fig. 3C

Step #4 – Install Cylinder and Secure Chassis

For devices without cylinder, skip this step.

1. Insert cylinder into ET control (Fig. 4A).

2. Mate cylinder tailpiece into hub of exit device chassis.

3. Make sure ET harness is clear of

cylinder and cylinder tailpiece.

4. Secure cylinder to exit chassis

using (2) #12-24 x 1-7/8”

connecting screws (Fig 4B).

5. Position cylinder so that the SARGENT

logo is right-side up (Fig. 4C).

Chassis

Lever

Fig. 3B

Lever arm

Inside of Door

(2) #12-24 x 1-7/8”

Connecting Screws

Correct

Incorrect

Fig. 4C

Fig. 4A

Fig. 4B

1-800-810-WIRE • www.sargentlock.com • A7856C 17

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 18

Profile Series v.G1.5 Mortise Exit Device

Step #5 – Exterior Door Options

A. Fire Stop Plate (P/N 52-0033)

Fire-rated doors require a fire stop plate on the outside of the door (Fig.5A).

1. Drill (2) 1/8" x 1-1/4" deep holes in the door if not already present.

Refer to template for fire-stop prep locations.

2. Attach with flap up and out using (2)

#8 x 1/2” self-tapping screws for

wood and metal doors.

B. Weather Conduit (P/N 52-2847)

Ribbon Cable Hole

Install weather conduit on NON FIRE-RATED

exterior doors only.

1. Carefully insert the weather conduit

into the ribbon cable hole on

the inside of the door (Fig 5B).

2. Place the O-ring around the

weather conduit on the outside

and up against the door (Fig. 5C).

Outside of Door

O-Ring

Fig.5C

Step #6 – Gasket Installation (for Exterior Doors)

For exterior applications, use a gasket between

escutcheon and outside door surface:

1. Carefully remove the backing from the gasket.

2. Apply gasket to escutcheon carefully.

a. Starting in one place, press the adhesive side

of the gasket firmly against the escutcheon.

b. Work around the escutcheon, pressing the

sticky side of the gasket firmly against the

escutcheon edge.

c. The gasket should be aligned so that all edges

of the escutcheon are covered.

4. Attach escutcheon to the door.

Fig.5B

Outside of Door

Fig. 6A

Fig. 5A

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

18 1-800-810-WIRE • www.sargentlock.com • A7856C

Fig. 6B

Page 19

Profile Series v.G1.5 Mortise Exit Device

Step #7 – Install Outside Escutcheon

For 12-fire rated exit devices, feed keypad

ribbon cable/connector from outside of

door through the gasket then fire stop

Fire

Stop

Plate

Weatherseal

Gasket

Ribbon

Cable

plate (Fig. 7).

For non fire-12-exit devices, feed keypad

ribbon cable/connector through gasket

then through the conduit hole in door.

Outside of Door

Fig. 7

Step #8 – Connect and Position Outside Escutcheon Wires

Images shown represent installation without gasket. If gasket is necessary, refer to Step #6.

Before the controller is attached to the door:

1. Attach the reader assembly ribbon cable to the inside face of the controller assembly (side that

faces towards the door when mounted (Fig. 8B).

Note: Install ribbon cable with side marked TOP facing up. (Fig. 8A).

2. Attach the ground wire to the bottom of the controller assembly (E1, Fig. 8A).

3. Connect the exit connector to the bottom of the controller (TB1, Fig. 8B).

If Hardwiring is required, go to “Hardwire Wiring Options” on page 14.

4. Place extra wire inside door hole and/or outside escutcheon,

being careful not to pinch wires.

Connectors go on only one way.

Do not offset connectors,

and make sure they are

completely seated.

Outside

escutcheon

Reader Cable

1

2

Ground Wire

Outside Escutcheon

Fig. 8A

3

Reader Cable

Ground

Wire

P1

1

1

2

TB1

Motor

Connector

TB1

3

1-800-810-WIRE • www.sargentlock.com • A7856C 19

Power/Data

E3

Connector

2

TB2

Fig. 8B

RedBlack

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 20

Profile Series v.G1.5 Mortise Exit Device

Step 9 – Install and Secure Inside Escutcheon

1. Secure the inside escutcheon using two #8-32

screws through top and bottom of the

escutcheon (Fig. 9).

Thread into outside escutcheon.

