Page 1

A3 Color Copier

CLX-9252/9352 series

SERVICE

A3 Color Copier Contents

MANUAL

1. Precautions

2. Product Description

3. Replacement Procedure

4. Service Mode

5. Updating Firmware

6. Preventive Maintenance

7. Troubleshooting

8. System Diagram

9. System Recovery

10. Reference Information

Page 2

chapter 1 Precautions

1.1 Safety Warning …………………………………………………… 1-1

1.2 Caution for safety ………………………………………………… 1-2

1.3 ESD Precautions ………………………………………………… 1-5

chapter 2 Product description

2.1 Specifi cations …………………………………………………… 2-1

2.2 System confi guration …………………………………………… 2-9

2.3 Sensor location …………………………………………………… 2-18

Contents

2.4 Paper handling section ………………………………………… 2-22

2.4.1 Components ………………………………………………… 2-24

2.4.2 Functions …………………………………………………… 2-25

2.4.3 Paper tray …………………………………………………… 2-26

2.4.4 Pick up unit …………………………………………………… 2-27

2.4.5 Registration unit …………………………………………… 2-28

2.4.6 MPF unit ……………………………………………………… 2-29

2.5 Image formation ………………………………………………… 2-30

2.5.1 Printing process overview ………………………………… 2-30

2.5.2 Imaging unit ………………………………………………… 2-32

2.5.3 Cartridge transfer unit ……………………………………… 2-36

2.6 Fuser unit ………………………………………………………… 2-39

2.6.1 Fuser unit overview ………………………………………… 2-39

2.6.2 Function of components …………………………………… 2-40

2.6.3 Fuser unit drive ……………………………………………… 2-41

2.6.4 Temperature control ………………………………………… 2-42

2.7 Laser scanning unit ……………………………………………… 2-43

2.7.1 Laser scanning unit overview ……………………………… 2-43

2.7.2 Laser scanning optical path ………………………………… 2-44

2.7.3 Laser synchronizing detectors …………………………… 2-45

2.7.4 Automatic line position adjustment ………………………… 2-46

Page 3

Contents

2.7.5 Shutter mechanism ………………………………………… 2-49

2.8 Printer Drive system ……………………………………………… 2-50

2.8.1 Drive Motors ………………………………………………… 2-50

2.8.2 Main drive unit (OPC, DEVE, ITB, T1 DIS/ENG) ………… 2-52

2.8.3 Pick-up Drive ………………………………………………… 2-53

2.8.4 MP, Regi and Duplex Drive ………………………………… 2-54

2.8.5 Fuser Exit and Duplex Return Drives ……………………… 2-55

2.8.6 LSU shutter Drive …………………………………………… 2-56

2.8.7 WTB leveling drive ………………………………………… 2-56

2.8.8 Toner Supply Drive …………………………………………… 2-57

2.9 Scanner system ………………………………………………… 2-58

2.9.1 Scannner system overview ………………………………… 2-58

2.9.2 Scanning System components …………………………… 2-59

2.10 DADF system …………………………………………………… 2-61

2.10.1 DADF systme overview …………………………………… 2-61

2.10.2 Electric parts layout ………………………………………… 2-62

2.10.3 Description of drive system operations …………………… 2-63

2.11 Printer Electronics confi guration ……………………………… 2-69

2.11.1 Main controller …………………………………………… 2-71

2.11.2 OPE controller …………………………………………… 2-78

2.11.3 DADF controller …………………………………………… 2-82

2.11.4 Interface part ……………………………………………… 2-83

2.11.5 Connection part …………………………………………… 2-83

2.11.6 SMPS board1 …………………………………………… 2-84

2.11.7 SMPS board2 …………………………………………… 2-86

2.11.8 FDB board ………………………………………………… 2-88

2.11.9 HVPS board ……………………………………………… 2-89

2.11.10 Eraser PBA ……………………………………………… 2-93

2.11.11 Side Joint PBA …………………………………………… 2-93

2.11.12 Fuser PBA ………………………………………………… 2-94

2.11.13 Waste Sensor PBA ……………………………………… 2-94

2.11.14 LED Panel PBA …………………………………………… 2-94

2.11.15 CRUM PBA ……………………………………………… 2-95

2.11.16 Development CRUM Interface PBA …………………… 2-95

Page 4

2.11.17 Deve CRUM Joint PBA ………………………………… 2-96

2.11.18 Toner CRUM Joint PBA ………………………………… 2-96

2.11.19 Scan Joint PBA …………………………………………… 2-97

2.11.20 White-LED(WLED) CTL PBA …………………………… 2-98

2.11.21 White-LED(WLED) AL FRONT PBA …………………… 2-98

2.12 Heating cables ………………………………………………… 2-99

chapter 3 Replacement procedure

3.1 General Disassembly Procedure Precautions ………………… 3-1

3.2 Cover ……………………………………………………………… 3-2

Contents

3.2.1 Front cover …………………………………………………… 3-2

3.2.2 Inner cover …………………………………………………… 3-4

3.2.3 Left cover …………………………………………………… 3-8

3.2.4 Rear cover …………………………………………………… 3-9

3.2.5 Right cover …………………………………………………… 3-9

3.3 OPE unit …………………………………………………………… 3-10

3.4 Scan unit ………………………………………………………… 3-15

3.4.1 Scan Assembly ……………………………………………… 3-16

3.4.2 Scan Glass …………………………………………………… 3-19

3.4.3 Lamp Assembly ……………………………………………… 3-20

3.4.4 Scanner Board ……………………………………………… 3-22

3.4.5 Scanner Paper Sensor …………………………………… 3-23

3.5 Fuser unit ………………………………………………………… 3-24

3.5.1 NC thermistor and thermostat ……………………………… 3-25

3.5.2 Fuser NIP Motor …………………………………………… 3-26

3.5.3 Halogen lamp ………………………………………………… 3-29

3.5.4 EEPROM and photo sensor ……………………………… 3-31

3.5.5 Gear ………………………………………………………… 3-32

3.5.6 Heat roller …………………………………………………… 3-33

3.5.7 Fuser belt …………………………………………………… 3-35

3.5.8 Pressure roller and pressure roller bearing ……………… 3-37

3.5.9 Cautions for reassembly …………………………………… 3-39

Page 5

Contents

3.6 Cartridge transfer unit …………………………………………… 3-44

3.7 Main Board ……………………………………………………… 3-48

3.8 Hard Disk Drive (HDD) …………………………………………… 3-50

3.9 SMPS Board ……………………………………………………… 3-51

3.10 FDB (Fuser Drive Board) ……………………………………… 3-52

3.11 HVPS board ……………………………………………………… 3-53

3.12 Lift Motor ………………………………………………………… 3-54

3.13 Toner motor and Toner PBA …………………………………… 3-55

3.14 Oznoe Filter Fan ………………………………………………… 3-56

3.15 Side Joint PBA ………………………………………………… 3-57

3.16 Main Drive Unit ………………………………………………… 3-58

3.17 Pick-Up Drive Unit ……………………………………………… 3-60

3.18 MP/Regi Drive Unit ……………………………………………… 3-62

3.19 Duplex Fan ……………………………………………………… 3-63

3.20 Fuser Duct Fan ………………………………………………… 3-64

3.21 Exit Drive Unit …………………………………………………… 3-65

3.22 DADF Unit ……………………………………………………… 3-67

3.23 Paper Handling section ………………………………………… 3-77

3.13.1 Pick up unit ………………………………………………… 3-77

3.13.2 Regi Bracket Assy ………………………………………… 3-79

3.13.3 Cover-Side unit …………………………………………… 3-81

3.13.3.1 Duplex unit …………………………………………… 3-82

3.13.3.2 MP tray ……………………………………………… 3-83

3.13.4 Exit unit …………………………………………………… 3-85

3.14 LSU ……………………………………………………………… 3-88

3.15 Cassette heating cable ………………………………………… 3-90

chapter 4 Service mode (Diagnostic mode)

4.1 Entering/Exiting Diagnostics Mode ……………………………… 4-1

4.2 Serive mode menu tree …………………………………………… 4-2

4.2.1 Information tab ……………………………………………… 4-2

4.2.2 Maintenance counts Tab ………………………………… 4-3

Page 6

Contents

4.2.3 Diagnostics Tab …………………………………………… 4-4

4.2.4 Service Functions ………………………………………… 4-5

4.3 Information Tab …………………………………………………… 4-6

4.3.1 General ……………………………………………………… 4-6

4.3.2 Supply status ……………………………………………… 4-6

4.3.3 Software version …………………………………………… 4-8

4.3.4 Service Hours ……………………………………………… 4-8

4.3.5 Fault Log …………………………………………………… 4-8

4.3.6 Print reports ………………………………………………… 4-8

4.4 Maintenance Counters Tab ……………………………………… 4-13

4.4.1 Fault counters ……………………………………………… 4-13

4.4.2 Jam counters ……………………………………………… 4-14

4.4.3 Part replacement count …………………………………… 4-16

4.5 Diagnotics Tab …………………………………………………… 4-17

4.5.1 Engine diagnostics ………………………………………… 4-17

4.5.1.1 NVM Read/Write ……………………………………… 4-17

4.5.1.2 Engine Test Routines ………………………………… 4-20

4.5.2 Fax diagnostics …………………………………………… 4-28

4.5.2.1 Fax NVM Read/Write ………………………………… 4-28

4.5.2.2 Fax Test Routines …………………………………… 4-29

4.5.3 Scanner diagnostics ……………………………………… 4-31

4.5.3.1 Shading Test …………………………………………… 4-31

4.5.3.2 Scanner/DADF NVM Read/Write …………………… 4-31

4.5.3.3 Scanner/DADF Test Routines ……………………… 4-32

4.5.4 Adjustment ………………………………………………… 4-33

4.5.4.1 Print Adjustment ……………………………………… 4-33

4.5.4.2 Copy Adjustment ……………………………………… 4-35

4.5.4.3 Scan Area Adjustment ………………………………… 4-36

4.5.4.4 DADF Adjustment …………………………………… 4-38

4.5.4.5 Finisher Adjustment …………………………………… 4-40

4.5.4.6 Buckle Adjustment …………………………………… 4-43

4.5.5 ACS(Auto Color Sensing) ………………………………… 4-45

4.5.6 Color Management ………………………………………… 4-46

4.5.6.1 Auto Color Registration ……………………………… 4-46

Page 7

Contents

4.5.6.2 Full Color Registration ………………………………… 4-47

4.5.6.2 Auto Color Tone Adjustment ………………………… 4-48

4.5.7 TR Contorl Mode …………………………………………… 4-51

4.6 Sevice functions ………………………………………………… 4-52

4.6.1 Main Memory Clear ……………………………………… 4-52

4.6.2 Hard Disk Maintenance …………………………………… 4-52

4.6.3 Debug Log ………………………………………………… 4-52

4.6.4 Port ………………………………………………………… 4-53

4.6.5 Capture Log ………………………………………………… 4-53

4.6.6 Toner Save ………………………………………………… 4-53

4.6.7 Count Setting of Large Page ……………………………… 4-53

4.6.8 System Recovery ………………………………………… 4-54

4.6.9 User Data Management …………………………………… 4-54

4.6.10 Cool Down Mode ………………………………………… 4-54

chapter 5 Updating Firmware

5.1 Updating from the Printer Control Panel ……………………… 5-2

5.2 Updating from the Network …………………………………… 5-8

chapter 6 Preventive maintenance (PM)

