Page 1

• Specifications

• Cautions at Service

• External Part Name

• Necessary equipments and Specifications in needing

Service(P/U replacement)

• Exploded Views & Part List

• Packing Options

• Block Diagram

• Troubleshooting

• Circuit Diagram

• Main Components Block Diagram & Pin Descriptions

• Electrical Parts List

The design and part of this product is subject to change without prior notice for performance improvement.

CONTENTS

SERVICE

Manual

SW-248B

CD-R/RW DRIVE

Page 2

1

1. General Specifications

- Drive type : Computer built-in

- Power consumption : DC +5V, 1.5A

DC +12V, 1.5A

- Dimensions : 146mm (W)X42mm (H)X184mm (L)

- Net Weight : 750g

2. Electrical Features

- Interface : ATAPI BUS(IDE)

-

Data transfer rate :

Write(CD-R) : 600KBytes/Sec(4X)

1,200KBytes/Sec(8X)

1,800KBytes/Sec(12X)

2,400KBytes/Sec(16X)

3,000KBytes/Sec(20X)

3,600KBytes/Sec(24X)

4,200KBytes/Sec(28X)

4,800KBytes/Sec(32X)

Write(CD-RW) : 600KBytes/Sec(4X)

Write(High Speed CD-RW) : 600KBytes/Sec(4X)

1,500KBytes/Sec(10X)

Resd(MAX) : 2,000~6,000KBytes/Sec(CAV 40X)

- Access time : 110ms (Random. TYPICAL)

- Buffer Capacity : 8Mbyte

- Error ratio : Mode 1: Below 10

-12

Mode 2: Below 10

-9

- Frequency response : 20Hz~20kHz (Lineout)

100Hz~20kHz (H/P out)

- Signal to noise ratio : 70dB(1kHz, Lineout)

- Distortion factor : 0.15% Less than(1KHz)

- Channel separation : 65dB(1kHz, Lineout)

55dB(1kHz, H/P out)

- Used laser : Semiconductor laser

- Audio Output : Line out 0.75 ±20%(Vrms), 47KΩ

H/P out 0.65 ±20%(Vrms), 33Ω

1. General Items

1) Be careful not to have your eyes or a part of body touch withlaser diode at repair because this product uses laser diode.

2) Do not disassemble Pick-up at repair. If the laser diode is

bad, replace the entire Pick-up.

3) Keep away from TV or other electrical units at repair to

prevent influence from surrounding units.

4) If you replace the parts during repair, be sure to unplug the

power cable before replacement.

5) If you insert a disc into the drive, be sure to load it corectly.

6) Because this unit can't be used by itself, surely mount it

on PC (586 DMA support) and check the operations in

use of private device driver floppy diskette.

Refer to Instruction manual.

7) This unit has many parts with features related to safety and

especially, for essential parts, the importance is indicated on

circuit diagram and part list.

Be certain to use the parts with same specifications at

replaing these parts.

2.

Earthing cautions at handling Pick-up

- Because the laser diode in optical Pick-up is subject

to get out of order due to the potential difference occurring

by electricity load charged in clothes or bodies, observe the

following earthing items at handling.

1) Body earthing(hand) : Be sure to wear a wrist strip

with one side earthed.(Impedance : Below 104).

It removes the electricity formed in body.

2) Work table earthing : Put the earthed conductive plate

(Impedance : Below 104) such as copper plate on work

table.

3) Cautions for clothes : Do not have any clothes touch with

Pick-up because the electricity formed in clothes is

destroyed easily.

Specifications

Cautions at Service

Page 3

2

Electricity sensing device

Safety instructions

Some semiconductor units may be damaged easily by

electricity.

These elements are called as electricity sensing

device(ESD) in general. For example, integrated circuit,

field effect transister, semiconductor chip.

The following methods have to be used to reduce the

accident of element damage generated by electricity.

1) Emit all electric charges in your body through contact

with earthing materail at once before handling a

semiconductor factor or device including it.

In other way, make use of commercial wristlet against

electricity

It shall be detached before power impression to the

unit on testing because of shock.

2) After detaching an electrical device including ESD, it

shall be placed on conductive surface such as

aluminium to prevent the charge acummulation and

unit exposure.

3) Utilize only the soldering iron with earthed end for

ESD soldering or release

4) Make use of only anti-static soldering release unit.

A soldering release unit not to be classified as

antistatic may generate the enough charge to damage

ESD unit.

5) Never use a Freon-propelling chemical product.

It may generate the enough charge to damage ESD.

6) Untill installing ESD unit for replacement, never it from

protection package.

(Most of ESD unit for replacement have lead

composed of package shorted electrically by

conductive foam, aluminium or similar conductive

material.)

7) Contact with shassis including ESD or protection

material in circuit parts just before detaching the

protection material from lead of ESD unit for replacement

8) Minimize the body action at handling an unpacked

ESD unit for replacement.

(Otherwise, an unconscious action, so to speak,

friction between clothes or foot lifting from carpet floor

may generate the enough charge to damage ESD

unit.)

