Page 1

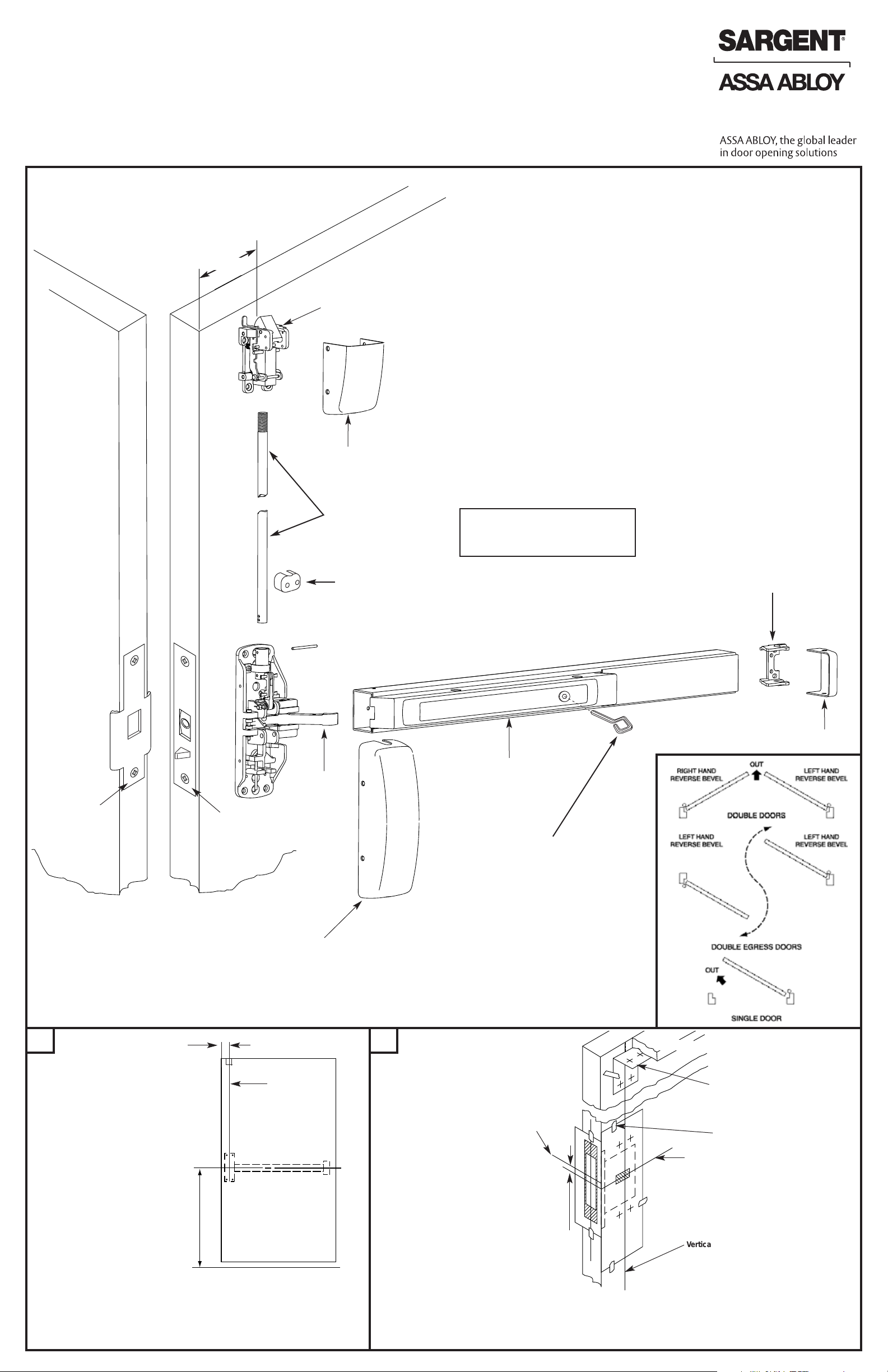

INSTRUCTIONS FOR INSTALLING PP8700 x PR8700 & 12-PP8700 SERIES

TOP AND CENTER LATCH PANIC AND FIRE EXIT DEVICES

ON DOUBLE EGRESS DOORS

SP8700 & 12-SP8700 TOP AND CENTER LATCH PANIC AND

FIRE EXIT DEVICE ON SINGLE DOOR

FOR ASSISTANCE, CALL SARGENT AT 1-800-727-5477 or www.sargentlock.com

Top

Case

Top

Rod

Top

Case

Cover

Cover

Touch Bar

Arm

Mortise Lock

Case

Primary

Mortise Lock

Case

Secondary

Mounting

Plate

End Cap

Important: Surface of door

where exit device is to be

applied must be flush. Clear

away any raised projections to

allow exit device to rest on flat

surface of door.

Left Hand Reverse Bevel Door

Shown Here Swinging In For

Parts Illustration Purposes Only

U.S. Patent No. 6,120,071

AVAILABLE STOCK LENGTHS

LENGTH “E” 32" DOOR, NO CUT OFF REQUIRED. CAN BE CUT TO FIT

DOORS DOWN TO 24" WIDE.

LENGTH “F” 36" DOOR, NO CUT OFF REQUIRED. CAN BE CUT TO FIT

DOORS DOWN TO 33" WIDE. USED FOR STANDARD AND

12- RAIL PREFIXES.

LENGTH “H” 36" DOOR, NO CUT OFF REQUIRED. CAN BE CUT TO FIT

DOORS DOWN TO 33" WIDE. USED FOR 16- AND

ELECTRONIC PREFIXES.

LENGTH “J” 42" DOOR, NO CUT OFF REQUIRED. CAN BE CUT TO FIT

DOORS DOWN TO 37" WIDE.

LENGTH “G” 48" DOOR, NO CUT OFF REQUIRED. CAN BE CUT TO FIT

DOORS DOWN TO 43" WIDE.

CAUTION: BEFORE STARTING:

• Check hand of door - this device is handed and not reversible

