Page 1

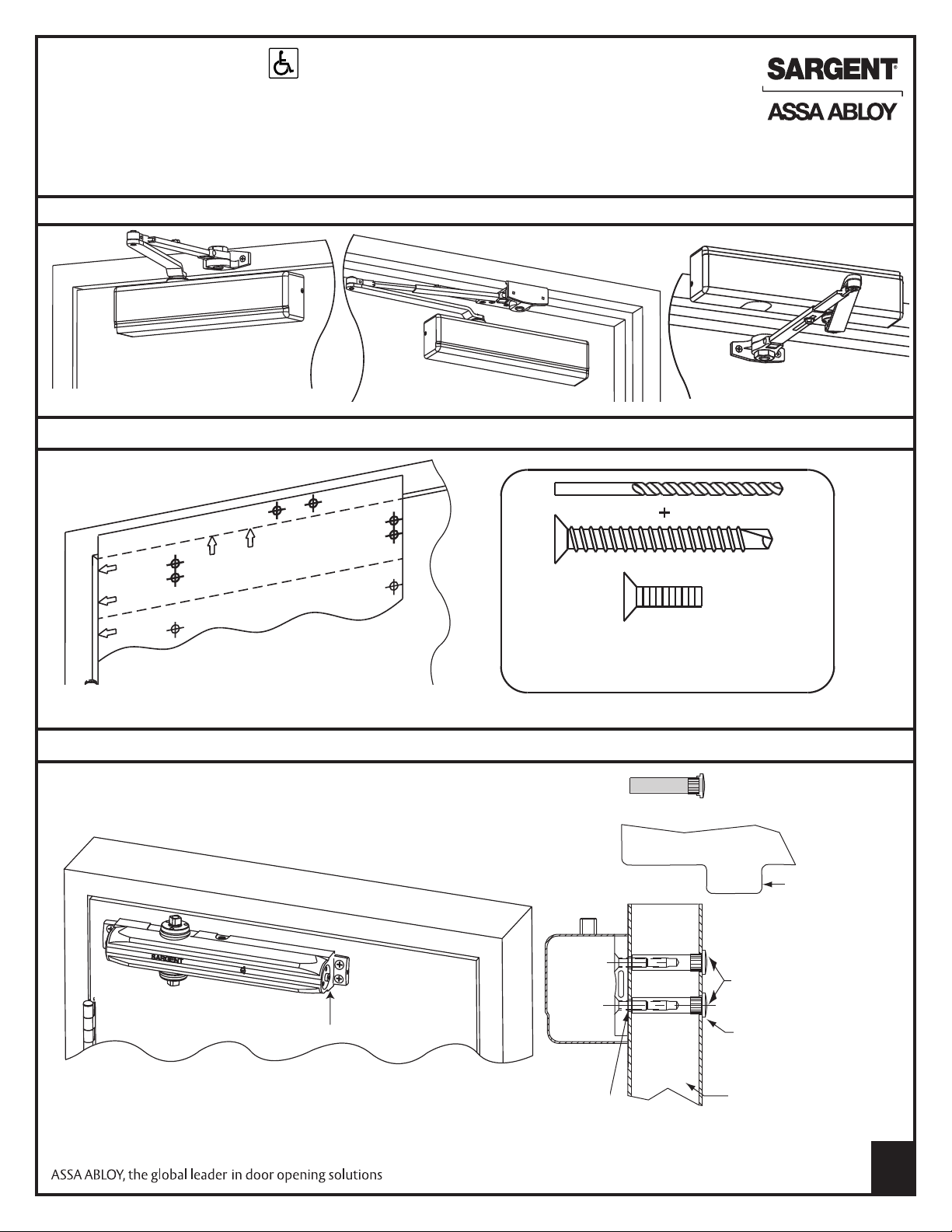

SARGENT®1331 DOOR CLOSER INSTALLATION

Frame

Unreinforced

Door stop

Mortise nut

Drill 3/8" Dia

hole for mortise

nut body

INSTRUCTIONS WITH JUH (HOLD OPEN) ARMS

Strength Adjustable From Size 1 Thru 6

CAUTION: FAILURE TO INSTALL OR ADJUST PROPERLY MAY RESULT IN INJURY OR DAMAGE.

