Samsung LH008IWR, SBB-MBOXR48 Installation Manual

LED Display

Installation Manual

Cabinet : LH008IWR (P0.84)

Samsung Electronics

Ver. 2.5

Media Box :

SBB-MBOXR48

Revision History

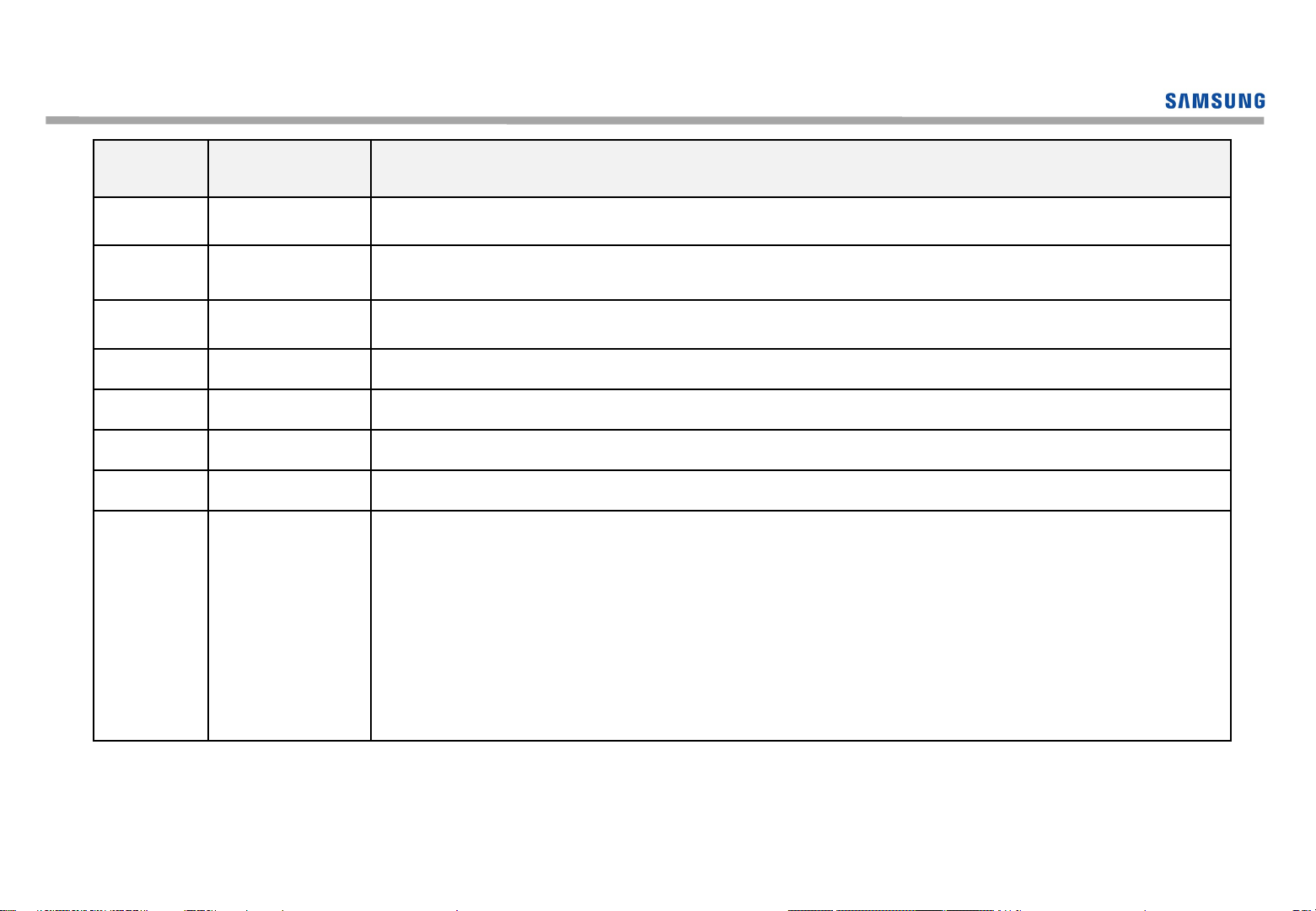

Version Date (Y/M/D) Description

2.0 2020/06/19 Revision History Page added

2.1 2020/11/04 Dehumidification guidance added

2.2 2020/11/26 Delete FAN installation part.

2.3 2020/11/27 Update LSM guide

2.4 2020/12/02 Update Dehumidification Guide

2.5 2020/12/14 Update Ventilation Guide

2.6 2020/12/28 Update recessed screen installation guide

Samsung Electronics

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

Samsung Electronics

When moist gets into LED package because of high humidity, ‘Line defect’ can

be caused by electrical short inside of LED Package.

For keeping the best quality of products during installation, please refer to the

below cautions.

- If the condition meets one of the below cases at least, dehumidification MUST be

processed. Do not play any contents on the screen before dehumidification finishes.

∙ Case when vacuum packaging is already unsealed before unpacking products.

∙ Case when environment condition is worse than Samsung working condition (0°C~40°C/10~80%RH).

∙ Case when it elapses longer than 7 days after unpacking them, even though the environment condition

satisfies Samsung working condition (0°C~40°C/10~80%RH).

∙ Case when production date on the label elapses more than 6 months, even though vacuum packaging is

sealed.

∙ Case when volatile chemicals such as oil paint, solvent are used in same place of installation.

(You can refer to Product Information and Precautions for Installation part in detail.)

- If the screen needs dehumidification on installation, MUST follow the directions of next page.

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

Samsung Electronics

How to install the screen in the case that dehumidification is necessary

※ Before finishing the directions explained in next pages, never play other contents or use them.

※ If the installation site has higher humidity, it is highly recommended to use dehumidifier.

(If A/C turned off after working hour, it may make humidity higher and cause line defects.)

※ Chilled air from A/C should never touch LED surface directly.

※ If thermo-hygrometer is equipped on the site while the screen is installed, it is useful to analyze

the cause of line defects.

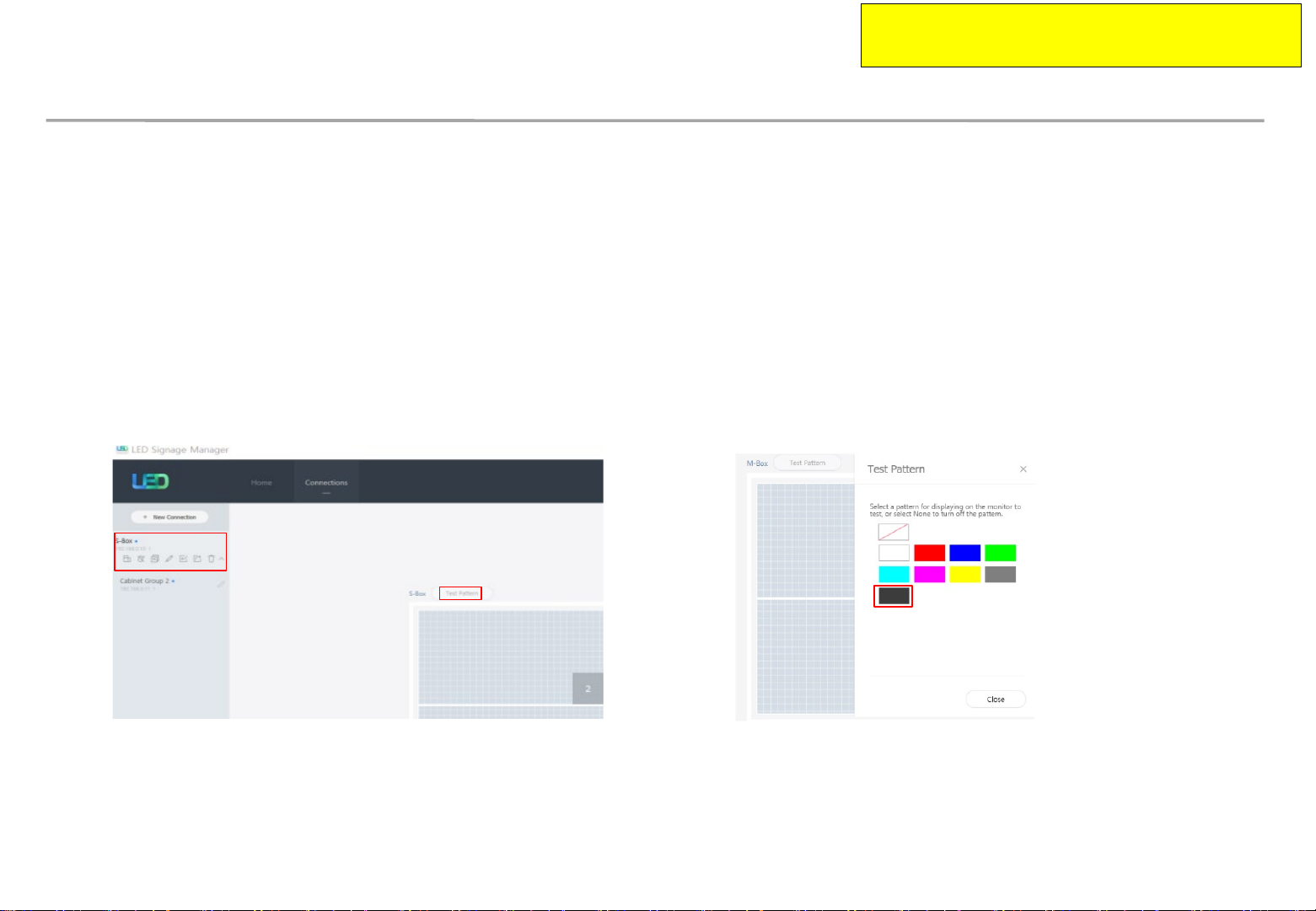

1. Play a specific pattern of LSM program without any cabinets.

(This pattern should be used. If other pattern is used, it can cause line defects.)

① Select M-Box and Test Pattern

② Set darker gray pattern among various patterns.

2. Inspect cabinets with darker solid patterns(W/R/G/B) and turn off cabinets.

(It should take less than 30 seconds to show each solid patter and you can refer to

Screen check’ category in detail.)

‘Process of

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during installation

How to install the screen in the case that dehumidification is necessary.

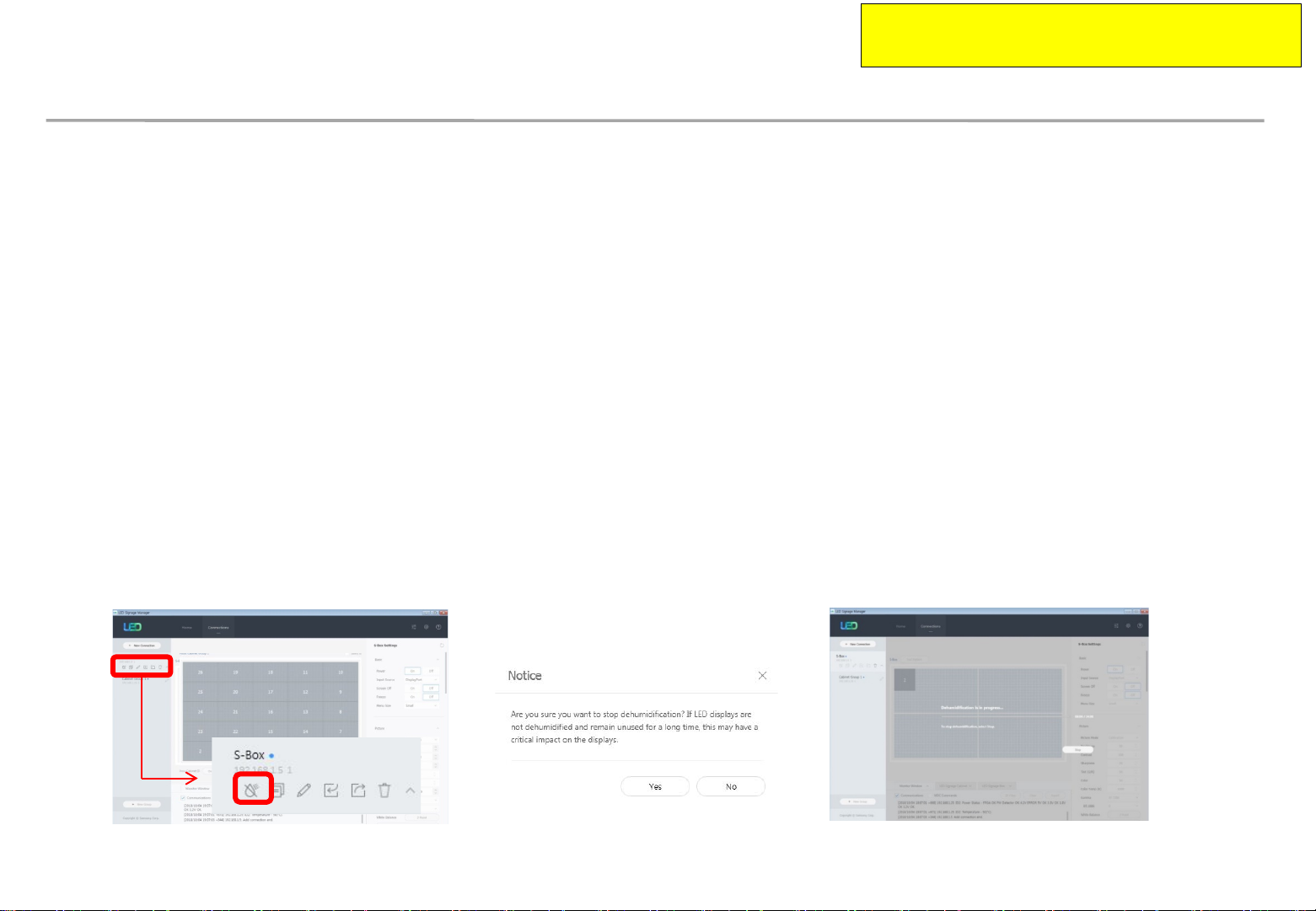

3. While installing cabinets, S-Box should play only this pattern.

• Check S-Box shows the pattern through monitor connected to S-Box service port.

