Samsung ML-6060 Service Manual

SERVICE

LASER PRINTER

ML-6060

ML-6060N

SAMSUNG

Manual

LASER PRINTER CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Electrical Parts List

7. Block Diagram

8. Connection Diagram

9. Schematic Diagrams

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

Read each caution carefully:

1. Do not use this printer near water or when

exposed to inclement weather.

2. Do not place this printer on an unstable cart, stand

or table; the product may fall, causing serious

damage to the product.

3. Slots and openings in the cabinet are provided for

ventilation. To ensure reliable operation and to protect the printer from everheating, do not block or

cover any of these openings. Do not place the

printer in an enclosure unless the enclosure provides adequate ventilation.

4. Never push objects of any kind into the printer

through the cabinet ventilation slots as they may

touch dangerous high voltage points, create short

circuits, cause a fire, or produce an electrical

shock. Never spill liquid of any kind on the printer.

5. Do not place the printer in a location where someone may trip on the cords.

6. Select a work surface that is large enough to hold

the printer.

7. Position the printer within six feet of the computer

and within five feet of an electrical outlet.

8. Operate this printer using the power source (110V,

220V, etc) indicated on the marking label. If you

are not sure of the type of power source available,

consult your dealer or local power company.

9. If you need to use an extension power cord with

this printer, make sure that it uses a three-wire

grounded cord and that the total ampere ratings for

all of the products using the extension do not

exceed the extension cord ampere rating. Also,

make sure that the total of all products plugged

into the wall outlet does not exceed 15 amperes.

10. Do not allow anything to rest on the power cord or

data communications cable.

11. Unplug this printer from the wall outlet before

cleaning. Do not use liquid cleaners or aerosol

sprays. Use a damp cloth for cleaning.

12. Do not touch the surface of the photo-sensitive

drum as marks or scratches may impair print quality.

13. Do not expose the drum unit to direct light for prolonged periods.

14. Use only standard papers, OHP films, and

approved envelopes. Feed OHP films though the

manual feed slot only. See specifications for

approved papers and envelopes.

15. Other than replacing consumables such as paper

and toner, refer all questions to qualified service

personnel.

LASER STATEMENT (LASERTURVALLISUUS)

WARNING : NEVER OPERATE AND SERVICE THE PRINTER

WITH THE PROTECTIVE COVER REMOVED

FROM LASER/SCANNER ASSEMBLY. THE

REFLECTIVE BEAM, ALTHOUGH INVISIBLE, CAN

DAMAGE YOUR EYES.

Class 1 laser product

Luokan 1 laserlaite

Klass 1 laser apparat

Allonpituus 770-795nm

Teho 0.29mW±0.02mW

CAUTION

VORSICHT

ATTENTION

ATTENZIONE

PRECAUCION

CAUTION : Avoid exposure to invisible laser radiation when the

development unit is not installed.

INVISIBLE LASER RADIATION WHEN

THIS COVER OPEN. DO NOT OPEN

THIS COVER.

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEOFFNET.

NIGHT DEM STRAHL AUSSETZEN.

REYONNEMENT LASER INVISIBLE EN CAS D’OUVERTURE. EXPOSITION DANGERUSE AU FAISCEAU.

RADIAZIONE LASER INVISIBLE IN CASO DI

APERTURA. EVITARE L’ESPOSIZONE LAFASCIO.

REDIACION LASER INVISIBLE CUANDO SE

ABRE. EVITAR EXPONERSE AL RAYO.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

1. Before disassembly, pull the power plug from the AC

power connector.

2. To avoid spilling toner inside the machine, do not turn

the printer over or on its side before removing the

developer cartridge.

3. Faulty installation of DRAMs may cause permanent

damage to the Laser Printer.

4. Use only+5V power for video controller-related circuitry.

5. When replacing parts, use only the same type of part

as the original. Replacing components with a second

vendor’s part may cause faulty operation.

6. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples :

metal panels and input ports).

7. Insulation Checking Procedure:

Disconnect the power cord from the AC power

source. Connect an insulation resistance meter

(500V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see left)

should be greater than 1 megaohm.

8. Never defeat any of the B+ voltage interlocks. Do not

apply AC power to the unit (or any of its assemblies)

unless all solid-state heat sinks are correctly installed.

9. Always connect a test instrument’s ground lead to the

instrument chassis ground before connecting the positive lead; always remove the instrument’s ground

lead last.

1-2 Samsung Electronics

Precautions

1-2 Servicing Precautions

Note : Requirements for AC power are described on the label affixed to the rear of the printer. Check the AC

voltage rating requirement before use.

CAUTION : Be sure the power is off to the chas-

sis or circuit board, and observe all

other safety precautions

1. Immediately before handling any semiconductor components assemblies, drain the electrostatic charge

from your body by touching a known earth ground.

Alternatively, wear a discharging wrist strap device.

(Be sure to remove the strap before applying power

to the unit under test to avoid potential shock.)

2. After removing ESD-equipped assembly, place it on a

conductive surface such as aluminum foil to prevent

accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a ground-tip soldering iron when soldering

or desoldering ESDs.

5. Use only anti-static solder removal device. Some solder removal devices are not rated as “antistatic;”these can accumulate sufficient electrical

charge to damage ESDs.

1-3 ESD Precautions

Some semiconductor (“solid state”) devices are easily damaged from static electricity. Such components commonly are called Electrostatically Sensitive Devices (ESDs); examples include integrated circuits (ICs), LargeScale Integrated circuits (LSIs), some field-effect transistors, and semiconductor chip components. The following techniques will reduce the occurrence of component damage caused by static electricity:

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

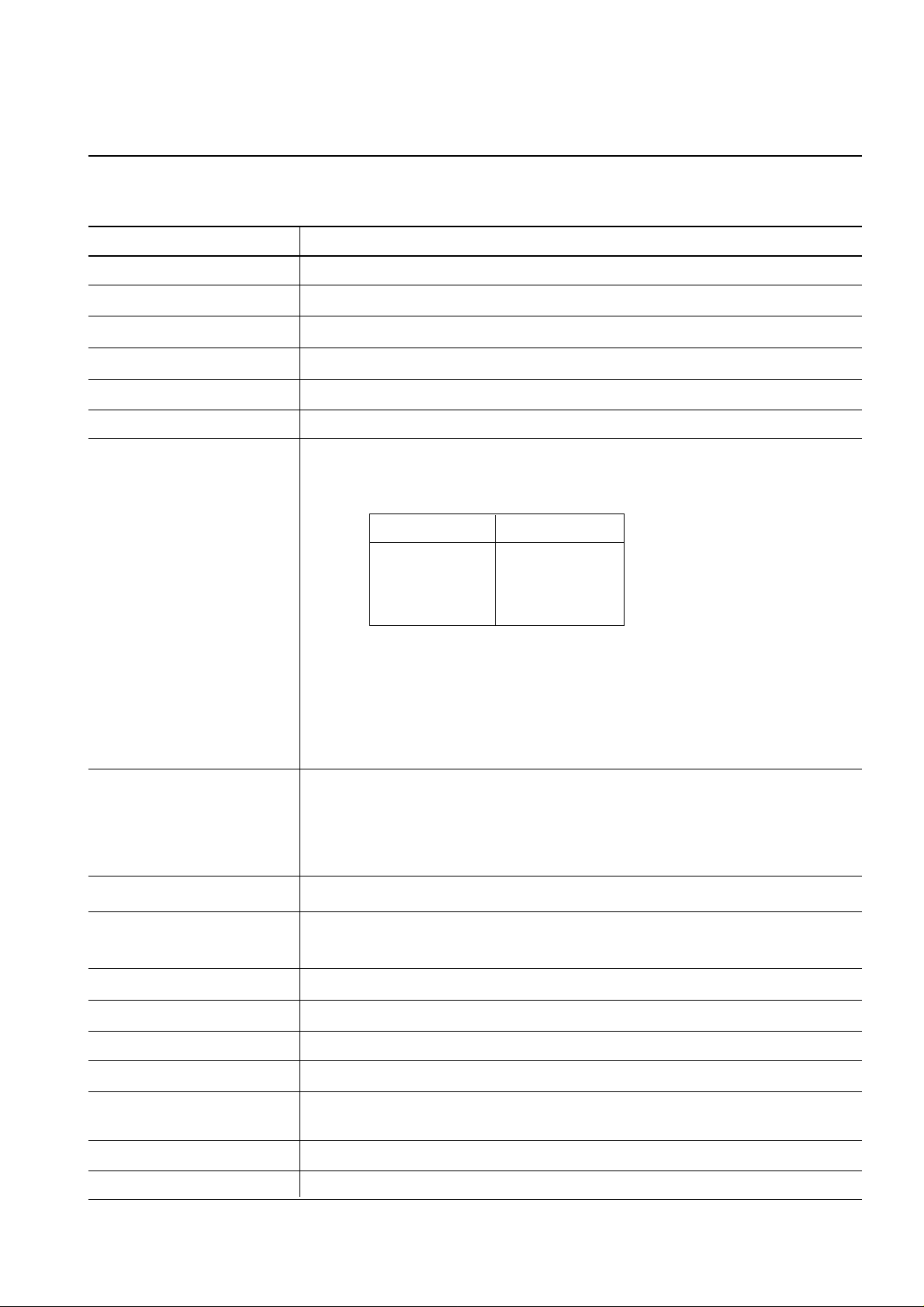

Item Specification & Description

Engine ML-6060

Print Speed 12PPM (A4 Size, 5% Character Pattern)

Resolution True 600 x 600 dpi, 1200 DPI class with SRT

Source of Light Laser Diode (LSU:Laser Scanner Unit) + Electrophotography

Print Method Non-impact Electrophotography

Feed Method Cassette & Manual, Option Feeder

Paper Handling (input) *Size

(1) Standard : A4, Letter, Legal, B5, Executive, Folio

(2) Envelope : MP Tray only

Paper Type Paper size(mm

2

)

Monarch 98.5 x 190.5

Com-10 104.9 x 241.3

Intl-DL 110 x 220

Intl C5 162 x 229

(3) Universal type

Length : 150 ~ 356 mm

Width : 90 ~ 216 mm

*Weigh : For Cassette, 60 ~ 90 g/m

2

For MPF, 60 ~ 143 g/m

2

Paper Handing (output) Face Down : 250 sheets, Face Up : 20 sheets

Feed Capacity Cassette : 550 sheets of paper (75g/m2)

MP Tray : 100 sheets of paper (75g/m2)

30 sheets of transparencies

10 envelopes or card stocks

25 paper labels

Option Cassette : 550 sheets of paper

Warm-up time 30 seconds or less (23°C, 50%)

First Print Time Tray1 : 15seconds or less

Tray2 : 17seconds or less

Power Rating AC100~120V/ 220~240V(±15%), 50/60Hz (±3%)

Power Consumption During Printing : 250WH (average)

Power Saving During Sleep : Less than 12W

Consumption Less than 50W during 1 hour when it turned on

Certification & Compliance 110V : UL,CSA,CDRH,FDA

220V : GS,SEMKO,FIMKO,NEMKO,DEMKO

Acoustic Noise Stand by : Less than 35dB, Operating : Less than 48dB

Toner Supply Print Cartridge

2. Specifications

Note: It is subject to change without notice.

Samsung Electronics 2-1

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

2-2 Samsung Electronics

Specifications

Item Specification & Description

Printing Area No-print area : 3mm from edge(Top,Bottom,Left,Right) of listed core media

No-print area : 3mm from edge(Top,Bottom,Left,Right) of envelope

Operating Environment Temperature : 10~30°C, Humidity : 20~80%RH

Storage Environment Temperature : 0~35°C, Humidity : 10~90%RH

Weigh Net : Max 11Kg, Gross : 15.5Kg

External Dimension 409.1 (W) x 362 (D) x 298.5 (H)mm

Print Cartridge Life Span : 6,000 pages, 5% Pattern

Developing : Non-magnetic Contact Developing

Charging : Conductive Roller Charging

Density Adjustment : 3 step (Light, Medium, Dark)

Toner Supply Method : Exchanging the Developer

Toner Checking Sensor : None

Transfer System : Conductive Roller Transfer

Fusing System : Temperature & Pressure

Ozone Emission : Less than 0.1 PPM

Emulation PCL5e,PCL6, optional PostScript Level 3 Compatible

Font 1 bitmap

45 scalable (35 intelligent, 10 truetype)

CPU ARM7 TDMI (clock speed 66MHz)

RAM Memory Standard : ML-6060,ML-6040 - 4M byte

ML-6060N -16M byte

Option SIMM Module ; 4, 8, 16, 32,64M byte

*Refer to Operator’s Guide for instructions on SIMM installation.