2. Straighten escutcheons and tighten securely,

being careful to avoid pinching wires.

Battery Cover

Battery Keeper

Security

Screw

Security Tool

(P/N 01-0297, Included

Fig. 9A

Step #10 – Install and Remove Batteries*

A. Install Batteries and Keeper

1. Place (6) “AA” batteries into the compartment, being careful to properly align polarity (Fig. 10A).

2. To install battery keeper, insert the tabs on the bottom of the keeper into the battery compartment slots

and press the keeper tightly against batteries and inserting tabs into bottom slots.

• For RF technology, use RF Technology lock information “RF Technology Lock” on page 20.

IMPORTANT: * Do not install batteries if controller is powered by external power supply.

• Test for proper operation before closing door.

B. Remove Battery Keeper

To remove the battery keeper, pull the keeper away from the batteries (Fig. 10B).

+

-

Battery Keeper

+

+

Tip Out

-

+

Bottom Tabs

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

20 1-800-810-WIRE • www.sargentlock.com • A7856C

(Battery Keeper)

Fig. 10A

Keeper Tabs

Fig. 10B

Page 21

Step #11 – Install Inside Cover

1. Attach inside cover to escutcheon making

sure to line up tabs with retaining

slots in cover.

2. Secure with security screw using

provided security tool (Fig. 11).

For information about the RF Technology versions (G1-TU, G1-TP, G1-TA),

refer to “RF Technology Lock” in next section.

For information about Wiring, refer to “Wiring Options” starting on page 21.

Profile Series v.G1.5 Mortise Exit Device

Tabs

Retaining Slots

Fig. 11

For information about the Testing,

refer to “Operational Check” on page 26.

Step #12 – Install Rail Assembly

Attach rail assembly according to Exit Installation Instructions A6770.