• After installing each cabinet, check whether the pattern is shown in it.

• OCM cable connection can be checked through this.

• Before turning off S-Box, turn off the cabinets, first.

• After being sure S-Box plays this pattern, turn on the cabinets.

Samsung Electronics

4. After completing installation of cabinets, start 24hr dehumidification process.

5. After finishing 24hr dehumidification process, do edge correction and module calibration.

This contents must be noticed to customer.

Please print this page and hand it to user.

Dehumidification guidance – during operation

Samsung Electronics

Electrical short in package is possible to happen during products are working.

For keeping quality of products during installation, please refer below

cautions.

- If one of below case meet during operation, MUST do dehumidification process.

∙ Case when environment condition is exceed operation condition.

∙ Case when products are not working more than 1 month, even though environment condition is under

operation condition.

- When environment condition is exceed operation condition, products are out of warranty. Please check

environment condition.

- Even products are operating, if the installed place have extra construction such as interior modification,

MUST do dehumidification following installation condition.

- It is possible to happen dew condensation on surface of products, even though working on operating

condition. When happening dew condensation, MUST operate after cleaning the dew condensation &

dehumidification.

5

Enterprise R&D Team

This contents must be noticed to customer.

Please print this page and hand it to user.

Dew condensation due to overcooling

Samsung Electronics

Even though meet with Samsung recommended operation

condition, dew condensation is possible to happen when

surface of products is colder than environment temperature or

hot & humid air blow to cooled surface of products.

(cf : Principle of happening dew on surface of glass which have ice)

Case when dew condensation is happen on products, it is

possible to be the root of defect. In this case, it is possible to

be out of warranty.

Table of Contents

Samsung Electronics

1. Product information and precautions for installation

2. Check point about the radiant heat

3. Frame installation

4. Preparation for cabinet installation

5. Cabinet + Frame installation

6. Cabinet + Frame + Bezel installation

7. Disassembly & Front Service

8. Media Box installation and connection

9. LSM Setting & Instructions

10. How to use The Wall

7

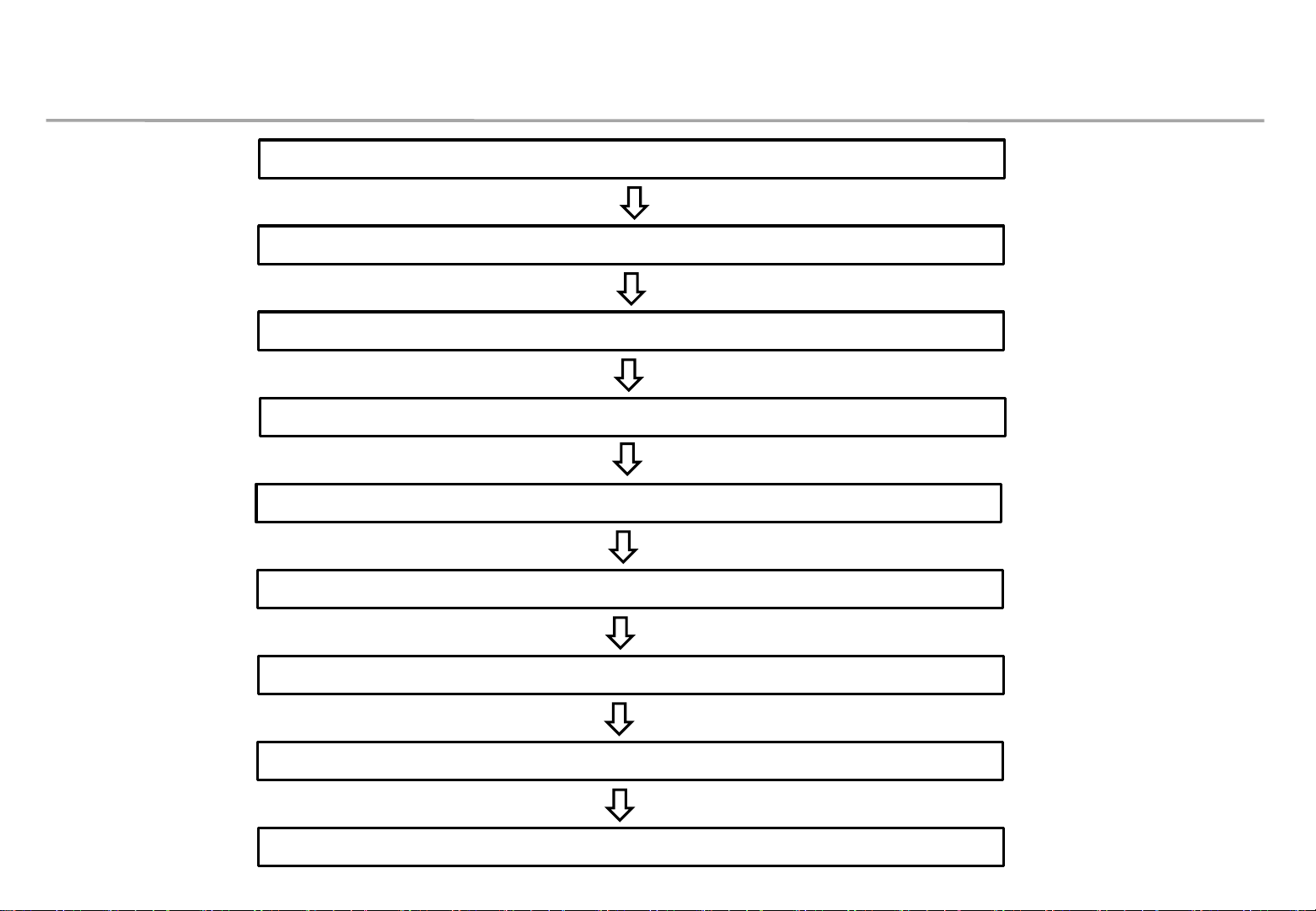

Product installation flow

Check product installation precautions

Check heat dissipation inspection

Installation frame

Check cabinet operation

Installation cabinets and cables

Samsung Electronics

Installation bezel and sensors

Installation Media Box and LSM

Calibration cabinets

Product and peripheral devices operation

8

Samsung Electronics

1. Product information and precautions for installation

2. Check point about the radiant heat

3. Frame installation

4. Preparation for cabinet installation

5. Cabinet + Frame installation

6. Cabinet + Frame + Bezel installation

7. Disassembly & Front Service

8. Media Box installation and connection

9. LSM Setting & Instructions

10.How to use The Wall

9

1. Product Information and Precautions for Installation

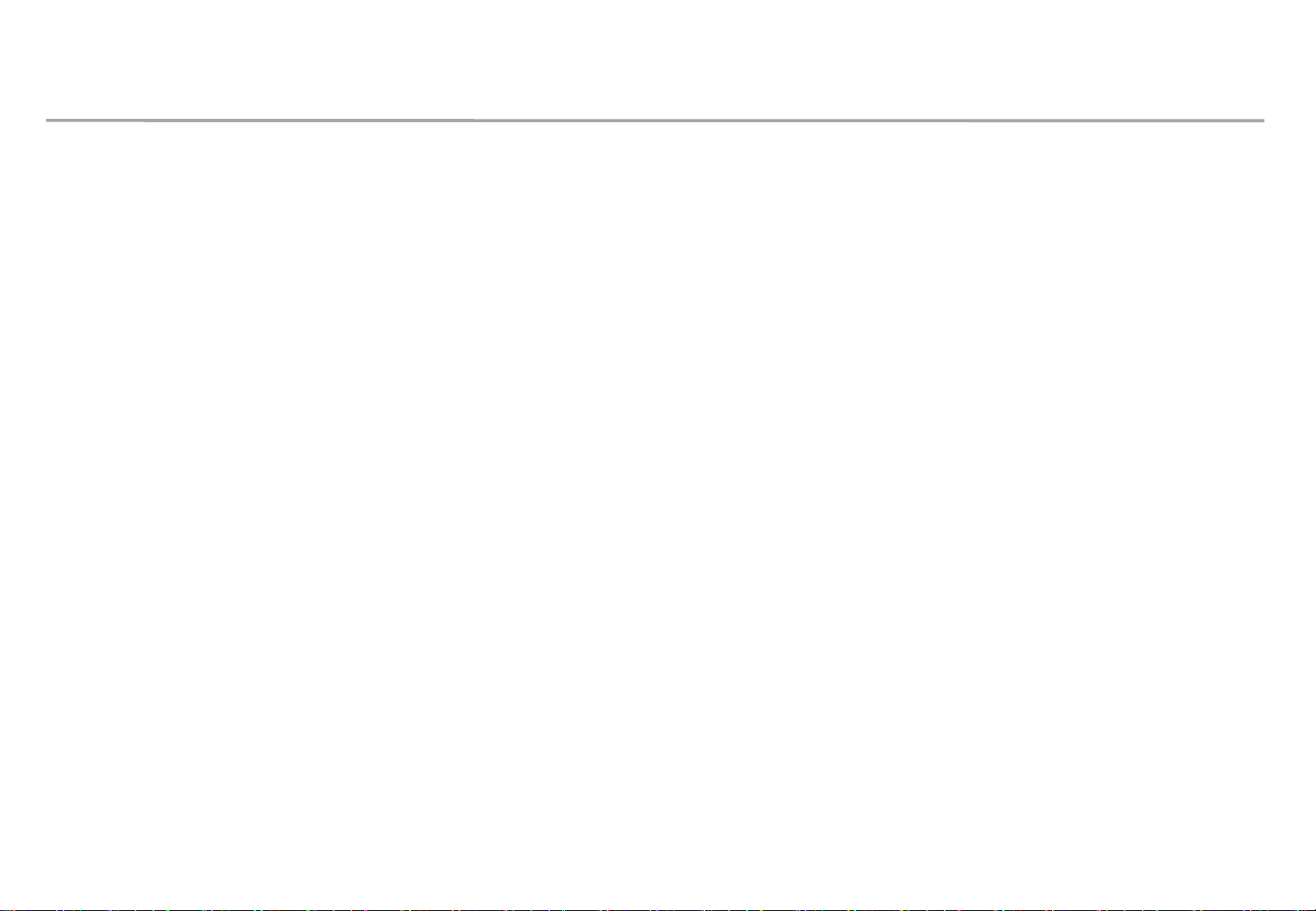

◇ Cabinet Installation Components

Samsung Electronics

Picture Description

Cabinet

LH008IWR

AC Power Cord

(to Cabinet)

AC Power Cord

(to Wall Outlet)

