Page 1

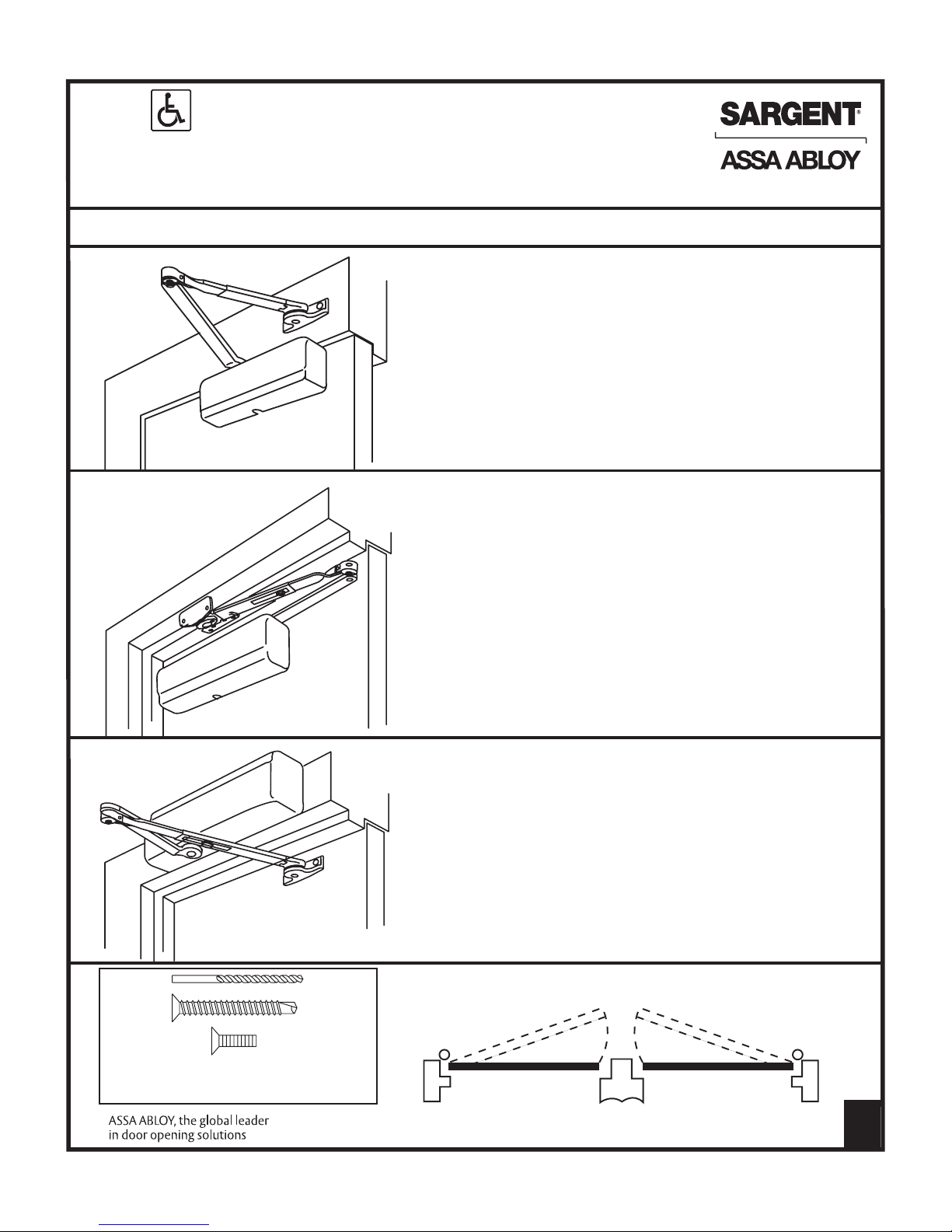

1431 Door Closer with Hold Open Arms

INSTALLATION INSTRUCTIONS

1431 SERIES ADJUSTABLE FROM SIZE 1 THRU 6

© SARGENT Manufacturing Company 2006, 2007

All rights reserved

IMPORTANT NOTICE

PRE-DRILL 3/32" HOLES FOR SELF-TAPPING SCREWS

OR TAP #12-24 FOR MACHINE SCREWS

+

or

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

Installation Instructions based on Application and Arm type

Standard Mounting Application -

H arm

For Standard Application - the Door Closer is mounted

on the hinge side of door (see page 2)

