Page 1

LCD-Monitor

Chassis : LS22TDS / LS20TDS

Model :

SERVICE

T220M / T200M

Manual

TFT-LCD Monitor Contens

1. Precautions

2. Product specications

3. Disassembly and Reassemble

4. Troubleshooting

5. Exploded View & Part List

6. Wiring Diagram

7. Schematic Diagram

T220M / T200M

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Page 2

Contents

1. Precautions ..............................................................................................................1-1

1-1. Safety Precautions .........................................................................................................1-1

1-2. Servicing Precautions .....................................................................................................1-2

1-3. Static Electricity Precautions ..........................................................................................1-2

1-4. Installation Precautions ..................................................................................................1-3

2. Product specications ............................................................................................2-1

2-1. Feature & Specications .................................................................................................2-1

2-2. Spec Comparison to the Old Models

2-3. Accessories

....................................................................................................................2-4

3. Disassembly and Assembly ................................................................................... 3-1

3-1. Disassembly ...................................................................................................................3-1

4. Troubleshooting ......................................................................................................4-1

4-1. First Checklist for Troubleshooting ................................................................................4-1

4-2. No Power

4-3. No Video (Analog PC)

4-4. No Video (Digital-HDMI) .................................................................................................4-7

4-5. No Picture (Tuner_CVBS) ............................................................................................4-10

4-6. No Picture (AV) .............................................................................................................4-13

4-7. No Picture (S-VIDEO) ...................................................................................................4-16

4-8. No Picture (Component) ...............................................................................................4-19

4-9. No Sound ......................................................................................................................4-22

4-10. Faults and Corrective Actions .....................................................................................4-25

4-11. Adjustment ..................................................................................................................4-26

4-13. Service Adjustment .....................................................................................................4-27

........................................................................................................................4-2

...................................................................................................4-4

..............................................................................2-3

5. Exploded View & Part List ...................................................................................... 5-1

5-1. Exploded View -20” .........................................................................................................5-1

5-2. Parts List .....................................................................................................................................................5-3

5-3. Exploded View -22” .......................................................................................................5-20

5-4. Parts List ...................................................................................................................................................5-22

6. Wiring Diagram ........................................................................................................6-1

6-1. Wiring Diagram - Main Board .........................................................................................6-1

6-2. Wiring Diagram - IP Board ..............................................................................................6-2

6-3. Connector Functions ......................................................................................................6-3

6-4. Cables ............................................................................................................................6-3

7. Schematic Diagram ................................................................................................. 7-1

7-1. Circuit Descriptions .........................................................................................................7-1

7-2. Block description

7-3. Schematic Diagrams ......................................................................................................7-3

7-3-1. Schematic Diagrams (POWER) ..................................................................................7-3

7-3-2. Schematic Diagrams (SOUND) ..................................................................................7-4

7-3-3. Schematic Diagrams -SIGNAL INPUT (HDMI)

7-3-4. Schematic Diagrams - SIGNAL INPUT (Component)

7-3-5. Schematic Diagrams - Scaler/LVDS Output ................................................................7-7

7-3-6. Schematic Diagrams - Tuner .......................................................................................7-8

7-3-7. Schematic Diagrams - PCMCIA ..................................................................................7-9

7-3-8. Schematic Diagrams - TV PCMCIA

7-3-9. Schematic Diagrams - SIGNAL INPUT (DVI)

............................................................................................................7-2

............................................................7-5

.................................................7-6

...........................................................................7-10

............................................................ 7-11

Page 3

GSPN (Global Service Partner Network)

Area Web Site

North America http://service.samsungportal.com

Latin America http://latin.samsungportal.com

CIS http://cis.samsungportal.com

Europe http://europe.samsungportal.com

China http://china.samsungportal.com

Asia http://asia.samsungportal.com

Mideast & Africa http://mea.samsungportal.com

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© 2008 Samsung Electronics Co.,Ltd.

All rights reserved.

Printed in Korea

P/N: BN82-00479A-00

Page 4

1. Precautions

1. Precautions

1-1. Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1-1. Warnings

For continued safety, do not attempt to modify the circuit board.

1.

Disconnect the AC power and DC power jack before servicing.

2.

1-1-2. Servicing the LCD Monitor

When servicing the LCD Monitor, Disconnect the AC line cord from the AC outlet.

1.

It is essential that service technicians have an accurate voltage meter available at all times. Check the calibration of

2.

this meter periodically.

1-1-3. Fire and Shock Hazard

Before returning the monitor to the user, perform the following safety checks:

Inspect each lead dress to make certain that the leads are not pinched or that hardware is not lodged between the

1.

chassis and other metal parts in the monitor.

Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet backs, adjustment and

2.

compartment covers or shields, isolation resistorcapacitor networks, mechanical insulators, etc.

