Page 1

FILE NO.

Multimedia ProjectorSERVICE MANUAL

Model No. PDG-DXL2000

U.S.A, Canada, Europe,

U.K, Asia, Brazil

Original Version

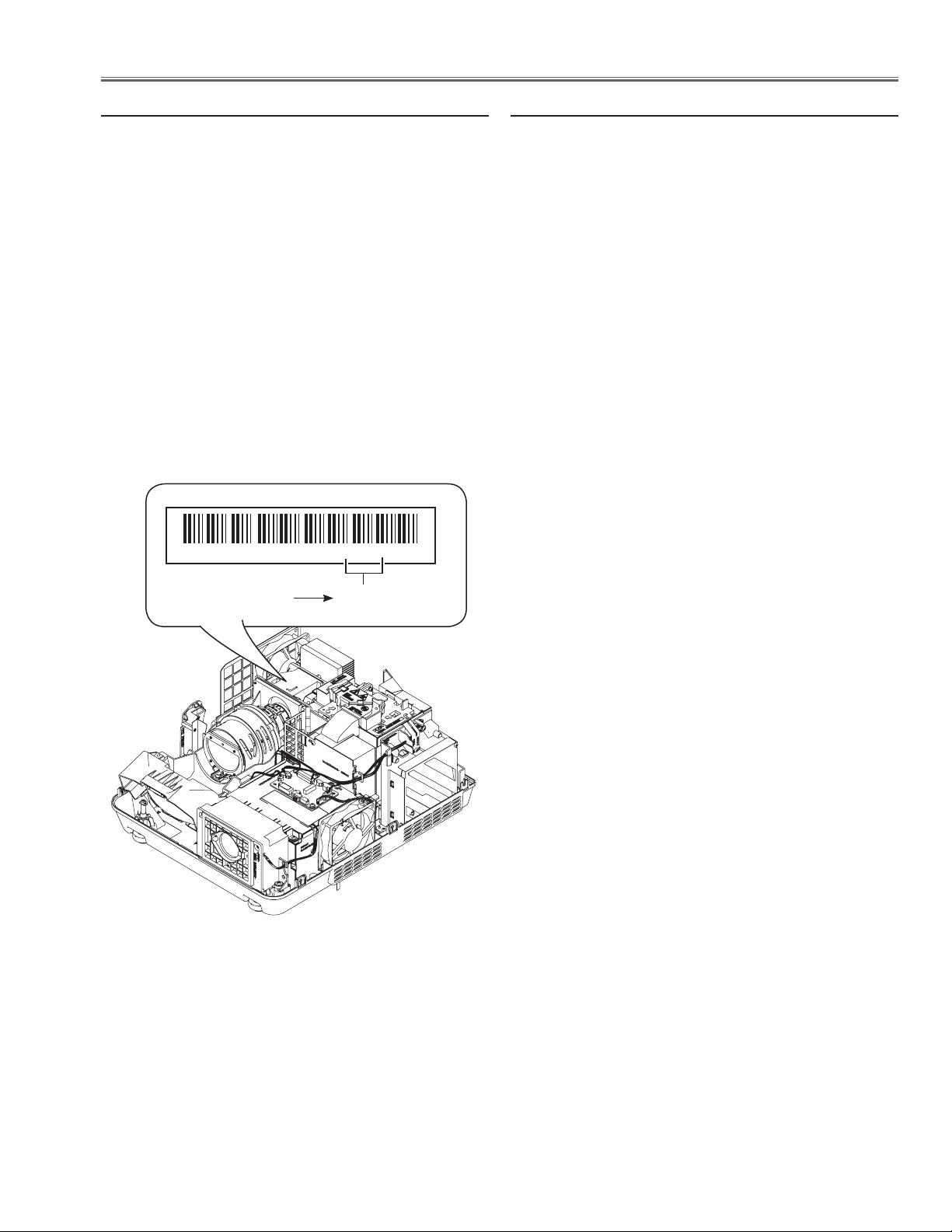

Chassis No. KV8-DXL200000

PRODUCT CODE

1 122 529 00 (KV8AC) USA, Canada

1 122 529 04 (KV8EC) Brazil

1 122 530 00 (LV8AC) Asia

1 122 530 02 (LV8CC) HK

1 122 530 03 (LV8DC) Europe, UK

Match the Chassis No. on the rating label on the projector

with the Chassis No. in the Service Manual.

If the Original Version Service Manual Chassis No. does

not match the projector’s, additional Service Literature is

required. You must refer to “Notices” to the Original Service Manual prior to servicing.

REFERENCE NO. SM5111287-00

Page 2

Contents

SERVICE MANUAL ....................................................... 1

Contents ........................................................................2

Safety Instructions .........................................................

Safety Precautions .....................................................

Product Safety Notice .................................................

Service Personnel Warning ........................................

Specifications ................................................................4

Circuit Protections .........................................................

Thermal switch ...........................................................

Fuse ............................................................................ 5

Lamp cover switch ......................................................

Warning temperature and power failure protection ....

Maintenance .................................................................. 7

Replacing the Filter .....................................................

Resetting the Filter Counter ......................................

Lamp Replacement ....................................................

Resetting the Lamp Counter .....................................

How to check Lamp Used Time ................................

Cleaning ................................................................... 10

Security Function Notice ..............................................

Resetting procedure ................................................

Standby Mode Notice ..................................................

Mechanical Disassembly .............................................

Adjustments ................................................................. 22

Adjustments after Parts Replacement ......................

Note on Main Board Replacement ...........................

Service Adjustment Menu Operation ........................

Circuit Adjustments ...................................................

Service Adjustment Data Table ................................

Chassis Block Diagrams ..............................................

Chassis over view .....................................................

System control ..........................................................

Power supply & protection circuit .............................

Fan control circuit .....................................................

Troubleshooting ........................................................... 38

Indicators and Projector Condition ...........................

No Power ..................................................................

No Picture .................................................................

No Sound ..................................................................

Error Log ...................................................................

Control Port Functions .................................................

System Control (DDP, IC401) ..................................

IIC Bus D/A Converter (Fan Control, IC7881) ..........

11

11

12

13

22

22

22

23

26

34

34

35

36

37

38

39

40

41

42

43

43

44

IC Block Diagrams .......................................................

Parts Location Diagrams .............................................

3

Mechanical Parts List ..................................................

3

Electrical Parts List ......................................................

3

3

Diagrams & Drawings ..................................................

Parts description and reading in schematic diagram ...

5

Schematic Diagrams ...................................................

5

Printed Wiring Board Diagrams ...................................

Pin description of diode, transistor and IC .................

5

Note on Soldering ......................................................

6

7

7

8

9

9

45

50

54

55

A1

A2

A3

A9

A13

A14

-2-

Page 3

Safety Instructions

Safety Precautions

WARNING:

The chassis of this projector is isolated (COLD) from AC line by using the converter transformer. Primary side

of the converter and lamp power supply unit circuit is connected to the AC line and it is hot, which hot circuit is

identified with the line ( ) in the schematic diagram. For continued product safety and protection of personnel injury, servicing should be made with qualified personnel.

The following precautions must be observed.

1: An isolation transformer should be connected in

the power line between the projector and the AC

line before any service is performed on the projector.

DO NOT OPERATE THIS PROJECTOR WITHOUT

THE PROTECTIVE SHIELD IN POSITION AND PR

OPERLY SECURED.

2: Comply with all caution and safety-related notes

provided on the cabinet back, cabinet bottom, inside

the cabinet or on the chassis.

3: When replacing a chassis in the cabinet, always

be certain that all the protective devices are

installed properly, such as, control knobs, adjustment covers or shields, barriers, etc.

4: Before replacing the cabinet cover, thoroughly

inspect the inside of the cabinet to see that no stray

parts or tools have been left inside.

Before returning any projector to the customer, the

service personnel must be sure it is completely safe

to operate without danger of electric shock.

Product Safety Notice

Product safety should be considered when a component replacement is made in any area of the projector.

Components indicated by mark ! in the parts list and the schematic diagram designate components in which

safety can be of special significance. It is, therefore, particularly recommended that the replacement of there

parts must be made by exactly the same parts.

Service Personnel Warning

Eye damage may result from directly viewing the light produced by the Lamp used in this equipment. Always

turn off Lamp before opening cover. The Ultraviolet radiation eye protection required during this servicing.

Never turn the power on without the lamp to avoid electric-shock or damage of the devices since the stabilizer

generates high voltages (15kV - 25kV) at its starts.

Since the lamp is very high temperature during units operation replacement of the lamp should be done at least

45 minutes after the power has been turned off, to allow the lamp cool-off.

-3-

Page 4

Specifications

Mechanical Information

Projector Type Multi-media Projector

Dimensions (W x H x D) 12.6" x 6.7" x 15.2" (321.0 mm x 170.0 mm x 385.0 mm) (Not including protrusions)

Net Weight 13.7 lbs (6.2 kg)

Feet Adjustment ±1.0˚

DLP Chip

Projection System 0.55" Single DLP chip, 6 segment Color Wheel

Number of Pixels 786,432 pixels (1,024 x 768 dots)

Signal Compatibility

Color System

SD/HDTV Signal Component: 480i, 480p, 575i, 575p, 720p and 1080i

HDMI; 480p, 575p, 720p and 1080i

Input Scanning Frequency H-sync. 15 kHz-93 kHz, V-sync. 50-120 Hz

Optical Information

Projection Image Size (Diagonal) Adjustable from 55” to 90”

Throw Distance 0.82’ - 1.43' (25.1 cm - 43.7 cm)

Projection Lens F 2.5 lens with f 4.83 mm with manual focus

Projection Lamp 275 W

Interface

Video Input Jack RCA Type x 1

S-Video Input Jack Mini DIN 4 pin x 1

Audio Input Jacks RCA Type x 2

Computer Input 1 / Component Input Terminal

Computer Input 2 / Monitor Output Terminal

Computer 1/ Component Audio Input Jack

Computer 2 Audio Input Jack

Audio Output Jack Mini Jack (stereo) x 1 (Variable)

HDMI HDMI (V.1.3 with Deep Color) x 1

Control port D-sub 9 pin x 1

LAN Connection Terminal RJ-45 x 1

3D Sync Output Mini DIN 3 pin x 1

Audio

Internal Audio Amp 10 W RMS

Built-in Speaker 1 speaker, ø1.46" (37 mm)

Power

Voltage and Power Consumption AC 100–120 V (4.4 A Max. Ampere), 50/60 Hz (The U.S.A and Canada)

AC 100–240 V (4.4 - 2.3 A Max. Ampere), 50/60 Hz (For other countries)

Operating Environment

Operating Temperature 41˚F–104˚F (5 ˚C–40 ˚C)

Storage Temperature 14˚F–140˚F (-10˚C–60 ˚C)

Remote Control

Battery AAA or LR03 1.5V ALKALINE TYPE x 2

Operating Range 16.4' (5 m)/±30˚

Dimensions 2.0" (W) x 0.7" (H) x 4.3" (D) (52 mm x 18 mm x 110 mm)

Net Weight 2.37 oz (67 g) (including batteries)

PAL, SECAM, NTSC, NTSC4.43, PAL-M, and PAL-N

Analog RGB (Mini D-sub 15 pin) Terminal x 1

Analog RGB (Mini D-sub 15 pin) Terminal x 1 (In/Out switchable)

Mini Jack (stereo) x 1

Mini Jack (stereo) x 1

Accessories

q Owner’s Manual( CD-ROM)

q Quick Reference Guide

q AC Power Cord

q Remote Control and Batteries

q VGA Cable

q PIN Code Label

l The specifications are subject to change without notice.

l DLP chips are manufactured to the highest possible standards. A tiny fraction of pixels may be ineffective or always lit, but this is not a

malfunction.

This symbol on the nameplate means the product is Listed by Underwriters Laboratories Inc. It is designed and manufactured to meet rigid U.L. safety standards

against risk of fire, casualty and electrical hazards.

-4-

Page 5

Circuit Protections

This projector provides the following circuit protections to operate in safety. If the abnormality occurs inside the projector, it will automatically turn off by operating one of the following protection circuits.

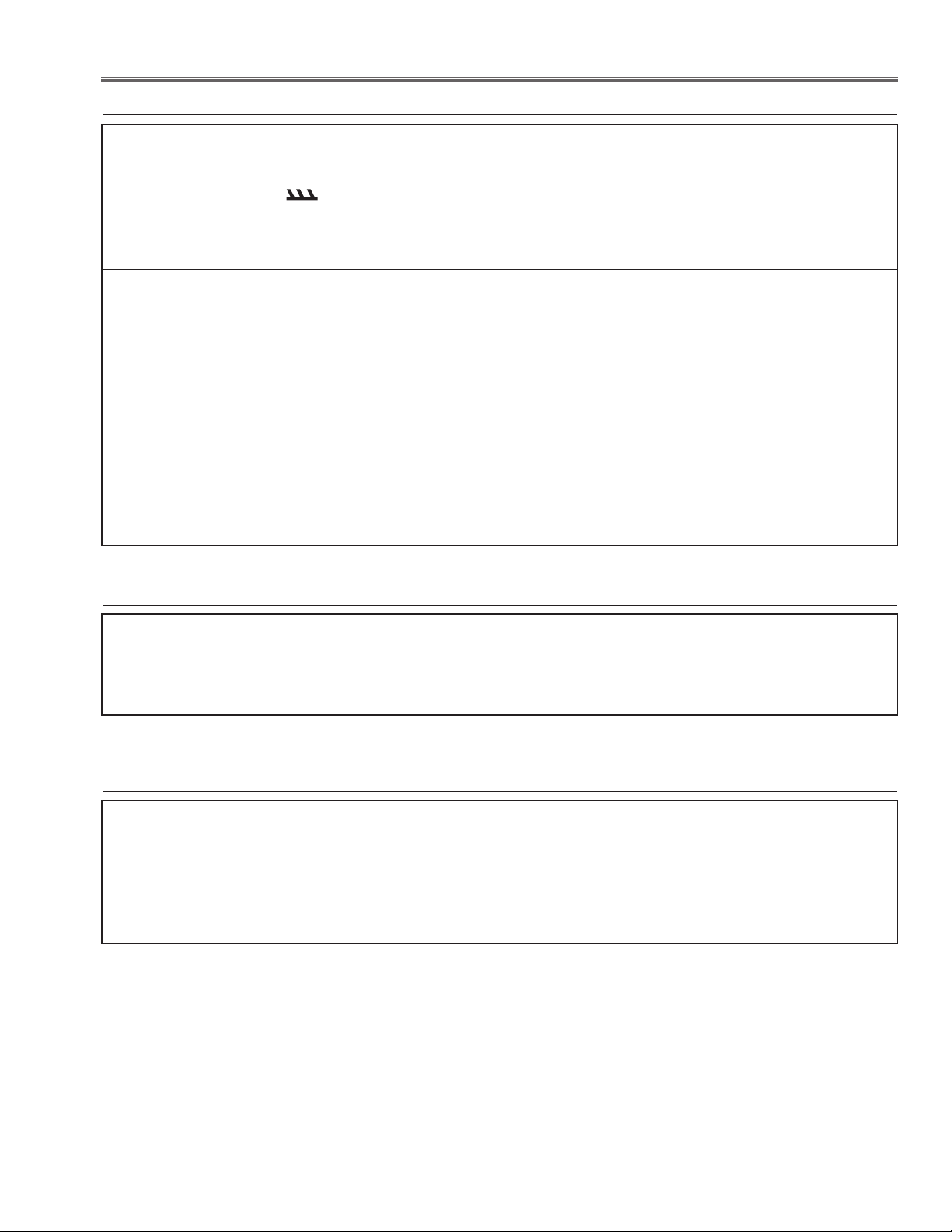

Thermal switch

There is the thermal switch (SW902) inside of the projector to detect the internal temperature rising abnormally.

When the internal temperature reaches near 120˚C, the

thermal switch opens to cut off the power to the power

circuit.

The thermal switch can be reset itself automatically

when the internal temperature becomes normal.

When the internal temperature reaches near 80˚C, the

thermal switch returns automatically.

Fuse

A fuse is located inside of the projector. When the POWER indicator is not lighting, the fuse may be opened.

Check the fuse as following steps.

The fuse should be used with the type listed right;

How to replace the fuse

1. The fuse is placed on the filter board behind the optical unit. Remove the cabinet top.

2. Take the fuse off from the filter board, and replace the

new one with the specified type.

Lamp cover switch

The lamp cover switch (SW901) cuts off the drive signal

to the lamp circuit when the lamp cover is removed or

not closed completely. After opening the lamp cover for

replacing the lamp ass’y, place the lamp cover correctly

otherwise the projector can not turn on.

Fuse Part No.: 323 025 1204

TYPE 8A 250V FUSE

LITTLE FUSE INC. TYPE 215008

Thermal switch

(SW902)

Lamp cover switch

(SW901)

Fuse

(F601)

-5-

Page 6

Circuit Protections

Warning temperature and power failure protection

The projector will be automatically turned off when the internal temperature of the projector is abnormally high, or the

cooling fans stop spinning, or the power supplies in the projector are failed.

- If both of the POWER and WARNING TEMP. indicators are flashing, it may detect the abnormal temperature inside

the projector. Check the following possible causes and wait until the POWER indicator stops flashing, and then try

to turn on the projector.

- If the WARNING TEMP. indicator lights red, it may defect the cooling fans or power supply circuits. Check fans

operation and power supply lines referring to the chapter “Power supply & protection circuit” in the Chassis Block

Diagram section.

Possible causes

- Air filters are clogged with dust particles. Remove dust from the air filters by following instructions in the “Air filter

care and cleaning” below.

- Ventilation slots of the projector are blocked. In such an event, reposition the projector so that ventilation slots are

not obstructed.

- Check if projector is used at higher temperature place (Normal operating temperature is 5 to 40 ˚C or 41 to 104˚F)

The projector is shut down and the WARNING

TEMP. indicator lights red.

When the projector detects an abnormal condition, it is automatically shut down to protect the inside of the projector

and the WARNING TEMP. indicator lights red. In this case,

unplug the AC power cord and reconnect it, and then turn the

projector on once again to verify operation. If the projector

cannot be turned on and the WARNING TEMP. indicator still

lights red, unplug the AC power cord and contact the service

station.

CAUTION

DO NOT LEAVE THE PROJECTOR WITH THE

AC POWER CORD CONNECTED UNDER AN ABNORMAL CONDITION. IT MAY RESULT IN FIRE

OR ELECTRIC SHOCK.

