Page 1

Samsung Electronics

2-1

2. Alignment and Adjustment

2-1 VCR Adjustment

2-1-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the SET key when adjusting VCR.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the Set.

ˇ You can change the adjustment value to move the “MENU Selector” Up or Down.

¨ Press the push the “MENU Selector” when storing confirmed adjustment value of each adjustment step in

EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø To clear the adjustment mode, pull out the power source.

2) Function of each buttons on the Set Key

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector down (Data Down)

Changes data in the adjustment state.

MENU Selector up (Data Up)

EASY-Q (Mode Up)

Changes mode.

DISPLAY (Mode Down)

<Table 2-1>

3) How to get into the VCR adjust mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “PLAYER” position and Mode Switch to “TAPE” position.

Fig. 2-1

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

MEMORY MIX Button

DISPLAY Button

Mode switch

Power switch

STOP Button

Page 2

2-2

Alignment and Adjustments

Samsung Electronics

[STEP 2]

ΠPress and hold the "STOP" and "MEMORY MIX" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 2-2, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight VCR ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 2-3.

Then VCR adjustment mode has been activated successfully.

[STEP 3]

If you want to finish the adjustment mode, you have to do Power Reset.

The Power Reset means that you pull out the power source and pull in it again.

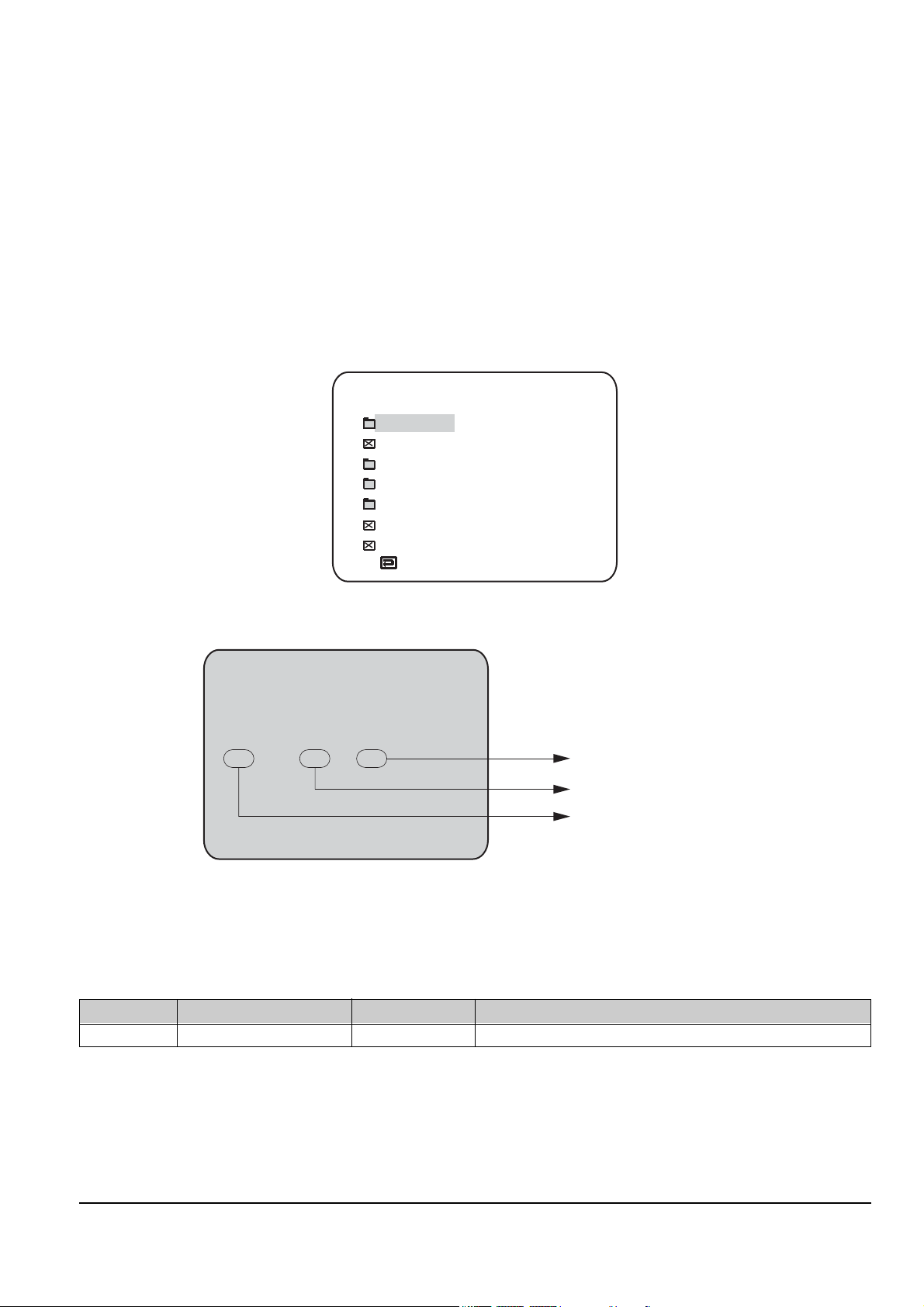

Fig. 2-2

ADJ ITEM

VCR ADJ

CAM ADJ

CODEC ADJ

PRML ADJ

CAM DISP

DSC ADJ

LCD/CVF ADJ

VCRADJ EPR

002 00

EVR

00

Indicates current adjustment item

Indicates the adjusted values

Indicates preset values

Fig. 2-3

2-1-2 VCR Adjustment

ΠGet into VCR ADJUST mode.

´ Move to the VCR ADJUST address “620”.

ˇ Play standard tape, and “Head Switching Position” will be adjusted automatically.

Mode

(Address)

Name Value Description

620 SWP Position 80 Head Switching Position Adjust

<Table 2-2>

Page 3

Alignment and Adjustments

2-3

Samsung Electronics

2-2 Camera Adjustment