• Check hand of device against application

• 2-3/4" backset only

• 1-3/4" thick door only (No glass bead shim available, No inside panel

application)

• Door should be fitted and hung

• Verify box label for size of exit device, function and hand

2-3/4"

MARK VERTICAL

AND HORIZONTAL

REFERENCE LINES

ON DOOR

A

Vertical

Reference Line

(C Top and Center Case)

L

Obtain dimensions

to finished floor

from template

2-3/4"

FINISHED FLOOR

INSIDE FACE

OF DOOR

Vertical

Reference

Line

Tape

C of lock

front (See

template)

Top Case

Template

Door Stop

C Line of

Chassis &

Rail

Obtain dimension

to finished floor

from template

PREPARE DOOR

1.Tape templates

on inside of door

along reference

lines

2.Spot and drill

holes

3.Mortise holes for

outside trim, if

required

Note: For wood

doors that have

a mortise cutout

for the lock body

over 1", install

shims to prevent

lock from moving

around and

causing lost

latchbolt travel.

B

L

L

11/32"

“Lock Down Key”

To operate: Depress pushrail,

insert hex key (or cylinder key

when used) and turn clockwise.

Not for fire exit hardware.

A7212C

Rod Guide

Copyright ©2005, 2008, Sargent Manufacturing Company, an ASSA ABLOY

Group company. All rights reserved. Reproduction in whole or in part without the

express written permission of Sargent Manufacturing Company is prohibited.