Note : Be sure to avoid the power impression to the

shassis or circuit and observe the safety instruction.

1) Read all safety and operational manuals before

operating this product

2) Keep the safety and operational manuals for future

reference.

3) Observe all precations and operational instructions in

or on the surface of this product.

4) Follow all operation and maintenance cautions.

5) Be sure to plug off the power cable before cleaning.

Use a dry cloth to clean a dusty cover of cabinet

instead of liquid or aersol cleaner.

6) Never use a attachment not to be recommended by

this company. It may result in danger and damage.

7) Never use this product around water such as

bathtub, washbasin, laundry machine, swimming pool

or lakeside.

8) Never place this product on bed, sofa or around

radiator and heater.

9) Power : Utilize the only power displayed on lebel

If the power type can't be checked, call to dealer or

Korea Electricity, Co, Ltd. Refer tooperate this product

by battery or other power.

10) Lightning : Plug off the power cable for product

protection during thunder and lightning flashes or this

product is unused for a long time.

11) Overload : Be careful that the wall outlet and

expanded cord is overloaded due to danger of fire

and electrical shock.

12) Never insert a substance or liquid into this product.

It may cause fire or shorck by contact with voltage

point or short.

13) Part replacement : The service engineer has to use

the parts of same specification at replacement.

Otherwire, fire, shock or other dangers may be

occurred.

14) Safety check : Be sure to perform the safety check

at service or repair completion

Importance : This product includes special impotrant

parts on safety.

These parts are indicated by on schematic

diagram.

At replacement of these parts, use the

parts of same specification due to shock,

fire or other dangers.

Never transform the original design without

permission of this company.

Page 4

3

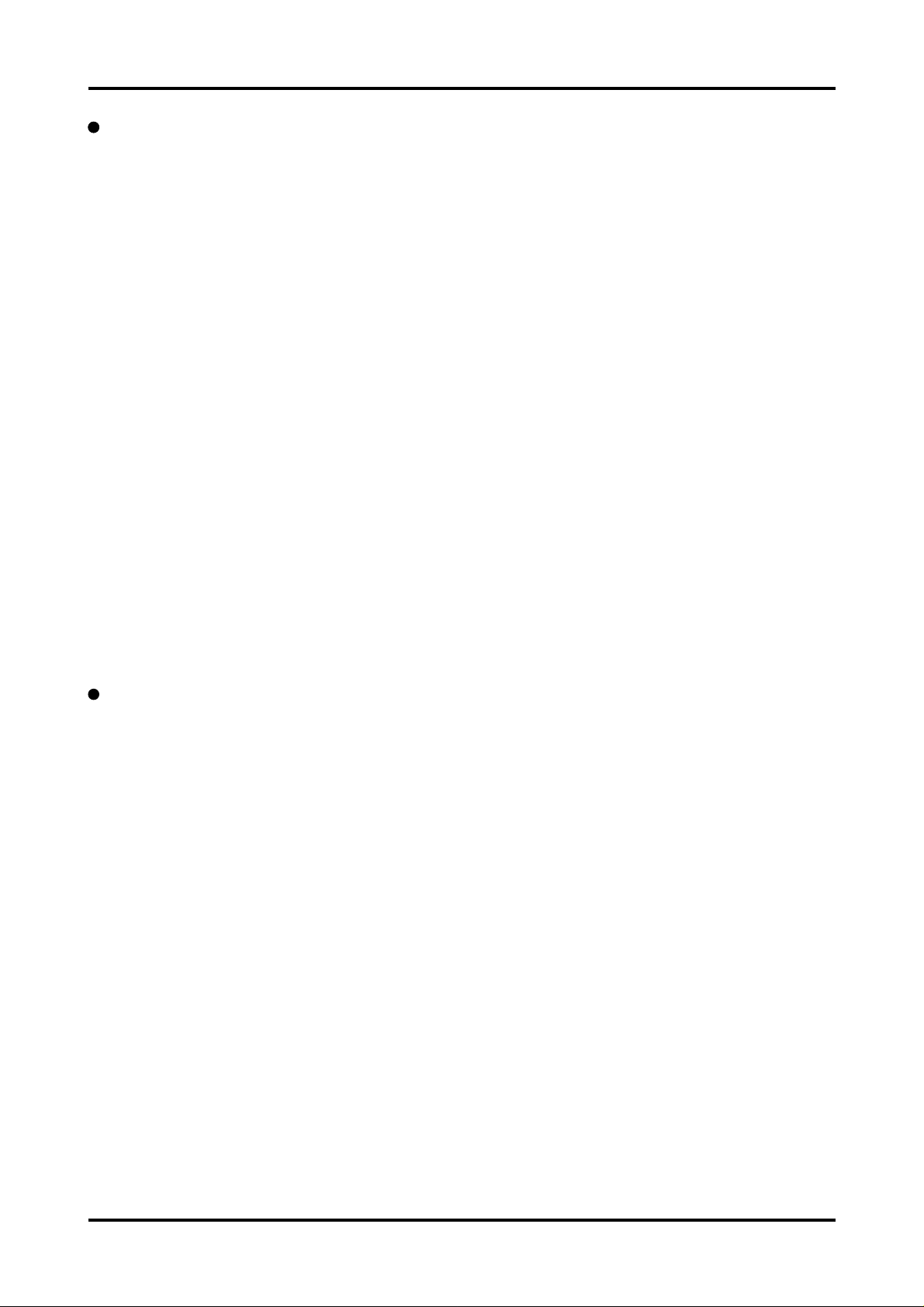

1. Front

2. Rear

Digital

output terminal

(Optional)

