Page 1

II 2GD T5

SERVICE & OPERATING MANUAL

Original Instructions

Model U1F Metallic Design Level 1

Table of Contents

See pages 2, 24 and 25

for ATEX ratings.

Engineering Data and Temperature Limitations .................................................... 1

Explanation of Pump Nomenclature ...................................................................... 2

Performance Curve ............................................................................................... 3

Dimensions ........................................................................................................... 4

Metric Dimensions ................................................................................................ 5

Principle of Pump Operation.................................................................................. 6

Installation and Start-Up ........................................................................................ 6

Air Supply .............................................................................................................. 6

Air Valve Lubrication .............................................................................................. 6

Air Line Moisture.................................................................................................... 6

Air Inlet and Priming .............................................................................................. 6

Between Uses ....................................................................................................... 6

Installation Guide ................................................................................................... 7

Troubleshooting ..................................................................................................... 8

Warranty ................................................................................................................ 8

Recycling ............................................................................................................... 9

Important Safety Information ................................................................................. 9

Material Codes .................................................................................................... 10

Composite Repair Parts Drawing ........................................................................ 12

Available Service and Conversion Kits ................................................................ 12

Composite Repair Parts List ................................................................................ 13

Air Distribution Valve Assembly Drawing and Parts List ...................................... 14

Air Distribution Valve Servicing ............................................................................15

Pilot Valve Servicing, Assembly Drawing & Parts List ......................................... 16

Diaphragm Service Drawing, with Overlay .......................................................... 17

Diaphragm Service Drawing, Non-Overlay.......................................................... 17

Diaphragm Servicing ........................................................................................... 18

Overlay Diaphragm Servicing ............................................................................. 18

Actuator Plunger Servicing .................................................................................. 19

Check Valve Servicing .........................................................................................20

Check Valve Drawing ..........................................................................................20

Mufer Drawing and Provision for Piping Air Exhaust ......................................... 21

Pumping Hazardous Liquids................................................................................ 21

Converting Pump for Piping Exhaust Air .............................................................21

Converted Exhaust Illustration............................................................................. 21

Grounding The Pump .......................................................................................... 22

CE Declaration of Conformity .............................................................................. 23

CE Declaration of Conformity ATEX .................................................................... 24

Explanation of ATEX Certications ...................................................................... 25

u1fmdl1sm-rev0214

Warren Rupp, Inc. • A Unit of IDEX Corporation • 800 N. Main St., Manseld, Ohio 44902 USA

Telephone (419) 524-8388 • Fax (419) 522-7867 • warrenrupp.com

©Copyright 2014 Warren Rupp, Inc. All rights reserved.

Page 2

Page 3

Quality System

II 2GD T5

ISO 9001 Certied

Environmental

Management System

ISO 14001 Certied

See pages 2, 24 and 25

for ATEX ratings.

U1F Metallic

Air-Operated

Double Diaphragm Pump

ENGINEERING, PERFORMANCE

& CONSTRUCTION DATA

INTAKE/DISCHARGE PIPE SIZE

1" NPT(internal)

1" BSPT Tapered (internal)

CAUTION! Operating temperature limitations are as follows:

CAPACITY

0 to 45 gallons per minute

(0 to 170 liters per minute)

AIR VALVE

No-lube, no-stall

design

SOLIDS-HANDLING

Up to .25 in. (6mm)

HEADS UP TO

100 psi or 230.7 ft. of water

(7 Kg/cm2 or 70 meters)

Maximum and Minimum Temperatures are the limits for which these

materials can be operated. Temperatures coupled with pressure affect the

longevity of diaphragm pump components. Maximum life should not be

expected at the extreme limits of the temperature ranges.

Operating Temperatures

DISPLACEMENT/STROKE

.11 Gallon / .42 liter

Materials Maximum Minimum

Nitrile General purpose, oil-resistant. Shows good solvent, oil, water and hydraulic uid resistance. Should not be used with highly polar

solvents like acetone and MEK, ozone, chlorinated hydrocarbons and nitro hydrocarbons.

NEOPRENE All purpose. Resistant to vegetable oils. Generally not affected by moderate chemicals, fats, greases and many oils and

solvents. Generally attacked by strong oxidizing acids, ketones, esters, nitro hydrocarbons and chlorinated aromatic hydrocarbons.

PTFE Chemically inert, virtually impervious. Very few chemicals are known to react chemically with PTFE: molten alkali metals, turbulent liquid or gaseous uorine and a few uoro-chemicals such as chlorine triuoride or oxygen diuoride which readily liberate free

uorine at elevated temperatures.

Polypropylene: A thermoplastic polymer. Moderate tensile and ex strength. Resists strong acids and alkalie. Attacked by chlorine,

fuming nitric acid and other strong oxidizing agents.

UHMW PE: A thermoplastic polymer that is highly resistant to a broad range of chemicals. Exhibits outstanding abrasion and impact

resistance, along with environmental stress-cracking resistance.

For specic applications, always consult Warren Rupp's “Chemical Resistance Chart”

SANDPIPER® pumps are designed to be powered only by compressed air.

190°F -10°F

88°C -23°C

200°F -10°F

93°C -23°C

220°F -35°F

104°C -37°C

180°F 32°F

82°C 0°C

180°F -35°F

82°C -37°C

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 1

Page 4

Explanation of Pump Nomenclature

II 2GD T5

U1F UL79 Listed Metallic · Design Level 1· Ball Valve

Check Diaphragm/ Check Non-Wetted Shipping

MODEL Pump Pump Valve Design Wetted Check Valve Valve Material Porting Pump Pump Kit Weight

Brand Size Type Level Material Materials Seat Options Options Style Options Options lbs. (kg)

U1F B1XBTXNS600. U 1F B 1 X B T X N S 6 00. 53 (24)

U1F B1XGTXNS600. U 1F B 1 X G T X N S 6 00. 53 (24)

U1F B1XGAXNS600. U 1F B 1 X G A X N S 6 00. 53 (24)

U1FB1CBTCNS600. U 1F B 1 C B T C N S 6 00. 53 (24)

U1FB1CGTCNS600. U 1F B 1 C G T C N S 6 00. 53 (24)

U1F B1XBTXSS600. U 1F B 1 X B T X S S 6 00. 53 (24)

U1F B1XGTXSS600. U 1F B 1 X G T X S S 6 00. 53 (24)

Pump Brand

U= UL79 Listed SANDPIPER

Pump Size

1F=1"

Check Valve Type

B= Ball

Design Level

1= Design Level

®

Wetted Material

X= Unpainted Aluminum

C= Conductive Painted Aluminum

Diaphragm Check Valve Materials

B= Nitrile/Nitrile

G= PTFE-Neoprene/PTFE

Check Valve Seat

A= Aluminum

T= PTFE

Non-Wetted Material Options

X= Unpainted Aluminum

C= Conductive Painted Aluminum

Porting Options

N= NPT Threads

B= BSPT (Tapered) Threads

S= NPT Suction Port Facing Air

Inlet, NPT Discharge Port

Facing Air Exhaust

Model U1FB1XBTXNS600 is UL79 listed for pumping: Gasoline, Diesel Fuel, No. 4 Fuel Oils (or lighter), Motor

Oil, Kerosene, Aviation Fuel and Water

Model U1FB1XGTXNS600 and U1FB1XGAXNS600 are UL79 listed for pumping: Gasoline (Including

Alcohol Blends up to 15%), Diesel Fuel, Motor Oil, No. 4 Oil (or lighter), Kerosene, Aviation Fuel, Automatic

Transmission Fluid, Water, Waste Oil, and Ethylene Glycol.

II 2G c T5

II 3/2 G c T5

II 2D c T100°C

.

NOTE: See page 25 for ATEX Explanation

of Type Examination Certicate

pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate

area for safe disposition.