Parallel Arm Application PH9 Arm

For Parallel Arm Application - the Door Closer is mounted

on the stop side of door (see page 4)

Top Jamb Application H, HZ & HZA Arm

For Top Jamb Application - the Door Closer is mounted on the

frame on the stop side of the door (see page 6)

LEFT

HAND DOOR

HINGE SIDE HINGE SIDE

STOP SIDE STOP SIDE

RIGHT

HAND DOOR

PAGE

1

Page 2

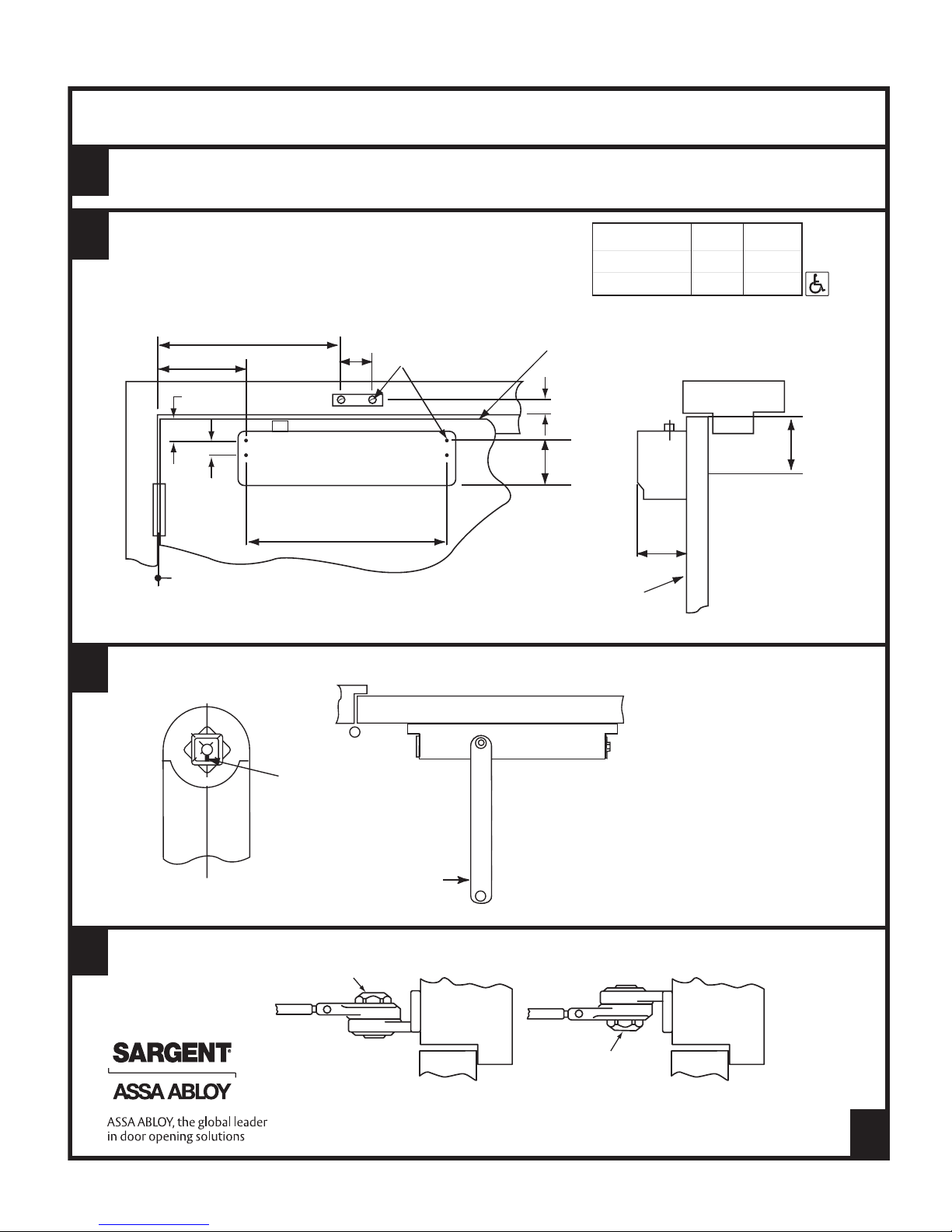

STANDARD APPLICATION

© SARGENT Manufacturing Company 2006, 2007

All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

A

B

A1) Select closer mounting position based on the maximum door opening, as listed below

Note: For ADA applications, select the 160° position

B1) Prep door and frame

Note: 3/32" pilot holes are required when Self Tapping Screws are being used

Note: If machine screws are being used, use a drill #16 (.177) and a #12-24 tap

B2) Install closer body onto the door

