Samsung DX8-AC, DX8-A, DX7-AC, DX7-A Service Manual

DX7-A/DX7-AC

DX8-A/DX8-AC

1. Disassembly and Reassembly

2. Alignment and Adjustment

VHS DECK CONTENTS

MECHANICAL

Manual

3 File with the SERVICE MANUAL.

© Samsung Electronics Co., Ltd. NOV. 1997 AC68-20392A

Samsung Electronics 1-1

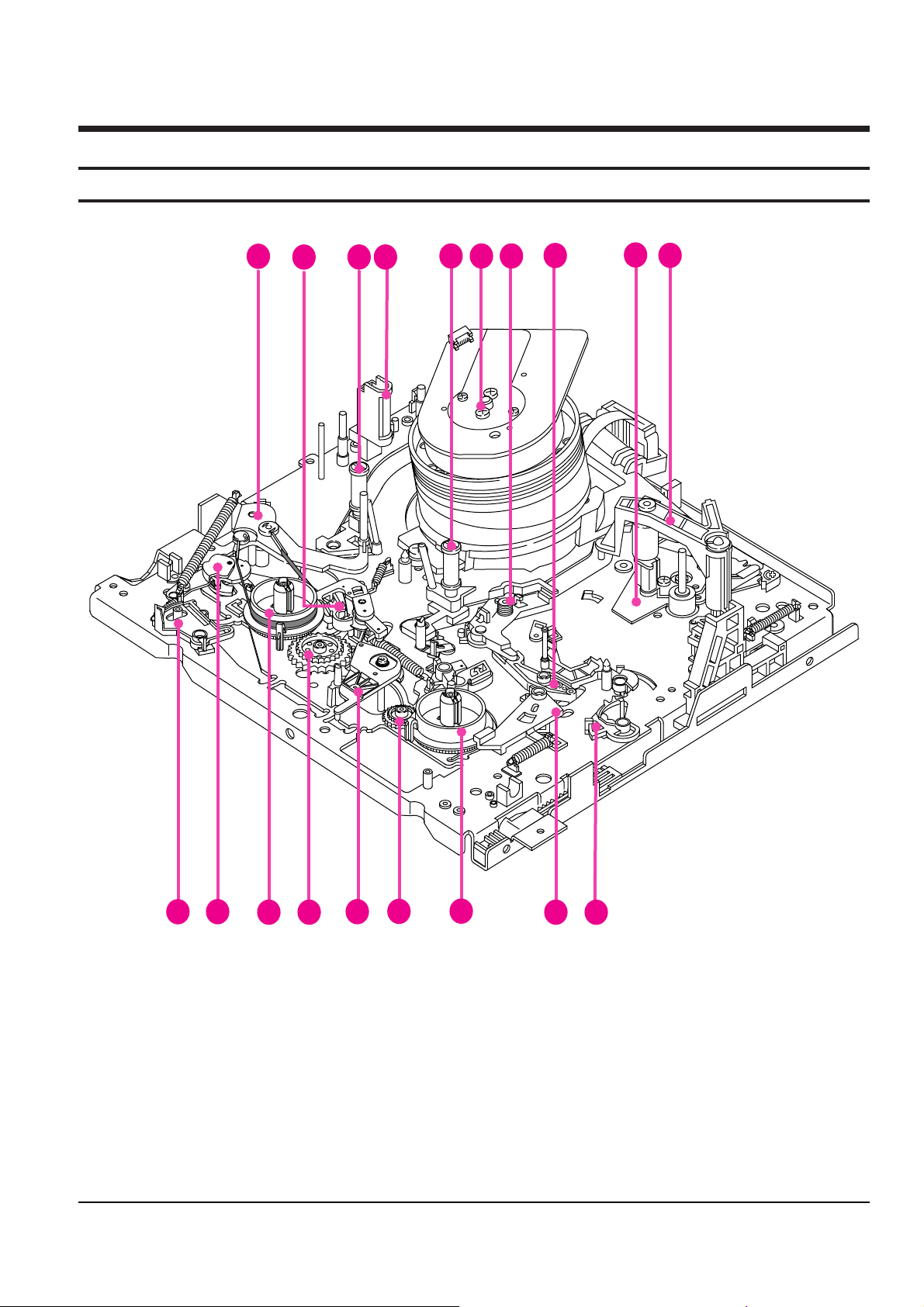

1-1 Deck Parts Locations

1-1-1 Deck (Top View)

1

2

3 4

5

8

9

10

11

12

13

14

15

1617

18

19

76

Fig. 1-1 Deck Top Parts Location (DX7-A/DX8-A DECK ONLY)

1. ARM TENSION FULL ASS’Y

2. BRAKE MAIN “L” ASS’Y

3. GUIDE ROLLER ASS’Y “T”

4. FULL ERASE HEAD

5. GUIDE ROLLER ASS’Y “S”

6. CYLINDER ASS’Y

7. LEVER PINCH COMP ASS’Y

8. LEVER PINCH CAM

9. FULL ACE HEAD AAS’Y

10. UNIT PINCH ROLLER ASS’Y

11. LEVER REVIEW

12. BRAKE SUB “R” ASS’Y

13. REEL DISK “R” ASS’Y

14. GEAR RELAY “T” ASS’Y

15. IDLER ASS’Y

16. GEAR RELAY “S” ASS’Y

17. REEL DISK “L” ASS’Y

18. LEVER JOG ASS’Y

(DX8-A/AC ONLY)

