Page 1

Installation Instructions

80-9311-0011-021 Rev 2

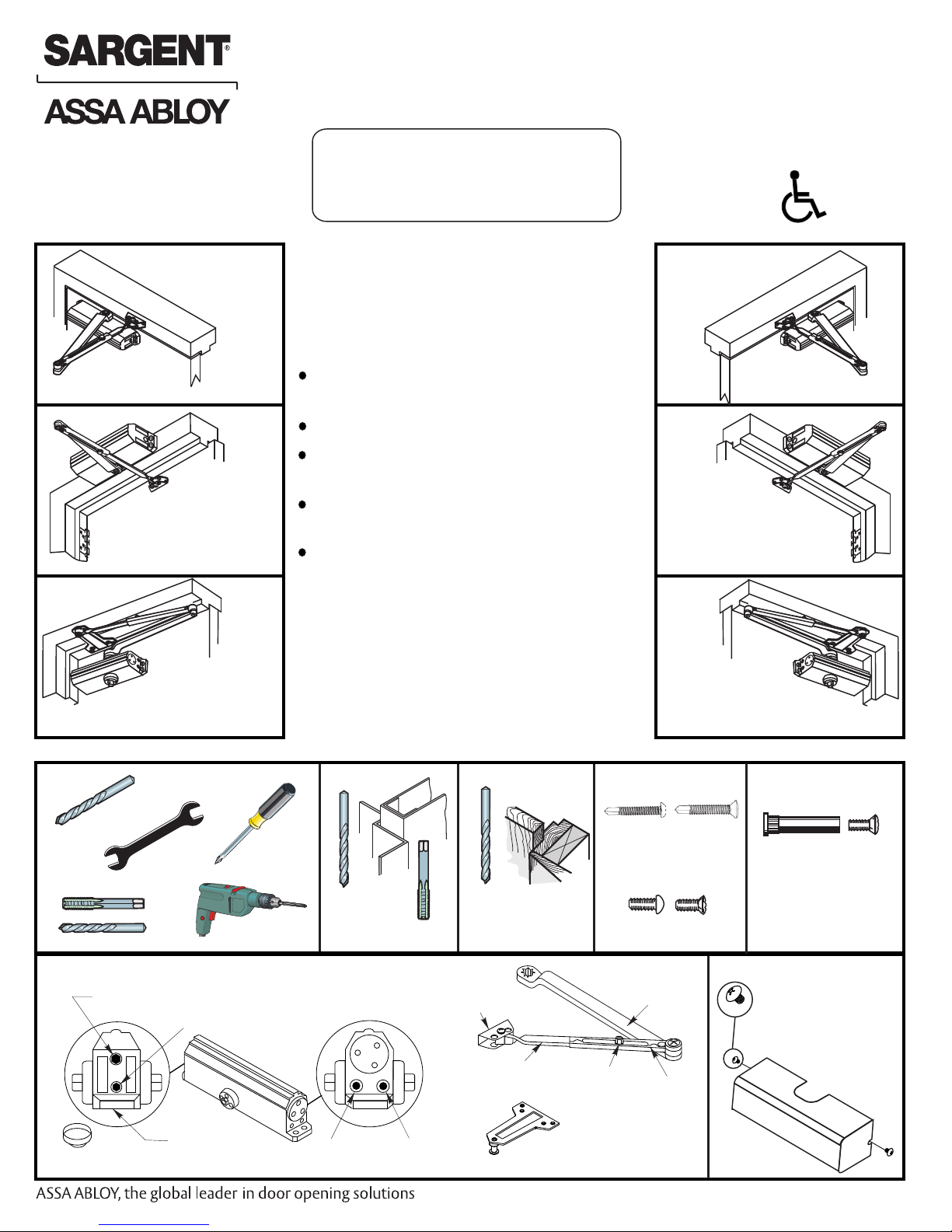

Non Hold Open Models

Adjustable

(Sizes 1 thru 6)

1130 Series

Non Handed Door Closer

Regular Arm

Installation

See Page 2

Right Hand Door - RH

Left Hand Reverse - LHR

Top Jamb

Installation

See Page 5

Left Hand Door - LH

Right Hand Reverse - RHR

An Incorrectly installed or improperly adjusted

door closer can cause property damage or

personal injury. These installation instructions

should be followed to avoid the possibility of

misapplication or misadjustment.

CAUTION

CAUTION

Doors should be hung on ball bearing or

anti-friction hinges.

A separate door stop is recommended.

Door and frame must be properly

reinforced.

Adjust closing time speed between 3 and 7

seconds from 90° to 0°.

These door closers should NOT be

installed on the exposed side (weather

side) of exterior doors.

