Page 1

SOURCE

MENU

CH CH

VOL VOL

PDP TV

SERVICE MANUALPDP-32XS7

FILE NO.

PRODUCT CODE No.

PRODUCT CODE No.

1 682 344 44

REFERENCE No.:SM0915054

Page 2

CONTENTS

Safety precautions………………………………………………………………………..…

Alignment instructions …………………………….…….…………………………………

Method of software upgrading……………………………………………………………..

Working principle analysis of the unit……………………………….………….………….

Block diagram…………………………………..………………………………….…………

IC block diagram………………………………………………………………………..……

Wiring diagram …………………………………………………………………………….

Troubleshooting guide ………………………………………………………………..……

Schematic diagram…………………………………………………………………………

APPENDIX-A: Assembly list

APPENDIX-B: Exploded View

1

3

6

12

13

14

19

20

25

Page 3

Note: This maintenance manual is intended only for the reference of the maintenance people.

Please pay attention to the following points before carrying out the maintenance work.

Safety Precautions

Please read the “Points for attention for the Maintenance & Repair of PDP” and “Criterion for

Identifying the Defects on Screen” as below, before inspecting and adjusting the TV set.

1. “Points for attention for the Maintenance & Repair of PDP”

To avoid possible danger, damage or jeopardy to health and to prevent PDP screen from new

damage, the maintenance people must read the following carefully. If they ignore the following

warnings, there will be deathful risks:

1.1 Screens vary from one model to another and therefore not interchangeable. Be sure to use the

same type of screen in the replacement.

1.2 The operation voltage is approximately 350V for PDP module (including screen, driving circuit,

logic circuit and power module). If you want to conduct maintenance work on PDP module when the

set is in normal operation or just after the power is off, you must take proper measures to avoid

electric shock and never have direct contact or touch with the circuitry of the working module or

metal parts. That’s because within a short time relatively high voltage still remains on the capacitor

of the driving part even after the power is off. Make sure to begin relevant maintenance operation at

least one minute after the power is off.

1.3 Don’t apply on the module any power supply that is higher than the specification. If the power

supply used deviates from the value given in the specification, there might be a possibility of leading

to fire or damage to the module.

1.4 Never have operation or mounting work under unsuitable environment such as areas in the

vicinity of water – bathroom, laundry, water chute of kitchen – sources of fire, heat-radiation parts or

direct exposure to sunlight. Otherwise there will be kickbacks.

1.5 In case foreign substances such as water, liquid, metal slices or others fall into the module

carelessly power must be cut off immediately. Keep the module as it is and do not move anything on

the module. Otherwise it might be possible to contact the high voltage or cause shock short circuit

so that it may lead to fire or electric shock.

1.6 If there is smoke, abnormal smell or sound from the module, please cut the power off

immediately. Likewise in case the screen doesn’t work when the power is on or during the operation,

please also cut off the power at once. No more operation in this case.

1.7 Do not remove or plug its connection wire when the module is in operation or right after the

power is off. That’s because there remains a relatively high voltage on the capacitor of the driving

circuit. If there is a need to remove or plug in the connection wire, please wait at least one minute

after the power is off.

1.8 Considering the module has a glass faceplate, please avoid extrusion by external force lest it

should cause glass breakage that may get people injured. Two people are needed in cooperation to

move this module lest contingency takes place.

1.9 The complete TV set is designed on the basis of full consideration of thermal dissipation by

convection, with the round hole on the top for heat emission. To avoid overheat, please do not have

any covering on the hole during normal operation and never put it in the place where the space is

narrow and in bad ventilation.

1.10 There is quite a number of circuits in PDP that are integrated ones. Please be on guard against

1

Page 4

static electricity. During maintenance operation be sure to cover yourself with anti-static bag and

before operation make sure to have it sufficiently grounded.

1.11 There are a big number of connection wires distributed around the screen. Please take care

not to touch or scuff them during maintenance or removing the screen, because once they are

damaged the screen will fail to work and it’s not possible to repair it.

If the connection wires, connectors or components fixed by the thermotropic glue need to disengage

when service, please soak the thermotropic glue into the alcohol and then pull them out in case of

damage.

1.12 Connector for the circuit board of the screen part is relatively fine and delicate. Please take

care in the replacement operation lest it should get damaged.

1.13 Special care must be taken during transportation and handling because strenuous vibration

could lead to screen glass breakage or damage on the driving circuitry. Be sure to use a strong

outer case to pack it up before transportation or handling.

1.14 Please put it for storage in an environment in which the conditions are under control so as to

prevent the temperature and humidity from exceeding the scope stipulated in the specification. For

prolonged storage please cover it with anti-moisture bag and have them piled and stored in one

place. The environmental conditions are tabulated as below:

Temperature Scope for operation 0~50centigrade

Scope for storage -15~60centigrade

Humidity Scope for operation 20%~80%

Scope for storage 20%~80%

1.15 If a fixed picture is displayed for a long time, difference in its brightness and color may occur

compared with movable pictures. But it doesn’t show any problem and the reason is that there is

reduced density of fluorescent powder in the former. On the other hand, even if changes take place

in the picture, it can keep its brightness for a period of time (several minutes). It’s a feature inherent

with plasma and it’s not abnormal. However please try as much as possible to avoid showing a still

picture of high brightness for a long time during operation.

1.16 As a digitalized display devise, this module is provided with error diffusion technology and the

gray scale and false enhancement of contour can be displayed by reusing of sub-field. As compared

with cathode ray tube, it can be found in the moving picture that at the brim of the face of a person

there are some wrong colors.

1.17 During the display of graph (indicating the gradual change in brightness horizontally or

vertically) resulting from gray scale test it can be found that the brightness for the two adjacent

levels is uneven. This is caused by the reuse of sub-field, the display of load rectification and the

electrolysis.

1.18 The screen front plate is of glass. Please make sure that the screen has been put in place

during erection. If it is not in place before the erection begins it may lead to screen crack or

breakage.

1.19 Make sure the screw used in the mounting of the screen is of the original specs lest it should

cause damage to the screen due to mismatch. Special care should be taken not to use too long or

too big screw.

1.20 Care must be taken to guard against dust during assembling or dismantling, especially to avoid

dirt from falling in between the screen and the glass lest it should harm the receiving and viewing

2

Page 5

effect.

1.21 There is piece of insulator stuck on the rear chassis corresponding to the power supply board.

It is used to isolate the cool part from the hot part. Please take care to keep it intact lest it should

become a potential safety trouble.

1.22 In addition to plasma screen, the glass is a part of high value. It has such functions as

anti-radiation, adjustment of color temperature etc. Please handle it carefully.

Alignment instructions

1. Test equipment

PM5518 (video signal generator)

VG-848 (VGA, HDMI signal generator)

VG-849 (digital video signal generator)

CA210 (color analyzer)

2. Power test

Connect main board, power board and IR board according the wiring diagram, connect the power

and press “standby” to turn on the TV.