19. LEVER REC SWITCH

1. Disassembly and Reassembly

Disassembly and Reassembly

1-2 Samsung Electronics

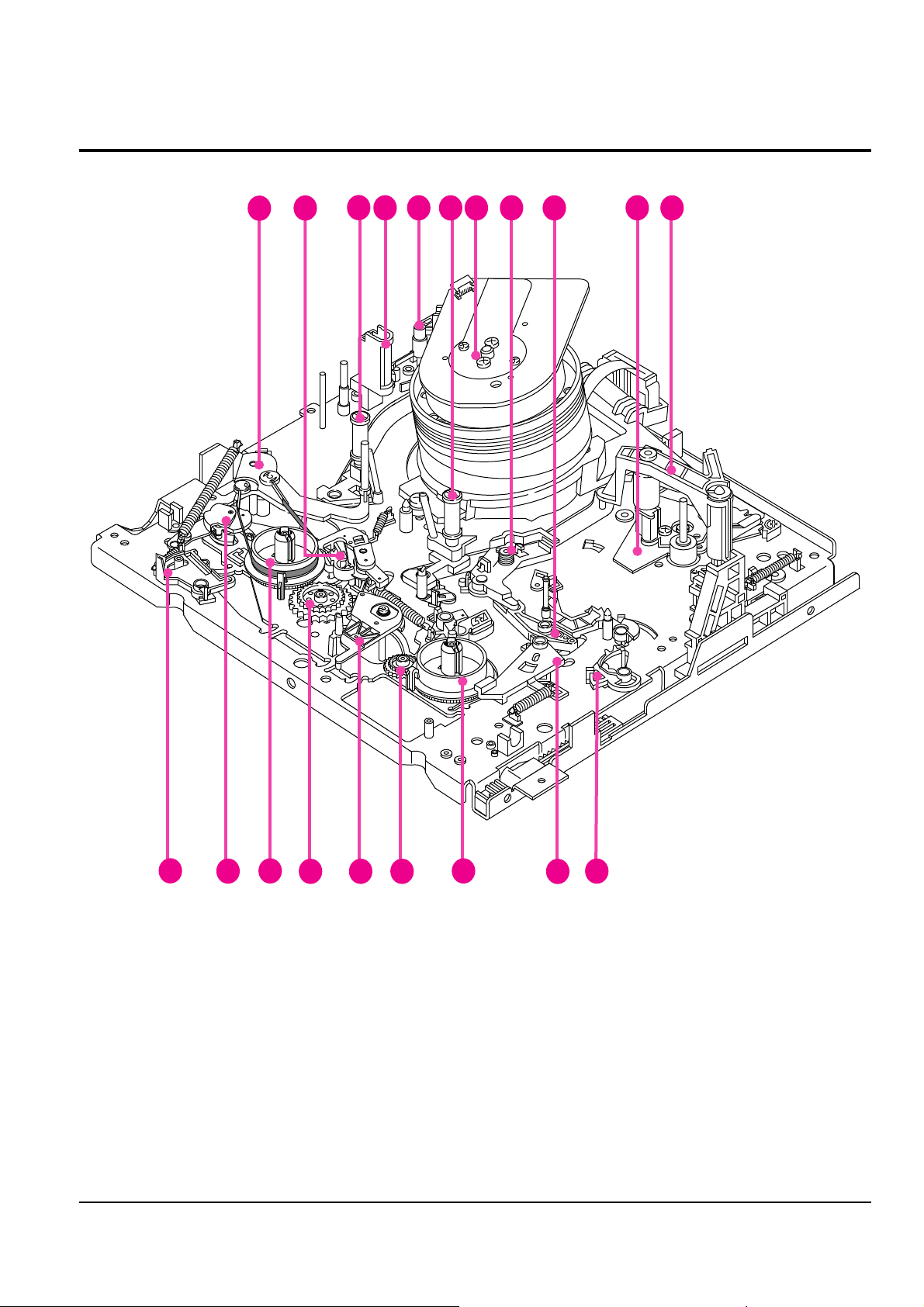

1-1-2 Deck (Top View)

1

2

3

465

7

8

9

10

11

12

13

14

151617

18

19

20

Fig. 1-2 Deck Top Parts Location (DX7-AC/DX8-AC DECK ONLY)

1. ARM TENSION FULL ASS’Y

2. BRAKE MAIN “L” ASS’Y

3. GUIDE ROLLER ASS’Y “T”

4. FULL ERASE HEAD

5. HEAD CLEANER ASS’Y

(DX7-AC/DX8-AC ONLY)

6. GUIDE ROLLER ASS’Y “S”

7. CYLINDER ASS’Y

8. LEVER PINCH COMP ASS’Y

9. LEVER PINCH CAM

10. FULL ACE HEAD AAS’Y

11. UNIT PINCH ROLLER ASS’Y

12. LEVER REVIEW

13. BRAKE SUB “R” ASS’Y

14. REEL DISK “R” ASS’Y

15. GEAR RELAY “T” ASS’Y

16. IDLER ASS’Y

17. GEAR RELAY “S” ASS’Y

18. REEL DISK “L” ASS’Y

19. LEVER JOG ASS’Y

(DX8-A/AC ONLY)

20. LEVER REC SWITCH

Disassembly and Reassembly

Samsung Electronics 1-3

1-1-3 Deck (Bottom View)

