Page 1

LED/LCD-TV

Chassis : U59C/U59E

Model : UN19D4003BD

UN26D4003BD

UN32D4003BD

UN22D5003BF

UN40D5003BF

LN32D40*E*D

SERVICE

TFT-LCD TV Contents

1. Precautions

2. Product specications

3. Disassembly and Reassembly

4. Troubleshooting

5. Wiring Diagram

Manual

UN32D4003BD

Page 2

Contents

1. Precautions .............................................................................................................. 1-1

1-1. Safety Precautions ......................................................................................................... 1-1

1-2. Servicing Precautions ..................................................................................................... 1-2

1-3. Electrostatically Sensitive Devices (ESD) Precautions .................................................. 1-2

1-4. Installation Precautions .................................................................................................. 1-3

2. Product specications ............................................................................................ 2-1

2-1. Specications Information .............................................................................................. 2-1

2-2. Detail Factory Option .................................................................................................... 2-12

2-3. Accessories .................................................................................................................. 2-14

3. Disassembly and Reassembly ............................................................................... 3-1

3-1. Disassembly and Reassembly ....................................................................................... 3-1

3-2. How to disassembly Function & IR ASSY ....................................................................... 3-7

4. Troubleshooting ...................................................................................................... 4-1

4-1. Troubleshooting .............................................................................................................. 4-1

4-2. Factory Mode Adjustments ........................................................................................... 4-22

4-3. White Balance - Calibration .......................................................................................... 4-32

4-4. White Ratio (Balance) Adjustment ................................................................................ 4-34

4-5. Software Upgrade ......................................................................................................... 4-37

4-6. Rear Cover Dimension ................................................................................................. 4-39

5. Wiring Diagram ........................................................................................................ 5-1

5-1. Wiring Diagram ............................................................................................................... 5-1

5-2. Position of Connector ..................................................................................................... 5-3

5-3. Connector Functions .................................................................................................... 5-13

5-4. Cables .......................................................................................................................... 5-13

Page 3

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© 2011 Samsung Electronics Co.,Ltd.

All rights reserved.

Printed in Korea

Page 4

1. Precautions

1. Precautions

1-1. Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1-1. Warnings

For continued safety, do not attempt to modify the circuit board.1.

Disconnect the AC power and DC power jack before servicing.2.

1-1-2. Servicing the LED TV

When servicing the LED TV, Disconnect the AC line cord from the AC outlet.1.

It is essential that service technicians have an accurate voltage meter available at all times. 2.

Check the calibration of this meter periodically.

1-1-3. Fire and Shock Hazard

Before returning the LED TV to the user, perform the following safety checks:

Inspect each lead dress to make certain that the leads are not pinched or that hardware is not lodged between the 1.

chassis and other metal parts in the LED TV.

Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet backs, adjustment and 2.

compartment covers or shields, isolation resistorcapacitor networks, mechanical insulators, etc.

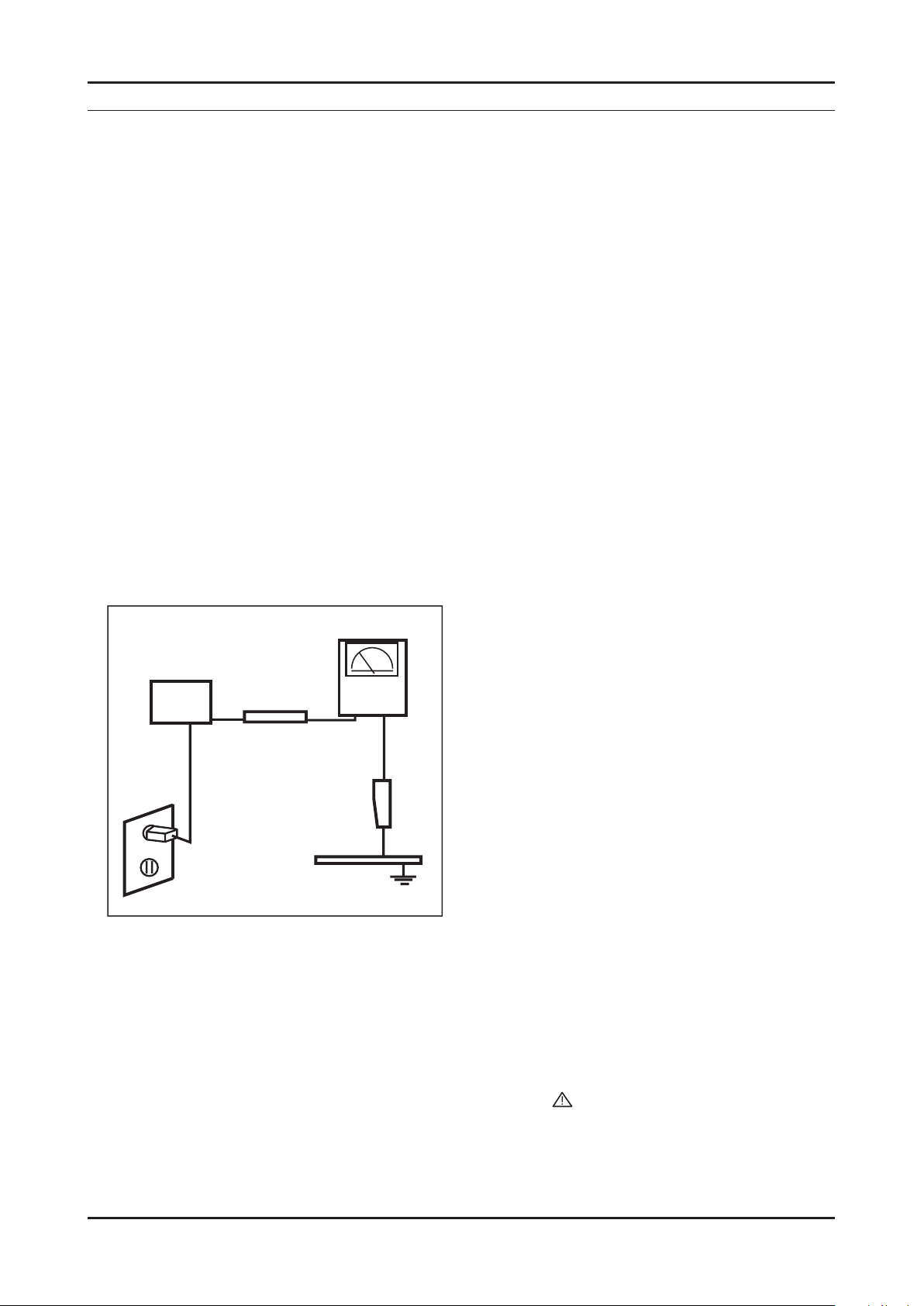

Leakage Current Hot Check (Figure 1-1): 3.

WARNING : Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system that complies with American National Standards Institute (ANSI

C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL Publication UL1410, 59.7).

(READING SHOULD)

NOT BE ABOVE 0.5mA

DEVICE

UNDER

TEST

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

EXPOSED METAL

SURFACES

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

Figure 1-1. Leakage Current Test Circuit

With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit’s AC switch 4.

rst in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, conduit,

etc.) and all exposed metal parts, including: metal cabinets, screwheads and control shafts.

The current measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

1-1-4. Product Safety Notices

Some electrical and mechanical parts have special safetyrelated characteristics which are often not evident from visual

inspection. The protection they give may not be obtained by replacing them with components rated for higher voltage,

wattage, etc. Parts that have special safety characteristics are identied by on schematics and parts lists. A substitute

replacement that does not have the same safety characteristics as the recommended replacement part might create

shock, re and/or other hazards. Product safety is under review continuously and new instructions are issued whenever

appropriate.

1-1

Page 5

1-2

1. Precautions

1-2. Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions section of

this manual.

Note: If unforeseen circumstances create conict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-2-1 General Servicing Precautions

Always unplug the unit’s AC power cord from the AC power source and disconnect the DC Power Jack before 1.

attempting to:

(a) remove or reinstall any component or assembly, (b) disconnect PCB plugs or connectors, (c) connect a test

component in parallel with an electrolytic capacitor.

Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes 2.

used. The internal wiring is sometimes clamped to prevent contact with thermally hot components. Reinstall all such

elements to their original position.

After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that 3.

the area around the serviced part has not been damaged.

Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels, 4.

input terminals and earphone jacks).

Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON. 5.

Connect an insulation resistance meter (500 V) to theblades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive parts (see above) should be

greater than 1 megohm.

Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead; 6.

always remove the instrument’s ground lead last.

1-3. Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some eld-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your 1.

body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. To avoid a shock hazard,

be sure to remove the wrist strap before applying power to the LED TV.

After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent 2.

accumulation of an electrostatic charge.

Do not use freon-propelled chemicals. These can generate electrical charges sufcient to damage ESDs.3.

Use only a grounded-tip soldering iron to solder or desolder ESDs.4.

Use only an anti-static solder removal device. Some solder removal devices not classied as “anti-static” can generate 5.

electrical charges sufcient to damage ESDs.

Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs 6.

are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive

materials.

Immediately before removing the protective material from the leads of a replacement ESD, touch the protective 7.

material to the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing clothes together, 8.

or lifting your foot from a carpeted oor can generate enough static electricity to damage an ESD.

Page 6

1-3

1. Precautions

1-4. Installation Precautions

For safety reasons, more than a people are required for carrying the product.1.

Keep the power cord away from any heat emitting devices, as a melted covering may cause re or electric shock.2.

Do not place the product in areas with poor ventilation such as a bookshelf or closet. The increased internal 3.

temperature may cause re.

Bend the external antenna cable when connecting it to the product. This is a measure to protect it from being exposed 4.

to moisture. Otherwise, it may cause a re or electric shock.

Make sure to turn the power off and unplug the power cord from the outlet before repositioning the product. Also check 5.

the antenna cable or the external connectors if they are fully unplugged. Damage to the cord may cause re or electric

shock.

Keep the antenna far away from any high-voltage cables and install it rmly. Contact with the highvoltage cable or the 6.

antenna falling over may cause re or electric shock.

When installing the product, leave enough space (0.4m) between the product and the wall for ventilation purposes. 7.

A rise in temperature within the product may cause re.

