Samsung VP-L10, VP-L150, SCL100, SCL150 Service Manual

8mm CAMCORDER

VP-L100/VP-L150

SCL100/SCL150

SERVICE

1. Precautions

2. Reference Information

3. Product Specifications and

Comparison Chart

4. Disassembly and Reassembly

5. Alignment and Adjustment

6. Exploded View and Parts List

7. Electrical Parts List

8. Block Diagrams

9. PCB Diagrams

10. Wiring Diagram

11. Schematic Diagrams

Manual

8mm CAMCORDER

CONTENTS

For mechanical disassembly and adjustment, refer to the “Mechanical Manual”

(DE-6 AD68-30200A).

A

Samsung Electronics 1-1

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all protective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unitÕs

AC switch first in the ON position and then OFF,

measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

Fig. 1 AC Leakage Test

7. Antenna Cold Check :

With the unitÕs AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (Òsolid stateÓ) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Precautions

1-2 Samsung Electronics

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also, any

design changes or additions will void the

manufacturerÕs warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrumentÕs ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrumentÕs

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

Òintegral implosionÓ protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some Òin-lineÓ picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

Òpermanently attachedÓ yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. A replacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

2. Reference Information

2-1 IC Blocks

Reference Information

Samsung Electronics 2-1

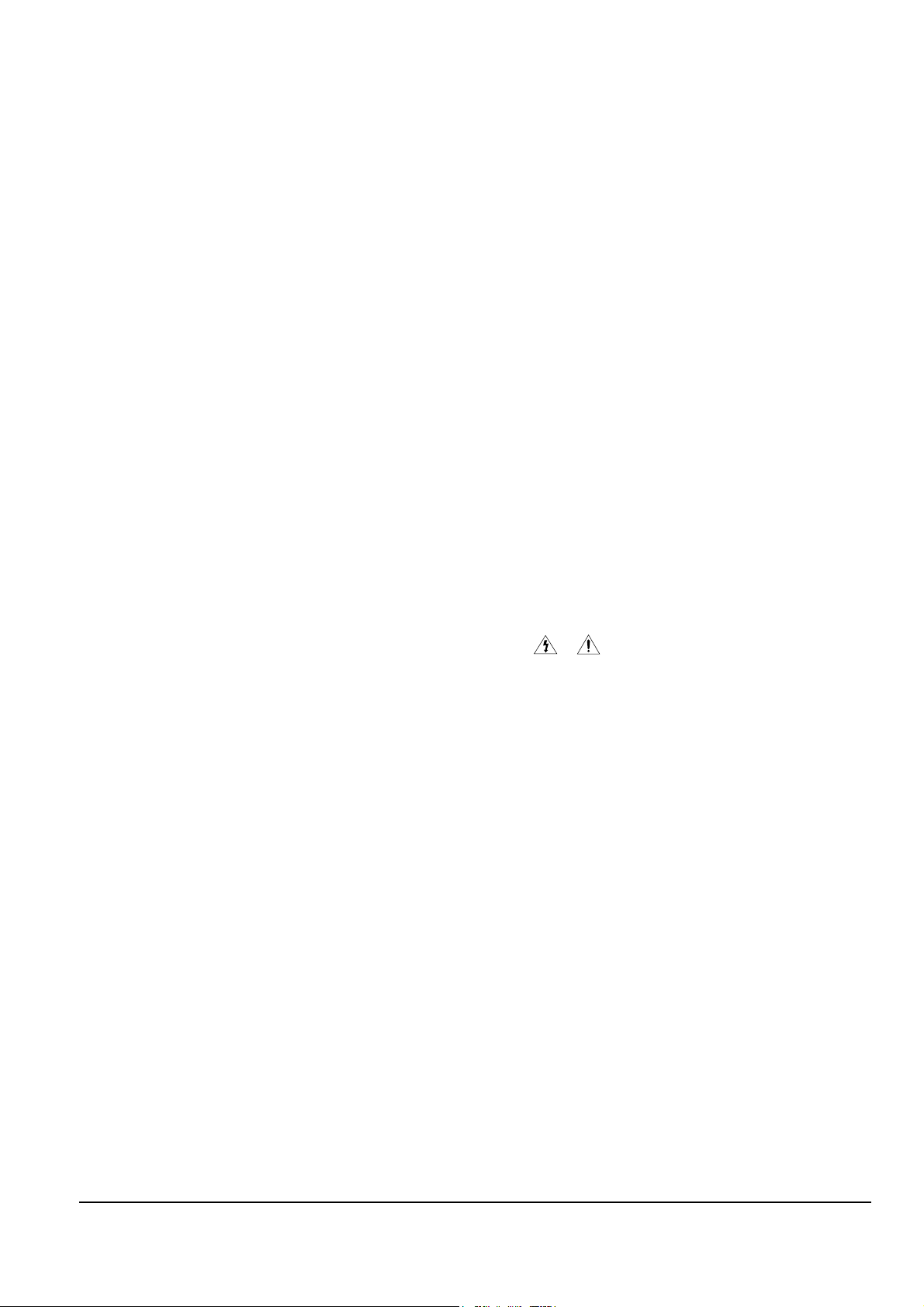

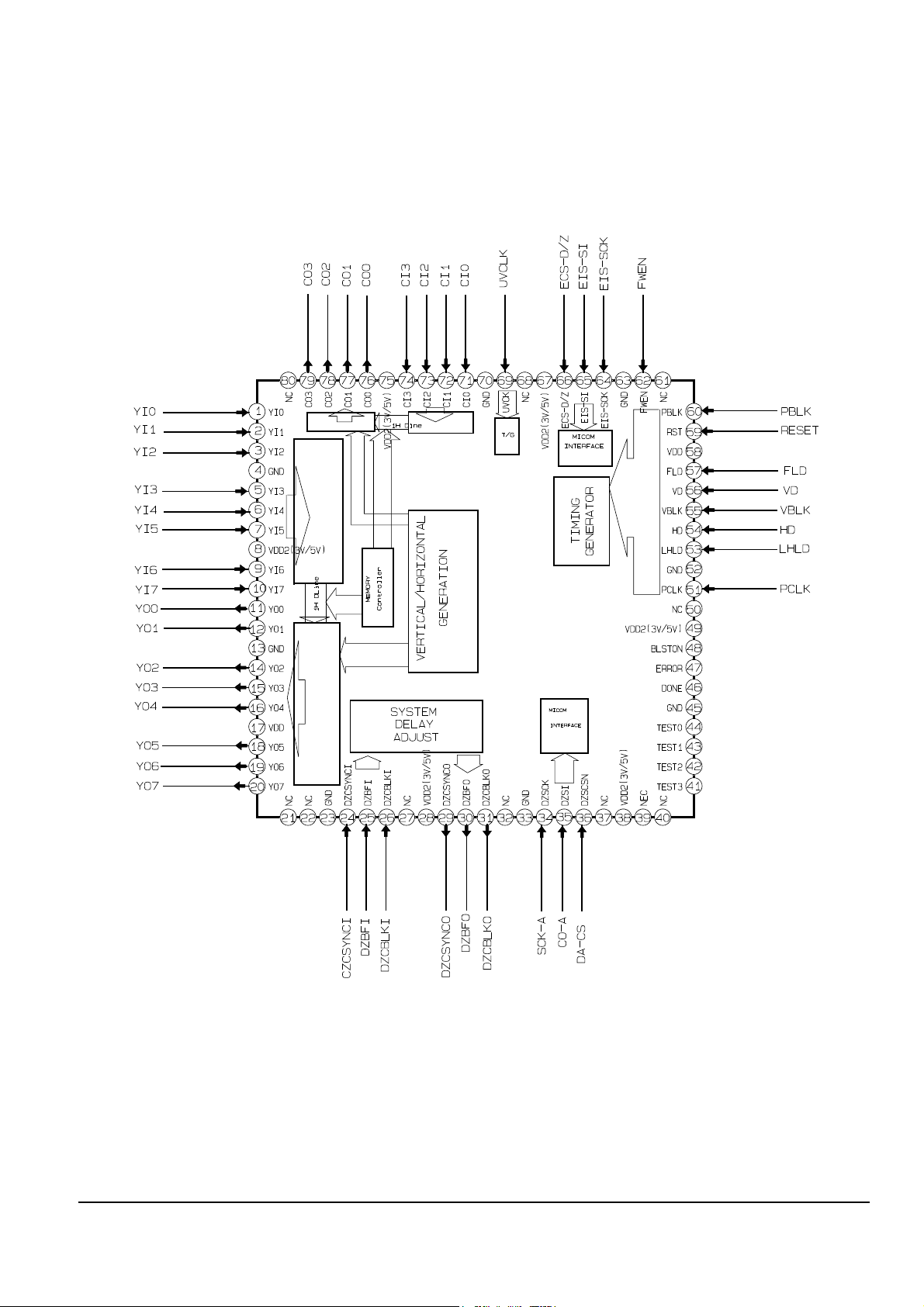

2-1-1 IC501 (KA8322)

Reference Information

2-2 Samsung Electronics

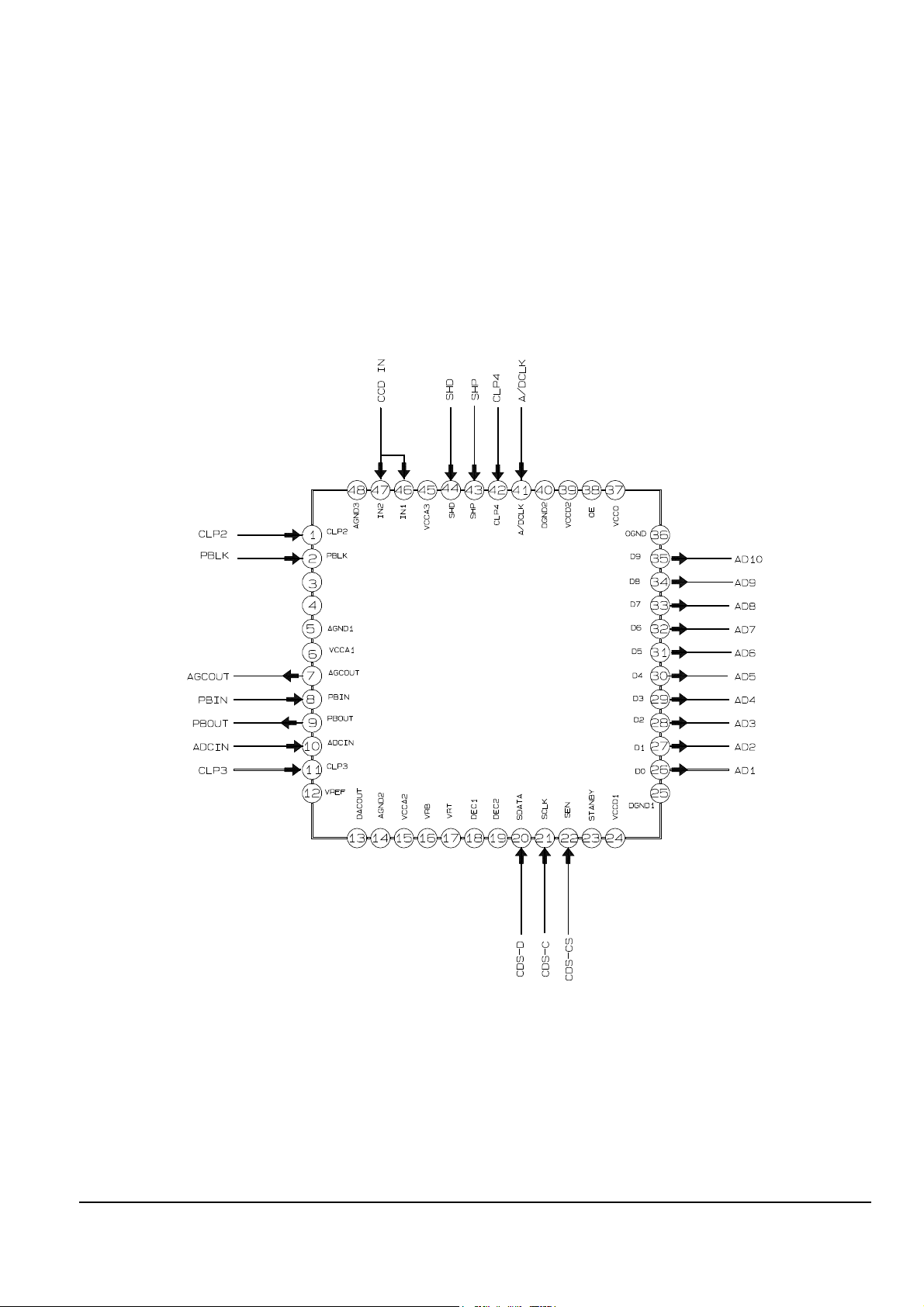

2-1-2 IC601 (CXP87240A)