1

2

3

4

6

5

7

8

9

10

11

13

12

Fig. 1-3 Deck Bottom Parts Location

1. LEVER SLIDE PINCH

2. BELT CAPSTAN

3. MOTOR D.D CAPSTAN

4. BRAKE CAPSTAN ASS’Y

5. GEAR LOADING “R” ASS’Y

6. MOTOR CYLINDER

7. GEAR LOADING “L” ASS’Y

8. SLIDE MAIN

9. LEVER REC SWITCH

10. LEVER IDLER CHANGE

11. CLUTCH ASS’Y

12. UNIT LOADING

13. GEAR MASTER

Disassembly and Reassembly

1-4 Samsung Electronics

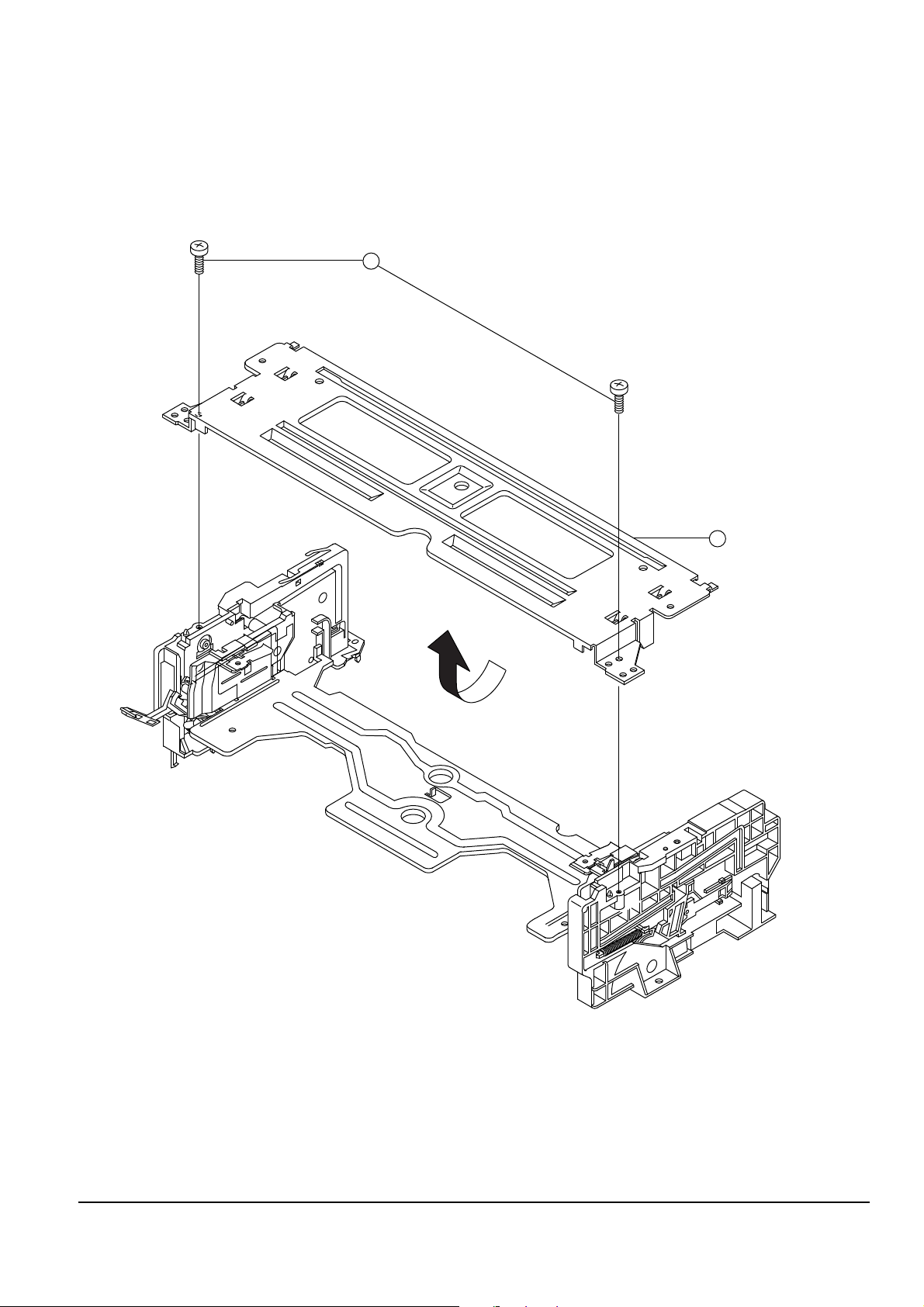

1-1-4 Housing

1

2 3

4

6

5

Fig. 1-4 Housing Parts Location

1. CHASSIS SIDE “L” ASS’Y

2. UPPER CHASSIS

3. CHASSIS SIDE “R” ASS’Y

4. SHAFT ARM ASS’Y

5. HOLDER CASSETTE ASS’Y

6. LEVER DOOR

Disassembly and Reassembly

Samsung Electronics 1-5

1-2 Housing Assembly

1-2-1 Removal from Main Base

1. Remove 3 Screws !.

2. Lift the Housing AssÕy in the direction of arrow ÒBÓ, while pushing the tab @ in the direction of arrow ÒAÓ.

(Refer to detail drawing)

3 SCREWS

1

MAIN BASE

TAB

"A"

2

Fig. 1-5 Housing Ass’y Removal from Main Base

Disassembly and Reassembly

1-6 Samsung Electronics

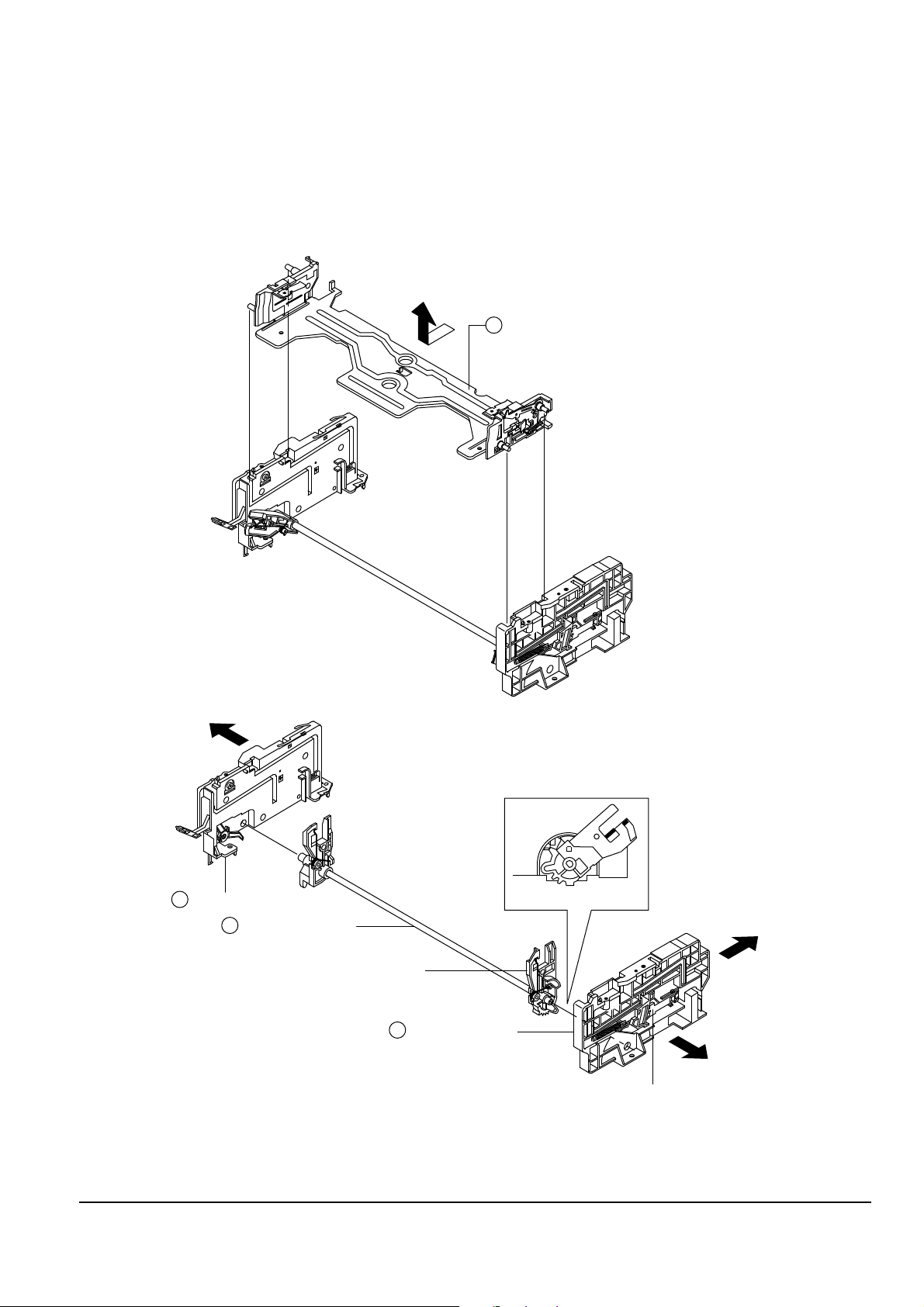

1-2-2 Diassembly

2 SCREWS

UPPER CHASSIS

CHASSIS SIDE "R"