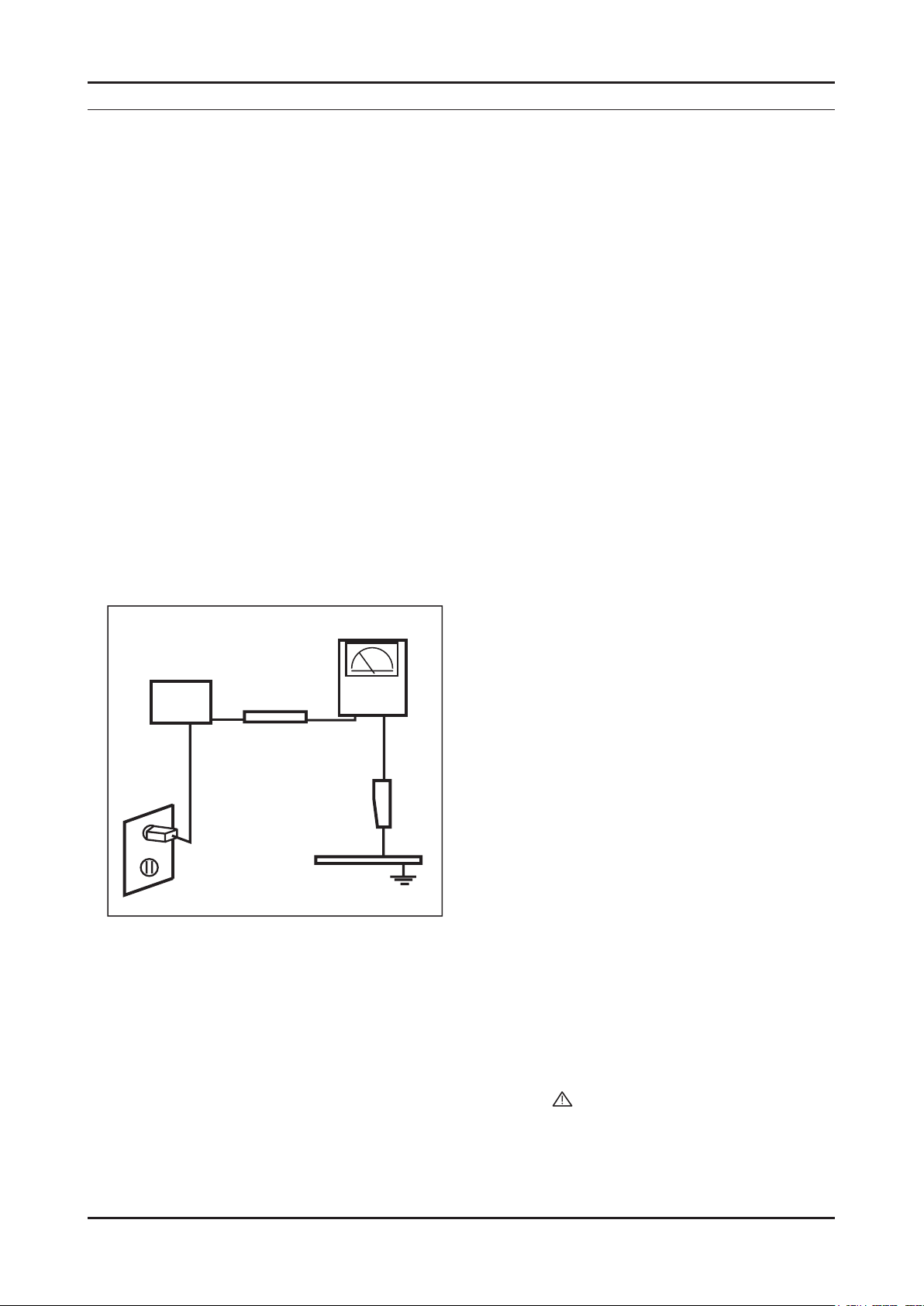

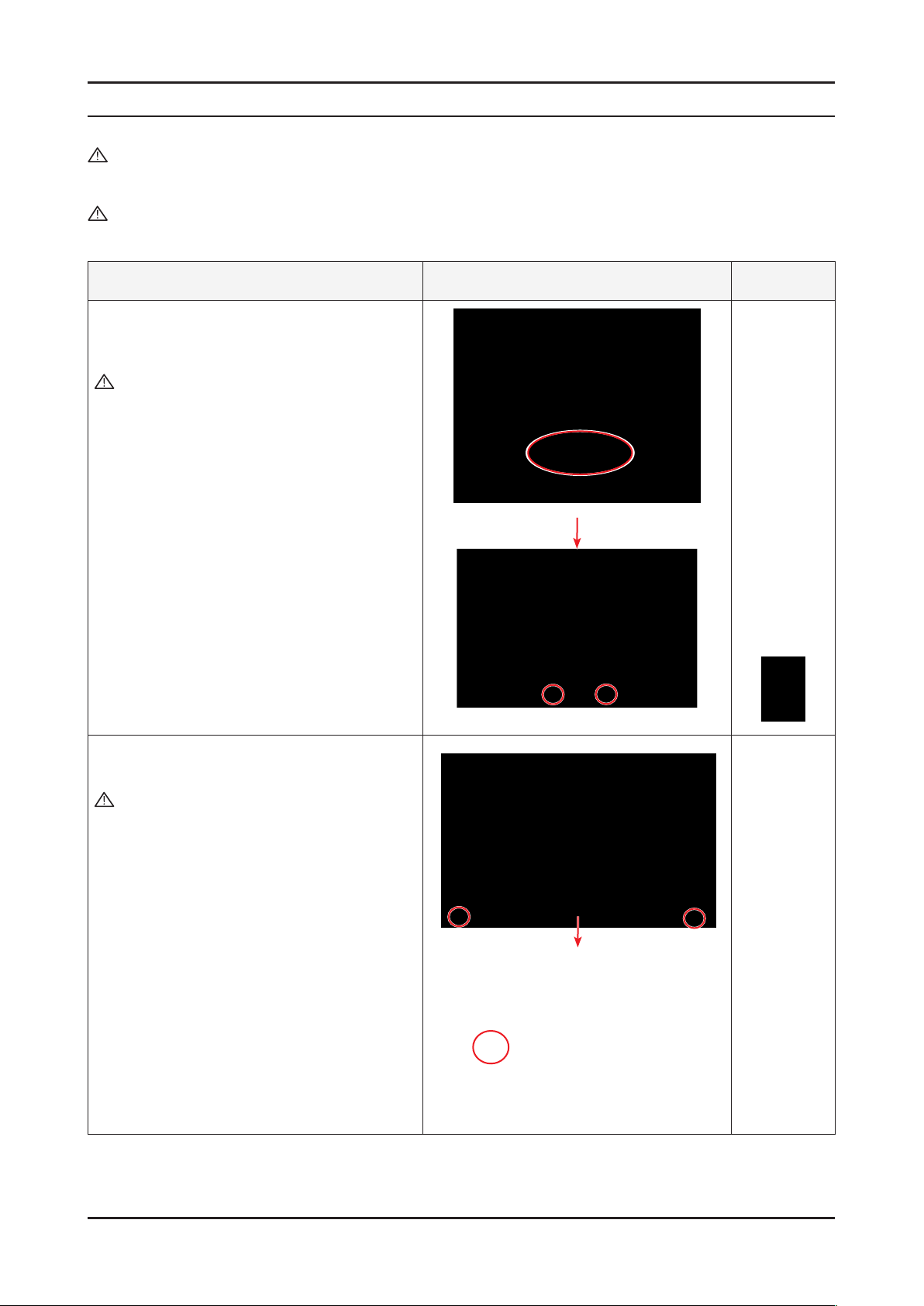

Leakage Current Hot Check (Figure 1-1):

3.

WARNING : Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system that complies with American National Standards Institute (ANSI

C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL Publication UL1410, 59.7).

(READING SHOULD)

NOT BE ABOVE 0.5mA

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit’s AC switch

4.

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

Figure 1-1. Leakage Current Test Circuit

rst in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, conduit,

etc.) and all exposed metal parts, including: metal cabinets, screwheads and control shafts.

The current measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

1-1-4. Product Safety Notices

Some electrical and mechanical parts have special safetyrelated characteristics which are often not evident from visual

inspection. The protection they give may not be obtained by replacing them with components rated for higher voltage,

wattage, etc. Parts that have special safety characteristics are identied by on schematics and parts lists. A substitute

replacement that does not have the same safety characteristics as the recommended replacement part might create

shock, re and/or other hazards. Product safety is under review continuously and new instructions are issued whenever

appropriate.

1-1

Page 5

1-2

1. Precautions

1-2. Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions section of

this manual.

Note: If unforeseen circumstances create conict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-2-1 General Servicing Precautions

Always unplug the unit’s AC power cord from the AC power source and disconnect the DC Power Jack before

1.

attempting to:

(a) remove or reinstall any component or assembly, (b) disconnect PCB plugs or connectors, (c) connect a test

component in parallel with an electrolytic capacitor.

Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes

2.

used. The internal wiring is sometimes clamped to prevent contact with thermally hot components. Reinstall all such

elements to their original position.

After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that

3.

the area around the serviced part has not been damaged.

Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels,

4.

input terminals and earphone jacks).

Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON.

5.

Connect an insulation resistance meter (500 V) to theblades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive parts (see above) should be

greater than 1 megohm.

Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead;

6.

always remove the instrument’s ground lead last.

1-3. Static Electricity Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some eld-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your

1.

body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. To avoid a shock hazard,

be sure to remove the wrist strap before applying power to the monitor.

After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent

2.

accumulation of an electrostatic charge.

Do not use freon-propelled chemicals. These can generate electrical charges sufcient to damage ESDs.

3.

Use only a grounded-tip soldering iron to solder or desolder ESDs.

4.

Use only an anti-static solder removal device. Some solder removal devices not classied as “anti-static” can generate

5.

electrical charges sufcient to damage ESDs.

Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs

6.

are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive

materials.

Immediately before removing the protective material from the leads of a replacement ESD, touch the protective

7.

material to the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing clothes together,

8.

or lifting your foot from a carpeted oor can generate enough static electricity to damage an ESD.

Page 6

1. Precautions

1-4. Installation Precautions

For safety reasons, more than two people are required for carrying the product.

1.

Keep the power cord away from any heat emitting devices, as a melted covering may cause re or electric shock.

2.

Do not place the product in areas with poor ventilation such as a bookshelf or closet. The increased internal

3.

temperature may cause re.

Bend the external antenna cable when connecting it to the product. This is a measure to protect it from being exposed

4.

to moisture. Otherwise, it may cause a re or electric shock.

Make sure to turn the power off and unplug the power cord from the outlet before repositioning the product. Also check

5.

the antenna cable or the external connectors if they are fully unplugged. Damage to the cord may cause re or electric

shock.

Keep the antenna far away from any high-voltage cables and install it rmly. Contact with the highvoltage cable or the

6.

antenna falling over may cause re or electric shock.

When installing the product, leave enough space (10cm) between the product and the wall for ventilation purposes.

7.

A rise in temperature within the product may cause re.

1-3

Page 7

1. Precautions

Memo

1-4

Page 8

2. Product specications

2-1. Feature & Specications

Model T220M / T200M

Feature

�

Supreme Digital Interface & Networking

- With a built-in with no particular set-top box and provides simple access with a single remote control.

�

Excellent Picture Quality

- DNIe technology provides life-like clear images.

Dynamic Contrast

�

- Automatically detects the input visual signal and adjusts to create optimum contrast.

Convenience

�

-The TV utilizes the HDMI system to implement perfect digital sound and picture quality.

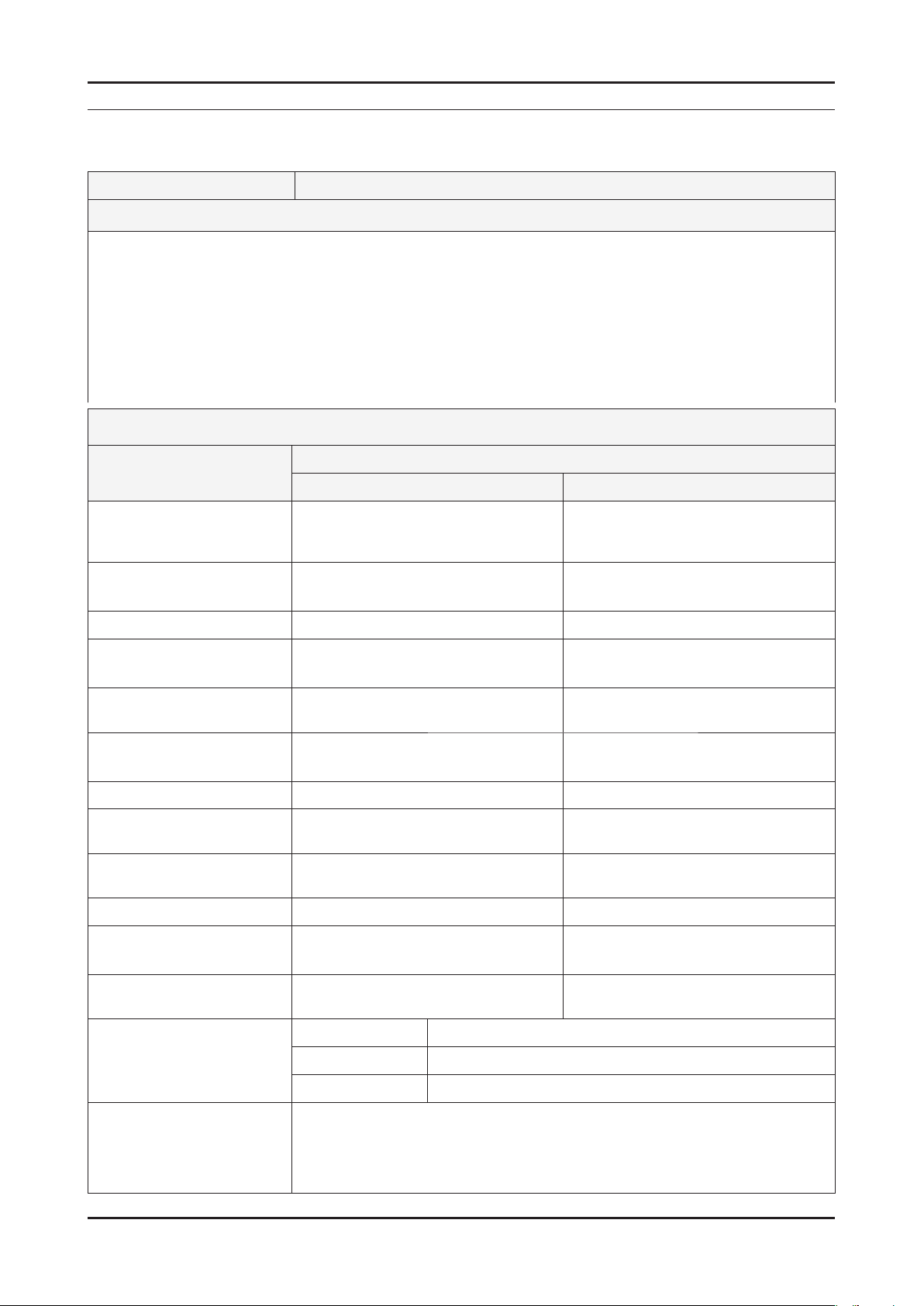

Specications

2. Product specications

Item

LCD Panel TFT-LCD Panel, RGB Vertical strip,

normaly White, 22-Inch viewable,

0.282(H) X 0.282(V)mm Pixel Pitch

Scanning Frequency Horizontal : 30KHz ~ 81KHz(Automatic)

