Page 1

4-1

Samsung Electronics

4. Troubleshooting

4.1 Tech Mode

4.1.1 How to Enter Tech Mode

In TECH MODE, the technician can check the machine and perform various test to isolate the cause of a malfunction.

To enter the TECH MODE, press MENU, #, 1, 9, 3, 4 in sequence, and the LCD briefly displays ‘ ’, the machine has

entered service (tech) mode.

While in TECH MODE, the machine still performs all normal operations.

To return to normal user mode, press MENU, #, 1, 9, 3, 4 in sequence again, or turn the power off, then on by unplugging and plugging the power cord. Options changed while in TECH MODE do not remain changed unless you clear the

machine’s memory. Because the explanation of the User Mode items is already mentioned at the User guide in detail, It

will not be described at Service manual.

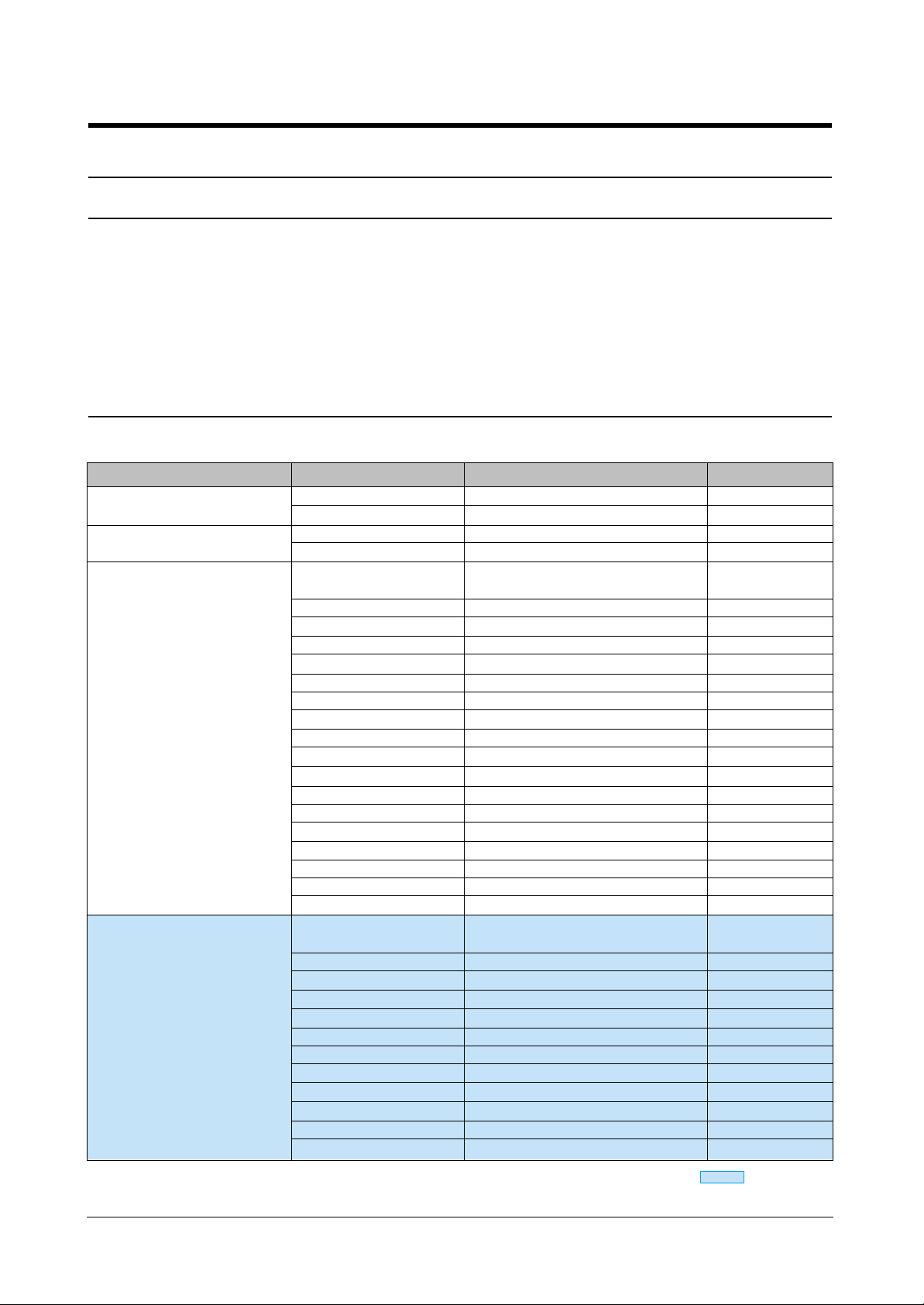

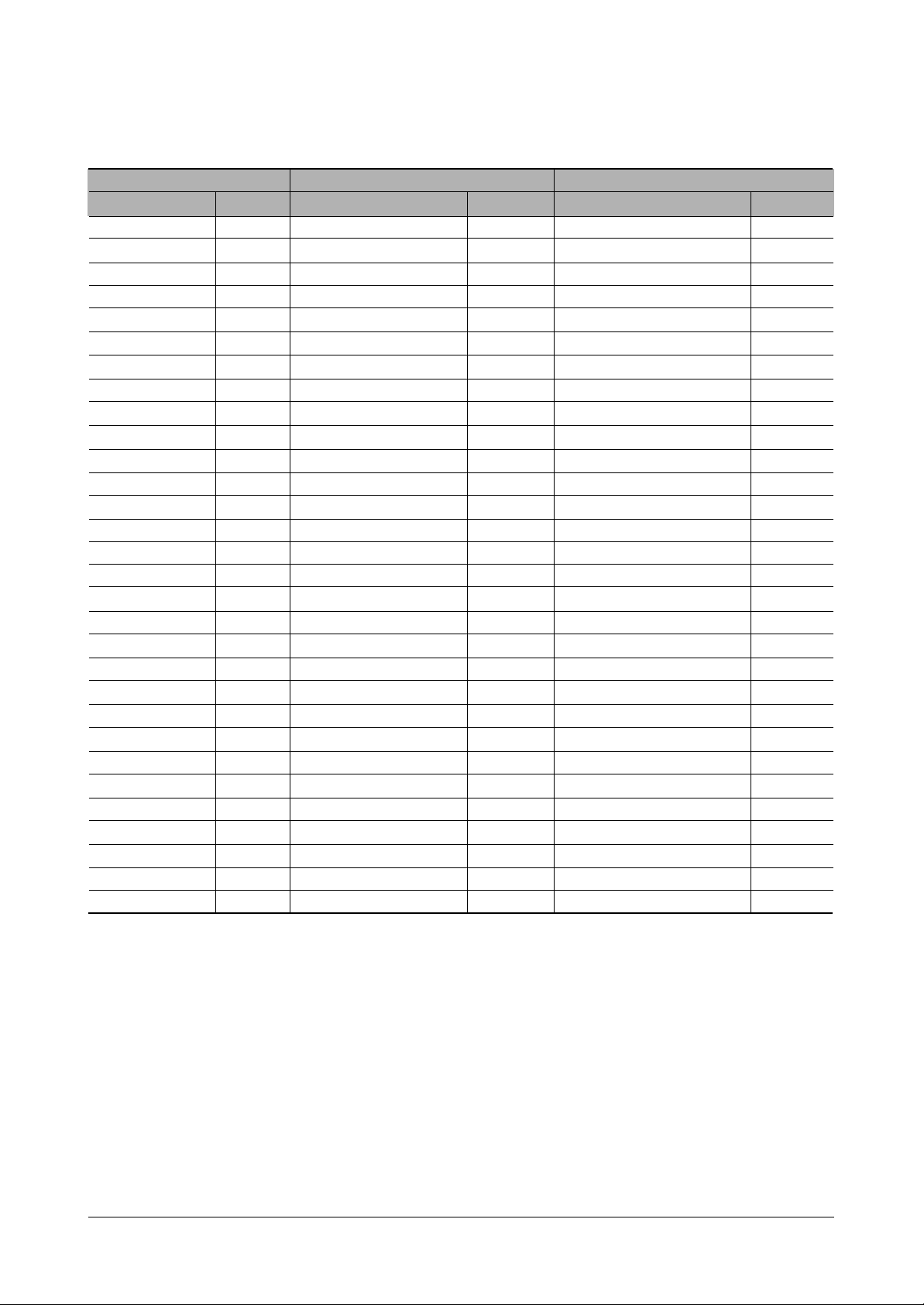

4.1.2 Selectable Options

A default values are different by nations. Please check the default values for coming under nations.