6.1 PM Supplies ……………………………………………………… 6-1

6.2. PM Procedures ………………………………………………… 6-4

6.2.1 Toner cartridge ……………………………………………… 6-4

6.2.2 Imaging unit ………………………………………………… 6-6

6.2.3 Cartridge Transfer Unit …………………………………… 6-10

6.2.4 2nd Transfer roller ………………………………………… 6-14

6.2.5 Fuser Unit …………………………………………………… 6-15

6.2.6 Pick up/ Retard/ Forward roller …………………………… 6-16

6.2.7 Ozone Filter ………………………………………………… 6-16

6.2.8 Dust Filters ………………………………………………… 6-17

6.2.9 DADF Pick up roller Assy ………………………………… 6-18

Page 8

6.2.10 DADF friction pad ………………………………………… 6-18

6.2.11 MP Pick up/ Retard/ Forward roller …………………… 6-19

6.3. Cleaning the PM parts ………………………………………… 6-21

6.3.1 Cleaning the charge scorotron …………………………… 6-21

6.3.2 Cleaning the pick up roller ………………………………… 6-22

6.3.3 Cleaning the Regi roller …………………………………… 6-23

6.3.4 Cleaning the tray1 feed roller ……………………………… 6-23

6.3.5 Cleaning the tray2 feed roller ……………………………… 6-24

6.3.6 Cleaning the LSU window ………………………………… 6-25

chapter 7 Troubleshooting

Contents

7.1 Procedure of checking the symptoms ………………………… 7-1

7.2 Error code and troubleshooting ………………………………… 7-3

7.2.1 Error code and error message …………………………… 7-3

7.2.2 Error Code Details ………………………………………… 7-15

7.3 Image quality problems and solutions ………………………… 7-121

7.3.1 Vertical white band / Dark band …………………………… 7-124

7.3.2 Horizontal white band / dark band ………………………… 7-126

7.3.3 Color spot …………………………………………………… 7-127

7.3.4 Foggy background ………………………………………… 7-128

7.3.5 Blurred image ……………………………………………… 7-129

7.3.6 Incorrect color registration ………………………………… 7-130

7.3.7 Uneven pitch and jitter image ……………………………… 7-132

7.3.8 Skewed image ……………………………………………… 7-133

7.3.9 Low image density ………………………………………… 7-134

7.3.10 Blank copy, Black copys ………………………………… 7-141

7.3.11 Uneven density in sub scan direction …………………… 7-143

7.3.12 Uneven density in main scan direction ………………… 7-144

7.3.13 Gradation reproduction failure …………………………… 7-145

7.3.14 Void areas, white spots ………………………………… 7-147

7.3.15 Poor fusing performance, offset ………………………… 7-148

7.3.16 Stain on the paper back side …………………………… 7-149

7.3.17 White Halo ………………………………………………… 7-150

Page 9

7.4. DADF skew testing ……………………………………………… 7-151

7.5 Other Errors ……………………………………………………… 7-153

chapter 8 System diagram

8.1 Main 1 ……………………………………………………………… 8-1

8.2 Main 2 ……………………………………………………………… 8-2

8.3 Main 3 …………………………………………………………… 8-3

8.4 Main 4 …………………………………………………………… 8-4

8.5 SCAN & DADF …………………………………………………… 8-5

Contents

chapter 9

chapter 10

8.6 DADF ……………………………………………………………… 8-6

System Recovery

9.1 Entry Point ………………………………………………………… 9-1

9.2 USB ………………………………………………………………… 9-2

9.3 Network …………………………………………………………… 9-4

9.4 Confi rmation Page ……………………………………………… 9-5

9.5 Error Page ………………………………………………………… 9-6

9.6 Progress Page …………………………………………………… 9-7

9.7 Error List …………………………………………………………… 9-8

9.8 HDD Repair ……………………………………………………… 9-8

9.9 HDD Failure ……………………………………………………… 9-10

Reference information

10.1 Tools for troubleshooting ……………………………………… 10-1

10.2 Abbreviations …………………………………………………… 10-4

Page 10

1. Prec

a

n

o

(2) Use only Samsung replacement parts

t

e

s

f

IEC 825. Cl

n

t

o

-

o

utions

1. Warning and cautio

In order to prevent accidents and to prevent damage t

below carefully before servicing the printer and follow

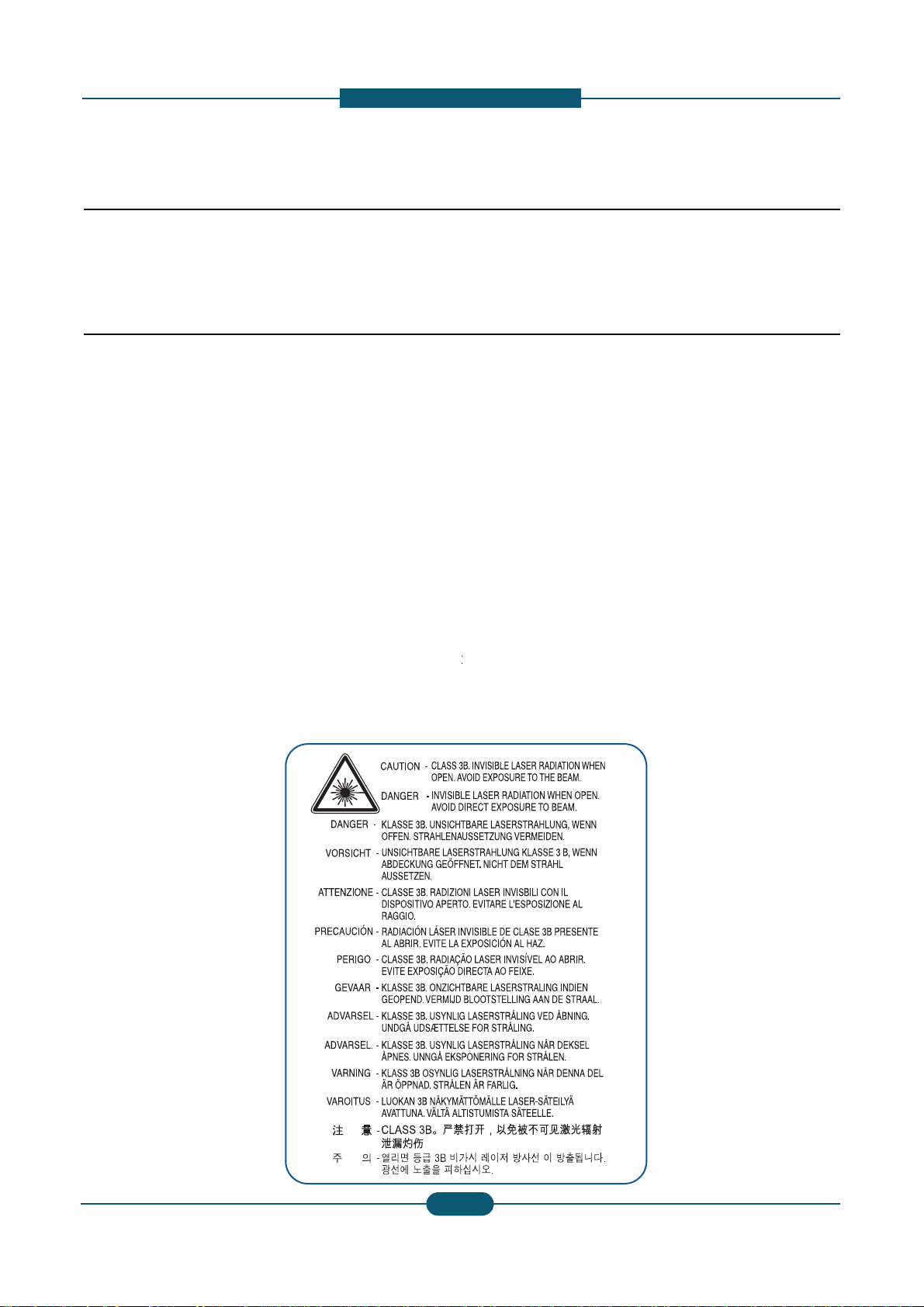

1.1 Safety Warning

(1) Only to be serviced by appropriately qualified servi

High voltages and lasers inside this product are da

qualified service technician.

.

There are no user serviceable parts inside the prin

additions to the printer as these could cause the pr

fire hazards.

(3) Laser Safety Statement

The Printer is certified in the U.S. to conform to th

Subchapter J for Class 1(1) laser products, and el

orming to the requirements of

laser system and printer are designed so there is n

Class I level during normal operation, user mainte

ass I las

for s afety

the equipment please read the precautions listed

them closely.

ce technician.

ngerous. This printer should only be serviced by a

er. Do not make any unauthorized changes or

inter to malfunction and create an electric shock or

requirements of DHHS 21 CFR, chap ter 1

ewhere, it is certified as a Class I laser product coner products are not considered to be hazardous. The

ever any human access to laser radiation above a

ance, or prescribed service condition.

Warning >> Never operate or service the printer with

assembly. The reflected beam, although invisible, can

When using this product, these basic safety pre-cauti

electric shock, and personal injury.

he protective cover removed from Laser Scanner

damage your eyes.

ns should always be followed to reduce risk of fire,

Service Manual

1

1

SAMSUNG ELECTRONICS

Page 11

a

1.2 Caution for safety

i

o

e

w

w

u

p

e

d

(2)

() y p pp p

o

(5)

a

() p g p

f

c

t

c

r

a

cable immediately, do not reuse or repair the dama

a

m

o

p

i

p

c

d

w

e

h

-

t

y sp

yp

cable. Some chemicals can attack the coating on

1.2.1 Toxic material

1. Prec

utions

This product contains toxic materials that could cause

(1) If the LCD control panel is damaged it is possible f

with the skin should be avoided. Wash any splash

doctor. If the liquid gets into the mouth or is swallo

(2) Please keep Drum cartridge and Toner cartridge a

Drum cartridge and Toner Cartridge may be harmf

1.2.2 Electric shock and fire safety

Failure to follow the following instructions could cause

(1) Use only the correct voltage, failure to do so could

electric shock.

Use only the power cable supplied with the printer.

cable to overheat and potentially cause a fire.

(3) Do not overload the power socket, this could lead t

lead to a fire.

(4) Do not allow water or other liquids to spill into the p

paper clips, pins or other foreign objects to fall into

to an electric shock or fire hazard.

Never touch the plugs on either end of the power c

When servicing the printer remove the power plug

(6) Use caution when inserting or removing the power

firmly and pull. The power connector must be inser

overheating possibly leading to a fire.

(7) Take care of the power cable. Do not allow it to be

damaged. Do not place objects on top of the powe

overheat and cause a fire. Exposed cables could c

the power cable, weakening the cover or exposing

(8) Ensure that the power sockets and plugs are not cr

should be repaired immediately. Take care not to c

the machine.

(9) Use caution during thunder or lightning storms. Sa

from the power source when such weather conditi

ower cord if it is still connected to the wall socket

(10) Avoid damp or dusty areas, install the printer in a

machine near a humidifier or in front of an air con

can lead to overheating and cause a fire or cause

(11) Do not position the printer in direct sunlight. This

possibly leading to the printer failing to work prop

(12) Do not insert any metal objects into the machine t

could make contact with a high voltage conductor

llness if ingested.

r the liquid inside to leak. This liquid is toxic. Contac

s from eyes or skin immediately and contact your

ed see a doctor immediately.

ay from children. The toner powder contained in the

l and if swallowed you should contact a doctor.

recautions

lectric shock or potentially cause a fire.

amage the printer and potentially cause a fire or

Use of an incorrectl

overheating of the cables inside the wall and could

rinter, this can cause electric shock. Do not allow

the printer these could cause a short circuit leading

ble with wet hands, this can cause electric shock.

rom the wall socket.

onnector. When removing the power connector, grip it

ed completely, otherwise a poor contact could cause

ome twisted, bent sharply around corners or wise

cable. If the power cable is damaged it could

use an electric shock. Replace the damaged power

cables causing fire and shock risks.

cked or broken in any way. Any such defects

ut or damage the power cable or plugs when moving

sung recommends that this machine be disconnected

ns are expected. Do not touch the machine or the

n these weather conditions.

lean well ventilated location. Do not position the

itioner. Moisture and dust built up inside the machine

parts to rust.

ill cause the temperature inside the printer to rise

rly and in extreme conditions could lead to a fire.

rough the ventilator fan or other part of the casing, it

inside the machine and cause an electric shock.

ecified cable could cause the

Service Manual

1

2

SAMSUNG ELECTRONICS

Page 12

a

1.2.3 Handling Precautions

a

(1) Ensure the printer is installed on a level surface, ca

v

o

u

o

o

u

g

o

t

g

(3) Disconnect printer interface cables and power cabl

u

x

-

The OPC Drum can be irreparably damaged if it e

d

c

o

g

)

C

t

-

supporting its weight. Failure to do so could

p

light

1. Prec

utions

The following instructions are for your own personal s

product.

cause the printer to tip or fall.

(2) The printer contains many rollers, gears and fans.

fingers, hair or clothing in any of these rotating de

(3) Do not place any small metal objects, containers

which if spilled could get into the machine and ca

(4) Do not install the machine in areas with high dust

a humidifier or heater. Damage could be caused t

(5) Do not place candles, burning cigarettes, etc on th

(6) When reinstalling the imaging unit or ITB unit at p

1.2.4 Assembly / Disassembly Preca

Replace parts carefully and always use Samsung par

cable routing before dismantling any part of the machi

Please carry out the following procedures before dism

(1) Check the contents of the machine memory and m

if the main board or network card is replaced.

(2) Ensure that power is disconnected before servicin

(4) Only use approved spare parts. Ensure that part n

temperature rating are correct.

(5) When removing or re-fitting any parts do not use e

plastic.

(6) Take care not to drop any small parts into the mac

(7) Handling of the OPC Drum

Take care not to expose the OPC Drum either to

room lighting. Exposure for as little as 5 minutes

properties and will result in print quality degradati

Remove the OPC Drum and store it in a black ba

working with the Covers (especially the top cover

damage the OPC Drum.

- Take care not to scratch the green surface of OP

If the green surface of the Drum Cartridge is scra

compromised.

fety, to avoid injury and so as not to damage the

of

Take great care to ensure that you do not catch your

ices.

f water, chemicals or other liquids close to the printer

se damage, shock or fire hazard.

r moisture levels, beside on open window or close to

the printer in such areas.

e printer, These could cause a fire.

wer off, perform the OPC-ACR surely.

tions

s. Take care to note the exact location of parts and

ne. Ensure all parts and cables are replaced correctly.

antling the printer or replacing any parts.

ake a note of any user settings. These will be erased

or replacing any electrical parts.

.

mber, product name, voltage, current and

cessive force, especially when fitting screws into

hine.

to

irect sunlight or to fluorescent or incandescent

an damage the surface of the photoconductive

n. Take extra care when servicing the printer.

or other lightproof container. Take care when

open as light is admitted to the OPC area and can

Drum Unit.

ched or touched the print quality will be

.

Service Manual

1-1

3

3

SAMSUNG ELECTRONICS

Page 13

1. Prec

a

u

r

o

w

v

quip

qp

e

h

h

m

-

e

utions

1.2.5 Disregarding this warning may

(1) Be careful with high temperature compone nts.

The fuser unit works at a high temperature. Use ca

cool down before disassembly.

(2) Do not put fingers or hair into the rotating parts.

When operating a printer, keep your hands and hai

motor, fan, etc.).

(3) When moving the printer :

- When transporting/installing the equipment, employ f

- Be sure not to hold the movable parts or units (e.g. th

equipment.

- Be sure to use a dedicated outlet with 110V/220V po

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessi

sunlight.

- Provide proper ventilation since the equipment emits

- The e

-Be sure to fix and plug in the power cable securely aft

-If you are moving the machine a short distance, you s

(e.g : same building through elevator)

-If you are moving the machine a long distance, you s

& staple unit, tape and disassemble all trays. (e.g :

ment must be installed near the socket outl

cause bodily injury

tion when working on the printer. Wait for the fuser to

away form the rotating parts (Paper feeding entrance,

ur people and be sure to hold the lifting handles.

e control panel, DADF) when transporting the

er input.

e heat, high humidity, dust, vibration and direct

a slight amount of ozone.

et and must be accessible.

r the installation so that no one trips over it.

ould separate the finisher.

ould remove toner & imaging unit, lock scan carrier

oved by truck or so)

1

Service Manual

4

SAMSUNG ELECTRONICS

Page 14

a

1.3 ESD Precautions

d

integrated circuits, some field effect transistors, and se

h

p

n

o

h

m

d

4. Use only an anti

static solder removal device. Som

y

v

s

g

E

d

n

electricity sufficient to damage an ESD

-

chip components

solder removal devices not classified as anti

v

s

1. Prec

utions

Certain semiconductor devices can be easily damage

commonly called “Electrostatically Sensitive (ES) Dev

The techniques outlined below should be followed to

caused by static electricity.

Caution >>Be sure no power is applied to the chassis

1. Immediately before handling a semiconductor com

off any electrostatic charge on your body by touchi

commercially available wrist strap device, which sh

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped wit

such as aluminum or copper foil, or conductive foa

vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder or

“

”

-

static” can generate electrical charges sufficient to

5. Do not use Freon-propelled chemicals. When spra

damage ESDs.

6. Do not remove a replacement ESD from its protecti

Most replacement ESDs are packaged with all lead

or a comparable conductive material.

by static electricity. Such components are

ices” or ESDs. Examples of typical ESDs are:

“”

.

elp reduce the incidence of component damag e

or circuit, and observe all other safety precautions.

onent or semiconductor-equipped assembly, drain

g a known earth ground. Alternatively, employ a

uld be removed for your personal safety reasons

ESDs, place the assembly on a conductive surface ,

, to prevent electrostatic charge buildup in the

esolder ESDs.

“

-

damage ESDs.

ed, these can generate electrical charges sufficient to

e packaging until immediately before installing it.

shorted together by conductive foam, aluminum foil,

7. Immediately before removing the protective shortin

touch the protective material to the chassis or circui

8. Maintain continuous electrical contact between the

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackage

the brushing together of clothing fabric and lifting o

.

material from the leads of a replacement ESD,

t assembly into which the device will be installed.

SD and the assembly into which it will be installed,

replacement ESDs. Normal motions, such as

e’s foot from a carpeted floor, can generate static

Service Manual

1

5

SAMSUNG ELECTRONICS

Page 15

2. Product

d

-

Print and Copy speed (Color/Mono)

A9 Dual Core 1GHz

Booklet Finisher(3K)

2. Product description

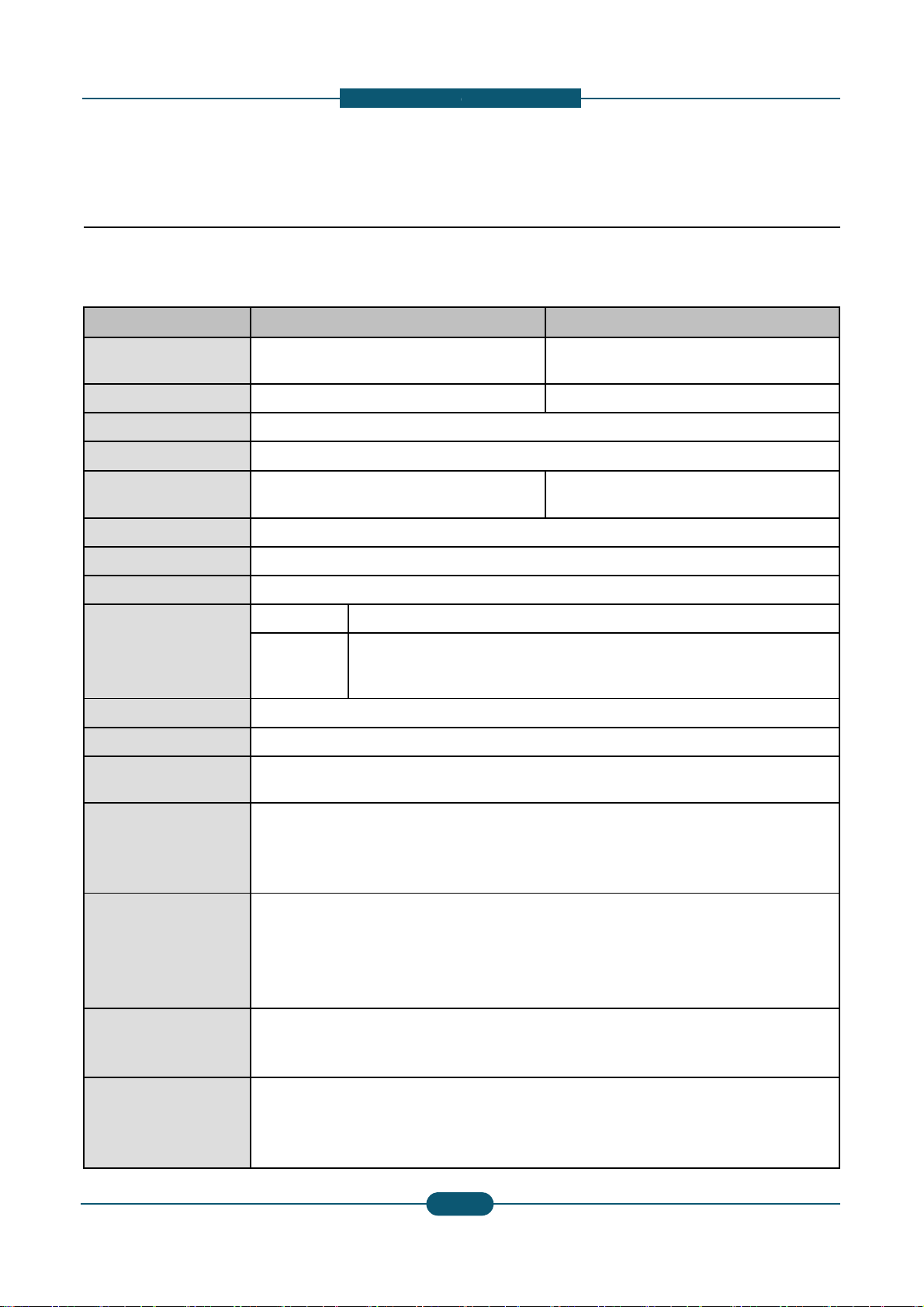

2.1 Specifications

2.1.1 Product Overview

escription

CLX-9252NA : Up to 25 ppmin A4

CLX-9352NA : Up to 35 ppmin A4

Scan Speed

60 ipm @ 300 dpi

CLX-9252/9352 series

Processor

HDD : 320 GB

1.5GB memory

Options

HCF, DCF, Standard Finisher(1K)

, Fax etc.