Pump Style

S= Standard

Pump Options

6= Metal Mufer

WARNING

In the event of diaphragm

rupture, pumped material

may enter the air end of the

pump, and be discharged

into the atmosphere. If

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 2

Page 5

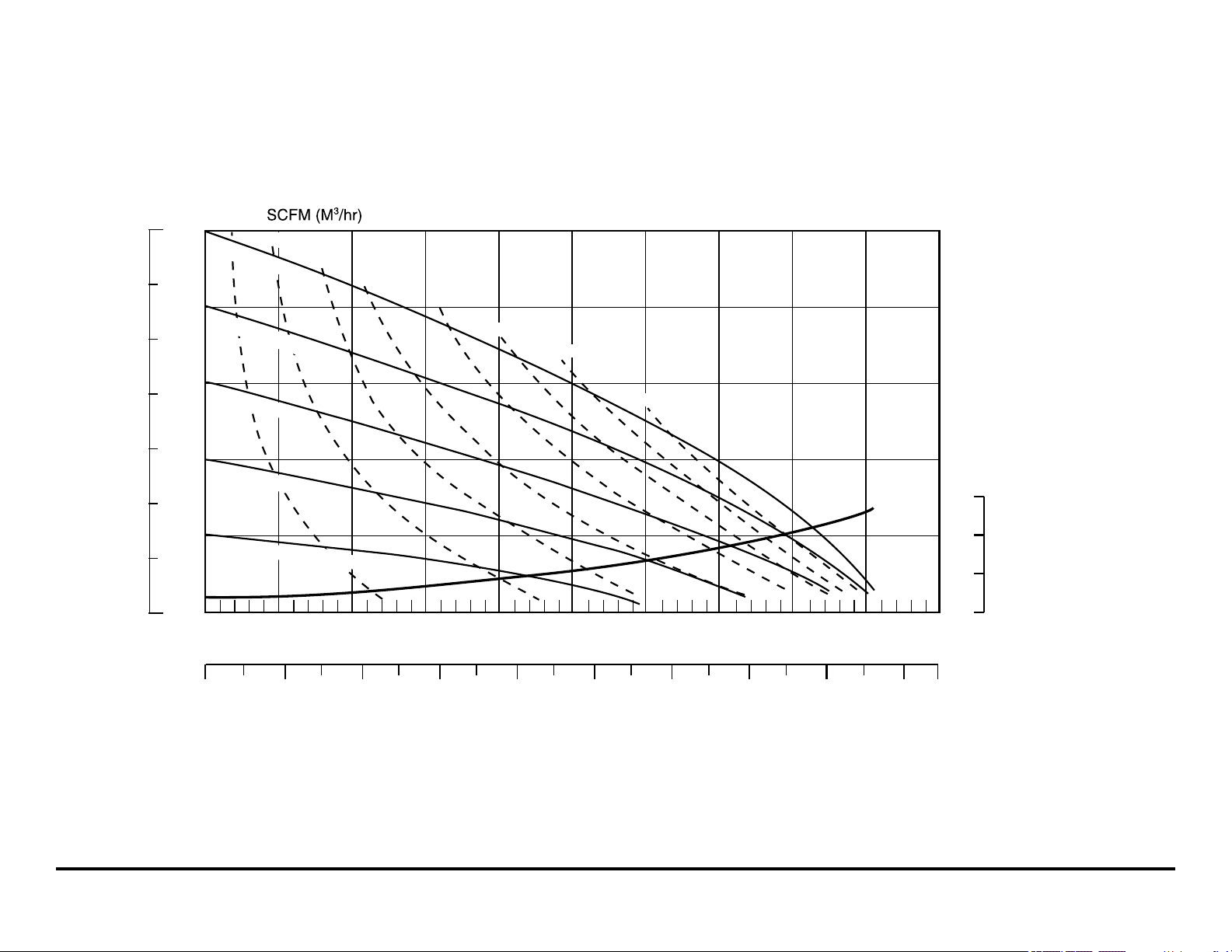

5(8.5)

15(25.5)

20(34)

25(42.5)

0 5 10 15 20

25 30 35 40 45

160140

180120100806040200

BAR

PSI

100

80

60

40

20

0

0

1

2

3

4

5

6

7

30

20

25

10

15

5

9.1

6

7.6

3

4.5

1.5

50

100 PSI (6.8 Bar)

60 PSI (4.08 Bar)

40 PSI (2.72 Bar)

80 PSI (5.44 Bar)

10(17)

30(51)

35(59.5)

40(68)

CAPACITY

Liters per minute

HEAD

U.S. Gallons per minute

NPSHR

METERS

FEET

20 PSI (1.36 Bar) Air Inlet Pressure

MODEL U1F Metallic Performance Curve

Performance based on the following: elastomer fitted pump, flooded suction, water at ambient conditions.

The use of other materials and varying hydraulic conditions may result in deviations in excess of 5%.