AC Power Daisy chain

Cable

OCM Cable

Picture Description

Product Certification

Standard guide

Cover-PCB x1ea

Screw-Machine (M3*L5) x1ea

Holder-Screw (M4*L5) x1ea

Holder-Screw (M4*L6) x3ea

Cloth-Clean x1ea

10

1. Product Information and Precautions for Installation

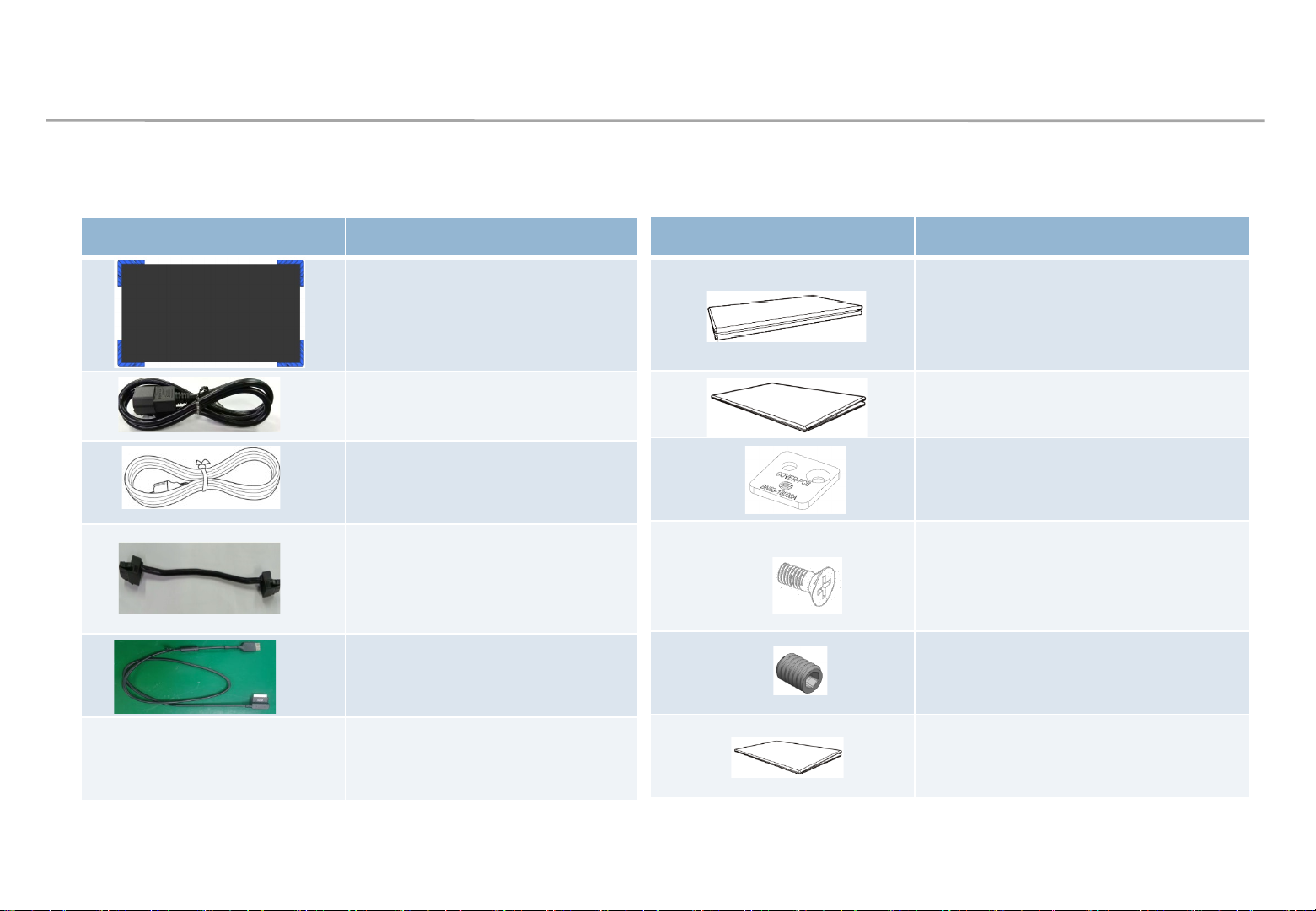

• Media Box Installation Components

Samsung Electronics

Picture Description

Media Box

SBB-MBOXR48

Remote control

AC/DC Adaptor, Power

cable

Module Rx x 8

Bluetooth/Wi-Fi Module

Sensor Top x 2

Sensor Bottom x 2

Picture Description

Bridge Box

24pin system cable x 5

Bluetooth/Wi-Fi module cable

Rack case mounting bracket x 2

Batteries x 2

Screw (M4 x L8) x 4

Screw (M5 x L12) x 4

11

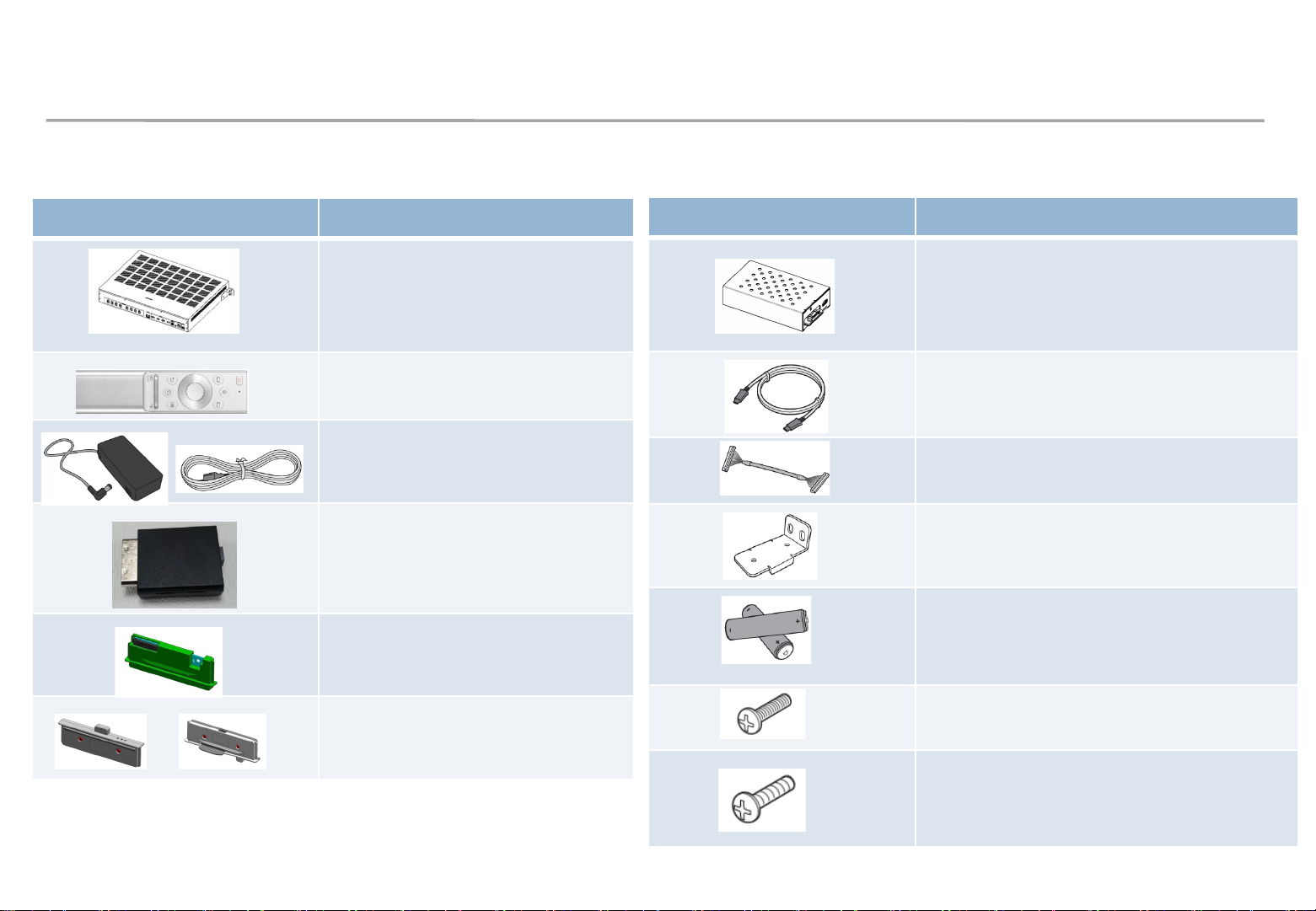

1. Product Information and Precautions for Installation

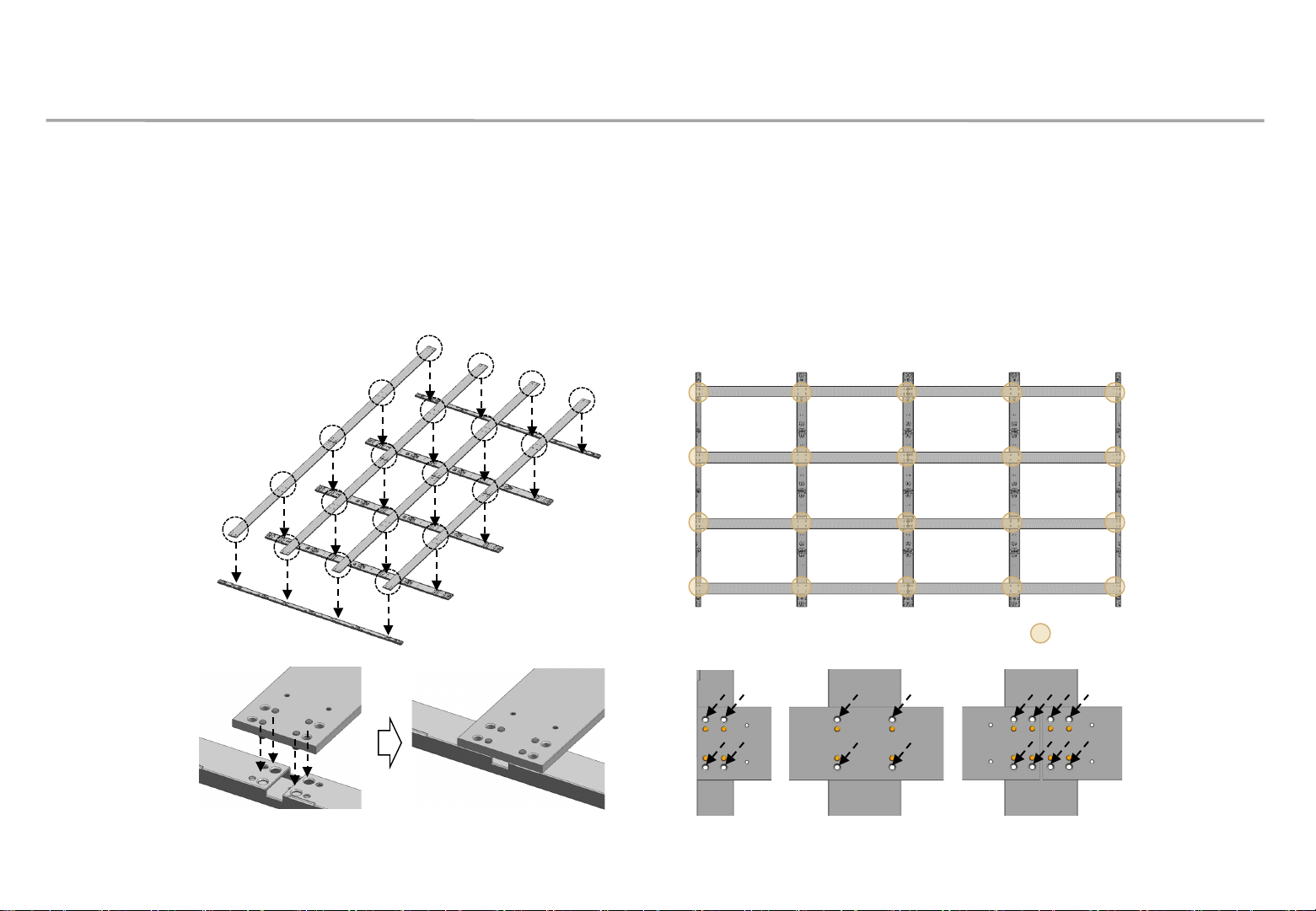

◇ Frame Kit (refer to page 19,20)

Samsung Electronics

Frame Kit

VG-LFR08SWW

VG-LFR08FWW

VG-LFR08TWW

VG-LFR08UWW

VG-LFR08FWW x2

VG-LFR08TWW x2

VG-LFR08UWW x2

VG-LFR08TWW x4

VG-LFR08TWW x2

VG-LFR08UWW x2

VG-LFR08UWW x4

Installation

configuration

1x1 (1 Set)

2x2 (4 Set)

3x3 (9 Set)

4x4 (16 Set)

5x5 (25 Set)

6x4 (24 Set)

6x6 (36 Set)

7x7 (49 Set)

8x8 (64 Set)

Note

-

2K (FHD)

-

4K (UHD)