Note : How to adjust the camera system.

1) EEPROM stores confirmed adjustment value of each adjustment step.

2) DSP (Digital Signal Process : ICA01-Main PCB) digitalizes the camera signal.

3) When changing IC705-Main PCB of EEPROM, readjust Main PCB.

While changing LCD PCB and CVF PCB- always readjust each part.

Since EEPROM stores confirmed adjustment value of each adjustment step, readjusting must be performed in order

to store the changed data.

4) Adjust the following items after changing LENS Ass’y.

ΠLens Zoom Track

´ Auto HALL

ˇ Auto IRIS

5) Adjust the following items after changing EEPROM and Camera Main PCB.

ΠLens Zoom Track

´ Zoom VR Center

ˇ Auto HALL

¨ Auto IRIS

ˆ Auto White Balance (indoor)

Ø Auto White Balance (outdoor)

2-2-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the SET key when adjusting Camera.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the Set.

ˇ You can change the adjustment value to move the “MENU Selector” Up or Down.

¨ Press the push the “MENU Selector” when storing confirmed adjustment value of each adjustment step in

EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø To clear the adjustment mode, pull out the power source.

2) Function of each buttons on the Sst Key

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector down (Data Down)

Changes data in the adjustment state.

MENU Selector up (Data Up)

EASY-Q (address Up)

Changes mode.

DISPLAY (address Down)

<Table 2-3>

Page 4

2-4

Alignment and Adjustments

Samsung Electronics

5) How to set up the camera adjustment mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “CAM” position and Mode Switch to “TAPE” position.

[STEP 2]

ΠPress and hold the "STOP" and "MEMORY MIX" buttons on the video camera at the same time for more than

5 seconds.

´ When monitor OSD appears as shown Fig. 2-5, the adjustment mode has been activated successfully.

ˇ Move the “MENU Selector” to highlight CAM ADJ and push the “MENU Selector”.

¨ Monitor OSD shows Fig. 2-6.

Then Camera adjustment mode has been activated successfully.

[STEP 3]

If you want to finish the adjustment mode, you have to do Power Reset.

The Power Reset means that you pull out the power source and pull in it again.