Performance Curve, U1F UL79 Listed Metallic Design Level 1

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 3

Page 6

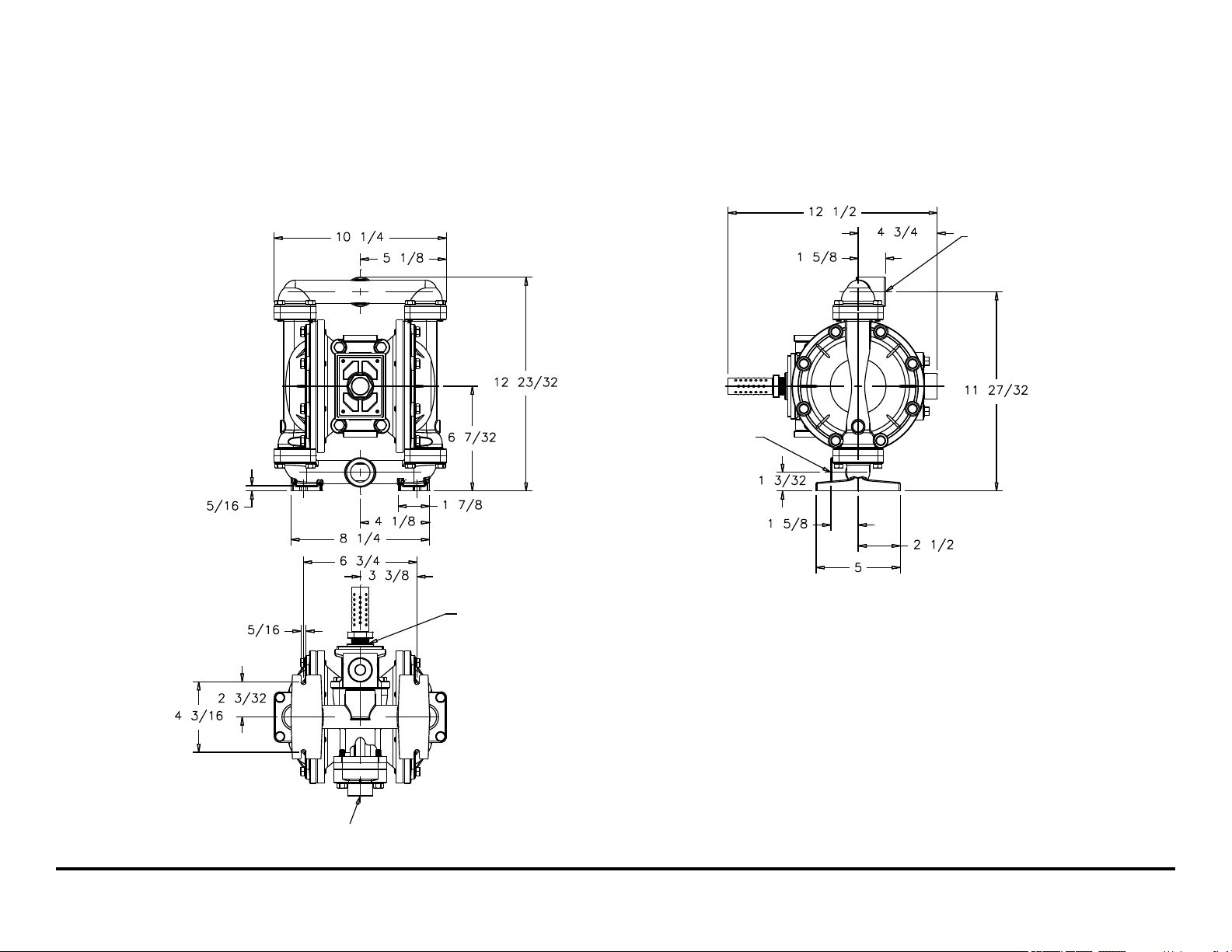

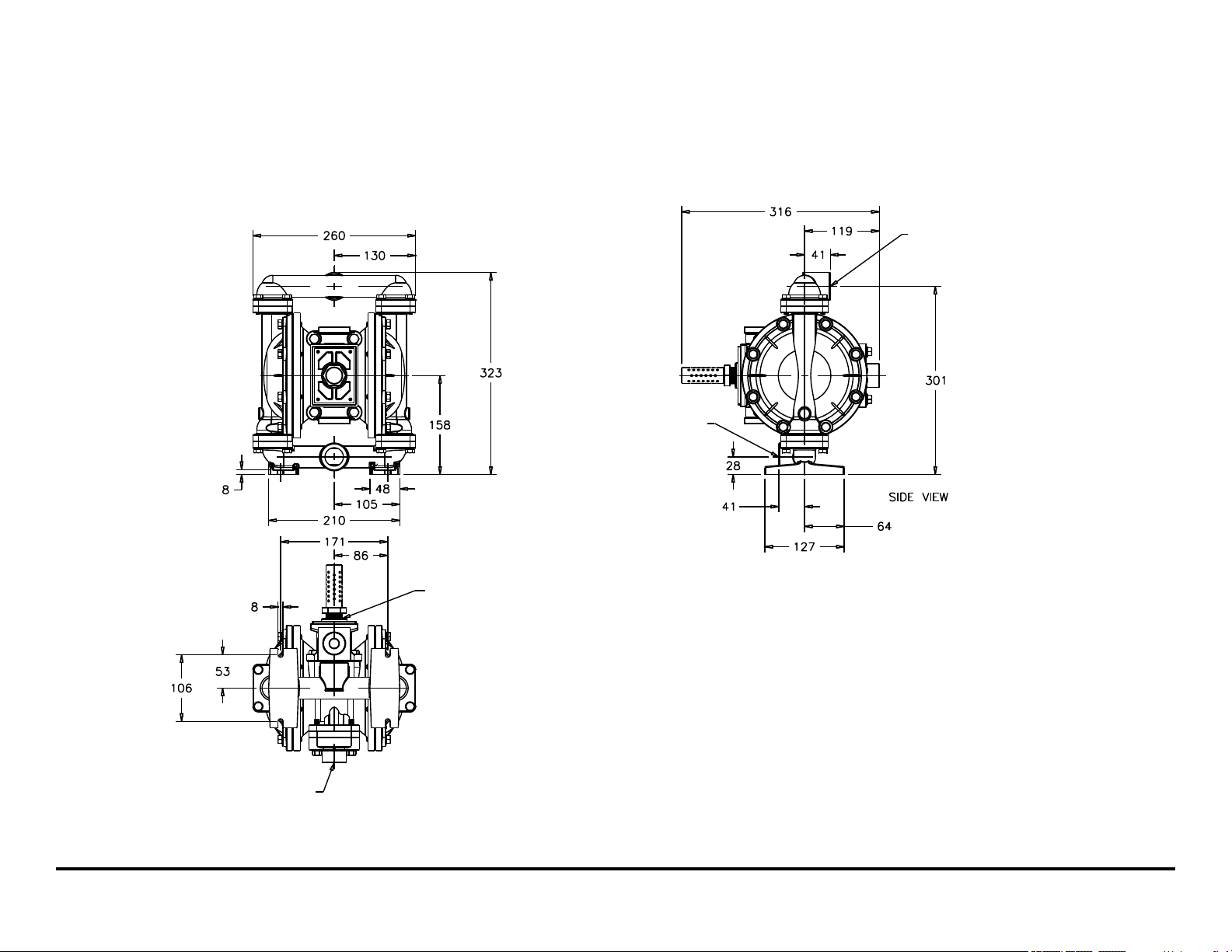

Dimensions: U1F UL79 LISTED Metallic

Dimensions in Inches

Dimensional Tolerance:±1/8"

DISCHARGE PORT

1” NPT

SUCTION PORT

1” NPT

SIDE VIEW

FRONT VIEW

1” NPT EXHAUST PORT

FOR OPTIONAL MUFFLER

STYLES OR PIPING EXHAUST

AIR IN SUBMERGED

APPLICATIONS.

WITH 530-033-000

MUFFLER

BOTH SUCTION AND

BOTTOM VIEW

DISCHARGE PORTS ARE

AVAILABLE WITH

1” BSPT TAPERED THREADS

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 4

Page 7

Metric Dimensions: U1F UL79 Listed Metallic

Dimensions in Millimeters

Dimensional Tolerance:± 3mm

SUCTION PORT

DISCHARGE PORT

1” NPT

1” NPT

FRONT VIEW

1” NPT EXHAUST PORT

FOR OPTIONAL MUFFLER

STYLES OR PIPING EXHAUST

AIR IN SUBMERGED

APPLICATIONS.

WITH 530-033-000

MUFFLER

SIDE VIEW

BOTH SUCTION AND

BOTTOM VIEW

DISCHARGE PORTS ARE

AVAILABLE WITH

1” BSPT TAPERED THREADS

AIR INLET

1/2” NPT

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 5

Page 8

PRINCIPLE OF PUMP OPERATION

This ball type check valve pump

is powered by compressed air and is

a 1:1 ratio design. The inner side of

one diaphragm chamber is alternately

pressurized while simultaneously

exhausting the other inner chamber.

This causes the diaphragms, which are

connected by a common rod secured by

plates to the centers of the diaphragms,

to move in a reciprocating action. (As

one diaphragm performs the discharge

stroke the other diaphragm is pulled

to perform the suction stroke in the

opposite chamber.) Air pressure is

applied over the entire inner surface of

the diaphragm while liquid is discharged

from the opposite side of the diaphragm.

The diaphragm operates in a balanced

condition during the discharge stroke

which allows the pump to be operated

at discharge heads over 200 feet (61

meters) of water.

For maximum diaphragm life, keep

the pump as close to the liquid being

pumped as possible. Positive suction

head in excess of 10 feet of liquid

(3.048 meters) may require a back

pressure regulating device to maximize

diaphragm life.

Alternate pressurizing and

exhausting of the diaphragm chamber

is performed by an externally mounted,

pilot operated, four way spool type

air distribution valve. When the spool

shifts to one end of the valve body, inlet

pressure is applied to one diaphragm

chamber and the other diaphragm

chamber exhausts. When the spool

shifts to the opposite end of the valve

body, the pressure to the chambers is

reversed. The air distribution valve spool

is moved by a internal pilot valve which

alternately pressurizes one end of the air

distribution valve spool while exhausting

the other end. The pilot valve is shifted

at each end of the diaphragm stroke

when a actuator plunger is contacted

by the diaphragm plate. This actuator

plunger then pushes the end of the pilot

valve spool into position to activate the

air distribution valve.

The chambers are connected with

manifolds with a suction and discharge

check valve for each chamber,

maintaining ow in one direction through

the pump.

INSTALLATION AND START-UP

Locate the pump as close to the

product being pumped as possible. Keep

the suction line length and number of

ttings to a minimum. Do not reduce the

suction line diameter.

For installations of rigid piping, short

sections of flexible conductive hose

should be installed between the pump

and the piping. The exible conductive

hose reduces vibration and strain to the

pumping system. A surge suppressor

is recommended to further reduce

pulsation in ow.

AIR SUPPLY

Air supply pressure cannot exceed

100 psi (7 bar). Connect the pump air

inlet to an air supply of sufcient capacity

and pressure required for desired

performance. When the air supply line

is solid piping, use a short length of

exible conductive hose not less than

1/2" (13mm) in diameter between

the pump and the piping to reduce

strain to the piping. The weight of the

air supply line, regulators and lters

must be supported by some means

other than the air inlet cap. Failure to

provide support for the piping may result

in damage to the pump. A pressure

regulating valve should be installed

to insure air supply pressure does not

exceed recommended limits.

AIR VALVE LUBRICATION

The air distribution valve and the

pilot valve are designed to operate

WITHOUT lubrication. This is the

preferred mode of operation. There may

be instances of personal preference

or poor quality air supplies when

lubrication of the compressed air

supply is required. The pump air system

will operate with properly lubricated

compressed air supply. Proper

lubrication requires the use of an air line

lubricator (available from Warren Rupp)

set to deliver one drop of SAE 10 nondetergent oil for every 20 SCFM (9.4

liters/sec.) of air the pump consumes

at the point of operation. Consult the

pump’s published Performance Curve

to determine this.

AIR LINE MOISTURE

Water in the compressed air supply

can create problems such as icing or

freezing of the exhaust air, causing

the pump to cycle erratically or stop

operating. Water in the air supply can

be reduced by using a point-of-use

air dryer to supplement the user’s air

drying equipment. This device removes

water from the compressed air supply

and alleviates the icing or freezing

problems.

AIR INLET AND PRIMING

To start the pump, open the air

valve approximately 1/2" to 3/4" turn.

After the pump primes, the air valve

can be opened to increase air ow as

desired. If opening the valve increases

cycling rate, but does not increase the

rate of ow, cavitation has occurred.

The valve should be closed slightly to

obtain the most efcient air ow to pump

ow ratio.

