LASER PRINTER

ML-347x Series

LASER PRINTER The keynote of Product

Upgrade to Speed_up model(ML-347x)

of the ML-3050 serie

1. Speed: Up to 33ppm (Ltr. 35ppm),

1200x1200dpi Effective output

2. Paper Path: MPF Type Cassette

3. Emulation: PCL6, PS3

4. CPU: SPGPv3

5. Memory: 16~64MB Standard

6. Cassette: 250 sheet Cassette

7. MP: 50 sheet MP

8. Lan: 10/100 Base TX (ML-3471ND)

9. I/O: USB 2.0, IEEE1284

10. Toner: 10K Toner (4K initial)

11. Option: 802.11b/g Wireless N/W,

250 sheet Opt. SCF

12. Duplex: Built in Duplex

Basic Model :ML-3471ND

Manual

SERVICE

ML-347x Series

ML-3471ND/XAX

1. Precautions

1.1 Safety Warning 1-1

1.2 Caution for safety

1-2

1.3 ESD Precautions

1-4

2. Product spec and feature

2.1 Product Specifications 2-1

2.1.1 Product Overview

2-1

2.1.2 Specifications

2-1

2.1.3 Model Comparison Table

2-6

2.1.4 Accessory List

2-6

2.2 System Overview

2-7

2.2.1 System Construction

2-7

2.2.2 Mechanical Parts Specifications

2-12

2.2.3 Engine H/W Specifications

2-18

2.2.4 S/W Descriptions

2-28

3. Disassembly and Reassembly

3

.1 General Precautions on Disassembly 3-1

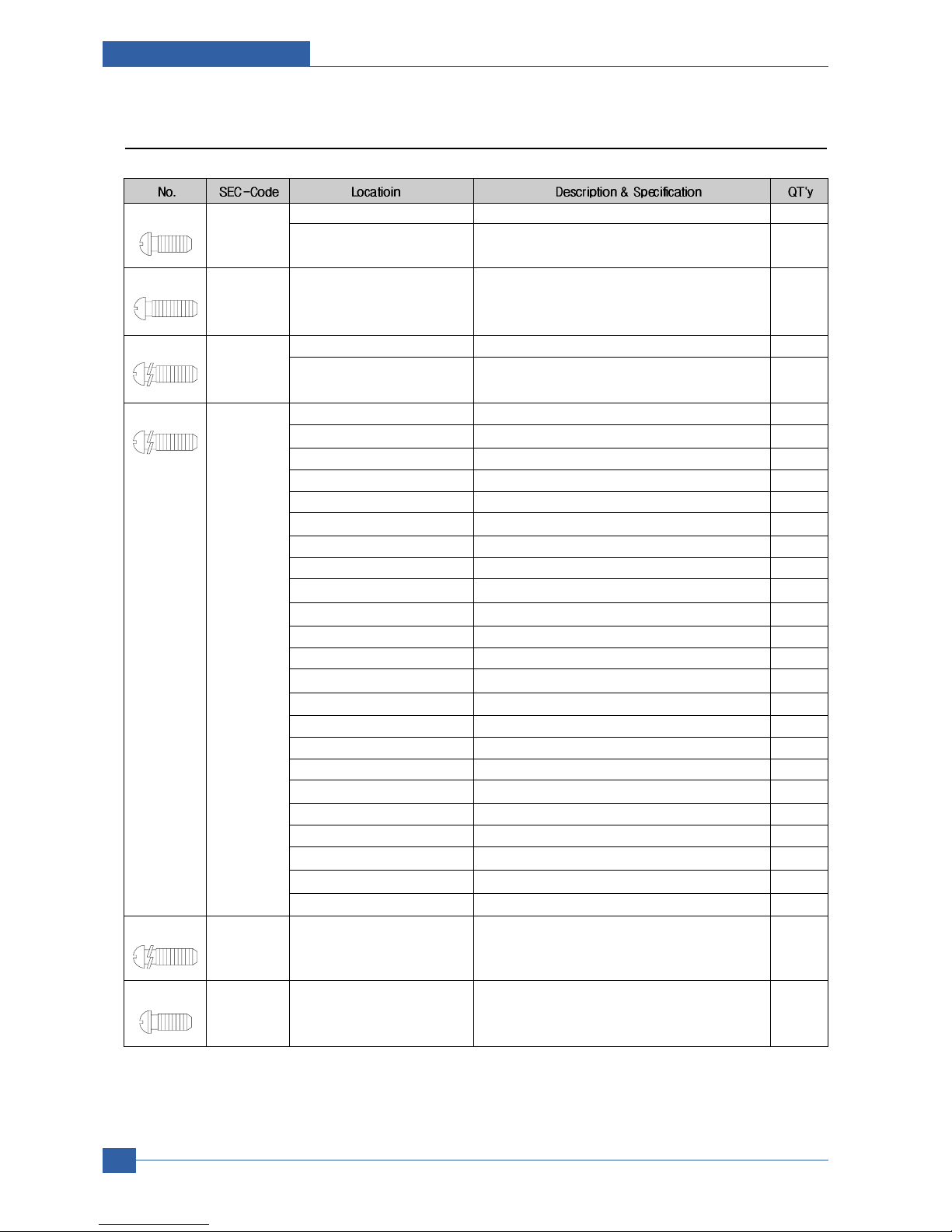

3.2 Screws used in the Printer

3-2

3.3 Front Cover

3-4

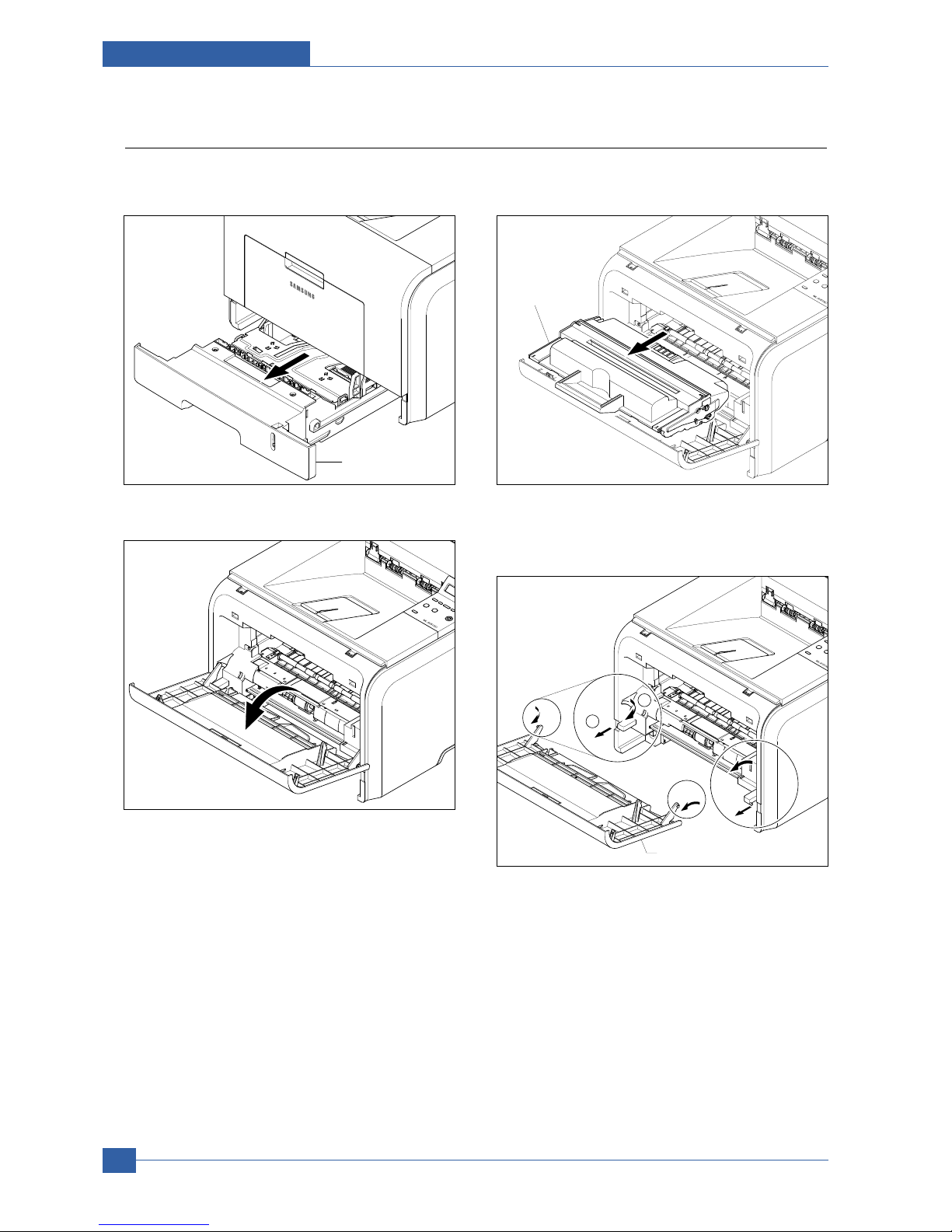

3.4 MP Tray Ass'y

3-5

3.5 Rear Cover

3-6

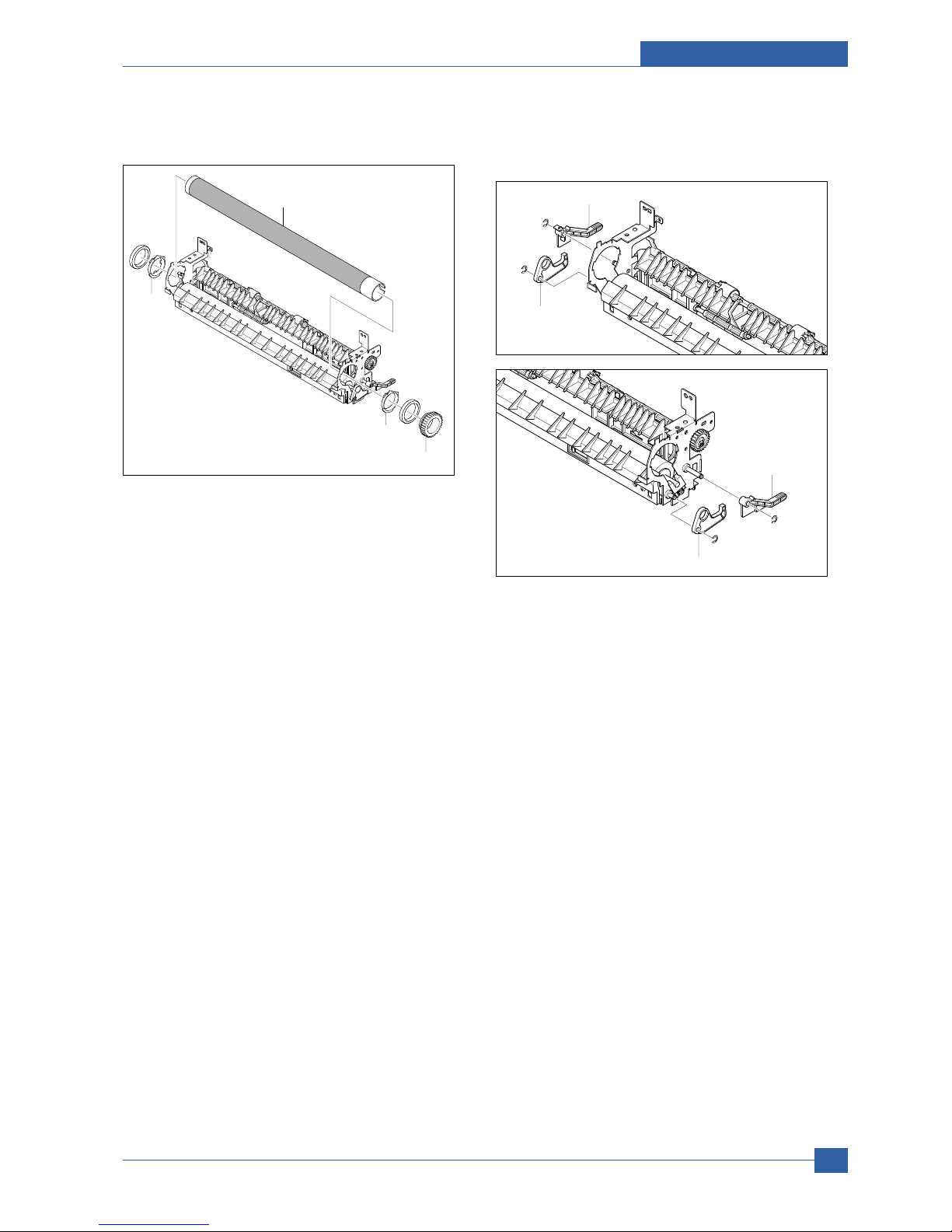

3.6 Fuser Ass'y

3-7

3.7 Top Cover

3-10

3.8 OPE Unit

3-11

3.9 Side Cover (Left, Right)

3-12

3.10 Shield Controller Ass'y

3-14

Contents

3.11 Drive Ass'y 3-15

3.12 Duplex Drive Ass'y

3-16

3.13 Shield SMPS Ass'y

3-17

3.14 Connection PCB

3-18

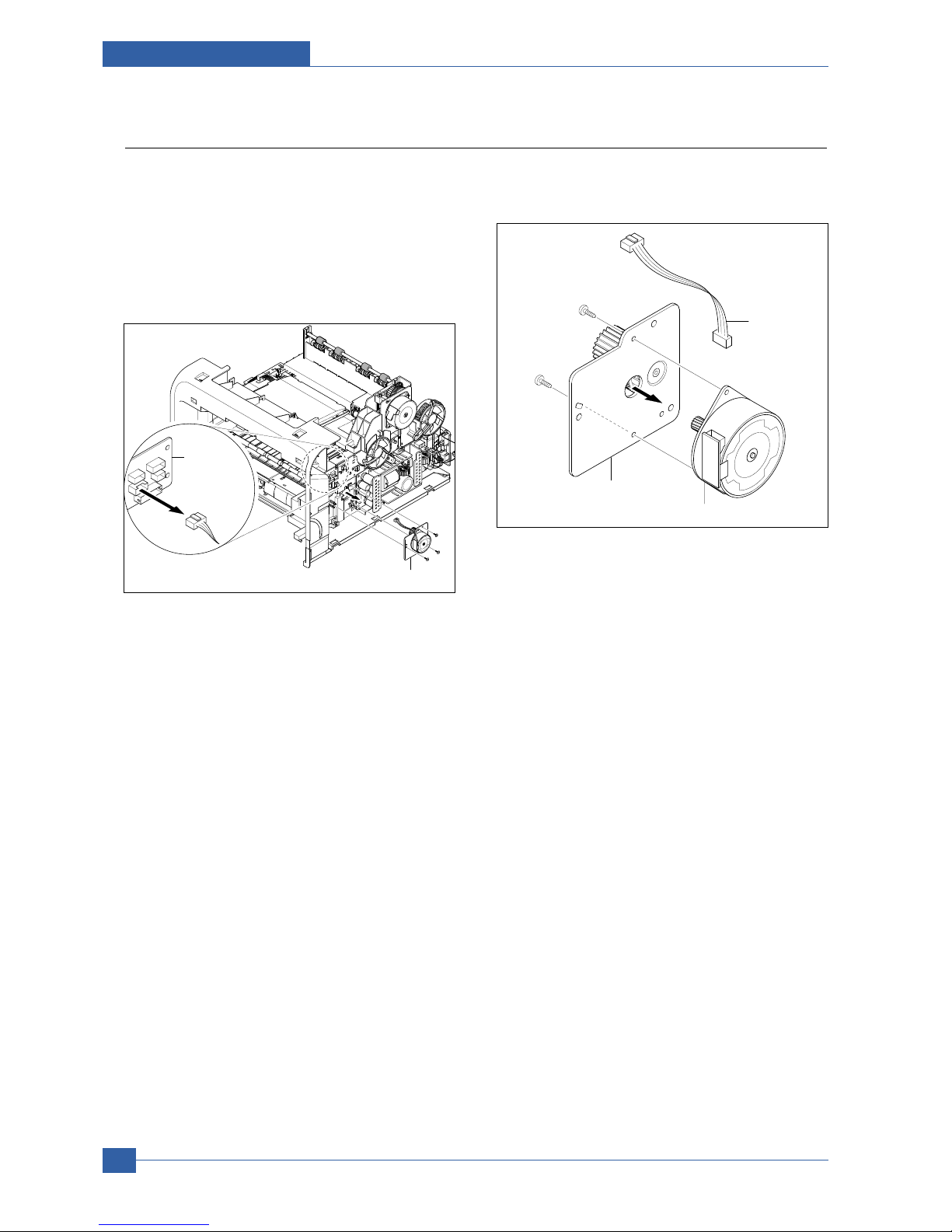

3.15 Fuser Drive Ass'y

3-19

3.16 Fan

3-20

3.17 Pick Up Roller Ass'y

3-21

3.18 Duplex Guide Housing (With Feed Roller)

3-22

3.19 HVPS Housing

3-23

3.20 Cover Mid Front

3-24

3.21 MPF Housing

3-24

3.22 Feed Roller Parts

3-25

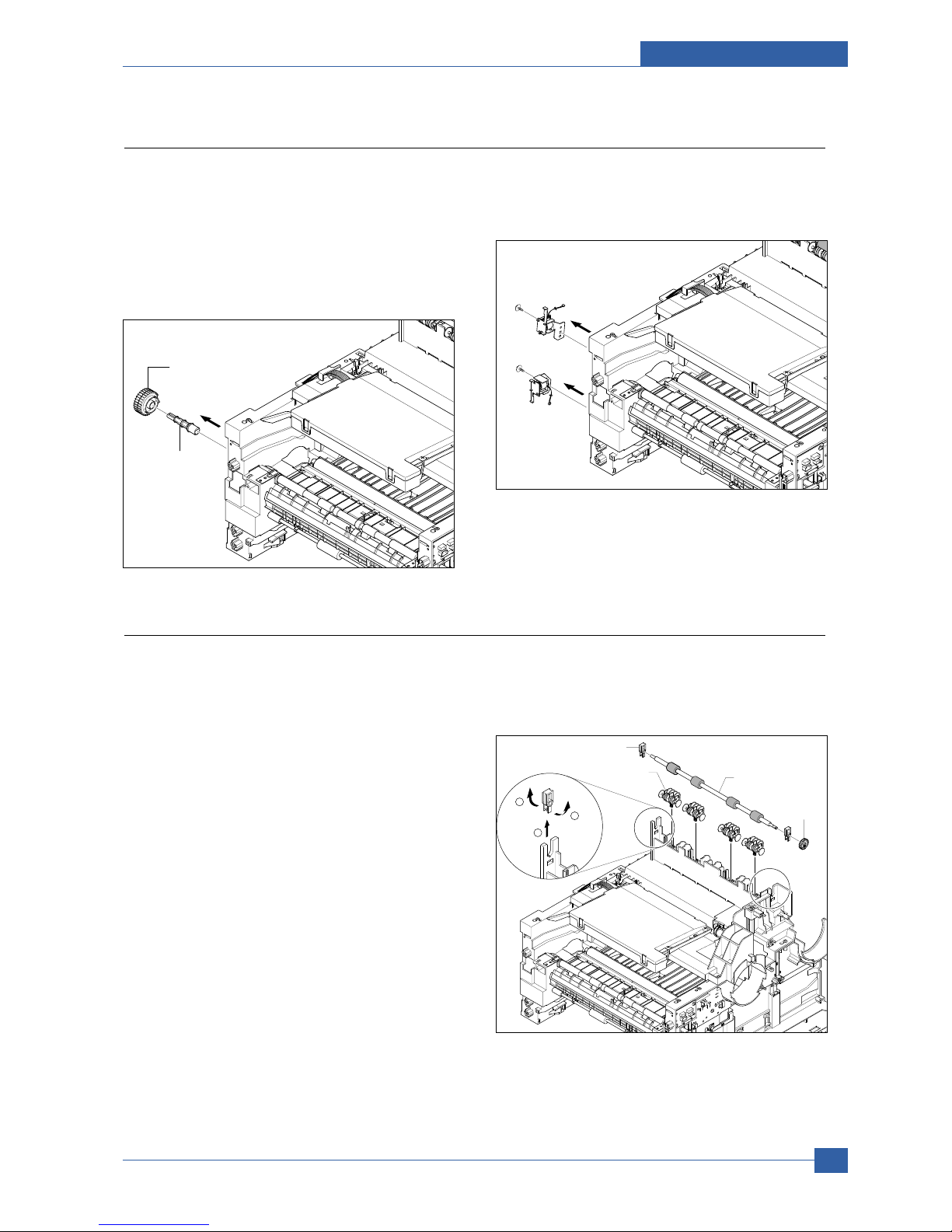

3.23 Pick Up Gear Ass'y & Solenoids

3-27

3.24 Exit Roller

3-27

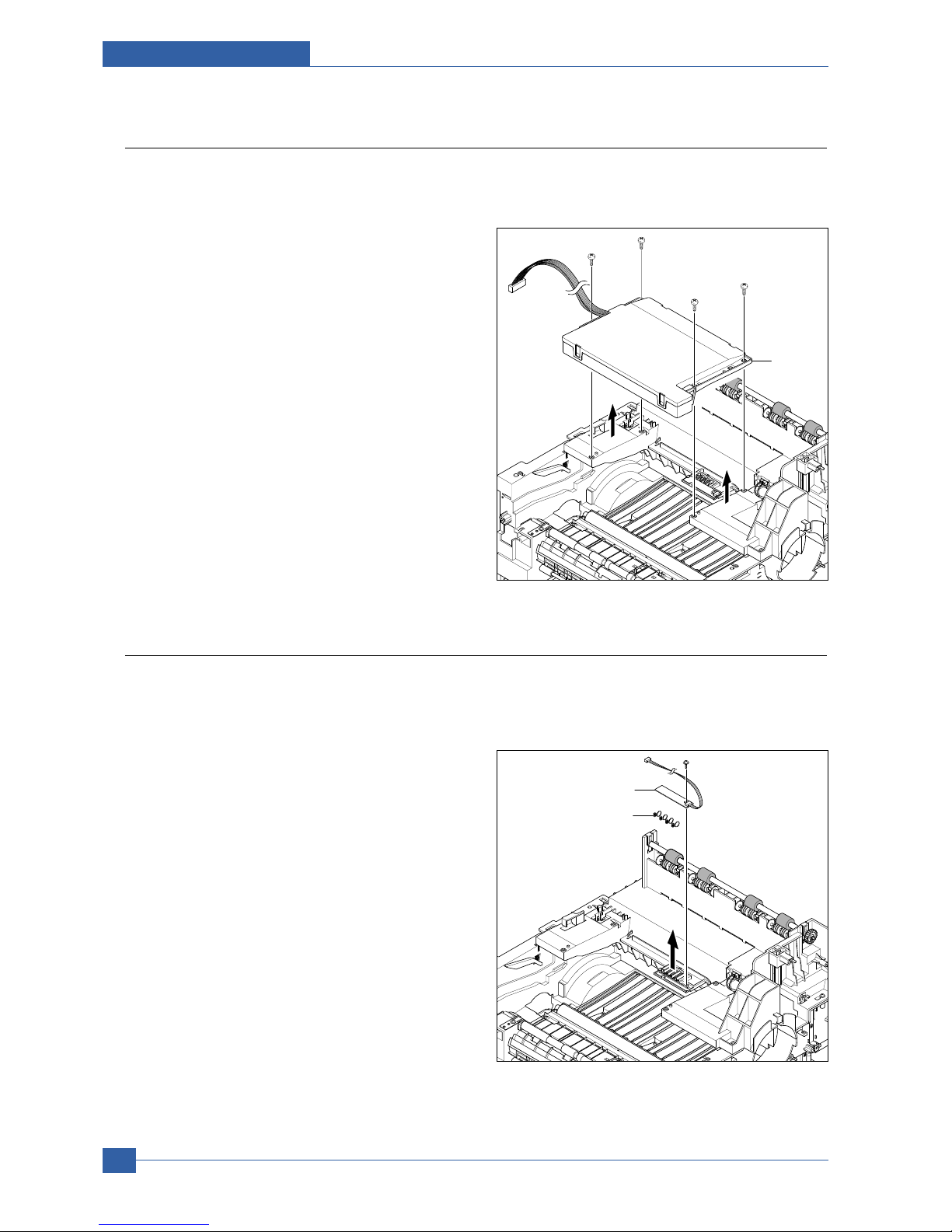

3.25 LSU

3-28

3.26 TERMINAL

3-28

3.27 Transfer Roller Parts

3-29

4. Alignment & Troubleshooting

4.1 Alignment and Adjustments 4-1

4.1.1 Sample Pattern

4-1

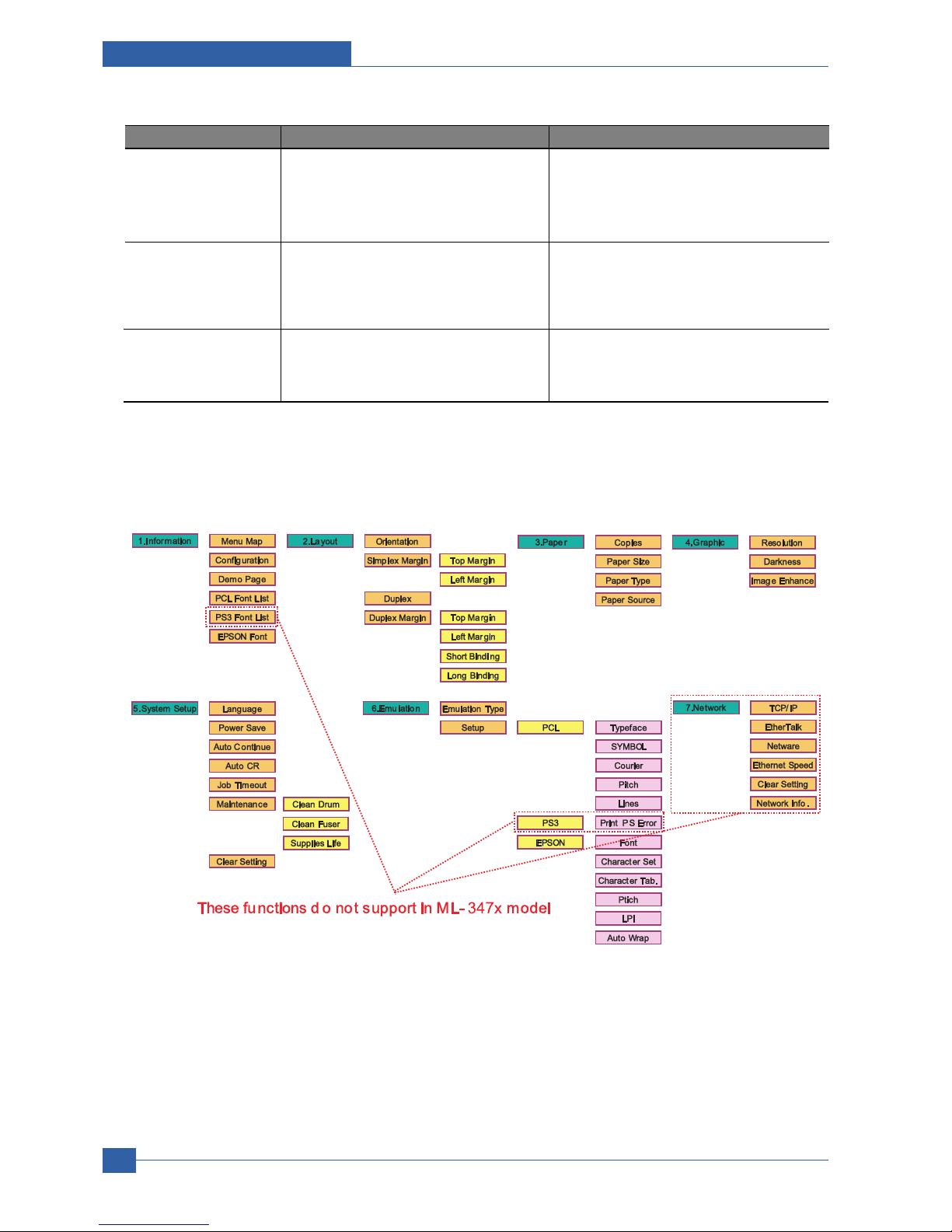

4.1.2 Control Panel

4-2

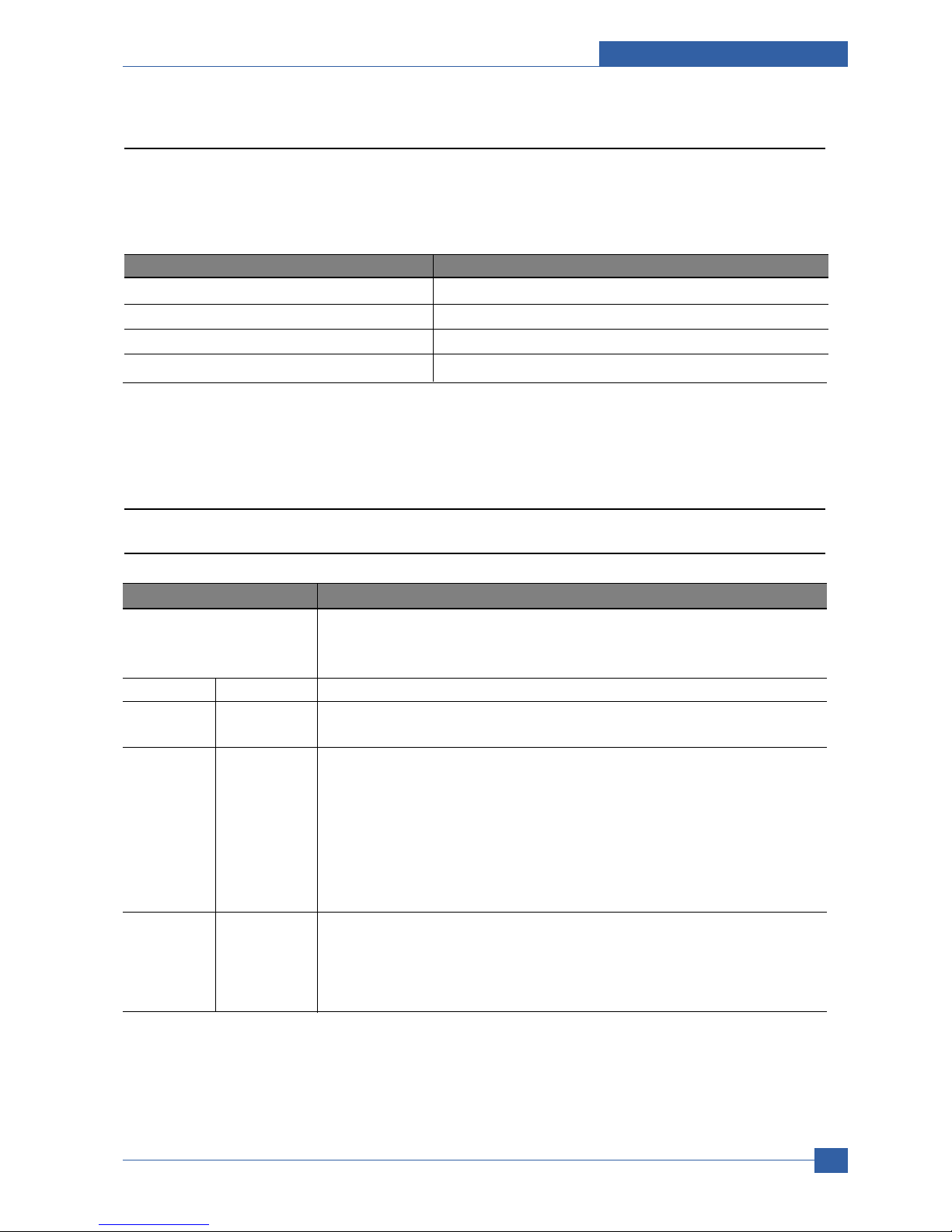

4.1.3 Consumables and Replacement Parts

4-7

4.1.4 LED Status Error Message

4-7

4.1.5 Abnormal Image Printing and Defective Roller

4-10

4.1.6 How to use DCU

4-11

4.1.7 Paper Jam

4-16

4.1.8 Download & Reset F/W

4-22

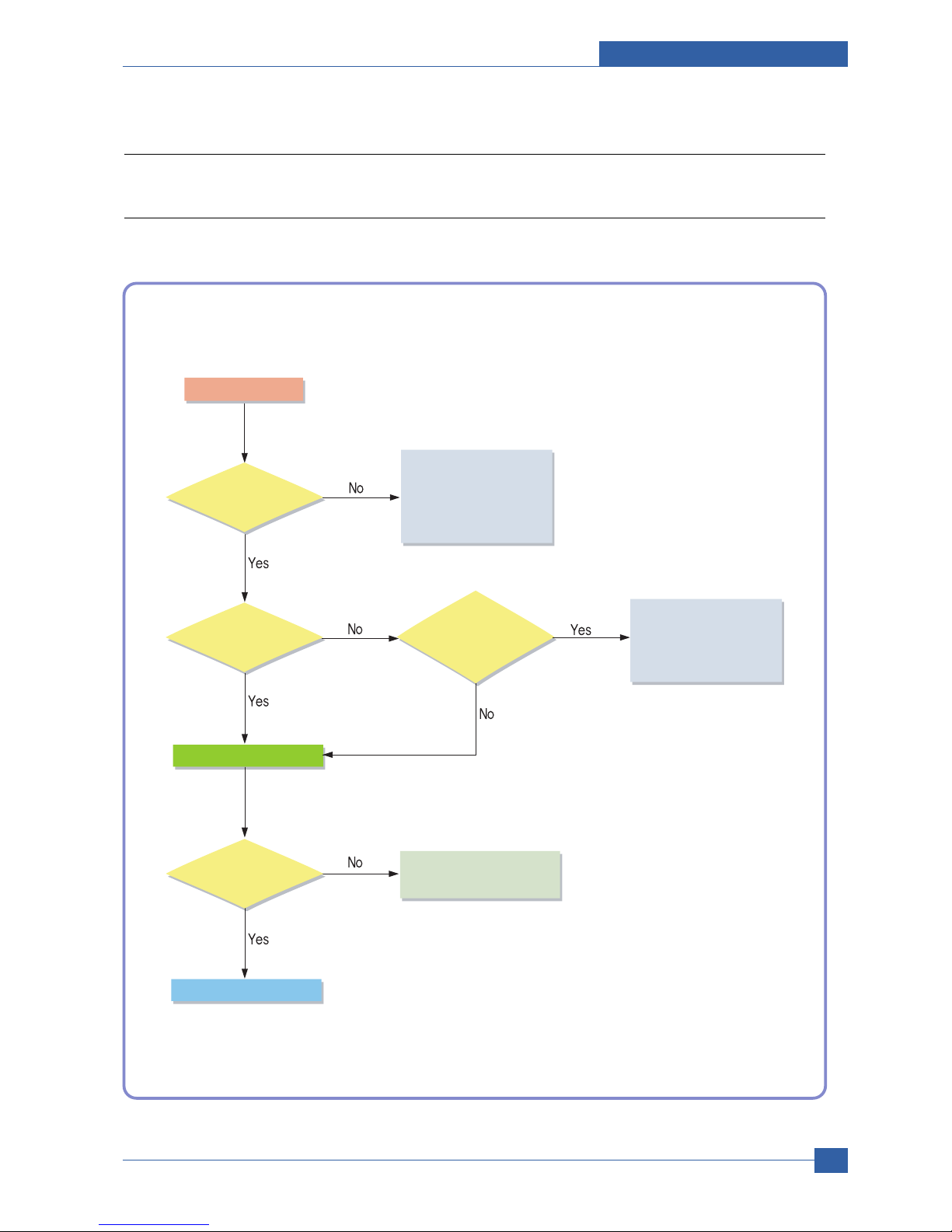

4.2 Troubleshooting

4-23

4.2.1 Procedure of Checking the Symptoms

4-23

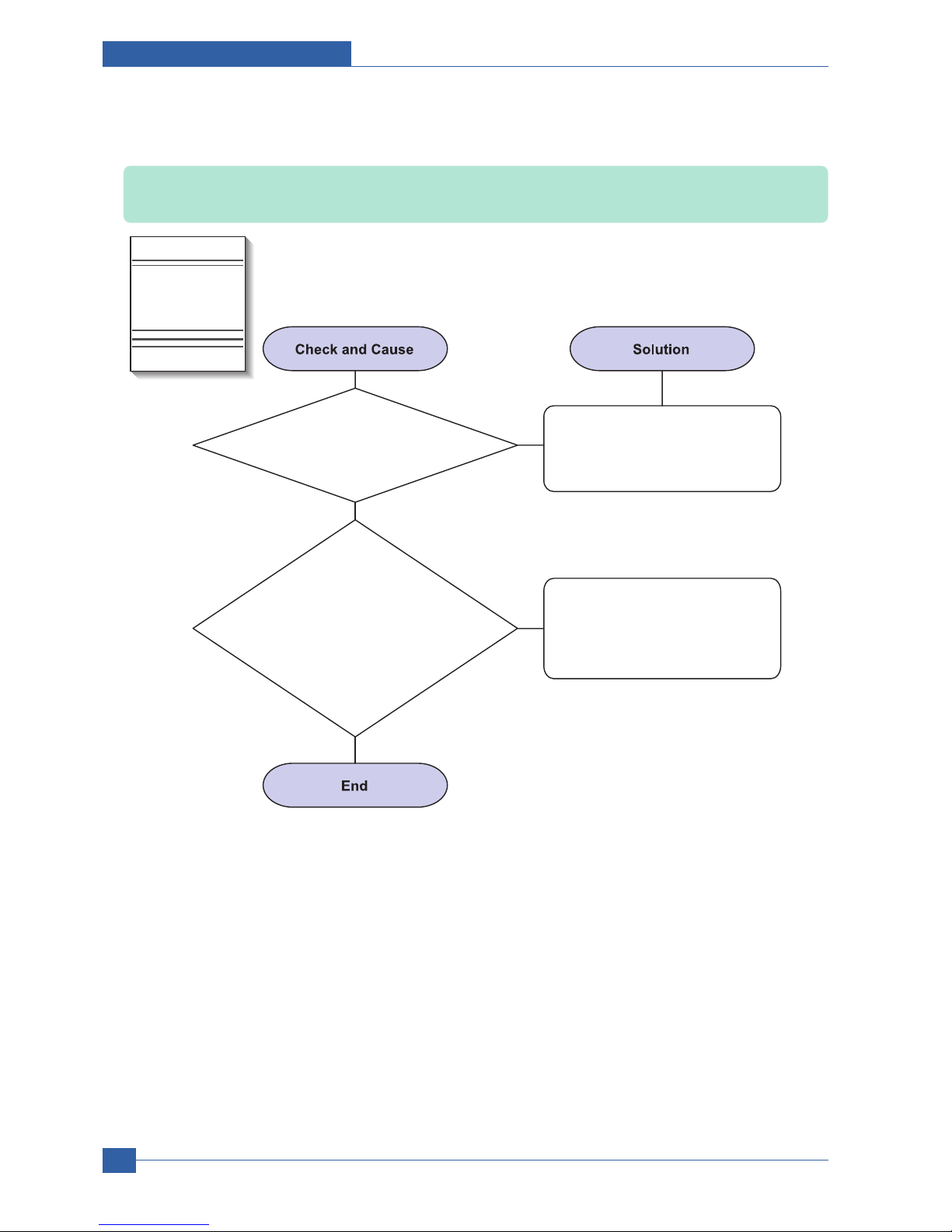

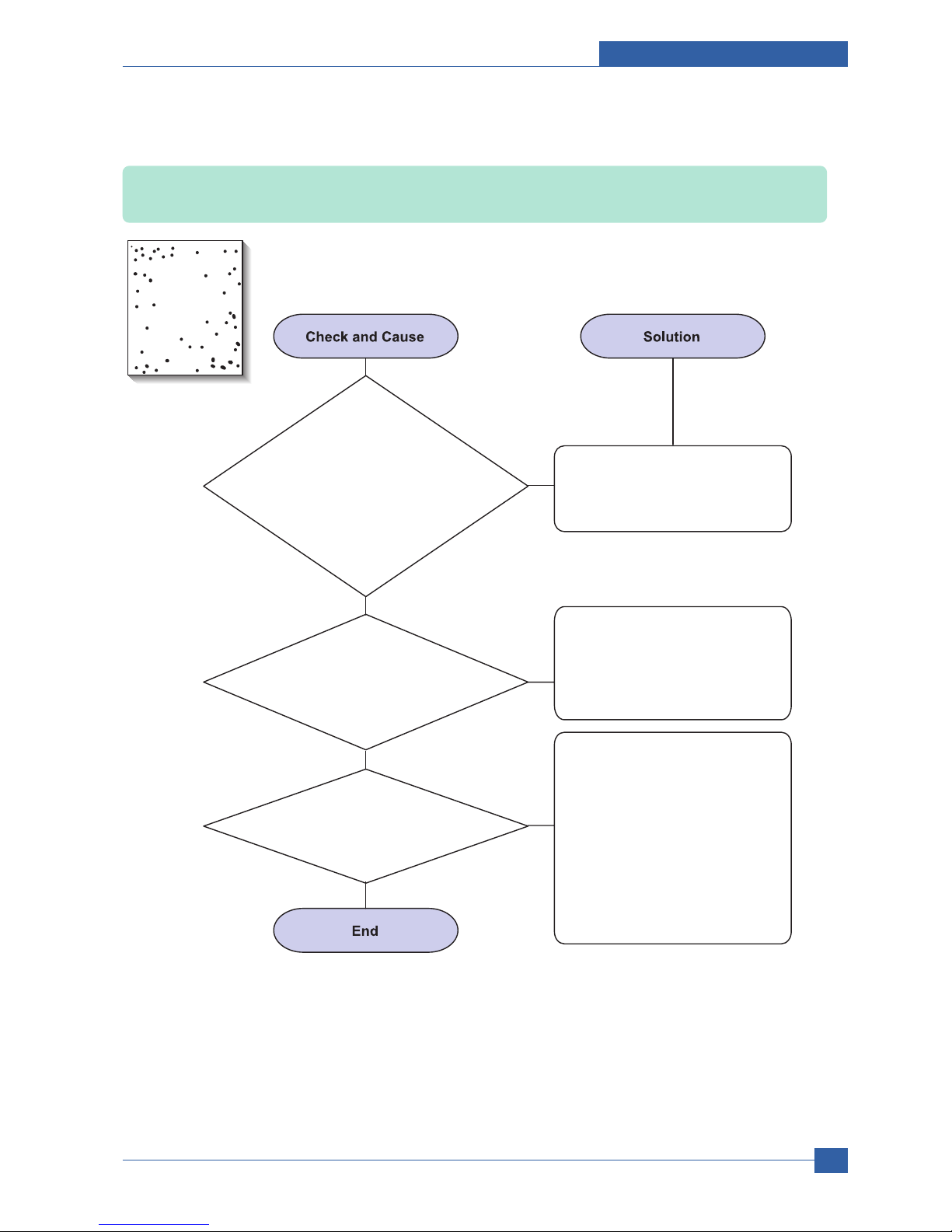

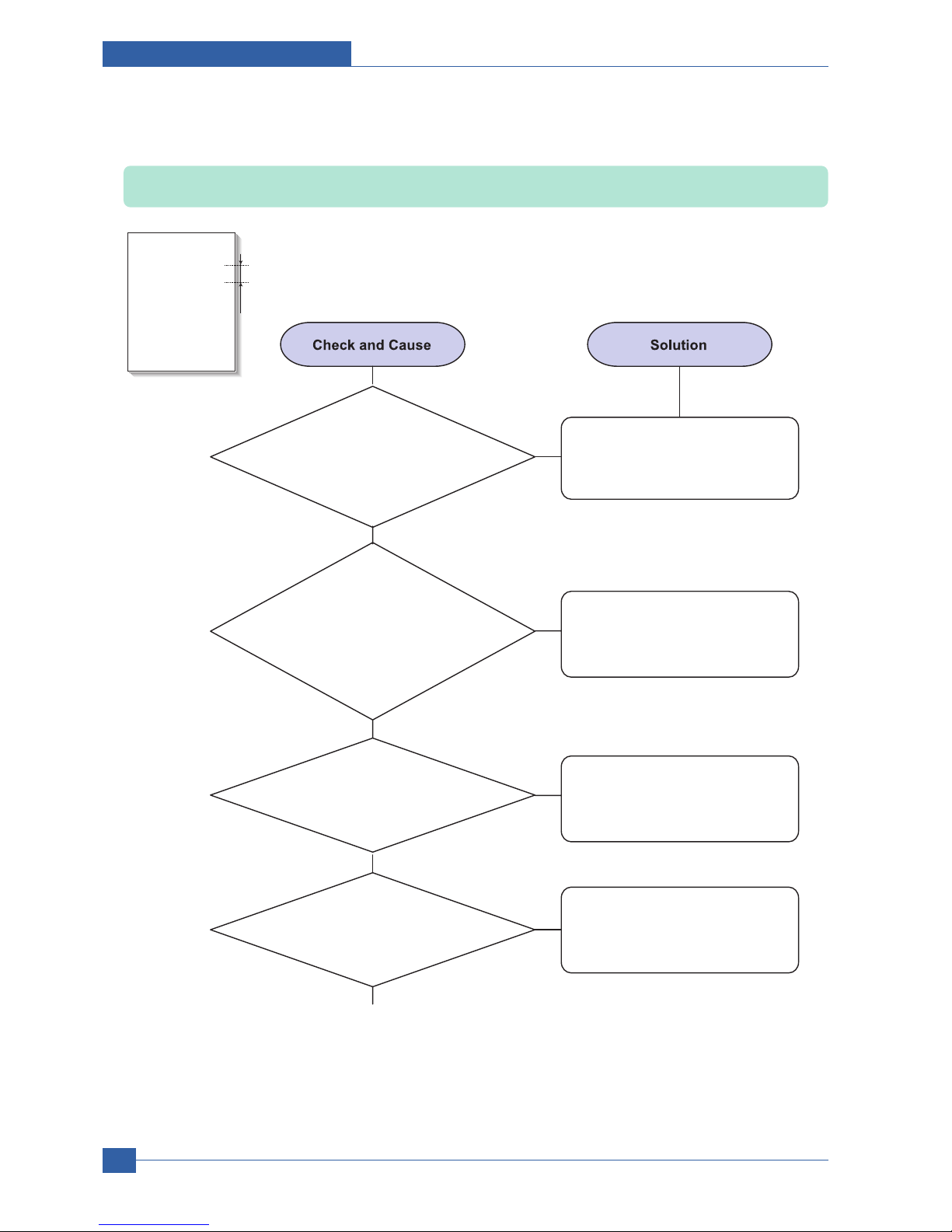

4.2.2 The cause and solution of Bad image

4-24

Continued

4.2.3 The cause and solution of the bad discharge 4-40

4.2.4 The cause and solution of the malfunction

4-49

4.2.5 Toner Cartridge Service

4-59

4.2.6 The cause and solutions of bad environment of the software 4-64

5. Exploded Views & Parts List

5.1 Main 5-2

5.2 Cover Ass'y

5-4

5.3 Front Cover Ass'y

5-6

5.4 Rear Cover Ass'y

5-8

5.5 OPE Cover Ass'y

5-9

5.6 Frame

5-10

5.7 MP Ass'y

5-14

5.8 Main Drive Ass'y

5-16

5.9 Fuser Drive Ass'y

5-18

5.10 Duplex Unit (Optional)

5-19

5.11 Fuser Unit

5-21

5.12 Cassette Unit

5-23

6. System Diagram

6.1 Block Diagram 6-1

6.1 Connection Dia ram

6-2

7. Reference Information

7.1 Troubleshooting Tools 7-1

7.2 Acronyms and Abbreviations

7-2

7.3 Selecting printer locations

7-4

Continued

7.4 LAN (Optional Function) 7-4

7.5 Sample Tests Patterns

7-5

7.6 Series model solution(ML-3470D and ML-3471ND)

7-6

7.6.1 Double Feed Erro

7-6

7.6.2 Jam0

7-7

7.6.3 Jam1

7-8

7.6.4

No Paper/Add Paper" error on the printer and have been unable

to clear it, even when they have verified there is paper in the printer

7-9

7.6.5 Open Cover Error

7-10

7.6.6 Low Toner

7-11

7.6.7 Over Heat Error

7-12

7.6.8 Low Heat Error

7-13

7.6.9 Fuser Door Open

7-14

7.6.10 A noise troubleshooting tree

7-15

7.6.11 LSU Error

7-16

7.6.12 Scan Lock Error

7-17

7.6.13 Nothing Displayed on LCD

7-18

7.6.14 All black printing

7-19

7.6.15 Blank Copy

7-20

7.6.16 Images at 1 Copy

7-21

7.6.17 Glass Broken

7-22

7.6.18 Document Jam

7-23

7.7 Parts Life Cycle Maintenance Table

7-24

7.7.1 Parts Life Cycle Maintenance Table

7-24

7.7.2 Toner Cartridge Criterion

7-24

7.8 Model Information

7-25

7.8.1 Model List

7-25

7.8.2 Understanding for Model Code

7-25

7.8.3 Understanding Material Code & Name

7-26

7.8.4 F/W Upgrade Method

7-26

Continued

Precautions

Samsung Electronics

Service Manual

1-1

1

1. Precautions

The cautions below are items needed to keep in mind when maintaining and servicing.

Please read carefully and keep the contents in mind to prevent accidents while servicing and to prevent the

machine from getting damaged.