Page 7

2. Product specications

2-1. Specications Information

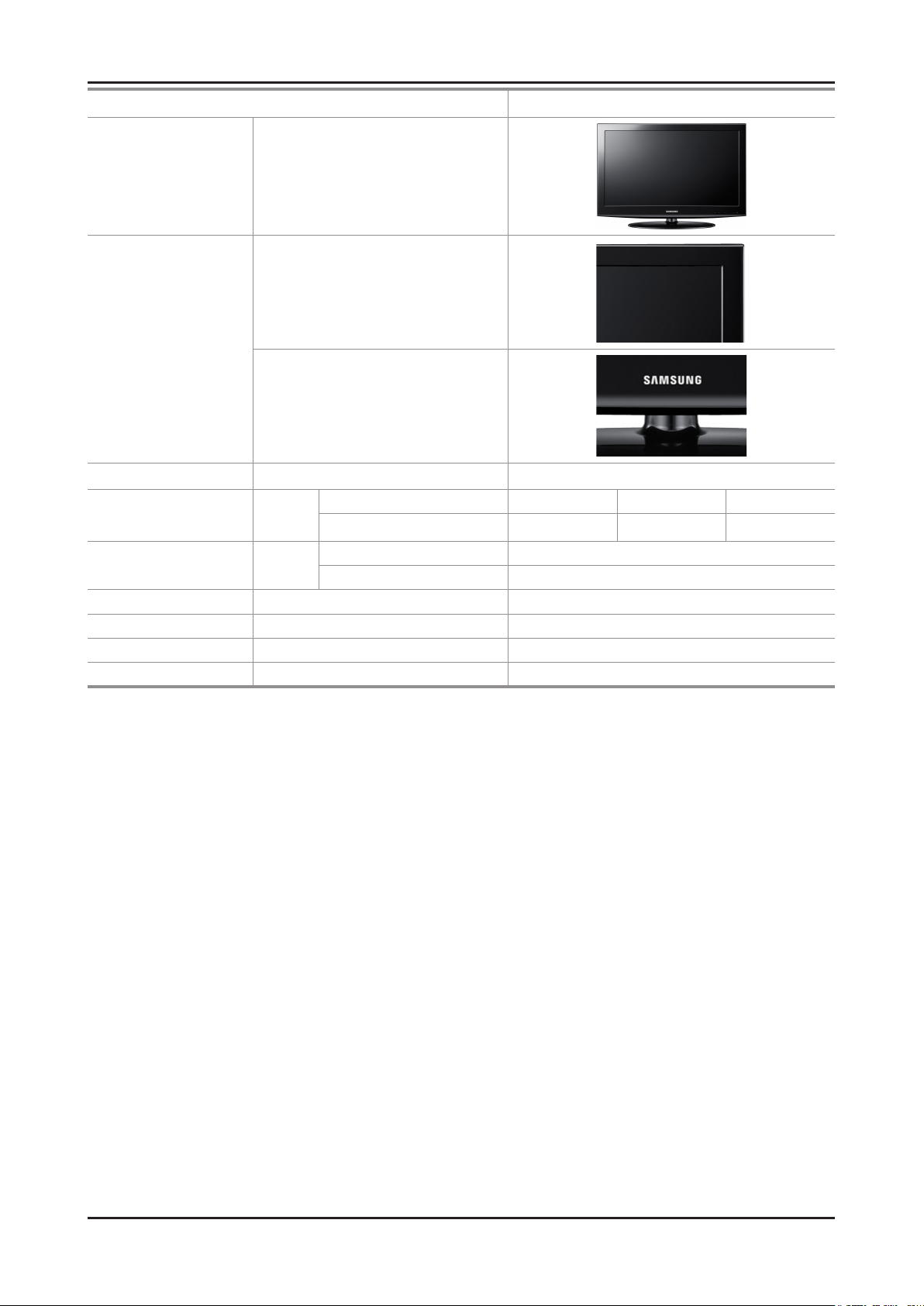

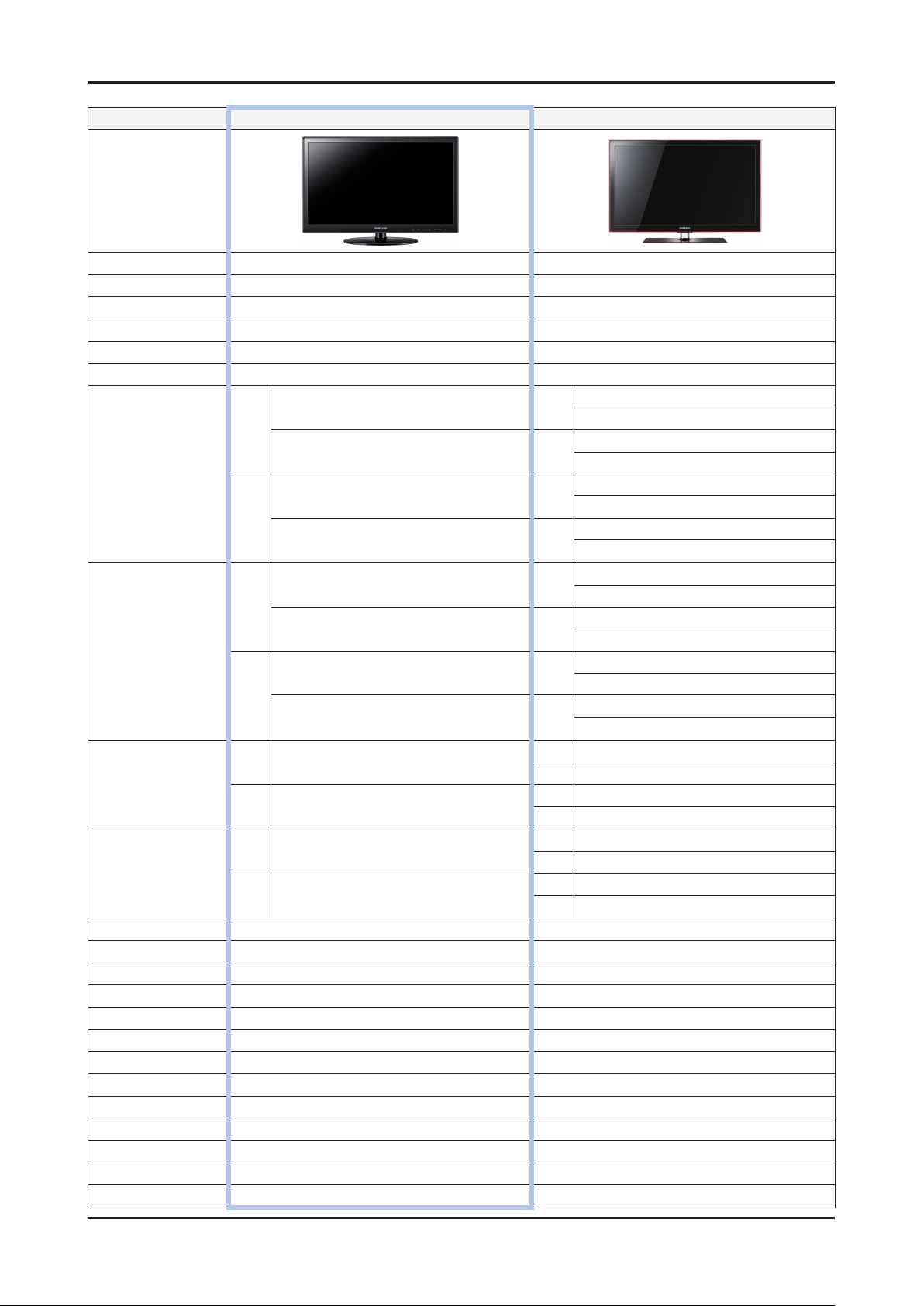

2-1-1. Model Comparison

Model UD4000ND UD5003

Front view All

All

Detail view

2. Product specications

All

Front Color All Steam Mold Black ToC Dark Gray

19"

22"

Dimensions

W x D x H

(inches)

Weight

(lbs)

Panel Type All Anti Glear Anti Glear

Internal Memory All None None

DDR All 64 Mbtye 64 Mbtye

Feature All Media Play(JPEG) Media Play(JPEG)

26"

32"

40"

19"

22"

26"

32"

40"

Without Stnand 17.6 1.6 10.9

With Stand 17.6 4.9 12.3

Without Stnand 20.3 1.6 12.4

With Stand 20.3 4.9 13.8

Without Stnand 24.6 1.8 14.9

With Stand 24.6 6.7 16.5

Without Stnand 29.8 1.9 17.9

With Stand 29.8 7.2 19.6

Without Stnand 37.2 8.6 22.1

With Stand 37.2 1.4 23.8

Without Stnand 6.2

With Stand 6.4

Without Stnand 7.5

With Stand 7.7

Without Stnand 9.0

With Stand 9.7

Without Stnand 13.9

With Stand 15.9

Without Stnand 21.2

With Stand 24.3

2-1

Page 8

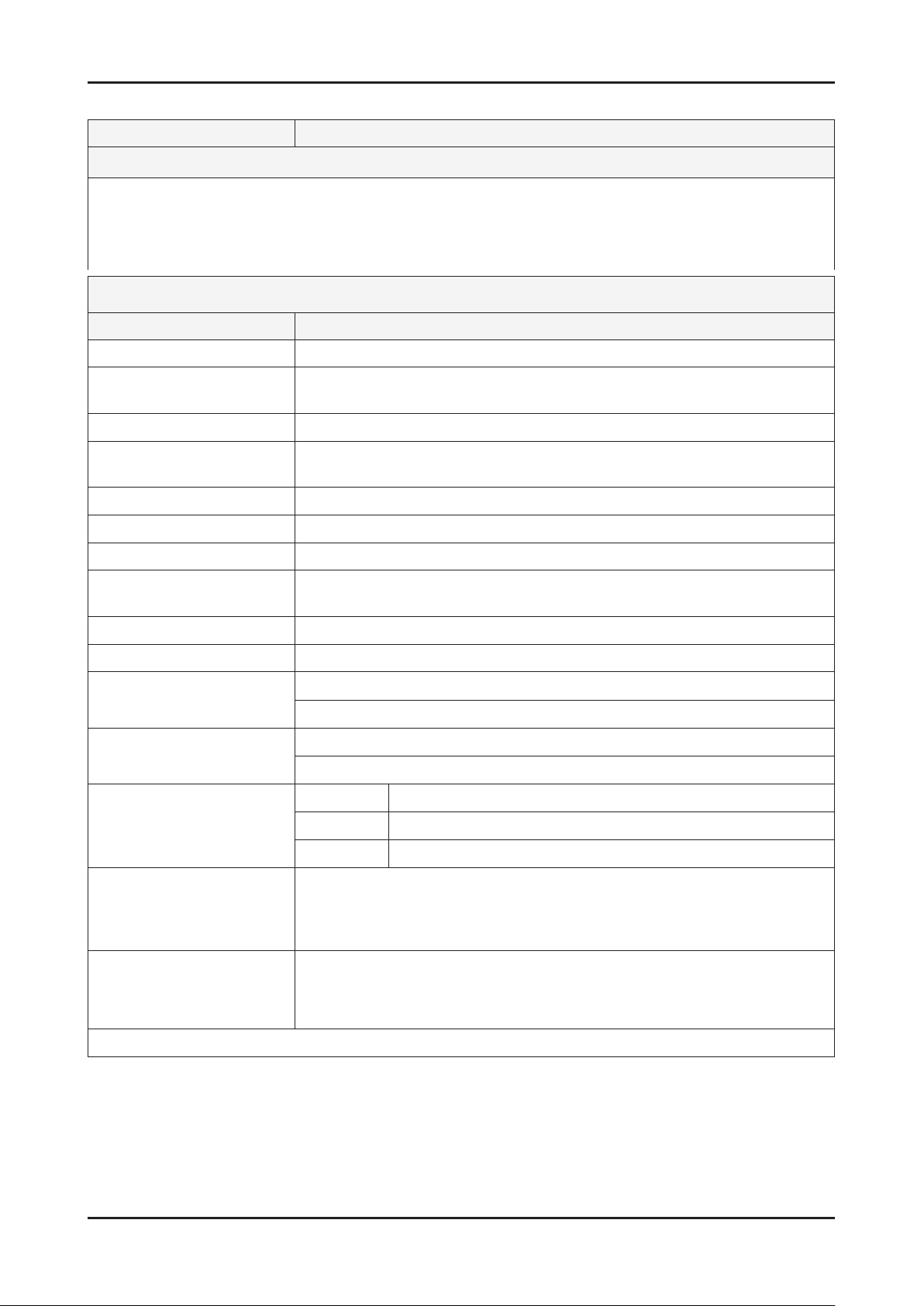

2-2

2. Product specications

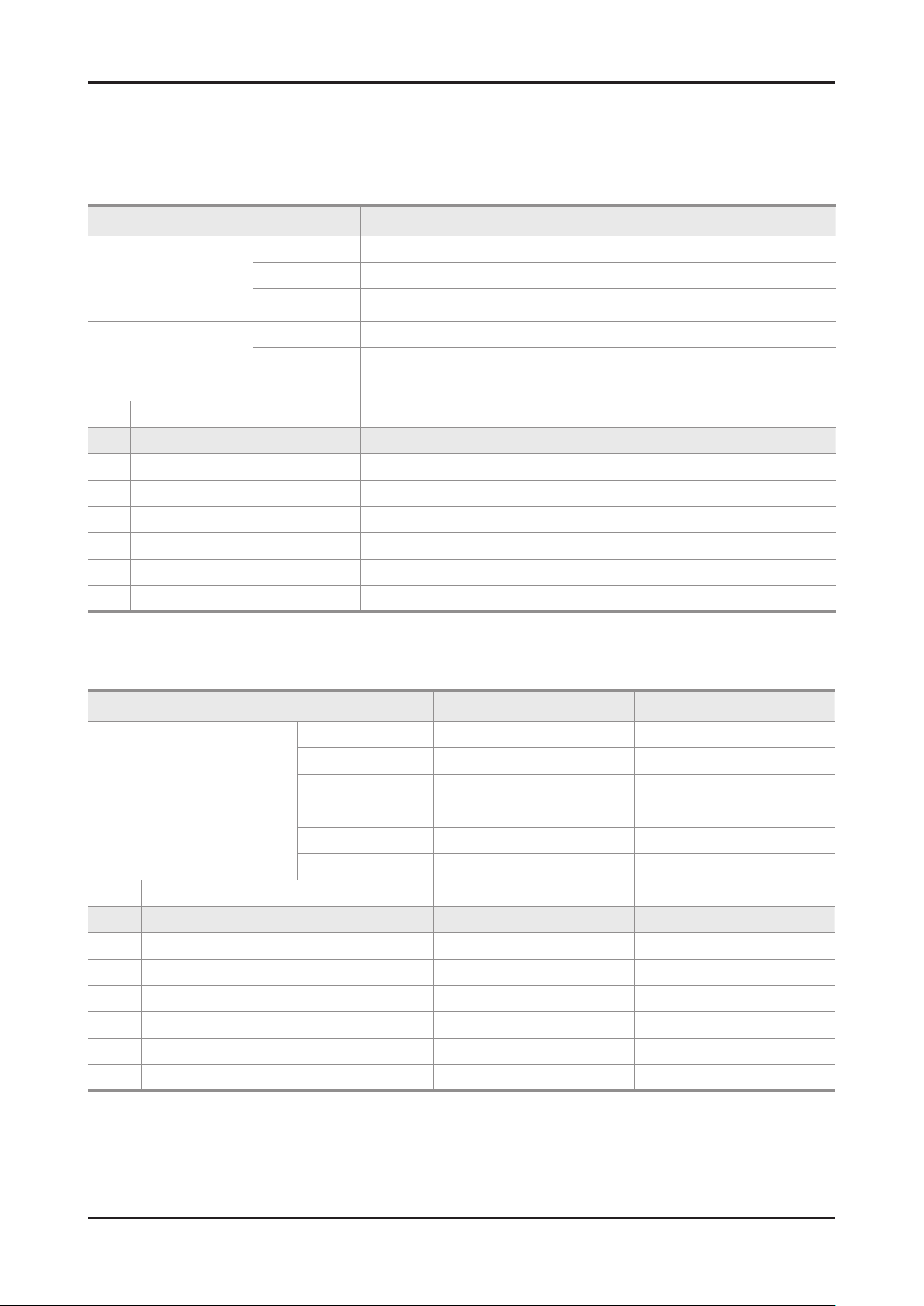

Model LD40*

Front view All

All

Detail view

All

Front Color All Steam Mold Black

Dimensions

W x D x H

(inches)

