Page 1

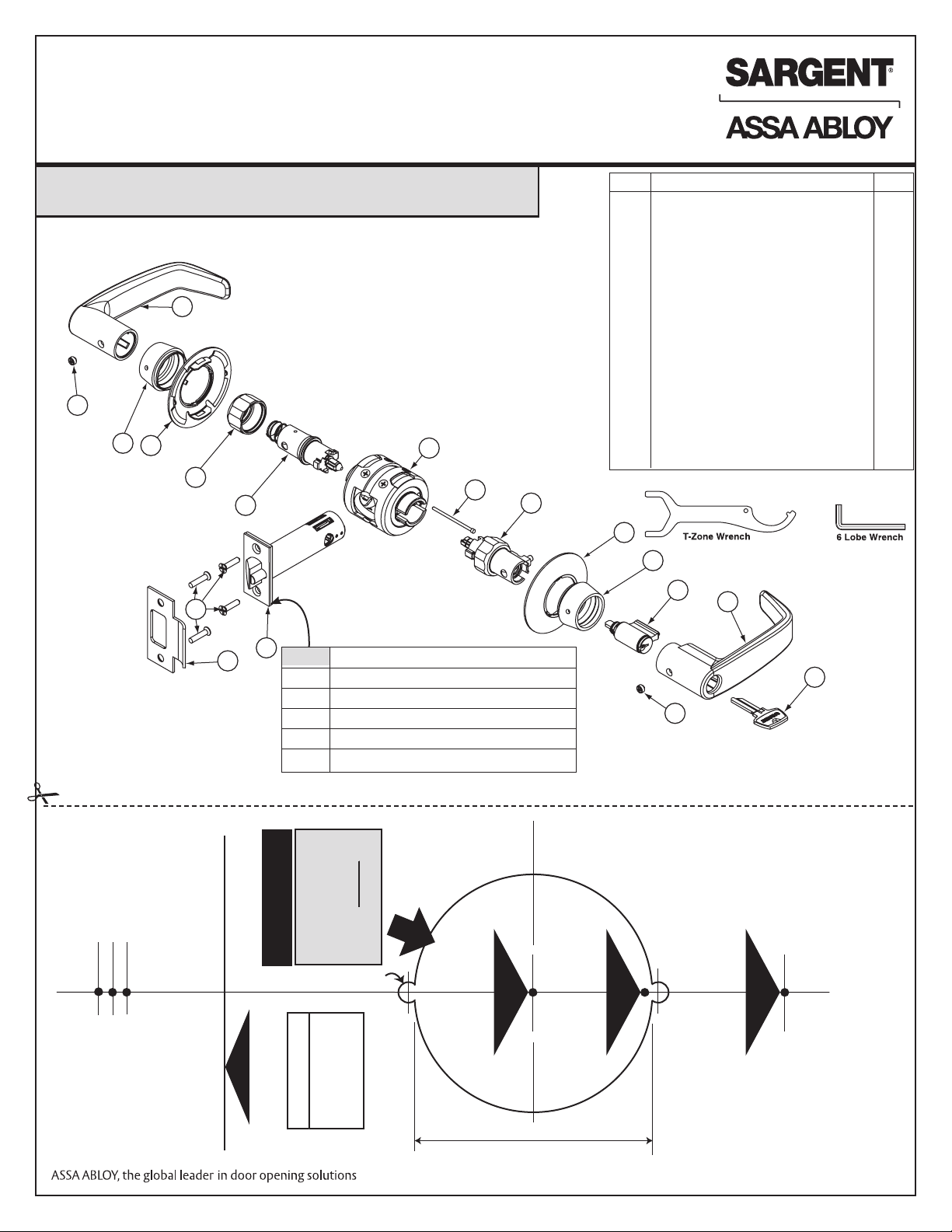

INSTALLATION INSTRUCTIONS FOR

Mark for 1" hole

at center of

door thickness

FOLD HERE

IMPORTANT

Place fold on

HIGH EDGE

of beveled door

Mark center for

2-1/8" crossbore

hole at correct

backset

IMPORTANT

2"

1-3/4"

2-3/4" (70 mm) BACKSET

3-3/4" (95 mm) BACKSET

5" (127 mm) BACKSET

11 Line U.S. Patent No. 6,626,018

FOR ASSISTANCE, CONTACT SARGENT AT 800-727-5477 or www.sargentlock.com

To view helpful video installation tips, scan the Microsoft® Tags with

your mobile phone. Download the free mobile app at http://gettag.mobi.