1.1 Safety Warning

(1) Request service by qualified service person.

Service for this machine must be performed by a Qualified service person. It is dangerous if unqualified service personnel or users try to fix the machine.

(2) Do not rebuild.

Do not attach or change parts discretionary. Do not dissemble, fix of rebuilt it. If so, printer will abnormally

work and electric shock or fire may occur.

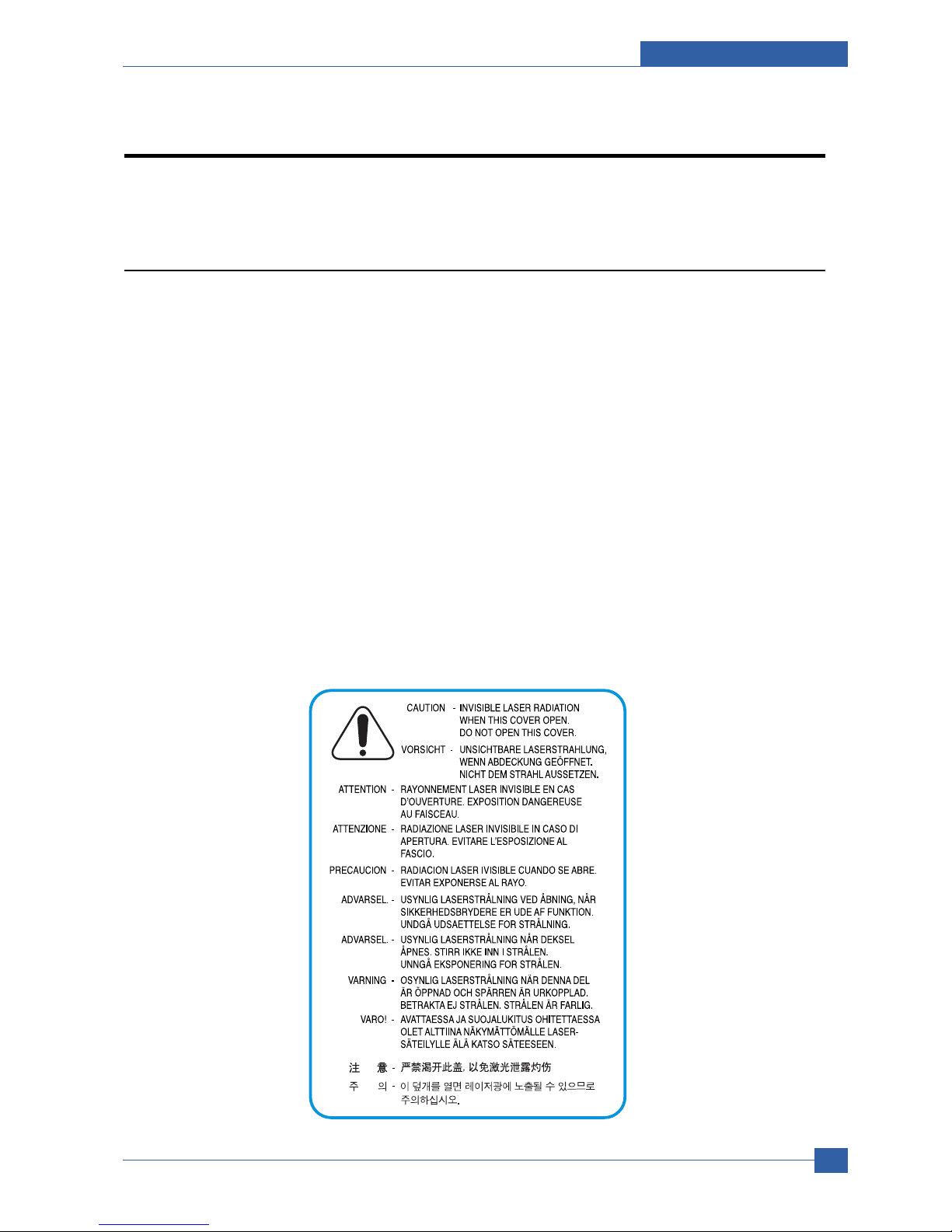

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter J

for Class 1(1) laser products, and elsewhere, is certified as a Class I laser product conforming to the

requirements of IEC 825.

Class I laser products are not considered to be hazardous. The laser system and printer are designed so

there is never any human access to laser radiation above a Class I level during normal operation, user

maintenance, or prescribed service condition.

Warning >> Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The reflected

beam, although invisible, can damage your eyes. When using this product, these basic safety precautions should

always be followed to reduce risk of fire, electric shock, and injury to persons.

Samsung Electronics

Service Manual

Precautions

1-2

1.2 Caution for safety

1.2.1 Noxious Material Precaution

The toner in a printer cartridge contains a chemical material, which may harm human body if it is swallowed.

Please keep children out of reach of the toner cartridge.

1.2.2 Electric Shock or fire Precaution

It is possible to get electric shock or burn by fire if you don't fallow the instructions of the manual.

(1) Use exact voltage. Please use an exact voltage and wall socket. If not, a fire or an electric leakage can be

caused.

(2) Use authorized power cord. Do use the power cord supplied with PRINTER. A fire can happen when over cur-

rent flows in the power cord.

(3) Do not insert many cords in an outlet. A fire can be occurred due to flow over current in an outlet.

(4) Do not put water or extraneous matter in the PRINTER. Please do not put water, other liquid, pin, clip, etc. It

can cause a fire, electric shock, or malfunction. If this occurs, turn off the power and remove the power plug

from outlet immediately.

(5) Do not touch the power plug with wet hand. When servicing, remove the power plug from outlet. Do not insert

or take off it with wet hand. Electric shock can be occurr.

(6) Caution when inserting or taking off the power plug. The power plug has to be inserted completely. If not, a fire

can be caused due to poor contact. When taking off the power plug, grip the plug and take it off. If grip the line

and pull over, it could be damaged. A fire or electric shock could happen.

(7) Management of power cord. Do not bend, twist, or bind it and place other materials on it. Do not fix with sta-

ples. If the power cord gets damaged, a fire or electric shock can happen. A damaged power cord must be

replaced immediately. Do not repair the damaged part and reuse it. A repaired part with plastic tape can be

cause a fire or electric shock. Do not spread chemicals on the power cord. Do not spread insecticide on the

power cord. A fire or electric shock can be happen due to thinner(weak) cover of the power cord.

(8) Check whether the power outlet and the power plug are damaged, pressed, chopped, or blazing fire or not.

When such inferiorities are found, repair it immediately. Do not make it pressed or chopped when moving the

machine.

(9) Caution when there is thundering or lightning, and being flash of lightening. It causes a fire or electric shock.

Take the power plug off there is thunder. Do not touch cable and device when thundering and flash of lighten-

ing.

(10) Avoid the place where is moisture or has dust. Do not install the printer where lots of dust or around humidifi-

er. A fire can occurred. A plug part need to clean well with dried fabric to remove dust. If water drops are

dripped on the place covered with dust, a fire can occurred.

(11) Avoid direct sunlight. Do not install the printer near window where direct contacts to the sunlight. If the

machine contacts sunlight long time, the machine cannot work properly because inner temperature of the

machine is getting hotter. A fire can occur.

(12) Turn off the power and take off the plug when smoke, strange smell, or sound from the machine. If you keep

using it, a fire can be occurred.

(13) Do not insert steel or metal piece inside/outside of the machine. Do not put steel or metal piece into a ventila-

tor. An electric shock could happened.

Precautions

Samsung Electronics

Service Manual

1-3

1.2.3 Handling Precautions

If you ignore this information, you could harm machine and could be damaged.

(1) Do not install it on different levels, or slanted floor.

Please confirm whether it is balanced or not after installation. If it is unbalanced, an accident can be hap-

pened due to the machine falling over.

(2) Be careful not to insert a finger or hair in the rotating unit.

