Page 1

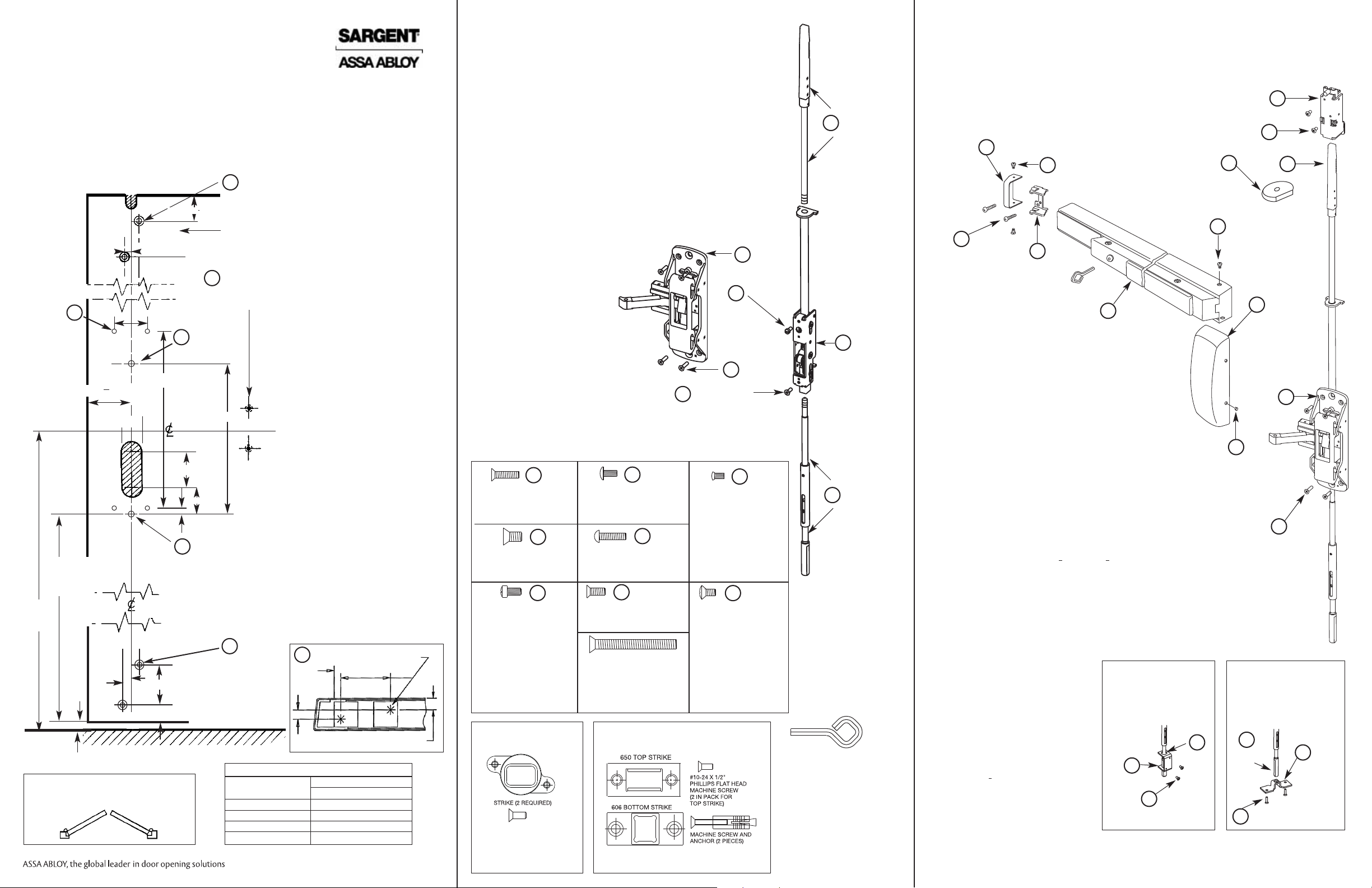

2) Screw top bolt & rod assembly (A) and bottom bolt & rod

assembly (C) into inner chassis (B).

