Page 1

INSTALLATION INSTRUCTIONS

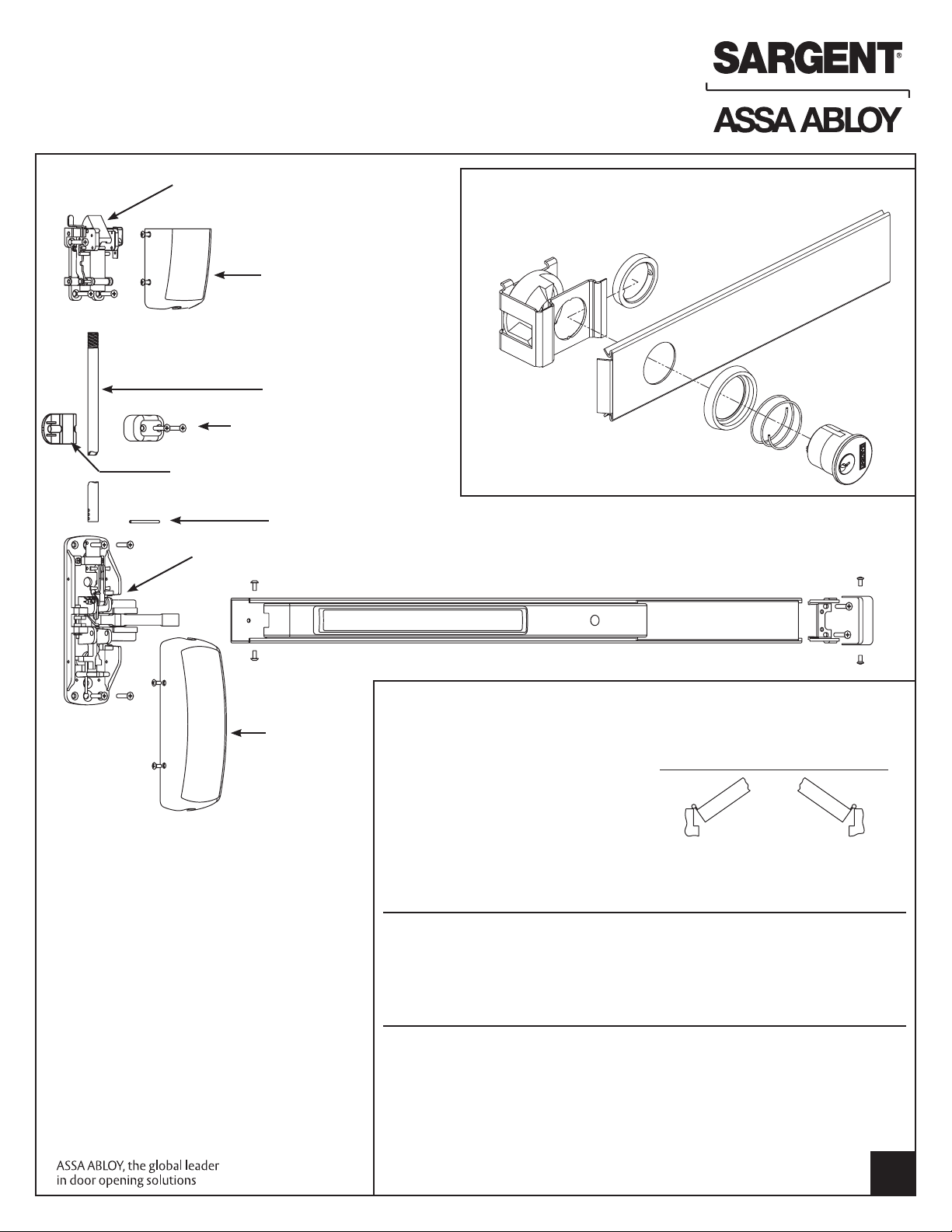

16- Cylinder Lockdown

NB8700 & 12-NB8700 Series Surface Vertical Rod Exit Device

FOR INSTALLATION ASSISTANCE CALL SARGENT AT 1-800-727-5477 • www.sargentlock.com

Top case

(Exploded View for clarity)

Top cover

Top rod

Rod guide

Rod Silencer

Adjusting pin

Chassis

Chassis cover

CAUTION: CHECK BEFORE STARTING DOOR

PREP

Door should be tted and hung.