FOR ASSISTANCE, CALL SARGENT AT 1-800-727-5477 or www.sargentlock.com

Choose From 1 of the 3 Applications Below

JH Standard Arm JPH9 Parallel Arm JH Top Jamb Arm

Use Standard & Parallel Full Size Templates Provided

NOTE: With swing clear hinges, use data sheets provided.

* 1/4" Variance allowed for retrofit of existing closers

With fasteners provided, secure closer body to door with

power adjustment away from hinge.

OR

Pre-drill - 3/32” holes

for self tapping screws or #16 drill for

#12-24 tap for machine screws

Using optional mortise nuts when through-bolting

Frame

Door stop

Mortise nut

Power Adjustment

Drill 3/8" dia.

hole for mortise

nut body

Drill 1/4" dia. hole

for screws

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All rights

reserved. Reproduction in whole or in part without the express written permission of Sargent

Unreinforced

door

Manufacturing Company is prohibited.

A7742A

1

Page 2

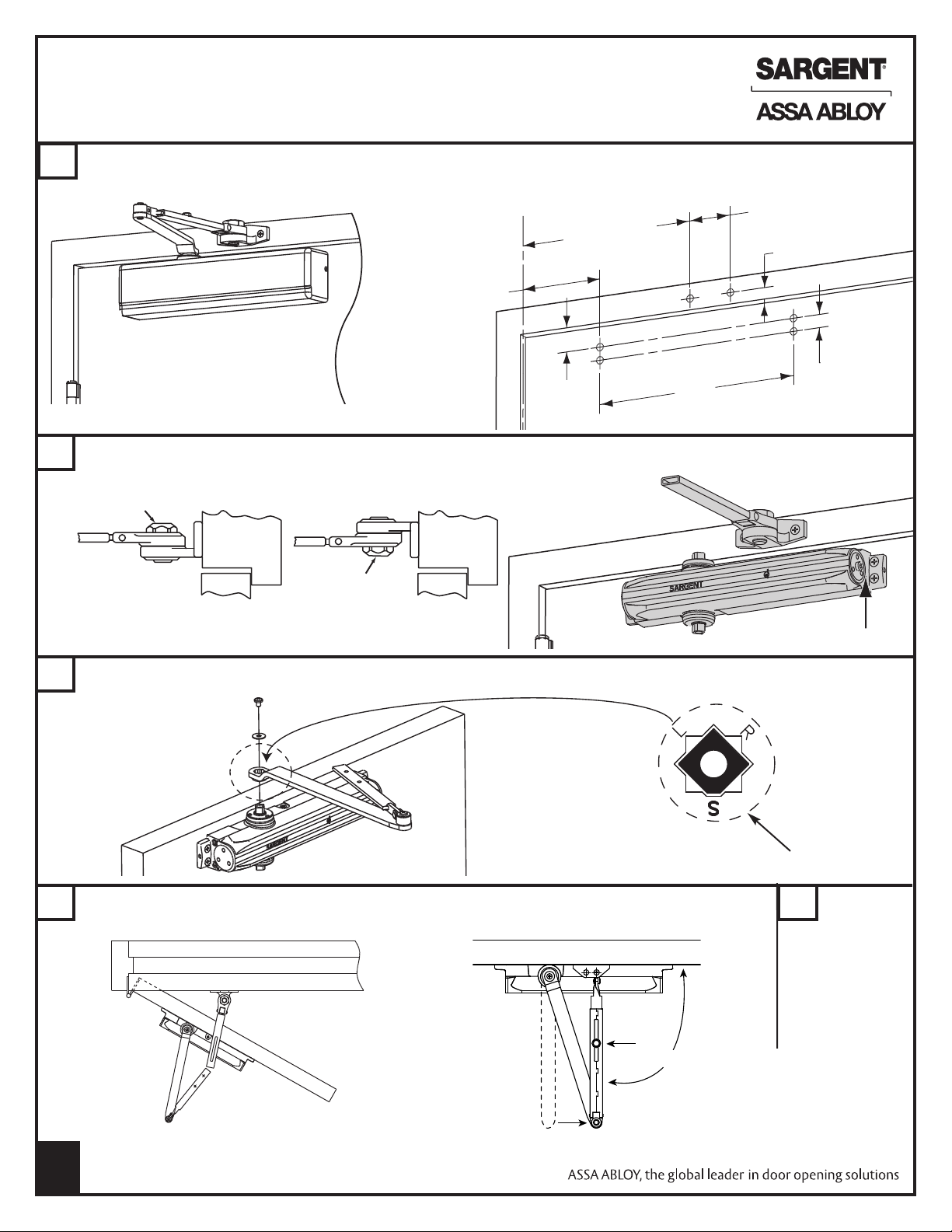

1331 STANDARD APPLICATION JH

-

-

-

-

-

-

-

-

-

-

Frame Frame

Nut faces down

Nut faces up

Left hand

door shown

Right hand

door shown

HOLD OPEN ARM INSTRUCTIONS

Determine maximum degree of door opening required. Use a #16 drill. Drill and tap door and frame for 12-24 machine screws.

1

When using the included self tapping screw, predrill with a 3/32" drill. *Provides maximum power for heavy or drafty doors

2-

1/2"

120° - 12”)

*(

180° - 10-1/8"

*(120° - 6-12")

180° - 4-5/8"

1"

With provided fasteners, install foot to frame and secure closer body to door with power adjustment away from hinge

2

On both right and left hand doors, secure main arm to top spindle with screw and washer provided. Align flat mark as shown

3

1-3/8"

Right hand shown, left hand similar.

12"

3/4"

Power adjustment

Flat mark

Open door and insert foot into main arm. Close door fully, and while pushing arm as shown in picture,

4

tighten arm bolt

Arm

Bolt

90°

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All

rights reserved. Reproduction in whole or in part without the express written permissionof

Sargent Manufacturing Company is prohibited.

2 7

A7742A

5

See page 5

for closer

adjustment

and cover

installation.