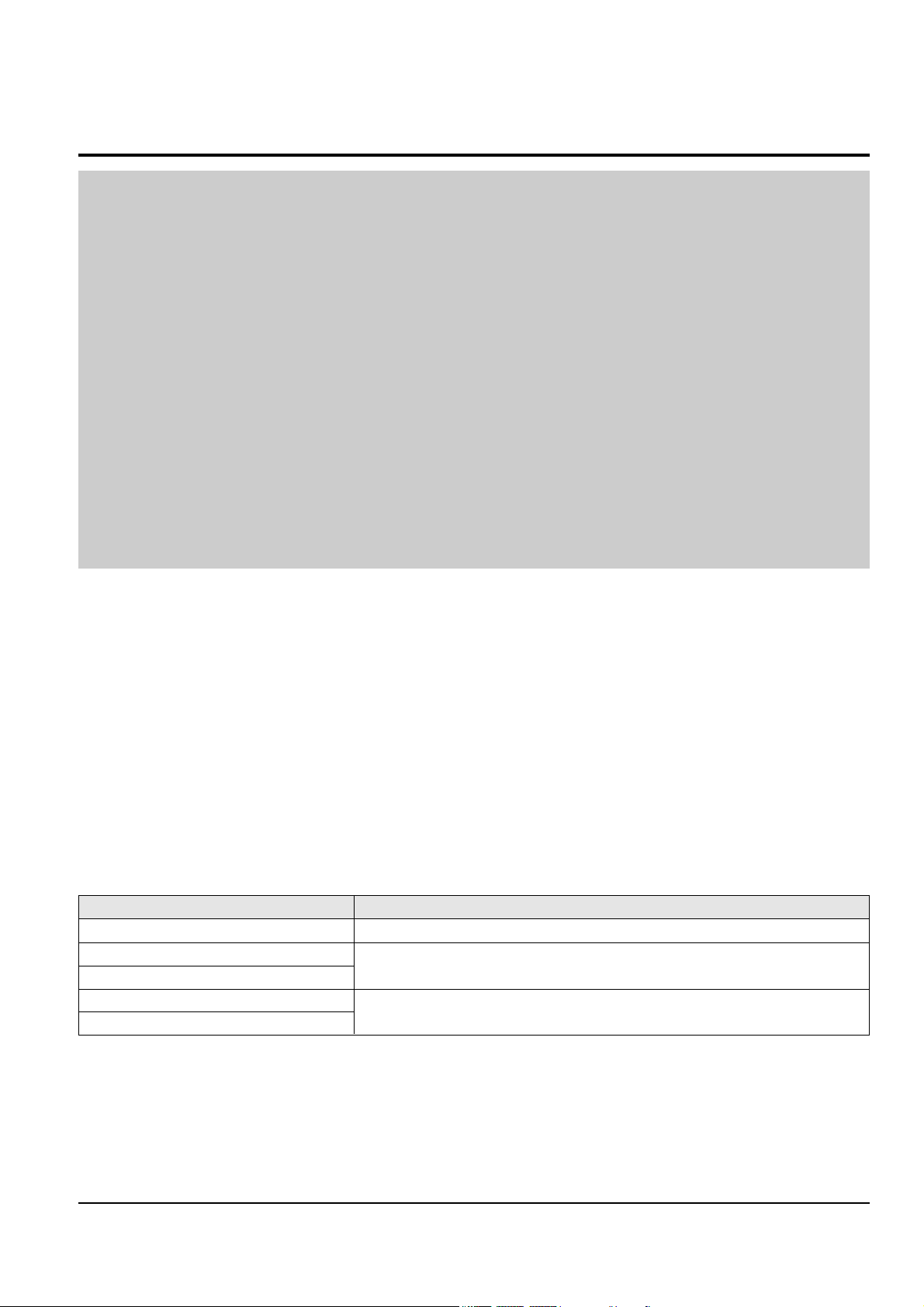

Fig. 2-5

ADJ ITEM

VCR ADJ

CAM ADJ

CODEC ADJ

PRML ADJ

CAM DISP

DSC ADJ

LCD/CVF ADJ

Fig. 2-4

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

MEMORY MIX Button

DISPLAY Button

Mode switch

Power switch

STOP Button

Page 5

Alignment and Adjustments

2-5

Samsung Electronics

2-2-2 Camera Adjustment

Note : "XX XX" indicate the previous preset value and adjusted value.

Press the “MENU Selector” (Confirm) to store the adjusted value.

CAMADJ EPR EVR

00DF 00 00

Adjusted values

Stored values

Fig. 2-6

1) EEPROM Data Initialize

Caution : This adjustment must do following items changing new EEPROM (ICP09) or Main PCB.

Œ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows “00DF XX XX”.

´ Using “MENU Selector”(Data Up/Down) so that display data of EVR is “AA”

ˇ Press the “MENU Selector” (Confirm).

¨ The OSD shows “OK” after finishing the initalize.

2) Lens Zoom Track

Caution : For whole zoom range, it shall be in focus.

The location of a focus lens is moving depending on the location of Zoom Lens.

During adjusting, micom measures the focus location from a near distance to a long.

ΠCamera is set to E-E mode.

´ Focus chart photo.

ˇ Ensure that camera is left an about 3m distance from a focus chart and the focus of lens is placed vertically.