ROM 2M byte (8M bit x 2 : Program) Flash Memory

EEPROM 512 bytes

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

2-3Samsung Electronics

Specifications

Item Specification & Description

Interface Bidirectional Parallel Standard

- IEEE 1284 COMPATIBLE MODE

- IEEE 1284 NIBBLE MODE

- IEEE 1284 BYTE MODE

- IEEE 1284 ECP WITHOUT RLE

- IEEE 1284 ECP WITH RLE

USB Interface Standard

- USB 1.0 compliant

- 12Mbps 1 port

Network Interface

100 Base T or 10 Base T (Autoselect)

Ethernet

Interface Switching Automatic (Parallel, USB, Network)

Interface Time Out 5 min (max.)

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

2-4 Samsung Electronics

Specifications

Item Specification & Description

Network

Network Operating Systems Windows 95/98 and Windows NT (3.51, 4.x )

Netware (3.x, 4.x), NDS and Bindery Mode /RPRINT, PSERVER Mode

UNIX and Apple Talk

Network Protocols Supported TCP/IP : Windows 95/98, Windows NT, UNIX

IPX/SPX : Windows 95/98, Novell Netware

DLC/LLC : Windows 95/98, Windows NT

Ethertalk : Apple Talk

SNMP : for Network Printer Administration

Network Card Interface Ethernet 10/100 BaseTX (Auto Negotiation)

Network Management S/W Samsung’s Admin. Software Utility (SyncThru)

SNMP and MIB-II Support,

GUI based utility for Windows Systems and Test based utility for UNIX Systems

HTTP server for web browser based network management (can manage

NPC and printer options on Web Browser)

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

3-1Samsung Electronics

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of

cables to moving parts makes proper routing a must. If components are removed, any cables disturbed by the

procedure must be restored as close as possible to their original positions. Before removing any component

from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Remove the paper cassette(s), and the print cartridge. Do not expose the cartridge to direct room light or sun

light, and be careful not to scratch the drum surface.

2. Turn the power switch off.

3. Unplug all the cables from the printer.

4. Replace with only an authorized component.

5. Do not force to open or fasten a plastic material component.

6. Be careful no obstacles are included when you reassemble components.

7. When you reassemble components, be careful small size components are located in place.

8. If you turn the machine over to replace some parts, toner or paper particles may contaminate the LSU window. Protect the LSU window with clean paper.

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them carefully. To remove such parts, press the hook end of

the latch away from the part to which it is latched.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-2 Samsung Electronics