*

FUNCTION ITEM CONTENT DEFAULT

SET SYSTEM ID Fax Number

Fax Name

SET DATE & TIME Date Format EUROPE/USA

Date&Time

SETUP SYSTEM Language English/German/French/Italian/

(In User Mode) Spanish/Portuguese/Dutch

Sending Confirm ON/OFF/Error Error

Paper Size A4/Letter/Legal A4

Auto Reduction ON/OFF ON

Discard Size [00-30]mm 15 mm

Ring To Answer [2-7] 2

Rcv. Start Code [0-9] *9*

ECM Mode ON/OFF ON

Send From Memory ON/OFF ON

Caller ID ON, ON/w Junk Fax, OFF ON

Set Junk Fax No. Add , Delete

Auto Journal ON/OFF ON

DRPD Mode

Remote Test ON/OFF OFF

Silent Mode Manual/Daily Manual

Resolution Standard/Fine/Superfine Standard

Contrast Normal/Lighten/Photo/Darken Normal

Image TCR ON/OFF OFF

SETUP SYSTEM Modem Speed 14400/12000/9600/7200/ 14400bps

(In Tech Mode) 4800/2400 bps

Fax TX Level [00-15] dBm -12 dBm

Fax RX Level [43-48] dBm -48 dBm

CNG Count [1-4] 2

T1 Time [030-150] 055

Fax Error Rate 5/10/20 % 10%

Flash Time 100/280/600 ms 100 ms

Pause Time [1-9] sec 4 sec

Make/Break 33/66 , 40/60 33/66

Ring ON Time [00-99] * 10 ms 15 * 10 ms

Ring OFF Time [00-99] * 10 ms 80 * 10 ms

DTMF High Level [00-99] dBm -08 dBm

: Only Tech Mode

Page 2

Troubleshooting

4-2

Samsung Electronics

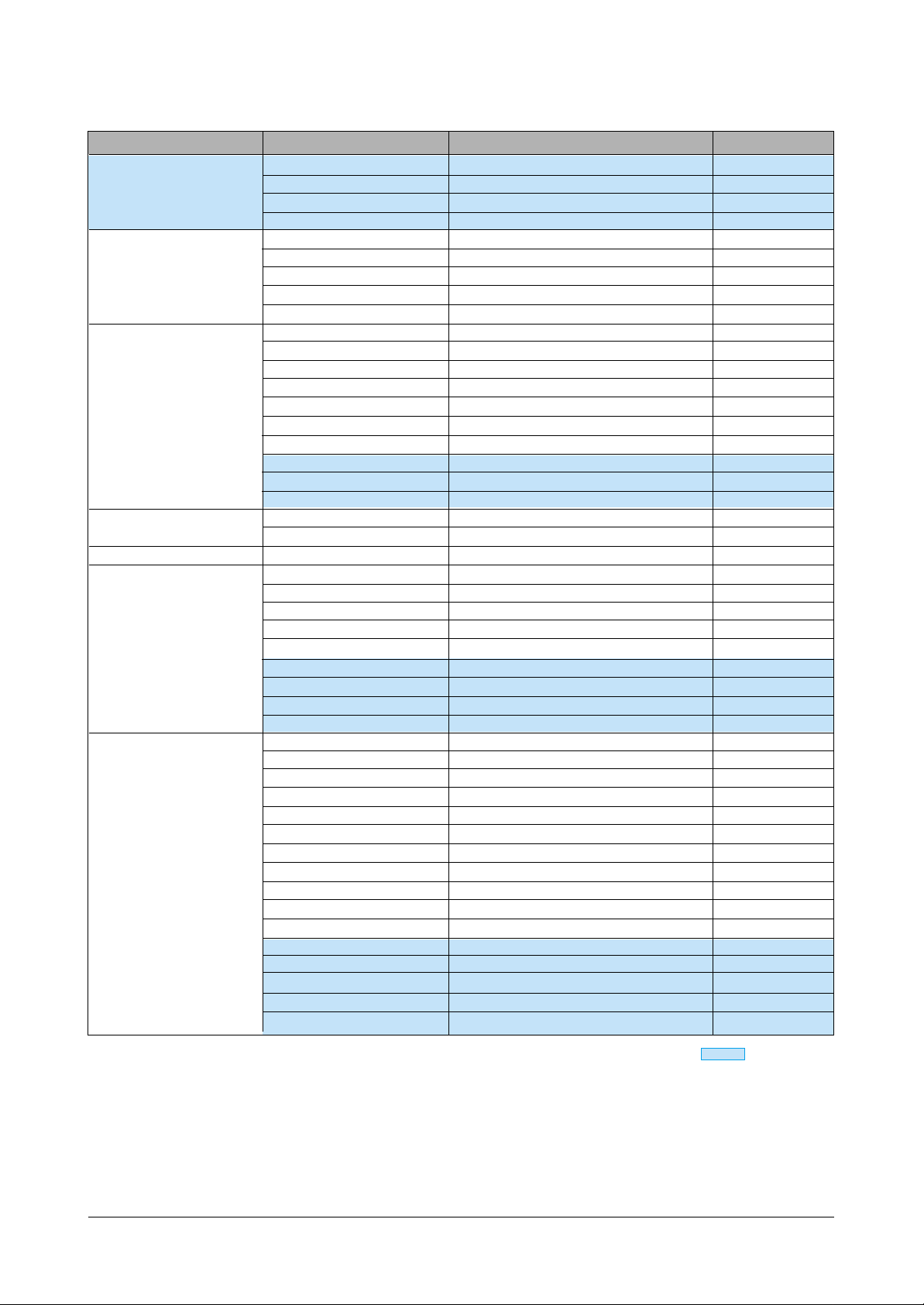

FUNCTION ITEM CONTENT DEFAULT

DTMF Low Level [00-99] dBm -11 dBm

USB Mode FASK/SLOW

PWM Value Setup [000-208] 105

Dial Mode Tone/Pulse Different by nations

ADVANCED FAX Set Broadcasting

Set Delayed Fax

Set Polling Send

Cancel Schedule

Set Fax Forward

SETUP TAM Save Charge ON/OFF OFF

(ONly SF-335T) Call Monitor ON/OFF ON

ICM Record Time 0/30/60/90 sec 60

Remort Password [000-999] #139#

Silence Action Disconnect/Receive Fax/Record Silence Disconnect

Howler Action Disconnect/Record Howler Disconnect

Message Forward ON/OFF OFF

Howler Time [000-150] ms 090

Silence Time [000-200] ms 105

Parallel Level [100-200] 130

SETUP SOUND Alarm Sound ON/OFF

Key Sound ON/OFF

MEMORY CLEAR All Memory Clear

MAINTENANCE Clean Head

Align Head

View Ink Level

Adjust Scanner

Self Test

ASF Test

Modem Test

DTMF Test

Program Download

REPORT/HELP Help List

Send Journal

Received Journal

Phonebook

Sending Confirm

Schedule Inform

System Data

Caller ID

Junk Fax

TAM Status

Print Fax

Shading Profile

Protocol Dump

NVRAM Dump

Memory Dump

Task History

4.1.2 Selectable Options (cont.)

: Only Tech Mode

Page 3

Troubleshooting

4-3

Samsung Electronics

♦ Modem Speed

You can set the maximum modem speed.

Communication is done with modem speed automatically set at lower speed when communicating with the

modem with lower speed since communication is done

on the standard of the side where modem speed is low for

transmission/reception. It is better set 14400 bps as

default setting.

(14400 → 12000 → 9600 → 7200 → 4800 → 2400 bps).

♦ Fax TX Level

You can set the level of the transmission signal. T ypically,

the Tx level should be under -12 dBm. The level within the

range of 1 to -15 dBm is acceptable.

The Send Fax Level is set at the best condition in the shipment from factory. Never

change settings arbitrarily.

♦ Fax RX Level

• You can set the level of the receiving signal.

• The reception level may be too low due to the cable

losses.

• If it is set to -43 dBm, the reception sensitivity will be

between 0 and -43 dBm. If it is set to -48 dBm, the

reception sensitivity will be between 0 and -48 dBm.

♦ CNG Count

The function is to control the CNG TONE cognition times

for entering receiving mode from the AUTO MODE or

ANS/FAX MODE

♦ T1 Time

It is the certain time to be converting to ST ANDBYin case

of a receiver doesn't answer when caller uses AUTO

DIAL, such as ONE-TOUCH/SPEED DIAL/RESERVED

SENDING and etc.

♦ FAX ERROR RATE

• When the error rate is about to be over the setting value,

the Baud rate automatically lowers up to 2400 bps to

make the error rate remain below the setting value.

• You can select the rate between 5% and 10%., 20%

♦ Flash Time

When the recall button on the OPE is pressed, it displays

time to operate a recall. It is possible to select 100,280 or

600 milliseconds.

♦ Pause Time

• Pause time mean delay time (unit: second) inserted

between dial number signal and the next number of signal in the automatic dial (One touch, Speed dial, Redial)

and the manual dial.

• Caution : The Send Fax Level is set at the best condi-

tion in the shipment from factory. Never

change settings arbitrarily.

♦ Make/Break

• Select the dial pulse make and break time: 33/66 or

40/60

• Caution : Send Fax Level is set at the best condition in

the shipment from factory. Never change settings arbitrarily.

♦ Ring On Time

It is used to acknowledge the effective ring. When a

phone call coming, a ring is ringing if an input range of the

ring is bigger than ring-on-time. The input range is 00990ms.

♦ Ring Off Time

Once you are in the Ring On Time Mode, if the ring signal

is not equal to or greater than the ring off time, you should,

increase the ring count.

If the ring signal is not set equal to or less than the ring off

time, do not increase the ring count. Instead, check the

Ring On & Off time again. The input range is between

00~990msec.

♦ DTMF High Level

• Select high frequency level when dialing in the MF

mode. The input range is between 00~15dBm.

• Caution : The DTMF High Level is set at the best condi-

tion in the shipment from factory. Never

change settings arbitrarily . (DTMF : Dual Tone

Multi-Frequency)

♦ DTMF Low Level

• Select low frequency level when dialing in theMF mode.

The input range is between 00~15dBm.

• Caution : The DTMF Low Level is set at the best condi-

tion in the shipment from factory. Never

change settings arbitrarily . (DTMF : Dual Tone

Multi-Frequency)

♦ USB Mode

Selectable USB packet size, Fast and Slow.(SF-331P

only)

♦ PWM Value Setup

This function is used in factory for production not for service

person. If a service person tries to use it, an image can be

abnormal during printing; therefore, do not touch it.

4.1.2.1 Setup System (In Tech Mode)

Page 4

Troubleshooting

4-4

Samsung Electronics

♦ Save Charge

When the user accesses the product from the outside via

phone, if the New ICM messages are exist, the product

answers after ringing as number of Rings to Answer the

user set. If there are no New ICM messages, the product

will answer after ringing as number of Rings to Answer

plus two times more. The user can check whether there

is New ICM message or not using this function without

physical phone line connection and this makes to save

money for the user. On or Off is selectable.

• ICM((In Coming Message)

♦ Call Monitor

When the caller leave a message on the product, the user

can hear the caller's message via speaker of the product

using this function. On or Off is selectable.

♦ ICM Record Time

The user can specify the maximum recording time for

ICM message. If this maximum recording time is elapsed,

the product will disconnect the line. 0, 30, 60 or 90seconds are selectable.

♦ Remote Password

When the user accesses the product from the outside via

phone, the user should specify this remote password to

keep user's personal privacy . The user can change 3 digits of the password except two # and the default value is

#139#.

♦ Silence Action

When the product recording ICM message, if the silence

is continued for 10seconds, the user can select the operation of the product about this silence. Disconnect,

Recording silence or Receiving fax are selectable.

♦ Howler Action

The howler means serious noise such like siren.

Technically we decide as a howler signal if the input signal is maintained by active state for 9 seconds without any

transition between active and inactive states. The user

can select the operation of the product at howler tone is

detected. Disconnect or Recording howler are selectable.

♦ Message Forward

When you're out of the office or home and you want to be

notified whenever there is new message left on your

machine, you need to use the Message Forwarding feature supplied with

your machine.In TAM Mode,you can set your machine to

transfer incoming calls to another number.In order to use

the Message Forwarding feature.

♦ Howler Time

While the setting value is over, it acknowledges the

Howler tone as Howler tone. The possible setting rage is

[000~150] (Unit : 100 ms).

♦ Silence Time

While the setting value is over, it acknowledges the

Silence as Silence. The possible setting range is

[000~200] (Unit : 100 ms).

♦ Silence Level

When a signal lower than setting value is coming, it

acknowledges it as Silence.

♦ Parallel Level

During OGM is playing or ICM is being recorded, when a

signal level difference is bigger than setting value it

acknowledger parallel is lift.

4.1.2.2 Setup TAM (Only SF-335T)

Page 5

Troubleshooting

4-5

Samsung Electronics

♦ ALL MEMORY CLEAR

This is a function to return a system to the initial state.

There are two ways for performing MEMORY CLEAR.

♦ Using TECH MODE

In the TECH MODE, perform a MEMORY CLEAR.

It is a function to help to select a firmware for the right

nation after replacing a main board.

• Operation method •

1. Enter to the TECH MODE by pressing

MENU, #, 1, 9, 3, 4 in order.

2. Press "MENU" button until "MEMORY

CLEAR" is displayed at LCD window.

3. When push a "ENTER" button, a message

that requests to input a country code will be

displayed.

4. Input a country code you wish then, press

"ENTER" button.

5. Country name will be displayed at LCD.

6. If it is correct, press "ENTER" button. If not,

press "CANCEL" button to return to the previous step.

7. MEMORY CLEAR will be performed. (Please

refer to the country code in the below table)

Caution : By each country, the default values

are little different. After replace the

main board, perform this function for

setting the firmware fitted for each

country to make a machine to work

properly .

♦ Using BUTTON

When the machine is abnormally operated, this function is performed for resetting the system to initial value.

All the setting values are returned to the default values,

and inputted information by user will be erased but

country code.

• Operation method •

1. Turn off the power.

2. Turn on the power while press "STOP" button.

3. Press "STOP" button until the "MEMORY

CLEAR" is displayed at LCD panel.

Note : This method doesn't have a function to

input the country code.