21:9

6K

8K

<1x1> <2x2> <3x3> <4x4>

1. Product Information and Precautions for Installation

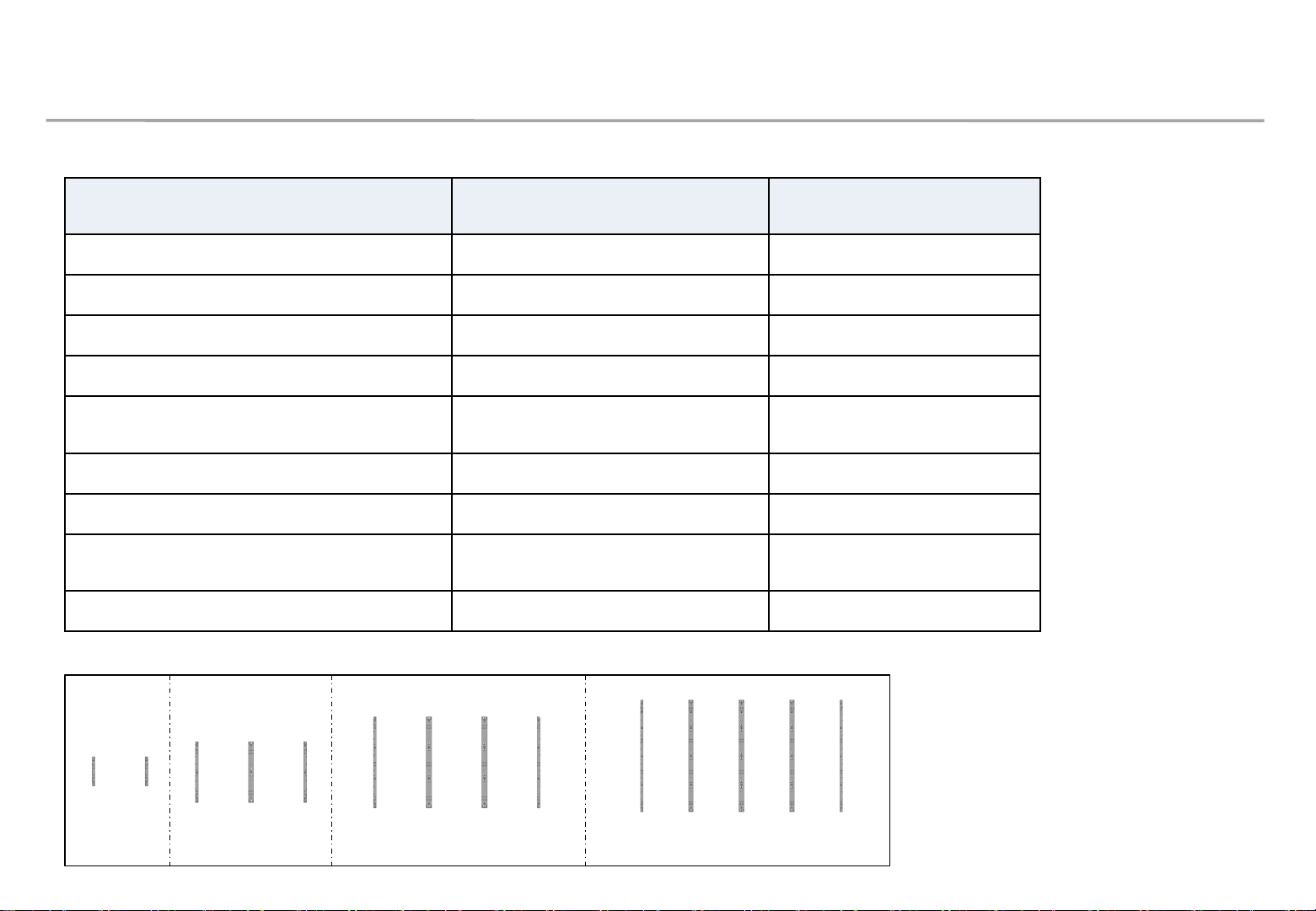

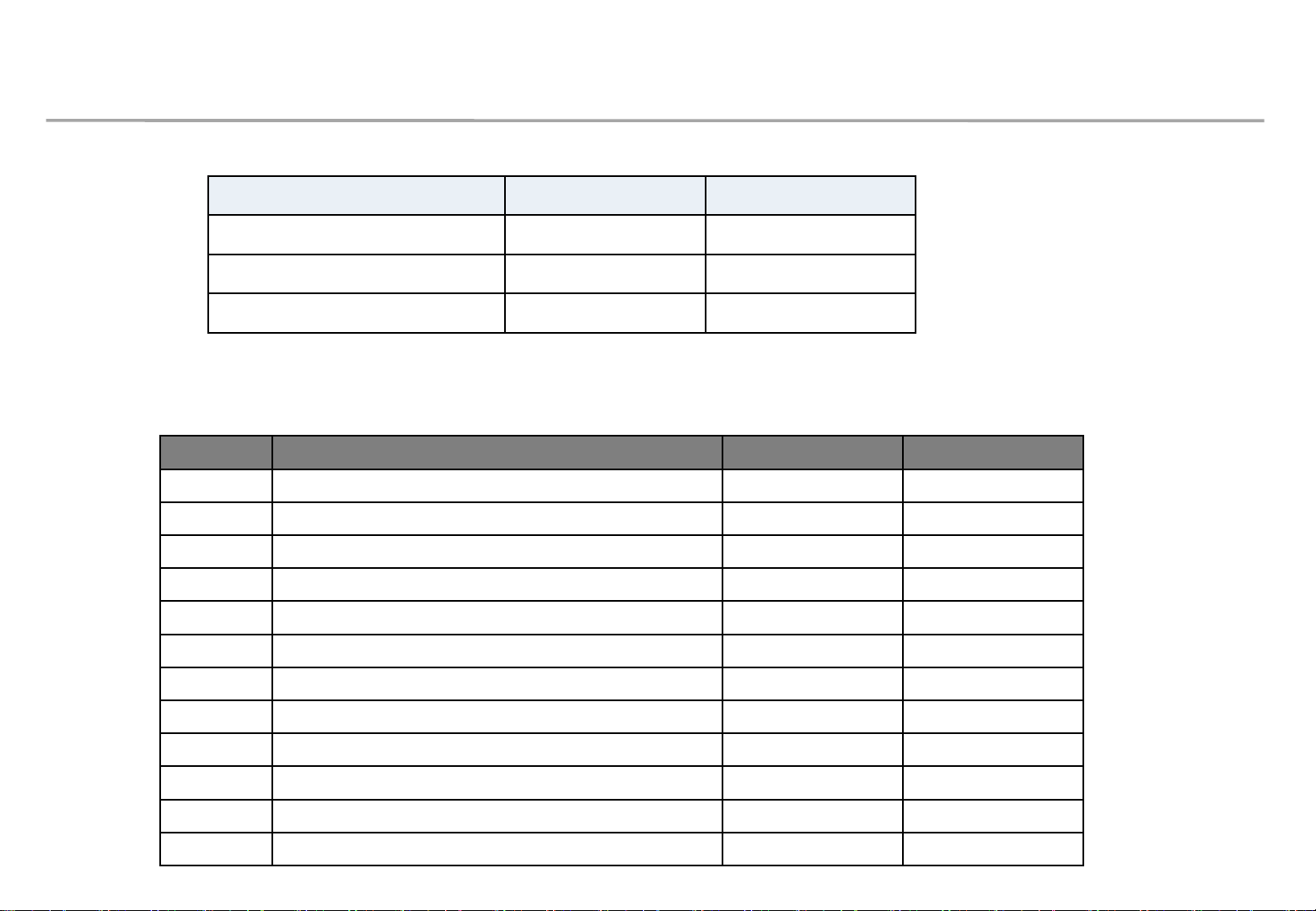

◇ Storage Condition

Condition Value Recommend

Temperature -20℃ ~ +45℃ -20℃ ~ +45℃

Humidity 5~95% 5~65%

Hight 3000m 3000m

◇ Pre-heating Process

If you do not operate for more than 30 days, you need to dehumidify it before operation. (refer to page 40)

Step condition Brightness Time

1 Lighting up display with 10 gray scale 5% 2 hr

2 Lighting up display with 20 gray scale 8% 2 hr

3 Lighting up display with 30 gray scale 10% 2 hr

Samsung Electronics

4 Lighting up display with 40 gray scale 15% 2 hr

5 Lighting up display with 50 gray scale 20% 2 hr

6 Lighting up display with 70 gray scale 25% 2 hr

7 Lighting up display with 90 gray scale 35% 2 hr

8 Lighting up display with 120 gray scale 45% 2 hr

9 Lighting up display with 150 gray scale 60% 2 hr

10 Lighting up display with 180 gray scale 70% 2 hr

11 Lighting up display with 200 gray scale 80% 2 hr

12 Lighting up display with 255 gray scale 100% 2 hr

13

1. Product Information and Precautions for Installation

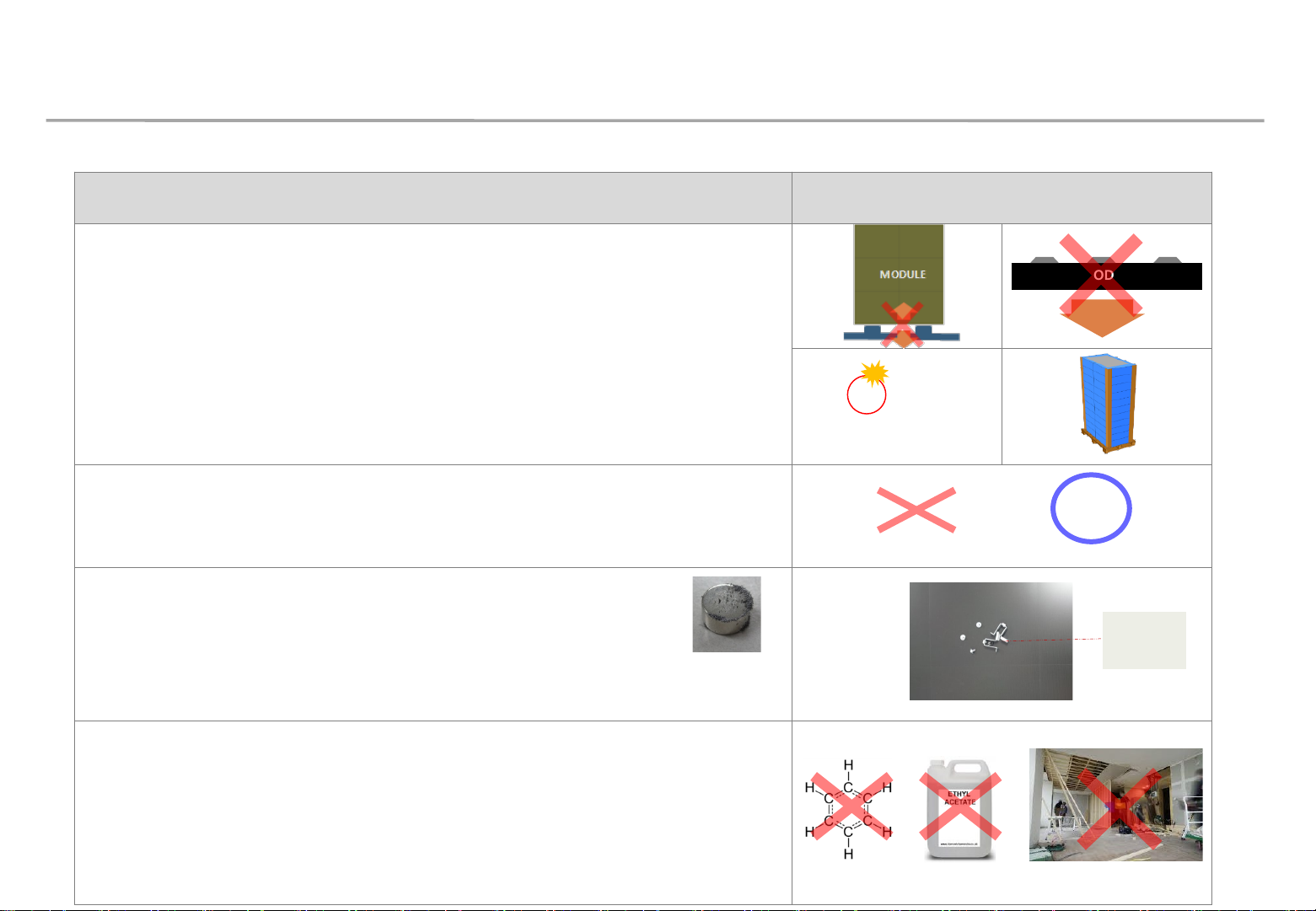

• Precautions for Installation (LED damage)

Caution Image

[ Beware of Outside Impact, Fall]

Samsung Electronics

① Beware not to cause any impact on the LED screen or drop the product on the floor

after the protection gets taken off for installation.

② Beware not to put the LED side headed downwards to the floor after the protection

gets taken off for installation.

③ Beware not to have the corner area of LED module be damaged due to the contact

with the outside.

④ Beware not to put more than 12 layers.

[Beware of LED Damage due to Static Electricity]

▶ Beware not to touch LED screen with bare hands without putting gloves on.

[Beware of LED & Film Damage due to Metallic Substances]

▶ Beware not to have metallic substances pulled in to the surface

due to the magnetic force on the front side of the LED.

▶ If any metallic substances get drawn in on the surface, please remove the

pollutants by using a magnet.

[Beware of LED Damage due to chemicals.]

MODULE

Front

① ②

③ ④

LED &

Film

▶ Beware not to contact water, waxes, benzene, thinners, mosquito repellents,

lubricants, cleaners, solvents or surfactants on edge of LED Module.

▶

When installing on the construction site, it should be installed after construction & cleaning.

▶ If the installation site requires construction work, the product is covered with a

curtain and operated 50% white or video for 2 hours every day.

14

1. Product Information and Precautions for Installation

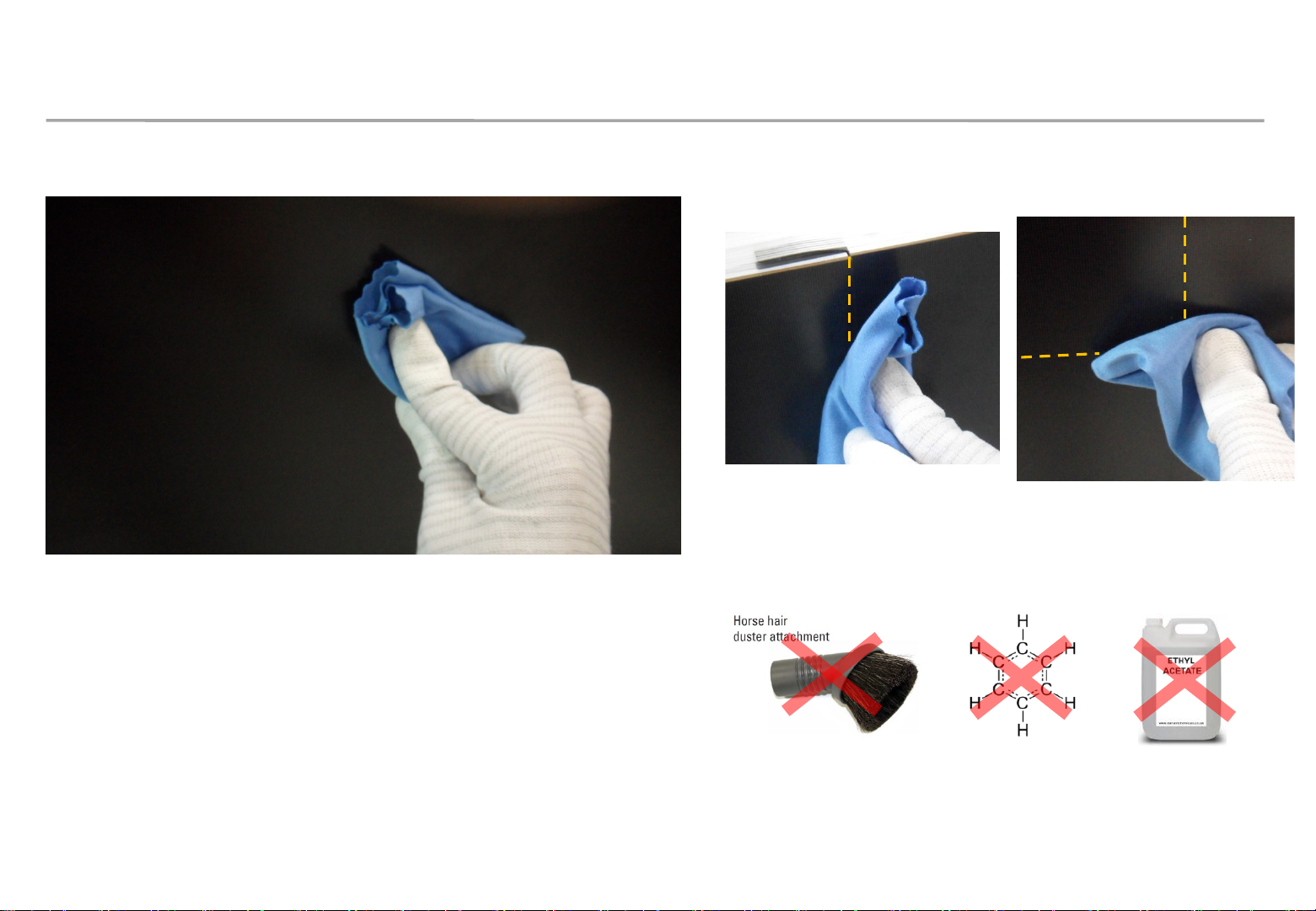

◇ Caution for cleaning screen

★Caution★

- Watch out for damage when cleaning gap between HalfCabinets

- Watch out for damage when cleaning gap between Modules

- Do not insert any cleaning tool or spay cleaner directly into

- Wipe lightly with the soft cleaning cloth provided with the product

(Watch out for surface LED damage)