Check box label for size of exit device,

function, hand and design.

Surface of door must be ush.

Clear away any raised projections

to allow exit device to rest on at

surface of door.

AVAILABLE STOCK LENGTHS

Length E: 32" door, no cut off required. Can be cut to t doors down to 24" wide.

Length F: 36" door, no cut off required. Can be cut to t doors down to 33" wide.

Length J: 42" door, no cut off required. Can be cut to t doors down to 37" wide.

Length G: 48" door, no cut off required. Can be cut to t doors down to 43" wide.

TOOLS REQUIRED

1. Measuring tape

2. Power drill

3. Drill bits:

3/32", 1/4", 11/32", 3/8", 3/4", #25

4. Taps: #10-24

Copyright © 2008, 2010, 2012 Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

THIS EXIT DEVICE IS HANDED

OUT

5

Right hand

reverse bevel

5. Hack saw or any power cutter

(for cutting rail if necessary)

6. Screwdrivers: Phillips #2 and #3

7. Level

Left hand

reverse bevel

A7617C

1

Page 2

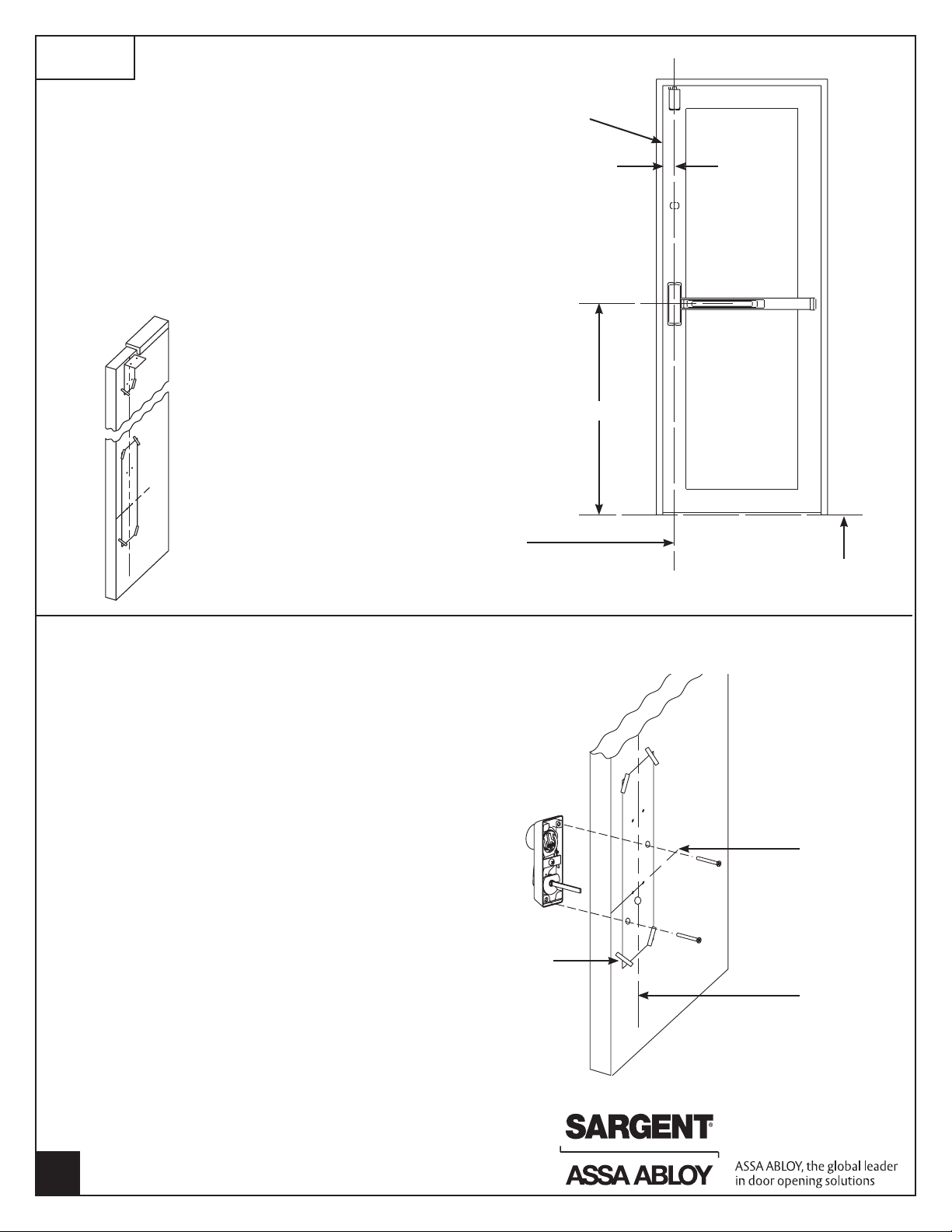

FIRST

DETERMINING CENTER LINES

AND PREP DOOR

1. Determine dimension “A” to locate vertical reference line.

If lock stile is 4-1/2" wide or wider, “A” is 2-3/4".

If lock stile is less than 4-1/2", “A” is 1/2 of the exposed

width of the lock stile when the door is closed against the stop.

2. Standard rail centerline height is 41" above the nished oor.

3. Tape templates on inside of door along reference lines.

4. Spot and drill all holes from inside of door for exit and trim

being used.

5. For ET Controls, see templates supplied for trim.

Frame edge

“A”

Inside face

of door

41”

Vertical reference line

(centerline of chassis and top case)

ATTACHING NB-300 AUXILIARY CONTROL (IF USED)

Note: This section is used only to install

NB-300 auxiliary control.

Note: NB-300 must be installed prior to installing

exit device on door.

1. Verify that the required 3 holes for NB-300

auxiliary control from template A7616 are

drilled and c’sunk. These holes should be

located from the inside of the door.

Note: Verify that NB-300 auxiliary control is

handed correctly. The top of the turn must

rotate toward door hinges.

2. Position NB-300 control on the outside of

the door with the cylinder up.

3. Throughbolt the NB-300 control to the door with