Reference Information

Samsung Electronics 2-3

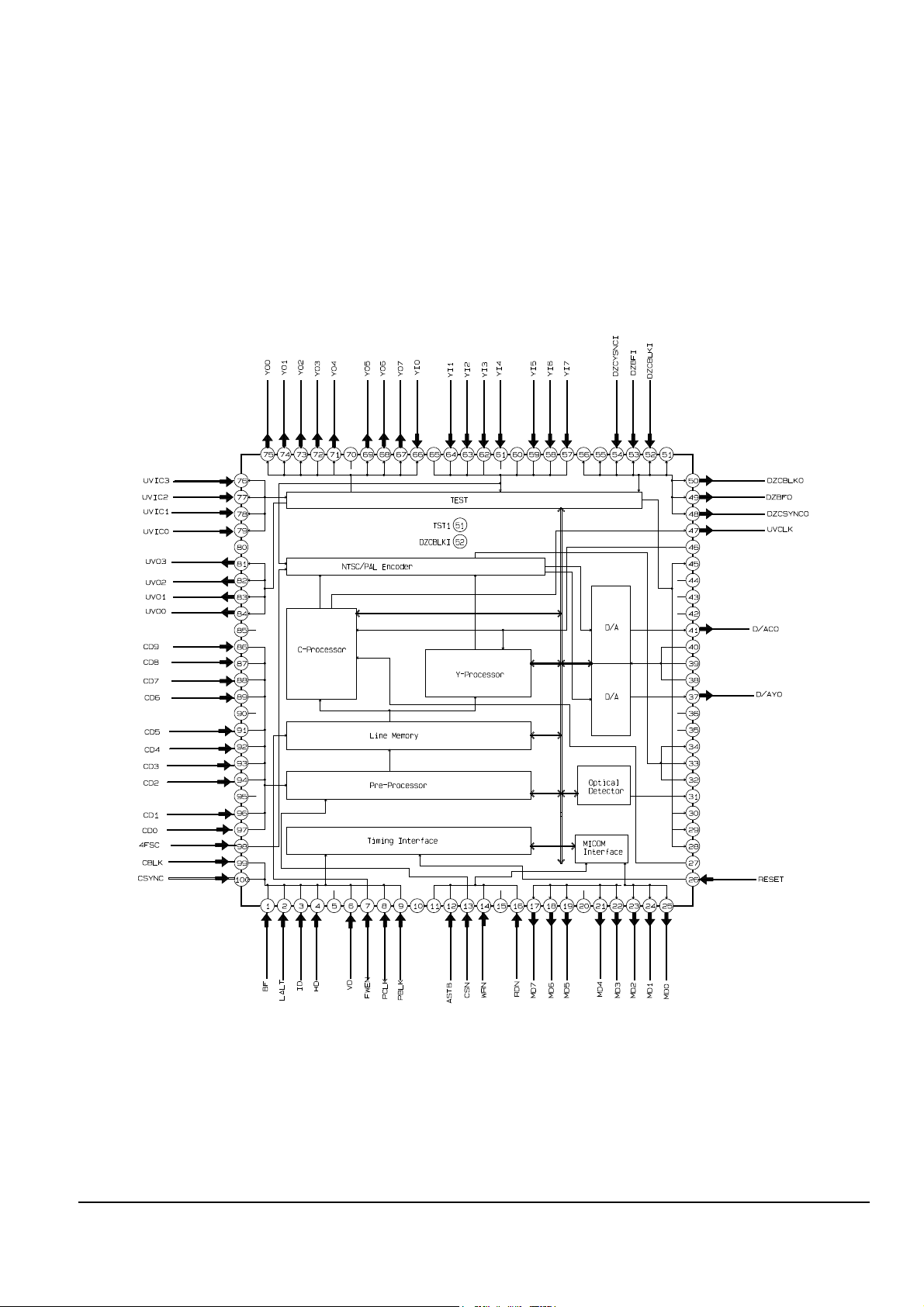

2-1-3 ICP01 (KS7213)

Reference Information

2-4 Samsung Electronics

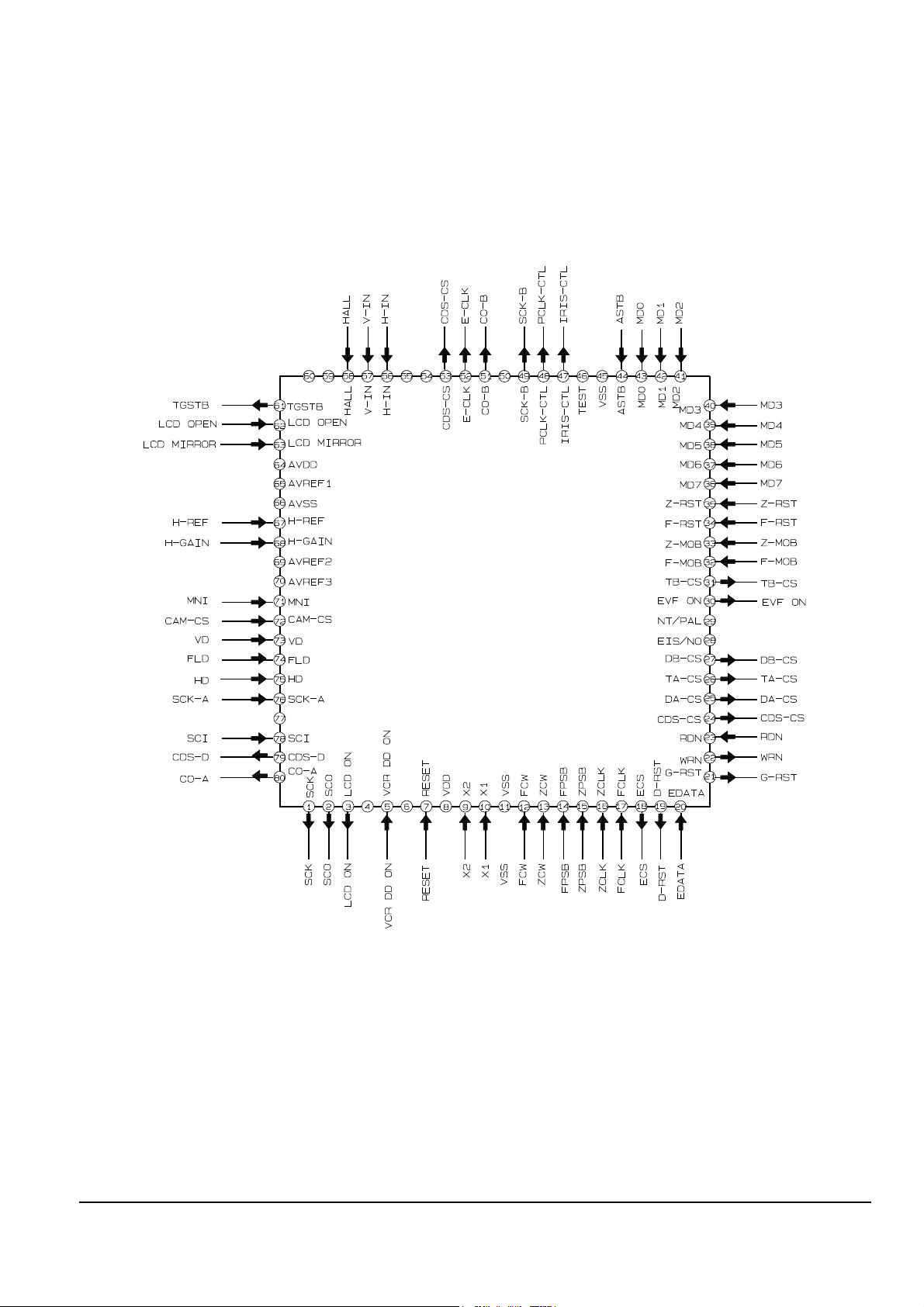

2-1-4 ICP03 (TDA8786A)

Reference Information

Samsung Electronics 2-5

2-1-5 ICP04 (KS7306B)

Reference Information

2-6 Samsung Electronics

2-1-6 ICP05 (UPD784038 / AF MICOM)

Reference Information

Samsung Electronics 2-7

2-1-7 ICZ01 (KS7314 / D.ZOOM)

Reference Information

2-8 Samsung Electronics

MEMO

Samsung Electronics 3-1

3. Product Specifications and Comparison Chart

3-1 Product Specifications (SCL100 / SCL150)

Design and specifications are subject to change without notice.

Operation

Description

SYSTEM

LCD Three-inch color TFT Liquid Crystal Display (LCD) screen

Recording systems Video : Two rotary heads, helical FM scanning / Audio : FM stereo system

Video signal NTSC color, EIA standard

Cassette format 8 mm

Tape speed SP mode (Standard Play) : approx. 14.345 mm/sec

Recording/Playback time SP mode (Standard Play) : 1 hour (P6-60)

Fast-forward/rewind time Approx. 3 minute 30 seconds (P6-60)

Image device CCD (Charge Coupled Device)

Viewfinder Black and White electronic viewfinder

Lens Combined 16X power zoom and (32X:SCL100, 64X:SCL150) digital zoom lens,

f=3.9 ~ 62.4mm, F1.4 Auto wide macro, Filter diameter 46mm.