Indicators

WARNING TEMP.

emit a red light

-6-

Page 7

Maintenance

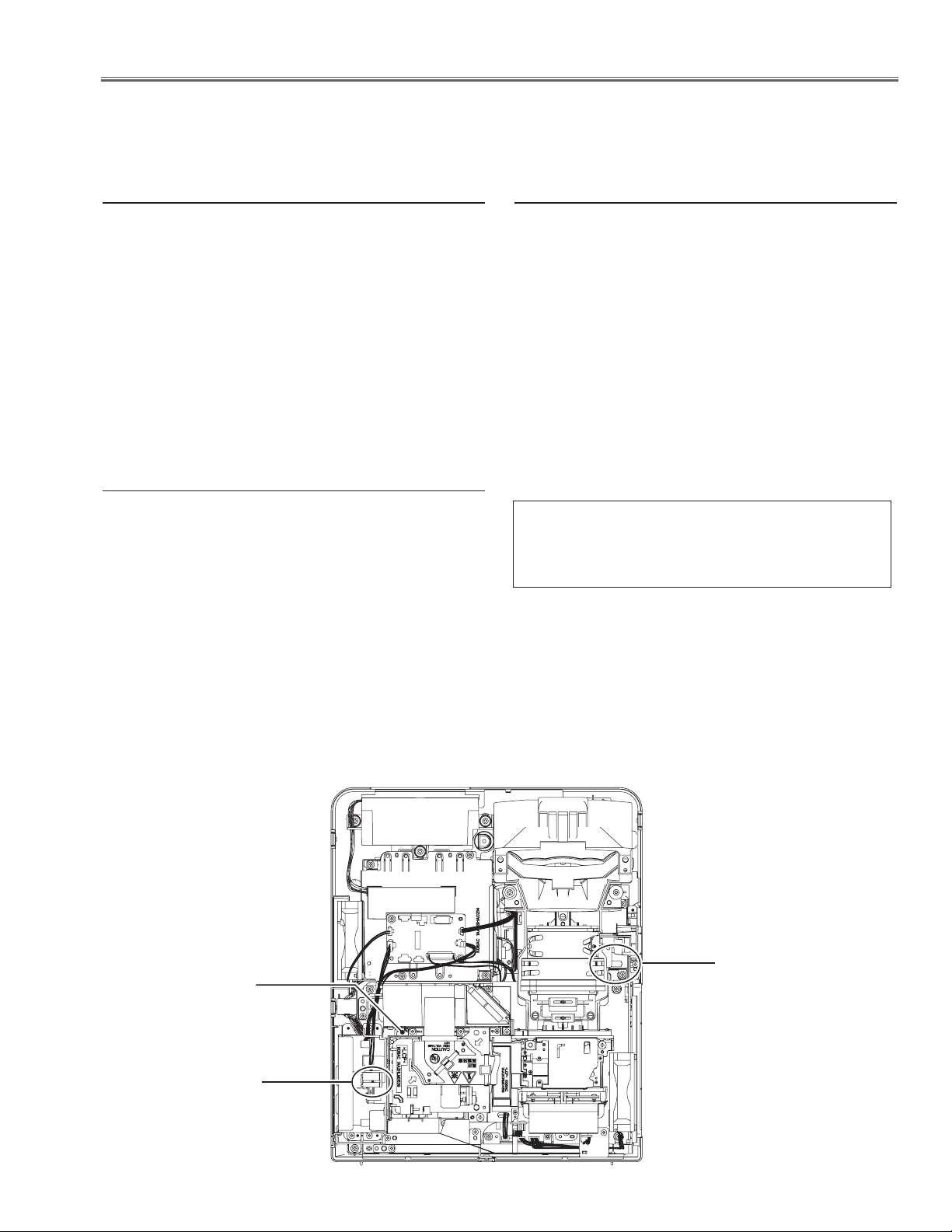

Replacing the Filter

Filter prevents dust from accumulating on the optical elements inside the projector. Should the filter become

clogged with dust particles, it will reduce cooling fans’ effectiveness and may result in internal heat buildup and

adversely affect the life of the projector. If a “Filter warning” icon appears on the screen, replace the filter immediately by following the steps below.

Turn off the projector, and unplug the AC power cord

1

from the AC outlet.

First, clean up the dust on the projector and around the

2

air vents.

Loosen the screw and open the lamp cover and lift the

3

filter out of the projector.

Reinstall the filter completely and close the lamp cover

4

and secure the screw.

Connect the AC power cord to the projector and turn on

5

the projector.

Reset the filter counter.

6

CAUTION

- Do not operate the projector with the filter removed. Dust may accumulate on the optical elements degrading picture quality.

- Do not put anything into the air vents. Doing so

may result in malfunction of the projector.

- Do not wash the filter with water or any other liquid matter. Otherwise the filter may be damaged.

RECOMMENDATION

We recommend avoiding dusty/smoky environments when

you operate the projector. Usage in these environments may

cause poor image quality.

When using the projector under dusty or smoky conditions,

dust may accumulate on a lens, or optical elements inside

the projector degrading the quality of a projected image.

When the symptoms above are noticed, clean up the lens

or other optical parts by referring to the chapter "Cleaning

the projector".

Filter

Filter counter

Lamp cover

Screw

Resetting the Filter Counter

Be sure to reset the Filter counter after replacing the filter.

Press the MENU button to display the On-Screen

1

Menu. Use the Point ed buttons to select Setting and

then press the Point 8 or SELECT button.

Use the Point ed buttons to select Filter counter and

2

then press the Point 8 or the SELECT button. Use the

Point ed buttons to select Filter counter reset and

then press the SELECT button. Filter counter Reset?

appears. Select Yes to continue.

Another confirmation dialog box appears, select Yes to

3

reset the Filter counter.

-7-

Filter counter

Reset? appears.

Select Yes, then

another confirmation

box appears.

Select Yes again to

reset the Filter coun

ter.

-

Page 8

Maintenance

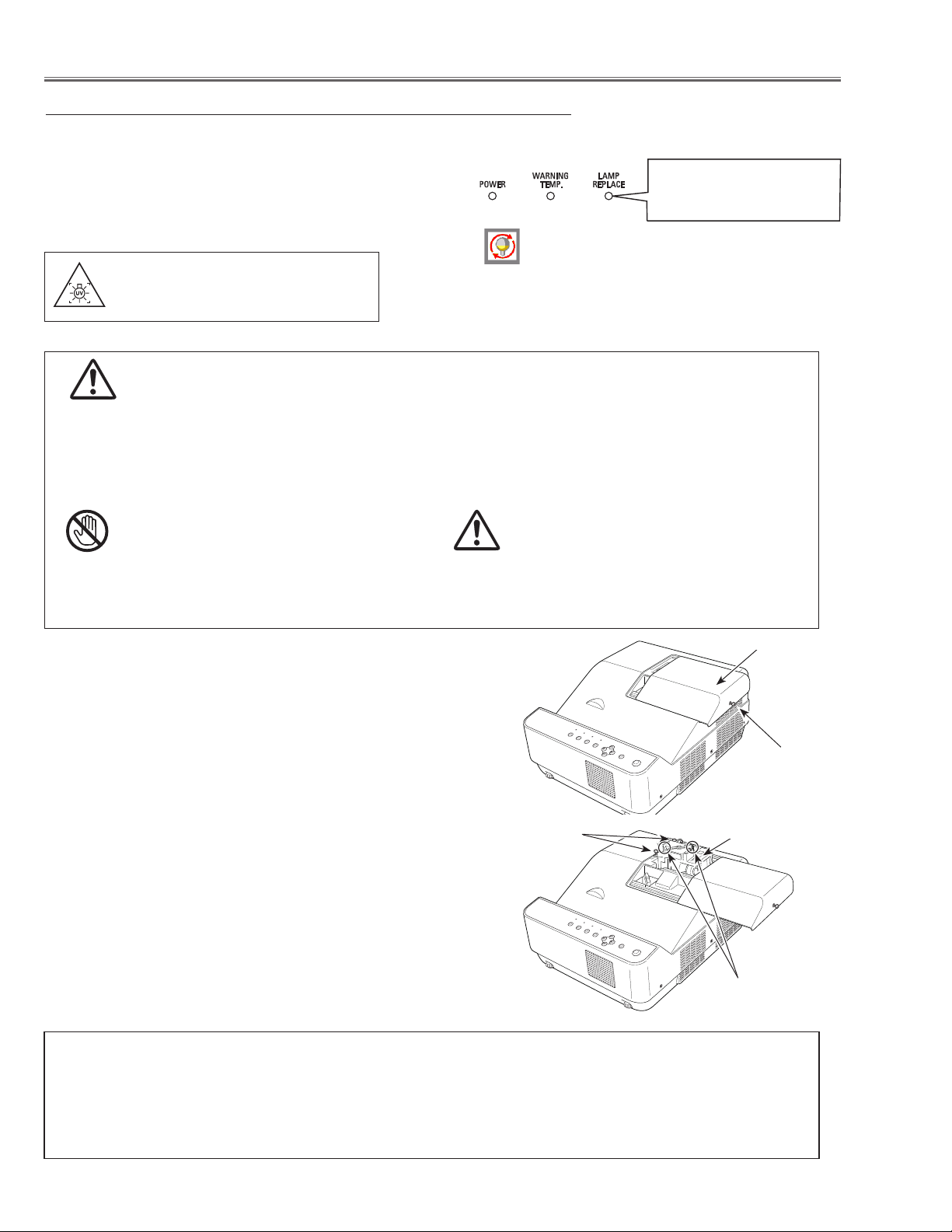

Lamp Replacement

When the projection lamp of the projector reaches its end

of life, the Lamp replacement icon appears on the screen

and LAMP REPLACE indicator lights yellow. Replace the

lamp with a new one promptly. The timing when the LAMP

REPLACE indicator should light is depending on the lamp

mode.

WARNING:

TURN OFF THE UV LAMP BEFORE

OPENING THE LAMP COVER

Top Panel

This indicator turns yellow

when the projection lamp

reaches the end of its life.

Lamp replacement icon

Note:

The Lamp replacement icon will not appear when the

Display function is set to Off, during Freeze, or No show.

CAUTION

When replacing the lamp because it has stopped illuminating, there is a possibility that the lamp may be bro

ken. If replacing the lamp of a projector which has been installed on the ceiling, you should always assume

that the lamp is broken, and you should stand to the side of the lamp cover, not underneath it. Remove the

lamp cover gently. Small pieces of glass may fall out when the lamp cover is opened. If pieces of glass get

into your eyes or mouth, seek medical advice immediately.

CAUTION

Allow a projector to cool for at least 45 minutes

before you open the Lamp Cover. The inside of

the projector can become very hot.

For continued safety, replace with a lamp of the

same type. Do not drop a lamp or touch a glass

bulb! The glass can shatter and may cause injury.

CAUTION

-

Follow these steps to replace the lamp.

Turn off the projector and unplug the AC power cord. Let

1

the projector cool for at least 45 minutes.

Loosen the screw and open the lamp cover.

2

Loosen the two (2) screws that secure the lamp. Lift the

3

lamp out of the projector by using the handle.

Replace the lamp with a new one and secure the two (2)

4

screws. Make sure that the lamp is set properly. Close

the lamp cover and secure the screw.

Connect the AC power cord to the projector and turn on

5

the projector.

Reset the lamp counter.

6

See “Resetting the Lamp Counter” on the next page.

Screws

Lamp Cover

Screw

Lamp

Handle

ORDER REPLACEMENT LAMP

Replacement lamp can be ordered through your dealer. When ordering a projection lamp, give the following

information to the dealer.

Replacement Lamp Type No. : POA-LMP143

Service Parts No. : 610 351 3744

-8-

Page 9

Counter

Projector 500H

Lamp

Normal 200 H

Eco 300 H

Corresponding value 600 H

Maintenance

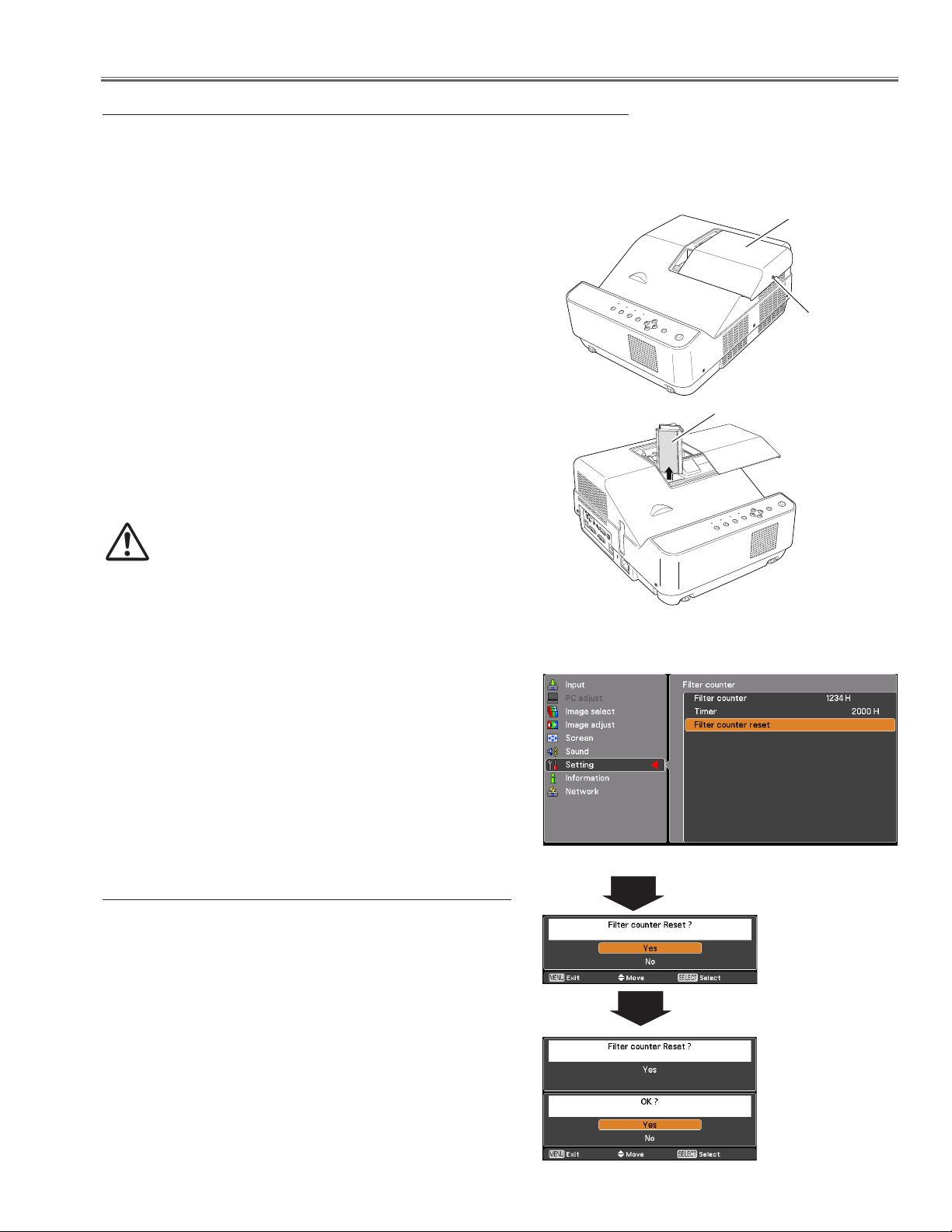

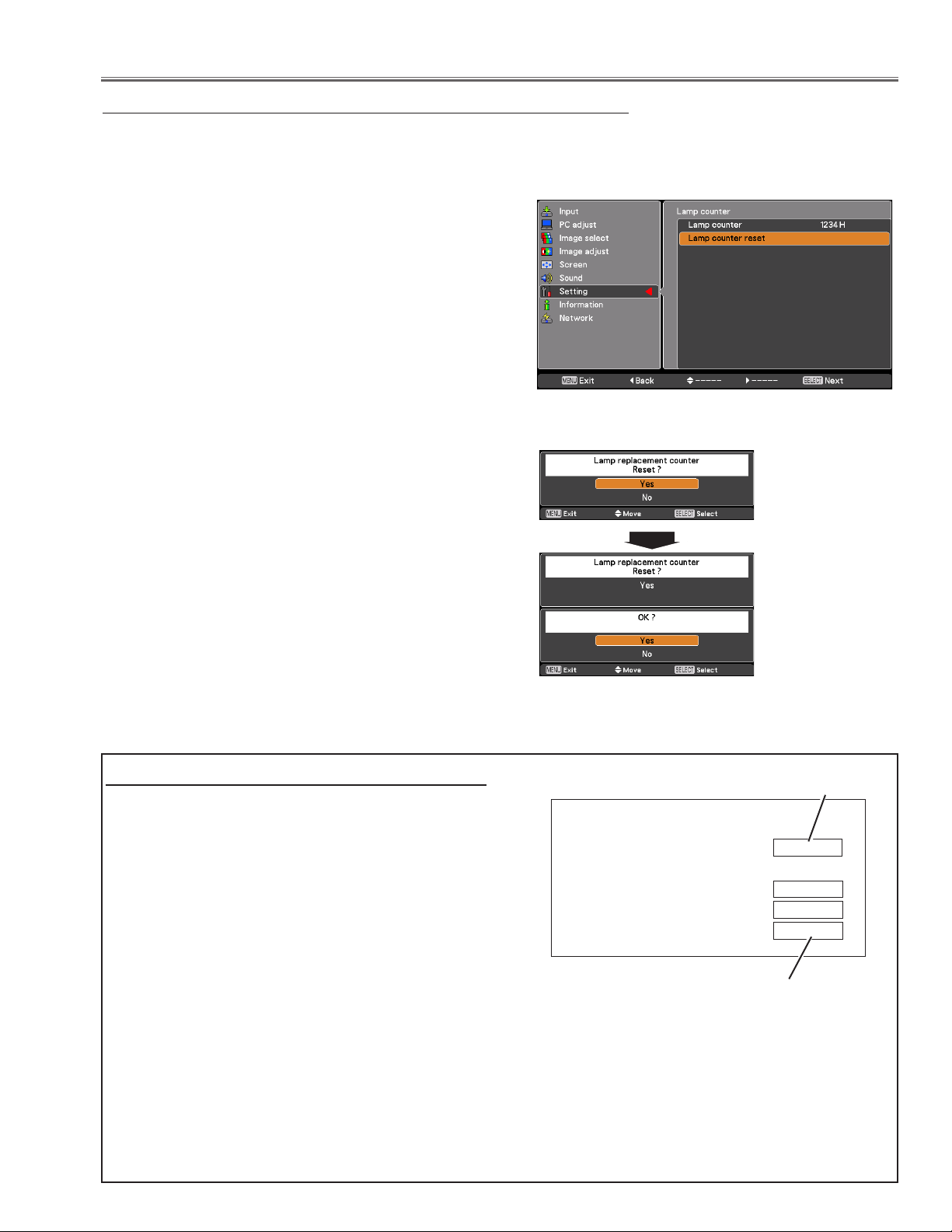

Resetting the Lamp Counter

Be sure to reset the Lamp counter after the lamp is replaced. When the Lamp counter is reset, the LAMP REPLACE

indicator stops lighting and the Lamp replacement icon disappears.

Press the MENU button to display the On-Screen

1

Menu. Use the Point ed buttons to select Setting

and then press the Point 8 or the SELECT button.

Use the Point ed buttons to select Lamp counter

2

and then press the SELECT button. Use the Point ed

buttons to select Lamp counter reset and then press

SELECT button. Lamp replacement counter Reset?

appears. Select Yes to continue.

Another confirmation dialog box appears, select Yes to

3

reset the Lamp counter.

Note:

Do not reset the Lamp counter without implementing lamp

replacement. Be sure to reset the Lamp counter only after

replacing the lamp.

Lamp counter reset

Lamp replacement

counter Reset?

appears.

Select Yes, then

another confirma

tion box appears.

-

How to check Lamp Used Time

The LAMP REPLACE indicator will light yellow when

the total lamp used time (Corresponding value) reaches

3,000 hours. This is to indicate that lamp replacement

is required.

The total lamp used time is calculated by using the below expression,

Total lamp used time (Corresponding value)

= Teco + Tnormal x 1.5

Tnormal : used time in the normal mode

Teco : used time in the eco mode

You can check the lamp used time following to the below procedure.

1 Press and hold the ON/STAND-BY button on the re-

mote control for more than 20 seconds.

2 The projector used time and lamp used time will be

displayed on the screen briefly as follows.

Select Yes again

to reset the Lamp

counter.

