Page 1

P2

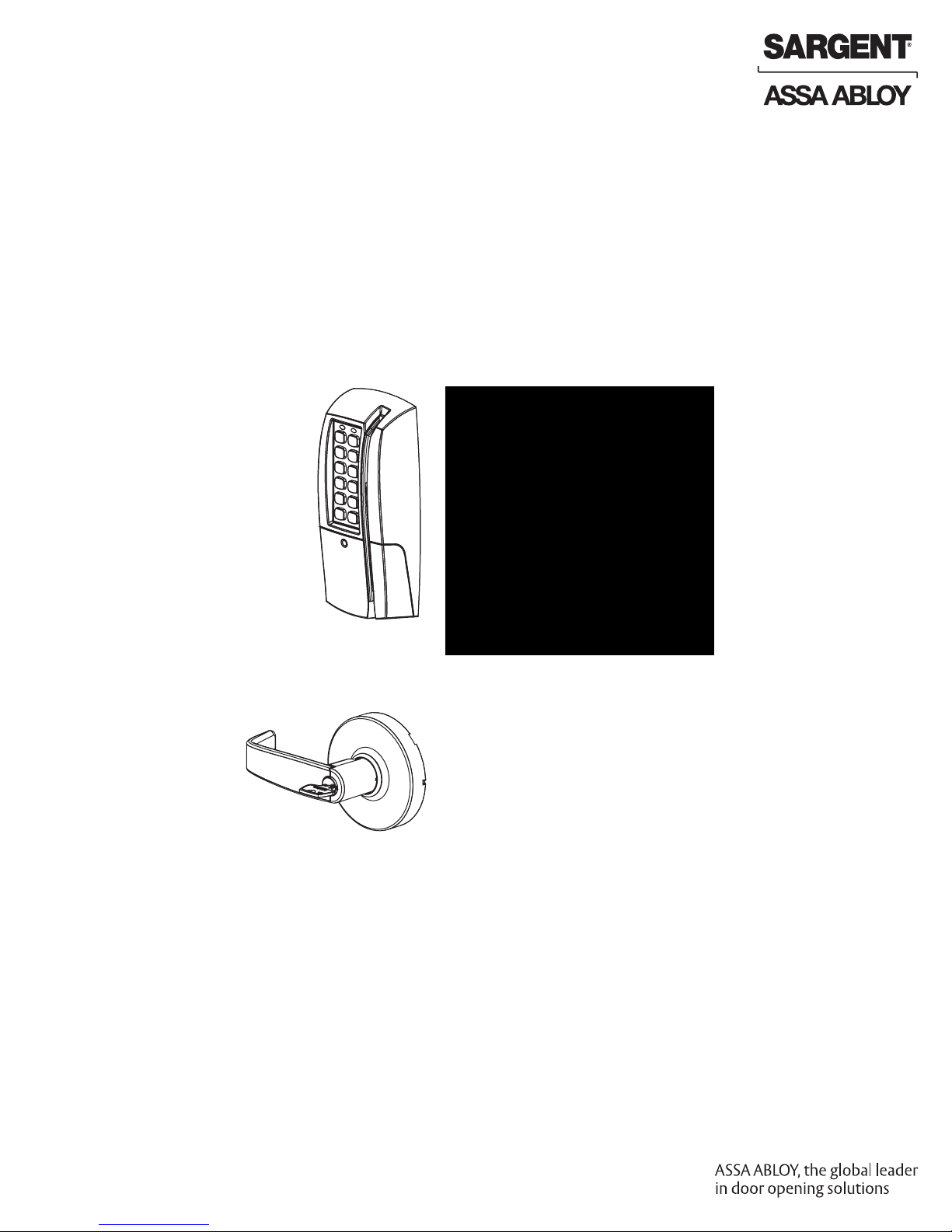

PASSPORT 1000

Cylindrical Lock

Installation Instructions

A8013H

04/16

Copyright 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

Page 2

Page 3

Table of Contents

1

Warning ...................................................................................3

General Description .................................................................4

2

3

Hardware Specifications .........................................................4

4

Electronic Specifications .........................................................4

Parts Breakdown .....................................................................5

5

Installation Instructions ..........................................................7

6

7

Operational Check ................................................................17

1

Warning

Changes or modifications to this unit not expressly approved by the party responsible for compliance could void the user’s authority to operate the equipment.