the gap

Samsung Electronics

- Hard stuff on screen surface can damage LED chip and film during

cleaning. Clear screen surface before cleaning

- It is recommended to wipe with soft cleaning cloth provided with

the product, and if there is a contaminant area that is not well

removed, it should be injected into a cleaning cloth provided with

a glass detergent of the surfactant and washed. (However, do not

spray the glass detergent directly on the screen)

- Do not wipe the LED surface with hard materials such as

paper towels, brushes comb or brush, acrylic or steel.

- Do not use chemicals such as wax, benzene, cinna, mosquito

repellent, air freshener, lubricant, and detergent in products

15

1. Product Information and Precautions for Installation

Samsung Electronics

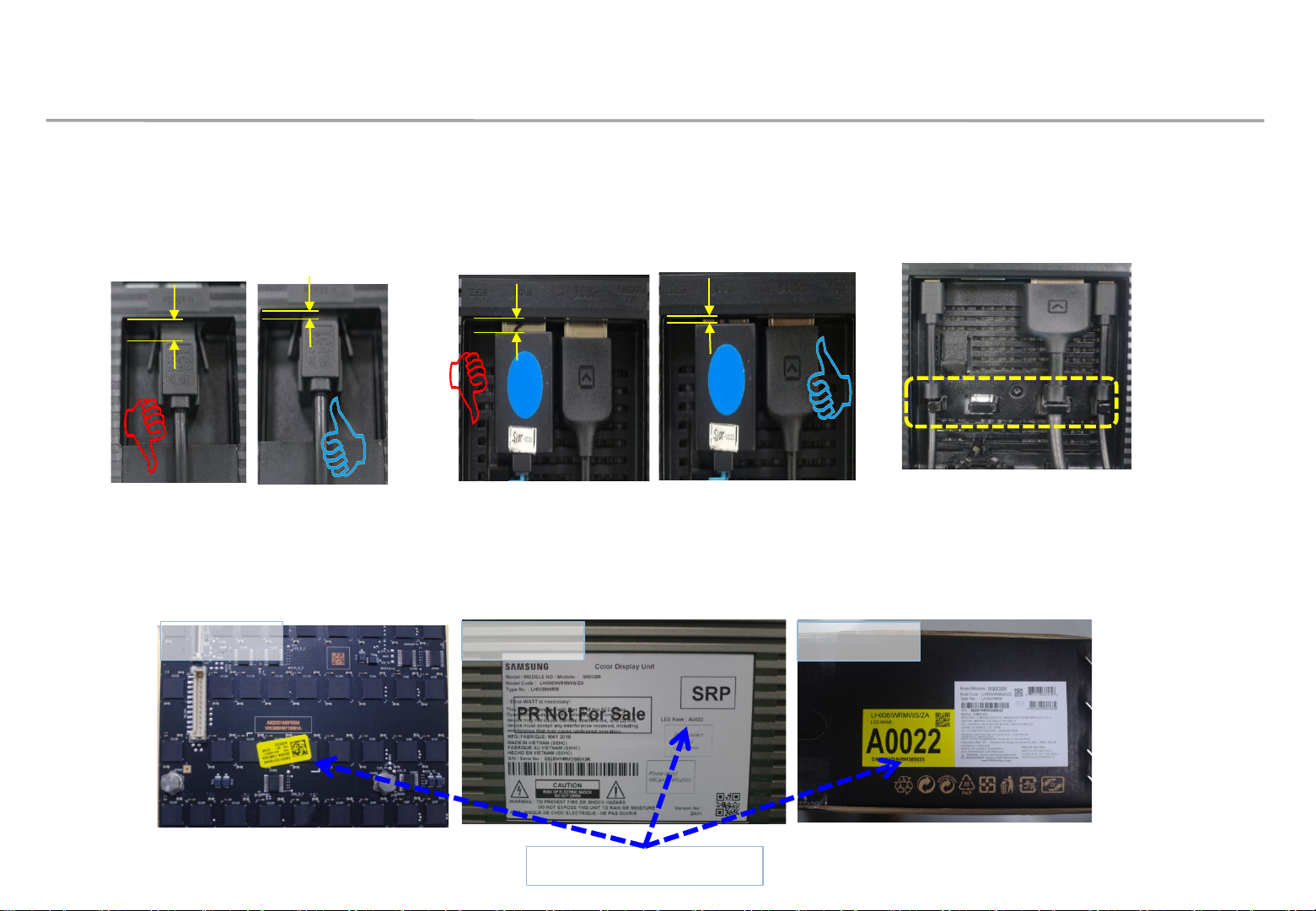

• The power cable must have a click sound, and the WDM module must be pushed into the rear fixing

holder.

The OCM cable and the USB-C cable should be inserted into the fixing holder.

0

AC Power Cable

WDM Module

OCM & USB-C Cable

• Do not mix cabinet which have different project number, each cabinet have its own project number

Module Cabinet

ex) Project No : A0022

Box

16

1. Product Information and Precautions for Installation

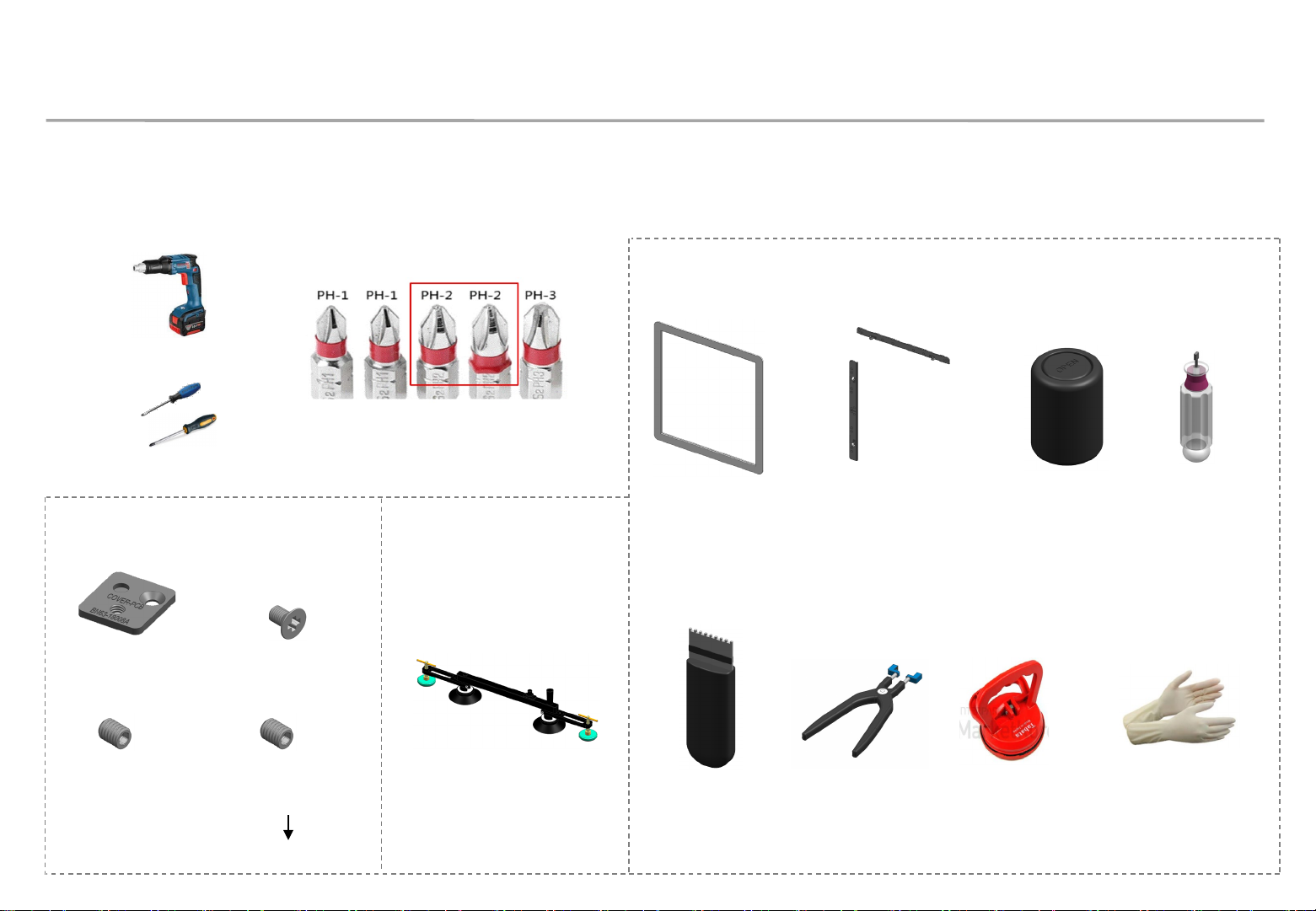

◇ Installation preparation

• It is on the Prepare Frame kit installation page(p.19) included in Frame Kit (IWJPA-WL008F).

Samsung Electronics

Electric driver

(-) (+) driver

• Provided in the set accessory

(BN96-49595A).

x3

Cover-PCB

(BN63-18008A)

M4, L5 M4, L6

x3

SCREW-MACHINE

(6001-002996)

※ Recommended standard

• Provided in accessory kit

(CY-WJRPWP).

※ It should be purchased

together when purchasing

the product separately.

x3

x3

x2

• Provided in accessory kit. (CY-WJJPWP).

※ It should be purchased together when purchasing the product separately.

PROTECTION

(BN81-17111A)

EDGE PROTECTION V/H

(BN81-17514A/BN81-17515A)

MAGNET JIG

(BN81-17114A)

x4

GAP TOOL

(BN81-17113A)

HOLDER-SCREW

(BN61-16452A)

※ wrapped in a small zipper bag.

HOLDER-SCREW

(BN61-16452B)

MODULE

SEPARATE JIG

(BN81-17904A)

Step control JIG

(BN81-17112A)

PLIER

(BN81-17541A)

Adsorber

(BN81-17124A)

Latex gloves

(RA00400E-002539)