B3) Install Foot & Rod Assembly onto the frames

DIM. “B”

DIM. “A”

11⁄4"

1"

C OF HINGE PIVOT

L

RIGHT HAND DOOR ILLUSTRATED. SAME DIMENSIONS APPLY FOR LEFT HAND DOOR.

*SEE PAGE 8 FOR MORTISE NUTS

2-1/2"

1

⁄8"

11

#12 X 1 1/2 SCREWS OR

#12-24 X 5/8 FLAT HEAD

MACHINE SCREW*

DOOR CLOSER

TOP OF DOOR

MAXIMUM DOOR

7

⁄8"

29⁄16"

FACE OF DOOR

OPENING

**If Butt, Frame and Wall Conditions Permit

Door Will Open 180°

DIM. A DIM. B

120° 7 1/2" 13 1/4"

160°** 4 1/4" 10"

FRAME

3

⁄4" MAY BE

25⁄16"

RAILS TO 1

USED PROVIDED FRAME

DOES NOT PROJECT

BEYOND FACE OF DOOR

DOOR

25⁄8" MIN

TOP RAIL

C

D

C1) Install main arm on the closer with the index mark on the spindle aligning with the # 2 on the main arm (as shown)

RIGHT HAND DOOR

5

4

1

3

2

MAIN

ARM

Attach hold open foot to frame with adjusting nut facing down for left hand door or up for right hand door, as illustrated below