1

2

4

3

5

14

6

13

15

Code stamp

location

Code Latchbolt Functions

A 15

B 04, 05, 13, 15-3, 16, 17, 30, 37, 38

C 65

D 44, 50, 54

K 24

7

8

Item Description Qty.

1 Inside Lever 1

2 6 Lobe Security Set Screw, 2

1/4-28 x 11/64" 2

3 Rose 2

4 Rosette 2

5 Inner Collar 1

6 Inner Sleeve 1

7 Bearing Assembly 1

8 Aligning Pin 1

9 Outer Sleeve (with captive Collar) 1

10 Cylinder 1

11 Outside Lever 2

12 Keys 1

13 Latch Assembly 4

14 Screw, Flat Hd, #8-32 x 3/4" 1

15 Strike (800 shown)

9

3

4

10

11

12

2

2-1/4" (57mm)

2" (51mm)

1-3/4" 44mm)

Mark for

1" hole (25mm)

at center of

door thickness

LATCHBOLTS ARE NOT INTERCHANGEABLE.

IMPORTANT

Mark center for

2-1/8" crossbore

hole at correct

backset

2 x 5/32" (4 mm) Dia

2-3/4" (70 mm)

HIGH EDGE

Place fold on

IMPORTANT

FOLD HERE

of beveled door

2-1/8" (54 mm) Diameter

NOTE– CONSULT FACTORY FOR

CORRECT TEMPLATE INFORMATION

FOR 11G93, 11G94 AND 11G94-2

FUNCTIONS

BACKSET

BACKSET

3-3/4" (95 mm)

5" (127 mm) BACKSET

Copyright © 2013 SARGENT Manufacturing. All rights

reserved. Reproduction in whole or in part without

the express written permission of SARGENT

Manufacturing is prohibited.