17

Samsung Electronics

1. Product information and precautions for installation

2. Check point about the radiant heat

3. Frame installation

4. Preparation for cabinet installation

5. Cabinet + Frame installation

6. Cabinet + Frame + Bezel installation

7. Disassembly & Front Service

8. Media Box installation and connection

9. LSM Setting & Instructions

10.How to use The Wall – Setting

18

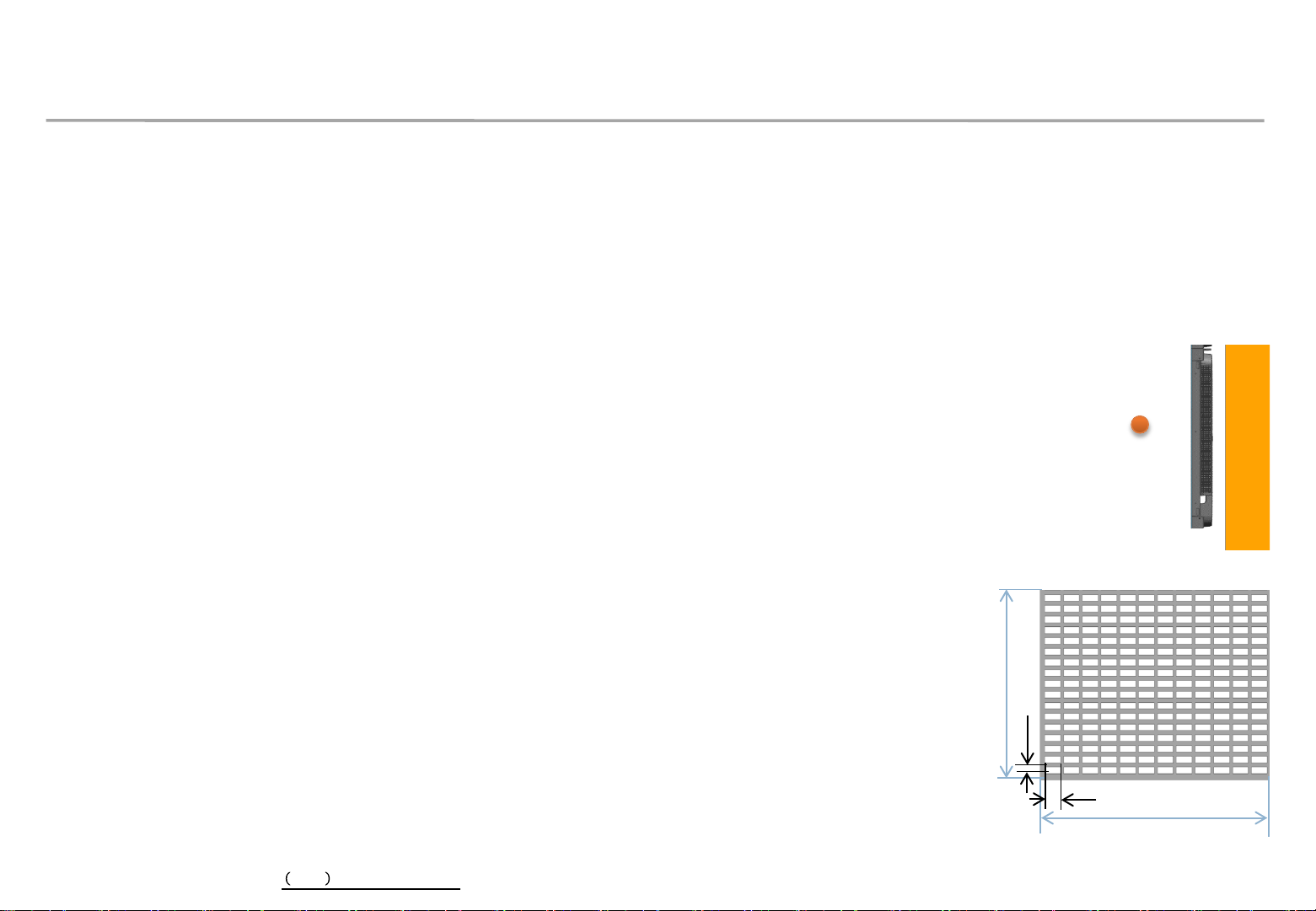

2. Check Point about the Radiant Heat

Samsung Electronics

Installation condition

- SAMSUNG FRAME usage condition

- The installation of direct solar window conditions is avoided. (If it is inevitable to install directly, make sure to contact our technical

team)

. Window side adjacent installation case,

. Weak solar survey at the time of work except noon time is allowed.

. If windows adjacent installation is inevitable, use UV blocking /light blocking film.

- Room temperature recommended using 0 to 25 ℃ conditions

- Effect of Air Conditioning System on Cold / Hot Wind

∙ If the cold / warm wind is the same air conditioning system,

Be careful not to let warm air get into the products

- Ambient temperature measurement position

∙ Measure at a distance of 0.3m from the center of the product

Air vent specification

- More than 60% opening rate, mesh air vent should be used

- Opening ratio (%) =

. ℎ

Ambient temperature

measurement position

B

d

c

wall

A

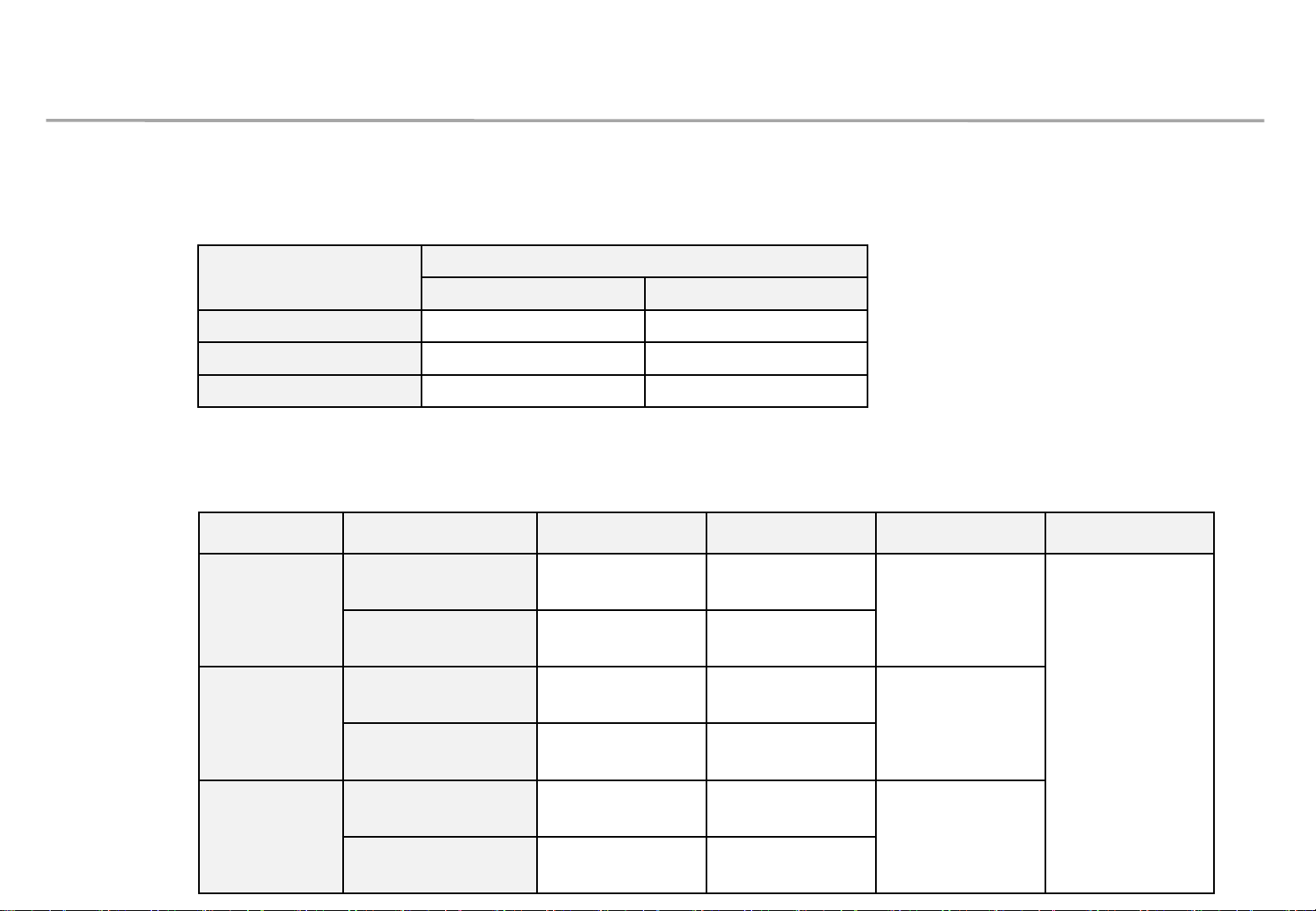

2. Check Point about the Radiant Heat

Samsung Electronics

Heat generation during screen installation (Additional air conditioning)

- Heat generation value is according to the screen size and should be added to the existing air conditioning amount.

Screen size

4K 2,720 9,281

6K 6,120 20,882

8K 10,880 37,124

Additional air conditioning load

Watt∙h BTU

Minimum height when installing the screen

- Minimum height considering upper and lower air vent height

Screen size Temperature Min. height Upper air vent Set height Lower air vent

Air conditioning

not operation

4K

Air conditioning

operation (25℃)

Air conditioning

not operation

6K

Air conditioning

operation (25℃)

2.41m 0.5m

2.01m 0.1m

3.32m 0.5m

2.93m 0.1m

1.81m

2.72m

0.1m

8K

Air conditioning

not operation

Air conditioning

operation (25℃)