Attach a focus chart to white or gray wall of a flat surface.

¨ Connect a video output terminal to a TV.

ˆ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "00DE XX XX".

Ø Press the “MENU Selector” (Confirm).

Never impact on the lens when adjusting zoom and focus Lens.

The OSD shows “OK” after finishing the adjustment.

Fig. 2-7

3M ± 1cm

(Be sure to maintain the distance)

CCDLENS

Page 6

2-6

Alignment and Adjustments

Samsung Electronics

3) Zoom VR Center

ΠConnect a video output terminal to a TV.

´ Press the “EASY”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows “00D6 XX XX”.

ˇ Press the “MENU Selector” (Confirm).

¨ Then Micom finds out Zoom VR center position.

Store Zoom VR center value in OB7.

4) Auto HALL

ΠConnect a video output terminal to a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "00CD XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min. Hall value with an iris closed.

Store max. and min. value of Hall in OAD and OAC respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

5) Auto IRIS Level

ΠConnect a video output terminal to a wave form monitor and a TV.

´ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "00CE XX XX".

ˇ Press the “MENU Selector” (Confirm).

¨ Then micom finds out max. Hall value with an iris opened and min.

Hall value with an iris closed. Store max. and min. value of in 00BC, 00BD and 00BB respectively.

ˆ The OSD shows “OK” after finishing the adjustment.

6) Auto White Balance (indoor)

Œ Camera mode & 3100˚ K/5100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "00D4 XX XX".

¨ Ensure that camera picks up image 40µs on 3100˚K gray scale chart precisely and the illumination is 1500~2000

Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

7) Auto White Balance (outdoor)

Œ Camera mode & 3100˚ K/5100˚ K gray scale chart.

´ Connect a video output terminal to a vectorscope and a TV.

ˇ Press the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that OSD shows "00D5 XX XX".

¨ Ensure that camera picks up image 40 µs on 5100 gray scale chart (3100 gray scale chart + C16 filter) precisely

and the illumination is 1500~2000 Lux.

ˆ Press the “MENU Selector” (Confirm) to ensure that white spot on a vectorscope is moving in the middle of

screen.

Ø The OSD shows “OK” after finishing the adjustment.

Page 7

Alignment and Adjustments

2-7

Samsung Electronics

2-3 LCD Adjustment

2-3-1 Adjustment Preparation

1) Before you start

ΠUse the buttons on the SET key when adjusting LCD.

´ When changing the adjustment item, please press the “EASY-Q” and “DISPLAY” buttons on the Set.

ˇ You can change the adjustment value to move the “MENU Selector” Up or Down.

¨ Press the push the “MENU Selector” when storing confirmed adjustment value of each adjustment step in

EEPROM.

ˆ The OSD shows “OK” after finishing each adjustment step.

Ø To clear the adjustment mode, pull out the power source.

2) Function of each buttons on the Set Key

Buttons Description

MENU Selector push (Confirm) Stores changed value in the adjustment and auto adjustment mode.

MENU Selector down (Data Down)

Changes data in the adjustment state.

MENU Selector up (Data Up)

EASY-Q (Mode Up)

Changes mode.

DISPLAY (Mode Down)