INDEX MARK

ON SPINDLE

NUT FACES UP

RIGHT HAND

DOOR SHOWN

POSITION OF

MAIN ARM WHEN

ASSEMBLING

TO SPINDLE

FRAME FRAME

NUT FACES DOWN

LEFT HAND

DOOR SHOWN

PAG E

2

Page 3

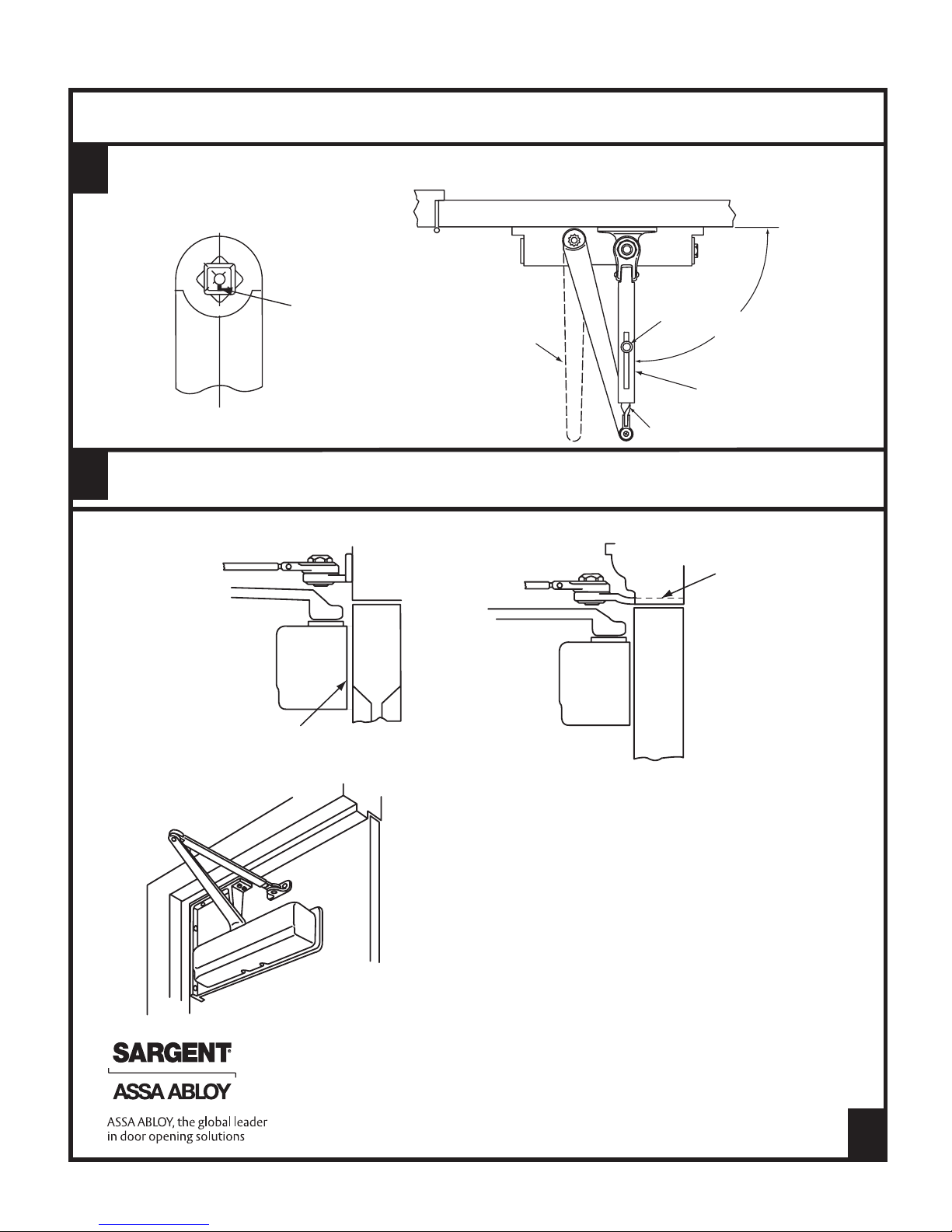

STANDARD APPLICATION

© SARGENT Manufacturing Company 2006, 2007 All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

E1) Opening the door slightly, slide rod into swivel arm and then close the door

E2) With the door closed, position the swivel arm so that it is 90º to the door surface

E

E3) Tighten the arm screw securely

5

4

1

3

2

MAIN

ARM

Adjust closer as required (See page 8 for details).

INDEX MARK

ON SPINDLE

POSITION OF MAIN

ARM WHEN ASSEMBLING

TO SPINDLE

F

ACCESSORIES INFORMATION

RIGHT HAND DOOR

ARM

SCREW

ROD

90°

HOLD

OPEN ARM

H8 MORTISE FOOT

FOR USE WHERE THE

STANDARD SURFACE

APPLIED FOOT CANNOT

BE ATTACHED TO THE

TOP CASING OR WHERE

APPEARANCE IS A

MAJOR FACTOR

1430-J COVER PLATE

MAY BE USED WHEN CLOSER IS MOUNTED

ON A NARROW RAIL TO IMPROVE APPEARANCE

WHEN CLOSER IS VIEWED THRU GLASS

1431-W corner bracket closer is mounted on bracket which is attached to door jamb

on stop side of door

Use this application for exterior doors to keep the closer inside of building; Also may be

used to obtain full 180° door opening

MORTISE NUTS FOR BOLTING THRU THE DOOR ARE FURNISHED WHEN ORDERED

PAG E

3

Page 4

MAXIMUM DOOR

© SARGENT Manufacturing Company 2006, 2007 All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

OPENING

Page 5

INSTRUCTIONS FOR INSTALLING PARALLEL ARM APPLICATION

© SARGENT Manufacturing Company 2006, 2007 All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

CLOSER MOUNTED ON

STOP SIDE OF DOOR

C

D

E

Attach hold open foot to frame with adjusting nut facing down for left hand door or up for right hand door, as illustrated below.