3) Slide complete assembly into top of door.

4) Attach inner chassis (B) to door with screw (GG) using hole (5A).

5) Then secure with screw (FF) using hole (3A).

Note: If 700 Series ET Controls is being used, it must be installed

at this point, prior to step 6. See appropriate instructions.

6) Position chassis (D) over fillister head screw and attach to door

with (4) screws (AA) using holes (2A). Do not tighten yet.

Note: Rods must be retracted while adjusting bolt projection.

Use Chassis (D) to retract top bolt & rod assy (A) & bottom

bolt & rod assy (C).

Manual dogging key

(not used with 12-)

To operate: Depress push

rail, insert hex key (or cylinder

key when used) and turn

clockwise.

Not furnished with 12-MD8600

7A) Adjusting the top bolt & rod

assembly (A)

1) 1/8" gap or less between

door top and frame.

Rotate bolt to make

even with top of the door.

2) 1/8"gap or greater. Bolt to extend

above door equal to gap minus

an 1/8".

7B) Adjusting the bottom bolt & rod

assembly (C)

1) 1/8" gap or less between door bottom

& high point. Rotate bolt to make even with

bottom of door.

2) 1/8"gap or greater. Bolt to extend below door equal

to gap minus an 1/8".

10) Install door into the frame using hinges.

11) Slide rail assembly (J) onto center

case chassis (D).

12) Align holes for screws (BB).

13) Level rail.

14) Locate & mark holes for mounting plate (I)

on hinge side. Drill & tap (2) holes (4A).

15) Attach mounting plate (I) and secure rail assembly

(J) to door with (2) screws (EE).

16) Tighten screws (AA) to secure center case chassis

(D) to door.

17) Before closing door check the following:

a) Push rail in to retract bolts.

b) Bolts stay retracted (

hold back).

c) Bolts release when door closes. Button inside

top of door hits frame.

d) Bolt engagement with strike 1/4"- 5/16".

e) Adjust bolts per steps 7A & 7B.

18) For AD-8600: Attach 640 strike using instruction

sheet A8037 supplied with strike pack.

19) For MD-8600 & 12-MD-8600:

Attach 650 top strike to frame

with two #10-24 x 1/2" flat

head screws & 606 bottom

strikes with anchors supplied

and two 1/4-20 x 2” flat head

screws. (See chart on left)

20) Attach cover (K) to center case

chassis

(D) with (4) screws (CC).

21) Attach end cap (H) to mounting

plate (I) with (2) screws (CC).

22) Secure rail assembly (J)

to chassis (D) with (2)

screws (BB).

Instructions for Installing

AD-8600, MD-8600 & 12-MD-8600

Concealed Vertical Rod Exit Devices

8) Slide rod silencer (G) over Top Bolt (F) onto rod, followed by top chassis (E).

Secure top chassis (E) to door with (2) screws (HH) using holes (1A).

9A) For AD-8600 bottom bolt: Install bottom plate (N) over bottom bolt (M) and

secure with (2) screws (HH) using holes (6A).

9B) For MD-8600 & 12-MD-8600: Install bottom plate (O)

over bottom bolt (M) and secure with (2) screws (DD)

using tapped holes (7A).

Top bolt &

rod assembly

Fillister head

screw

#10-24 x 3/8"

Flat head screw

#10-24 x 1/2"

Bottom bolt &

rod assembly

Chassis

Flat head

screw

#10-24 x 3/4"

Copyright ©2008, 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

A7002F: 6-1-09

For additional information, contact SARGENT at 1-800-727-5477

A

FF

D

AA

B

GG

C

Top chassis

Oval head screw

#10-24 x 3/8"

Truss head screw

#8-32 x 3/8"

Top bolt

Silencer

Oval head screw

#8-32 x 5/16"

End cap

Round head

screw

#10-32 x 3/4"

Mounting

plate

Rail assembly

Cover

Center

case

chassis

Flat head

screw

#10-24 x 3/4"

H

E

HH

F

G

BB

K

D

AA

CC

EE

I

J

Verify the correct exit device is being installed on the correct door. Function, finish and size

should all be verified. Note: Before removing door from hinges determine the gap

between top of door and frame. Determine smallest gap between bottom of door or

threshold and high point of floor as door swings. This information is needed for step #7.