Be careful not to insert a finger of hair in the rotating unit (motor, fan, paper feeding part, etc) while the

machine is operating. Once it happens, you could be harmed.

(3) Do not place a pot containing water/chemical or small metals. If they got caught into the inner side of

machine, a fire or electric shock can be occurred.

(4) Do not install it where lots of moisture or dust exists or where raindrop reaches. A fire or electric shock

can be caused.

(5) Do not place a candlelight, burning cigarette, and etc. on the machine. Do not install it near to heater. A

fire can be occurred.

1.2.4 Assembly/Disassembly precaution

When replacing parts, do it very carefully. Memorize the location of each cable before replace parts for reconnecting it afterwards. Do memorize. Please perform the steps below before replace or disassembly the parts.

(1) Check the contents stored in the memory. All the information will be erased after replacing main board.

The information needed to keep has to be written down.

(2) Before servicing or replacing electric parts, take off a plug.

(3) Take off printer cables and power cord connected to printer.

(4) Do use formal parts and same standardized goods when replacing parts.Must check the product name,

part cord, rated voltage, rated current, operating temperature, etc.

(5) Do not give an over-force when release or tighten up the plastic parts.

(6) Be careful not to drop the small parts such as screws in the printer.

(7) Be careful not to change the location of small parts such as screws when assembling and disassembling.

(8) Do remove dust or foreign matters completely to prevent fire of tracking, short, or etc.

(9) After finished repair, check the assembling state whether it is same as before the repair or not.

Samsung Electronics

Service Manual

Precautions

1-4

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs. Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage caused by

static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your personal safety reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface, such

as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufficient to dam-

age ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed, until

completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as the brushing

together of clothing fabric and lifting one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

Product specification and feature

Service Manual

2-1

Samsung Electronics

2

2

2.1.2 Specifications

Product Specifications are subject to change without notice. See below for product specifications.

2.1.2.1 General Print Engine

ML-347x Series ML-3470D ML-3471ND

Engine Speed Simplex Up to 33 ppm in A4 (35 ppm in Letter)

Duplex Up to 17 ipm in A4 (17.5 ipm in Letter)

Warmup time From Sleep Less than 15 sec, Cold warm-Up time : 15sec

FPOT From Ready Less than 8.5 sec

From Idle Less than 23.5 sec

From Coldboot Less than 30 sec

Resolution - Up to 1,200 x 1,200 dpi effective output

2. Product specification and feature

2.1 Product Specifications

2.1.1 Product Overview

Up to 33ppm (Ltr. 35ppm)

- 250 sheet Cassette

- 50 sheet MP

- 250 sheet Opt. SCF

USB 2.0, IEEE1284

10K Toner (4K Standard)

PCL6, PS3, 1200x1200dpi

400 MHz, 64MB Standard

ML-3471ND

- 10/100 Base TX

- Opt. 802.11b/g Wireless N/W

Built in Duplex

Service Manual

Product specification and feature

2-2

Samsung Electronics

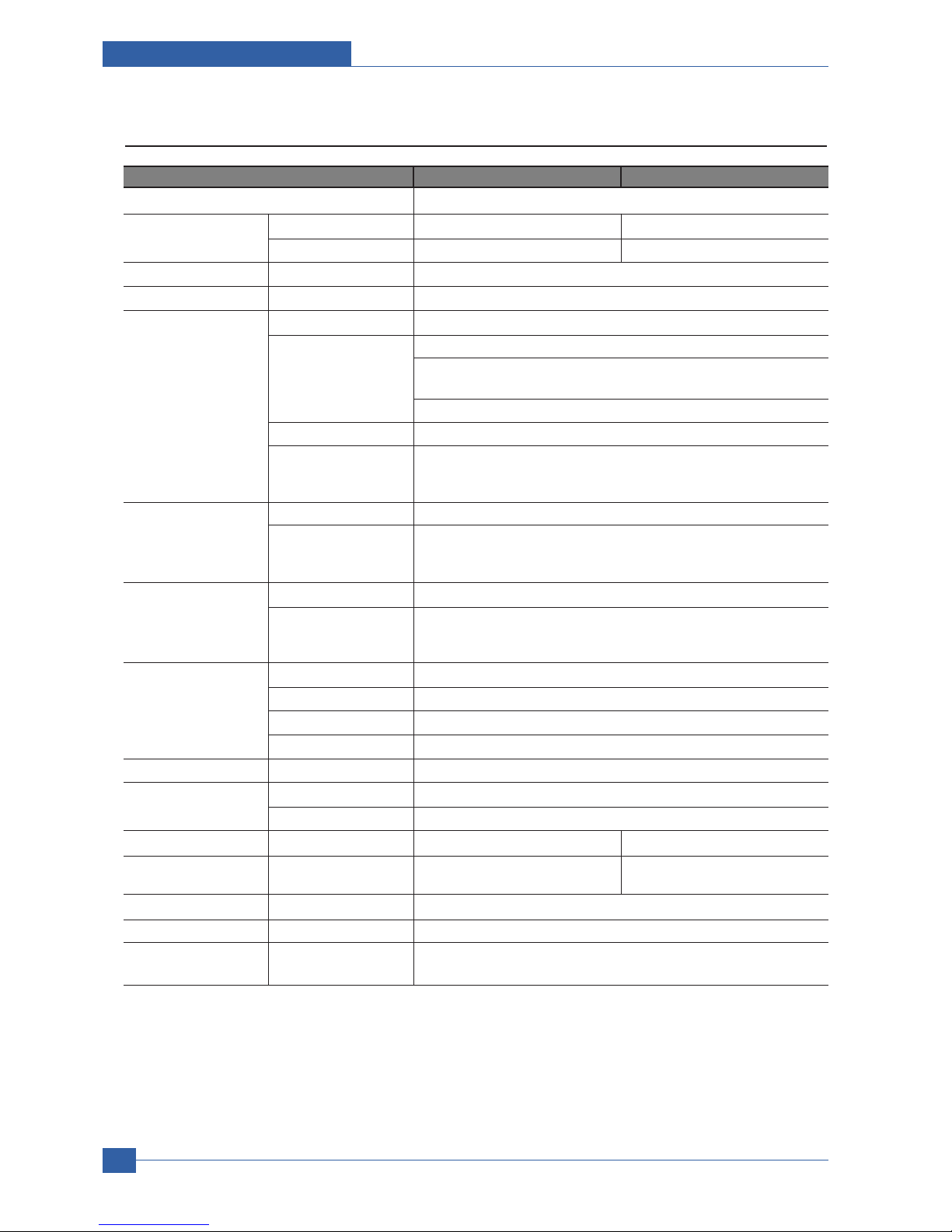

2.1.2.2 Controller & S/W

ML-347x Series ML-3470D ML-3471ND

Processor Samsung 400 MHz

Memory Std. 32 MB 64 MB

Max. 288 MB 320 MB

Printer Languages - PostScript3, PCL6, SPL, IBM ProPrinter, EPSON

Fonts - 45 scalable, 1 bitmap, 136 PostScript3 fonts

Driver Default Driver SPL

Supporting OS Windows 2000/XP/2003/Vista

Various Linux OS including Red Hat, Caldera, Debian, Mandrake, Slackware,

SuSE and Turbo Linux

Mac OS 8.6~9.2/10.1~10.4

WHQL Windows XP/2000/2003

Compatibility PCL6: Win95/98/NT4.0/2000/Me/XP/2003

PS3: Win9x/NT4.0/2000/Me/XP/2003 PPD, Mac PPD, Linux PPD

KS/KSSM: DOS

Wired Network Protocol External : SPX/IPX, TCP/IP, SNMP, HTTP 1.1

Supporting OS Microsoft Windows 98/ME/2000/XP/2003 Microsoft Windows NT 4.xMac OS

8.6 and aboverVarious Linux OS including Red Hat, Caldera, Debian,

Mandrake, Slackware, SuSE and Turbo LinuxNovell 4.x,5.x,6.x

Wireless Network Protocol External : SPX/IPX, TCP/IP, SNMP, HTTP 1.1

Supporting OS Microsoft Windows 98/ME/2000/XP/2003 Microsoft Windows NT 4.xMac OS

8.6 and aboverVarious Linux OS including Red Hat, Caldera, Debian,

Mandrake, Slackware, SuSE and Turbo LinuxNovell 4.x,5.x,6.x

Application RCP N/A

Status Monitor N/A

Smart Panel YES (RCP,SM)

Network Management SAS (Samsung Admin Service), SetIP

Interface

Parallel - IEEE 1284

USB - USB 2.0

Wired Network - N/A Ethernet 10/100 Base TX (Internal)

Wireless Network - N/A Optional (Internal) 802.11b/g

Wireless LAN (Internal)