Weight

(lbs)

Panel Type All Anti Glear

Internal Memory All None

DDR All 64 Mbtye

Feature All Media Play(JPEG)

32"

32"

Without Stnand 30.9 4.1 19.8

With Stand 30.9 7.2 21.4

Without Stnand 16.9

With Stand 19.1

Page 9

2-3

2. Product specications

2-1-2. Feature & Specications

Model UN19D4003BD

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Item Description

LCD Panel 19 inch HD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

2

Specications

Vertical : 47 Hz ~ 63 Hz (Automatic)

Vertical : 768 Pixels

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

409.8(H) x 230.4(V) mm / 16.7(H) x 9.4(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 35 W (Under 1 W, Stand by)

Dimensions Set

447.2 x 124.0 x 312.4 (mm) / 17.6 x 4.9 x 12.3 (inches)_with stand

(W x D x H)

447.2 x 39.9 x 277.8 (mm) / 17.6 x 1.6 x 10.9 (inches)_without stand

Weight (Set)

2.9(kg) / 6.39(lbs)_with stand

2.8(kg) / 6.17(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 10

2-4

2. Product specications

Model UN26D4003BD

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

2

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Specications

Item Description

LCD Panel 26 inch HD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Vertical : 47 Hz ~ 63 Hz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

575.7(H) x 323.7(V) mm / 23.5(H) x 13.2(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 50 W (Under 1 W, Stand by)

Dimensions Set

624.0 x 169.4 x 418.3 (mm) / 24.6 x 6.7 x 16.5 (inches)_with stand

(W x D x H)

624.0 x 45.1 x 377.2 (mm) / 24.6 x 1.8 x 14.9 (inches)_without stand

Weight (Set)

4.1(kg) / 9.04(lbs)_with stand

4.4(kg) / 9.7(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 11

2-5

2. Product specications

Model UN32D4003BD

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

2

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Specications

Item Description

LCD Panel 32 inch HD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Vertical : 47 Hz ~ 63 Hz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

700.4(H) x 394.8(V) mm / 28.6(H) x 16.1(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 70 W (Under 1 W, Stand by)

Dimensions Set

756.4 x 182.4 x 498.1 (mm) / 29.8 x 7.2 x 19.6 (inches)_with stand

(W x D x H)

756.4 x 47.8 x 454.0 (mm) / 29.8 x 7.2 x 19.6 (inches)_without stand

Weight (Set)

6.30(kg) / 13.89(lbs)_with stand

7.20(kg) /15.87(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 12

2-6

2. Product specications

Model UN22D5003BF

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

2

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Specications

Item Description

LCD Panel 22 inch FHD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Vertical : 47 Hz ~ 63 Hz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

476.6(H) x 268.1(V) mm / 19.5(H) x 10.9(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 45 W (Under 1 W, Stand by)

Dimensions Set

515.8 x 124.0 x 350.0 (mm) / 20.3 x 4.9 x 13.8 (inches)_with stand

(W x D x H)

515.8 x 39.9 x 315.6 (mm) / 20.3 x 1.6 x 12.4 (inches)_without stand

Weight (Set)

3.50(kg) / 7.72(lbs)_with stand

3.40(kg) / 7.50(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 13

2-7

2. Product specications

Model UN40D5003BF

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

2

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Specications

Item Description

LCD Panel 40 inch FHD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Vertical : 47 Hz ~ 63 Hz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

888.2(H) x 501.3(V) mm / 36.3(H) x 20.5(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 100 W (Under 1 W, Stand by)

Dimensions Set

943.8 x 219.4 x 603.5 (mm) / 37.2 x 8.6 x 23.8 (inches)_with stand

(W x D x H)

943.8 x 51.0 x 561.4 (mm) / 37.2 x 2.0 x 22.1 (inches)_without stand

Weight (Set)

9.60(kg) / 21.16(lbs)_with stand

11.00(kg) / 24.25(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 14

2-8

2. Product specications

Model LN32D40*E*D

Feature

Digital-TV, RF, 2-HDMI, 1-Component, 1-A/V, 1-USB2.0 ሪ

Brightness : 250 cd/m ሪ

2

High Contrast Ratio : MEGA ሪ

Response Time : 5 ms ሪ

Specications

Item Description

LCD Panel 32 inch HD 60Hz

Scanning Frequency Horizontal : 60 kHz ~ 73 kHz (Automatic)

Vertical : 47 Hz ~ 63 Hz (Automatic)

Display Colors 16.7M color

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω, internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 74.25MHz

Active Display

Horizontal/Vertical

669.4(H) x 394.3(V) mm / 27.3(H) x 16.1(V) inches

AC power voltage & Frequency AC 110 V ~ 120 V, 60 Hz

Power Consumption Under 110 W (Under 1 W, Stand by)

Dimensions Set

784.4 x 181.9 x 542.3 (mm) / 30.9 x 7.2 x 21.4 (inches)_with stand

(W x D x H)

784.4 x 103.3 x 502.9 (mm) / 30.9 x 4.1 x 19.8 (inches)_without stand

Weight (Set)

8.66(kg) / 19.09(lbs)_with stand

7.65(kg) / 16.87(lbs)_without stand

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC & Clear QAM

Sound NTSC-M

Environmental Considerations Operating Temperature: 32˚F ~ 122˚F (0˚C ~ 50˚C)

Operating Humidity: 20% ~ 90%

Storage Temperature: -4˚F ~ 140˚F (-20˚C ~ 60˚C)

Storage Humidity: 10% ~ 90%

Audio Spec. - MAX Internal Audio Output Power : Each 3W(Left/Right)

- Equalizer : 5band

- Output Frequency : RF : 20 Hz ~ 15.4 kHz

AV/Componet/HDMI : 20 Hz ~ 20 kHz

Note: SRS Trusurround HD, Film mode, Energy Saving

Page 15

2-9

2. Product specications

2-1-3. Specication Comparison to Old Models

Model

Design

UD4N(UN**D4003BD) UD4N(UN32D4000ND)

O : application, X : non-application ※

Display Type

Built-in Tuner

Resolution

LCD Panel

Screen Size

Picture ratio

Dimensions (WxHxD)

Weight

Brightness

Contrast Ratio

Picture Enhacer

Equalizer

Auto Volume Control

LED TV LED TV

O O

1366 X 768 1366 X 768

TFT LCD Panel 60Hz TFT LCD Panel 60Hz

19" / 26" / 32" 19" / 32"

16 : 9 16 : 9

19"

26"

32"

19"

26"

32"

17.6 x 4.9 x 12.3(inches) with stand

17.6 x 1.6 x 10.9(inches) without stand

24.6 x 6.7 x 16.5(inches) with stand

24.6 x 1.8 x 14.9(inches) without stand

29.8 x 7.2 x 19.6(inches)with stand

29.8 x 1.9 x 17.9(inches) without stand

6.39(lbs) with stand

6.17(lbs) without stand

9.04 (lbs) with stand

9.70 (lbs) without stand

13.89 (lbs) with stand

15.87 (lbs) without stand

19" 250 cd/m

26" 250 cd/m

32" 250 cd/m

19" Mega

26" Mega

32" Mega

DNIe (Saturn4) HyperReal Engine (X5)

5 Band 5 Band

O O

18.8 x 7.5 x 14.7(inches) with stand

19"

18.8 x 1.2 x 12.6(inches) without stand

30.1 x 8.8 x 20.8(inches) with stand

32"

30.1 x 8.8 x 18.2(inches) without stand

8.60(lbs) with stand

19"

7.90(lbs) without stand

19.80(lbs) with stand

32"

15.40(lbs) without stand

2

2

2

19" 450 cd/m

32" 450 cd/m

2

2

19" Mega

32" Mega

Surround Sound

Speaker Output

PIP

Caption

Entertainment Mode

Game Mode

Energy Saving

Network

+

Anynet

Antenna

SRS TruSurround HD Dolby Digital Plus/Pulse

5 W x 5 W 3 W(19"), 5 W(32")

X O

O O

X X

X O

O O

X X

X O

1(Cable/Air) 1(Cable/Air)

Page 16

2-10

2. Product specications

Model

Design

O : application, X : non-application ※

UD5P(UN**D5003BF) UD5P(UN22/27D5000NF) / UD5R(UN32/40D5500RF)

Display Type

Built-in Tuner

Resolution

LCD Panel

Screen Size

Picture ratio

Dimensions (WxHxD)

Weight

Brightness

Contrast Ratio

Picture Enhacer

Equalizer

Auto Volume Control

Surround Sound

Speaker Output

PIP

Caption

Entertainment Mode

Game Mode

Energy Saving

Network

+

Anynet

Antenna

LED TV LED TV

O O

1366 X 768 1366 X 768

TFT LCD Panel 60Hz TFT LCD Panel 60Hz

22" / 40" 22" / 27" / 32" / 40"

16 : 9 16 : 9

20.3 x 4.9 x 13.8(inches) with stand

22"

20.3 x 1.6 x 12.4(inches) without stand

37.2 x 8.6 x 23.8(inches) with stand

40"

37.2 x 2.0 x 22.1(inches) without stand

7.72(lbs) with stand

22"

7.50(lbs) without stand

21.26(lbs) with stand

40"

24.25(lbs) without stand

22" 250 cd/m

40" 250 cd/m

22" Mega

40" Mega

DNIe (Saturn4) HyperReal Engine (X5)

5 Band 5 Band

O O

SRS TruSurround HD Dolby Digital Plus/Pulse

22" : 5 W / 40" : 10W 22" : 3 W / 22" : 5 W / 32" / 40" : 10W

X O

O O

X X

X O

O O

X X

X O

1(Cable/Air) 1(Cable/Air)

22"

27"

32"

40"

22"

27"

32"

40"

2

22" 450 cd/m

27" 450 cd/m

2

32" 450 cd/m

40" 450 cd/m

21.5 x 7.5 x 16.2(inches) with stand

21.5 x 1.2 x 14.1(inches) without stand

25.7 x 8.7 x 18.9(inches) with stand

25.7 x 1.2 x 16.6(inches) without stand

30.2 x 1.2 x 18.4(inches) with stand

30.2 x 9.4 x 20.9(inches) without stand

37.6 x 10.0 x 25.1(inches) with stand

37.6 x 1.2 x 22.6(inches) without stand

9.00(lbs) with stand

8.20(lbs) without stand

13.70(lbs) with stand

12.10(lbs) without stand

9.96(lbs) with stand

7.22(lbs) without stand

14.36(lbs) with stand

11.08(lbs) without stand

2

2

2

2

22" Mega

27" Mega

32" Mega

40" Mega

Page 17

2-11

2. Product specications

Design

Model

O : application, X : non-application ※

LD4E(LN**D40*E*D) LD4G(LN**D450G1D)

Display Type

Built-in Tuner

Resolution

LCD Panel

Screen Size

Picture ratio

Dimensions (WxHxD)

Weight

Brightness

Contrast Ratio

Picture Enhacer

Equalizer

Auto Volume Control

LCD TV LCD TV

O O

1366 X 768 1366 X 768

TFT LCD Panel 60Hz TFT LCD Panel 60Hz

32" 26" / 32"

16 : 9 16 : 9

30.9 x 7.2 x 21.4(inches)with stand

32"

30.9 x 4.1 x 19.8(inches) without stand

6.39(lbs) with stand

32"

6.17(lbs) without stand

32" 250 cd/m

32" Mega

DNIe (Saturn4) HyperReal Engine (X5)

5 Band 5 Band

O O

26"

32"

26"

32"

2

26" 400 cd/m

32" 400 cd/m

26.0 x 8.7 x 19.0(inches) with stand

26.0 x 3.1 x 17.1(inches) without stand

31.3 x 9.9 x 22.5(inches) with stand

31.3 x 3.2 x 20.1(inches) without stand

14.80(lbs) with stand

13.80(lbs) without stand

23.90(lbs) with stand

19.00(lbs) without stand

2

2

19" TBD

32" Mega

Surround Sound

Speaker Output

PIP

Caption

Entertainment Mode

Game Mode

Energy Saving

Network

+

Anynet

Antenna

SRS TruSurround HD Dolby Digital Plus/Pulse

5 W 5 W(26"), 10 W(32")

X O

O O

X X

X O

O O

X X

X O

1(Cable/Air) 1(Cable/Air)

Page 18

2-12

2. Product specications

2-2. Detail Factory Option

If you replace the main board with new one, please change the factory option as well. ※

The options you must change are “Type”.