Remove door from the frame.

INSIDE

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

REVERSE

BEVEL

THIS EXIT DEVICE IS HANDED

CHECK HAND OF DEVICE AGAINST APPLICATION

OUTSIDE

Information for Cutting Rails

Rail Sizes

Door Widths

Max Min

E 32" 24"

F 36" 33"

J 42" 37"

G 48" 43"

Oval head screw

#8-32 x 5/16"

CC

For AD-8600 Bottom Bolt

Install bottom plate (N) over

the bottom bolt (M) and

secure with two #10-24 x 3/8"

oval head screws (DD) using

holes (6A)

For MD-8600 & 12-MD-8600

Bottom Bolt

Install bottom plate (O) over

the bottom bolt (M) and secure

with two 1/4-20 x 1/2" flat

head screws (GG) using

tapped holes (7A)

Bottom

bolt

Bottom

Plate

#10-24 x 3/8"

Oval Head Screws

Bottom

Plate

1/4-20 x 1/2" flat

head screw

N

HH

M

O

DD

Bottom

bolt

M

FINISHED FLOOR

OF CHASSIS

1/4"

5/8"

GAP

36-3/4"

UNLESS

OTHERWISE

SPECIFIED

41"

STD.

HGT.

4-1/2"

Door prep shown

is the same for the

MD-8600, 12-MD-8600

and AD-8600 Series

exit devices, except

for attaching the

bottom plate. 12- and

MD- is shown

separately below.

Note: If 100 Series

auxiliary control is

being used, door must

be prepped for Aux

Control prior to

installing device on to

the door. Aux Control

can be installed after

exit device is installed.

See appropriate

instructions.

4A

1A

5A

DRILL AND CUTOUT

THIS SIDE OF DOOR

ONLY

7/32" DIA.

C'SINK FOR

#10 SCREW

DRILL &

C’SINK

FOR #10

SCREWS

2 PLACES

(HOLES ONLY

USED WITH

AD PREFIX)

POSITION OF

MOUNTING SCREW

HOLES ARE IDENTICAL

FOR EITHER HAND

1/4"

5/8"

1-1/4"

6A

5/8"

2-3/4"

3/8"

1/2

7A

#1/4-20 Tapped holes (2 PLACES)

View of door bottom for

MD-8600 & 12-MD-8600

HINGE STILE

INSIDE SURFACE OF LHRB DOOR SHOWN

(2) 7/32" DIA & C'SINK

POSITION OF MOUNTING SCREW

HOLES ARE IDENTICAL FOR

EITHER HAND.

DRILL AND TAP HINGE STILE FOR

#10-24 SCREW. USE MOUNTING

PLATE TO LOCATE HOLES.

7/8"

1) Drill, tap & cʼsink the door per template, except

for the (2) #10-24 (4A) on the hinge side.

STRIKE PACK FOR AD-8600 STRIKE PACK FOR MD-8600 & 12-MD-8600

640 TOP AND BOTTOM STRIKE

#10 X 1/2"

PHILLIPS FLAT HEAD

MACHINE SCREW

(4 IN PACK FOR TOP

AND BOTTOM STRIKE)

Inner

chassis

Chassis mounting screw

metal door application

(#10-24 x 3/4" ph. fl.hd.

mach. screws, 4 pcs)

Bottom case mounting screw

(1/4"-20 x 1/2" ph. fl. hd.

mach. screw 2 pcs)

[not used with nb prefix]

End cap mounting bracket

(#10-24 x 3/4" ph. rd.

hd. mach. screw 4 pcs)

Rail mounting screw

(#8-32 x 3/8" ph. truss

head machine screw.

by finish 2 pcs)

Cover & end cap

mounting screw

(#8-32 x 5/16" with

#6 ph. ov. u'cut hd.

machine screw,

by finish 6 pcs)

Aligning and inner chassis

screw (#10-24 x 3/8" ph.

