Samsung Electronics 5-1

5. Troubleshooting

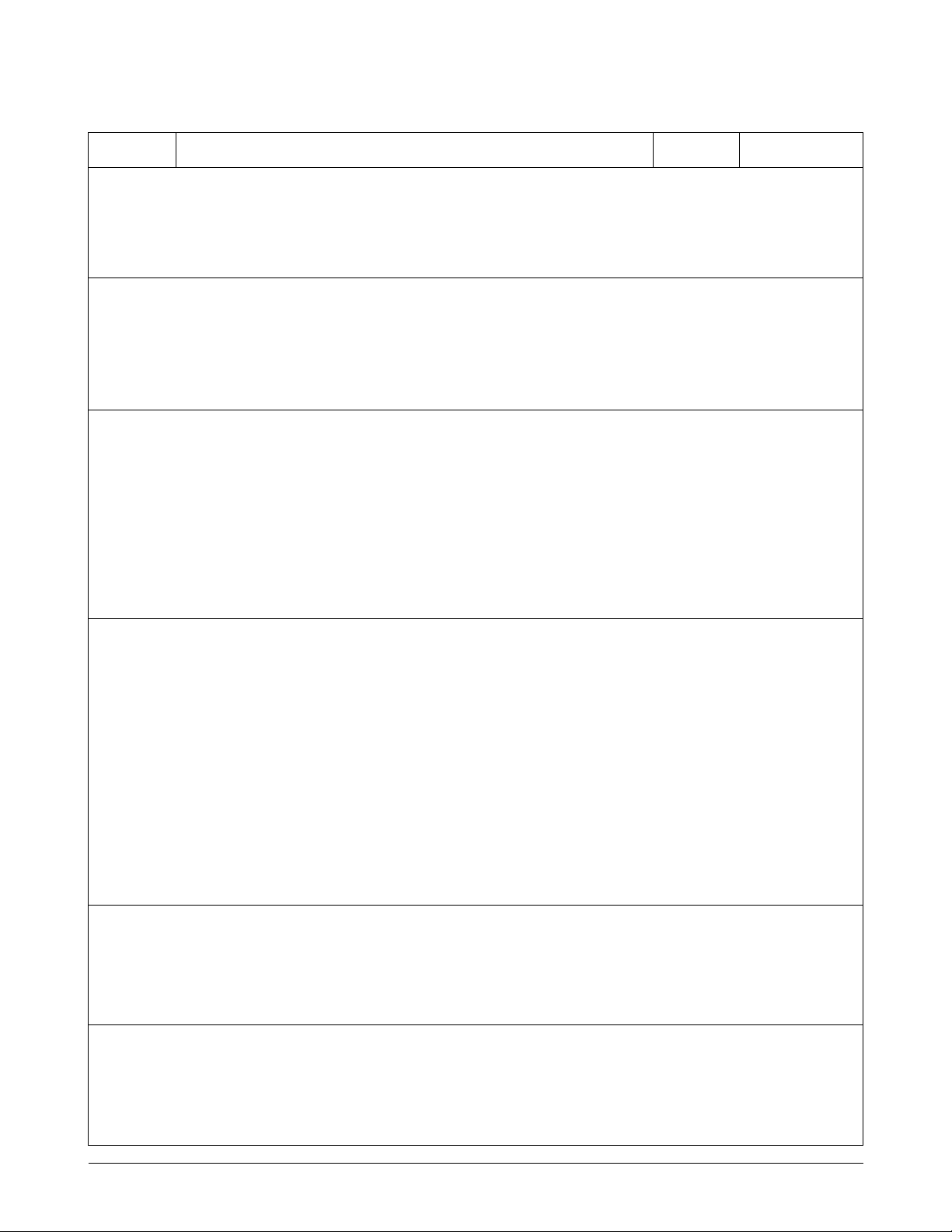

Error code 1-010

Fault

Description

Black vertical stripes occur in the printing.

Black vertical stripes

Model ML-xxxx

Check

1. Developer cartridge

2. Transfer roller

3. Charge roller

Cause

1. Defective develop roller or bad blade of toner cartridge.

2. Defective transfer roller or charge roller.

Solution

1. Replace the toner cartridge, if defective.

2. Replace the roller defective.

Remark

Others

5-2 Samsung Electronics

Troubleshooting

Error code 1-020

Fault

Description

White vertical voids in the image.