Projector used time

Total lamp used time

-9-

Page 10

Maintenance

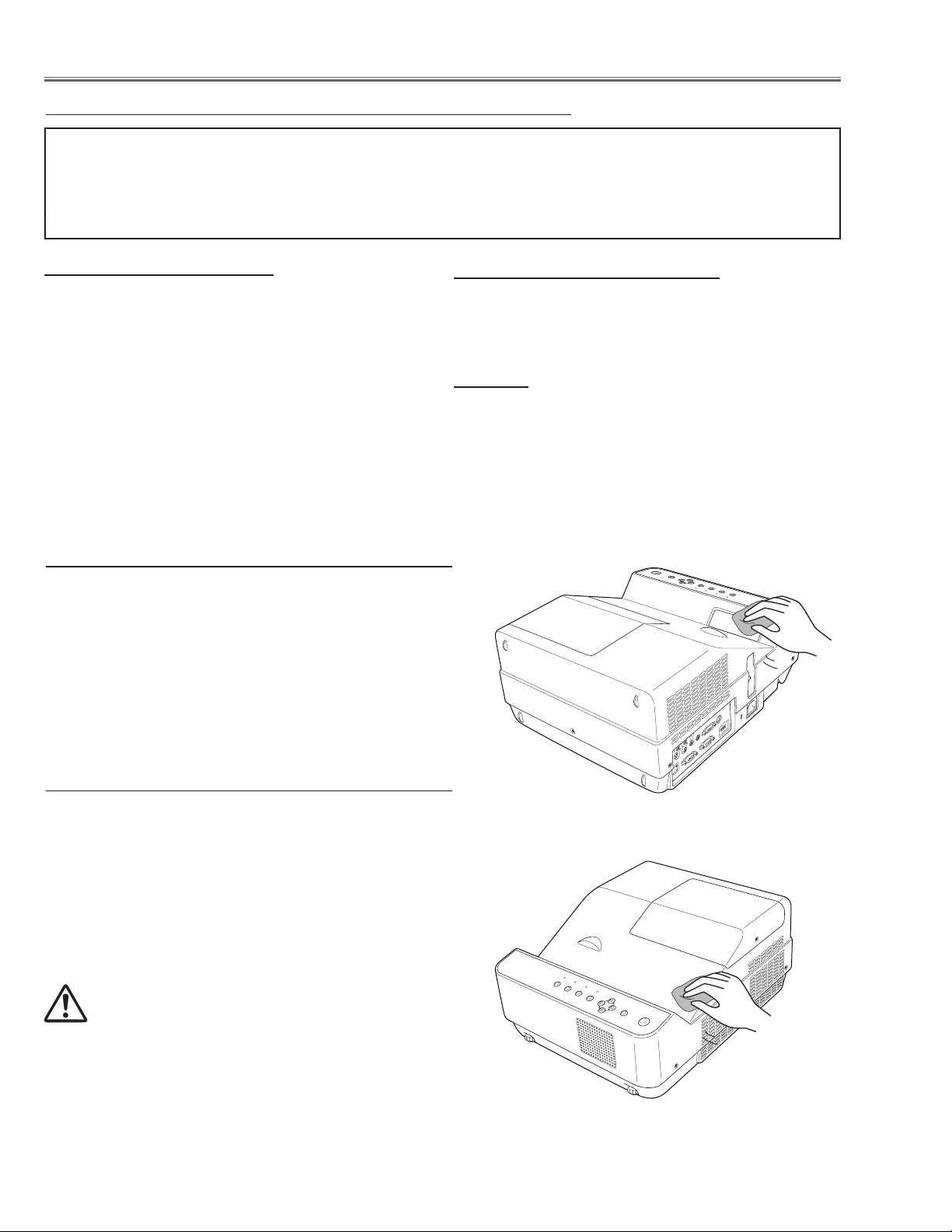

Cleaning

After long periods of use, dust and other particles will accumulate on the optical parts, mirror, color wheel, lens etc.,

causing the picture to darken or color to blur. If this occurs, remove dust and other particles using air spray. Before

taking the cleaning, turn off the projector and allow the projector to cool for more than 45 minutes. Never disassemble the optical unit, mirror or projection lens because those parts are aligned preciously in the factory . If do so,

the projector may have the miss-alignment in optical and reduce the optical performance.

Cleaning the Color Wheel

- The color wheel is made of thin glass. Be very careful

when handing the color wheel.

- In case of fingerprints, etc. on the surface, gently wipe

with a Cleaning Cloth for optical parts that contains a

small amount of non-abrasive camera lens cleaner to

clean the surface.

- Do not use detergents as this could cause peeling of

the color filter.

Cleaning the Projection Window

Unplug the AC power cord before cleaning.

First, remove the dust with a commercially available air blower. Then gently wipe the projection window surface. Use a

cleaning paper moistened with methyl alcohol (methanol).

Avoid using an excessive amount of cleaner.

Do not use abrasive cleaners, solvents, or other harsh

chemical cleaners to avoid damaging the projection window.

Cleaning the Reflecting Mirror

- Be careful not to touch the reflecting mirror. Touching

it directly with the hands may cause reducing the burnishing.

- Do not clean other than with air.

Caution:

The optical components may have a crack or spot when

you use the air spray directly to the optical components

while they are in the state of hot. Use a commercial (inert

gas) air spray designed for cleaning camera and computer equipment. Use a resin-based nozzle only. Be very

careful not to damage optical parts with the nozzle tip.

Cleaning the Projector Cabinet

Unplug the AC power cord before cleaning.

Gently wipe the projector body with a soft dry cleaning cloth.

When the cabinet is heavily soiled, use a small amount of

mild detergent and finish with a soft dry cleaning cloth. Avoid

using an excessive amount of cleaner. Abrasive cleaners,

solvents, or other harsh chemicals might scratch the surface of the cabinet.

When the projector is not in use, put the projector in an appropriate carrying case to protect it from dust and scratches.

CAUTION

Do not use any flammable solvents or air sprays on the projector and in its vicinity. The explosion or fire hazard may

occur even after the AC power cord is unplugged because

the temperature inside the projector is extremely high due to

the lamps. In addition, there is a risk that the internal parts

may be damaged not only by the flammable air spray but

also by the cold air.

-10-

Page 11

Security Function Notice

This projector provides security functions such as "Key lock", "PIN code lock" and "Logo PIN code lock". When the

projector has set these security function on, you are required to enter correct PIN code to use the projector. If you

do not know the correct PIN code to the projector, the projector can no longer be operated or started. In this case,

you must reset those function first according to the resetting procedure described below and then check up on the

projector.

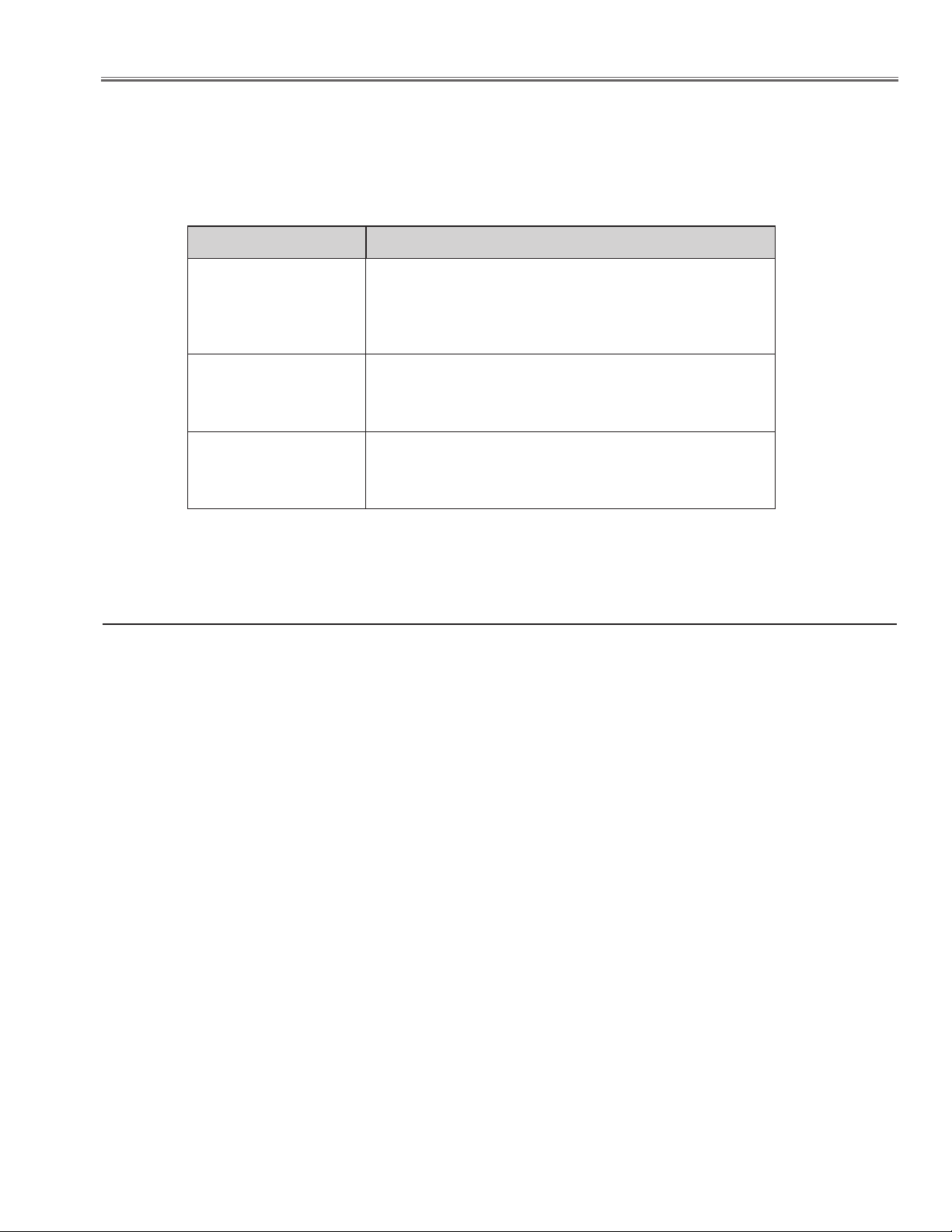

Function Description

Locks operation of the side control or the remote control.

Key lock

PIN code lock

Logo PIN code lock

If the Key lock is enabled with side control lock, the projector can no longer be started.

Initial setting: Key lock function is disabled

Prevents the projector from being operated by an unauthorized person.

Initial code: “1234”

Prevents an unauthorized person for changing the startup logo on the screen.

Initial code: “4321”

Resetting procedure

1 Disconnect the AC power cord from the AC outlet.

2 As pressing the SELECT button, connect the AC power cord into an AC outlet again.

3 Keep pressing the SELECT button and then press the ON/STAND-BY button.

4 Release the ON/STAND-BY button first and then release the SELECT button.

- The PIN code lock and Logo PIN code lock will be reset as the initial PIN code at the factory and the Key lock

function is disabled.

Please refer to the owner's manual for further information of the security functions.

-11-

Page 12

Standby Mode Notice

This projector provides 2 types of standby mode, Eco standby and Network standby. According to the standby mode

"Eco" or "Network", several functions are restricted as shown in the table below. To change the standby mode, use

the projector's menu "Setting".

Network ............ Supply the power to the network function even after turning off the projector. You can turn on /off

the projector via network, modify network environment, and receive an e-mail about projector status

while the projector is powered off.

Eco ................... Select "Eco" when you do not use the projector via network. The projector's network function will stop

when turning off the projector.

When "Eco" is selected, several functions will be restricted.

Function in the standby mode

Function Eco Network

Serial command control -- *1

Network Function --

Monitor Out --

Audio Out -- --

Direct On

*1 Effective only Power-On command.

4 4

4

4

4

-12-

Page 13

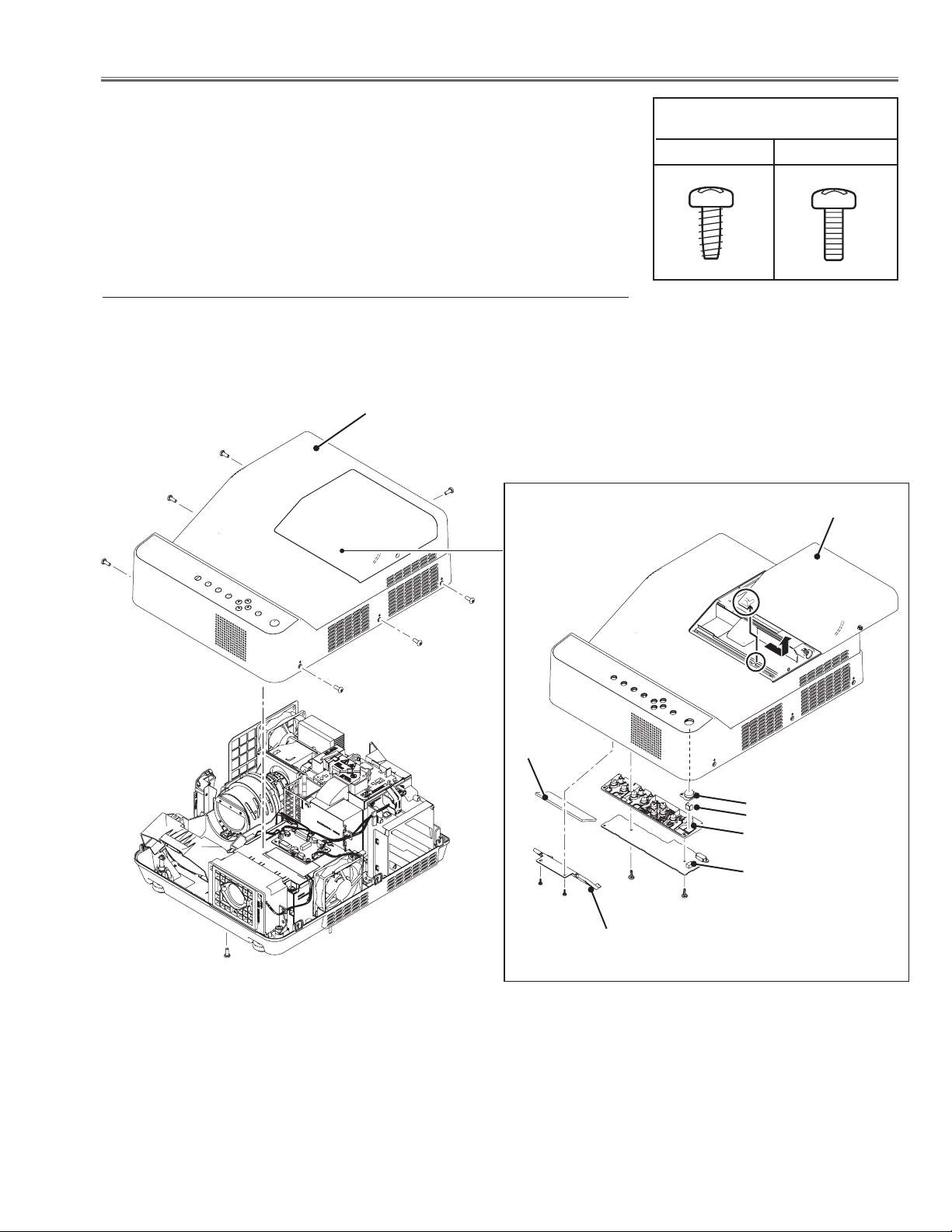

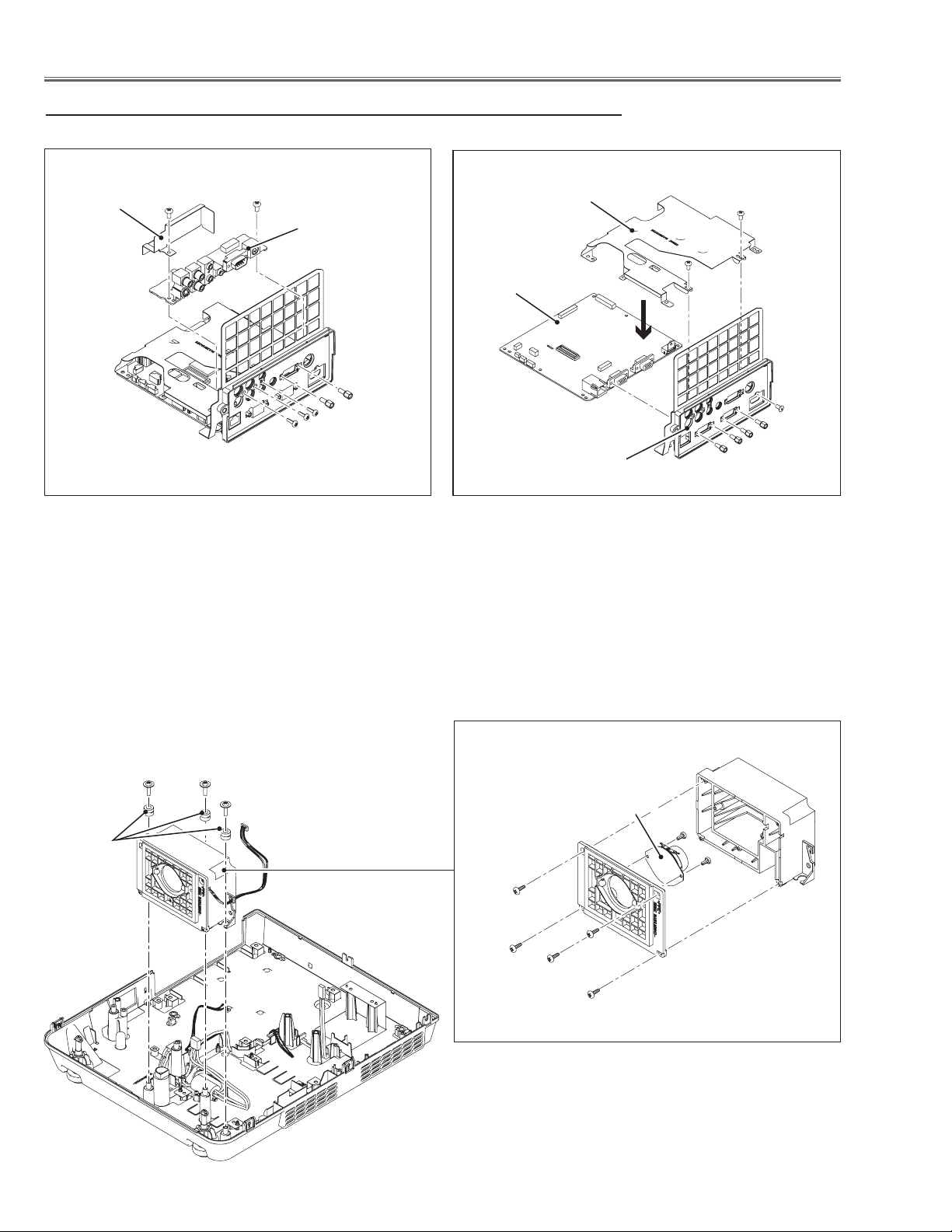

Mechanical Disassembly

Mechanical disassembly should be made following procedures in numerical

order.

Following steps show the basic procedures, therefore unnecessary step may

be ignored.

Caution:

The parts and screws should be placed exactly the same position as the original otherwise it may cause loss of performance and product safety.

z Cabinet Top removal

1. Remove 8 screws A(M3x8) to remove the cabinet top assy upward

off.