User Interface

LCD - 2 x 16 Character without backlit

Key - 8 Key: Stop, Toner Save, Duplex

< , OK, >, Menu, Back

Product specification and feature

Service Manual

2-3

Samsung Electronics

2.1.2.3 Paper Handling

ML-347x Series ML-3470D ML-3471ND

Standard Capacity - 250-sheet Cassette Tray, 50-sheet Multi Purpose Tray @ 75g/

Max. Capacity - 550 sheets @ 75g/

Printing Max. Size 216 x 356 mm (8.5" x 14")

Min. Size 76 x 127 mm (3.0" x 5.0")

Multi-purpose tray

Capacity - 50 sheets @ 75g/

(20lb bond)

Media sizes - A4, A5, A6, Letter, Legal, Folio, Oficio, Executive,ISO B5, JIS B5,

3"x5",Monarch, No.10, DL, C5, C6

Media type - Plain Paper, Transparency, Envelope, Labels, Post Card, Card stock

Media weight - 16~43lb (60 to 163g/ )

Sensing - Paper empty sensor

Standard Cassette Tray

Capacity - 250 sheets @ 75g/

Media sizes - A4, A5, Letter, Legal, Executive, Folio, Oficio, ISO B5, JIS B5

Media types - Plain paper, Thick, Thin, Recycled, Archive

Media weight - 16~28lb (60 to 105g/

)

Sensing - Paper empty sensor

Optional Cassette Tray

Capacity - 250 sheets @ 75g/

Media sizes - A4, A5, Letter, Legal, Executive, Folio, Oficio, ISO B5, JIS B5

Media types - Plain paper, Thick, Thin, Recycled, Archive

Media weight - 16~28lb (60 to 105g/

)

Sensing - Paper empty sensor

Output Stacking

Capacity Face-Down 150 sheets @ 75g/

Face-Up 1 sheet @ 75g/

Output Full sensing - N/A

Duplex

Supporting - Built-in

Media sizes - A4, Letter, Legal, Folio, Oficio

Media types - Plain Paper

Media weight - 20~24lb (75 to 90g/ )

Service Manual

Product specification and feature

2-4

Samsung Electronics

2.1.2.4 Consumables

ML-347x Series ML-3470D ML-3471ND

Toner Black 4,000 pages @ ISO 19752 Coverage(Standard 4,000 pages, High Yield

10,000 pages)

Key Electronic key(CRUM) Only

Life detect Toner gauge sensor by dot count

Drum Yield 12,000 Images

2.1.2.5 Reliability & Service

ML-347x Series ML-3470D ML-3471ND

Printing Volume - 9,200 sheets-per year / 767 sheets-per month / 38 sheets-per day

(SET AMPV)

5.2 Max. Monthly Duty - 35,000 sheets

5.3 MPBF - 100,000 sheets

5.4 MTTR - 30 min.

5.5 SET Life Cycle - 250,000 sheets or 5 years (whichever comes first)

5.6 RDS Comm. Mode Yes

Operation Yes

2.1.2.6 Environment

ML-347x Series ML-3470D ML-3471ND

Acoustic Noise Level Printing Less than 52.0 dBA

(Sound Power/Pressure)

Standby Less than 26.0 dBA

Sleep Back Ground Level

Power Consumption Ready Less than 130W

AVG. Less than 400W

Max/Peak Less than 700W

Sleep/Power Off Less than 11W / Less than 0.4W

Dimension(W x D x H) SET 400 x 433.4 x 285 mm

Weight SET 10.5 kg (23.15 Pounds)

Gross 14.5kg (31.9 Pounds)

Product specification and feature

Service Manual

2-5

Samsung Electronics

2.1.2.7 Options

ML-347x Series ML-3470D ML-3471ND

*Memory - 16 MB, 32 MB, 64 MB, 128 MB, 256MB

Second Cassette - 250-sheet Cassette Tray

Wired Network - N/A Ethernet 10/100 Base TX

(External) - ML-00ND

Wireless Network - N/A 802.11b/g Wireless LAN (Internal)

Hard Disk - N/A

Duplex Unit - Default

2.1.2.8 Others

ML-347x Series ML-3470D ML-3471ND

Memory Upgradable Mem. Slot 1 EA

Upgradable Mem. Type 100 Pin SDRAM DIMM

Upgradable Mem. Unit 16MB, 32MB, 64MB, 128MB, 256MB

Sensor Paper Empty YES

Paper Size NO

Media Type NO

Paper Full NO

Service Service Item & Period 1. Transfer Roller : 70K pages

2. Fuser Unit : 80K pages

3. Pick-up Roller : 150K pages

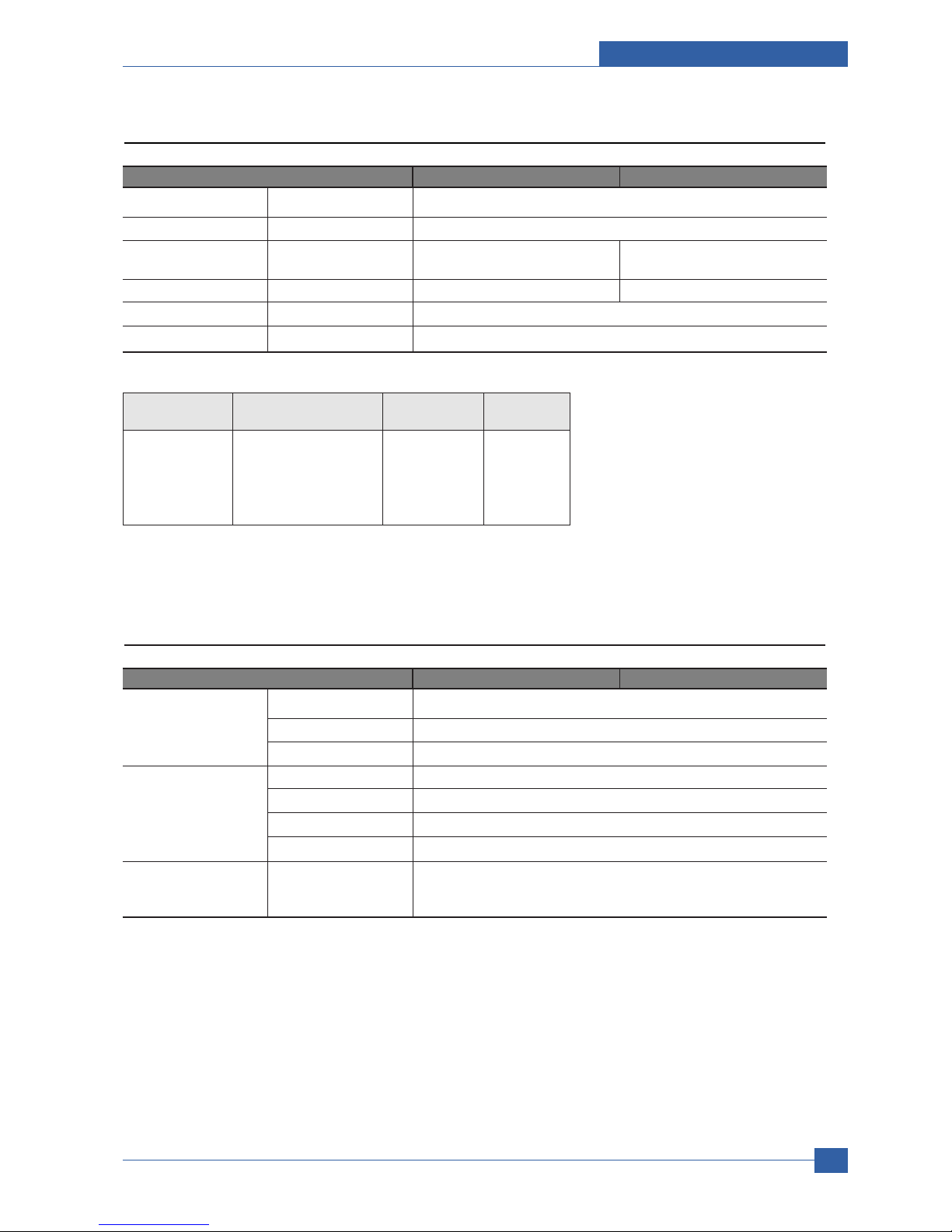

* Memory : The ML-3470D or ML-3471ND has 64MB of memory which can be expanded to 320MB.

* Use only the samsung-approved DIMM.

Item Description Model Code Size

(order)

Memory DIMM Exlends your Printers ML-00MA 16MB

memory capacity. ML-00MB 32MB

ML-00MC 64MB

ML-00MD 128MB

ML-MEM140 256MB

Service Manual

Product specification and feature

2-6

Samsung Electronics

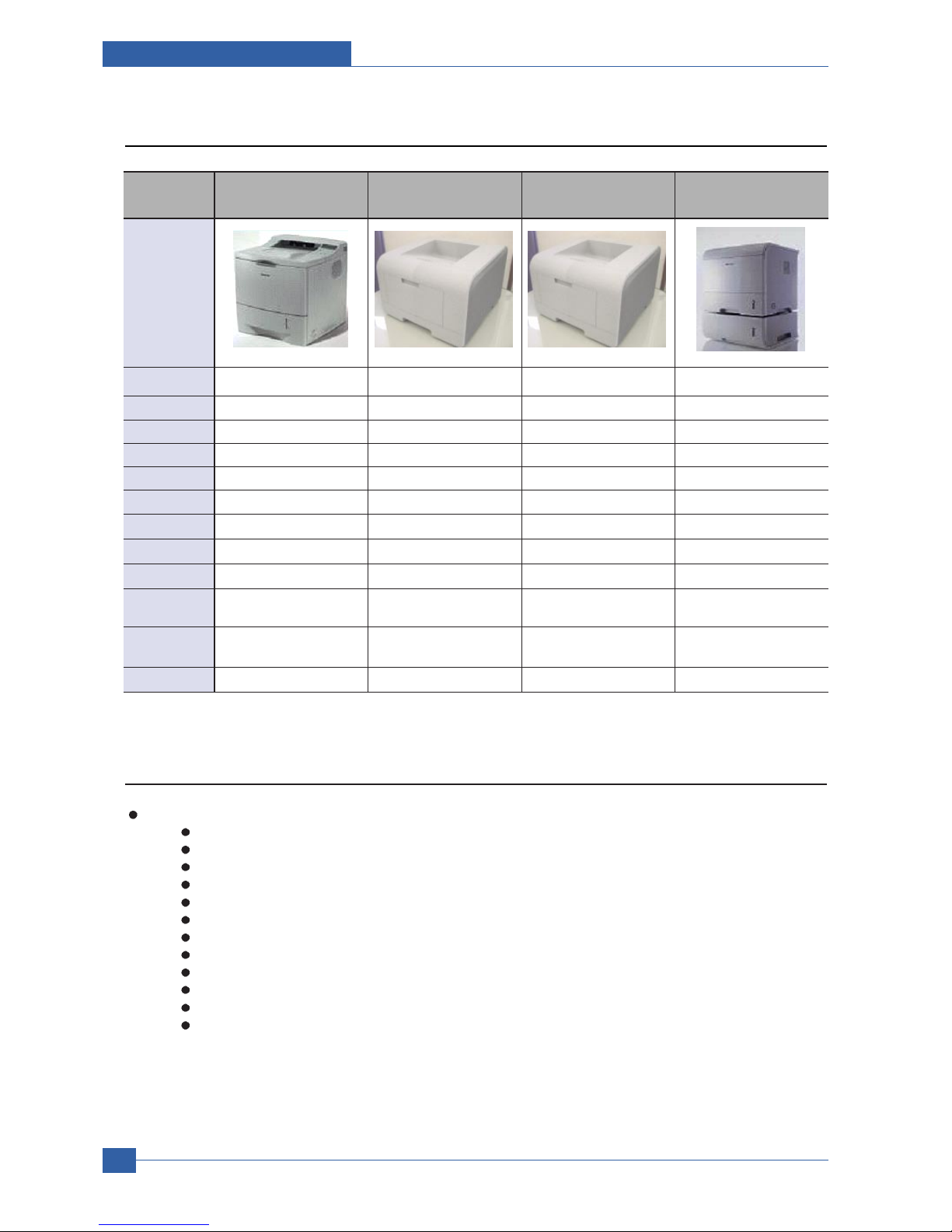

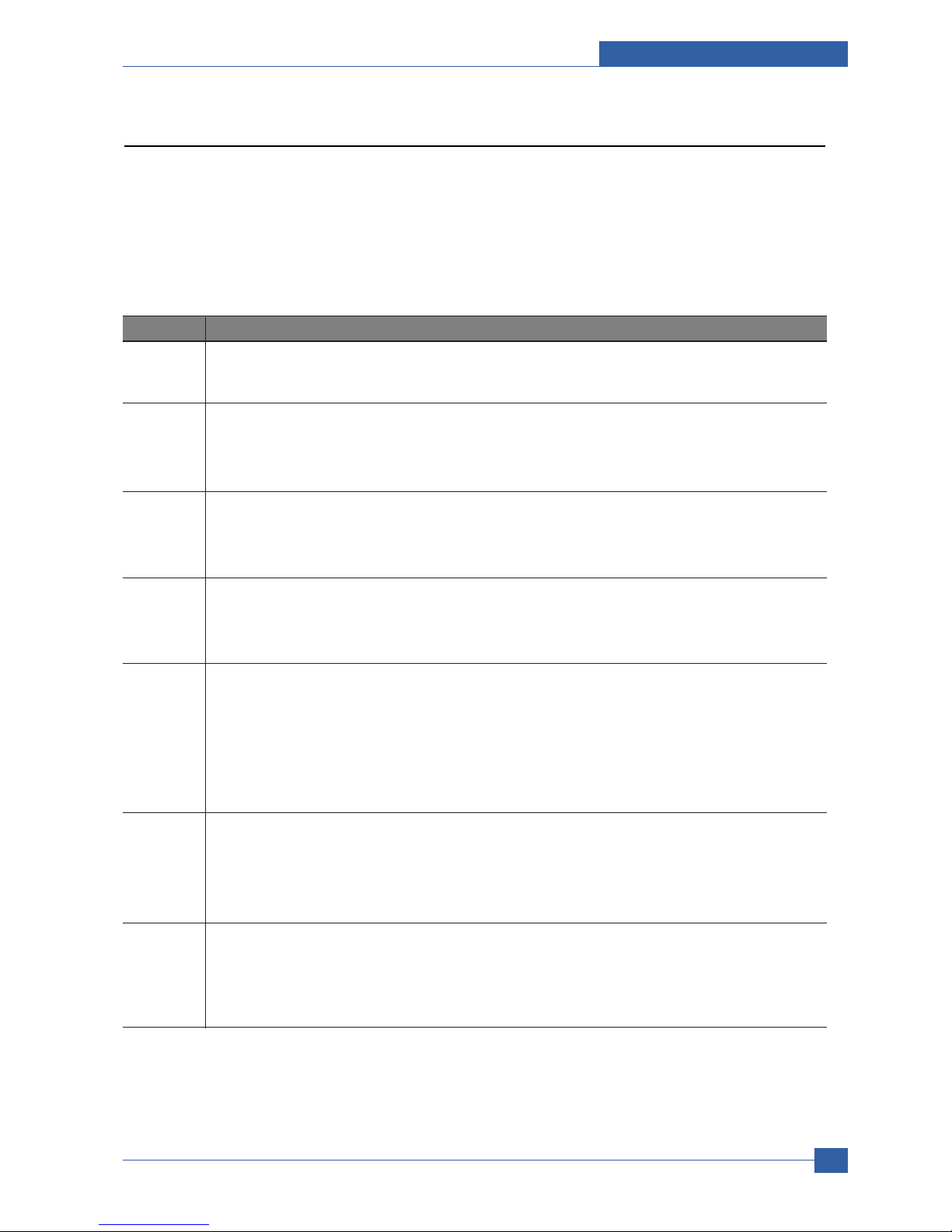

2.1.3 Model Comparison Table

Image

Engine SEC SEC SEC SEC

Speed(ppm) 24ppm 28ppm 33ppm 33ppm

Processor 266MHz 400MHz 400MHz 400MHz

Resolution 1,200X1,200 dpi 1,200X1,200 dpi 1,200X1,200 dpi 1,200X1,200 dpi

FPOT 12 sec 8.5 sec 8.5 sec 10 sec

Emulation PS3, PCL6 PCL6 PS3, PCL6 PS3, PCL6

Ram(Std.) 32MB(Max. 160MB) 16MB(Max. 272MB) 64MB(Max. 320MB) 32MB(Max. 288MB)

Interface IEEE1284, USB 2.0 IEEE1284, USB 2.0 IEEE1284, USB 2.0 IEEE1284, USB 2.0

Duplex Yes Factory Option Yes Option

Paper Input 550 Cassette, 100 MP 250 Cassette, 50 MP 250 Cassette, 50 MP 500 Cassette, 100 MP

(Capa./Type) 250 SCF Opt. 250 SCF Opt. 500 SCF Option

Os Compatibility

Win 95/98/NT/2000/ Win 95/98/NT/2000/ Win 2000/ Win 95/98/NT/2000/

Me/XP, Mac Me/XP, Linux Me/XP, Linux Me/XP, Linux

Toner 10K 4K/8K 4K/10K 6K/12 K

SEC SEC SEC SAMSUNG

ML-2550 ML-3050 ML-3471ND ML-3560

2.1.4 Accessory List

JC99-02059A [INA-ACCESSORY]

3903-000085 [CBF-POWER CORD]

6801-00761C [CARD-WARRANTY]

6902-000809 [BAG PE]

JC46-00293A [S/W APPLICATION-CD]

JC46-00354A [S/W APPLICATION-CD]

JC68-00761B [MANUAL-REGISTRATION_FROM]

JC68-01579A [MANUAL-NETWORK GUIDE]

JC68-01584A [LABEL(P)-BLANK 90*25]

JC68-00690A [MANUAL-(CARD)WARRANTY CARD]

JC68-00761D [MANUAL-REGISTRATION]

JC68-01344A [MANUAL-WARRANTY CARD]

JC68-01563A [MANUAL-800 SEC CARD]

Service Manual

Samsung Electronics

2.2 System Overview

2.2.1 System Construction

2.2.1.1 SUMMARY

ML-347x Series is consisted of the Engine parts and F/W, and said engine parts is consisted of the mechanical parts

comprising Frame, Feeding, Developing, Driving, Transferring, Fusing, Cabinet and H/W comprising the main control

board, power board, operation panel, PC Interface.

In ML-347x Series, the main controller is consisted of Asic(SPGPv3) parts, Memory parts, Engine Interface parts and it

functions as Bus Control, I/O Handling, drivers & PC Interface by CPU.

Memory Access supports 16bit Operation, and Program Memory 32MB and Working Memory as well.

In ML-347x Series, the paper path is consisted of 250 sheets Cassette containing friction Pad, pickup-roller,

feed-roller for functioning as registration, Earth-transfer for guiding the transfer inlet, Guide-Tr for guiding sheets

between transferring and fixing, Fuser, Exit Assy.

In ML-347x Series, the driving device is consisted of f55 BLDC motor, OPC, Pick-up, Feed, Gear-Train connected with

Mounting member. - to be changed

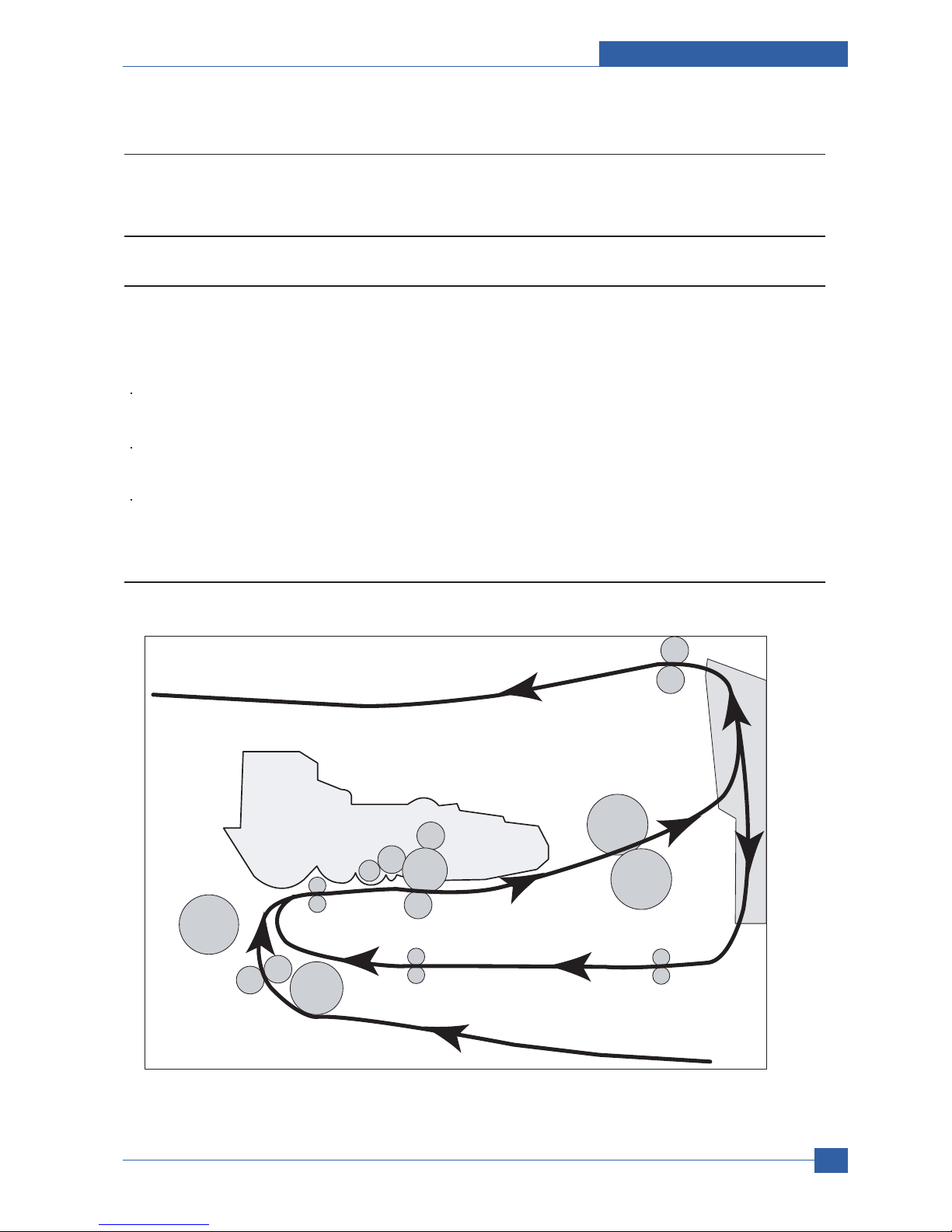

2.2.1.2 System Layout

Roller-Heat

Roller-Exit

Roller-Transfer

Roller-Pickup

Roller-Feed

Roller-MP

Roller-Pressure

Roller-REGI

OPC

Duplex

Duplex

Roller-REGI

OPC

Product specification and feature

Service Manual

2-7

Samsung Electronics

Service Manual

Product specification and feature

2-8

Samsung Electronics

2.2.1.2(a) Feeding Section

Feeding Method : Universal Cassette Type

Feeding Standard : Center Loading

Feeding Capacity : Cassette 250 Sheets (75g/ , 20lb StandardPaper)

