Page 1

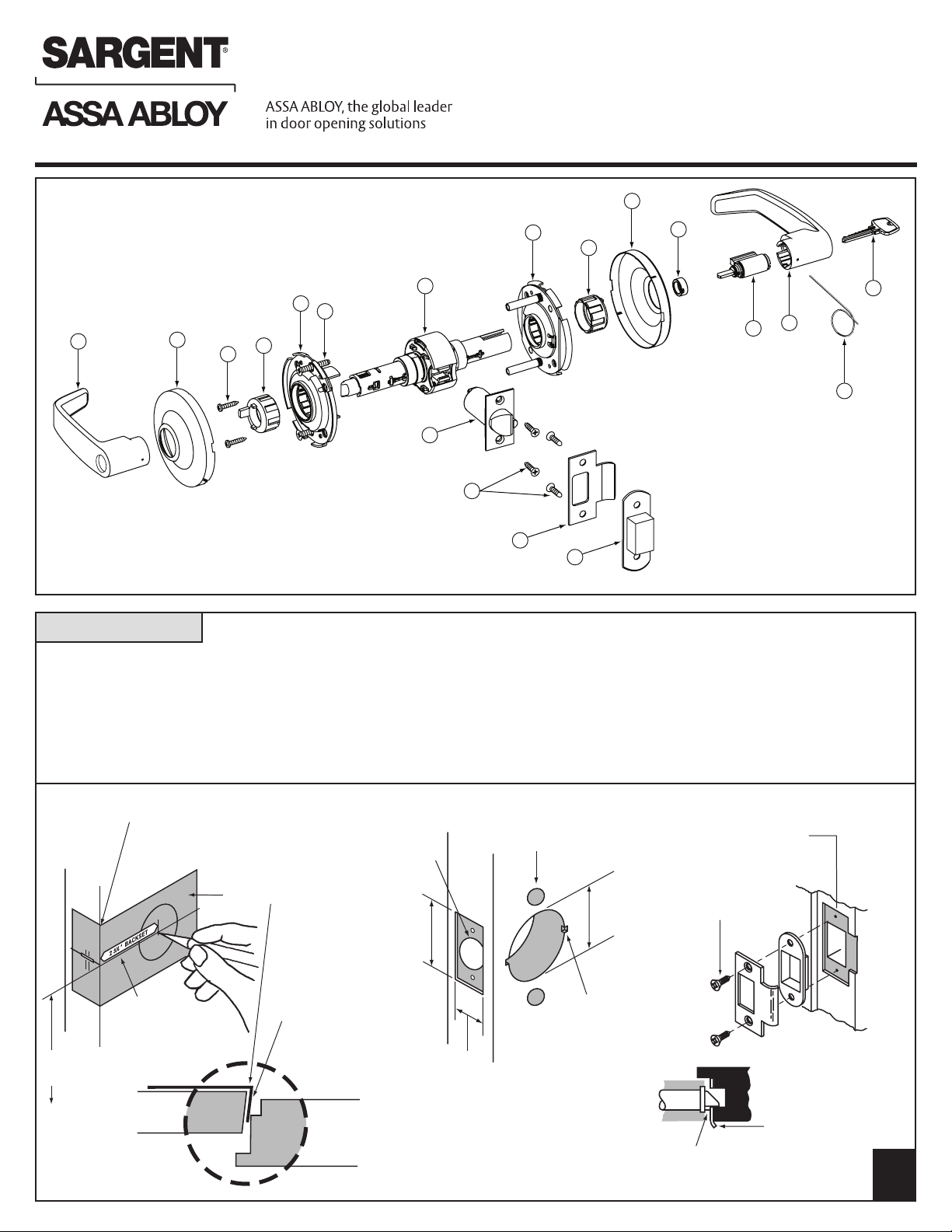

INSTALLATION INSTRUCTIONS FOR

38" fr

Finished Floor

10 Line Lever Lock

For installation assistance, contact SARGENT at 800-727-5477

www.sargentlock.com

(Patents Pending)

Tools

#2 Phillips screwdriver

Push pin (provided)

7/16” drill bit

1/8” drill bit

2-1/8” bore

1” bore

1

Parts

1. Inside lever

2. Scalp (2)

3. Screws – mounting plate

(2) #6 x 3/4” self-tapping

4. Spacer bushing (2)

* Used with 68 Function only

2

Door Preparation

5

6

4

3

Inside of Door

5. Inside rose assembly

6. Screws – through-bolt

(2) #10-32 x 1-1/4”

7. Lockbody

8. Outside rose assembly

9. Cylinder spacer

2

8

4

7

Outside of Door

(secured side)

14

15

16

17

9

11

10

13

10. Cylinder

11. Outside lever

12. Key

13. Push pin

14. Latch

15. Screws – latch & strike

(4) #8-32 x 3/4”

16. Strike

17. Strike box

12

• All doors should be properly reinforced for lock support. If support is not provided, contact door manufacturer.