4.1.2.3

MEMORY CLEAR

Page 6

Troubleshooting

4-6

Samsung Electronics

EUROPE ASIA AMERICA

Country Code Country Code Country Code

England 01 Korea 31 USA 61

Germany 02 Australia 32 Canada 62

Switzerland 03 NewZealand 33 Brazil 63

Austria 04 SouthAfrica 34 Chile 64

Italy 05 Chinese 35 Mexico 65

France 06 HongKong 36 Panama 66

Spain 07 Singapole 37 Argentina 67

Portugal 08 India 38 Peru 68

Netherlands 09 Indonesia 39 Colombia 69

Belgium 10 Malaysia 40 Uruguay 70

Sweden 1 1 VietNam 41 Venezuela 71

Norway 12 Philippines 42 Reserve_USA 72

Finland 13 Bangladesh 43 Reserve_USA2 73

Denmark 14 Israel 44 Reserve_USA3 74

Hungary 15 Kuwait 45 Reserve_USA4 75

Poland 16 Iran 46

Czecho 17 Iraq 47

Yugo 18 UAE 48

Romania 19 Syria 49

Bulgaria 20 Lebanon 50

Turkey 21 Jordan 51

Greece 22 SaudiArabia 52

Russia 23 Egypt 53

ReserveEU1 24 Tunisia 54

Reserve_EU2 25 Morocco 55

Reserve_EU3 26 Thailand 56

Reserve_EU4 27 Taiwan 57

Reserve_EU5 28 Reserve_Asia3 58

Reserve_EU6 29 Reserve_Asia4 59

Eu_Std 30 Asia_Std 60

< Rhine Country Code >

Page 7

Troubleshooting

4-7

Samsung Electronics

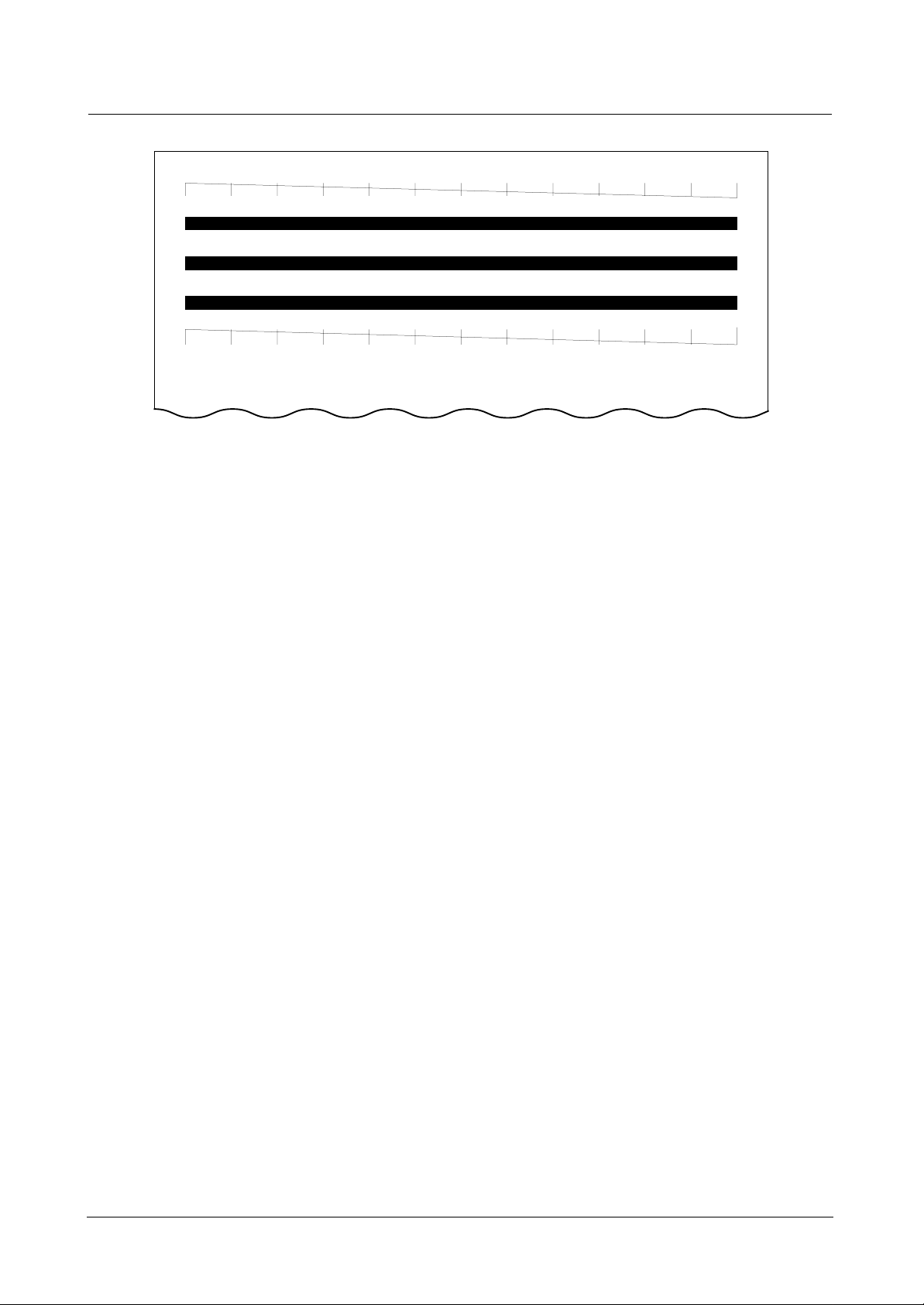

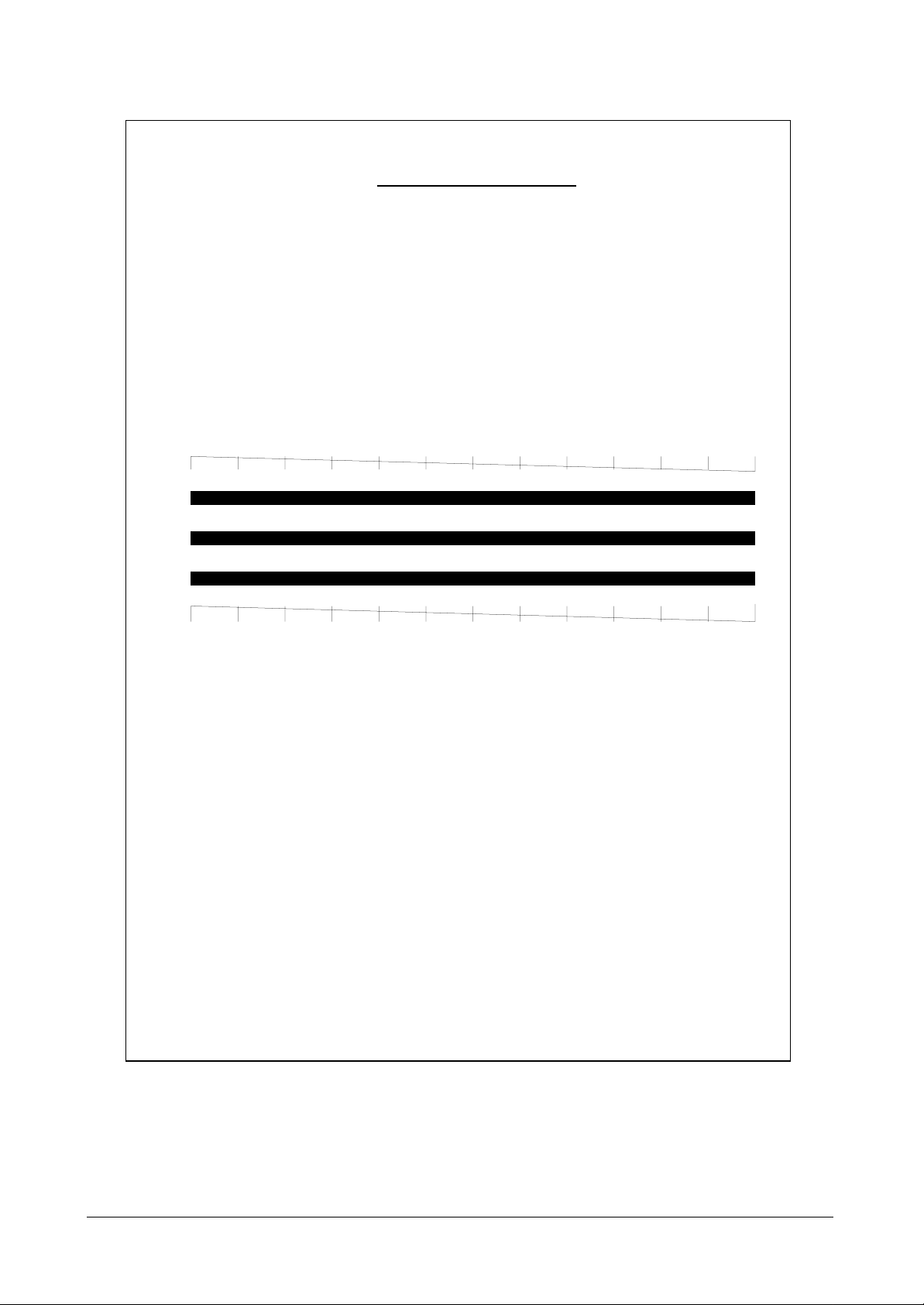

♦ Clean Head

When white lines are appeared, when image is printed

poorly in part, sweep the nozzle of the ink cartridge and

contacting surface of the cartridge, then clean the cartridge.

Until it gets better, do it several times.

On the inkjet print system, the print quality can be degraded by several causes , and the main root cause among

the causes will be from the head.If the print quality is not

good, the user should do this process to get a good print

quality . This operation can be initiated from the printer dri ver menu or Maintenance menu from the control panel of

the product. When the operation is initiated , the diagonal

patterns and purge patterns are printed out. The first diagonal pattern is to indicate the current nozzle status before

cleaning. The 3 purge patterns are operations for cleaning cartridge.This operation includes purging , wiping and

spitting. The second diagonal pattern is to indicate the

current nozzle status after cleaning.

♦ Align Head

Using this feature to get fine print quality when a vertical

line is printed not in straight or when ink cartridge is just

replaced.

♦ View Ink Level

To check the amount of the mounted ink cartridge.

The product has no ink level monitor sensor. Therefore

the firmware counts ink dot whenever the ink is fired , and

we call it as ink level monitor gauge. This is not automatic method , so the user should do proper operation whenever the user installs the new ink head. The firmware will

record the ink dot count be fired into the backup information memory whenever the printing job is finished and the

machine is in idle state. The user can monitor the current

ink level on the Maintenance menu. The level will be displayed as like x/8 and this value indicates the remained

ink level.

If the current ink level reaches to 1/8 , the firmware will display 'Install new cartridge'. message to indicate current

remained ink can be exhausted soon .

This message will be displayed continuously unless the

ink is replaced and the user selects the New Ink. Under

Ink Low state , the received fax message will not be printed out unless the user replaces the ink and selects the

New Ink. But , PC printing and copy job will be done under

this Ink low condition.

4.1.2.4 Maintenance

[ Clean Head ]