Sound

output terminal

Master/Slave

select pin

Interface

terminal

Power terminal

External Part Name

Earphhone jack

Stop/Open

button

Emergency

HOLE

Up/Down

Volume

LEDDisc tray

Page 5

4

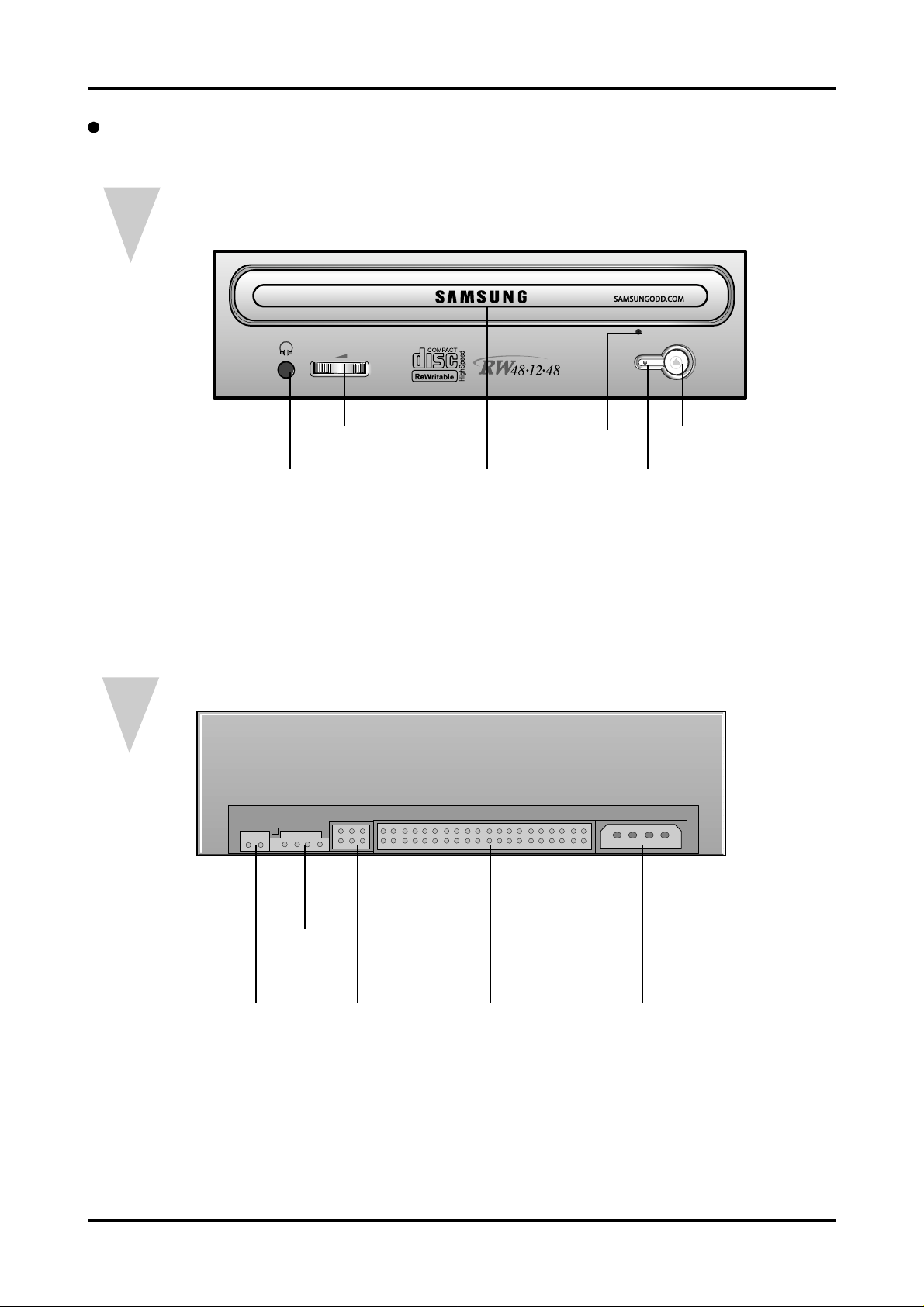

Disassembly Diagram

Page 6

5

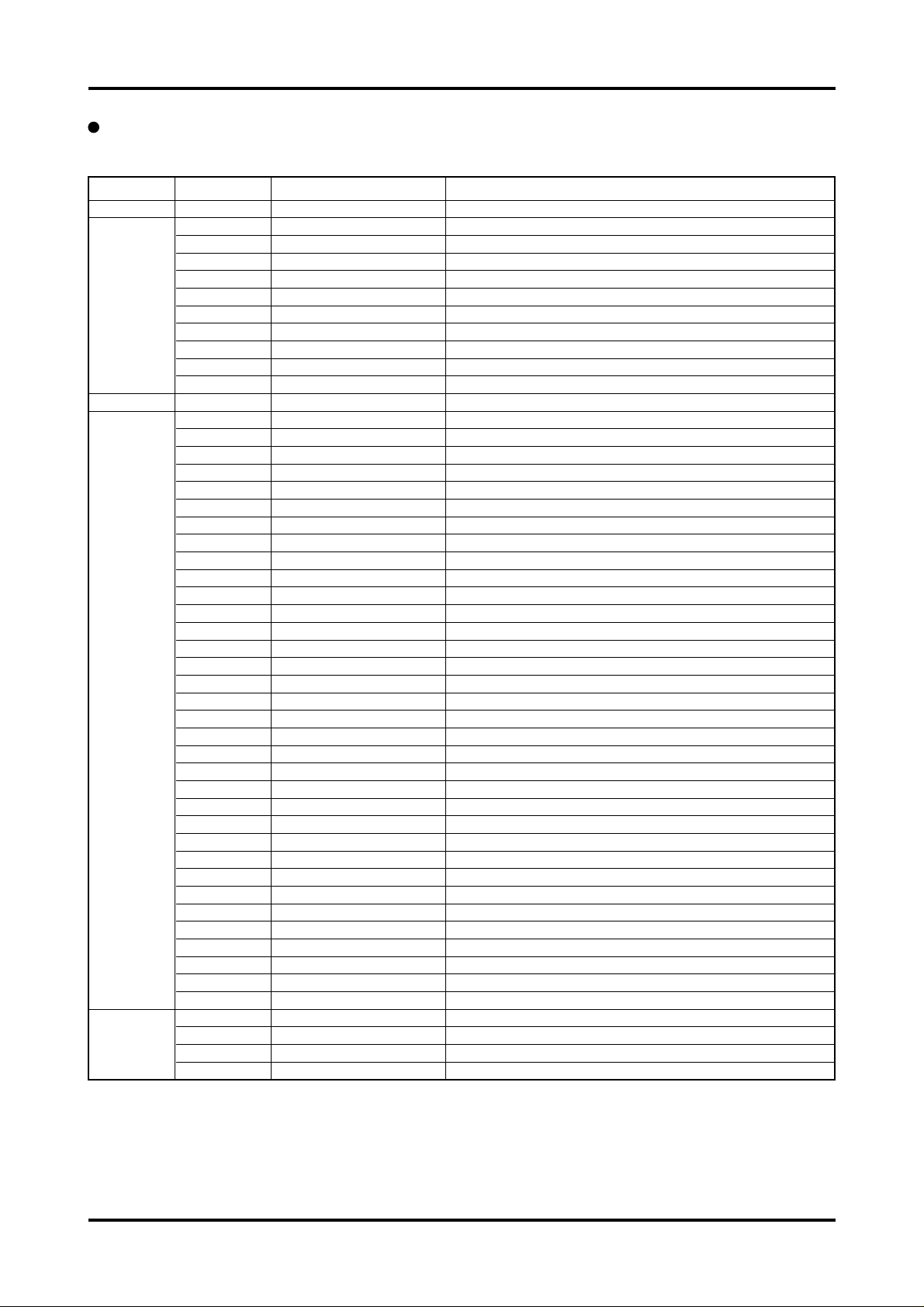

Device Part List

PART NAME CODE No SPECFICATION

ASSY DECK BG97-02248A -

BG60-00009A 1.SCREW TITE M1.7*5(10)

LOADING BG97-02250A 1.ASSY LOADING -

BG61-00203A 1.MAIN FRAME HIPS(HG1760S)

BG66-00061A 2.GEAR TRAY POM(F20-03)

BG66-00032A 3.GEAR PULLEY POM(F20-03)

BG66-00044A 4.BELT PULLEY CR-70(BLK 1.3t)

BG97-00789A 5.ASSY LOADING M/T BG31-00027A - LOADING MOTOR RF-300CH-11440 ¿Ü

BG66-00033A - PULLEY MOTOR POM(F20-03)

BG66-00034A 6.LEVER EJECT POM(F20-03)

BG66-00062A 7.SLIDE CAM KOCETAL(K700)

TRAY DISC BG66-00060A 1.TRAY DISC ABS ( SR-0320D )

FEEDING BG97-02251A 1.ASSY FEEDING -

BG61-00078A 1.SUB CHASSIS ABS(GF20%)