White vertical stripes

Model ML-xxxx

Check

1. LSU

2. Developer cartridge

3. Fuser

Cause

1. Foreign matter stuck onto the window of internal lens of LSU mirror

2. Foreign matter or toner particles between the developer roller and blade

3. If the fuser is defective, voids occur periodically at the top of a black image.

Solution

1. Clean the LSU window with a recommended cleaner, or replace the LSU window.

2. Replace the developer cartridge if defective.

3. Open rear cover and check ribs in the fuser for contamination. Clean if necessary.

Remark

Use LSU cleaner dated after January 1997.

Others

If white streaks occurs fewer than 5 or 6 times, it can be considered as normal.

5-3

Samsung Electronics

Troubleshooting

Error code 1-030

Fault

Description

Dark or blurry horizontal stripes occur in the printing periodically.

Black horizontal stripes

Model ML-xxxx

Check

Developer cartridge

Cause

1. Bad contacts of the voltage terminals to developer

2. The rollers may be stained with toner particles.

* Abnormal image periodicity :

37.7 mm = Charge roller

31.3 mm = Supply roller

94.2 mm = OPC drum

46 mm = Develop roller

non periodical = Blade

Solution

1. Check all voltages, and adjust as necessary.

2. Check for terminal contacts, and replace the cartridge, if necessary.

Remark

Others

5-4 Samsung Electronics

Troubleshooting

Error code 1-040

Fault

Description

Dark or blurry black or white spots occur periodically.

Black or white spots

Model ML-xxxx

Check

1. Developer cartridge

2. Transfer voltage

3. Transfer roller’s life

Cause

1. If dark or blurry black spots occur periodically, the rollers in the Developer may be contaminated

with foreign matter or paper particles.

(Charge roller : 37 mm interval, OPC drum : 94 mm interval).

2. If faded areas or voids occur in a black image at intervals of 94 mm, or black spots occur

elsewhere, the OPC drum surface is damaged.

3. If a black image is partially broken, the transfer voltage is abnormal or the transfer roller’s life has

expired.

Solution

1. Run OPC cleaning to remove excess toner and paper particles on the charge roller and OPC drum.

Repeat 2 or 3 times. Run the self-test. If the same problem persists, replace the developer.