Test the pin voltage of XS15, the data is shown in table1:

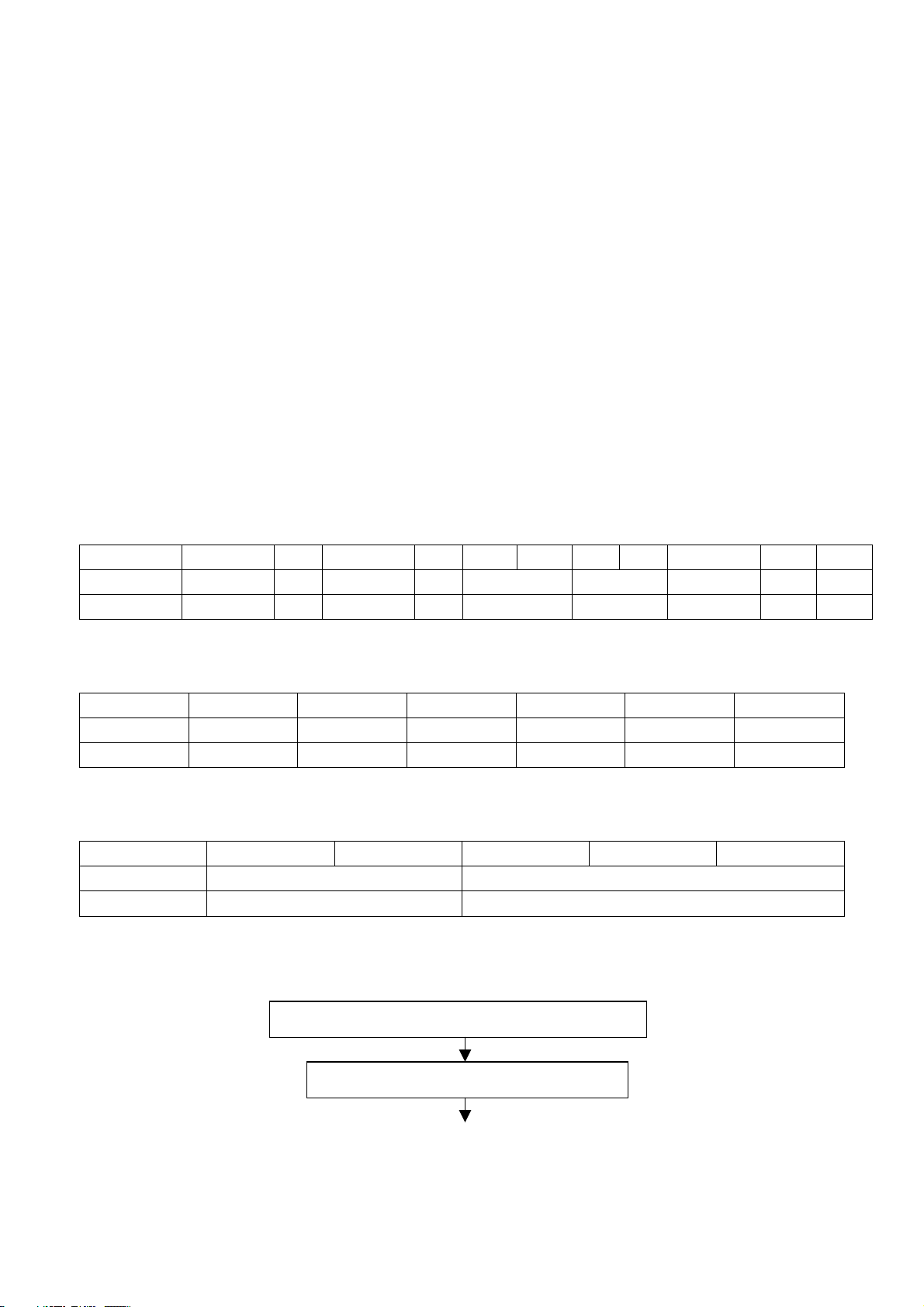

Table1 voltage data of XS15

Pin1 Pin2 Pin3 Pin4 Pin5 Pin6 Pin7 Pin8 Pin9 Pin10 Pin11

LC-26HUXX 8.55-9.45V 0 4.75-5.5V 0 11.69-12.92V 0 4.75-5.5V 0 H

LC-32HUXX 8.55-9.45V 0 4.85-5.36V 0 11.4-12.6V 0 4.85-5.36V 0 H

Test the pin voltage of XS16, the data is shown in table2:

Table2 voltage data of XS16

Pin1 Pin2 Pin3 Pin4 Pin5 Pin6

LC-26HUXX 0 4.75-5.5V 0 8.55-9.45V 0 30.4-33.6V

LC-32HUXX 0 4.85-5.36V 0 8.55-9.45V 0 31.36-32.64V

Test the pin voltage of XS11, the data is shown in table3:

Table3 voltage data of XS11

Pin1 Pin2 Pin3 Pin4 Pin5

LC-26HUXX 20.25-23.63V 0

LC-32HUXX 22.8-25.2V 0

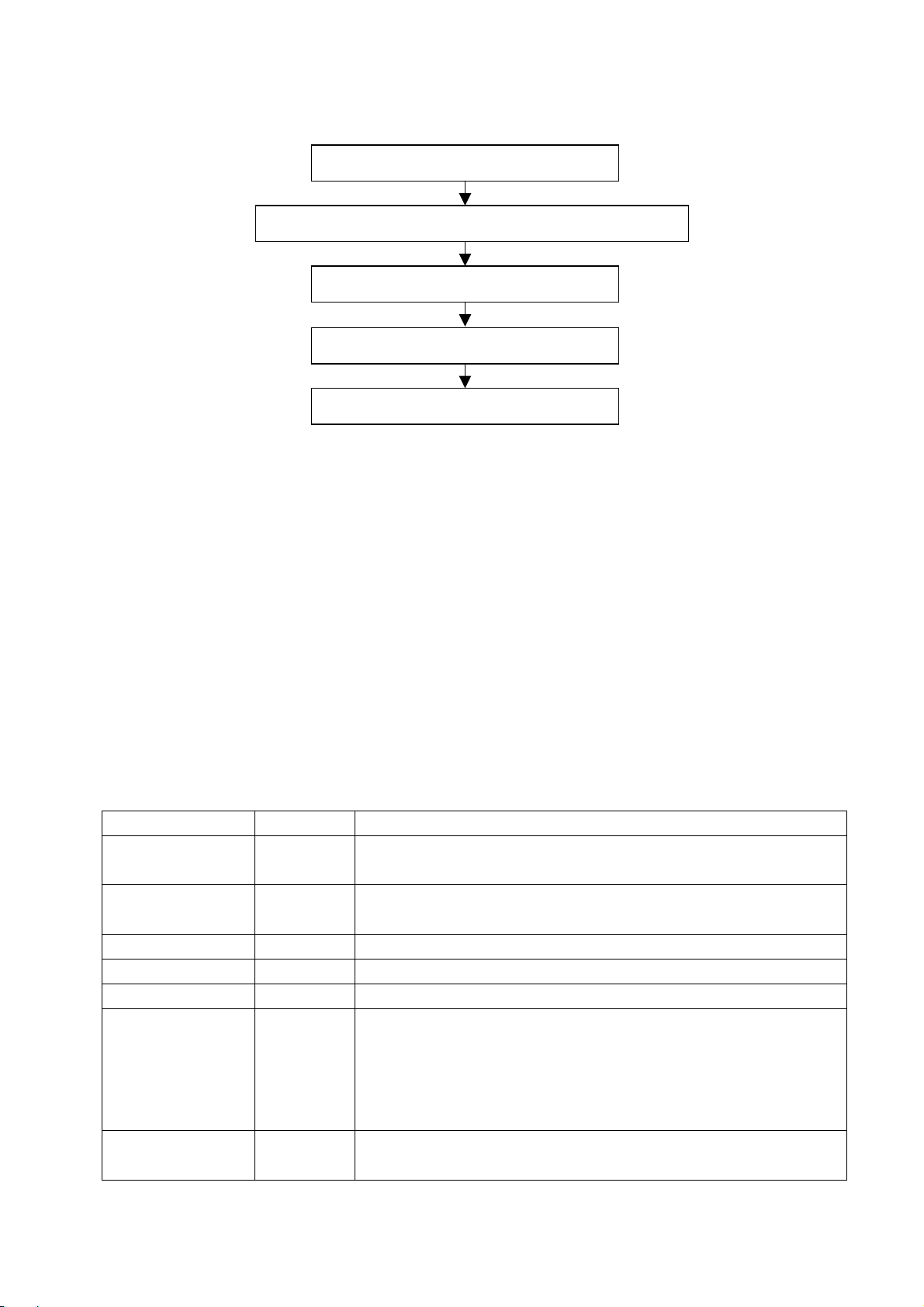

3. Alignment flow-chart

The alignment flow-chart is shown as fig-1

Check DDC, FLASH, HDCP and power control IC

Combined test for general assembly

3

Page 6

Factory initialization setup

IF channel voltage of TV and AGC voltage adjustment

White balance adjustment

Performance check

Preset ex-factory

Fig-1 adjustment flow-chart

4. Adjustment instruction

4.1 Unit adjustments

Connect all the boards according to wiring diagram, then power on and observe the display.

Method for entering factory menu: press “INPUT”, “2”, “5”, ”8” and “0” in turn to enter factory

menu; press “CH+” and “CH-” to select adjustment items and press “VOL+” and “VOL-” to adjust

value items, press “MENU” repeatedly to exit.

Method for software upgrading: When software upgrading please enter factory menu first, select

ISP of OPTION, set ISP to 1 and you can begin to upgrade. After upgrade finished, it needs to set

ISP back to 0. If the picture can’t display when upgrading, it needs to solder JB1 on main board.

Please unsolder JB1 again after upgrading.

4.2 Initialization

Enter factory menu, select “OPTION”, “EEPROM” and “HOTEL OPTION” sub-menu, adjustment of

items to see table4.

Table1 sub-menu adjustment

Items Preset Introduce

HOTEL 0 1: HOTEL OPTION of factory menu is optional

0: HOTEL OPTION of factory menu is not optional

LOGO 1 1: display LOGO in no signal or turn on

0: no LOGO display

ADC PRESCALE 046 Software will preset the data according unit

SIF PRESCALE 02E Software will preset the data according unit

BACK LIGHT FF Software will preset the data according the type of panel

ALL COLOR 1 1: white balance of each channel auto offset based on the HDMI white

balance

0: white balance of each channel adjust the offset base separately

Note: don’t set ALL COLOR to 1after the offset adjustment, if you do so, the

adjusted parameter of each channel will recover to the parameter of HDMI.

EEPROM-MEMORAY

RECALL

> EEPROM Initialization (operate when EEPROM data chaos)

4

Page 7

4.3 Adjustment for AFT voltage and AGC voltage of IF channel in TV

4.3.1 IF AFC adjustment

Disconnect J1(B face), input 38.9MHz PAL signal of 80dB to the pole of J1 near L11, Adjust L5

to value 1.25V of TP2. Enter factory menu, adjust TDA4470 from BG to LL, input 33.9MHz SECAM

signal of 80dB, adjust R71 to value 1.25V of TP2 then solder J1.

4.3.2 IF AGC adjustment

Input 184.25MHz(PAL/BG) RF signal of 60dBuv to RF terminal, adjust R64 to value 4V of TP4

and there should be no obvious snowy picture. Increase the signal to 90dBuv and it should be

display normally and no obvious noise.

4.4 White balance adjustment

4.4.1 white balance adjustment of HDMI

a. Input VG-849 signal from HDMI: TIMING854 (800* 600/60Hz) and eighth-level gray scale

signal of PAT920. Use color analyzer CA210 to adjust white balance.

b. Enter submenu of COLOR TEMP, Select 9300k of color temperature

c. Fixed value of B OFF, adjust R OFF and G OFF, let the color coordinate of the second level

be (285, 293) and the brightness be about 3nit-6nit. Fixed value of B GAIN, adjust R GAIN and G

GAIN, let the color coordinate of the seventh level be (285, 293). Adjustment R OFF, GOFF, R GAIN

and G GAIN repeatedly until the value of the two levels gray-scale are (285, 293).

4.4.2 VGA/YPBPR/AV white balance check and correct

a. Input VG-848 signal of VGA to VGA terminal: TIMING854(800*600/60Hz) (PATIERN:CROSS)

and auto adjust to full screen, then input PAT948 black/white signal, enter factory menu ADC ADJ,

select AUTOTUNE and wait for OK display. Input PAT920(8 gray levels), check if the white balance

is normal, if not, enter COLOR TEMP menu and set ALL COLOR to 0 and fine adjust according the

method of 4.4.1c)

b. Connect VG-848 signal of YPBPR to YPBPR terminal and input TIMING972(1080i/60HZ)

100% color bar of PAT976(include black/white bars), Enter ADC ADJ submenu, select AUTOTUNE

and wait for OK display. Input PAT920(8 gray levels), check if the white balance is normal, if not, set

ALL COLOR to 0 and fine adjust according the method of 4.4.1c)

c. Input AV signal (PM5518, 8 gray levels, NTSC) to VIDEO1 terminal, check if the white

balance is normal, if not, set ALL COLOR to 0 and fine adjust according the method of 4.4.1c)

Note: it can’t set back to 1 once ALL COLOR changes to 0.

5. Performance check

5.1 TV function

Enter searching menu → auto search, connect RF-TV terminal with central signal source and check

if the picture is normal, if there are channels be skipped. Check TXT and parental control.

5.2 AV, YPbPr terminals

Input AV/S, YPbPr/YCbCr HD signal, check if it is normal.

5.3 VGA terminal

Insert VGA terminal, input VGA format signal of 640X480@60 Hz and check if the display is normal.

5.4 check sound channel

Check the speaker of each channel.

5.5 other function check

Check the turn on/turn off timer, asleep timer, picture/sound mode, OSD, freeze/mute, stereo, etc.