Automatic focus system Inner

Color temperature Auto

Aperture correction Automatic with back light adjustment

OUTPUT CONNECTORS

Video output Mini jack, 1Vp-p, 75 ohms, unbalanced, SYNC negative

Audio output Mini jack, 7.5dBs for an output impedance of less than 2.2 Kohms

GENERAL

Power requirement AC power adapter (7.2V) ; battery pack (6.0V)

Power consumption 6.5W (Camera Recording, LCD on)

Tripod attachment thread Attachment screw less than 6mm long

Microphone Electric condensor microphone, omni-directional, monaural type

Temperature range Operating : 0°C to 40°C (32°F to 104°F); storage : -20°C to 60°C (-4°F to 140°F)

Dimensions/weight Approx. 213 X 116 X 107 mm (L X H X W); Approx. 1000 g

Excluding battery pack and cassette.

Product Specifications

3-2 Samsung Electronics

3-2 Product Specifications (VP-L100 / VP-L150)

Design and specifications are subject to change without notice.

Operation

Description

SYSTEM

LCD Three-inch colour TFT Liquid Crystal Display (LCD) screen

Recording systems Video : Two rotary heads, helical FM scanning / Audio : FM stereo system

Video signal PAL colour, CCIR standard

Cassette format 8 mm

Tape speed SP mode (Standard Play) : approx. 20.051 mm/sec

Recording/Playback time SP mode (Standard Play) : 1 hour (P5-60)

Fast-forward/rewind time Approx. 4 minute (P5-60)

Image device CCD (Charge Coupled Device)

Viewfinder Black and White electronic viewfinder

Lens Combined 16X power zoom and 32X(VP-L150) digital zoom lens,

f=3.9 ~ 62.4mm, F1.4 Auto wide macro, Filter diameter 46mm.

Automatic focus system Inner

Colour temperature Auto

Aperture correction Automatic with back light adjustment

OUTPUT CONNECTORS

Video output Mini jack, 1Vp-p, 75 ohms, unbalanced, SYNC negative

Audio output Mini jack, 7.5dBs for an output impedance of less than 2.2 Kohms

GENERAL

Power requirement AC power adapter (7.2V) ; battery pack (6.0V)

Power consumption 6.5W (Camera Recording, LCD on)

Tripod attachment thread Attachment screw less than 6mm long

Microphone Electric condensor microphone, omni-directional, monaural type

Temperature range Operating : 0°C to 40°C (32°F to 104°F); storage : -20°C to 60°C (-4°F to 140°F)

Dimensions/weight Approx. 213 X 116 X 107 mm (L X H X W); Approx. 1000 g

Excluding battery pack and cassette.

Product Specifications

Samsung Electronics 3-3

3-3 Comparison Chart

VIEWFINDER EVF EVF EVF EVF

D.ZOOM X16 X32 D.ZOOM X32 D.ZOOM X64 D.ZOOM

VIDEO NORMAL NORMAL NORMAL NORMAL

STEREO X X X X

EIS X O X O

LCD 3 inch 3 inch 3 inch 3 inch

MODEL

FUNCTION

VP-L100 VP-L150 SCL100 SCL150

Product Specifications

3-4 Samsung Electronics

MEMO

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1 Cabinet and PCB

4-1-1 Ass’y Cover-Housing removal

ΠAPPLY POWER AND EJECT THE COVER HOUSING.

´ REMOVE 2 SCREWS.

ˇ REMOVE THE ASS'Y COVER-HOUSING IN

THE DIRECTION OF ARROW.

Fig. 4-1 Ass’y Cover-Housing removal

Disassembly and Reassembly

4-2 Samsung Electronics

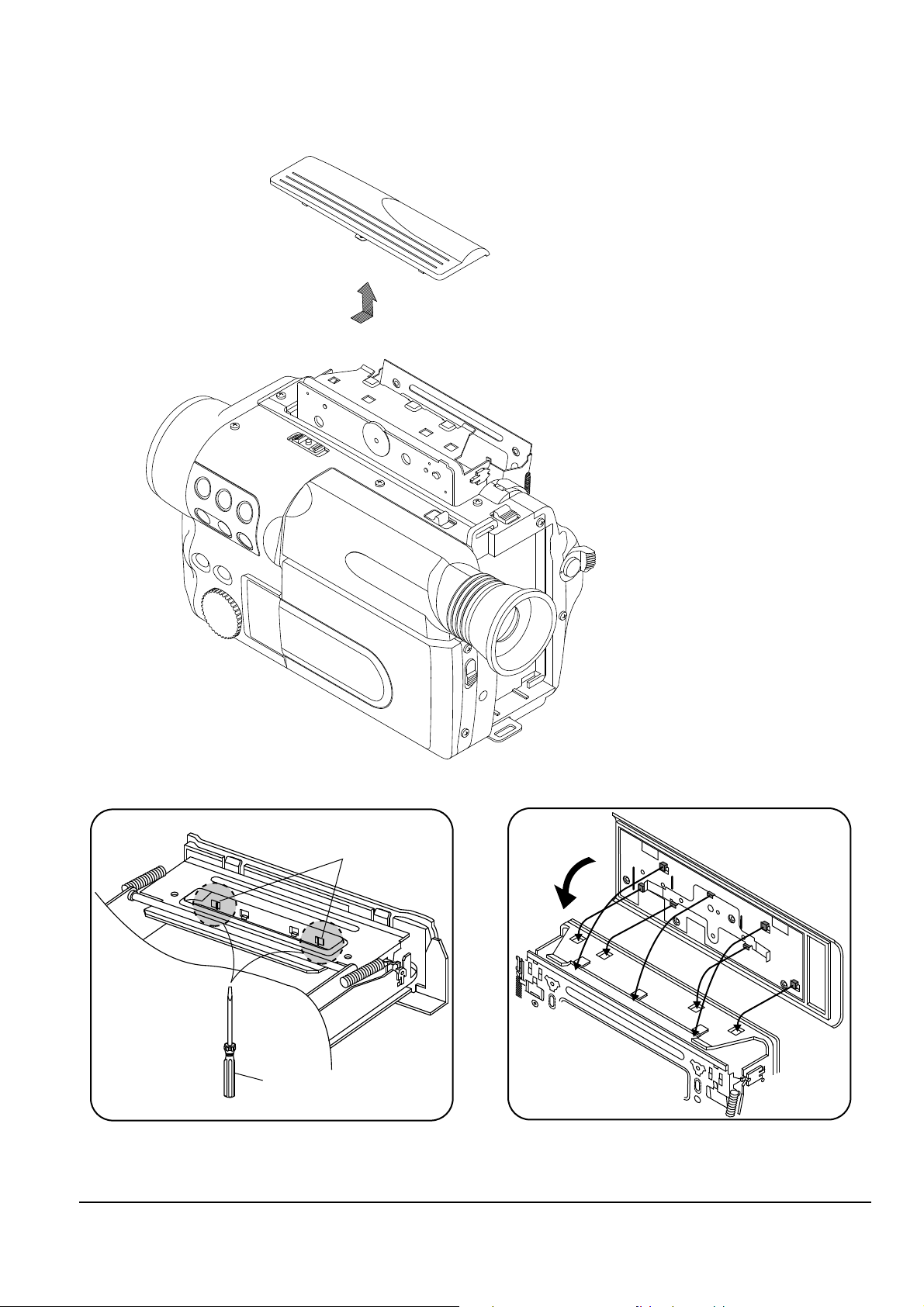

4-1-2 Ass’y Case-Top removal

"B"

2 LOCKING TABS

PRECISION SCREW DRIVER

< DETAIL "A" >

< DETAIL "B" >

ΠREMOVE THE ASS'Y-CASE-TOP BY GENTLY RELEASING 2 LOCKING TABS

WITH A PRECISION SCREW DRIVER. (SEE DETAIL "A")

• NOTE : CLOSE THE HOUSING ASS'Y AFTER DISASSEMBLING.