FCC

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Industry Canada:

This Class B digital apparatus meets all requirements of the Canadian Interference Causing Equipment Regulations. Operation is subject

to the following two conditions: (1) this device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Cet appareillage numérique de la classe B répond à toutes les exigences de l’interférence canadienne causant des règlements

d’équipement. L’opération est sujette aux deux conditions suivantes: (1) ce dispositif peut ne pas causer l’interférence nocive, et (2) ce

dispositif doit accepter n’importe quelle interférence reçue, y compris l’interférence qui peut causer l’opération peu désirée.

“This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This equipment should be installed and operated with minimum distance 20cm between the radiator and your body. This transmitter must not be co-located or operating in conjunction with any other antenna or transmitter.”

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

Conformément à la réglementation d’Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d’un type et d’un

gain maximal (ou inférieur) approuvé pour l’émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique

à l’intention des autres utilisateurs, il faut choisir le type d’antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l’intensité nécessaire à l’établissement d’une communication satisfaisante.

Any retrofit or other field modification to a fire rated opening can potentially impact the fire rating of the opening, and SARGENT Manufacturing makes no representations or warranties concerning what such impact may be in any specific situation. When retrofitting any portion

of an existing fire rated opening, or specifying and installing a new fire-rated opening, please consult with a code specialist or local code

!

official (Authority Having Jurisdiction) to ensure compliance with all applicable codes and ratings.

To avoid possible damage from electrostatic discharge (ESD), some basic precautions should be used when handling

electronic components:

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

• Minimize build-up of static by touching and/or maintaining contact with unpainted metal surfaces such as

door hinges, latches, and mounting plates especially when mounting electronic components such as readers

and controllers onto the door.

• Leave components (reader and controller) protected in their respective anti-static bags until ready

for installation

04/30/16

1-800-810-WIRE • www.sargentlock.com • A8013H

• Do not touch pins, leads or solder connections on the circuit boards

Page 4

Passport 1000 P2 WiFi Cylindrical Lock

2

General Description

An ANSI/BHMA Grade 1 lock using WiFi technology, the Passport 1000 P2 cylindrical lock provides a

cost-effective, future-proof solution for campuses.

Featuring multiCLASS SE® Technology from HID Global®, it provides simultaneous support for multiple

credentials and offers an easy migration path to higher security credentials and mobile access.

With no wiring required, installation is fast, easy and affordable.

3

Hardware Specifications

• Complete locksets with controller

• Easily retrofits existing Passport 1000

(cylindrical lock) door preps

• ADA Compliant

• Latch 1/2” standard 3/4” throw fire-rated

double doors (optional) (41- prefix)

• Deadlocking latch

4

Electronic Specifications

• HID® multiCLASS SE® technology offers

support for the following credentials:

• 2.4 GHz credential compatibility:

• Secure Identity Object™ (SIO) on

Mobile IDs (Bluetooth Smart)

• 13.56 MHz credential compatibility:

• iCLASS®

• iCLASS SE® (SIO-enabled)

®

Classic

®

®

®

Classic

• iCLASS Seos

• SIO on MIFARE

• SIO on MIFARE® DESfire® EV1

• MIFARE

• DESfire® EV1

• NFC-enabled mobile phones

• 125 kHz credential compatibilty:

• HID Prox

*For specific security information, please contact your local

ASSA ABLOY Door Security Solutions sales consultant or

call 800-810-WIRE.

• Inside lever retracts latch

• Outside lever controlled by any combination of

keypad, magnetic swipe, contactless reader or

mechanical cylinder

• ANSI/BHMA A156.25 Listed Grade 1 Compliant

• May be used for indoor and outdoor applications

Note: A weather-protective gasket is required

for outdoor applications.