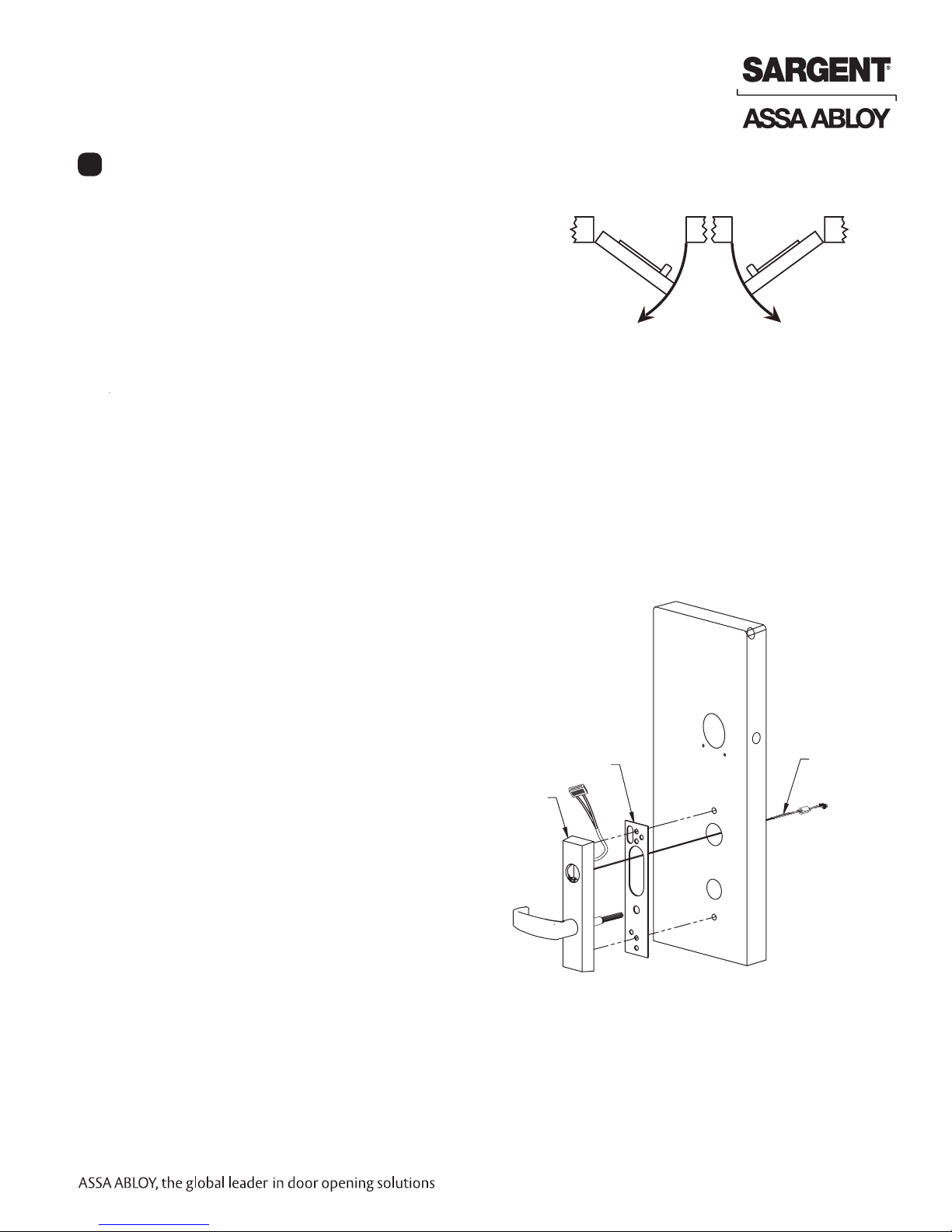

RF Technology Lock

8

Installation for the RF Technology Lock for

G1-TU, G1-TA, G1-TP is, for the most part,

installed as described in section 6.

In addition:

The antenna board must be carefully

moved to access the upper through-bolt

screw. Care should be taken to prevent

damage to the antenna retaining tabs

during this process (Fig. 12).

1. Press the two tabs away from the

antenna board and lift the board

off the mounting posts.

2. Insert the flat head through-bolt and

secure the escutcheon in place.

3. After tightening the top through-bolt,

replace the antenna board by placing

it on the mounting posts and pressing

into the retaining tabs.

Antenna

Board

Mounting

Posts

Flathead

Through-bolt

Antenna

Board

Antenna Board

Retaining Tabs

Fig. 12

Copyright © 2016 Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

21 1-800-810-WIRE • www.sargentlock.com • A7856C

Controller

Assembly

Page 22

Profile Series v.G1.5/LK Exit Device

Wiring Options

9

Hardwiring options include one or a combination of Forced/Propped Door, Hard Power and/or Remote

Unlock (REX). Refer to the examples on the following pages:

1. Forced/Propped Door Option (DM-).

2. Hard Power and Remote Unlock (91-).

3. Hard Power and Remote Unlock (-91), with Forced Propped Door (DM-).

Important

1. Caution: Disconnect all input power before beginning installation to prevent electrical shock and

equipment damage.

2. Installer must be a trained, experienced service person.

3. All wiring must comply with applicable local electrical codes, ordinances and regulations.

Installation Notes

1. With new applications, an ElectroLynx® door harness with 8 and 4 pin connectors will be

pre-installed inside door by Assa Abloy door manufacturer when specified during ordering process.

2. Wiring to pigtail harness is per facility wiring requirement.

ElectroLynx® connector terminations and wire colors all match.

3. If door does not have an ElectroLynx® type door harness, cut connectors off product and hard-wire,

or consult factory for appropriate mating harness.

ElectroLynx® Connector System Notes

The system is designed to be installation friendly with connectors

from the electric hinge through the door to the rail. The only wiring

required is to the loose wires on the pigtail harness

assembly on the frame side of the electric hinge.

IMPORTANT:

The plug and receptacle connectors are designed to mate and lock

together as shown in the figure. Plug the connectors into each other

with the locking mechanism aligned as indicated.

Do NOT force connectors on any other way.

ElectroLynx®

As part of their promise to provide innovative, fast and effective, and higher security

solutions to their customers, ASSA ABLOY Group companies offer ElectroLynx, a

universal quick-connect system that simplifies the electrification of the door opening.

ElectroLynx® is a registered trademark of ASSA ABLOY, Inc.

Receptical

Locking Mechanism

Plug

1-800-810-WIRE • www.sargentlock.com • A7856C 22

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 23

Profile Series v.G1.5/LK Exit Device

ElectroLynx Lock Wire Connections

A

Door Position Switch (DPS)

Install the SARGENT 3287 Door Status Switch according to

instructions included in the kit.

Wire the 3287 Door Status Switch to the ElectroLynx frame harness and to the door status wires:

1. Connect the common wire of the switch to the common wire

of the harness.