HOLDER

CASSETTE ASS'Y

SHAFT ARM ASS'Y

CHASSIS SIDE "L"

Fig. 1-6 Housing Ass’y Removal

Disassembly and Reassembly

Samsung Electronics 1-7

1-2-3 Upper Chassis Removal

1. Remove 2 Screws !.

2. Lift the Upper Chassis @ in the direction of arrow ÒAÓ.

2 SCREWS

UPPER CHASSIS

2

"A"

1

Fig. 1-7 Upper Chassis Removal

Disassembly and Reassembly

1-8 Samsung Electronics

1-2-4 Holder Cassette Ass’y and Chassis Side L/R Removal

1. Lift the Cassette Holder ! in the direction of arrow ÒAÓ (Refer to Fig. A).

2. Remove the Side Chassis ÒLÓ @ and ÒRÓ # from Arm Shaft AssÕy $ in the direction of arrow ÒBÓ, ÒCÓ

(Refer to Fig. B).

HOLDER CASSETTE ASS'Y

"A"

1

2

4

SHAFT ARM ASS'Y

CHASSIS SIDE "L"

3

CHASSIS SIDE "R"

SLIDE DAMPER

"B"

<Fig. A>

<Fig. B>

<DETAIL>

(REASSEMBLY OF CHASSIS

SIDE "R" & SHAFT ARM "R")

(SIDE VIEW)

"C"

"D"

SHAFT ARM "R"

Fig. 1-8 Holder Cassette Ass’y and Chassis Side L/R

Disassembly and Reassembly

Samsung Electronics 1-9

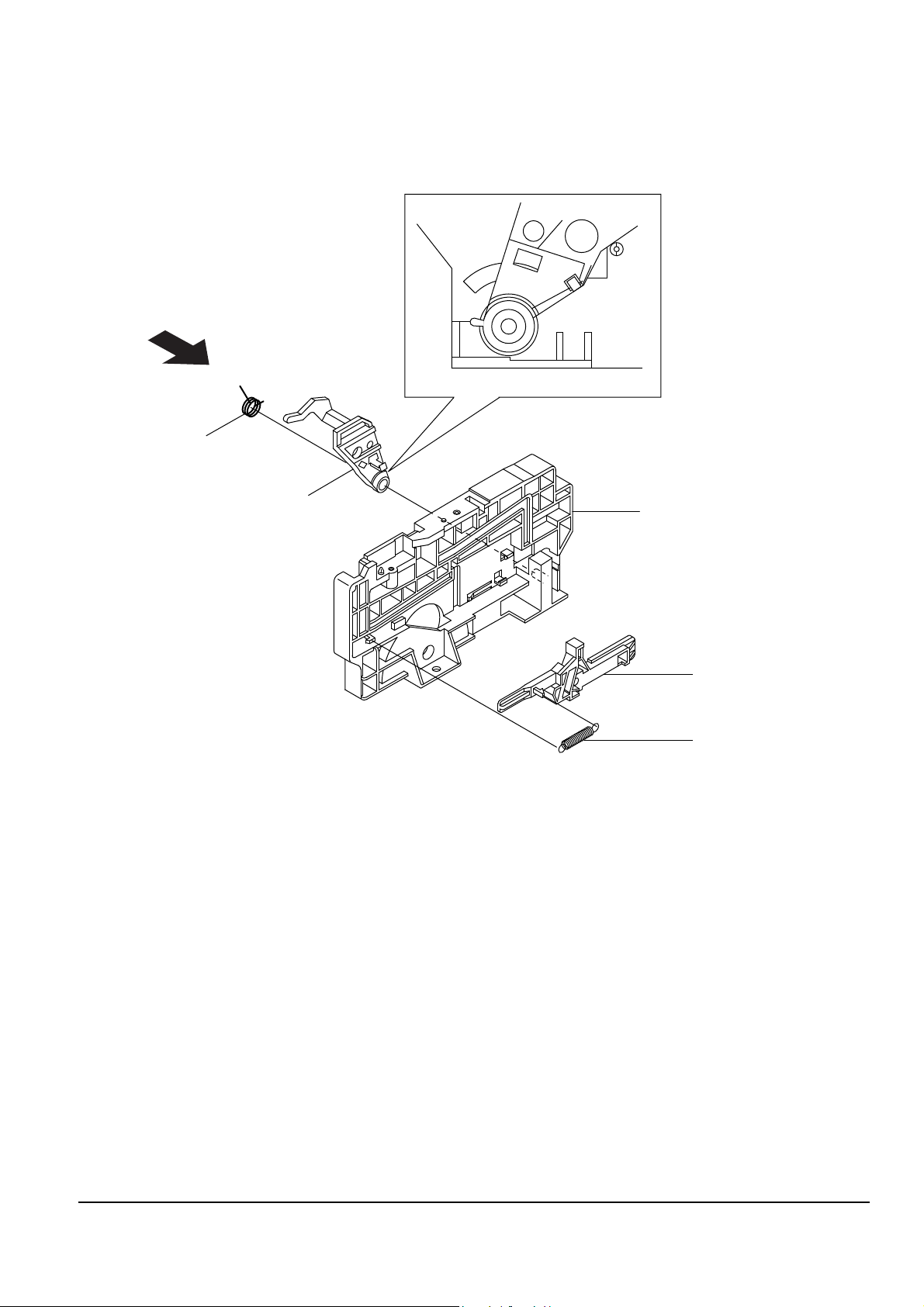

1-2-5 Chassis Side “R” Parts Locations

CHASSIS SIDE "R"

(SIDE VIEW "A")

SLIDE DAMPER

LEVER-LID OPENDER

"A"

SPRING-SLIDE DAMPER

SPRING-LID OPENDER

Fig. 1-9 Chassis Side “R” Parts Locations

Note : If you operate the deck when the Cassette AssÕy Holder is removed, the Arm Shaft ÒRÓ and the Damper

Slide are not returned to their original positions. If this happens by accident, push the Damper Slide of

Side Chassis ÒRÓ in the direction of arrow ÒDÓ, and return the Damper Slide in the reverse direction of

arrow ÒDÓ when the Arm Shaft AssÕy is in eject mode.