• WiFi (IEEE 802.11 b/g/n)

• Multiple time zone and holiday access scheduling

• First-in unlock or automatic unlock configuration,

based on specified time schedule

• Support for most advanced wireless encryption

and authentication standards such as WEP, WPA,

WPA2 and 802.1x*

• 2,400 users per lock; 10,000 event audit trail

• Privacy button

• UL Listed - UL 294 Indoor Use

• CUL Listed - S319: Class 1

• UL 294 Access Control Ratings:

Destructive Attack Level 1

Line Security Level 1

Endurance Level 4

Standby Power Level 1

Power Requirements:

• Alkaline AA Batteries: 9V, 300mA

• Optional Hard Power (UL294 Listed Power

Supply Required): 9-24VDC, 300mA

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

4 1-800-810-WIRE • www.sargentlock.com • A8013H

Page 5

Passport 1000 P2 WiFi Cylindrical Lock

5

Parts Breakdown

P2 WiFi Lock with Magnetic Card Swipe With or Without Keypad

4

3

1

ITEM No. PART No. DESCRIPTION

1 52-3583-[finish] Outside Escutcheon Assemby, mag stripe

52-3582-[finish] Outside Escutcheon Assemby, mag stripe and Keypad (shown)

52-4244-[finish] Outside Escutcheon Assemby, Mag Swipe, Keypad, and HID 125 kHz Prox

52-4759-[finish] Outside Escutcheon Assemby, iCLASS, keypad, mag stripe, Prox, smart card (MIFARE, DESFIRE - shown)

52-4777-[finish] Outside Escutcheon Assemby, iCLASS, mag stripe, Prox, smart card (MIFARE, DESFIRE)