Cabinet top assy

A

A

A

A

Screws Expression

(Type Diameter x Length) mm

T type M Type

Lamp cover

A

A

A

A

Optical

filter

RC Window

RC Reflector

Control buttons

Key sw board

(T3x8)x2

(T3x8)x2

Glass holder

Fig.1

-13-

Page 14

Mechanical Disassembly

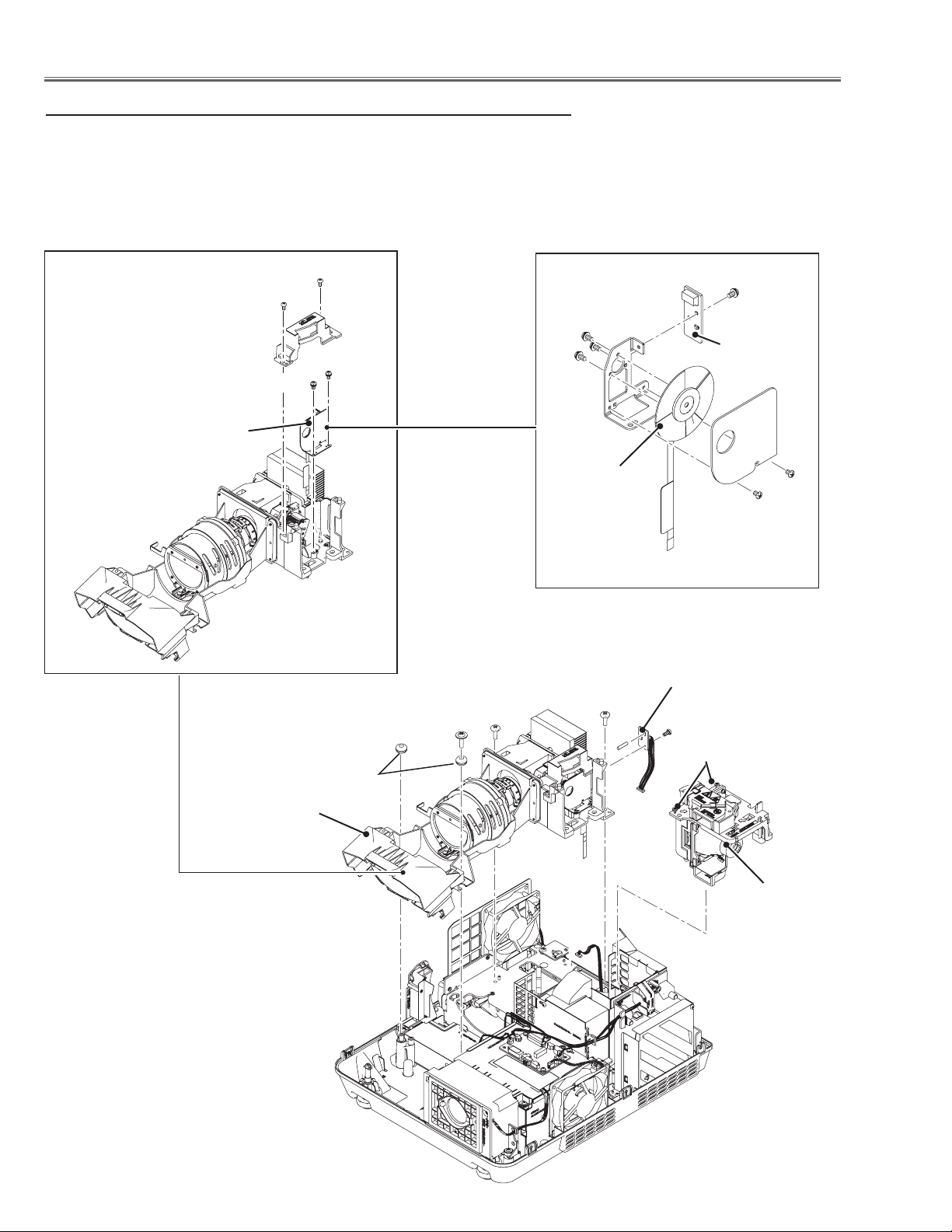

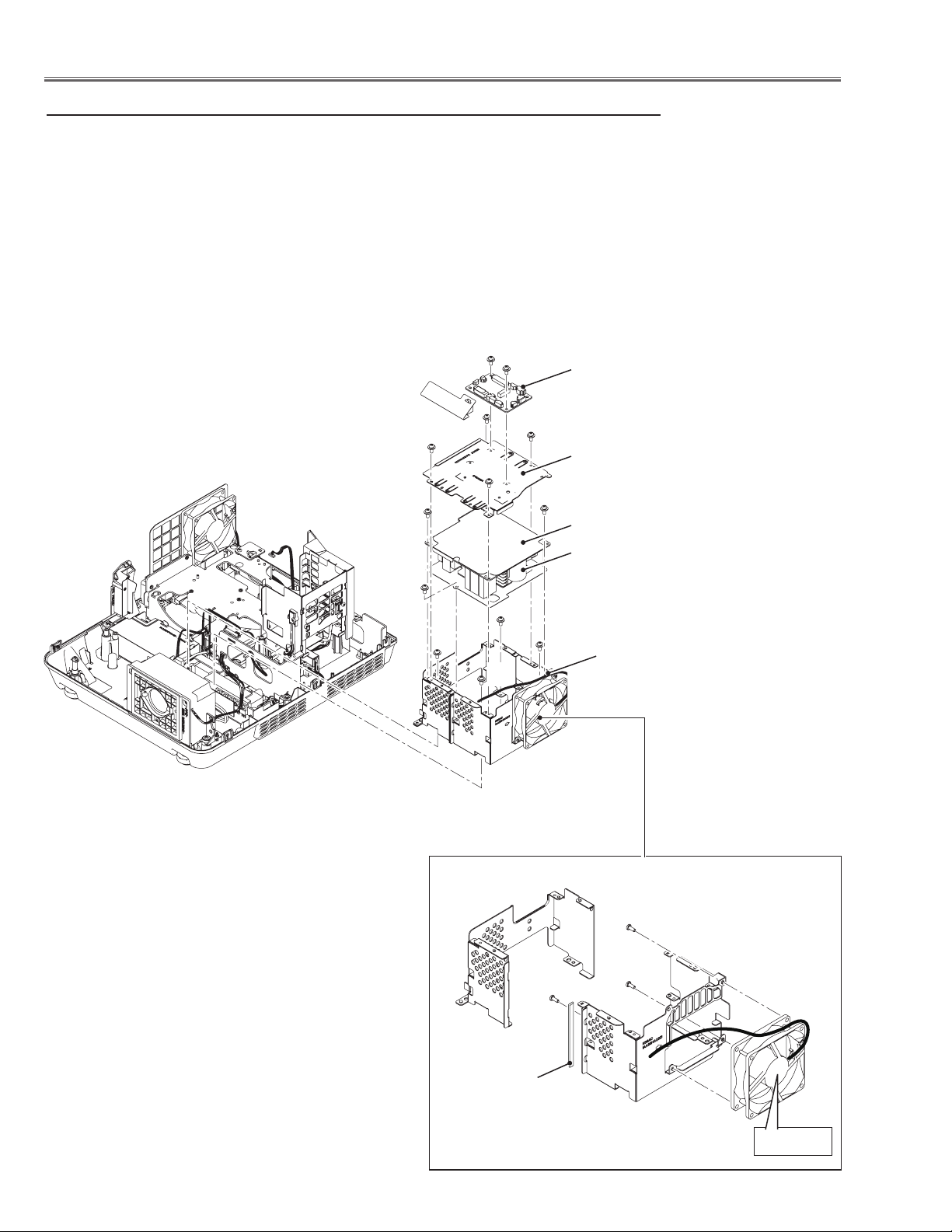

x Optical unit Lamp and CW removal

1. Loosen 2 screws A and pull the Lamp assy upward off.

2. Remove 1 screw B(M2.5x6) to remove Temp. Sensor 2 board.

3. Remove 1 screw C(T3x12)x2 and 2 screws D (M4x8) to remove the Optical Unit upward

off.

Color Wheel

assy

(M2x8)x2

(M2x6)x2

(M2x8)x1

(M2x8)x3

CW Sensor

board

Color Wheel

(M2x6)x2

Temp Sensor 2

board

D

C

D

B

Optical unit

Fig.2

A

Bushes

Lamp assy

-14-

Page 15

Mechanical Disassembly

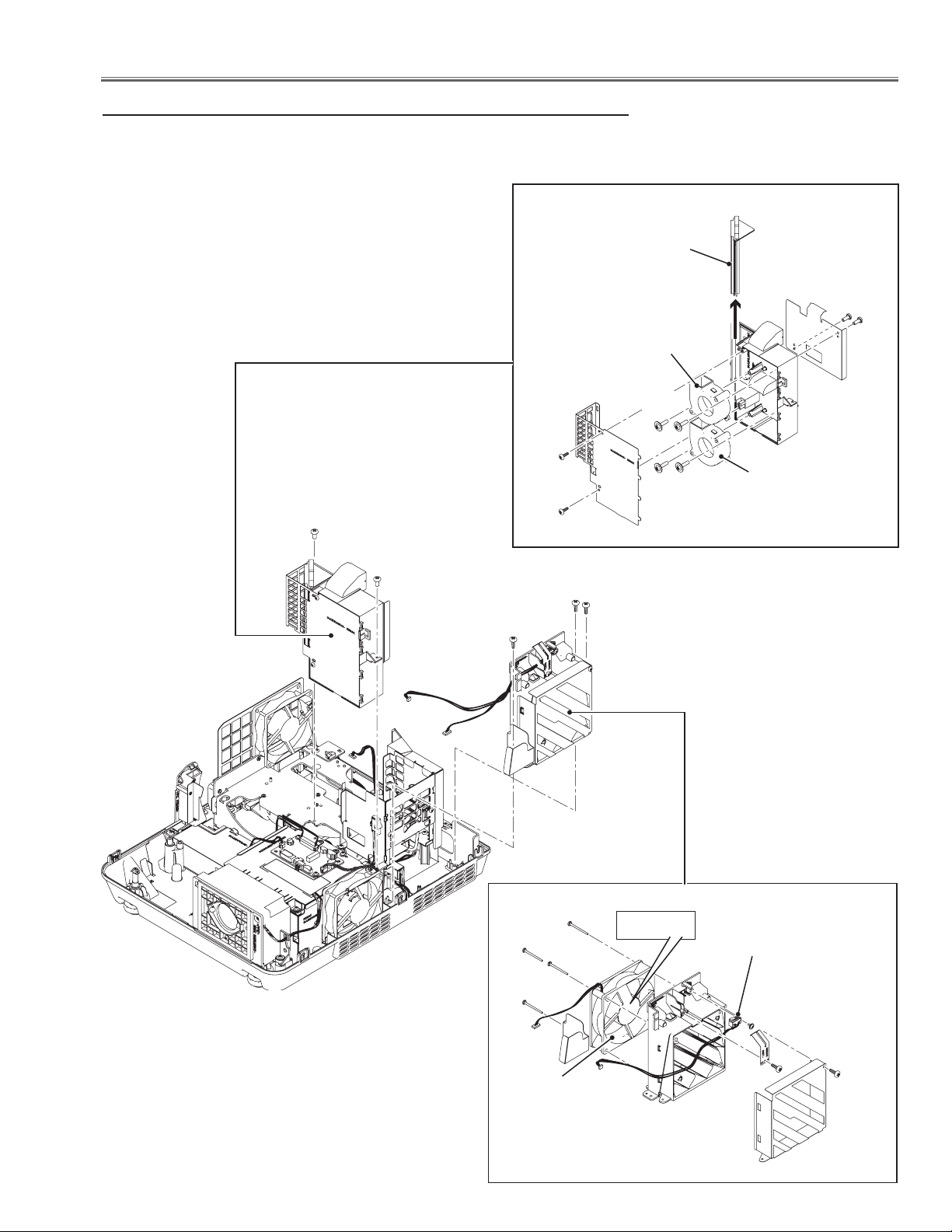

c Fans (FN902, FN903, FN904) and SW901 removal

1. Remove 3 screws A(T3x8) to remove the exhaust fan assy.

2. Remove 2 screws B(M3x6) to remove the fan duct assy.

Air Filter

(T3x8)x2

FN902

(T3x12)x2

Fan duct assy

(T3x8)x2

(T3x12)x2

FN903

B

B

A

A

A

Exhaust fan assy

(T3x32)x4

Label side

SW901

Lamp cover switch

Fig.3

(T3x6)x1

(T3x8)x1

(T3x8)x1

FN904

-15-

Page 16

Mechanical Disassembly

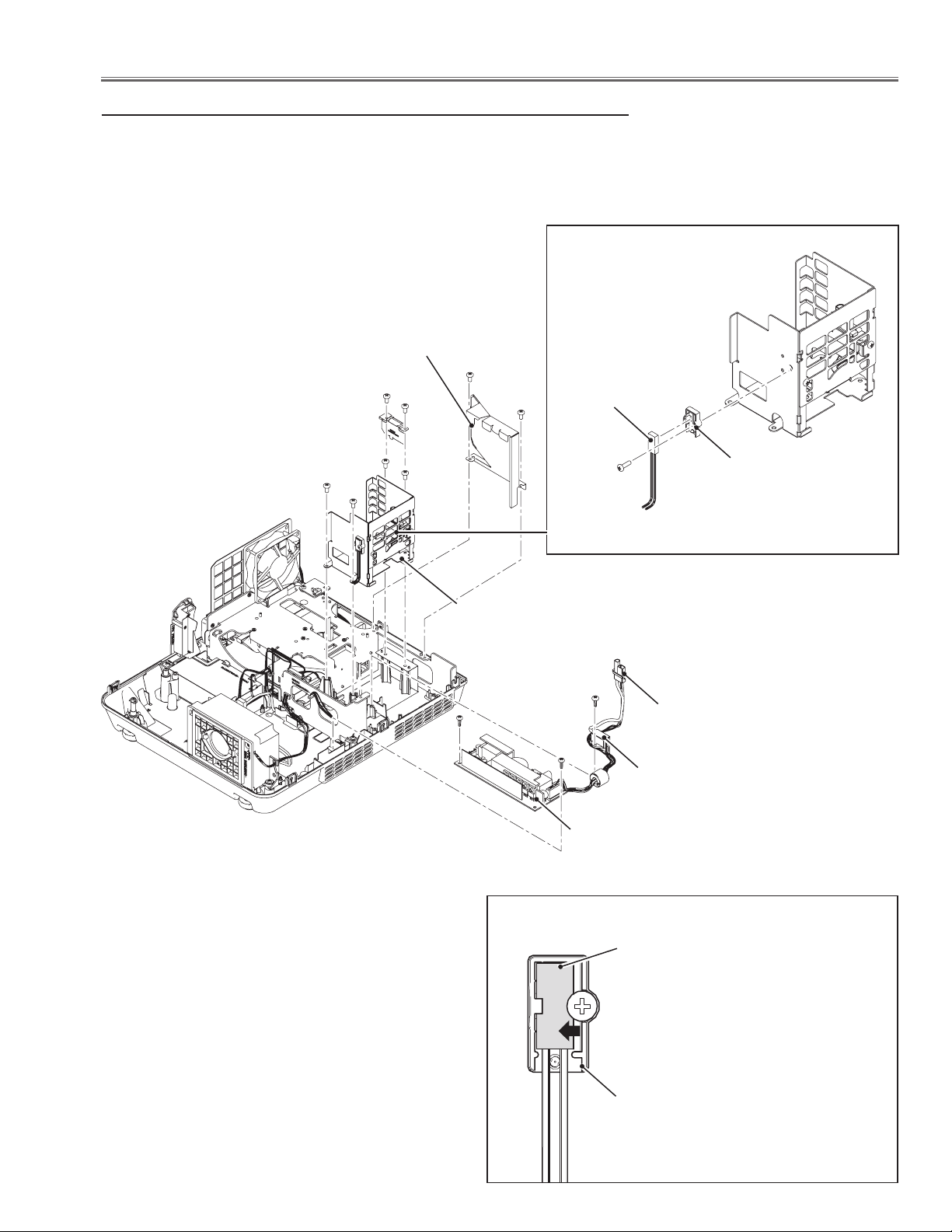

v Power and FanNet Board and fan(FN905) removal

1. Remove 2 screws A(M3x8) to remove the FanNet board.

2. Remove 4 screws B(M3x8) to remove the Power box cover.

3. Remove 2 screws C(M3x8) and 1 screw D(M3x8) to remove the Power board and insulation sheet.

4. Remove 4 screws E(M3x8) to remove the Power box frame assy.

A

A

B

B

B

FanNet Board

B

Power box cover

Fig.4

C

C

Insulation sheet

Power Board

D

E

E

E

Power box frame assy

E

-16-

(M3x10)x3

FN905

Gasket

Label side

Page 17

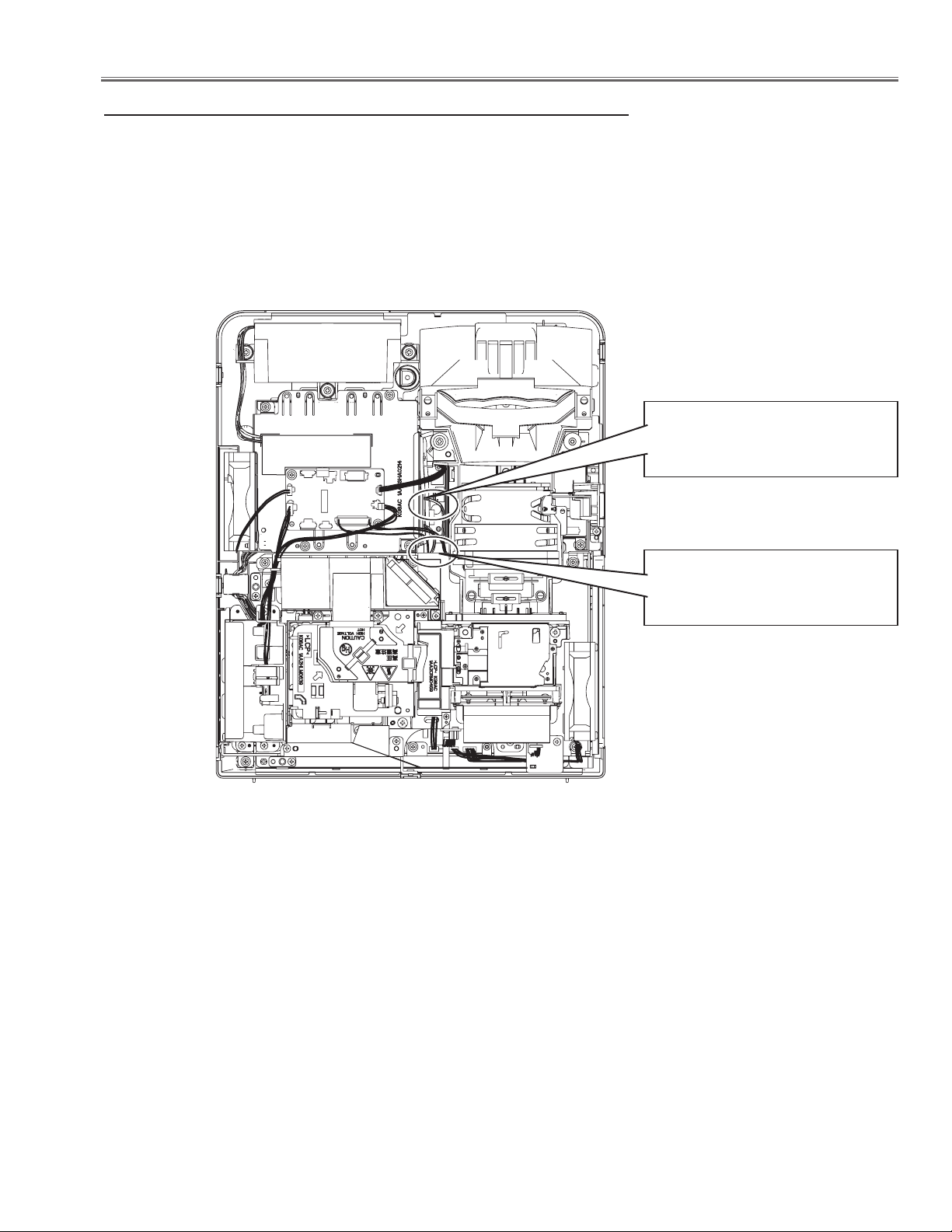

Mechanical Disassembly

b Ballast Board and Thermal Switch(SW902) removal

1. Remove 2 screws A(M3x6) to remove Side lamp shield.

2. Remove 4 screws B(M3x8) to remove the Lamp house frame.

3. Remove 2 screws C(T3x8) to remove the Ballast board, remove 1 screw

D(T3x8) to remove the Trigger box , remove 2 screws E(M3x6) to remove

the Ballast socket.

Side lamp

shield

E

E

B

B

B

A

A

Thermal switch

SW902

B

(M3x10)x1

Thermal switch

holder

Fig.5

Lamp house

frame

C

Note on mounting the thermal switch (SW902)

D

Socket

C

Trigger box

Ballast board

SW902

Thermal switch

Put the thermal switch on the

holder and slide it in the arrow

direction and then tighten the

screw to fix the thermal switch.