4.23m 0.5m

3.63m

3.82m 0.1m

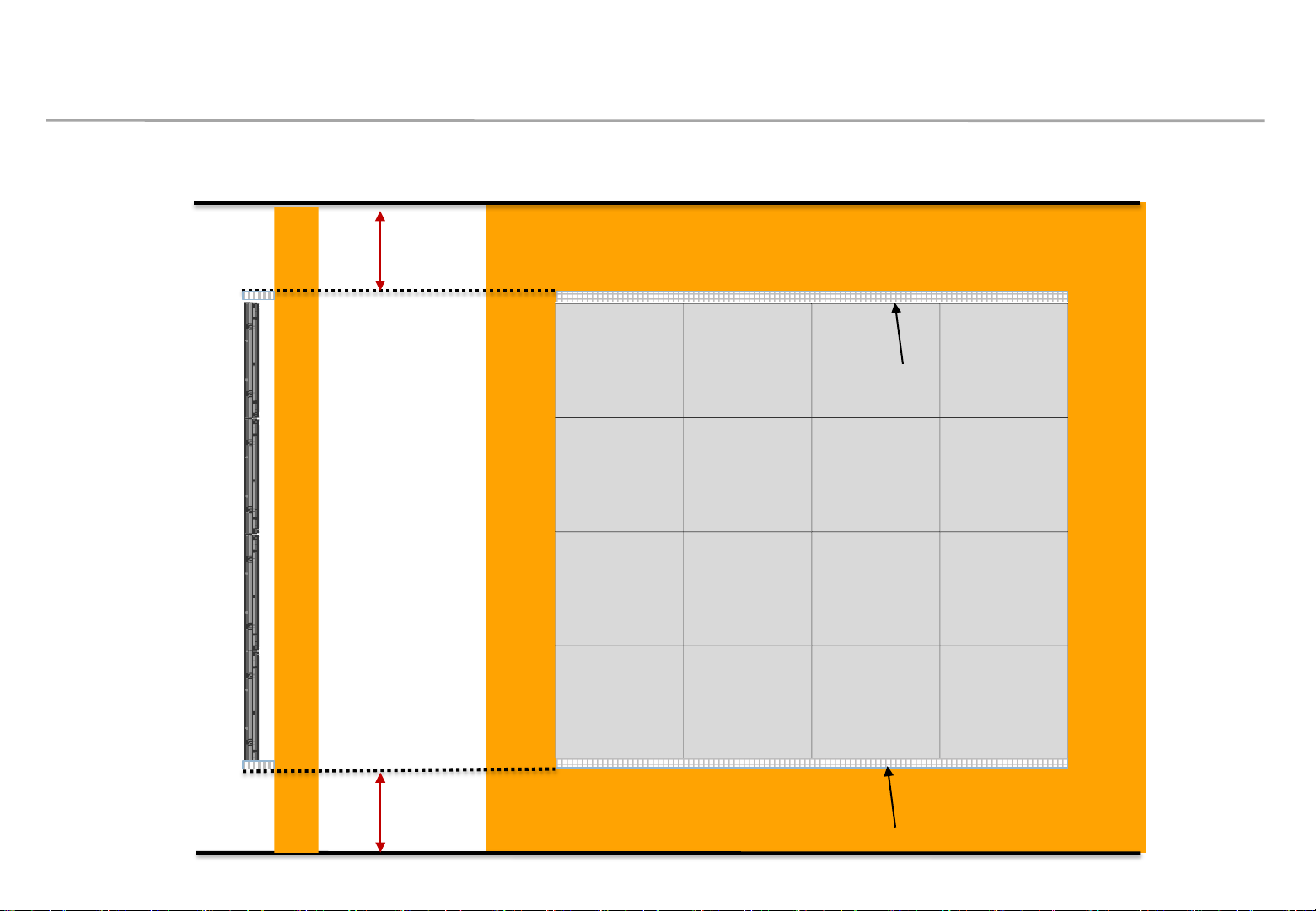

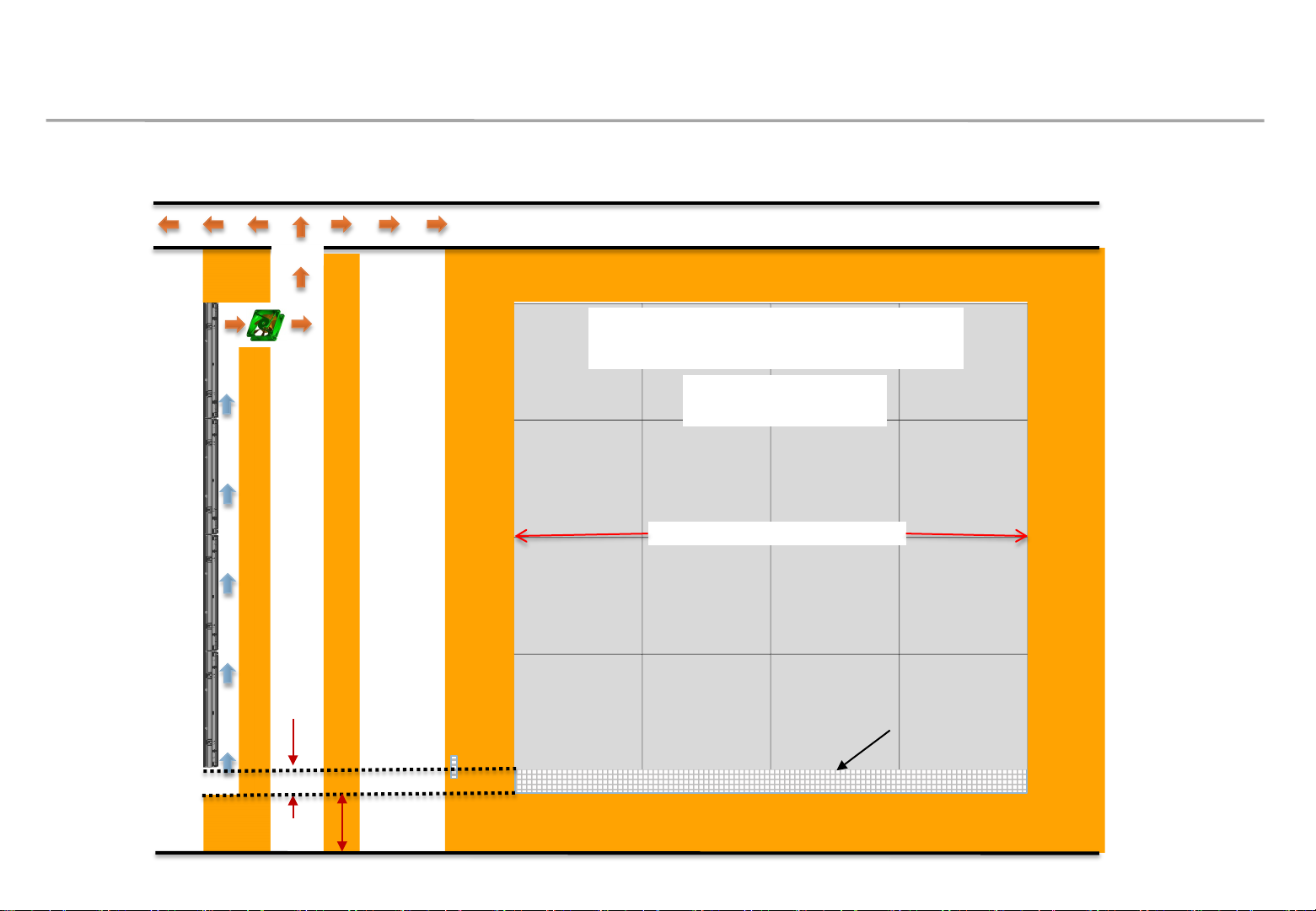

2. Check Point about the Radiant Heat– without Fan

Minimum spacing for wall mounting installation

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

Air vent area

Air vent area

WALL

(more than 60%

of opening rate)

Samsung Electronics

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

Air vent area

(more than 60%

of opening rate)

21

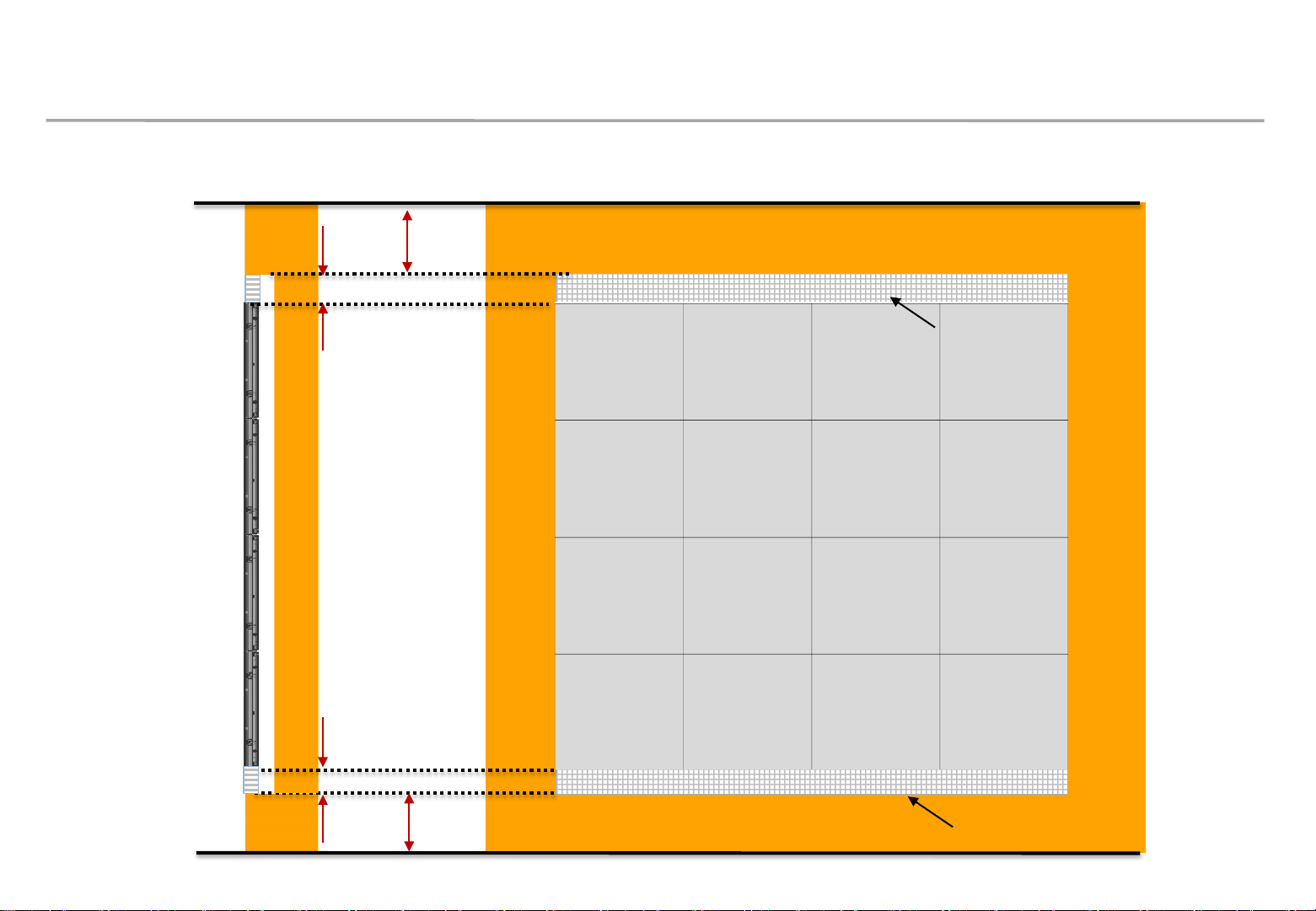

2. Check Point about the Radiant Heat– without Fan

Minimum spacing for processed installation

Min condition : 0mm (set ~ ceiling)

Recommended condition : more than 500mm

Samsung Electronics

Essential cond. : more than 30mm of 100% opening rate

WALL

Essential cond. : more than 30mm of 100% opening rate

Min condition: 0mm (set ~ floor)

Recommended condition : more than 500mm

Air vent area

Air vent area

22

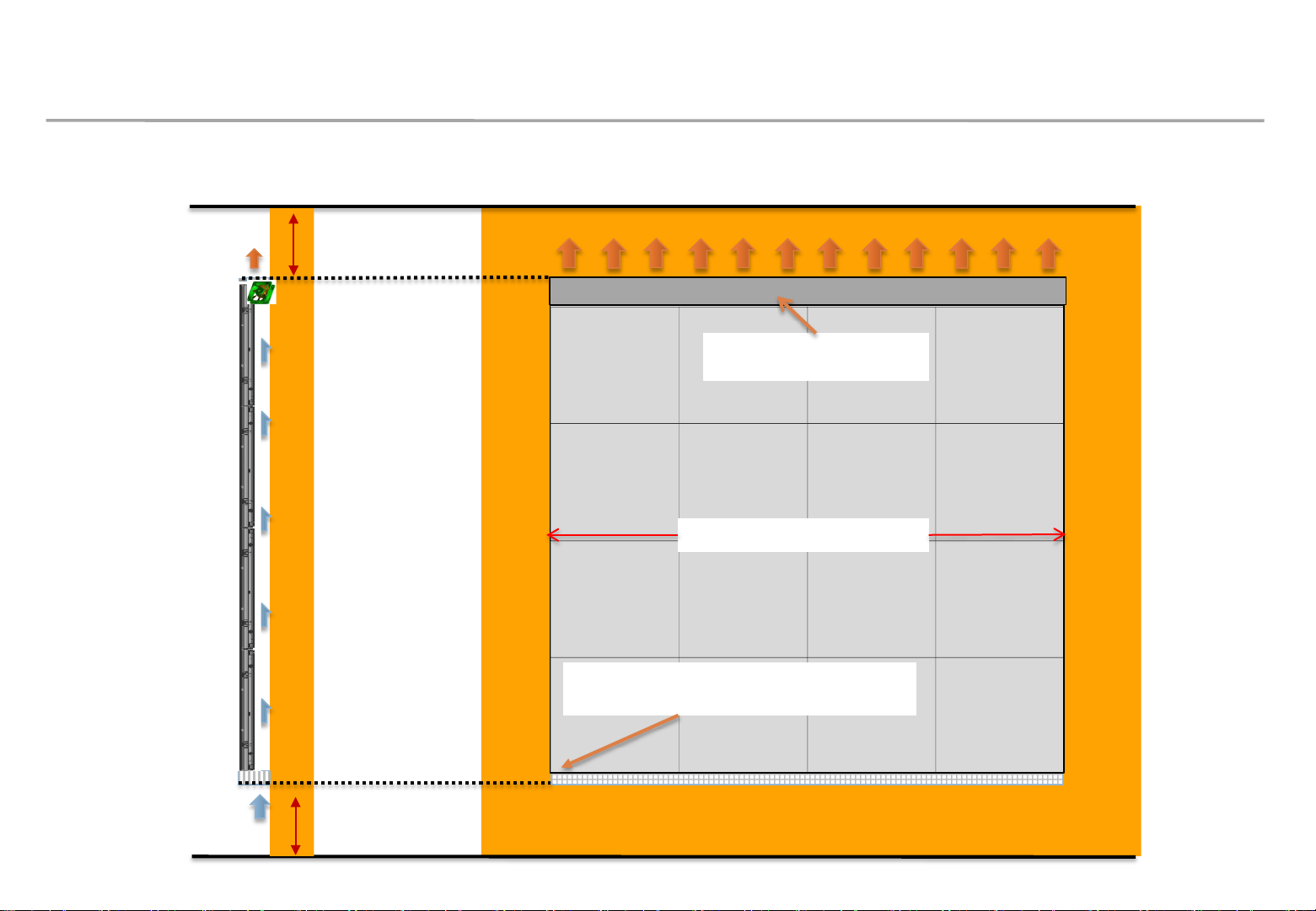

2. Check Point about the Radiant Heat– with Fan

Samsung Electronics

Example of minimum spacing and FAN allocation for wall mounting installation

Min condition : 30mm (set ~ ceiling)

Recommended condition : more than 500mm

Other parts except for FAN

area should be sealed

left and right should be sealed

WALL

left and right sealing

Air vent area should be mesh type with

an opening rate of more than 60%.

Min condition: 30mm (set ~ floor)

Recommended condition : more than 500mm

23

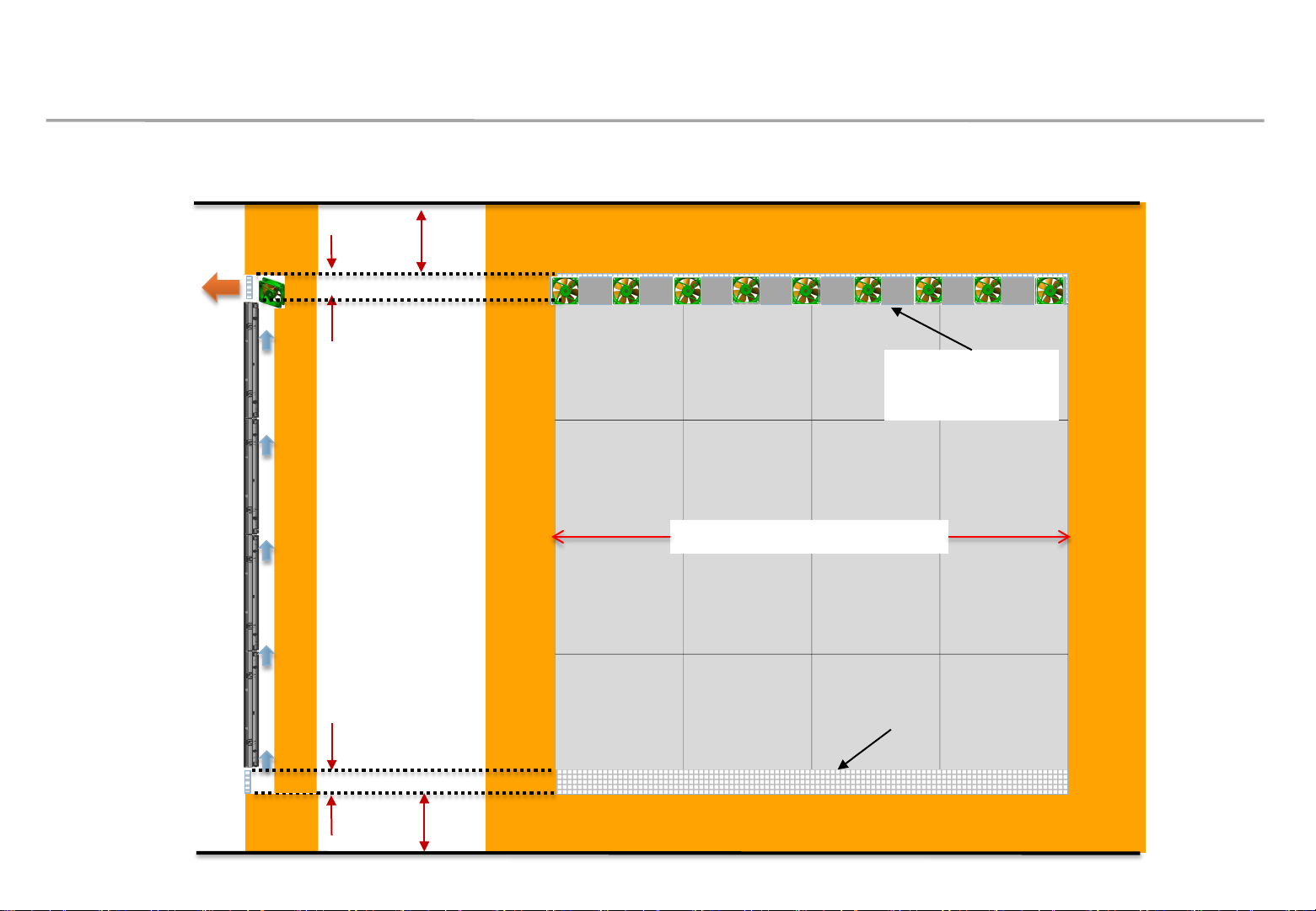

2. Check Point about the Radiant Heat– with Fan

Example of minimum spacing and fan allocation for recessed installation

Min condition: 0mm (set ~ ceiling)

Recommended condition : 500mm

Essential cond. : more than 30mm of 100% opening rate

Other parts except

for FAN area should

be sealed

Samsung Electronics

WALL

Essential cond. : more than 30mm of 100% opening rate

Min condition: 0mm (set ~ floor)

Recommended condition : 500mm

left and right should be sealed.