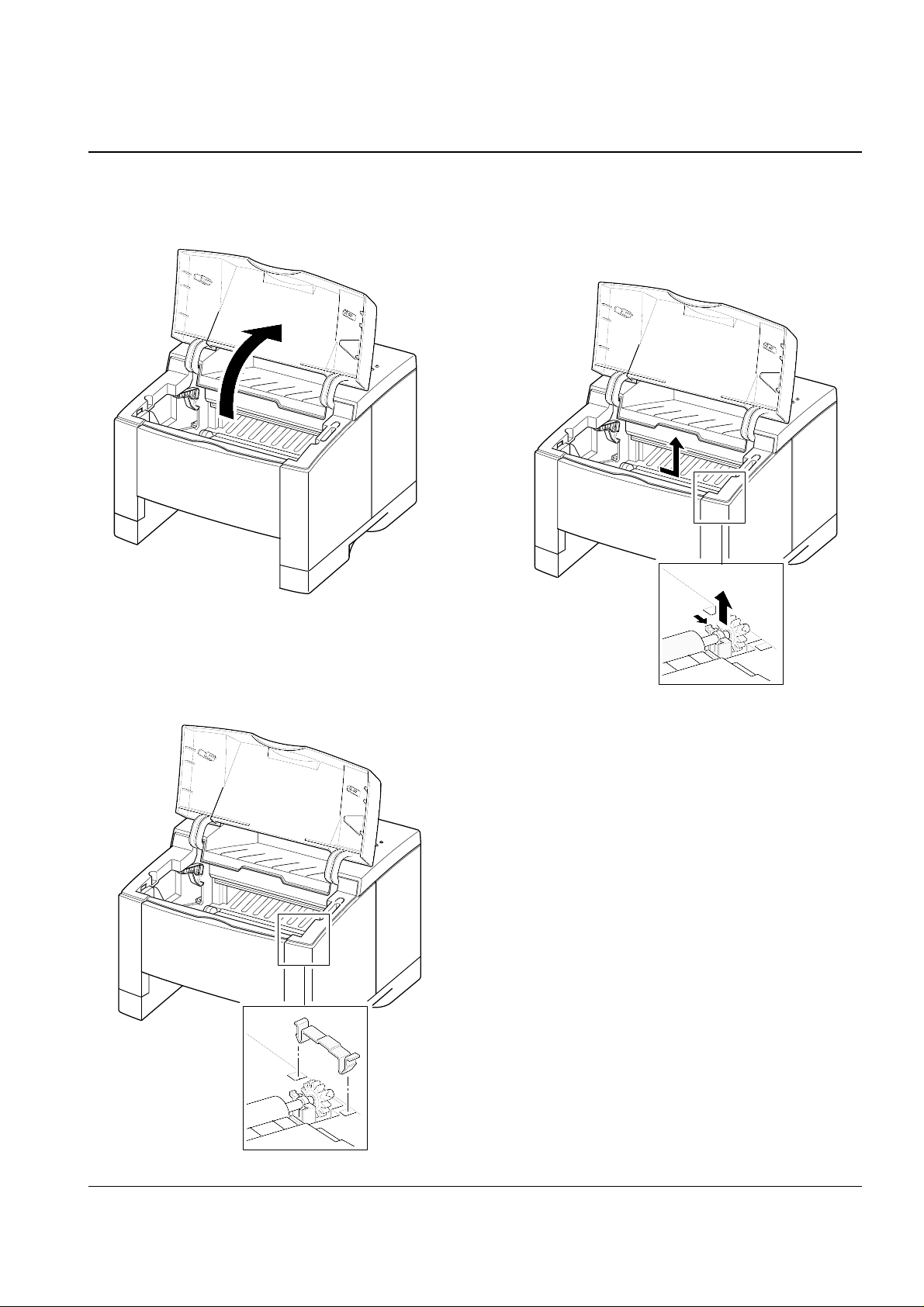

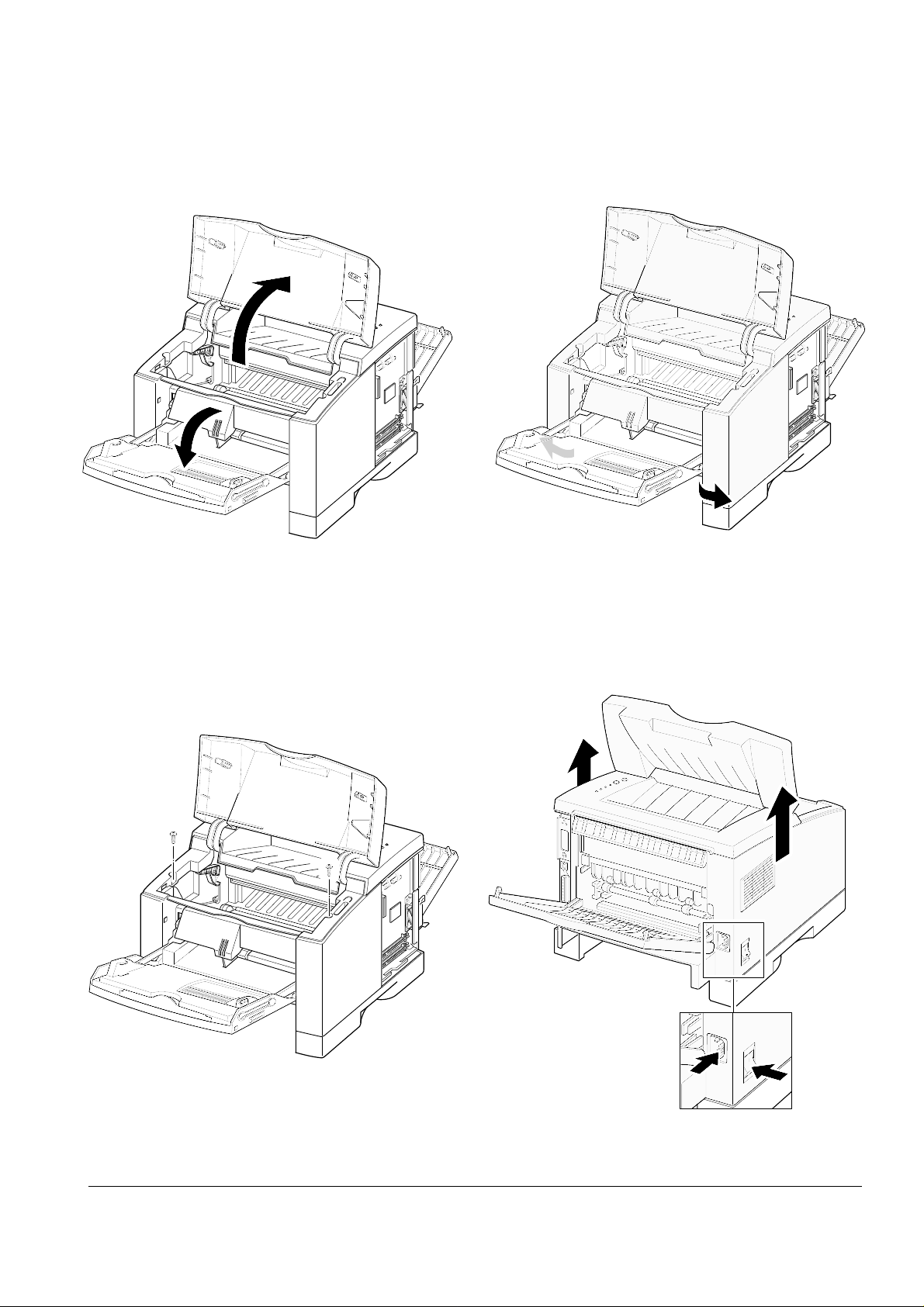

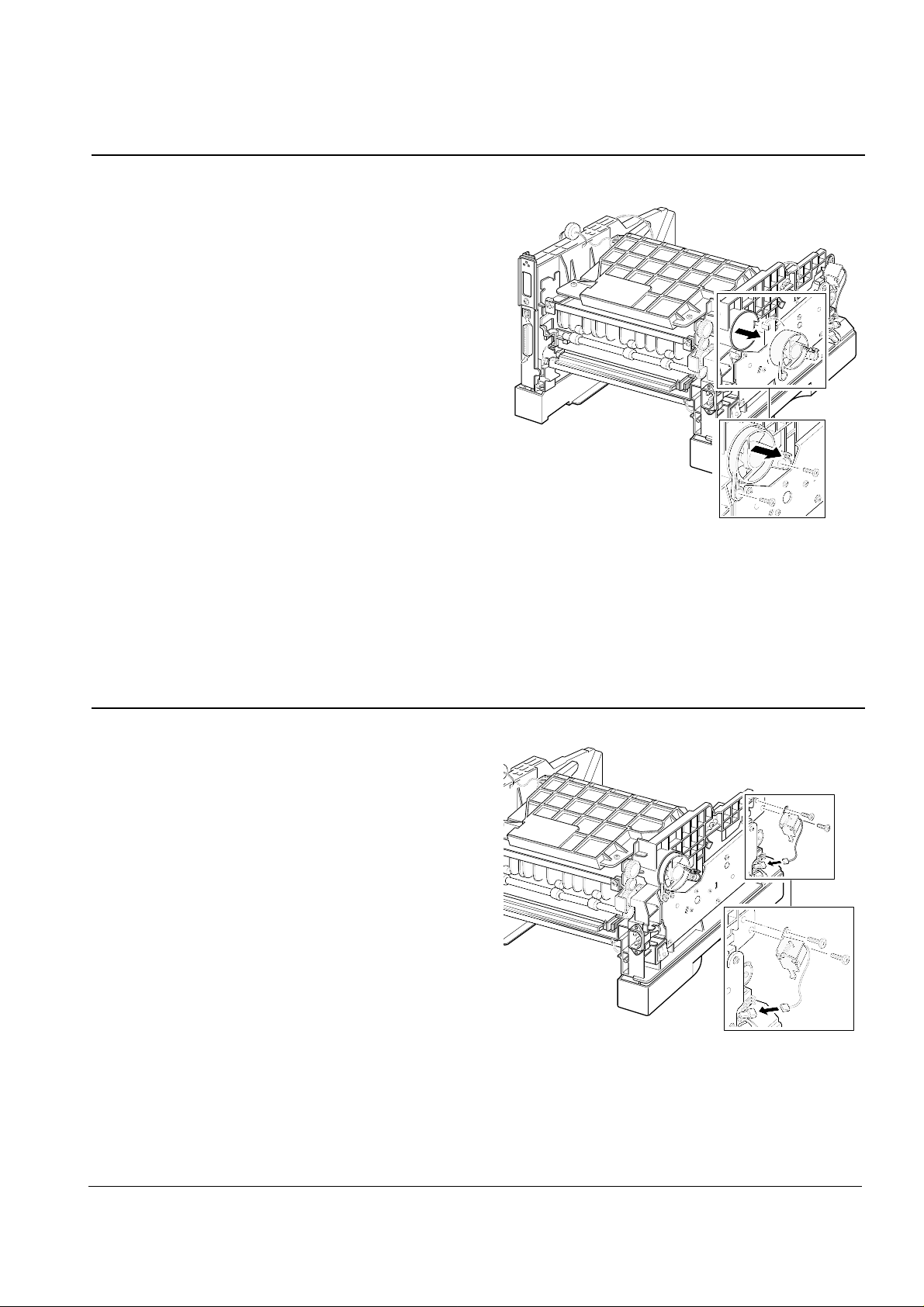

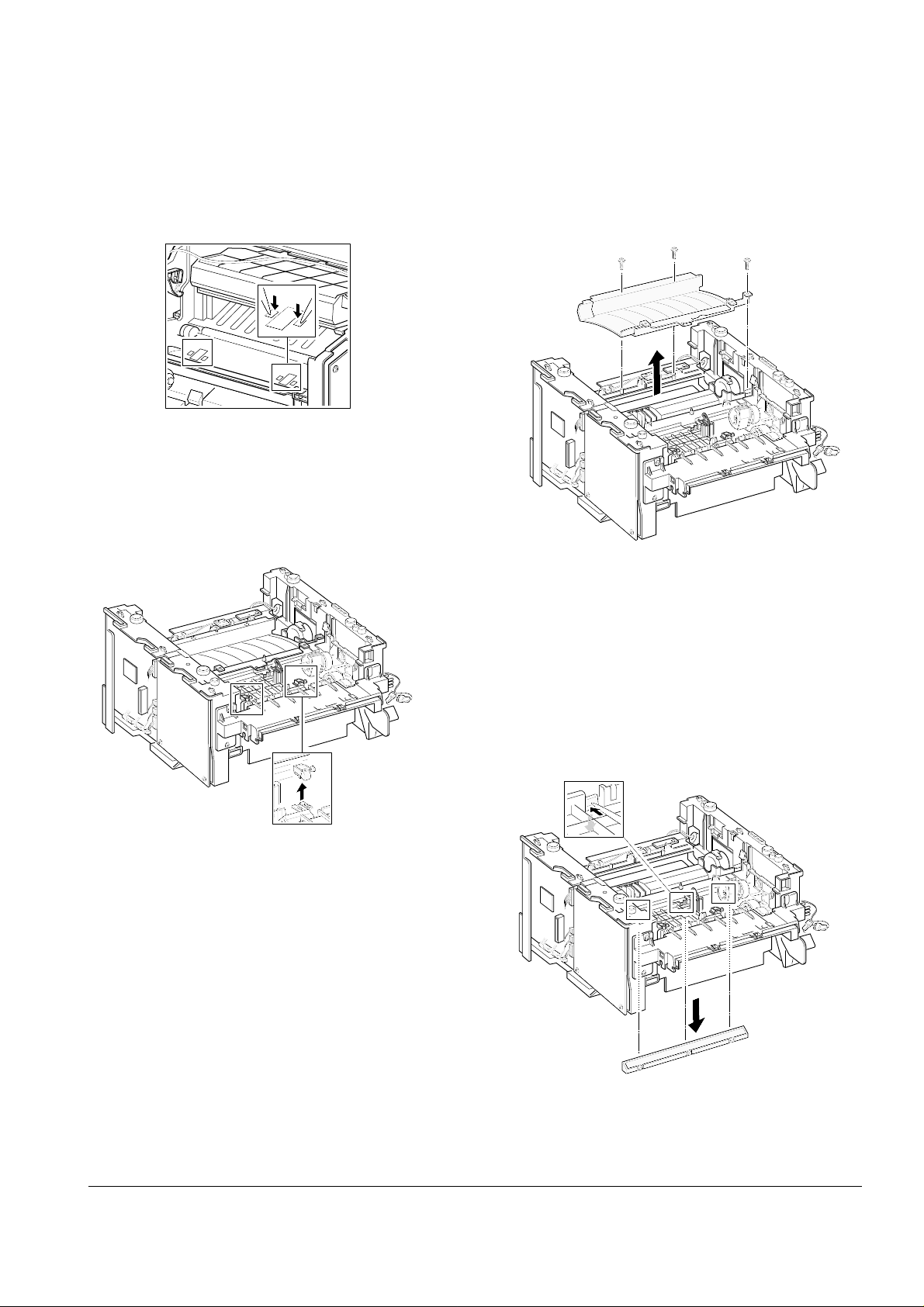

3-2 Transfer Roller

1. Open the printer cover.

3. Hold the cap at the both end of the roller, then

remove the roller.

2. Remove the cap.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-3Samsung Electronics

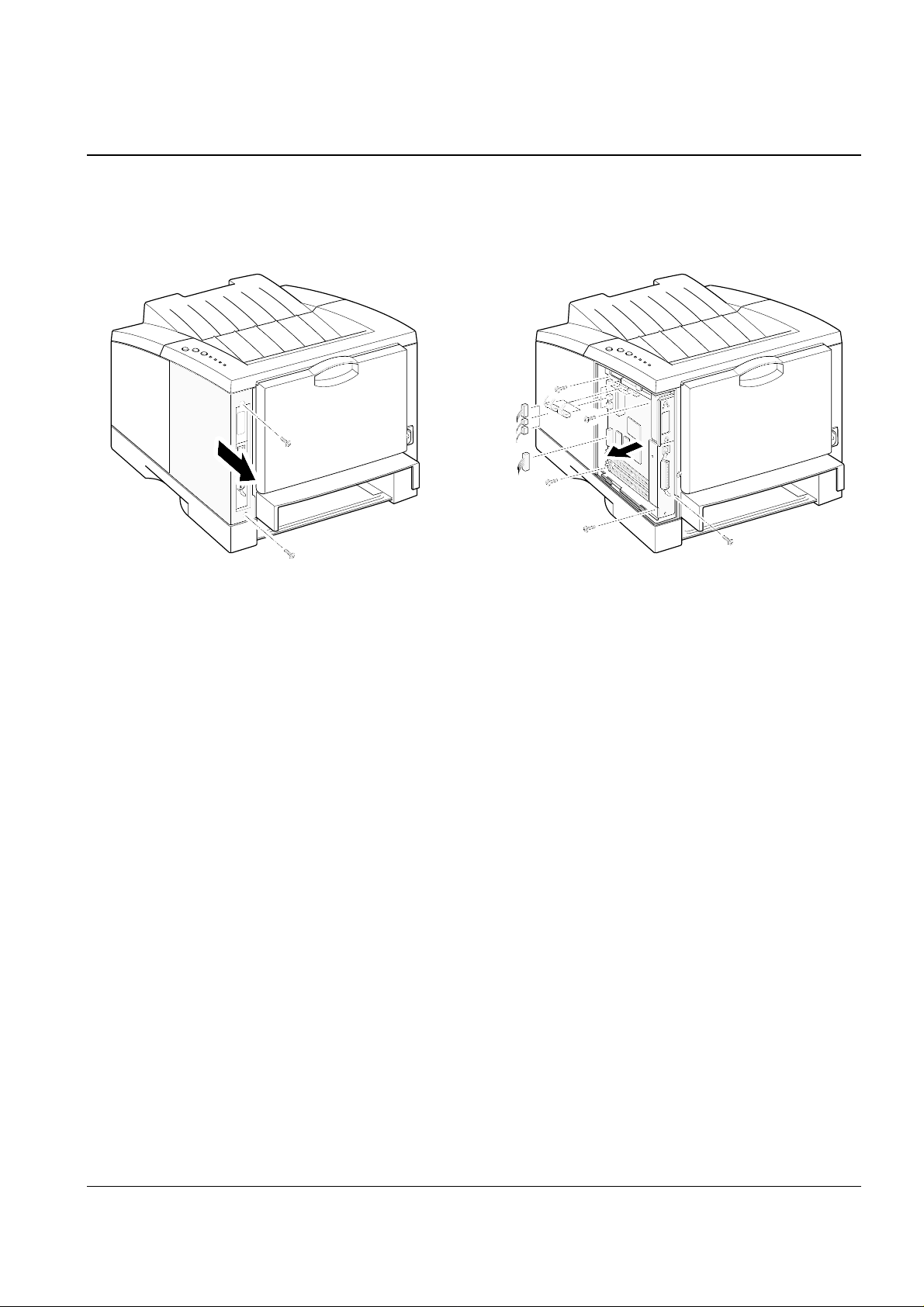

3-3 Controller Board

1. Remove two screws and remove the controller

board.

2. Remove five screws securing the board and

unplug all connectors, and then take the controller board out of the printer.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-4 Samsung Electronics