5

Page 8

5.6 presetting before ex-factory

Item Setting Item Setting Item Setting

PICTURE MODE STANDARD BALANCE 50 OSD LANGUAGE English

COLOR MODE NORMAL VOLUME 50 OSD HPOSITION 50

NR WEAK SLEEP TIMER OFF OSD VPOSITION 50

ZOOM FULL TTX LANGUAGE WEST OSD HALFTONE 50

SOUND MODE STANDARD BLUE SCREEN OFF OSD DURATION 15

AVC OFF WSS OFF

6. Software instruction

Table6 software instruction

No. Code No. Type Function Flash written

before paste

NS14 5270008001 ATMEGA8L Power image Yes

NS3 5272540001 PM25VF040 Main CPU program Yes

NB3 5272402002 24C02N-10SI27 HDMI EDID Yes

NB7 5272402002 24C02N-10SI27 VGA EDID Yes

NS5 5272404002 24C02N-10SI27 Store some important

information

No No written

Method

Written with

instrument like

ALL11

software

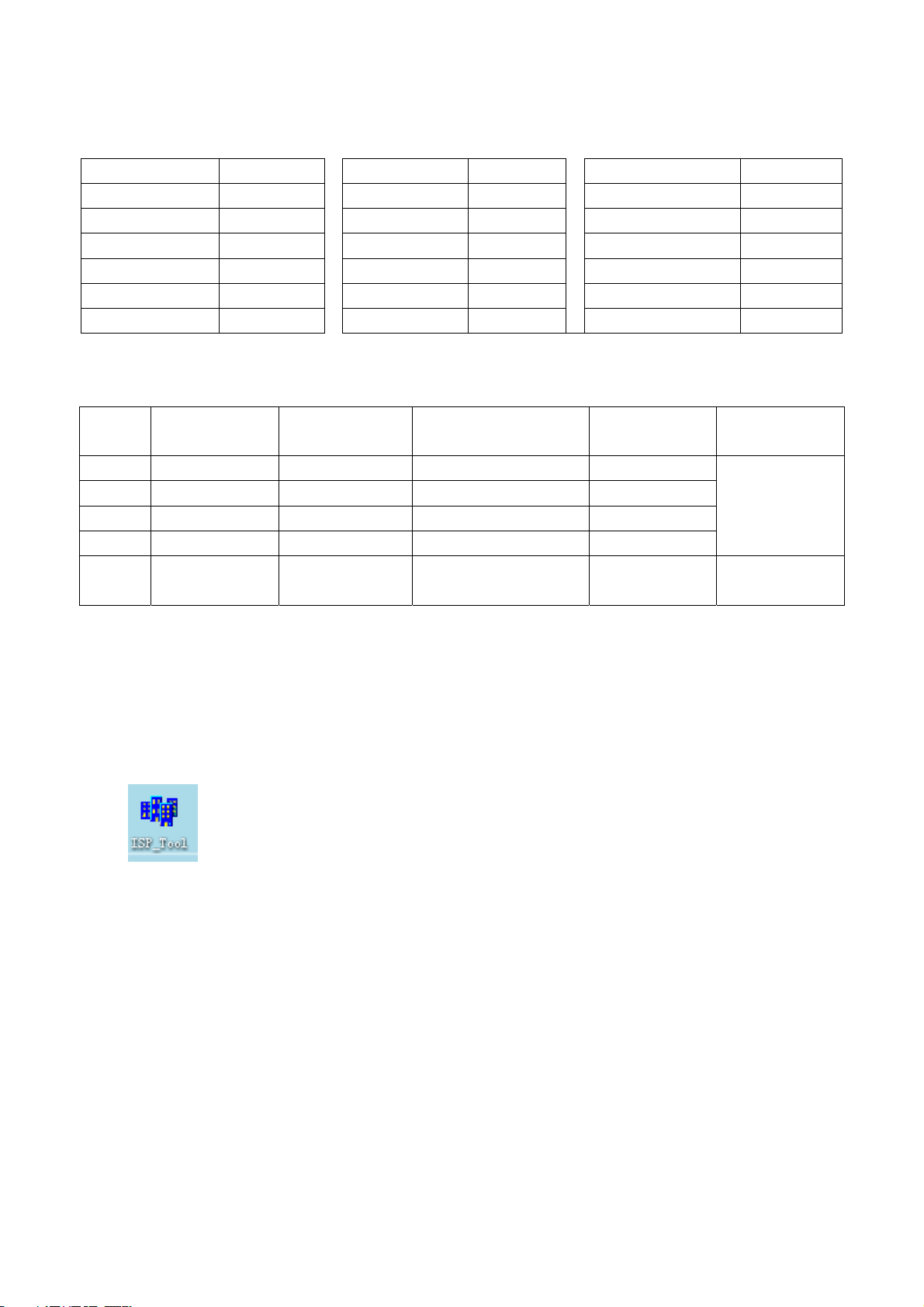

Method of software upgrading

1. The tools and software demanded

1) Please confirm that PC has the software of ISP_TOOL and install the parallel interface drive

program Port95nt.

2) ISP_TOOL icon is bellow:

3) One parallel cable (25 pins) and one VGA cable (15 pins), the parallel cable connects the PC and

the upgrade instrument, the VGA cable connects the TV and the upgrade instrument.

2. The steps for upgrading software

1) Please confirm that the connection wires and the upgrade instrument are connected well before

the software written and then power on the TV.