BG73-00012A 2.RUBBER-INSULATOR BUTHYL 25Hs

BG73-00027A 3.RUBBER-INSULATOR BUTHYL 25Hs

BG61-00238A 4.MAIN BASE M SECC+POM

BG61-00237A - MAIN BASE P SECC 2.0T

BG31-00025A 5.ASSY STEP M/T “SPS-15RF-054K, P4.5mm”

BG61-00180A 6.GUIDE PU POM(NW-02)

BG61-00122A 7.SHAFT PU R “SUS420J2,¥õ3.0,L85.5mm”

BG31-00036A 8.MOTOR SPINDLE “RSM-2615A,DMBSPC75A”

- FFC-SPM 15 PIN

BG97-02247A 9. ASSY TURN TABLE BG59-00017A TURN TABLE ABS ADC12

BG63-00084A COVER T/T ABS SN PLATE T0.6

BG59-00018A TURN TABLE BALL “STEEL ¥Õ2.5,11EA”

BG73-00026A RUBBER-T/T ABS CR(NEO-B-6150)

BG59-00019A MAGNET T1.5

BG61-00018A BRKT-T/T SECC T1.0

BG30-00025A 10.PICK-UP SW-232B

BG41-00184A 11.EFFC PU “32 PIN (P0.5),88mm”

BG97-01729A 12.ASSY SLIDER STEP BG66-00052A - SLIDE STEP POM(NW-02)

BG61-00225A - SPRING STEP SUS 304-WPB

BG61-20031A 13.HOLDER CAM POM(M90-44)

AH60-10145A 14.SCREW TITE M1.7*5(5.5)