Disassembly and Reassembly

1-10 Samsung Electronics

1-2-6 Slide Damper Removal

1. Remove the Slide Damper Spring !.

2. Push the Stopper # of the Side Chassis ÒRÓ $. Move the Damper Slide @ in the direction of arrow.

3. Align the Damper Slide @ with the chassis side tab (as shown detail drawing).

CHASSIS SIDE "R"

CHASSIS SIDE "R" TAB

SLIDE DAMPER

4

STOPPER

3

SLIDE DAMPER

2

SPRING- SLIDE DAMPER

1

Fig. 1-10 Slide Damper Removal

Disassembly and Reassembly

Samsung Electronics 1-11

1-3 Cylinder Ass’y

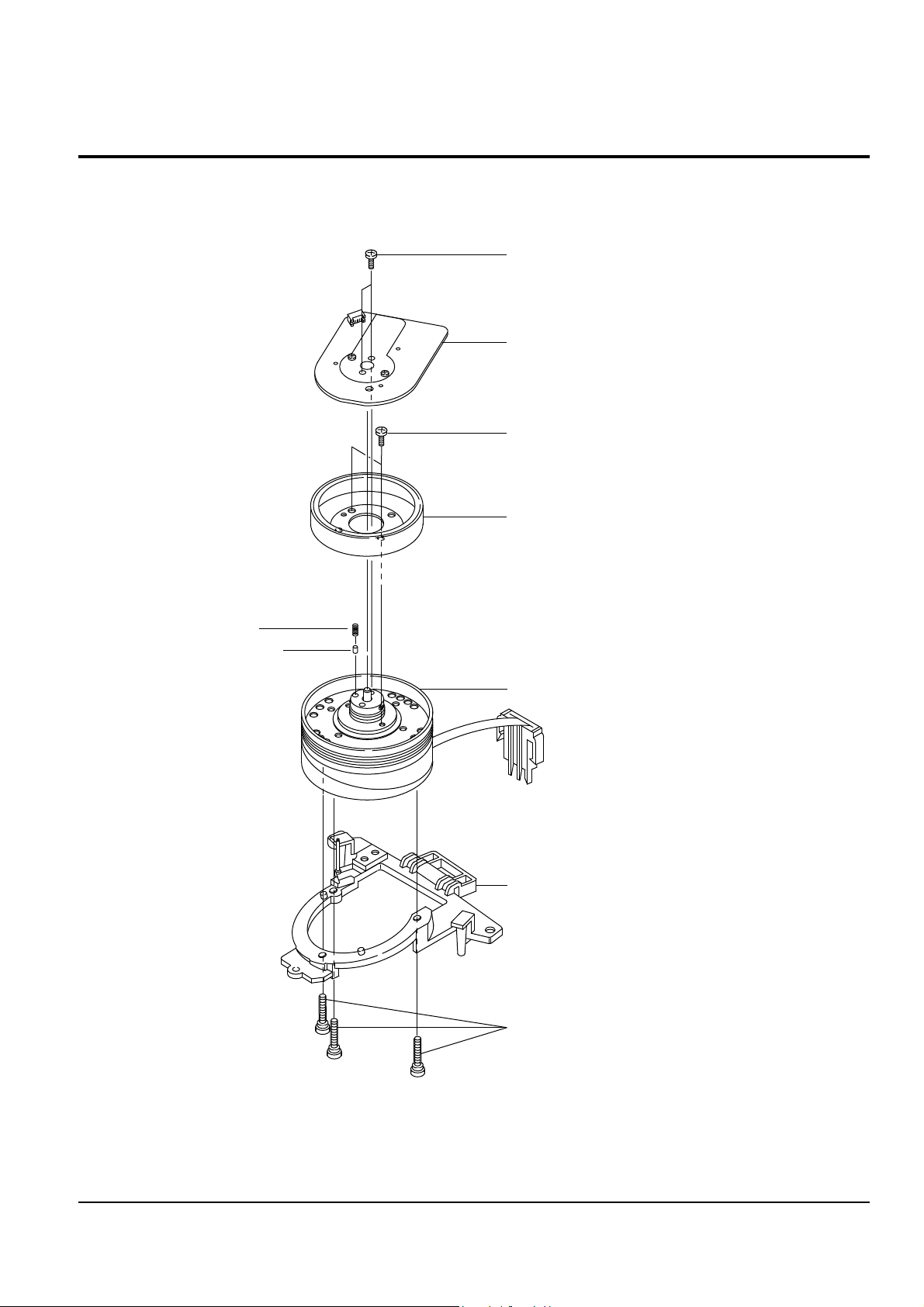

1-3-1 Exploded View of Cylinder Ass’y

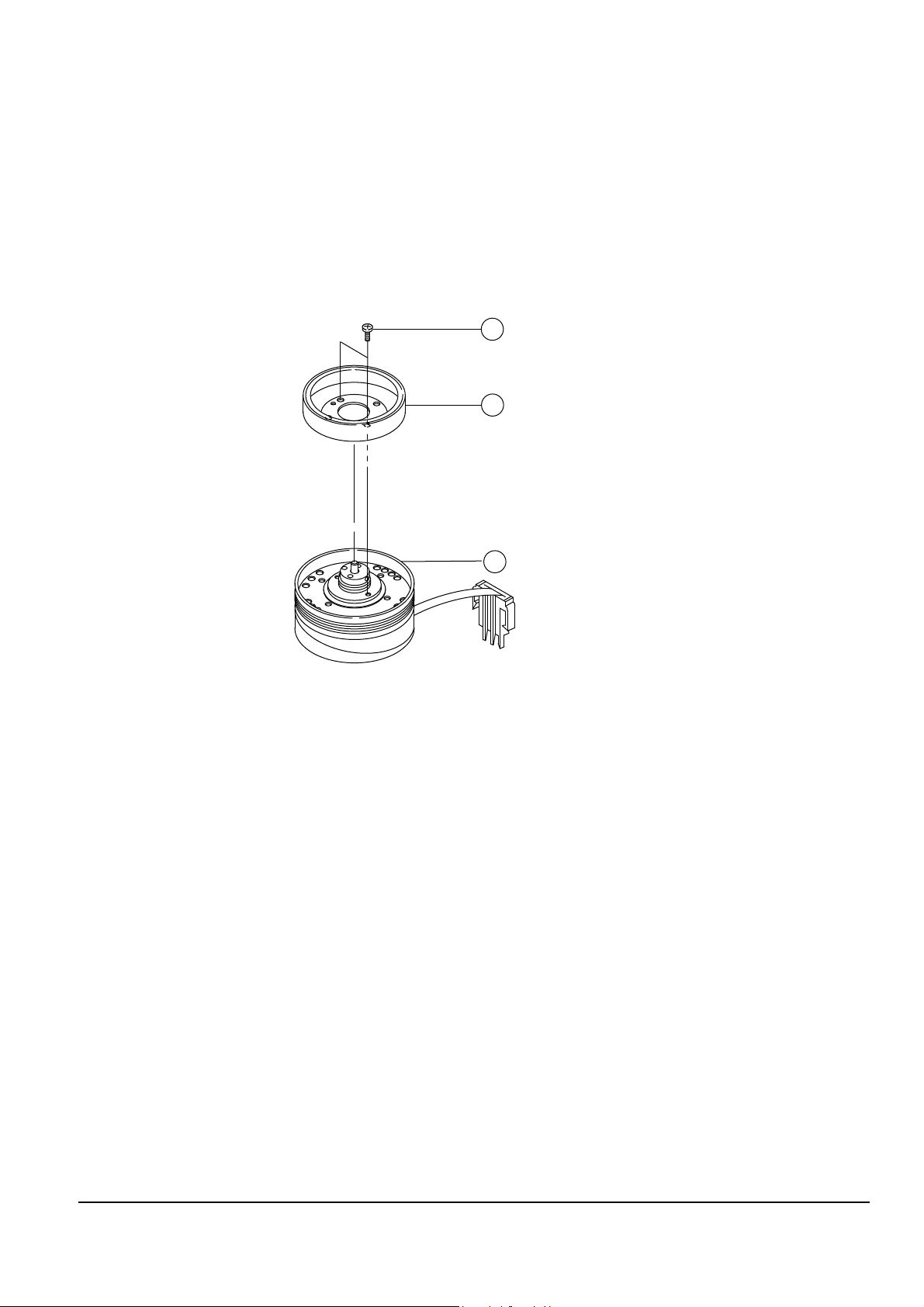

ASS'Y MOTOR - ROTOR

ASS'Y - SUB CYLINDER

2 SCREWS

3 SCREWS

2 SCREWS

ASS'Y - MOTOR STATOR

ASS'Y - BASE CYLINDER

SPRING

CARBON TIP

Fig. 1-11 Expleded View of Cylinder Ass’y

Disassembly and Reassembly

1-12 Samsung Electronics

1-3-2 Stopper Tape Removal (Only for Deck : DX7-A/DX8-A)

1. Release 1 tab ! in the direction of arrow ÒAÓ. (Refer to detail drawing)

2. Lift the Tape Stopper @ in the direction of arrow ÒBÓ.

"B"

TAB

<DETAIL>

"A"

1

STOPPER TAPE

2

Fig. 1-12 Stopper Tape Removal

1-3-3 Head Cleaner Ass’y Removal (Only for Deck : DX7-AC/DX8-AC)

1. Release 1 tab ! in the direction of arrow ÒAÓ. (Refer to detail drawing)

2. Lift the Head Cleaner @ in the direction of arrow ÒBÓ.

ASS'Y HEAD CLEANER

"B"

2

TAB

<DETAIL>

"A"