(2) # 10-24x2" long at head screws and

tighten rmly.

4. Center case chassis is located with NB-300’s at

spindle engaging lower hub of center case chassis

Tape (supplied)

Finished oor

Horizontal

reference line

Vertical

reference line

Copyright © 2008, 2010, 2012 Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

2

A7617C

Page 3

SECOND

ATTACHING CENTER CHASSIS AND

700 SERIES ET CONTROL TRIM (IF USED)

ATTACHING THE CHASSIS

1. Secure chassis to door with (4) #10 at head screws (A) using

the four corner holes of the chassis and the appropriate screws

(Wood/Metal).

NOTE: See instruction sheet A6374 for ET details

(changing hands, etc).

ATTACHING ET CONTROL

2. To install ET control, rst loosen 2 screws (B) holding the tube

support (C) and adjusting tube (D) on chassis. Slide off to remove

the tube support (C).

3. Slide ET control spindle (E) into the lower chassis hub (F)

and position ET control against the door.

4. Throughbolt ET control to chassis with (2) 1/4-20 at head screws (G).

5. Re-attach adjusting tube (D) and tube support (C) with 2 screws (B).

6. Attach 646 top strike using holes marked in the rst step with (2)

#12-24 at head screws.

(E) ET control

spindle

(C)

Tube

support

(B) Oval

head screws

(D) Adjusting tube

(G) 1/4-20

Flat head

screws

(F) Chassis

hub

(A) #10 Flat

head screws

THIRD

Check box label.

The following prexes are provided “factory cut” to size: AL-, 56- and 58.

If cutting is required continue with step “A”.

If cutting is not required proceed to step “B”.

A

Determine cut off dimension “X” by subtracting

1-3/4" from dimension “Y”.

PREPARING AND INSTALLING RAIL ASSEMBLY

B

TOP VIEW OF EXIT DEVICE

For doors with a stile, the rail must

overlap stile by 1/2" or more

Vertical reference line

(CL of chassis)

1-3/4" min.

“X”

“Y”

Cut off mark

1. Push lift arm toward the door and slide rail onto

chassis and over the lift arm.

2. Attach rail assembly to chassis with two (2) #8-32

truss head machine screws (H).

NOTE: Do NOT tighten screws.

Lift arm

(H) Rail mounting screw

(2 places) (#8-32 x 3/8 Truss hd

machine screw)

3. Level rail assembly (I) on the door. Locate mounting

plate (J) to attach the rail assembly to door with two

(2) #10-24 rd hd screws (K).