• 8.9” Full color touch LCD

• XOA(eXtensible Open Architecture) support

Service Manual

2

1

SAMSUNG ELECTRONICS

Page 16

d

2.1.2 Specifications

0

0

c

s

s

W

0

1

W

C

h

2

h

e

-

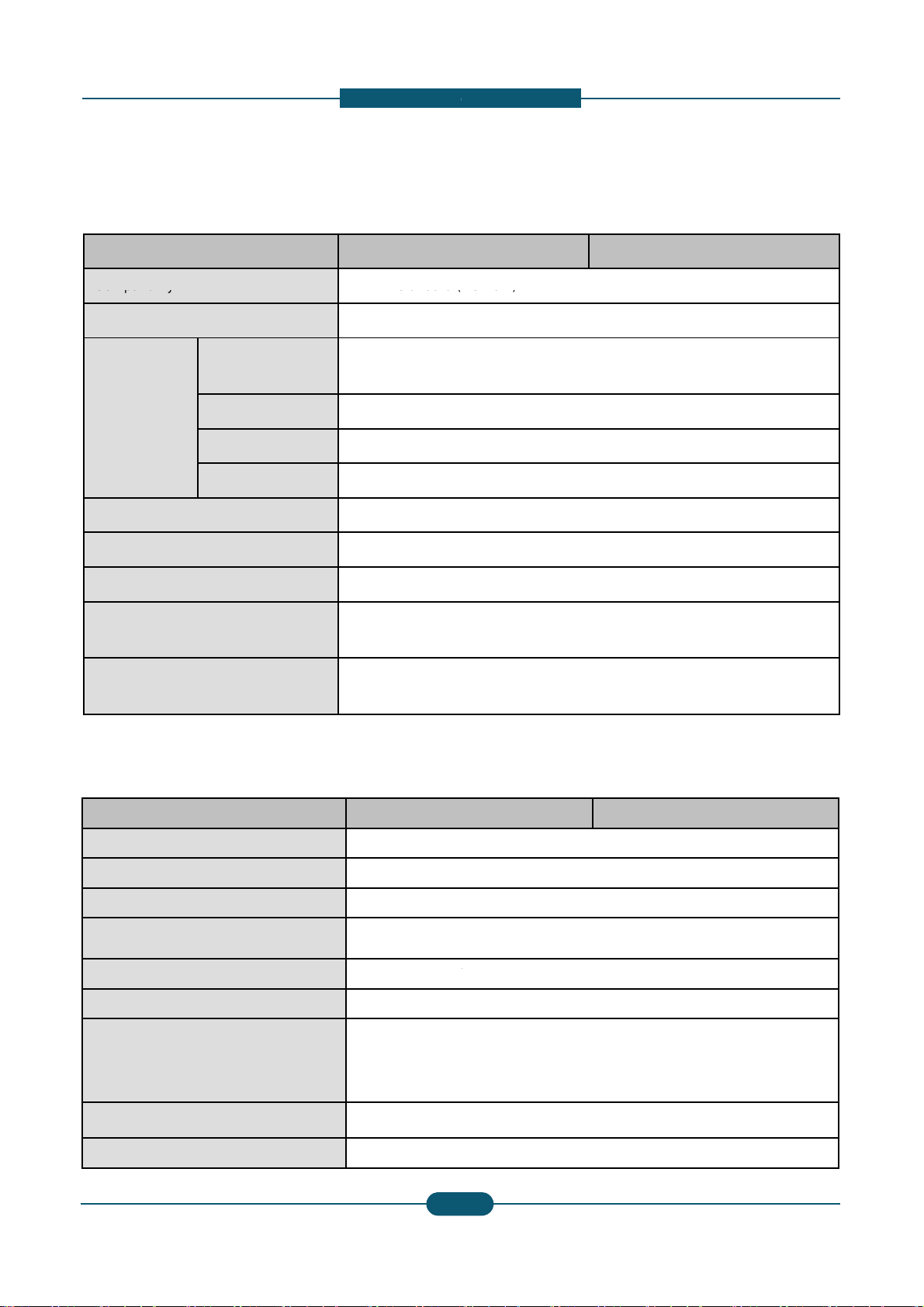

General Specifications

2. Product

escription

Item CLX-9252NA

Printing Speed (A4)

(Color / Mono)

FCOT (Color / Mono) < 10.6 sec / < 9.0 sec

Warm-up Time < 45 sec from Power Save

Duplex Printing Speed Same as rated engine speed

Scanning Speed (A4)

Memory 1.5GB

HDD 320 GB

CPU

Resolution

Gradation 256

Size (W x D x H ) 675.5 x 722 x 1153 mm (26.6 x

Weight

25 ppm/ 25 ppm

60 ipm @ 300 dpi

40 ipm @ 600 dpi

A9 Dual Core 1GHz

Optical • 600 x 600 dpi

• Draft 600 x 60

Enhanced

96.71 Kg (213.21 lbs.) (without

110 Kg (312 lbs.) (including con

• Default 600 x 6

• Up to 600 x 60

CLX-9352NA

35 ppm/ 35 ppm

< 8.5 sec / < 7.5 sec

60 ipm @ 300 dpi

40 ipm @ 600 dpi

x 1bit

00 x 2 bit

x 4 bit

28.4 x 45.4 inches)

onsumables and options )

umables without options)

Noise (dB)

Power consumption

Power requirement

Power output rating for

heating wire in

DCF/HCF

Service Manual

• Low Power mode : 34 dB(A)

• Ready mode : 43 dB(A)

• Printing mode : 54 dB(A)

• Copying mode : 57 dB(A)

• Average operating mode : Les

• Ready mode : Less than 250

• Low power mode : Less than 5

• Power save mode : Less than

• Power off mode : Less than 0

AC 110-127 V , 50/60 Hz or: A

Note - See the Rating label on t

type of current.

AC 110-127 V , 50/60 Hz or AC

Note - See the Rating label on t

of current.

The voltage rating of heating wir

than 1,100 W

W

1 W

220-240 V , 50/60 Hz

e machine for the correct voltage, frequency (hertz) and

20-240 V , 50/60 Hz

e machine for correct voltage, frequency (hertz) and type

is the same as the machine’s voltage rating.

2

2

SAMSUNG ELECTRONICS

Page 17

d

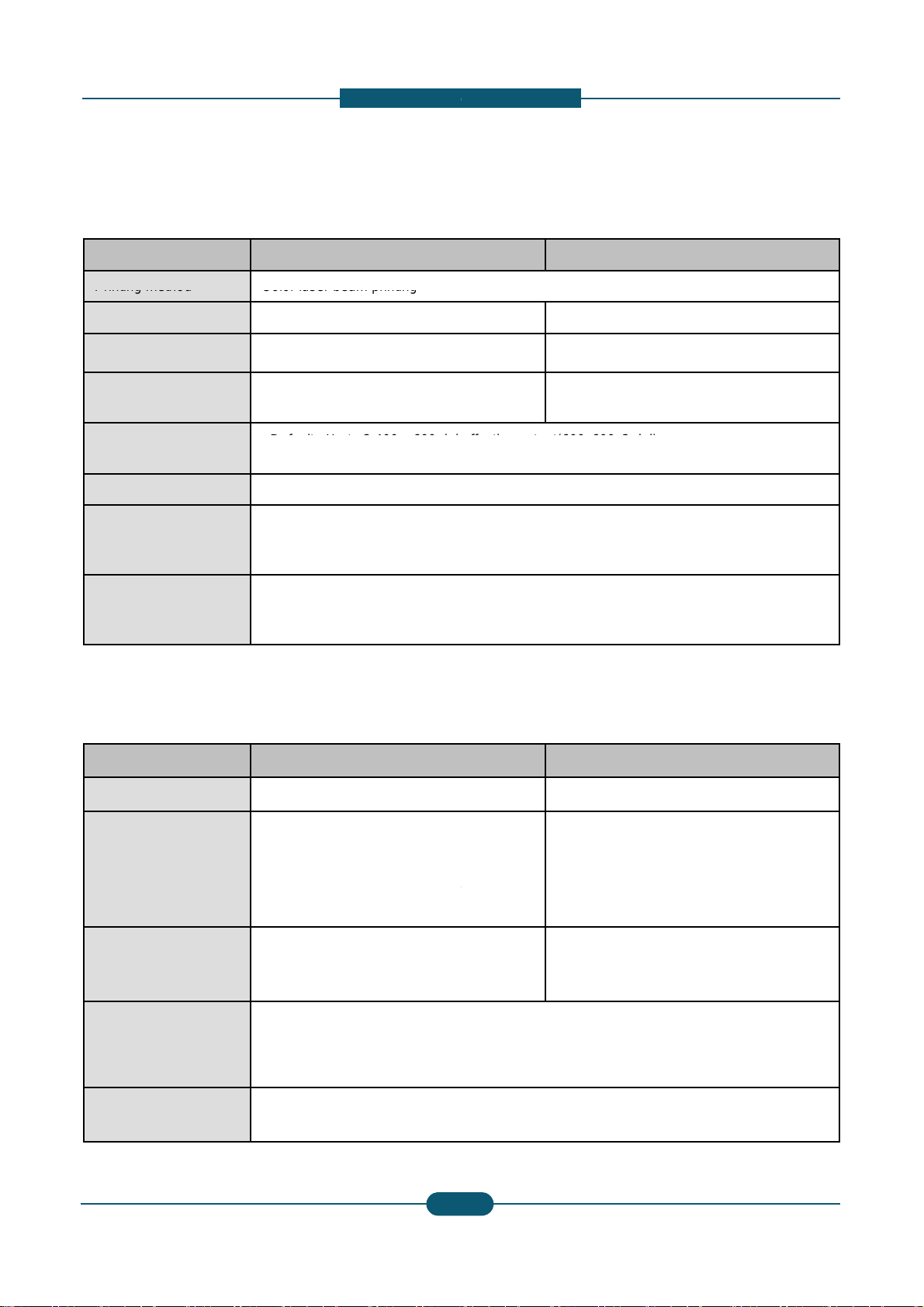

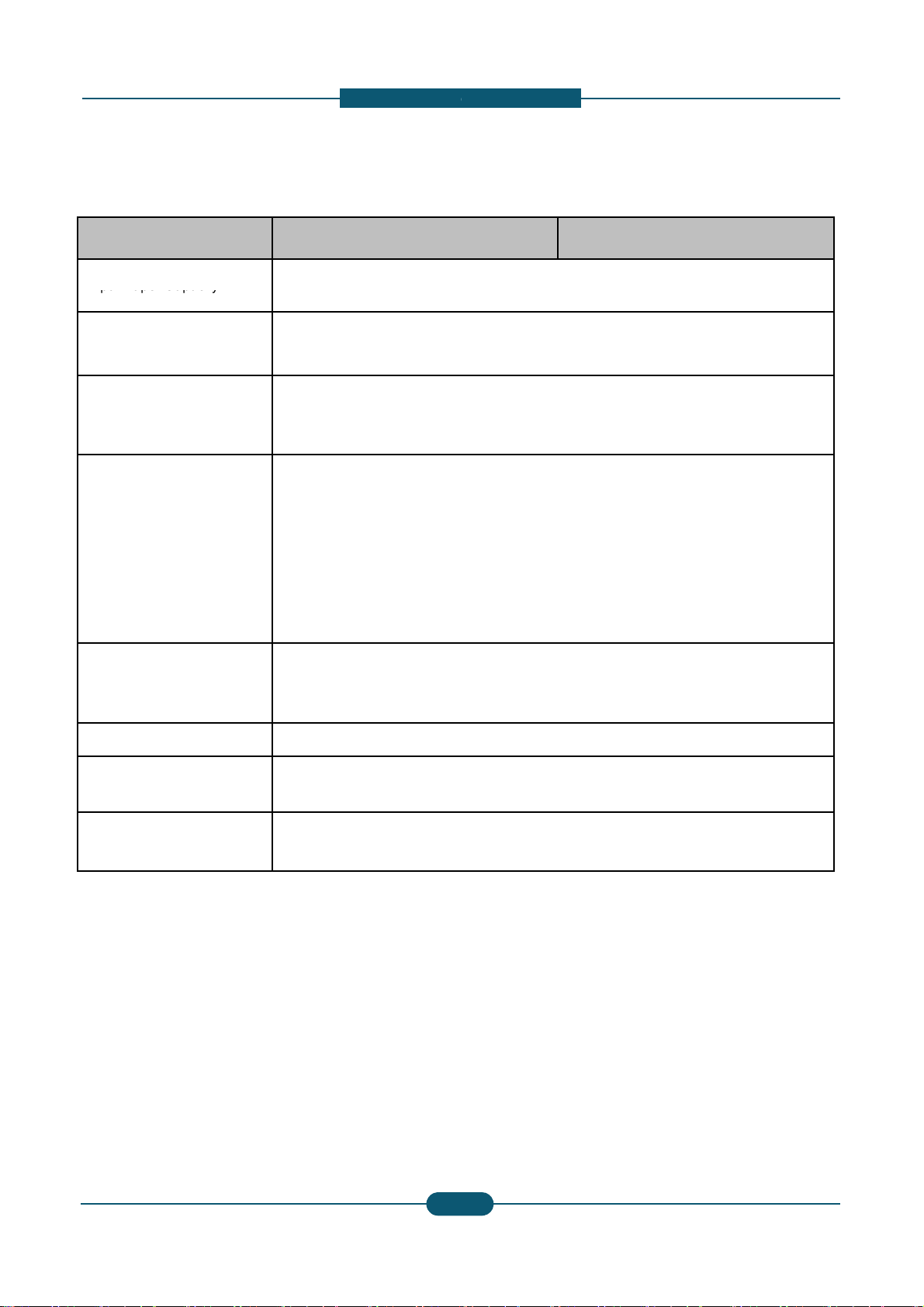

Printer Specifications

Printing method

Color laser beam printing

r

Default

400

600 dpi

e

P

a

.