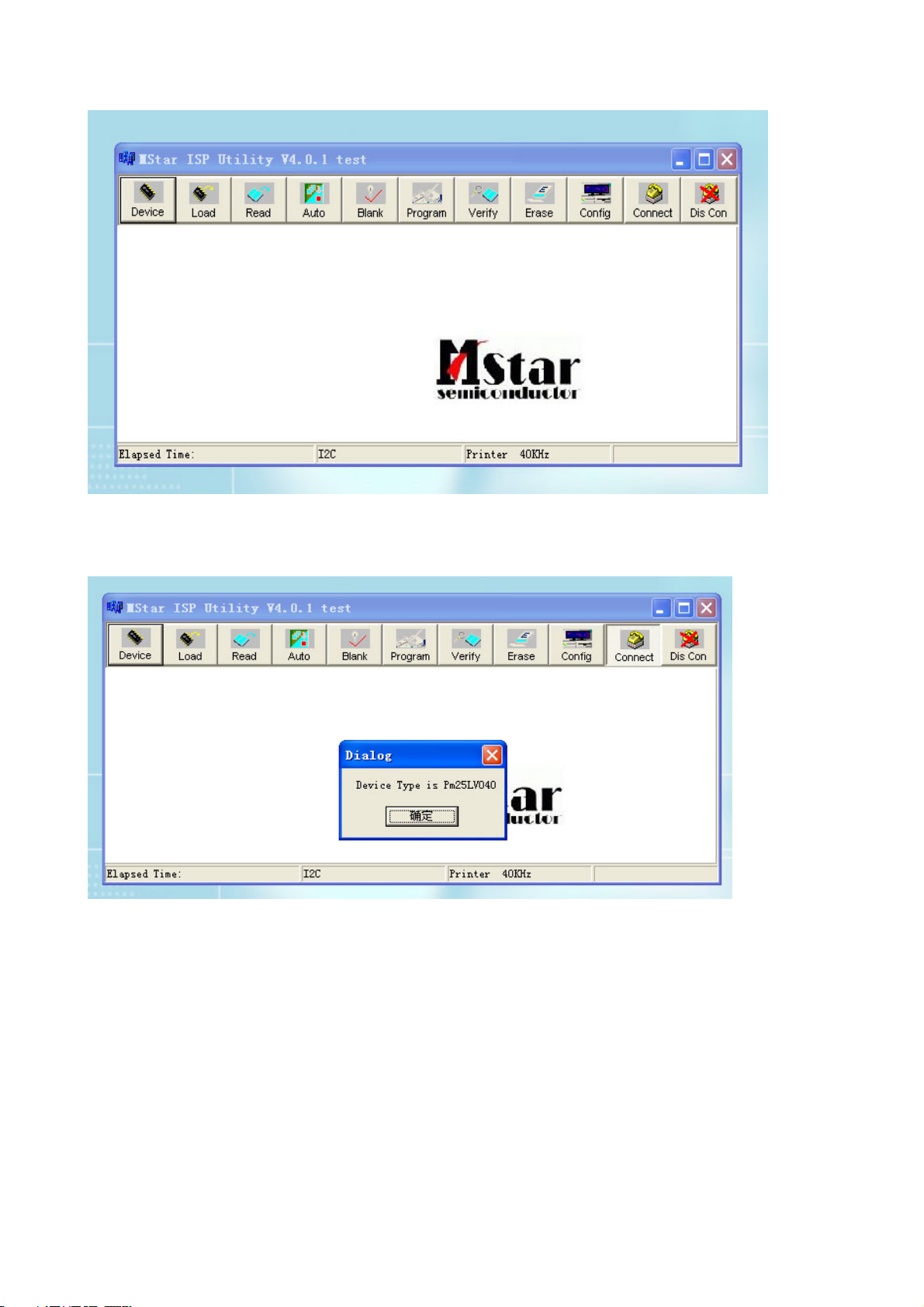

2) Double click the icon ISP_TOOL to open it:

6

Page 9

3) Press “Connect“ to connect TV, if the connection is done successfully as shown below, then

press “enter”.

Note: if it appears error, check the connection wires and check if ISP item of the factory menu is set

to 1, if not, please set it to 1.

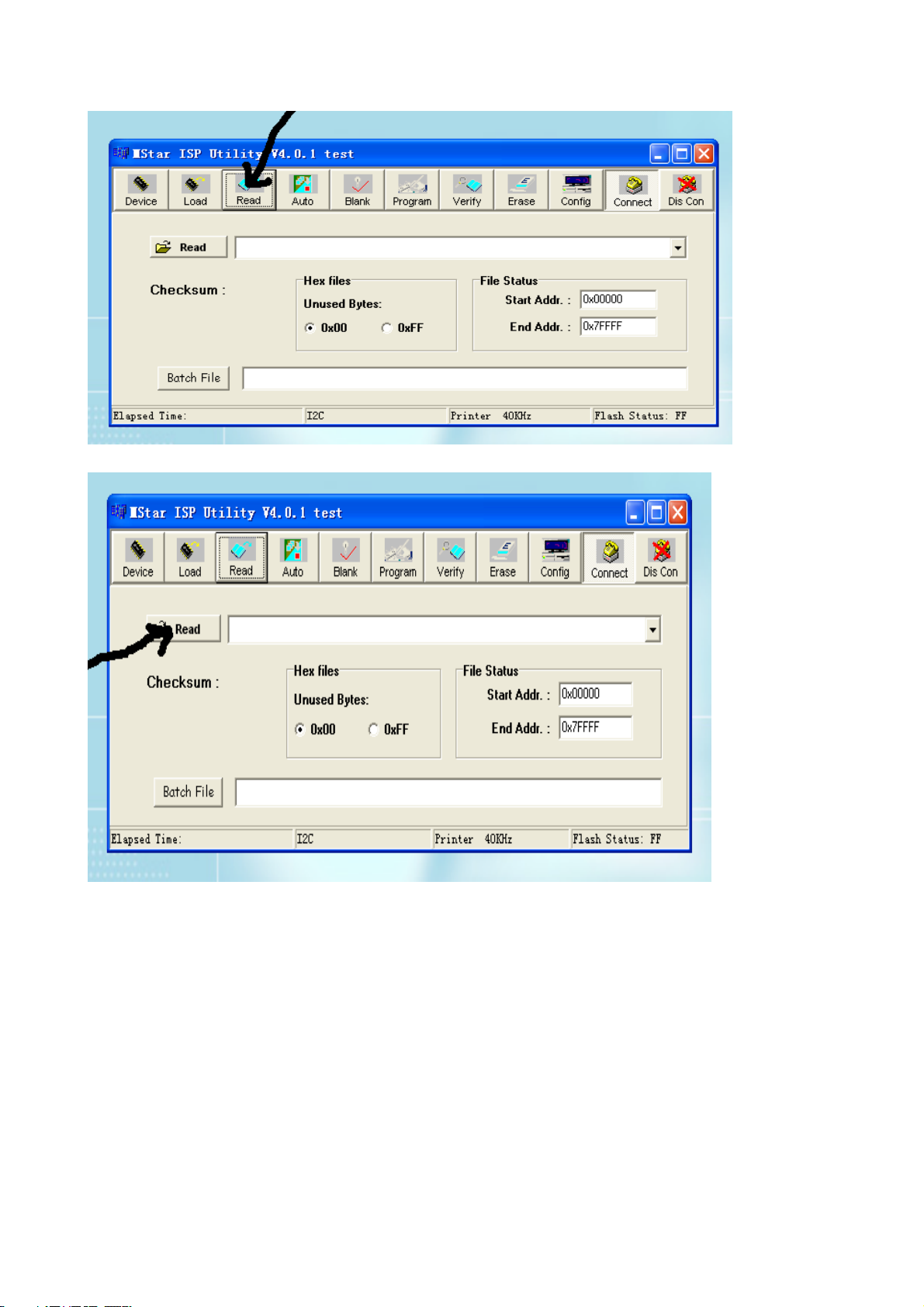

4) After connection is done, it needs to read the Binary document. Press “Read” as shown below:

7

Page 10

5) Search the document needed to write in the “Read” check box.