2-2-1. UD4003

Model Name UN19D4003BD UN26D4003BD UN32D4003BD

Vendor AMLCD CMI AMLCD

Panel

SMPS

1 Factory Reset - - -

2 Type - - -

3 Model D4003 D4003 D4003

4 Tuner ALPS ALPS ALPS

5 Audio Amp NTP7411S NTP7411S NTP7411S

6 Front Color NONE NONE NONE

7

8 Exhibition Mode Off Off Off

Local Set

CODE BN07-01043A BN07-01049A BN95-00437A

SPEC LTM185AT05-V

Vendor Powernet SEM DONGYANG

CODE BN44-00467A BN44-00471A BN44-00472B

SPEC PD22A0_BPNV PD26G0S_BSM PD32G0S_BSY

Other Other Other

LD260AGC-C1

S260L1-H62

LTJ320AP02

2-2-2. UD5003

Model Name UN22D5003BF UN40D5003BF

Vendor AMLCD AMLCD

Panel

SMPS

1 Factory Reset - -

2 Type - -

3 Model D5003 D5003

4 Tuner ALPS ALPS

5 Audio Amp NTP7411S NTP7411S

6 Front Color NONE NONE

7

8 Exhibition Mode Off Off

Local Set

CODE BN07-01044A BN95-00434A

SPEC LTM215HT04 LTJ400HM05

Vendor Powernet SEM

CODE BN44-00467A BN44-00473A

SPEC PD22A0_BPNV PD46G0_BSM

Other Other

Page 19

2-13

2. Product specications

2-2-3. LD40*

Model Name LN32D40*E*D

Vendor Sharp

Panel

SMPS

1 Factory Reset -

2 Type -

3 Model D40*

4 Tuner ALPS

5 Audio Amp NTP7411S

6 Front Color NONE

7

8 Exhibition Mode Off

Local Set

CODE BN07-01050A

SPEC CD320AGD

Vendor SEM

CODE BN44-00468A

SPEC PSIV121411C

Other

Page 20

2. Product specications

2-3. Accessories

Product Description Code. No Remark

Remote Control /

Batteries (AAA x 2)

Power Cord

Warranty Card /

Safety Guide Manual

Cleaning Cloth BN63-01798B

BN59-01006A

19D4003 : 3903-000599

26D4003 : 3903-000599

32D4003 : 3903-000599

22D5003 : 3903-000599

40D5003 : 3903-000598

32D40* : 3903-000599

BN68-03703A

Samsung Electronics

Service center

2-14

Page 21

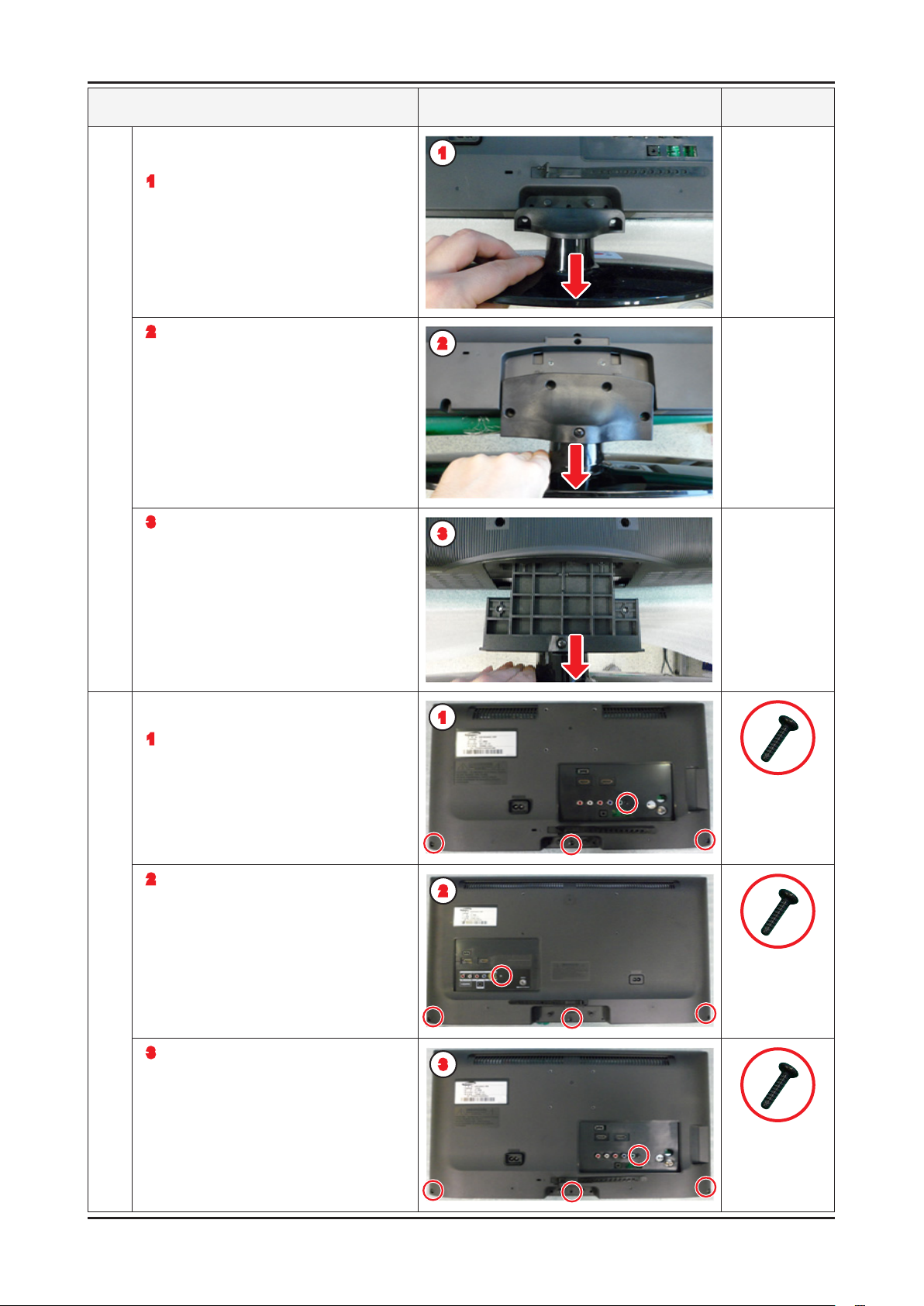

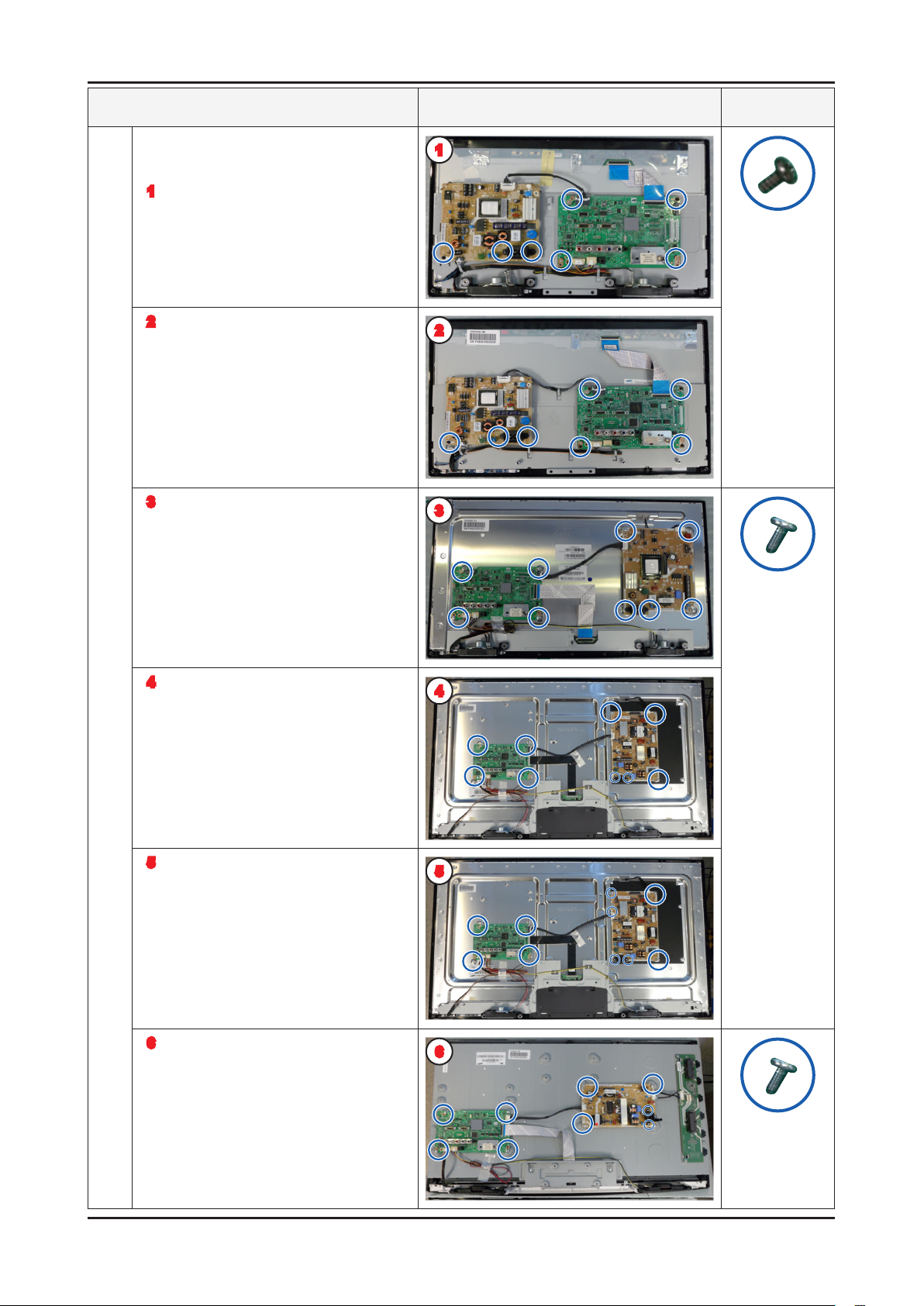

3. Disassembly and Reassembly

3. Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the LED/LCD TV.

WARNING: This LED/LCD TV contains electrostatically sensitive devices. Use caution when handling these

components.

3-1. Disassembly and Reassembly

Cautions: 1. Disconnect the LED TV from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

Description Picture Description

Place TV face down on cushioned table.

1

Remove screws from the Stand.

2

1 19D4003 : 2 EA

26D4003 : 2 EA

22D5003 : 2 EA

Screws

1

6003-001782

2 32D4003 : 4 EA

40D5003 : 4 EA

3 32D40* : 4 EA

2

6001-002621

3

6002-001294

3-1

Page 22

3-2

3. Disassembly and Reassembly

Remove stand.

3

1 19D4003

2 32D4003

3 32D40*

Description Picture Description

1

26D4003

22D5003

40D5003

2

3

Screws

Remove the screws of rear-cover.