-17-

Thermal switch

holder

Page 18

Mechanical Disassembly

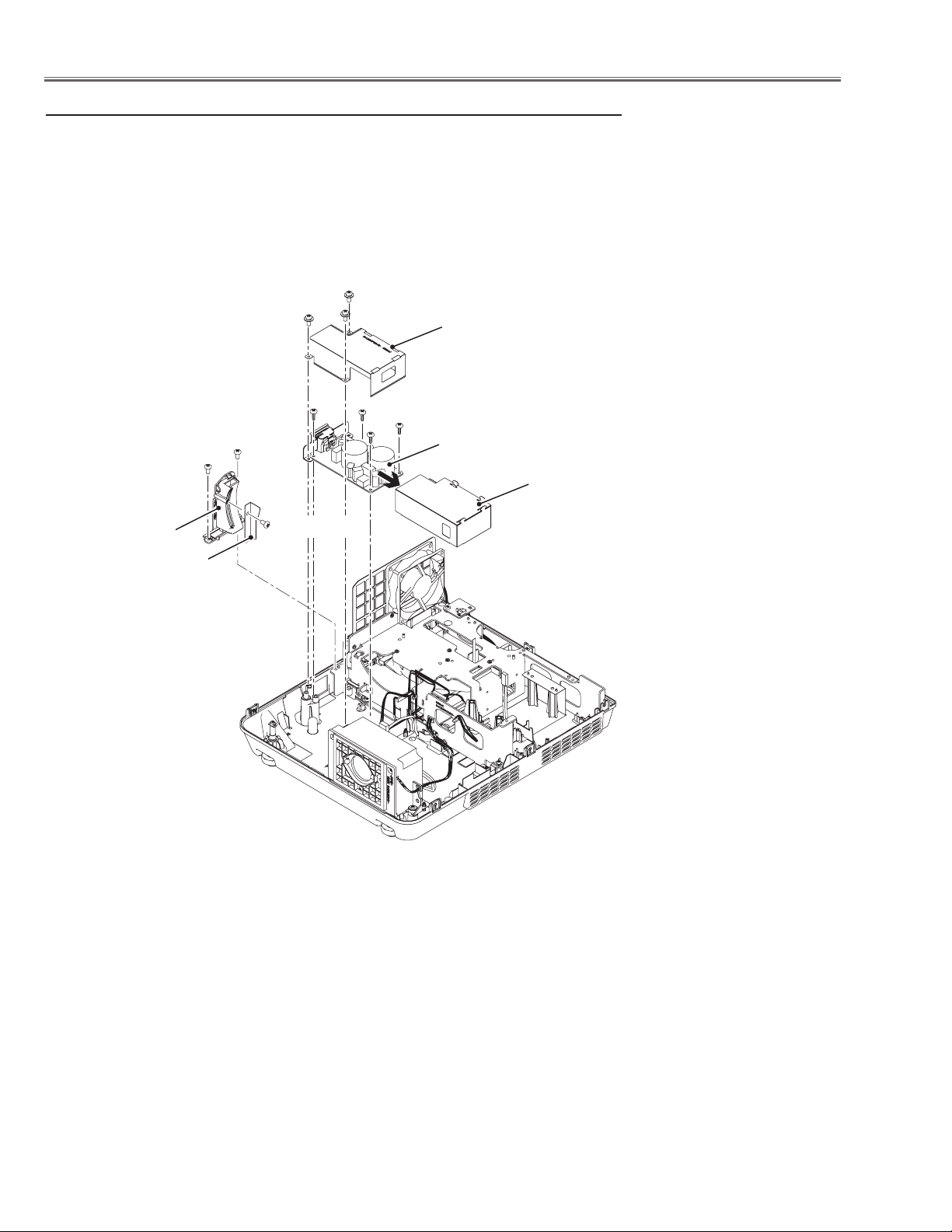

n Line Filter Board removal

1. Remove 2 screw A(M3x6) to remove the Focus lever cover.

2. Remove 3 screws B(M3x8) to remove the Line filter shield.

3. Remove 4 screws C(T3x8) to remove the Line filter board and insulation sheet.

B

Focus lever cover

Spacer

sheet

B

C

A

A

(M2.6x6)x1

B

Line filter shield

C

C

C

Line filter board

Insulation sheet

Fig.6

-18-

Page 19

Mechanical Disassembly

m Main, AV Board and Fans (FN901, FN906) removal-1

1. Remove 1 screw A(M3x6) to remove the Temp. sensor 1 board.

2. Remove 6 screws B(M3x12) to remove the Main and AV board assy.

B

B

A

B

Temp sensor 1 board

Main and AV board

assy

Fig.7

B

B

B

(M3x6)x2

-19-

(M3x10)x2

FN906

FN901

Label side

Fan Duct

(M3x28)x2

(M3x6)x2

Page 20

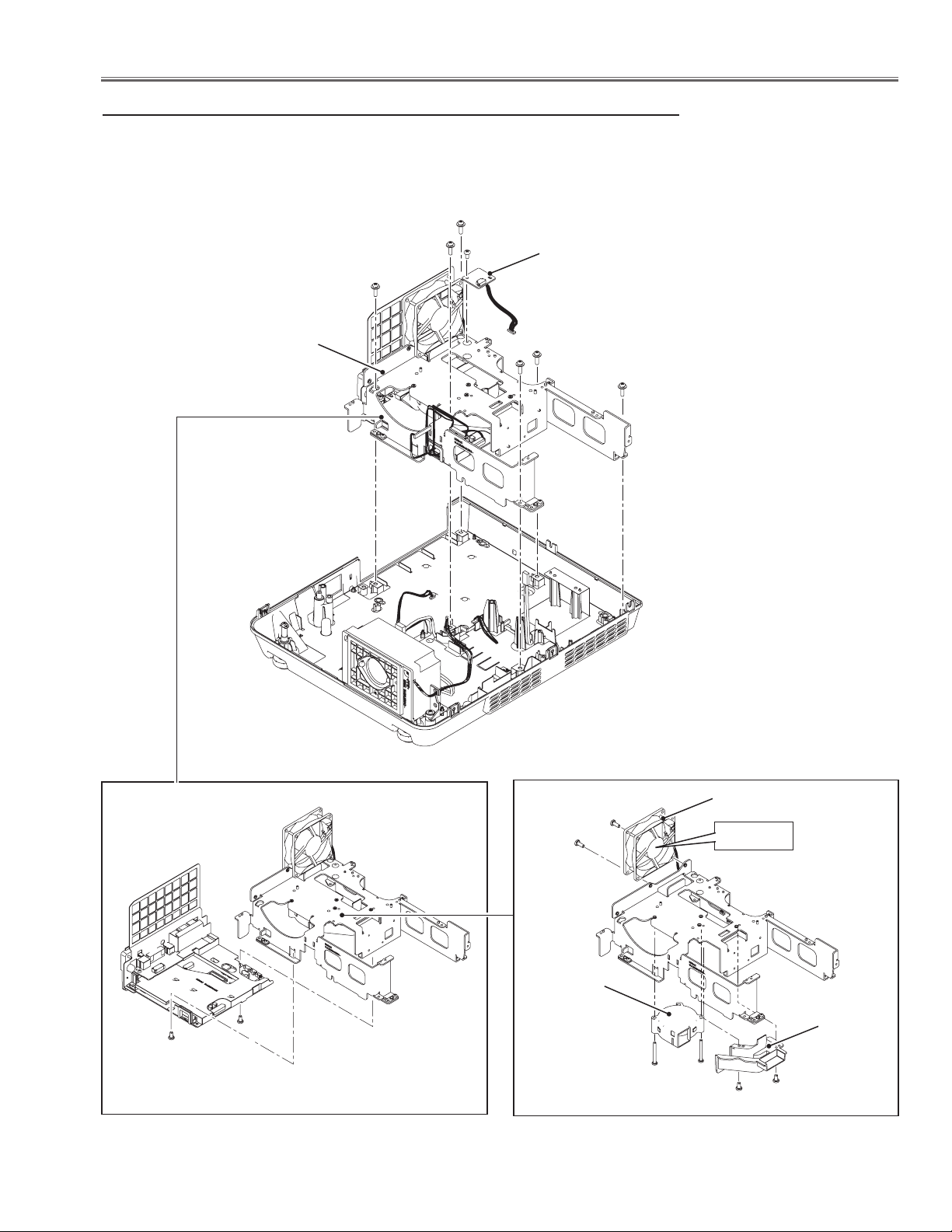

Mechanical Disassembly

, Main, AV Board and Fans (FN901, FN906) removal-2

Insulation

sheet

(M3x6)x2

AV board

(T3x6)x3

(Hex bolt)

x2

Shield cover

Main board

AV panel

(M3x6)x2

(M3x6)x1

(Hex bolt) x4

Bushes

Fig.8

AA

A

Speaker

(T3x6)x2

(T3x8)x5

-20-

Page 21

Mechanical Disassembly

⁄0 Note on wiring

After disassembling the mechanical parts or electrical parts, the wiring cables

must be placed in the original position.

Especially the cable dressing indicated in the figure below, use a fixer not to

touch the cable to the parts on the primary power circuit.

Fix the cables connected to SW902

by using a fixer not to touch the radia

tor on the ballast board.

-

Fig.9

Fix the cables by using a fixer not

to touch the radiator on the ballast

board.

-21-

Page 22

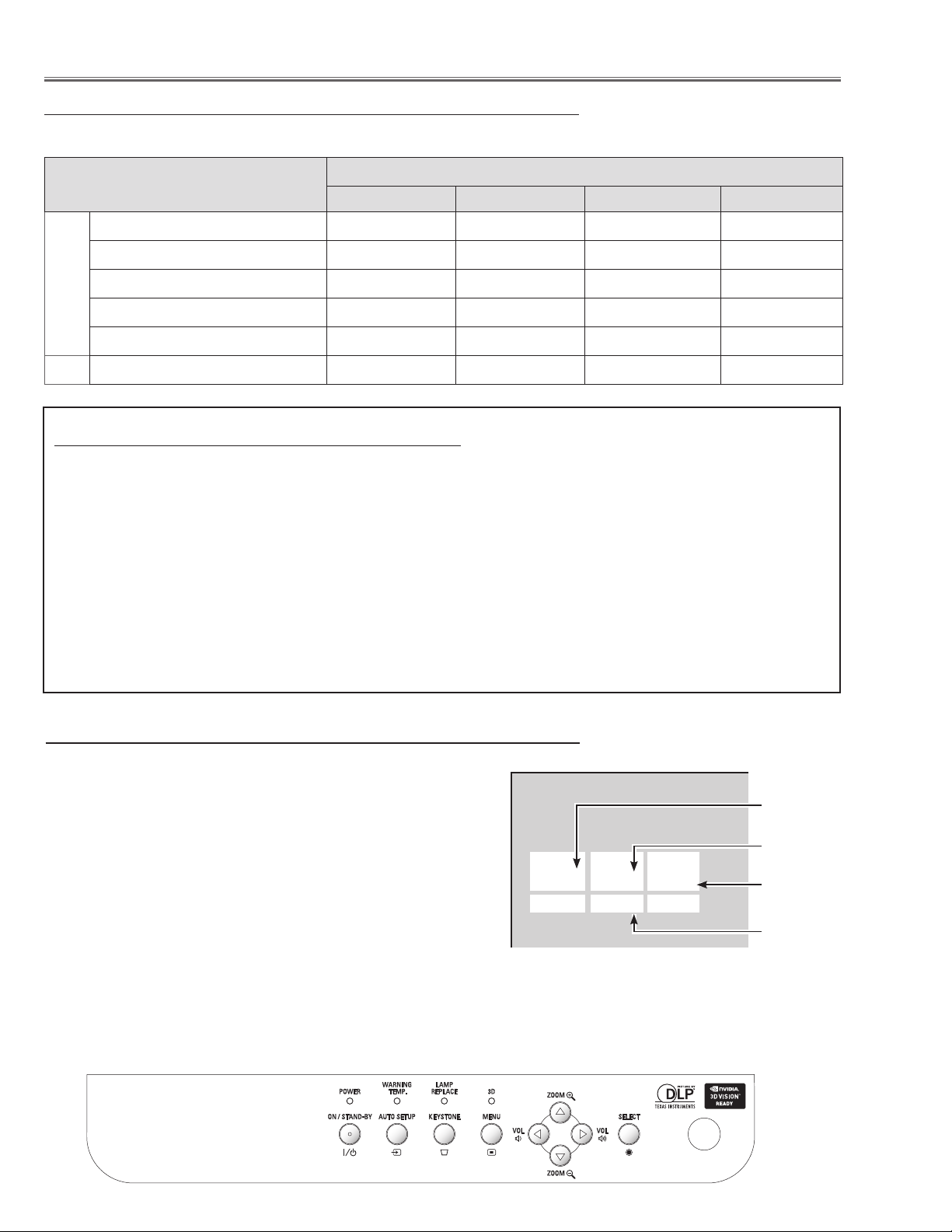

Service Mode

Input Input 1

Image Standard

Group No. Data

0 0 32

Ver. 1.00

Adjustments

Adjustments after Parts Replacement

Optical Unit Color Wheel Power Board Main Board

l : Adjustment necessary ❍ : Check necessary

Disassembly / Replaced Parts

Fan voltage adjustment

Adjustments

Auto calibration adjustment [PC]

Auto calibration adjustment [Component]

Color Index Adjustment-1

Color Index Adjustment-2

Serial no. setting

l l

l

l l

❍

❍

l

Note on Main Board Replacement

l Memory IC replacement (IC1431)

Memory IC on the main board stores the user control value including lamp used time and product serial no. When

the main board is replaced with new one, the lamp used time and serial no. have a null value. To keep the lamp use

time and serial no., the memory IC should be replaced with the one on the previous main board.

l Serial No. Setting

The serial no. displayed on the on-screen menu "Information" is stored in the memory IC on the main board. After

replacing the memory IC on the main board, if the serial no. on the "Information" menu is not displayed correctly,

use the serial no. setting tool to write the correct serial no. referring to the serial no. printed on the rating label. For

further details, refer to the operation manual of the serial no. setting tool [SST LITE v1.00]. The serial no. setting

tool is included in the service CD-RO below;

PROJECTOR SERVICE TOOL CD-ROM v4.20

SERVICE CODE: 610 343 5596

Service Adjustment Menu Operation

To enter the service mode

To enter the “Service Mode”, press and hold the MENU and SELECT button for more than 3 seconds, or press and hold the

MENU button on the remote control for more than 20 seconds.

The service menu appears on the screen as follows.

To adjust service data

Select the adjustment group no. by pressing the MENU button

(increase) or SELECT button (decrease), and select the adjustment item no. by pressing the pointer e or d button, and change

the data value by pressing the 7 or 8 button. Refer to the “Service Adjustment Data Table” for further description of adjustment

group no., item no. and data value.

To exit the service mode

To exit the service mode, press the ON/STAND-BY button.

-22-

Group No.

Item No.

Data value

Firmware

Version No.

Page 23

Adjustments

White 100%

Black 100%

W

Y C

G

M

R

B

BLK

BK-W

BK-R

BK-G

BK-B

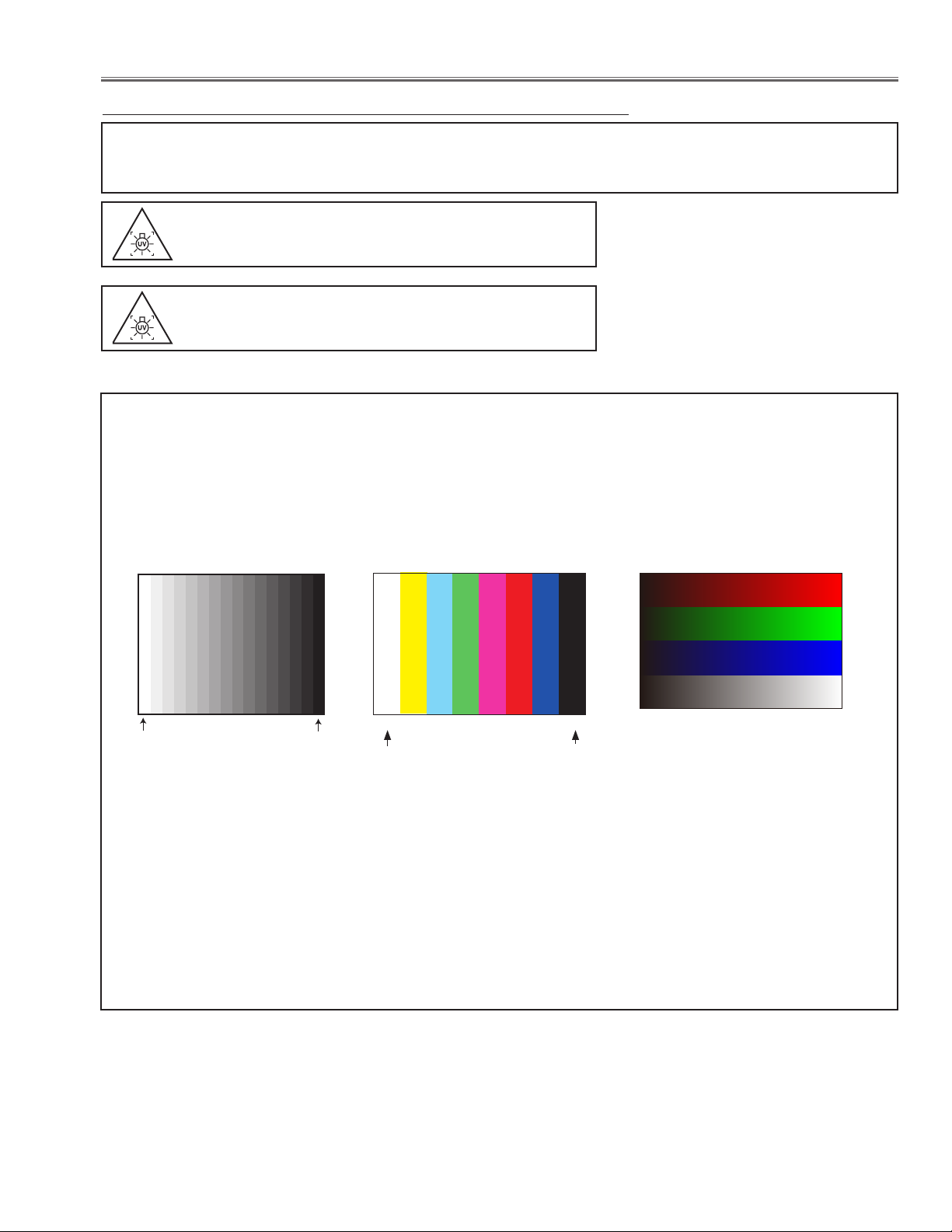

Circuit Adjustments

CAUTION: The each circuit has been made by the fine adjustment at factory. Do not attempt to adjust the following

adjustments except requiring the readjustments in servicing otherwise it may cause loss of performance

and product safety. Before adjustment, please turn on the projector more than ten minutes.

WARNING : USE UV RADIATION EYE AND SKIN

PROTECTION DURING SERVICING.

CAUTION:

To prevent suffer of UV radiation, those adjust

ments must be completed within 25 minutes.

[Adjustment Condition]

l Input signal

Analog Computer signal ..... 0.7Vp-p/75W terminated (XGA)

Composite Video signal ....

Component Video signal .... 0.7Vp-p/75W terminated (480i)

1.0Vp-p/75W terminated (NTSC / PAL)

-

l Input signal patterns

RGBW Ramp pattern

16 steps gray scale pattern

l Image mode ........................

l Lamp control .......................

White 100%

Standard

Normal

8 color 100% color bar

Black 100%

(Internal signal)

l 3D mode ............................ Off

Note:

* Please refer to “Service Adjustment Menu Operation” for entering the service mode and adjusting the service data.

-23-

Page 24

Adjustments

K47A

1

2

49

50

K07A

2

29

30

K07B

K00A

K77B

K77C

K77D

K77E

K77F

K47B

TPFAN1

TPFAN2

TPFAN3

TPFAN4

TPFAN5

TPFAN6

TPFANGND

z Fan Voltages adjustment

Equipment Digital voltmeter

1. Enter the service mode.

2. Connect the Digital voltmeter to the test point listed

below.

3. Adjust the voltage on each test point by changing the

data values of the Group - No.

Group No. Test Point Adjustment value

250 - 0 TPFAN1 4.5 -0 +0.1Vdc

250 - 1 TPFAN1 13.8 -0 +0.1Vdc

250 - 2 TPFAN1 4.5 -0 +0.1Vdc

250 - 3 TPFAN2 13.8 -0 +0.1Vdc

250 - 4 TPFAN3 4.5 -0 +0.1Vdc

250 - 5 TPFAN3 13.8 -0 +0.1Vdc

250 - 6 TPFAN4 4.5 -0 +0.1Vdc

250 - 7 TPFAN4 13.8 -0 +0.1Vdc

250 - 8 TPFAN5 4.5 -0 +0.1Vdc

250 - 9 TPFAN5 13.8 -0 +0.1Vdc

250 - 10 TPFAN6 4.5 -0 +0.1Vdc

250 - 11 TPFAN6 13.8 -0 +0.1Vdc

x PC Auto calibration

Input mode Computer 1 (RGB) mode

Input signal 16-step gray scale computer signal

1. Enter the service mode.

2.

Select Group "260", No. "0" and set data value "0" to

"1".

The projector begins auto-calibration and then "OK"

will appear on the screen.

c

Component Auto calibration

Input mode Computer 1 (Component) mode

Input signal 100% color bar signal (480i)

1. Enter the service mode.

2.