A7469K

Page 2

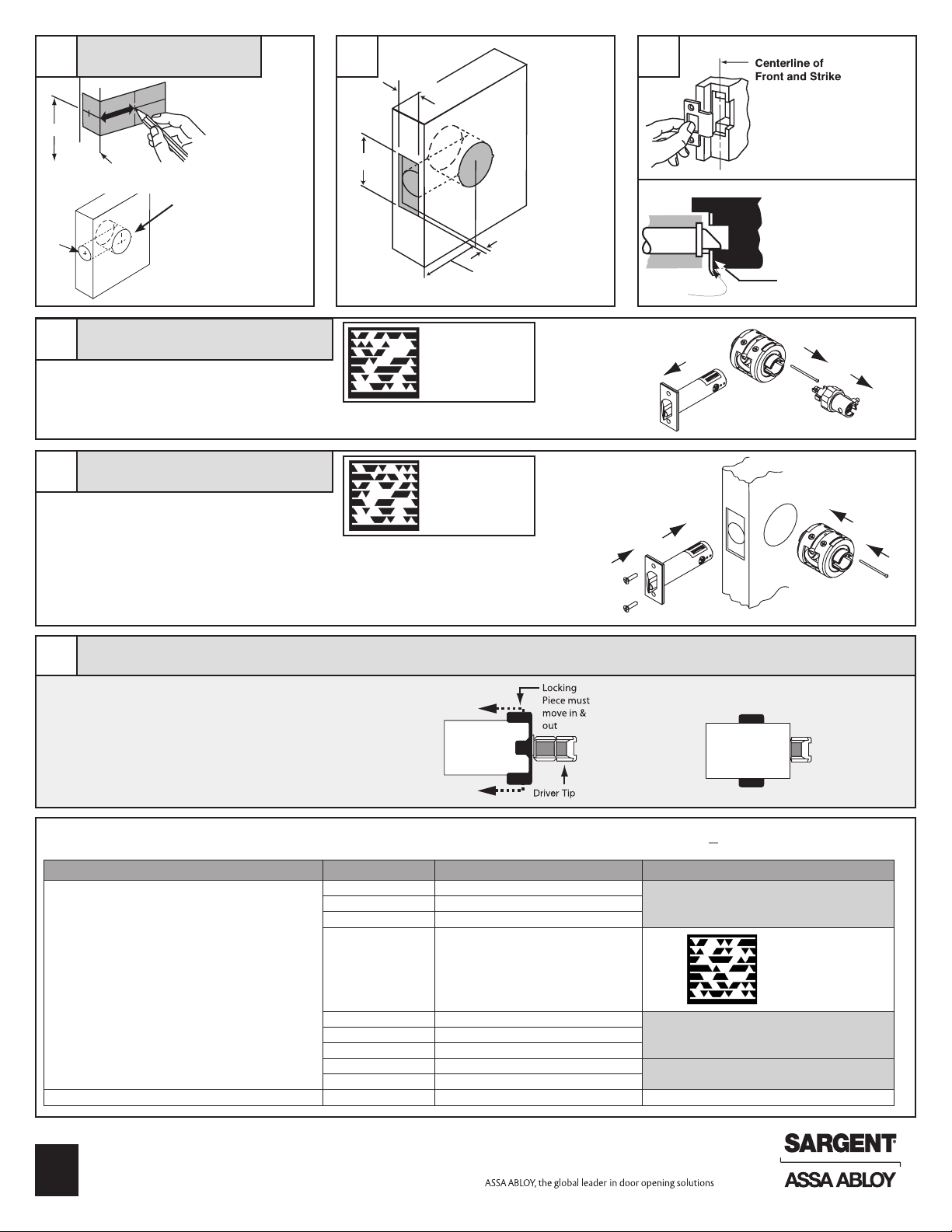

Door Preparation

Outside

Sleeve

"Spring loaded"

1

38"

• Fold template on

door and mark

hole centers

2 3

1-1/8"

•

Mark centerline on jamb

•

Mark outline of strike

Finished

floor

1"

4

5

High edge of

beveled door

2-1/8" Hole

• Bore 2-1/8"

• Bore 1" hole

Lock Disassembly

1. Unthread collar and remove OUTSIDE sleeve

2. Remove aligning pin from bearing assembly

3. Separate latch from bearing assembly

Latchset Installation

Hold door open with door stop

1. Insert bearing assembly

2. Insert latch assembly

3. Insert aligning pin from secure side (outside)

of door

4. Install latch plate screws. Do not tighten

completely until lock installation is finished

2-1/4"

• Cut rectangular front recess

Scan to see a video of

this installation step.

Scan to see a video of

this installation step.

5/32" DEEP

RECESS

DESIRED BACKSET

Inside

•

Cut recess for latch bolt

•

Install strike; secure with

two screws

IMPORTANT

Guardbolt stops on strike

STRIKE

3

INSIDE

Inside

2

4

when door is closed

GUARDBOLT

2

Outside

1

OUTSIDE

Outside

1

3

Function Specific Instructions - Sleeve Assembly

6

IMPORTANT: Sleeves with colored driver tips require that the slotted cam be

rotated allowing the spring loaded locking piece to move freely in and out of

the outside sleeve

Driver Tips with red markings must match up before assembling lock

PLEASE NOTE — Some driver tips have two color markings for function

identification

11G54 - green 11U65 - blue

11G24 - yellow 11G05 - only red

Outside

Sleeve

See Specific Instructions Per Function. Identify Function On Box (Example: 11G05)

For functions not shown proceed to step 7

Outside Sleeve Function Number Function Description Inside Sleeve

04 Storeroom/Closet

16 Classroom Security/Apartment

17 Utility/Asylum

Align driver tips matching the painted sections

24 Entry

See A7608B 50 Hotel/Motel See A7608B

65 Privacy/Bathroom

38 Classroom Security

54 Dormitory

Note: Outside sleeve has collar

attached

Outside

Sleeve

position

Follow Step 705 Entrance/Ofce

Scan to see a video of

this installation step.

Follow Step 744 Service Station

Follow Step 7

Copyright © 2013 SARGENT Manufacturing. All rights reserved. Reproduction in whole or in

part without the express written permission of SARGENT Manufacturing is prohibited.

2

A7469K

Page 3

Sleeve Installation

7

1. With driver tips aligned, insert outside

sleeve first. Dimple must face door edge

2. Thread outside collar by hand.

Tighten to bearing assembly with wrench

3. Insert inside sleeve. Dimple must face door edge

4. Thread inside collar by hand. Tighten to bearing

assembly with wrench

Caution: If excessive wrench

torque is required, stop and

check alignment of driver tips

Cam Orientation

8

1. Lock lever by button if applicable

2. Turn slotted cam until lever catch button can

be depressed

Scan to see a video of

this installation step.

Scan to see a video of

this installation step.

Inside

4

3

2

DIMPLE

1

CAM

NOTE: Dark colored cams on the inside designate for

use with standard cylinders. Silver colored cams on the

inside designate for use iwth I/C & R/C cylinders.