Vertical: 56Hz ~ 75Hz(Automatic)

Display Colors 16.7 Million colors 16.7Million colors

Maximum resolution

Input Signal Analog 0.7Vp-p±10% positive at

Input Sync Signal Type: separate H/V,composite

Maximum Pixel Clock rate 146.250MHz 146.250MHz

Active Display

(Horizontal/Vertical)

AC power voltage &

Frequency

Horizontal: 1680pixels

Vertical: 1050pixels

75Ω,internally terminated

Level : TTL Level

473.76(H) X 296.1(V) 433.44(H) X 270.9(V)

AC 110 ~ 240V, 50 ~ 60 Hz AC110 ~ 240V, 50 ~ 60Hz

T220M T200M

Description

TFT-LCD Panel, RGB Vertical strip,

normaly White, 20.1-Inch viewable,

0.258(H) X 0.258(V)mm Pixel Pitch

Horizontal :30KHz ~ 81KHz(Automatic)

Vertical:56Hz ~ 75Hz(Automatic)

Horizontal : 1680pixels

Vertical:1050pixels

Analog 0.7Vp-p±10% positive at

75Ω,internally terminated

Type: separate H/V,composite

Level : TTL Level

Power Consumption

Dimensions Set

(W x D x H)

Weight Set

(After installation Stand)

TV System Tuning Frequency Synthesize

Environmental Considerations Operating Temperature: 50˚C ~ 104˚F(10˚C ~ 40˚C)

54W < 2W 50W < 2W

520x215x441.5mm (After installation stand)

520x86.5x373.5mm (Without stand)

6.2kg 6.0kg

System NT3.58, PAL-M, PAL-N

Sound MONO, STEREO

Operating Humidity : 10% ~ 80%

Storage Temperature: -4˚C ~ 113˚C(-20˚C ~ 45˚C)

Storage Humidity: 5% ~ 95%

486x215x417.5mm (After installation stand)

486x86x350mm (Without stand)

2-1

Page 9

2-2

2. Product specications

Specications

Item

Antenna Input 75Ω

Sound Characteristic

-MAX Internal speaker Out : Right : 3W / Left : 3W

-BASS Control Range : -8 dB ~ + 8dB

-TREBLE Control Range : -8 dB ~ +8 dB

-Headphone Out : 10 mW MAX

-Output Frequency : RF : 80 Hz ~ 15 kHz

Description

T220M T200M

A/V : 80 Hz ~ 20 kHz

Page 10

2-2. Spec Comparison to the Old Models

Model T220M / T200M Curie (225MD)

Design

Screen Size 20” / 22” 22”

2. Product specications

Frequency

Horizontal

Vertical

Display Color

PC Resolution

Maximum mode

Input Signal

Sync Signal

Video Signal

Power Consumption

Normal

Power Saving

WSXGA+, 1680 x 1050 @ 60 Hz 1680 x 1050

H/V Separate, TTL, P. or N.

30 ~ 81 kHz

56 ~ 75 Hz

16,777,216 colors

0.7 Vp-p @ 75ohm

22” 54W < 2W

20” 50W < 2W

30 ~ 81 kHz

56 ~ 75 Hz

16,777,216 colors

H/V Separate, TTL, P. or N.

0.7 Vp-p @ 75ohm

58W < 2W

*Color Effect

- Grey scale: Images are displayed in a grey tone on the screen.

- Green: Images are displayed in a green tone on the screen.

- Aqua: Images are displayed in a blue tone on the screen.

- Sepia: Images are displayed in a brown tone on the screen.

Image Size : : If the resolution is not wide resolution, this option allows the screen size to be selected as normal or wide.

2-3

Page 11

2. Product specications

2-3. Accessories

Product Description Ccde. No Remark

Remote Control

&

Batteries (AAA x 2)

Power Cord 3903-000190

Stand Body BN96-07347D

Stand Base BN96-07345A

BN59-00678A

Samsung Electronics

Service center

D-Sub Cable BN39-00244G

User’s Guide,

Monitor Driver,

Natural Color Pro Software

Cleaning Cloth BN63-01798A

BN96-07540A

2-4

Page 12

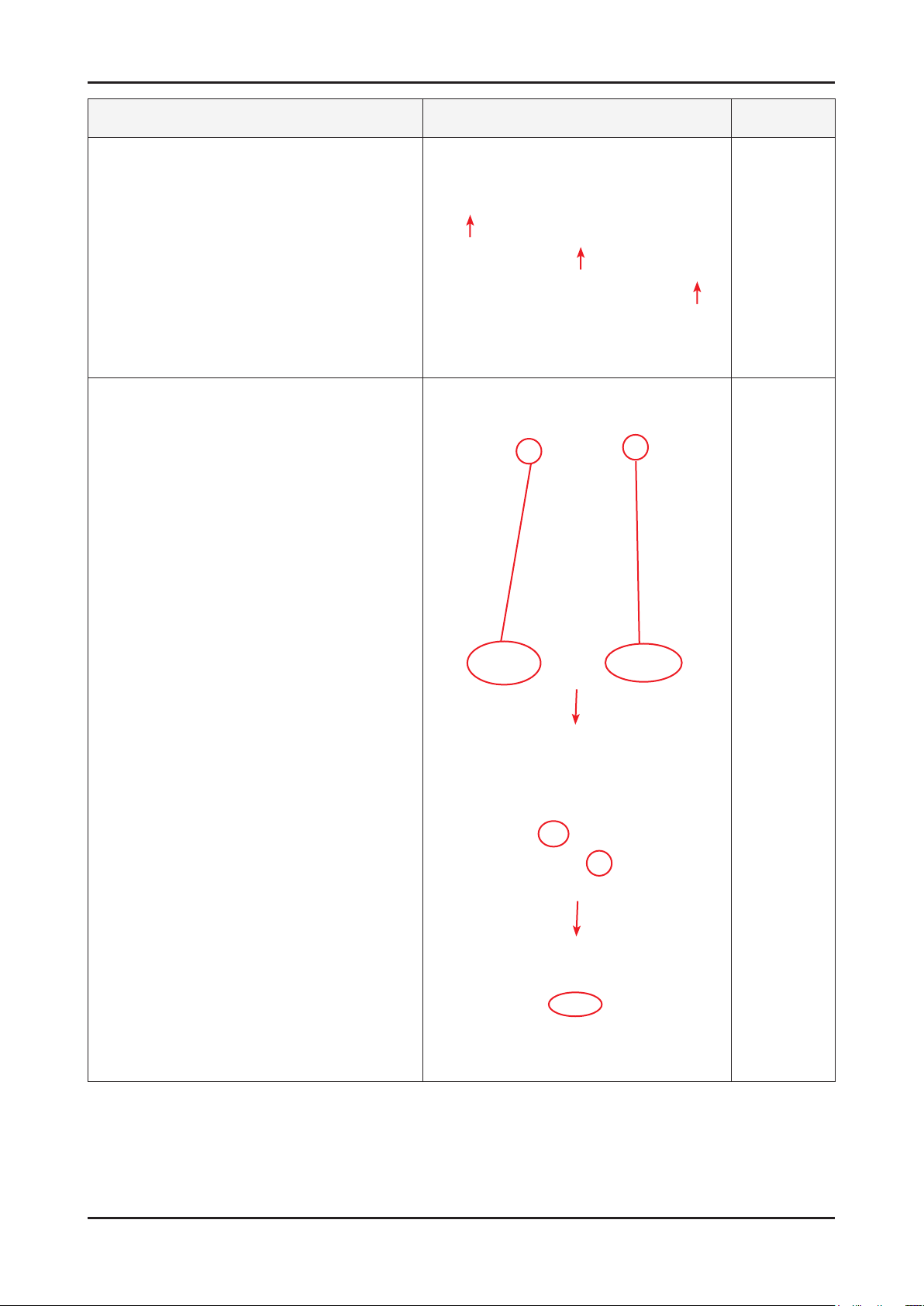

3. Disassembly and Assembly

3. Disassembly and Assembly

This section describes the disassembly and reassembly sequences for this monitor.

Warning: As this monitor has parts that are sensitive to static electricity, be careful when handling them.

3-1. Disassembly

Caution: 1. Turn the monitor off before beginning the disassembly process.

2. When disassembling the monitor, do not use any metal tools except for the provided jig.

3. Remove the signal cable and the power cord before beginning the disassembly.

Description Photo Screws

1. Place monitor face down on cushioned table.

Remove Stand, then remove 2 marked screws

from the rear cover.

Caution : If you do not tilt the stand and use too

much force to remove it, the connection

pin may break.

2. Remove the cover and the LCD panel using the

provided jig on both grooves at the bottom.

Caution : Remove the cover and the LCD panel

using the provided jig on both grooves

at the bottom.