2.2.1.2(b) Transfer Ass’y

In Warranty( Life time) : Within 70,000 sheets printing

Product specification and feature

Service Manual

2-9

Samsung Electronics

2.2.1.2(c) Driver Ass’y

MAIN Motor ass’y is for Cassette,MPF and Toner Cartridge

EXIT Motor ass’y is for fuser,exit roller and the initial duplexing feeding

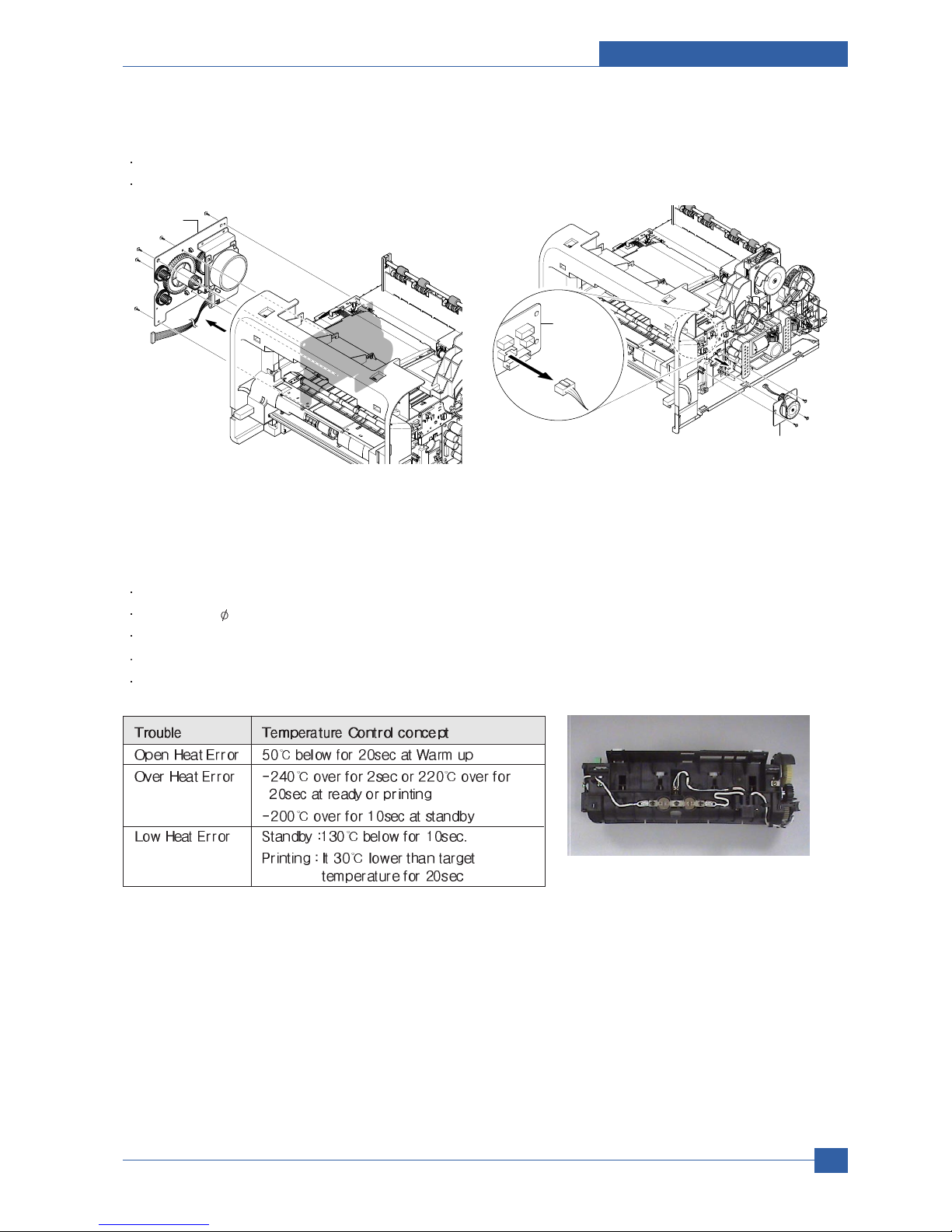

2.2.1.2(d) Fuser Ass’y

Fusing Type : Lamp Type

Heat Roller : [ 28.3 with 0.1 Crown ]

Pressure Roller Pressure Roller 2 : [electrically conductive]

Thermistor - Temperature Detecting Sensor

Thermostat - Overheat Protection Device

Drive Ass'y

Duplex Drive Ass'y

Connection

PCB

Duplex Motor

Service Manual

Product specification and feature

2-10

Samsung Electronics

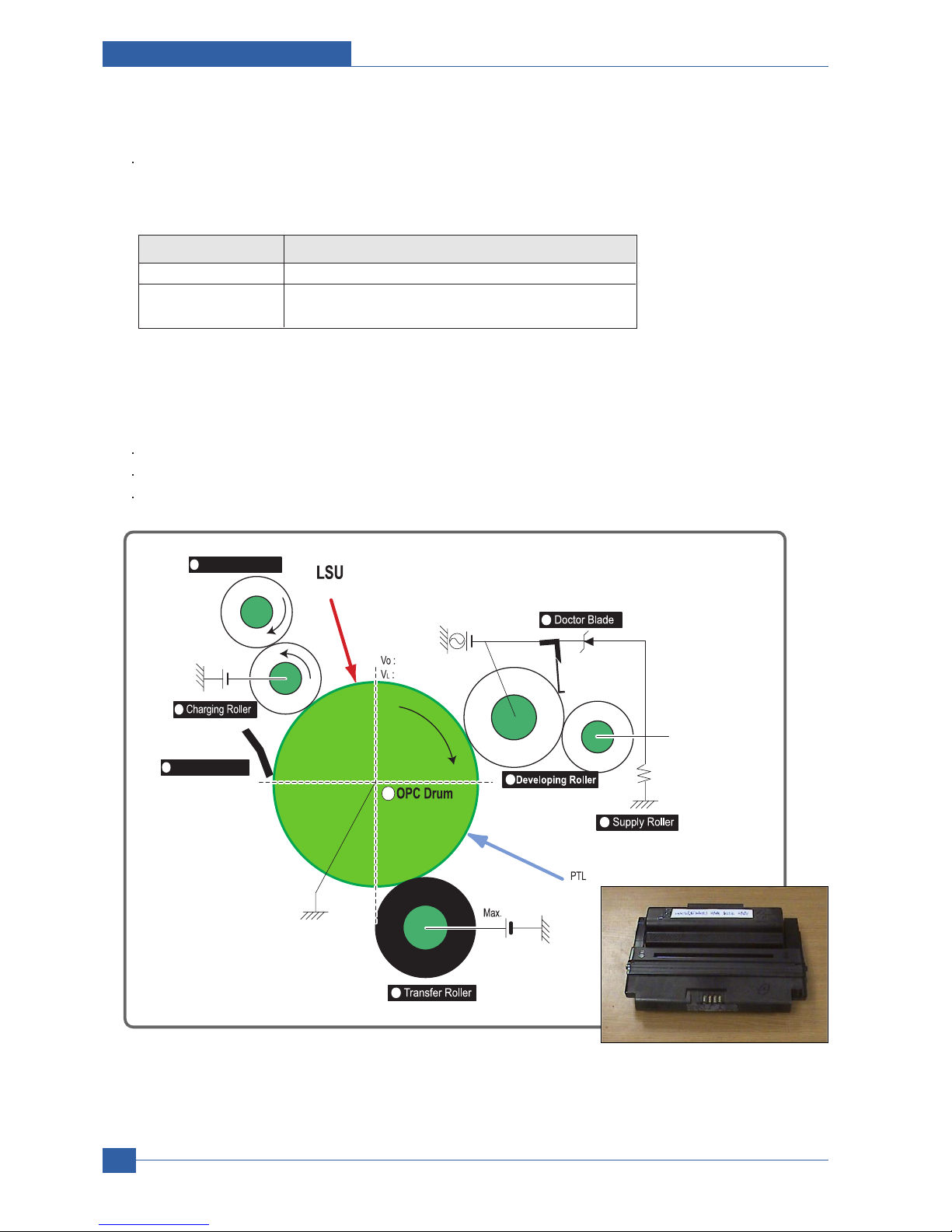

2.2.1.2(f) Toner Cartridge

OPC Cleaning :Mechanical Cleaning by the cleaning blade.

The recycled toner : Trash room for the recycled toner

No shutter for protecting the OPC Drum

2.2.1.2(e) LSU

LSU is consist of LD(Laser Diode) and polygon motor control. When the controller generate the printing signal LD will

turn on and Polygon motor starts.If the receiving part in LSU detect the beam and then Hsync is generated. When the

rotation of poygon motor is steady, it is time of LSU ready status for printing. If either of two condition is not satisfied,

LSU error is expected.

Trouble Failure Analysis

Polygon Motor Error No steady rotation of Polygon Motor

Hsync Error In spite of steady rotation of Polygon Motor,

There is no generation of the Hsync signal

Cleaning Roller

Cleaning Blade

-650V

0.16mW

200V

-1.25KV

V

DC

= -460V

V

PP

= 1520V, f = 2.5KHz, Duty(-) = 32%

1

2

3

4

5

6

7

8

+4.2kV

-50V

+

-

Product specification and feature

Service Manual

2-11

Samsung Electronics

2.2.1.2(g) Duplex Unit

Duplex printing function as factory option

Available Paper : Letter, Legal, Folio, Oficio and A4

2.21.2(h) Optional Tray (SCF)

For customer covenience in managing paper

Capacity : 250 sheets

Service Manual

Product specification and feature

2-12

Samsung Electronics

2.2.2 Mechanical Parts Specifications

2.2.2.1 Frame

Material : PC + ABS V0 NH-1000T(Cheil Industries)

Weight : 1.0kg

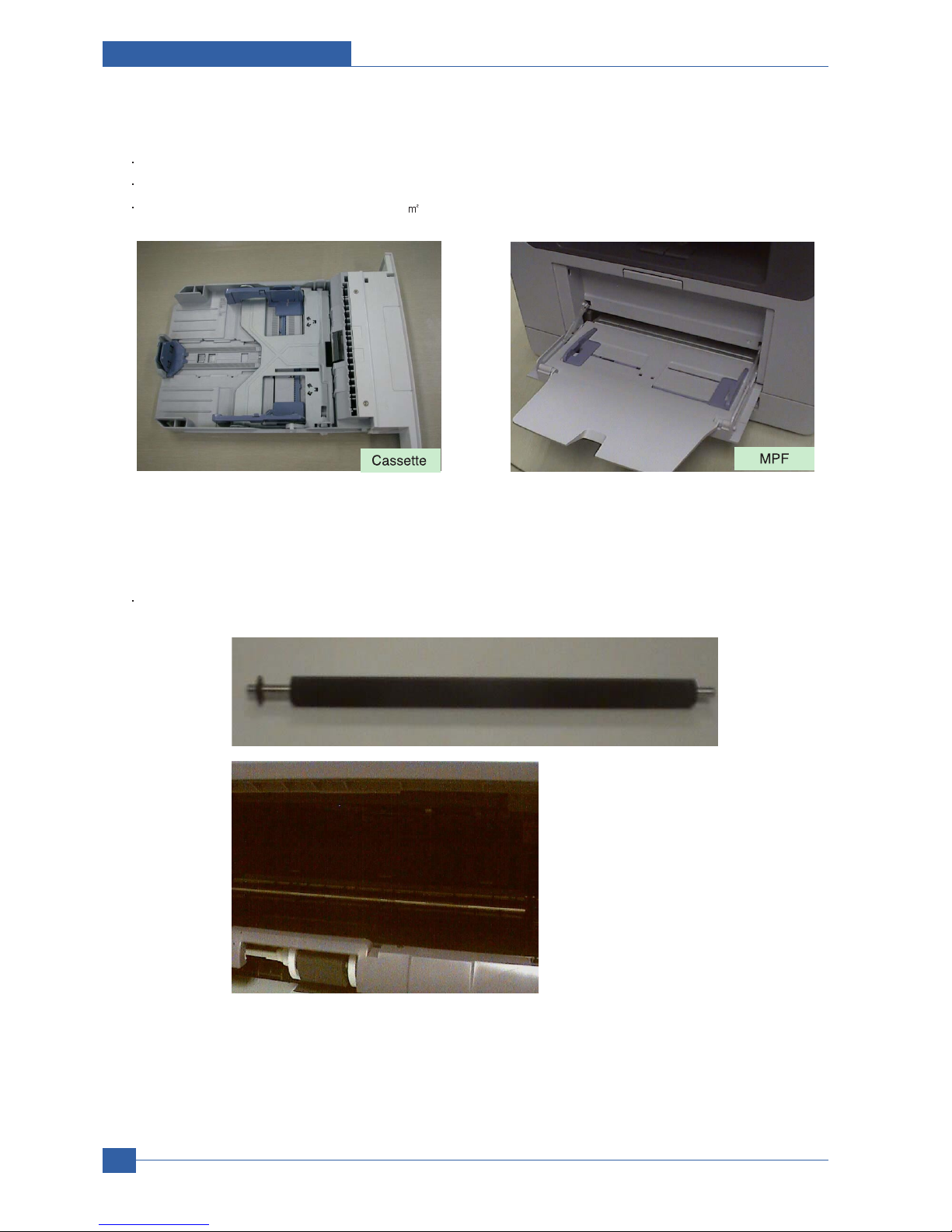

2.2.2.2 Feeding Part

Feeding Type : Universal Cassette Type

Feeding Standard : Center Loading

Feeding Qty : Cassette 250 sheets (75g/ , 20Ib paper standard)

MPF 50 sheets (75g/ , 20Ib paper standard)

Special Media 5 sheets in MPF (OHP, Envelope, Label, Post Card, Index Paper etc.)

Separating Type : Cassette-Friction Pad Type

MPF-Friction Pad Type

Driver Type : Driving by Gearing from Main Motor

Pick Up Roller Driver : Solenoid

Pick Up Roller Rubber Material : EPDM + IR = 1.6 or more

Paper detecting Sensor : Photo Sensor

Paper Size Sensor : None

Paper Separating Pad Material : NBB 52 = 0.8~1.2

Separating Pad Pressure : 190gf

Feeding Pressure (Cassette) : 250 gf 10% (SPRING H mm, based on 1 sheet)

320 gf 10% (SPRING H mm, based on 250 sheet)

Paper Exit Type : Face Down

Feed Roller Driver : Solenoid

2.2.2.3 Transfer Ass’y

It is consisted of PTL(pre-transfer lamp) and Transfer Roller. The PTL sends a light to the OPC drum, makes the current

on the drum surface to low, and improve the transfer efficiency.

The transfer roller delivers the toner of the OPC drum to the paper.

TR Voltage : +1.3KV 5% (based on 200 , in accordance with media area, Transfer table)

-1.20KV 10% (In cleaning)

Transfer Trigger Current : 6.5 5%

Transfer Efficiency : 85% or more (All envirmnment : preferable media)

Voltage System : Voltage PWM Control System

Transfer Roller

- Material : NBR FOAM ROLL

- Structure : Mono layer

- Resistance : 3E +07 ~ 8E +07 (N/N)

- Hardness : 40 3% (ASKER-C)

- Validlength : 224.2 +0.5/-0mm

- OD : 15.0 0.5mm

- SHAFT Material : SUM -24L + Non-electrolysis Ni. Coating

Life Span : Print over 70,000 sheets (in 15~30 )

Product specification and feature

Service Manual

2-13

Samsung Electronics

2.2.2.4 Driver Ass’y

2.2.2.4(a) Motor

Spec : BLDC 62 + PM 55 Motor (2-2 Bipolar) + PM 42 Motor (2-2 Bipolar)

Pull-Out Torque:

BLDC 62 : 1500 gf.cm(based on actual value) or more (1342.4rpm, 1.8A)

PM 55 : 1490gf.cm(based on actual value) or more (711pps, 0.9A)

PM 42 : 240gf.cm(based on actual value) or more (1850pps, 0.6A)

TORQUE MARGIN (Tp/o Tsys) : BLDC 62 Motor : 1500/1100 gf.cm=1.36

PM 55 Motor : 1490/1053 gf.cm = 1.41

PM 42 Motor: 240/165 gf.cm = 1.45

Driving Frequency: BLDC 62 Motor : 1342.4 rpm(1006.8 Clock)

PM 55 Motor : 888.75 rpm(711 pps)

PM 42 Motor : 1156 .25rpm(1850 pps)

It is a power delivery unit by gearing: BLDC 62 Motor -> Pickup/Feeder/Developer

PM 55 Motor -> Fuser/Exit

PM 42 Motor -> Duplex

2.2.2.4(b) Process Speed

Print Speed : 33/35 PPM (based on A4/LTR )

Process Speed : 211.78 mm/sec

Jitter

Vertical : 3 0.018 or less in Vision System

Horizontal : within 2% of partial magnificence error

Orthogonality : SPEC : 1.0 mm or less

2.2.2.4(c) Acoustic Noise

Warming Up : 43dB or less

Printing : 52dB or less

Stand-by : 26dB or less

Service Manual

Product specification and feature

2-14

Samsung Electronics

2.2.2.5 Fixing Part (Fuser)

The fuser is consisted of the E-Coil, Heat Roller, Pressure Roller, Thermistor and Themostat.

It adheres the toner to the paper with pressure and a heat to complete the printing job.

2.2.2.5(a) Halogen Lamp

Voltage 120V : 115 5%

220V : 230 5%

Capacity : 800 Watt 25W

Temp. Distribution : 120%

2.2.2.5(b) Temperature-Interception Device (Thermostat)

Thermostat Type : Non-Contact type THERMOSTAT

Control Temperature : 170 5

THERMOSTAT-ROLLER Gap : 1.6 0.2mm

2.2.2.5(c) Temperature Detecting Sensor(Thermistor)

Thermistor Type : HF-R0060 (SEMITEC 364FL Type)

Temperature Resistance : 7 (180 )

SYSTEM Temperature SETTING

- Stand by : 165 5

- Printing : 189 5 (5 minutes before)

184 5 (5 minutes after)

- Overshoot : 200 less

- Overheat : 210 less

2.2.2.5(d) Heat Roller

Length : 247.5mm

Valid length : 224mm

OD : 28.3 + 0.05, -0.03 (Tubing incl., Crown 0.09~-0.15)

Material : AL(AL5052) + PFA Tubing

Thickness : 0.9mm

Coating Material : PFA 100%

Coating Thickness : 20um (Thickness after abrasion)

GND Type : H/R Bearing Grounding type By SECC Fuser lower frame

Product specification and feature

Service Manual

2-15

Samsung Electronics

2.2.2.5(e) Pressure Roller

Shaft

- Length : 251.3mm

- Material : SUM

- Thickness : 6( 14 - RUBBER portion)

Rubber 1

- Material : Silicon Rubber (Tubing Type : 20)

- Length : 226.4mm

- Thickness : 5mm(one-side)

Rubber 2

- Material : Silicon Rubber (Tubing Type : 16)

- Length : 226.4mm

- Thickness : 5mm(one-side)

OD : 1) 20 0.2(Center part Crown -0.2)

2) 16 0.2(Center part Crown -0.15)

2.2.2.5(f) Media Separating System

PI Coating with PPS Claw System

2.2.2.5(g) Safety Relevant Facts

Proteciong device when overheating

- 1st protecting device : H/W cuts off when detecting an overheating

- 2st protecting device : S/W cuts off when detecting overheating

- 3st protecting device : Thermostat cuts off the power

Safety device

- The power of Fuser is cut-off after front cover is open

- The overheating safety device for customer

- The surface temperature of the Fuser Cover is under 80

2.2.2.7 Toner Cartridge

In the toner cartridge, the OPC unit and the developer unit are in a body.

The OPC unit has OPC drum and charging roller, and the developer unit has toner, toner cartridge, supply roller,

developing roller, and the blade.

2.2.2.7(a) Summary

Developing Method : Non magnetic 1 element contacting method

Toner : Non magnetic 1 element shatter type toner

Charging capacity : -39.1 3 C/g (KAO meas. method)

Average OD : 8.5 0.5 (Toner)

Toner Qty : 125 gf/250gf (4k / 10k)

The life span of toner: 4k/10k sheets (ISO 19752 Pattern / A4 standard )

Toner Residual Sensor : Dot count with CRUM(CRU Monitor)

OPC Cleaning : Collect the toner by using cleaning blade+ FILM OPC

Handling of wasted toner : Collect the wasted toner in the cleaning frame by using cleaning blade

OPC Drum Protecting Shutter : None

Classifying device for toner cartridge: ID is classified by interruption of the frame channel.