Page 8

Troubleshooting

4-8

Samsung Electronics

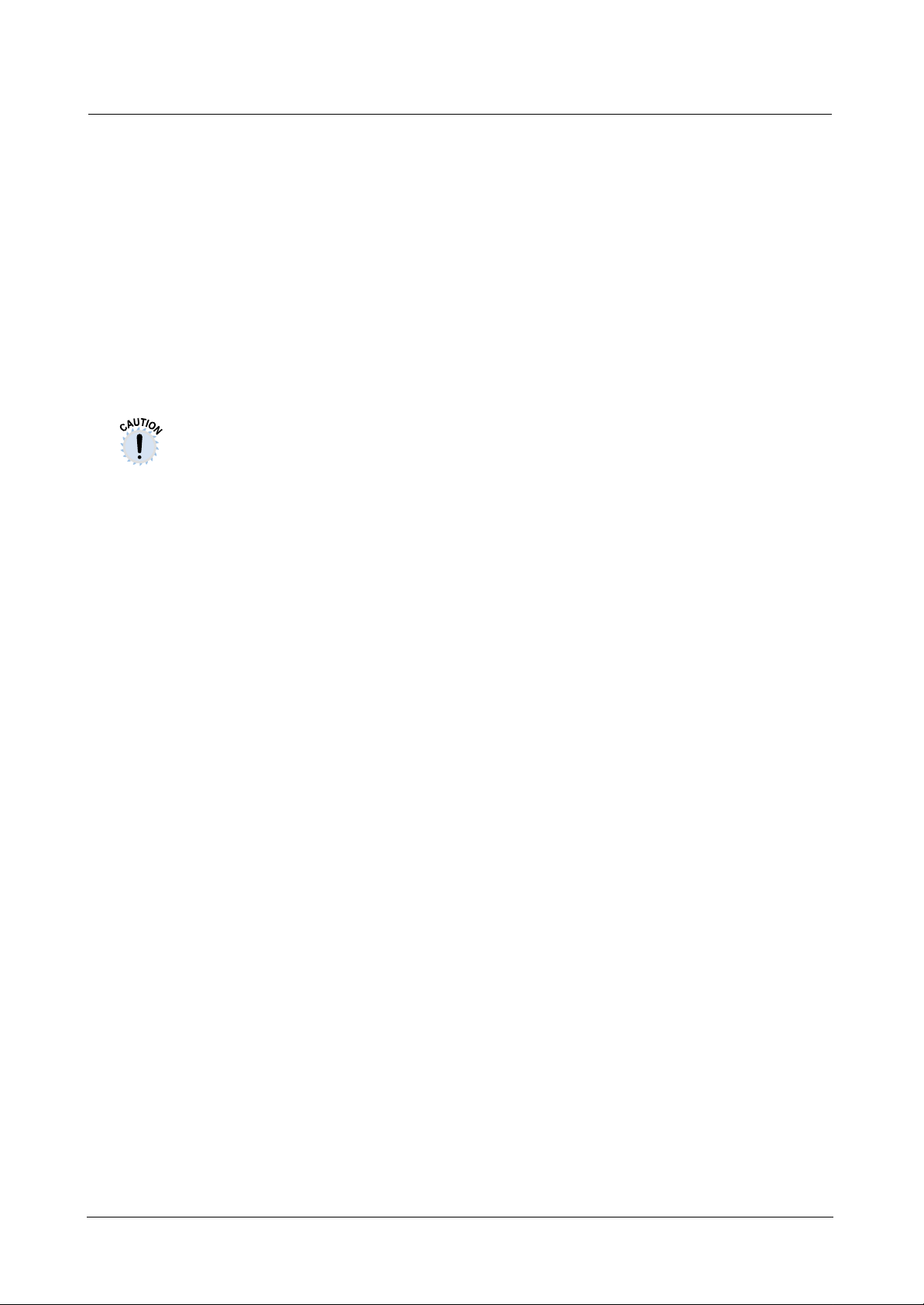

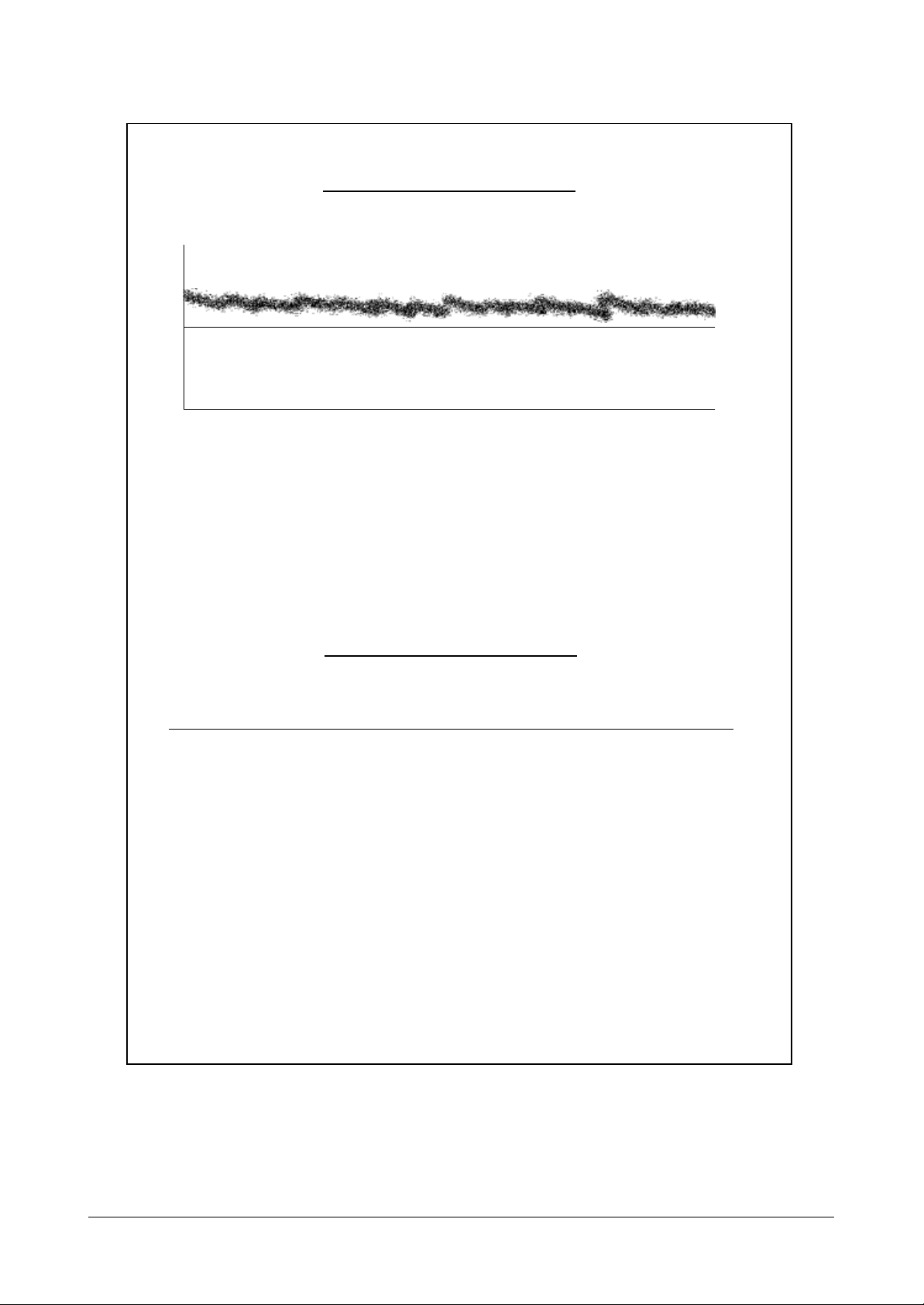

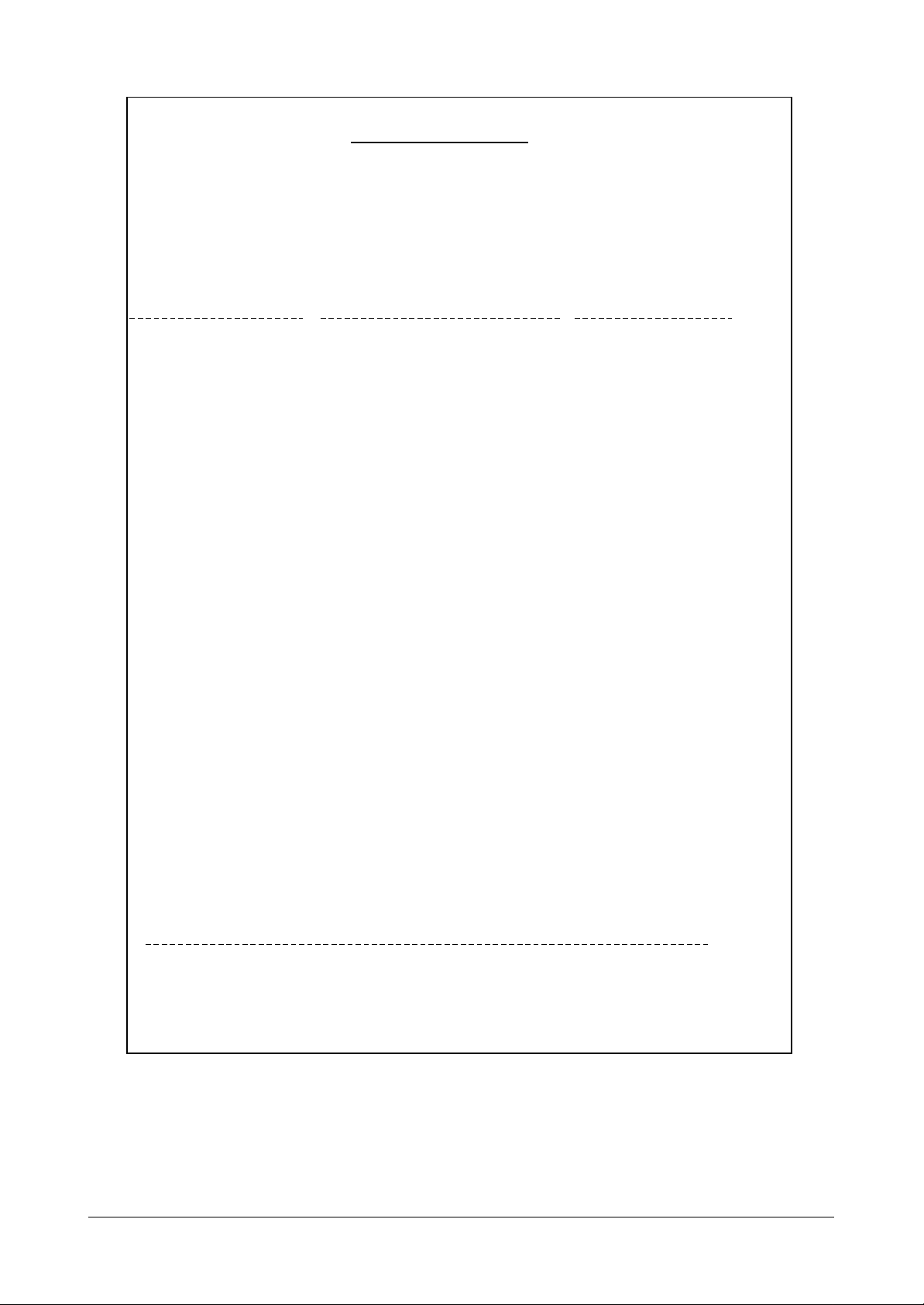

Shading Profile

Shading History

Maximum Lever : 0196 OK

Minimum Lever : 0135 OK

CIS LED on time : 4960

CIS MAX. UP : 0018 OK

CIS MAX. DV : 0032 OK

CIS Lower Counter : 0000

CIS Lower Valur : 0135

255

0 1728

NO. Shading Time Stored Checksum Calculated Checksum

1. 01-01 2002 13:02 Ox428e 0x428e

[ Adjust Scanner ]

Page 9

Troubleshooting

4-9

Samsung Electronics

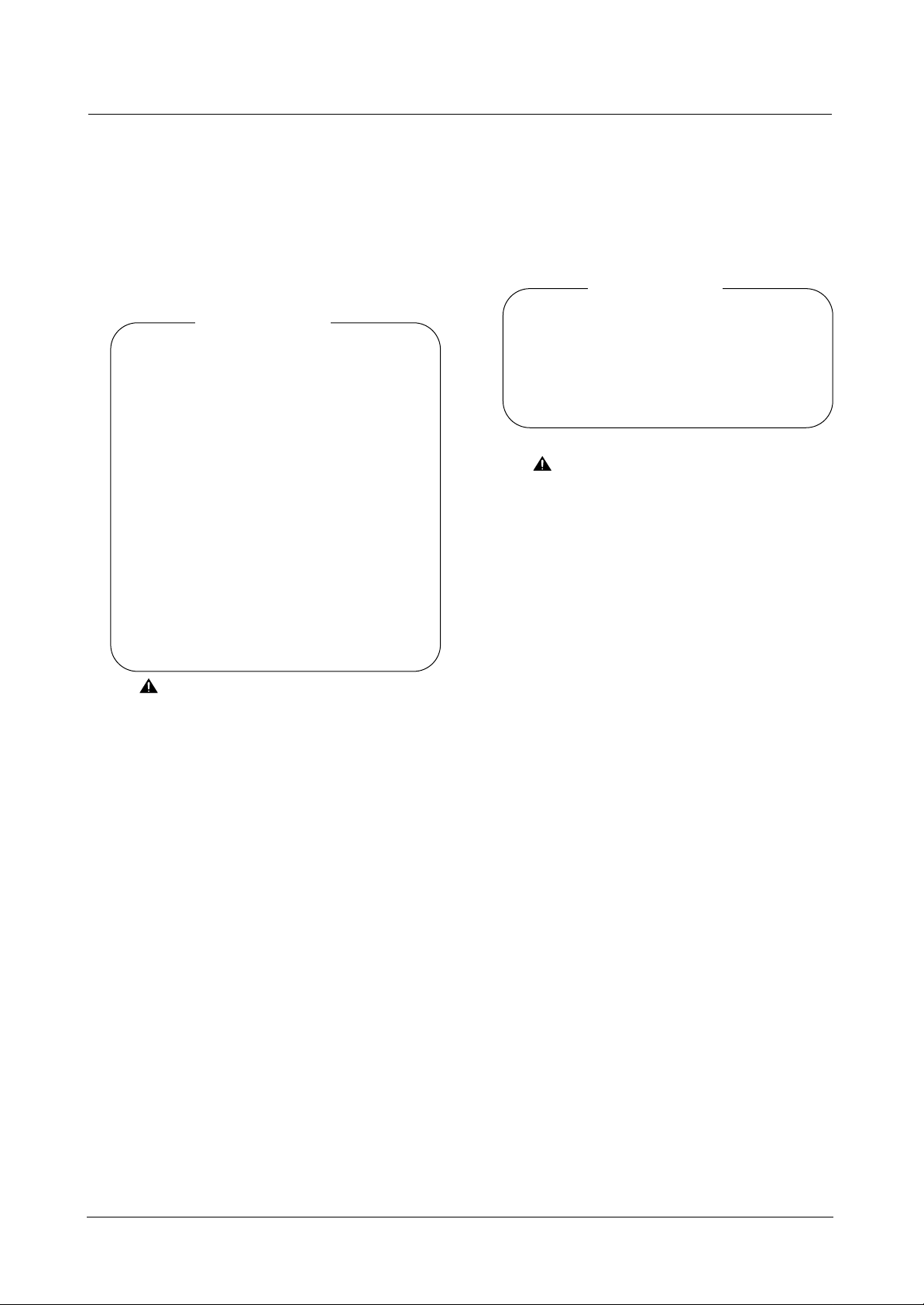

♦ Adjust Scanner(see page 4.8)

Use this adjustment feature to achieve best image (scan)

quality depending on the characteristics of the CIS

(Contact Image Sensor) parts.

Use this feature to correct the reference of the CIS if you

experience bad copy images. When using this feature, a

white paper should be used to get clean copy images.

1. Select [Adjust Scanner] in Service mode

2. Press

'Start/Enter'(A message “Load white paper docu-

ment and press Start/Enter”

is displayed on LCD)

3. Place the empty white paper (Letter size) in a Feeding

unit.

4. The original is scanned when press 'Start/Enter' button.

5. After finish the scan, a message is displayed on LCD

and the ìAdjust scanner profileî is outputted.

6. If the outputted image is different to the normal image,

a CIS is inferiority.

Caution :

1. Always perform Adjust Scanner

after replacing the CIS.

2. Always use a clean white paper in

Adjust Scanner (Maximum paper

width: Letter Size).

3. Adjust Scanner may be performed even in the User Mode but

Adjust Scanner profile is output

only in the TECH MODE.

<Reference>

The CIS type scanner needs scanner adjustment operation to get a good scanning quality. This is called as

Shading Compensation .

All kinds of scanner use light have a distortion according

to component tolerance. This tolerance can make a distorted scan signal. To cover this problem , the firmware

has a reference scan waveform into the non-volatile

memory for each CIS .

This reference waveform will be made in the factory when

producing the product. But , the scanner , CIS , characteristics can be changed as it is used therefore the scanning quality can be different with first time. At this time , the

user should initiate this operation from the control panel

menu using white document. Then the old reference

waveform will be replaced with new reference waveform

for current CIS characteristics. This function can be initiated in Maintenance menu.

When the new shading waveform is generated , the

waveform will be stored into a Flash memory sector , and

the checksum value is calculated and stored also.

Whenever the scanning job is initiated , the checksum

value is re-calculated and compared with stored checksum value. If the value is different , the Firmware regards

as the shading waveform be stored into Flash memory is

broken due to unknown reason and will display the message to indicate retrying Adjusting Scanner operation

before the scanning job.

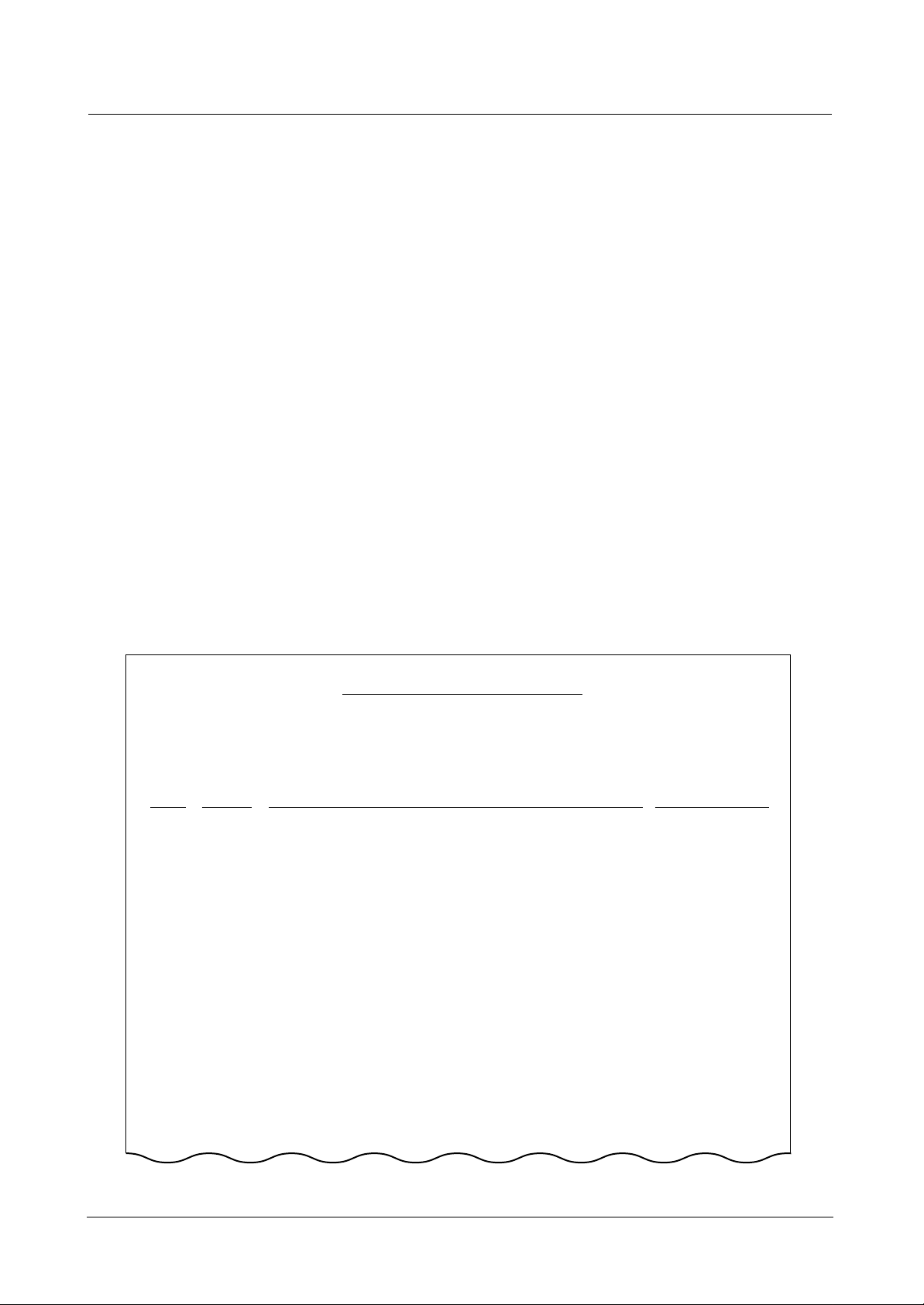

♦ Self Test (see page 4.11)

It is possible to check whether a machine works properly

or not.