3-1

Page 13

3-2

3. Disassembly and Assembly

Description Photo Screws

3. Insertaatscrewdriverintothegrooveandthen

lift up and remove the cover.

4. After remove COVER-REAR, then disconnect

SPEAKER , FUNCTION wire.

5. Disconnect LVDS cable from panel.

Page 14

Description Photo Screws

6. After disconnecting SHIELD-LAMP of left side,

disassemble lamp wire between panel and IP

Board.

3. Disassembly and Assembly

7. Remove 8 marked SCREW of left picture.

Disconnect IP board.

※ Reassembly procedures are in the reverse order

of disassembly procedures.

8. Remove the LCD panel.

3-3

Page 15

3-4

3. Disassembly and Assembly

Description Photo Screws

9. Remove the IR module by tilting the left snap to

the right.

10. Remove the LED module by sliding the snap

designatedintherightgurebackwards.

11. Remove the two (2) screws and then remove the

holders from the four (4) snaps designated in the

rightgureusingtheprovidedjig.

Page 16

Description Photo Screws

12. Remove the two (2) connectors.

Caution : Servicing is not supported for the PCB.

▶Assembly

3. Disassembly and Assembly

13. The assembly is in the reverse order of the

disassembly.

14. Connect the disassembled snap and the LED

module again.

15.Fixtheconnectingwirewithlamenttape

Caution : If the wire is damaged when closing the

cover, an operating error may occur.

Therefore, make sure to close the

coverafterxingitwithlamenttape.

※ The assembly is in the reverse order of disassembly.

lamenttape

3-5

Page 17

3. Disassembly and Assembly

Memo

3-6

Page 18

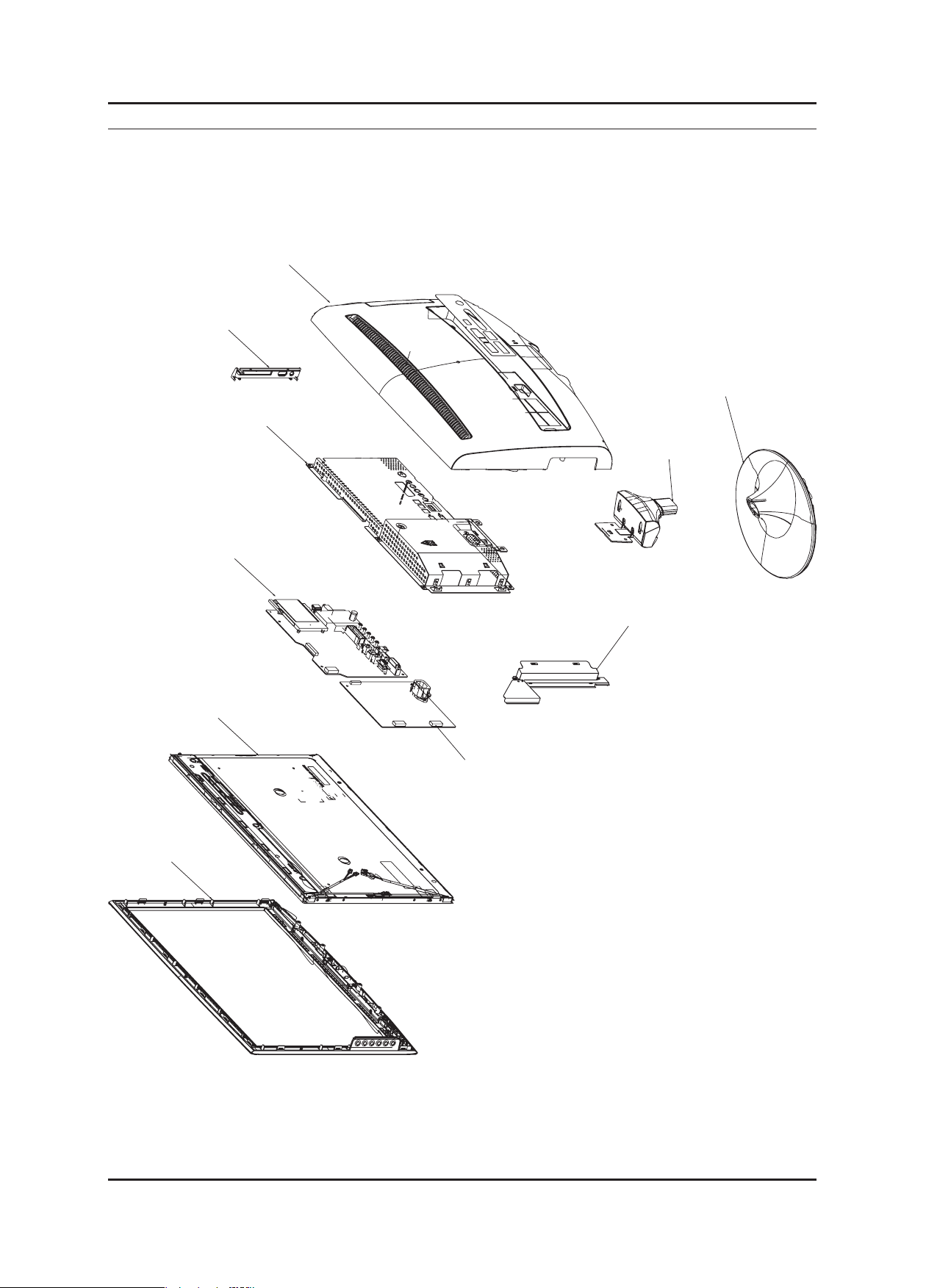

5. Exploded View & Part List

T0003

M0215

M0014

M0006

T0279

M0013

M0090

STD

M0027

M0174

5-1. LS20TDSSUMZD - Exploded View (T220M)

5. Exploded View & Part List

5-1

Page 19

5-2

5. Exploded View & Part List

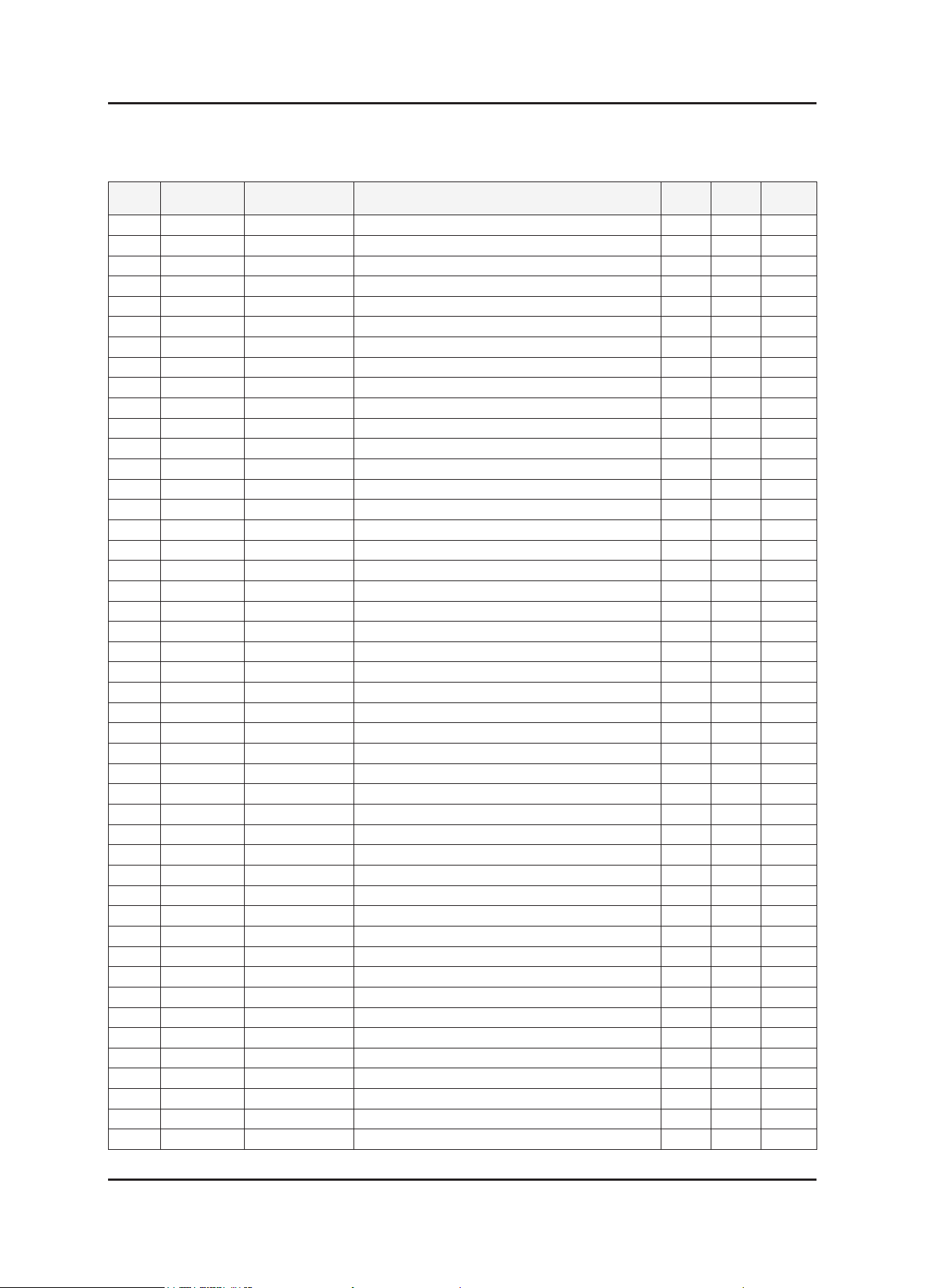

5-1-1. LS20TDSSUMZD - Parts List (T220M)