2. Clean the rollers. If problem persists, replace the Developer.

3. The transfer roller guarantees 50,000 sheets printing. If the roller’s life is expired, replace it.

Remark

Others

5-5Samsung Electronics

Troubleshooting

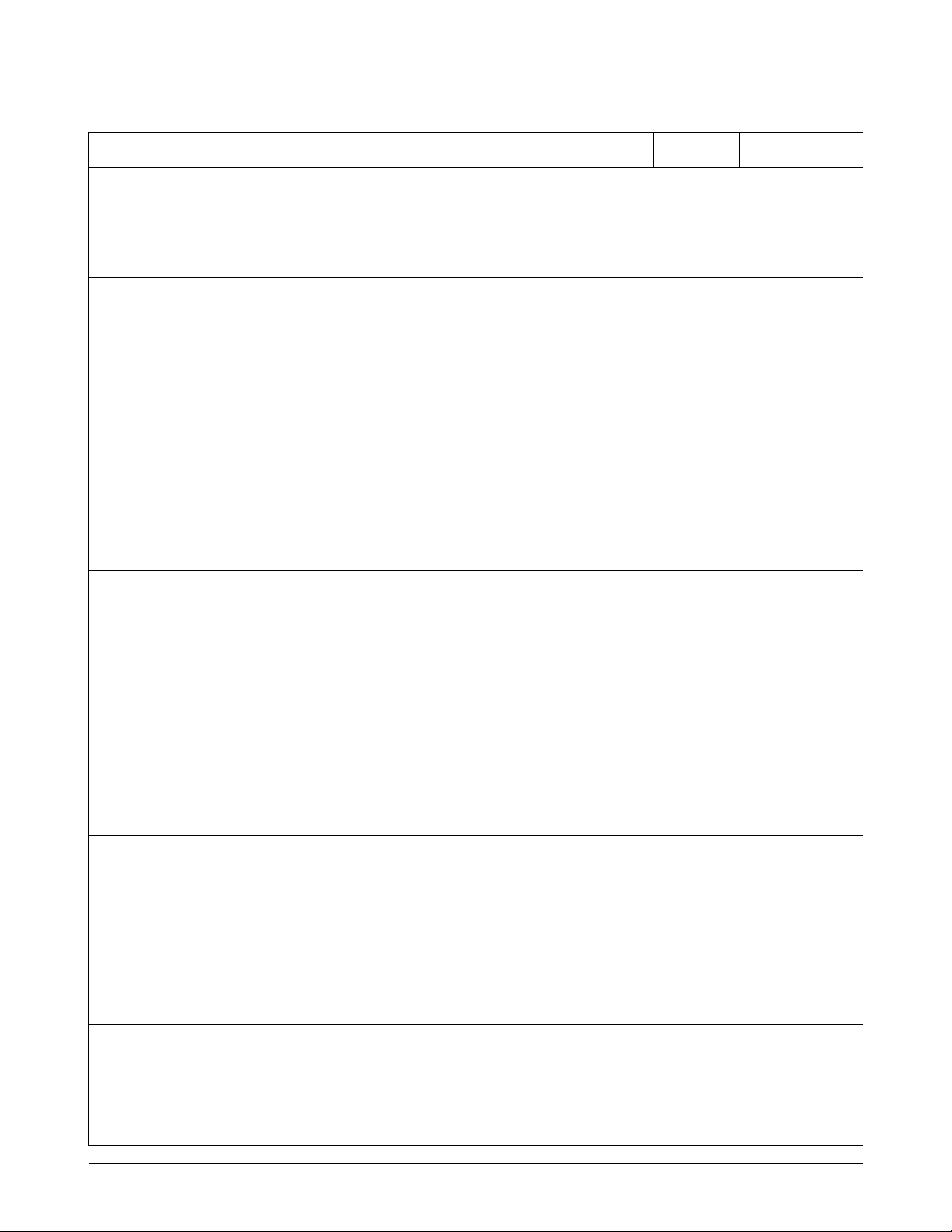

Error code 1-050

Fault

Description

The printed image is light, with no ghost.

Light image (1)

Model ML-xxxx

Check

Developer cartridge

Cause

1. The life of cartridge is ended.

2. Ambient temperature is below than 10 oC.

3. Agitator gear in the Developer is defective.

4. Bad contact of supply roller and abnormal supply voltage.

Solution

1. Check the weight of the developer cartridge, and replace if necessary. When the cartridge is almost

used up, the weight will be as follows:

ML+6000D5 : 960 grams +/- 20 grams

2. In low temperature, wait 30 minutes after printer is powered on before you start printing.

3. Check if the hopper gear is visible from the side of the developer. If not, replace the developer.

4. Check for the supply roller contact and the supply voltage.

Remark

Others

5-6 Samsung Electronics

Troubleshooting

Error code 1-051

Fault

Description

The printed image is light, with no ghost.

Light image (2)

Model ML-xxxx

Check

Engine board

Cause

1. Charge voltage (=MHV) on the engine board exceeds 1520V. (Perform DCU diagnostic mode 01 to

measure the voltage).

2. No power to the supply roller.

Solution

Check the following parts and replace if defective :

U201(KA324), Q211(C1008), T202(Transformer),

resistors, and diodes in the output and feedback area.

Remark

Check the charge voltage (MHV) at :

U201; while operating, #10/#9 2.5~2.9V, #8 5.5~8.5V

while idling, #9 2.7V, #10/#8 0V

Q201 operating voltage; Base 2~2.5V, Emitter 0~1V, Collector 30~60V

U203; #1 0V input, #2 0V output

Others

5-7Samsung Electronics

Troubleshooting

Error code 1-052

Fault

Description

The printed image is light, with no ghost.

Light image (3)

Model ML-xxxx

Check

1. Engine board

2. Main body

Cause

1. Engine board bias (350-485V) and supply voltage (570-630V) may be low (Perform DCU diagnostic

mode 04 to measure the voltage).

2. Direct strong light may be entered into the manual feed slot.

Solution

1. Check the following parts :

U201(KA324), Q204(D526-Y), T204(Transformer), U203(SN7407N), resistors, diodes in the output

and feedback area.