52-4787-[finish] Outside Escutcheon Assemby, FeliCa, keypad, mag stripe, Prox

52-4788-[finish] Outside Escutcheon Assemby, FeliCa, mag stripe, Prox

52-4894-[finish]* Outside Escutcheon Assemby, Standard Reader and Keypad

52-4895-[finish]* Outside Escutcheon Assemby, Standard Reader

52-4896-[finish]* Outside Escutcheon Assemby, Felica Reader and Keypad

52-4897-[finish]* Outside Escutcheon Assemby, Felica Reader

52-4779 Mounting Plate Assembly

2

3 52-5409 WiFi Controller Assembly

4 52-4776-[finish] Inside Escutcheon Assembly with Privacy Button

5 52-5373 Door Position Switch Kit

2

5

*Bluetooth® Smart option

1-800-810-WIRE • www.sargentlock.com • A8013H 5

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 6

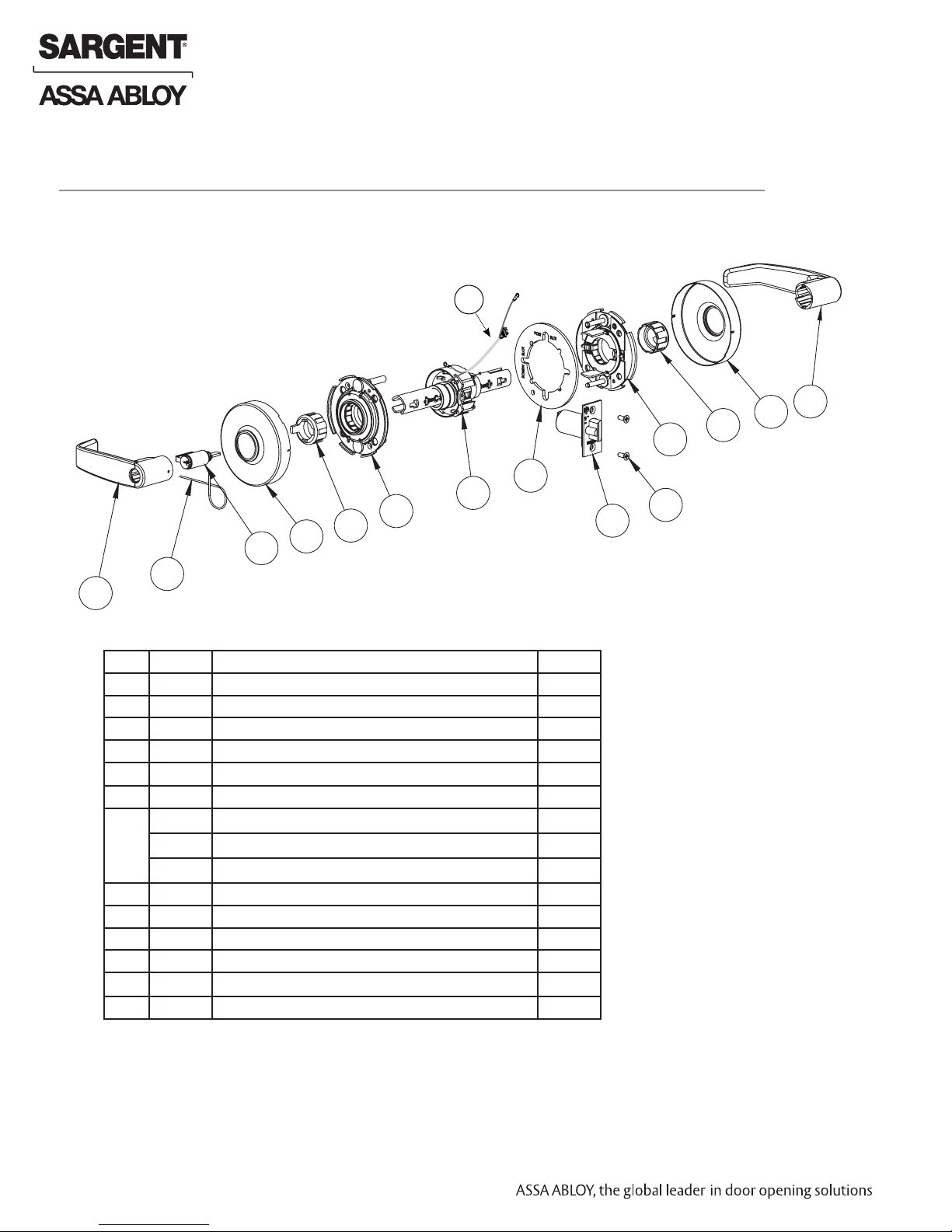

Parts Breakdown (Continued)

10 Line Series Cylindrical Lock

5

4

3

2

1

Passport 1000 P2 WiFi Cylindrical Lock

7a

12

11

5

8

7

6

*

10

9

*Adapter Plate/Spacer (10-0847)

only shipped with orders that

specify 1-3/8” doors.

4

ITEM PART No. DESCRIPTION REQ’D

1 --- Outside Lever (Reference Catalog for Available Styles) 1

2 10-0043 Lever Retainer Key (In Screw Pack 10-2052) 1

3 --- Cylinder Assembly (Reference Catalog for Available Cylinders) 1

4 --- Rose (Reference Catalog for Avalable Styles) 2

5 10-0792 Spacer Bushing 2

6 10-3049 Outside Rose Spring Assembly 1

7 10-3449 Lockbody Assembly 10G77 - Standard Cylinder 1

10-3450 Lockbody - LFIC 1

10-3451 Lockbody - SFIC 1

7a 52-4844 Lockbody Harness 1

8 10-0847 Adapter Plate/Spacer (*Only Included With 1-3/8” Thick Doors) 2

9 10-3192 Latch Assembly 1

10 10-2052 Screw Pack 2

11 10-3048 Inside Rose Spring Assembly 1

12 --- Inside Lever (Reference Catalog for Available Styles) 1

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Tools Required:

• #2 Phillips screwdriver

• Flat head

• T20 Torx® driver

04/30/16

6 1-800-810-WIRE • www.sargentlock.com • A8013H

Page 7

Passport 1000 P2 WiFi Cylindrical Lock

6

Installation Instructions

1 Door Preparation

A. Verify Hand and Bevel of Door

Stand on outside of locked door when determining door hand.

Left Hand (LH)

Hinges Left.

Open Inward.

B. Door Preparation

• Prior to installation, all holes must be free of burrs, debris and sharp edges.

• If doors are not properly reinforced per ANSI 115.2, commercially available

reinforcements should be installed.

• Prepare door according to appropriate template:

• Field template A8068 (for wood doors) with DPS

• Field template A8069 (for wood doors) without DPS

• Manufacturer’s template 4655 with DPS.

• Manufacturer’s template 4691 without DPS.

Left Hand

Reverse Bevel

(LHRB)

Hinges Left.

Open Outward.

Right Hand (RH)

Hinges Right.

Open Inward.

Right Hand

Reverse Bevel

(RHRB)

Hinges Right.

Open Outward.