Select Group "260", No. "0" and set data value "0" to

"1".

The projector begins auto-calibration and then "OK"

will appear on the screen.

FANNET Board

Adjustments item no. [2] to [3] are carried out at the

spare parts shipment in the factory, therefore they are

not required when the main board is replaced with

new one.

-24-

Page 25

Adjustments

�

9 0 0 0 0 0 0 0 0 2 W 0 7 0

�

“ 0 7 0 ”

v Color Index adjustment-1

Condition Dark room

Input mode Computer 1 (RGB) mode

Image mode Dynamic

Input signal RGBW-Ramp pattern (Internal sig-

nal)

1. Enter the service mode.

2.

Select Group "151", No. "21" and set data value to

"1". The RGBW-Ramp internal pattern is displayed on

the screen.

3.

Select Group "151", No. "0" and set data value to the

specified index value which is printed on the label of

the optical unit.

4. Check that the proper gradation color image is reproduced on the screen.

* Only this adjustment is needed when the Optical unit or

Main board is replaced.

Label on the optical unit

b Color Index adjustment-2

Condition Dark room

Input mode Computer 1 (RGB) mode

Image mode Dynamic

Input signal RGBW-Ramp pattern (Internal sig-

nal)

1. Enter the service mode.

2.

Select Group "151", No. "21" and set data value to

"1". The RGBW-Ramp internal pattern is displayed on

the screen.

3.

Select Group "151", No. "0" and change data value to

obtain the proper gradation color image is reproduced

on the screen

* Only this adjustment is needed when the Color Wheel

is replaced.

3-digit index value

-25-

Page 26

Adjustments

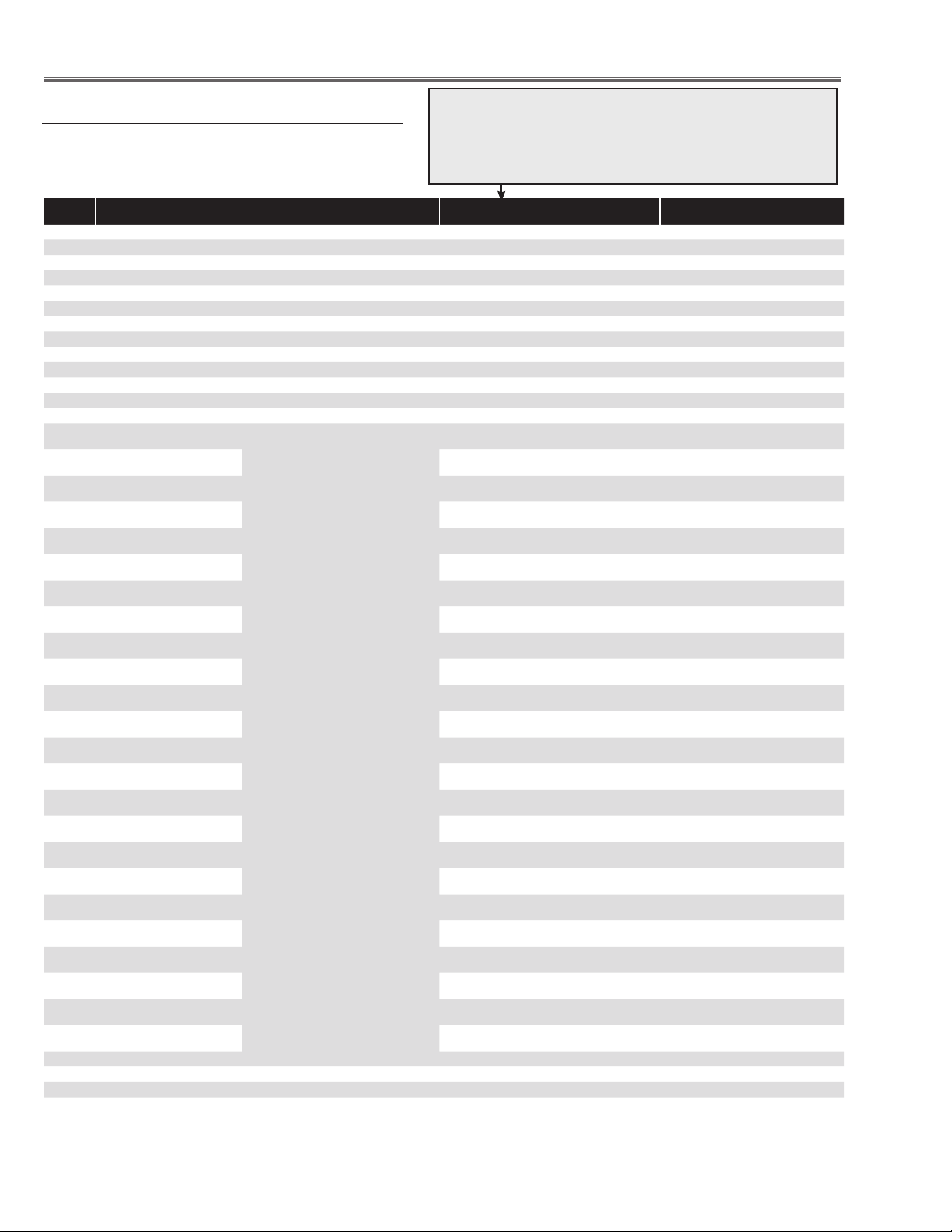

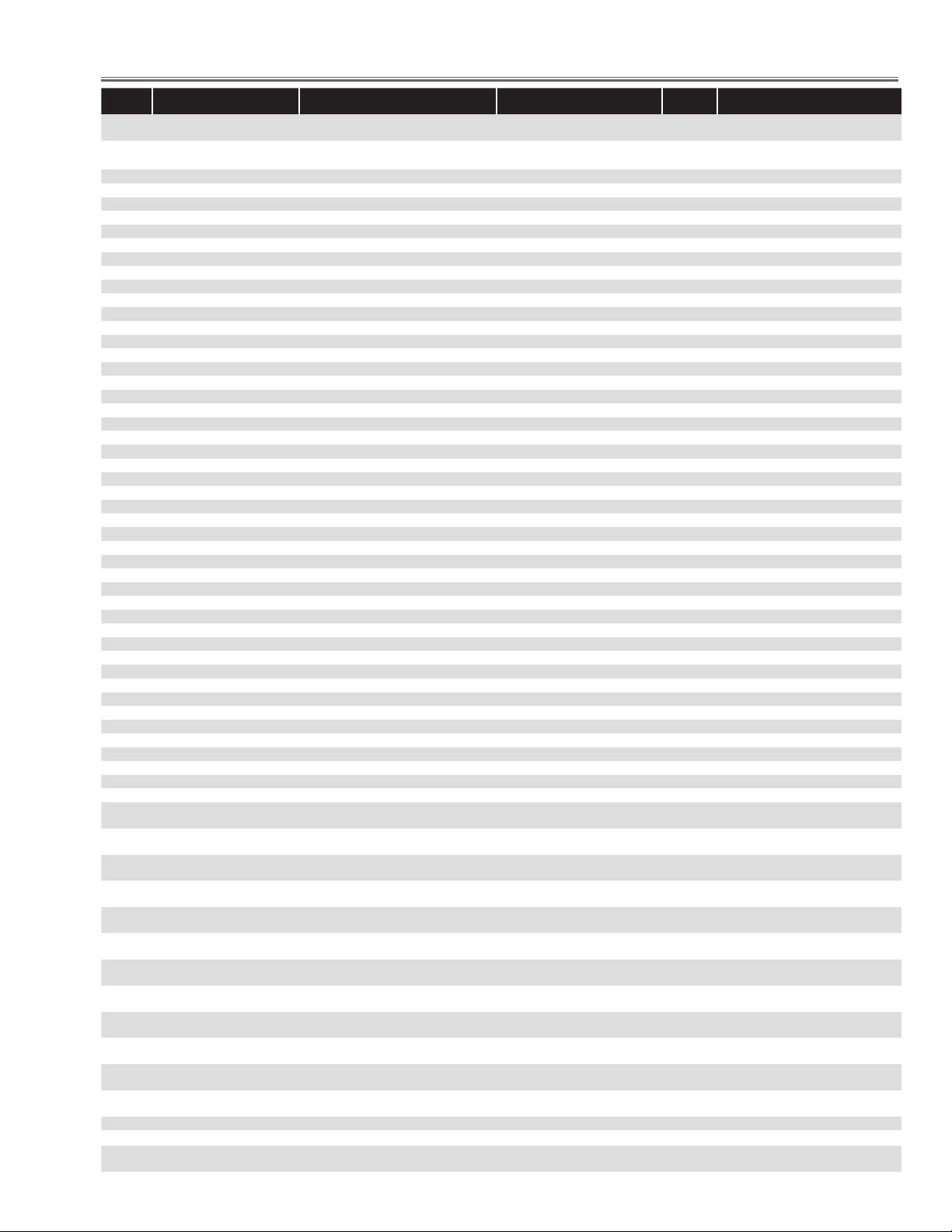

Service Adjustment Data Table

These initial values are the reference data written from the CPU

ROM to memory IC when replaced new memory IC. The adjust

ment items indicated with “

to the “Electrical adjustments”. Other items should be used with

the initial data value.

Group/

Group 0 AD Converter (AF1000)

Group 60 Image

Item Name Function Initial Range Note

Item

0 Green Offset PC / Component 512/512 0 - 4095

1 Red Offset PC / Component 512/512 0 - 4095

2 Blue Offset PC / Component 512/512 0 - 4095

3 Green Coarse Gain PC / Component 7/7 0 - 15

4 Red Coarse Gain PC / Component 7/7 0 - 15

5 Blue Coarse Gain PC / Component 7/7 0 - 15

6 Green Fine Gain PC / Component 0/0 0 - 255

7 Red Fine Gain PC / Component 0/0 0 - 255

8 Blue Fine Gain PC / Component 0/0 0 - 255

9 SCART SOG Thresh SCART only 12 0 - 31

0 Center Contrast

1 Center Brightness

2 Center Color

3 Center Tint

4 Fixed Sharpness (Up scaling)

5 Fixed Sharpness (Down scaling)

6 Center Sharpness (not FPGA)

7 Center WB Red

8 Center WB Green

9 Center WB Blue

10 Center BB Red

11 Center BB Green

12 Center BB Blue

13 Alpha Contrast

14 Alpha Brightness

15 Alpha Color

16 Alpha Tint

17 Alpha Sharpness

18 Alpha WB Red

19 ALpha WB Green

20 Alpha WB Blue

21 Alpha BB Red

22 Alpha BB Green

23 Alpha BB Blue

Group:

Composite/S-Video/Component/Digital/D-RGBVideo/Alanou RGB

RGB-Video/HDCP-PC/HDCP-AV/SCART

98/98/106/98/98/106

106/98/98/106/100

0/0/0/0/0/0

0/0/0/0/0

100/100/100/100100/100

100/100/100/100/100

0/0/0/0/00

0/0/0/0/0

8/8/8/12/8/12

8/12/8/8/8

8/8/8/8/8/8

8/8/8/8/8

16/16/16/16/16/16

16/16/16/16/16

512/512/512/512/512/512

512/512/512/512/512

512/512/512/512/512/512

512/512/512/512/512

512/512/512/512/512/512

512/512/512/512/512

512/512/512/512/512/512

512/512/512/512/512

512/512/512/512/512/512

512/512/512/512/512

512/512/512/512/512/512

512/512/512/512/512

60/60/60/60/60/60

60/60/60/60/60

90/90/90/90/90/90

90/90/90/90/90

40/140/140/140/140/140

140/140/140/140/140

10/10/10/10/10/10

10/10/10/10/10

10/10/10/10/10/10

10/10/10/10/10

40/40/40/40/40/40

40/40/40/40/40

40/40/40/40/40/40

40/40/40/40/40

40/40/40/40/40/40

40/40/40/40/40

20/20/20/20/20/20

20/20/20/20/20

20/20/20/20/20/20

20/20/20/20/20

20/20/20/20/20/20

20/20/20/20/20

-

✻” are required to readjust following

0 - 1023

0 - 1023

0 - 1023

0-180

0 - 37

0 - 37

0 - 37

0 - 1023

0 - 1023

0 - 1023

0 - 1023

0 - 1023

0 - 1023

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0 - 1000

0-1000

Group 151 Color Wheel

0 Index Delay Index Value of Color Wheel 70 0 - 360

20 Raster Pattern

0: Off

1: Blue Back 2: Green Back

3: Red Back 4: Black Back

5: White Back 6: 60% Blue Back

7: 10% Gray Back 8: 30% Gray Back

9: 50% Gray Back 10: Cyan Back

11: Magenta Back 12: Yellow Back

0 0 - 12

-26-

Page 27

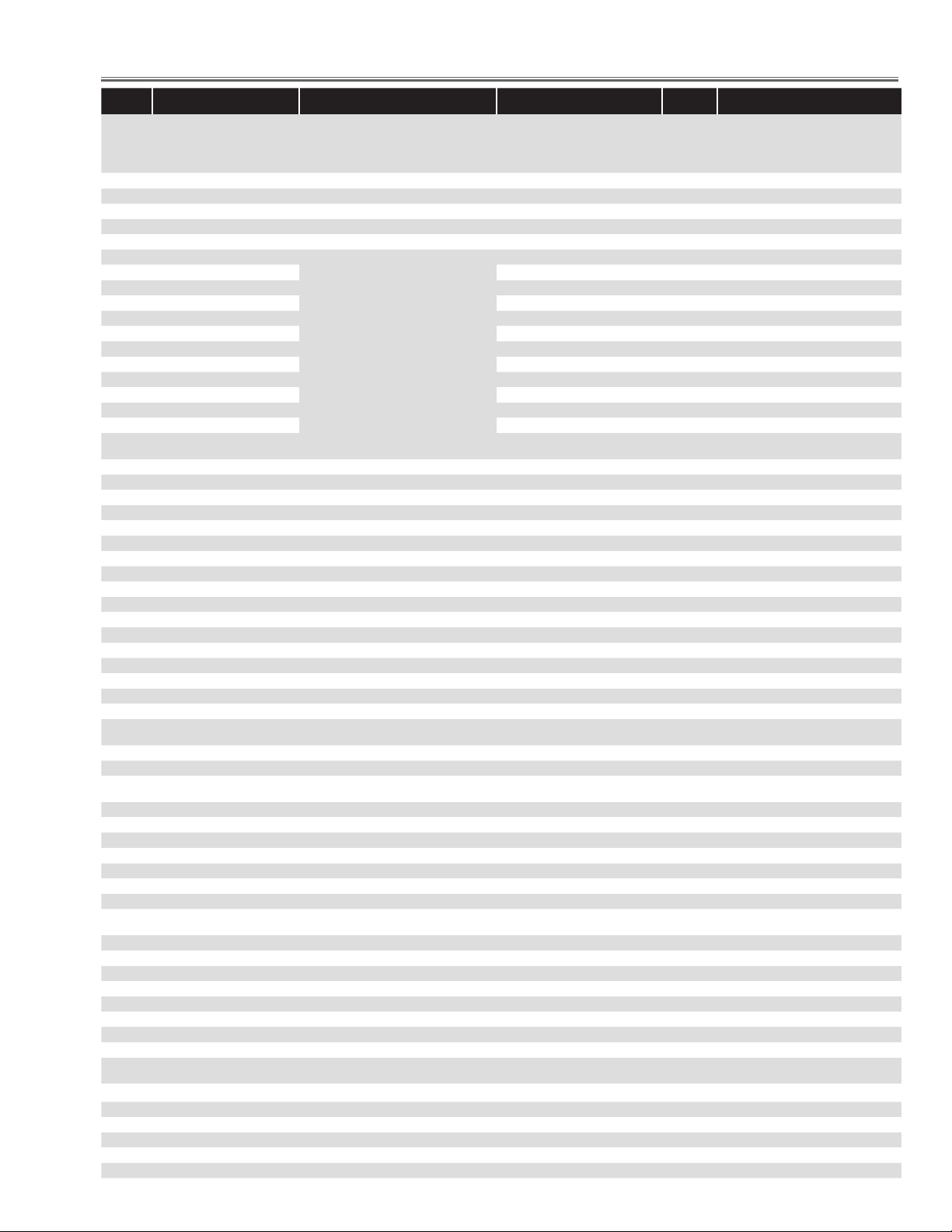

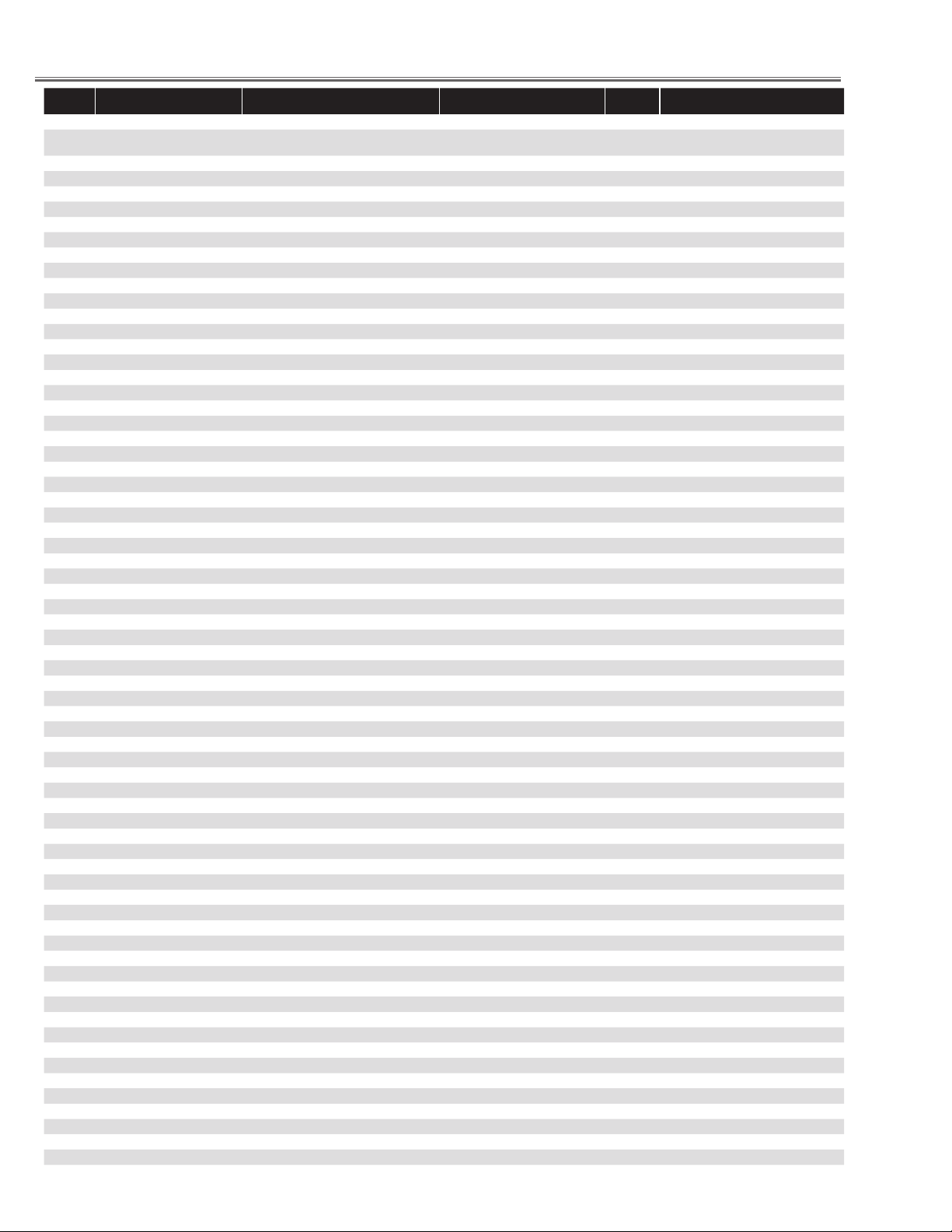

Adjustments

Group/

Group 155 CCA

Group 156 Color Matching - Measured Data

Group 160 Waveform Index

Item Name Function Initial Range Note

Item

21 Test Pattern

0 CCA Disable 0: CCA Enable, 1: Disable 0 0 - 1

0 Measured Red -X

1 Measured Red -Y 0 - 1000

2 Measured Red -Luma 0 - 32767

10 Measured Green -X 0 - 1000

11 Measured Green -Y 0 - 1000

12 Measured Green -Luma 0 - 32767

20 Measured Blue -X 0 - 1000

21 Measured Blue -Y 0 - 1000

22 Measured Blue -Luma 0 - 32767

70 Measured Full White -X 0 - 1000

71 Measured Full White -Y 0 - 1000

72 Measured Full White -Luma 0 - 32767

100 measured Data Update

120 Measured Test Pattern OFF / Red / Green / Blue / Full White 0 - 4

0 Bright Image Mode Image = Dynamic 0 0 - 10

1 Normal Image Mode Image = Standard 0 0 - 10

2 Color Image Mode Image = Cinema 0 0 - 10

3 Normal 120Hz 120Hz Mode 0 0 -10

4 3D Image Mode 3D Mode 0 0 - 10

0: Off 1: Color Ramp

2: Color Bar 3: 16 step

4: Grid 5: Green Grid

6: 1-line Pattern 7: 1-dot Pattern

8: BC Calibration 9: Half Cross

Adjust Color matching Data

0: Image = Dynamic mode

1: Image = Standard mode

2: Image = Cinema mode

3: 120Hz Output mde

4: 3D mode

* This data will be effective after executing the

item 100.