AC60-10074A 15.SCREW TITE M2.6*6

6001-001348 16.SCREW M1.7*3.5

6003-001260 17.SCREW TITE M1.7*4.0*3.5

BG69-00127A 18.PAD-DECK PORON LE-20 2T

BG73-00022A 19.RUBBER-DVA SILICON 25µµ

BG61-00178A 20.PLA-VIB/ABSORBER SECC 2T

ETC 3409-001138 -.SWITCH DETECTOR

BG63-00052A -.SHEET PU PVC FILM 0.85T

BG41-00182A -.FFC MAIN 13 PIN

- -.OIL EP-100

- -.GREASE KG-110

- -.GREASE G-754

Page 7

6

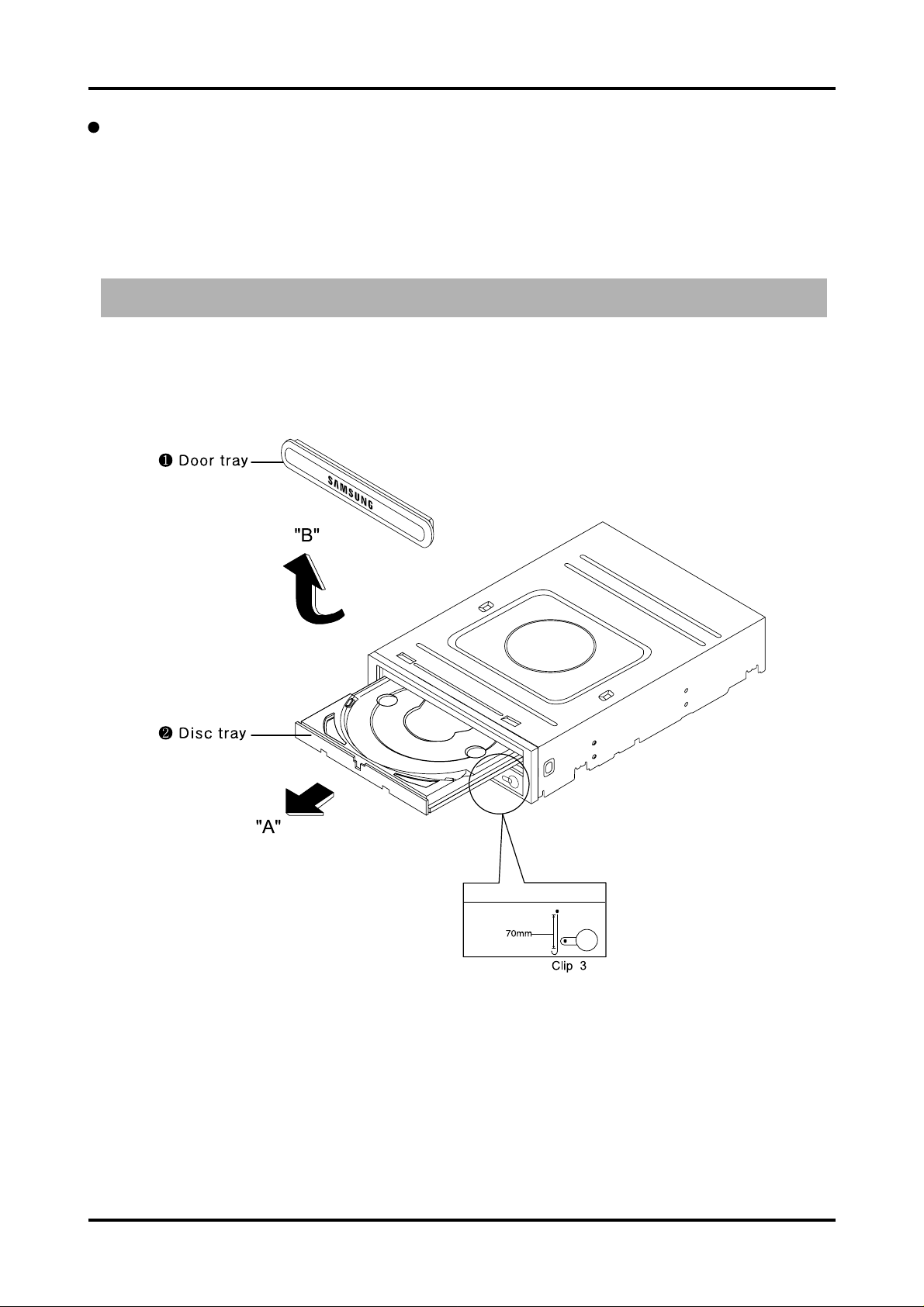

Disassembly and assembly

Door-tray

Exterior and PCB disassembly

Figure - Door-tray

1) Supply power to open the tray¶Êin direction of arrow “A”

2) Lift up the door¶Â in direction of arrow “B”

3) Close the tray¶Êand power off.

Reference : If the tray¶Êdoesn't open, push the clip3 into specified hole shown in detailed figure to open

it compulsorily.

Page 8

7

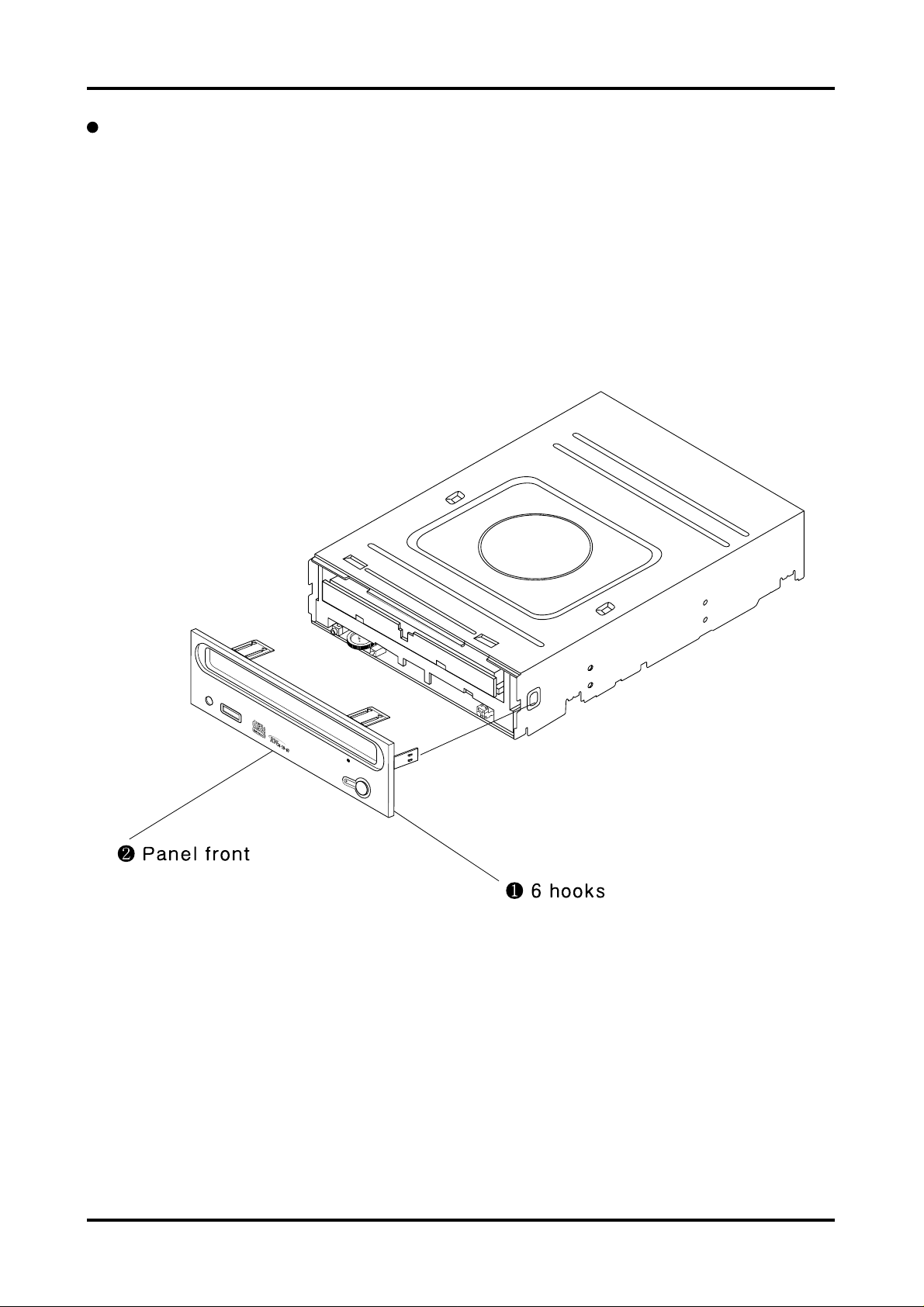

Disassembly and assembly

Panel-front

Exterior and PCB disassembly

1) Remove 6 hooks¶Â

2) Take out the panel-front¶Êforward.