• For all metal door preparations use template A4375, EXCEPT for functions 10G70 or 10G71 which uses template 4409

(provided), or functions 10U93, 10U94 and 10U94-2 which require template A4375.

• For all wood door preparations use template A6719, EXCEPT for functions 10G70 & 10G71 which uses template 4409

(provided), or functions 10U93, 10U94 and 10U94-2 which requires template A4375.

• Template information is available on our website, www@sargentlock.com.

• Mark and Drill Holes

IMPORTANT:

Fold template onto high

edge of door bevel

• Final Door Prep • Frame Prep for Strike

1"

(25mm)

7/16" (11mm) hole

Centerline of

latch front and

strike

hole

Template

2-1/4"

2-1/8"

(54mm)

hole

Screws (2)

#8-32 x 3/4"

(57mm)

Door

Bevel

FRAME

5/32"

(4mm)

1-1/8"

(29mm)

Strike

om

Backset

must match lock

(2-3/8" or 2-3/4")

DOOR

IMPORTANT: Deadlocking latch must

stop on strike when door is closed

© SARGENT Manufacturing Company A7133J

1

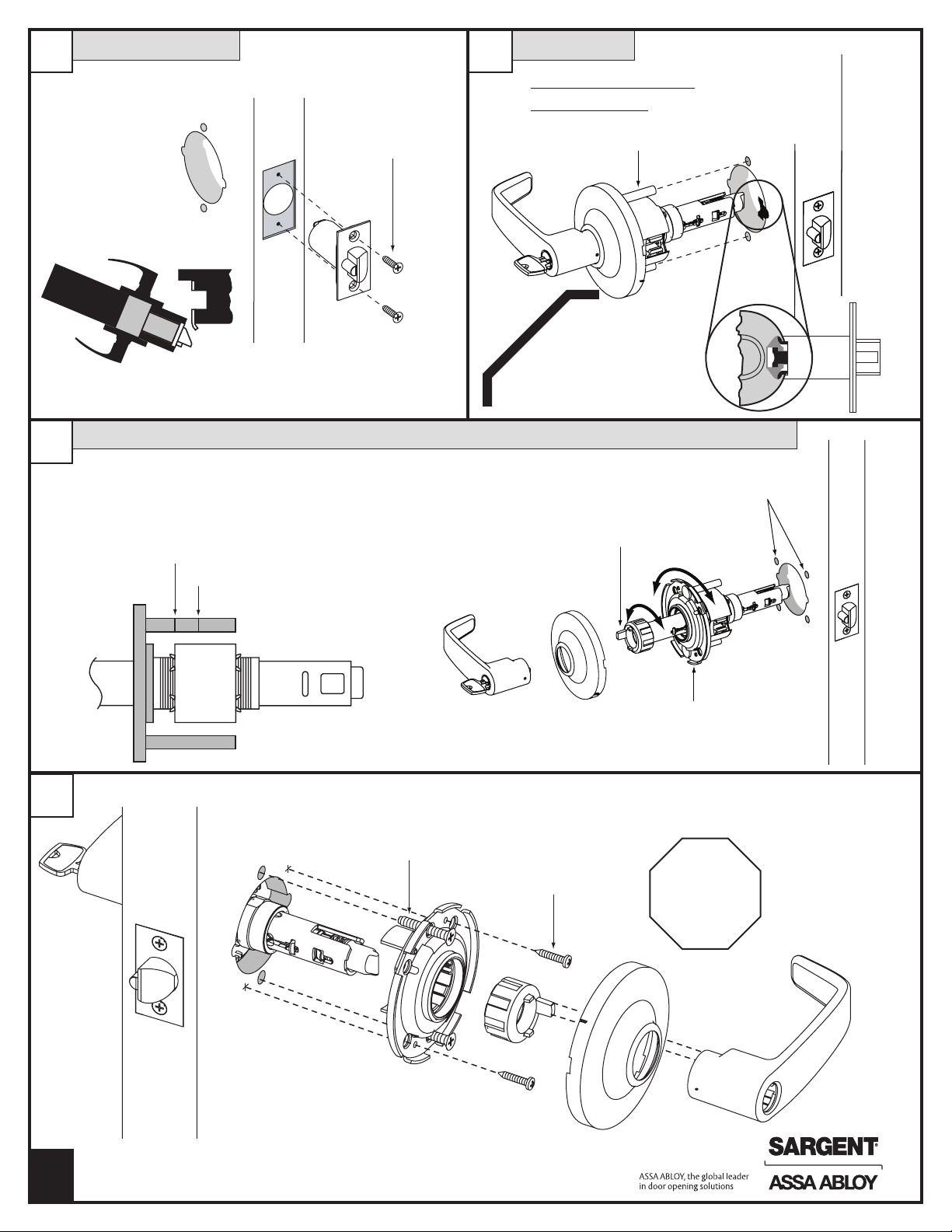

Page 2

Door

frame

bladed screwdriver at notch

1

Preset thrubolt locations –

for different locations see

instructions to the right

Outside

of Door

Install loosely;

tighten after step #3

Screws (2)

#8-32 x 3/4”

Please note: Doors without a beveled edge need to be

adjusted to center the latch - adjust per step 2A.