• REASSEMBLY : PUT THE 7 TABS INTO THE SLOT WHILE

SLIDING IT AS SHOWN IN DETAIL "B".

Fig. 4-2 Ass’y Case-Top removal

Disassembly and Reassembly

Samsung Electronics 4-3

4-1-3 Ass’y Front removal

ΠREMOVE 2 SCREWS.

´ REMOVE 2 SCREWS.

¨ REMOVE THE ASS'Y-FRONT IN THE DIRECTION OF ARROW.

ˆ DISCONNECT 2 CONNECTORS FROM THE

CN891,CN893 OF AUDIO PCB.

ˇ REMOVE 1 SCREW.

Fig. 4-3 Ass’y Front removal

Disassembly and Reassembly

4-4 Samsung Electronics

4-1-4 Ass’y Case-Right removal

¨ REMOVE THE ASS'Y CASE-RIGHT IN THE DIRECTION OF ARROW "B".

ˇ SLIDE THE ZOOM SWITCH IN

THE DIRECTION OF ARROW "A".

ΠREMOVE 1 SCREW.

´ REMOVE 2 SCREWS.

Fig. 4-4 Ass’y Case-Rignt removal

Disassembly and Reassembly

Samsung Electronics 4-5

4-1-5 Ass’y Case-Left removal

¨ REMOVE 2 SCREWS.

ˆ REMOVE THE ASS'Y CASE-LEFT IN THE DIRECTION OF ARROW.

∏ DISCONNECT THE CONNECTER FROM THE CN502 OF MAIN PCB.

ˇ REMOVE 1 SCREW.

´ REMOVE 3 SCREWS.

ΠREMOVE 1 SCREW.

Fig. 4-5 Ass’y Case-Left removal

Disassembly and Reassembly

4-6 Samsung Electronics

4-1-6 Ass’y Case-Battery removal

´ DISCONNECT THE CN961 OF THE REAR PCB FROM

THE CN501 OF MAIN PCB AND THEN REMOVE THE

ASS'Y CASE-BATTERY IN THE DIRECTION OF ARROW.

ΠREMOVE 1 SCREW.

Fig. 4-6 Ass’y Case-Battery removal

Disassembly and Reassembly

Samsung Electronics 4-7

4-1-7 Ass’y Case-Bottom removal

Fig. 4-7 Ass’y Case-Bottom removal

´ REMOVE THE CASE- BOTTOM

IN THE DIRECTION OF ARROW.

ΠREMOVE 2 SCREWS.

Disassembly and Reassembly

4-8 Samsung Electronics

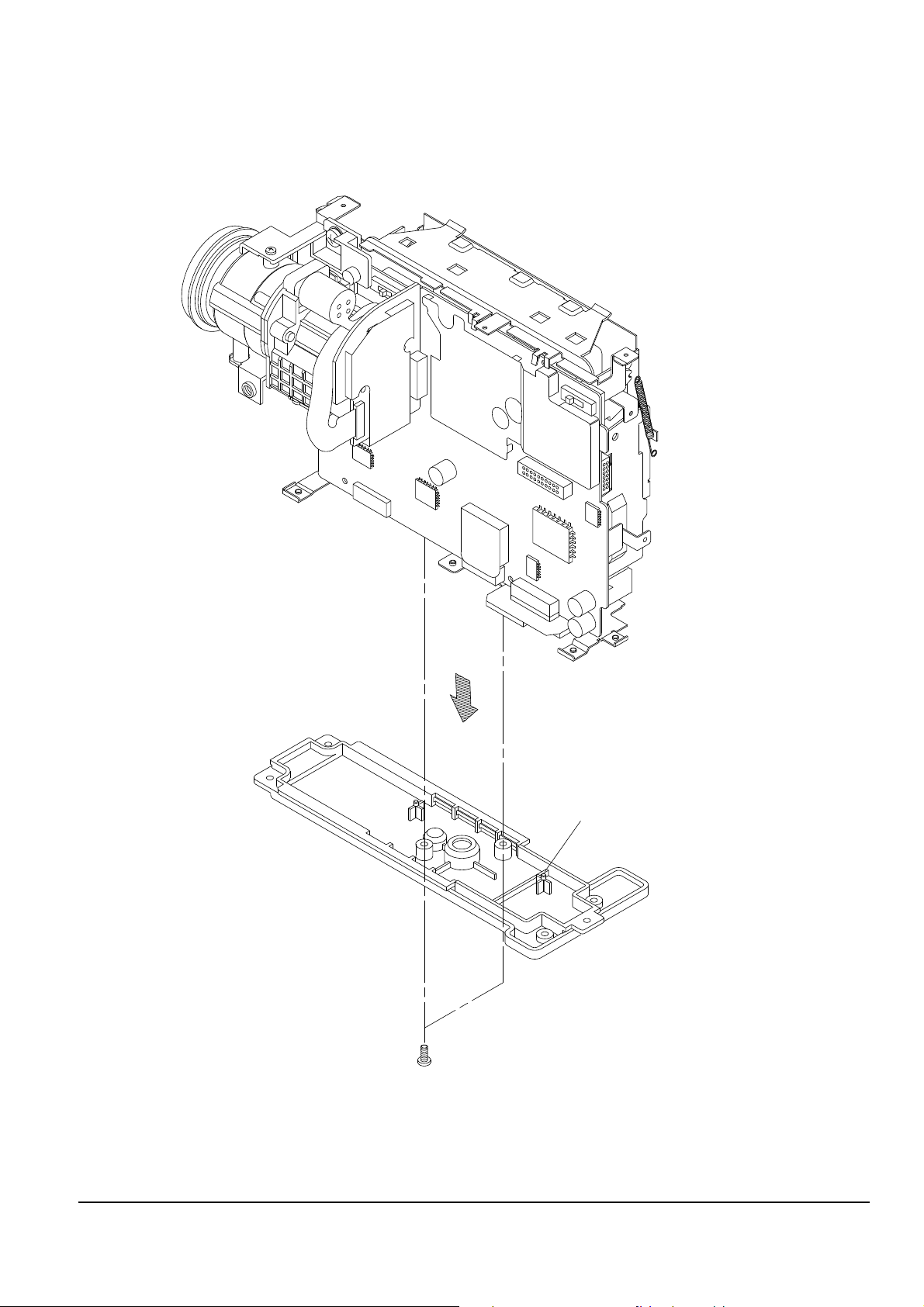

4-1-8 Ass’y-Deck removal

¨ REMOVE 1 SCREW.

ˇ REMOVE 2 SCREWS.

ˆ DISCONNECT THE FPC FROM THE ASS'Y DECK.

Ø DISCONNECT THE FPC FROM

THE CN501 OF MAIN PCB.

∏ REMOVE THE ASS'Y DECK IN THE DIRECTION OF ARROW .