Location No. Code No. Description & Specication Q’ty SA/SNA Remark

M0006 BN96-08149G ASSY SHIELD P-COVER;LS20TD(ANALOG),SECC 1 S.N.A

M0013 BN96-07447H ASSY COVER P-REAR;LS20TD(ANALOG),PMMA AB 1 S.A

M0014 BN94-01893R ASSY PCB MAIN;LS20TDSSU/ZB 1 S.A

M0027 BN96-07345B ASSY STAND P-BASE;LS22TW,ABS HB PMMA,RD0 1 S.A

M0090 BN96-08016A ASSY SHIELD P-LAMP;LS20TD(MFM),SPTE,T 0. 1 S.N.A

M0174 BN44-00177D IP BOARD;PWI2204ST(A),T 20” MFM,1.4 ~2.8 1 S.A

M0215 BN07-00374A LCD-PANEL;CLAA201WA04 1 S.A

STD BN96-07347D ASSY STAND P-BODY;LS22TD,PMMA ABS HB, SM 1 S.A

T0003 BN96-07446L ASSY COVER P-FRONT;LS20TD,BRAZIL,PMMA+AB 1 S.A

T0279 BN63-05063A COVER-JACK;T220M ANALOG,ABS + PC,HB,BK26 1 S.N.A

Page 20

5-3

5. Exploded View & Part List

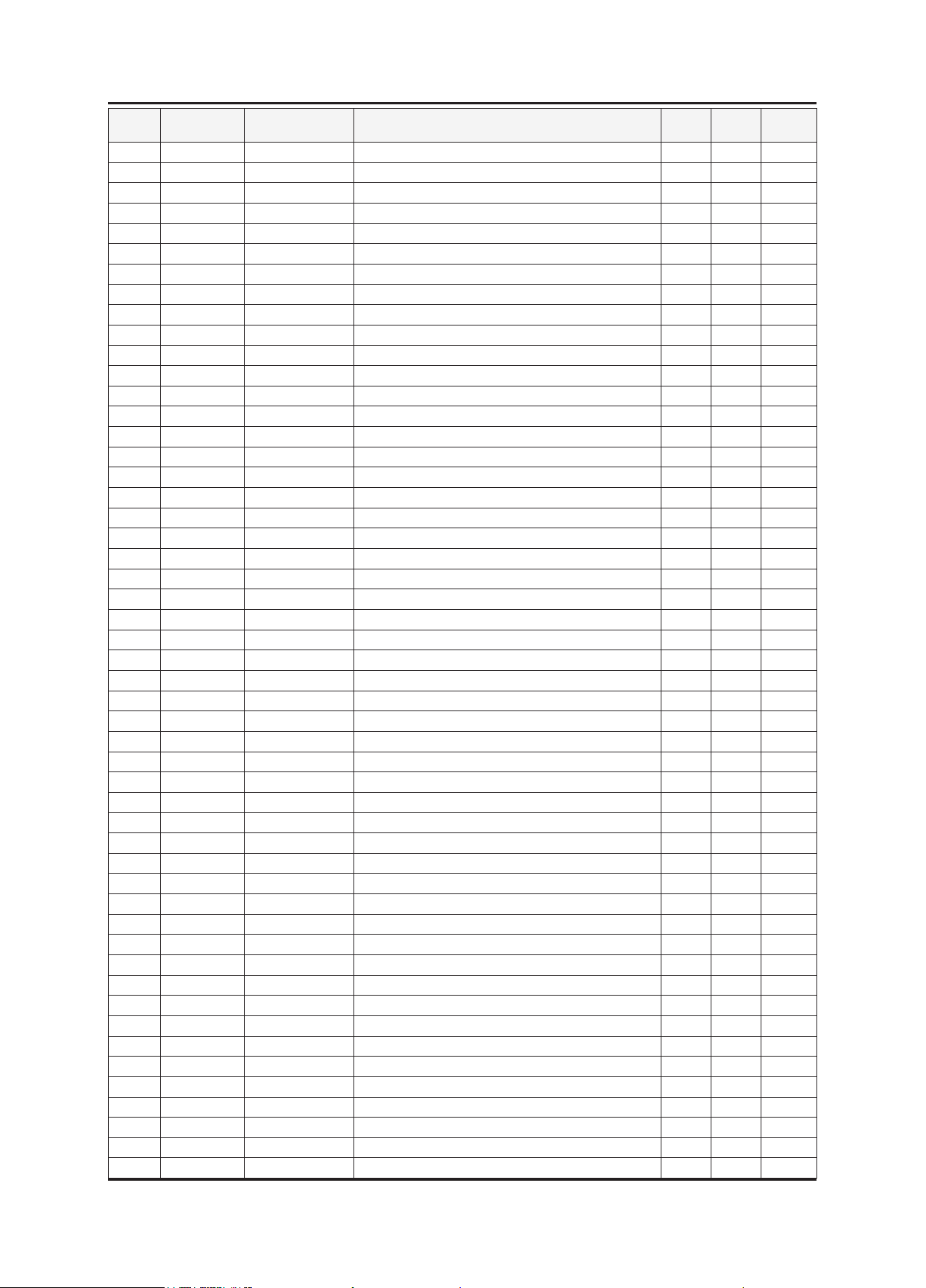

5-2. LS20TDSSUMZD Parts List

Service Bom (SA: SERVICE AVAILABLE, SNA: SERVICE NOT AVAILABLE)

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

LS20TDSSUMZD T200M,WST1/S20A4-LTD,20,LCD-MO,BRAZIL

0.1 M0001 BN90-01634H ASSY COVER FRONT;LS20TD_MFM,TOC,ROSE BLA 1 S.N.A

..2 M0081 6006-001096 SCREW-TAPTITE;BH,+,WP,B,M4.0,L12,ZPC(BLK 4 S.N.A

..2 T0175 BN96-06823C ASSY SPEAKER P;16ohm,T-project,MFM,3W,11 1 S.A

...3 BN83-00813A CKD-SPEAKER;Bordeaux New Rubber,pi 15 x 4 S.N.A

...3 BN83-01026A CKD-SPEAKER;L530 32” Fullrange Sleeve-#1 2 S.N.A

...3 BN83-01027A CKD-SPEAKER;L530 32” Fullrange Sleeve-#1 2 S.N.A

...3 BN83-01322A CKD-SPEAKER;T-MFM Speaker Unit,63mm X 35 2 S.N.A

...3 BN83-01323A CKD-SPEAKER;T-MFM Speaker Holder,95mm X 2 S.N.A

...3 BN83-01324A CKD-SPEAKER;T-MFM Speaker Wire Ass’y,4Pi 1 S.N.A

...3 BN83-01325A CKD-SPEAKER;T-MFM Speaker Cushion,52 X23 2 S.N.A

...3 BN83-01326A CKD-SPEAKER;T-MFM Speaker Label,20mmX10m 1 S.N.A

...3 BN83-00781A CKD-SPEAKER;Bordeax26 Screw,pi3 * 6mm 8 S.N.A

..2 T0003 BN96-07446L ASSY COVER P-FRONT;LS20TD,BRAZIL,PMMA+AB 1 S.A

...3 M0081 6003-000282 SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(BLK),SW 2 S.N.A

...3 M0960 BN61-03932A HOLDER-BOSS;T200,PMMA+ABS HB,WH15 1 S.N.A

...3 CCM1 BN63-02183D COVER-SHEET;Rhcm,PE Vinyl,T0.05,680mm,20 1 S.N.A

...3 M0112 BN63-04426X COVER-FRONT;LS20TD(ANALOG),PMMA+ABS,ROSE 1 S.N.A

...3 M0145 BN96-07556D ASSY BOARD P-FUNCTION;T220HD,CT5000-5800 1 S.A

....4 BN94-02473F ASSY PCB MAIN-FUNCTION PCB;LS22TDSSUMZD 1 S.N.A

.....5 M2893 BN39-01051B LEAD CONNECTOR;T-MFM24,UL1571#30,UL1571# 1 S.A

.....5 T0174 BN97-02920J ASSY SMD;LS22TDSSUMZD 1 S.N.A

......6 D3 0406-001172 DIODE-TVS;CDS3C30GTH,48/-/50V,SMD 1 S.A

......6 D4 0406-001172

......6 R6 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

......6 R7 2007-000076 R-CHIP;330ohm,5%,1/10W,TP,1608 1 S.A

......6 R1 2007-000121 R-CHIP;820ohm,5%,1/10W,TP,1608 1 S.N.A

......6 R4 2007-000121 R-CHIP;820ohm,5%,1/10W,TP,1608 1 S.N.A

......6 R2 2007-000124 R-CHIP;2.2Kohm,5%,1/10W,TP,1608 1 S.N.A

......6 R5 2007-000124 R-CHIP;2.2Kohm,5%,1/10W,TP,1608 1 S.N.A

......6 C3 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

......6 C4 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0313 3404-001209 SWITCH-TACT;12VDC,50mA,250gf,4.5x4.5x1.5 1 S.A