Page 2

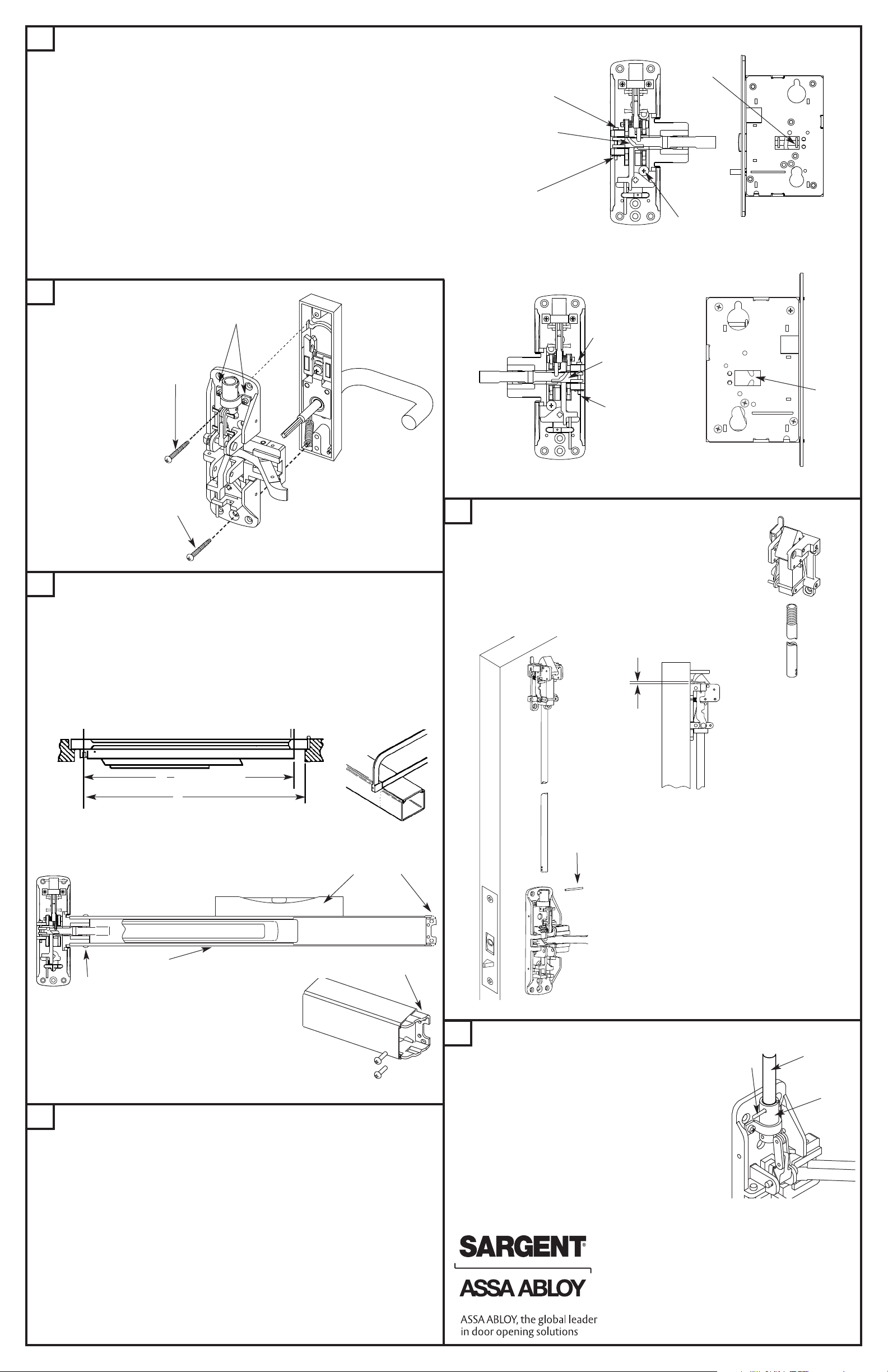

APPLY HARDWARE

ASSEMBLE TOP ROD AND TOP CASE

APPLY RAIL ASSEMBLY

ATTACH OUTSIDE TRIM IF USED

Note: Check box label. If cutting is not required, proceed to step “B”.

If cutting is required, continue with step “A”.

Bottom

Mounting

Trim Screw

Shim top strike when

necessary to obtain

1/8" gap

1/8"

gap

Top Mounting

Screw

Pivot Pin

Center Link

Hair Pin

1. Mount primary and secondary mortise locks in the doors with (2) #12

screws provided. Install outside primary and secondary lock fronts.

2. Remove hairpin, pivot pin, and center link from center case chassis

(set aside for reassembly).