X

e

e

Duplex copy speed

Duplex to Duplex (2

-

2)

e

6

%

-

t(600x600x2 dpi)

Duplex to Duplex (2

-

2)

2. Product

escription

Item CLX-9252NA

Printing speed Up to 25 ppm (A4), 25 ppm (Lett

Duplex printing speed Up to 25 ipm (A4), 25 ipm (Lette

First print out time

(Color / Mono)

Print resolution

Printer language PCL5Ce, PCL6C, PostScript 3,

OS compatibility

Interface

< 12.2 sec / < 10.6 sec

•

• Max : Up to 9,600 x 600 dpi eff

• Windows: 2000 ,XP,2003 ,Vist

• Various Linux OS

• Macintosh: Mac OS X 10.5~10

• High speed USB 2.0

• Ethernet 10/100/1000 Base T

• FDI (optional)

: Up to 2,

x

Copier specifications

CLX-9352NA

er) Up to 35 ppm (A4), 35 ppm (Letter)

) Up to 35 ipm (A4), 35 ipm (Letter)

< 10.5 sec / < 9.5sec

effective outpu

ctive output(600x600x2 dpi)

DF 1.5+, TIFF, PJL, XPS

,2008 ,Win7

6

(embedded type)

Item CLX-9252NA

Copy Speed Up to 25 cpm (A4), 25 cpm (Lett

Simplex to Duplex (1-2)

: Up to 25 ipm in A4 (25 ipm in L

: Up to 8 ipm in A4 (8 ipm in Lett

@ normal mode

• Black & white: 9.0 seconds

First copy out time

Copy resolution • Platen : 600 x 600 dpi

Zoom range

Service Manual

(from ready)

• Color: 10.6 seconds (from read

• Document feeder: Up to 600 x

• Platen : 25% to 400%

• Document feeder: 25% to 400

CLX-9352NA

r) Up to 35 cpm (A4), 35 cpm (Letter)

Simplex to Duplex (1-2)

y)

2

3

tter)

r)

00 dpi

: Up to 35 ipm in A4 (35 ipm in Letter)

: Up to 22 ipm in A4 (22 ipm in Letter) @

normal mode

• Black & white: 7.5 seconds

(from ready)

• Color: 8.5 seconds (from ready)

SAMSUNG ELECTRONICS

Page 18

d

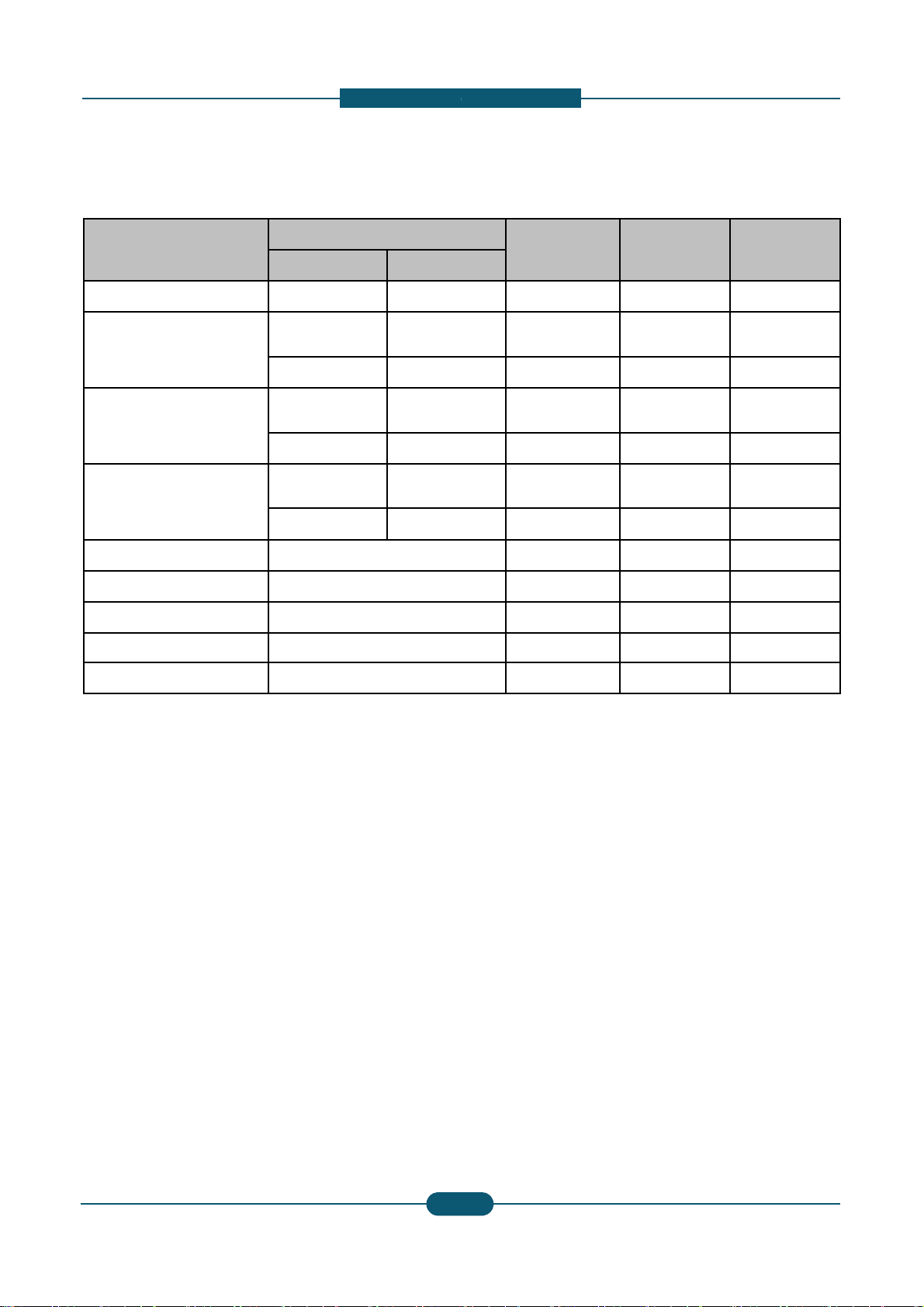

Scanner specifications

Compatibility

TWAIN standard (

p

0

0

0

0

Effecti

idth

M

297

(11

h

e

Applicable line

Public Switched T

/

x

6

-

Network)

7 inches)

Network (PSTN) or behind PABX

x

2. Product

escription

Item CLX-9252NA

Scanning method Color CCD

TWAIN standard

Resolution

Network Scan File format PDF, TIFF, JPEG

Effective scanning length Max. 432 mm (17

ve scanning w

Color bit depth

Mono bit depth

Scan to USB 100, 200, 300, 40

Scan to Email 100, 200, 300, 40

Scan to Server 100, 200, 300, 40

Up to 600 x 600 d

(Up to 4,800 x 4,8

ax.

mm

Internal: 30 bit

External: 24 bit

1 bit for lineart &

8 bit for gray scal

CLX-9352NA

i

0 dpi by software enhancement)

, 600 dpi

, 600 dpi

, 600 dpi

inches)

.

alftone

Fax Specifications

Item CLX-9252NA

Compatibility Super G3

Data coding MH/MR/MMR/JB

Modem speed 33.6kbps

Transmission speed Up to 3 seconds

Maximum document length 356 mm (14 inch

• Standard : 203

Resolution

Memory HDD Backup

Auto dialer up to 500 numbe

Service Manual

• Fine : 203 x 19

• Super Fine : 30

• Ultra Fine : 600

IG/JPEG

page

es)

98 dpi

dpi

0 x 300 dpi

x 600 dpi

rs

2

4

CLX-9352NA

SAMSUNG ELECTRONICS

Page 19

d

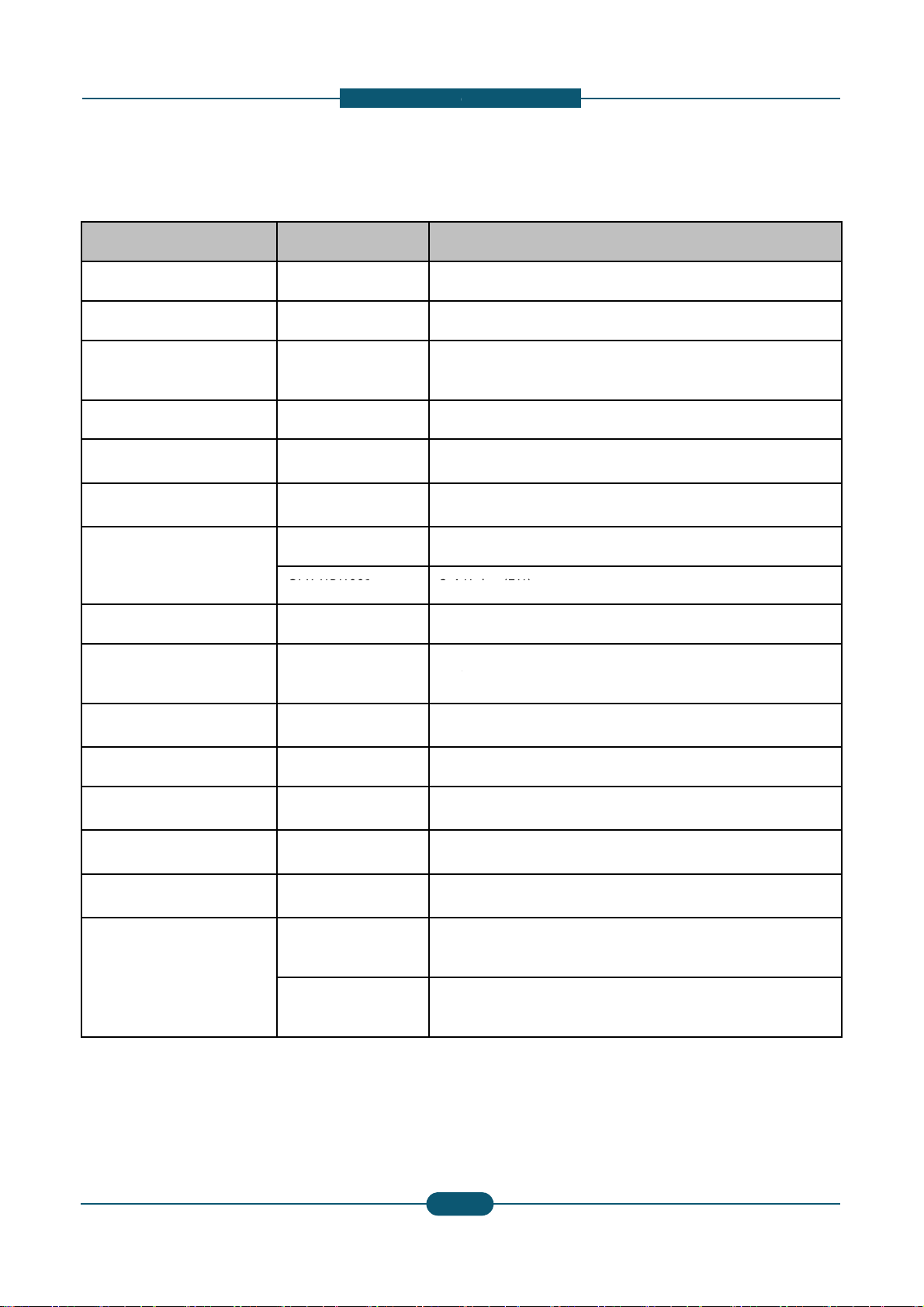

Paper Specifications

Input Paper Capacity

040

tte

p

F

.

High Capacity Feeder : A4 /

p

k

a

c

iRec

6

~

4

0

b

-

000 (High C

r

)

100 (MP T

)

Letter

y

2. Product

escription

Item CLX-9252NA

• Standard : 1,040 (Cassette

•Maximum : 1,

Output Paper Capacity

Paper Size

Paper Type

Paper Weight

• Standard : 500 (Center Out

• Maximum : 3,250 (Booklet

• Cassette :

•MP Tray :

•

• Cassette :

Label, CardStoc

• MP Tray :

• High Capacity Feeder :

• Cassette : 60 ~ 216 gsm

• MP Tray : 60 ~ 253 gsm

• High Capacity Feeder : 60

(Casse

148 x 210 mm

98 x 148 mm(3

Plain Pa

Printer Default,

Color Paper, C

Letterhead, Re

er, Th

Pla

(1

(1

CLX-9352NA

1 & 2) + 100 (MP Tray)

1 & 2) + 2,

ut Tray)

inisher)

(5.83”x 8.27”) ~ 305 x 457 mm (12”x 18”)

8”x 5.8”) ~ 320 x 1200 mm (12.6”47”)

in Paper, Bond, Punched, Pre-Printed, Recycled,

, Letterhead, Thick, Cotton, Colored, Archive, Glossy

Plain Paper, Thick Paper, Thin Paper, Bond Paper,

rdStock, Labels, Transparency, Envelope, Preprinted,

cled Paper, Cotton, Archive, Gloss

n Paper, Thin Paper, Bond, Punched, Pre-Printed,

cled, Letterhead,Thick paper

6lb Bond ~ 90lb Index)

lb Bond ~ 90lb Cover)

120 gsm

(16lb Bond ~ 90lb Index)

apacity Feede

+

ray

Original Capacity for DADF 100 sheets

Original Size for DADF

Original Weight for DADF

• Full supported Size : 140 X

• Auto-detected Size : A3, B

• Simplex : 42 ~ 163 gsm (3

• Duplex : 50 ~ 128 gsm (30l

140mm ~ 297 x 432mm (5.5" x 5.5" ~ A3/Ledger)

, B4 SEF, A4, A4 SEF, B5, B5 SEF, A5, A5 SEF

lb Book ~ 90lb Index)

Book ~ 34lb Bond)

Service Manual

2

5

SAMSUNG ELECTRONICS

Page 20

d

Consumables

r

0

0

* Decl

ith 6%

n

a

-

Product

2. Product

Model name

N.A / KOR ELS

escription

Life CLX-9252NA CLX-9352NA

Black Tone

Cyan Toner

Magenta Toner

Yellow Toner

Black Imaging Unit CLT-R607K

Cyan Imaging Unit CLT-R607C

Magenta Imaging Unit CLT-R607M

Yellow Imaging Unit CLT-R607Y

Waste Toner Container CLT-W606

ared yield value in accordance w

CLT-K606S CLT-K60

CLT-C606S CLT-C60

CLT-C607S CLT-C60

CLT-M606S CLT-M6

CLT-M607S CLT-M6

CLT-Y606S CLT-Y60

CLT-Y607S CLT-Y60

patter

** Image counts are based on one color on each pag

Magenta, Cyan, Black), the number of image is 4 im

62S 25K pages O O

62S 20K pages

72S 15K pages O O

62S 20K pages

72S 15K pages O O

62S 20K pages

72S 15K pages O O

75K pages O O

75K pages O O

75K pages O O

75K pages O O

75K images O O

X (Not

Available)

X (Not

Available)

X (Not

Available)

e. If you print a document in full color (Yellow,

ges.

O

O

O

Service Manual

2

6

SAMSUNG ELECTRONICS

Page 21

d

m

Option Unit

0

0

5

5

CLX-HPU001

2-4

r

Fax Kit

CLX-FAX160

G3

c

u

a

0

H

0

of H

-

Hol

(EU)

37/38, PC Fax SW, Fax Manual Softcopy

Wire is the same as the machine s voltage rating)

2. Product

escription

Option Unit Model name Re

Stand CLX-DSK10T

Dual Cassette Tray CLX-PFP000 52

HCF

(High Capacity Feeder)

Bridge Unit CLX-BRG200

Standard Finisher CLX-FIN40S 1,2

Booklet Finisher CLX-FIN40L 3,2

Punch Kit

Working Table CLX-WKT000

Foreign Device Interface

(FDI) Kit

CLX-HCF102 2,0

CLX-HPU000 2-3

CLX-KIT10F Se

ark

Sheet Tray x 2

0 Sheets (LTR, A4)

0 Stacking, Stapling (4 Pos)

0 Stacking, Stapling (4 Pos), Booklet

Holes (NA)

es

ial Port

Fax Multiline Kit CLX-FAX260 G3

SmarThru Workflow Do

CounThru2 Co

Advanced PDF Kit Se

CLX-DHK11C

Heating wire for Cassette,

HCF, DCF

CLX-DHK12C

11

of

22

,

T.

ument Distribution Solution

nter and Cost Management Solution

rchable PDF, Barcode, etc.