8

Page 11

Select

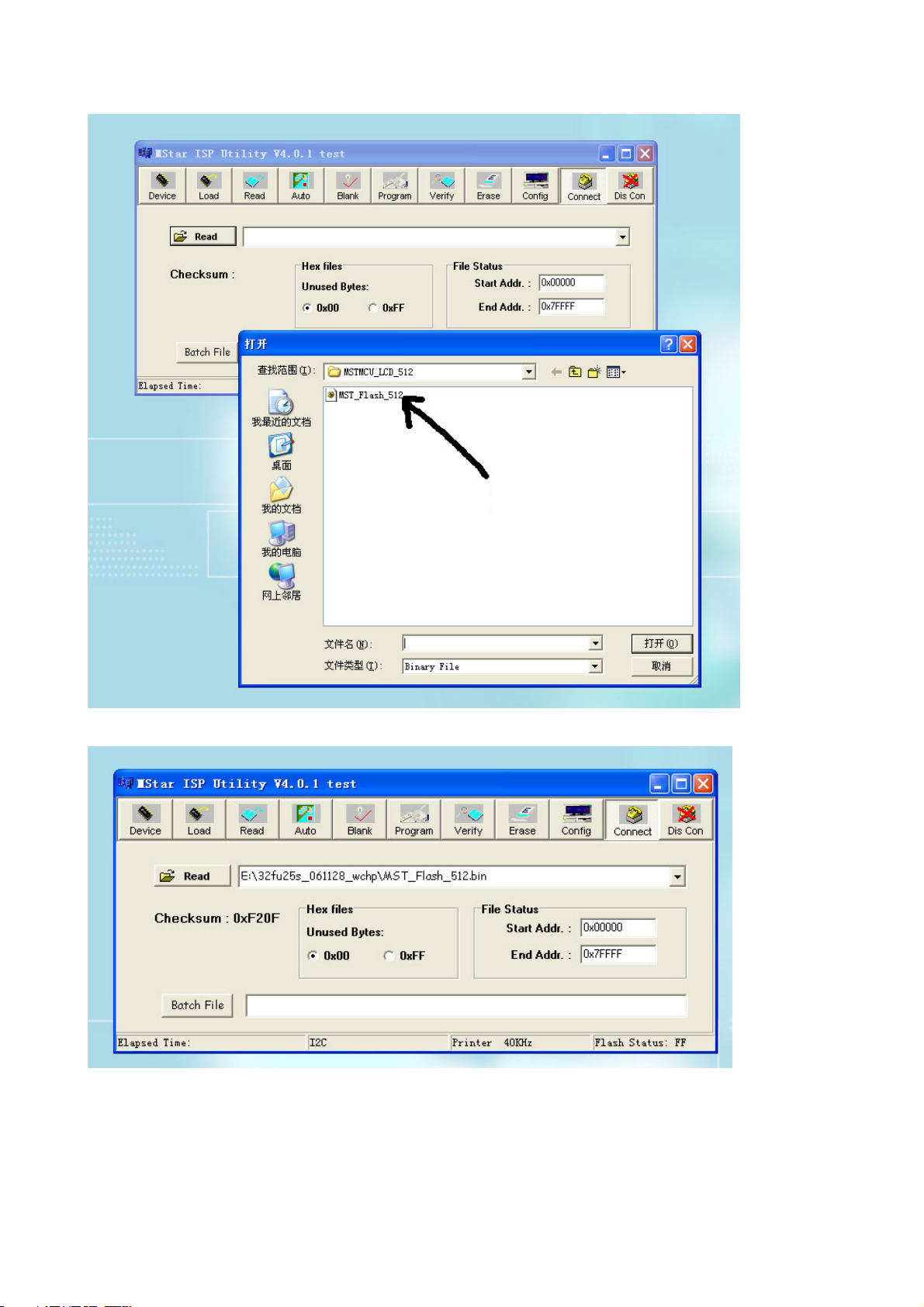

6) Select the document then the window will appear as shown below:

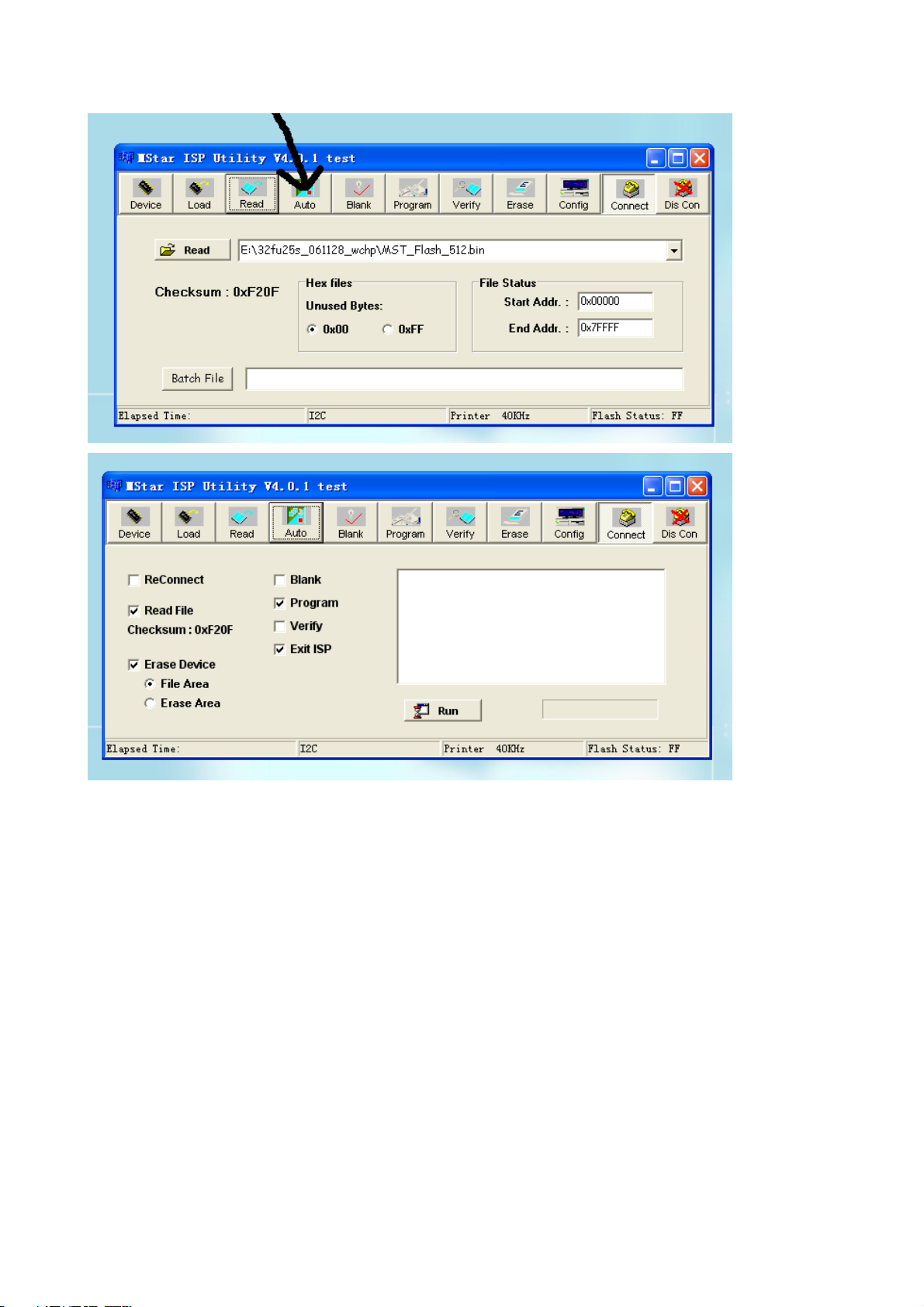

7) Press “Auto” to select the writing function.

9

Page 12

Select the items shown in the picture above:

(a) Read File

(b) Program

(c) Exit ISP

(d) Erase Device

(e) File Area

8) Press “Run” to begin the writing program, wait till the blue bar is complete.

10

Page 13

After writing, it will display OK:

If there is error appeared (shown as below), press “Run” again to rewrite the program till it is

success.

Note1: keep the connection well and don’t cut off the power during the writing process.

Note2: the writing speed can be adjusted as shown below. Select “Config” then adjust Speed BAR,

11

Page 14

the value is bigger the speed is faster. But it is easier to appear error when increase the speed, so it

need to select a suitable speed according the PC.