2.2.2.7(b) Developing Roller

Roller type : conductive elastic roller

Rotary Speed : 203.06 mm/sec

Roller Bias : -220V ~ -400 20V

Control Type : Bias PWM Control type

Roller material : Conductive NBR + Surface UV process

- Structure : Mono layer

- Resistance : 1.0E+03~ 1.5E+06 (N/N Condition)

- Hardness : 52 5

- Valid Length : 228 mm

- OD : 14.07 mm 0.05

- Shaft material : SUS 303

- Surface roughness (Ra) : Ra 2.0 ~ 2.5 (Circular-direction)

- Friction coefficient (u) : 0.1 ~ 0.5 (70gf, 50mm/min, OHP (3M,#CG3300))

- Life : 10,000 sheets or more

Service Manual

Product specification and feature

2-16

Samsung Electronics

2.2.2.6 LSU (Laser Scanner Unit)

The LSU unit is controlled by video controller. It scans the video data received from video controller with laser beam by

using the rotation principle of the polygon mirror to create the latent image on the OPC drum. It is the core part of LBP.

The OPC drum rotates as the same speed as the paper feeding speed. It creates the /HSYNC signal and sends it to the

engine when the laser beam of the LSU reaches the end of the polygon mirror, and the engine detects the /HSYNC signal

to arrange the vertical line of the image on the paper. After detecting the /HSYNC signal, the image data is sent to the

LSU to arrange the its margin on the paper.

The one side of the polygon mirror is one line for scanning.

Product specification and feature

Service Manual

2-17

Samsung Electronics

2.2.2.7(c) Supply Roller

Rotary Speed : 131.98 mm/sec

Roller Bias : -370V ~ -550V

Control Type : Bias

Roller material : Nylon Fur

- Structure : Closed cell

- Resistance : 0.6E+05 ~ 3.0E+06 (N/N cond.)

- Hardness : 16 ~ 25 (Asker "C")

- Valid Length : 218 mm

- OD : 11.2 0.1 mm

- Shaft material : SUM 24L Non-electrolysis Ni. Coating

- Shaft OD : 8.2 mm + 0 / -0.05

- Driver : Gear Driver (in a direction opposed to D/R)

- Sponge Density : 0.45 , 0.1 g/

- Life : 10,000 sheets or more

2.2.2.7(d) REGULATING BLADE

Type : Regulating toner layer by pressure

Material : SUS 301 1/2H CSP t0.08

Valid Length : 228mm

Voltage : -420V ~ -600V

Regulating edge R value : 0.3 0.02mm

Pressure : 42 gf/cm

2.2.2.7(e) CHARGING PORTION

Type : Conductive Roller Contact-Charge

Rotary Velocity : 179.7 mm/sec

Surface potential : -760 70V (based on OPC , N/N cond.)

Residual potential : -130 V or less (initial)

Control Type : Bias PWM Control

Roller material : Conductive elastic roller (Conductive NBR + SBR)

- Structure : Mono layer (Surface UV process)

- Resistance : 0.75E+06 ~ 5.0E+06 ( N/N cond.)

- Hardness : 50 3 (Asker "A")

- Length : 230 mm

- OD : 12.0 0.05 mm

- Shaft Material : SUM-24L + Non-electrolysis Ni Coating

- Shaft OD : 6 + 0 / -0.05 mm

- Driver : Gear Driver

- Pressure : L:300 gf / R:350 gf

- Roller surface roughness : Ra 1.8 um or less (shaft direction)

- Roller life : 10,000 sheets or more

Roller Voltage : -1.25 ~ -1.70 KV

Service Manual

Product specification and feature

2-18

Samsung Electronics

2.2.3 Engine H/W Specifications

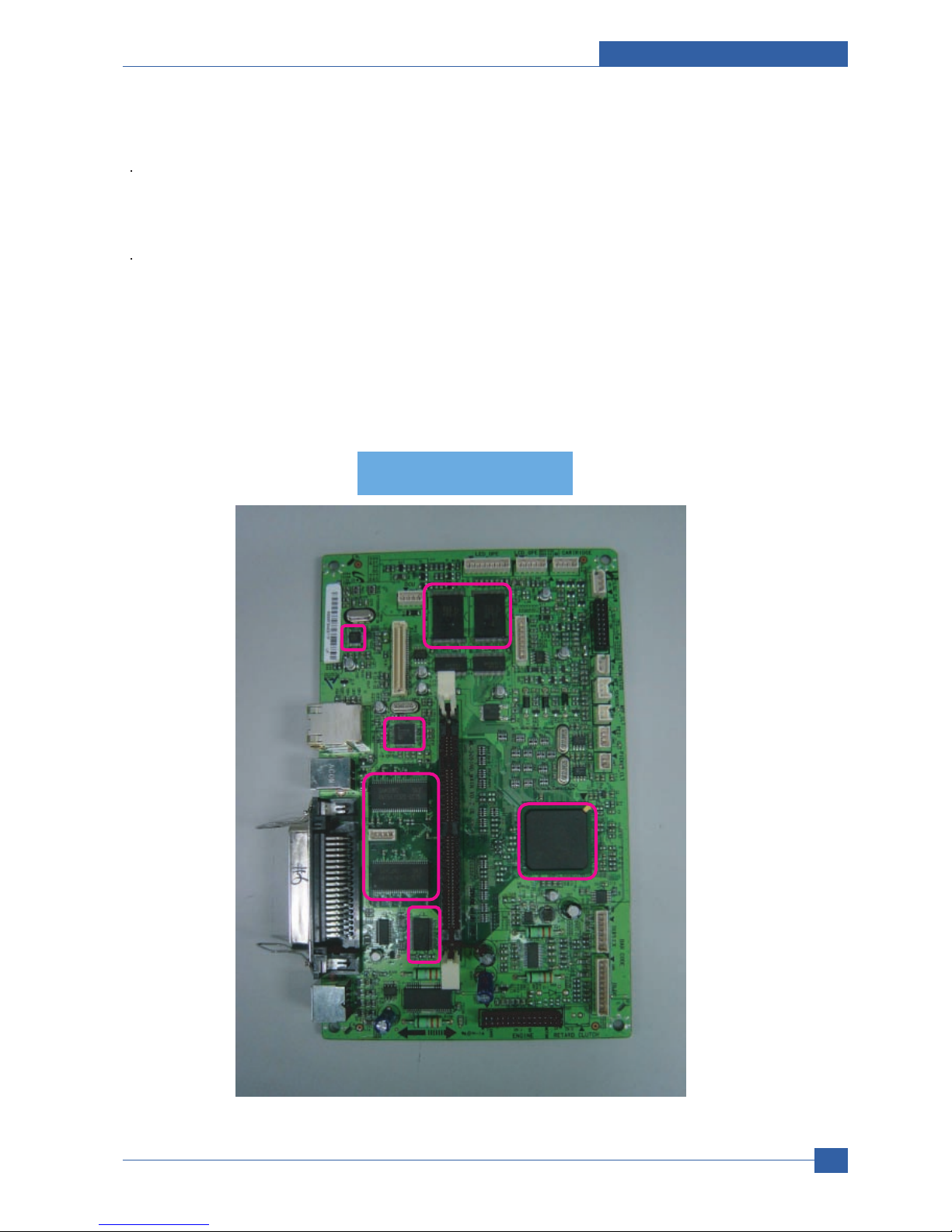

2.2.3.1 ML-347x (PCL) Main Board

The Engine Board and the Controller Board are in one united board, and it is consisted of CPU part and print part in

functional aspect. The CPU is functioned as the bus control, I/O handling, drivers, and PC interface. The main board

sends the Current Image of Video data to the LSU and manages the conduct of Electrophotography for printing. It is

consisted of the circuits of the motor (paper feed, pass) driving, clutch driving, pre-transfer lamp driving, current driving,

and fan driving.

The signals from the paper feed jam sensor and paper empty sensor are directly inputted to the main board.

2.2.3.1(a) Asic(SPGPv3)

CPU Core : ARM1020E

- 32KB instruction cache and 32KB data cache

Operating Frequency

- CPU Core : over 300MHz

- System Bus : 100MHz

SDRAMC

- 32Bits Only, 100MHz

- 5 Banks (Up to 128MB per Bank)

ROMC

- 4 Banks (Up to 16MB per Bank)

IOC

- 6 Banks (Up to 16MB per Bank

DMAC

- 4 Channels

HPVC

- Dual/Single Beam

- LVDS Pad(VDO, HSYNC)

UART

- 5 Channels (1 Channels Supports DMA Operation)

PCI Controller

- 32Bits, 33/66MHz

- PCI Local Bus Specification rev2.2 Complaint

- Host / Agent Mode (Support 4 Devices in Host Mode)

NAND Flash Controller

- 8/16Bits, H/W EEC Generation

- Auto Boot Mode (Using Internal SRAM, 4KB)

MAC

- 10M/100Mbps

- Full IEEE 802.3 Compatibility

Engine Controller

- LSU Interface Unit

- Step Motor : 2 Channels

- PWM : 8 Channels

- ADC : 6 Channels

I2C Controller

- I2C(S-BUS) Slave Device Support(I2C Version 2.1)

RTC

- RTC Core Voltage : 3V

PLL

- 3 PLL : MAIN, PCI, PVC

Product specification and feature

Service Manual

2-19

Samsung Electronics

2.2.3.1(b) Memory

Flash Memory : It stores System Program and downloads the System Program through PC Interface, and in case of

model for export it compresses the PCL font, then stores it.

- Capacity : 32M Byte (NAND Flash)

- Random Access Time : 10 us (Max)

- Serial Page Access Time : 50ns (Min)

DRAM : It is used as Swath Buffer, System Working Memory Area, etc. when printing.

It stores Font List, compressed into Flash memory, on DRAM and uses it as PCL font in case of model for export.

- Capacity : 64M Byte(Basic), up to 320Mbyte (User Option)

- Type : SDRAM 100MHz/133MHz , 16bit

2.2.3.1(c) Others

The Option PBA can be mounted for supporting the serial communication.

Main board

Main board

PHY IC

PHY IC

USB IC

USB IC

SPGPv3

SPGPv3

(ASIC)

(ASIC)

SRAM

SRAM

SDRAM

SDRAM

Flash ROM

Flash ROM

Service Manual

Product specification and feature

2-20

Samsung Electronics

2.2.3.1(d) Flash Memory

It stores the system program and downloads system program through the PC Interface.

Capacity : 16M Byte (NOR Flash)

Access Time : 90ns

Page read Time : 25ns

2.2.3.1(e) SDRAM

It is used as swath buffer, system working memory area, etc. while Printing.

Capacity : The 64M Bytes is for this model (64M : Printing System Working Memory Area)

2.2.3.1(f) Sensor Input Circuit

Paper Empty Sensing

The Paper empty sensor (Photo Interrupter) on the HVPS informs the state of paper to CPU whether it is empty or not

with operation of the actuator.

When cassette is empty, it detects the fact by reading the E20 of CPU, and then informs the fact by displaying the RED.

MP Sensing

By operation of Actuator on the frame, an individual MP Sensor (Photo interrupter) informs the state of paper to CPU

whether it is empty or not. It reads the D17 of CPU for recognizing paper in MP, and paper is fed from MP if there is.

Paper Feeding/With Toner Cartridge Sensing

When paper passes the actuator (feed sensor part), it detects the signal of Photo interrupter, informs the paper feeding

state to CPU, and then sprays the image data after certain time.

If it doesn t detect the feed sensor within 1sec. after paper is fed, paper Jam0 is occurred (LED will be display RED

color). The fact whether the developer is inserted or not is detected by CRUM. After the developer is mounted, the subCRUM can read the information of toner cartridge from contact with CRUM involved in toner cartridge. If the information of

toner cartridge is invalid, it will show invalid sign on a LCD or LED.

Paper Exit Sensing

It detects paper state whether paper gets out from the set with operation of exit sensor on the HVPS and actuator on the

frame. Paper detects the on/off time of exit sensor by reading D22 of CPU, and the normal operation or jam information is

informed to the CPU.

The paper JAM2 is informed. (LED will be display RED color)

Cover Open Sensing

The Cover open sensor is located on the HVPS. After the front cover is opened, +24VS (DC fan, Solenoid, Main Motor,

Polygon motor part of LSU and HVPS), which is supplied to the each unit, is cut off. The cover-open sensing is operated

by the D23 of CPU.

In case, the red will be ON for informing the facts to user.

Product specification and feature

Service Manual

2-21

Samsung Electronics

DC FAN / SOLENOID Driving

It is driven by transistor and controlled by D14(FAN MAIN), E16(FAN DUPLEX), C23(PICK-UP CLUTCH), C18(REGI

CLUTCH), D15(MPF CLUTCH) of CPU.

When it is high, the fan is driving by turning on the TR, and it is off when the sleep mode is selected. There are three

solenoids, and they are driven by paper pick-up, regi and MPF signal. It is turned on or off by C23, C18, D15 of CPU. The

diode protects the driving TR from the noise pulse, which is flown when the solenoid id de-energizing.

FAN Driving Circuit is driven by Transistor, and controlled by D14, E16 of CPU.

Motor Driving

The main motor driving circuits is on the BLDC Motor Ass y Unit. Main Controller has the interfacing circuits. There is

motor driver IC on the motor control board of Motor Ass y Unit.

The exit motor driving circuits is formed when the driver IC is selected. The AN44060A Motor Driver IC is used in this

case. The resistance Rs value for sensing and voltage value for the V reference can be changed by motor driving voltage

value. The motor driving voltage is calculated with the following formula.

The motor driving circuit is formed when the Driver IC is selected. The A3977 Motor Driver IC is used in this case. The

resistance Rs value for sensing and voltage value for the V reference can be changed by motor driving voltage value. The

motor driving voltage is calculated with the following formula.

I = Vref / Rs, wherein Vref is (R1 5V) / (R1+R2).

IN 0, 2 IN 1, 3 Output Current

L L Vref / (10*Rs) = Iout

H L Vref / (15*Rs) = Iout * 2/3

L H Vref / (30*Rs) = Iout * 1/3

HH0

Service Manual

Product specification and feature

2-22

Samsung Electronics

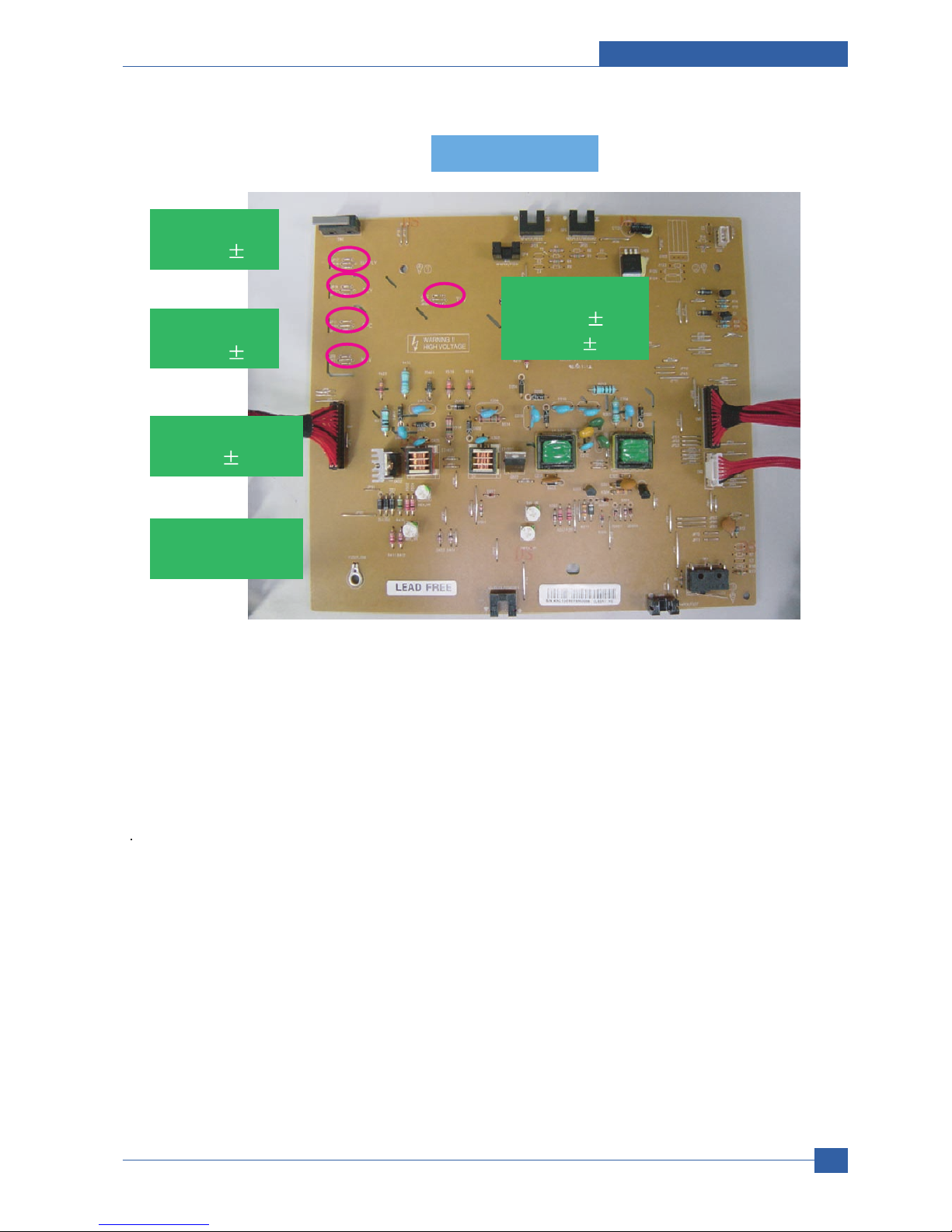

2.2.3.2 SMPS & HVPS board

The SMPS supplies DC Power to the System.

It takes 110V/220V and outputs the +5V, +24V to supply the power to the main board. The HVPS board creates the high

voltage of THV/MHV/Supply/Dev and supplies it to the developer part for making best condition to display the image. The

HVPS part takes the 24V and outputs the high voltage for THV/MHV/BIAS, and the outputted high voltage is supplied to

the toner, OPC cartridge, and transfer roller.

2.2.3.2(a) HVPS (High Voltage Power Supply)

Transfer High Voltage (THV+)

- Input Voltage : 24 V DC 15%

- Output Voltage : MAX +5.0KV 5 %,(Duty Variable, no loading )

->1.2KV 15% (when cleaning,200 )

- Output Voltage Trigger : 6.5

- Input contrast of the Voltage stability degree :under 5 % (fluctuating input 21.6V 26.4V)

Loading contrast : 5 % or less

- Output Voltage Rising Time : 100 ms Max

- Output Voltage Falling Time : 100 ms Max

- Fluctuating transfer voltage with environmental various : +650 V(Duty 10%) ~ 5 KV (Duty 90%)

- Environment Recognition Control Method : The THV-PWM ACTIVE is transfer active signal. It detects the resistance

by recognizing the voltage value, F/B, while permits the environmental recognition voltage.

- Output Voltage Control Method : Transfer Output Voltage is outputted and controlled by changing Duty of THVPWM

Signal. 10% Duty : +650V, 90% Duty : +5KV 5%

Charge Voltage (MHV)

- Input Voltage : 24 V DC 15%

- Output Voltage : -1.3KV ~ -1.8KV DC 50V

- Output Voltage Rising Time : 50 ms Max

- Output Voltage Falling Time : 50 ms Max

- Output Loading range : 30 M ~ 1000 M

- Output Control Signal(MHV-PWM) : CPU is HV output when PWM is Low

Cleaning Voltage (THV-)

- The (+) Transfer Voltage is not outputted because the THV PWM is controlled with high.

- The (-) Transfer Voltage is outputted because the THV-Enable Signal is controlled with low

- The output fluctuation range is big because there is no Feedback control.

Developing Voltage (DEV)

- Input Voltage : 24 V DC 15%

- Output Voltage: -200V ~ -600V DC 20 V

- Output Voltage Fluctuation range: PWM Control

- Input contrast of the output stability degree : 5 % or less

Loading contrast : 5 % or less

- Output Voltage Rising Time : 50 ms Max

- Output Voltage Falling Time : 50 ms Max

- Output Loading range : 10M ~ 1000 M

- Output Control Signal (BIAS-PWM) : the CPU output is HV output when PWM is low.

Supply

- Output Voltage : -400 V ~ -800V DC 50 V(ZENER using, DEV )

- Input contrast of the output stability degree : under 5 %

Loading contrast : 5 % or less

- Output Voltage Rising Time : 50 ms Max

- Output Voltage Falling Time : 50 ms Max

- Output Loading range : 10 M ~ 1000 M

- Output Control Signal (BIAS-PWM) : the CPU is HV output when PWM is low.

Product specification and feature

Service Manual

2-23

Samsung Electronics

2.2.3.2(b) SMPS (Switching Mode Power Supply)

It is the power source of entire system. It is assembled by an independent module, so it is possible to use for common

use. It is mounted at the side of the set.

It is consisted of the SMPS part, which supplies the DC power for driving the system, and the AC heater control part,

which supplies the power to fuser. SMPS has two output channels. Which are +5V and +24V.

AC Input

- Input Rated Voltage : AC 220V ~ 240V AC 110V ~ 127V

- Input Voltage fluctuating range : AC 198V ~ 264V AC 99V ~ 135V

- Rated Frequency : 50/60 Hz

- Frequency Fluctuating range : 47 ~ 63 Hz

- Input Current : Under 4.0Arms / 2.0Arms (But, the status when e-coil is off or rated voltage is inputted/outputted )

HVPS PBA

HVPS PBA

SUPPLY

-630

3%

THV

+1300

3%

-1200

3%

OPC

-130

15.4%

MHV

-1350¡ 3%

DEV

-430

3%

Service Manual

Product specification and feature

2-24

Samsung Electronics

NO ITEM CH1 CH2 Remark

1 CHANNEL NAME +5V +24.0V

2 CONNECTOR PIN CON 35V PIN: 11,13,15 CON 324V PIN:3,5,7,9

GND PIN: 12,14,16 GND PIN:4,6,8,10

3 Rated Output +5V 5%(4.75 5.25V) +24V 10%(21.6 26.4V)

4 Max. Output Current 3 A 4.4 A

5 Peak Loading Current 3.6 A 5.3 A 1ms

6 RIPPLE NOISEVoltage 100mVp-p Under 500mVp-p

7 Maximum output 15W 105.6W

8 Peak output 18W 127.2W 1ms

9 Protection for loading Shut down or Fuse Shut down or Output

shortage and Protection Voltage Drop

overflowing current

NO ITEM System

1 Stand-By Less than 130W

2 PRINTING Less than 400W

3 Sleep-Mode Less than 11W

Fuse 5V

Fuse 5V

Fuse 24V

Fuse 24V

Fuse 5V

Fuse 5V

Product specification and feature

Service Manual

2-25

Samsung Electronics

Length of Power Cord : 1830 50mm

Power Switch : Use

Feature

- Insulating Resistance : 100 or more (at DC 500V)

- Withstanding Voltage : Must be no problem within 1 min.