Regular Arm

Installation

See Page 2

Top Jamb

Installation

See Page 5

Right Hand Door - RH

Left Hand Reverse - LHR

1131

Left Hand Door - LH

Right Hand Reverse - RHR

Parallel Arm

Installation

See Pages

Left Hand Door - LH

Right Hand Reverse - RHR

Spring Power Adjustment

Screw 1131 Series

3 & 4

Standard Components

"BC" Valve

Closer Body

1-6

Closer

Size

Pinion Cap

Stamp

"L"Valve

#7

Metal Wood

1/4-20

3/16"

Regular Arm/Top

Jamb Shoe

Connecting Rod

Soffit Plate

"S"Valve

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company, All rights reserved. Reproduction

in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

RU Soffit Plate

Used with Parallel

Arm Closers Only

Parallel Arm

Installation

See Pages

Self Drilling Screws

Wood and Metal

For Wood drill 3/16 hole

Machine Screws

#7 Drill, 1/4-20 Tap

Arm Assembly

Main Arm

Forearm

Screw

Arm Slide

3 & 4

Right Hand Door - RH

Left Hand Reverse - LHR

(Optional)

Sleeve Nut and Bolt

Drill 9/32 thru from Closer Side

3/8 Drill other side

Optional Components

Co

ver

A7674C

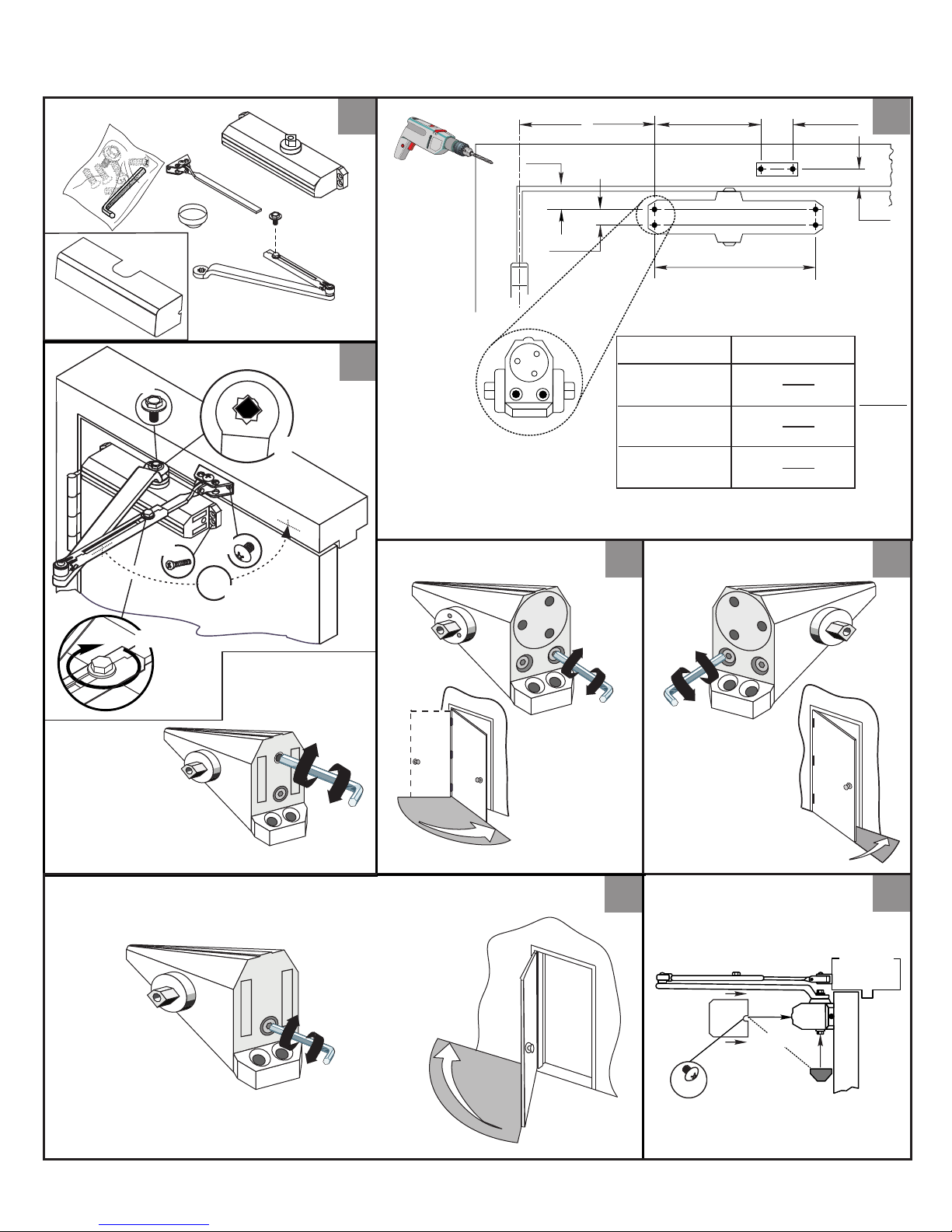

Page 2

1130 Series

Non Hold Open Door Closers — Regular Arm

80-9311-0011-021 Rev 2

Parts

Cover

Optional

1

A

1-1/4

(32)

3/4

(19)

Right Hand Shown

Opening

6

(152)

9-1/16

(230)

Dimension "A"

3

L

D

L

R

Y

Z

S

C

A

B

Sweep

90°

E

S

To 100°

101° to 120°

121° to 180°

*

Door/Wall/Hardware/Jamb

*

conditions permitting

4

Latch

7

(178)