......6 T0077 BN41-01011A PCB MAIN;T220HD,FR-4,2L,PCB1.0,1.0T 1 S.N.A

....4 BN94-02473K ASSY PCB MAIN-IR PCB;LS22TDSSUMZD 1 S.N.A

.....5 M2893 BN39-01052B LEAD CONNECTOR;T200HD,UL1571#30,UL,5P,20 1 S.A

.....5 M2893 BN39-01053A LEAD CONNECTOR;T220D,UL1571#30,8P,200mm, 1 S.A

.....5 T0174 BN97-02902J ASSY SMD;LS22TDSSUMZD 1 S.N.A

......6 D1 0403-000510 DIODE-ZENER;MTZJ6.2B,5.96-6.27V,500mW,DO 1 S.A

......6 R1 2001-000290 R-CARBON;10Kohm,5%,1/8W,AA,TP,1.8x3.2mm 1 S.N.A

DIODE-TVS;CDS3C30GTH,48/-/50V,SMD 1 S.A

Page 21

5-4

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

......6 C 2401-001507 C-AL;47uF,20%,16V,GP,TP,6.3x5,5 1 S.A

......6 T0077 BN41-01013A PCB MAIN;T220D,FR-1,1L,PCB1.0,1.6T 1 S.N.A

.....5 D0254 0609-001204 MODULE REMOCON;HORIZONTAL,6.5mm,TR 1 S.N.A

....4 BN94-02473N ASSY PCB MAIN-POWER PCB;LS22TDSSUMZD 1 S.N.A

.....5 BN81-02334A A/S-DOUBLE SIDE TAPE;T MFM POWER,103*52, 1 S.N.A

.....5 T0174 BN97-02902K ASSY SMD;LS22TDSSUMZD 1 S.N.A

......6 R1 2007-000819 R-CHIP;390Kohm,5%,1/10W,TP,1608 1 S.N.A

......6 C1 2203-000125 C-CER,CHIP;1.2nF,10%,50V,X7R,TP,1608,- 1 S.A

......6 C5 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

......6 CN330 3711-002162 HEADER-BOARD TO CABLE;BOX,2P,1R,1.25mm,S 1 S.A

......6 CN330 3711-005935 HEADER-BOARD TO CABLE;BOX,4P,1R,1mm,SMD- 1 S.A

......6 CN906 3711-006471 CONNECTOR-HEADER;BOX,5P,1R,1mm,SMD-A,AU, 1 S.N.A

......6 IC125 BN13-00007A IC ASIC;ADA03,6,2.2 TO 6.5 V,-20 TO +75 1 S.N.A

......6 T0077 BN41-01012A PCB MAIN;T220D,FR-4,2L,PCB1.0,1.6T 1 S.N.A

.....5 M0102 BN96-07569B ASSY BLU P;T220HD,A7-10040180-A0,WHITE,B 1 S.A

...3 BN64-00843A KNOB-GUIDE;T220HD,PMMA ABS,HB,BK23,H/GLO 1 S.N.A

...3 T0022 BN64-00845A KNOB CONTROL;T220HD,PMMA ABS,HB,BK23,H/G 1 S.N.A

0.1 M0002 BN90-01635D ASSY COVER REAR;LS20TD_MFM,ANALOG 1 S.N.A

..2 M0013 BN96-07447H ASSY COVER P-REAR;LS20TD(ANALOG),PMMA AB 1 S.A

...3 M0081 6003-000282 SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(BLK),SW 2 S.N.A

...3 BN61-03947A GUIDE-CONTROL;T200D / T220D / T240D / T2 2 S.N.A

...3 CCM1 BN63-02183D COVER-SHEET;Rhcm,PE Vinyl,T0.05,680mm,20 0.5

...3 M0006 BN63-04435A COVER-REAR;T200D,PMMA+ABS,HB,BK23,H/GLOS 1 S.N.A

...3 T0071 BN64-00959A INLAY-TERMINAL;T220N ANALOG,PS SHEET T0. 1 S.N.A

...3 M0126 BN73-00096A RUBBER-PANEL;BI19BS,RUBBER,T1.0,50~60,NT 2 S.N.A

...3 T0151 BN64-00861A DOOR-CONTROL;T( 20W MFM),ABS HB,BK23,H/G 1 S.N.A

..2 M0081 6003-001086 SCREW-TAPTITE;BH,+,-,B,M3,L12,ZPC(BLK),S 4 S.A

0.1 M0135 BN91-01517B ASSY LCD-PTZ;LS20MEW* 1 S.N.A

..2 M0215 BN07-00374A LCD-PANEL;CLAA201WA04 1 S.A

0.1 M0112 BN91-02443C ASSY SHIELD;LS20TD_MFM,TOC,ANALOG 1 S.N.A

..2 T0279 BN63-05063A COVER-JACK;T220M ANALOG,ABS + PC,HB,BK26 1 S.N.A

..2 M0090 BN96-08016A ASSY SHIELD P-LAMP;LS20TD(MFM),SPTE,T 0. 1 S.N.A

...3 BN63-04401A SHIELD-LAMP;T(22W MFM),SPTE,T 0.3 1 S.N.A

...3 M0125 BN63-04772A SHIELD-PANEL;LS20TD,SPTE,0.3 1 S.N.A

0.1 M0017 BN91-02524G ASSY CHASSIS;LS20TDSSU/ZB 1 S.N.A

..2 M0081 6003-000275 SCREW-TAPTITE;BH,+,-,B,M3,L10,ZPC(BLK),S 3 S.N.A

..2 M0081 6003-000275 SCREW-TAPTITE;BH,+,-,B,M3,L10,ZPC(BLK),S 4 S.N.A

..2 M0081 6003-001439 SCREW-TAPTITE;BH,+,-,S,M4,L8,ZPC(WHT),SW 1 S.N.A

..2 T0562 6046-001014 STAND OFF;#4-40,L6,NI PLT,C3601,- 4 S.N.A

..2 M0174 BN44-00177D IP BOARD;PWI2204ST(A),T 20” MFM,1.4 ~2.8 1 S.A

..2 CCMM1 BN73-00143A SILICON/RUBBER;CURIE,SILICON+ALUMINA,W13 1 S.N.A

..2 CCMM1 BN73-00192A SILICON/RUBBER;T-MFM,GAPPAD1500,20X20X8 1 S.N.A

..2 M0014 BN94-01893R ASSY PCB MAIN;LS20TDSSU/ZB 1 S.A

...3 T0245 0202-001608 SOLDER-WIRE FLUX;LFC7-107,D0.8,99.3Sn/0. 0.025 S.N.A

...3 CN3000

...3 CN9001 3701-001386 CONNECTOR-DVI;24P,3R,FEMALE,AU 1 S.A

...3 CN906 3707-001081 CONNECTOR-OPTICAL;STRAIGHT,SPDIF 1 S.A

3701-001385 CONNECTOR-DSUB;15P,3R,FEMALE,STRAIGHT,AU 1 S.A

S.N.A

Page 22

5-5

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

...3 CN330 3711-006715 HEADER-BOARD TO CABLE;BOX,4P,1R,2.5mm,AN 1 S.N.A

...3 JA330 3722-002176 JACK-PHONE;7P/4C,SN,L-BLU,STRAIGHT 1 S.A

...3 CN3005 3722-002275 JACK-DIN;4P,SN,BLK,ANGLE 1 S.A

...3 CN2003 3722-002680 JACK-EAR PHONE;6P,NiSn,BLK,ANGLE 1 S.A

...3 JA333 3722-002702 JACK-PIN;3P,Ni,GRN/BLU/RED,STRAIGHT 1 S.A

...3 JA333 3722-002781 JACK-PIN;2P(Shield),Ni,WHT/RED,straight 1 S.A

...3

...3 CIS3 BN40-00113A TUNER;HTM-6M/13F2S,HTM-6M/13F2S,PAL M,18 1 S.A

...3 T0510 BN97-02567B ASSY SMD-MAIN;LS20TDSSU/ZB 1 S.N.A

....4 SUB05 0202-001477 SOLDER-CREAM;LST309-M,-,D20~45um,96.5Sn/ 2.39 S.N.A

....4 D2006 0401-000133 DIODE-SWITCHING;RLS4148,75V,150mA,LL-34, 1 S.A

....4 D2007 0401-000133 DIODE-SWITCHING;RLS4148,75V,150mA,LL-34, 1 S.A

....4 D2008 0401-000133 DIODE-SWITCHING;RLS4148,75V,150mA,LL-34, 1 S.A

....4 D2009 0401-000133 DIODE-SWITCHING;RLS4148,75V,150mA,LL-34, 1 S.A

....4 D2022 0401-000133 DIODE-SWITCHING;RLS4148,75V,150mA,LL-34, 1 S.A

....4 D1003 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D2003 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3003 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3004 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3006 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3007 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3008 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3009 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3010 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3011 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3012 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3013 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3014 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3015 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3016 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3230 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D4102 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D4109 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D4110 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D4111 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9301 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9302 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9303 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9304 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9305 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9306 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9307 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D9308 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D2010

....4 D3244 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D4112 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D4113 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D4114 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D0254 0402-000553 DIODE-SCHOTTKY;SS24/B240,40V,2000mA,DO-2 1 S.A

....4 D2004 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

TUNER_

GASK

AA63-01388A GASKET-EMI,SPONGE;SP-P300M,Conductive Fa 1 S.A

0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

Page 23

5-6

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 D2023 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3005 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3017 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3018 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3019 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3020 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3021 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D5001 0403-000002 DIODE-ZENER;VLZ5V6B,5.45/5.73V,500mW,SOD 1 S.A

....4 D3022 0403-000258 DIODE-ZENER;BZX84C5V6,5.2-6V,225mW,SOT-2 1 S.A

....4 D9300 0403-000579 DIODE-ZENER;BZX84C5V1,4.8-5.4V,200mW,SOT 1 S.A

....4 D9317 0403-000579 DIODE-ZENER;BZX84C5V1,4.8-5.4V,200mW,SOT 1 S.A

....4 D3002 0403-000771 DIODE-ZENER;VLZ6V2B,5.96-6.27V,500mW,SOD 1 S.A

....4 D3001 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200mW,SOT-2 1 S.A

