Page 1

SERVICE MANUAL

FILE NO.

Digital Camera

AC adaptor

Contents

1. OUTLINE OF CIRCUIT DESCRIPTION .................... 2

2. DISASSEMBLY ........................................................ 11

3. ELECTRICAL ADJUSTMENT .................................. 13

4. USB STORAGE INFORMATION

REGISTRATION ...................................................... 18

5. TROUBLESHOOTING GUIDE................................. 19

6. PARTS LIST............................................................. 20

CABINET AND CHASSIS PARTS 1 ........................ 20

CABINET AND CHASSIS PARTS 2 ........................ 21

ELECTRICAL PARTS .............................................. 22

ACCESSORIES & PACKING MATERIALS ............. 26

AC Adaptor .............................................................. 26

CIRCUIT DIAGRAMS &

PRINTED WIRING BOARDS ...................................... C1

VPC-R1

(Product Code : 126 293 00)

(U.S.A., Canada)

VPC-R1E

(Product Code : 126 293 01)

(U.K.)

VPC-R1EX

(Product Code : 126 293 02)

(Europe, PAL General)

VPC-R1G

(Product Code : 126 293 06)

(No Tax)

VAR-G5U

(Product Code : 126 301 01)

(U.S.A., Canada)

VAR-G5EX

(Product Code : 126 301 02)

(Europe, PAL General)

VAR-G5E

(Product Code : 126 301 03)

(U.K.)

PRODUCT SAFETY NOTICE

The components designated by a symbol ( ! ) in this schematic diagram designates components whose value are of

special significance to product safety. Should any component designated by a symbol need to be replaced, use only the part

designated in the Parts List. Do not deviate from the resistance, wattage, and voltage ratings shown.

CAUTION : Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

NOTE : 1. Parts order must contain model number, part number, and description.

2. Substitute parts may be supplied as the service parts.

3. N. S. P. : Not available as service parts.

Design and specification are subject to change without notice.

SB117/U, E, EX, EX2, SVA01/U, EX, E

REFERENCE No. SM5310265

Page 2

1. OUTLINE OF CIRCUIT DESCRIPTION

1-1. CA-A CIRCUIT DESCRIPTIONS

Around CCD block

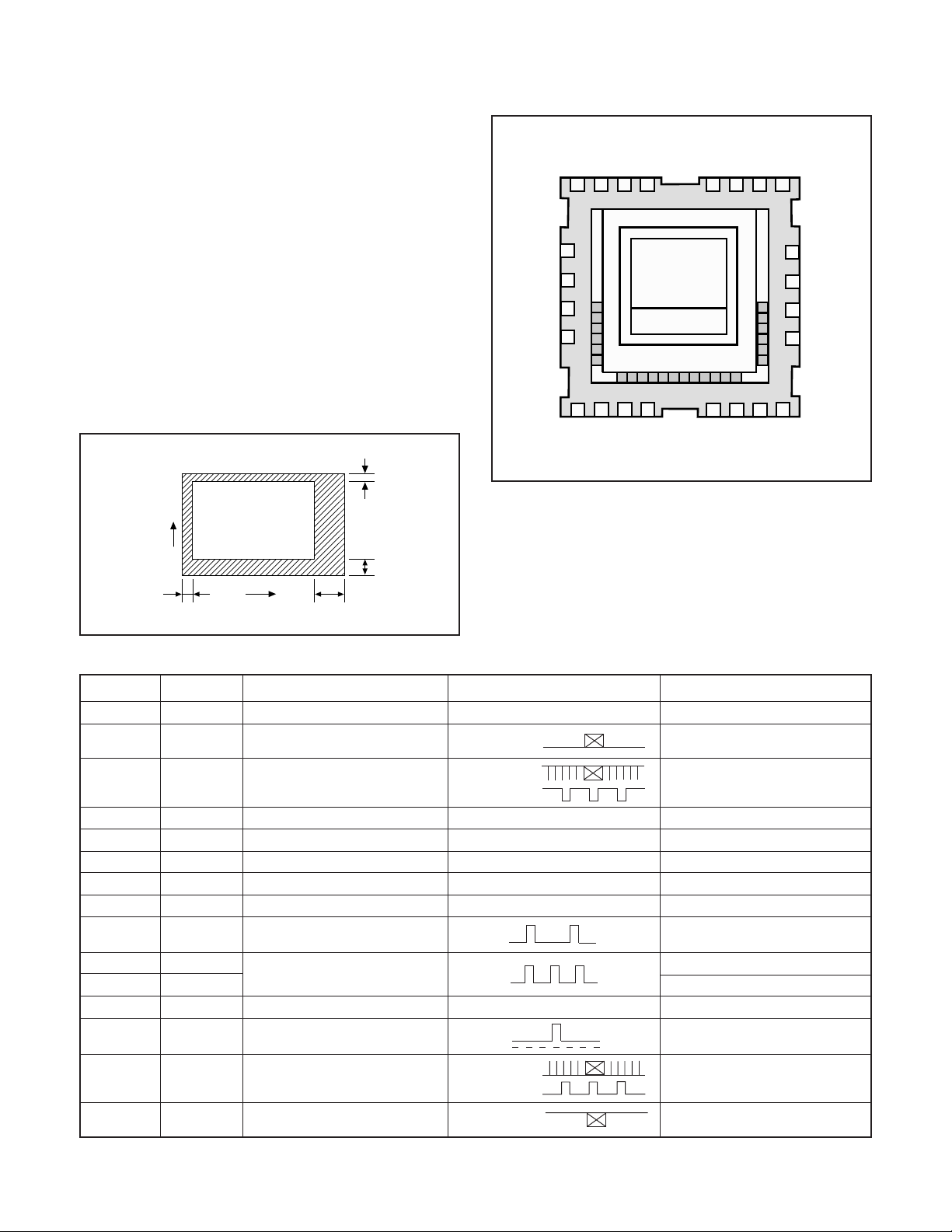

1. IC Configuration

IC903 (RJ24J1AA0PT) CCD imager

IC902 (TC74VHC04FTP) H driver

IC904 (LR366854) V driver

IC905 (AD9806KST) CDS, AGC, A/D converter

PI4

PI3

(NC)

3 2 1 21

4

(NC)

(NC)

2324

(NC)

22

PI2

PI1

2. IC905 (CCD)

[Structure]

Frame transfer type CCD image sensor

Optical size 1/2.8 type

Effective pixels 1300 (H) x 980 (V)

Pixels in total 1353 (H) x 1006 (V)

Optical black

Horizontal (H) direction: left 2 pixels, right 51 pixels

Vertical (V) direction: upper 10 pixels, below 12 pixels

Dummy bit number Horizontal : 20 Vertical : 4

10

V

12

2

Fig. 1-1.Optical Black Location (Top View)

Pin No. Symbol

1, 2, 23, 24

NC

H

Pin Description

-

51

PS1

5

PS2

6

7

VPW

8

VOUT

9

Waveform

(LCC24

Top View)

10

11 12 16

PR

VSS

VDD

VRD

PH4

151413

PH1

Fig. 1-2. CCD Terminal Name

Voltage

PH2

20

19

18

17

PH3

PS3

PS4

NSUB

VOG

3, 4

5, 6

7

8

9

10

11

12

13, 15

14, 16

17

18

19, 20

PI3, PI4

PS1, PS2

PW

VOUT

VDD

VSS GND

VRD

PR

PH4, PH2

PH1, PH3

VOG

VSUB

PS4, PS3

21, 22 PI1, PI2

Image clock

Accumulation clock

P well

CCD output

Power

Reset drain

Reset gate

Horizontal register clock

CCD output gate

N substrate

Accumulation clock

Image clock

Table 1-1. CCD Pin Description

Frame shift

Frame shift

Line sending

Frame shift

Line sending

Frame shift

DC

DC

DC

DC

DC

DC

0~12 V

0~12 V

8 V

Approx. 13 V

20 V

0 V

20 V

L=18 V, H=23 V

L=2.5 V, H=7.5 V

L=0 V, H=5 V

3.3 V

L=26 V, H=29 V

0~12 V

0~12 V

– 2 –

Page 3

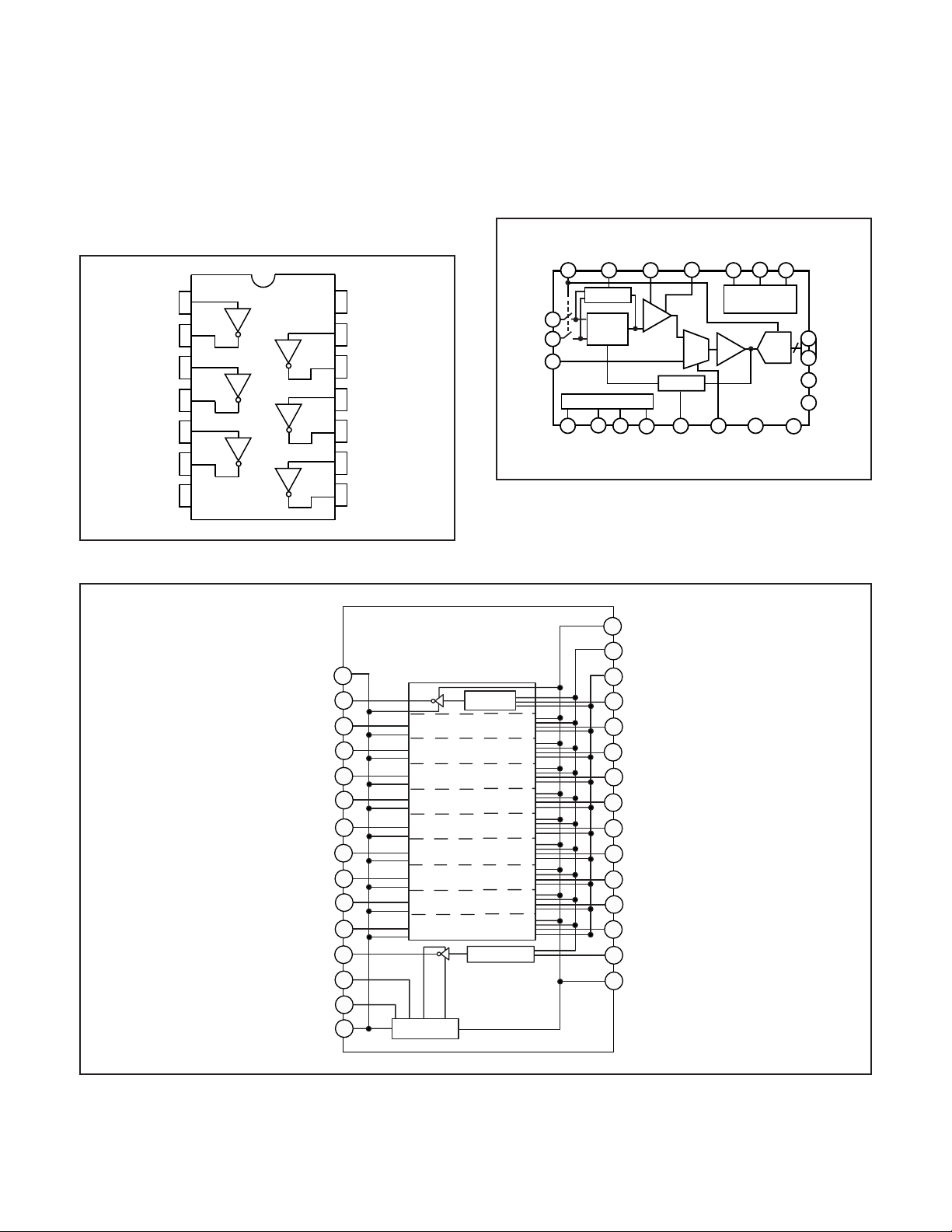

3. IC903 (H Driver) and IC902 (V Driver)

An H driver (IC903) and V driver (IC902) are necessary in

order to generate the clocks (vertical transfer clock, horizontal transfer clock and electronic shutter clock) which driver

the CCD.

IC902 is an inverter IC which drives the horizontal CCDs (H1

and H2). In addition the VREG 0~7, VXREG2 and VXREG3

signals which are output from IC102 are the vertical transfer

clocks. The clock is drived until peak value which necessary

CCD at IC902.

14

CC

1A

1Y

2A

2Y

3A

3Y

GND

1

2

3

4

5

6

7

V

13

6A

12

6Y

11

5A

10

5Y

4A

9

4Y

8

4. IC901 (CDS, AGC Circuit and A/D Converter)

The video signal which is output from the CCD is input to

Pins (26) and (27) of IC901. There are S/H blocks inside IC905

generated from the XSHP and XSHD pulses, and it is here

that CDS (correlated double sampling) is carried out.

After passing through the CDS circuit, the signal passes

through the AGC amplifier. It is A/C converted internally into

a 10-bit signal, and is then input to IC102.

SHD ADCCLK

22

21

GENERATOR

16

TIMING

A/D

AD9802

3341

ACVDD

ADVDD

43

10

2

DOUT

11

DRVDD

12

DVDD

17

PIN

DIN

ADCIN

PBLK

CLPDM SHP

CLAMP

27

26

CDS

29

2319

PGA

36

CLAMP

REFERENCE

48

37 20

CMLEVEL

VRT

47

VTB

STBY CLPOB

18

Fig. 1-5. IC901 Block Diagram

30

MUX S/H

ADCMODE

Fig. 1-3. IC903 Block Diagram

GND

1

OUT_1

2

OUT_2

3

OUT_3

4

OUT_4

5

OUT_5

6

OUT_6

7

OUT_7

8

OUT_8

9

OUT_9

10

OUT_10

OUT_NSUB

CAP5V

CAPNS

GND

11

12

13

14

15

Power circuit

OCNT circuit

DUTY circuit

OCNT circuit

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

VDD

OCNT

DUTY

IN_1

IN_2

IN_3

IN_4

IN_5

IN_6

IN_7

IN_8

IN_9

IN_10

IN_NSUB

VDD

Fig. 1-4. IC902 Block Diagram

– 3 –

Page 4

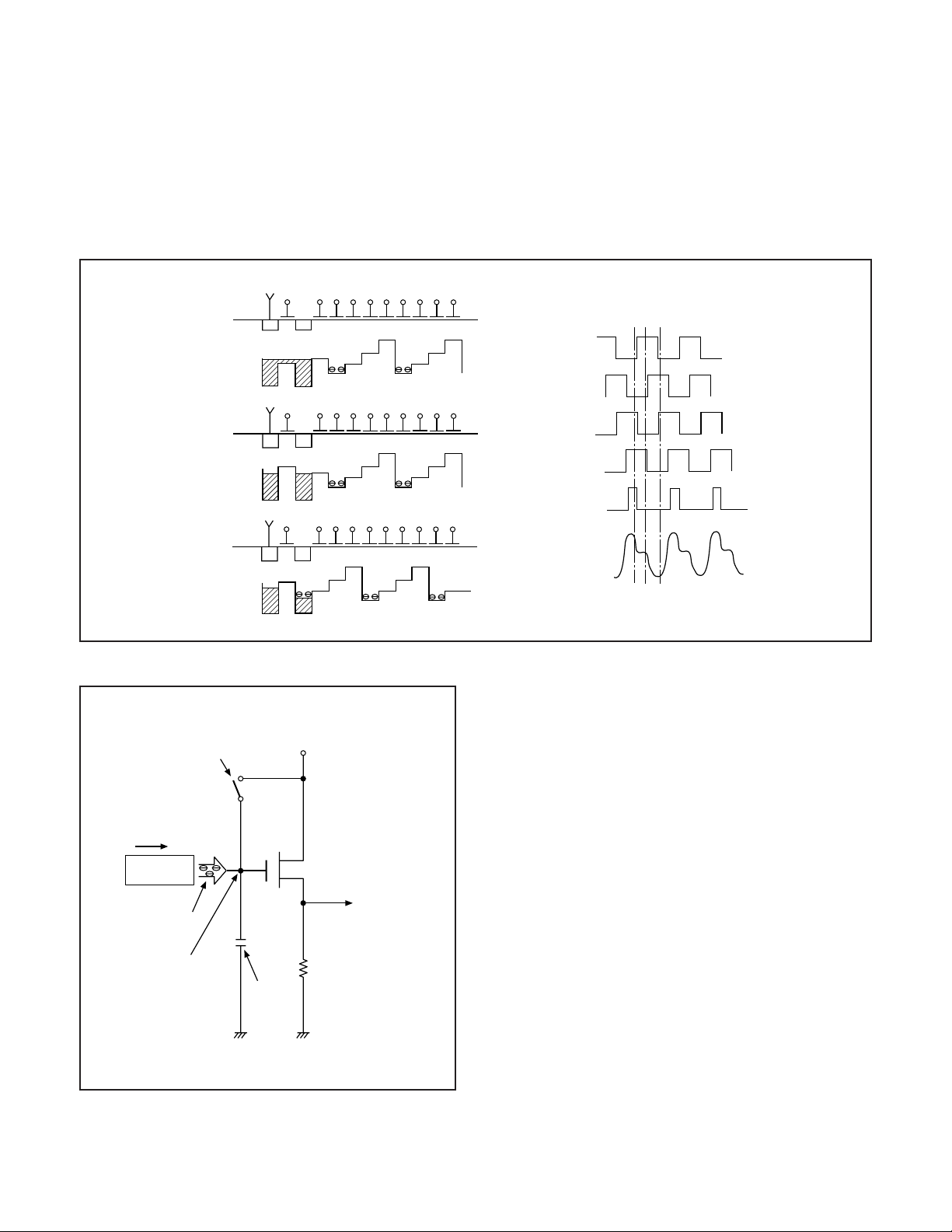

5. Transfer of Electric Charge by the Horizontal CCD

The transfer system for the horizontal CCD emplays a 4-phase drive method.