4

1 19D4003 : 4 EA

2 22D5003 : 4 EA

3 26D4003 : 4 EA

1

6003-001782

2

6003-001782

3

6003-001782

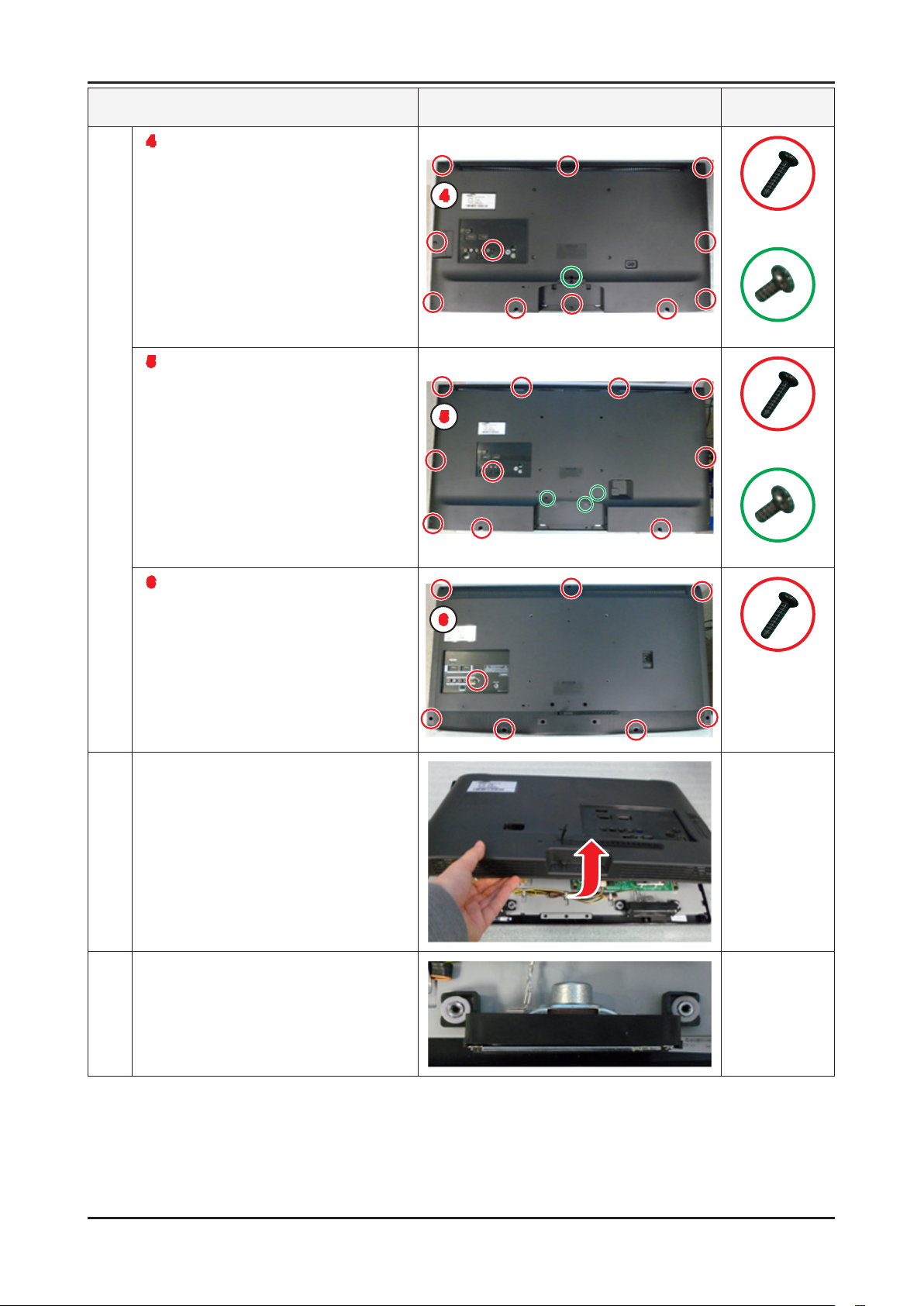

Page 23

3-3

3. Disassembly and Reassembly

Description Picture Description

4 32D4003 : 4EA

5 40D5003 : 12 EA

Screws

4

6003-001782

6001-002671

5

6003-001782

6001-002671

6 32D40* : 8 EA

Lift up the rear-cover.

5

Remove the left and right speaker.

6

6

6002-001294

Page 24

3-4

3. Disassembly and Reassembly

Description Picture Description

Remove the screws of main board and IP

7

board.

1 19D4003 : 7 EA

2 22D5003 : 7 EA

3 26D4003 : 9 EA

Screws

1

6003-000115

2

3

4 32D4003 : 9 EA

5 40D5003 : 10 EA

6001-002653

4

5

6 32D40* : 9 EA

6

6001-002284

Page 25

3-5

3. Disassembly and Reassembly

Description Picture Description

Remove the 2 screws of stand link cover

8

and Remove the stand link.

40D5003

Remove the screws of stand link.

9

32D4003

40D5003

Screws

6003-001782

6001-002653

40D5003

Lift up the stand link.

10

19D4003

22D5003

26D4003

32D4003

40D5003

6001-002653

6003-001782

Page 26

3-6

3. Disassembly and Reassembly

32D4003

40D5003

Lift up the panel.

11

Reassembly procedures are in the reverse order of disassembly procedures. ※

Screw Size

Description Picture Description

Screws

Code No. A (mm) B (mm) C (mm) Q'ty

19D4003 : 6 EA

26D4003 : 6 EA

6003-001782 7.80~8.30 11.20~12.00 3.81~3.91

6001-002621 7.80~8.20 7.40~8.00 3.83~3.98

6002-001294 7.80~8.30 15.2~16.0 3.85~4.00

6001-002671 7.10~7.50 5.70~6.00 2.98~3.02

6003-000115 5.80~6.30 5.20~6.00 2.85~2.95

6001-002653 7.10~7.50 5.70~6.00 2.98~3.02

22D5003 : 6 EA

32D4003 : 11 EA

40D5003 : 13 EA

32D40* : 7 EA

32D4003 : 4 EA

40D5003 : 4 EA

32D40* : 8EA

40D503 :

32D4003 : 1 EA

40D5003 : 3 EA

19D5003 : 7 EA

22D5003 : 7 EA

26D4003 : 9 EA

32D4003 : 13 EA

40D5003 :15 EA

6001-002284 7.80~8.30 7.40~8.60 3.83~3.98 32D40* : 11 EA

Page 27

3-7

3. Disassembly and Reassembly

3-2. How to disassembly Function & IR ASSY

Description Picture Description

Check the 2 Function Clips.

1

(for 32D40*)

Remove the front cover.

2

Heat the Function Assy by Heat Gun

3

and Lift up the Function Assy.

Screws

Page 28

4. Troubleshooting

4-1. Troubleshooting

4-1-1. Previous check

Check the various cable connections rst. 1.

• Check to see if there is a burnt or damaged cable.

• Check to see if there is a disconnected or loose cable connection.

• Check to see if the cables are connected according to the connection diagram.

Check the power input to the Main Board.2.

4. Troubleshooting

14p cable

Power Assy

Speaker

Main Assy (CN202 / 204)

1 B5V 2 SW_PW

3 B5V 4 A5V

5 GND 6 GND

7 B12VS 8 GND

9 B12VS 10 SW_INV

11 B13V 12 NC

13 B13V 14 DMM

LVDS Cable

Main Assy

Speaker

Power Assy (CMN801)

1 B5V 2 SW_PW

3 B5V 4 A5V

5 GND 6 GND

7 B12VS 8 GND

9 B12VS 10 SW_INV

11 B13V 12 NC

13 B13V 14 DMM

14p cable

Main Assy

LVDS Cable

Speaker

Main Assy (CN201 / 203)

1 B5V 2 SW_PW

3 B5V 4 A5V

5 GND 6 GND

7 B12VS 8 GND

9 B12VS 10 SW_INV

11 B13V 12 NC

13 B13V 14 DMM

Power Assy

T-CON

Speaker

Power Assy (CMN801)

1 B5V 2 SW_PW

3 B5V 4 A5V

5 GND 6 GND

7 B12VS 8 GND

9 B12VS 10 SW_INV

11 B13V 12 NC

13 B13V 14 DMM

4-1

Page 29

4-2

4. Troubleshooting

4-1-2. How to check fault symptom

No Power

The LEDs on the front panel do not work when connecting the power cord. -

Symptom

Major

checkpoints

The SMPS relay does not work when connecting the power cord. -

The units appears to be dead. -

The IP relay or the LEDs on the front panel does not work when connecting the power cord if the

cables are improperly connected or the Main Board or SMPS is not functioning.

In this case, check the following:

Check the internal cable connection status inside the unit. -

Check the fuses of each part. -

Check the output voltage of SMPS. -

Replace the Main Board. -

Power indicator LED on?

Yes

Check the 14P power cable

Yes

No

Check an AC power connection.

No

Change 14p power cable or SMPS.

Diagnostics

Check ‘Stand-By 5V’ DC5V appear at

BD207(middle)/BD214(small)?

Yes

Check ‘Power input of Main Assy’ ?

DC B13V, B5V appear at BD209(M)/BD221(S)

(B13V), BD208, BD213(M)/BD210, 212(S)

Yes

Check ‘Power of main IC(B1.1V)’

Check ‘Power of DDR IC(B1.9V)’

appear at L201 (B1.1V)

BD1012 (B1.9V) ?

Yes

Check ‘Power of LVDS (13V)’ appear at

LVDS connector Pin #1~5 of T-con b’d?

Yes

Does proper DC B13V appear at F1 of

T-con b’d?

Yes

(B5V)?

No

No

No

No

No

Change SMPS.

Change the Main Assy.

Change the LVDS cable.

Change the T-con b’d.

Please, Contact tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 30

4-3

4. Troubleshooting

Location (Main) - TOP

Location (Main) - T-CON

Page 31

4-4

4. Troubleshooting

No video_HDMI1, 2 - Digital signal

Symptom Audio is normal but no picture is displayed on the screen. -

Major

checkpoints

Check the HDMI source. -

Check the HDMI switch, Check the Chelsea. -

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected. -

Power indicator LED is off.

Lamp(Backlight) on, no video ?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Check the HDMI source and

check the connection of HDMI cable ?

Yes

Does the signal appear at

CN602 (Pin#12 , #7 )(HDMI1)

CN601 (Pin#12 , #7 )(HDMI2)

(HDMI RX_Clk , RX_Data) ?

Yes

No

No

No

No

Check a set in the 'Stand-by mode'.

Check external devices and

connections.

Input the HDMI signal properly.

Check CN502, CN503.

Check HDMI cable.

Change the Main Assy.

Diagnostics

Does the digital data appear at

TP-E_TXCLK+, E_TXCLK- ,

O_TXCLK+, O_TXCLK-?

Yes

Check the LVDS cable ?

Check the T-Con B’d ?

Replace the LCD panel ?

No

No

Check IC1001 (X5N)

Change the Main Assy.

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 32

4-5

4. Troubleshooting

Location (Main) - TOP

Page 33

4-6

4. Troubleshooting

WAVEFORMS

HDMI input (RX_Data, RX_Clk)

LVDS output

Page 34

4-7

4. Troubleshooting

No Video_Tuner - CVBS

Symptom Audio is normal but no picture is displayed on the screen. -

Major

checkpoints

Check the Tuner CVBS source. -

Check the Tuner, Check the Chelsea. -

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected. -

Power indicator LED is off.

Lamp(Backlight) on, no video ?

Yes

Check the RF source and

check the connection of RF cable ?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Does the DC B1.8V B3.3V

appear at #3, #5 Pin of Tuner ?

Yes

Check the CVBS data

at #15 Pin of Tuner ?

No

No

No

No

No

Check a set in the 'Stand-by mode'

Input the RF source properly.

Check external devices and

connections.

Change the Main Assy.

Change the Main Assy.

Diagnostics

Yes

Does the digital data appear at

TP-E_TXCLK+, E_TXCLK- ,

O_TXCLK+, O_TXCLK- ?

Yes

Check the LVDS cable ?

Check the T-Con B’d ?

Replace the LCD panel ?

No

No

Check IC1001 (X5N).

Change the Main Assy.

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 35

4-8

4. Troubleshooting

Location (Main) - TOP

Page 36

4-9

4. Troubleshooting

WAVEFORMS

LVDS output

Page 37

4-10

4. Troubleshooting

No Video_Tuner DTV

Symptom Audio is normal but no picture is displayed on the screen. -

Major

checkpoints

Check the DTV source. -

Check the Tuner, Check the Chelsea. -

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected. -

Power indicator LED is off.

Lamp(Backlight) on, no video ?

Yes

Check the connection of RF cable ?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Check the 'signal strength' in Self Diagnosis

menu Strength is enough ?

Yes

Does the DC B1.8V B3.3V

appear at #3, #5 Pin of Tuner ?

Yes

No

No

No

No

No

Check a set in the 'Stand-by mode'

Input the RF source properly.

Check external devices and

connections.

Check the D-TV source.

Change the Main Assy.

Diagnostics

Check the DTV data(DIF+, DIF-)

appear at #11, #10 Pin of Tuner ?

Yes

Does the digital data appear at

TP-E_TXCLK+, E_TXCLK- ,

O_TXCLK+, O_TXCLK- ?

Yes

Check the LVDS cable ?

Check the T-Con B'd ?

Replace the LCD panel ?

No

No

No

Change the Main Assy.