2. Connect the normally open wire of the switch to the door

position wire of the harness.

Note: The third wire (normally closed) of the 3287 Door

Status Switch is not used for this type of system.

Before the controller is attached to the door (Fig. 1A):

1. Attach the reader cable to the controller.

2. Attach the connector from the lock into the bottom

of the circuit board (TB2, Fig. 3B).

3. Plug the ground wire into the bottom of the controller assembly (E1, Fig. 3B).

4. Route the connector from the raceway through the top opening between the controller and the escutcheon, along the battery keeper, back under the bottom opening between the controller and escutcheon and

attach at the bottom of the controller.

Note: Connectors go on only one way.

Do not offset connectors and make sure they are completely seated.

D

B

C

A

Fig. 1

Inside

Escutcheon

(Front)

Inside

4

1

1

3

2

2

Inside of Door

Escutcheon

(Back)

4

Fig. 1A

4

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

1-800-810-WIRE • www.sargentlock.com • A7856C 23

Page 24

Option #1 – Forced / Propped Door (DM-)

Installation

1. ElectroLynx® System Wiring Instructions (Fig. 1, 1A and Fig. 2):

a. Look for the mating part on ASSA ABLOY doors and frames.

b. Plug in all connectors during product installation (Fig. 2).

c. Hard wire door status switch as shown

2. Non-ElectroLynx® System Wiring Instructions (Fig. 1 and Fig. 2):

a. Cut the 4-pin connector off the Forced/Propped harness and hard wire to

non-ElectroLynx® two conductor door harness.

b. DM- requires two conductors.

c. Hard wire door harness to power transfer device.

d. Hard wire door status switch to power transfer device.

Profile Series v.G1.5/LK Exit Device

C

D

Door Status Switch

*Wire for switch contact closure

when door is opened - Typical

locations shown in Fig. 1

D

Door

B

A

Outside

Escutcheon

Fig. 1

1 - Red

2 - Black

3 - White (C)

4 - Green (*NC)

QC4A Electric Hinge

C B

With 4-pin connectors and pigtail harness

Inside

Escutcheon

(TB1) Motor

Connector

A

Ground

Forced/Propped Door

Tab E3

4-pin

Connector

Connector J4

4 - Tan

3 - Pink

DM- Prefix (52-3409)

Forced/Propped Door Harness

ElectroLynx Door Harness

With 8 and 4-pin connectors

(Harness location dependent on door type)

(TB2) Remote/Power

Unlock Connector

321

Forced/Propped Door Option

ElectroLynx Wiring System

1 - Red

2 - Black

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written vpermission of Sargent Manufacturing Company is prohibited.

10/31/16

3 - White

4 - Green

24 1-800-810-WIRE • www.sargentlock.com • A7856C

Fig. 2

Page 25

Profile Series v.G1.5/LK Exit Device

Option #2 – Remote Power and Remote Unlock (91-)

Installation

1. ElectroLynx® System Wiring Instructions (Fig. 1, 1A and Fig. 3):

D

B

C

A

a. Look for the mating part on ASSA ABLOY doors and frames.

b. Plug in all connectors during product installation (Fig. 3).

c. Hard wire hard power and/or remote unlock (REX) (Fig. 3).

2. Non-ElectroLynx® System Wiring Instructions (Fig. 1 and Fig. 3):

a. Cut the 8-pin connector off the Remote Power/Unlock

harness and hard wire to non-ElectroLynx® door harness.

b. Remote power requires three conductors and

remote unlock requires two conductors.

c. Hard wire door harness to power transfer device.

d. Hard wire door status switch to power transfer device.

*IMPORTANT: (6) “AA” batteries MUST be removed from

controller when using 3267 power supply.