The electric charges sent to the final stage of the horizontal CCD are transferred to the floating diffusion (FD), as shown in Fig.

1-6. PR is turned on by the timing in (1), and the floating diffusion is charged to the potential of RD.

The PR is turned off by the timing in (2). In this condition, the floating diffusion is floated at high impedance.

The H2 potential becomes shallow by the timing in (3), and the electric charge now moves to the floating diffusion.

Here, the electric charges are converted into voltages at the rate of V = Q/C by the equivalent capacitance C of the floating

diffusion. PR is then turned on again by the timing in (1) when the H2 potential becomes deep.

Thus, the potential of the floating diffusion changes in proportion to the quantity of transferred electric charge, and becomes

CCD output after being received by the source follower. The equivalent circuit for the output circuit is shown in Fig. 1-7.

Reset gate pulse

Direction of transfer

(1)

(2)

(3)

PR

PR

PR

OG

H2

H1 H4 H3 H2 H1 H4 H3

(1)(2)

FDRD

H3

H4

OG

H2

H1 H4 H3 H2 H1 H4 H3

H1

FDRD

H2

PR

OG

H2

H1 H4 H3 H2 H1 H4 H3

FDRD

CCD OUT

(3)

Fig. 1-6. Horizontal Transfer of CCD Imager and Extraction of Signal Voltage

6. Lens drive block

6-1. Shutter drive

The regulator (IC952) drives by P ON signal which is output

20 V Pre-charge drain bias (PD)

from the power control IC (IC501) is drived, and then power is

supplied to iris shutter drive IC (IC951). The drive signal

(GPIO4, GPIO5, GPIO6, GPIO7) which is output from the

ASIC (IC102) is drived the iris shutter drive IC (IC951), and

the iris shutter spring is open and closed.

H Register

Electric

charge

Floating diffusion gate is

floated at a high impedance.

C is charged

equivalently

Voltage output

Fig. 1-7. Theory of Signal Extraction Operation

– 4 –

Page 5

1-2. CA-B CIRCUIT DESCRIPTION

1. Circuit description

1-1. PTG

This is program timing generator. Generates the timing signal

that is needed in order to drive the FT-CCD sensor.

1-2. FCP

The FCP receives the output data from the FT-CCD sensor

via the PTG, and then carries out various processing operations on the data (such as gamma correction and white

banance).

1-3. ITP

The ITP is a pixel conversion processor. It carries out various

processing operations (such as contour emphasis and chroma)

on the image data that is input from the FCP or from memory,

and then stores the processed data in memory.

1-4. CPU

This is 32 bit RISC CPU.

1-5. Memory controller

This is controlled SDRAM, flash ROM and CF card etc.

1-6. Video player

Outputs the RGB signals that are needed to control the graphic

overlay function and to drive the LCD.

1-7. GPIO

This is a multipurpose I/O. (It can be used as an input/output

port.)

1-8. COM port

This is communication block. Supports USB communication.

2. Outline of Operation

When the shutter opens, detect the 8-bit microprocessor and

transmit to record operation starts.

When the PTG drives the FT-CCD, picture data passes

through the A/D and is then input to the ASIC as 10-bit data.

This data then sends FCP, after which it is carried out various

processing operations on the data (such as gamma correction and white balance). The data is then sent to the ITP where

processing such as contour emphasis and chroma are carried out, after which it is temporarily stored in the SDRAM.

In case of still picture the data is then compressed by the

JPEG method and in case of picture it is compressed by

MJPEG method and is written to compact flash card.

3. LCD Block

RGB signals corresponding to the LCD driver are output from

the ASIC (video player). The LCD driver converts the RGB

signals that are output from the ASIC to a signal level that is

appropriate for the LCD monitor. These RGB signals and the

control signal which is output by the LCD driver are used to

drive the LCD panel.

The RGB signals are 1H transposed so that no DC component is present in the LCD element, and the two horizontal

shift register clocks drive the horizontal shift registers inside

the LCD panel so that the 1H transposed RGB signals are

applied to the LCD panel.

Because the LCD closes more as the difference in potential

between the VCOM (common polar voltage: fixed at DC) and

the R, G and B signals becomes greater, the display becomes

darker; if the difference in potential is smaller, the element

opens and the LCD become brighter. In addition, the brightness and contrast settings for the LCD can be varied by means

of the serial data from the ASIC.

1-9. Serial communication

This is the interface for the 8-bit microprocessor.

1-10. LCD driver

The RGB output signals that are output from the ASIC are

converted to a signal level that is appropriate for the LCD monitor.

1-11. LCD monitor

This is the image display device which displays the image

signals supplied from the LCD driver.

– 5 –

Page 6

1-3. CP1 POWER CIRCUIT DESCRIPTION

1. Outline

This is the main power circuit, and is comprised of the following blocks.

Switching controller (IC501)

Digital 5 V and analog system power output (T5001, Q5001)

Digital 2.5 V system power supply (Q5007)

Digital 3.4 V system power supply (Q5018)

LCD system power supply (Q5008, T5002)

Backlight power supply output (Q5013)

Inverter output (T5003, Q5017)

2. Switching Controller (IC501)

This is the basic circuit which is necessary for controlling the

power supply for a PWM-type switching regulator, and is provided with five built-in channels, only CH2 (digital 5 V, analog

system), CH4 (LCD system), CH3 (digital 2.5 V), CH1 (digital

3.4 V) and CH5 (backlight system) are used. Feedback from

5 V (D) (CH2), 2.5 V (D) (CH3) , 12.4 V (L) (CH4), 3.4 V (D)

(CH1) and 7 V (L) (CH5) power supply outputs are received,

and the PWM duty is varied so that each one is maintained at

the correct voltage setting level.

2-1. Short-circuit protection circuit

If output is short-circuited for the length of time determined

by the condenser which is connected to Pin (29) of IC501, all

output is turned off. The control signal (P ON) are recontrolled

to restore output.

3. Digital 3.4 V Power Output

3.4 V (D) is output. Feedback is sent to pin (41) of the switching controller (IC501) for PWM control to be carried out.

4. Digital 5 V and Analog System Power Output

5.1 V (D) , 26.4 V (A), 20 V (A), 13 V (A) and 5.1 V (A) are

output. Feedback for the 5.1 V (D) is provided to the switching controller (Pins (35) of IC501) so that PWM control can

be carried out.

5. Digital 2.5 V System Power Output

2.5 V (D) is output. Feedback is provided to the swiching controller (Pin (23) of IC501) so that PWM control can be carried

out.

6. LCD System Power Output

12.4 V (L) is output. Feedback for the 12.4 V (L) is provided

to the switching controller (Pins (22) of IC501) so that PWM

control can be carried out.

7. Backlight Power Supply output

7.0 V (L) is output. Feedback is sent to pin (17) of the switching controller (IC501) for PWM control to be carried out.

8. Inverter Output

The backlight uses a flat picture tube. When INV CLK is input, Q5017 carries out switching operations, so that T5003 is

energized and a high-voltage pulse is generated between pins

(3) and (4) of T5003. This high-voltage pulse is applied to the

backlight to make it illuminate.

– 6 –

Page 7

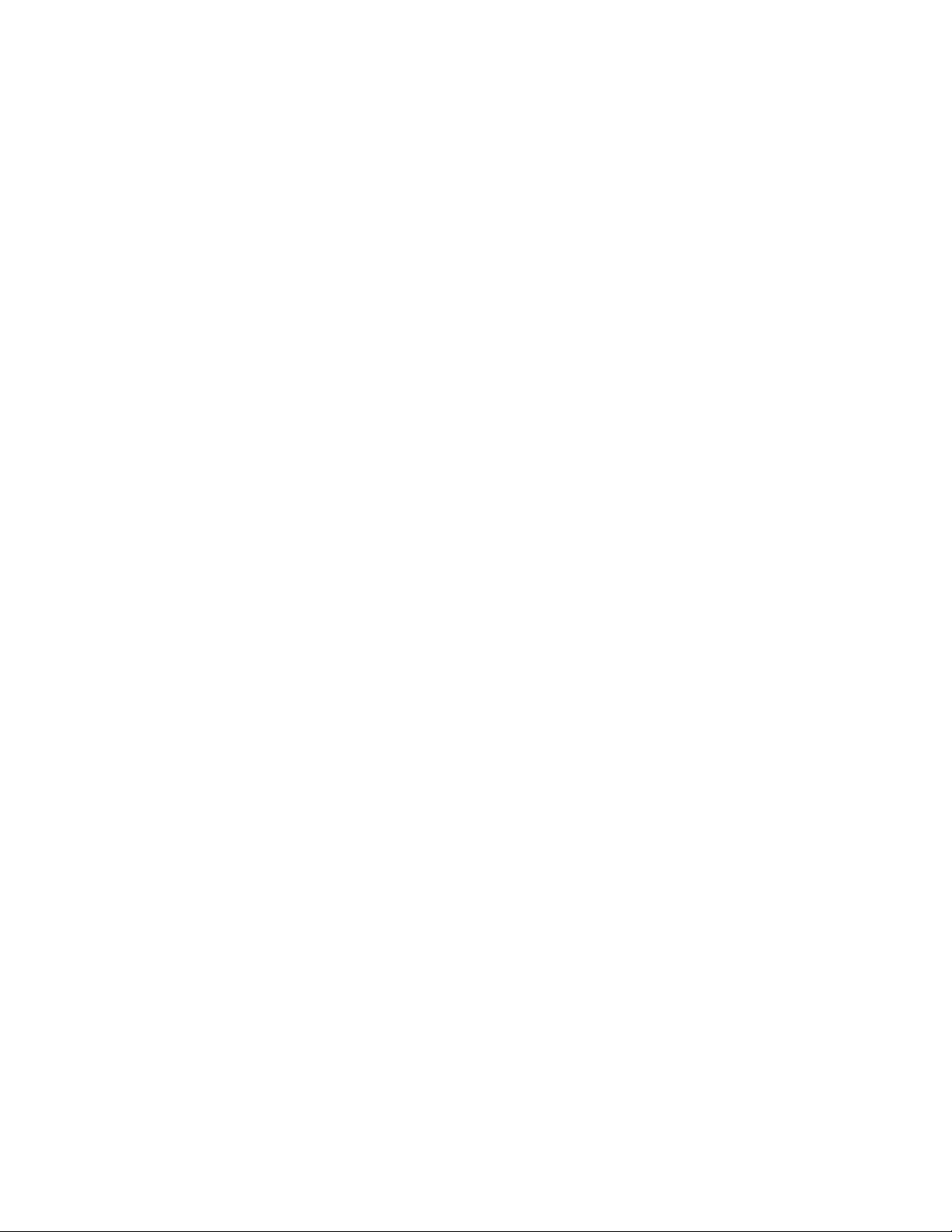

1-4. CP1 STROBO CIRCUIT DESCRIPTION

1. Charging Circuit

When UNREG power is supplied to the charge circuit and the

CHG signal becomes High (3.3 V), the charging circuit starts

operating and the main electorolytic capacitor is charged with

high-voltage direct current.

However, when the CHG signal is Low (0 V), the charging

circuit does not operate.

1-1. Power switch

When the CHG signal switches to Hi, Q5406 turns ON and

the charging circuit starts operating.

1-2. Power supply filter

L5401 and C5405 constitute the power supply filter. They

smooth out ripples in the current which accompany the switching of the oscillation transformer.

1-3. Oscillation circuit

This circuit generates an AC voltage (pulse) in order to increase the UNREG power supply voltage when drops in current occur. This circuit generates a drive pulse with a frequency

of approximately 50-100 kHz. Because self-excited light omission is used, the oscillation frequency changes according to

the drive conditions.

2. Light Emission Circuit

When RDY and TRIG signals are input from the ASIC, the

stroboscope emits light.

2-1. Emission control circuit

When the RDY signal is input to the emission control circuit,

Q5409 switches on and preparation is made to let current

flow to the light emitting element. Moreover, when a STOP

signal is input, the stroboscope stops emitting light.

2-2. Trigger circuit

When a TRIG signal is input to the trigger circuit, D5405

switches on, a high-voltage pulse of several kilovolts is generated inside the trigger circuit, and this pulse is then applied

to the light emitting part.

2-3. Light emitting element

When the high-voltage pulse form the trigger circuit is applied to the light emitting part, currnet flows to the light emitting element and light is emitted.

Beware of electric shocks.

1-4. Oscillation transformer

The low-voltage alternating current which is generated by the

oscillation control circuit is converted to a high-voltage alternating current by the oscillation transformer.

1-5. Rectifier circuit

The high-voltage alternating current which is generated at

the secondary side of T5401 is rectified to produce a highvoltage direct current and is accumulated at electrolytic capacitor C5412 on the main circuit board.

1-6. Voltage monitoring circuit

This circuit is used to maintain the voltage accumulated at

C5412 at a constance level.

After the charging voltage is divided and converted to a lower

voltage by R5417 and R5419, it is output to the SY-A block as

the monitoring voltage VMONIT. When this VMONIT voltage

reaches a specified level at the SY-A block, the CHG signal is

switched to Low and charging is interrupted.

– 7 –

Page 8

1-5. SY-A CIRCUIT DESCRIPTION

1. Configuration and Functions

For the overall configuration of the SY-A block, refer to the block diagram. The SY-A block centers around a 8-bit microprocessor

(IC301), and controls camera system condition (mode).

The 8-bit microprocessor handles the following functions.