Fig. 4-8 Audio PCB and Ass’y-Deck removal

Disassembly and Reassembly

Samsung Electronics 4-9

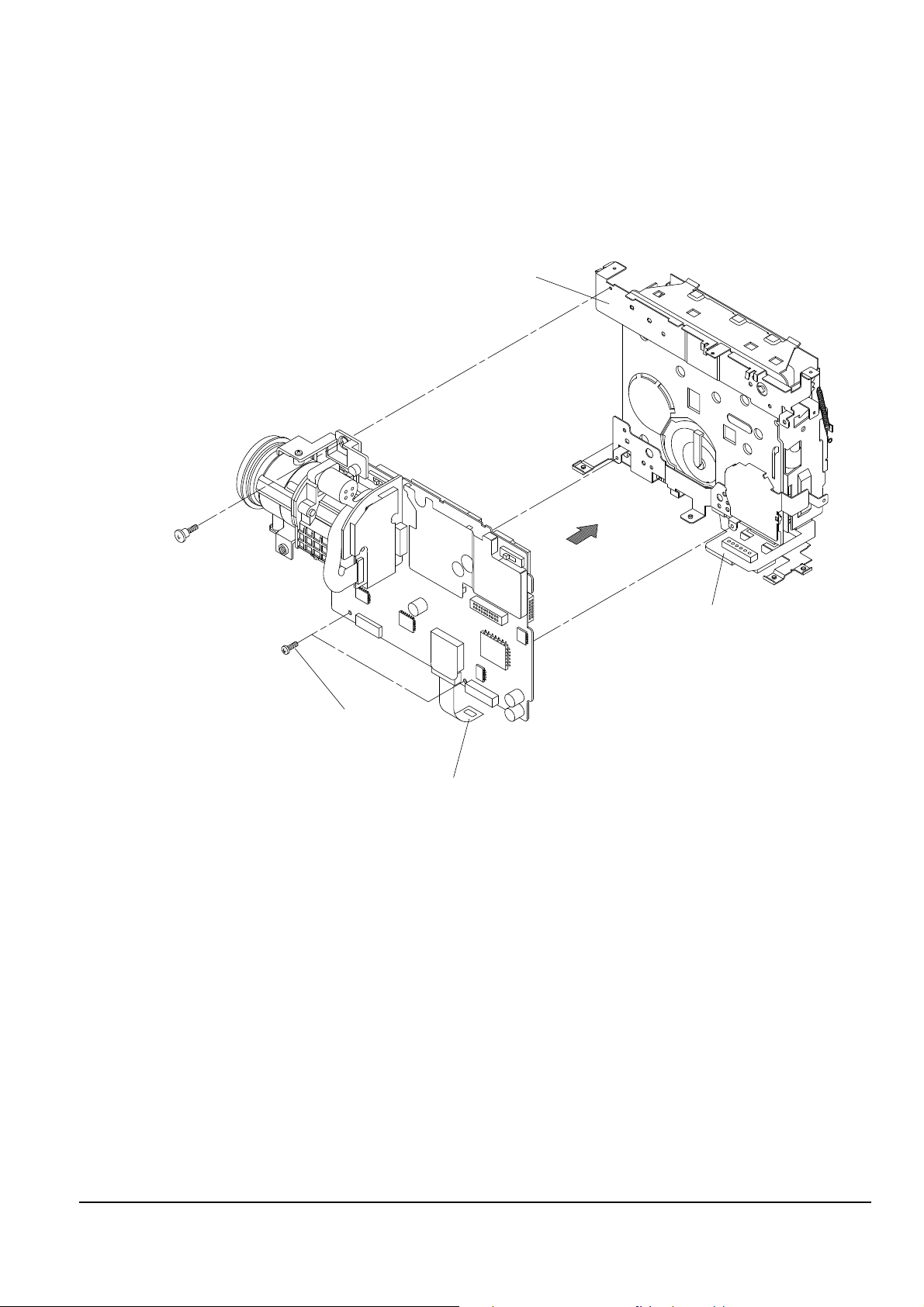

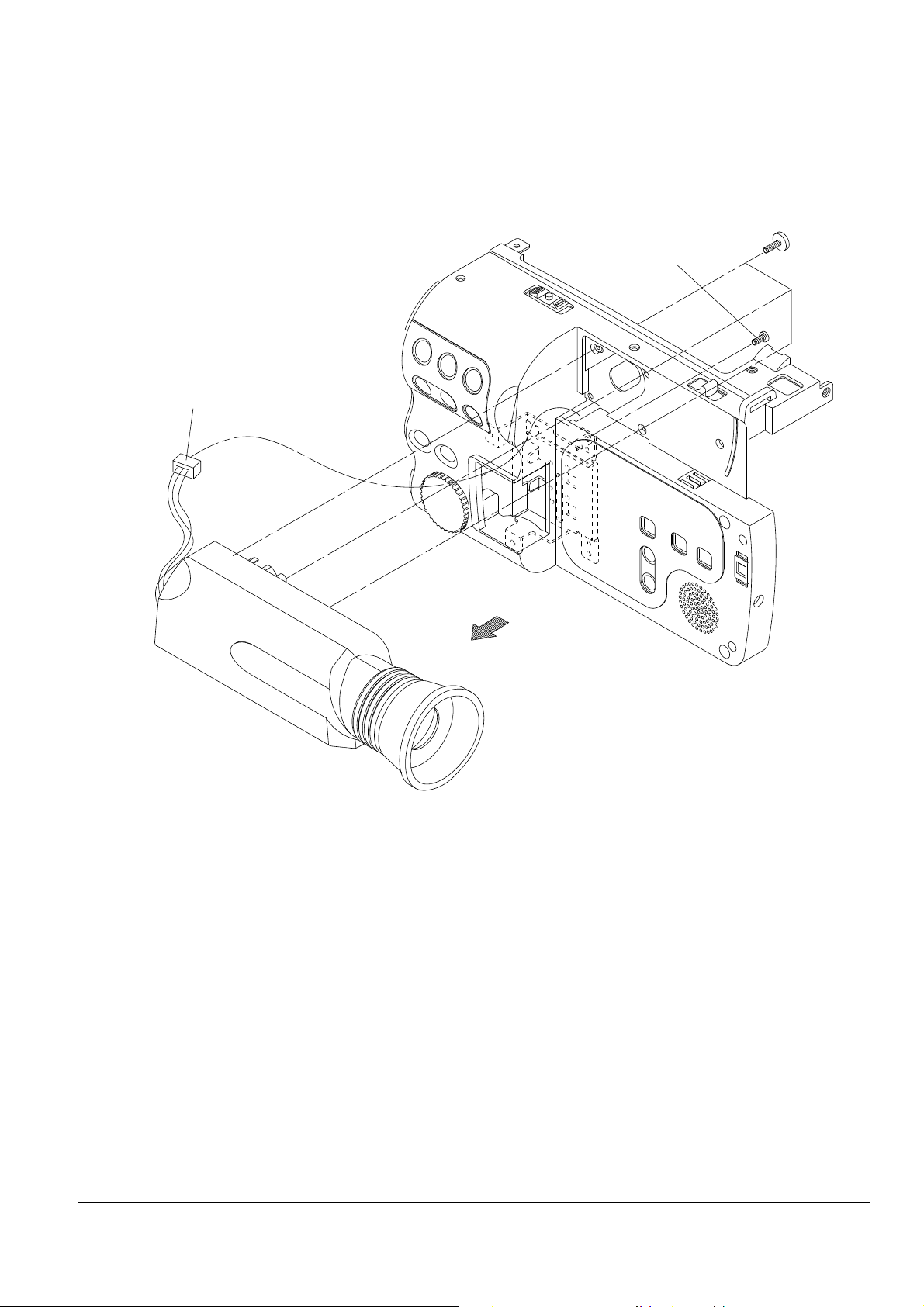

4-1-9 Ass’y Camera and Main PCB removal

CNC01

CNP01

ΠDESOLDER

ˇ DISCONNECT THE CNC01 FROM THE CNP01 OF MAIN PCB

AND THEN REMOVE THE ASS'Y CAMERA IN THE DIRECTION OF ARROW.