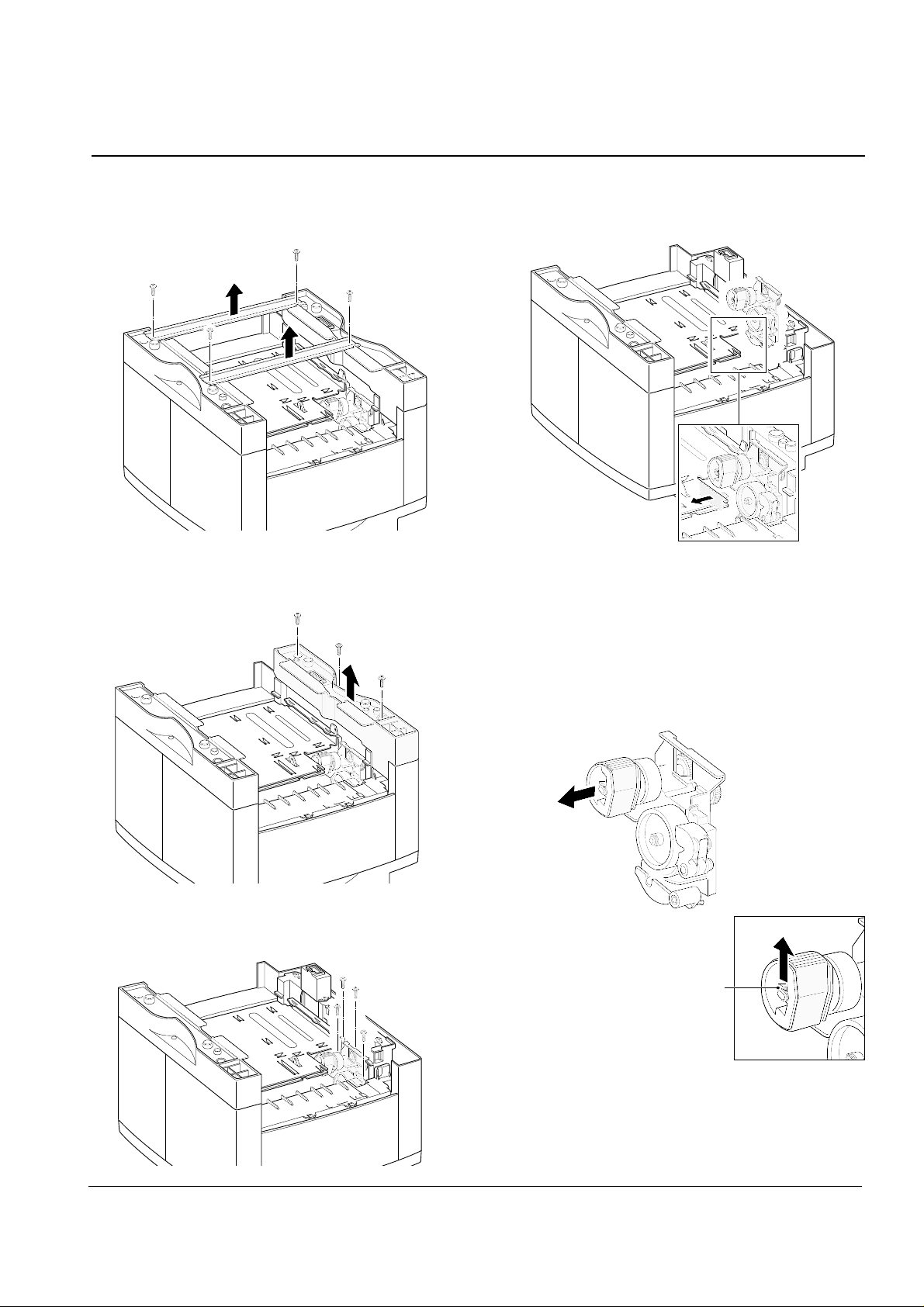

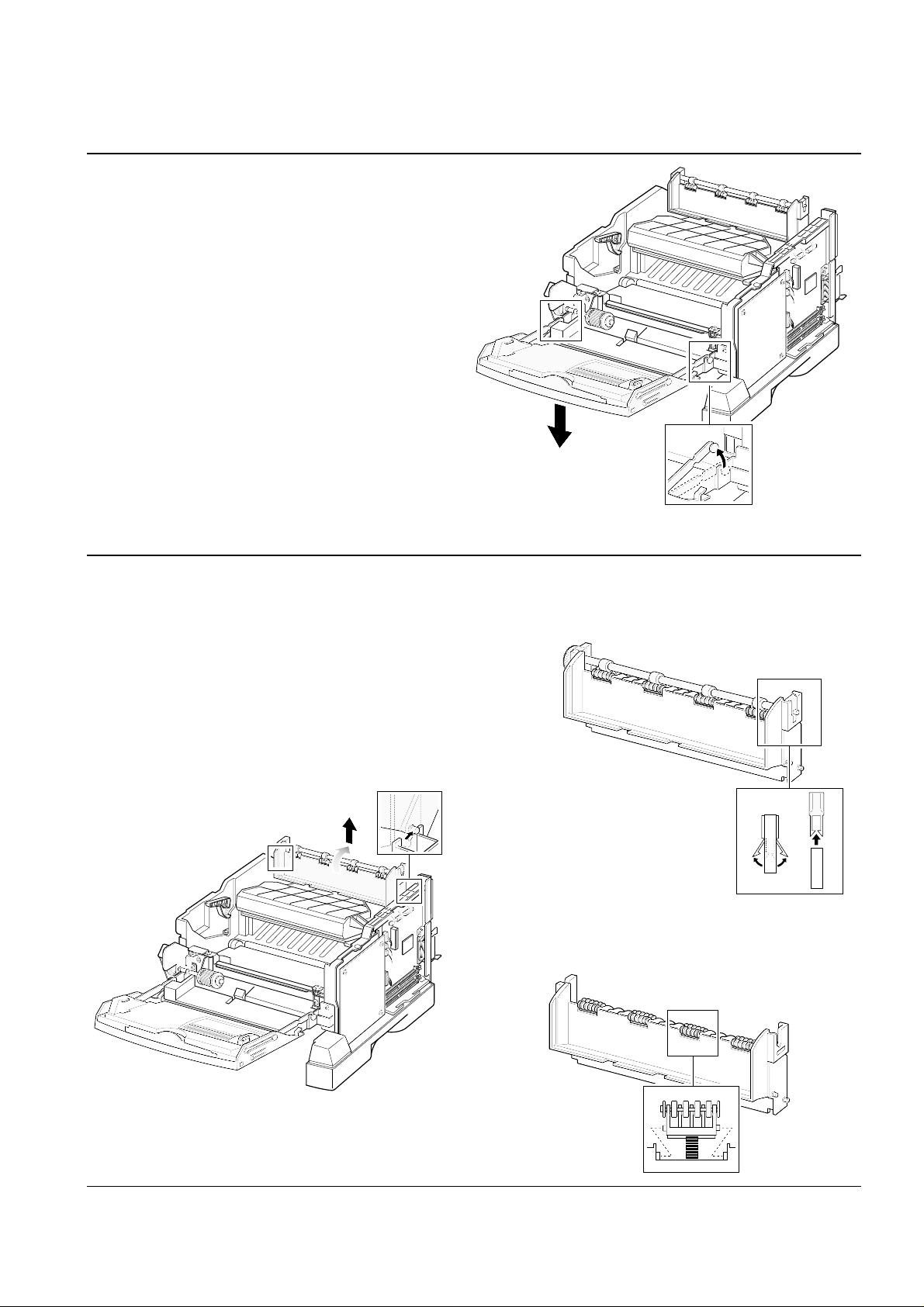

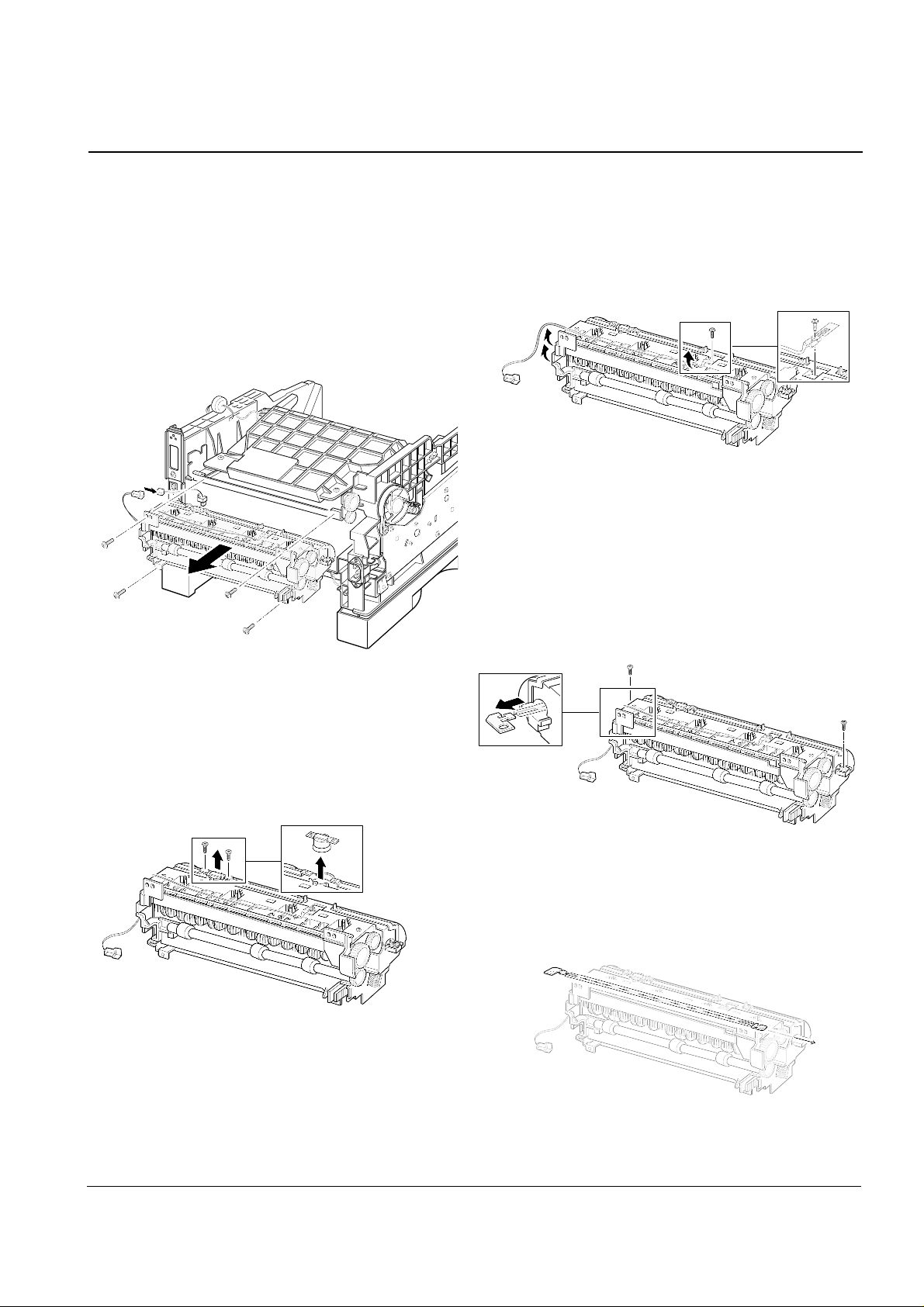

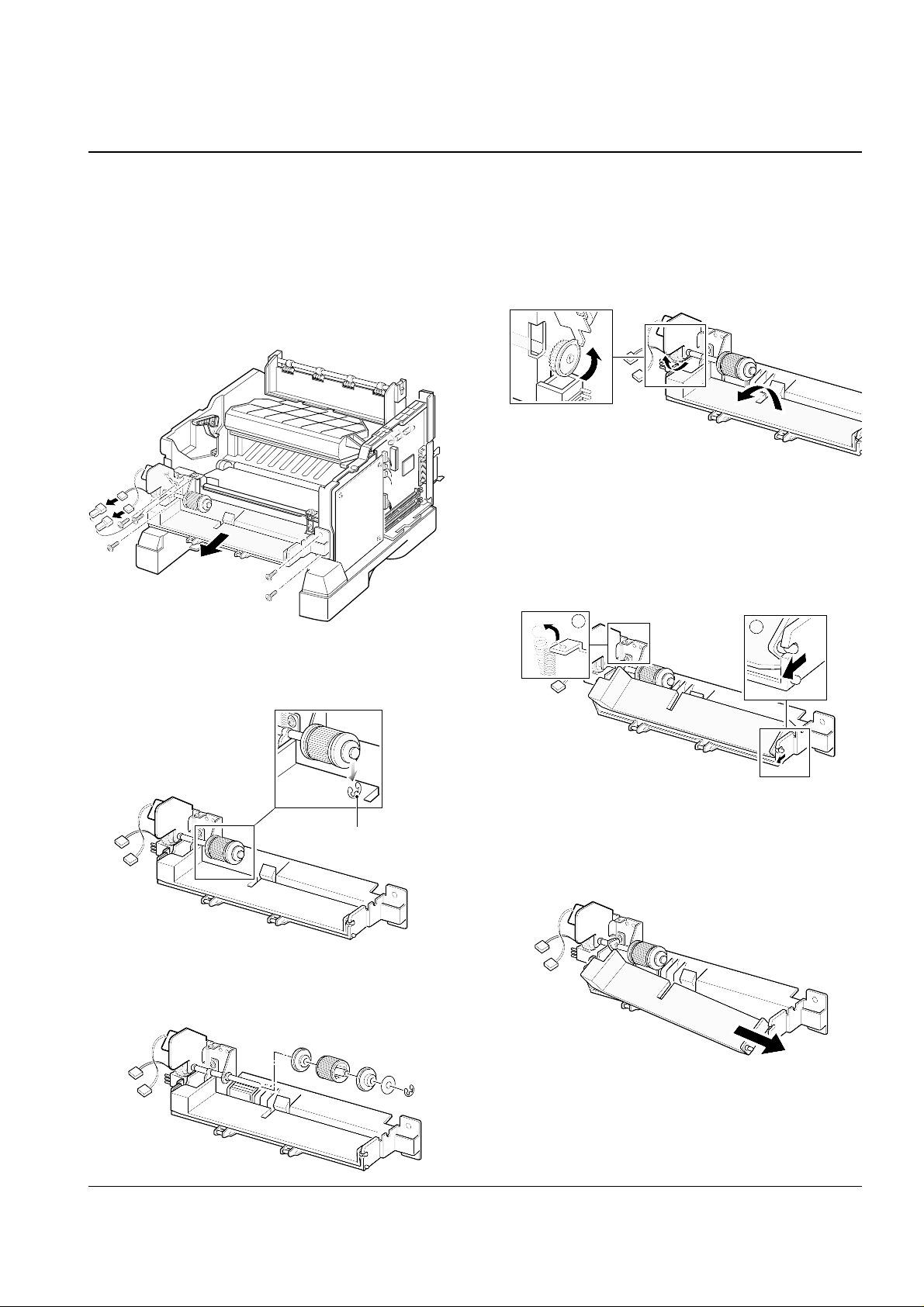

3-4 Pickup Assembly

1. Turn the printer upside down. Remove four

screws, then remove the bar cross bottom.