1. Operation key input, 2. Clock control, 3. Power ON/OFF, 4. Strobe charge control.

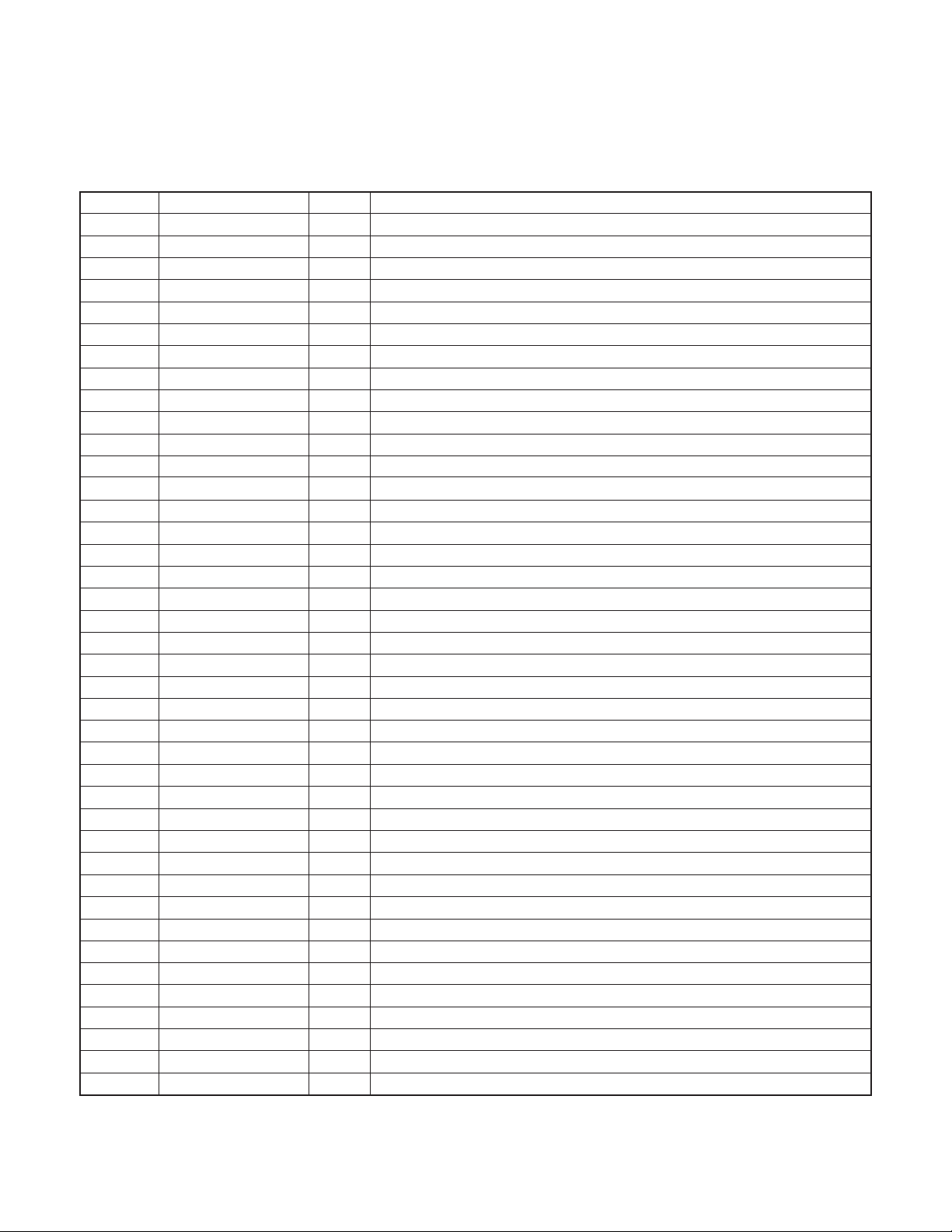

Pin

1~2

3

4

5

6

7

8

9

10~12

13

14

15~16

17~18

19

20~23

24

25~26

27

28

29

30 SDIR

31 BAT_OFF

32 +3.2_SW

33

34 P ON

35~36

37

38

39~40

41

42

43

44~45

46

47

48~52

53

54~74

75~78

79~80

Signal

NOT USED

AVSS

AVR

AVCC

VDD3

UNREG (S)

VDD3

STROBO_V

P54~P56

VSS

DC_IN

X1, X0

MOD1, 0

P. ST.

S10~S13

P04

P05~P06

PLL_EN

USB_CNT

REQACK

RESET B

NOT USED

VF_LED_G

EXT_IRQ1

SDATA

SCLK

SELF_LED_R

NOT USED

X0A, X1A

BUZZER

CHARGE

NOT USED

VCC

NOT USED

SO0~SO3

NOT USED

I/O

O

O

O

O

O

O

O

I/O

O

O

O

O

O

Outline

-

-

-

-

I

I

I

I

I

-

I

-

I

I

I

I

I

I

I

I

-

-

-

-

-

-

-

-

GND

Analog power

Analog power

Main (ASIC system) power detection

Battery power input (analog input)

Main (ASIC system) power detection

Strobo charge voltage input (analog input)

Connect to GND through register

GND

AC adaptor connection detection (analog input)

Main clock oscillation terminal (4 MHz)

Connect to GND

Reset input

Key matrix input

Connect to GND through register

Connect to GND through register

ASIC PLL permission signal

USB connection detection H : Connection

Serial communication control signal

Serial communication control signal

Battery OFF detection H : OFF

3.2 V power (switch)

Reset output to ASIC L : Reset

DC/DC converter (analog) ON/OFF signal H : ON

-

VF LED (green) ON/OFF signal L : Light

External interruption signal

Serial communication control signal

Serial communication control signal

Self LED (red) ON/OFF signal L : Light

-

Sub clock oscillation terminal (32.768 kHz)

Buzzer output terminal

Strobo charge ON/OFF signal L : ON

-

Digital power

-

Key matrix output

-

Table 4-1. 8-bit Microprocessor Port Specification

– 8 –

Page 9

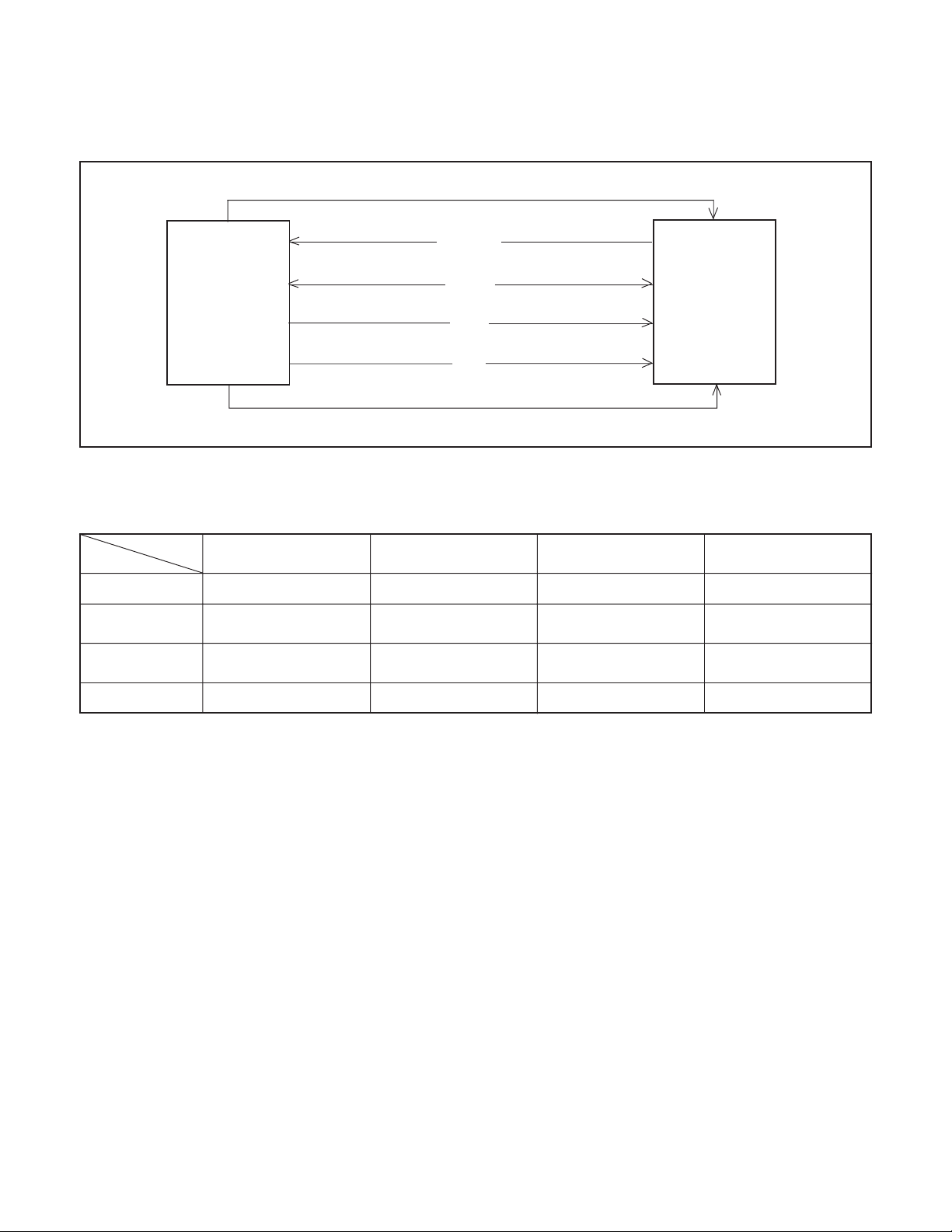

2. Internal Communication Bus

The SY-A block carries out overall control of camera operation by detecting the input from the keyboard and the condition of the

camera circuits. The 8-bit microprocessor reads the signals from each sensor element as input data and outputs this data to the

camera circuits (ASIC) or to the LCD display device as operation mode setting data. Fig. 4-1 shows the internal communication

between the 8-bit microprocessor, ASIC and SPARC lite circuits.

RESET B

REQACK

8-bit

Microprocessor

Fig. 4-1 Internal Bus Communication System

SDATA

SDIR

SCK

EXT_IRQ1

3. Key Operaiton

For details of the key operation, refer to the instruction manual.

SCAN

SCAN

OUT

IN

0

1

MAIN SW-PLAY POSITION

2

3

0

CF_IN

DOWN

-

1

TEST

MAIN SW-LCD OFF

POSITION

RIGHT

SET

Table 4-2. Key Operation

2

MAIN SW-LCD ON

POSITION

LEFT

MODE

ASIC

3

SHUTTER 1stSHUTTER 2nd

COVER SW

UP

FOCUS SW

– 9 –

Page 10

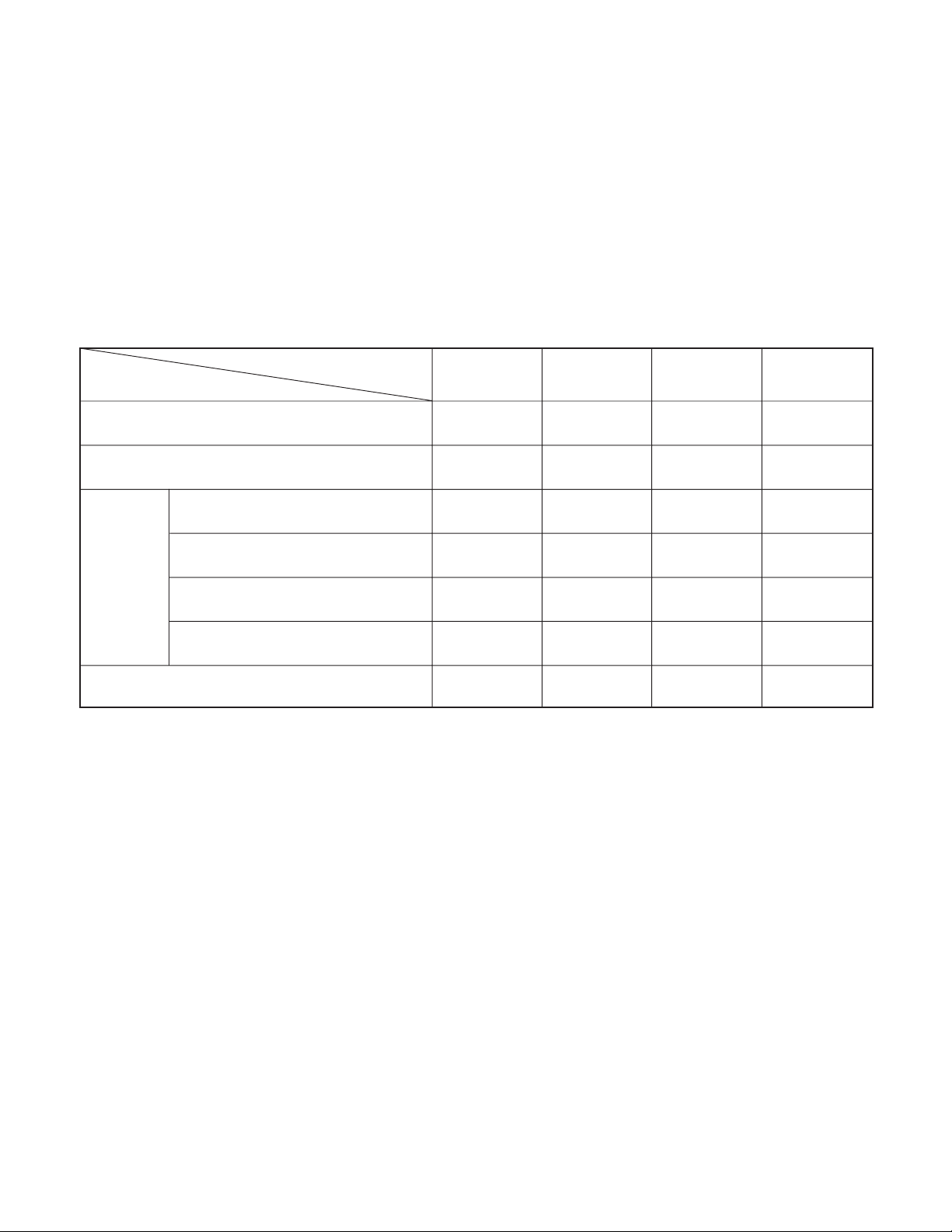

4. Power Supply Control

The 8-bit microprocessor controls the power supply for the overall system.

The following is a description of how the power supply is turned on and off. When the battery is attached, a regulated 3.2 V

voltage is normally input to the 8-bit microprocessor (IC301) by IC302, so that clock counting and key scanning is carried out

even when the power switch is turned off, so that the camera can start up again. When the battery is removed, the 8-bit microprocessor operates in sleep mode using the backup capacitor. At this time, the 8-bit microprocessor only carries out clock

counting, and waits in standby for the battery to be attached again. When a switch is operated, the 8-bit microprocessor supplies

power to the system as required.

The 8-bit microprocessor first sets the P ON signal at pin (34) to high, and then turns on the DC/DC converter for the digital

system. After this, it sets RESET B signal at pin (33) to high so that the ASIC is set to the active condition.

After this, in case of driving the CCD, it sets the P (A) ON signal at pin (176) of the ASIC to high, and then turns on the DC/DC

converter for the analog system.

If the LCD monitor is on, the LCD ON signal at pin (175) of the ASIC set to high, and the DC/DC converter for the LCD monitor

is turned on. Once it is completed, the ASIC returns to the reset condition, all DC/DC converters are turned off and the power

supply to the whole system is halted.

ASIC,

memory

Power voltage

Power OFF

Power switch ON-

Auto power OFF

Shutter switch ON

CAMERA

Resolution, flash, self-timer switch ON

LCD finder

Play back

Table 4-3. Camera Mode

Note) 4 MHz = Main clock operation, 32 kHz = Sub clock operation

3.3 V

OFF

OFF

ON

OFF

ON

ON

CCD

5 V (A)

+12 V etc.

OFF

OFF

→→

ON

→OFF

→→

OFF

ON

OFF

8 bit

CPU

3.2 V

(ALWAYS)

32KHz OFF

4 MHz OFF

4 MHz OFF

4 MHz OFF

4 MHz ON

4 MHz ON

MONITOR

+12 V etc.