BETWEEN USES

When the pump is used for materials

that tend to settle out or solidify when

not in motion, the pump should be

flushed after each use to prevent

damage. (Product remaining in the

pump between uses could dry out or

settle out. This could cause problems

with the diaphragms and check valves

at restart.) In freezing temperatures

the pump must be completely drained

between uses in all cases.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 6

Page 9

INSTALLATION GUIDE

Top Discharge Ball Valve Pump

1

Surge Suppressor

Filter/Regulator

2

3

Air Dryer

CAUTION

Use a gasoline-resistant pipe

compound to make pipe joints tight.

Pump shall be installed in accordance to Flammable

and Combustible Liquids Code, NFPA 30 or the Automotive

and Marine Service Station Code, NFPA 30A, as appropriate

to the intended use of the pump.

CAUTION

The air exhaust should be

piped to an area for safe

disposition of the product

being pumped, in the event

of a diaphragm failure.

1

WARNING

To maintain conductivity,

do not paint the pump, or if

painted, use a conductive

paint or coating.

The pump must be rigidly mounted

with fasteners to a conductive base

or natural ground.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 7

2

3

Page 10

TROUBLESHOOTING

Possible Symptoms:

• Pump will not cycle.

• Pump cycles, but produces no ow.

• Pump cycles, but ow rate is

unsatisfactory.

• Pump cycle seems unbalanced.

• Pump cycle seems to produce

excessive vibration.

What to Check: Excessive suction lift

in system.

Corrective Action: For lifts exceeding

20 feet (6 meters), lling the pumping

chambers with liquid will prime the

pump in most cases.

What to Check: Excessive flooded

suction in system.

Corrective Action: For flooded

conditions exceeding 10 feet (3 meters)

of liquid, install a back pressure device.

What to Check: System head exceeds

air supply pressure.

Corrective Action: Increase the

inlet air pressure to the pump. Most

diaphragm pumps are designed for 1:1

pressure ratio at zero ow.

What to Check: Air supply pressure or

volume exceeds system head.

Corrective Action: Decrease inlet

air pressure and volume to the

pump as calculated on the published

PERFORMANCE CURVE. Pump is

cavitating the uid by fast cycling.

What to Check: Undersized suction

line.

Corrective Action: Meet or exceed

pump connection recommendations

shown on the DIMENSIONAL

DRAWING.

What to Check: Restricted or

undersized air line.

Corrective Action: Install a larger

air line and connection. Refer to air

inlet recommendations shown in your

pump’s SERVICE MANUAL.

What to Check: Check ESADS, the

Externally Serviceable Air Distribution

System of the pump.

Corrective Action: Disassemble and

inspect the main air distribution valve,

pilot valve and pilot valve actuators.

Refer to the parts drawing and air valve

section of the SERVICE MANUAL.

Check for clogged discharge or closed

valve before reassembly.

What to Check: Rigid pipe connections

to pump.

Corrective Action: Install flexible

connectors and a surge suppressor.

What to Check: Blocked air exhaust

mufer.

Corrective Action: Remove mufer

screen, clean or de-ice and reinstall.

Refer to the Air Exhaust section of your

pump SERVICE MANUAL.

What to Check: Pumped uid in air

exhaust mufer.

Corrective Action: Disassemble

pump chambers. Inspect for diaphragm

rupture or loose diaphragm plate

assembly. Refer to the Diaphragm

Replacement section of your pump

SERVICE MANUAL.

What to Check: Suction side air

leakage or air in product.

Corrective Action: Visually inspect

all suction side gaskets and pipe

connections.

What to Check: Obstructed check

valve.

Corrective Action: Disassemble the

wet end of the pump and manually

dislodge obstruction in the check valve

pocket. Refer to the Check Valve

section of the pump SERVICE MANUAL

for disassembly instructions.

What to Check: Worn or misaligned

check valve or check valve seat.

Corrective Action: Inspect check

valves and seats for wear and proper

seating. Replace if necessary. Refer

to Check Valve section of the pump

SERVICE MANUAL for disassembly

instructions.

What to Check: Blocked suction line.

Corrective Action: Remove or ush

obstruction. Check and clear all suction

screens and strainers.

What to Check: Blocked discharge

line.

Corrective Action: Check for

obstruction or closed discharge line

valves.

What to Check: Blocked pumping

chamber.

Corrective Action: Disassemble

and inspect the wetted chambers

of the pump. Remove or flush any

obstructions. Refer to the pump

SERVICE MANUAL for disassembly

instructions.

What to Check: Entrained air or vapor

lock in one or both pumping chambers.

Corrective Action: Purge chambers

through tapped chamber vent plugs.

PURGING THE CHAMBERS OF

AIR CAN BE DANGEROUS! Contact

the Warren Rupp Technical Services

Department before performing this

procedure. Any model with top-ported

discharge will reduce or eliminate

problems with entrained air.

If your pump continues to perform

below your expectations, contact your

local Warren Rupp Distributor or factory

Technical Services Group for a service

evaluation.

WARRANTY

Refer to the enclosed Warren Rupp

Warranty Certicate.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 8

Page 11

RECYCLING

Many components of SANDPIPER®

Metallic AODD pumps are made of

recyclable materials (see chart on

page 10 for material specications).

We encourage pump users to recycle

worn out parts and pumps whenever

possible, after any hazardous pumped

uids are thoroughly ushed.

Underwriters Laboratories,

Inc., an Internationally

recognized independent

organization for testing

products to ensure public

safety.

WARNING

Use safe practices

when lifting

kg

WARNING

Before maintenance

or repair, shut off the

compressed air line,

bleed the pressure, and

disconnect the air line from

line may be pressurized and must be bled of

its pressure.

the pump. The discharge

WARNING

Do not smoke near the

pump or use the pump

near an open ame. Fire or

explosion could result.

WARNING

Do not use this pump with potable water

or uids for human consumption.

IMPORTANT SAFETY

INFORMATION

IMPORTANT

Read these safety warnings

and instructions in this

manual completely, before

installation and start-up

of the pump. It is the

responsibility of the purchaser to retain this

manual for reference. Failure to comply with

the recommendations stated in this manual will

damage the pump, and void factory warranty.

CAUTION

Before pump operation,

inspect all gasketed

fasteners for looseness

caused by gasket creep. Re-

torque loose fasteners to

prevent leakage. Follow recommended torques

stated in this manual.

CAUTION

Pump not designed,

tested or certied to be

powered by compressed

natural gas. Powering

the pump with natural

gas will void the warranty.

WARNING

In the event of diaphragm

rupture, pumped material

may enter the air end of the

pump, and be discharged

into the atmosphere. If

pumping a product which is hazardous or toxic,

the air exhaust must be piped to an appropriate

area for safe disposition.

WARNING

Take action to prevent static

sparking. Fire or explosion

can result, especially

when handling ammable

liquids. The pump, piping,

other miscellaneous equipment must be

grounded. (See page 22)

valves, containers or

WARNING

This pump is pressurized

internally with air pressure

during operation. Always

make certain that all bolting

is in good condition and

bolting is reinstalled during assembly.

that all of the correct

WARNING

When used for toxic or

aggressive uids, the pump

should always be ushed

clean prior to disassembly.

WARNING

Before doing any

maintenance on the pump,

be certain all pressure is

completely vented from the

pump, suction, discharge,

openings and connections. Be certain the air

supply is locked out or made non-operational,

so that it cannot be started while work is being

done on the pump. Be certain that approved

eye protection and protective clothing are worn

all times in the vicinity of the pump. Failure to

follow these recommendations may result in

serious injury or death.

piping, and all other

WARNING

Airborne particles and loud

noise hazards.