V, 10W (equipped by service person at field, voltage rating

eating Wire is the same as the machine’s voltage rating)

V, 10W (equipped by service person at field, voltage rating

’

Service Manual

2

7

SAMSUNG ELECTRONICS

Page 22

d

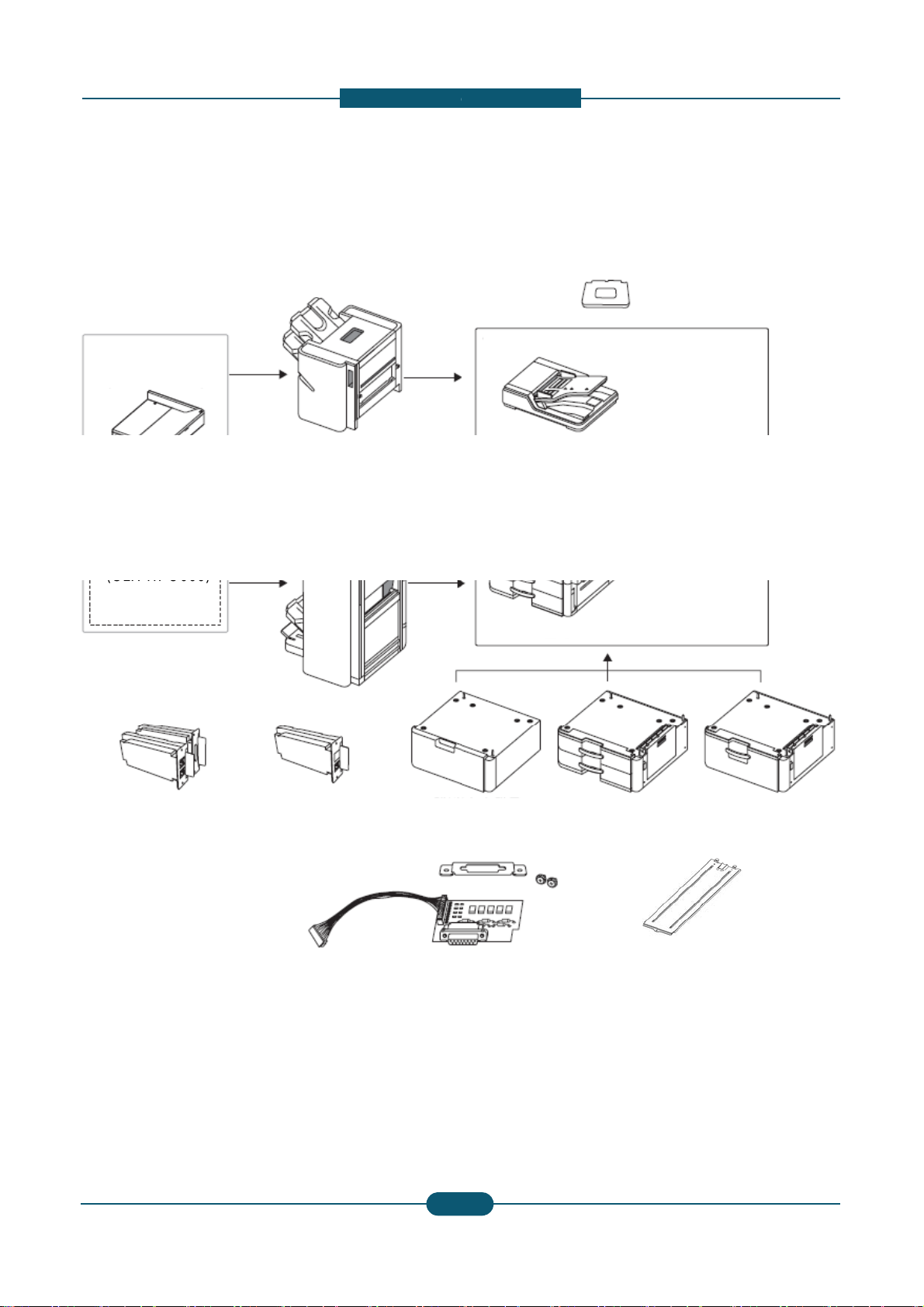

Option unit configuration

(CLX

FIN40S)

(CLX

HPU000)

D

D

X

-

1,250-sheet standard finisher

Bridge kit

(CLX-BRG200)

3,250-sheet booklet finisher

(CLX-FIN40L)

2. Product

escription

Working Table

(CLX-WKT000)

-

Duplex Automatic Document Feeder

2/3 hole Punch kit

-

2/4 hole Punch kit

(CLX-HPU001)

Fax kit

(CLX-FAX160)

Fax multi-line kit

(CLX-FAX260)

(CLX-

(CL

St

and

SK10T)

F

I kit

-KIT10F)

Main unit

(CLX-PFP000)

Optional tray

Cassette Heating cable

(CLX-DHK11C/12C)

High capacity feeder

(CLX-HCF102)

Service Manual

2

8

SAMSUNG ELECTRONICS

Page 23

2. Product

d

C

p

Job seperator

SCX-JST000

X

-

y

XOO

escription

Cosmos / Cosmos-R Option Unit Com

Item Model

Stand CLX-DSK10T O

DCF CLX-PFP000 O

HCF CLX-HCF102 O

Bridge Unit CLX-BRG200 O

1K Finisher CLX-FIN40S O

3K Finisher CLX-FIN40L O

CLX-HPU000 O

Punch Kit

CLX-HPU001 O

Staples Cartridge SCX-STP000 O

Working Table CLX-WKT000 O

FDI Kit CLX-KIT10F O

CLX-FAX150 O

Fax Kit

CLX-FAX160 X

CLX-9250/9350

(Cosmos Color)C(

atibilit

LX-9252/9352

osmos-R Color)

OOO

OOO

OOO

OOO

OOO

OOO

OOO

OOO

OOO

OOO

OOO

XOX

OXO

SCX-8030/8040

(Cosmos Mono)

SCX-8230/8240

(Cosmos-R Mono)

Fax Multi Kit

Heating Wire

for HCF, DCF

Heating Wire

for Scan

CLX-FAX250 O

CLX-FAX260 X

CLX-DHK11C O

CLX-DHK12C O

CLX-DHK11S O

CLX-DHK12S O

XOX

OXO

OOO

OOO

XOX

XOX

Service Manual

2

9

SAMSUNG ELECTRONICS

Page 24

2. Product

d

1

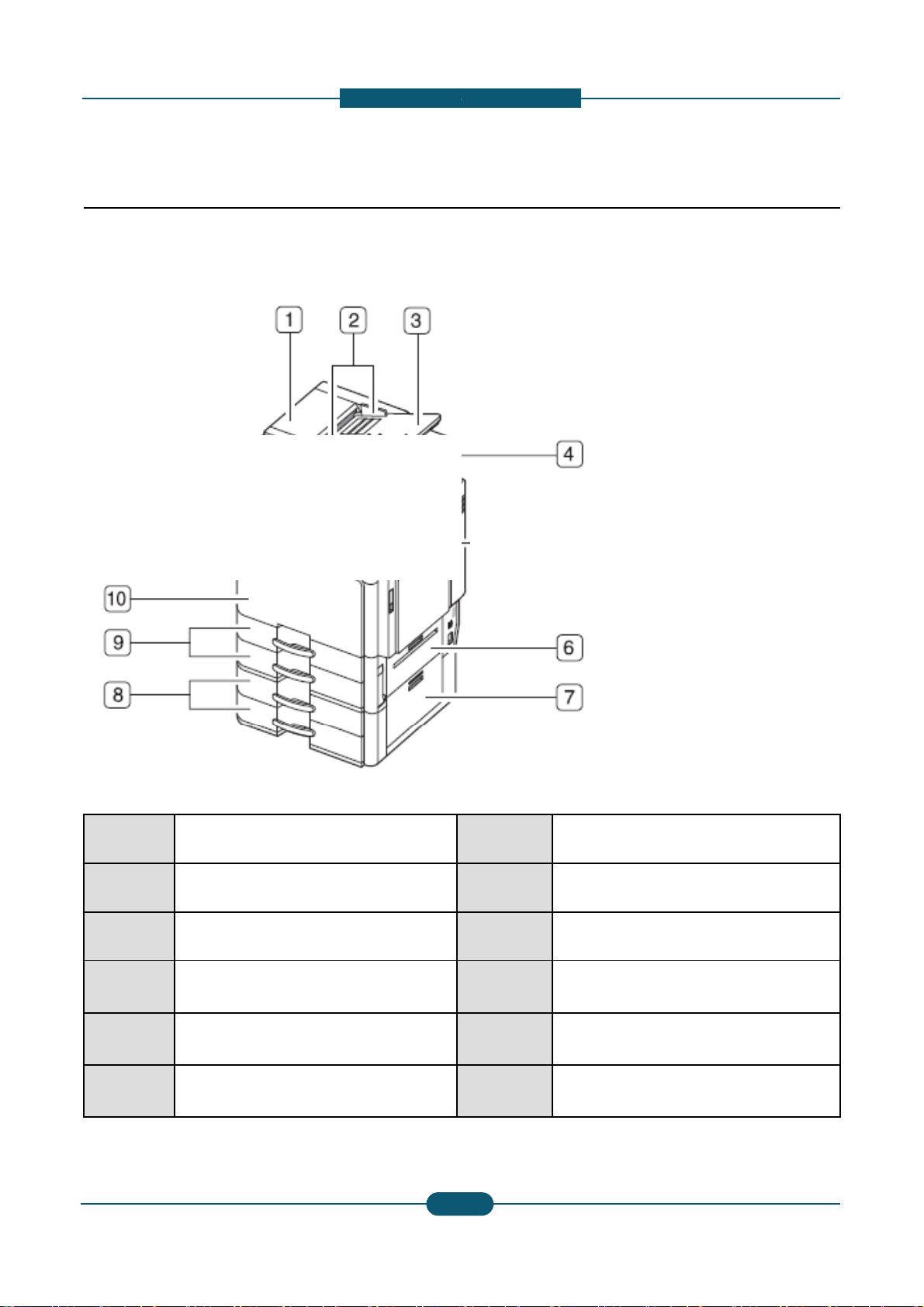

2.2 System configuration

Front view 1

escription

1

2

3

4

6 Standard tray right bottom door

7

Service Manual

Duplex automatic document feeder

cover

Duplex automatic document feeder

width guides

Duplex automatic document feeder

input tray

Duplex automatic document feeder

output tray

Optional dual cassette feeder right

bottom door

8

9 Standard tray (tray 1, tray 2)

10 Front door

11 Front door hand le

12 Contro l panel

13 Cente r tray

2-

0

Optional dual cassette feeder (tray 3,

tray 4)