Step 1

Step 2

Working principle analysis of the unit

The RF signal received by antenna will be sent to tuner TUNER101, then IF signal will be

obtained through high amplifier and mixed frequency, through pre-intermediate amplified by V15,

then it will be sent to acoustic surface-wave Z17 to do IF filter and get better IF characteristics, then

it will be sent to N3 (TDA4470) to do intermediate amplification, phase-locked loop VCO and

synchronous wave detection to get video signal TV-V; after pre-intermediate amplification IF will

also be sent to acoustic surface-wave Z16 to do filter at the same time, then it will be sent to

TDA4470 to do intermediate amplification and output the second sound intermediate frequency

signal (TV-SIF).

The TV-V signal output from TDA4470 together with TV-SIF will be sent to main IC

NS2(MST9E19B).

Video signals of VGA and HDMI will be sent to MST9E19B, too.

Video signal of YPbPr and Video RGB of SCART1 via video switch NB24(PI5V330) will be sent

to MST9E19B.

Video signal V (CVBS) of SCART1, YPbPr L/R and SCART1 L/R will be sent to MST9E19B.

The main IC NS2(MST9E19B) is a high performance and fully integrated IC, which can realize

HDMI processing, video demodulating, video switch selection, A/D and D/A conversion,

interlace/de-interlace processing, modes conversion, OSD and low-voltage differential output, etc.

And it also has functions of audio selection, processing and MCU.

The video signal via MST9E19B processing, output 4 pairs differential signal and 1 pair clock

signal for PDP panel display. TV-V output from TDA4470 via double video amplifying, it will be sent

to SCART1 for AV-OUT.

Audio signal via MST9E19B processing will be sent to sound amplifier NV4 (R2S15102NP)

amplifying to speaker. TV-SIF via MST9E19B demodulating and sound processing then output to

NV3(LM358D) amplifying, the signal will be sent to SCART1 as AV-OUT.

12

Page 15

Block diagram

VGA

YPbPr

SCART1-RGB

SCART1-V

SCART1-L/R

HDMI

L/R-VGA

L/R-YPbPr

L/R

TUNER

HDTV SW.

PI5V330

PRE AMP

SAW

TV-SIF

TV-V

SCART1-V OUT

TV-L/R SCART1-L/R OUT

IF AMP

TDA4470

EDID

24C02

2*AMP

POWER MEG.

ATMEG8 L

LCD TV

CONTROLLER

MST9E19B

FLASH

EEPROM

PANEL

AUDIO AMP .

R2S15102NP

SPEAKER

PRE AMP

LM358D

13

Page 16

IC block diagram

1. MST9E19A

The MST9E19A is a high performance and fully integrated IC for multi-function LDC monitor/TV with

resolutions up to SXGA (1280X1024)/WXGA+(1440X900). It is configured with an integrated

triple-ADC/PLL, an integrated DVI/HDCP/HDMI receiver, a multi-standard TV video and audio

decoder, a video de-interlacer, a scaling engine, the MStarACE-3 color engine, an on-screen

display controller, an 8-bit MCU, and a built-in output panel interface. To further reduce system costs,

the MST9E19A also integrates intelligent power management control capability for green-mode

requirements and spread-spectrum support for EMI management.

14

Page 17

2. R2S15102NP

15

Page 18

16

Page 19

3. TDA4470

The TDA4470 is an integrated bipolar circuit for multi-standard video/sound IF(VIF/SIF) signal

processing in TV/VCR and multimedia applications. The circuit processed all TV video IF signals

with negative modulation (e.g., B/G standard), positive modulation (e.g., L standard) and the AM,

FM/NICAM sound IF signals.

17

Page 20

18

Page 21

Wiring diagram

patch plug

patch plug

signal board

power board

patch plug

patch plug

patch plug

patch plug

patch plug

patch plug

patch plug

main board

brown

blue

power switch

brown

blue

weld

weld

weld

fix the screws on the metal frame of the panel

ground (yellow and green wire)

weld

patch plug

three-pin power plug

IR board

patch plug

key board

speaker socket

19

Page 22

Trouble shooting

1. Fault clearance

Before servicing please check to find the possible causes of the troubles according to the table

below.

1.1 Antenna (signal):

Picture is out of focus or jumping Bad status in signal receiving

Poor signal

Check if there are failures with the electrical connector or

the antenna.

Check if the antenna is properly connected.

Fringe in picture Check if the antenna is correctly oriented.

Maybe there is electric wave reflected from hilltop or

building.

Picture is interfered by stripe shaped

bright spots

There appear streaks or light color

on the screen

1.2 TV set:

Symptoms Possible cause

Unable to switch the power on Check to see if the power plug has been inserted properly

No picture and sound Check to see if the power supply of liquid crystal TV has

Deterioration of color phase or color

tone

Screen position or size is not proper Check is the screen position and size is correctly set up.

Picture is twisted and deformed Check to see if the picture-frame ratio is properly set up.

Picture color changed or colorless Check the “Component” or “RGB” settings of the liquid

Possibly due to interference from automobile, train, high

voltage transmission line, neon lamp etc.

Maybe there is interference between antenna and power

supply line. Please try to separate them in a longer

distance.

Maybe the shielded-layer of signal wire is not connected

properly to the connector.

Check if interfered by other equipment and if interfered

possibly by the equipment like transmitting antenna,

non-professional radio station and cellular phone.

into the socket.

been switched on. (As can be indicated by the red LED at

the front of the TV set)

See if it’s receiving the signal that is transmitted from other

source than the station

Check if it’s connected to the wrong terminal or if the input

mode is correct.

Check if the signal cable connection between video

frequency source and the liquid crystal TV set is correct.

Check if all the picture setups have been corrected.

crystal TV set and make proper adjustment according to the

20

Page 23

signal types.

Picture too bright and there is

distortion in the brightest area

Check if the contrast setting is too high.

Possibly the output quality of DVD broadcaster is set too

high.

It maybe also due to improper terminal connection of the

video frequency signal in a certain position of the system.

Picture is whitish or too bright in the

darkest area of the picture

Check if the setting for the brightness is too high

Possibly the brightness grade of DVD player (broadcaster)

is set too high.

No picture or signal produced from

the displayer if “XXX in search”

appears.

There appears an indication -

“outside the receivable scope)

Check if the cable is disconnected.

Check if it’s connected to the proper terminal or if the input

mode is correct.

Check if the TV set can receive input signal. The signal is

not correctly identified and VGA format is beyond the

specified scope.

Remote control cannot work

properly

Check if the batteries are installed in the reverse order.

Check if the battery is effective.

Check the distance or angle from the monitor.

Check if there is any obstruct between the remote control

and the TV set.

Check if the remote control signal- receiving window is

exposed to strong fluorescence.

No picture and sound, but only

hash.

Check if the antenna cable is correctly connected, or if it

has received the video signal correctly.

Blur picture Check if the antenna cable is correctly connected.

Of if it has received the right video signal.

No sound Check if the “mute” audio frequency setting is selected.

Check if the sound volume is set to minimum.

Make sure the earphone is not connected.