1

Fig. 1-13 Head Cleaner Ass’y Removal

Note: Stopper tape has deleted from JAN.1998

Disassembly and Reassembly

Samsung Electronics 1-13

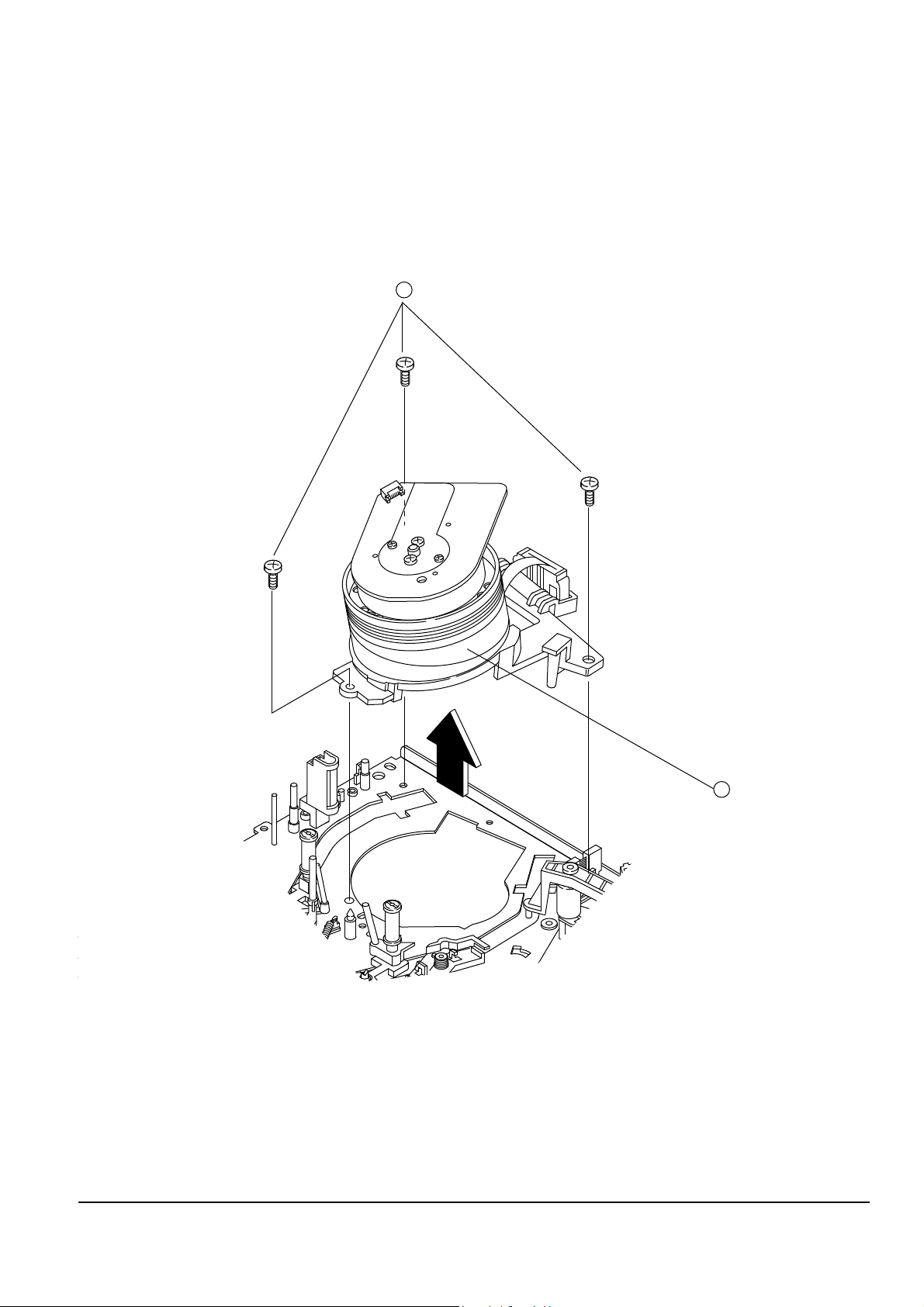

1-3-4 Cylinder Ass’y Removal from Main Base

1. Remove 3 Screws ! holding the Main Base and the Cylinder AssÕy.

2. Lift the Cylinder AssÕy @ in the direction of arrow.

Note : Do not touch the video heads during removal or installation.

3 SCREWS

1

CYLINDER ASS'Y

2

Fig. 1-14 Cylinder Ass’y Removal from Main Base

Disassembly and Reassembly

1-14 Samsung Electronics

1-3-5 Holder FPC Removal

1. Release the Holder FPC tab holding the Cylinder Base @ in the direction of arrow. (Refer to detail drawing)

2. Disconnect the Holder FPC ! from the Cylinder Base @.

Note : When disconnecting the FPC Holder ! from the Cylinder Base @ :

Take care not to disconnect the FPC cable from the FPC Holder (The FPC cable is very short).

HOLDER FPC

CYLINDER BASE

CYLINDER BASE

HOLDER FPC

<DETAIL : BOTTOM VIEW>

2

1

Fig. 1-15 Head Brush and Holder FPC Removal

Disassembly and Reassembly

Samsung Electronics 1-15

1-3-6 Cylinder Ass’y Removal from Cylinder Base