2. Remove three screws from the left base bracket,

and take the bracket out.

3. Remove four screws securing the pickup assembly.

4. Take the assembly out.

5. Check the pickup rubber wear. If the rubber is

heavily worn, replace it with a new one.

Squeeze this tab to

remove the rubber.

Push the solenoid if

you have difficulty to

remove the pickup

assembly.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-5Samsung Electronics

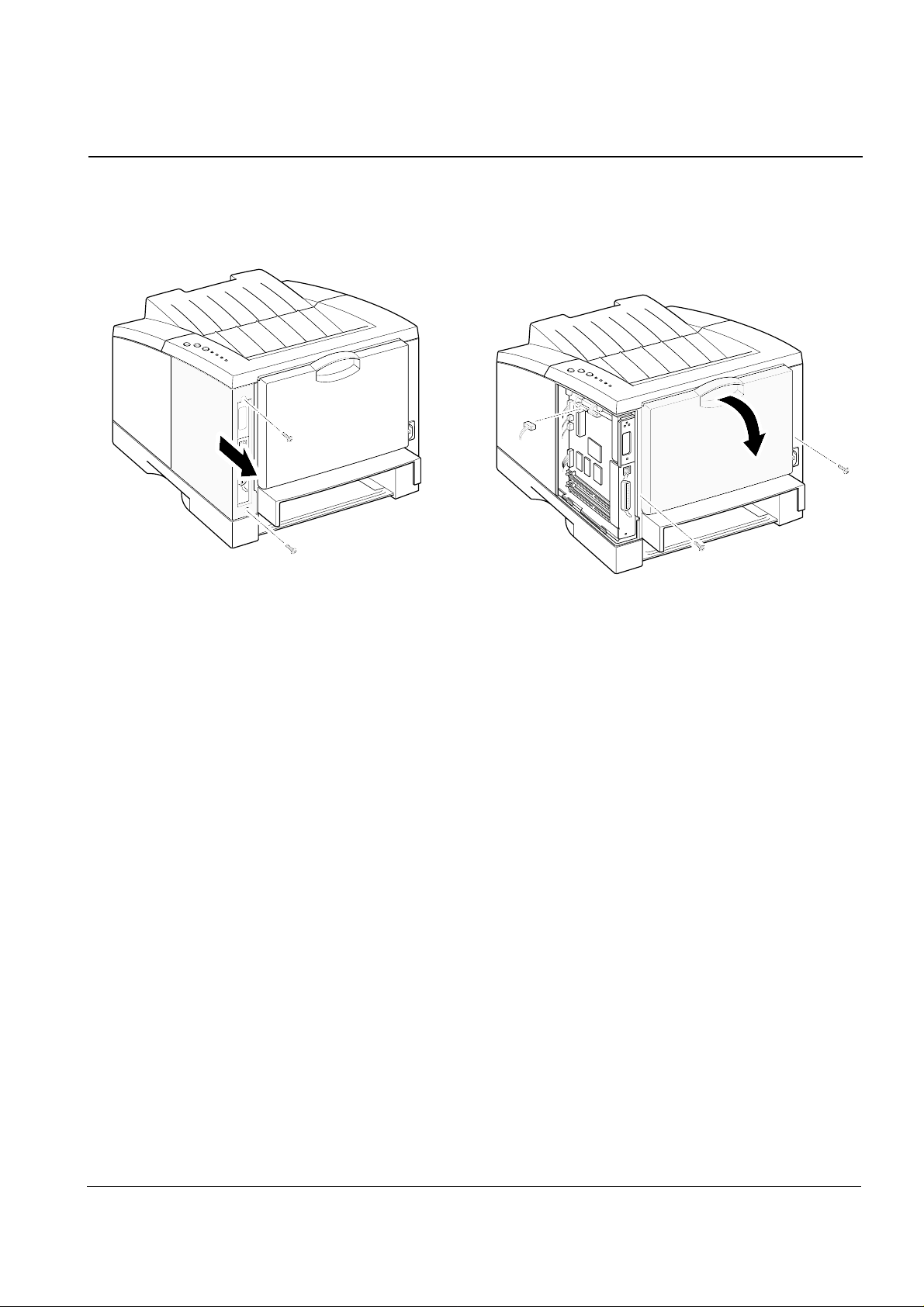

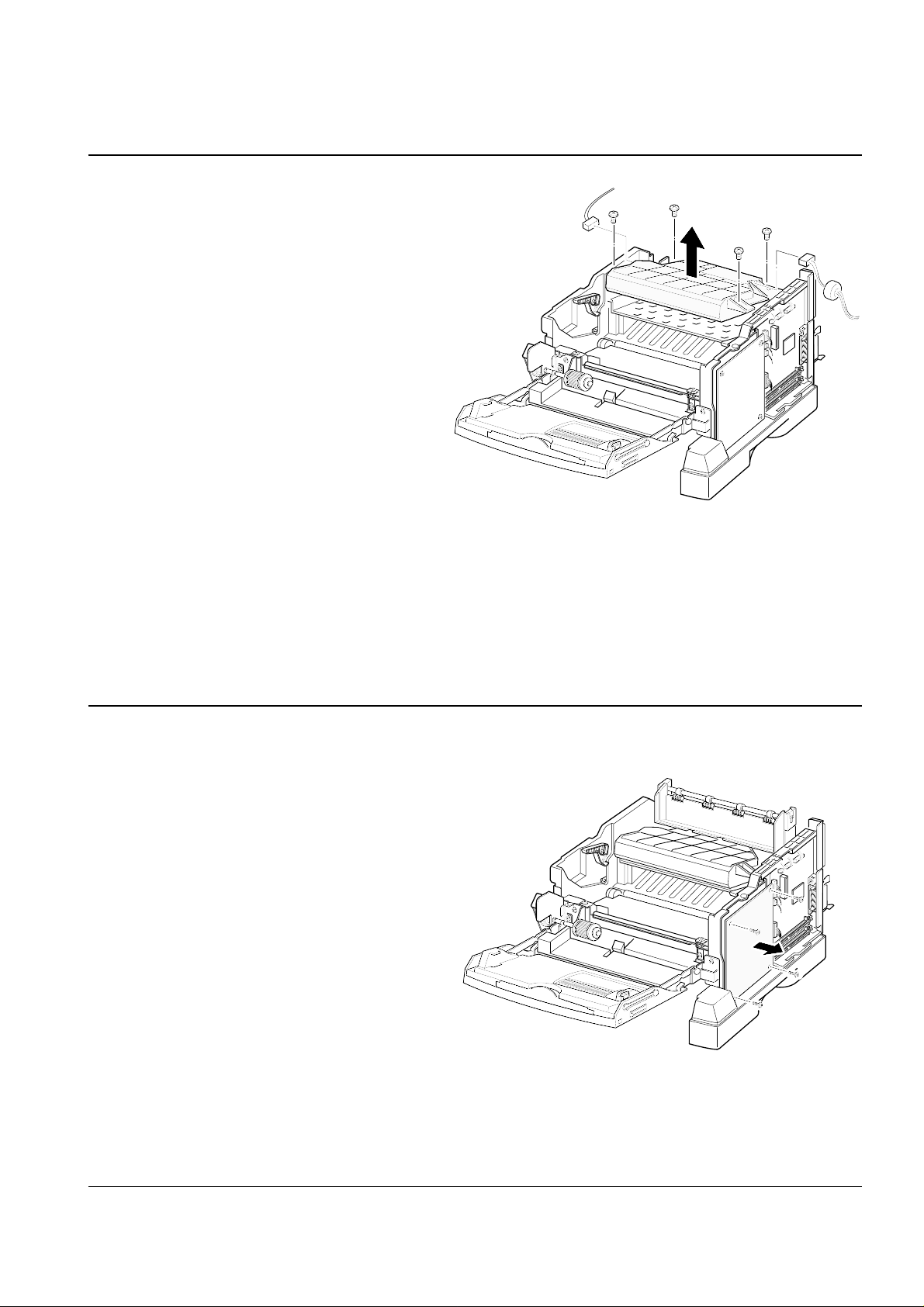

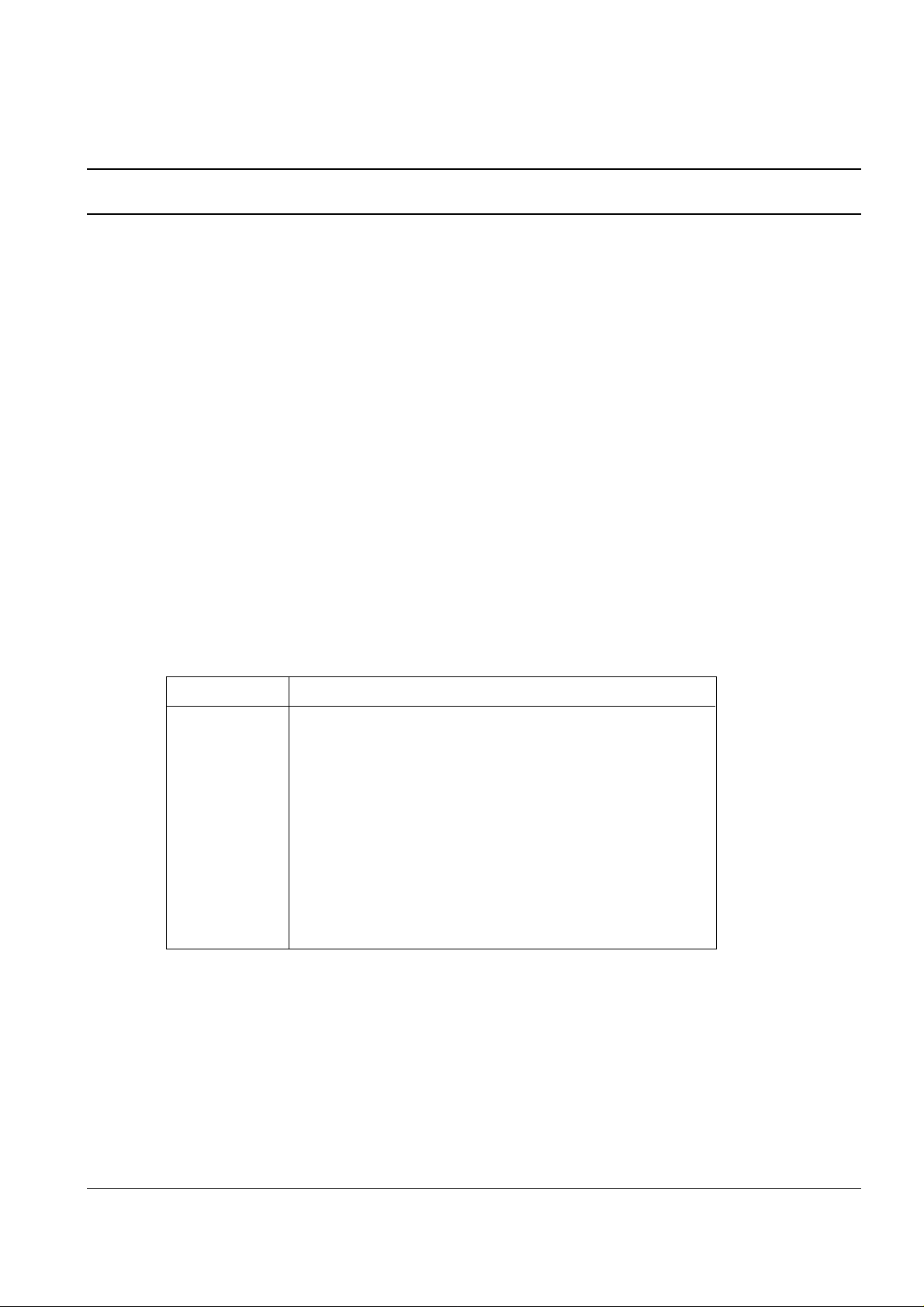

3-5 Main Cover

1. Remove two screws and remove the controller

board.