Escutcheon Through Bolt Holes

Raceway for Power (Optional)

Controller Wire Hole

Lockbody Through Bolt Holes

Alignment Notches

Lock Body Prep

Outside of Door

Door

Position

Switch

Latch

Front

and Hole

Fig. 1

Inside of Door

Escutcheon Through Bolt Holes

Inside Mouthing Plate Holes

Raceway for Power (Optional)

Controller Wire Hole

Wire Run Channel

Lock Body Through Bolt Hoes

Alignment Notches

Lock Body Prep

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

1-800-810-WIRE • www.sargentlock.com • A8013H 7

04/30/16

Page 8

Passport 1000 P2 WiFi Cylindrical Lock

2 Install Strike

Install strike in the door frame (Fig.2).

3

Install Latchbolt

Centerline of Latch

Front and Strike

(2) #8-32 x 3/4” Screws

Fig. 2

1. Install latch with beveled bolt facing strike.

2. Attach with two screws.

DO NOT tighten completely at this time.

IMPORTANT: Latch bevel must match door bevel and

deadlocking latch must stop on strike when door is closed.

Strike

Deadlocking Latch

Fig. 3B Detail

IMPORTANT:

• Door must remain open during installation

• Use door stop

Outside of Door

Fig. 3A

Latch Assembly

(2) #8-32 x 3/4”

Combination

Screws

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

8 1-800-810-WIRE • www.sargentlock.com • A8013H

Page 9

Passport 1000 P2 WiFi Cylindrical Lock

4

Install Door Position Switch (DPS)

1. Insert connector end of DPS harness through raceway on latch

edge of door.

Note: Use collar in METAL door only.

2. Push DPS firmly into place by hand.

Important: DO NOT TAP SWITCH WITH ANY TOOL.

Collar is used only

with metal doors.

Door Position

Dim 1

Switch Hole

Vertical

of Strike

Door Position

Switch (DPS)

Dim 2

(See template)

Horizontal

of Strike

Fig. 4A

Dim 1

Strike for Cylindrical Lock

Wood Frame Metal Frame

3/8” 3/4”

Inside of Door

Fig. 4B

1-800-810-WIRE • www.sargentlock.com • A8013H 9

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 10

5

Lock Presets and Adjustments (If Required)

A. Lock Preset

▪ Lock body holes – 12 and 6 o’clock

(Fig. 5A).

▪ Door thickness – 1-3/4” thick. Refer to

adjustments below for other door

conditions (Fig. 5B).

B. Through-Bolt and Door Thickness Adjustment

(If Required)

▪ Remove outside lever (Fig. 5A), scalp and

spacer bushing.

▪ Rotate mounting plate to either align with

through-bolt holes in door or adjust for

proper door thicknesses (Fig. 5A and 5B).

See markings on through-bolt post.

▪ Re-install spacer bushing (to align

with back of lever), scalp and lever.

1-3/4” Thick Doors

2” Thick Doors

Passport 1000 P2 WiFi Cylindrical Lock

Spacer Bushing

Lock Body Holes

Rotate to match

lock body holes in door.

Fig. 5A

Fig. 5B Detail

C. How To Remove Outside Lever (If Necessary)

1. Insert key, rotate 45° clockwise and hold (Fig. 5C).

2. Depress lever retainer with push pin tool (provided).

D. How To Change Cylinder (If Necessary)

1. With outside lever in hand, use standard

pliers to pull out cylinder retainer.

2. Remove key and cylinder from lever.

3. Insert new cylinder.

4. Secure by pressing cylinder retainer flush.

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

Cylinder Retainer

Washers (Only 30- Prefix)

Cylinder

Fig. 5C

Outside Lever

Fig. 5D

Key

04/30/16

10 1-800-810-WIRE • www.sargentlock.com • A8013H

Page 11

Passport 1000 P2 WiFi Cylindrical Lock

6

Install Lock

IMPORTANT: If lock is being installed as a retrofit;

(replacing an existing P2 product), remove the

DPS wires and connector (Fig. 6A) by simply

severing the wires as indicated (see arrow).

If this is a new lock being installed for the first

time, DO NOT REMOVE wires and connector.

1. Feed wires followed by the lockbody from

outside of door through the lockbody hole (Fig. 6A).

2. Lockbody must engage both the latchbolt unit prongs

and tail piece (Fig. 6B).

Cylindrical Lock Body

Fig. 6B Detail

and Outside Trim

Grounding Harness

from Lock Body

(Wood Doors Only)

Wire Harness

(From Lock Body)

Cut wires here

(if required)

7

Secure Lock To Door

1. Feed wire and connector:

• For wood door, feed connectors and wires through the door and up

the wire run channel (Fig. 7A).