LCD

– 10 –

Page 11

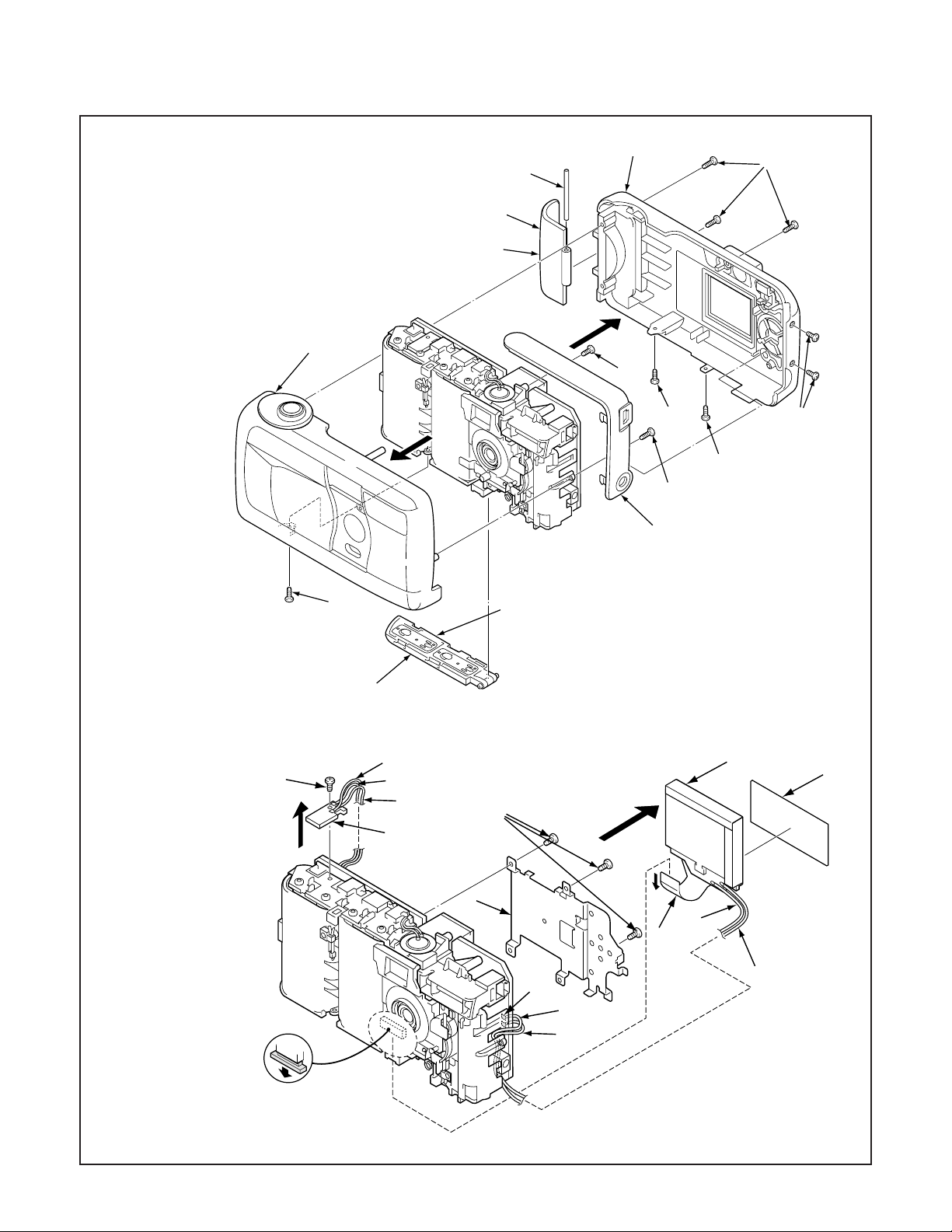

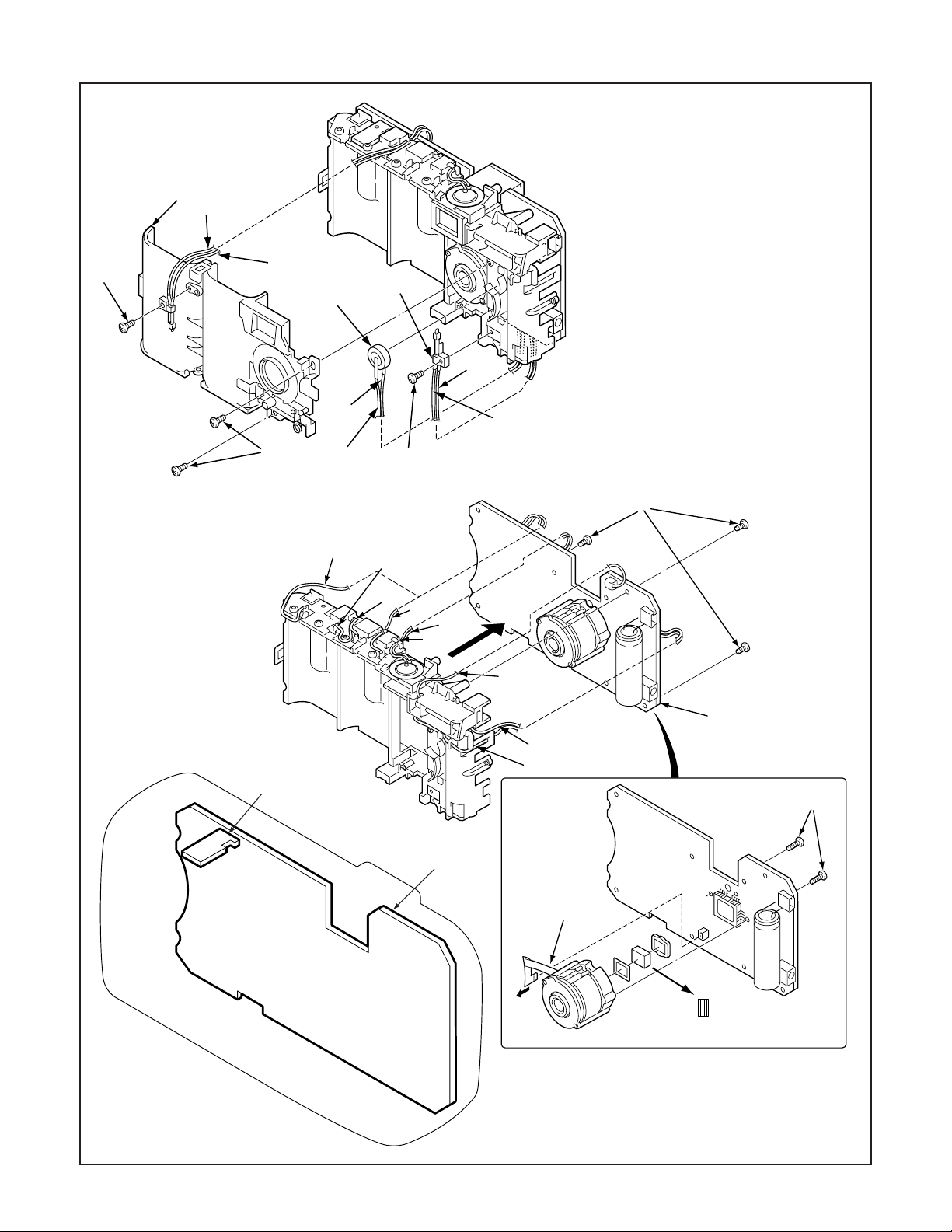

2. DISASSEMBLY

2-1. REMOVAL OF CABINET BACK, CABINET FRONT, TB1 BOARD AND LCD

1. Open the cover battery.

2. Four screws 1.7 x 4

3. Open the cover card.

4. Four screws 1.7 x 6

5. Cabinet back

6. Screw 1.7 x 4

7. Screw 1.7 x 6

8. Cabinet top A

9. Cabinet front

10. Cover battery

11. Cover card

12. Shaft card

5

12

11

3

9

6

F

2

7

8

D

4

E

H

4

C

B

A

2

The order of tighting screws

A→B→C→D→E→F→G→H

13. Screw 1.7 x 3.5

14. TB1 board

15. Spacer CV monitor 2

16. FPC

17. Remove the solder.

18. LCD

19. Three screws 1.7 x 4

20. Holder monitor

13

2

G

1

When assembling cabinet front

1. The cover lens should be closed.

2. Set the knob macro at the normal position.

10

brown

yellow

gray

18

15

19

14

20

pink

16

17

white

pink

white

– 11 –

Page 12

2-2. REMOVAL OF HOLDER CHASSIS, LENS ASSEMBLY, CP1 BOARD AND BOARD LOCATION

3

yellow

white

1

6

4

pink

gray

violet

1. Screw 1.7 x 3

2. Two screws 1.7 x 4

3. Holder chassis B

4. DL-elect

5. Screw 1.7 x 3

6. Switch leaf

7. Three screws 1.7 x 4

8. Two screws 1.7 x 5

9. FPC

10. CP1 board

2

TB1 board

blue

red

5

7

black

red

black

black

red

gray

10

black

red

8

CP1 board

– 12 –

9

Lens

CCD

Page 13

3. ELECTRICAL ADJUSTMENT

Firmware

Image

AWB

Focus

UV Matrix

R Bright

RGB Offset

Tint

B Bright

Gain

Phase

LCD

Calibration

Upload

Initialize

LCD Type

H AFC Test

VCOMDC

VCOMPP

Cal Data

Cal Mode

OK

OK

EVF

USB storage

Get

Set

VID

Set

PID

Set

Serial

Set

Rev.

Set

Setting

Language

Video Mode

VCO

Firmware Version:

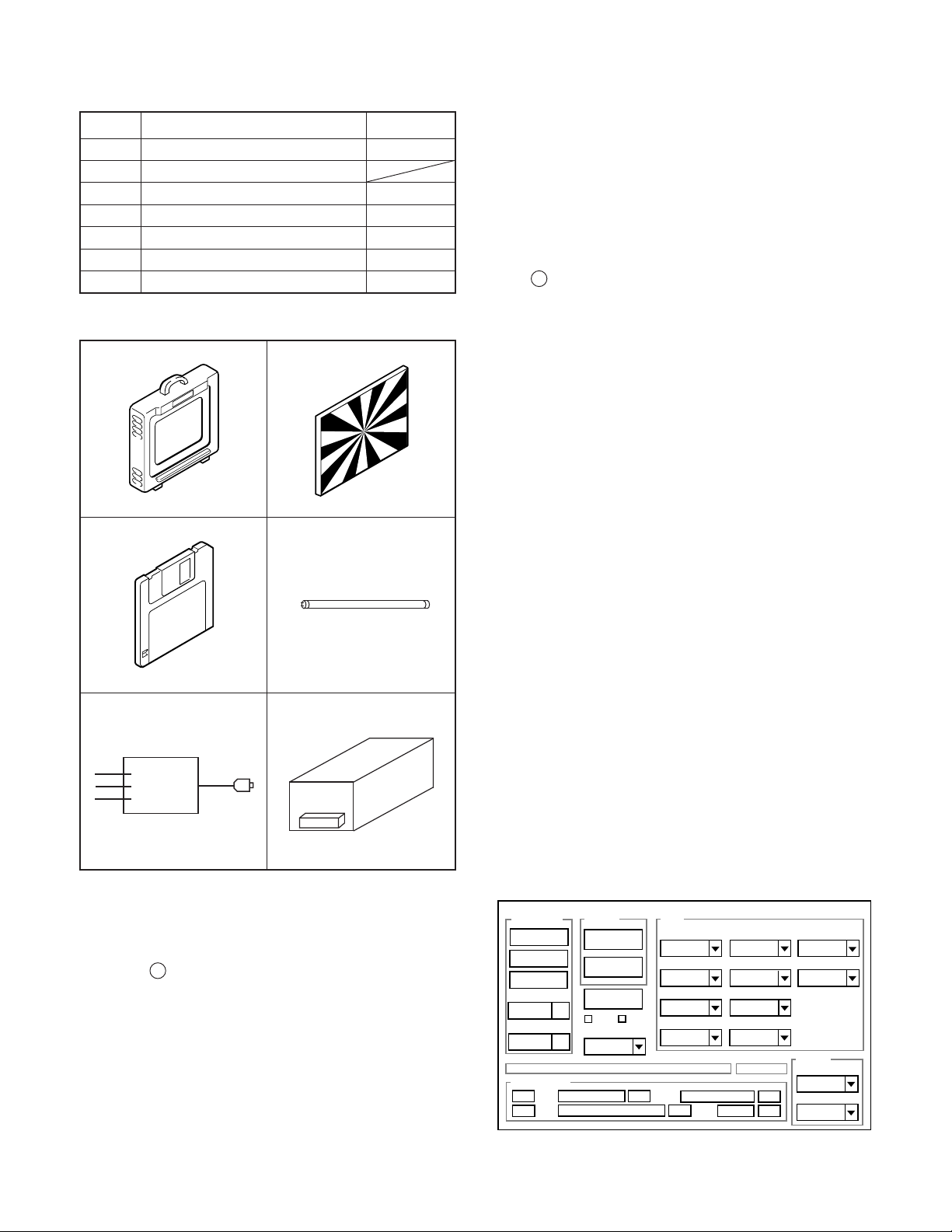

3-1. Table for Servicing Tools

Ref. No. Name

J-1

J-2

J-3

J-4

J-5

J-6

J-7

Note: J-1 color viewer is 100 - 110 VAC only.

J-1 J-2

J-3/J-7

Color viewer

Siemens star chart

Calibration software

Spare lamp

Pictured jig

Strobe adjustment box

CCD calibration

J-4

Part code

VJ8-0007

VJ8-0186

VJ8-0028

VJ8-0181

VJ8-0182

VJ8-0185

5. LCD Panel Adjustment

5-1. LCD H AFC Adjustment

5-2. LCD RGB Offset Adjustment

5-3. LCD Gain Adjustment

5-4. LCD Red Brightness Adjustment

5-5. LCD Blue Brightness Adjustment

3-4. Setup

1. System requirements

Windows 98 or Me

IBM R -compatible PC with pentium processor

CD-ROM drive

3.5-inch high-density diskette drive

USB port

40 MB RAM

Hard disk drive with at least 15 MB available

VGA or SVGA monitor with at least 256-color display

2. Installing calibration software

1. Insert the calibration software installation diskette into your

diskette drive.

2. Open the explorer.

3. Copy the DscCalDI_128a folder on the floppy disk in the

FD drive to a folder on the hard disk.

3. Installing USB drive

Install the USB drive with camera or connection kit for PC.

3-2. Equipment

1. Oscilloscope

2. Digital voltmeter

3. AC adaptor

4. PC (IBM R -compatible PC, Pentium processor, Window

5. Monitor TV

6. USB cable

3-3. Adjustment Items and Order

1. 5.1 V (A) Voltage Adjustment

2. Back Focus Adjustment

3. CCD Adjustment

4. Strobe Adjustment

J-5

98 or Me)

J-6

4. Color Viewer

1. Turn on the switch and wait for 30 minutes for aging to take

place before using Color Pure.

2. The luminance adjustment control on the color viewer

should be set to around the middle position (memory 5)

during use.

3. The fluorescent lamps which are used in the color viewer

are consumable parts. After the cumulative usage time

reaches 2000 hours, the color temperature will start to increase as the usage time increases, and correct adjustment will not be possible. When the cumulative usage time

reaches 2000 hours, all of the fluorescent lamps should be

simultaneously replaced with new lamps.