2. Remove two screws at the back of the printer

and unplug one connector from the board, then

open the rear cover.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-6 Samsung Electronics

6. Remove two screws securing the main cover.

5. Open the printer cover, and open the MP tray.

8. Slide the main cover upward, out of the printer.

Note that the power

switch and the power

connecter are properly

released when you

remove the cover.

7. Unlatch the front ends of the cover.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-7Samsung Electronics

3-6 MP (Multi-Purpose) Tray

1. Before you remove the MP tray, you should

remove:

-Main Cover (see page 3-5)

2. Remove the stoppers securing the MP tray.

3-7 Exit Assembly

1. Before you remove the exit assembly, you should

remove:

-Main Cover (see page 3-5)

2. Remove the exit tray in the direction of arrow.

3. If you want to remove the roller shaft, unlatch

both ends of the shaft and take it out.

4. If you want to remove the exit roller, sqeeze the

bottom of the roller and take it out.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-8 Samsung Electronics

3-8 LSU

1. Before you remove the LSU, you should remove:

-Main Cover (see page 3-5)

-Exit assembly (see page above)

2. Remove four screws, and remove the LSU. Then

unplug two connectors from the LSU.

3-9 HVPS board

1. Before you remove the HVPS board, you should

remove:

-Main Cover (see page 3-5)

2. Remove four screws and take the HVPS board out.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-9Samsung Electronics

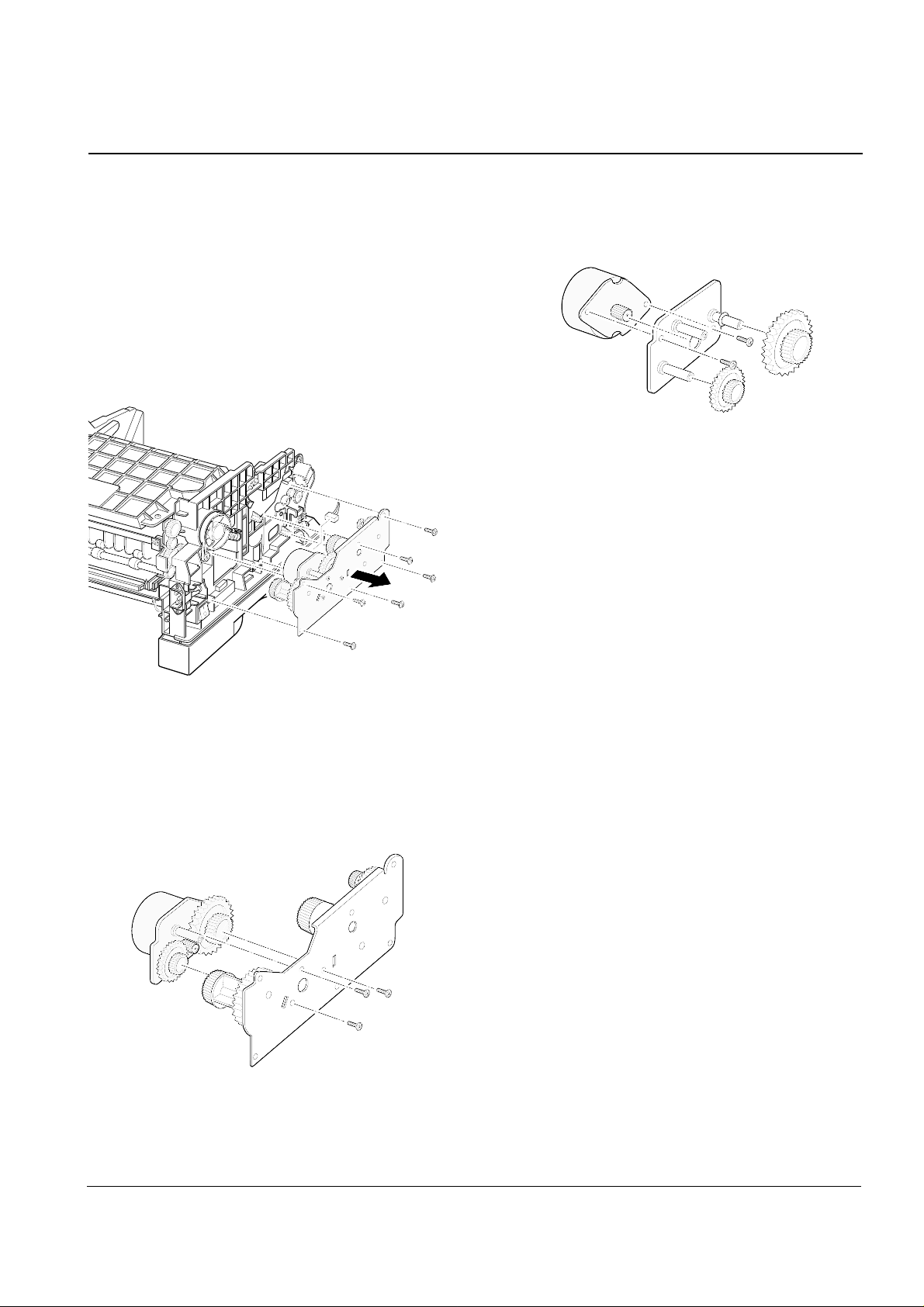

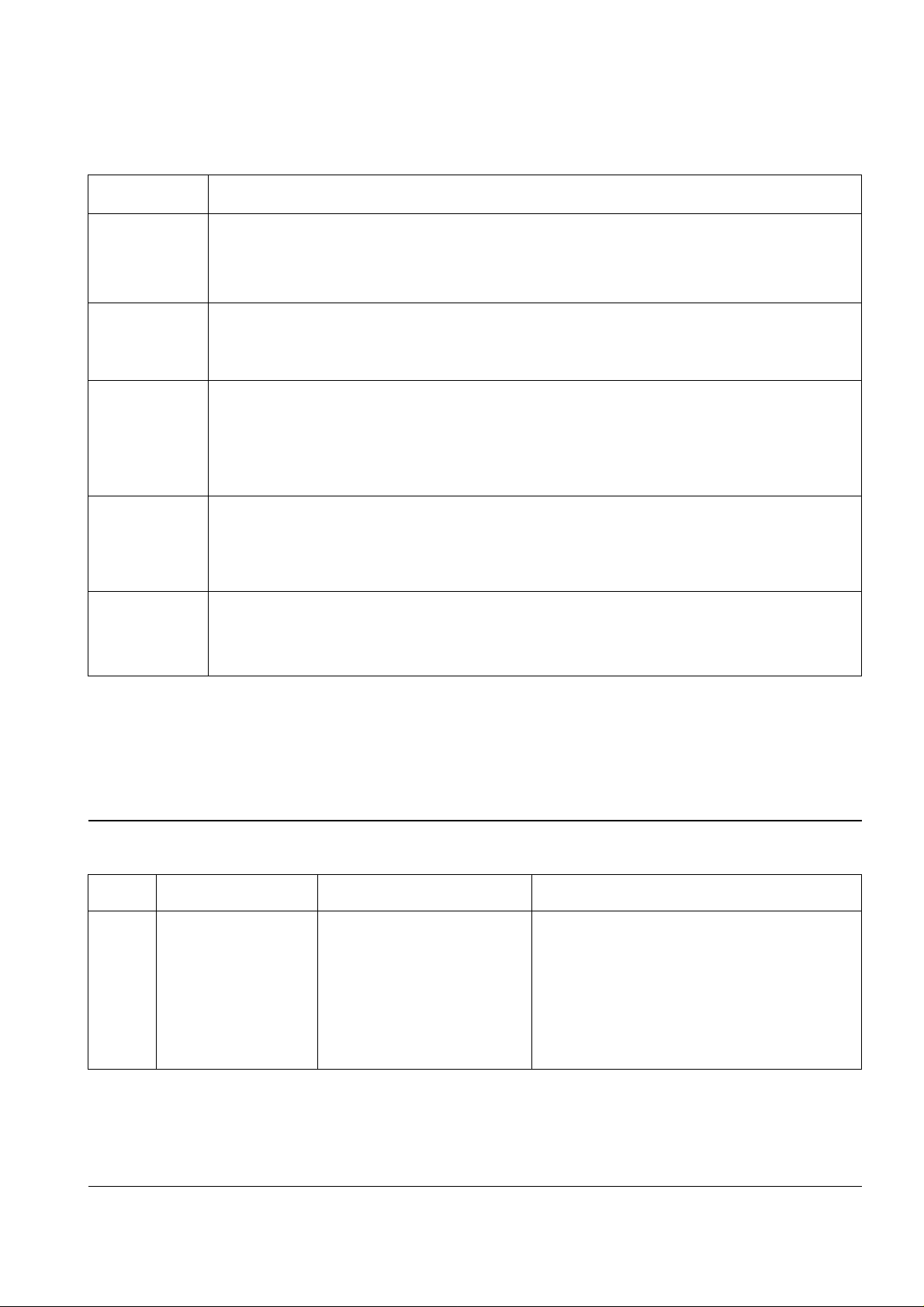

3-10 Drive Assembly

1. Before you remove the drive assembly, you

should remove:

-Main Cover (see page 3-5)

2. Remove six screws securing the drive assembly

from the gear bracket and unplug one connector

from the motor, and then take the drive assembly

out.

3. If you want to remove the motor from the drive

assembly, remove three gold screws securing the

motor assembly to the gear bracket.

4. Remove the motor assembly. Remove two screws

securing the motor to the motor bracket, then

take the motor out.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-10 Samsung Electronics

3-11 Fan

1. Before you remove the fan, you should remove:

-Main Cover (see page 3-5)

2. Remove two screws, and remove the fan. Then

unplug one connector.