ROM Version/Connect Telephone Line/Shading area

checksum check/Modem check/Cartridge check, etc.

♦ ASF Test

The function is to test the function of ASF (AUT O SHEET

FEEDER), and it is needed in the production progress.

Service person doesn't need to use it.

♦ Modem Test

Use this feature to hear various transmission signals to

the telephone line from the modem and to check the

modem.

If no transmission signal sound is heard, it means that the

modem part of the main board is poor.

♦ DTMF Test

DTMF (Dual Tone Multi Frequency) signal. When you

press any key on the number keypad including • and #,

you will hear the corresponding key tone.

Page 10

Troubleshooting

4-10

Samsung Electronics

♦ Program Download (Firmware Upgrade)

A new firmware can be downloaded from PC through

USB CABLE. Connect the machine to PC with USB

CABLE, and use additional Firmware upgrade utility.

To download the F/W code,

First, the machine should be Download mode status.

(See How to enter the download mode in machine)

• How to enter the download mode in machine.

1) Press the buttons in sequence

(Menu, #, 1, 9, 3, 4)

2) Press the Menu button repeatedly until

“Maintenance” is display

ed.

3) Press the Start/Enter button when “Maintenance”

is displayed.

4) Press the Scroll/Volume button repeatedly until

“Program Download” is displayed.

5) Press the Start/Enter button when “Program

Download” is displayed.

Second, files needed for download is as follow (Files are

needed for download)

1) ROM FIle

2) SSMFPUSB.inf

3) SSMFPUSB.sys

4) SSUSBCI.DLL

5) usbdown.bat

6) usblist.exe

7) dwcdpcl.bin

8) lxusbopn.dll

• How to Download •

1. Connect a printer and PC with USB CABLE.

2. When a communication box of Plug & Play

shows up, select the location in where the

‘SSMFPUSB.INF’ is.

3. If the communication box of Plug & Play

doesn’t show up, please do the step 6.

4. After USB driver is set up, for confirm it,

select the ‘properties’ by pressing right

mouse button of ‘my computer’ on the

Desktop.

5. Check whether the SF-331P in

‘SamsungUSB’ exists or not at tap in Setting

control. (If not, the down load is impossible)

6. Open a DOS window, change the Directory

Path to where the FIRMWARE exists.

7. Input “USBLIST <FIRMWARE filename>”

and enter.

Page 11

Troubleshooting

4-11

Samsung Electronics

Self Test

VO.90B 21/06/2002 SF-330 CHECKSUM : FC2EH

Paper Size : A4

1.Tel. Line Test : Check Telephone Line Cord

2. Shading Test : Ok

3. Modem Test : Ok

4. Cartridge Test :

- Head Test Result : OK

- Ink Level : 8/8

[ Self Test ]

Page 12

Troubleshooting

4-12

Samsung Electronics

System Data

Date : 10-JUL-2002 WED 12:02

Name : SVC MANUAL

Tel. : 0312003956

Total Page Counts : 17

Total Feed Document Counts : 1

Options Item Status

SET DATE & TIME

Date Format [USA/Europe] Europe

SETUP SYSTEM

Modem Speed [14.4K/12.0K//9.6K/7.2K/4.8K/2.4K] 14.4 KBPS

Fax TX Level [00-15] 12

Fax RX Level [40-50] 48

CNG Count [1-4] 2

T1 Time [030-150] 55

Fax Error Rate [5% /10% /20%] 10%

Flash Time [100ms/280ms/600ms] 100ms

Pause Time [1-9] 4

Make/Break [40:60 /33:66] 33:66

Ring On Time [00-99] x 10ms 15

Ring Off Time [00-99] x 10ms 90

DTMF High Level [00-15] 08

DTMF Low Level [00-15] 11

Usb Mode [Fast/Slow] Fast

PWM Value Setup [000-208] 109

Dial Mode [Tone/Pulse] Tone

ADVANCED FAX

Fax Forward [Off/forward/(Forward&Print)] Off

SETUP TAM

Save Charge [On/Off] on

Call Monitor [On/Off] on

ICM Record Time [30sec/60sec/90sec] 60sec

Remote Password [000-999] #139#

Silence Action [Disconnect/Receive Fax/Record Silence] Disconnect

Howler Action [Disconnect/Receive Howler] Disconnect

Message Forward [on/Off] Off

Howler Time [000-150] 90*100ms

Silence Time [000-200] 105*100ms

Silence Level [00-48] -36dBm

Parallel Level [100-200] 130

SETUP SOUND

Alarm Sound [On/Off] On

Key Sound [On/Off] On

Flash Rom Version : V0.90T

[ System Data ]

Page 13

Protocol Dump

Date : 10-JUL-2002 WED 12:03

Name : SVC MANUAL

Tel. : 0312003956

S/R FCF FIF Data ASCII

Tx/Rx Speed : 2.4

Tx/Rx Resolution :

Tx/Rx Mode : G3

T30_State

T30_Error

OK

T4_Return

00:T4_SUCCESS

01:T4_UNKNOWN_IN-FORMAT

02:T4_UNKNOWN_OUT_FORMAT

03:T4_ILLEGAL_CONVERSION

04:T4_ABORTED

05:T4_DECODE_ERROR

06:T4_TIME_OUT_ERROR

07:T4_NO_REAL_IMAGE

08:T4_NOT_FOUND_RTC

09:T4_MEMORY_FULL

0a:T4_TASK_BEGINNING

Troubleshooting

4-13

Samsung Electronics

4.1.2.5 Report/Helf

♦ Help List

It shows a brief description on the machine's basic functions and commands.

Use it as a quick reference guide

♦ Sent Journal

This journal shows a specific information concerning

transmission activities, the time and dates of up to 40 of

the most recent transmissions.

♦ Received Journal

This journal shows a specific information concerning

reception activities, the time and dates of up to 40 of the

most recent receptions.

♦ Phonebook

It lists all telephone numbers that have been stored in the

machine.

♦ Sending Confirm

It shows the result of the last send operation.

♦ Schedule Inform

This list shows a specific information on the documents

currently stored for delayed transmission. It provides the

operation number, starting time, type of operation, etc.

♦ System Data (see page 4.12)

This list provides a list of the user system data settings

and tech mode settings.

♦ Caller ID

In the country which supports CALLER ID, information of

the dates and numbers of calls is stored when RING is

receiving.

(CALLER ID : it is a telephone service to send a caller's

number to the receiver.)

♦ Junk Fax

It is possible not to receive a fax by registering a specific

number, from which you don't want to get fax, with the

Caller ID function.

The fax number registered as Junk Fax can be checked.

A maximum 20 numbers can be registered.

♦ TAM Status

The list shows recorded date & time, recording time and

index of the OGM, ICMs and conversation messages.

♦ Fax Print

The machine stores fax data into memory as far as the

memory is available and lets you print it at laster time.

♦ Shading Profile

It shows the result of the Adjust Scanner.

♦ Protocol Dump

This list shows the sequence of the CCITT group 3 T.30

protocol during the most recent sending or receiving operation. Use this list to check for send and receive errors. If

a communication error occurs while the machine is in

TECH mode, the protocol list will print automatically.

[ Protocol Dump ]

Page 14

Troubleshooting

4-14

Samsung Electronics

♦ NVRAM Dump

NVRAM(nonvolatile random access memory) is nonvolatile RAM, therefore, information still reminds after

power off.

Arelative information of using amount of ink cartridge can

be checked.

♦ Memory Dump

Ainner information, which helps to analyze a cause when

a machine has failed during operation, can be printed out.

This is a function to check the memory area to improve a

machine. Do not handle it at will.

♦ Task History

Ainner information, which helps to analyze a cause when

a machine has failed during operation, can be printed out.

This function works to improve goods. When it is handled

at will, it can be malfunctioned. Do not handle it at will.

♦ POWER FAILURE

After the power is off and on , if the received fax image or

stored scheduled fax image are lost , this report is printed

out automatically to indicate what image was lost .

That is , if the power is off during the machine operates ,

the current information can't be backed up .

♦ MULTI COMMUNICATION

When sending original documents to 2 or more locations

with broadcasting , the product prints out the transmission

results automatically after all transmissions are completed.

NVRAM Dump

Date : 13-MAY-2002 MON 14:09

Name : SVC MANUAL

Tel. : 0312003956

< Device Identification >

MFG : Samsung;

MDL : SF-331P;

CMD : MLC, PCL, PML;

CLASS : PRINTER;

DESCRIPTION : Samsung SF-331P;

< Dot Count Variables >

Black Dot Count : 9035623

Color Cyan Dot Cout : 0

Color Magenta Dot Count : 0

Color Yellow Dot Count : 0

Total Black Dot Count : 9078831

Total Color Cyan Dot Count : 0

Total Magenta Dot Count : 0

Total Yellow Dot Count : 0

< Page Count Variables >

Totoal Page count : 23

< Alignment Variables >

Horizontal Align Value : 6

[ NVRAM Dump ]

Page 15

Troubleshooting

4-15

Samsung Electronics

4.2 Maintenance

4.2.1 Cleaning the document scanner

To keep your machine working properly, occasionally

clean the White Roller, ADF Rubber, and the Scanning

Glass. If they are dirty, documents sent to another fax

machine won t be clear.

If you turn the power off to clean the scanner, documents

stored in memory will be lost.

1. Open the Control Panel.

2. Remove the White Roller.

• At the right-hand end of the White Roller there is a bushing that is secured with a small tab.

• Push the tab slightly inward, then rotate towards you.

Then pull up the right-hand part to take it out.

3. Wipe the roller surface with a soft cloth dampened with

water.

4. Clean the ADF Rubber piece at the back of the Control

Panel, too.

5. Carefully wipe the Scanning Glass with a soft, dry cloth.

• If the glass is very dirty, first wipe it with a slightly

dampened cloth, then with a dry one.

• Be careful not to scratch the glass surface.

6. Replace the roller in reverse order, and then close the

Control Panel firmly until it clicks into place.