※ Vent and interior finishing work will proceed after screen installation

Air vent area

24

2. Check Point about the Radiant Heat– with Fan

Example of minimum spacing and placement during rear exhaust

Ambient temperature on the back of

the wall should be less than 30 ℃.

Other parts except for

FAN should be sealed.

WALL

left and right should be sealed.

Samsung Electronics

Essential cond. : more than 30mm of 100% opening rate.

Min condition: 0mm (set ~ floor)

Recommended condition : 500mm

Air vent area

25

Samsung Electronics

1. Product information and precautions for installation

2. Check point about the radiant heat

3. Frame installation

4. Preparation for cabinet installation

5. Cabinet + Frame installation

6. Cabinet + Frame + Bezel installation

7. Disassembly & Front Service

8. Media Box installation and connection

9. LSM Setting & Instructions

10.How to use The Wall – Setting

26

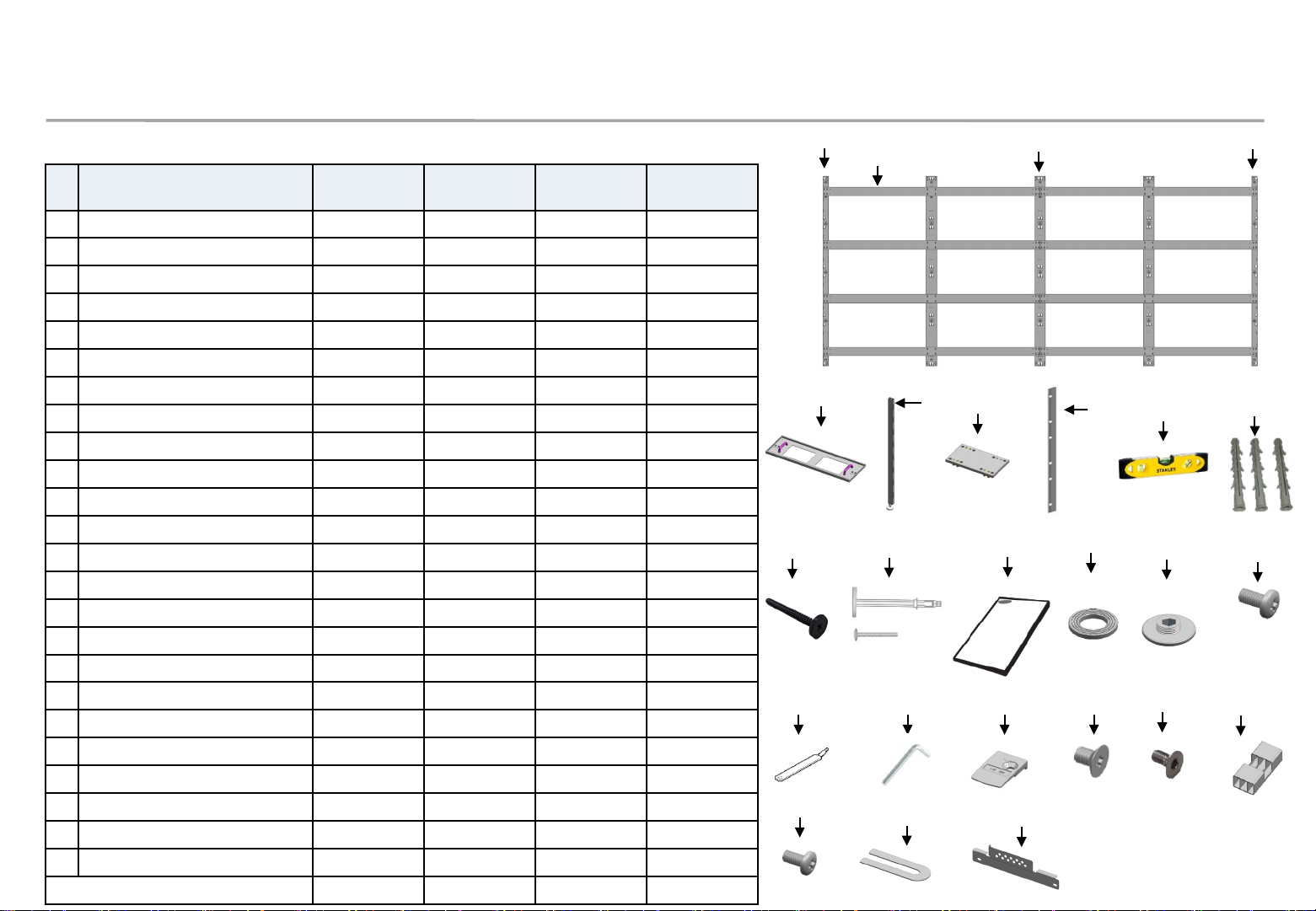

3. Frame Installation

Samsung Electronics

◇ Frame Kit Composition (1/2)

No Item

ⓐ

ⓑ

ⓒ BRACKET MIDDLE (vertical) - 2 3 4

ⓓ BRACKET JIG - 1 1 1

ⓔ LEVELER - 2 2 2

ⓕ JOINT V 2 3 4 5

ⓖ

ⓗ Level - 1 1 2

ⓘ

ⓙ

ⓚ

ⓛ

ⓜ

ⓝ

ⓞ

ⓟ

ⓠ

ⓡ

ⓢ

ⓣ

ⓤ

ⓥ

ⓦ

ⓧ

BRACKET H (horizontal)

BRACKET SIDE (vertical)

ALIGN JIG

Anchor

SCREW-MACHINE

DRY WALL SCREW 4 10 18 28

MANUAL-INSTALL 1 1 1 1

TAPE WASHER

HOLDER LEVEL

SCREW-MACHINE(JOINT

DELPHINUS

hexagon L wrench 2mm/6mm 1/1 1/1 1/1 1/1

HODER-PCB

SCREW-MACHINE

SCREW-MACHINE

HOLDER-STAND - 2 2 4

SCREW-MACHINE 5 5 5 5

SPACER-ETC 5 10 15 20

BRACKET-COVER 1 1 1 1

installation Size (mm)

/FRAME) 5/18 10/28 14/66 18/102

VG-LFR08SWW

( 1 X 1 )

2 2 6 8

2 2 2 2

- - 1 1

4 10 18 28

4 10 18 28

4 8 16 26

4 4 8 12

1 1 1 1

15 30 45 60

15 30 45 60

15 30 45 60

806.4x453.6 1612.8x907.2 2419.2*1360.8 3225.6*1814.4

VG-LFR08FWW

( 2X 2 )

VG-LFR08TWW

( 3 X 3 )

VG-LFR08UWW

( 4 X 4 )

(Units)

ⓑ

ⓒ

ⓐ

ⓙ

ⓓ

ⓚ

ⓔ

ⓕ

ⓛ

ⓟ ⓠ ⓡ ⓢ

ⓥ

M4

ⓦ

ⓧ

FH,M4,L6

ⓜ

ⓖ

ⓗ

ⓝ

ⓣ

FH,M3,L6

ⓑ

ⓘ

ⓞ

M6, L12

ⓤ

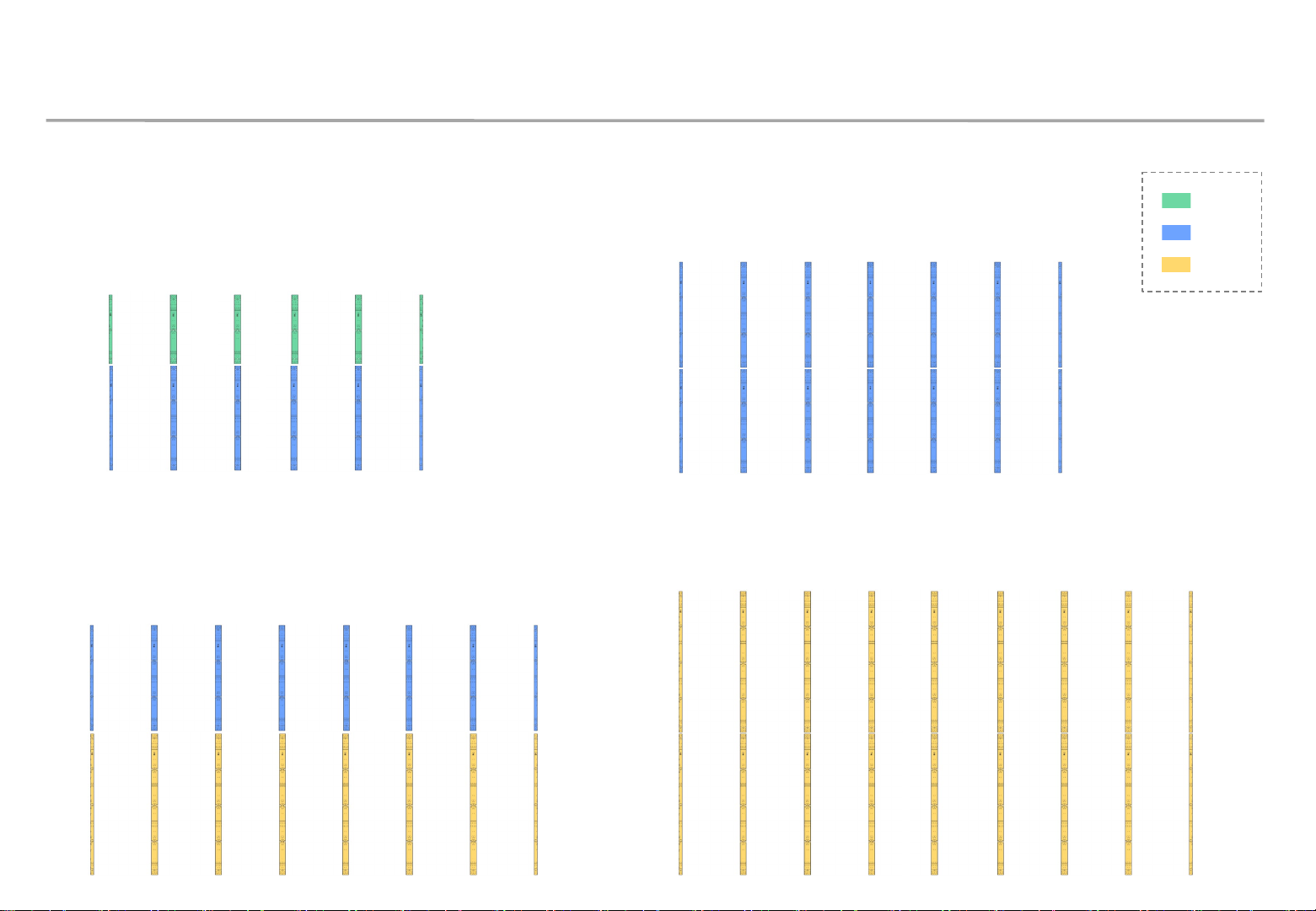

3. Frame Installation

◇ Frame Kit Composition (2/2)

● 5X5 : 2 of 2X2 & 2 of 3X3 ● 6X6 : 4 of 3X3

Samsung Electronics

2X2

3X3

4X4

● 7X7 : 2 of 3X3 & 2 of 4X4

● 8X8 : 4 of 4X4

28

3. Frame Installation

Samsung Electronics

① Assemble the Bracket Side / Middle and Bracket H.

- Place the bracket side / Middle on the floor and assemble it by inserting the Stud-Pem of the bracket H. (Fig.1)

. Bracket Side: Both Side Frames, Bracket Middle : Middle Frame

- Assemble using M6 Screw. (Fig.2)

ⓒⓒ’ ⓒ’

ⓐ

ⓑ,ⓒ

Fig.1 Bracket Side / Middle and Bracket H Assembly

ⓑ

ⓐ

ⓒ’

ⓐ

Fig.2 Screw connection

M6,L8

ⓒ

ⓐ ⓐ

29

Loading...

Loading...