2. Check if contrast mode is set to ‘Light’. If not, change the install position of the printer or attach

OPC cover sheet (P/No: JC72-49093A).

Remark

Bias and supply voltage check point:

U203; #9 pulse input, #8 pulse output

Others

5-8 Samsung Electronics

Troubleshooting

Error code 1-060

Fault

Description

The printed image is dark.

Dark image (1)

Model ML-xxxx

Check

Engine board

Cause

1. No charge voltage in the engine board. (Perform DCU diagnostic code ‘01’ to measure the voltage).

Solution

1-1. Check the following parts :

U201(KA324), Q211(C1008), Q201(D526-Y), T202, U203 (SN7407N),

resistors, diodes in the output and feedback area.

1-2. Clean the high voltage terminal on the engine and its PBA.

1-3. Refer to the following information.

U201(KA324)’s pin #12, #13 ; 2.5~2.9 V, pin #14 ; 5.5~8.5 V

For standby, pin #13 ; 2.7V, pin #12 & #14 ; 0V

Q201’s operating voltage ; base=+2~2.5 V, emitter=0~1 V collector=30~60 V

U203(7407N)’s pin #1 ; 0V input, pin #2 ; 0V output

Remark

Others

5-9Samsung Electronics

Troubleshooting

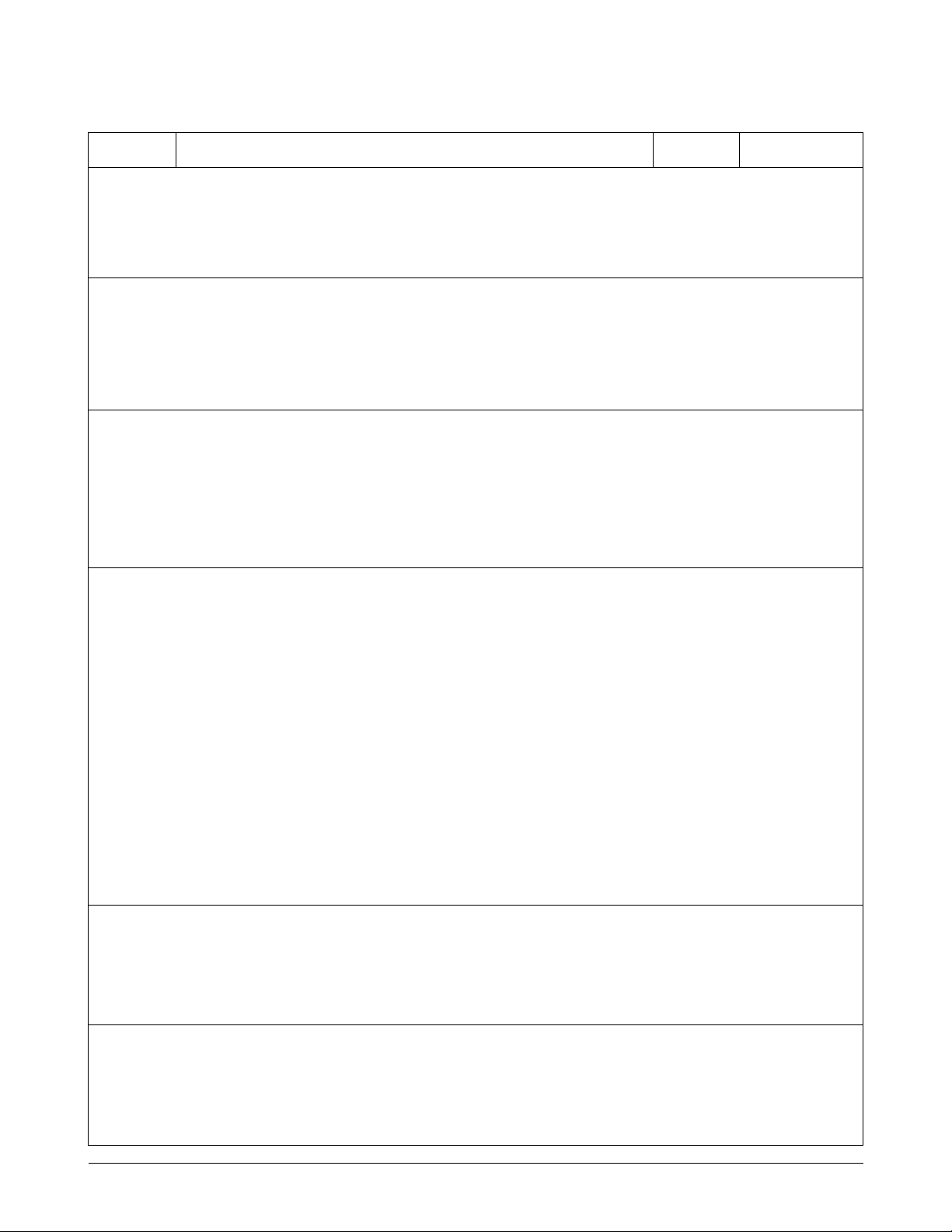

Error code 1-061

Fault

Description

The printed image is dark.

Dark image (2)

Model ML-xxxx

Check

Engine board

Cause

1. No supply or bias voltage at the engine board

(Perform DCU diagnostic code ‘04’ to measure the voltage).

Solution

1-1. Check the following parts :

U201(KA324), Q204(D526-Y), T204, U203 (SN7407N),

resistors, diodes in the output and feedback area.

1-2. Refer to the following information.

U203(7407N)’s pin #1; pulse input, pin #2; pulse output.

Remark

Others

5-10 Samsung Electronics

Troubleshooting

Error code 1-062

Fault

Description

The printed image is dark.

Dark image (3)

Model ML-xxxx

Check

Engine board

Cause

1. Voltage higher than normal. (normal supply voltage : 570-630V, normal bias voltage : 350-485V).