Figure - Panel-front

Page 9

8

Disassembly and assembly

Top-cabinet

Exterior and PCB disassembly

Figure - Top-cabinet

1) Remove 4screws¶Â in the bottom

2) Lift up the top-cabinet ¶Ê

Page 10

9

Disassembly and assembly

Ass'y-frame Low

Exterior and PCB disassembly

Figure - Ass'y-frame Low

1) Lift up the ass’y frame¶Ê low

Page 11

10

Disassembly and assembly

MAIN-PCB

Exterior and PCB disassembly

Figure - Disassembly connector

1) Disassemble the PICK-UP FPC¶Â in PCB.

2) Disassemble the FFC¶Êbetween Main PCB and Front PCB.

3) Disassemble the FFC¶Ábetween Main PCB and Front PCB.

4) Push 2hooks¶Ëfor PCB fixing in deck.

5) Disassemble the MAIN-PCB

¶È

6) Remove soldering at motor connection wire¶ÍPCB.

7) Press 2hooks¶Îfor PCB fixing in deck and Disassemble the FRONT-PCB

Page 12

11

Disassembly and assembly

Tray

Deck disassembly

Figure - Tray

1) Push 2hooks¶Â.

2) Take out the Tray¶Êin direction of arrow.

Page 13

12

Disassembly and assembly

Ass’y-Deck

Deck disassembly

Figure - Ass’y-Deck

1) Move the slide cam¶Â in left direction.

2) Remove screws¶Ê.

3) Disassemble the Ass’y-feeding ¶Áin arrow “B” direction with pushing the 2hooks in direction of arrow “A”

Page 14

13

Packing Diagram and Part List

NO CODE-NO DESCRIPTION SPECIFICATION Q’TY

1 BG69-00146A MASTER CATON-BOX DM 3 1/8EA

2 BG69-00147A PACKING-CASE SW-224B/DOM SW-1 MANILA 240g 1EA

3 BG69-00034A CUSHION-SET EPS 2EA

4 BG69-30305A BAG-PE T0.05 2EA

5 BG46-00024A S-W UTILITY 1EA

6 BG68-00352A MANUAL USERS 1EA

7 BG95-50004A ASSY-SCREW 1EA

8 BG60-12001H SCREW-MACHINE M3 * 6 1EA

9 BG39-30002A BAG-PE 1EA

10 BG39-00010A CABLE-IF SR 380MM 1EA

11 BG39-42001B CABLE-WIRE HARNESS 4P, 3P, N, UL2547/UL1061 4EA

12 BG69-30307A BAG-PE T0.05 1EA

13 0203-001222 TAPE-MASKING PP-BEING 0.34M

14 BG68-00355A LABEL-RATING SW-224B/DOM, ART PAPER 1EA

15 BG68-50005A LABEL-QMS ART PAPER 1EA

16 BG68-00296C LABEL-BAR CODE DOM MODEL, ARTPAPER 1/8EA

17 BG68-00327A LABEL-BROKEN ART PAPER 1EA

ASS’Y

Page 15

14

Block Diagram

Page 16

15

Trouble Shooting

Check the power source and initial state.

Is electrity of 5V and 12V normally input

after the connecting the power cable ?

Y

Do RL3E804, RL5E935 oscillate ?

Y

Dose the voltage of the 1pin of IC502

change from 3.3V ?

Y

Is electricity of 2.5V normally

output from the 3pin of IC503?

Y

When you transfer the PICK-UP

to the outer cycle, and turn the power on,

dose it move to the inner one?

Y

TRAY IN / OUT ?

Y

Refer to ‘NO SLED operation’

Refer to ‘Check TRAY IN / OUT’

Refer to ‘check LASER DIODE ON’LASER DIODE ON ?

Check the connection of the

power short and cable.

If the power of RL3E804, RL5E935

is normal when you check,

replace X201, X301.

N

N

If the power of ICIC502 (3pin) is normal

when you check, replace IC502.

If the power of IC503 (2pin) 5V is normal

when you check, replace IC503.

N

N

N

N

N

Page 17

16

FOCUS UP / DOWN ?

Y

FOCUS LOCK ?

Y

DISC rotation ?

Y

SPINDLE LOCK ?

Y

AUDIO OUTPUT ?

Y

WRITING Normall ?

Refer to ‘ FOCUS LOCK ’

NN

N

N

N

Refer to ‘ NO DISC ROTATION ’

N

Refer to ‘ NO AUDIO OUTPUT ’

N

Refer to ‘ NO WRITING ’

N

Page 18

17

When you transfer the pick-up to the outer

cycle and turn the power on, dose the

pick-up move to the inner one ?