SOLDERING POINT

´ REMOVE 2 SCREWS.

Fig. 4-9 Ass’y Camera and Main PCB removal

Disassembly and Reassembly

4-10 Samsung Electronics

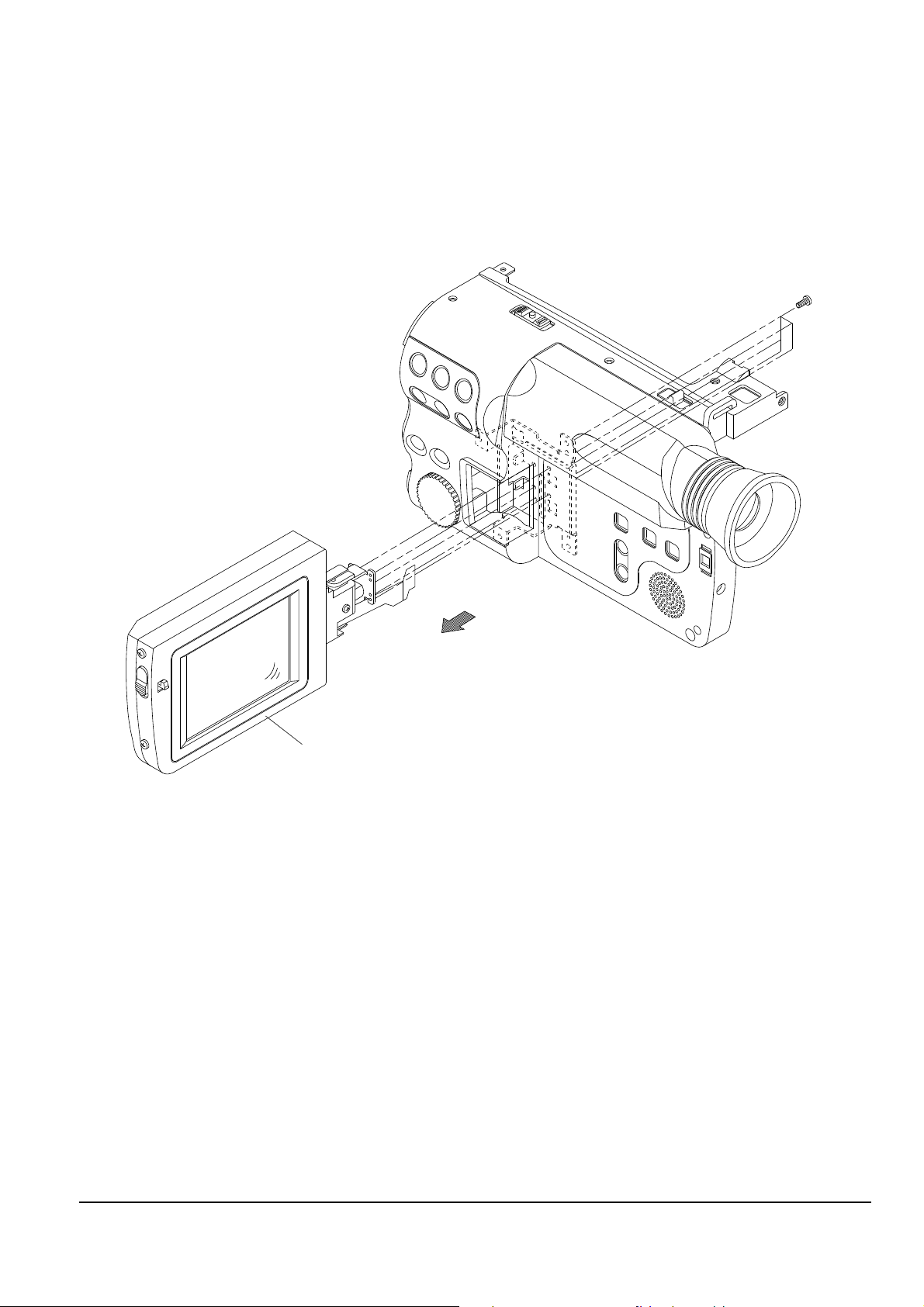

4-1-10 Ass’y LCD removal

"A"

ΠREMOVE 5 SCREWS.

´ REMOVE THE ASS'Y LCD IN THE DIRECTION OF ARROW "A".

Fig. 4-10 Ass’y LCD removal

Disassembly and Reassembly

Samsung Electronics 4-11

4-1-11 Ass’y EVF removal

¨ REMOVE THE ASS'Y EVF IN THE DIRECTION OF ARROW "B".

ΠDISCONNECT THE LEAD CONNECTOR FROM

THE CN803 OF FUNCTION MENU PCB.

´ REMOVE 1 SCREW.

ˇ REMOVE 3 SCREWS.