3. Using alignment screw to align center case chassis with mortise lock,

secure chassis with #10 screws using locations marked in step B.

4. Primary mortise case. Insert the center link in primary mortise lock case.

Insert center link pin thru the pivot hole in the chassis and center link and

fasten in place with hair pin.

5. Secondary mortise lock. Insert the center link in to the mortise lock case in

front of pusher levers. Insert the center link pin thru the pivot hole in

chassis and center link and fasten in place with hair pin.

If “ET” lever handle trim is used, go to step “D”.

Level

Mounting

Plate

Rail Assembly

Attach to Chassis with (2) #8-32 x 3/4

Phillips truss head machine screws

Tight Against

Rail

LEVEL THE RAIL ASSEMBLY

1. Depress arm into rail opening and slide rail onto chassis. Level

rail and fasten mounting plate.

2. Secure the (2) truss head screws through

rail assembly into chassis assembly.

3. Attach mounting plate to door with

(2) round head screws.

E

D

C

F

Determine cut off dimension “X” by subtracting 1-3/4" from

dimension “Y”. Mark cut off point on mounting rail.

ADJUSTING THE PRIMARY MORTISE LOCK LATCHBOLT

G

H

VERTICAL

REFERENCE

LINE (CHASSIS)

FOR DOORS WITH STILE, CUT OFF MUST

LEAVE 5/16" MIN. OVERLAP WITH RAIL

CUT-OFF ON MARK

AND DEBURR CUT

RAIL WITH INSERT

INSTALLED

Cut-Off Length

X

Y

If ET or dummy trim

is used, remove

tube support

screws and rotate

linkage down to

gain access to

countersunk hole in

chassis.

Install trim per trim

instructions and

reinstall tube

support.

3. Insert the lower end of the top rod into

adjusting tube in the center case

assembly. Attach the top case and rod

assembly to the door in the location

marked in step B. Secure the top

case, top case cover and guide with

screws provided.

2. Mount top strike to

frame as marked in

step two with (2)

#12 mounting

screws.

1. Thread end of top rod

into the top rod link

until hand tight.

Insert

Center

Link

Pivot Pin

Center Link

Hair Pin

With the rail in the depressed or dogged position, pull the top

rod down so that the top latchbolt is in the retracted position.

Adjust the top rod by aligning a set of holes in the top rod with

the hole in the adjusting tube, then insert the

adjusting pin. Top bolt should latch securely and retract fully, if

not adjust rod.

If fine adjustment is required – turn the rod into or out of the

top rod link.

If coarse adjustment is required – use the different set of

holes in the top rod.

With the push rail depressed, the active latchbolt must be fully retracted and clear the lock front

in adjacent door to open freely. With the push rail depressed on the adjacent door, the

recessed bolt must push the active bolt out beyond the lock front face allowing this door to

open freely.

The latchbolt is factory adjusted for 1/8" clearance between the doors. If the clearance is more

than 1/8", the latchbolt must be extended to get full engagement when the door is closed.*

With the latchbolt projected when the door is open, pull the latchbolt out with pliers until the

pins clear the face of the adjusting screw. Insert a 5/32" allen wrench into the adjusting screw.

To increase latch projection, rotate screw counterclockwise. To decrease latchbolt projection,

rotate screw clockwise. When desired projection is achieved, rotate adjustment screw to align

flats with the (2) press fit pins to allow the latchbolt to snap back into position when released

by pliers.

Finally, check both doors for operation to insure that either door can open or close freely.

*If the clearance between a pair of doors is 3/8" or more, the doors must be

shimmed/repositioned to minimize this gap.

Adjusting

Pin

Top

Rod

Adjusting

Tube

Adjusting

Pin

Insert

Center

Link

Tube

Support

Screws

TOP LATCHBOLT ADJUSTMENT

Alignment Screw

ETJ

Shown

B.

A.

SECONDARY MORTISE LOCK

PRIMARY MORTISE CASE

A7212C

Copyright ©2005, 2008, Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Loading...

Loading...