(at 1000V-LV model / 1500Vac-HV model,10mA)

- Leaking Current : under 3.5mA

- Running Current : under 40A PEAK (AT 25 , COLD START)

under 60A PEAK (In other conditions)

- Rising Time : within 2Sec

- Falling Time : over 20ms

- Surge : Bi-Wave 3kV - Normal, 6KV - Common

Environment Condition

- Operating temperature range : 0 40

- Maintaining temperature range : -25 85

- Preserving Humidity Condition : 30% 90% RH

- Operating atmospheric pressure range : 1atm

EMI Requirement : CISPR ,FCC, CE, MIC, C-Tick,

Safty Requrement :IEC950 UL1950, CSA950, C-UL,NOM, TUV, Semko, Nemko, iK, CB, CCC(CCIB), GOST, EPA,

Power Save

2.2.3.2(c) FUSER AC POWER CONTROL

Fuser(e-coil) gets heat from AC power. The AV power controls the switch with the Triac, a semiconductor switch. The

ON/OFF control is operated when the gate of the Triac is turned on/off by Phototriac (insulting part).

In other words, the AC control part is passive circuit, so it turns the heater on/off with taking signal from engine control

part.

When the HEATER ON signal is turned on at engine, the LED of PC501 (Photo Triac) takes the voltage and flashes.

From the flashing light, the Triac part (light receiving part) takes the voltage, and the voltage is supplied to the gate of

Triac and flows into the Triac. As a result, the AC current flows in the e-coil, and heat is occurred.

On the other hand, when the signal is off, the PC501 is off, the voltage is cut off at the gate of Triac, the Triac becomes

off, and then the e-coil is turned off.

Triac (Q501) feature : 24A-LV model / 16A-HV model, 600V SWITCHING

Phototriac Coupler (PC501)

- Turn On If Current : 15mA 50mA(Design: 16mA)

- High Repetive Peak Off State Voltage : Min 600V

Service Manual

Product specification and feature

2-26

Samsung Electronics

2.2.3.3 Engine F/W

2.2.3.3(a) Control Algorithm

Feeding

If feeding from a cassette, the drive of the pickup roller is controlled by controlling the solenoid. The on/off of the solenoid

is controlled by controlling the general output port or the external output port. While paper moves, occurrence of Jam is

judged as below.

Transfer

The charging voltage, developing voltage and the transfer voltage are controlled by PWM (Pulse Width Modulation). The

each output voltage is changeable due to the PWM duty. The transfer voltage admitted when the paper passes the

transfer roller is decided by environment recognition. The resistance value of the transfer roller is changed due to the

surrounding environment or the environment of the set, and the voltage value, which changes due to the environments, is

changed through AD converter. The voltage value for impressing to the transfer roller is decided by the changed value.

Each voltage value is controlled according to 3.3.3.2 Timing Chart.

Fusing

The temperature change of the heat roller s surface is changed to the resistance value through the thermistor. By

converting the voltage value, which impressed to the resistance, to the digital value through the AD converter, the

temperature is decided. The AC power is controller by comparing the target temperature to the value from the thermistor.

If the value from the thermistor is out of controlling range while controlling the fusing, the error stated in the below table

occurs.

ITEM Description

JAM 0 - After picking up, paper cannot be entered due to paper is not fed.

- After picking up, paper entered but it cannot reach to the feed sensor in certain time due to slip, etc.

- After picking up, if the feed sensor is not on, re-pick up. After re-picking up, if the feed sensor is not on

after certain time, it is JAM 0.

*It is a status that the leading edge of the paper doesn t pass the feed sensor.

-Even though the paper reaches to the feed sensor, the feed sensor doesn t be ON.

*It is a status that the leading edge of the paper already passes the feed sensor.

JAM 1 - After the leading edge of the paper passes the feed sensor, the trailing edge of the paper cannot pass

the feed sensor after a certain time. (The feed sensor cannot be OFF)

- After the leading edge of the paper passes the feed sensor, the paper cannot reach the exit sensor after

certain time. (The exit sensor cannot be ON)

*The paper exists between the feed sensor and the exit sensor.

JAM 2 - After the trailing edge of the paper passes the feed sensor, the paper cannot pass the exit sensor after

certain time.

Product specification and feature

Service Manual

2-27

Samsung Electronics

Open Heat Error

When the engine operates the warm-up process, if the temperature of the fixing unit is not higher than a specified

temperature, the engine defines Open Heat Error. When this error is broken out, the engine stops all functions and keeps

the error state. Also, the engine informs the error status of the main system. And then the error message is displayed at

LCD window or LED informing the error status of the user.

Low Heat Error

When the engine is at stand-by, printing or warm-up mode, if the temperature of the fixing unit is lower than the specified

temperature at each state and the lower temperature state is maintained during the specified time, the engine defines

Low Heat Error. When this error is broken out, the engine stops all functions and keeps it at the error state. Also the

engine informs the error status of the main system. And then the error message is displayed at LCD window or LED

informing the error status of the user.

Over Heat Error

For overall engine state, if the temperature of the fixing unit is higher than the specified temperature and the temperature

state is kept during the specified time, the engine defines Over Heat Error. When this error is broken out, the engine stops

all functions and keeps it at the error state. Also, the engine informs the error status of the main system. And then the

error message is displayed at LCD window or LED to inform the error status of the user.

* To recover the heat error: The heat error recovery is operated automatically when the error is only caused by Low Heat

Error, not the Heat Errors in Warm-up state and the Over Heat Error. If an error happens, then the engine memorizes a

present temperature. In case of Low Heat Error, the maximum heat is supplied to the fixing unit. When a specified time

is elapsed, the engine detects the temperature again. If the present temperature is higher than the memorized

temperature, the error is recovered. In case of Over Heat Error, no heat is supplied to the fixing unit. When a specified

time is elapsed, the engine detects a present temperature again. If the present temperature is a specified degree lower

than the memorized temperature, the error is recovered.

LSU

LSU receives the image data from PVC or HPVC and make the latent image on OPC surface.

It uses the dual beam, LD1 and LD2. But the control method of them is the same.

Just in comparison with the single beam, the dual beam has the half of lsu s frequency.

->The frequency of the dual beam = the frequency of the single beam /2.

The errors related to LSU are as follows:

* By LReady: When the printing is started, the engine drives the polygon motor of LSU. After the specified time is elapsed,

if the motor is not in a ready status, the engine detects the error that the polygon motor is not in a ready status. If this

error happens, the engine stops all functions and keeps it at the error state. Also, the engine informs the error status of

the main system and the error message is displayed at LCD window to inform the error status of the user.

* By Hsync: When the polygon motor is ready, the LSU sends out the signal called Hsync and used to synchronize with

each image line. So, if the engine does not detect consecutively the signal for a fixed time, it defines the Hsync Error. If

this error happens, the engine stops all functions and keeps it at the error state. Also, the engine informs the error status

of the main system and then the error message is displayed at LCD window to inform the error status of the user.

LSU Error Recovery: If the LReady or Hsync error happens, the paper exits out beforehand. The engine mode is

changed to recovery mode and the engine informs the main system of the engine mode. And the engine checks the LSU

error. If the error doesn t happen, the printing job will be proceeding.

Service Manual

Product specification and feature

2-28

Samsung Electronics

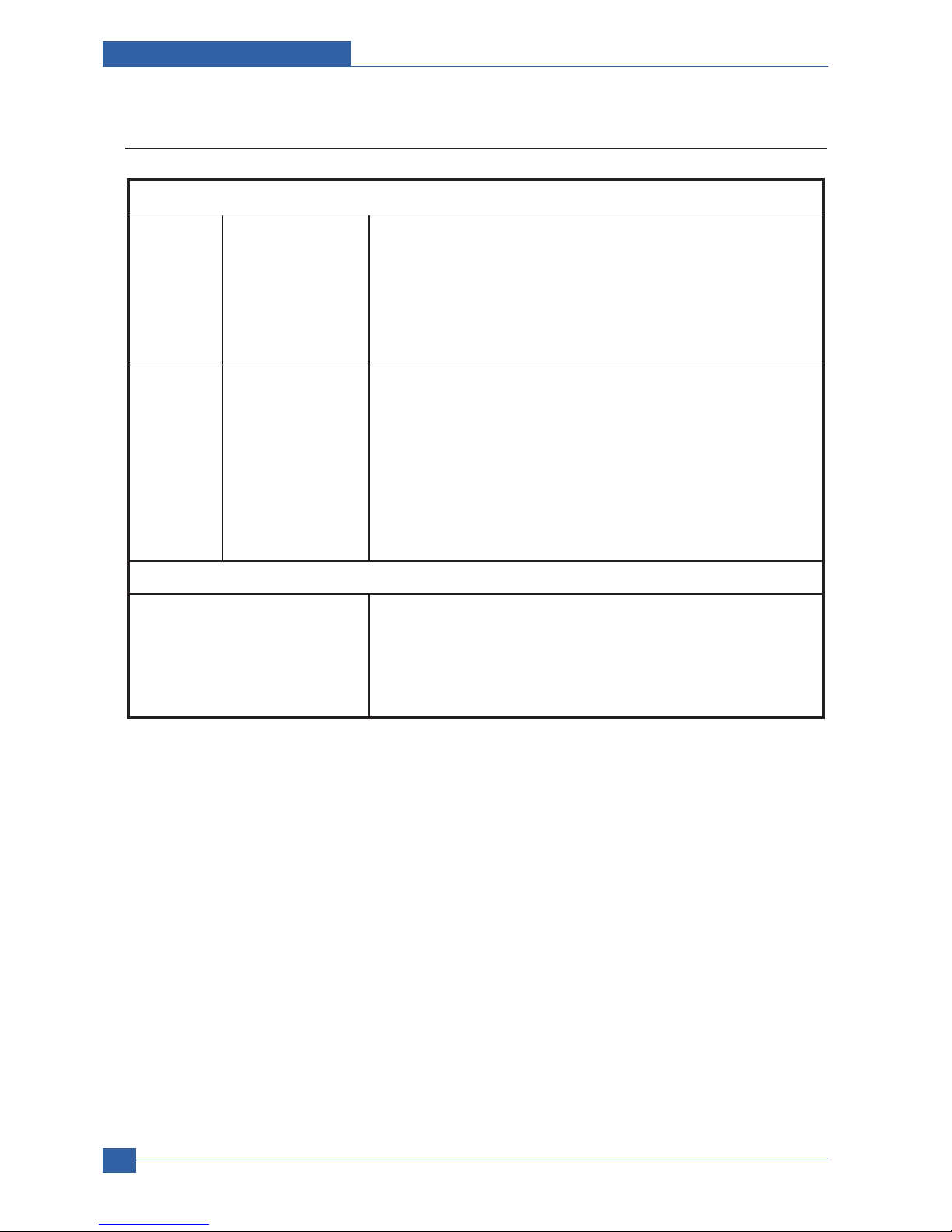

2.2.4 S/W Descriptions

2.2.4.1 Overview

The software of Cygnus system is constructed with

1) Host Software part that the application software operated in Window and Web Environment, and

2) Firmware parts that is a Embedded software controls printing job.

2.2.4.2 Architecture

Host Software is made up of

1. Graphic User Interface that offers the various editing functions to user in Host,

2. Driver that translates the received document to a Printing Command language which printer can understand and

transfers data to spooler,

3. Stand-alone Application that offers the various printing application, DMS(Document Management System),

RCP(Remote Control Panel), Printer Status Monitor, Network Management in Window system,

4. Web-based-Application that offers the same functions as Stand-alone Application and RDC(Remote Diagnosis

Control) in Web environment.

Firmware is made up of

1. Application (Emulation) that is a interpreter translate data received from Host to a printing language (PCL, PS, GDI,

etc.) to be able to make the user to take same output as originally one what composed in Host.

2. Kernel that control and management the whole procedure include of Control flow and Printing Job before transfer to

Engine system.

Product specification and feature

Service Manual

2-29

Samsung Electronics

2.2.4.3 Data and Control Flow

The above Block Diagram is explained that:

Host Side is made up of

1. Driver that is Windows application software translate printed data to one of printer language and create spooler file,

2. Web-based Application that offer a various printer additional functions, management of printing job, printer

administration, Status monitor to monitoring the printer status by real time in Web, independent environment on OS.

3. Stand-alone Application that is a similar Window software as same as above 2,

4. Port Monitor that manages the network communication between spooler and Network Interface Card, or various

additional application and Network Interface Card,(this is, at first, make communication logical port, manage the data,

transfer them from spooler to network port, and offer the result of printing).

Service Manual

Product specification and feature

2-30

Samsung Electronics

Firmware Side is made up of

1. Network Interface Card is that relay the communication between Host and kernel using various network protocol,

2. Kernel is that manages the flow control of emulation procedure, receiving data from Host or Network card and printing

with engine & rendering job,

3. Emulation is that interprets the various output data from selected emulation,

4. Engine is that prints rendered bit-map data to paper with required size and type by Kernel.

And then, for Job Spooling function for Multi-User, Multi-Printing that is occurred in Network printing and various additional

printing functions, this Kernel use max. 10 Queuing systems in a memory.

In Printing, the two procedures are

(1) Case of using Parallel or USB Port

After user start to print the wanted document to PCL string or compressed GDI bit-map data, Driver translate the all

graphic data of it and send data to host spooler. And then the spooler sends the data stream to the printer via

parallel port or USB port.

Kernel receives this data from Host, and then select emulation fit to data and start selected one. After emulation job

end, Kernel sends the output bit-map data to Engine using Printer Video Controller (by clock type for LSU).

Engine print the received data to required paper with the sequential developing process.

(2) Case of using Network Interface Card

After user start to print the wanted document to PCL string or compressed GDI bit-map data, Driver translate the all

graphic data of it and send data to host spooler.

If so, Port monitor managing network port receives data from spooler and sends a data stream to the Network

Interface Card.

Network interface card receives it and send to Kernel part,

Kernel receives this data from Host, and then select emulation fit to data and start selected one. After emulation job

end, Kernel sends the output bit-map data to Engine using Printer Video Controller (by clock type for LSU).

Engine print the received data to required paper with the sequential developing process.

The additional printing function are realized in

(1) Web environment

(2) Window environment.

On addition, Kernel informs a status of printing status and printer status to user made printing job with the Status Monitor.

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-1

3

3. Disassembly and Reassembly

3.1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of cables

to moving parts makes proper routing a must.

If components are removed, any cables disturbed by the procedure must be restored as close as possible to their

original positions. Before removing any component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you

must perform as follows:

1. Check to verify that documents are not stored in

memory.

2. Be sure to remove the toner cartridge before you

disassemble parts.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic-material components.

7. Make sure all components are in their proper position.

Releasing Plastic Latches

Many of the parts are held in place with plastic latches.

The latches break easily; release them carefully.

To remove such parts, press the hook end of the latch

away from the part to which it is latched.

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-2

3.2 Screws used in the Printer

S1(BH Short) 6001-000130 SCREW-MACHINE;BH,+,M3,L6,ZPC(WHT),SWRCH18A,-,- 3

SCREW-MACHINE;BH,+,M3,L6,ZPC(WHT),SWRCH18A,-,- 2

S2(PH Long) 6001-000568 SHIELD+PARRALLEL PORT SCREW-MACHINE;PH,+,M3,L8,NI PLT,SWRCH18A,FP,- 2

S3(WH Long) 6002-000440 SCREW-TAPPING;PWH,+,-,2,M3,L8,ZPC(BLK),SWRCH18A,- 4

SCREW-TAPPING;PWH,+,-,2,M3,L8,ZPC(BLK),SWRCH18A,- 1

S4(WH Long) 6003-000196 COVER MIDDLE+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 6

COVER REAR SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 4

COVER SIDE L SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

COVER SIDE R SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

COVER TOP SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 4

DUP DRIVE ASS'Y+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 3

DUP FAN+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

MAIN DRIVE ASS'Y+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 6

SHIELD CONTROLLER+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 3

SHIELD SMPS+FRAME BASE SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 3

Frame Base+Fuser SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 4

frame assy SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 33

SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

FRAME MP+BRACKET FEED SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 2

FRAME MP+HOLDER IDLE FEED SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 2

FRAME MP+SOLENOID SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 3

Frame Dup+Bracket Align Dup SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 2

Frame Dup+Guide Upper Dup SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 4

COVER FRONT+HOLDER LOCKER SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 2

COVER MIDDLE+CAP SUB ACTUATOR

SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 1

PBA+COVER KEY MENU_LCD SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 4

COVER CASSETTE+FRAME CASSETTE

SCREW-TAPTITE;PWH,+,B,M3,L10,NI PLT,SWRCH18A 2

S5(WH Long) 6003-000221 BLDC MOTOR+BRKT MOTOR SCREW-TAPTITE;PWH,+,-,S,M4,L8,ZPC(WHT),SWRCH18A,- 4

S6(BH Short) 6003-000261 PLATE KNOCKUP+CAM KNOCKUP SCREW-TAPTITE;BH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,- 1

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-3

S7(WH Short) 6003-000264

TRAYASF INPUT UPPER+GEAR PINION

SCREW-TAPTITE;PWH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,- 1

SCREW-TAPTITE;PWH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,- 2

LCD+COVER KEY MENU_LCD SCREW-TAPTITE;PWH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,- 2

GEAR PINION+FRAME CASSETTE SCREW-TAPTITE;PWH,+,-,B,M3,L6,ZPC(WHT),SWRCH18A,- 1

S8(BH Short) 6003-000269 BRKT MOTOR+BRKT GEAR SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 4

SHIELD CONTROLLER+PBA SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 3

SHIELD SMPS+SMPS SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 4

HVPS+SHIELD HVPS SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 3

SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 2

SCREW-TAPTITE;BH,+,-,S,M3,L6,ZPC(WHT),SWRCH18A,- 4

S9(BH Short) 6003-000282 SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,- 8

SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,- 5

SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(BLK),SWRCH18A,- 10

S10(BH Long) 6003-000301 SHIELD SMPS+EARTH HARNESS SCREW-TAPTITE;BH,+,-,S,M4,L6,ZPC(WHT),SWRCH18A,- 1

S11(BH Short) 6003-001256 LSU+FRAME BASE SCREW-TAPTITE;BH,+,B,M4,L10,NI PLT,SWRCH18A 4

S12(BH Long) 6006-001078 SCREW-TAPTITE;PH,+,WSP,B,M3,L10,ZPC(WHT),SWRCH18A,- 3

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-4

3.3 Front Cover

1. Take out the Cassette.

2. Open the Cover.

3. If necessary, remove the Toner Cartridge.

4. To remove the Front Cover, first pull the part below

the both side of the Front Cover with a light pressure to the direction of arrow.

Cassette

Toner Cartridge

Front Cover

2

1

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-5

3.4 MP Tray Ass'y

1. Open the MP Tray Ass'y

2. Pull the Tray Links from the both side of the Front

Cover with a light pressure to the direction of arrow.

3. Apply light pressure to the both side of the MP Tray

Ass'y and pull it in the direction of arrow, as shown

below.

MP Tray Ass'y

Tray Link

MP Tray Ass'y

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-6

3.5 Rear Cover

1. Take out the Duplex Unit.

2. Remove the four screws securing the Rear Cover

and then Release the Rear Cover from the Set.

3. To remove the Face Up Cover, first release the

Stopper Strap in the direction of arrow.

4. Unlatch the Face Up Cover from the Rear Cover

and then release the Face Up Cover, as shown

below.

Duplex Unit

Stopper Strap

1

2

Face Up Cover

Rear Cover

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-7

3.6 Fuser Ass'y

1. Before you remove the Fuser Ass'y, you should open

the face up cover and open the guide output fuser.

- Rear Cover (Refer to 3.5)

2. Remove the four screws securing the Fuser Ass'y

and then pull the Fuser Ass'y.

3. Release the CON Harness and REC Harness from

the Thermostat and then remove the three screws

securing the Thermostat and remove it.

4. To remove the Electrodes, first release REC

Harness from the left side of the Electrode and

then release the CON Harness from the right side

of the Electrode, as shown below.

Fuser Ass'y

Thermostat

CON Harness

REC Harness

REC Harness

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-8

6. Remove the two screws securing the IInput Guide

and remove it.