1. Remove 3 Screws ! from the Cylinder Base @.

2. Lift the Cylinder AssÕy # from the Cylinder Base @ in the direction of arrow.

CYLINDER SUB ASS'Y

CYLINDER BASE

3 SCREWS

2

1

3

Fig. 1-16 Cylinder Ass’y Removal from Cylinder Base

Disassembly and Reassembly

1-16 Samsung Electronics

1-3-7 Motor Stator Removal

1. Remove 2 Screws !.

2. Remove the Motor Stator @ from the Cylinder Sub AssÕy %.

MOTOR - STATOR

CYLINDER SUB ASS'Y

2

2SCREWS

1

5

SPRING

CARBON TIP

3

4

Fig. 1-17 Motor Stator Removal

Note : When disassembling the Motor-Stator, take extreme care not to loose the carbon-tip and

spring.

Disassembly and Reassembly

Samsung Electronics 1-17

1-3-8 Motor Rotor Removal

1. Remove 2 Screws !.

2. Lift The Motor Rotor@.

MOTOR - ROTOR

DRUM SUB ASS'Y

2

3

2 SCREWS

1

Fig. 1-18 Motor Rotor Removal

Disassembly and Reassembly

1-18 Samsung Electronics

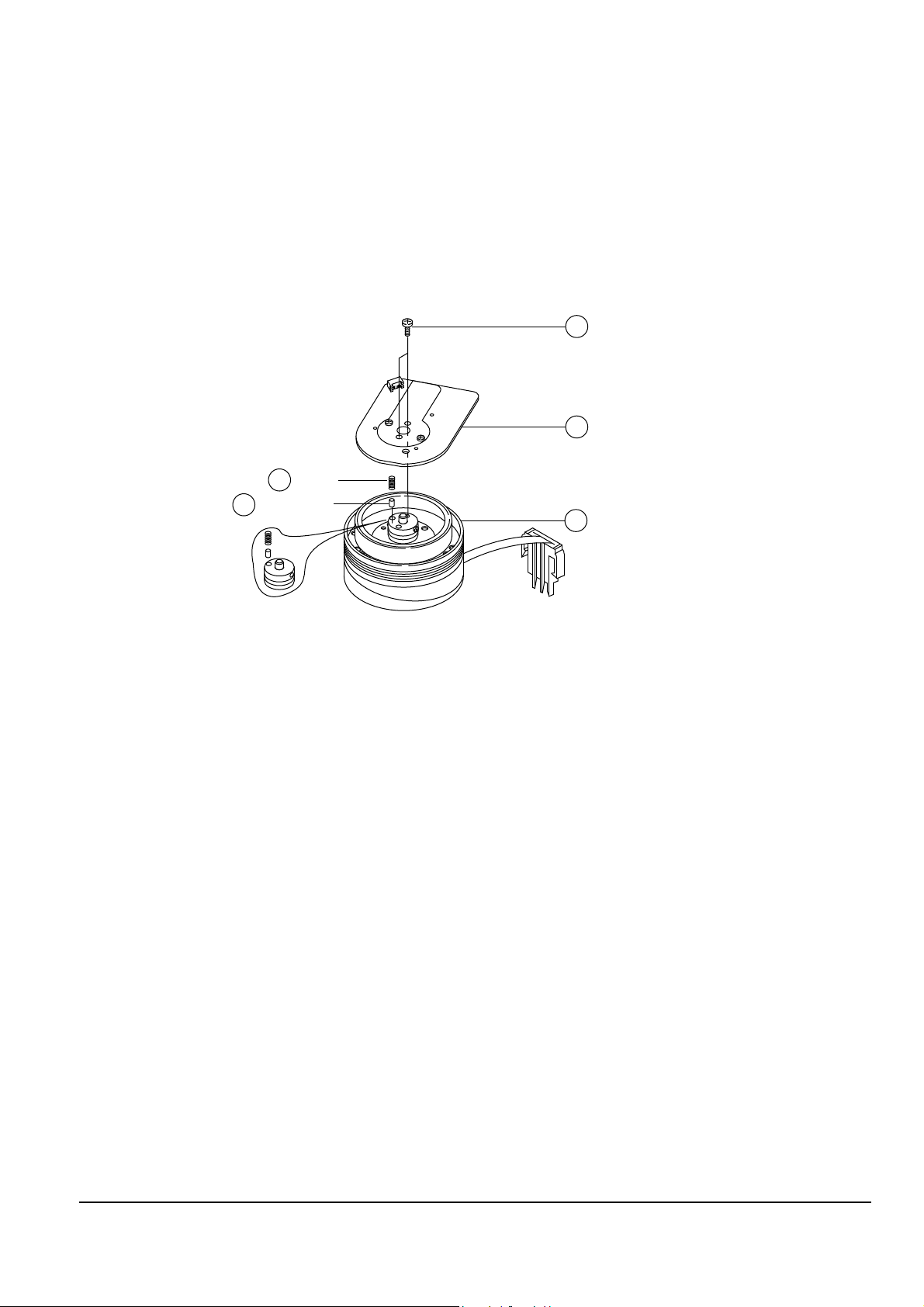

1-3-9 Motor Rotor and Cylinder Sub Ass’y

1. Make sure that phase matching holes of the Motor Rotor and the Cylinder Sub AssÕy are aligned correctly as

shown in Fig. 1-19 (Refer to phase matching hole).