Fig. 4-11Ass’y EVF removal

Disassembly and Reassembly

4-12 Samsung Electronics

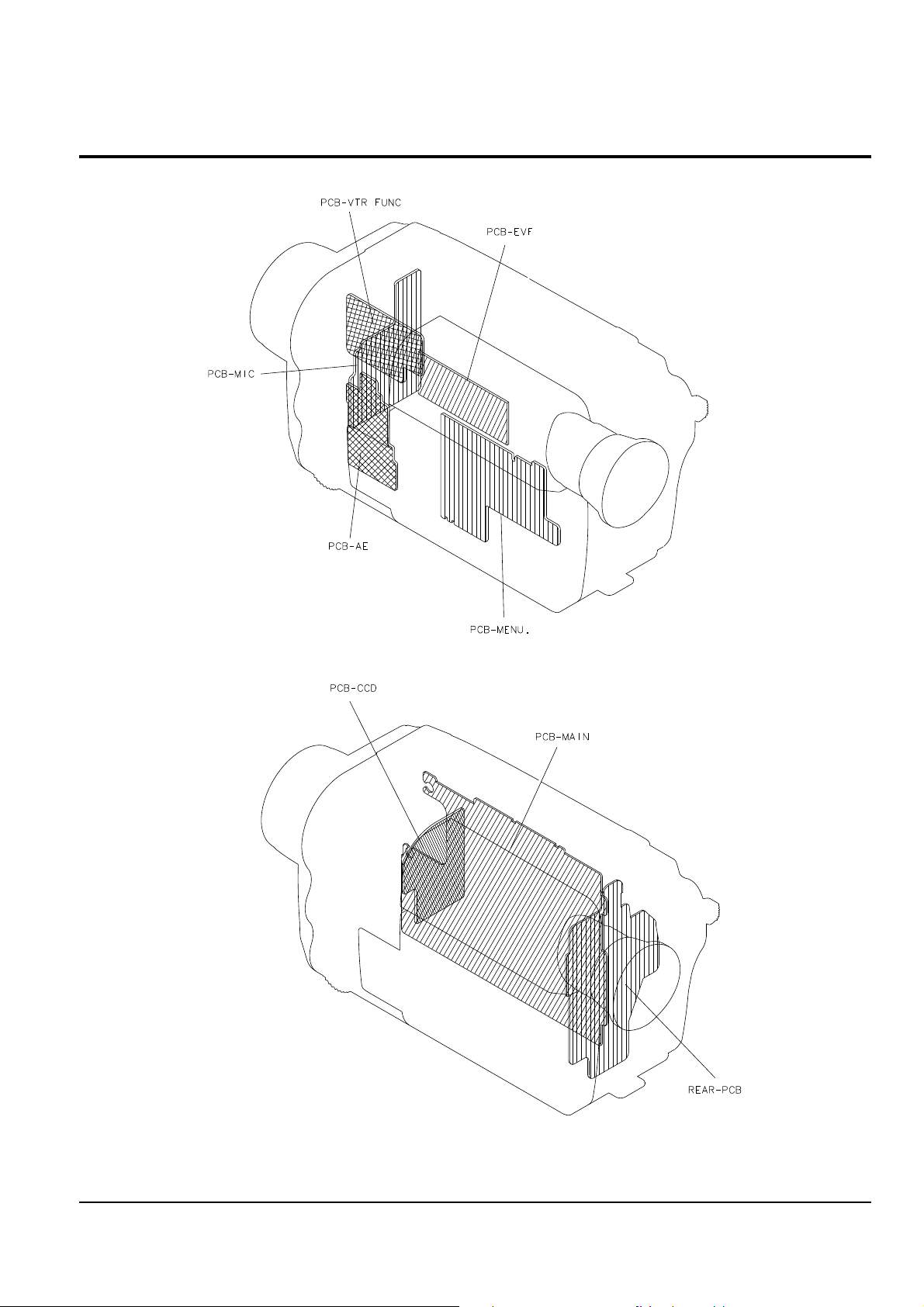

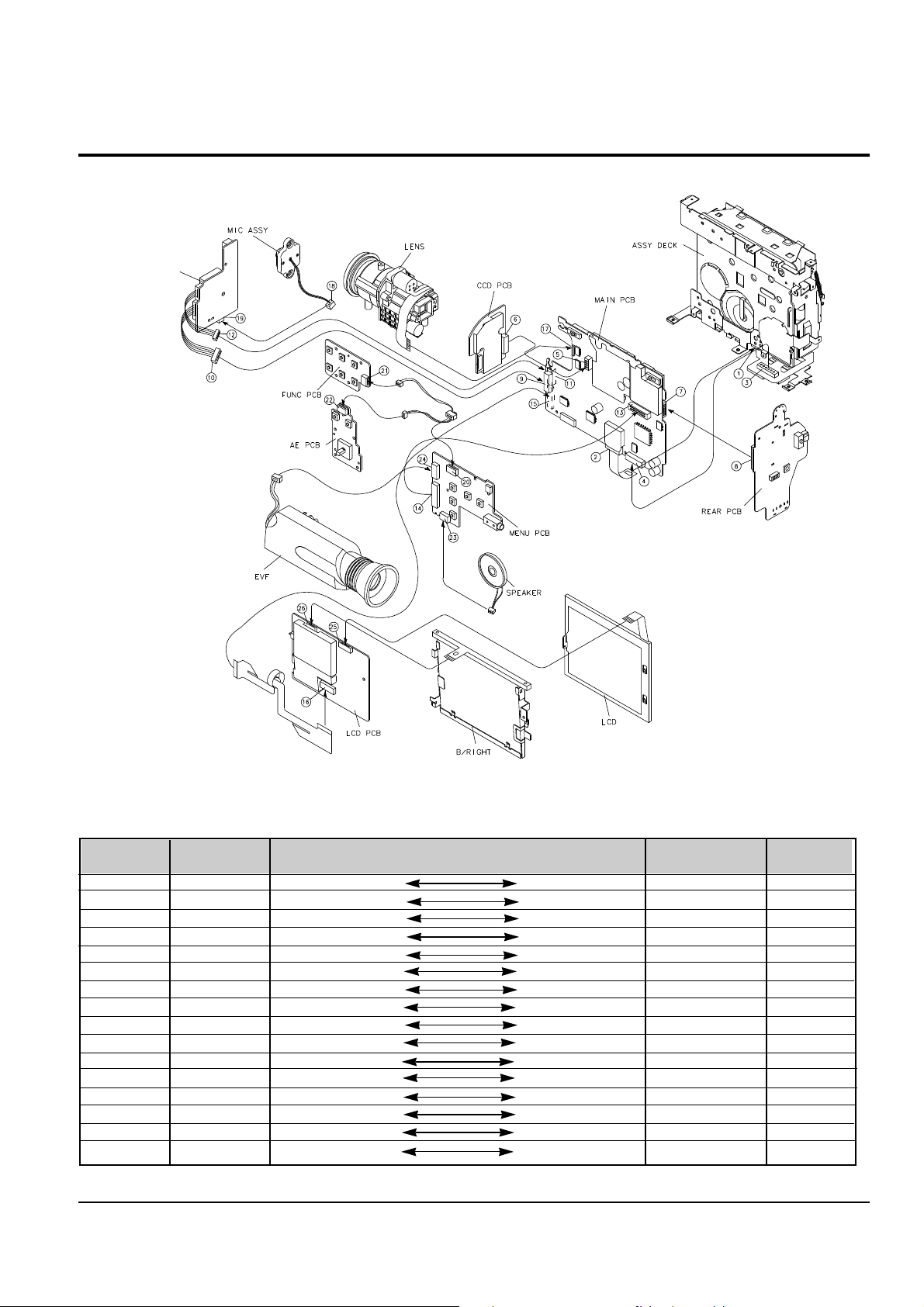

4-2 Circuit Boards Location

Fig. 4-12 Circuit Boards Location

NO. CONNECTOR DIRECTION CONNECTOR NO.

LOCA-NO. LOCA-NO.

2 CN101 MAIN PCB DECK -- 1

4 CN503 MAIN PCB DECK -- 3

7 CN501 MAIN PCB REAR CN961 8

19 CN892 MIC CPB MIC -- 18

11 CN851 MAIN PCB MIC PCB CN891 12

9 CNP03 MAIN PCB MIC PCB CN893 10

16 CNL201 LCD PCB MAIN PCB CN702 15

25 CNL301 LCD PCB LCD -- -26 CNL102 LCD PCB B/LIGHT -- --

-- CNE02 EVF MANU PCB CN803 24

21 CN805 FUNC MENU CN802 20

22 CN806 AE MENU CN802 20

14 CN801 MENU MAIN CN502 13

23 CN804 MENU SPEAKER -- -17 CNP02 MAIN PCB LENS -- --

5 CNP01 MAIN PCB CCD PCB CNC01 6

Disassembly and Reassembly

Samsung Electronics 4-13

4-3 Connector Diagram

FRONT PCB

Fig. 4-13 Connector Diagram

Fig. 4-14

Disassembly and Reassembly

4-14 Samsung Electronics

MEMO

Samsung Electronics 5-1

5. Alignment and Adjustment

5-1 Mechanical Adjustment

Test Point :

PB RF - Pin 45 of IC201

Head Switching Trigger - Pin 96 of IC601

Fig. 1 The location of test point

(PIN 45)

(PIN 96)

(PIN 67)

* Note 1 : Mechanical alignment is performed for the linearity of PB-RF(Envelope).

* Note 2 : Refer to the mechanism manual ÒDE-6Ó(AD68-30200A) for the mechanism alignment.

1) Short between pin #67 of IC601 and GND in order to set the TEST MODE.(ThatÕs Track Shift Mode)

2) Connect the Head SW Pulse in CH1 and the PB-RF in CH2 to oscilloscope.

3) Refer to the Fig1 for the location of test point.

4) Play the alignment tape supplied, and fit the PB-RF form like as Fig1.

(Refer to the alignment manual of the DE-6 described above).

5) If the alignment is completed, then remove the short wire for the release of the test mode.

Loading...

Loading...