Solution

1-1. Check the following parts :

U201(KA324), Q204(D526-Y), T204, U203 (SN7407N)

resistors, diodes in the output and feedback area.

1-2. Refer to the following information.

U203(7407N)’s pin #9; pulse input, pin #8; pulse output.

1-3. Check developer contacts for contamination by toner particles.

Remark

Others

Samsung Electronics 5-11

Troubleshooting

Error code 1-070

Fault

Description

Print density is uneven between left and right.

Uneven density

Model ML-xxxx

Check

1. Transfer roller pressure

2. Developer cartridge

Cause

1. The pressure force on the left and right springs of the transfer roller is not even (left : 450 gf, right :

600 gf), the springs are damaged, the transfer roller is improperly installed, or the transfer roller

bushing or holder is damaged.

2. The toner level is not even on the developer roller due to the bad blade.

Solution

1. Replace defective holder or springs. Adjust the transfer voltage.

2. Replace the developer cartridge.

Remark

Others

5-12 Samsung Electronics

Troubleshooting

Error code 1-080

Fault

Description

Background appears in the printing.

Background

Model ML-xxxx

Check

1. Engine board

2. Developer cartridge

3. Transfer roller

4. Operating environment

Cause

1-1. Low transfer voltage (10% below than normal)

1-2. High supply and / or bias voltage.

1-3. No transfer voltage.

2. Unauthorized recording paper has been used.

3. Abnormal ambient temperature or humidity.

4. Defective develop roller.

Solution

1-1. Refer to Error Code 1-060.

1-2. Refer to Error Code 1-061.

1-3. Refer to Error Codes 1-090 and 1-091.

2. Use a recommended type of recording paper.

3. If the printer is under abnormal ambient condition for a long time, print errors may occur. Improve

the operating environment.