Wear ear and eye protection.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 9

Page 12

MATERIAL CODES

THE LAST 3 DIGITS OF PART NUMBER

000 Assembly, sub-assembly;

and some purchased items

010 Cast Iron

012 Powered Metal

015 Ductile Iron

020 Ferritic Malleable Iron

025 Music Wire

080 Carbon Steel, AISI B-1112

100 Alloy 20

110 Alloy Type 316 Stainless Steel

111 Alloy Type 316 Stainless Steel

(Electro Polished)

112 Alloy C

113 Alloy Type 316 Stainless Steel

(Hand Polished)

114 303 Stainless Steel

115 302/304 Stainless Steel

117 440-C Stainless Steel (Martensitic)

120 416 Stainless Steel

(Wrought Martensitic)

123 410 Stainless Steel

(Wrought Martensitic)

148 Hardcoat Anodized Aluminum

149 2024-T4 Aluminum

150 6061-T6 Aluminum

151 6063-T6 Aluminum

152 2024-T4 Aluminum (2023-T351)

154 Almag 35 Aluminum

155 356-T6 Aluminum

156 356-T6 Aluminum

157 Die Cast Aluminum Alloy #380

158 Aluminum Alloy SR-319

159 Anodized Aluminum

162 Brass, Yellow, Screw Machine Stock

165 Cast Bronze, 85-5-5-5

166 Bronze, SAE 660

170 Bronze, Bearing Type,

Oil Impregnated

175 Die Cast Zinc

180 Copper Alloy

305 Carbon Steel, Black Epoxy Coated

306 Carbon Steel, Black PTFE Coated

307 Aluminum, Black Epoxy Coated

308 Stainless Steel, Black PTFE Coated

309 Aluminum, Black PTFE Coated

310 PVDF Coated

313 Aluminum, White Epoxy Coated

330 Zinc Plated Steel

331 Chrome Plated Steel

332 Aluminum, Electroless Nickel Plated

333 Carbon Steel, Electroless

Nickel Plated

335 Galvanized Steel

336 Zinc Plated Yellow Brass

337 Silver Plated Steel

340 Nickel Plated

342 Filled Nylon

351 Food Grade Santoprene

353 Geolast; Color: Black

354 Injection Molded #203-40

Santoprene- Duro 40D +/-5;

Color: RED

355 Thermal Plastic

356 Hytrel

357 Injection Molded Polyurethane

358 Urethane Rubber

(Some Applications)

(Compression Mold)

359 Urethane Rubber

360 Nitrile Rubber Color coded: RED

361 Nitrile

363 FKM (Fluorocarbon).

Color coded: YELLOW

364 E.P.D.M. Rubber.

Color coded: BLUE

365 Neoprene Rubber.

Color coded: GREEN

366 Food Grade Nitrile

368 Food Grade EPDM

370 Butyl Rubber

Color coded: BROWN

371 Philthane (Tuftane)

374 Carboxylated Nitrile

375 Fluorinated Nitrile

378 High Density Polypropylene

379 Conductive Nitrile

405 Cellulose Fibre

408 Cork and Neoprene

425 Compressed Fibre

426 Blue Gard

440 Vegetable Fibre

465 Fibre

500 Delrin 500

501 Delrin 570

502 Conductive Acetal, ESD-800

503 Conductive Acetal, Glass-Filled

505 Acrylic Resin Plastic

506 Delrin 150

520 Injection Molded PVDF

Natural color

540 Nylon

541 Nylon

542 Nylon

544 Nylon Injection Molded

550 Polyethylene

551 Glass Filled Polypropylene

552 Unlled Polypropylene

553 Unlled Polypropylene

555 Polyvinyl Chloride

556 Black Vinyl

558 Conductive HDPE

570 Rulon II

580 Ryton

590 Valox

591 Nylatron G-S

592 Nylatron NSB

600 PTFE (virgin material)

Tetrauorocarbon (TFE)

601 PTFE (Bronze and moly lled)

602 Filled PTFE

603 Blue Gylon

604 PTFE

606 PTFE

607 Envelon

608 Conductive PTFE

610 PTFE Encapsulated Silicon

611 PTFE Encapsulated FKM

632 Neoprene/Hytrel

633 FKM/PTFE

634 EPDM/PTFE

635 Neoprene/PTFE

637 PTFE, FKM/PTFE

638 PTFE, Hytrel/PTFE

639 Nitrile/TFE

643 Santoprene

644 Santoprene®/PTFE

656 Santoprene Diaphragm and

Check Balls/EPDM Seats

661 EPDM/Santoprene

666 FDA Nitrile Diaphragm,

PTFE Overlay, Balls, and Seals

668 PTFE, FDA Santoprene/PTFE

Delrin and Hytrel are registered

tradenames of E.I. DuPont.

Gylon is a registered tradename

of Garlock, Inc.

Nylatron is a registered tradename

of Polymer Corp.

Santoprene is a registered tradename

of Exxon Mobil Corp.

Rulon II is a registered tradename

of Dixion Industries Corp.

Ryton is a registered tradename

of Phillips Chemical Co.

Valox is a registered tradename

of General Electric Co.

PortaPump, Tranquilizer and

SludgeMaster are registered tradenames

of Warren Rupp, Inc.

®

/EPDM

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 10

Page 13

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 11

Page 14

Composite Repair Parts Drawing

Add Kits: AIR END KIT (Available Service Kits:)

476-230-000 Air End Kit

Seals, O-Rings, Gaskets, Retaining Rings, Air Valve Assembly

and Pilot Valve Assembly

476-213-760 Wetted End Kit

Nitrile Diaphragms, Nitrile Check Balls and

PTFE Check Valve Seats

476-213-635 Wetted End Kit

Neoprene Backup Diaphragms, PTFE Overlay

Diaphragms, PTFE Check Balls and

PTFE Check Valve Seat

476-213-671 Wetted End Kit

Neoprene Backup Diaphragms,

PTFE Overlay Diaphragms,

PTFE Check Balls and PTFE -

Encapsulated FKM O-rings

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 12

Page 15

Composite Repair Parts List

ITEM PART NUMBER DESCRIPTION QTY

1 031-183-000 Air Valve Assembly 1

2 050-028-760 Ball, Check 4

050-028-600 Ball, Check 4

3 070-012-170 Bushing 2

4 095-110-000 Pilot Valve Assembly 1

5 114-025-157 Intermediate 1

6 132-019-360 Bumper 2

7 135-036-506 Bushing 2

8 165-120-157 Cap, Air Inlet Assembly 1

9 170-044-330 Capscrew, Hex Hd 5/16-18 X 1.00 16

10 170-045-330 Capscrew, Hex Hd 5/16-18 X 1.25 16

11 170-069-330 Capscrew, Hex Hd 5/16-18 X 1.75 4

12 170-006-330 Capscrew, Hex Hd 3/8-16 X 1.00 4

13 196-173-156 Chamber, Outer 2

14 286-008-760 Diaphragm 2

286-008-365 Diaphragm 2

15 286-015-604 Diaphragm, Overlay 2

16 360-093-360 Gasket, Air Valve 1

ITEM PART NUMBER DESCRIPTION QTY

17 360-103-360 Gasket, Pilot Valve 1

18 360-104-379 Gasket, Air Inlet 1

19 518-175-156 Manifold, Suction 1

518-175-156E Manifold, Suction 1" BSP Tapered 1

20 518-176-156 Manifold, Discharge 1

518-176-156E Manifold, Discharge 1" BSP Tapered 1

21 560-001-379 O-Ring 2

22 560-091-611 O-Ring (used with seat #722.098.150) 8

23 612-022-330 Plate, Inner Diaphragm 2

24 612-108-157 Plate, Outer Diaphragm Assembly 2

25 620-022-115 Pin, Actuator 2

26 675-042-115 Ring, Retaining 2

27 685-060-120 Rod, Diaphragm 1

28 720-010-375 Seal, U-Cup 2

29 722-098-600 Seat, Check Ball 4

722.098.150 Seat, Check Ball 4

30 900-004-330 Lockwasher 16

31 901-038-330 Flatwasher 4

32 920-025-000 Ground Strap 1

33 530-033-000 Metal Mufer 1

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 13

Page 16

Air Valve Assembly Drawing, Parts List

1-F

1-E

1-E

1-D

1-C

1-A

1-D

1-B

1-B

1-D

1-C

AIR VALVE ASSEMBLY PARTS LIST

ITEM PART NUMBER DESCRIPTION QTY

1 031-183-000 Gas Valve Assembly 1

1-A 095-109-157 Valve Body 1

1-B 031-139-000 Sleeve and Spool Set 1

1-C 132-029-357 Bumper 2

1-D 560-020-360 O-Ring 10

1-E 165-127-157 Cap, End 2

1-F 170-032-330 Capscrew 8

1-F

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 14

Page 17

AIR DISTRIBUTION VALVE

SERVICING

To service the air valve rst shut

off the compressed air, bleed pressure

from the pump, and disconnect the air

supply line from the pump.

STEP #1: See COMPOSITE

REPAIR PARTS DRAWING.

Using a 9/16" wrench or socket,

remove the four hex head capscrews

(item 10). Remove the air valve

assembly from the pump.

Remove and inspect gasket (item

16) for cracks or damage. Replace

gasket if needed.

STEP #2: Disassembly of the air

valve.

Using a 7/16" wrench or socket,

remove the eight hex caprscrews (item

1-F) that fasten the end caps to the

valve body.

Next remove the two end caps

(items 1-E). Inspect two o-rings (items

1-D) on each end cap for damage or

wear. Replace the o-rings as needed.

Remove the bumpers (items 1-C).