Page 16

Troubleshooting

4-16

Samsung Electronics

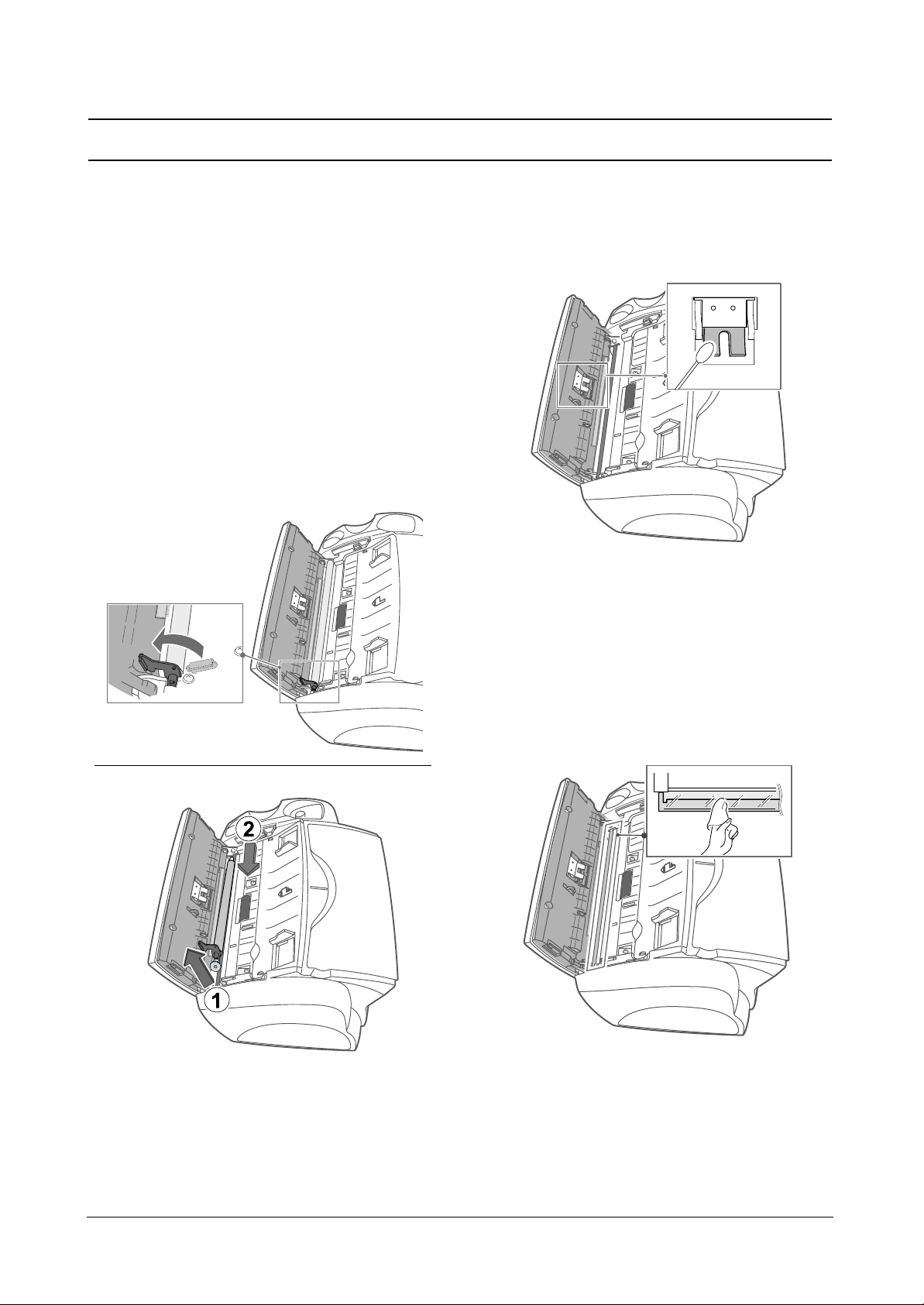

4.2.2 Replacing the print cartridge

When you notice that the print becomes light or “Ink Low.Install new ink cartridge”appears in the display, replace the print cartridge. You should replace the cartridge with the same one which was provided with the machine.

The part number for replacement cartridges are:

•mono : INK-M40, color: INK-C40 (available only for SF-331P)

1. Prepare a cartridge.

•Take out a cartridge from its packaging and carefully remove the tape covering the printhead.

•Hold the cartridge by the colored top or black areas only. Do not touch the copper area.

2. Press “Cartridge” .The Cartridge Carrier moves to the install position.

3. Open the Control Panel and Cartridge Compartment cover.

4. Push down the cartridge, and remove it.

5. Place the cartridge in the Carrier, then push it firmly until it clicks into place.

•If the cartridge moves loosely in the Carrier, it has not clicked into place. Repeat this step.

6. Replace the Cartridge Compartment Cover and Control Panel.

7. Press “Start/Enter”.

8. Press 1 for new cartridge, or 2 for the old one.

•In case you selected the 1: “New” , the alignment form will print.

•When you put in a new cartridge, you must choose 1: “New” .

•When you put in a used cartridge, choose 2: “Used” . This helps you to check the correct amount of ink you have left.

•If you mix up several used cartridges, it is not possible to check the correct amount of remaining ink. Once you have put in a

new cartridge, use it until it is completely exhausted.

9. Enter the number which represents the straightest line, and press “Start/Enter” .

Page 17

Troubleshooting

4-17

Samsung Electronics

4.2.3 Cleaning the cartridge

To maintain good printing quality, we recommend you occasionally wipe the and Contacts as described below:

For print cartridge and print quality problems, see section 4.4.

4.2.3.1 Wiping and contacts

When the print is not clear or dots are missing, the problem may be caused by dried ink on the:

•Print cartridge contacts

•Print cartridge carrier contacts

1. Press “Cartridge” .

2. Open the Control Panel and Cartridge Compartment Cover and remove the cartridge.

3. Gently blot and wipe the contacts dry.

• Use a clean cloth dampened with water only to gently clean the entire copper-colored area,

including contacts.

4. Reinstall the cartridge and close the Cover and Panel.

• If you spend a long time cleaning the cartridge, the cartridge carrier may have moved back

to the original position. If so, press “Cartridge” again to move the carrier to the install position.

5. Press 1 for new cartridge, or 2 for the old one.

• If the line is still broken, clean the Cartridge Carrier contacts. For more information, see "Cleaning the cartridge carrier contacts" on page 4.17.

4.2.3.2 Cleaning the cartridge carrier contacts

Before cleaning these parts, there should be no scheduled job such as Delayed Fax, Send Polling, or faxes received into memory. Once you have unplugged the power cord from the machine, all data will be lost.

1. Press “Cartridge” .

2. Open the Control Panel and Cartridge Compartment Cover and remove the

cartridge.

3. Remove the print cartridge.

4. Unplug the power cord from the electrical outlet of the rear of the machine.

5. Clean the Cartridge Carrier contacts with clean and dry cloth.

6. Plug in the power cord and reinstall the cartridge.

4.2.3.3 Print cartridge maintenance

The print cartridge life is very sensitive to the content of the received fax or a copy you made. To increase its life, we recom-mend

you follow the instructions below:

• DO NOT unpack the cartridge until you are ready to use it.

• Store it in the same environment as the printer.

• If you have unpacked the cartridge but are not using it, store it in a storage unit. If you do not have a storage unit, store the

cartridge in an airtight plastic bag.

• DO NOT leave it exposed for an extended period.

• DO NOT refill the cartridge. The warranty will not cover damage caused by using refilled cartridges.

Page 18

Troubleshooting

4-18

Samsung Electronics

4.2.5 LCD error messages

Display Status/Solution Related to:

Display Adjust scanner first

in Maintenance menu

Check white paper

document and try

again

Clean white roller,

glass and try again

Duplicated with

[Speed No.xx ]

The xx indicates the location number.

Exceeded Job Memory

Cancel scheduled job

and try again

Exceeded Total Message Memory

ICM Memory Full

Ink Low.Install new

ink cartridge

Install ink cartridge

Install mono ink

cartridge

Job Not Assigned

Junk Fax Empty

Junk Fax Full

Load Document

Memory Full

Memory Full

Press Start/Enter to

continue

Memory Received

When it toggles with:

Ink Low.Install new

ink cartridge

Load paper and press

Start/Enter

Install ink cartridge

The shading waveform to be used as a reference is corrupted due to

unknown reason. Adjust the scanner to fix this problem as described in

"Adjust Scanner" on page 4.9.

The scanning level is too low to compare with reference level. T o adjust

shading, you should use the plain and white paper.

The scanning level is slightly low, which can affect the image quality.

To clean concerned parts, see "Cleaning the document scanner" on

page 4.15.

The same number has already been registered into another speed dial

location.

The broadcasting and delayed fax can hold 5 jobs in total. Cancel

scheduled job and try again.

The machine can hold up to 100 messages (OGM + ICM + recorded

conversations).

Erase old messages to make a room in the memory.

The voice memory is full. No more caller’s messages can be recorded

(Total recording time is about 15 minutes).

The print cartridge has run out of ink. To install a new Print Car- tridge,

see "Replacing the print cartridge" on page 4.16. Although this message is displayed, you can make a copy or print a report. But, stored

data in memory can be printed by changing the cartridge.

Print cartridge is not installed or improperly installed.

The mono print cartridge should be installed to copy, print a report or

receive a fax.

You attempted to cancel the scheduled job but there is no jobs scheduled.

You attempted to delete the junk fax number when there is no junk fax

number.

The machine can hold 20 junk fax numbers but you tried to add more.

You have tried to make a copy and there is no document loaded into

the machine.

Memory has become full while receiving a fax.

Memory has become full while scanning a document. Press

“Start/Enter” to send or copy the scanned pages only. To cancel the

job press “Stop/Cancel” and try again when memory becomes available, or split the new document into smaller parts.

The machine has data stored in memory. Depending on the message

do as follows:

Replace the print cartridge with new one.

Load the paper, and press “Start/Enter”. There might be paper out.

Scanner

Scanner

Scanner

Telephone

Fax

TAM (SF-335T only)

TAM (SF-335T only)

Cartridge

Cartridge

Cartridge

(SF-331P only)

Fax

Fax

Fax

Document

Fax

Fax/Copy

Fax

Page 19

Troubleshooting

4-19

Samsung Electronics

Display Status/Solution Related to:

No answer from

remote fax

No CID Number

No Dial Number

No Message

No New Message

Not Found

Number already reg-

istered

Number Not Assigned

Poll Code Error

Poll job exists

already

Polling Error

Check remote site

Record T AM OGM

Remove jammed document

System Busy

Try again later

To redial now,press

Start/Enter

The other machine has not answered after all your attempts to send a

fax.

The machine could not detect the CID (Caller ID) number.

There is no number in the redial memory, which is successfully dialled

up to now.

There is no message to play or erase.

There is no new caller message.

The number you are searching does not exist in memory.

The number you are trying to register already exists in the phone-book

or junk fax list.

There is no number assigned to the One-Touch or two-digit Speed

number.

The remote user entered wrong poll code.

You have programmed a polling send. Cancel scheduled job and try

again.

The machine you want to poll is not ready to answer your poll. The

person you are polling should have loaded their fax machine with a

document and be in send poll state.

To select TAM receive mode, you should record OGM prior to pressing the Answer button.

Th

e document you are sending has jammed in the feeder. To clear the-

document jam, see "Document jams during transmission" on page 4.22

.

You tried to copy or fax a document which is longer than 390mm.

There is no available resource to execute job you ordered.

The machine is waiting to automatically redial the fax number that was

busy or did not answer.

Fax

Telephone

Telephone

TAM (SF-335T only)

TAM (SF-335T only)

Telephone

Telephone

Telephone

Fax

Fax

Fax

TAM (SF-335T only)

Document

Fax

Fax

Page 20

Troubleshooting

4-20

Samsung Electronics

4.2.6 Fixing Simple Problems (A quotation from users Guide)

The problem may be listed in "LCD error messages" on page 4.18. The chart below shows other problems users can solve

themselves.

Fax problems

Problem Solution

The machine is not working, Unplug the power cord and plug it in again. Check that your socket is live.

there is no display

and the buttons are not working.

No dial tone. Check that the phone is connected properly. Check the phone socket in the wall by

plugging in another phone.

The numbers stored in memory Make sure the numbers are programmed correctly.

do not dial correctly. To print a Phonebook Report, see "To Print a report" on page 4.13.

The document does not feed Be sure the document is not wrinkled, and you are putting it in correctly.

into the machine. Check that the document is the right size and not too thick or too thin.

You cannot receive faxes Check if “TEL” appears on the right side of the display.

automatically. In TEL mode, you cannot receive a fax automatically. Be sure the handset is seated on

the cradle properly.

The machine cannot receive Do not hang up the handset before pressing “Start/Enter”.

faxes manually.

The machine does not send anything. Check that the document is loaded face down. should show up in the dis-play.

You may have hung up the handset before you pressed “Start/Enter”.

Check if the machine to which you are sending can receive your fax.

You cannot poll another machine. The fax machine you are polling may be using a poll code.

The fax you received has blank The machine sending to you may be faulty. Anoisy phone line can cause line errors.

bits on it. Check your machine by making a copy.

Spots or lines missing from Check if your phone line is noisy. Check if the printhead is clean by making a copy.

the fax you receive.

You are receiving poor quality copies. The fax machine sending to you may have a dirty scan glass.

Check for a noisy phone line.

Some of the stretched words on The machine sending to you had a temporary document jam.

the fax you receive

Your machine does not make copies. Make sure your document is loaded face down.

There are lines on copies or Check your scan glass for marks and clean it

documents you send. (see "Cleaning the document scanner" on page 4.15.)

The machine dials a number, The remote fax machine may be turned off, or unable to answer incoming calls.

but fails to make a connection with Speak with the remote operator and ask for the problem to be rectified.

a remote fax machine.

You cannot store a document . There may not be enough memory available to hold the document you want to store.

in memory If the display shows a “Memory Full” message, delete any documents you no longer

need, then retry the document.

Blank areas appear at the bottom You may have selected the wrong paper settings. To select the proper paper size.

pages, with only a small strip of

material printed at the top.

Page 21

Troubleshooting

4-21

Samsung Electronics

Print quality problems

Problem Solution

Light or blurred characters. Check Ink Level Viewas described in "Ink level view" on page 4.7.

If the printer cartridge has completely run out, “Ink Low.Install new ink cartridge”is dis-

played. To install a new print cartridge, see "Replacing the print cartridge" on page 4.17

.

Make sure the print cartridge is installed correctly.

To clean the print cartridge, see "Cleaning the cartridge" on page 4.17.

Smudged or dark characters. Make sure the paper is straight and unwrinkled. Let ink dry before handling the paper.

To clean the Print Cartridge, See 4.17 .

Characters with white lines. ”If Ink Low.Install new ink cartridge” is displayed, install a new print cartridge as described

in "Replacing the print cartridge" on page 4.16.