5. Computer screen during adjustment

– 13 –

Page 14

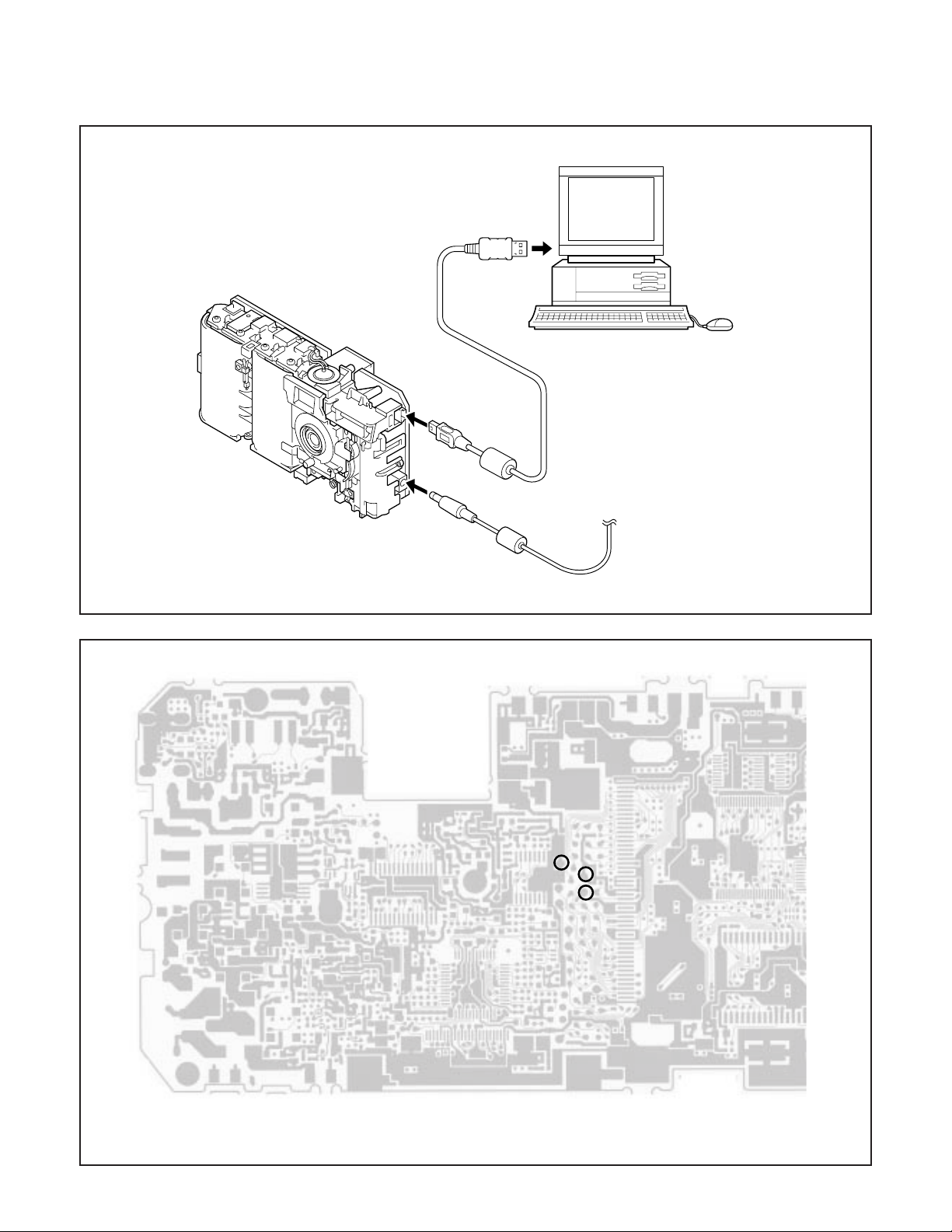

3-5. Connecting the camera to the computer and the pictured jig connection point

1. Line up the arrow on the cable connector with the notch on the camera's USB port. Insert the connector.

2. Locate a USB port on your computer.

To USB port

USB cable

GND

AC adaptor

VDD3

V OUT

Picutured jig connection point (CP1 board side B)

– 14 –

Page 15

3-6. Adjust Specifications

[CP1 board (Side B)]

CL307

CL528

VR502

(Side A)

Note:

1. Voltage adjustment is necessary to repair in the CP1 board

and replace the parts.

Preparation:

1. Shorten the CL307 and CL310 (connection parts of power

switch wires).

2. Insert the CF card.

3. Connect the power, and turn on the LCD monitor.

CL415

CL414

CL411

CL310

CL413

CL400

1. 5.1 V (A) Voltage Adjustment

6. Set the siemens star chart 130 cm +5 /–0 cm so that it becomes center of the screen.

7. Set the macro lever (2) at normal position.

8. Turn the adjustment screw (1) until the siemens is exactly

in focus. Focusing is done by moving from far focal length

to near focal length (conterclockwise motion of the dial), so

start adjustment by moving to the far focus position if the

camera in not already at that position.

9. Set the siemens star chart 25 cm + 3/–0 cm from the camera, check that the chart is out of focus this time.

10. Confirm that there are no operational problems in the com-

puter in taking still pictures in a set condition.

11. Pull the DC jack to turn off the camera after completing the

adjustment, and pull the CF card.

12. Remove the lead of the pictured jig. Confirm that there are

no operational problems in taking still pictures in a set

condition.

13. When this adjustment is carried out, it is necessary to per-

form the 3. CCD adjustment and 4. Strobe adjustment.

Perform the 4. Strobe adjustment after completing the

3. CCD adjustment.

3. CCD Adjustment

Measuring Point

Measuring Equipment

ADJ. Location

ADJ. Value

Adjustment method:

1. Adjust with VR502 to 5.10 ± 0.05 V.

CL528

Digital voltmeter

VR502

5.10 ± 0.05 V

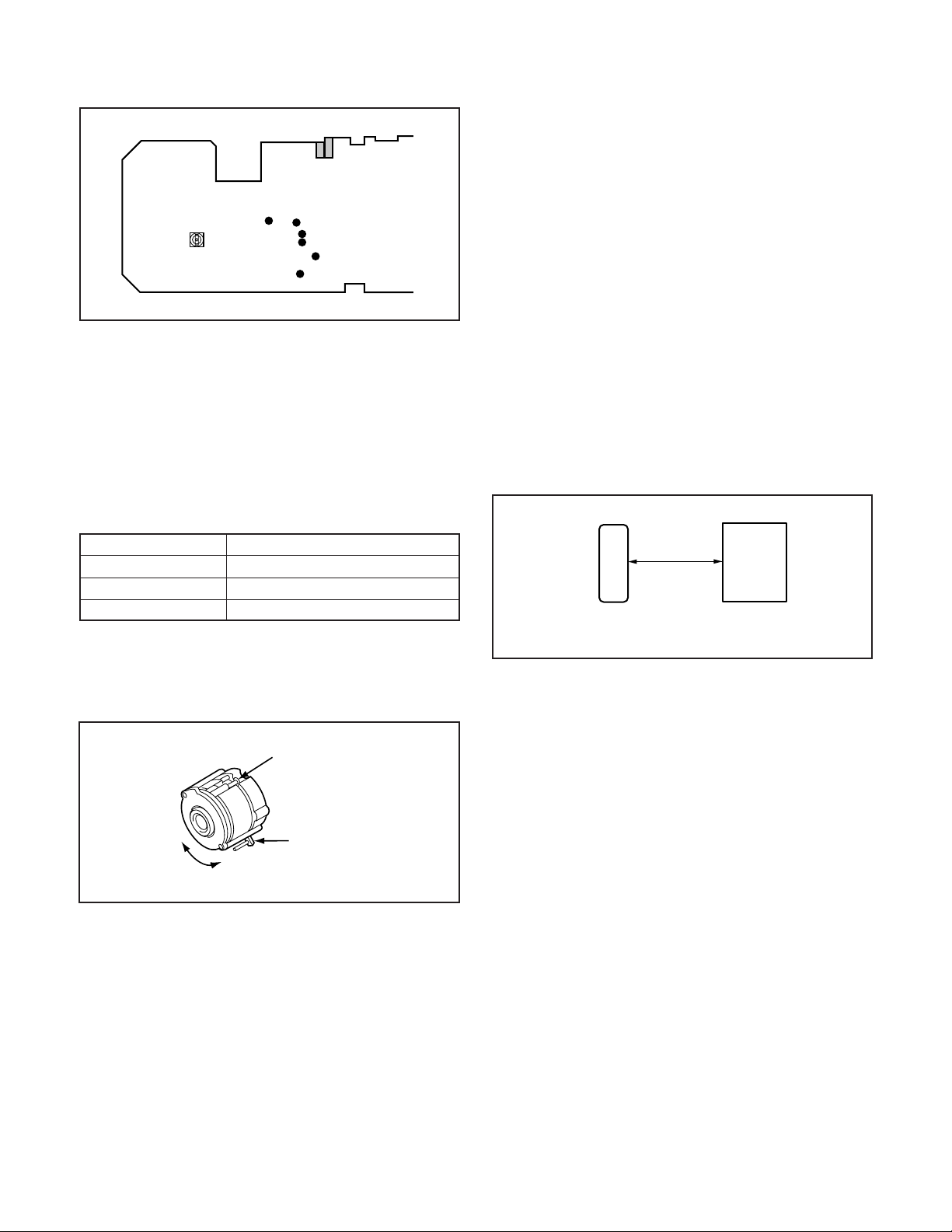

2. Back Focus Adjustment

Adjustment

screw (1)

Macro

lever (2)

Normal position

Adjustment method:

1. Copy all the CCD calibration files to the CF card.

2. Click on Cmdfile.txt to activate the name field in the CF

card, and push the enter key to change the name to

“backfocus” using all lower case letters. Click the save button to save.

3. Take the lead of the pictured jig and solder it to the CP1

board, then connect the TV monitor. (Refer to page 14 below figure.)

4. Set the CF card which is saved to the camera.

5. Slide the lens cover and put DC jack to the camera in order

to turn on the camera.

Camera

18 cm

All white pattern

Color viewer

Adjustment method:

1. Copy all the CCD calibration files to the CF card.

2. Click on Cmdfile.txt to activate the name field in the CF

card, and push the enter key to change the name to “ccdcal”

using all lower case letters. Click the save button to save.

3. Set the CF card which is saved to the camera.

4. Set the color viewer 18 cm from the camera. Do not enter

any light at this time.

5. Slide the lens cover and put DC jack to the camera in order

to turn on the camera. Start the adjustment automatically.

When the adjustment is completed, the “OK” message will

appear on the LCD monitor. If an error occurs during the

process, the “EC***” message will be displayed, and you

must perform the adjustment again.

6. Pull the DC jack to turn off the camera after completing the

adjustment, and pull the CF card.

7. When this adjustment is carried out, it is necessary to perform the 4. Strobe adjustment.

– 15 –

Page 16

4. Strobe Adjustment

Camera

Gray

sheet

5-1. LCD H AFC Adjustment

Adjusting method:

1. Double-click on the DscCalDi.exe in the DscCalDI.128a.

2. Select 0 on the LCD “H AFC”.

3. Apply a trigger using CL400, and adjust LCD “H AFC” so

that the time A from the rising signal at CL400 to the falling signal at CL411 is 5.54 ± 0.1 µsec.

○○○○○○○○

○○

A

Adjustment method:

1. Copy all the CCD calibration files to the CF card.

2. Click on Cmdfile.txt to activate the name field in the CF

card, and push the enter key to change the name to

“strobecal” using all lower case letters. Click the save button to save.

3. Set the CF card which is saved to the camera.

4. Place the camera on the stand in a condition turned to the

bottom of the strobe adjustment box straightly.

5. Slide the lens cover and put DC jack to the camera in order

to turn on the camera. Start the adjustment automatically,

and strobe emits several times.

When the adjustment is completed, the “OK” message will

appear on the LCD monitor. If an error occurs during the

process, the “EC***” message will be displayed, and you

must perform the adjustment again.

6. Pull the DC jack to turn off the camera after completing the

adjustment, and pull the CF card.

5. LCD Panel Adjustment

[CP1 board (Side B)]

CL307

CL310

CL411

CL400

Enlargement

○○○○○○○○

○○

A

CL411

CL400

5-2. LCD RGB Offset Adjustment

Adjusting method:

1. Adjust LCD “RGB Offset” so that the amplitude of the CL415

waveform is 4.0 V ± 0.1 Vp-p.

4.0 V ±

0.1 Vp-p

CL528

VR502

(Side A)

CL415

CL414

CL413

CL400

CL411

Note:

This adjustment is not necessary only the case of exchanging

LCD. Perform the 3. CCD adjustment and 4. Strobe adjustment after completing the LCD adjustment.

Adjustment method:

1. Copy all the CCD calibration files to the CF card.

2. Click on Cmdfile.txt to activate the name field in the CF

card, and push the enter key to change the name to “lcdcal”

using all lower case letters. Click the save button to save.

3. Set the CF card which is saved to the camera.

4. Put DC jack to the camera in order to turn on the camera.

CL415 waveform

5-3. LCD Gain Adjustment

Adjusting method:

1. Adjust LCD “Gain” so that the amplitude of the CL415 waveform is 6.6 V ± 0.2 Vp-p.

Note:

5-2. LCD RGB Offset adjustment should always be carried

out first.

– 16 –

Page 17

6.6 V ±

0.2 Vp-p

VG

CL415 waveform

5-4. LCD Red Brightness Adjustment

Adjusting method:

1. Adjust LCD “R Bright” so that the amplitude of the CL414

waveform is VG ± 0.1 Vp-p with respect to the CL415 (VG)

waveform.

Note:

5-2. LCD RGB Offset adjustment and 5-3. LCD Gain adjustment should always be carried out first.

VG

CL415 waveform

CL415 waveform

VG ±

0.1 Vp-p

CL413 waveform

VG ±

0.1 Vp-p

CL414 waveform

5-5. LCD Blue Brightness Adjustment

Adjusting method:

1. Adjust LCD “B Bright” so that the amplitude of the CL413

waveform is VG ± 0.1 Vp-p with respect to the CL415 (VG)

waveform.

Note:

5-2. LCD RGB Offset adjustment and 5-3. LCD Gain adjustment have done.

– 17 –

Page 18

4. USB STORAGE INFORMATION

REGISTRATION

USB storage data is important for when the camera is connected to a computer via a USB connection.

If there are any errors in the USB storage data, or if it has not

been saved, the USB specification conditions will not be satisfied, so always check and save the USB storage data.

Preparation:

POWER switch: ON

Adjustment method:

1. Connect the camera to a computer. (Refer to 3-5. Connecting the camera to the computer on the page 14.)

2. Double-click on the DscCalDi128a.

3. Click on the Get button in the USB storage window and

check the USB storage data.

VID: SANYO

PID: VPC-R1 or VPC-R1E or VPC-R1EX or VPC-R1G

Serial:

Rev. : 1.00

4. Check the “Serial” in the above USB storage data. If the

displayed value is different from the serial number printed

on the base of the camera, enter the number on the base

of the camera. Then click the Set button.

5. Next, check VID, PID and Rev. entries in the USB storage

data. If any of them are different from the values in 3. above,

make the changes and then click the corresponding Set

button.

Calibration

AWB

Focus

UV Matrix

Cal Mode

OK

Cal Data

OK

Firmware Version:

USB storage

VID

Get

PID

Set

Upload

Firmware

Image

Initialize

EVF

LCD Type

LCD

R Bright

RGB Offset

Tint

VCO

H AFC Test

Serial

Set

Set

Rev.

B Bright

Gain

Phase

Set

Set

VCOMDC

VCOMPP

Setting

Language

Video Mode

– 18 –

Page 19

5. TROUBLESHOOTING GUIDE

POWER LOSS INOPERTIVE

BARRIER SW

ON

IC301-20 (SCAN IN 0)

PULSE INPUT

YES

IC302-7 (UNREG)

HIGH

IC301-53

(VDD)

HIGH

IC301-19

(RESET)

HIGH

IC301-31

(BAT OFF)

HIGH

IC301-15

OSCILLATION

YES

IC301-44

OSCILLATION

YES

OFF

NO

LOW

POWER BLOCK

LOW

LOW

CHECK IC302, R3054

LOW

CHECK IC302, R3053

NO

NO

MAIN SW ON

CHECK

BARRIER SW,

RB301, D3007

CHECK

CHECK IC302

CHECK X3001

CHECK X3002

NORMAL

TAKING INOPERATIVE

PUSH SHUTTER

BUTTON

IC301-20, 21

(SCAN IN 0, 1)

PULSE INPUT

YES

CN301-34

(P ON)

HIGH

IC102-176

(P(A) ON)

HIGH

SERIAL

COMMUNICATION

OK

CHECK CP1

NO

LOW

CHECK, IC301, ASIC

LOW

(IC102), CA-A BLOCK,

NG

IC301, CA-A BLOCK

CHECK RB301,

D3006, D3007

CHECK IC301,

POWER BLOCK

POWER BLOCK

CHECK

CHECK IC301

NO PICTURE

CLK (28.63636MHz)

OSCILLATION

CHECK X1102

YES

SD CLK (57.27 MHz)

OSCILLATION

IC103-38

OK

IC102-237

IC301-39, 40

OK

CHECK SOLDERING OF

MEMORY PIN

MAIN CLOCK FOR SYSTEM OPERATION

NO

NO OPERATION IF ABSENT

CHECK X1102 OSCILLATOR, C1104, C1105

SD RAM (IC103) MOVEMENT CLOCK

NG

NO READ PROGRAM FROM IC121 IF ABSENT

CHECK IC102, IC103

INCORRECT HANDSHAKING BETWEEN 8-BIT

NG

CPU AND RS-232C

CHECK EACH INTERFACE

– 19 –

Page 20

6. PARTS LIST

[VPC-R1/R1E/R1EX/R1G]