fillister hd. machine screw,

1 pcs)

Inner chassis bottom screw &

top strike screws (# 10-24 x 1/2"

ph. fl.hd.mach. screws, 3 pcs)

ET mounting screw

(1/4"-20 x 2 3/8" ph. fl. hd.

mach. screw 2 pcs)

Top case and bottom case

mounting screws (#10-24 x

3/8" ph. ov. hd.machine

screw, 4 pcs) [Only 2 pcs

used with 12 ,MD and

NB prefix]

For 1 3/4" door length

shown size varies by 1/4"

depending on width of

cladding or inside panel

CC

BB

AA

DD

EE

FF

GG

HH

7/32" DIA

3A

6-11/16"

2 3/4"

BACKSET

1-1/4"

2A

(4) #10-24

TAPPED

HOLES

1-17/32”

1/4"

7/8"

Page 2

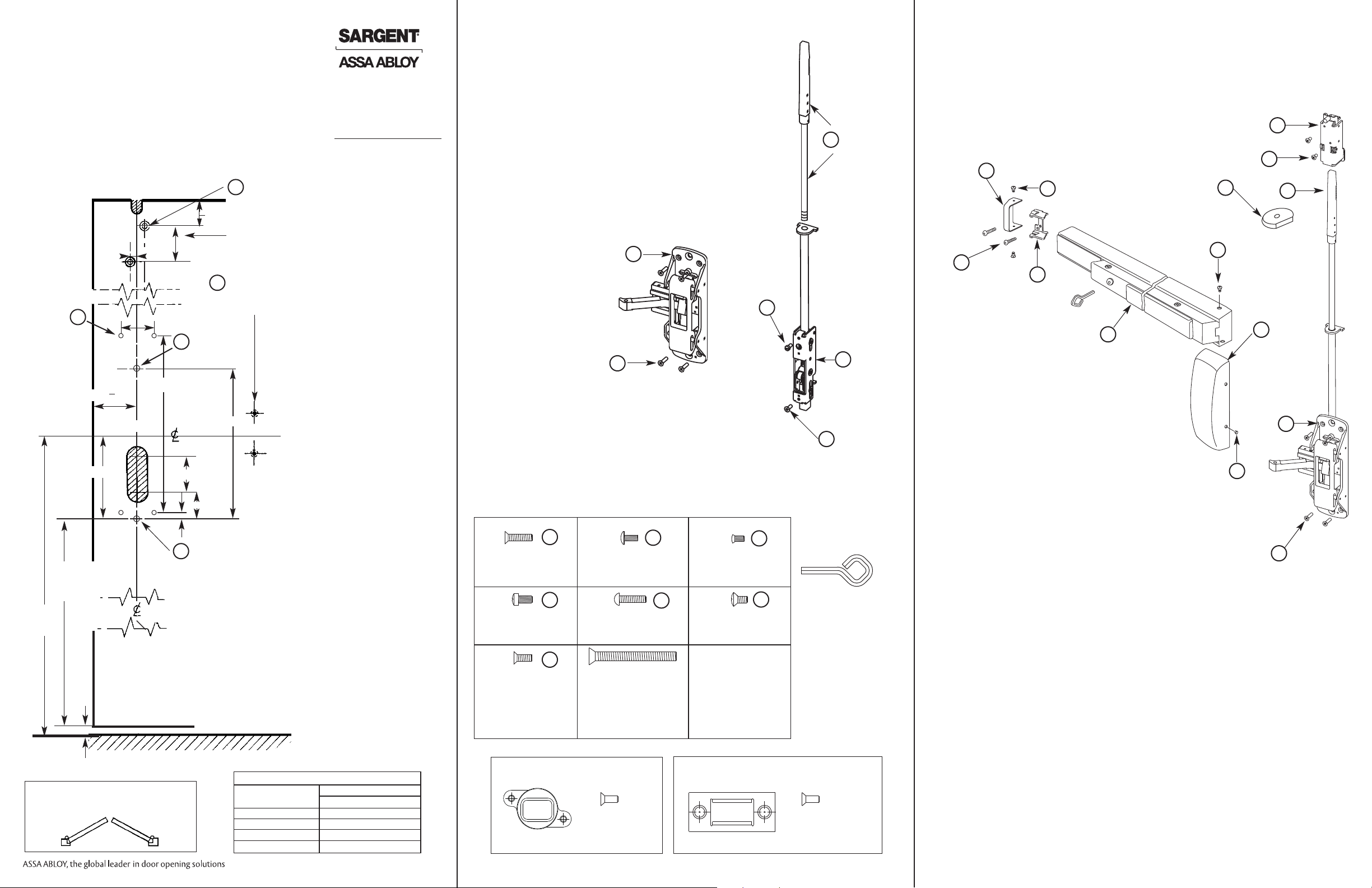

10) Slide rail assembly (J) onto center case

chassis (D).

11) Align holes for screws (BB).

12) Level rail.

13) Locate & mark holes for mounting plate (I)

on hinge side. Drill & tap (2) holes (4A).

14) Attach mounting plate (I) and secure rail

assembly (J) to door with (2) screws (EE).

15) Tighten screws (AA) to secure center case

chassis (D) to door.

16) Before closing door, check the following:

a) Push rail in to retract bolt.

b) Bolt stays retracted (Hold Back).

c) Bolt releases when door closes. Button

inside top of door hits frame.

d) Bolt engagement with strike 1/4"- 5/16".

e) Adjust bolts per step 7.

17) For NB-AD-8600: Attach 640 strike using

instruction sheet A8037 supplied with strike pack.

18) For NB-MD-8600 and 12-NB-MD-8600: Attach

650 top strike to frame with two #10-24 x 1/2" flat

head screws. See chart on left.

19) Attach cover (K) to center case chassis (D) with

(4) screws (CC).

20) Attach end cap (H) to mounting plate (I)

with (2) screws (CC).

21) Secure rail assembly (J) to chassis (D)

with (2) screws (BB).

Instructions for Installing

NB-AD-8600, NB-MD-8600 & 12-NB-MD-8600

Concealed Vertical Rod Exit Devices

without Bottom Bolt

2) Screw top bolt & rod assembly (A) into inner chassis (B).

3) Slide complete assembly into top of door.