Check IC1001 (X5)

Change the Main Assy.

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 38

4-11

4. Troubleshooting

Location (Main) - TOP

Page 39

4-12

4. Troubleshooting

WAVEFORMS

LVDS output

Page 40

4-13

4. Troubleshooting

No Video_Video CVBS

Symptom Audio is normal but no picture is displayed on the screen. -

Major

checkpoints

Check the Video CVBS source -

Check the Chelsea. -

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected. -

Power indicator LED is off.

Lamp(Backlight) on, no video ?

Yes

Check the video source and

check the connection of video cable?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Does the CVBS data appear at

R809/R814(CVBS1) ?

Yes

Does the digital data appear at

TP-E_TXCLK+, E_TXCLK- ,

O_TXCLK+, O_TXCLK- ?

Yes

No

No

No

No

No

Check a set in the 'Stand-by mode'

Input the video source properly.

Check external devices and

connections.

Check CN503

Change the Main Assy.

Check IC1001 (X5)

Change the Main Assy.

Diagnostics

Check the LVDS cable ?

Check the T-Con B'd ?

Replace the LCD panel ?

No

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 41

4-14

4. Troubleshooting

Location (Main) - TOP

Page 42

4-15

4. Troubleshooting

WAVEFORMS

CVBS OUT (Grey Bar)

LVDS output

Page 43

4-16

4. Troubleshooting

No Video_Component

Symptom Audio is normal but no picture is displayed on the screen. -

Major

checkpoints

Check the Component source -

Check the chelsea. -

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected. -

Power indicator LED is off.

Lamp(Backlight) on, no video ?

Yes

Check the component source and check the

connection of component cables (Y,Pb,Pr) ?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Does the data appear at

R816/R821(COMP_Y)

R817 (COMP_PB)

R815(COMP_PR)

Yes

No

No

No

No

Check a set in the 'Stand-by mode'.

Input the component source properly.

Check external devices and

connections.

Check CN403.

Change the Main Assy.

Diagnostics

Does the digital data appear at

TP-E_TXCLK+, E_TXCLK- ,

O_TXCLK+, O_TXCLK- ?

Yes

Check the LVDS cable ?

Check the T-Con B'd ?

Replace the LCD panel ?

No

No

Check IC1001 (X5N).

Change the Main Assy.

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 44

4-17

4. Troubleshooting

Location (Main) - TOP

Page 45

4-18

4. Troubleshooting

WAVEFORMS

Compnent_Y (Gray scale) / Pb / Pr (Color bar)

LVDS output

Page 46

4-19

4. Troubleshooting

No Sound

Symptom Video is normal but there is no sound.. -

Major

checkpoints

When the speaker connectors are disconnected or damaged. -

When the sound processing part of the Main Board is not functioning. -

Speaker defect.. -

Check the source and check the connection of

sound cable (Comp/PC/DVI to HDMI) ?

Yes

check the Self Diagnosis

(SupportSelf DiagnosisPicture Test)

Dose the promblem still exist self diagnosis ?

Yes

Does the sound data appear at

R404/R405 (AV1, COMP1)

Yes

Does the DC B12V

appear at BD301?

Yes

No

No

No

No

Input the sound source properly.

Check external devices and

connections.

Check CN403.

Change the Main Assy

Change the Main Assy.

Diagnostics

Does the sound data appear at

- L-, L+, R-, R+ ?

Yes

Replace speaker ?

No

No

Check IC1001 (X5N).

Check IC301 (Sound AMP).

Change the Main Assy.

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

Page 47

4-20

4. Troubleshooting

Location (Main) - TOP

Page 48

4-21

4. Troubleshooting

WAVEFORMS

Speaker out

Page 49

4-22

4. Troubleshooting

4-2. Factory Mode Adjustments

4-2-1 Entering Factory Mode

• If you do not have Factory remote - control

• If you do not have Factory remote - control

If you don’t have Factory remote control, can’t control some menu.

MUTEPower OFF 1 8 2 Power ON

FactoryINFO

Option

Control

SVC

Expert

ADC/WB

T-MX5FAUSC(FHD)/T-MX5HAUSC(HD)

X7-MW-0013

X5-App-0013

OPTION : XXXXXXXX

ADC : HDMI / COMP / PC / AV

EDID SUCCESS

HDCP : SUCCESS

Current Flash : Flash 0

Build Date : XX-XX-XXXX

DATE OF PURCHASE : XX/XX/XX

Page 50

4-23

4. Troubleshooting

4-2-2. Factory Data

Option

Factory Menu Name Data Range Remark

Factory Reset -

Type

UD5003

Model

TUNER ALPS ALPS/Xugang/SECCustom

Audio Amp TAS5715 TAS5715/NTP3200

Front Color NONE

Local Set Other Other/S,America

Exhibition Mode Off On

Control

UD4003

LD503

LD403

UD5003/UD4003/LD503/LD403

Factory Menu Name Data Range

EDID

EDID ON/OFF Off On/Off

EDID WRITE ALL Success/Failure

EDID WRITE PC Success/Failure

EDID WRITE DVI Success/Failure

EDID WRITE HDMI1 Success/Failure

EDID WRITE HDMI2 Success/Failure

EDID WRITE HDMI3 Success/Failure

EDID WRITE HDMI4 HDMI 1.3/HDMI1/2

EDID VERSION

Sub Option

Mute Time(VIDEO) 4 0ms~1000ms

ready Failure Debug/Login/UART

HotPlug On ON/OFF

Hotplugcontrol On 0~255

Spread Spectrum

Spread Spectrum On On/Off

Period 60K 40K/50K/60K

Amplitude 2 0/0.5/1/1.5/2

DDR Spread 2% Off/1%/2%

Auto Power On

Arab Off

NT Conversion Off

Mirror ON(Middle) / OFF(Small) ON(Middle) / OFF(Small)

Page 51

4-24

4. Troubleshooting

HDMI EQ1 Middle Low/Middle/High/Strong

HDMI EQ2 Middle Low/Middle/High/Strong

HDMI EQ3 Middle Low/Middle/High/Strong

HDMI EQ4 Middle Low/Middle/High/Strong

EER Count 2230

WM Calib

Panel Enter Key

Panel Display Time

Checksum XXXX

View Log

Font Data Viewer

Dimm Type EXT EXT/INT

Gamma 0.88 0.88/0.90/0.93/0.95/0.98/Off

Carrier Mute Off On/Off

Anynet+ Off On/Off

HPD Polarity

High Devi Off On/Off

Volume Cureve NT NT/EU/EA

HotPlug Delay 3 0~63

HP Ident Low High/Low

PC Ident On On/Off

Info Live

Watchdog On On/Off

LVDS Format

OSD Resolution 1366*768

Bus Stop

OTA Code

OTA Duration Test

Alternate Del

Ignore VCT Version On On/Off

Change OSD Language KOR ENG/KOR

VCR Mode Off On/Off

JEIDA /

VESA(19D4003.32D403)

JEIDA / VESA

PDP Option

Hotel Option

Shop Option

Shop Mode OFF ON/OFF

Shop Mode OFF ON/OFF

USB DEMO ON(SEC)

USB DEMO OFF(SEC)