Note: Refer to 3267 Power

Supply

Instruction Sheet A7477

120VAC L/N/G

* 3267 9VDC

Power Supply

Normally Open

Momentary Switch

(Remote Unlock

REX Option)

-9VDC

+9VDC

EGND

Fig. 1

Escutcheon

1 - Black

2 - Red

3 - White (NO)

4 - Green

5 - Orange (C)

6 - Blue

7 - Brown

8 - Yellow

Door

Outside

* Inside

Escutcheon

A

(TB1) Motor

Connector

Ground Tab E3

Fig. 3A

Remote Powering and Remote Unlocking

ElectroLynx Wiring System

(TB2) Remote/Power

Unlock Connector

+9V

(-)

REX

REX

1 - Red

2 - Black

Data Out

3 - White

4 - Orange

5 - Blue

1 2 3 4 5 6 7 8

91-Prefix (52-3010)

Remote Power and

Unlocking Harness

Data In

RTS

6 - Brown

7 - Yellow

EGND

8 - Green

1 - Black

2 - Red

3 - White (NO)

4 - Green

5 - Orange (C)

6 - Blue

7 - Brown

8 - Yellow

QC4A Electric Hinge

C B

With 8-pin connectors,

8 wires and pigtail harness

1-800-810-WIRE • www.sargentlock.com • A7856C 25

ElectroLynx Door Harness

With 8 and 4-pin connectors - Harness location is

dependent

on door type

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 26

Profile Series v.G1.5/LK Exit Device

Option #3 – Hard Power/Remote Unlock (91-) Combined With Forced/Propped Door (DM-)

Installation

1. ElectroLynx® System Wiring Instructions (Fig. 1, 1A and Fig. 3):

D

B

C

A

a. Look for the mating part on ASSA ABLOY doors and frames.

b. Plug in all connectors during product installation (Fig. 3).

c. Hard wire hard power and/or remote unlock (REX) (Fig. 3).

2. Non-ElectroLynx® System Wiring Instructions (Fig. 1 and Fig. 3):

a. Cut the 8 and 4-pin connectors off the Remote Power/Unlock

harness and hard wire to non-ElectroLynx® door harness.

b. Remote power requires three conductors; and remote unlock

and DM- require two conductors.

c. Hard wire door harness to power transfer device.

d. Hard wire door status switch to power transfer device.

*IMPORTANT: (6) “AA” batteries MUST be removed from

controller when using 3267 power supply.

1 - Black

2 - Red

3 - White (NO)

4 - Green

5 - Orange (C)

6 - Blue

7 - Brown

8 - Yellow

120VAC L/N/G

* 3267 9VDC

Power Supply

Note: Refer to 3267 Power

Supply

Instruction Sheet A7477

-9VDC

+9VDC

EGND

Normally Open

Momentary Switch

(Remote Unlock

REX Option)

D

Fig. 1

Outside

Escutcheon

1 - Black

2 - Red

3 - White (NO)

4 - Green

5 - Orange (C)

6 - Blue

7 - Brown

8 - Yellow

1 - Red

2 - Black

3 - White (C)

4 - Green (*NC)

Door

* Inside

Escutcheon

A

(TB1) Motor

Connector

Ground Tab E3

Fig. 3A

Remote Powering and Remote Unlocking

ElectroLynx Wiring System

(TB2) Remote/Power

Unlock Connector

1 - Red

2 - Black

3 - White

4 - Green

+9V

(-)

REX

REX

Data Out

Data In

4 - Orange

5 - Blue

6 - Brown

321

RTS

7 - Yellow

1 2 3 4 5 6 7 8

1 - Red

2 - Black

3 - White

4 - Tan

3 - Pink

EGND

8 - Green

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written vpermission of Sargent Manufacturing Company is prohibited.

10/31/16

Door Status Switch

*Wire for switch contact closure

when door is opened - Typical

locations shown in Fig. 1

QC4A Electric Hinge

C B

With 8-pin connectors,

8 wires and pigtail harness

26 1-800-810-WIRE • www.sargentlock.com • A7856C

ElectroLynx Door Harness

With 8 and 4-pin connectors - Harness location is

dependent

on door type

Page 27

Profile Series v.G1.5/LK Exit Device

10

Operational Check

For devices with cylinders, insert key into cylinder and rotate.

Check to see if:

1. The key retracts the latch (if applicable).

Key should rotate freely.

2. Depress inside rail to retract latch.

3. Enter 1234* to unlock outside lever handle and retract latch.

4. If the lock is prox only (G1-PA) or RF Technology with Prox (G1-TA),

refer to keypad programming instructions A7716B or A7857.

~½”

1-800-810-WIRE • www.sargentlock.com • A7856C 27

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

10/31/16

Page 28

SARGENT Manufacturing Company

100 Sargent Drive

New Haven, CT 06511 USA

800-810-WIRE (9473) • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A7856C-10/16

Loading...

Loading...