4) Attach inner chassis (B) to door with screw (GG) using

hole (5A).

5) Then secure with screw (FF) using hole (3A).

6) Position chassis (D) over fillister head screw and attach to

door with (4) screws (AA) using holes (2A). Do not tighten yet.

Use chassis (D) to retract top bolt & rod assy (A) to adjust bolt

projection.

Note: Rod must be retracted while adjusting bolt projection.

Use chassis (D) to retract top bolt & rod assy (A).

7) Adjusting the top bolt & rod assembly (A)

1) 1/8" gap or less between door top and frame. Rotate

bolt to make even with top of the door.

2) 1/8" gap or greater. Bolt to extend above door equal to gap

minus an 1/8".

8) Slide rod silencer (G) over top bolt (F) onto rod,

followed by top chassis (E). Secure top chassis (E)

to door with (2) screws (HH) using holes (1A).

9) Install door into the frame using hinges.

Top bolt &

rod assembly

Fillister head

screw

#10-24 x 3/8"

Flat head screw

#10-24 x 1/2"

Inner

chassis

Center case

chassis

Flat head

screw

#10-24 x 3/4"

Chassis mounting screw

metal door application

(#10-24 x 3/4" ph. fl.hd.

mach. screws, 4 pcs)

End cap mounting bracket

(#10-24 x 3/4" ph. rd.

hd. mach. screw 4 pcs)

Rail mounting screw

(#8-32 x 3/8" ph. truss

head machine screw.

by finish 2 pcs)

Cover & end cap mounting

screw (#8-32 x 5/16" with

#6 ph. ov. u'cut hd. machine

screw, by finish 6 pcs)

Aligning and inner chassis

screw (#10-24 x 3/8" ph.

fillister hd. machine screw,

1 pcs)

Inner chassis bottom screw

& top strike screws

(#10-24 x 1/2" ph. fl.hd.mach.

screws, 3 pcs)

ET mounting screw

(1/4"-20 x 2 3/8" ph. fl. hd.

mach. screw 2 pcs)

Top case mounting screw

(#10-24 x 3/8" ph. ov. hd.

machine screw 2 pcs)

For 1 3/4" door length

shown size varies by 1/4"

depending on width of

cladding or inside panel

Manual dogging key

(not used with 12-)

To operate: Depress push

rail, insert hex key (or cylinder

key when used) and turn

clockwise.