SAMSUNG ELECTRONICS

Page 25

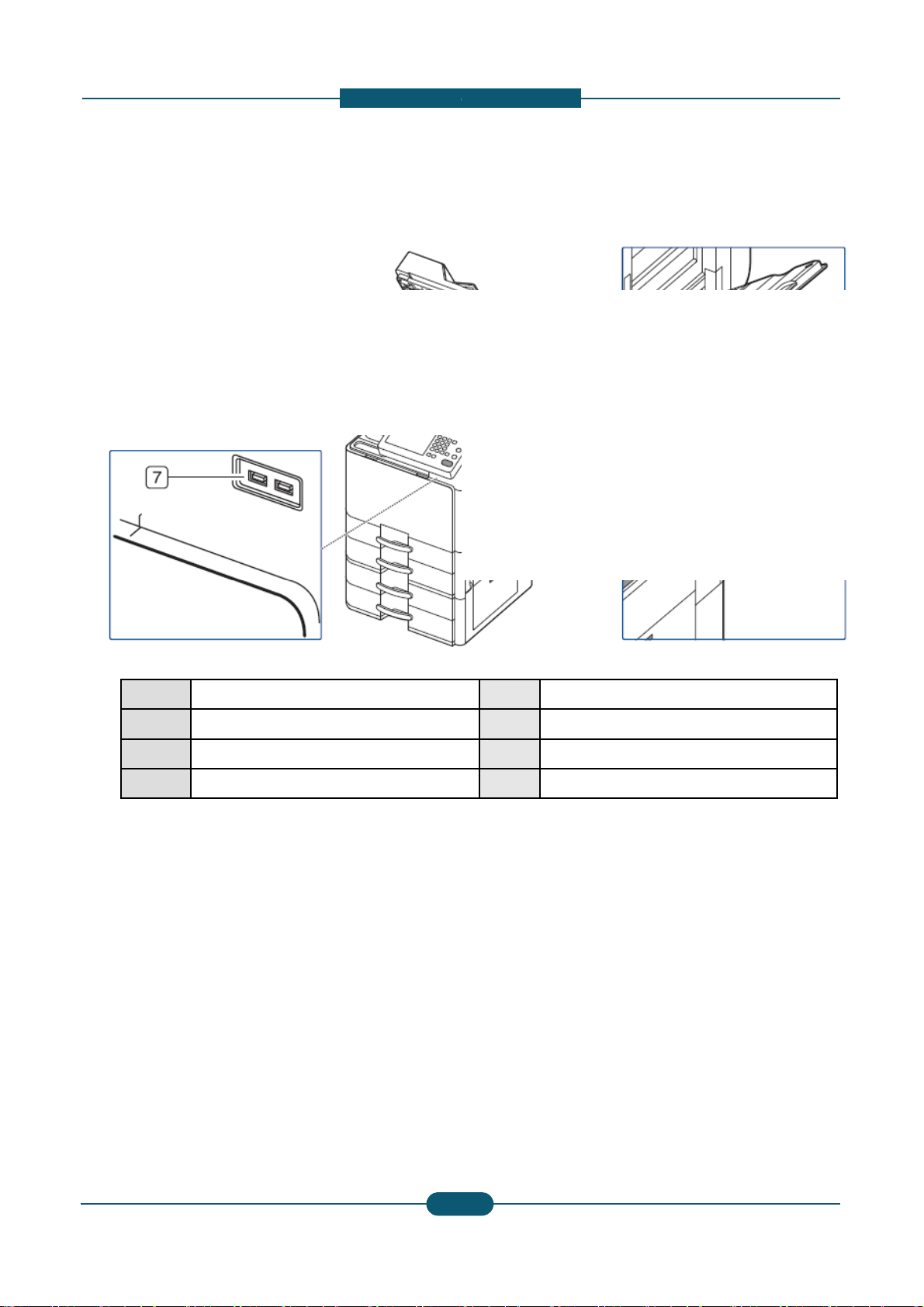

d

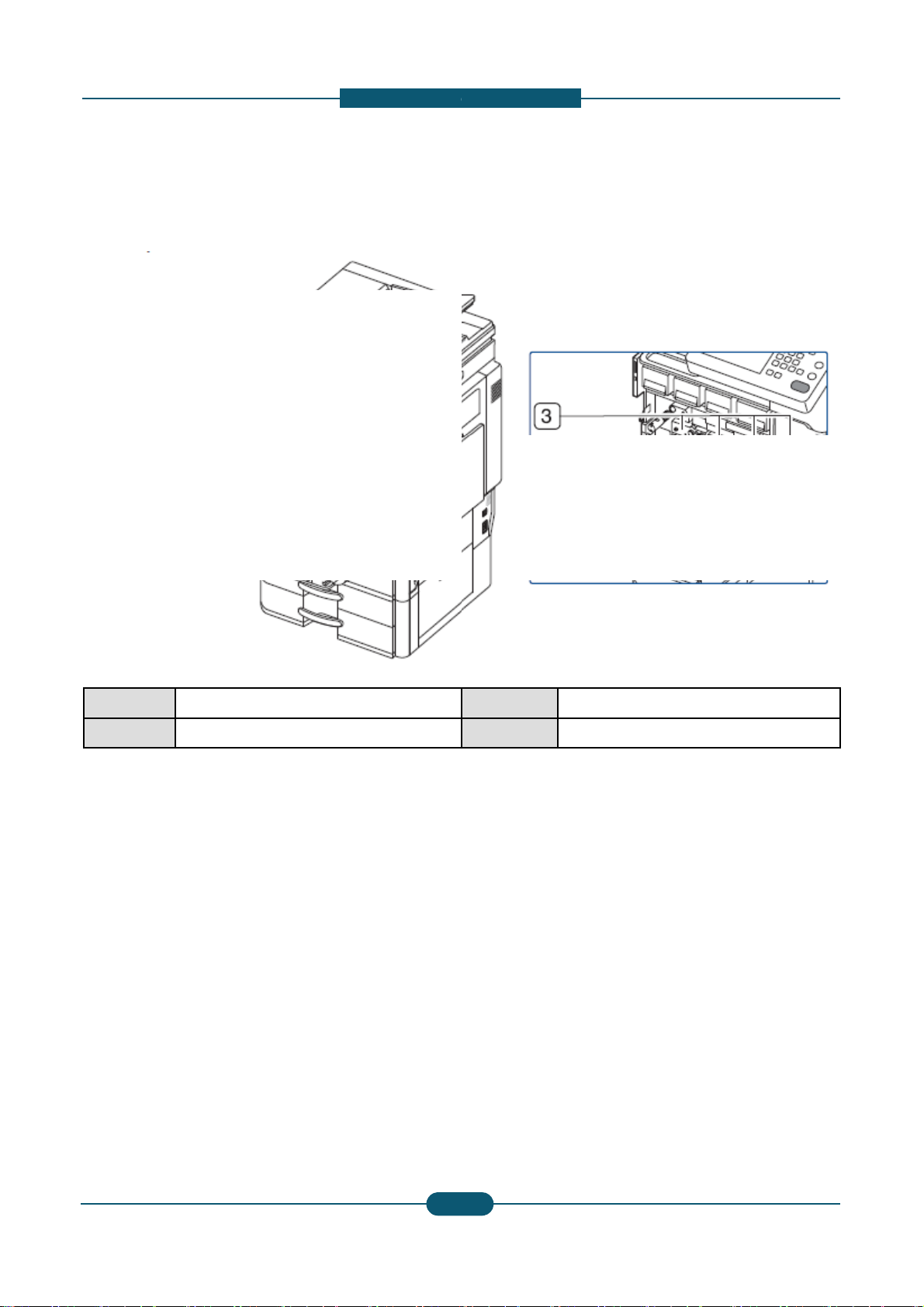

Front view 2

2

White sheet

1

6

Power receptacle

2. Product

escription

1 Scanner glass

3 Multi-purpose tray

4 Multi-purpose tray paper width guide

5 Power-switch

7 USB port (2 EA)

Service Manual

2-

1

SAMSUNG ELECTRONICS

Page 26

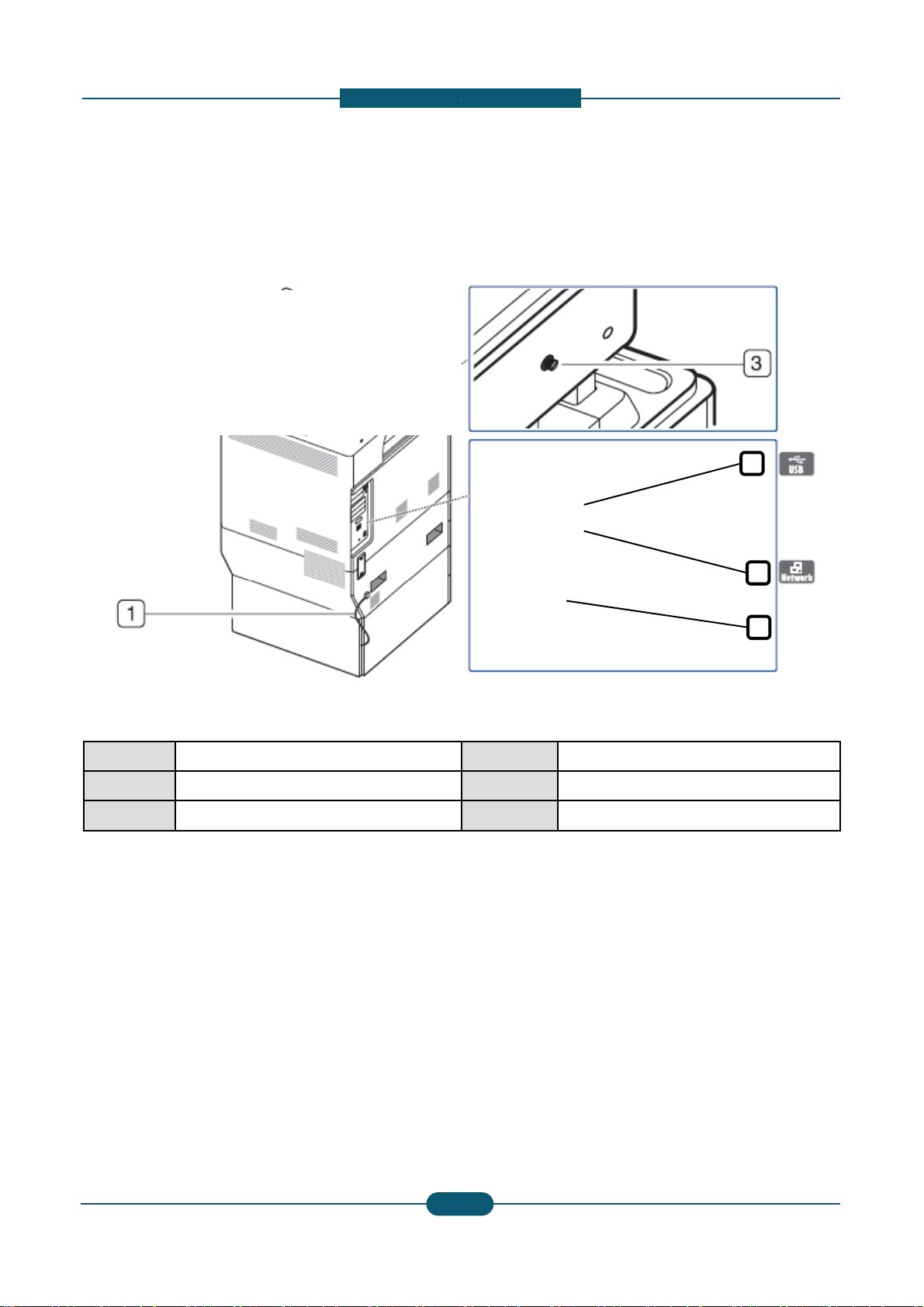

d

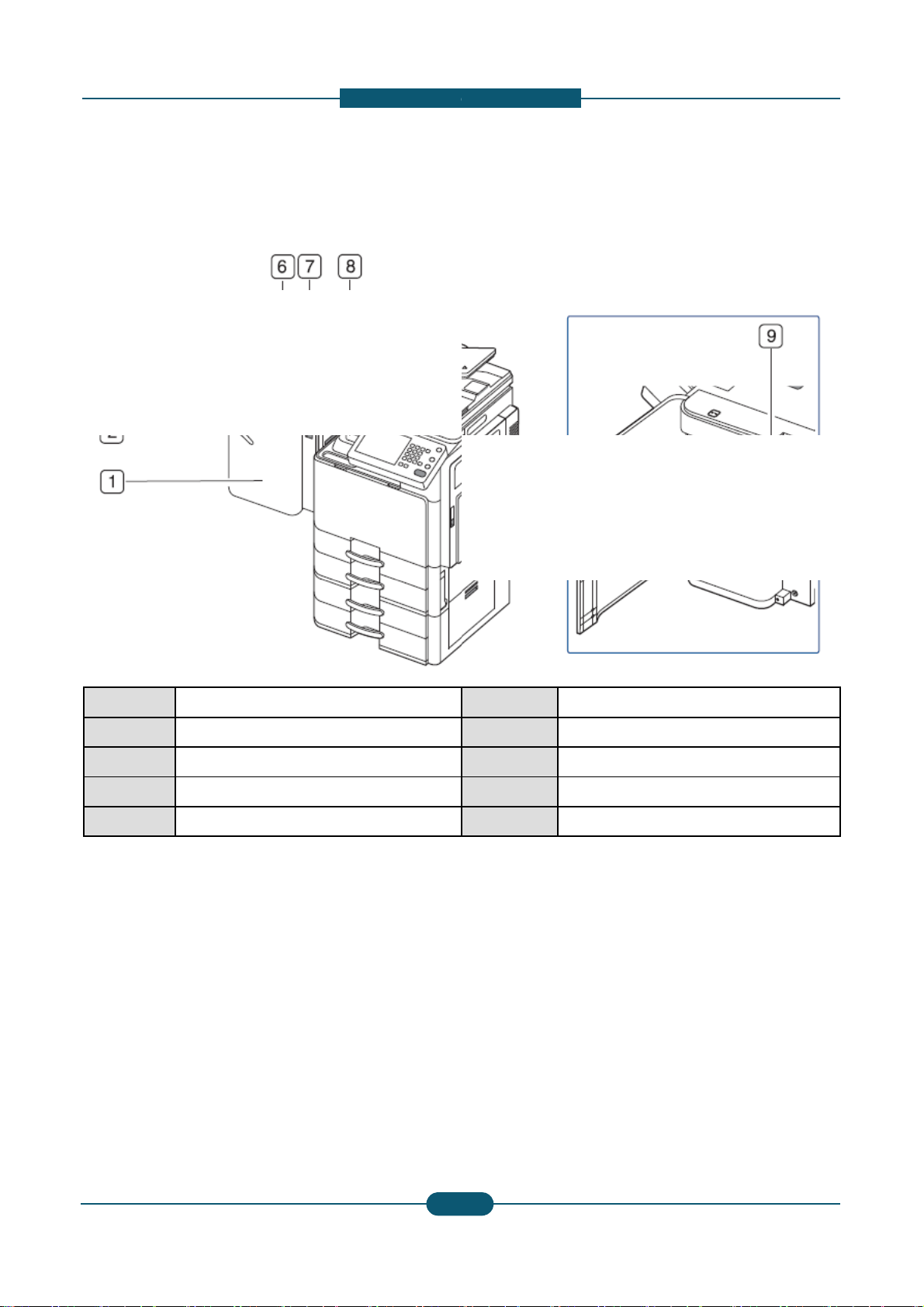

Rear view

1

2. Product

escription

4

1 Optional dual cassette feeder cable

2 DADF cable

3 Scanner locking screw

6

5

4 USB host port

5 Finisher connector

6 Network port

2-

Service Manual

2

SAMSUNG ELECTRONICS

Page 27

d

Inner view

1

2. Product

escription

1 Waste toner container

2 Toner cartridge

3 Imaging units

4 Inner cover

2-

Service Manual

3

SAMSUNG ELECTRONICS

Page 28

2. Product

d

V

1

escription

iew with standard finisher (option

al)

1 Standard finisher front door

2 Manual stapler

3 Manual stapler button

4 Finishing tray

5 Top tray

6 Top door

7 Standard finisher Front door handle

8 Bridge Unit

9 Staple

Service Manual

2-

4

SAMSUNG ELECTRONICS

Page 29

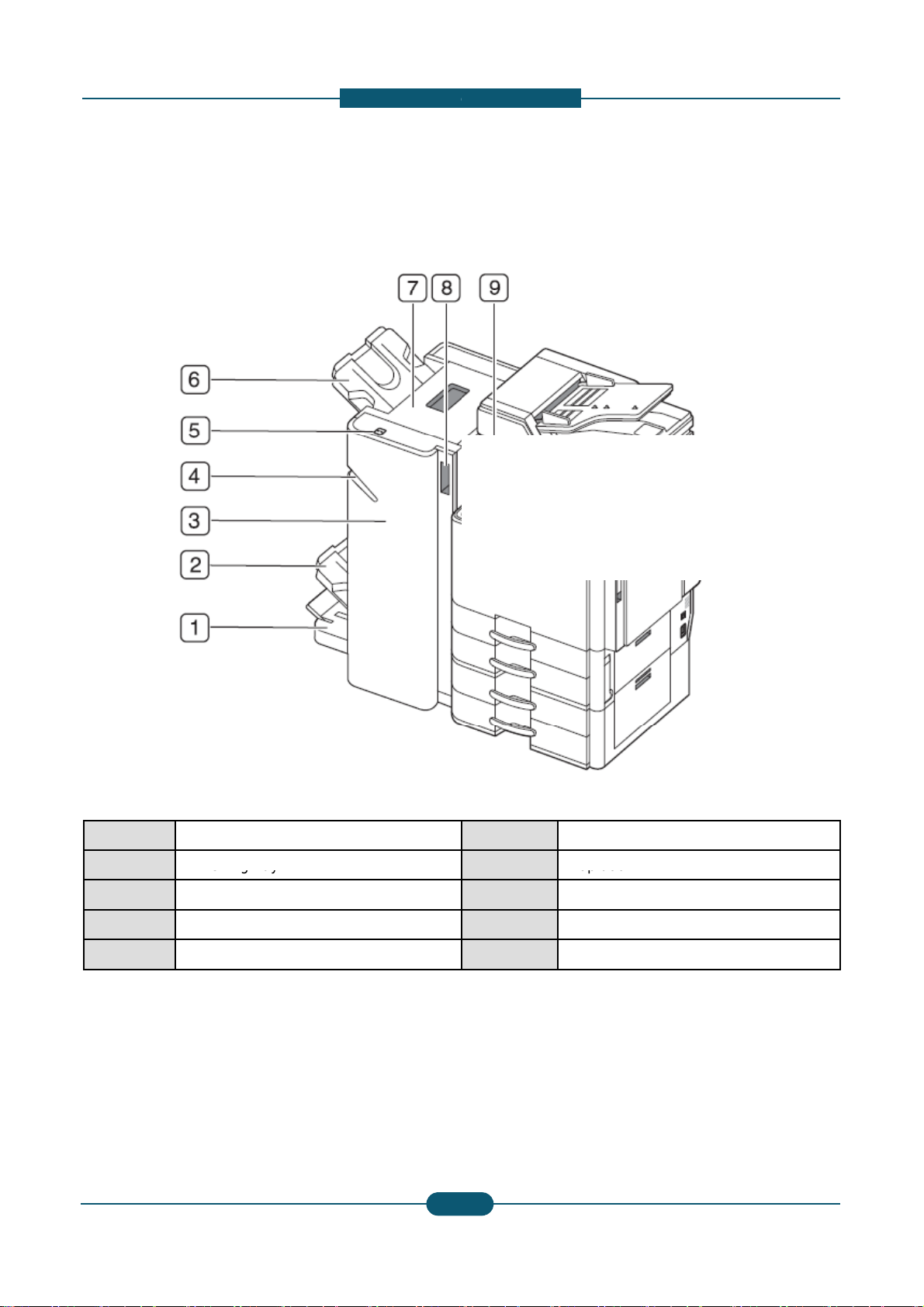

2. Product

d

a

2

Finishing tray

1

7

Top door

escription

View with booklet finisher1 (option

l)