Inspect the bumpers for damage or

wear.

Remove the spool (part of item

1-A) from the sleeve. Be careful not to

scratch or damage the outer diameter

of the spool. Wipe spool with a soft cloth

and inspect for scratches or wear.

Inspect the inner diameter of the

sleeve (part of item 1-A) for dirt,

scratches, or other contaminants. Remove

the sleeve if needed and replace with

a new sleeve and spool set (item 1-A).

STEP #3: Reassembly of the air

valve.

Install one bumper (item 1-C) and

one end cap (item 1-E) with two o-rings

(item 1-D) and fasten with four hex

capscrews (items (1-F) to the valve

body (items 1-A).

Remove the new sleeve an spool

set (item 1-A) from the plastic bag.

Carefully remove the spool from the

sleeve. Install the six o-rings (item 1-G)

into the six grooves on the sleeve. Apply

a light coating of grease to the o-rings

before installing the sleeve into the

valve body (item 1-B), align the slots

in the sleeve with the slots in the valve

body. Insert the spool into the sleeve.

Be careful not to scratch or damage

the spool during installation. Push the

spool in until it touches the bumper on

the opposite end.

Install the remaining bumper, end

cap (with o-rings), and fasten with the

remaining hex capscrews.

Fasten the air valve assembly (item

1) and gasket (item 16) to the pump.

Connect the compressed air line to

the pump. The pump is now ready for

operation.

IMPORTANT

Read these instructions

completely, before

installation and start-up.

It is the responsibility of

the purchaser to retain

this manual for reference. Failure to

comply with the recommendations stated

in this manual will damage the pump, and

void factory warranty.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 15

Page 18

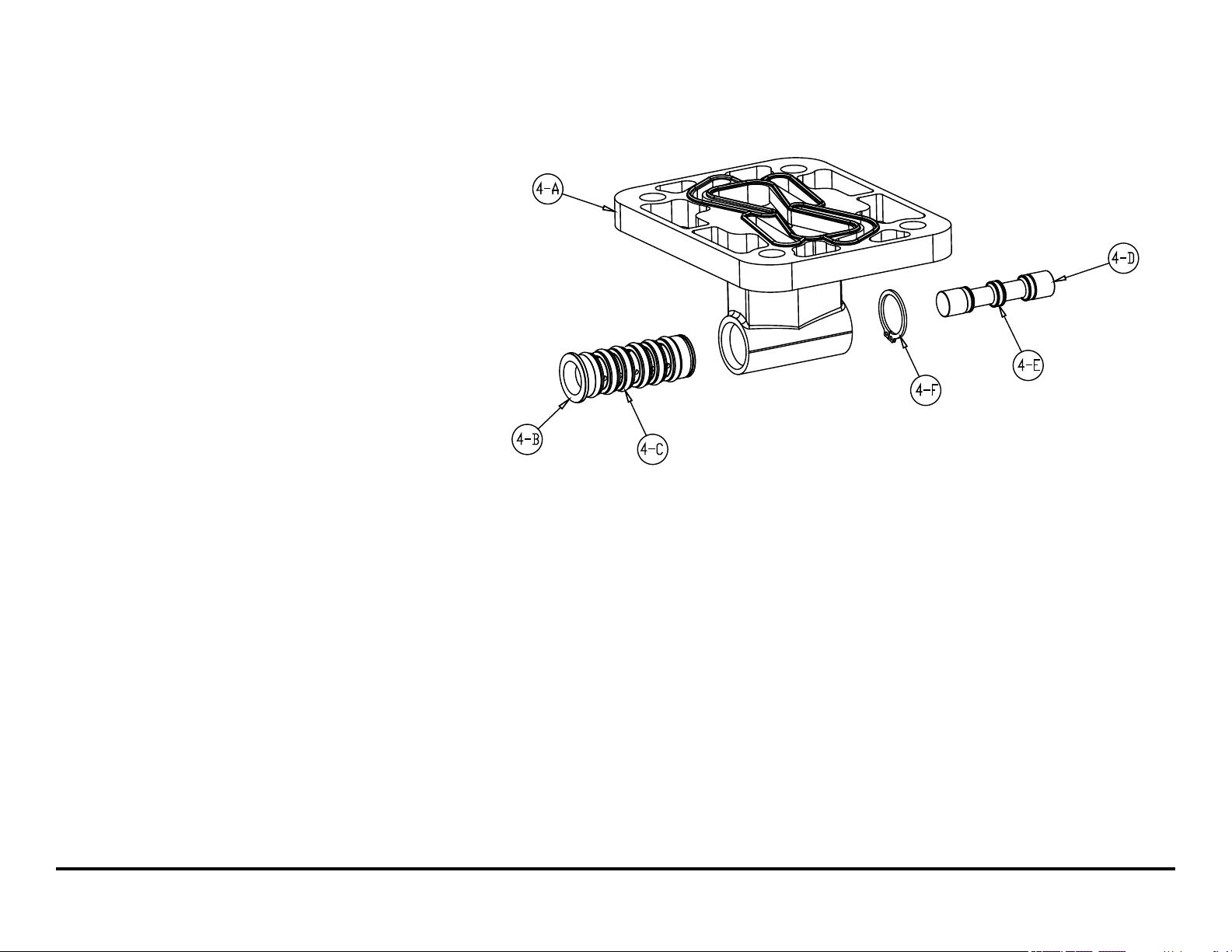

Pilot Valve Servicing, Assembly Drawing & Parts List

PILOT VALVE ASSEMBLY PARTS LIST

ITEM PART NUMBER DESCRIPTION QTY

4 095-110-000 Pilot Valve Assembly 1

4-A 095-095-157 Valve Body 1

4-B 755-052-000 Sleeve (With O-rings) 1

4-C 560-033-360 O-ring (Sleeve) 6

4-D 775-055-000 Spool (With O-rings) 1

4-E 560-023-360 O-ring (Spool) 3

4-F 675-037-080 Retaining Ring 1

PILOT VALVE SERVICING

To service the pilot valve rst shut

off the compressed air supply, bleed

the pressure from the pump, and

disconnect the air supply line from

the pump.

STEP #1: See pump assembly

drawing.

Using a 1/2" wrench or socket,

remove the four capscrews (item 12).

Remove the air inlet cap (item 8) and

air inlet gasket (item 18). The pilot valve

assembly (item 4) can now be removed

STEP #2: Disassembly of the

pilot valve.

Remove the pilot valve spool (item

4-D). Wipe clean and inspect spool and

o-rings for dirt, cuts or wear. Replace

the o-rings and spool if necessary.

Remove the retaining ring (item

4-F) from the end of the sleeve (item

4-B) and remove the sleeve from the

valve body (item 4-A). Wipe clean and

inspect sleeve and o-rings for dirt, cuts

or wear. Replace the o-rings and sleeve

if necessary.

STEP #3: Re-assembly of the

pilot valve.

Generously lubricate outside

diameter of the sleeve and o-rings.

Then carefully insert sleeve into valve

body. Take CAUTION when inserting

sleeve, not to shear any o-rings. Install

retaining ring to sleeve. Generously

lubricate outside diameter of spool and

o-rings. Then carefully insert spool into

sleeve. Take CAUTION when inserting

spool, not to shear any o-rings. Use

BP-LS-EP-2 multipurpose grease, or

equivalent.

STEP #4: Re-install the pilot valve

assembly into the intermediate.

Be careful to align the ends of the

pilot valve stem between the plunger

pins when inserting the pilot valve into

the cavity of the intermediate.

Re-install the gasket, air inlet cap

and capscrews. Connect the air supply

to the pump. The pump is now ready

for operation.

for inspection and service.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 16

Page 19

Diaphragm Service Drawing,

Diaphragm Service Drawing,

with Overlay

5

Non-Overlay

6

23

5

6

23 14

15

28

24

28

14

24

11

13

11

13

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 17

Page 20

DIAPHRAGM SERVICING

To service the diaphragms rst shut

off the suction, then shut off the discharge lines to the pump. Shut off the

compressed air supply, bleed the

pressure from the pump and disconnect

the air supply line from the pump. Drain

any remaining liquid from the pump.

Step #1: See the pump assembly

drawing and the diaphragm servicing

illustration.

Using a 1/2” wrench or socket,

remove the 16 capscrews (item 9) that

fasten the manifolds (items 19 & 20) to

the outer chambers (item 13).

Step #2: Removing outer

chambers.

Using a 1/2” wrench or socket,

remove the 16 capscrews (item 11), that

fasten the outer chambers (item 13),

diaphragms (item 14) and intermediate

(item 5) together.