Update the Measured Data when the value is

set to 10.

0 0 - 9

0 - 1000

0 - 10

Group 161 Lamp Sync Delay

0 Bright Image Mode Image = Dynamic 190 0 - 32767

1 Normal Image Mode Image = Standard 190 0 - 32767

2 Color Image Mode Image = Cinema 190 0 - 32767

3 Normal 120Hz 120Hz Mode 190 0 - 32767

4 3D Image Mode 3D Mode 190 0 - 32767

Group 200 Option

0

Logo Prohibition (Forced No Brand)

1 RS232C Baudrate Baud Rate 0: 19200bps, 1: 9600bps 0 0 - 1

4 CABLE SW Long Cable 0: Disable, 1: Enable 0 0 - 1

5 PW Debug Command Enable

8 Network Hung up Check 0: Enable, 1: Disable 0 0 - 1

51 Filter Warning Display Filter Waring Display On/Off 0: Off, 1: On 1 0 - 1

53 Filter Counter Reset Times Reset Times 0 0 - 255

54 Factory Default Execute Times Reset Times 0 0 - 255

63 Source Search Enable Siurce Search Enable o: Disable, 1: Enable 1 0 - 1

80 Destination Setting Shipping Destination 0: English, 1: Japanese 0 0 - 1

111 Sound Mute 0: work alone, 1: Work with Video Mute 1 0 - 1

120 HDMI CONT

Group 201 Option (signal)

0 VSBEG 8 0 - 255

Group 220 Error Log

0 Waring Log 1 Latest Error Log 0 0 - 32767

~ Warning Log x th x th old Error Log 0 0 - 32767

49 Warinig Log 50 50th old Error Log 0 0 - 32767

50 Warinig Log Reset

Logo Prohibition (0: Menu, 1: Forced, 2: China,

3-9: not used) Effective after AC On

0:Disable (Serial Command Eanble)

1: Enable (PW Debug Mode)

0: EDID/HPD Manual Control in the Standby

1: EDID/HPD Auto Control in the Standby

Resets All Warning Logs when the value is set

to 10.

0 0 - 2

0 0 - 1

1 0 - 1

0 0 - 10

Group 250 FAN Voltage Adjustment

0 Fan1 Min. Adjust (DAC) 25 0 - 255

1 Fan1 Max. Adjustt(DAC) 235 0 - 255

2 Fan2 Min. Adjust (DAC) 27 0 - 255

3 Fan2 Max. Adjust (DAC) 237 0 - 255

-27-

Page 28

Adjustments

L3

L2

L4

L1

Group/

Group 252 Fan Option

Item Name Function Initial Range Note

Item

4 Fan3 Min. Adjust (DAC) 31 0 - 255

5 Fan3 Max. Adjust (DAC) 234 0 - 255

6 Fan4 Min. Adjust (DAC) 27 0 - 255

7 Fan4 Max. Adjust (DAC) 237 0 - 255

8 Fan5 Min. Adjust (DAC) 28 0 - 255

9 Fan5 Max. Adjust (DAC) 239 0 - 255

10 Fan6 Min. Adjust (DAC) 28 0 - 255

11 Fan6 Max. Adjust (DAC) 238 0 - 255

1 Safety Switch For Safety Application purpose 0 0 - 4

2 Fan Manual Switch 0: Auto, 1: Manual 0 0 - 1

3 Fan1 Manual Voltage Fan1 Voltage (x0.1V) 100 0 - 145

4 Fan2 Manual Voltage Fan2 Voltage (x0.1V) 100 0 - 145

5 Fan3 Manual Voltage Fan3 Voltage (x0.1V) 100 0 - 145

6 Fan4 Manual Voltage Fan4 Voltage (x0.1V) 100 0 - 145

7 Fan5 Manual Voltage Fan5 Voltage (x0.1V) 100 0 - 145

8 Fan6 Manual Voltage Fan6 Voltage (x0.1V) 100 0 - 145

9 All Fan MaxMin Control

Forced Fan Mode

0: Normal, 1: Normal-Min, 2: Normal-Max,

3: Eco-Min, 4: Eco Mox

0 0 - 4

Group 253 FAN Error Setting

L1

0 Temp A Warning (Normal)

1 Temp B Warning (Normal)

2 Temp C Warning (Normal)

3 Temp B-A Waninig (Normal)

4 Temp C-A Warning (Normal)

5 Temp A Warning (Eco)

6 Temp B Warning (Eco)

7 Temp C Warning (Eco)

8 Temp B-A Warninig (Eco)

9 Temp C-A Warning (Eco)

10 Temp A Warning Offset (Temp) 12 0 - 100

11 Temp B Warning Offset (Temp) 11 0 - 100

12 Temp C Warning Offset (Temp) 13 0 - 100

13 Temp B-A Warning Offset (Temp) 11 0 - 100

14 Temp C-A Warning Offset (Temp) 13 0 - 100

15 Temp A Warning Offset (Time) 30 0 - 40

16 Temp B Warning Offset (Time) 15 0 - 40

17 Temp C Warning Offset (Time) 15 0 - 40

18 Temp B-A Warning Offset (Time) 15 0 - 40

19 Temp C-A Warning Offset (Time) 15 0 - 40

Temperature A to judge the Temp. Failure

Outside at Normal

Temperature B to judge the Temp. Failure DMD

at Normal

Temperature C to judge the Temp. Failure Lamp

at Normal

Temperature B-A to judge the Temp. Failure

Filter Clogged at Normal

Temperature C-A to judge the Temp. Failure

Filter Clogged at Normal

Temperature A to judge the Temp. Failure

Outside at Eco

Temperature B to judge the Temp. Failure DMD

at Eco

Temperature C to judge the Temp. Failure Lamp

at Eco

Temperature B-A to judge the Temp. Failure

Filter Clogged at Eco

Temperature C-A to judge the Temp. Failure

Filter Clogged at Eco

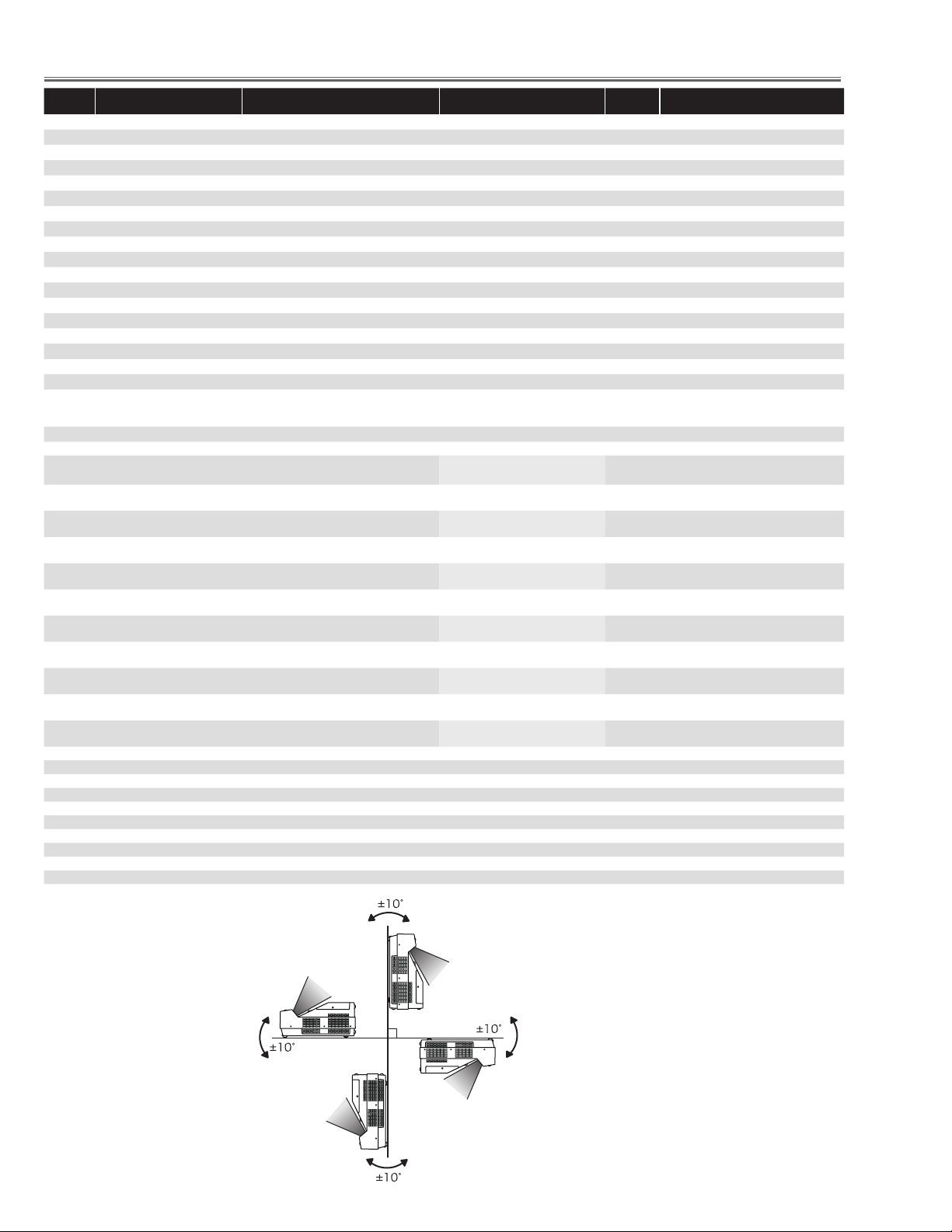

NormalL2CeilingL3BottomL4Up

48 48 48 48 30 - 100

68 67 67 68 30-100

68 67 68 68 30-100

100 100 100 100 0-100

100 100 100 100 0-100

50 49 49 49 30 - 100

71 71 70 70 0 - 100

73 72 73 73 0 - 100

100 100 100 100 0 - 100

100 100 100 100 0 - 100

-28-

Page 29

Adjustments

Group/

Group 254 FAN Control Range Setting (Temp./Voltage)

Item Name Function Initial Range Note

Item

L1

0 Normal Fan Control Min. Temp Temp Sensor Control Start/End at Normal 27 27 27 27 20 - 100

1 Normal Fan Control Max. Temp 36 36 36 36 20 - 100

2 Normal Fan1 Min. Fan Voltage at Normal (x0.1V) 62 62 62 62 0 - 255

3 Normal Fan1 Max. 138 138 138 138 0 - 255

4 Normal Fan2 Min. 90 70 105 55 0 - 255

5 Normal Fan2 Max. 95 70 110 70 0 - 255

6 Normal Fan3 Min. 75 95 55 115 0 - 255

7 Normal Fan3 Max. 75 105 75 120 0 - 255

8 Normal Fan4 Min. 80 80 80 80 0 - 255

9 Normal Fan4 Max. 138 138 138 138 0 - 255

10 Normal Fan5 Min. 75 78 78 75 0 - 255

11 Normal Fan5 Max. 138 138 138 138 0 - 255

12 Normal Fan6 Min. 55 55 55 55 0 - 255

13 Normal Fan6 Max. 135 135 135 135 0 - 255

16 Eco Fan Control Min. Temp Temp Sensor Control Start/End at Eco 27 27 27 27 20 - 100

17 Eco Fan Control Max. Temp 37 37 37 37 20 - 100

18 Eco Fan1 Min. Fan Voltage at Eco (x0.1V) 60 60 60 60 0 - 255

19 Eco Fan1 Max. 70 70 70 70 0 - 255

20 Eco Fan2 Min. 60 50 60 45 0 - 255

21 Eco Fan2 Max. 70 55 70 50 0 - 255

22 Eco Fan3 Min. 50 65 50 65 0 - 255

23 Eco Fan3 Max. 55 75 55 75 0 - 255

24 Eco Fan4 Min. 60 60 60 60 0 - 255

25 Eco Fan4 Max. 120 120 120 120 0 - 255

26 Eco Fan5 Min. 52 55 55 52 0 - 255

27 Eco Fan5 Max. 110 110 110 110 0 - 255

28 Eco Fan6 Min. 50 50 50 50 0 - 255

29 Eco Fan6 Max. 115 115 115 115 0 - 255

NormalL2CeilingL3BottomL4Up

Group 255 FAN Start/Cooling Setting

0 Fan1 Initial Volt Fan Voltage at Startup (x0.1V) 70 0 - 255

1 Fan2 Initial Volt 60 0 - 255

2 Fan3 Initial Volt 60 0 - 255

3 Fan4 Initial Volt 65 0 - 255

4 Fan5 Initial Volt 70 0 - 255

5 Fan6 Initial Volt 60 0 - 255

7 Cooling Time L1 Cooling Time at L1 (x 30 sec.) 2 1 - 15

8 Cooling Time L2 Cooling Time at L2 (x 30 sec.) 3 1 - 15

9 Temp Error Cooling Time Cooling Time at Temp Error (x 30sec.) 3 1 - 15

10 onStart Cooling Start Threshold Cooling Star t Threshold Temp at On Start 46 0 - 100

11 After Shutdown Cooling Cooling On/Off After Shutdown 1 0 - 1

12 L1 Cooling Volt Fan2 Cooling Fan Voltage at L1 (x0.1V) 40 0 - 255

13 L1 Cooling Volt Fan3 40 0 - 255

14 L1 Cooling Volt Fan4 60 0 - 255

Group 259 FAN Atmosphere Setting

Temp A Warning (Normal, High-

10

Land ON1)

Temp B Warning (Normal, High-

11

Land ON1)

Temp C Warning (Normal, High-

12

Land ON1)

Temp A Warning (Eco, HighLand

13

ON1)

Temp B Warning (Eco, HighLand

14

ON1)

Temp C Warning (Eco, HighLand

15

ON1)

Temp A Warning (Normal, High-

16

Land ON2)

Temp B Warning (Normal, High-

17

Land ON2)

Temp C Warning (Normal, High-

18

Land ON2)

Temp A Warning (Eco, HighLand

19

ON1)

Temp B Warning (Eco, HighLand

20

ON1)

Temp C Warning (Eco, HighLand

21

ON1)

Temperature A to judge the Temp. Failure

Outside at Normal and HighLand ON1

Temperature B to judge the Temp. Failure DMD

at Normal and HighLand ON1

Temperature C to judge the Temp. Failure Lamp

at Normal and HighLand ON1

Temperature A to judge the Temp. Failure

Outside at Eco and HighLand ON1

Temperature B to judge the Temp. Failure DMD

at Eco and HighLand ON1

Temperature C to judge the Temp. Failure Lamp

at Eco and HighLand ON1

Temperature A to judge the Temp. Failure

Outside at Normal and HighLand ON2

Temperature B to judge the Temp. Failure DMD

at Normal and HighLand ON2

Temperature C to judge the Temp. Failure Lamp

at Normal and HighLand ON2

Temperature A to judge the Temp. Failure

Outside at Eco and HighLand ON2

Temperature B to judge the Temp. Failure DMD

at Eco and HighLand ON2

Temperature C to judge the Temp. Failure Lamp

at Eco and HighLand ON2

42 0 - 100

62 0 - 100

62 0 - 100

42 0 - 100

61 0 - 100

64 0 - 100

37 0 - 100

58 0 - 100

53 0 - 100

59 0 - 100

38 0 - 100

58 0 - 100

Group 260 Auto Calibration (Commn) * Auto Calibration

0 Execute Calibration

Executes Auto-Calibration when the value is set

to1

0 0 - 1

-29-

Page 30

Adjustments

Group/

Group 261 Auto Calibration (RGB)

Group 262 Auto Calibration (CVBS/SVIDEO/YCbCr 480i)

Item Name Function Initial Range Note

Item

1 Loop Count Maximum Execution Times (OFFSET->GAIN) 20 1 - 30

2 Auto Status

3 AutoWait Wait Value for each setting - 1 - 20

4 CHECK -Tolelance Torelance of OFFSET 16 1 - 255

5 Time out Wait Wait Time until Time out 20 1 - 255

0 OFFSET AREA H START Black Level Acquiring Area H-Start Position 975 0 - 1000

1 OFFSET AREA V START Black Level Acquiring Area V-Start Position 500 0 - 1000

2 GAIN AREA H START White Level Acquiring Area H-Start Position 25 0 - 1000

3 GAIN AREA V START White Level Acquiring Area V-Star t Position 500 0 - 1000

4 Image AREA H WIDTH Black/White Level Acquiring Area 13 0 - 4095

5 Image AREA V HIGHT Black/White Level Acquiring Area Height 9 0 - 4095

6 OFFSET target Target Value of Black Level Adj. 0 0 - 1023

7 OFFSET torelance Torelance of Black Level Adj. 8 1 - 1023

8 GAIN target Target Value of White Level Adj. 940 0 - 1023

9 GAIN torelance Torelance of White Level Adj. 2 1 - 1023

10 Image Level Tolerance Tolerance of Image Level Adj. 4 1 - 255

0 Y Image Area Start X Y Acquiring Area H-Star t Position 0 - 1000

1 Y Image Area Start Y Y Acquiring Area V-Start Position 0 - 1000

6 Image Area H Width Image Level Acquiring Area 0 - 4095

7 Image Area V Hight Image Level Acquiring Area Height 0 - 4095

8 Y Target Level Target Value of Y Level Adj. 0 - 1023

11 Gain Tolerance Torelance of Level Adj. 1 - 255

12 Image Level Tolerance Tolerance of Image Level Adj. 1 - 255

Result of Auto-Calibration (Last Memory)

0: OK, 1: Adjusting, 2: Error

0 0 / 1 / 9

Group 264 Auto Calibration (YCbCr)

0 Y-OFFSET AREA H START Y - Offset Acquiring Area H-Start Position 925 0 - 1000

1 Y-OFFSET AREA V START Y - Offset Acquiring Area V-Start Position 500 0 - 1000

2 CB - OFFSET AREA H START CB - Offset Acquiring Area H-Start Position 925 0 - 1000 If not used: use Y's value

3 CB - OFFSET AREA V START CB - Offset Acquiring Area V-Start Position 500 0 - 1000 If not used: use Y's value

4 CR - OFFSET AREA H START CR - Offset Acquiring Area H-Star t Position 925 0 - 1000 If not used: use Y's value

5 CR - OFFSET AREA V START CR - Offset Acquir ing Area V-Start Position 500 0 - 1000 If not used: use Y's value

6 Y - GAIN AREA H START Y-Gain 50 0 - 1000

7 Y - GAIN AREA V START Y-Gain 500 0 - 1000

8 CB - GAIN AREA H START CB-Gain 800 0 - 1000

9 CB - GAIN AREA V START CB-Gain 500 0 - 1000

10 CR - GAIN AREA H START CR-Gain 700 0 - 1000

11 CR - GAIN AREA V START CR-Gain 500 0 - 1000

12 Image AREA H WIDTH YCBCR Level Acquiring Area 13 0 - 4095

13 Image AREA V HIGHT YCBCR Level Acquiring Area Height 9 0 - 4095

14 Y - OFFSET TARTGET 1 0 - 1023

15 CB OFFSET TARGET 512 0 - 1023

16 CR OFFSET TARGET 512 0 - 1023

17 Y - GAIN TARGET 808 0 - 1023

18 CB - GAIN TARGET 892 0 - 1023

19 CR - GAIN TARGET 892 0 - 1023

20 OFFSET torelance Torelance of OFFSET Adj. 4 1 - 255

21 GAIN torelance Torelance of GAIN Adj. 4 1 - 255

22 Image Level Tolerance Tolerance of Image Level Adj. 4 1 - 255

Group 500 SCART (480i)