Sound

Page 52

4-25

4. Troubleshooting

BD Mode

A2K Prescale 20 0~40

BTSC Mono Prescale 20 0~40

BTSC streo Prescale 20 0~40

SAP Prescale 20 0~40

BTSC M2S Threshold 0x80 0xA0~0x9F

BTSC S2M Threshold 0x70 0xA0~0x9F

BTSC Pilot NSR On Thr

BTSC Pilot NSR Off Thr

BTSC Stereo On Thr

BTSC Stereo Off Thr

SAP Amp On Thr

SAP Amp Off Thr

SAP NSR On Thr

SAP NSR Off Thr

Carrier Mute Amp On Thr

Carrier Mute Amp Off Thr

Carrier NSR On Thr

Carrier NSR Off Thr

Carrier Mute Thr High 0x39 0x00~0x7F

Carrier Mute Thr Low 0x26 0x00~0x7F

MP3 Level -6dB -12dB~0dB

Master Vol 16 0~255

PWM Modulation 85 0~255

DRC1 Threshold 0x35 0x00~0x7F

DRC2 Threshold 0x23 0x00~0x7F

SPEAKER EQ On On/Off

SC1 Vol 16 0~255

SC2 Vol 16 0~255

Audio Delay 20ms 0~150ms

SUB AMP Master Vol

SUB AMP PWM Mod

SUB DRC Thresh

SUB Speaker EQ

[Edu] SPK Level 1 0~8

[Edu] MIC Level 1 0~8

[Edu] PGA Gain 2dB 0~59dB

EQ Check Sum 0xFA9C

Cong Option

Num of AV 1 0~3

Num of SVIDEO 0 1~3

Page 53

4-26

4. Troubleshooting

Num of Comp 1 1~3

Num of HDMI 2 0~4

Num of SCART 0

DVI Sound 1 0~1

HeadPhone 0 0~1

Num of USB Port

LNA SUPPORT On On/Off

MFT Offset

Test Pattern

Master Test Pattern Off Off/1~13

FBE Test Pattern

LOGIC Test Pattern Off Off/1~31

Advanced

Factory Menu Name Data Range Remark

PBE

WM Movie

Mode Off On/Off

Color Mode Movie

Color Tone Cool

Msub Brigh 128

Msub Contr 128

W1_RGAIN 138

W1_BGAIN 104

W1_ROFFS 130

W1_BOFFS 127

W2_RGAIN 131

W2_BGAIN 64

W2_ROFFS 133

W2_BOFFS 129

W3_RGAIN 128

W3_BGAIN 128

W3_ROFFS 128

W3_BOFFS 128

N_RGAIN 131

N_BGAIN 122

N_ROFFS 128

N_BOFFS 129

Movie Countr 100

Movie Brigh 45

Movie Color 55

Page 54

4-27

4. Troubleshooting

Movie Sharp 55

Movie Tint 50

Movie BkLight 10

M.Gamma Off

M_Sub Gamma 0

EPA Standard

Std Contr 100 0~100

Std Bright 45 0~100

Std Sharp 50 0~100

Std Color 50 0~100

Std Tint 50 0~100

Std Backight 8 0~10

ADJUST

Dynamic Dimming

LNA Plus

RF dB1 Level 4 0~255

RF dB2 Level 6 0~255

RF dB3 Level 10 0~255

RF dB4 Level 20 0~255

LNA Plus

Power Key Protect Off On/Off

UART Select Auto Wall Auto Wall/Debug/MDC/On1/On2

Debug Mode Debug Off Debug Off/Debug Smart/Debug RunTime

Back End Mute

PDP FRC

VisualTEST Plus Disable

Standby Mode Time 45 Min 2 Min/45 Min

Delete alt.ver 2 Flash

OTA conrm Time 90 Min 3 Min/90 Min

OTA limit Time 3 Hour 3 Min/3Hour

Dynamic CE Off On/Off

FWC Off On/Off

1080p 48Hz On On/Off

PWM Max 100 1~100

Quick Start

DTV LNA Auto On/Off

HDCP Download Off On/Off

USB Download Off On/Off

YC_Delay

PAL BG 1 0~3

PAL DK 1 0~3

Page 55

4-28

4. Troubleshooting

PAL I 1 0~3

SECAM BG 4 0~3

SECAM DK 4 0~3

SECAML 4 0~3

NTSC 358 1 0~3

NTSC 443 0 0~3

AV PAL 1 0~3

AV SECAM 4 0~3

AV NT358 1 0~3

AV NT443 1 0~3

AV PAL60 1 0~3

SHARPNESS

H1 GAIN 0X12 0X00~0XFF

H2 GAIN 0X08 0X00~0XFF

H3 GAIN 0X08 0X00~0XFF

H4 GAIN 0X08 0X00~0XFF

V1 GAIN 0X10 0X00~0XFF

V2 GAIN 0X0E 0X00~0XFF

H OVERSHOOT 0X20 0X00~0XFF

V OVERSHOOT 0X20 0X00~0XFF

H UNDERSHOOT 0X20 0X00~0XFF

V UNDERSHOOT 0X20 0X00~0XFF

CORING TH2 0X01 0X01~0X0F

CORING TH1 0X01 0X01~0X0F

PE

SKIN_X 0X00 0X00~0XFF

SKIN_Y 0X01 0X00~0XFF

B_SLOPE 0X8A 0X00~0XFF

DLC_ML 0X90 0X00~0XFF

DLC_MH 0X90 0X00~0XFF

DLC_H 0XEB 0X00~0XFF

SKIN_SAT 0X00 0X00~0XFF

SKIN_HUE 0X20 0X00~0XFF

M_SKIN_HUE 0X40 0X00~0XFF

M_SKIN_X 0X00 0X00~0XFF

M_SKIN_Y 0X00 0X01~0X0F

MID_COLOR_LEVEL 0XB8 0X01~0X0F

M_MID_COLOR_LEVE 0X95 0X01~0X0F

PQ OTHERS

7.5 IRE NTSC OFF ON/OFF

7.5 IRE OFFSET 16 0~60

Page 56

4-29

4. Troubleshooting

COLOR SPACE

RED SAT 0X12 0X00~0XFF

RED HUE 0X40 0X00~0XFF

GREEN SAT 0X16 0X00~0XFF

GREEN HUE 0X70 0X00~0XFF

BLUE SAT 0X1A 0X00~0XFF

BLUE HUE 0X70 0X00~0XFF

CYAN SAT 0X16 0X00~0XFF

CYAN HUE 0X40 0X00~0XFF

MAGENTA SAT 0X16 0X00~0XFF

MAGENTA HUE 0X40 0X00~0XFF

YELLOW SAT 0X0F 0X00~0XFF

YELLOW HUE 0X70 0X00~0XFF

FWC BLUE 0X0F 0X00~0XFF

FWC RED 0X0F 0X00~0XFF

EEPROM RESET

EEPROM RESET OFF ON/OFF

NVR ALL CLEAR OFF ON/OFF

EXPERT

Factory Menu Name Data Range Remark

N/D ADJ OFF ON/OFF

SOURCE CURRENT

SVC

Factory Menu Name Data Range Remark

MODE DYNAMIC DYNAMIC/MOVIE

SCC ON/OFF OFF ON/OFF

SCC INPUT DATA

HX 272 0~1024

HY 278 0~1024

LX 272 0~1024

LY 278 0~1024

SSCC CONST

SSCC HX 554 0~1024

SSCC HY 573 0~1024

SSCC LX 550 0~1024

SSCC LY 576 0~1024

PSCC CONST …

PSCC HX 554 0~1024

PSCC HY 573 0~1024

PSCC LX 550 0~1024

Page 57

4-30

4. Troubleshooting

PSCC LY 576 0~1024

SCC SOURCE DATA PBA PBA/PANEL

SWAP PBA PBA/PANEL

PANEL AUTO SETTING

1st_AV_Low 64 0 ~ 1020

1st_AV_High 880 0 ~ 1020

1st_AV_Delta 2 0 ~ 7

1st_COMP_Y_Low 64 0 ~ 1020

1st_COMP_Cb_Low …

1st_COMP_Cr_Low …

1st_COMP_Y_High 940 0 ~ 1020

1st_COMP_Cb_High …

1st_COMP_Cr_High …

1st_COMP_Delta 2 0~7

1st_PC_R_Low 16 0 ~ 1020

1st_PC_G_Low …

1st_PC_B_Low …

1st_PC_R_High 1004 0 ~ 1020

1st_PC_G_Low …

1st_PC_B_Low …

1st_PC_Delta 2 0~7

2nd_AV_R_Low 4 xed

2nd_AV_G_Low 4 xed

2nd_AV_B_Low 4 xed

2nd_AV_R_High 940 xed

2nd_AV_G_High 940 xed

2nd_AV_B_High 940 xed

2nd_AV_Delta 2 0~7

2nd_COMP_R_Low 4 xed

2nd_COMP_G_Low 4 xed

2nd_COMP_B_Low 4 xed

2nd_COMP_R_High 940 xed

2nd_COMP_G_High 940 xed

2nd_COMP_B_High 940 xed

2nd_COMP_Delta 2 0~7

2nd_PC_R_Low 4 xed

2nd_PC_G_Low 4 xed

2nd_PC_B_Low 4 xed

2nd_PC_R_High 940 xed

2nd_PC_G_High 940 xed

2nd_PC_B_High 940 xed

Page 58

4-31

4. Troubleshooting

2nd_PC_Delta 2 0~7

2nd_HDMI_R_Low 4 xed

2nd_HDMI_G_Low 4 xed

2nd_HDMI_B_Low 4 xed

2nd_HDMI_R_High 940 xed

2nd_HDMI_G_High 940 xed

2nd_HDMI_B_High 940 xed

2nd_HDMI_Delta 2 0~7

ADC Result

1st_Y_GH 0 xed

1st_Y_GL 0 xed

1st_Cb_BH 0 xed

1st_Cb_BL 0 xed

1st_Cr_RH 0 xed

1st_Cr_RL 0 xed

2nd_R_L 134 0 ~ 255

2nd_G_L 134 0 ~ 255

2nd_B_L 134 0 ~ 255

2nd_R_H 49 0 ~ 255

2nd_G_H 49 0 ~ 255

2nd_B_H 49 0 ~ 255

WB

Sub Brightness 128 0 ~ 1023

R_Offset 512 0 ~ 1023

G_Offset 512 0 ~ 1023

B_Offset 512 0 ~ 1023

Sub Contrast 128 0 ~ 1023

R_Gain 512 0 ~ 1023

G_Gain 512 0 ~ 1023

B_Gain 512 0 ~ 1023

Movie R Offset … xed

Movie B Offset … xed

Movie R Gain … xed

Movie B Gain … xed

Page 59

4-32

4. Troubleshooting

4-3. White Balance - Calibration

4-3-1. White Balance -Calibration

Factory

ADC / WB

AV Calibration

Comp Calibration

PC Calibration

HDMI Calibration

4-3-2. Service Adjustment

You must perform Calibration in the Lattice Pattern before adjusting the White Balance.

Color Calibration

Adjust spec.

Source : HDMI1.

Setting Mode : 1280*720@60Hz2.

Pattern : Pattern #24 (Chess Pattern)3.

Use Equipment : CA210 & Master MSPG925 Generator4.

Use other equipment only after comparing The result with that of The Master equipment.

Input mode Calibration Pattern

CVBS IN (Model_#1) Perform in NTSC B&W Pattern #24 Lattice

Component IN (Model_#6) Perform in 720p B&W Pattern #24 Lattice

PC Analog IN (Model_#21) Perform in VESA XGA (1024x768) B&W Pattern #24 Lattice

HDMI IN Perform in 720p B&W Pattern #24 Lattice

Page 60

4-33

4. Troubleshooting

Method of Color Calibration (AV)

1) Apply the NTSC Lattice (N0. 3) pattern signal to the AV IN 1 port.

2) Press the Source key to switch to “AV1” mode.

3) Enter Service mode.

4) Select the “ADC” menu.

5) Select the “AV Calibration” menu.

6) In “AV Calibration Off” status, press the “ ” key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the “AV Calibration” status from Failure to Success.

Method of Color Calibration (Component)

1) Apply the 720p Lattice (N0. 6) pattern signal to the Component IN 1 port.

2) Press the Source key to switch to “Component1” mode.

3) Enter Service mode.

4) Select the “ADC” menu.

5) Select the “Comp Calibration” menu.

6) In “Comp Calibration Off” status, press the “ ” key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the “Comp Calibration” status from Failure to Success.

Method of Color Calibration (PC)

1) Apply the VESA XGA Lattice (N0. 21) pattern signal to the PC IN port.

2) Press the Source key to switch to “PC” mode.

3) Enter Service mode.

4) Select the “ADC” menu.

5) Select the “PC Calibration” menu.

6) In “PC Calibration Off” status, press the “ ” key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the “PC Calibration” status from Failure to Success.

Method of Color Calibration (HDMI)

1) Apply the 720p Lattice (N0. 6) pattern signal to the HDMI1/DVI IN port.

2) Press the Source key to switch to “HDMI1” mode.

3) Enter Service mode.

4) Select the “ADC” menu.

5) Select the “HDMI Calibration” menu.

6) In “HDMI Calibration Off” status, press the “ ” key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the “HDMI Calibration” status from Failure to Success.

4-3-3. White Balance - Adjustment

Factory (Low light) (High light)

ADC / WB - White Balance

Sub Bright

R offset

G offset

B offset

Sub Contrast

R gain

G gain

B gain

Page 61

4-34

4. Troubleshooting

4-4. White Ratio (Balance) Adjustment

You can adjust the white ratio in factory mode (1:Calibration, 3:White-Balance).1.

Since the adjustment value and the data value vary depending on the input source, you have to 2.

adjust these in CVBS, Component 1 and HDMI 1 modes.

The optimal values for each mode are congured by default. (Refer to Table 1, 2) 3.

It varies with Panel’s size and Specication.

- Equipment : CS-210

- Pattern: MIK K-7256 #92 “Flat W/B Pattern" as standard

- Use other equipment only after comparing the result with

that of the Master equipment.

- Set Aging time : 60min

- Calibration and Manual setting for WB adjustment.

HDMI : Calibration at #24 Chessboard Pattern Manual adjustment #92 pattern (720p)

COMP: Calibration at #24 Chessboard Pattern Manual adjustment at #92 pattern (720p)

CVBS: Calibration at #24 Chessboard Pattern Manual adjustment at #92 pattern (NTSC)

- If nishing in HDMI mode, adjustment coordinate is almost same in AV/COMP mode.

- White Balance Manual Adjustment

Page 62

4-35

4. Troubleshooting

UN19D4003BD

P-Mode

[Dynamic Cool1]

HDMI

Comp

CVBS

[Movie Warm2]

HDMI

Comp

CVBS

UN26D4003BD

x y Y(Luminance) T(K)+MPCD

H/L 281 288

L/L - -

H/L - -

L/L - -

Adjustment Coordinate CA-210

R-Gain : 132

B-Gain : 154

Sub_CT : 128

(Sub_Brt:128 Fix)

R-Offset, B-Offset : 128

(M-Sub_CT:128 Fix)

appiled Movie W2 R/B-gain

(M-Sub_Brt:128 Fix)

appiled Movie W2 R/B-gain

10,000 (+/- 0)

-

-

-

P-Mode

[Dynamic Cool1]

HDMI

Comp

CVBS

[Movie Warm2]

HDMI

Comp

CVBS

UN32D4003BD

P-Mode

[Dynamic Cool1]

HDMI

Comp

CVBS

[Movie Warm2]

HDMI

Comp

CVBS

x y Y(Luminance) T(K)+MPCD

H/L 264 274

L/L - -

H/L 319 340

L/L - -

x y Y(Luminance) T(K)+MPCD

H/L 264 274

L/L - -

H/L 319 340

L/L - -

Adjustment Coordinate CA-210

30.1 fL

(Sub_CT:133 Fix)

1.8 fL

(Sub-Brt:128 Fix)

- fL

(M_Sub_CT:128 Fix)

- fL

(M_Sub_CT:128 Fix)

Adjustment Coordinate CA-210

31.8 fL

(Sub_CT:136 Fix)

1.8 fL

(Sub-Brt:128 Fix)

- fL

(M_Sub_CT:128 Fix)

- fL

(M_Sub_CT:128 Fix)

12,000 (±0)

-

6,500(+-0)

-

12,000 (±0)

-

6,500(+-0)

-

UN22D5003BF

P-Mode

[Dynamic Cool1]

HDMI

Comp

CVBS

[Movie Warm2]

HDMI

Comp

CVBS

x y Y(Luminance) T(K)+MPCD

H/L 264 274

L/L - -

H/L 319 340

L/L - -

Adjustment Coordinate CA-210

31.8 fL

(Sub_CT:136 Fix)

1.8 fL

(Sub-Brt:128 Fix)

- fL

(M_Sub_CT:128 Fix)

- fL

(M_Sub_CT:128 Fix)

12,000 (±0)

-

6,500(+-0)

-

Page 63

4-36

4. Troubleshooting

LN32D40*E*D

P-Mode

[Dynamic Cool1]

HDMI

Comp

CVBS

[Movie Warm2]

HDMI

Comp

CVBS

x y Y(Luminance) T(K)+MPCD

H/L 272 278

L/L 272 278

H/L 306 327

L/L 306 327

Adjustment Coordinate CA-210

38.0 fL

(Sub_CT:134 Fix)

2.2 fL

(Sub-Brt:128 Fix)

- fL

(M_Sub_CT:128 Fix)

- fL

(M_Sub_CT:128 Fix)

12,000 (±0)

12,000 (±0)

6,500 (±0)

6,500 (±0)

Page 64

4-37

4. Troubleshooting

4-5. Software Upgrade

Software Upgrade can be performed by downloading the latest rmware from samsung.com to a USB memory device.

Current Version - the software already installed in the TV.

Note : Software is represented as ‘Year/Month/Day_Version’.

4-5-1. How to check the SW version

Use the main menu

Click the “menu” key in remote controler.1.

Select Support menu.2.

Locate the menu cursor “Software Upgrade” menu.3.

Click the “info” key.4.

Check the Main SW and Micom version.5.