Page 3

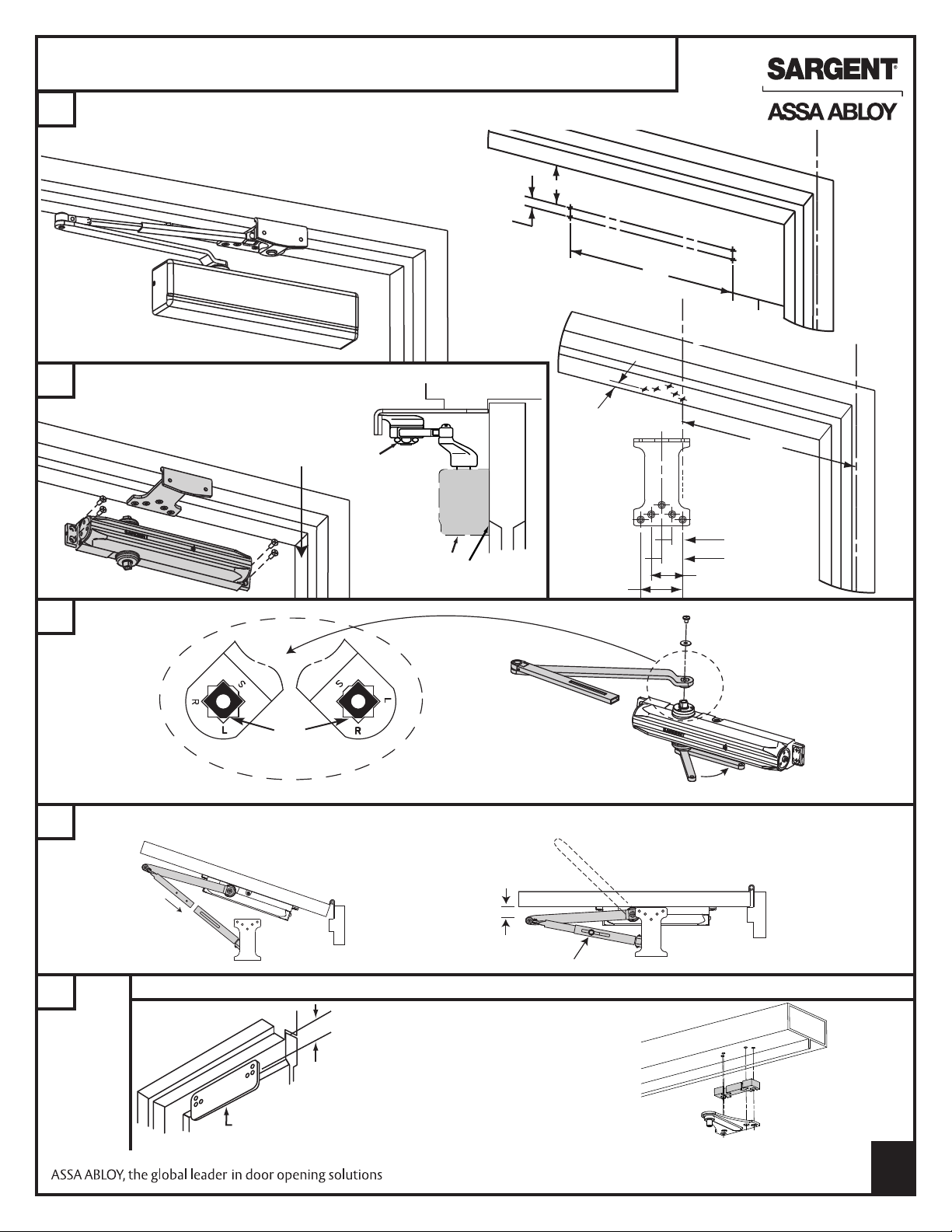

1331 JPH9 PARALLEL HOLD OPEN INSTRUCTIONS

F

rame

Door

IMPORTANT

Nut faces

down for

left hand

and faces

up for right

hand door

Cover

Use 1331-D Drop

bracket if door

rail is too narrow

2-1/2" Min.

1331D

Drop plate used when

top rail is less than 2 1/2"

1

Determine maximum degree of door opening required.

Use a #16 drill. Drill and tap door and frame for 12-24 machine

screws. When using the included self tapping screws, predrill

with a 3/32" drill.

*Provides maximum power for

heavy or drafty doors

Right hand shown, left hand opposite.

With fasteners provided, install foot to frame

2

with nut as shown and closer body to door

with power adjustment toward hinge

Center line

of hinge

3/4"

3-1/2"

1/2"

2-1/2"

12"

Center line

*(120° - 3-3/4")

180° - 1-3/8"

*(120° - 9-1/2")

180° - 7-1/8"

5/8"

1-1/4"

1-7/8"

of hinge

Center line

of hinge

3

Open door and insert foot into main arm. Close door fully, while holding elbow 1-1/4" from door. Tighten arm bolt

4

5

See page

5 for

adjustment

and cover

installation

Left Hand

Door

Drop Plate

Flat

mark

Right Hand

Door

With wrench on bottom

spindle, preload/index by

turning spindle as shown

and secure main arm to top

spindle with flat mark as

indicated at left with screw

and washer

1-1/4"

Arm bolt

Accessory Information

581-1 Blade Stop Spacer Kit

Metal spacer for use on 1/2"

blade stops on aluminum

store fronts

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All rights

reserved. Reproduction in whole or in part without the express written permission of Sargent

Manufacturing Company is prohibited.

A7742A

Page 4

1331 JH TOP JAMB PARALLEL HOLD

Nut faces down

Nut faces up

Right hand

door shown

Left hand

door shown

OPEN INSTRUCTIONS

Determine maximum degree of door opening required. Use a #16 drill. Drill and tap door and frame for

1

12-24 machine screws. When using provided self tapping screws, predrill with a 3/32" drill.