7. Unplug the connector from the Input Guide and

remove the one screw securing the Thermistor and

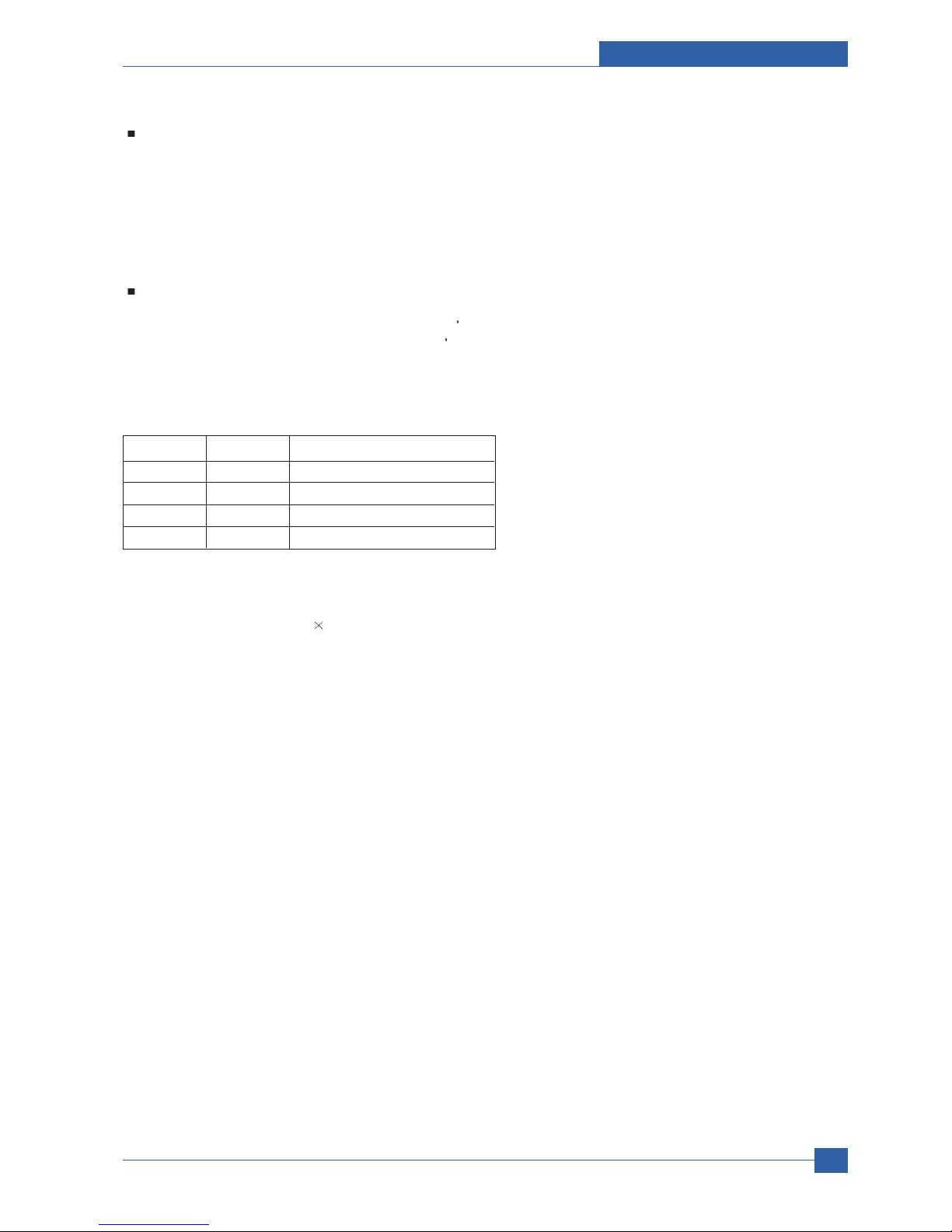

remove it.

8. Remove the three screws securing the Idle Gear

Bracket and remove it.

9. Remove the one screw securing the Fuser Cover

and release the Fuser Cover from the Fuser

Frame.

Input Guide

Thermister

Idle Gear Bracket

Fuser Cover

Fuser Frame

10. Release the Fuser Gear and HR Bush and then

remove the Heat Roller, as shown below.

11. Remove the Jam Link Lever (L,R) and Jam

Holder (L,R) and then remove the Pressure Roller,

as shown below.

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-9

Heat Roller

HR Bush

HR Bush

Fuser Gear

Jam Holder

Jam Link Lever

Jam Holder

Jam Link Lever

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-10

3.7 Top Cover

1. Before you remove the Top Cover, you should

remove:

- Rear Cover (Left, Right) (Refer to 3.5)

2. Remove the four screws securing the Top Cover,

as shown below.

3. To remove the Top Cover, first lift the Top Cover

with a light pressure to the direction of arrow. Then

unplug the OPE Harness, as shown below.

Top Cover

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-11

3.8 OPE Unit

1. To remove the OPE Unit, first lift the OPE Unit with

a light pressure to the direction of arrow, Then

unplug the OPE Harness, as shown below.

Notice : When reassembly the OPE Unit, hole inside

of figure insert a harness.

2. Remove the six screws securing the OPE PBA and

LCD Panel to the OPE Cover and remove it, as

shown below.

3. Release the Lens and Keys from the OPE Cover.

OPE Unit

LCD Panel

OPE PBA

OPE Cover

Lens

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-12

3.9 Side Cover (Left, Right)

1. Before you remove the Side Cover (Left, Right),

you should remove:

- Rear Cover (Refer to 3.5)

- Top Cover (Refer to 3.7)

2. Remove the one screw securing the Right Side

Cover, as shown below.

3. Apply light pressure to the bottom of the Right Side

Cover and pull it to the right side in the direction of

arrows, as shown below.

4. Remove the one screw securing the Left Side

Cover, as shown below.

5. Apply light pressure to the bottom of the Left Side

Cover and pull it to the left side in the direction of

arrows, as shown below.

Right Side Cover

Left Side Cover

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-13

6. If necessary, pull the DIMM Cover in the direction

of arrow and remove it, as shown below.

Notice : Be careful not to damage the hooks when

remove the Side Cover (Left, Right).

DIMM Cover

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-14

3.10 Shield Controller Ass'y

1. Before you remove the Shield Controller Ass'y, you

should remove:

- Side Cover Left (Refer to 3.9)

2. Unplug the all connectors from the Main PBA.

3. Remove the three screws securing the Shield

Controller Ass'y and remove it.

4. Remove the five screws securing the Main PBA to

the Shield and remove it.

5. The connectors are located, as shown below.

Shield Controller Ass'y

Shield

Insulator Sheet

Main PBA

LCD OPE

Cartridge

USB

Line

Duplex

Engine

BLDC

Pick Up

REGI

LSU S/W

LSU

Thermistor

MPF_SEN

MPF

LED OPE

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-15

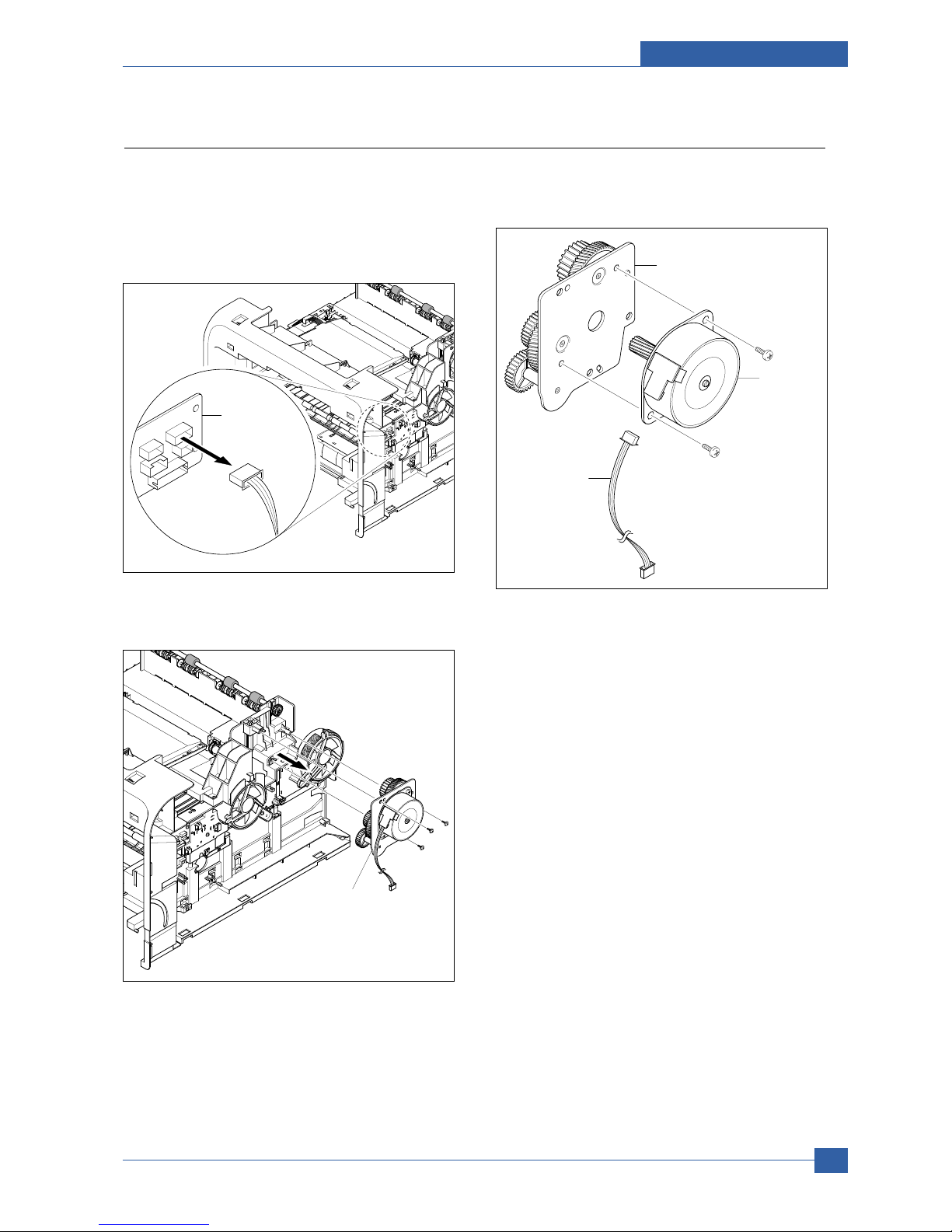

3.11 Drive Ass'y

1. Before you remove the Drive Ass'y, you should

remove:

- Side Cover Left (Refer to 3.9)

2. Remove the six screws securing the Drive Ass'y

and remove it.

Notice : The six screws have numbers stamped into

the Drive Ass'y base plate. When refitting the

Drive Ass'y tighten the screws the order they

are numbered. Only screws numbered 1 to 5

are fitted at this stage. Screw 6 is fitted when

the Shield Controller Ass'y is refitted.

3. If necessary, remove the four screws securing the

BLDC Motor Ass'y and remove it.

Drive Ass'y

Gear Bracket Ass'y

BLDC Motor Ass'y

Harness

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-16

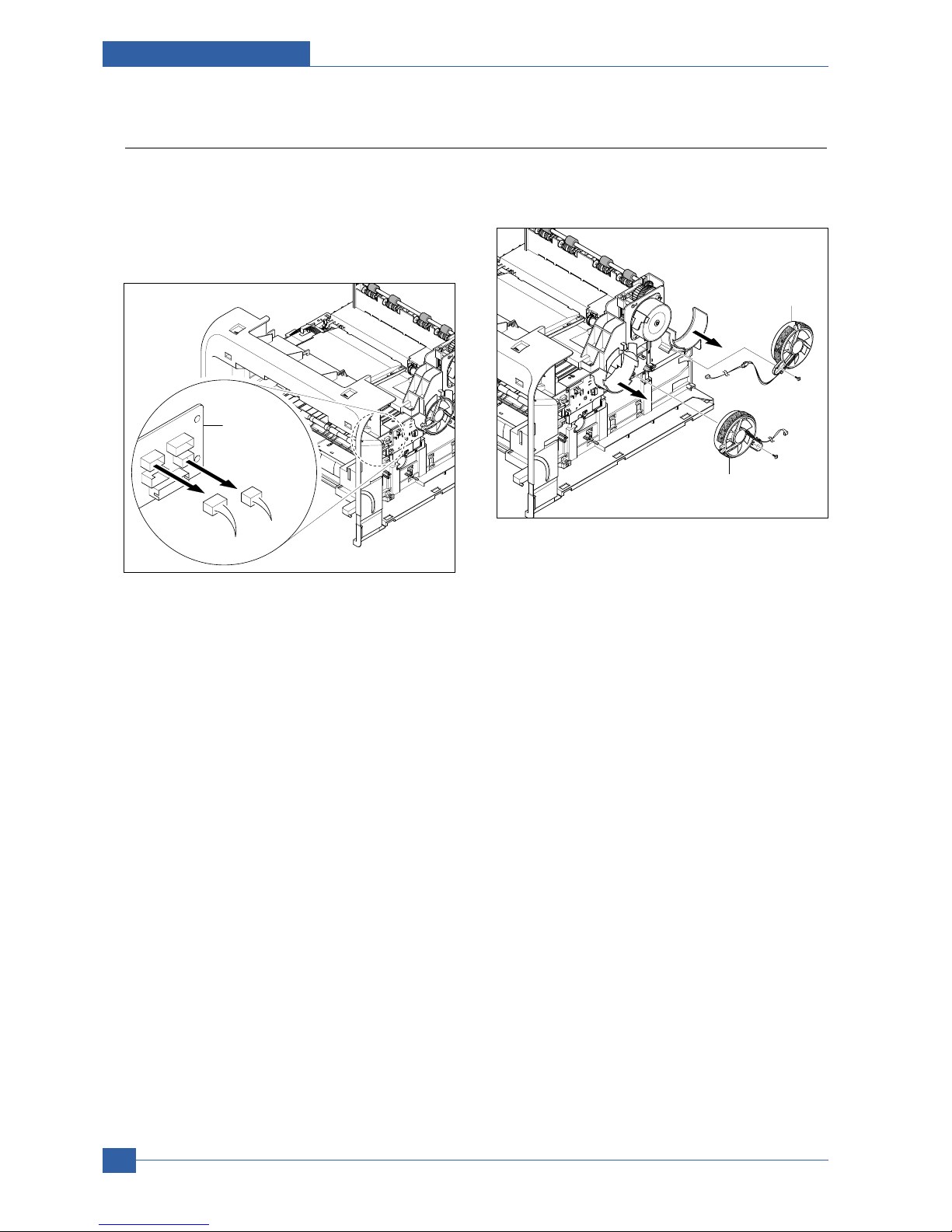

3.12 Duplex Drive Ass'y

1. Before you remove the Duplex Drive Ass'y, you

should remove:

- Side Cover Right (Refer to 3.9)

2. Unplug the connector from the Connection PCB

and remove the three screws securing the Duplex

Drive Unit and remove it.

3. If necessary, remove the two screws securing the

Duplex Motor and remove it.

Duplex Drive Ass'y

Connection

PCB

Duplex Motor

Harness

Duplex Motor

Bracket Ass'y

Disassembly and Reassembly

Samsung Electronics

Service Manual

3-17

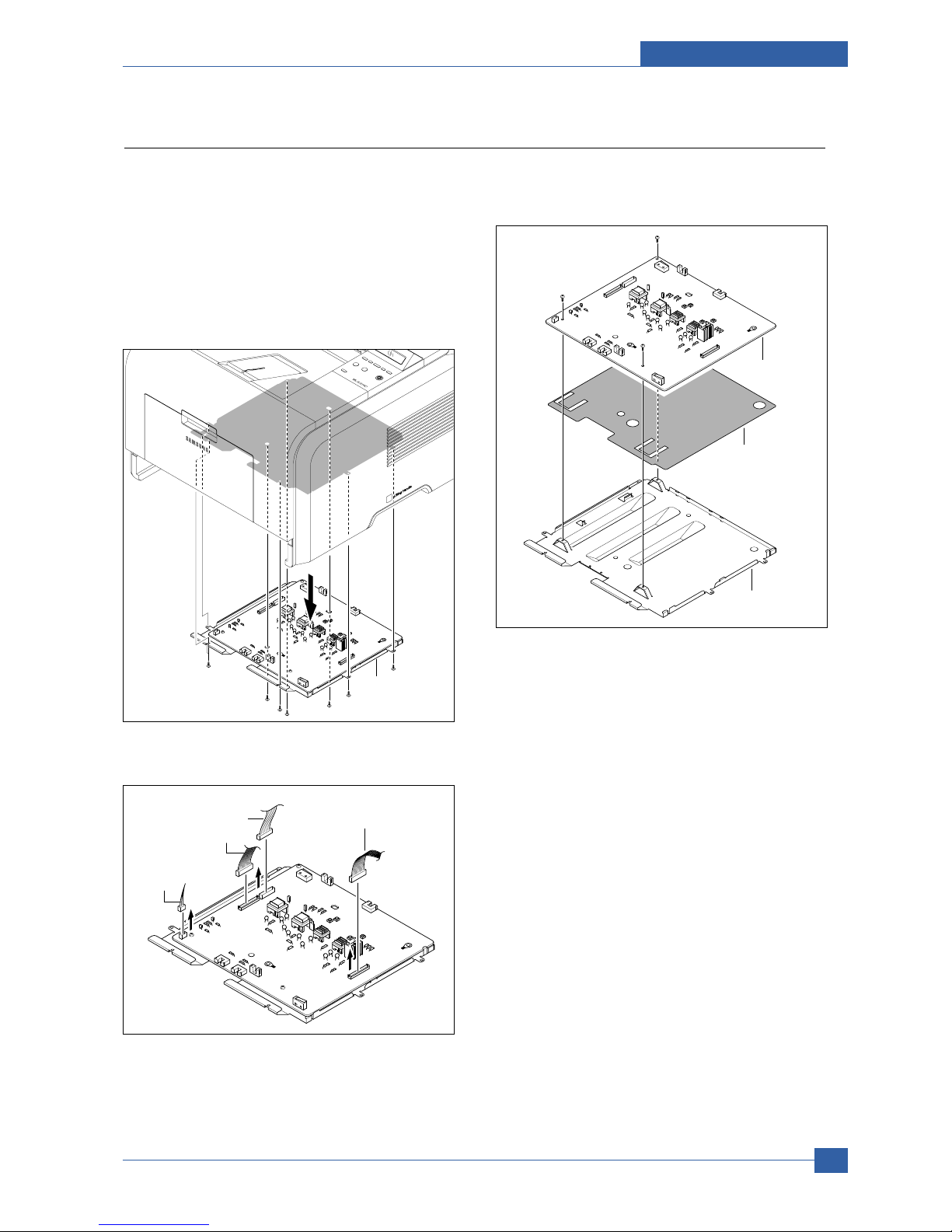

3.13 Shield SMPS Ass'y

1. Before you remove the Shield SMPS Ass'y, you

should remove:

- Side Cover Right (Refer to 3.9)

- Duplex Drive Ass'y (Refer to 3.12)

2. Unplug the two connectors (HVPS, Fuser).

3. Remove the three screws securing the Shield

SMPS Ass'y and remove it.

4. Unplug the connector (AC Inlet) and remove the

four screws securing SMPS and remove it.

HVPS Connector

Fuser Connector

Shield SMPS Ass'y

SMPS

Insulator Sheet

Shield SMPS (With AC Inlet)

AC Inlet Connector

Samsung Electronics

Service Manual

Disassembly and Reassembly

3-18

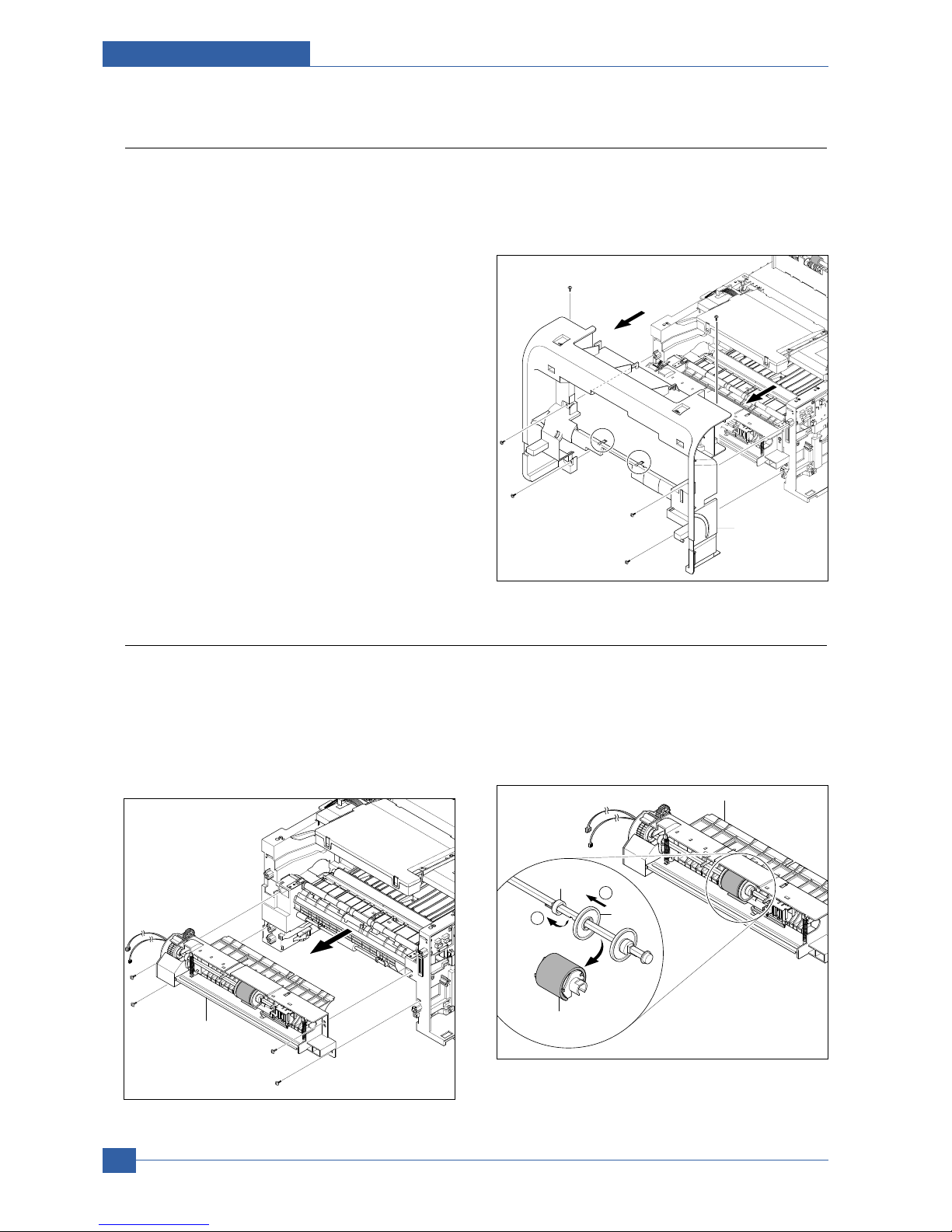

3.14 Connection PCB

1. Before you remove the Connection PCB, you

should remove:

- Side Cover Right (Refer to 3.9)

2. Unplug the all connectors.

3. Remove the two screws securing the Connection

PCB and remove it.

4. The connectors are located, as shown below.

Connection

PCB

Connection

PCB

FAN Duplex Exit Motor

Fan Main

HVPS

Duplex

Motor