<Table 2-4>

Page 8

2-8

Alignment and Adjustments

Samsung Electronics

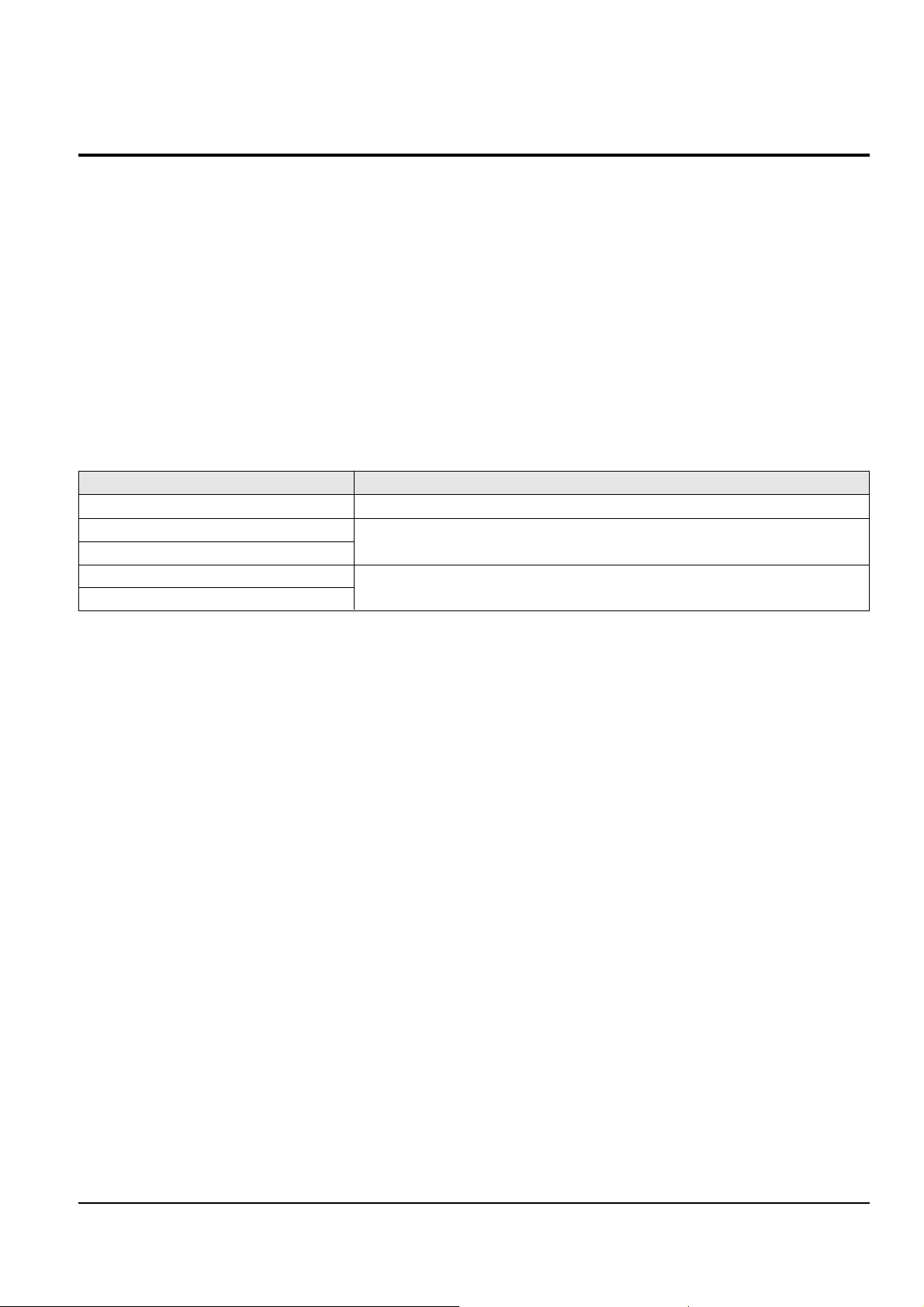

Fig. 2-9

ADJ ITEM

VCR ADJ

CAM ADJ

CODEC ADJ

PRML ADJ

CAM DISP

DSC ADJ

LCD/CVF ADJ

3) How to get into the LCD adjust mode

[STEP 1]

ΠConnect the Power source.

´ Set the Power Switch to “CAM” position and Mode Switch to “TAPE” position.

[STEP 2]

ΠPress and hold the "STOP" and "MEMORY MIX" buttons on the video camera at the same time for more than

5 seconds.

´ When “ADJ ITEM” OSD appears at the monitor as shown Fig. 2-9, move to a “ CAM ADJ” through

“Menu Selector” scrolling and press the “Menu Selector”.

Fig. 2-10 will be shown in LCD screen and move to Address No. “012C” to adjust its value as “01”.

In order to save the modification value, press the “Menu Selector” again.

(this is for setting up of Color Bar output.)

◆ After completing all of adjustment, the Value of Address No. “012C” must necessarily return as “00”.

ˇ Move a Power Switch to OFF. (Don’t have to plug it out)

Fig. 2-8

MENU Button

EASY Q Button

Start/Stop Button

MENU Selector

MEMORY MIX Button

DISPLAY Button

Mode switch

Power switch

STOP Button

Fig. 2-10

CAMADJ EPR EVR

012C XX 01

Adjusted values [01]

Address values [012C]

Page 9

Alignment and Adjustments

2-9

Samsung Electronics

[STEP 3]

Œ Set the Power Switch to “CAM” position and Mode Switch to “TAPE” position.

´ Press and hold the "STOP" and "MEMORY MIX" buttons on the video camera at the same time for more than

5 seconds.

ˇ When monitor OSD appears as shown Fig. 2-11, the adjustment mode has been activated successfully.