*Provides maximum power for heavy or drafty doors

3/4"

2-1/2"

Right hand door shown, left hand door similar

2

With provided fasteners, install foot to door as shown and closer body to frame with power adjustment away from hinge

Hinge edge

Power Adjustment

12"

*(120° - 12-3/8")

180° - 10-1/8"

Center line

of hinge

*(120° - 6-3/4")

180° - 4-5/8"

1/2"

2-1/4"

3

On both right and left hand doors, secure main arm to spindle with screw and washer provided. Align flat mark as shown

4

Open door and insert foot into main arm. Close door fully, and while pushing arm as shown in picture, tighten arm bolt

Arm

Bolt

Flat mark

Accessories

90°

See page 5 for adjustment and cover installation

5

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All

rights reserved. Reproduction in whole or in part without the express written permissionof

Sargent Manufacturing Company is prohibited.

4

A7742A

Page 5

CLOSER ADJUSTMENT AND COVER INSTALLATION

HE 1331 IS FACTORY ADJUSTED FOR MOST APPLICATIONS, HOWEVER,

T

ADDITIONAL ADJUSTMENT MAY BE REQUIRED DUE TO ACTUAL CONDITIONS

MINIMUM RECOMMENDED DOOR CLOSING TIME FOR DOORS OPENED TO 90° IS 6 SECONDS.

5

Use 1/8" hex (Allen) wrench to adjust valves as needed.

SWEEP AND LATCHING SPEEDS:

Turn valves clockwise to slow down or counterclockwise to speed up door movement

BACKCHECK:

To regulate the intensity of backcheck action, turn valve clockwise to increase or counterclockwise to decrease checking

CAUTION: SET VALVE FOR SLIGHT CUSHIONING EFFECT. CLOSER CAN BE DAMAGED IF THE CHECKING ACTION IS

TOO ABRUPT. NEVER USE THE BACKCHECK AS A DOOR STOP. ALWAYS USE A DOOR STOP TO STOP THE DOOR

IF ADJUSTMENTS ARE INEFFECTIVE, CHECK INDEXING AS SHOWN IN STEP 3 AND

CHECK FOR CORRECT TEMPLATING

Sweep (Closing)

Speed

up

Slow

down

Spring power adjustment

1/8" HEX wrench

Latching speed

1/8"

speed range

Backcheck

range

range

CLOSING POWER:

Certain applications may require closing power adjustment:

If the door will not latch properly, increase power by turning

the power adjustment clockwise in full turn increments.

If the door is hard to open, reduce power by turning the power

adjustment counter-clockwise in full turn increments.

COVER INSTALLATION

6

Move insert if needed. Install cover

with two #6- 32 X 5/16" machine

screws as shown.

7

ADJUSTMENT HOLD OPEN ARM

Slight tightening or loosening of hold open nut changes holding

position of door.

NOTE: To protect wall, trim and closer, use a door stop located 5°

beyond hold open positions, but not beyond the max. door opening shown on instructions.

Sweep

Backcheck

Latch

Insert

Use 15/16"

wrench to

adjust nut

Hold

open

nut

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All rights

reserved. Reproduction in whole or in part without the express written permission of Sargent

Manufacturing Company is prohibited.

A7742A

5

Page 6

F

rame

Door

IMPORTANT

Nut faces

down for

left hand

and faces

up for right

hand door

Cover

Use 1331-D Drop

bracket if door

rail is too narrow

2-1/2" Min.

1331D

Drop plate used when

top rail is less than 2 1/2"

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All

rights reserved. Reproduction in whole or in part without the express written permissionof

Sargent Manufacturing Company is prohibited.

6 3

A7742A

Page 7

-

-

-

-

-

-

-

-

-

-

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All rights

reserved. Reproduction in whole or in part without the express written permission of Sargent

Manufacturing Company is prohibited.

A7742A

Page 8

-

-

-

-

-

-

Frame

Unreinforced

Door stop

Mortise nut

Drill 3/8" Dia

hole for mortise

nut body

Copyright©2008, Sargent Manufacturing Company,anASSAABLOY Group company. All

rights reserved. Reproduction in whole or in part without the express written permissionof

Sargent Manufacturing Company is prohibited.

8

A7742A

Loading...

Loading...