2 H Back Porch 119 0 ~ 4095

3 V Back Porch 19 0 ~ 4095

7 Overscan 52 0 - 255

8 VSBEG 14 0 - 255

16 Field Diff Even/Odd Phase Compensation 1 0 - 2

Group 501 SCART (525i)

2 H Back Porch 128 0 ~ 4095

3 V Back Porch 24 0 ~ 4095

7 Overscan 66 0 - 255

8 VSBEG 14 0 - 255

16 Field Diff Even/Odd Phase Compensation 1 0 - 2

Group 510 RGB Video (480i)

2 H Back Porch 116 0 ~ 4095

3 V Back Porch 19 0 ~ 4095

7 Overscan 52 0 - 255

-30-

Page 31

Adjustments

Group/

Group 511 RGB Video (575i)

Group 512 RGB Video (480p)

Group 513 RGB Video (575p)

Group 514 RGB Video (720p - 60)

Group 515 RGB Video (720p - 50)

Group 516 RGB Video (1080i - 60)

Group 517 RGB Video (1080i - 50)

Group 519 RGB Video (1080p - 60)

Group 520 RGB Video (1080p -50)

Group 521 RGB Video (1080p - 30)

Group 522 RGB Video (1080p - 25)

Group 523 RGB Video (1080p - 24)

Item Name Function Initial Range Note

Item

8 VSBEG 66 0 - 255

15 Field Diff (SEP) Even/Odd Phase Compensation on HV Sync 0 0 - 2

16 Field (SOG) Even/Odd Phase Compensation on SOG Sync 1 0 - 2

2 H Back Porch 134 0 ~ 4095

3 V Back Porch 22 0 ~ 4095

7 Overscan 68 0 - 255

8 VSBEG 50 0 - 255

15 Field Diff (SEP) Even/Odd Phase Compensation on HV Sync 1 0 - 2

16 Field (SOG) Even/Odd Phase Compensation on SOG Sync 1 0 - 2

2 H Back Porch 123 0 ~ 4095

3 V Back Porch 36 0 ~ 4095

7 Overscan 48 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 133 0 ~ 4095

3 V Back Porch 44 0 ~ 4095

7 Overscan 38 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 300 0 ~ 4095

3 V Back Porch 25 0 ~ 4095

7 Overscan 24 0 - 255

8 VSBEG 10 0 - 255

2 H Back Porch 298 0 ~ 4095

3 V Back Porch 25 0 ~ 4095

7 Overscan 24 0 - 255

8 VSBEG 10 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 20 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 11 0 - 255

15 Field Diff (SEP) Even/Odd Phase Compensation on HV Sync 1 0 - 2

16 Field (SOG) Even/Odd Phase Compensation on SOG Sync 1 0 - 2

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 22 0 ~ 4095

7 Overscan 24 0 - 255

8 VSBEG 9 0 - 255

15 Field Diff (SEP) Even/Odd Phase Compensation on HV Sync 0 0 - 2

16 Field (SOG) Even/Odd Phase Compensation on SOG Sync 1 0 - 2

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 41 0 ~ 4095

7 Overscan 25 0 - 255

8 VSBEG 5 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 41 0 ~ 4095

7 Overscan 25 0 - 255

8 VSBEG 5 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 41 0 ~ 4095

7 Overscan 25 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 41 0 ~ 4095

7 Overscan 25 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 41 0 ~ 4095

7 Overscan 25 0 - 255

8 VSBEG 8 0 - 255

-31-

Page 32

Adjustments

Group/

Group 526 RGB Video (1080PSF - 24)

Group 530 Composite (NTSC) For Composite / S-Video

Group 531 Composite (PAL) For Composite / S-Video

Group 540 YCbCr (480i)

Group 541 YCbCr (575i)

Group 542 YCbCr (480p)

Group 543 YCrCb (575p)

Group 544 YCrCb (720p - 60)

Group 545 YCrCb (720p - 50)

Group 546 YCrCb (1080i - 60)

Group 547 YCbCr (1080i - 50)

Group 549 YCrCb (1080p - 60)

Group 550 YCrCb (1080p - 50)

Group 551 YCrCb (1080p - 30)

Item Name Function Initial Range Note

Item

2 H Back Porch 242 0 ~ 4095

3 V Back Porch 20 0 ~ 4095

7 Overscan 22 0 - 255

8 VSBEG 8 0 - 255

15 Field Diff (SEP) Even/Odd Phase Compensation on HV Sync 1 0 - 2

16 Field (SOG) Even/Odd Phase Compensation on SOG Sync 1 0 - 2

2 H Back Porch 78 0 ~ 4095

3 V Back Porch 18 0 ~ 4095

7 Overscan 54 0 - 255

2 H Back Porch 2 0 ~ 4095

3 V Back Porch 20 0 ~ 4095

7 Overscan 70 0 - 255

2 H Back Porch 124 0 ~ 4095

3 V Back Porch 18 0 ~ 4095

7 Overscan 36 0 - 255

8 VSBEG 8 0 - 255

16 Field (SOG) Even/Odd Phase Compensation 1 0 - 2

2 H Back Porch 134 0 ~ 4095

3 V Back Porch 23 0 ~ 4095

7 Overscan 52 0 - 255

8 VSBEG 8 0 - 255

16 Field (SOG) Even/Odd Phase Compensation 1 0 - 2

2 H Back Porch 125 0 ~ 4095

3 V Back Porch 38 0 ~ 4095

7 Overscan 30 0 - 255

8 VSBEG 8 0 - 255

2 H Back Porch 133 0 ~ 4095

3 V Back Porch 44 0 ~ 4095

7 Overscan 22 0 - 255

8 VSBEG 8 0 - 255

2 H Back Porch 300 0 ~ 4095

3 V Back Porch 26 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 298 0 ~ 4095

3 V Back Porch 26 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 20 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 20 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

16 Field (SOG) Even/Odd Phase Compensation 1 0 - 2

2 H Back Porch 234 0 ~ 4095

3 V Back Porch 42 0 ~ 4095

7 Overscan 28 0 - 255

8 VSBEG 8 0 - 255

2 H Back Porch 234 0 ~ 4095

3 V Back Porch 42 0 ~ 4095

7 Overscan 28 0 - 255

8 VSBEG 8 0 - 255

-32-

Page 33

Adjustments

Group/

Group 552 YCrCb (1080p - 25)

Group 553 YCrCb (1080p - 24)

Item Name Function Initial Range Note

Item

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 42 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 42 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

2 H Back Porch 236 0 ~ 4095

3 V Back Porch 42 0 ~ 4095

7 Overscan 26 0 - 255

8 VSBEG 9 0 - 255

Group 900 Lamp Option

0 Lamp Replace Display

Group 901 Lamp Warning Time

0 Lamp Warning Time (Normal) Lamp Life at Normal (x 500) 4 1 - 16

1 Lamp Warning Time (Eco) Lamp Life at Eco (x 500) 6 1 - 16

Group 902 Lamp Reset Counter

0 Lamp Counter Reset Times Reset Times - 0 - 255

Lamp Warning Display On/Off

0: Off, 1: On

1 0 - 1

-33-

Page 34

IC8001

HDMI

RECEIVER

<SII9127>

IC8201

A/D

CONVERTER

AFE1000

<2509209>

IC6201

DDC

HDMI

M

M

M

M

M

M

M

IC401

DLP DATA

RPOCESSOR

DDP2431

<2509006>

IC1421

IC1411

IC1431

IC1401

Dsub15Dsub15

TMDS

DIN4CVBS

SCL2/SDA2

RGB/YCbCr/YPbPr

RGB/YCbCr/YPbPr

S-VIDEO

COMPOSITE

RGB 10bits

HS/VS/CS

CLK

IC3501

DMD POWER &

RESET DRIVER

DAD2000

<2506593>

IC2501

DMD POWER &

MOTOR DRIVER

PMD1000

<2506224>

DMD

DDR2

SRAM

FLASH EEPROM

USB Dsub9RJ45

SCL1/SDA1

SCL0/SDA0

SCL0/SDA0

SCL0/SDA0

PIN-JACKJACK

IC5101

AUDIO SW

<NJM1156>

IC001

AUDIO OUT

<LV49152>

PC_IN1 L/R

PC_IN2 L/R

VIDEO L/R

AUDIO_OUT L/R

USB D+/D-/VBUS

IC4501

SUB-MICOM

<LC87F2G08>

IC8301

NETWORK

<PIC18F67J>

IC3811

RS232C

<ICL3232>

IC3821

IC3831

KEY SW

IN+/-

OUT+/-

RX/TX MCI

R/C

RX/TX

RX/TX MCU

RX/TX DDP

<POWER>

COLOR

WHEEL

FN901

FANNET

FN902

FN903

P3P3V

P1P2V

P2P5V

P1P8V

A1P8V

P5V

LAMP BALLAST

POWER

UNIT

12V

AC CORD

LAMP

DIN3

3D SYNC OUT

IC8821

TEMP SENSOR B

(LAMP)

IC8801

TEMP SENSOR A

(ROOM)

IC8811

TEMP SENSOR C

(DMD)

SCL2_SDA2

SCL2_SDA2

LED

IC8151

HDMI AUDIO

<PCM1754>

HDMI L/R

LVDS

SDI/SDO/SCK MCU

RX/TX PMD

RX/TX BALLAST

LAMPCTRL

HDMI

PC Analog

AV Analog

Monitor OUT

PC Analog

AV analog

S-Video

Video

AUDIO IN

AUDIO OUT

USB

LAN

SERIAL

RS232C

R/C

CONTROL

KEY SW

AUDIO

R/C

Drive

Position

Bus

Bus

Bus

SP_OUT

AV

DMD MODULE

PC IN1PC IN2VIDEO IN DIGITAL

KEY

LED

FN905

FN906

SW901

LAMP

COVER

SW

FN904

P12V

DC-DC

Q5611

DC-DC

Q5641

DC-DC

Q5642

Q5661

Q5651

ES16V

12V

ES3.3V

S-5V

16VA

16VF

IC7881

FAN DAC

<M62393>

Reg.

Reg.

Reg.

Reg.

Reg.

Reg.

IC7811

IC7821

IC7831

IC7841

IC7851

IC7861

IC8911

G-SENSOR

Chassis Block Diagrams

Chassis over view

-34-

Page 35

Chassis Block Diagrams

POWERMAIN

FANNET

KEY

LAMP BALLAST

IC001

AUDIO-OUT

<LV49152>

IC5101

AUDIO-SW

<NJW1156>

RC

RECEIVER

POWER SUPPLY

SW901

LAMP

COVER

SWITCH

P.F. CONTROL

SP901

SPEAKER

MUTE

OUT_DET

LAMPDC_ON

POWER_SW_A

Q2816

R/CLP_IR

IR0

4

ON:H

ON:H

ON:H

ON:H

ERROR:H

P-ON:H

2

1

1

Mute On:H

Power On:L

L/R

VOLUME

LAMPCTRL

FAN_ERR

LAMP_SYNC

139

ON:H

DDP_RDY_LED

42

229

137

138

276

98

43

DDP_3D_LED

MCU_LAMP_LED

MCU_RDY_LED

MCU_PWR_LED

140

PFAIL

DDP_LAMP_LED

143

FAN_SW_BUFF

135

230,141,

44

228

UART3_LMPCTL_TXD

BALLAST_TXD

BALLAST_RXD

LAMPSTAT

KEY

CONTROLS

KEY

CONTROLS

SCL1/SDA1

SCL2/SDA2

226,307

SCL0/SDA0

274,351

223,304

IC401

DLP DATA PROCESSOR

DDP2431

Q2813

Q2814

Q2812

Q2811

D2813

D2816

D2818

Q5152

Q4501

Q5151

LAMP REPLACE

D2811

3D

WARNING

POWER

IC4721

NAND

IC4701

8

1

4

12

19

17

18

7,8,9

11

4

1

13

13

16

15

12

10

K8A

K6R

K47A

CN2

1

4

5

FAN

CONTROL

CIRCUIT

KEY SWITCH

SCL0_5V/SDA0_5V

1

3

K00A

K47B

1

3

1

2

IC2851

IC4511

IC4501

SUB-MICOM

<LC87F2G>

DDP_SDO/DDP_SDI

DDP_SCK

KEYPD_PWR

UART2_232C_MCU

UART2_MCU_232C

K8B K07A

K68AK07B

15

17

19

21

23

10

3

|

11

29

23

25

27

29

314733 |49

48

1

3

40

42

44

LAMPCTRL

Power-On: H

Standby: L

Power-On: H

Error: H

Error: L

Network Standby: L

Eco Standby: H

Power Failure: H

LAMPDC_ON

305

POWER_SW_A

POWER_SW_A

DDP_TEMP_LED

DDP_PWR_LED

System control

-35-

Page 36

Chassis Block Diagrams

Q3651

9,22,27,37,42

14

10

45

463324

29

26

PFAIL_-5V

ES3.3V

P3P3VA3P3V_AFE

P3P3V_HDMI

P1P9V_AFE

P3P3V_SYNC

P1P8V

P5V

P2P5V

A1P8V

RC3.3V

ES16V ES16V

Q5611

K6RK8A

12V

P12V

12V_AUDIO

Q5641

Q5101

Q2524

P1P2V

Q2516

P1P2V_EDRAM

A1P8V_PLLD

A1P8V_PLLM

P1P2V_PLLD

P1P2V_PLLM

Q1482

IC8281

P1P2V_HDMI

IC8081

3.3V_LAN

Q8371

P5V_HDMI

IC8071

S-5V

Q5642

16VF

Q5651

16VA

Q5661

Q5091

Q5662

IC5631

IC2501

DLP

POWER

&

MOTOR

DRIVER

IC401

DLP DATA

PROCESSOR

IC4501

SUB-

MICOM

POWERMAIN

S16V

IC5611

PFAIL_16VA

PFAIL_FAN

AUDIO_PWR_ON

POWER_SW_B

Q5652

Q5631 Q5632

12V_AUDIO_SW

AUDIO_PWR_ON

LAMPDC_ON LAMPDC_ON

POWER_SW_A POWER_SW_A

Q5102

Q4501

Q8372

Q8091

Q8291

Q1481

39

45

143

378

305

FAN CONTROL

PFAIL_P1P9V_AFE

PFAIL_P1P2V_HDMI

PWR_CTRL

310

12V_AUDIO_SW

PWR_SW_LAN

Err: L

Err: H

Err: H

Err: H

Err: H

Err: H

ON: H

ON: H

Power fail: L

ON: H

ON: H

Err: L

PFAIL_16V

PFAIL_P1P9V_AFE

PFAIL_P1P2V_HDMI

PFAIL

IC5851

IC5852

POWER FAIL LOGIC

3

9

|

11

1

Power supply & protection circuit

L H H

L H L

H L L

Mode POWER_SW_A POWER_SW_B LAMPDC_ON

Network Standby

Eco Standby

Normal operation

-36-

Page 37

Chassis Block Diagrams

Q7891

TEMP SENSOR 2

<DMD>

TEMP SENSOR 1

<ROOM>

<LAMP>

LAMP

BALLAST

BOARD

K77B

FN902

1

2

2 1

IC7881

DAC

<M62393>

PFAIL

D7702

K77C

FN903

1

2

D7703

K77D

FN904

1

2

D7704

K77E

FN905

1

2

D7705

K77F

FN906

1

2

D7706

IC8801

TEMP.

SENSOR A

<MCP9801>

2 1

IC8821

TEMP.

SENSOR B

<MCP9801>

MAIN

FANNET

IC401

DLP DATA PROCESSOR

DDP2431

IC4721

NAND

2

1

4

135

223,304

SCL2

SDA2

SCL2_DAC

SDA2_DAC

Q7871

Q7872

Fan Error: On

Error: L

Error: H

Fan Error: H

SIGNAL/MODE

POWER-ON STAND-BY

H L

POWER-ON STAND-BY

H L

NORMAL ERROR

L H

FAN_SW_BUFF

LAMPCTRL

PFAIL

PFAIL_FAN

FAN_ERR

K47A

K07AK8B

K8E

3

LAMPCTRL

143

98

5

2,3

4

15

14

13

12

34

2 1

IC8811

TEMP.

SENSOR C

<MCP9801>

K8H

34

K8F

FN901

1

2

D7812

D7811

D7821

D7831

D7841

D7851

D7861

FAN1

16VF

FAN3

FAN4

FAN5

FAN6

FAN_LOCK

IC7811

IC7821

IC7831

IC7841

IC7851

IC7861

PFAIL LOGC ICs

IC5851, IC5852

Q7801

Q7802

Q7821

Q7811

Q7831

Q7841

Q7851

Q7861

FAN2

FAN_CONT6

FAN_CONT5

FAN_CONT4

FAN_CONT2

FAN_SW_BUFF

FAN_CONT1

FAN_CONT3

PFAIL_FAN

SW901

LAMP

COVER

SW

K47B

1

1

2

4

LAMP_SYNC

9

11

13

15

17

5

40

Fan control circuit

-37-

Page 38

Troubleshooting

Indicators and Projector Condition

Check the indicators for projector condition.

Indicators

POWER

red/green

WARNING

TEMP

red

LAMP RE-

PLACE

yellow

3D

blue

Projector Condition

j j j j

J

red

Normal condition

J

green

K

red

K

green

J

green

K

red

Abnormal condition

j

j

j

j

j

K

]

]

]

]

]

]

v

v

v

v

J

v

The projector is off. (The AC power cord is unplugged.)

The projector is in stand-by mode. Press the ON/STANDBY button to turn on the projector.

The projector is operating normally.

The projector is preparing for stand-by or the projection lamp

is being cooled down. The projector cannot be turned on

until cooling is completed and the POWER indicator stops

blinking.

The projector is in the Power management mode.

The projector is in 3D display mode.

The temperature inside the projector is abnormally high.

The projector cannot be turned on. When the projector is

cooled down enough and the temperature returns to normal,

the POWER indicator stops blinking and the projector can

be turned on. (The WARNING TEMP indicator keeps blinking.)

J

] /v

J

red

K

j J

J

green

• • • on

• • • Differs according to conditions

j J

]

]

K j

The projector has been cooled down enough and the tem-

v

v

v

• • • blinking • • • off

perature returns to normal. When turning on the projector,

the WARNING TEMP indicator stops blinking.

The projector detects an abnormal condition and cannot be

turned on. Unplug the AC power cord and plug it again to

turn on the projector. If the projector is turned off again, unplug the AC power cord and contact the dealer or the service

center for service and checkup. Do not leave the projector

on. It may cause an electric shock or a fire hazard.

The lamp has been used overtime. Replace the lamp immediately and then reset the lamp counter. The indicator will be

turned off after resetting the counter.

-38-

Page 39

Troubleshooting

No Power

This projector provides a function which can be specified a defective area simply by indicating the LEDs. Connect the

AC cord and press the Power button once and then check the LED indication.

- When all of LED indicators are not lighting, the symptom indicates that the primary power supply circuit does

not operate properly. Check the power primary circuit and parts as follow;

AC cord, F601 (Fuse), Line Filter board,

SW902 (Thermal sw.) ............... short in normal

SW902 opens when the surrounding temperature of the switch exceeds 120°C.

- When the WARNING TEMP (red) and POWER (red) indicators are blinking, the symptom indicates that the

projector detected an abnormal temperature risen inside the projector. Check the air filter and remove the object

near the intake and exhaust fan openings, and wait until the POWER indicator stops blinking, and then try to turn

on the projector.

The internal temperature is monitored by sensor ICs, IC8801 on the Temp Sensor 1 board, IC8811 on the Temp

Sensor 2 board, IC8821 on the Main board.

- When the WARNING TEMP indicator lights red, the symptom indicates that the projector detected an abnor-