NUT FACES UP

LEFT HAND

DOOR SHOWN

NUT FACES DOWN

RIGHT HAND

DOOR SHOWN

D1) Install main arm on the closer with the index mark on

spindle aligned with the number on the arm

Note: Left Hand Doors -align index mark with the # 4

on the main arm (as shown).

Note: Right Hand Doors -align index mark with the # 5

PRELOAD 45°

on the main arm (as shown).

D2) This requires the spindle to be rotated

D3) Rotate the spindle on the bottom of the closer to align

LEFT HAND DOOR

index mark with the required number on the arm

IND

EX MARK

ON SPINDLE

5

45°

4

Left Hand Door

1

MAIN

ARM

2

3

IN

A

M

M

R

A

INDEX MARK

ON S

4

3

2

5

1

Right Hand Door

PINDLE

45°

FOOT BRACKET

HOLD

OPEN ARM

ARM

SCREW

ROD

E1) Opening the door slightly, slide rod into swivel arm and

then close the door

E2) With the door in the closed position, swivel the arm so that

PRELOAD 45°

the pivot is 1-1/2" off the door surface (as shown below)

E3) Tighten the arm screw securely

LEFT HAND DOOR

1-1/2"

Adjust closer as required (See page 8 for details)

F

ACCESSORIES INFORMATION

1430-D DROP BRACKET

CLOSER IS MOUNTED ON PLATE WHEN

TOP RAIL IS TOO NARROW

2 1/2" MIN.

FOOT BRACKET

1430-J COVER PLATE

May be used when closer is mounted on

a narrow rail to improve appearance when

closer is viewed through glass

MORTISE NUTS FOR BOLTING THRU THE DOOR

ARE FURNISHED WHEN ORDERED

HOLD

OPEN ARM

ROD

ARM

SCREW

#H8 MORTISE FOOT

#8 MORTISE FOOT

For use where the

standard surface applied

foot cannot be attached

to the top casing or where

appearance is a major

facto r

PAG E

5

Page 6

TOP JAMB APPLICATION

© SARGENT Manufacturing Company 2006, 2007 All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

A

B

C

A1) Select closer mounting position based on Reveal Depth as listed below

B1) Locate and mark hole locations

Note: 3/32" pilot holes are required when Self Tapping Screws are being used.

Note: If machine screws are being used, use a drill #16 (.177) and a #12-24 tap.

C1) Install closer body onto the frame

C2) Install the Foot & Rod Assembly onto the door

ARM ASSEMBLY

TYPE

“O” ARM 0" TO 2" 5 3/4"

“OZ”ARM

“OZA” ARM

**IF BUTT, FRAME AND WALL CONDITIONS PERMIT, DOOR WILL OPEN 180°

LEFT HAND DOOR ILLUSTRATED.

SAME DIMENSIONS APPLY FOR

RIGHT HAND DOOR. MEASURE

FROM HINGE C

L

REVEAL DEPTH DIM. A

2 1/8" TO 5" 6 1/2"

5 1/8" TO 8" 7 1/4" 80° - 140°

MAXIMUM DOOR

OPENING

80° - 180°

80° - 180°

#12 X 1 1/2 WOOD SCREWS

OR #12-24 X 5/8 FLAT HEAD

MACHINE SCREW

3

⁄8"

3

5

⁄8"

DOOR CLOSER

1"

DIM. “A”

21⁄2"

111⁄8"