• For metal door (not shown), feed connectors and wires into the lockbody hole and out the controller hole.

2. Position ground lug between (top) #10-32x1-1/4”

through-bolt and rose assembly (Fig. 7A).

NOTE: Proper placement of

ground wire (Fig. 7A, B)

will prevent pinching or

damage to the ground wire.

3. Secure rose assembly with (2)

#10-32x1-1/4” through-bolts.

4. Secure latch by fully tightening (2) #6 x 3/4” self-tapping

screws (refer to previous section 3 - Install Latchbolt).

Fig. 6A

Ground

Wire

Wire Harness

(From Lockbody)

Fig. 7B Detail

Grounding Harness

(Wood Doors Only)

Put ground ring terminal

through top flat head

screw and tighten down.

(2) #10-32 x 1-1/4”

Flat Head Machine

Fig. 7A

Spring housing

assembly

Screws (Secures

outer spring housing)

1-800-810-WIRE • www.sargentlock.com • A8013H 11

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 12

8

Assemble Inside Trim

1. Verify spacer bushing is inserted horizontally and aligned

with lever (Fig. 8).

2. Place rose (scalp) over shaft of lock body against

surface of door; hand-tighten, turning clockwise.

3. Attach lever. Push until engaged.

Passport 1000 P2 WiFi Cylindrical Lock

DPS (Door Position Switch)

Inside of door

Spacer Bushing

9

Install Wire Cover Plate (Wood Door Only)

1. Position the wire cover plate above the rose and covering

the wire channel. Mark the hole positions.

2. Ensure stamped side of plate is against the door.

3. Drill (2) 3/32” diameter by 1/2” deep holes (Fig. 9A).

4. Cover wires with cover plate by securing plate to door

directly above rose using two (2) #6 x 1/2” flat head security

torx wood screws (Fig. 9A).

Note: Tuck wires and ferrite in hole at top of wire channel

(Fig. 9A). Position lower edge of cover plate against the rose

to ensure no wires are visible and make sure the plate is

oriented correctly (Fig. 9B).

Back Side of

Wire Cover Plate

Fig. 8

Inside Lever

Rose (Scalp)

Inside of door

Wire Cover

(2) #6 x 1/2”

Flat Head Security

Torx Wood Screws

Fig. 9B Detail

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

This Side Down

04/30/16

12 1-800-810-WIRE • www.sargentlock.com • A8013H

Fig. 9A

Page 13

Passport 1000 P2 WiFi Cylindrical Lock

10

Install Outside Escutcheon with (Optional) Gasket

Note: Gasket optional, for non-fire rated doors only.

For non-fire rated door applications, an optional gasket

(Part number 52-0782) may be used as a weather seal

between the escutcheon and the outside door surface.

Peel off adhesive backing and attach to (outside) escutcheon.

1. Position the outside escutcheon, aligning the posts with

the door prep (Fig. 10).

2. Feed reader cable through opening.

Outside of Door

Gasket

Reader

Cable

Escutcheon

11

Mounting Plate Assembly

1. On the inside of the door, position the mounting plate

over the indicated holes.

2. Feed lockbody, reader and DPS cables through central

opening (Fig. 11).

3. Route ground ring terminal from lock body under bot-

tom of mounting plate and attach to bottom left corner

using one #8-32 x 1-7/8” flat head machine screw.

4. Insert other three #8-32 x 1-7/8” flat head machine

screws and tighten, fastening the outside escutcheon

to the door (Fig. 11).

IMPORTANT: If the following step is skipped, the product

will not be UL-compliant:

3. Attach two (2) #8 x 3/8” flat head wood screws for

wood doors or (2) #8-32 x 3/8” flat head machine

screws for metal doors (Fig. 11).

Outside

Fig. 10

Mounting Plate

(4) #8 - 32 x 1-7/8” Flat

Head Machine Screws

(2) #8 - 3/8” flat head

Wood Screws

Ground Lug

Fig. 11

1-800-810-WIRE • www.sargentlock.com • A8013H 13

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 14

Passport 1000 P2 WiFi Cylindrical Lock

12 Installation of Connectors

CAUTION - Do not touch or allow debris to enter connector contacts.