Use the factory mode

Access the factory mode

Option

Control

SVC

Expert

ADC/WB

Advanced

T-MX5FAUSC(FHD)/T-MX5HAUSC(HD) : SW Ver,

X7-MW-0013

X5-App-0013

OPTION : XXXXXXXX

ADC : HDMI / COMP / PC / AV

EDID SUCCESS

HDCP : SUCCESS

Current Flash : Flash 0

Build Date : XX-XX-XXXX

DATE OF PURCHASE : XX/XX/XX

Page 65

4-38

4. Troubleshooting

4-5-2. How to Upgade SW and Micom

Insert a USB drive containing the rmware upgrade downloaded from samsung.com into the TV.

Please be careful to not disconnect the power or remove the USB drive while upgrades are being applied. The TV will

turn off and turn on automatically after completing the rmware upgrade. Please check the rmware version after the

upgrades are complete (the new version will have a higher number than the older version). When software is upgraded,

video and audio settings you have When software is upgraded, video and audio settings you have you write down your

settings so that you can easily reset them after the upgrade.

Main SW upgrade

Store the sw program named "T-MX5FAUSC"(FHD) or 1.

"T-MX5HAUSC"(HD) in USB memory stick.

Connect the USB. -

Click the2. MENU key in remote controler.

Select 3. Support menu.

Locate the menu cursor - Software Upgrade menu.

Click the 4. ENTER key.

Click the 5. ENTER key.

Wait for upgrade complete and check the SW version. -

Page 66

4-39

4. Troubleshooting

4-6. Rear Cover Dimension

Cover-Rear Area

19D4003

26D4003

32D4003

22D5003

40D5003

32D40*

1 2 3 4 5 6

121.8 203.5 51.8 67.5 75.0 75.0

166.0 68.0 82.7 378.0 200.0 200.0

183.4 80.3 142.1 496.4 200.0 200.0

157.6 268.8 53.8 68.8 75.0 75.0

236.3 159.4 196.6 604.7 200.0 200.0

235.8 50.7 125 542.7 200 200

Page 67

5. Wiring Diagram

PANEL

Main Board

IP Board

PANEL

Speaker

CNI802

CN801

Speaker

FUNCTION& IR

CN1

CN201

CN1202

CN301

CN1601

UN26D4003BD_UN32D403BD

UN22D5003BF_UN19D4003BD

T-CON

Function

Main Board

Speaker

SMPS

Speaker

CNM801

CN1801

PANEL

CN202

CN1202

CN301

CN1602

CN1

5-1. Wiring Diagram

5. Wiring Diagram

5-1

Page 68

UN40D5003BF

T-CON

Main Board

IP Board

PANEL

Speaker

CNI802

CN801

Speaker

FUNCTION& IR

CN1

CN203

CN1202

CN301

CN1604

LN32D40*E*D

PANEL

Main

Board

Speaker

CN301

CN1202

IP Board

Driver

CN203

CN1601

Speaker

CNI802

CN801

Function&IR

CN1

5-2

5. Wiring Diagram

Page 69

5-2. Position of Connector

5-3

5. Wiring Diagram

5-2-1. UN19D4003BD

1 CN1604_S_HD

9 CN1502 (USB1)

7 CN502 (HDMI1) 8 CN503 (HDMI2)

6 CN403(COMPONETN)

3 CN1201 (FUNCTION)

4 CN301 (SPEAKER)

Connector

2 CN201_S_LED (to Powr board)

5 CN1203(DEBUG)

1 CN1604_S_HD

1 PANEL_VCC 16 ODD_CLK+

2 PANEL_VCC 17 ODD_CLK-

3 PANEL_VCC 18 GND

4 PANEL_VCC 19 ODD2+

5 PANEL_VCC 20 ODD2-

6 GND 21 GND

7 GND 22 ODD1+

8 GND 23 ODD1-

9 WP_PANEL 24 GND

10 LVDS FORMAT 25 ODD0+

11 NC 26 ODD0-

12 GND 27 GND

13 ODD3+ 28 SDA

14 ODD3- 29 SCL

15 GND 30 NC

2 CN201_S_LED (to Powr board)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

3 CN1201 (FUNCTION)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

4 CN301 (SPEAKER)

1 R+ 3 L+

2 R- 4 L-

Page 70

5-4

5. Wiring Diagram

5 CN1203(DEBUG)

1 GND 4 DEBUG_TX

2 DEBUG_RX 5 DEBUG_TX

3 DEBUG_TX 6 GND

6 CN403(COMPONETN)

1 GND 9 GND

2 COMP1_Y 10 GND

3 IDENT_AV 11 SL

4 GND 12 SR

5 PB 13 GND

6 IDENT_COMP 14 SR

7 GND 15 SL

8 PR

7 CN502 (HDMI1)

1 HDMI1_RX2+ 11 GND

2 GND 12 HDMI1_RXCLK-

3 HDMI1_RX2- 13 HDMI_CEC

4 HDMI1_RX1+ 14 GND

5 GND 15 SCL

6 HDMI1_RX1- 16 SDA

7 HDMI1_RX0+ 17 GND

8 GND 18 5V

9 HDMI1_RX0- 19 HPD

10 HDMI1_RXCLK+

8 CN503 (HDMI2)

1 HDMI2_RX2+ 11 GND

2 GND 12 HDMI2_RXCLK-

3 HDMI2_RX2- 13 HDMI_CEC

4 HDMI2_RX1+ 14 GND

5 GND 15 SCL

6 HDMI2_RX1- 16 SDA

7 HDMI2_RX0+ 17 GND

8 GND 18 5V

9 HDMI2_RX0- 19 HPD

10 HDMI2_RXCLK+

9 CN1502 (USB1)

1 USB_VCC 3 USB_DP

2 USB_DM 4 GND

Page 71

5-2-2. UN32D4003BD_UN26D4003BD

5-5

5. Wiring Diagram

9 CN1502 (USB1)

7 CN502 (HDMI1) 8 CN503 (HDMI2)

6 CN403(COMPONETN)

3 CN1201 (FUNCTION) 5 CN1203(DEBUG)

4 CN301 (SPEAKER)

Connector

2 CN202_L_LED (to Powr board)

1 CN1602_L_HD

1 CN1602_L_HD

1 PANEL_VCC 16 ODD_CLK+

2 PANEL_VCC 17 ODD_CLK-

3 PANEL_VCC 18 GND

4 PANEL_VCC 19 ODD2+

5 PANEL_VCC 20 ODD2-

6 GND 21 GND

7 GND 22 ODD1+

8 GND 23 ODD1-

9 WP_PANEL 24 GND

10 LVDS FORMAT 25 ODD0+

11 NC 26 ODD0-

12 GND 27 GND

13 ODD3+ 28 SDA

14 ODD3- 29 SCL

15 GND 30 NC

2 CN202_L_LED (to Powr board)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

3 CN1201 (FUNCTION)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

4 CN301 (SPEAKER)

1 R+ 3 L+

2 R- 4 L-

Page 72

5-6

5. Wiring Diagram

5 CN1203(DEBUG)

1 GND 4 DEBUG_TX

2 DEBUG_RX 5 DEBUG_TX

3 DEBUG_TX 6 GND

6 CN403(COMPONETN)

1 GND 9 GND

2 COMP1_Y 10 GND

3 IDENT_AV 11 SL

4 GND 12 SR

5 PB 13 GND

6 IDENT_COMP 14 SR

7 GND 15 SL

8 PR

7 CN502 (HDMI1)

1 HDMI1_RX2+ 11 GND

2 GND 12 HDMI1_RXCLK-

3 HDMI1_RX2- 13 HDMI_CEC

4 HDMI1_RX1+ 14 GND

5 GND 15 SCL

6 HDMI1_RX1- 16 SDA

7 HDMI1_RX0+ 17 GND

8 GND 18 5V

9 HDMI1_RX0- 19 HPD

10 HDMI1_RXCLK+

8 CN503 (HDMI2)

1 HDMI2_RX2+ 11 GND

2 GND 12 HDMI2_RXCLK-

3 HDMI2_RX2- 13 HDMI_CEC

4 HDMI2_RX1+ 14 GND

5 GND 15 SCL

6 HDMI2_RX1- 16 SDA

7 HDMI2_RX0+ 17 GND

8 GND 18 5V

9 HDMI2_RX0- 19 HPD

10 HDMI2_RXCLK+

9 CN1502 (USB1)

1 USB_VCC 3 USB_DP

2 USB_DM 4 GND

Page 73

5-2-3. UN22D5003BF

5-7

5. Wiring Diagram

2 CN201_S_LED (to Powr board)

9 CN1502 (USB1)

7 CN502 (HDMI1) 8 CN503 (HDMI2)

6 CN403(COMPONETN)

1 CN1603_S_FHD

3 CN1201 (FUNCTION)

5 CN1203(DEBUG)

4 CN301 (SPEAKER)

Connector

1 CN1603_S_FHD

1 PANEL_VCC 16 ODD_CLK+

2 PANEL_VCC 17 ODD_CLK-

3 PANEL_VCC 18 GND

4 PANEL_VCC 19 ODD2+

5 PANEL_VCC 20 ODD2-

6 GND 21 GND

7 GND 22 ODD1+

8 GND 23 ODD1-

9 WP_PANEL 24 GND

10 LVDS FORMAT 25 ODD0+

11 NC 26 ODD0-

12 GND 27 GND

13 ODD3+ 28 SDA

14 ODD3- 29 SCL

15 GND 30 NC

2 CN201_S_LED (to Powr board)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

3 CN1201 (FUNCTION)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V

5 GND 12 NC

6 GND 13 B13V

7 B12VS 14 PWM_DIMM

4 CN301 (SPEAKER)

1 R+ 3 L+

2 R- 4 L-

Page 74

5-8

5. Wiring Diagram

5 CN1203(DEBUG)

1 GND 4 DEBUG_TX

2 DEBUG_RX 5 DEBUG_TX

3 DEBUG_TX 6 GND

6 CN403(COMPONETN)

1 GND 9 GND

2 COMP1_Y 10 GND

3 IDENT_AV 11 SL

4 GND 12 SR

5 PB 13 GND

6 IDENT_COMP 14 SR

7 GND 15 SL

8 PR

7 CN502 (HDMI1)

1 HDMI1_RX2+ 11 GND

2 GND 12 HDMI1_RXCLK-

3 HDMI1_RX2- 13 HDMI_CEC

4 HDMI1_RX1+ 14 GND

5 GND 15 SCL

6 HDMI1_RX1- 16 SDA

7 HDMI1_RX0+ 17 GND

8 GND 18 5V

9 HDMI1_RX0- 19 HPD

10 HDMI1_RXCLK+

8 CN503 (HDMI2)

1 HDMI2_RX2+ 11 GND

2 GND 12 HDMI2_RXCLK-

3 HDMI2_RX2- 13 HDMI_CEC

4 HDMI2_RX1+ 14 GND

5 GND 15 SCL

6 HDMI2_RX1- 16 SDA

7 HDMI2_RX0+ 17 GND

8 GND 18 5V

9 HDMI2_RX0- 19 HPD

10 HDMI2_RXCLK+

9 CN1502 (USB1)

1 USB_VCC 3 USB_DP

2 USB_DM 4 GND

Page 75

5-2-4. UN40D5003BF

5-9

5. Wiring Diagram

9 CN1502 (USB1)

7 CN502 (HDMI1) 8 CN503 (HDMI2)

6 CN403(COMPONETN)

3 CN1201 (FUNCTION)

4 CN301 (SPEAKER)

Connector

2 CN202_L_LED (to Powr board)

1 CN1601_L_FHD (to Panel)

5 CN1203(DEBUG)

1 CN1601_L_FHD (to Panel)

1 NC 27 EVEN[0]-

2 NC 28 GND

3 NC 29 ODD[4]+

4 NC 30 ODD[4]-

5 NC 31 ODD[3]+

6 NC 32 ODD[3]-

7 FORMAT 33 GND

8 SDA_Panel 34 ODDCLK+

9 TCON_WP 35 ODDCLK-

10 NC 36 GND

11 SDA_Panel 37 ODD[2]+

12 SCL_Panel 38 ODD[2]-

13 GND 39 ODD[1]+

14 EVEN[4]+ 40 ODD[1]-

15 EVEN[4]- 41 ODD[0]+

16 EVEN[3]+ 42 ODD[0]-

17 EVEN[3]- 43 GND

18 GND 44 GND

19 EVENCLK+ 45 GND

20 EVENCLK- 46 NC

21 GND 47 Panel_VCC

22 EVEN[2]+ 48 Panel_VCC

23 EVEN[2]- 49 Panel_VCC

24 EVEN[1]+ 50 Panel_VCC

25 EVEN[1]- 51 Panel_VCC

26 EVEN[0]+

2 CN202_L_LED (to Powr board)

1 B5V 8 GND

2 SW_POWER 9 B12VS

3 B5V 10 SW_INVERTER

4 A5V 11 B13V