Check if the cable connection is loose.

When playing VHS picture search

tape, there are lines at the top or

bottom of the picture.

When being played or in pause VHS picture search tape

sometimes can’t provide stable picture, which may lead to

incorrect display of the liquid crystal TV, In this case please

press “auto” key on the remote control so as to enable the

liquid crystal TV set to recheck the signal and then to

display correct picture signal

21

Page 24

2. Troubleshooting guide

k

f

p

d

d

p

2.1. No raster

Turn-on power supply, chec

if the red indicator is light in

the STANDBY?

no

Check if PIN9(5V) of XS15

on main board is normal?

no

Check STANDBY circuit o

ower supply board

yes

Press POWER button in the

unit or sensor control an

check the indicator.

blue

Check the power board an

anel drive

no

Check NS14 and its

peripheral circuit

red

Check if the PIN1, 2of XS15

on main board is low-level?

yes

Check the power

supply board

22

Page 25

2.2. Raster, but no picture

y

p

d

f

V

t

f

n

p

p

N

Check if the unit button

and remote control

operation?

yes

no

no

Replace

main board

no

Enter factory-menu,

initialization EEPROM,

then turn off the TV,

turn on again, displa

icture?

Adjust main boar

Check TUNER101

and its periphery

Does display OSD

menu in screen when

ress menu button?

yes

again

yes

no

yes

yes

Check if 1VPP signal

and noise wave o

TP1 on the T

board?

Check if all channels

have no signal?

Which is no signal

of channels

TV

no

Check if outpu

IF signal o

TUNER101 (pi

11) is normal?

yes

Check N3 and its

eriphery

YPRPB/SCART(RGB)

no

VGA/SCART(CVBS)/HDMI

Replace

main board

Check if NB24

output signal?

yes

Replace

main board

no

Replace

B24

23

Page 26

2.3.no sound

d

N

p

p

p

Check if PIN2, 9,10 an

14 voltage of NV4 is

normal?

Check power supply

no

yes

Check the wave of

PIN5,11 of NV4

no

Check PIN24 wave of

3

no

Check PIN11 wave of

TUNER101

no

Check TUNER101 and

its periphery

yes

yes

yes

Check NV4 and its

eriphery

Check NS2 and its

eriphery

Check N3 and its

eriphery

24

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

APPENDIX-A: Main assembly 9432HU3522

NAME NO.

Main board

IR board

Key board

Remote control

Panel

6HU06801G0

6HU0660910

6HU0660510

6010Y03507

5205321202

MAIN COMPONENT AND IT'S NO.

N3

NV4

NS2

RC-Y35-0F

PDP32F1X031

TDA4470M (5274470001)

R2S15102 (5271510201)

MST9E19B (5270919002)

Page 33

APPENDIX-B: Exploded view (PS-32X35)

Page 34

PART LIST OF EXPLODED VIEW

NO. DESCRIPTION

1 front cabinet

2 glass for filter

3 pressing board(top)

4 pressing board(left)

5 display panel

6 connection bracket

7 wall-mounting bracket

8 main frame

9 digital processing board

10 back cover

11 decorative bar

12 speaker

13 power button

14 IR assembly

15 key board

16 pressing board(bottom)

17 pressing board(right)

18 back baffle

19 back cover for bottom speaker

20 screw

21 stand

Note: design and specifications are subject to change without notice.

Page 35

PART LIST ———————————————————————————

—

PDP-32XS7 ver. 1.0

REF NO. PARTS NO. DESCRIPTION QTY. REMARK

1 5Q635L1010 front cabinet 1

2 5710152000 glass for filter 1

3 5810062500 pressing board(top) 1

4 5810062700 pressing board(left) 1

5 5205321203 display panel 1

6 6153157000 connection bracket 2

7 58A0066600 wall-mounting bracket 2

8 5740211010 main frame 1

9 6HE0106910 digital processing board 1

10 5H635L101A back cover 1

11 573G245010 decorative bar 1

12 6170770000 speaker 1

13 5906063210 power button 1

14 6HE0100910 IR assembly 1

15 6HU0660510 key board 1

16 5810062600 pressing board(bottom) 1

17 5810062800 pressing board(right) 1

18 5810H6291A back baffle 1

19 5750301010 back cover for bottom speaker 1

20 5981340141 screw 18

21 6150091100 stand 1

· Only the parts in above list are used for reparing.

· Other parts except the above parts can't be supplied.

Page 36

Removing or Installing the Stand

Cautions:

1. Carefully handle the unit during setup and consult authorized service personnel to ensure successful

installation.

2. Before performing work spread cushioning over the base area to lay the Display on. This will prevent it from

being damaged.

3. Disconnect the AC power cord firstly.

To remove the stand: (if wall mounting)

1.Lay your TV flat (screen down) on a table or bench. Make sure that you put down a soft cushion or cloth so that your TV

is not scratched.

2.Loosen the four M4 screws on the Stand to remove the Stand. (Please keep these screws for future use if you want

to install the stand again.)

Remove four screws

To install the stand

1.Lay your TV flat (screen down) on a table or bench. Make sure that you put down a soft cushion or cloth so that your TV

is not scratched.

2. Align the holes in the stand column with the holes in the TV back, and then secure the stand to the TV with four M4

screws.

Use four screws to secure

the stand to the TV

Note

Note

NoteNote

! Do not remove the stand from the TV unless using an optional bracket to mount it.

! The appearance of the unit may differ from the actual one.

Page 37

WALL MOUNTING INSTRUCTIONS

Safety Precautions:

1. Be sure to ask an authorized service personnel to carry out setup.

2. Thoroughly read this instruction before setup and follow the steps below precisely.

3.The wall to be mounted should be made from solid materials. Only use accessories supplied by the manufacturer.

4.Very carefully handle the unit during setup. We are not liable for any damage or injury caused by mishandling or improper installation.

5.Be sure to place the unit on a stable and soft platform which is strong enough to support the unit.

6.Do not uplift the speaker when moving the display. The appearance of the unit may different from the actual ones.

7.Design and specifications are subject to change without notice.

8. Retain these instructions for future reference.

Note: All the wall mounting parts are optional and may be unavailable in your model.

Below we will show you how to mount the Display on the wall using our company’s wall mounting components.

11

Take out these parts from the box.

Wall Mounting

Component

(including bracket

and connector)

Expansion Bolt

Wood Screw

M4 Screw

Fig. 1

Fully insert the two insertions on the wall mounting connector into the

44

locating grooves on the wall mounting bracket from top to bottom end.

22

Screw 4pcs expansion bolts to fix

the wall mounting bracket on the

wall.

Wall

Wall Mounting Bracket

Fig. 2a

If your wall is a wooden structure, please

fix the wall mounting bracket on the wall

with 8 pcs wood screws.

Wall

Wall Mounting Bracket

Fig. 2b

55

Use screwdriver to revolve the Clasper to the Positioner

following the direction of the arrow.

33

Use the 4pcs M4 screws to fix the wall

mounting connector to the rear of the

display unit.

Wall Mounting Connector

Fig. 3

Clasper

Positioner

Fig. 4

Fig. 5

Page 38

March/2009

Loading...

Loading...