4. Tighten all screws securely.

Level

(I) Rail assembly

(J) Mounting

plate

1. Depress push rail and cut

off at mark.

2. Cut must be straight.

3. For (43-) ush end cap use

cutting guide provided.

4. Remove sharp edges with le.

Copyright © 2008, 2010, 2012 Sargent Manufacturing Company, an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

(J) Mounting plate

(K) Mounting plate screws

(#10-24 x 3/4" Rd hd

machine screws)

A7617C

3

Page 4

FOURTH

ATTACHING TOP CASE AND ADJUSTING TOP ROD

1. Verify that the rail assembly is not dogged (locked down).

2. Screw top rod (M) into top case (not shown) until nger tight.

Be careful not to cross thread.

3. Slide top rod (M) into adjustment tube (D). Do not pin in place.

4. Attach top case to the door where prepped in the rst step.

Note: Top cases on re rated wood doors must be throughbolted.

5. Visually align the hole in adj tube (D) with the lower hole on the

top rod (M). Then unscrew to extend top bolt out as much as possible.

Realign the two holes and insert rod adj pin (L).

6. Check for proper operation.

a) When door is closed, bolt and strike engagement should be 7/16" to 3/8"

b) When door is opened, rod should be held back, which means bolt

remains in the retracted position.

c) Top bolt should not disengage strike until rail is fully pushed in.

How to adjust for proper operation:

a. Issue: Top bolt has very little engagement with top strike:

Solution: Top rod (M) must be lengthened by either: 1) unscrewing the top rod (M) from top case; 2) relocating the rod adjusting pin;

3) adding a shim under the strike to bring the strike closer; 4) repositioning top case closer to the strike.

b. Issue: Top bolt will not disengage from strike, indicating too much engagement between top bolt and strike:

Solution: Top rod (M) must be shortened by either: 1) relocating the rod adj pin (L); 2) screwing the top rod (M)

into top case to shorten it.

c. Issue: Top bolt will not go into hold back position, indicating too little engagement between top bolt and strike.

Door is opening before top bolt is retracted far enough to go into hold back position:

Solution: Top rod (M) must be lengthened by either: 1) unscrewing the top rod (M) from top case; 2) relocating the rod adjusting pin;

3) adding a shim under the strike to bring the strike closer; 4) repositioning top case closer to the strike.

d. Issue: Push rail can not be dogged or pushed in completely, indicating that the top bolt has never been fully extended:

Solution: Top rod (M) must be lengthened by either: 1) unscrewing the top rod (M) from top case; 2) relocating the rod adjusting pin;

3) adding a shim under the strike to bring the strike closer; 4) repositioning top case closer to the strike.

(L) Rod

adjustment pin

(M) Top rod

(D) Adjusting tube

FIFTH

Top case cover

Rod silencer

Rod guide

Chassis cover

End cap

SIXTH

12-NB8700 re rated devices require the installation of a thermal pin assembly to maintain Fire Listing.

See Instruction Sheet A7436 for proper installation in wood and metal doors.

APPLYING GUIDE, COVERS AND END CAP

1. Conrm operation of exit device. Adjust rods

as needed.

2. Attach top and center chassis covers and end cap

as shown and secure with #8-32 oval head screws.

3. Locate rod guide and rod silencer at center of rod.

Rod must move freely in rod guide without rubbing.

4. For doors over 96": Install two (2) top rod guides

equally spaced between the top case and chassis

cover. Rod must move freely in guides.

Note: Additional information for prexes: AL-, 55, 56,

57, & 58, see appropriate instructions:

AL- prex - A7224

55- prex - A6808

56- prex - A6876

57- prex - A6810

58- prex - A6835

Note: Use two (2) No. 10 steel screws and mortise nuts

(when provided) in the position illustrated in the top chase.

Steel mortise nuts are twin knurled for identication.

INSTALLING THERMAL PIN FOR 12-NB8700

NOTE: SHIM TOP STRIKE

WHEN NECESSARY TO

OBTAIN 1/8" GAP

Copyright © 2008, 2010, 2012 Sargent Manufacturing Company,

an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written

permission of Sargent Manufacturing Company is prohibited.

4

A7617C

Loading...

Loading...