Step #3: Removing the diaphragms and diaphragm plates.

Use a 7/8” wrench or six point

socket to remove the outer diaphragm

plate assemblies (item 24), diaphragms

(item 14) and inner diaphragm plates

(item 23) from the diaphragm rod (item

28) by turning counterclockwise. Inspect the diaphragm for cuts, punctures,

abrasive wear or chemical attack.

Replace the diaphragms if necessary.

DO NOT USE A WRENCH ON THE

DIAPHRAGM ROD. FLAWS ON THE

SURFACE MAY DAMAGE BEARINGS

AND SEALS.

Step #4: Assembling the

diaphragm and diaphragm plates to the

diaphragm rod.

Push the threaded stud of one outer

diaphragm plate assembly through the

center of one diaphragm and through

one inner diaphragm plate. Install the

diaphragm with the natural bulge facing

away from the diaphragm rod and make

sure the radius on the inner diaphragm

plate is towards the diaphragm, as

indicated on the diaphragm servicing

illustration. Thread the assembly onto

the diaphragm rod, leaving loose.

Step #5: Installing the diaphragm

and rod assembly to the pump.

Make sure the bumper (item 6) is

installed over the diaphragm rod. Insert

rod into pump.

On the opposite side of the pump,

pull the diaphragm rod out as far as

possible. Make sure the second bumper

is installed over the diaphragm rod.

Push the threaded stud of the other

outer diaphragm plate assembly through

the center of the other diaphragm and

through the other inner diaphragm

plate. Make sure the radius on the inner

diaphragm plate is towards the

diaphragm. Thread the assembly onto

the diaphragm rod. Use a 7/8” wrench

or socket to hold one outer diaphragm

plate. Then, use a torque wrench to

tighten the other outer diaphragm plate

to the diaphragm rod to 350 in. lbs.

(39.5 Newton meters).

Align one diaphragm with the

intermediate and install the outer

chamber to the pump using the 8

capscrews. Tighten the opposite

diaphragm plate until the holes in the

diaphragm align with the holes in the

intermediate. Then, install the other

outer chamber using the 8 capscrews.

Step #6: Reinstall the manifolds

to the pump using the 16 capscrews.

The pump is now ready to be

reinstalled, connected and returned to

operation.

OVERLAY DIAPHRAGM SERVICING

The overlay diaphragm (item 15)

is designed to t over the exterior of the

standard diaphragm (item 14).

Follow the same procedures

described for the standard diaphragm

for removal and installation, except

tighten the outer diaphragm plate

assembly, diaphragms and inner diaphragm plate to the diaphragm rod to

350 in. lbs. (39.5 Newton meters).

IMPORTANT

Read these instructions

completely, before

installation and start-up.

It is the responsibility of

the purchaser to retain

this manual for reference. Failure to

comply with the recommendations stated

in this manual will damage the pump, and

void factory warranty.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 18

Page 21

ACTUATOR PLUNGER SERVICING

25

22

7

26

5

To service the actuator plunger rst

shut off the compressed air supply,

bleed the pressure from the pump, and

disconnect the air supply line from

the pump.

Step #1: See PUMP ASSEMBLY

DRAWING.

Using a 1/2" wrench or socket,

remove the four capscrews (items 11).

Remove the air inlet cap (item 8) and

air inlet gasket (item 18). The pilot

valve assembly (item 4) can now be

removed.

Step #2: Inspect the actuator

plungers.

See ILLUSTRATION AT RIGHT.

The actuator plungers (items 25)

can be reached through the pilot valve

cavity in the intermediate assembly

(item 5).

Remove the plungers (item 25) from

the bushings (item 7) in each end of

the cavity. Inspect the installed o-ring

(items 22) for cuts and/or wear. Replace

the o-rings if necessary. Apply a light

coating of grease to each o-ring and

re-install the plungers in to the bushings.

Push the plungers in as far as they

will go.

To remove the bushings (item 7),

rst remove the retaining rings (item

26) by using a at screwdriver. NOTE:

It is recommended that new retaining

rings be installed.

Step #3: Re-install the pilot valve

assembly into the intermediate assembly.

Be careful to align the ends of

the stem between the plungers when

inserting the stem of the pilot valve into

the cavity of the intermediate.

Re-install the gasket (item 18),

air inlet cap (item 8) and capscrews

(item 11).

Connect the air supply to the pump.

The pump is now ready for operation.

ACTUATOR PLUNGER SERVICING

IMPORTANT

Read these instructions

completely, before

installation and start-up.

It is the responsibility of

the purchaser to retain

this manual for reference. Failure to

comply with the recommendations stated

in this manual will damage the pump, and

void factory warranty.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 19

Page 22

CHECK VALVE SERVICING

Before servicing the check valve

components, rst shut off the suction

line and then the discharge line to the

pump. Next, shut off the compressed

air supply, bleed air pressure from the

pump, and disconnect the air supply

line from the pump. Drain any remaining

uid from the pump. The pump can now

be removed for service.

To access the check valve

components, remove the manifold

(item 20 or item 19 not shown). Use a

1/2" wrench or socket to remove

the fasteners. Once the manifold is

removed, the check valve components

can be seen.

Inspect the check balls (items 2) for

wear, abrasion, or cuts on the spherical

surface. The check valve seats (item

30) should be inspected for cuts,

abrasive wear, or embedded material

on the surfaces of both the external

and internal chambers. The spherical

surface of the check balls must seat

ush to the surface of the check valve

seats for the pump to operate to

peak efciency. Replace any worn or

damaged parts as necessary.

Re-assemble the check valve

components. The seat should t into

the counter bore of the outer chamber.

The pump can now be reassembled,

reconnected and returned to operation.

Check Valve Drawing

20

9

30

22

2

29

29

22

METALLIC SEATS

Two o-rings (item 22) are required

for each metallic seats.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 20

with Non-Metallic

Seats

with Metallic Seats

Page 23

PUMPING HAZARDOUS LIQUIDS

1

When a diaphragm fails, the pumped

liquid or fumes enter the air end of the

pump. Fumes are exhausted into

the surrounding environment. When

pumping hazardous or toxic materials,

the exhaust air must be piped to an

appropriate area for safe disposal. See

illustration #1 at right.

This pump can be submerged if

the pump materials of construction

are compatible with the liquid being

pumped. The air exhaust must be

piped above the liquid level. See

illustration #2 at right. Piping used for

the air exhaust must not be smaller

than 1" (2.54 cm) diameter. Reducing

the pipe size will restrict air ow and

reduce pump performance. When the

pumped product source is at a higher

level than the pump (ooded suction

condition), pipe the exhaust higher than

the product source to prevent siphoning

spills. See illustration #3 at right.

CONVERTING THE PUMP FOR

PIPING THE EXHAUST AIR

The following steps are necessary

to convert the pump to pipe the exhaust

air away from the pump.

Remove the mufer (item 21). The

air distribution valve (item 1) has 1" NPT

threads for piped exhaust.

IMPORTANT INSTALLATION

NOTE: The manufacturer recommends

installing a exible conductive hose

or connection between the pump

and any rigid plumbing. This reduces

stresses on the molded threads of the

air exhaust port. Failure to do so may

result in damage to the air distribution

valve body.

Any piping or hose connected to

the pump’s air exhaust port must be

conductive and physically supported.

Failure to support these connections

could also result in damage to the air

distribution valve body.

Air Valve Assembly

21

The pump comes equipped

with a standard metal mufer

CONVERTED EXHAUST ILLUSTRATION

PUMP INSTALLATION AREA

1" DIAMETER AIR

EXHAUST PIPING

Illustration #1

LIQUID

LEVEL

SUCTION

LINE

Illustration #2

LIQUID

LEVEL

SAFE AIR

EXHAUST

DISPOSAL

AREA

MUFFLER

MUFFLER

1" DIAMETER AIR

EXHAUST PIPING

MUFFLER

1" DIAMETER AIR

EXHAUST PIPING

SUCTION

LINE

Illustration #3

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 21

Page 24

Grounding The Pump

One eyelet is installed to a true earth ground. (Requires a 5/16 or 8mm maximum diameter bolt)

This 8 foot long (244 centimeters) Ground Strap (Item 32) is

shipped with the eyelet end fastened to the pump hardware.

To reduce the risk of static electrical sparking, this pump

must be grounded. Check the local electrical code for

detailed grounding instruction and the type of equipment

required, or in the absence of local codes, an industry or

nationally recognized code having jurisdiction over specic

installations and installation codes.

WARNING

Take action to prevent static

sparking. Fire or explosion

can result, especially when

handling ammable liquids.