4. Replace the toner cartridge.

Remark

Others

Samsung Electronics 5-13

Troubleshooting

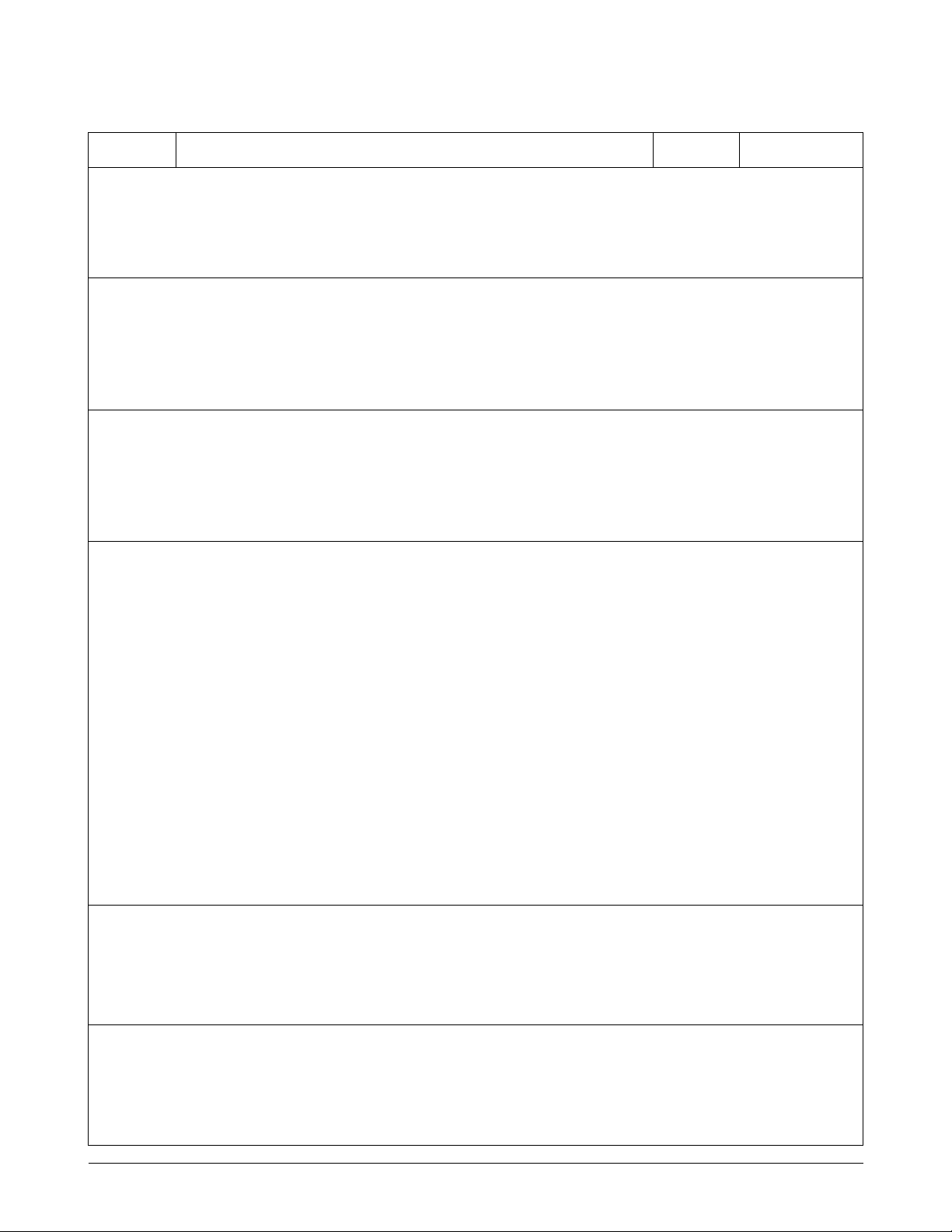

Error code 1-090

Fault

Description

Ghost occurs at 94 mm intervals.

Ghost (1)

Model ML-xxxx

Check

1. Developer cartridge

2. Main body

Cause

1. Contamination of high voltage terminals in the main body , engine board, and / or developer.

2. Transfer roller lifetime has expired.

3. No using recommended recording paper.

4. The Pre-Transfer Lamp (Refer to 18 on page 6-6.)

Solution

1. Open top cover and disassemble the unit and clean contamination components.

2. After replacing the transfer roller, make sure the transfer voltage is normal.

3. Use a recommended type of recording paper.

4. Check for the PTL operation, and if required, check for the main board.

Remark

Others

5-14 Samsung Electronics

Troubleshooting

Error code 1-090-1

Fault

Description

Ghost occurs at 94 mm intervals.

Ghost (2)

Model ML-xxxx

Check

Operating environment

Cause

1. Abnormal low temperature and humidity. In this case, ghost occurs on the entire page and the

print density is too light.

Solution

1. If the operating temperature and relative humidity are too low, try waiting about 1 hour after power

on before using printer.

Remark

Others

Loading...

Loading...