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 1

1 636 064 3505 COVER LENS-SB117/EX2,VPC-R1G ONLY

1 636 062 7628 COVER LENS-SB117/U,EXCEPT VPC-R1G

2 636 064 3581 DEC FRONT-SB117/EX2,VPC-R1G ONLY

2 636 063 1595 DEC FRONT-SB117/U,EXCEPT VPC-R1G

3 636 065 3832 ASSY,CABI FRONT SV-117/U ,EXCEPT VPC-R1G

3 636 065 3863 ASSY,CABI FRONT SV-117/EX2 ,VPC-R1G ONLY

4 636 064 3567 COVER BATTERY-SB117/EX2,VPC-R1G ONLY

4 636 062 7642 COVER BATTERY-SB117/U,EXCEPT VPC-R1G

5 636 063 0925 TERMINAL BATT D-SB117/U

6 636 062 8090 STAND-SB117/U, STAND

7 636 063 1663 SPRING COVER LENS-SB117/U

8 636 062 7697 HOLDER COVER LENS-SB117/U

9 636 065 1333 SPACER CABI FRONT-SB117/U

10 636 064 3475 CABINET TOP B-SB117/EX2,VPC-R1G ONLY

10 636 062 7611 CABINET TOP B-SB117/U,EXCEPT VPC-R1G

11 636 063 2189 SPRING SHUTTER-SB117/U

12 636 064 2997 ASSY,BUT SHUTTER-SB117/U,

EXCEPT VPC-R1G

18

16

12 636 064 3147 ASSY,BUT SHUTTER-SB117EX2,

13 636 064 3444 CABINET TOP A-SB117/EX2,VPC-R1G ONLY

13 636 062 7604 CABINET TOP A-SB117/U,EXCEPT VPC-R1G

14 636 063 1625 SPACER MONITOR-SB117/U

15 636 062 8335 SLIDE FUNCTION-SB117/U

16 636 063 1632 SHAFT CARD-SB117/U

17 636 064 3536 COVER CARD-SB117/EX2,VPC-R1G ONLY

17 636 062 7635 COVER CARD-SB117/U,EXCEPT VPC-R1G

18 636 065 3870 ASSY,CABI BACK SV-117/U ,EXCEPT VPC-R1G

18 636 065 3917 ASSY,CABI BACK SV-117/EX2 ,VPC-R1G ONLY

19 636 062 8304 KNOB FUNCTION-SB117/U

20 636 062 8076 DEC MONITOR-SB117/U

101 411 177 6502 SCR S-TPG PAN PCS 1.7X4

102 411 177 8100 SCR S-TPG PAN PCS 1.7X2.5

103 411 177 8407 SCR S-TPG PAN PCS 1.7X3

104 411 177 9503 SCR S-TPG PAN PCS 1.7X3

105 411 181 7007 SCR S-TPG PAN PCS 1.7X6.0

105

VPC-R1G ONLY

20

10

11

12

17

14

103

19

103

101

15

101

105

13

101

105

8

9

104

103

6

7

101

1

2

3

N.S.P.: Not available as service parts.

20

102

5

102

4

SB117/U Parts Lisut-1

Page 21

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

CABINET & CHASSIS PARTS 2

1 645 049 8633 LENS(ASSY)

2 636 064 7015 SPACER,L04

3 645 049 7384 OPTICAL FILTER

4 636 063 2653 SPACER

5 636 062 8137 COMPL PWB,CP-1

6 636 062 7666 HOLDER MONITOR-SB117/U

7 636 063 2110 COMPL,LCD-SB117

8 636 065 0909 SPACER CV MONITOR 2-117J2

9 636 064 2935 SPACER CV MONITOR-SB117/U

10 636 063 1656 SPRING MACRO-SB117/U

11 636 062 8083 KNOB MACRO-SB117/U

12 645 025 1252 SWITCH,LEAF 1P-1T

13 636 062 7680 HOLDER CHASSIS B-SB117/U

14 403 324 3502 DL-ELECT 0.1F Z 5.5V

15 645 025 1252 SWITCH,LEAF 1P-1T

16 645 048 9969 ASSY,LAMP,SB117

17 636 063 0918 TERMINAL BATT C-SB117/U

18 636 062 7765 TERMINAL BATT B-SB117/U

19 636 062 7758 TERMINAL BATT A-SB117/U

20 636 065 1838 ASSY,HLD CHASSIS A-SV 117

21 636 062 8144 COMPL PWB,TB-1

22 419 002 6604 PIEZO BUZZER PS1550L40N

23 645 049 8664 LENS,VF(ASSY)

24 636 062 8069 DEC SELF-SB117/U

101 411 177 6502 SCR S-TPG PAN PCS 1.7X4

103 411 177 8407 SCR S-TPG PAN PCS 1.7X3

106 411 182 3701 SCRS-TPG PAN PCS 1.7X5

107 411 175 3701 SCR S-TPG PAN PCS 1.7X3.5

107

22

19

18

20

21

23

17

101

103

12

13

101

10

24

107

16

N.S.P.

15

107

14

11

8

7

101

101

106

101

101

9

106

4

3

2

6

101

5

1

SB117/J Parts Lisut-2

N.S.P.: Not available as service parts.

21

Page 22

ELECTRICAL PARTS

Note:

1. Materials of Capacitors and Resistors are abbreviated as follows ;

Resistors Capacitors

MT-FILM Metallized Film Resistor MT-POLYEST Metallized Polyester Capacitor

MT-GLAZE Metallized Glaze Resistor MT-COMPO Metallized Composite Capacitor

OXIDE-MT Oxide Metallized Film Resistor TA-SOLD Tantalum Solid Capacitor

AL-SOLID Aluminum Solid Capacitor

NP-ELECT Non-Polarized Electrolytic Capacitor

OS-SOLID Aluminum Solid Capacitors with Organic

2. Tolerance of Capacitor (10pF over) and Resistor are noted with follow symboles.

DL-ELECT Double Layered Electrolytic Capacitor

F ............1% G ............2% J ............5% K ............10%

M ..........20% N ..........30% Z ..........+80% ~ -20%

3. Capacitors

µ

F P : pF

U :

4. Inductors

µ

H MH : mH

UH :

5. N.S.P. : Not available as service parts.

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

COMPL PWB,CP-1

636 062 8137

(SEMICONDUCTORS)

Q1302 405 102 5609 TR 2SD1819A-R

OR 405 092 4101 TR 2SC4081-R

Q1601 405 133 8907 TR DTC114EUA

OR 405 119 0802 TR UN5211

OR 405 078 7300 TR 2SC4398

Q1602 405 102 6705 TR 2SA1745-7

OR 405 102 8303 TR 2SA1745-6

Q1706 405 115 7201 TR DTC144EE

OR 405 102 5500 TR 2SB1218A-R

OR 405 137 2000 TR 2SA1576A-R

Q3001 405 102 5609 TR 2SD1819A-R

OR 405 092 4101 TR 2SC4081-R

OR 405 078 7300 TR 2SC4398

Q3002 405 102 5609 TR 2SD1819A-R

OR 405 092 4101 TR 2SC4081-R

OR 405 078 7300 TR 2SC4398

Q3004 405 115 5504 TR DTA114EE

Q5001 405 150 5002 TR CPH3109

Q5002 405 115 5108 TR 2SA1774 R

Q5003 405 115 5108 TR 2SA1774 R

Q5005 405 157 1403 TR 2SA2018

Q5006 405 129 2902 TR UMH11N

Q5007 405 153 7508 TR CPH5701

Q5008 405 150 5002 TR CPH3109

Q5009 405 129 2902 TR UMH11N

Q5010 405 157 1403 TR 2SA2018

Q5013 405 150 5200 TR CPH5703

Q5014 405 157 1403 TR 2SA2018

Q5015 405 115 6907 TR DTC114EE

Q5016 405 130 1109 TR UMY1N

Q5017 405 153 8406 TR FTS2005

Q5018 405 153 7508 TR CPH5701

Q5401 405 115 7508 TR DTC123JE

Q5402 405 115 6907 TR DTC114EE

Q5405 405 147 9709 TR CPH3205

Q5406 405 150 5002 TR CPH3109

Q5407 405 115 5207 TR 2SC4617 R

Q5409 405 158 0306 TR CY25AAJ-8

Q9001 405 133 8907 TR DTC114EUA

OR 405 119 0802 TR UN5211

OR 405 078 7300 TR 2SC4398

Q9002 405 165 7305 TR BFR92AW

Q9003 405 102 5500 TR 2SB1218A-R

OR 405 137 2000 TR 2SA1576A-R

(INTEGRATED CIRCUITS)

IC102 409 509 6504 IC CX11637-21 (BGA) (N.S.P.)

IC103 409 482 0506 IC HY57V651620BTC-10S

OR 409 502 3807 IC HY57V641620HGT-H

IC106 409 484 7602 IC NC7SZ08P5

IC121 4095 220 0305 IC 29300117F

IC141 409 471 4102 IC SN74LV244ADB

IC142 409 471 4201 IC SN74LV245ADB

IC143 409 471 4201 IC SN74LV245ADB

IC145 409 368 5809 IC TC7SH08FU

IC171 409 462 2902 IC LV4135W

IC173 409 453 0702 IC TK11330BM

IC175 409 400 9109 IC TC7SET08FU

IC301 410 426 0209 IC MB89165LPFV-G-360-BND

IC302 409 383 1008 S-8423NFS

IC501 409 496 5009 IC BD9731KV

IC502 409 301 5507 IC TC7S08FU

IC901 409 498 6806 IC AD9806KST

IC902 409 507 4403 IC LC89906V(TE-L)

IC903 409 514 2102 IC 74ACTQ04MTC

IC904 409 407 0505 IC TK11331BM

IC905 409 503 0508 IC LC99351(CCD)

IC951 409 247 1205 IC LB1837M

IC952 409 513 0505 IC TK71735S

(DIODES)

D1001 407 149 0807 DIODE 1SS355

D1701 407 166 0606 DIODE MA365

D3002 407 205 2707 LED SML-310LT

D3003 407 201 7607 LED SML-310MT

D3004 407 220 5905 DIODE HN1D01FU

OR 407 175 2202 DIODE UMP11N

D3005 407 220 5905 DIODE HN1D01FU

OR 407 175 2202 DIODE UMP11N

D3006 407 220 5905 DIODE HN1D01FU

OR 407 175 2202 DIODE UMP11N

D3007 407 220 5905 DIODE HN1D01FU

OR 407 175 2202 DIODE UMP11N

D3051 407 149 0807 DIODE 1SS355

D5001 407 199 4909 DIODE 1SS376

D5002 407 149 0807 DIODE 1SS355

D5003 407 210 5403 DIODE RB551V-30

D5004 407 162 8507 DIODE DAN222

D5005 407 190 3703 DIODE RB050L-40-TE25

D5006 407 149 0807 DIODE 1SS355

D5007 407 190 3703 DIODE RB050L-40-TE25

D5008 407 149 0807 DIODE 1SS355

D5013 407 210 5403 DIODE RB551V-30

D5402 407 202 0300 DIODE F1F16

D5404 407 202 0102 DIODE F1SN4

D5405 407 199 4503 DIODE CR08AS-8-T1

D5407 407 162 8507 DIODE DAN222

D9001 407 105 6102 DIODE SB007-03Q

D9002 407 105 6102 DIODE SB007-03Q

D9003 407 113 5609 DIODE DSH015

OR 407 134 7200 DIODE MA141K

OR 407 220 7305 DIODE MA142K-G

OR 407 153 7205 DIODE MA142K

D9004 407 113 5609 DIODE DSH015

Semiconductive Electrolytic Capacitor

22

Page 23

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

D9004 407 134 7200 DIODE MA141K

OR 407 220 7305 DIODE MA142K-G

OR 407 153 7205 DIODE MA142K

D9005 407 113 5609 DIODE DSH015

OR 407 134 7200 DIODE MA141K

OR 407 220 7305 DIODE MA142K-G

OR 407 153 7205 DIODE MA142K

D9006 407 113 5609 DIODE DSH015

OR 407 134 7200 DIODE MA141K

OR 407 220 7305 DIODE MA142K-G

OR 407 153 7205 DIODE MA142K

(OSC)

X1101 645 049 1085 OSC,CRYSTAL 48.000MHZ

X1102 645 049 1078 OSC,CRYSTAL 28.63636MHZ

X3001 645 046 1415 OSC,CERAMIC 4.00MHZ

X3002 636 040 1129 OSC CRYSTAL 32.768KHZ

(FILTER)

XF131 645 049 3430 FILTER,220-100M

(VARIABLE RESISTORS)

VR502 645 046 7844 VR,SEMI,2.2K S

(INDUCTORS)

L1001 645 041 1977 INDUCTOR,330 OHM

L1002 645 041 1977 INDUCTOR,330 OHM

L1071 645 020 1899 INDUCTOR,68 OHM

L1101 645 021 1645 INDUCTOR,2.2U J

L1502 645 041 1977 INDUCTOR,330 OHM

L1701 645 035 7183 INDUCTOR,10U J

L1702 645 004 2478 INDUCTOR,10U J

L1703 645 041 1977 INDUCTOR,330 OHM

L3001 645 049 1504 IMPEDANCE,120 OHM P

L5001 645 033 8762 INDUCTOR,47U K

L5002 645 033 8762 INDUCTOR,47U K

L5003 645 033 8762 INDUCTOR,47U K

L5004 645 033 8663 INDUCTOR,10U K

L5006 645 037 0632 INDUCTOR,47U M

L5007 645 033 8762 INDUCTOR,47U K

L5009 645 049 1825 IMPEDANCE,180 OHM P

L5010 645 049 1825 IMPEDANCE,180 OHM P

L5011 645 040 3286 INDUCTOR,22U M

L5012 645 033 8663 INDUCTOR,10U K

L5013 645 033 8663 INDUCTOR,10U K

L5014 645 021 5315 INDUCTOR,110 OHM

L5016 645 037 0632 INDUCTOR,47U M

L5401 645 037 0618 INDUCTOR,15U M

L9001 645 020 1912 INDUCTOR,240 OHM

(TRANSFORMERS)

T5001 645 048 5831 TRANS,POWER,PULSE

T5002 645 047 2336 TRANS,POWER,PULSE

T5003 645 027 5425 TRANS,POWER,PULSE

T5401 645 044 6641 TRANS,STEP UP

T5402 645 031 6951 TRANS,STEP UP

(CAPACITORS)