The pump, piping, valves, containers or other miscellaneous

equipment must be grounded.

u1fmdl1sm-rev0614 Model U1F UL79 Listed Metallic Design Level 1 Page 22

Page 25

Declaration of Conformity

Manufacturer: Warren Rupp, Inc.®, 800 N. Main Street

Mansfield, Ohio, 44902 USA

Certifies that Air-Operated Double Diaphragm Pump Series: HDB, HDF, M Non-Metallic,

S Non-Metallic, M Metallic, S Metallic, T Series, G Series, U Series, EH and SH High Pressure,

RS Series, W Series, SMA and SPA Submersibles, and Tranquilizer Surge Suppressors comply with

the European Community Directive 2006/42/EC on Machinery, according to Annex VIII.

This product has used Harmonized Standard EN809:1998+A1:2009, Pumps and Pump Units

for Liquids - Common Safety Requirements, to verify conformance.

October 20, 2005

Signature of authorized person

Date of issue

David Roseberry

Printed name of authorized person

Revision Level: F

Engineering Manager

Title

August 23, 2012

Date of revision

Page 26

EC Declaration of Conformity

In accordance with ATEX Directive 94/9/EC,

Equipment intended for use in potentially explosive environments.

Manufacturer: Warren Rupp, Inc.

800 North Main Street, P.O. Box 1568, Mansfield, OH 44902 USA

EN 60079-25: 2004

For pumps equipped with Pulse Output ATEX Option

KEMA Quality B.V. (0344)

AODD Pumps and Surge Suppressors

For Type Examination Designations, see page 2 (back)

AODD (Air-Operated Double Diaphragm) Pumps

EC Type Examination Certificate No. Pumps: KEMA 09ATEX0071 X

KEMA Quality B.V.

Utrechtseweg 310

6812 AR Arnhem, The Netherlands

DATE/APPROVAL/TITLE:

27 MAY 2010

®

, A Unit of IDEX Corportion

Applicable Standard:

EN13463-1: 2001,

EN13463-5: 2003

David Roseberry, Engineering Manager

Page 27

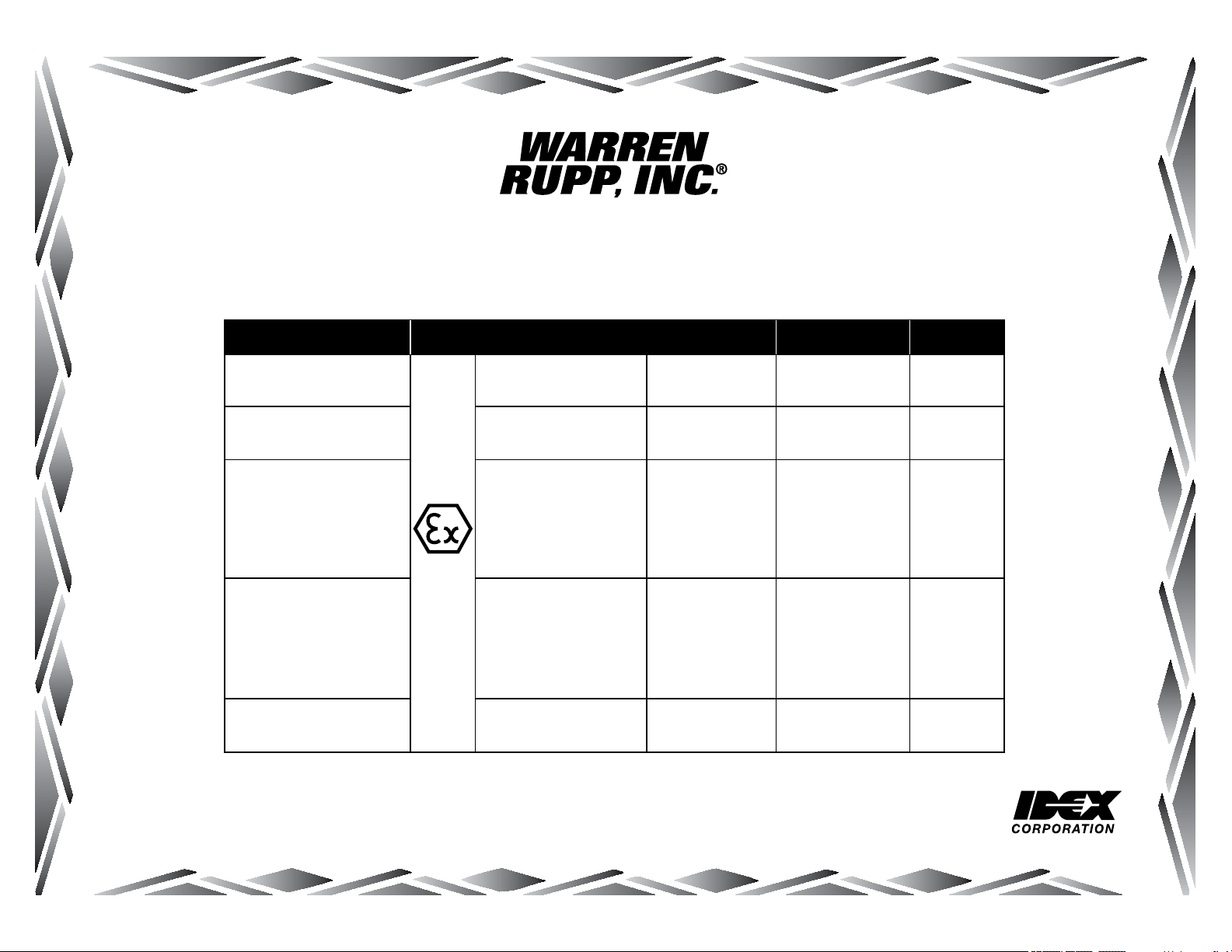

EC Declaration of Conformity

ATEX Summary of Markings

Type Marking Listed In

Pump types, S1F, S15, S20,

and S30 provided with the

pulse output option

Pump types, S1F, S15, S20,

and S30 provided with the

integral solenoid option

Pump types, HDB1½, HDB40,

HDB2, HDB50, HDB3, HDF1,

HDF25, HDF2, HDF3M, PB¼,

S05, S1F, S15, S20, S30, SB1,

SB25, ST1½, ST40, G15, G20,

and G30, without the above

listed options, no aluminum

parts

Pump types, DMF2, DMF3,

HDB1½, HDB40, HDB2,

HDB50, HDB3, HDF1, HDF25,

HDF2, HDF3M, PB¼, S05, S1F,

S15, S20, S30, SB1, SB25,

SE½, ST1, ST25, ST1½, ST40,

U1F, G05, G1F, G15, G20, and

G30

Surge Suppressors all types II 2 G T5

EC Type Certificate No. Pumps: KEMA 09ATEX0071 X

Type Certificate No. Pumps: KEMA 09ATEX0072 X

Type Certificate No. Suppressors: KEMA 09ATEX0073

II 2 G Ex ia c IIC T5

II 3/2 G Ex ia c IIC T5

II 2 D

Ex c iaD 20 IP67 T100oC

II 2 G EEx m c II T5

II 3/2 G EEx m c II T5

II 2 D c IP65 T100

II 1 G c T5

II 3/1 G c T5

II 1 D c T100

I M1 c

I M2 c

II 2 G c T5

II 3/2 G c T5

II 2 D c T100

II 3/2 G T5

II 2 D T100

Non-Conductive

KEMA 09ATEX0071 X

CE 0344

KEMA 09ATEX0071 X

o

C

o

C

o

C

o

C

Pumps marked with equipment Category II 3/1 G (internal 3 G / eternal 1 G), 1D, M1 and M2 when

used for non-conductive fluids. The pumps are Category II 2 G when used for conductive fluids.

Pumps and surge suppressors marked with equipment Category II 3/2 (internal 3 G / external 2 G), 2D

when used for non-conductive fluids. The pumps are Category II 2 G when used for conductive fluids.

CE 0344

KEMA 09ATEX0071 X

KEMA 09ATEX0072 X

CE 0344

KEMA 09ATEX0072 X

CE

KEMA 09ATEX0073

CE

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0071 X

KEMA 09ATEX0072 X

KEMA 09ATEX0072 X

KEMA 09ATEX0072 X

KEMA 09ATEX0072 X

KEMA 09ATEX0073

KEMA 09ATEX0073

KEMA 09ATEX0073

Fluids

No

Yes

Yes

No

Yes

Yes

No

Yes

Yes

No

Yes

No

Yes

Yes

No

Yes

Yes

Loading...

Loading...