Secure the following connectors to their respective terminals (Fig. 12):

A. Secure the 4-pin DPS connector.

B. Secure the 10-pin lock body assembly connector.

IMPORTANT: Do not run wires through bottom hole in plate (Fig. 12) - it will damage wires and the controller connector. Route

wires around flange, do not route wires through the flange hole (Fig. 12).

Secure Mounting Plate

1. Tuck excess cable into wire hole on inside of door.

2. Secure the mounting assembly while ensuring proper alignment of outside reader and fully tighten

the (2) through-bolts on the inside of the door to secure the reader and plate to the door.

C. Secure the 24-pin card reader connector (Fig. 12).

Reader

(24-pin)

Ground

Lugs

Board-to-Board

Connector

C

A

DPS (4-pin)

B

Lock

Body

(10-pin)

Fig. 12

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

14 1-800-810-WIRE • www.sargentlock.com • A8013H

Page 15

Passport 1000 P2 WiFi Cylindrical Lock

13

Install Inside Module Component Assembly

1. Insert top tabs of controller into slots on mounting plate (Fig. 13).

2. Ensure proper alignment of board-to-board connectors while pivoting

bottom of controller toward door until tab on bottom snaps securely

into place on mounting plate.

CAUTION: To avoid possible damage to board-to-board connectors, care should be

taken when securing controller to mounting plate. If there is resistance when

securing, detach controller to determine cause before re-attaching controller.

Fig. 13

1-800-810-WIRE • www.sargentlock.com • A8013H 15

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 16

14

Battery Installation

1. Place (6) “AA” batteries into the compartment being

careful to align polarity (- & +) properly.

2. After batteries are properly installed, there is a slight

delay followed by a amber LED flash; the lock motor

will cycle.

Passport 1000 P2 WiFi Cylindrical Lock

Inside of Door

15

Installation of Inside Escutcheon

1. Position inside escutcheon as shown (Fig. 13).

Verify that all wires are positioned within the escutcheon

to avoid pinching.

2. Attach escutcheon with (2) #8-32 x 1/2” T-20 Torx pan

head screws.

3. Straighten escutcheon and tighten securely.

DO NOT OVERTIGHTEN.

Fig. 14

(2) #8-32 x 1/2”

Secure Torx

Machine Screws

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

16 1-800-810-WIRE • www.sargentlock.com • A8013H

Fig. 15

Page 17

Passport 1000 P2 WiFi Cylindrical Lock

7

Operational Check

IMPORTANT: Be sure to test functions prior to closing door.

In all cases, perform the following checks:

1. Ensure that inside lever retracts latch.

• For units with cylinders, the following checks apply:

Insert key into cylinder and rotate:

a. There should be no friction against lock case or any other

obstructions. If friction or binding occurs, readjust cylinder to

eliminate issues.

b. The key should retract the latch and the key should rotate freely.

• For units without a keypad, add card using LCT software* and test.

• For units with a keypad, add pin and card using LCT software*

and test.

2. LED signaling:

• After using a valid credential, a green flash followed by three fast

amber flashes indicates a low power condition.

Check the battery voltage.

If the voltage is low, replace the batteries.

• If the lock loses power, it will flash rapid blue for approximately one

minute. Lock will default to programmed fail safe or fail secure.

3. When you have completed the tests, close the door, ensuring latchbolt fully

extends into strike plate without binding.

*Refer to Network and Lock Configuration Tool user manual (WFMN1) for

information on how to configure and program locks.

1-800-810-WIRE • www.sargentlock.com • A8013H 17

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproductions in whole or in part without express written permission of Sargent Manufacturing Company is prohibited.

04/30/16

Page 18

NOTES

Page 19

Page 20

SARGENT Manufacturing

100 Sargent Drive

New Haven, CT 06511 USA

800-810-WIRE (9473) • www.sargentlock.com

Founded in the early 1800s, SARGENT® is a market leader in locksets, cylinders, door closers, exit devices,

electro-mechanical products and access control systems for new construction, renovation, and replacement applications.

The company’s customer base includes commercial construction, institutional, and industrial markets.

Copyright © 2015, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

ASSA ABLOY is the global leader in door opening solutions, dedicated to

satisfying end-user needs for security, safety and convenience.

A8013H -04/16

Loading...

Loading...