¨ Move the “MENU Selector” to highlight LCD/CVF ADJ and push the “MENU Selector”.

ˆ Monitor OSD shows Fig. 2-12.

Then LCD adjustment mode has been activated successfully.

Fig. 2-11

ADJ ITEM

VCR ADJ

CAM ADJ

CODEC ADJ

PRML ADJ

CAM DISP

DSC ADJ

LCD/CVF ADJ

Fig. 2-12

LCD

XX EPR : XX EVR : XX

Adjusted values

Address values

Page 10

2-10

Alignment and Adjustments

Samsung Electronics

2-3-2 LCD Adjustment

SHORT POINT (SOLDER LAND 2 POINTS SHORT)

Fig. 2-13 Location of Test point

1) Initial Adjustment

ΠLet two solder lands short. (Refer to Fig. 2-13, two short point)

´ Press a “STOP” button for 3 seconds or more until “INT OK” appears. (See Fig. 2-14)

Fig. 2-14

INT OK

◆ You continuously let two solder lands short until completing all adjustment (from 1] Initial Adj. to 7] VCO Adj.)

and they must be opened after completing all adjustment.

◆ If two solder lands are continuously shorted, the product doesn’t work correctly.

Page 11

Alignment and Adjustments

2-11

Samsung Electronics

2) Contrast Adjustment

Œ Move address to “04”.

´ Connect an oscilloscope to the TP “G”.

ˇ Adjust the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that White Level is 2.4Vp-p.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-15

2.4Vp-p

3) R-Contrast Adjustment

Œ Move address to “05”.

´ Connect an oscilloscope to the TP “R”.

ˇ Adjust the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that White Level is 2.4Vp-p.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-16

2.4Vp-p

Page 12

2-12

Alignment and Adjustments

Samsung Electronics

4) B-Contrast Adjustment

Œ Move address to “06”.

´ Connect an oscilloscope to the TP “B”.

ˇ Adjust the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that White Level is 2.4Vp-p.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-17

2.4Vp-p

5) Color Adjustment

Œ Move address to “0B”.

´ Connect an oscilloscope to the TP “B”.

ˇ Adjust Yellow Level with the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that it should be

more 1.0Vp-p than the Pedestal Level.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-18

1.0Vp-p

PEDESTAL LEVEL YELLOW LEVEL

Page 13

Alignment and Adjustments

2-13

Samsung Electronics

6) Tint Adjustment

Œ Move address to “0C”.

´ Connect an oscilloscope to the TP “B”.

ˇ Adjust Yellow Level with the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that it should be

paralle on a Green Level.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-19

YELLOW LEVEL GREEN LEVEL

7) VCO Adjustment

Œ Move address to “0D”.

´ Connect an oscilloscope to the TP “VCO”.

ˇ Adjust the “EASY-Q”(Mode Up)/”DISPLAY”(Mode Down) buttons so that Peak from signal level is

-50mV±10mVp-p.

¨ Be sure to press the “MENU Selector”(Confirm) push button to memorize setting.

ˆ The OSD shows “OK”.

Fig. 2-20

-50mVp-p 10mV

V-Sync

Page 14

2-14

Alignment and Adjustments

Samsung Electronics

2-4 Deck Adjustment

2-4-1 Operation Without Housing Assembly

1) Remove the Housing Ass’y from the Deck Ass’y.

2) Connect the Mechanical Chassis to the recorder

circuit to supply voltage.

3) Set to Unload mode.

4) Press the S/W Push (Keep ON status)to start loading, and push the PLAY Key.

(Cover the Top/End sensor with black tape,

because they do not operate.)

Note : For the removal of the Housing Ass’y refer to

4-2-2 (Training Manual;page 4-7).

Connceted the Recorder Circuit

SWITCH C-IN

Fig. 2-21

2-4-2 Setting Mechanical Mode (Without Recorder Circuit)

1) Set the power-supply output to approx. 3V~5V.

2) Choose the polarity (depending on whether loading or unloading).

3) Supply the voltage to the Motor Loading, and set

to the desired mode.

Fig. 2-22

A

B

DC POWER SUPPLY

<Table 2-5>

AB Movement of Chassis

+- Unloading

-+ Loading

Page 15

Alignment and Adjustments

2-15

Samsung Electronics

2-4-3 Maintenance

Carry out the following periodic maintenance checks in order to fully exercise all functions, operations and tape.