2

Through-bolt and door thickness adjustment other than preset

2A

• Remove – outside lever (usually keyed), scalp and spacer bushing

• Rotate – mounting plate to either align with through-bolt holes in door

or adjust for proper door thicknesses (see markings on through-bolt)

• Reinstall – spacer bushing (to align with back of lever), scalp and lever

1-3/4" thick door

2" thick door

Preset Lock Latch Installation

• Through-bolt Location – 12 and 6 o’clock

• Door Thickness – 1-3/4” thick

• See Step 2A for other door conditions

Outside

of Door

Through-bolt

holes

Spacer bushing

3

Screws (2)

10-32 x 1-1/4"

Screws (2)

#6 x 3/4"

Scalp to be removed with flat

Mounting plate

with through-bolts

Test

for proper

operation

before

closing

door

2

A7133J © SARGENT Manufacturing Company

Page 3

Lever and Cylinder Removal

Rotate key 45ϒ

and hold

Remove/Reuse

6 Pin Tailpiece

Plastic Core

Construction

Core

7-pin –

in box

6-pin –

in core

Keyed

Keyed

Cylinder

Washers

(only 30-prefix)

Cylinder

Outside

lever

Key

Cylinder

spacer

4

7-pin –

in box

Keyed

Cylinder

Remove/Reuse

6 Pin Tailpiece

Plastic Core

7-pin –

in box

6-pin –

in core

Keyed

Keyed

Cylinder

7-pin –

in box

Keyed

Cylinder

Standard Cylinder

Rotate key 45ϒ

and hold

Depress lever retainer

with push pin tool

Standard Cylinder Installation

IMPORTANT:

Before cylinder installation 10G16, 10G30,

10G37, 10G38 and 10G54 functions

lock, must be timed/preset by rotating

cam (within the the lever support tube)

completely counterclockwise.

Interchangeable and Removable Core Cylinder

• Remove cylinder and tailpiece, using

control key (stamped “C”)

• Insert Phillips #2 screw driver into

C

Control key*

cylinder opening making contact with

lever retainer.

• Pull lever retainer horizontally towards

door hinge and remove lever.

*Note- 1 Bitted cylinders utilize a control

key cut 113511

Lever retainer

Interchangeable or Removable Core Installation

• Remove construction core

or plastic core

If keyed – use Control Key

(stamped “C”) rotate 15

degrees and pull

C

• IMPORTANT:

Remove tailpiece from construction

core and insert into new cylinder

Remove

Construction

Core

Remove/Reuse

6 Pin Tailpiece

Plastic Core

Construction

Core

7-pin –

in box

Install

New/Final

Cylinder

Cylinder

6-pin –

in core

Keyed

Keyed

Cylinder

Correct key orientation

during assembly

• Install Cylinder

Insert cylinder with control key (stamped “C”)

into lever; rotate 15 degrees and remove key

C

© SARGENT Manufacturing Company A7133J

New Cylinder

3

Page 4

Remove 10G13

• Remove inside (non-rigid) lever with standard

push pin

• Insert long push pin into inside lockbody tube

and push to release spring loaded lever catch

plug assembly for the outside lever

• Remove the outside lever with lever catch plug

assembly attached

Install 10G70 & 10G71

• Power Required: 24Volt DC, .25 amps,

wiring information provided

• Wires must be protected from

abrasion

• Important- See correct door template

4409 provided or on the

website at www@sargentlock.com.

Function Description:

10G70 Fail Secure

Power OFF unlocks outside lever

Power ON locks outside lever

Key retracts latch at all times

10G71 Fail Secure

Power ON unlocks outside lever

Power OFF locks outside lever

Key retracts latch at all times

Install 10U94/10U94-2

Install 10U93

Screw

1/4 x 20

Cup

washer

2 holes to align with

2 tabs on rose

Screws (2) #6 x 3/4"

Rose

Scalp to be removed

with flat bladed screwdriver

4

A7133J © SARGENT Manufacturing Company

Tab

Screws (2)

#8-32 x 3/4"

2 holes to align with

2 tabs on rose

Screws (2) 10-32 x 1-1/4"

Screws (2) #6 x 3/4"

Rose

Scalp to be removed

with flat bladed screwdriver

Loading...

Loading...