1 Booklet tray

3 Booklet finisher front door

4 Manual stapler

5 Manual stapler button

Service Manual

6 Top tray

8 Booklet finisher front door handle

9 Bridge Unit

2-

5

SAMSUNG ELECTRONICS

Page 30

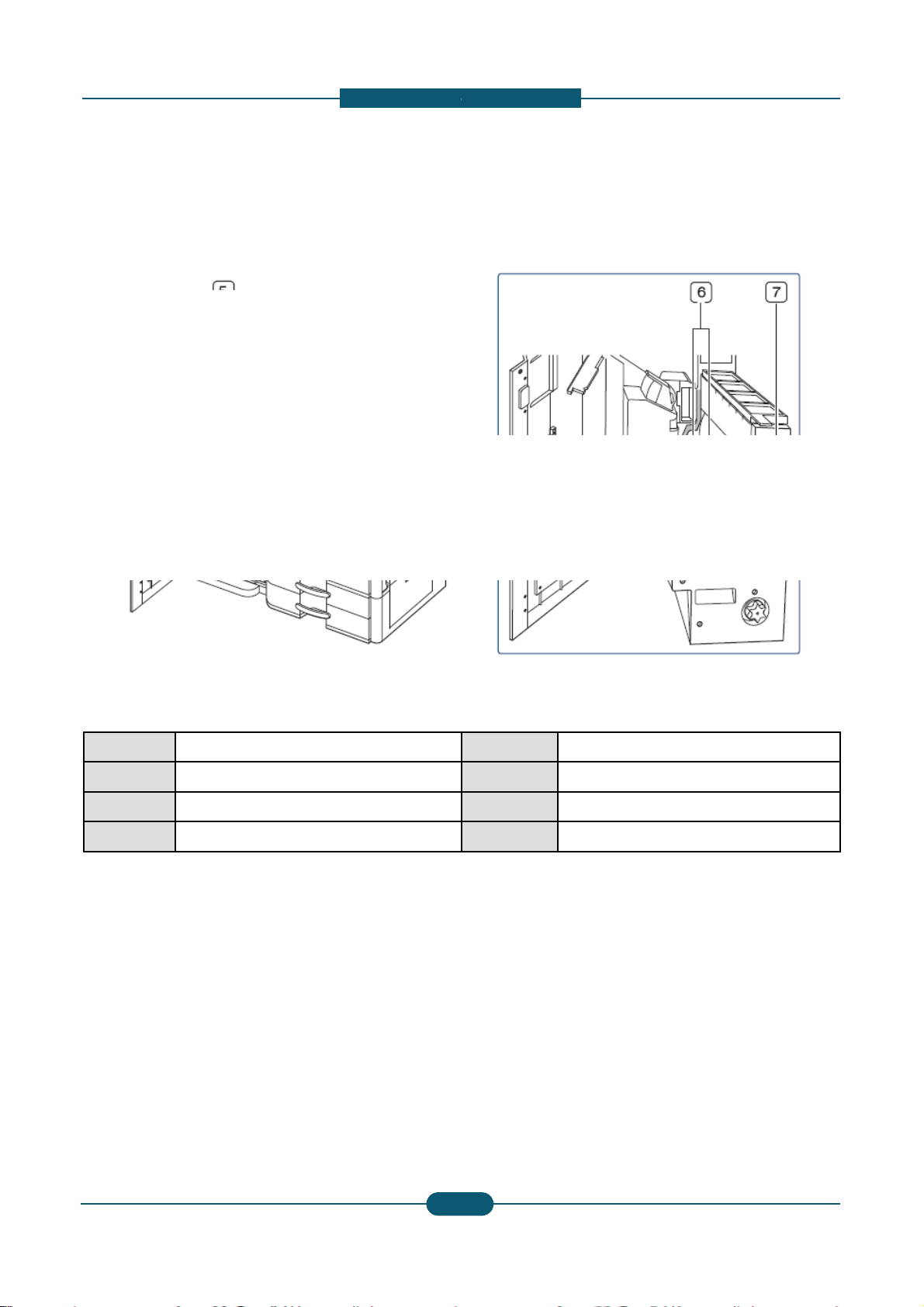

2. Product

d

a

1

escription

View with booklet finisher2 (option

l)

1 Knife wheel

2 Booklet maker handle

3 Fold wheel

4 Booklet jam removal wheel

5 Staple

6 Booklet Staple (2 EA)

7 Booklet maker cover

2-

Service Manual

6

SAMSUNG ELECTRONICS

Page 31

2. Product

d

p

y

pg

y

a

/

d

1

y

15

escription

Layout

1

2

3

4

5

6

7

17

16

14

13

12

8

9

1 DADF 7 Laser s

2 Du

3 Output tray 9 2ndtray

4 Toner cartridges 10 Option

5 Image Transfer Belt

lex guide 8 1sttra

11 Pick up

(ITB) unit

(Stand

Forwar

11

10

canning unit 13 2ndtransfer roller unit

14 Fuser unit

15 Flatbed scanner

l tray

HCF / DCF)

/ Retard /

rollers

16 Document output tray

17 Document input tray

Service Manual

6 Imaging units 12 MP tra

2-

7

SAMSUNG ELECTRONICS

Page 32

d

o

Paper Path

D

Finisher

1

Simplex

2. Product

escription

The following diagram displays the path the paper foll

path

ws during the printing process.

ADF

path

path

Duplex

path

Service Manual

2-

8

SAMSUNG ELECTRONICS

Page 33

d

2.3 Sensor location

a

S1

PBA SENSOR ACR

S7

PHOTO

INTERRUPTER

1

JC32

00012A

JC92

02580A

0604

001393

2. Product

escription

The following diagrams display the printer sensor loc

tions.

Ref. Description

S3 SENSOR-HUMIDITY

S4 PBA SENSOR ACR

S5 PBA SENSOR ACR

S6 SWITCH FRONT COVER

S8 PHOTO-INTERRUPTER

S9 PHOTO-INTERRUPTER

S10 PHOTO-INTERRUPTER

S11 PHOTO-INTERRUPTER

S12 SENSOR-PAPER SIZE

Service Manual

Part

Number

Controller PCB

JC32-00005A

JC32-00012A

JC32-00012A

JC32-00012A

-

0604-001393

0604-001393

PBA-MAIN

CLX-9352NA

:

-

CLX-9252NA

: JC92-02581A

0604-001393

0604-001393

JC32-00013A

2-

9

SAMSUNG ELECTRONICS

Page 34

2. Product

d

S17

PHOTO

INTERRUPTER

2

S23

SENSOR

DEVELOPER

: JC92

02580A

0604

001370

PBA

MAIN

Part

A

JC32

00010A

escription

Ref. Description

S13 SENSOR-PAPER SIZE

S14 SENSOR-HUMIDITY

S15 PBA-COVER OPEN SENSOR

S16 PHOTO-INTERRUPTER

-

S18 PHOTO-INTERRUPTER

S19 CCD

Part

Number

JC32-00013A

JC32-00005A

JC92-02143A

0604-001393

-

0604-001370

0605-001158

Controller PCB

PBA-MAIN

CLX-9352NA

-

CLX-9252NA

: JC92-02581A

PBA-SCAN JOINT

(JC92-02144A)

-

CLX-9352NA

: JC92-02580A

CLX-9252NA

: JC92-02581A

Service Manual

Ref. Description

S20 SENSOR-DEVELOPER

S21 SENSOR-DEVELOPER

S22 SENSOR-DEVELOPER

-

Number

JC32-00010A

JC32-00010A

JC32-00010A

-

2-

0

Controller PCB

PBA-MAIN

CLX-9352NA

: JC92-02580A

CLX-9252N

: JC92-02581A

SAMSUNG ELECTRONICS

Page 35

2. Product

d

2

CLX-9252NA

escription

Ref. Description

S31 PHOTO-INTERRUPTER

S32 PHOTO-INTERRUPTER

S33 PHOTO-INTERRUPTER

S34 PHOTO-INTERRUPTER

S35 PHOTO-INTERRUPTER

S36 PHOTO-INTERRUPTER

S37 PHOTO-INTERRUPTER

Service Manual

Part

Number

Controller PCB

0604-001393

0604-001393

PBA-ENGINE

0604-001393

CLX-9352NA

0604-001393

: JC92-02129A

0604-001381

0604-001393

: JC92-02239A

0604-001393

2-

1

SAMSUNG ELECTRONICS

Page 36

2. Product

d

S40

PHOTO

INTERRUPTER

S

2

0604

001393

0604-001399

escription

Ref. Description

S38 PHOTO-INTERRUPTER

S39 PHOTO-INTERRUPTER

S41 PHOTO-INTERRUPTER

S42 PHOTO-INTERRUPTER

S43 PHOTO-INTERRUPTER

S44 PHOTO-INTERRUPTER

45 PHOTO-INTERRUPTER

S46 PHOTO-INTERRUPTER

S47 VR-SLIDE

S48 PHOTO-INTERRUPTER

S49 PHOTO-INTERRUPTER

S50 PHOTO-INTERRUPTER

S51 PHOTO-INTERRUPTER

Part

Number

0604-001393

0604-001393

0604-001393

0604-001393

0604-001393

0604-001393

0604-001381

2102-001020

0604-001393

0604-001381

0604-001393

0604-001393

Controller PCB

PBA-MAIN

CLX-9352NA

: JC92-02580A

CLX-9252NA

: JC92-02581A

S52 PHOTO-INTERRUPTER

S53 PHOTO-INTERRUPTER

S54 PHOTO-INTERRUPTER

S55 PHOTO-INTERRUPTER

0604-001393

0604-001381

0604-001393

0604-001393

Service Manual

2-

2

SAMSUNG ELECTRONICS

Page 37

2. Product

d

u

e

s

p

p

Tray1 paper

motor

2

T

e

e

T2

Tray2 upper limit detection

2.4 Paper handling section

escription

The paper feeding system mainly consists of the Pick

Registration roller, MP Paper sensor, Paper Empty s

Tray Feed sensor, Registration sensor, and Drive sy

Return

Exit tray1 paper

full detection

Exit tray1 jam detection

Return

Paper jam detection

Paper curl detection

ath solenoid

Exit

Fuser

p roller, Forward roller, Retard roller, Transport roller,

nsor, Tray Paper Stock sensor, MP Feed sensor,

tem for these components.

Exit2 tray path solenoid

Exit tray2 paper

full detection

Duplex jam detection1

Duplex

Paper regi. time detection

Tray1 paper remaining

quantity detection

Tray1 paper

empty detection

Paper tray

size detection

Tray2 paper

empty detection

Tray2 paper

size detection

Service Manual

ITB

Regi

MPF solenoid

Tray1 upper limit detection

Tray1 lift

Tray2 lift

motor

ray2 pap

quantity d

Pick Up

r remaining

tection

2-

3

Duplex jam detection2

Duplex clutch

MPF

clutch

MPF paper

empty

detection

MPF media size detection

Tray1 transport detection

Tray2 transport detection

MPF

MPF media

size detection

(Long media)

SAMSUNG ELECTRONICS

Page 38

2. Product

d

s

r

Tray1 paper empty detection

Detects tray1 paper e

i

p

s

r

T

Detects t

e

i

p

T

o

Paper jam detection

Detects fuser jam

MPF solenoid

MPF pick up roller up

s

s

o

Duplex jam detection 2

Detects duplex jam 2

p

e

e

e

2

y

CN4@ Cassette Joint PBA, 3Pin

y

ty

CN4@ C

PBA, 3Pi

CN5 @ SIDE JOINT PBA, 3PIN

CN2 @ SIDE JOINT PBA, 3PIN

CN6 @ SIDE JOINT PBA, 3PIN

y

escription

Name Funct

Tray1 paper size detection Detects tray1 paper

Tray1 paper remaining quantity

detection

Detects tray1 paper

Tray1 upper limit detection Detects tray1 upper l

Tray1 transport detection Detects tray1 paper

Tray2 paper size detection Detects tray2 paper

Tray2 paper remaining quantity

detection

ray2 paper empty detection

Detects tray2 paper

ray2 paper

Tray2 upper limit detection Detects tray2 upper l

Tray2 transport detection Detects tray2 paper

Paper regi. time detection Detects paper regi.

Paper curl detection Detects paper positi

Face down tray jam detection Detects exit jam

Face down tray paper full

detection

Detect paper full

Exit2 tray path solenoid Change paper path

ion connector & pin information

ize (installation) CN2@ Cassette Joint PBA, 4Pin

emaining quantit

CN8@ Cassette Joint PBA, 6Pin

mit CN3@ Cassette Joint PBA, 3Pin

ass CN3@ Cassette Joint PBA, 3Pin

ize (installation) CN2@ Cassette Joint PBA, 4Pin

emaining quantit

mp

CN8@ Cassette Joint PBA, 6Pin

assette Joint

n

mit CN3@ Cassette Joint PBA, 3Pin

ass CN3@ Cassette Joint PBA, 3Pin

ime CN18@ Engine PBA, 3PIN

n CN5@ SIDE JOINT PBA, 6PIN

CN18@ Engine PBA, 3PIN

CN18@ Engine PBA, 3PIN

CN8 @ SIDE JOINT PBA, 3PIN

Return path solenoid Change paper path

MPF media size detection Detects MPF paper

MP media size detection

(Long media)

Detects MPF paper

MPF clutch MPF driving control

Duplex clutch Duplex driving contr

Duplex jam detection 1 Detects duplex jam 1

Exit tray 2 paper full detection Detects exit tray2 pa

MPF Paper empty detection Detects MPF paper

Tray1 Lift Motor Lifting knock up plat

Tray2 Lift Motor Lifting knock up plat

CN18@ Engine PBA, 3PIN

ize CN7 @ SIDE JOINT PBA, 3PIN

ize CN7 @ SIDE JOINT PBA, 3PIN

CN2 @ SIDE JOINT PBA, 2PIN

l CN4 @ SIDE JOINT PBA, 2PIN

CN6 @ SIDE JOINT PBA, 3PIN

er full CN6 @ SIDE JOINT PBA, 3PIN

mpt

CN7 @ SIDE JOINT PBA, 3PIN

CN4@ Cassette Joint PBA, 3Pin

CN4@ Cassette Joint PBA, 3Pin

Service Manual

2-

4

SAMSUNG ELECTRONICS

Page 39

d

2.4.1 Components

i

2

25

forward rollers

19

13

Tray 4 feed roller

full

2. Product

escription

The following diagrams display the positions of the pr

22

23

21

nter components

24

20

16

14

17

18

15

1 Tray 1 Paper tray

2 Tray 2 Paper tray

3 Tray 3 Paper tray

4 Tray 4 Paper tray

5 Tray 1 pick up / retard /

6 Tray 2 pick up / retard /

forward rollers

7 Tray 3 pick up / retard /

forward rollers

8 Tray 4 pick up / retard /

forward rollers

9 MP Tray pick up /

retard / forward rollers

10 Tray 1 feed roller

11 Tray 2 feed roller

12 Tray 3 feed roller

14 Bypass feed roller

9

10

1

5

11

2

6

12

7

15 Sensor registration

16 Roller registration

nd

17 Roller 2

18 Sensor fuser in

19 Roller fuser

20 Sensor fuser out

transfer

3

13

8

21 Roller exit

22 Roller face down exit

4

23 Actuator face down bin

24 Sensor duplex return

25 Roller duplex return

Service Manual

2-

5

SAMSUNG ELECTRONICS

Page 40

d

d

2.4.2 Functions

Pickup Roller (paper tray and bypass feed)

o

Retard Roll

d)

d

e

d

yg (pp y yp

e

a

e

This sensor detects whether paper is set in the bypass

o

a

d

c

Feed Sensor

e

r

r

2

)

tray

When it is, bypass feeding always comes

2. Product

escription

This section describes the functions of the paper han

This roller moves up and down and draws out the pap

the feed roller.

Forward Roller (paper tray and bypass feed)

This roller is placed against the retard roller. It transp

transport roller.

er (paper tray and bypass fee

This roller is placed against the feed roller. When two

pickup roller, the load of the torque limiter of the retar

sheets. As a result, the retard roller is stopped and th

only one sheet is transported from the pickup roller, th

roller.

Conveying Roller (paper tray and bypass fee

This roller transports the paper sent from the feed roll

Registration Roller

Paper transported from the transport roller is pushed

edge of the paper. Then, the registration rollers rotat

ling components.

er from the bypass tray or drawer and transports it to

rts the paper from the pickup roller to the

sheets of paper or more are transported from the

roller is heavier than the frictional force between the

lower paper does not advance any further. When

e retard roller rotates following the feed

r to the registration roller.

gainst the registration roller which aligns the leading

to transport the paper to the transfer unit.

Bypass Paper Sensor

before drawer feeding.

Empty Sensor (Tray 1 / Tray 2)

This is a transmissive-type sensor and it detects the a

When there is no paper in the drawer, the actuator bl

determines that there is no paper.

Paper Stock Sensor

This is a transmissive-type sensor which detects the

actuator. When the remaining paper is consumed an

blocks

the light path for the transmissive-type sensor to dete

This sensor detects if the leading edge or trailing edg

detects jamming such as missfeeding.

Registration Sensor

This sensor detects that the leading edge of the pape

trailing edge of the paper has passed the registration

.

vailability of paper in the drawer by using an actuator.

cks the light path of the sensor, and the sensor

mount of remaining paper in the drawer using an

approximately 100 sheets remain, the actuator

t that there is less paper.

of the paper has passed the feed roller. It also

has reached the registration roller and that the

oller.

Service Manual

2-

6

SAMSUNG ELECTRONICS

Page 41

d

2.4.3 Paper tray

e

p, pp

A

m

•

Paper

:

7

s

o

2

2. Product

escription

The paper trays consist of the Main trays, Optional tra

The MP tray is located on the right side of the machin

envelopes, and custom size paper.