After repairing, service the set as follows:

1) Cleaning of Drum Assembly

ΠGently apply lens tissue soaked in ethyl alcohol to the Drum assembly.

Clean the Upper Drum assembly while rotating it slowly counterclockwise(by hand).

Note : Do not rotate the motor by power or rotate the Upper Drum assembly clockwise.

Also, the Head tip will be damaged if the lens tissue is moved in a perpendicular direction.

Be sure to follow these instructions when cleaning the Drum Ass’y

2) Cleaning of Tape Path

ΠIn EJECT mode, clean the tape path system(from Pole Tension P1 through Pole Review P8, Pinch Roller and

Capstan Shaft) and the Lower Drum. Using the lens tissue soaked in ethyl alcohol.

Note : Make sure that no oil or grease adheres to the lens tissue.

Fig. 2-23

P1

P2

P3

P4

P7

P5

P6

P8

PINCH ROLLER

Page 16

2-16

Alignment and Adjustments

Samsung Electronics

3) Periodic Maintenance and Check List

When overhauling, refer to the following table.

2mm

OIL

◆ When lubrication bearings, be sure to keep the oil

free of dust. (Oil contaminated with dust might

cause the bearings to wear out or seize.)

◆ A “drop”of oil is defined as the amount attached to

the tip of a Ø 2mm stick as shown in Fig. 2-24.

<Table 2-6>

Fig. 2-24

O : Cleaning ∆ : Oil ◆ : Confirmation

Tape

path

system

D

R

I

V

I

N

G

S

Y

S

T

E

M

- Never let oil get on to the tape path

surface.

Maintenance checks

Hours of use (H)

Remark

500 1000 1500 2000 2500 3000 3500 4000 4500 5000

Cleaning of tape path O O O O O O O O O O

Cleaning and degaussing of drum ass’y

OOOOOOOOOO

Capstan Shaft ∆∆∆∆∆

Gear Capstan ∆∆∆∆∆

Gear Pully Shaft ∆∆∆∆∆

Belt Timing ◆ ◆◆◆◆

Motor Loading ◆ ◆◆◆◆

Abnormal Noise ◆◆◆◆◆◆◆◆◆

Back Tension ◆ ◆◆◆◆

Brake System ◆ ◆◆◆◆

PB, REV Torque Measurement

◆ ◆◆◆◆

Confir-

mation

Perform-

ance

Page 17

Alignment and Adjustments

2-17

Samsung Electronics

2-4-4 Mechanical Check and Adjustment

2-4-4(a) Tension Regulator Adjustment

1) Disassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (Training Manual;page 4-7).

2) Adjustment

ΠSet to PLAY mode (without cassette tape).

´ Check that the distance between external surface of Holder Loading and extenal diamater of Arm Tension is

0.7±0.3mm. (Fig. 2-25)

ˇ If necessary, proceed to step 4.

¨ If the Arm Tension Œ is located inside (or right) the position specified, adjust the Cap Adjust Œ toward

arrow “A”. (If it is located outside (or left), adjust toward arrow “B”.)

Note : Check if the Arm Tension can be moved toward arrow “C” in PB mode.

3) Reassembly

Œ For the removal of the Housing Ass’y refer to 4-2-2 (Training Manual;page 4-7).

Fig. 2-25

ARM TENSION Œ

CAP ADJUST ´

"A"

"B"

"C"

Page 18

2-18

Alignment and Adjustments

Samsung Electronics

2-4-4(b) Back Tension Confirmation

1) Set up the cassette-torque tape.

2) Set to CAMERA mode, push the EDIT(+) KEY and check that the torque value of Reel S is 5.5±1g.cm.

3) If necessary, proceed to step 4.

4) If the Tension value is Low specified, moved to toward “a”.

If the Tension value is High specified, moved to toward “c”.

Reference : After changed, insert Cassette torque tape and confirm torque value.

Fig. 2-27

REEL DISK S TABLE

RESTING SURFACE

REEL DISK T TABLE

RESTING SURFACE

CHASSIS SUB

Fig. 2-26

2-4-4(c) PB/REV Torque check

1) Set up the cassette torque tape.

2) Set to CAMERA mode, Push the EDIT(+) button and check that the torque value of Reel T is 9±3g.cm.

3) Push the EDIT(-) button and check that the torque value of Reel S is 15±3g.cm.

4) If necessary, replace the defective Reel Disk S, T Ass’y.

2-4-4(d) Reel Table Height Check

1) Removal

Œ For the removal of the Housing Ass’y refer to 4-2-2 (Training Manual;page 4-7).