3-12 Solenoid

1. Before you remove the solenoid, you should

remove:

-Main Cover (see page 3-5)

2. Remove two screws, and remove the solenoid.

Then unplug one connector.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-11Samsung Electronics

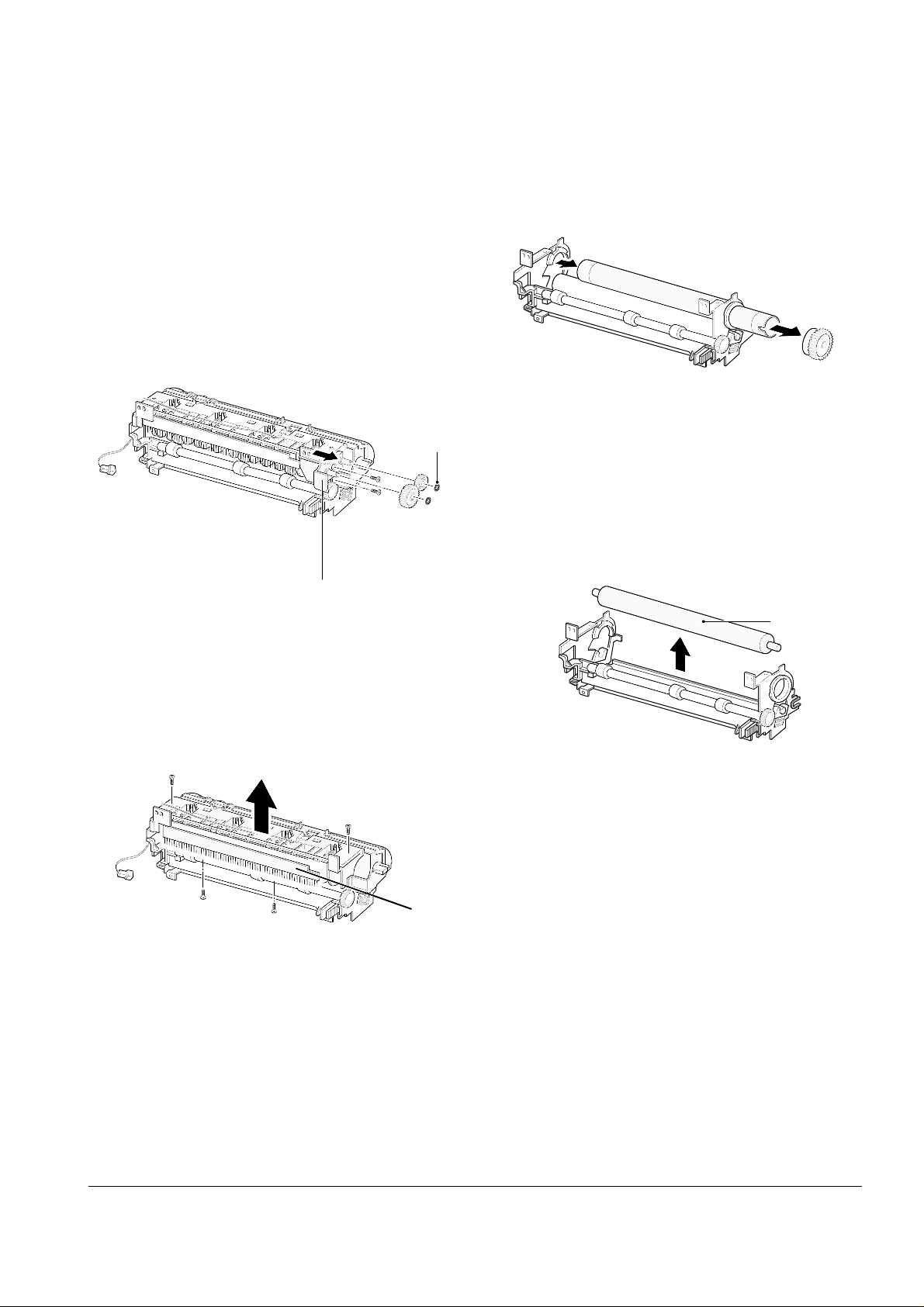

3-13 Fuser Assembly

1. Before you remove the fuser, you should remove:

-Main Cover (see page 3-5)

2. Remove four screws and unplug one connector,

and then remove the fuser assembly.

To remove the thermostat from the fuser assembly

Remove two screws and take the thermostat out.

To remove the thermistor from the fuser assembly :

Remove one screw, and release the wire from the

three holders, and then take the thermistor out.

To remove the halogen lamp from the fuser assembly :

Remove two screws and take the halogen lamp out

of the fuser assembly.

Note: When you reassemble the halogen lamp,

make sure that it is inserted into the slot

properly.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-12 Samsung Electronics

3. Remove two screws and take the cover fuser out.

4. Remove two screws and take the holder brush

ant out.

4. Remove the heat roller.

To remove the pressure roller from the fuser

assembly :

Remove the roller.

To remove the heat roller from the fuser assembly :

1. Remove the halogen lamp. (see page 3-11)

2. Remove two CS-rings and two gears. Then remove

two screws securing the BRKT gear fuser and take

the gear fuser out.

pressure roller

BRKT gear fuser

CS-ring

Holder brush ant

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-13Samsung Electronics

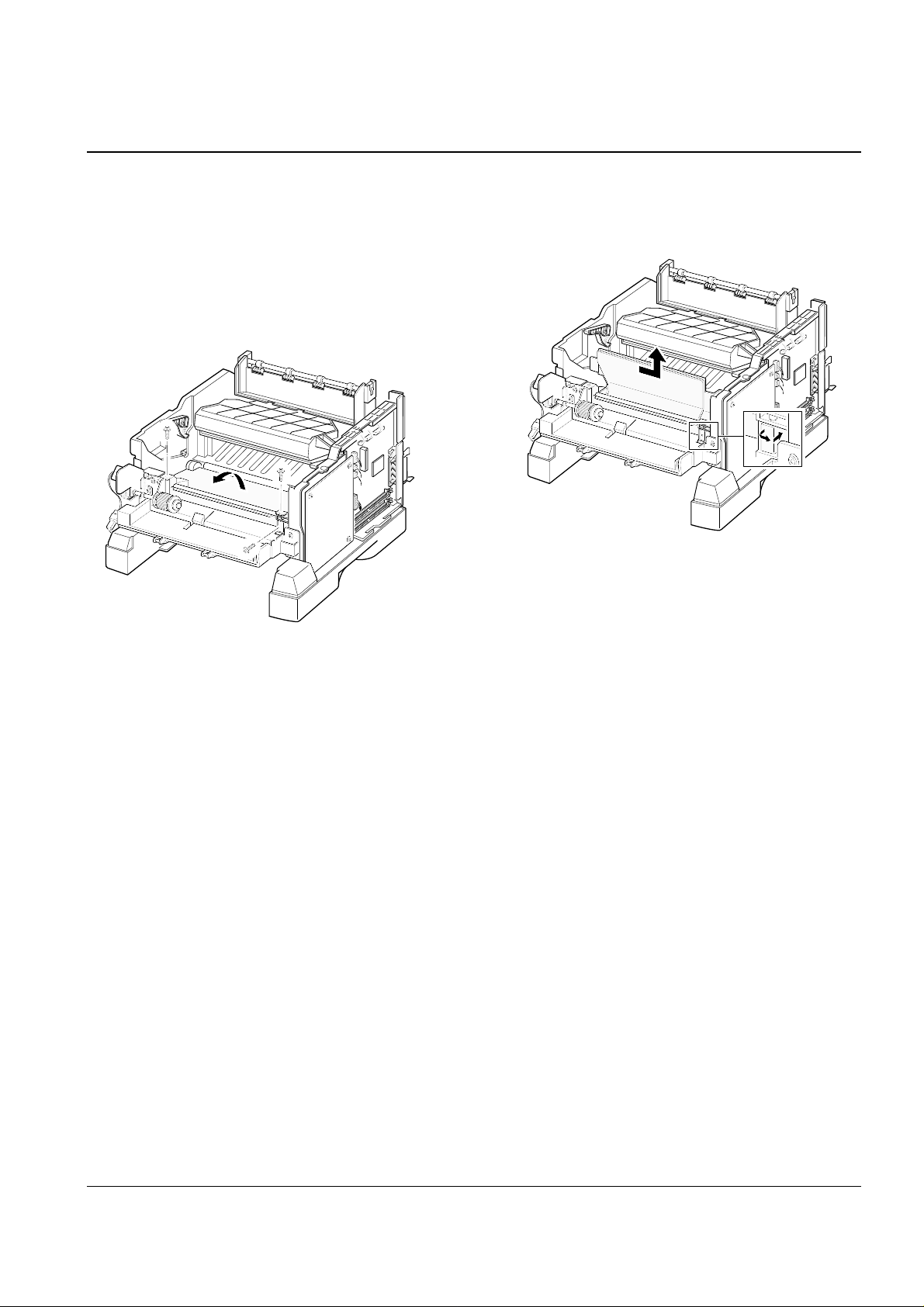

3-14 Guide Feed

1. Before you remove the guide feed, you should

remove:

-Main Cover (see page 3-5)

2. Remove two screws and raise the guide feed in

the direction of arrow.

3. Remove the guide feed.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-14 Samsung Electronics

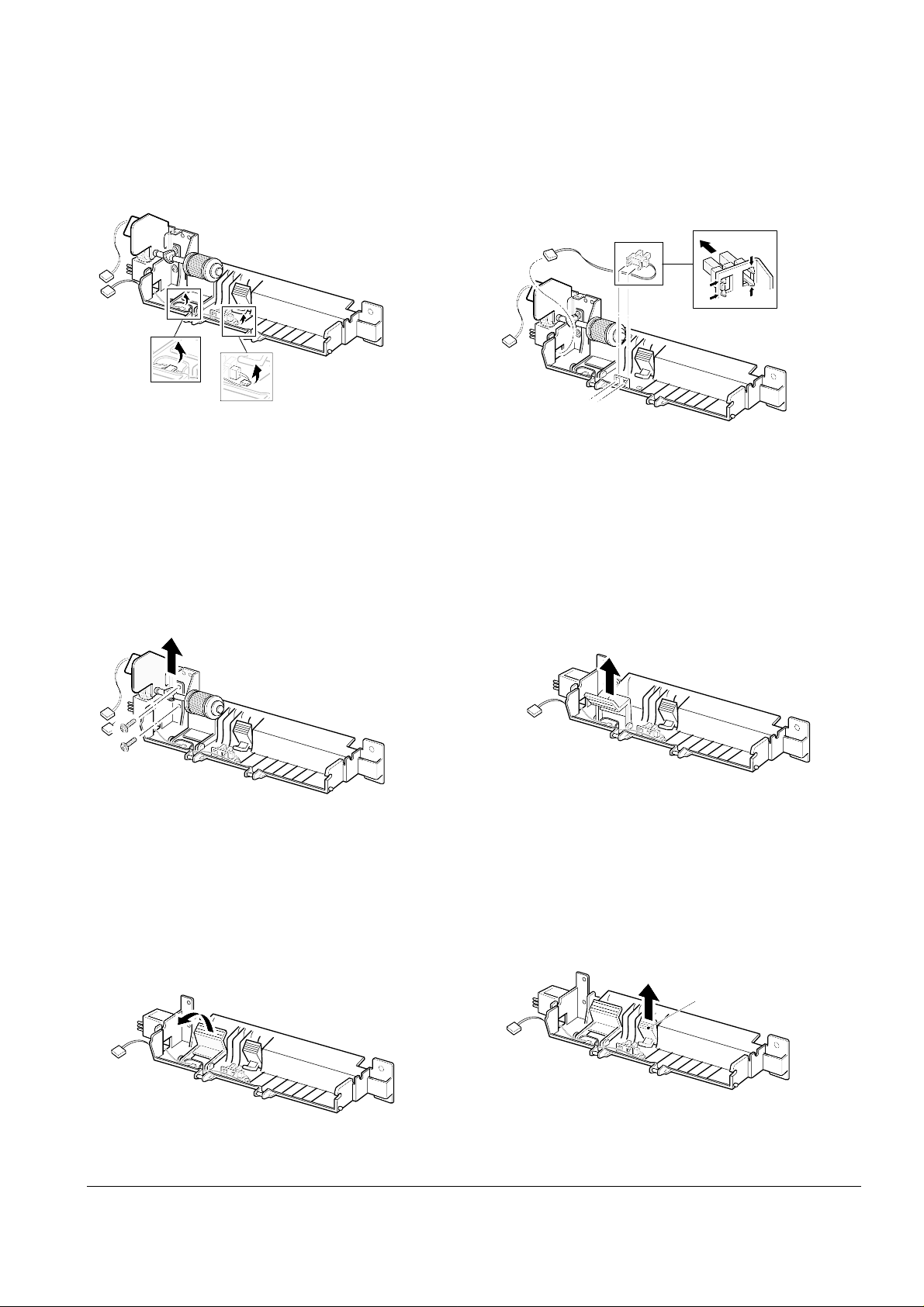

3-15 MPF Assembly and Miscellaneous on MPF Assembly

1. Before you remove the MPF assembly, you

should remove:

-Main Cover (see page 3-5)

2. Unplug two connectors and remove five screws,

and then take the MPF assembly out.