C1001 403 312 6805 CERAMIC 0.1U Z 16V

C1002 403 312 6805 CERAMIC 0.1U Z 16V

C1003 403 312 6805 CERAMIC 0.1U Z 16V

C1004 403 312 6805 CERAMIC 0.1U Z 16V

C1005 403 312 6805 CERAMIC 0.1U Z 16V

C1006 403 312 6805 CERAMIC 0.1U Z 16V

C1007 403 312 6805 CERAMIC 0.1U Z 16V

C1008 403 312 6805 CERAMIC 0.1U Z 16V

C1009 403 311 4505 CERAMIC 1000P K 50V

C1010 403 312 6805 CERAMIC 0.1U Z 16V

C1011 403 312 6805 CERAMIC 0.1U Z 16V

C1012 403 312 6805 CERAMIC 0.1U Z 16V

C1013 403 312 6805 CERAMIC 0.1U Z 16V

C1014 403 312 6805 CERAMIC 0.1U Z 16V

C1015 403 312 6805 CERAMIC 0.1U Z 16V

C1016 403 312 6805 CERAMIC 0.1U Z 16V

C1017 403 312 6805 CERAMIC 0.1U Z 16V

C1061 403 312 6805 CERAMIC 0.1U Z 16V

C1062 403 312 6805 CERAMIC 0.1U Z 16V

C1063 403 324 0501 CERAMIC 10U Z 10V

C1064 403 312 6805 CERAMIC 0.1U Z 16V

C1071 403 312 6805 CERAMIC 0.1U Z 16V

C1072 403 312 6805 CERAMIC 0.1U Z 16V

C1073 403 312 6805 CERAMIC 0.1U Z 16V

C1074 403 312 6805 CERAMIC 0.1U Z 16V

C1101 403 311 5809 CERAMIC 47P J 50V

C1102 403 309 8102 CERAMIC 5P C 50V

C1103 403 309 8102 CERAMIC 5P C 50V

C1104 403 311 7803 CERAMIC 8P D 50V

C1105 403 311 7803 CERAMIC 8P D 50V

C1201 403 332 9503 CERAMIC 1U M 6.3V

C1301 403 311 5809 CERAMIC 47P J 50V

C1302 403 311 5809 CERAMIC 47P J 50V

C1401 403 312 6805 CERAMIC 0.1U Z 16V

C1402 403 312 6805 CERAMIC 0.1U Z 16V

C1403 403 312 6805 CERAMIC 0.1U Z 16V

C1412 403 312 6805 CERAMIC 0.1U Z 16V

C1502 403 324 0501 CERAMIC 10U Z 10V

C1503 403 311 3409 CERAMIC 0.01U K 16V

C1504 403 311 3409 CERAMIC 0.01U K 16V

C1704 403 311 3409 CERAMIC 0.01U K 16V

C1705 403 312 6003 CERAMIC 39P J 50V

C1706 403 319 3005 CERAMIC 220P J 25V

C1707 403 155 1807 CERAMIC 0.01U K 25V

C1709 403 317 1904 CERAMIC 6800P K 25V

C1711 403 283 6309 CERAMIC 1U Z 10V

C1712 403 346 2309 CERAMIC 0.1U K 10V

C1713 403 311 3409 CERAMIC 0.01U K 16V

C1714 403 346 2309 CERAMIC 0.1U K 10V

C1715 403 323 6009 CERAMIC 10U M 16V

C1721 403 338 0405 CERAMIC 0.47U K 25V

C1722 403 338 0405 CERAMIC 0.47U K 25V

C1723 403 338 0405 CERAMIC 0.47U K 25V

C1726 403 155 1807 CERAMIC 0.01U K 25V

C1727 403 338 0405 CERAMIC 0.47U K 25V

C1731 403 332 9503 CERAMIC 1U M 6.3V

C1732 403 332 9503 CERAMIC 1U M 6.3V

C1733 403 332 9503 CERAMIC 1U M 6.3V

C1734 403 332 9503 CERAMIC 1U M 6.3V

C1735 403 335 4802 CERAMIC 0.33U K 6.3V

C1736 403 346 2309 CERAMIC 0.1U K 10V

C1737 403 346 2309 CERAMIC 0.1U K 10V

C1738 403 311 5809 CERAMIC 47P J 50V

C1739 403 311 5809 CERAMIC 47P J 50V

C1740 403 311 5809 CERAMIC 47P J 50V

C1741 403 358 3202 CERAMIC 10U K 6.3V

C1746 403 332 9503 CERAMIC 1U M 6.3V

C1748 403 358 3202 CERAMIC 10U K 6.3V

C1754 403 332 9503 CERAMIC 1U M 6.3V

C1775 403 207 0307 CERAMIC 1U Z 16V

C3001 403 345 4304 TA-SOLID 22U M 10V

C3002 403 312 6805 CERAMIC 0.1U Z 16V

C3003 403 312 6805 CERAMIC 0.1U Z 16V

C3005 403 312 6805 CERAMIC 0.1U Z 16V

C3007 403 312 6805 CERAMIC 0.1U Z 16V

C3008 403 323 9406 TA-SOLID 10U M 10V

C3009 403 312 6805 CERAMIC 0.1U Z 16V

C3010 403 311 4505 CERAMIC 1000P K 50V

C3011 403 311 7506 CERAMIC 22P J 50V

C3012 403 309 8607 CERAMIC 18P J 50V

C3051 403 207 0307 CERAMIC 1U Z 16V

C3052 403 312 6805 CERAMIC 0.1U Z 16V

C3053 403 312 6805 CERAMIC 0.1U Z 16V

C3054 403 312 6805 CERAMIC 0.1U Z 16V

C3056 403 311 3409 CERAMIC 0.01U K 16V

C3057 403 312 6805 CERAMIC 0.1U Z 16V

C5001 403 311 4505 CERAMIC 1000P K 50V

C5002 403 311 4505 CERAMIC 1000P K 50V

C5003 403 311 4505 CERAMIC 1000P K 50V

C5004 403 311 4505 CERAMIC 1000P K 50V

C5005 403 311 4505 CERAMIC 1000P K 50V

C5006 403 311 4505 CERAMIC 1000P K 50V

C5007 403 311 3409 CERAMIC 0.01U K 16V

C5008 403 311 3409 CERAMIC 0.01U K 16V

C5009 403 338 4403 CERAMIC 0.1U K 16V

C5010 403 338 4403 CERAMIC 0.1U K 16V

C5011 403 311 3409 CERAMIC 0.01U K 16V

C5012 403 343 8700 CERAMIC 1U M 12V

C5013 403 352 7305 CERAMIC 4.7U K 6.3V

C5014 403 343 8700 CERAMIC 1U M 12V

C5015 403 352 7305 CERAMIC 4.7U K 6.3V

C5016 403 348 9108 CERAMIC 0.47U K 6.3V

C5017 403 319 3005 CERAMIC 220P J 25V

C5018 403 338 4403 CERAMIC 0.1U K 16V

23

Page 24

C5019 403 311 7605 CERAMIC 2200P K 50V

C5020 403 338 4403 CERAMIC 0.1U K 16V

C5021 403 338 4403 CERAMIC 0.1U K 16V

C5022 403 317 1201 CERAMIC 0.22U K 50V

C5026 403 317 1201 CERAMIC 0.22U K 50V

C5027 403 311 1801 CERAMIC 1U K 10V

C5029 403 340 1803 CERAMIC 1U M 25V

C5030 403 340 1803 CERAMIC 1U M 25V

C5031 403 343 3101 CERAMIC 1U K 6.3V

C5033 403 334 3806 CERAMIC 10U K 6.3V

C5034 403 334 3806 CERAMIC 10U K 6.3V

C5035 403 311 7605 CERAMIC 2200P K 50V

C5036 403 340 6907 CERAMIC 1U K 16V

C5037 403 340 6907 CERAMIC 1U K 16V

C5038 403 340 6907 CERAMIC 1U K 16V

C5039 403 334 3806 CERAMIC 10U K 6.3V

C5040 403 311 1801 CERAMIC 1U K 10V

C5041 403 367 6607 POS-SOLID 47U M 6.3V

C5042 403 311 7704 CERAMIC 4700P K 25V

C5043 403 311 1801 CERAMIC 1U K 10V

C5044 403 367 6607 POS-SOLID 47U M 6.3V

C5045 403 311 7704 CERAMIC 4700P K 25V

C5047 403 325 0500 CERAMIC 2.2U K 16V

C5048 403 340 6907 CERAMIC 1U K 16V

C5049 403 311 7605 CERAMIC 2200P K 50V

C5050 403 348 9108 CERAMIC 0.47U K 6.3V

C5052 403 113 4109 CERAMIC 2200P K 50V

C5054 403 309 8706 CERAMIC 100P J 50V

C5055 403 340 6907 CERAMIC 1U K 16V

C5057 403 333 3609 POS-SOLID 33U M 10V

C5058 403 311 4505 CERAMIC 1000P K 50V

C5059 403 333 3609 POS-SOLID 33U M 10V

C5401 403 341 4407 CERAMIC 0.047U K 350V

C5402 403 330 5903 CERAMIC 0.01U K 500V

C5403 403 163 9604 CERAMIC 0.033U Z 25V

C5404 403 311 4505 CERAMIC 1000P K 50V

C5405 403 341 4803 CERAMIC 10U K 10V

C5406 403 307 7008 CERAMIC 0.068U K 16V

C5407 403 113 4109 CERAMIC 2200P K 50V

C5412 404 087 6601 ELECT 120U A 330V

C9001 403 312 6805 CERAMIC 0.1U Z 16V

C9002 403 312 6805 CERAMIC 0.1U Z 16V

C9003 403 312 6805 CERAMIC 0.1U Z 16V

C9004 403 312 6805 CERAMIC 0.1U Z 16V

C9005 403 311 7605 CERAMIC 2200P K 50V

C9006 403 312 6805 CERAMIC 0.1U Z 16V

C9008 403 312 6805 CERAMIC 0.1U Z 16V

C9009 403 312 6805 CERAMIC 0.1U Z 16V

C9010 403 312 6805 CERAMIC 0.1U Z 16V

C9011 403 312 6805 CERAMIC 0.1U Z 16V

C9012 403 320 5302 CERAMIC 0.15U K 25V

C9013 403 345 4304 TA-SOLID 22U M 10V

C9014 403 311 3409 CERAMIC 0.01U K 16V

C9015 403 311 3409 CERAMIC 0.01U K 16V

C9016 403 343 8700 CERAMIC 1U M 12V

C9017 403 311 3409 CERAMIC 0.01U K 16V

C9018 403 343 8700 CERAMIC 1U M 12V

C9019 403 312 6805 CERAMIC 0.1U Z 16V

C9022 403 312 6805 CERAMIC 0.1U Z 16V

C9023 403 312 6805 CERAMIC 0.1U Z 16V

C9024 403 312 6805 CERAMIC 0.1U Z 16V

C9025 403 312 6805 CERAMIC 0.1U Z 16V

C9026 403 367 6102 CERAMIC 4.7U K 16V

C9027 403 217 9604 ELECT 100U M 16V

C9028 403 312 6805 CERAMIC 0.1U Z 16V

C9029 403 312 6805 CERAMIC 0.1U Z 16V

C9030 403 338 4403 CERAMIC 0.1U K 16V

C9031 403 343 8700 CERAMIC 1U M 12V

C9040 403 343 8700 CERAMIC 1U M 12V

C9042 403 343 8700 CERAMIC 1U M 12V

C9043 403 164 0204 CERAMIC 0.1U Z 25V

C9044 403 311 3409 CERAMIC 0.01U K 16V

C9045 403 312 6805 CERAMIC 0.1U Z 16V

C9046 403 164 0204 CERAMIC 0.1U Z 25V

C9047 403 164 0204 CERAMIC 0.1U Z 25V

C9048 403 312 6805 CERAMIC 0.1U Z 16V

C9049 403 312 6805 CERAMIC 0.1U Z 16V

C9050 403 338 4403 CERAMIC 0.1U K 16V

C9051 403 213 5501 ELECT 10U M 25V

C9052 403 312 6805 CERAMIC 0.1U Z 16V

C9053 403 164 0204 CERAMIC 0.1U Z 25V

C9054 403 164 0204 CERAMIC 0.1U Z 25V

C9056 403 218 4905 ELECT 4.7U M 35V

C9057 403 312 6805 CERAMIC 0.1U Z 16V

C9058 403 164 0204 CERAMIC 0.1U Z 25V

C9059 403 280 3400 ELECT 47U M 35V

C9501 403 338 4403 CERAMIC 0.1U K 16V

C9502 403 332 9503 CERAMIC 1U M 6.3V

C9503 403 155 1807 CERAMIC 0.01U K 25V

(RESISTOR PACKS)

RB101 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB102 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB103 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB104 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB109 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB110 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB111 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB112 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB113 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB121 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB122 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB123 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB124 645 037 0816 R-NETWORK 0X4 1/32W

OR 645 036 3528 R-NETWORK 0X4 1/32W

RB301 645 020 7822 R-NETWORK 10KX4 0.063W

(RESISTORS)

R1001 401 224 9709 MT-GLAZE 22 JA 1/16W

R1002 401 224 9709 MT-GLAZE 22 JA 1/16W

R1003 401 224 9709 MT-GLAZE 22 JA 1/16W

R1004 401 224 9709 MT-GLAZE 22 JA 1/16W

R1005 401 224 9709 MT-GLAZE 22 JA 1/16W

R1006 401 224 9709 MT-GLAZE 22 JA 1/16W

R1007 401 224 9709 MT-GLAZE 22 JA 1/16W

R1008 401 224 9709 MT-GLAZE 22 JA 1/16W

R1016 401 224 9303 MT-GLAZE 1K JA 1/16W

R1018 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1019 401 224 8900 MT-GLAZE 100K JA 1/16W

R1020 401 224 8900 MT-GLAZE 100K JA 1/16W

R1021 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1061 401 226 2401 MT-GLAZE 560 JA 1/16W

R1062 401 226 2401 MT-GLAZE 560 JA 1/16W

R1063 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1101 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R1102 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1103 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R1104 401 301 3507 MT-GLAZE 200 JA 1/16W

R1105 401 224 9006 MT-GLAZE 10K JA 1/16W

R1301 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1302 401 224 8900 MT-GLAZE 100K JA 1/16W

R1303 401 225 3805 MT-GLAZE 1.5K JA 1/16W

R1304 401 225 1108 MT-GLAZE 27 JA 1/16W

R1305 401 225 1108 MT-GLAZE 27 JA 1/16W

R1306 401 224 9501 MT-GLAZE 2.2K JA 1/16W

R1307 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1419 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1421 401 224 9006 MT-GLAZE 10K JA 1/16W

R1422 401 224 9006 MT-GLAZE 10K JA 1/16W

R1423 401 224 9006 MT-GLAZE 10K JA 1/16W

R1424 401 224 9006 MT-GLAZE 10K JA 1/16W

R1501 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1502 401 225 1603 MT-GLAZE 390 JA 1/16W

R1604 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R1605 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R1702 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

24

Page 25

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

R1705 401 261 8109 MT-FILM 33K DD 1/16W

R1706 401 225 1801 MT-GLAZE 47 JA 1/16W

R1707 401 225 1801 MT-GLAZE 47 JA 1/16W

R1708 401 225 1801 MT-GLAZE 47 JA 1/16W

R1709 401 225 1801 MT-GLAZE 47 JA 1/16W

R1711 401 224 9006 MT-GLAZE 10K JA 1/16W

R1712 401 224 9006 MT-GLAZE 10K JA 1/16W

R1713 401 261 8307 MT-FILM 39K DD 1/16W

R1714 401 262 4508 MT-FILM 30K DD 1/16W

R1716 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1717 401 225 7902 MT-GLAZE 220 JA 1/16W

R1718 401 225 7902 MT-GLAZE 220 JA 1/16W

R1719 401 225 7902 MT-GLAZE 220 JA 1/16W

R1720 401 262 3400 MT-FILM 39 DD 1/16W

R1721 401 262 3400 MT-FILM 39 DD 1/16W

R1722 401 262 3400 MT-FILM 39 DD 1/16W

R1725 401 225 0507 MT-GLAZE 33K JA 1/16W

R1726 401 224 9303 MT-GLAZE 1K JA 1/16W

R1727 401 224 9006 MT-GLAZE 10K JA 1/16W

R1743 401 261 7508 MT-FILM 100K DD 1/16W

R1765 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R1766 401 224 9006 MT-GLAZE 10K JA 1/16W

R1767 401 261 8307 MT-FILM 39K DD 1/16W

R1768 401 261 8703 MT-FILM 22K DD 1/16W

R1775 401 261 3906 MT-FILM 2.2K DU 1/16W

R1901 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1902 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R1904 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R3001 401 224 9303 MT-GLAZE 1K JA 1/16W

R3002 401 224 9303 MT-GLAZE 1K JA 1/16W

R3003 401 224 8801 MT-GLAZE 100 JA 1/16W

R3004 401 224 8801 MT-GLAZE 100 JA 1/16W

R3005 401 224 8801 MT-GLAZE 100 JA 1/16W

R3006 401 224 9006 MT-GLAZE 10K JA 1/16W

R3007 401 224 8801 MT-GLAZE 100 JA 1/16W

R3010 401 224 9006 MT-GLAZE 10K JA 1/16W

R3011 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R3012 401 224 9006 MT-GLAZE 10K JA 1/16W

R3013 401 224 8801 MT-GLAZE 100 JA 1/16W

R3015 401 224 9006 MT-GLAZE 10K JA 1/16W

R3016 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3017 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3018 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3021 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3022 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3023 401 225 7902 MT-GLAZE 220 JA 1/16W

R3024 401 225 7902 MT-GLAZE 220 JA 1/16W

R3026 401 224 8900 MT-GLAZE 100K JA 1/16W

R3027 401 224 9907 MT-GLAZE 22K JA 1/16W

R3028 401 224 8900 MT-GLAZE 100K JA 1/16W

R3030 401 263 5809 MT-GLAZE 330K DC 1/16W

R3031 401 258 9300 MT-GLAZE 220K DC 1/16W

R3032 401 225 1702 MT-GLAZE 39K JA 1/16W

R3033 401 224 9006 MT-GLAZE 10K JA 1/16W

R3034 401 224 9006 MT-GLAZE 10K JA 1/16W

R3035 401 224 8900 MT-GLAZE 100K JA 1/16W

R3036 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R3037 401 224 8900 MT-GLAZE 100K JA 1/16W