DIMPLE

Outside

Correct Cam Orientation for Standard Cylinder

45º

ANGLE

Rose Installation

9

1. Slide rose over sleeves aligning tabs on rose with slots

on bearing assembly

2. Hand tighten rosettes to door surface

LEVER CATCH SLOT

LEVER CATCH BUTTON

CYLINDER TAIL PIECE SLOT

Caution: If excessive wrench

torque is required, stop and

check for cross-threading

Note: Rosettes must be tightened simultaneously to ensure

proper centering of lock on door.

Scan to see a video of

this installation step.

Correct Cam Orientation for IC/RC Cylinders

45º

ANGLE

(See also A7471 instructions)

LEVER CATCH SLOT

LEVER CATCH BUTTON

CYLINDER TAIL PIECE SLOT

4

Inside

Slots for tabs on rose

Rosette

b

2 Rose

(within sleeve)

Copyright © 2013 SARGENT Manufacturing.

All rights reserved. Reproduction in whole or

in part without the express written permission

of SARGENT Manufacturing is prohibited.

A7469K

3

Rosette

Outside

3

Page 4

Function Specific Directions - Lever Installation

For functions not shown proceed to step 10

Inside Sleeve Function Function Description Outside Sleeve

05 Entrance/Ofce

Lock lever by button

Rotate cam until lever catch button can be

depressed, holding cam in rotated position

24 Entry

44 Service Station

65 Privacy/Bathroom

04 Storeroom/Closet

17 Utility/Asylum

16 Classroom Security/ Apartment Rotate cam until lever catch button can be depressed

30 Communicating

Rotate cam until lever catch button

can be depressed, holding cam in

rotated position

Rotate cam counterclockwise until it stops. Then rotate back 45° until

lever catch button can be depressed.

Scan to see a

video of this

installation step.

Rotate cam counterclockwise until it stops.

Lock lever by button 54 Dormitory

See A7608B 50 Hotel/Motel See A7608B

Lever Installation

10

1. For conventional cylinder, place cylinder into lever. Insert

key and turn 45° CLOCKWISE to align cylinder tailpiece

with deep slot in cam (see slotted cam illustration in step

8). For removable or interchangeable core, see separate

instruction sheet (A7471).

2. Install outside lever. Push on until lever catch engages

Note: If outside lever won't secure in place, rotate key clockwise until lever catch is released.

3. Secure with 6 lobe security set screw until flush with

lever surface

4. Install inside lever. On 17 and 30 function, push on until

lever catch engages.

5. Secure with 6 lobe security set screw until flush with

lever surface

6. Complete tightening of two latchbolt screws

7. Check operation of levers and latchbolt before closing door

38 Classroom Security

Scan to see a video of

this installation step.

Rotate cam counterclockwise until

it stops. Then rotate back 45° until

lever catch button can be depressed.

Rotate cam counterclockwise until it stops. Then rotate back 45° until

lever catch button can be depressed.

Inside

Scan to see a

video of this

installation step.

Outside

11G38 Classroom Security Function

11

Function Description: Inside lever

is always unlocked. Inside key locks/

unlocks outside lever. When inside key

locks outside lever, outside key retracts

the latchbolt but cannot unlock the

outside lever.

Cylinder Removal (Conventional)

12

1. Remove 6 lobe security set screw

2. Insert key and rotate 45° clockwise to release lever catch

3. Depress lever catch and remove lever

Please Note: Removable and interchangeable core cylinders do not require

removing the lever to install. See separate instruction sheet (A7471).

Copyright © 2013 SARGENT Manufacturing. All rights reserved. Reproduction in whole or in

part without the express written permission of SARGENT Manufacturing is prohibited.

4

A7469K

Inside rose is marked with

“Lock” and direction arrows

to indicate locking direction

INSIDE:

Rotate key CLOCKWISE TO LOCK.

Rotate key COUNTER-CLOCKWISE

TO UNLOCK

Lever

catch

Note: If outside lever remains locked,

rotate key on inside lever 360 degrees

counterclockwise, and then rotate key

on outside lever 360 degrees clockwise.

OUTSIDE:

Rotate key COUNTER

CLOCKWISE TO LOCK.

Rotate key

CLOCKWISE TO UNLOCK.

Inside

13

Outside

11U65 Outside Lever

Removal

1. Remove 6 lobe security set screw

2. Lock outside lever by pushing in button on

inside lever.

3. Rotate slot on outside lever with flat blade screwdriver

45° to release lever catch and hold in place

4. Depress lever catch and remove lever

Loading...

Loading...