Paper size is set using the Size Guides in each tray.

paper size.

ys (DCF,HCF), and one Multi-Purpose (MP) tray.

and allows feeding of specialty media stock,

djust the Front, Rear, and End Guides to match the

Specification

• Structure : Paper tray Type, Auto Paper Size

• Capacity : 520 Sheets ( 80g/㎡ standard Xerox Pre

-. Plain paper : A5, A4, A3, B5, B4, Letter, 11"×1

-. Special Paper : 12"×18", Label, Card stock

• Weight : plain paper 60 ~ 216g/㎡

• Plate knock up Lift type : Lift Motor + Up Limit Sens

Service Manual

inum)

"(Ledger), Statement, Legal

(Label : 50 sheets, Thick Card

tock [170~216 g/㎡ : 350 sheets)

r

2-

7

SAMSUNG ELECTRONICS

Page 42

d

2.4.4 Pick up unit

w

o

roller serve to make sure that a single sheet of paper i

c

2

s moved to the paper path, and the paper is moved

2. Product

escription

When pickup takes place, the pickup roller moves do

The pickup roller moves down when the pickup solen

as far as the registration roller by the work of the verti

pickup roller:

Actuator-Empty Sensor

n to come into contact with the surface of the paper.

id is activated. The forward roller and the retard

al path roller. The following is a diagram of the

Forward Roller

Retard Roller

Pick Up Roller

Service Manual

2-

8

SAMSUNG ELECTRONICS

Page 43

d

t

l

2.4.5 Registration unit

roller in order to match paper and an image on the dru

a

■

Specification

F

F

Duplex Side Margin

±

2.0 mm

Tray3

2

the predetermined registration point

HCF : 4.23

±

2.0 mm )

2. Product

escription

The registration roller is driven by the registratio n mul

between the registration roller and the registration mu

Sh

Jam removal lever

Regi sensor

i motor. The registration clutch (CL6) is located

ti motor, and it controls ON/OFF of the registration

at

.

ft-regi

Regi roller

Transparency

detection sensor

1) Skew in Simplex

-. Top Skew : 1.5 mm

-. Side Skew : 2.0 mm

2) Dog Ear, Trees, Nicks, Wrinkling

-. Special Media : 1/500

3) Margin

-. Top Margin : 4.23 ± 1.5 mm ( Tray3, 4, HC

-. Side Margin : 4.23 ± 1.5 mm ( Tray3, 4, HC

-. Duplex Top Margin : 4.23 ± 2.0 mm ( Tray3

.

-

: 4.23

(

: 4.23 ± 2.0 mm )

: 4.23 ± 2.0 mm )

, 4, HCF : 4.23 ± 2.0 mm )

, 4,

Service Manual

2-

9

SAMSUNG ELECTRONICS

Page 44

d

2.4.6 MPF unit

P

n

g sp

L

gp

pp (

), pp (

n

3

MPF Clutch

g)

)(ggg)

The following is a diagram of the MFP unit:

MPF Pick up roller

Empty sensor

MPF

Tray

2. Product

escription

Long paper sensor

Specification

• Tray capacity : 100 sheets( 80g/㎡ standard Xerox

• Media Size : Max 12.6”×17.7” (320.6×450㎜) / Mi

• Media weight : Plain paper 60 ~ 253g/㎡

• Feedin

eed : 30 ppm (CLX-9352NA), 20 ppm (C

•Auto size sensing : A6 SEF, Statement SEF, B5 S

LTR(Letter) LEF, A3, A4 LEF

Paper Separation

When the by-pass paper detection [A] sensor detects

the by-pass solenoid [B] drops the pick-up roller [C] o

After that, the pick-up roller moves one

sheet of paper to the feed roller.

This machine uses an FRR (Feed and

Reverse Roller) system for feeding paper.

There is friction between the feed roller [E]

and retard roller [D]. This friction separates

the top sheet of paper from the stack.

reminum )

3.87”×5.8” (98×148㎜)

X-9252NA) in Letter/A4 LEF (Long Edge Feedin

EF, A4 SEF, A5 LEF, B4 B5(JIS) LEF, 11x17,

paper and the machine gets a by-pass printing job,

to the top of the paper stack on the by-pass tray.

Service Manual

2-

0

SAMSUNG ELECTRONICS

Page 45

d

2.5 Image creation

v

e

M

a

a

b

of a Drum unit and Development unit

Each Drum unit

n

d

g

o

iti

s

h

h

e

e

p

r

3

r

C

a

has an OPC drum, Charge

Scorotron

Eraser and

[E]

2. Product

escription

This section describes the image creation process us

2.5.1 Printing process ov er

This color printing system includes the LSU with four l

unit. The 4 imaging units are: Yellow, Magenta, Cyan

d by the printer.

iew

Paper path

ser beams, four imaging units, ITB unit and transfer

nd Black (from left to right as shown in the diagram).

This machine uses four Imaging units, and four laser

.

Cleaning blade. From the left, the Imaging unit statio

The OPC drum [A] is charged with a negative voltage

from the LSU (Laser Scanning unit) [B]. The light pro

discharging on the surface of the OPC drum. The ne

image due to an electric field. The toner (real image)

the positive bias applied to the first transfer roller [C].

paper by a pos

Process Steps

1. OPC drum charge: The Charge Scorotron gives t

2. Laser exposure: Light produced by a laser diode

3. Development: This machine uses a dual-compon

negatively charged toner to the latent image on th

imaging units (one for each color).

4. Transfer:

a. First transfer: The first transfer rollers op

the transfer belt. Four toner images are supe

ve charge applied to the second tran

eams for color printing. Each Imaging unit consists

s are: yellow, cyan, magenta, and black.

by the Charge Scorotronand is exposed by the light

uced by the laser creates a latent image by

atively charged toner is attracted to the latent drum

n each OPC drum is moved to the transfer belt by

All four toners (color image) are transferred to the

er roller

e drum a negative charge.

its the charged OPC through the lens and mirrors.

nt development system. The magnetic roller carries

drum surface. This machine uses four independent

osite the OPC drums transfer toner from the drums to

-imposed onto the belt.

.

,

b. Second transfer: The transfer roller transfe

Service Manual

s the toner from the transfer belt to the media.

2-

1

SAMSUNG ELECTRONICS

Page 46

2. Product

d

b

a

v

D

n

s

p

pg

o

3

escription

5. Cleaning for OPC drum: The cleaning brush and

after image transfer to the paper.

6. Quenching for OPC drum: Quenching is done by i

at the end of every job.

7. Cleaning and quenching for transfer belt: The cle

grounding roller inside the transfer belt unit remo

lade remove remaining toner on the drum surface

lluminating the whole area of the drum with the laser

ning brush and blade clean the belt surface. The

es the remaining charge on the belt.

8. ID sensors: The ID sensors detect the density of I

sensors for the line position adjustment (front, ce

[A]: Line position adjustment (front)

[B]: Line position adjustment (center) & proce

[C]: Line position adjustment (rear)

[D]: Humidity Sensor (Internal).

The ID sensor out

ut is used for the following:

- Process control and for automatic line positi

- Skew correction

- Color registration adjustments for the latent i

sensor patterns on the transfer belt. Three ID

ter, and rear) and process control.

s control

n

mage.

2-

Service Manual

2

SAMSUNG ELECTRONICS

Page 47

d

2.5.2 Imaging unit

e

b

r

g

b

o

u

u

C

3

2. Product

escription

2.5.2.1 Imaging unit ov ervi

Each Imaging Unit consists of the OPC drum unit and

OPC drum, Charge Scorotron, Eraser, and Cleaning

two mixing augers, developer, and a TD sensor. Fou

(drum unit, development unit, etc.), however, the Ima

The diameter of the drum is 30 mm (circumference: a

The developing gap between a drum and the corresp

they are assembled as one Imaging unit at the factory

The cleaning blade removes excess toner from the dr

The CRUM chip in the image unit stores the data abo

OP

Magnetic Roller

w

the development unit. The OPC drum unit has an

lade. The development unit has a magnetic roller,

color Imaging Units contain identical components

ing Units are not interchangeab le.

out 94.2 mm).

nding magnetic roller cannot be adjusted becaus e

.

m surface after image transfer to the transfer belt.

t the Imaging unit.

Drum

Cleaning blade

Eraser

harge scorotron

Mixing Auger

Service Manual

C

2-

3

SAMSUNG ELECTRONICS

Page 48

d

2.5.2.2 Drum drive

o

Y

e

Phase sync for each OPC

runout

prints the pattern on

K

D

C

3

r

the ITB and is adjusted by the data automatically

r

BLDC motor

2. Product

escription

Each color OPC and Mag Roller is driven by each col

Drive transmission gear

Drum phas

Coupling

Drum-Y

Drum-M

r motor.

senso

M Drum phase senso

C Drum phase sensor

.

K Drum phase sensor

rum-

Coupling OPC

Coupling Deve

Drum-

Drive motor BLDC

Gear-Drive OPC

Service Manual

2-

4

SAMSUNG ELECTRONICS

Page 49

2. Product

d

h

t

o

m

b

g

q

a

A

2.5.2.4 D

t

n

e

n

e

m

3

Mixing

Sensor

[B]

[] g g

escription

2.5.2.3 Phase Control Mec

The printer uses the drum gear position sensors to de

mode shows when it detects that the drum motor is n

initialize the relative positions of the gears when the

prevents phase fluctuation between printouts caused

There is an interrupter on each drum gear. The drum

interrupters. This mechanism makes sure that outp ut

Immediately after the printer power turns on, recovers

opened and closed, the printer executes the drum ph

occurs:

• When a new imaging unit is installed.

• When a new cartridge transfer belt unit is installed.

lso, when the printer detects a shift in the drum posit

executes the drum phase adjustment.

evelopmen

anism

ect whether the drum motors are rotating. Diagnostic

t moving. These sensors also help the printer to

ain switch is turned on, and during initializing. This

y incorrect gear meshing at the start of the job.

ear position sensors detect the positions of these

uality does not vary.

from the energy saver mode, or the front door is

se adjustment if one of the following conditions

ions during the line position adjustment, the printer

[A] Developme

This printer uses a dual-component development syst

the drum units; one for each color). Each new unit co

in each unit is supplied to the magnetic roller [A] by th

surface of the roller. The diameter of the magnetic rol

t Roller

[C] TD

Mixing Auger

m and has four imaging units (which are included in

tains 330g of magnetic toner carrier. The developer

two mixing augers [B] and is attracted onto the

ler is 18 mm.

[B]

Auger

Each imaging unit has a TD(Toner Developer) sensor

controlling the operating range of toner density. The i

information about the imaging unit is stored.

Service Manual

[C]. The TD sensor [C] in the imaging unit is used for

aging unit is equipped with a CRUM in which some

2-

5

SAMSUNG ELECTRONICS

Page 50

2. Product

d

d

h

h

3

escription

Two mixing augers [A] circulate the developer forwar

mix the developer and toner well.

This occurs at the following times:

• During TD calibration

• During development.

Filters [B] on the top of the development unit ensure t

During the operating, this prevents contamination of t

[B] Filter

and backward to agitate the developer in order to

at the internal pressure does not become too high.

e imaging unit by the toner.

[A] Auger

2-

Service Manual

6

SAMSUNG ELECTRONICS

Page 51

2. Product

d

u

s

a

th

iti

is

e

o

8

Paper Transfer Ro

A

3

escription

2.5.3 Cartridge Transfer un

2.5.3.1 Cartridge Transfer

The toner is moved from the four drums to the ITB by

rotation of the ITB (four toner images are super-impo

drums on the diagram shows the direction of ITB rotat

toner image from the transfer belt to the paper. The p

in the transfer unit cleans the belt surface with the cle

collected from the belt is transported to the toner colle

em are for the line pos

6

on adjustment. The other

4

1

2

it

nit overview

the four image transfer rollers. This is done with one

ed onto the belt). The arrow above the C and M

ion. The ITB drive roller then moves the four-colo r

aper transfer roller is an idle roller. The cleanin g unit

ning blade and tension roller. The used toner

ction bottle. There are three ACR sensors. Two of

for process control.

7

3

8

YM

CK

5

9

1

2

3

4

5

6

7

9

Image Transfer B

Image Transfer R

ITB Drive Roller

Tension Roller

Rotation Encoder

Cleaning Blade

ACR Sensor

Toner Collection

lt (ITB)

ller

uger

Service Manual

2-

7

SAMSUNG ELECTRONICS

Page 52

2. Product

d

3

2.5.3.2 T ransfer belt driv e

escription

The ITB drive motor [A] drives the image transfer belt

drive roller [C]. The speed of ITB drive depends on th

[B] and the Cleaning unit by using gears and the ITB

e process line speed.

[B]

[A]

[C]

2-

Service Manual

8

SAMSUNG ELECTRONICS

Page 53

2. Product

d

n

a

iti

lt

T

t

C

3

t cl

hile the i

t

escription

2.5.3.3 T ransfer belt c leani

The ITB-cleaning unit removes toner (during printing)

or automatic line pos

makes one rotation. The ITB drive motor drives the I

The cleaning blade [A] in the cleaning unit always con

toner from the belt. Then the toner collection auger [

container.

The Film [D] on the Cleaning Unit protects against ton

roller is transferred to the tension roller [E]. The Gear

on adjustment) on the belt. Be

[E]

[D]

g

nd the ACR sensor patterns (during process control

eaning is completed w

B-cleaning unit.

acts the image transfer belt [B], and removes used

] transports the toner towards the waste toner

er contamination. The driving power from the drive

[F] drives the Gear [G].

[B]

mage transfer belt

[C]

[A]

[F]

[C]

[G]

[E]

Other Side

Service Manual

2-

9

SAMSUNG ELECTRONICS

Page 54

d

2.6 Fuser unit

d

u

l

2.6.1 Fuser unit overview

h

m

p

c

4

Halogen Lamp

2. Product

escription

This section describes the image fusing process use

A belt fusing system is used. This has a faster warmsystem.

The heating roller is made of a thin steel pipe to quick

fusing roller and pressure roller are made of soft silico

nip. These rollers do not contain a fusing lamp. The

center heating lamp, heats the center and the other la

direction). NC sensors (non-contact type thermistors)

heating roller, control the temperature of the fusing be

ends, respectively.

Two NTC thermistors and two thermostats, located at

system from overheating by the heating lamps. Tem

the center heating lamp and side heating lamp, respe

temperatures.

by the printer.

p time than a conventional fusing and pressure roller

y increase the temperature of the fusing belt. The

ne rubber, which flatten slightly, increasing the fusing

eating roller contains two fusing lamps (one lamp,

p, side heating lamp, heats the ends in the axial

, located near the center and the rear end of the

lt just above the heating roller at the center and the

the center and the front end, protect the fusing

erature is normally controlled by turning on and off

tively, corresponding to predetermined target

Pressure Roller

Service Manual

Fuser Ro

2-

Fusing Belt

Heat Roller

Thermistor

(0.5mm-1.0mm

distance)

Thermostat

ller

NC Sensor

0

SAMSUNG ELECTRONICS

Page 55

2. Product

d

t

L

a

e

g

h

The fuser belt couples the heat roller with the fuser ro

h

r

t

belts easier

The melted toner is soaked into the pap

p

e

h

h

4

conducts heat from the heat roller to the fuser

improve the fusing ability, a fuser roller with

escription

2.6.2 Fuser unit componen

The Fuser unit includes the following components:

1. Center heater lamp (LAMP1) / Side heater lamp (

These halogen lamps heat the heat roller. The cente

(LAMP2) are lit alternately to heat the heat roller. E

coil of the center heater lamp (LAMP1) is in the cent

sides. The heater lamps are fixed inside of the heat

2. Heat roller

The heat roller is a steel roller which cond u cts heat

heat roller in this equipment is a thin roller which en

time is shortened.

3. Fuser belt

roller and paper. The thin fuser belt reduces warmin

fuser belt from adhering to the toner, the surface of t

4. Fuser roller

s

AMP2)

r heater lamp (LAMP1) and the side heater lamp

ch heater lamp has its coil in a different location. The

r, those of the side heater lamp (LAMP2) are on both

roller so that they will not rotate separately.

enerated by the heater lamp to the fuser belt. The

ances heat conduction, and thus the warming-up

It

g up time and mode changing time. To prevent the