Remove and reinstall the print cartridge. Clean the Print Cartridge. See 4.17 .

Improperly formed or misaligned Clean the print cartridge (see "Cleaning the cartridge" on page 4.17.)

characters.

Abnormal black horizontal lines. Clean the cartridge carrier (see "Cleaning the cartridge carrier contacts" on page 4.17.)

Paper feeding problems

Problem Solution

Paper is jammed during Clear paper jam as described in "Paper jams during printing" on page 4.22.

printing.

Paper sticks together. You can load up to 50 sheets in the ASF (Automatic Sheet Feeder).

Check if you overloaded. Humid conditions may cause some paper to stick together.

Paper fails to feed. Remove any obstructions inside the printer.

Multiple sheets of paper When loading paper, do not force the paper down into the printer.

feed. If multiple sheets have caused a paper jam, clear the paper jam.

(see "Paper jams during printing" on page 4.22.)

Paper skews or buckles in ASF can hold up to 50 sheets. Make sure the paper guides do not cause the paper to

the automatic sheet feeder. bow in the bin. When loading paper, do not force it down into the printer.

Page 22

Troubleshooting

4-22

Samsung Electronics

4.2.7 Clearing jams

4.2.7.1 Document jams during transmission

If a document jams during transmission or copying, Remove jammed document appears in the display. DO NOT pull the document out of the slot. Doing so could harm your machine.

• To clear document jam:

1. Open the Control Panel.

2. Carefully remove the jammed document.

3. Close the Control Panel firmly until it clicks into place.

• Paper jams during printing

If the fax paper jams while you are receiving or printing, Remove jammed paper and press Stop/Cancel appears in the message. DO NOT pull it out. Doing so could harm the fax machine.

If the paper is jammed in the Received Paper Output Area

1. Remove the jammed paper by pulling it out smoothly in the direction of

the arrow as shown.

2. Press Stop/Cancel .

If the paper is jammed in the Paper Feed Area

1. Remove the jammed paper as shown.

2. Reload new paper with the print side facing toward you.

3. Press Stop/Cancel when finished.

Page 23

Troubleshooting

4-23

Samsung Electronics

4.3. Troubleshooting

4.3.1 Defective Operation (LCD WINDOW ) Display . . . . . . . . . . . . . . . . . . . . . .page(4.24)

4.3.2 No Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.24)

4.3.3 Defective LCD Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.25)

4.3.4 Defective Operation of Key Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.25)

4.3.5 Paper Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.26)

4.3.6 Defective Paper Feed (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.26)

4.3.7 Defective Paper Feed (2) -Display of NO PAPER . . . . . . . . . . . . . . . . . . . . . . . .page(4.27)

4.3.8 Defective Document Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.27)

4.3.9 Multi-Feeding (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.28)

4.3.10 Defective ADF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.28)

4.3.11 Defective Sensing-ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.29)

4.3.12 Defective Sensing-paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.29)

4.3.13 Defective Motor Drive (LF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.30)

4.3.14 Defective Motor Drive (CR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.30)

4.3.15 Defective Motor Drive (TX) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.31)

4.3.16 Blank Page Print Out (When Copying) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.31)

4.3.17 Blank Page Print Out (When Receiving) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.32)

4.3.18 Vertical Black Line (When Copying) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.32)

4.3.19 Vertical Black Line (When Receiving) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.33)

4.3.20 Contaminated Stains on Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.33)

4.3.21 Bad printed Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.34)

4.3.22 Vertical Lines are printed crookedly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.34)

4.3.23 Bad Color (Intensity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.35)

4.3.24 No Dial Tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.35)

4.3.25 Defective MF DIAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.36)

4.3.26 Defective FAX FORWARD/RECEIVE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.36)

4.3.27 Defective FAX FORWARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.37)

4.3.28 Defective FAX RECEIVE (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.37)

4.3.29 Defective FAX RECEIVE (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.38)

4.3.30 Defective FAX RECEIVE (3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.38)

4.3.31 Defective FAX RECEIVE (4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.39)

4.3.32 Defective Automatic Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.39)

4.3.33 The Printer is Not Working (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.40)

4.3.34 The Printer is Not Working (2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.40)

4.3.35 Abnormal Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.41)

4.3.36 Spool Error and Release of Spool Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .page(4.42)

• The solutions of troubleshooting in this 'Service Manual' explain the expected causes and

how to check according to each problem and describe how to replace the defected parts (unit

of ASS'Y) if necessary.

• The contents of this 'Service Manual' describe general ones only among many kinds of problems and causes while using the Product.

• The contents of this 'Service Manual' describe mainly technical explanations of the Product

H/W and parts on the assumption that there is no problem in S/W.

Page 24

Troubleshooting

4-24

Samsung Electronics

4.3.1 Defective Operation (LCD WINDOW ) Display

4.3.2 No Power

• Description

• Location 1.OPE ASS'Y 2.Connection between the Main B'D and OPE ASS'Y 3.Main B'D.

Strange characters are displayed on the OPE Panel and buttons are not operated.

Check and Cause Solution

1. Clear the memory.

2. Check if OPE HARNESS is connected to the Main

Board correctly.

1. Try again after clearing the memory.

2. After confirming that OPE HARNESS is connected to the

Main Board correctly, if it is so, then replace the OPE

ASS'Y and Main Board in sequence.

• Description

• Location

1.Power code 2.Connection between the Main B'D and Power HARNESS 3.Power ASS'Y 4.Main B'D.

While the power S/W is turned on, it does not work at all.

Check and Cause Solution

1. Check if the connection of power code is normal. 1. Try to replace the power code.

2. If all the connections are correct, try to replace the power

ASS'Y and the Main B/D in sequence.

Page 25

Troubleshooting

4-25

Samsung Electronics

4.3.3 Defective LCD Operation

4.3.4 Defective Operation of Key Button

• Description The LCD screen is not turned on or has a strange display.

Check and Cause Solution

1. Clear the memory. (See page 4.5).

2. Confirm to catch a click sound, while a key on the

OPE panel is pressed on.

1. The key is wrong itself or wrongly assembled.

2. Even after the key has been replaced, it is still wrong, try

to replace the OPE ASS'Yand the Main B'D in

sequence.

• Description

• Location 1. OPE ASS'Y 2. Main Board

The button of the OPE Panel is not operated..

Check and Cause Solution

1. Confirm to catch a click sound while the key is pressed

on.

2. Check if a specific key is pressed by another equipment.

1. If you cannot catch a click sound, the key is wrong itself

or wrongly assembled.

2. Even after the key has been replaced, it is still wrong, try

to replace the OPE ASS'Yand the Main B'D in

sequence.

Page 26

Troubleshooting

4-26

Samsung Electronics

4.3.5 Paper Jam

4.3.6 Defective Paper Feed (1)

• Description

• Location ASF ASS'Y

The paper is jammed inside the set and not exited from.

Check and Cause Solution

1. Check if the paper is crumpled or preprinted.

2. Check if too many sheets of recording paper are put

into ASF (Automatic Sheet Feeder).

(Standard : up to 50 sheets).

3. Check if the remaining papers are stuck in the frame

base.

1. If the papers jammed or pieces of the paper are stuck

inside the set, remove them and then try it again.

2. If the problem still exists, try to replace ASF ASS'Y.

• Description

• Location ASF ASS'Y

A recording paper is tilted while feeding.

Check and Cause Solution

1. Check if the paper guide of ASF (Automatic Sheet

Feeder) is set up properly with the width of recording

paper.

2. Check if too many sheets of recording paper are put

into ASF (Automatic Sheet Feeder).

(Standard: up to 50 sheets).

3. Check if the recording paper is crumpled or preprinted.

1. After all have been checked, the problem still exists, try

to replace the ASF ASS'Y.

Page 27

Troubleshooting

4-27

Samsung Electronics

4.3.7 Defective Paper Feed (2)-Display of NO PAPER

4.3.8 Defective Document Feed

• Description

• Location ASF ASS'Y

paper does not feed into the printer.

Check and Cause Solution

Press ENTER button to check. Even if the ENTER button is pressed, a recording paper is

not drawn into, then try to replace the ASF ASS'Y.

• Description

• Location OPE ASS'Y

It cannot feed the documents to be scanned.

Check and Cause Solution

Check if the paper feeding is normal on the OPE panel.

(If some part of the paper is pulled into, it may be drawn

automatically .)

1. Replace the contaminated or damaged part.

2. If you cannot confirm the damaged part with the naked

eye, try to replace the OPE ASS'Yand the Main B'D in

sequence.

Page 28

Troubleshooting

4-28

Samsung Electronics

4.3.9 Multi-Feeding (1)

4.3.10 Defective ADF

• Description

• Location ASF ASS'Y

Multiple-sheets of recording paper are fed at once.

Check and Cause Solution

1. Adjust the paper guide of ASF to the width of paper

correctly .

2. Check if the recording paper is preprinted or crumpled.

3. Check if too many sheets of recording paper are put

into ASF (Automatic Sheet Feeder).

(Standard: up to 50 sheets).

1. Blow several times of puff into the paper in order to prevent static electricity.

2. Even after the papers are loaded correctly, if multiple

sheets of paper are still fed at once, then try to replace

the ASF ASS'Y.

• Description

• Location OPE ASS'Y.

ADF (Automatic document Feeder) is not properly operated.

Check and Cause Solution

1. Check if ADF rubber and HOLDER rubber are damaged.

2. Check if the document sensors of OPE ASS'Y

(2 paper sensors) are normal.

1. Replace the contaminated or damaged part.

2. If you cannot confirm the damaged part with the naked

eye, try to replace the OPE ASS'Y.

Page 29

Troubleshooting

4-29

Samsung Electronics

4.3.11 Defective Sensing-ink

4.3.12 Defective Sensing-paper

• Description

• Location 1.Main B'D 2.Cartridge ASS'Y

The ink is put in the set, but it cannot sensed.

Check and Cause Solution

1. Check if the cartridge is installed in the cartridge box

properly .

(It makes a click sound normally when it is normal.)

2. Check if the cartridge box is operated normally.

1. Even after the cartridge is installed normally, it still cannot

sense, then try to replace the Main B'D.

2. In case the cartridge box is not moved from side to side,

check the Flat Cable connection between the Main PBA

& Frame Home Unit, and even after being connected

properly, if it is still not improved, then try to replace the

cartridge ASS'Y.

• Description

• Location 1.Main B'D 2. LF Motor

The recording papers are put in already, but it cannot be sensed.

Check and Cause Solution

1. Check if the ENTER key on the OPE panel is pressed. 1. Refer to "Defective Paper Feed".

2. Even if the ENTER key on the OPE panel is pressed, it

still cannot sense, then try to replace the Main B'D and

LF Motor in sequence.

Notes:

Product has no paper sensor, instead it displays ERROR

when it cannot pick up the paper.

Page 30

Troubleshooting

4-30

Samsung Electronics

4.3.13 Defective Motor Drive (LF)

4.3.14 Defective Motor Drive (CR)

• Description

• Location 1.LF Motor 2.Main B'D.

The motor drive of Line Feeder is not working.

Check and Cause Solution

1. Check if the connector of LF Motor is connected to the

Main B'D normally.

1. Try to replace the LF Motor ASS'Y and the Main B'D in

sequence.

• Description

• Location 1.CR Motor 2.Main B'D.

The drive of CR Motor is not working.

Check and Cause Solution

1. Check if the connector of CR Motor is connected to

the Main B'D normally.

1. Try to replace the CR Motor ASS'Y, the Main B'D in

sequence.

Page 31

Troubleshooting

4-31

Samsung Electronics

4.3.15 Defective Motor Drive (TX)

4.3.16 Blank Page Print Out (When Copying)

• Description

• Location 1.TX Motor 2.Main B'D.

The TX Motor is not driven.

Check and Cause Solution

1. Check if the connector of TX Motor is connected to the

Main B'D normally.

1. Try to replace the TX Motor ASS'Y and the Main B'D in

sequence.

• Description

• Location 1.CIS ASS'Y 2.Main B'D

Blank page is printed out when copying.

Check and Cause Solution

1. Check if the recording papers are inserted reversely.

2. Perform the Adjust Scanner in the TECH MODE.

(See page 4.9)

1. Insert the paper with the copy side to be faced down.

2. In case the output waveform is abnormal in the Adjust

Scanner, replace the CIS ASS'Y, while replace the Main

B'D in normal.

Notes:

After replacing CIS, you must perform a Adjust Scanner.

Page 32

Troubleshooting

4-32

Samsung Electronics

4.3.17 Blank Page Print Out (When Receiving)

4.3.18 Vertical Black Line (When Copying)

• Description

• Location 1.Ink cartridge 2.Main B'D.

Blank page is printed out when receiving.

Check and Cause Solution

1. Check if the sender transmits the document properly.

2. Check if there remains some amount of ink.

(Ex: COPY TEST/SELF TEST)

1. Replace the ink cartridge.

2. If it is normal in the Copy Test and in the Self Test, try to

replace the Main B'D.

• Description

• Location 1.CIS ASS'Y 2.Main B'D.

Vertical black lines occur in the printing.

Check and Cause Solution

1. Check if there are substance materials on CIS.

2. Perform a Adjust Scanner to check if the waveform is

normal. (See page 4.9)

3. Clean the cartridge nozzle.

1. If there are some stains on the surface of CIS, wipe them

off with alcohol (IPA).

2. If the CIS waveform is abnormal, replace the CIS ASS'Y.

3. Clean the nozzle and confirm again.

4. After confirming the CIS waveform and cleaning the nozzle, if the vertical black lines still occur, then try to replace

the Main B'D.