R3038 401 224 8900 MT-GLAZE 100K JA 1/16W

R3039 401 224 8900 MT-GLAZE 100K JA 1/16W

R3051 401 224 9303 MT-GLAZE 1K JA 1/16W

R3052 401 224 9303 MT-GLAZE 1K JA 1/16W

R3053 401 224 8900 MT-GLAZE 100K JA 1/16W

R3054 401 224 8900 MT-GLAZE 100K JA 1/16W

R5001 401 224 8801 MT-GLAZE 100 JA 1/16W

R5002 401 224 8801 MT-GLAZE 100 JA 1/16W

R5003 401 224 8801 MT-GLAZE 100 JA 1/16W

R5004 401 224 8801 MT-GLAZE 100 JA 1/16W

R5005 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5006 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5007 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5008 401 224 8801 MT-GLAZE 100 JA 1/16W

R5009 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5010 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5011 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5012 401 267 6604 MT-GLAZE 270K DC 1/16W

R5013 401 267 6604 MT-GLAZE 270K DC 1/16W

R5014 401 240 9608 MT-GLAZE 680K JA 1/16W

R5015 401 240 9608 MT-GLAZE 680K JA 1/16W

R5016 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5017 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5020 401 261 3906 MT-FILM 2.2K DU 1/16W

R5021 401 261 8703 MT-FILM 22K DD 1/16W

R5022 401 267 6604 MT-GLAZE 270K DC 1/16W

R5025 401 240 9608 MT-GLAZE 680K JA 1/16W

R5026 401 267 6604 MT-GLAZE 270K DC 1/16W

R5027 401 263 5809 MT-GLAZE 330K DC 1/16W

R5028 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5029 401 224 9303 MT-GLAZE 1K JA 1/16W

R5030 401 224 9303 MT-GLAZE 1K JA 1/16W

R5031 401 224 9303 MT-GLAZE 1K JA 1/16W

R5032 401 224 9303 MT-GLAZE 1K JA 1/16W

R5033 401 224 9402 MT-GLAZE 1.0M JA 1/16W

R5034 401 224 8900 MT-GLAZE 100K JA 1/16W

R5035 401 224 8900 MT-GLAZE 100K JA 1/16W

R5036 401 224 8900 MT-GLAZE 100K JA 1/16W

R5037 401 225 0507 MT-GLAZE 33K JA 1/16W

R5038 401 224 8900 MT-GLAZE 100K JA 1/16W

R5039 401 224 9303 MT-GLAZE 1K JA 1/16W

R5040 401 224 9006 MT-GLAZE 10K JA 1/16W

R5041 401 261 8703 MT-FILM 22K DD 1/16W

R5042 401 224 8900 MT-GLAZE 100K JA 1/16W

R5043 401 261 2404 MT-FILM 8.2K DU 1/16W

R5044 401 224 9006 MT-GLAZE 10K JA 1/16W

R5045 401 261 8703 MT-FILM 22K DD 1/16W

R5046 401 261 9106 MT-FILM 12K DD 1/16W

R5047 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

R5049 401 261 9106 MT-FILM 12K DD 1/16W

R5050 401 105 0504 MT-GLAZE 1K JA 1/16W

R5051 401 261 2404 MT-FILM 8.2K DU 1/16W

R5052 401 261 5900 MT-FILM 330 DU 1/16W

R5053 401 261 4309 MT-FILM 1.2K DU 1/16W

R5054 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5056 401 261 9106 MT-FILM 12K DD 1/16W

R5057 401 224 9303 MT-GLAZE 1K JA 1/16W

R5058 401 261 9304 MT-FILM 15K DD 1/16W

R5059 401 261 3708 MT-FILM 1.8K DU 1/16W

R5060 401 261 5900 MT-FILM 330 DU 1/16W

R5061 401 258 7009 MT-GLAZE 150K DC 1/16W

R5062 401 224 9303 MT-GLAZE 1K JA 1/16W

R5063 401 258 7009 MT-GLAZE 150K DC 1/16W

R5064 401 261 8109 MT-FILM 33K DD 1/16W

R5065 401 261 9502 MT-FILM 18K DD 1/16W

R5066 401 226 1503 MT-GLAZE 0.000 ZA 1/16W

R5067 401 225 2105 MT-GLAZE 12K JA 1/16W

R5068 401 225 1702 MT-GLAZE 39K JA 1/16W

R5069 401 224 8801 MT-GLAZE 100 JA 1/16W

R5070 401 224 8900 MT-GLAZE 100K JA 1/16W

R5071 401 224 9303 MT-GLAZE 1K JA 1/16W

R5072 401 224 9006 MT-GLAZE 10K JA 1/16W

R5074 401 261 8901 MT-FILM 27K DD 1/16W

R5075 401 261 8901 MT-FILM 27K DD 1/16W

R5076 401 225 1207 MT-GLAZE 4.7K JA 1/16W

R5077 401 261 2602 MT-FILM 10K DU 1/16W

R5078 401 261 4903 MT-FILM 820 DU 1/16W

R5079 401 261 3708 MT-FILM 1.8K DU 1/16W

R5080 401 261 2701 MT-FILM 4.7K DU 1/16W

R5087 401 261 4101 MT-FILM 2.7K DU 1/16W

R5088 401 261 9601 MT-FILM 68 DD 1/16W

R5401 401 105 0504 MT-GLAZE 1K JA 1/16W

R5408 401 037 3406 MT-GLAZE 82 JA 1/8W

R5409 401 105 0504 MT-GLAZE 1K JA 1/16W

R5410 401 105 0504 MT-GLAZE 1K JA 1/16W

R5411 401 105 0504 MT-GLAZE 1K JA 1/16W

R5413 401 105 0603 MT-GLAZE 10K JA 1/16W

R5414 401 105 0504 MT-GLAZE 1K JA 1/16W

R5417 402 078 4407 MT-GLAZE 10M FKG 1/8W

R5418 401 105 5806 MT-GLAZE 56 JA 1/16W

R5419 401 261 7300 MT-FILME 82K DD 1/16W

R5422 402 079 0200 MT-GLAZE 220K JKG 1/8W

R5424 401 105 5806 MT-GLAZE 56 JA 1/16W

R5425 402 077 7409 MT-GLAZE 100K JKG 1/8W

R5426 401 105 5509 MT-GLAZE 470K JA 1/16W

R5429 401 105 0603 MT-GLAZE 10K JA 1/16W

R5432 401 105 3901 MT-GLAZE 33 JA 1/16W

R5471 401 105 5301 MT-GLAZE 4.7K JA 1/16W

25

Page 26

LOCATION PARTS NO. DESCRIPTION LOCATION PARTS NO. DESCRIPTION

R9003 401 225 7902 MT-GLAZE 220 JA 1/16W

R9004 401 225 7902 MT-GLAZE 220 JA 1/16W

R9005 401 225 7902 MT-GLAZE 220 JA 1/16W

R9006 401 225 7902 MT-GLAZE 220 JA 1/16W

R9007 401 225 7902 MT-GLAZE 220 JA 1/16W

R9008 401 225 7902 MT-GLAZE 220 JA 1/16W

R9009 401 225 7902 MT-GLAZE 220 JA 1/16W

R9010 401 225 7902 MT-GLAZE 220 JA 1/16W

R9011 401 225 7902 MT-GLAZE 220 JA 1/16W

R9012 401 225 7902 MT-GLAZE 220 JA 1/16W

R9016 401 261 3906 MT-FILM 2.2K DU 1/16W

R9017 401 224 8900 MT-GLAZE 100K JA 1/16W

R9024 401 224 8900 MT-GLAZE 100K JA 1/16W

R9025 401 225 1801 MT-GLAZE 47 JA 1/16W

R9026 401 261 7706 MT-FILM 56K DD 1/16W

R9027 401 261 8109 MT-FILM 33K DD 1/16W

R9028 401 261 2602 MT-FILM 10K DU 1/16W

R9029 401 225 0606 MT-GLAZE 5.6K JA 1/16W

R9030 401 237 2506 MT-GLAZE 4.7 JA 1/16W

R9031 401 224 9709 MT-GLAZE 22 JA 1/16W

R9032 401 224 9709 MT-GLAZE 22 JA 1/16W

R9034 401 224 9907 MT-GLAZE 22K JA 1/16W

R9035 401 225 0200 MT-GLAZE 3.3K JA 1/16W

R9036 401 224 8801 MT-GLAZE 100 JA 1/16W

R9037 401 224 8900 MT-GLAZE 100K JA 1/16W

R9038 401 258 0406 MT-GLAZE 120K DC 1/16W

R9039 401 224 9709 MT-GLAZE 22 JA 1/16W

R9040 401 224 9709 MT-GLAZE 22 JA 1/16W

R9041 401 261 7508 MT-FILM 100K DD 1/16W

R9043 401 224 8900 MT-GLAZE 100K JA 1/16W

R9045 401 261 8802 MT-FILM 24K DD 1/16W

R9046 401 224 8900 MT-GLAZE 100K JA 1/16W

R9047 401 224 8900 MT-GLAZE 100K JA 1/16W

R9501 401 301 1701 MT-GLAZE 200K DC 1/16W

R9502 401 261 8505 MT-FILM 47K DD 1/16W

R9504 401 105 7909 MT-GLAZE 0.000 ZA 1/16W

(SWITCHES)

S3001 645 045 2857 SWITCH,PUSH

S3002 645 045 2857 SWITCH,PUSH

S3003 645 045 2857 SWITCH,PUSH

S3004 645 045 2857 SWITCH,PUSH

S3005 645 045 2857 SWITCH,PUSH

S3006 645 045 2857 SWITCH,PUSH

S3008 645 029 5812 SWITCH,SLIDE 1P-3T

(FUSES)

PR501 423 028 0904 FUSE 32V 2A

PR502 423 028 1307 FUSE 32V 1.5A

PR503 423 028 1505 FUSE 32V 1A

PR504 423 028 1505 FUSE 32V 1A

(JACK)

JK501 645 050 0817 SOCKET,DC

(CONNECTORS)

CN110 645 049 1405 SOCKET,USB 5P

CN141 645 050 8431 PLUG,CARD 50P (N.S.P)

CN171 645 004 7183 SOCKET,FPC 24P (N.S.P)

CN951 645 037 6139 SOCKET,FFC 6P (N.S.P)

(MISCELLANEOUS)

636 063 8808 SPACER FL CONDENCER-117/U

Y1001 411 002 4901 SCR PAN 2X4

ACCESSORIES & PACKING MATERIALS

636 063 2004 CARTON CASE INNER-SB117/E,VPC-R1E ONLY

636 063 1991 CARTON CASE INNER-SB117/U,VPC-R1 ONLY

636 063 3599 CARTON CASE INNER-SB117EX,

VPC-R1EX ONLY

636 064 3642 CARTON CASE INNER-117/EX2,VPC-R1G ONLY

636 063 2042 REINFORCEMENT PAD,A-117/U

636 063 2059 REINFORCEMENT PAD,B-117/U

645 050 2248 CABLE,DSC USB,SB117

645 052 3182 DISC,CD-ROM DRIVER 117U[

Sanyo Software Pack 6.0],[PDF of the instruction

manual(English,German,French,Spanish)]

645 051 7518 DISC,CD-ROM MANUAL117ASIA,

[PDF of the instruction Manual(Chinese,Korea)],

VPC-R1G ONLY

9113 636 063 3490 INSTRUCTION MANUAL CAMERA(English)

9114 636 063 3506 INSTRUCTION MANUAL[About the PDF-format

instruction manuals]

9115 636 056 1007 STRAP HAND-SR662/J

9116 636 064 6070 INSTLUCTION MANUAL

[Sanyo Software Pack 6.0(English)]

9117 636 064 6087 INSTLUCTION MANUAL

[Panorama Sticher(English)]

9118 636 064 6094 INSTLUCTION MANUAL

[Ulead Photo Exprorer(English)]

STRAP HAND CABLE,DSC USB,SB117

AC Adaptor: VAR-G5U/G5EX/G5E (Option)

LOCATION PARTS NO. DESCRIPTION

645 030 1773 CORD,POWER-1.6MK, VAR-G5U ONLY

645 002 6805 CORD,POWER-1.875MK, VAR-G5EX ONLY

645 036 7434 CORD,POWER-1.2MK, VAR-G5E ONLY

N.S.P.

Cord, Power

N.S.P.: Not available as service parts.

(VAR-G5U)

(VAR-G5E)

(VAR-G5EX)

COMPL PWB,TB-1

636 062 8144

(SWITCH)

S3501 645 046 8452 SWITCH,PUSH 1P-2TX1,

26

Page 27

CIRCUIT DIAGRAMS & PRINTED WIRING BOARDS

TABLE OF CONTENTS

OVERALL WIRING & BLOCK DIAGRAMS

OVERALL WIRING C1

OVERALL CIRCUIT C2

CAMERA CIRCUIT C3

SYSTEM CONTROL CIRCUIT C4

LENS CIRCUIT C5

FLASH CIRCUIT

POWER SUPPLY CIRCUIT

CIRCUIT DIAGRAMS

CP1 BOARD (CAA) CAMERA C6

CP1 BOARD (CAB) MAIN, LCD DRIVER & LENS C7

CP1 BOARD (STA) FLASH & POWER SUPPLY C10

CP1 BOARD (SYA) SYSTEM CONTROL C13

MAIN & LCD DRIVER CIRCUIT WAVEFORMS C14

TB1 BOARD SWITCH

PRINTED WIRING BOARDS (P.W.B.)

CP1 P.W.B. (SIDE A & B) C15

TB1 P.W.B. (SIDE A & B)

Page 28

NOTES:

1. All resistance values in "OHMS" unless otherwise noted.

(K=1,000 ; M=1,000,000)

2. All capacitance values in "

p=pico farad ;

3. All inductance values in "

µ ,u or U=micro farad

µF" unless otherwise noted.

µH" unless otherwise noted.

µ ,u or U=micro henry ; m=milli henry

PRODUCT SAFETY NOTICE

THE COMPONENTS DESIGNATED BY A SYMBOL ( ) IN THIS

SCHEMATIC DIAGRAM DESIGNATES COMPONENTS WHOSE

VALUE ARE OF SPECIAL SIGNIFICANCE TO PRODUCT SAFETY.

SHOULD ANY COMPONENT DESIGNATED BY A SYMBOL NEED TO

BE REPLACED, USE ONLY THE PART DESIGNATED IN THE PARTS

LIST.

DO NOT DEVIATE FROM THE RESISTANCE, WATTAGE AND VOLTAGE RATINGS SHOWN.

EXPLANATORY NOTES (EXAMPLES)

Resistor 10K:1/16J means 10kilo ohm

1M:1/10K means 1mega ohm

Capacitor 0.047:F means 0.047micro farad, Ftype.

Electrolytic capacitor

10:16 means 10micro farad, 16volt max.

Inductor 330:J means 330micro henry ±5%

470:K means 470micro henry

No description J or K means

±5%, 1/16watt max.

±10%, 1/10watt max.

±10%

±5%

PAL-C-EX

Page 29

OVERALL WIRING & BLOCK DIAGRAMS

K

OVERALL WIRING

K

J

I

H

G

F

J

I

H

G

F

E

D

C

B

A

E

D

C

B

A

1 2 3 4 5 6 7 8 9 10111213141516171819

C1

Page 30

K

K

OVERALL CIRCUIT

J

J

SYA BLOCK

X3002

32.768KHz

I

8Bit Micro Controller

X3001

4MHz

SCAN OUT

SCAN IN

KEY

BUZZER

I

IC301

H

CAA BLOCK

IC905

G

CCDLENS

IC901

CDS

A/D

CAB BLOCK

IC102

ASIC

PTG

SIO

32BIT CPU

X1102

28.63636MHz

(MAIN)

CLOCK GENERATOR

X1101

48MHz

(USB)

H

G

IC171

RGB

FCP

VIDEO PLAYER

LCD DRIVER

F

LCD

DISPLAY

F

CN110

ITP

E

GPIO

MEMORY

CONTROLLER

COM PORT

USB I/F

E

IC121

D

FLASH MEMORY

D

IC103

SDRAM

CN141

C

CF CARD

B

C

B

A