C OF HINGE PIVOT

L

(BUTT HINGE shown)

CLOSER FOOT

APPLIED TO DOOR

(

SEE PAGE 8 FOR MORTISE NUTS)

C OF CLOSER

L

MOUNTING SCREWS

MAIN ARM

FOOT & ROD ASSY

STOP

FRAME

21⁄4"

9

2

DEPTH OF REVEAL

⁄16"

2 5⁄16"

DOOR

PAG E

6

Page 7

© SARGENT Manufacturing Company 2006, 2007

All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

Page 8

INSTALL COVER AS FOLLOWS:

FOR STANDARD AND PARALLEL ARM APPLICATION

• Screw short cover screw (#8-32 X 5/16) into top of case

approximately 2 turns

•Assemble plastic support and long cover screw (#8-32 X 1 1/4)

into bottom of case approximately 2 turns

• Hold support against case (approximately 2 turns)

between flange and screw head

•Position cover on closer and tighten screws

FOR TOP JAMB APPLICATION

•Assemble plastic support and long cover screw (#8-32 X 1 1/4")

into top of case approximately 2 turns

• Screw short cover screw (#8-32 X 5/16") into bottom of case

approximately 2 turns

• Slide cover into gap between flange and screw head. Position cover

on closer and tighten screws

GAP

SHORT COVER SCREW

PLASTIC SUPPORT AND

LONG COVER SCREW

INSERT IS REMOVABLE.

PLACE IN UNUSED OPENING

SHORT COVER SCREW

PLASTIC SUPPORT AND

LONG COVER SCREW

INSERT IS REMOVABLE. PLACE IN UNUSED OPENING

RIGHT HAND

ILLUSTRATED

8

PAG

E

FINAL ADJUSTMENT AND REGULATING PROCEDURE

FRAME

UNREINFORCED

DOOR

COVER

DOOR

STOP

MORTISE

NUT HEAD

DRILL

3/8" DIA.

HOLE FOR

MORTISE

NUT BODY

DRILL 1/4" DIA.

HOLE FOR MOUNTING SCREWS

1. For top jamb and corner bracket

applications: The door closer foot

will be attached to the door in a

manner similar to that shown for

mounting the closer body.

2. The appropriate mortise nuts

and screws will be suppled based

on door thickness.

Door construction must provide a

bridge type reinforcement to prevent

the door rail from collapsing when

through-bolts are tightened.

Adjustment hold open arm

Slight tightening or loosening of hold

open nut changes holding position of door.

Note: To protect wall, trim and closer, use a door stop

located 10° beyond hold open position but not beyond

the max. door opening shown on instructions.

HOLD

OPEN

NUT

USE 15/16"

WRENCH TO

ADJUST NUT

Minimum recommended door closing time is 6 Seconds for

DOOR WIDTH

1431 DOOR CLOSER

(INCHES)

24-30 TURN nut 1-3

30-36 FACTORY SET

36-42 TURN nut 1-4

42-48 TURN nut 7-9

NUMBER OF TURNS OF SPRING POWER ADJUSTING NUT

Adjusting door

to close due to

high draft

conditions may

exceed ADA

standards.

Consult local

ordinances

when fire doors

are involved

© SARGENT Manufacturing Company 2006, 2007 All rights reserved

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com A7140E

doors opened to 90 degrees.

Use 1/8” hex (Allen) wrench to adjust valves as needed.

Closing and latching speeds:

Turn valves clockwise to slow down or counterclockwise to

speed up door movement.

Backcheck:

To regulate the intensity of back check action, turn valve clockwise

to increase or counterclockwise to decrease checking.

CAUTION: Set valve for slight cushioning effect; closer can be

damaged if the checking action is too abrupt. Never use

the backcheck as a door stop. Always use a door stop to stop

the door.

Delayed action feature (Optional feature on some models):

“Delayed action” provides slow door closing through the

delayed action range. Turn valve clockwise to slow down or

counterclockwise to speed up door movement.

Loading...

Loading...