....4 D3070 0403-001052 DIODE-ZENER;RD8.2MB,7.7-8.7V,200mW,SOT-2 1 S.A

....4 D1002 0403-001425 DIODE-ZENER;BZX84C33,31-35V,350mW,SOT-23 1 S.A

....4 D9329 0403-001435 DIODE-ZENER;QZX363C5V6,5.32-5.88V,200MW, 1 S.A

....4 D9340 0403-001435 DIODE-ZENER;QZX363C5V6,5.32-5.88V,200MW, 1 S.A

....4 D3029 0407-000123 DIODE-ARRAY;DAN202K,80V,100mA,CA2-3,SOT- 1 S.N.A

....4 D3030 0407-000123 DIODE-ARRAY;DAN202K,80V,100mA,CA2-3,SOT- 1 S.N.A

....4 Q1001 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4 Q1005 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4

....4 Q2005 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4 Q3002 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4 Q3201 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4 Q5005 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

....4 Q1002 0501-002080 TR-SMALL SIGNAL;2SC2412K,NPN,200mW,SC-59 1 S.A

....4 Q1003 0501-002080 TR-SMALL SIGNAL;2SC2412K,NPN,200mW,SC-59 1 S.A

....4 Q1006 0501-002080 TR-SMALL SIGNAL;2SC2412K,NPN,200mW,SC-59 1 S.A

....4 Q9327 0501-002080 TR-SMALL SIGNAL;2SC2412K,NPN,200mW,SC-59 1 S.A

....4 Q409 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7.5ohm,0. 1 S.A

....4 Q409 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7.5ohm,0. 1 S.A

....4 Q409 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7.5ohm,0. 1 S.A

....4 Q409 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7.5ohm,0. 1 S.A

....4 Q409 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7.5ohm,0. 1 S.A

....4 Q409 0505-001170 FET-SILICON;SI9933ADY-T1,P,-20V,3.4A,0.0 1 S.A

....4 Q409 0505-002169 FET-SILICON;Si4435BDY-T1-E3,P,-30V,-9.1A 1 S.N.A

....4 IC105 0909-001032 IC-REAL TIME CLOCK;PCF8563,SOP,8P,4.9x3. 1 S.A

....4 IC106 1001-001516 IC-VIDEO SWITCH;PI3HDMI201ZFE,3HDMI201 : 1 S.A

....4 IC112 1103-000129 IC-EEPROM;24C02,2Kbit,256x8Bit,SOP,8P,5x 1 S.A

....4 IC112 1103-000129 IC-EEPROM;24C02,2Kbit,256x8Bit,SOP,8P,5x 1 S.A

....4 IC112 1103-000129 IC-EEPROM;24C02,2Kbit,256x8Bit,SOP,8P,5x 1 S.A

....4 IC112 1103-001385 IC-EEPROM;AT24C256,256Kbit,32Kx8,SOP,8P, 1 S.A

....4 IC6001 1105-001838

....4 DU410 1201-000166 IC-OP AMP;LM358,SOP,ST,8P,150MIL,DUAL,10 1 S.A

....4 T0124 1201-002430 IC-POWER AMP;NTP-3000,QFN,56P,8x8mm,DUAL 1 S.A

....4 T0085 1201-002487 IC-AUDIO AMP;MAX9728A,QFN,12P,3x3mm,DUAL 1 S.A

....4 T0087 1203-001815 IC-POSI.FIXED REG.;78M09,TO-252,3P,-,PLA 1 S.A

....4 T0087 1203-002842 IC-POSI.FIXED REG.;AP1117D-33A,TO-252,3P 1 S.A

....4 T0087 1203-002842 IC-POSI.FIXED REG.;AP1117D-33A,TO-252,3P 1 S.A

....4 T0087 1203-002974 IC-POSI.FIXED REG.;AP1117D-25A,TO-252,3P 1 S.A

Q2004 0501-000445 TR-SMALL SIGNAL;KTC3875S-Y,NPN,150mW,SOT 1 S.A

IC-DDR SDRAM;EM6A9160TS0A-5G,DDR SDRAM,1 1 S.A

Page 24

5-7

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 T0170 1203-003059 IC-SWITCH VOL. REG.;MP1583,SOIC,8P,4.9x3 1 S.A

....4 T0087 1203-003696 IC-POSI.FIXED REG.;NCP1117DT18T5G,DPAK,3 1 S.A

....4 IC5001 1203-004363 IC-VOL. DETECTOR;RT9818C-29PV,SOT-23,3P, 1 S.A

....4 IC2003 1203-004364 IC-VOL. DETECTOR;RT9818C-42PV,SOT-23,3P, 1 S.A

....4 IC1005 1203-005188 IC-DC/DC CONVERTER;AOZ1021AIL,SOP,8P,4.9 1 S.A

....4 D2001 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D2002 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3023 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3024 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3071 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3072 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3231 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3232 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D3233 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D4115 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 D4117 1405-001233 VARISTOR;30Vdc,5A,1.6x0.8x0.8mm,TP 1 S.A

....4 R1028 2007-000052 R-CHIP;10Kohm,1%,1/10W,TP,1608 1 S.N.A

....4 R1067 2007-000052 R-CHIP;10Kohm,1%,1/10W,TP,1608 1 S.N.A

....4 R1068 2007-000052 R-CHIP;10Kohm,1%,1/10W,TP,1608 1 S.N.A

....4 R1071 2007-000052 R-CHIP;10Kohm,1%,1/10W,TP,1608 1 S.N.A

....4 R6101 2007-000052 R-CHIP;10Kohm,1%,1/10W,TP,1608 1 S.N.A

....4

....4 R1002 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1004 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1063 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1064 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1301 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2013 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2066 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3001 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3002 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3003 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3004 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3005 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3006 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3007 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3008 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3010 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3066 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3259 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3260 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3261 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3264_H 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3265_H 2007-000070

....4 R4058 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R4101 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5001 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5028 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5036 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5037 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5052 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

R1029 2007-000067 R-CHIP;15Kohm,1%,1/10W,TP,1608 1 S.N.A

R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

Page 25

5-8

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 R5057 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5065 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5999 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6012 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6014 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6066_T 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6094 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9348_F3V 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9356 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9357 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3014 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3015 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3027 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3103 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5019 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5020 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5021 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5024 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5027 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5029 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5083 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4

....4 R5203 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5204 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5205 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9318 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9319 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9320 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9321 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9322 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9323 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9324 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9325 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3016 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3017 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3025 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3026 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5032 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5033 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5035 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6010 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6011 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6050 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6051 2007-000072

....4 R9336 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9337 2007-000072 R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2014 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R2017 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R3013 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R3030 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R3064 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

R5084 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 S.N.A

R-CHIP;47ohm,5%,1/10W,TP,1608 1 S.N.A

Page 26

5-9

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 R3065 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R4127 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5009 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5010 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5011 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5017 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5018 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5038 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5039 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5040 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5042 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5043 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5051 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5054 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5055 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5058 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5059 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5060 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5061 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5063 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5067 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4

....4 R5072 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R5073 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R6015 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R6016 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R6020 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R6093 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R9330 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

....4 R1010 2007-000076 R-CHIP;330ohm,5%,1/10W,TP,1608 1 S.A

....4 R2084 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 S.A

....4 R2085 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 S.A

....4 R5041 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 S.A

....4 R5085 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 S.A

....4 R2015 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2021 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2125 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2126 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3009 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3028 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3029 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5002 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R6048 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R6049 2007-000078

....4 R6052 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R6092 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9326 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9328 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9352 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9353 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3036 2007-000081 R-CHIP;2.7Kohm,5%,1/10W,TP,1608 1 S.N.A

R5068 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 S.A

R-CHIP;1Kohm,5%,1/10W,TP,1608 1 S.A

Page 27

5-10

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 R5070 2007-000082 R-CHIP;3.3Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5071 2007-000082 R-CHIP;3.3Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1031 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1032 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2004 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2005 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2009 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2010 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2069 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2081 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2083 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2088 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3012 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3044 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3062 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3063 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3254 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5069 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R6041 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R6042 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1006 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4

....4 R1030 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1043 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1048 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1049 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2028 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2080 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2082 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2089 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2156 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2157 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3018 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3019 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3023 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3024 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3031 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3034 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3035 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3042 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3057 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3058 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3059 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R3253 2007-000090

....4 R4119 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R4120 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5004 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5007 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5077 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5080 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5117 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

R1007 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

Page 28

5-11

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 R5119 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9331 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9334 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R9335 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 S.A

....4 R4121 2007-000091 R-CHIP;12Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R4123 2007-000091 R-CHIP;12Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9358 2007-000091 R-CHIP;12Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R9359 2007-000091 R-CHIP;12Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1012 2007-000094 R-CHIP;22Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5074 2007-000094 R-CHIP;22Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5076 2007-000094 R-CHIP;22Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5078 2007-000094 R-CHIP;22Kohm,5%,1/10W,TP,1608 1 S.A

....4 R5081 2007-000094 R-CHIP;22Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1015 2007-000097 R-CHIP;47Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1016 2007-000097 R-CHIP;47Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1008 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1011 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1040 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1041 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1042 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4 R1058 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

....4

....4 R6090 2007-000106 R-CHIP;220Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5082 2007-000109 R-CHIP;1Mohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2074 2007-000119 R-CHIP;560ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5006 2007-000124 R-CHIP;2.2Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5506 2007-000124 R-CHIP;2.2Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R5075 2007-000127 R-CHIP;9.1Kohm,5%,1/10W,TP,1608 1 S.A