SLED operation of normal.

If the constant of IC301 and GND, pattern’s

when you check, replace.

Y

Y

N

N

If the constant of IC401 and GND,

pattern’s when you check, replace.

N

The below waveform is outputted in

IC301 1, 99pin ?

Y

Y

Replace stepping Motor.

Y

The below waveform is outputted in

IC401 35, 37pin ?

Y

No SLED OPERATION

Page 19

18

Is the connector properly

inserted into CN30 ?

Try the operation after inserting the

connector to CN3 properly.

Check the SW701 patterns and the

welding condition.Replace it if the

condition is normal.

Y

N

N

Check the SW701 Open and Close

patterns and the welding condition.

Replace it if the condition is normal.

N

Check the condition and patterns of

R409, R410.If they are normal,

replace IC401.

N

When pressing the EJECT SW,

does the IC401 Pin26 vary from 1.65V

to the value between 1.15V and 2.15V

and then show 0V finally?

N

Is the Tray Motor able to output the

Pin49 and 50 of IC401?

Replace TRAYMOTER.

Y

When pressing the EJECT SW,

does the peak value of the

IC301 3Pin become 3.3V?

Y

When it is in the Tray Open mode,

does the IC301 6Pin show 1.65V?

Y

When pressing the EJECT SW, does the

IC401 Pin26 vary from 0V to the value

between1.15V and 2.15V and then show

1.65V finally?

N

Y

Y

Y

No Tray open / close operation

OPEN

CLOSE

Page 20

19

Is the connector inserted normally

into the CN10?

Y

Isn’t there any problem

with the FPC Wire ?

Y

When the SLED is moved to the

inner circle, is electricity of about 1.65V

output from the 80pin of IC101 ?

Y

Is electricity of about 1.65V input

through 71pin of CN101 ?

Y

Replace PICK -UP.

No LASER DIODE ON

Try again after a normal insertion of the

connector into CN10.

N

Try again after replace of FPC Wire.

N

If the pattern of IC101 and sodering is

normal when you checked, replace IC301.

If the time transfer 71pin of IC101

and soldering are ok is when you checked

replace IC101

N

N

The value of voltage can be modified slightly, depending on the result of power calibration or the media.

Page 21

20

CH 2 : Focus Up / Down FE

CH 3 : S curve

CH 4 : Focus Servo On

If the power of IC101 and GND, soldering

is normal when you check, replace IC101.

If the power of IC201 and GND, soldering

is normal when you check, replace IC401.

If the power of IC201 and GND, constant

is normal when you check, replace IC201.

The below waveform(CH B) is

outputted in ICIC401 45, 46pin ?

FOCUS UP / DOWN ?

Dose the S-curve below come out of the

76(TP:FE)pin of IC101after insertion of a disc ?

Is the waveform above input

through the 128pin of IC201 ?

Y

Y

If the power of IC201 and GND, soldering

is normal when you check, replace IC201.

N

N

The below waveform(CH B) is

outputted in IC201 132pin ?

N

N

N

N

Y

1. Is the FPC Wire inserted normally

into the CN10?

2. Isn’t the FPC wire disconnected ?

Y

1. Try again after a normal insertion of the

connector into FPC Wire.

2. Try again after replace of FPC Wire.

Replace Pick-up.

Y

Y

No FOCUS LOCK

Page 22

21

If the power of IC201 and pattern’s,

soldering is normal when you check,

replace IC201.

Is the waveform below output

through 140pin of IC201 ?

YNY

Is the waveform above input

through 24pin of IC401 ?

Y

Does output but spindle Motor rotate ? Replace MOTOR.

Y

Y

N

If the power of IC401 and pattern’s,

soldering is normal when you check,

replace IC401.

N

NN

No SPINDLE MOTOR ROTATION

Page 23

Replay of AUDIO after

insertion of AUDIO DISC ?

Y

Is the audio output from the

164, 167pin of IC201 ?

If the power of IC401, GND, soldering is

normal when you check, replace IC200.

Y

Is the audio output from the

11, 13pin of CN30 ?

Y

Is the audio input from the JK701 ?

Y

Check the connection of the JK701 is and

normal when you checked, replace JK701.

No AUDIO OUTPUT

22

N

Replace FRONT PCB

N

Check the connection of the CN30 is and

normal when you checked, replace VR701.

N

Page 24

No WRITING

23

Can WLT216B.EXE be

executed properly?

When you try to write the records

again,does it work properly?

Was the Power Calibration

executed properly?

When writing the records,does the

voltage at the PIN 20 (XWGATE)

of CN10 decrease from 5V to 0V?

N

Check the condition of the

power at CN10,

GND and the welded part.

If they are normal, replace IC101.

N

N

Y

Y

Y

Replace P/UP or the entire MECHA.

N

Page 25

24

Circuit Diagram

Main

Page 26

25

Circuit Diagram

Front

Loading...

Loading...