Not furnished with 12-MD8600

CC

BB

AA

EE

FF

GG

HH

A

FF

D

AA

B

GG

Top chassis

Oval head screw

#10-24 x 3/8"

Truss head screw

#8-32 x 3/8"

Top bolt

Silencer

Oval head screw

#8-32 x 5/16"

End cap

Round head

screw

#10-32 x 3/4"

Mounting

plate

Rail assembly

Cover

Center

case

chassis

Flat head

screw

#10-24 x 3/4"

H

E

HH

F

G

BB

K

D

AA

CC

EE

I

J

Verify the correct exit device is being installed on the correct door. Function, finish and size

should all be verified.

Note: Before removing door from hinges determine the gap between top of door and frame.

This information is needed for step #7. Remove door from the frame.

INSIDE

LEFT HAND

REVERSE

BEVEL

RIGHT HAND

REVERSE

BEVEL

THIS EXIT DEVICE IS HANDED

CHECK HAND OF DEVICE AGAINST APPLICATION

OUTSIDE

Information for Cutting Rails

Rail Sizes

Door Widths

Max Min

E 32" 24"

F 36" 33"

J 42" 37"

G 48" 43"

Oval head screw

#8-32 x 5/16"

CC

Note: 12-NB-MD8600 Series Exit

Devices require installation of

thermal pin to meet requirements

for fire rating.

Copyright ©2008, 2009 Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written permission

of Sargent Manufacturing Company is prohibited.

A7002F: 6-1-09

FINISHED FLOOR

HINGE STILE

1-1/4"

1/4"

5/8"

GAP

36-3/4"

UNLESS

OTHERWISE

SPECIFIED

3-11/16"

41"

STD.

HGT.

4-1/2"

7/32" DIA

1-17/32”

1-1/4"

1/4"

Door prep shown is

the same for all less

bottom rod 8600

Exit Devices, except

the 12-NB-MD-8600

requires the thermal

pin that is supplied.

Note: If 100 Series

Auxiliary Control is

being used, door

must be prepped for

Aux Control prior to

installing device on

to the door. Aux

Control can be

installed after exit

device is installed.

See appropriate

instructions.

4A

1A

3A

5A

DRILL AND CUTOUT

THIS SIDE OF DOOR

ONLY

7/32" DIA.

C'SINK FOR

#10 SCREW

INSIDE SURFACE OF LHRB DOOR SHOWN

(2) 7/32" DIA & C'SINK

POSITION OF MOUNTING SCREW

HOLES ARE IDENTICAL FOR

EITHER HAND

DRILL AND TAP HINGE STILE FOR

#10-24 SCREW. USE MOUNTING

PLATE TO LOCATE HOLES.

7/8"

1) Drill, tap & cʼsink the door per template, except

for the (2) #10-24 (4A) on the hinge side.

For additional information, contact SARGENT at 1-800-727-5477

STRIKE PACK FOR NB-MD-8600 & 12-NB-MD-8600

650 TOP STRIKE

STRIKE (1 REQUIRED)

#10 X 1/2"

PHILLIPS FLAT HEAD

MACHINE SCREW

(2 IN PACK FOR

TOP STRIKE)

STRIKE PACK FOR NB-AD-8600

STRIKE (1 REQUIRED)

#10 X 1/2"

PHILLIPS FLAT HEAD

MACHINE SCREW

(2 REQUIRED)

640 TOP STRIKE

2A

(4) #10-24

TAPPED

HOLES

6-11/16"

2-3/4"

BACKSET

7/8"

OF CHASSIS

Loading...

Loading...