´ For the removal of the Idler Ass’y refer to 4-2-3 (Training Manual;page 4-8).

2) Check

ΠUsing vernier calipers, check the following distances : From the upper surface of the Sub Chassis to the

resting surfaces of Reel S, T table should each be 3.9±0.1mm.

3) Mounting

Œ For the removal of the Idler Ass’y refer to 4-2-3 (Training Manual;page 4-8).

´ For the removal of the Housing Ass’y refer to 4-2-2 (Training Manual;page 4-7).

Page 19

Alignment and Adjustments

2-19

Samsung Electronics

2-4-5 Tape Path Adjustment

2-4-5(a) Preparation for Adjustment

ΠClean the tape running surface (Poles, Drum, Capstan Shaft, Pinch Roller).

´ Observe the PB RF signal and Head Switching Pulse on an oscilloscope.

ˇ Play back the alignment tape.

¨ Check that the waveform of the RF signal is flat at both inlet and outlet(A in Fig. 2-29).

If not flat (B or C in Fig. 2-29), do adjustments 2-4-5(b) through 2-4-5(d).

RF Signal

(Pin 3 of CNR01)

Head Switching

(Pin 2 of CNR01)

1

2

3

4

5

6

7

8

910

11

12

13

14

15

16

17

18

Fig. 2-28 Rear PCB (Bottom Side)

P1

P2

P5

P6

P7

P8

P3

Fig. 2-30

A

B

C

INLET OUTLET

NORMAL

DEFECT AT INLET

DEFECT AT OUTLET

Fig. 2-29

Page 20

2-20

Alignment and Adjustments

Samsung Electronics

2-4-5(b) Tracking adjustment

ΠPlay Back the alignment tape.

´ Turn P3 to flatten the waveform at the inlet.

ˇ Turn P5 to flatten the waveform at the outlet.

2-4-5(c) Take Up Path Adjustment

ΠPlay back the alignment tape, and confirm that the tape is not twisted between the Guide Roller T and

Capstan. (If the tape is twisted, turn P8, Fig. 2-31)

´ Set to REV mode and observe the outlet waveform of PB RF signal. (Fig. 2-32)

ˇ If the outlet waveform is out-of-spec, turn P8 counterclockwise, and redo steps 1 and 2.

P8

P6

MOTOR CAPSTAN

P2

Fig. 2-31

(DEFECTIVE) (CORRECT)

Fig. 2-32

Page 21

Alignment and Adjustments

2-21

Samsung Electronics

2-4-5(d) Check After Adjustment

1) Tracking Check

ΠPlayback the alignment tape.

´ Confirm that the minimum amplitude value(E min.)is 80% of the maximum value(E max.) or larger.

(Fig. 2-33)

ˇ Confirm that no large fluctuation occur on the waveform. (Fig. 2-34)

2) CUE and REV Check

ΠPlayback the alignment tape, and set to REV mode.

Confirm that the waveform peaks have a uniform Pitch. (Fig. 2-35 A)

If the track pitch is not uniform, do section 2-4-5(b) (Tracking adjustment) and 2-4-5(c) (P8 adjustment).

´ Set to CUE mode.

Confirm that the waveform peaks still have a uniform pitch. (Fig. 2-35 B)

If the track pitch is not uniform, do section 2-4-5(b) (Tracking Adjustment).

Emin Emax

Emax

Emin

80(%)

Fig. 2-33

A

A

C

C

C

1

8

Fig. 2-34

abc a

abc

bc

Fig. 2-35

Page 22

2-22

Alignment and Adjustments

Samsung Electronics

3) Rise Time Check

ΠPlayback the alignment tape.

´ Set to playback mode, and confirm that the waveform of PB RF signal rises flat within 3 seconds.

Also confirm that the tape is not twisted or curled around the Pinch Roller. (Fig. 2-36)

ˇ Run the tape in CUE/REV and FF/REW modes, then playback.

Confirm the waveform of PB RF signal rises flat within 3 seconds. Also confirm that the tape is not twisted or

curled around the Pinch Roller.

¨ Repeat steps 2. and 3.

4) Tape Path Check

ΠIn CUE and REV modes, check that the tape is not curled around the P2, P6 upper flange and P8

upper/Lower flanges.

P8

MOTOR CAPSTAN

P6

P2

Fig. 2-36

P1

FROM THE S REEL

TO THE T REEL

P2

P3

P5

P6

P8

Fig. 2-37

Loading...

Loading...