To replace the pickup roller :

1. Remove the e-ring.

2. Remove the roller.

To replace the nockup plate :

1. Turn the gear shown in the square in the direction of arrow to release the nockup plate.

2. Remove the spring , then release the right end of

the plate .

1

2

3. Remove the nockup plate.

e-ring

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-15Samsung Electronics

To replace the Paper Empty (PE) sensor :

1. Release the wire from the two holders.

2. Unlatch the PE sensor, then take it out.

To replace the pickup holder and the Adjust End

MP:

1. Remove two screws and remove the MPT bracket.

2. Raise the pickup holder in the direction of

arrow.

3. Remove the pickup holder.

4. Remove the Adjust End MP

Adjust End MP

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-16 Samsung Electronics

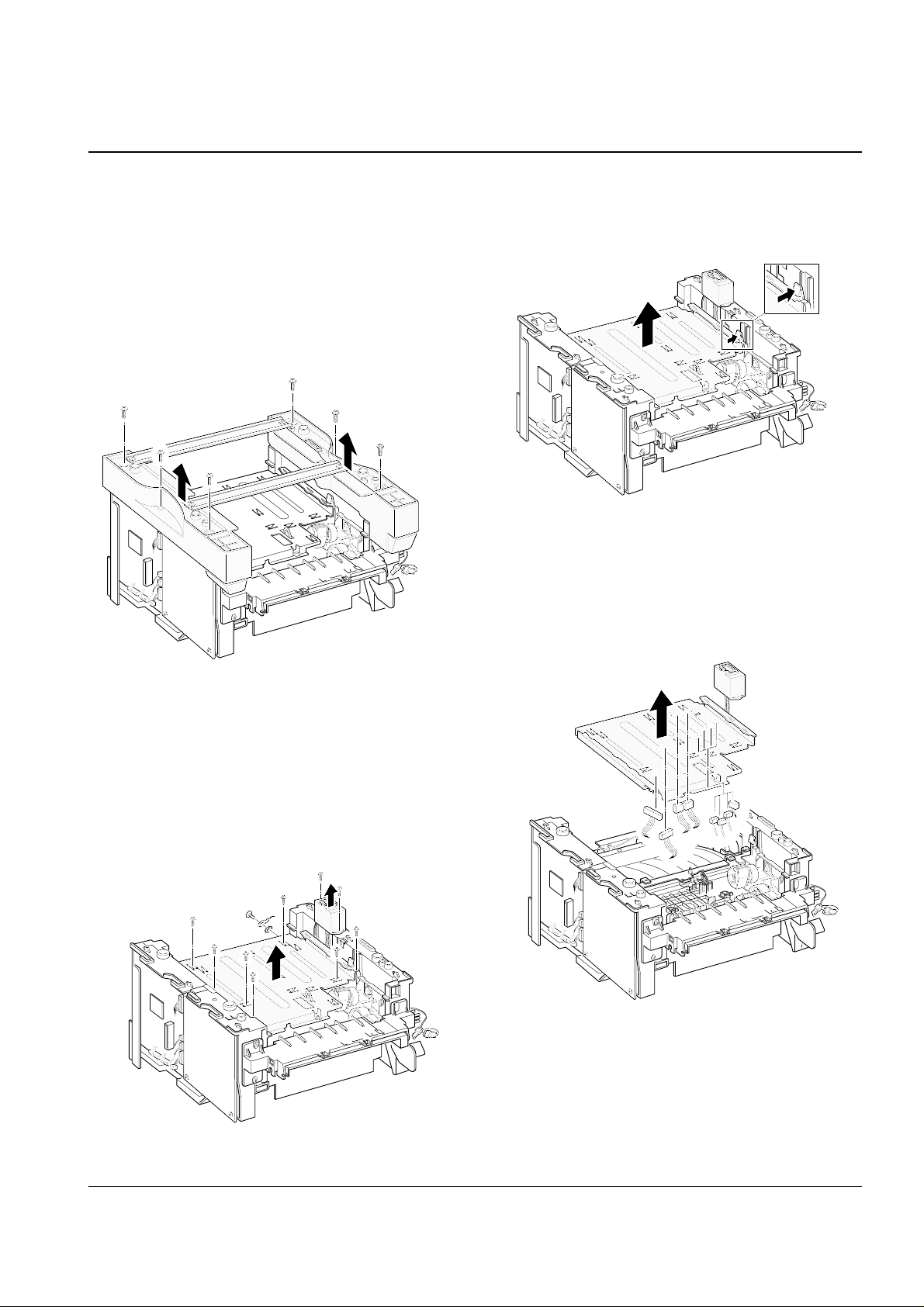

3-16 Engine Board and Miscellaneous

1. Before you remove the engine board, you should

remove:

-Main Cover (see page 3-5)

2. Remove six screws from the left and the right

base brackets and take them out.

4. While you push the latch to release the PCU

shield, take the PCU shield out of the printer.

3. Remove eight screws securing the PCU shield

and remove two screws securing the SCF connector, and then take the PCU shield out of the

printer.

5. Unplug all connectors from the PCU shield, and

remove the shield.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-17Samsung Electronics

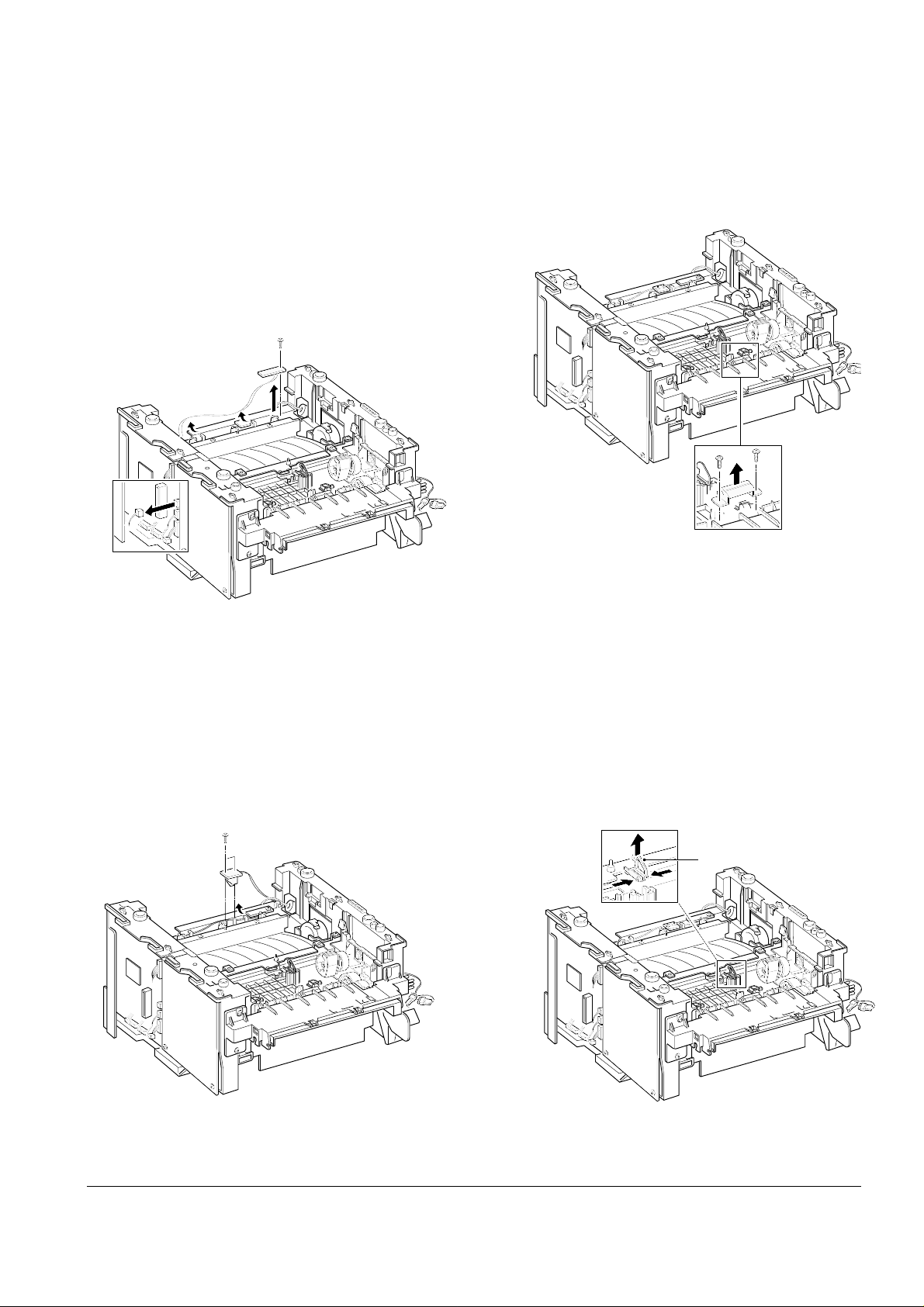

To replace the exit board :

Unplug one connector from the controller board

and remove one screw securing the board. Then

release the wire from two holders and take the

board out.

To replace the fuser sensor :

Remove two screws and take it out.

To replace the Cap sensor :

Remove two screws and take it out.

To replace the actuator empty :

Take the sensor out while you squeeze the both

ends of the sensor.

Actuator empty

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Disassembly and Reassembly

3-18 Samsung Electronics

To replace the actuator feed

1. Turn the mechanism back and push down the

points as shown to unlatch the actuator feed.

2. Turn the unit over again, and remove the actuator feed.

To remove the transfer guide :

Remove three screws and take the guide out.

To replace the PTL ass’y

Release the three tabs latching the sensor using a

phillips screwdriver, then push the sensor down.

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Troubleshooting

4-1Samsung Electronics

4. Troubleshooting

4-1 DCU Control

In case of ML-6060,you can not use the DCU under ‘Diagnostic mode’

But, you can check set condition by status code

4-1-1 DCU Setup

1) Connect DCU to Controller Board Connector CN9 (4 pins)).

4-1-2 DCU Error Status Code

DCU error code will indicate malfunction area of the machine.

Display Error status

60 OPEN FUSER ERROR

62 LOW HEAT ERROR

68 OVER HEAT ERROR

64 COVER OPEN ERROR

70 NO PAPER or NO CASSETTE

71 PAPER JAM 0

72 PAPER JAM 1

73 PAPER JAM 2

95 LSU NOT READY

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

4-1-3 Error Solution

Display Solution

60, 62, 68 1. Measure the resistance of the AC connector on the Fuser. Normal resistance is 2-4 ohms

for 110V, 6-8 ohms for 220V.

2. Check if the fuser lamp works properly.

3. Measure the resistance at Q7 on the engine board. If abnormal, replace U503,CN502,

70 1. Make sure that paper is loaded in the cassette.

2. Replace U555 sensor (photo interrupter).

3. Replace U7 on controller board.

71 1. Make sure that paper is loaded in the cassette.

2. Check for pick-up unit. If it is heavily worn, replace it with new one.

3. Replace U554 sensor.

4. Check if the feed clutch works properly.

5. If abnormal, replace the feed clutch or Q3 on the Engine board .

72, 73 1. Make sure that the paper being used meets the specification.

2. Check if there is a paper jam in the fuser.

3. Replace U554 on the engine board or exits ensor on the frame.

4. Check the fuser roller for any dirt. If dirty, clean the roller.

95 1. Check for CN11,CN6 on the Controller board.

2. Replace U5,OSC1 on the Engine board.

3. Replace LSU.

Troubleshooting

4-2 Samsung Electronics

4-2 Abnormal Image Printing and Defective Roller

If abnormal image prints periodically, check the parts shown below.

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 95.6mm White spot

2 Charge Roller 38.5mm Black spot

3 Supply Roller 45.3mm Horizontal density band

4 Develop Roller 47.1mm Horizontal density band

5 Transfer Roller 56.1mm Black side contamination/transfer fault

6 Heat Roller 69.3mm Black spot and fuser ghost

7 Pressure Roller 72.5mm Black side contamination

Download Service Manual And Resetter Printer at http://printer1.blogspot.com

Loading...

Loading...