....4 R2019 2007-000138 R-CHIP;100ohm,5%,1/16W,TP,1005 1 S.N.A

....4 R3074 2007-000138 R-CHIP;100ohm,5%,1/16W,TP,1005 1 S.N.A

....4 R3283 2007-000138 R-CHIP;100ohm,5%,1/16W,TP,1005 1 S.N.A

....4 R2077 2007-000140 R-CHIP;1Kohm,5%,1/16W,TP,1005 1 S.N.A

....4 R2078 2007-000140 R-CHIP;1Kohm,5%,1/16W,TP,1005 1 S.N.A

....4 R3284 2007-000148 R-CHIP;10Kohm,5%,1/16W,TP,1005 1 S.N.A

....4 R3285 2007-000148 R-CHIP;10Kohm,5%,1/16W,TP,1005 1 S.N.A

....4 R2075 2007-000174 R-CHIP;47ohm,5%,1/16W,TP,1005 1 S.N.A

....4 R2076 2007-000174 R-CHIP;47ohm,5%,1/16W,TP,1005 1 S.N.A

....4 R3011 2007-000309 R-CHIP;10ohm,5%,1/10W,TP,1608 1 S.A

....4 R2086 2007-000570 R-CHIP;220ohm,1%,1/10W,TP,1608 1 S.A

....4 R2087 2007-000570 R-CHIP;220ohm,1%,1/10W,TP,1608 1 S.A

....4 R2016 2007-000683 R-CHIP;3.3Kohm,1%,1/10W,TP,1608 1 S.A

....4 R1070 2007-000726 R-CHIP;300ohm,1%,1/10W,TP,1608 1 S.A

....4 R1057 2007-000839 R-CHIP;39ohm,5%,1/10W,TP,1608 1 S.A

....4 R2001 2007-000882

....4 R2002 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2003 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2006 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2007 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2008 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2011 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R2012 2007-000882 R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

R6022 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 S.A

R-CHIP;4.7ohm,5%,1/10W,TP,1608 1 S.N.A

Page 29

5-12

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 R1033 2007-000939 R-CHIP;47Kohm,1%,1/10W,TP,1608 1 S.A

....4 R3070 2007-000950 R-CHIP;47ohm,5%,1/4W,TP,3216 1 S.A

....4 R3071 2007-000950 R-CHIP;47ohm,5%,1/4W,TP,3216 1 S.A

....4 R3286 2007-000950 R-CHIP;47ohm,5%,1/4W,TP,3216 1 S.A

....4 R1069 2007-000965 R-CHIP;5.1Kohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6017 2007-001007 R-CHIP;51Kohm,1%,1/10W,TP,1608 1 S.A

....4 R2020 2007-001093 R-CHIP;620ohm,5%,1/10W,TP,1608 1 S.A

....4 R4103 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 S.N.A

....4 R4105 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 S.N.A

....4 R4107 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 S.N.A

....4 R3020 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3021 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3022 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3072 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3073 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3287 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R6027 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1003 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1022 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1023 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R1025 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

....4

....4 R1027 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

....4 R3288 2007-007309 R-CHIP;12Kohm,1%,1/16W,TP,1005 1 S.A

....4 R3289 2007-007309 R-CHIP;12Kohm,1%,1/16W,TP,1005 1 S.A

....4 R6006 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 R6007 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5008 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5009 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5010 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5011 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5012 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA6006 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA6009 2011-000585 R-NETWORK;47ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5024 2011-000881 R-NETWORK;33ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5026 2011-000881 R-NETWORK;33ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5027 2011-000881 R-NETWORK;33ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA6010 2011-000881 R-NETWORK;33ohm,5%,1/16W,L,CHIP,8P,TP,3. 1 S.N.A

....4 RA5007 2011-001001 R-NETWORK;0ohm,5%,1/16W,L,CHIP,8P,TP,3.2 1 S.A

....4 RA5001 2011-001011 R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5004 2011-001011 R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5017 2011-001011 R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5018 2011-001011 R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5032 2011-001011

....4 RA5033 2011-001011 R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5005 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5006 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5015 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5019 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5020 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5021 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

R1026 2007-002425 R-CHIP;1ohm,5%,1/10W,TP,1608 1 S.N.A

R-NETWORK;10Kohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

Page 30

5-13

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 RA5023 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5028 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5029 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 RA5030 2011-001093 R-NETWORK;100ohm,5%,1/16W,L,CHIP,8P,TP,3 1 S.A

....4 C1005 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C1047 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C1060 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C1071 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C1112 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C1120 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2004 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2005 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2013 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2014 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2015 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2036 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2037 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2043 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C2082 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C3002 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C3020 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4

....4 C5002 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5003 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5004 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5005 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5006 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5007 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5008 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5011 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5016 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5018 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5019 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5021 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5022 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5023 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5024 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5026 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5027 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5029 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5032 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5033 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5035 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5036 2203-000189

....4 C5037 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5042 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5044 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5048 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5049 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5050 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5051 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

C3251 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

Page 31

5-14

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 C5053 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5069 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5071 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5072 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5073 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5074 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5075 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5076 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5081 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5089 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5098 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5111 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5112 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5115 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5200 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C5208 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6016 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6024 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6025 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6026 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6027 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4

....4 C6031 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6032 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6033 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6034 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C6100 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9309 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9310 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9311 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9312 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9313 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9314 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9315 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9316 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C9338 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

....4 C3236 2203-000233 C-CER,CHIP;0.1nF,5%,50V,C0G,1005 1 S.A

....4 C2012 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C2019 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C3104 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C3105 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C4116 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C4118 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C6050 2203-000236

....4 C6051 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

....4 C1012 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1019 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1020 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1037 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1061 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1058 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

C6029 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 S.N.A

C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 S.N.A

Page 32

5-15

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 C2001 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2002 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2018 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2025 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2026 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2027 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2028 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2034 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2035 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2039 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2040 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2041 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C2079 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C3253 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C5039 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C5055 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C5099 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C6015 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 S.A

....4 C1017 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,1608 1 S.A

....4 C5091 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,1608 1 S.A

....4 C5094 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,1608 1 S.A

....4

....4 C5101 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,1608 1 S.A

....4 C3106 2203-000626 C-CER,CHIP;0.022nF,5%,50V,C0G,1608 1 S.N.A

....4 C5014 2203-000626 C-CER,CHIP;0.022nF,5%,50V,C0G,1608 1 S.N.A

....4 C5015 2203-000626 C-CER,CHIP;0.022nF,5%,50V,C0G,1608 1 S.N.A

....4 C3007 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,1608 1 S.A

....4 C3008 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,1608 1 S.A

....4 C2081 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 S.A

....4 C2083 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 S.A

....4 C4104 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 S.A

....4 C4106 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 S.A

....4 C4108 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 S.A

....4 C1018 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 S.A

....4 C1056 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 S.A

....4 C5038 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 S.A

....4 C5040 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 S.A

....4 C5041 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 S.A

....4 C2033 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 S.A

....4 C2080 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 S.A

....4 C5056 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5057 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5060 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5061 2203-000975

....4 C5062 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5063 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5065 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5066 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5067 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C5113 2203-000975 C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

....4 C1016 2203-000979 C-CER,CHIP;47nF,10%,50V,X7R,TP,2012 1 S.N.A

C5100 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,1608 1 S.A

C-CER,CHIP;47nF,10%,25V,X7R,TP,1608,- 1 S.N.A

Page 33

5-16

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 C6014 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,1608 1 S.N.A

....4 C3009 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C3010 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C4122 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C4124 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C1011 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 S.A

....4 C5000 2203-001630 C-CER,CHIP;330nF,+80-20%,16V,Y5V,1608 1 S.N.A

....4 C1063 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 S.N.A

....4 C2006 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 S.N.A

....4 C2008 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 S.N.A

....4 C2010 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 S.N.A

....4 C2024 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 S.N.A

....4 C3239 2203-002525 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1005 1 S.N.A

....4 C3240 2203-002525 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1005 1 S.N.A

....4 C2090 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C2091_22 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C2160 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C4009 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C5090 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C6006 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4 C6019 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

....4

....4 C1001_22 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C1022 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C1107 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C1114 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2007 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2009 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2011 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2023 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2158 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C2159 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C5087 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C9346 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C9347 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C9354 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C9355 2203-005065 C-CER,CHIP;1000nF,+80-20%,10V,Y5V,1608 1 S.N.A

....4 C1002 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C1064 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2029 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2030 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2031 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2032 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2075 2203-005249

....4 C2076 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2077 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C2078 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

....4 C1073 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C1103 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C1123 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C1124 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

C6021 2203-005005 C-CER,CHIP;100nF,10%,16V,X7R,1608 1 S.A

C-CER,CHIP;100nF,10%,50V,X7R,TP,1608 1 S.N.A

Page 34

5-17

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 C5077 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5078 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5079 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5080 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5084 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5085 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C5086 2203-005384 C-CER,CHIP;4700nF,+80-20%,10V,Y5V,TP,201 1 S.N.A

....4 C2154 2203-005533 C-CER,CHIP;1000nF,20%,6.3V,X7R,TP,1608 1 S.N.A

....4 C2155 2203-005533 C-CER,CHIP;1000nF,20%,6.3V,X7R,TP,1608 1 S.N.A

....4 C2044 2203-005809 C-CER,CHIP;1000nF,10%,16V,X7R,-,2012 1 S.A

....4 C5047 2203-005809 C-CER,CHIP;1000nF,10%,16V,X7R,-,2012 1 S.A

....4 C5207 2203-005809 C-CER,CHIP;1000nF,10%,16V,X7R,-,2012 1 S.A

....4 C1052 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 S.A

....4 C1053 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 S.A

....4 C1065 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 S.A

....4 C1066 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 S.A

....4 C2020 2203-006158 C-CER,CHIP;100nF,10%,16V,X7R,1005 1 S.N.A

....4 C2021 2203-006158 C-CER,CHIP;100nF,10%,16V,X7R,1005 1 S.N.A

....4 C1003 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4 C1007 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4 C1010 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4

....4 C1035 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4 C1036 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4 C1038 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A

....4 C1039 2203-006336 C-CER,CHIP;10000nF,10%,25V,X5R,3216 1 S.A