Notes:

After replacing the CIS, you must perform a Adjust Scanner.

Page 33

Troubleshooting

4-33

Samsung Electronics

4.3.19 Vertical Black Line (When Receiving)

4.3.20 Contaminated Stains on Paper

• Description

• Location Main B'D.

It is normal when copying, but the vertical black lines occur in the printing when receiving.

Check and Cause Solution

1. Check if the FAX status of the transmitting side is normal.

(Ex. Let the transmitter copy once.)

2. Clean the cartridge nozzle.

(See page 4.7)

1. Even when the transmitting side is normal and after having finished cleaning, if the same problem still exists, then

try to replace the Main B'D.

• Description

• Location 1.CIS ASS'Y 2.Main B'D.

Contaminated stains on the copied and received paper occur in the printing.

Check and Cause Solution

1. Check the status of document.

2. Check the waveform by performing a Adjust Scanner.

(See page 4.9)

1. If the CIS waveform is abnormal, try to replace the CIS

ASS'Y.

2. In case the CIS waveform is normal but the print quality

is bad, try to replace the Main B'D.

Notes :

After replacing the CIS, you must perform a Adjust Scanner (using

clean papers).

Page 34

Troubleshooting

4-34

Samsung Electronics

4.3.21 Bad Printed Image

4.3.22 Vertical Lines are printed crookedly

• Description

• Location 1.CIS ASS'Y

The copied and received image is light or bad.

Check and Cause Solution

1. Check the CIS waveform.

(See page 4.9 : Adjust Scanner)

2. Test and check the cartridge arrangement.

(See page 4.7 : Align Head)

3. Clean the cartridge nozzle.

(See page 4.7 : Clean Head)

1. In case the CIS waveform is good, clean the outlet of

cartridge.

2. In case the CIS waveform is abnormal, try to replace the

CIS ASS'Y.

3. Even after cleaning the outlet of nozzle, the received data

image is still bad, then replace the cartridge.

4. Try to replace the Main B'D.

Notes:

After replacing the CIS, you must perform a Adjust Scanner

(using pure clean papers).

• Description

• Location Cartridge

The vertical lines are printed crookedly.

Check and Cause Solution

1. Test and check the cartridge arrangement.

(See page 4.7 : Align Head)

1. Perform the cartridge arrangement to set up black/color

newly. Repeat it several times until you get the sufficient

condition.

Page 35

Troubleshooting

4-35

Samsung Electronics

4.3.23 Bad Color (Intensity)-only SF-331P

4.3.24 No Dial Tone

• Description

• Location 1.Capacity of Ink Cartridge

The color is different from the original document in the printing.

Check and Cause Solution

1. It may occur when the amount of specific ink in the ink

cartridge (color) is deficient.

1. After checking if the capacity of ink cartridge is deficient,

try to replace it.

• Description

• Location 1.LIU B'D 2.OPE ASS'Y 3.Main B'D.

While on-hook button is pressed, there is no dial tone.

Check and Cause Solution

1. Check if the telephone line cord is connected to TEL

LINE correctly.

2. Check if it makes CLICK sound while OHD key is

pressed.

3. Check the connection of HARNESS between the LIU

and the Main B'D.

4. Check if the SPEAKER is connected correctly.

1. If the telephone cord is normal but there is no dial tone,

then try to replace the LIU B'D.

2. If you cannot hear the OHD CLICK sound, the OPE

ASS'Y may be defective. Try to replace the OPE ASS'Y.

3. Check the connection of Speaker, and try to replace it.

4. Lastly, try to replace the Main B'D.

Page 36

Troubleshooting

4-36

Samsung Electronics

4.3.25 Defective MF DIAL

4.3.26 Defective FAX FORWARD/RECEIVE

• Description

• Location 1.LIU B'D 2.OPE ASS'Y 3.Main B'D.

The MF DIAL is not functioning.

Check and Cause Solution

1. Check if the telephone line is connected correctly.

2. Wile the BUTTON KEY is pressed, check to catch a

CLICK sound.

3. Check the connection of HARNESS between the LIU

and the Main PBA.

1. If you cannot catch the OHD CLICK sound, the OPE

ASS'Y may be defective. Try to replace the OPE ASS'Y.

2. If you can catch a CLICK sound, after checking the connection of HARNESS between the LIU and the Main

PBA, try to replace the HARNESS.

3. The problem still persists, then replace the LIU and the

main B'D in sequence.

Notes:

Product supports the MF DIAL type only.

• Description

• Location 1.LIU B'D 2.Main B'D.

The FAX FORWARD/RECEIVE is not functioning.

Check and Cause Solution

1. Check if you can catch a dial tone by pressing OHD.

2. Check if you can catch a RECEIVE tone while

MODEM testing in the TECH mode.

1. If the MODEM testing is normal and there is no dial tone,

then try to replace the LIU B'D.

2. If the MODEM testing is abnormal, try to replace the

Main B'D.

Page 37

Troubleshooting

4-37

Samsung Electronics

4.3.27 Defective FAX FORWARD

4.3.28 Defective FAX RECEIVE (1)

• Description

• Location Telephone line

RECEIVE is functioning, but FORWARD is not functioning or the received data are broken.

Check and Cause Solution

1. Check if there is NOISE when pressing on-hook dial.

2. Check the RECEIVE condition by trying to forward a

FAX to another fax machine from the forwarding side

FAX.

3. Check if the telephone line connected to the Product is

contaminated or gets stripped off or down.

1. If it makes NOISE while on-hooking, replace or repair the

telephone line.

• Description

• Location Telephone line

FORWARD is functioning, but RECEIVE is not functioning or the received data are broken.

Check and Cause Solution

1.Check if there is NOISE when pressing on-hook dial.

2.Check the RECEIVE condition by trying to receive a

FAX at another fax machine.

1.If it makes NOISE while on-hooking, replace or repair the

telephone line.

Page 38

Troubleshooting

4-38

Samsung Electronics

4.3.29 Defective FAX RECEIVE (2)

4.3.30 Defective FAX RECEIVE (3)

• Description

• Location Telephone line

The received data are lengthened or cut in the printing.

Check and Cause Solution

1. Check if there is NOISE when pressing on-hook dial.

2. Ask to the forwarding side, check the image quality of

another machine receiving a FAX additionally sent to.

1. If it makes NOISE, rearrange the telephone line. (Refer

to 'Defective FAX RECEIVE'.)

2. Check if the FAX status of the forwarding side is also normal.

• Description

• Location 1.OPR panel 2.LIU B'D 3.Main B'D.

The phone is ringing continuously, but it cannot receive.

Check and Cause Solution

Check if the RECEIVE mode is TEL MODE or FAX

MODE.

Even when the RECEIVE mode is changed to FAX MODE,

it cannot receive, then replace the LIU and the Main B'D in

sequence.

Page 39

Troubleshooting

4-39

Samsung Electronics

4.3.31 Defective FAX RECEIVE (4)

4.3.32 Defective Automatic Receiving

• Description

• Location Telephone line

The received data is reduced by more than 50% in the printing.

Check and Cause Solution

Check the FAX status of the forwarding side. After checking the data of the forwarding side, correct the

FAX of the forwarding side.

• Description

• Location 1.The RECEIVE mode (LCD WINDOW) 2.LIU BOARD 3.Main B'D.

The automatic receiving function is not working.

Check and Cause Solution

1. Check if the RECEIVE mode is TEL MODE or FAX

MODE.

1. If the RECEIVE mode is set to the TEL MODE, reset it to

the FAX MODE.

2. Even after the RECEIVE mode is changed to the FAX

mode, it cannot receive, then try to replace the LIU and

the Main B'D in sequence.

Page 40

Troubleshooting

4-40

Samsung Electronics

4.3.33 The Printer is Not Working (1)- Only SF-331P

4.3.34 The Printer is Not Working (2)- Only SF-331P

• Description

While the power is turned on, the printer is not working at all by the PRINT command from the computer.

Check and Cause Solution

1. Perform the Printer Self-Test.

(See page 4.9)

2. Check if the PC and the printer cable are properly connected.

3. Check if the printer driver is correctly installed.

1. Check the power source of the printer first and perform the

Printer Self-Test. If the test results in printing, it is considered

as there is no problem in the printer itself. If the printer is not

working, the function may be defective (not due to S/W), so

take another proper measure.

2. Check the status of the printer connection, and if it is defective, replace the printer cable (USB).

3. Check the connection between PC and printer port (USB

port). Check if the printer driver at the Printers on the Control

Panel is installed. If the printer driver is properly setup, check

in which program the printing is not working. The best way is

to try printing from the Wordpad, the WINDOWS basic program. Sometimes, the print out is normal within the WINDOWS basic programs, but it may not work in a specific program. In such case, reinstall the printer driver.

• Description Even after the Print command, there is no response at all or the printing speed is low.

Check and Cause Solution

It may due to wrong setup of the environment rather than

malfunction of the printer itself. And in case that abnormal

characters are printed out, also check the environment

setup.

1. Secure the hard disk space.

2. Printing error occurs even if there is enough space in

the hard disk.

3. Reboot the system, and try printing again.

1. Not working with the message 'Insufficient memory' means that

the hard disk space to store the print information is insufficient

rather than the RAM insufficiency. In this case, secure more

space for the hard disk.

Secure more space for C drive by using the Disk utilities program at 'PROGRAM - ACCESSORIES - SYSTEM TOOL' from

the Start menu.

2. The connection of the cable or printer port is not properly setup.

3. If characters are printed abnormally, the cable or the printer driver may be defective. Turn the PC and printer off, and reboot

the system to try printing again. If the problem still exists, double

click to install the printer from My Computer and right-click the

mouse, then click 'Test Print' button at the bottom of the file

information tab. If normal characters are not printed again, the

cable must be defective so replace the cable with a new one.

Page 41

Troubleshooting

4-41

Samsung Electronics

4.3.35 Abnormal Printing ( Only SF-331P)

• Description

The printing is not working properly even when the cable has no problem.

(even after the cable is replaced)

If the printer won't work at all or strange characters are only printed,

it may be the printer driver problem.

Check and Cause Solution

1. Printer driver error.

2. Error due to insufficient memory.

(The printing job sometimes stops during proceeding or

not completed due to insufficient memory.)

1. Check 'My Computer - Printers'.

(If the printer driver is installed not compatible with the

printer currently installed or an error occurs in the driver file,

remove the existing driver and reinstall the printer driver.

2. This is because of an insufficient virtual memory.

(It does not mean the actual capacity of RAM but the

space of hard disk.)

Delete unnecessary files to secure enough space of the

hard disk and try printing again.

Name of Printer Port :

To reinstall the printer driver, do after removing the current driver.

• While installing the driver, Set and PC should be connected.

(The printer setup may be wrong if they are not connected during installing.)

Page 42

Troubleshooting

4-42

Samsung Electronics

4.3.36 Spool Error and Release of Spool Error

• Description

Spool (Simultaneous Peripheral Operations Online) refers to process the document to be read and

stored in the hard disk or the mass storage media, and then to be printed at more convenient time.

While the printer is outputting other file, the file requested to output is undergone to be spooled in the

hard disk, the spool error may occur if a problem occurs in this process.

First, delete the Spool Data if the Spool Error occurs.

Check and Cause Solution

I. Insufficient space of the hard disk set as the default

spool directory.

2. In case a collision with other program is expected.

3. When an application program or the printer driver file

is damaged.

4. If some of OS related files are damaged or malfunctioning due to virus infections.

5. The memory is less than that recommended by the

OS.

1. Delete unnecessary files to provide more hard disk space

and try printing job.

2. Exit all other programs except the program currently

using, if possible, and print again.

3. Delete the printer driver completely and reinstall it.

4. After rebooting the computer, check viruses, restore the

damaged files and reinstall the program, then try print ing

again.

5. Add memory to the PC.

How to delete the data in the spool manager :

In the spool manager, the installed drivers and the list of all the documents waiting to be

printed are shown. Select the data of the document to be deleted and select Document menu

--> Delete.

If you intend to delete the current document being printed, the data being transferred to the

printer will be printed out and then the document will be removed. Before choosing the document data, the document menu is still inactive.

Or Hold the document in the waiting list and repeat the routine as the above or exit the Spool

manager

Page 43

Troubleshooting

4-43

Samsung Electronics

4.4 Print Cartridge & Print Quality

4.4.1 Print Cartridge Maintenance

The top of the carriage contains a spring latch for the print cartridge. The spring latch provides tension for consistent snapin of the print cartridge. The print cartridge should only be replaced when the carriage is in the designated service position, which is controlled from the product’s front panel.

When installing a print cartridge, the bottom portion of the print cartridge should be installed into the carriage assembly as

shown in Figure 1. Once the bottom is seated in the carriage, push the top portion of the cartridge toward the carriage until

it snaps into place beneath the spring latch. Always ensure that the electrical contacts inside the carriage are clean. Do

not handle or touch the contacts because oil from the user’s fingers can corrode the electrical contacts (see Figure in section b for carriage and cartridge contact cleaning instructions).

The service station, at the left end of the carriage path, contains two wipers and two nozzle caps to provide servicing and

capping for either a monochrome or a color print cartridge (see Figure 2). The caps and wipers are mounted on a rotary

assembly, which incorporates a micro-switch for accurate positioning.

The service station wipes and caps the orifice plate of the print cartridge after each print job and at predefined set points