2. Secure with 2 Screws.

MOTOR - ROTOR

PHASE MATCHING HOLE

DRUM SUB ASS'Y

2

3

2 SCREWS

1

Fig. 1-19 Assembly of Motor Rotor and Cylinder Sub Ass’y

Disassembly and Reassembly

Samsung Electronics 1-19

1-3-10 Motor Stator and Cylinder Sub Ass’y

1. Reinstall the Motor Stator ! toward the FPC cable of Cylinder Sub AssÕy @.

2. Secure 2 Screws. (Refer to Fig. 1-17)

MOTOR - STATOR

CYLINDER SUB ASS'Y

1

2

Fig. 1-20 Assembly of Motor Stator and Cylinder Sub Ass’y

Disassembly and Reassembly

1-20 Samsung Electronics

1-4 Main Deck Removal and Reassembly

1-4-1 Slide Rack Housing Removal

1. Lift the Slide Rack Housing.

SLIDE RACK HOUSING

Fig. 1-21 Slide Rack Housing Removal

Disassembly and Reassembly

Samsung Electronics 1-21

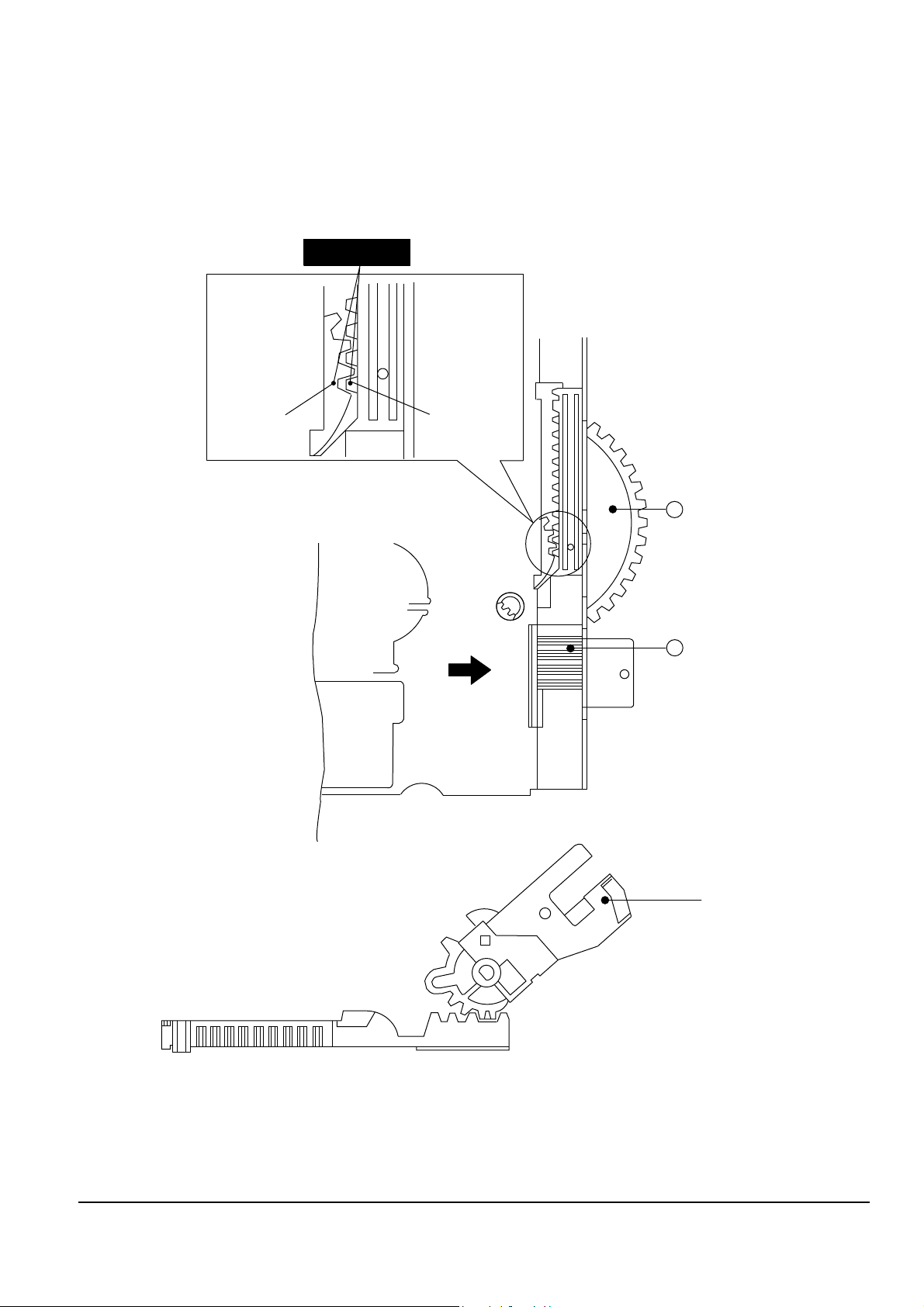

1-4-2 Assembly of Slide Rack Housing and Gear Master

1. Confirm that the hole of Master Gear ! and the hole ÒAÓ of Main Base are aligned correctly. (Eject mode)

2. Align the Slot #1 of Master Gear ! with the Tooth #1 of Rack Housing Slide @. (Refer to timing point)

(SLIDE VIEW)

DETAIL

A

TIMING POINT

SLOT #1

TOOTH #1

GEAR MASTER

( TOP VIEW )

( SIDE VIEW )

1

SLIDER RACK

HOUSING

ARM " R"

2

Fig. 1-22 Assembly of Slide Rack Housing and Gear Master

Loading...

Loading...