6

(152)

3-1/2

(89)

1-3/4

(44)

3

2

7/8

(22)

Inches

(mm)

5

F

1131 Spring

Power Adjust

(If Necessary)

Backcheck

G

P

BC

Stronger

A

Stronger

+

Weaker

-

+

Slower

S

L

-

Faster

+

Faster

+

Slower

-

Pinion Cap

6

or Optional Cover

L

S

7

or

Caution:

Don't completely

close valve

Weaker

(2)

-

— 2 —

A7674C

Page 3

1130 Series

Non Hold Open Door Closers — Parallel Arm

80-9311-0011-021 Rev 2

Parts

Door

Opening

To 100°

101° to 130°

131° to 180°

*

Door/Wall/Hardware/Jamb

*

conditions permitting

A

9-1/4

(235)

7-3/4

(197)

5-3/4

(146)

Co

ver

Optional

B

7-5/8

(194)

6-1/8

(156)

4-1/8

(105)

1

Right Hand Shown

Inches

(mm)

Top of

Door

7/16

(11)

2-3/4

(70)

9-1/16

(230)

2

(50)

3/8

(10)

Frame

3/4

(19)

A

1/2

(13)

B

3-1/4

(83)

2

C

L

Close Valves

Latch

3

Sweep

Slower

L

S

-

Slower

-

L

S

4

Remove Arm

from Spindle

Place Arm on

Spindle

R

o

5

t

a

t

e

See Step 6 on Page 4

— 3 —

A7674C

Page 4

1130 Series

Non Hold Open Door Closers — Parallel Arm

80-9311-0011-021 Rev 2

Right Hand

Door

or

Left Hand

Door

Flat

Arm Screw

L

R

S

Z

Y

B

Y

Z

S

R

6

Open Valves

7

Assemble Arm

8

L

A

Flat

Caution:

Do Not Back

Valve Out

Completely

Spring Power

9

Adjust 1131

(If necessary)

10

Sweep

11

1-1/2

(38)

Latch

Faster

+

Slower

-

Slower

S

Stronger

Weaker

Stronger

BC

Weaker

+

-

13

+

-

Pinion Cap

or Optional Cover

(2)

PA

12

L

S

Backcheck

L

-

Faster

+

14

or

Caution:

Don't completely

close valve

— 4 —

A7674C

Page 5

1130 Series

Parts

Cover

Optional

A

B

Z

S

R

L

C

E

90°

Y

D

Non Hold Open Door Closers — Top Jamb Arm

80-9311-0011-021 Rev 2

1

Inches

(mm)

9-1/16

(230)

1-1/2

(38)

1-3/4

(44)

Door/Wall/Hardware/Jamb

*

conditions permitting

3/4

(19)

6

(152)

Right Hand Shown

A

1/2

(13)

3

Opening

To 100°

101° to 120°

121° to 180°

*

Sweep

Dimension "A"

7-1/2

(191)

6

(152)

3-1/2

(89)

A longer connecting

rod is required

for reveals greater

than 3" (76)

4

Latch

Reveal

C

L

2

Top of

Door

5

G

P

Backcheck

Stronger

A

+

Weaker

-

F

1131 Spring

Power Adjust

(If Necessary)

Stronger

BC

+

Slower

S

L

-

Faster

+

Faster

Pinion Cap

6

or Optional Cover

+

Slower

-

(2)

L

S

7

or

Caution:

Don't completely

close valve

Weaker

-

— 5 —

A7674C

Page 6

1130 Series Adjustments Page

For installation assistance, contact SARGENT at 800-810-WIRE (9473)

Copyright © 2016, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

80-9311-0011-021 Rev 2

Sweep

(Use 1/8" Hex Wrench for these Adjustments)

Slower

S

L

-

Faster

+

Spring Power

Adjust 1131

PA

Faster

+

Slower

Latch

L

-

Stronger

+

Weaker

-

Backcheck

S

Adjustment Chart

TYPE

OF

DOOR

INST.

Regular Arm

Top Jamb

Parallel Arm

INTERIOR

1131

Regular Arm

Top Jamb

Parallel Arm

EXTERIOR

Stronger

BC

30 FULL (360°) TURNS MAXIMUM AVAILABLE

*

+

Weaker

-

*

3/16 POWER

FULL 360° TURNS OF

70°

10°

CLOSED

Number of Turns Required

MAXIMUM DOOR SIZE

34”

(0.85M)

2

5

ADJUSTMENT WRENCH

= 8 Turns As Shipped

36”

(0.90M)

3

3

40”

(1.00M)

4

5

5

8

6

8

8

11

44”

(1.10M)

10

11

11

16

48”

(1.20M)

12

14

14

19

(Use 3/16" Hex Wrench for this Adjustment)

To identify your model:

Size

Code

1-6

BE

Date

Code

1- 6=1131

Arm Placement in Shoe

— 6 —

7-1/2 % Stronger

+

or

or

7-1/2 % Weaker

-

A7674C

Loading...

Loading...