Page 1

Mounting and

Operating Instructions

EB 8135/8136 EN

Edition August 2016

Type3535 Three-way Valve with bellows seal and rod-type yoke (partial view)

Series V2001 Valves

Type3535 Three-way Valve for Heat

Transfer Oil

Page 2

Denition of signal words

DANGER!

Hazardous situations which, if not

avoided, will result in death or serious injury

WARNING!

Hazardous situations which, if not

avoided, could result in death or serious injury

NOTICE

Property damage message or malfunction

Note:

Additional information

Tip:

Recommended action

2 EB 8135/8136 EN

Page 3

Contents

EB 8135/8136 EN 3

1 General safety instructions .............................................................................4

2 Design and principle of operation ..................................................................6

2.1 Technical data ...............................................................................................8

2.2 Materials .......................................................................................................8

2.3 K

VS

and CV coefcients, seat diameters and travel .............................................8

3 Installation ....................................................................................................9

3.1 Mounting position ..........................................................................................9

3.2 Arrangement of the valve ...............................................................................9

3.3 Strainer and bypass .......................................................................................9

4 Operation ...................................................................................................11

5 Maintenance ...............................................................................................11

5.1 Replacing the bellows seal ............................................................................12

5.1.1 Disassembly ................................................................................................12

5.1.2 Assembly ....................................................................................................13

5.2 Replacing the seat and plug ..........................................................................15

5.2.1 Mixing valve ................................................................................................15

5.2.2 Diverting valve ............................................................................................. 19

5.3 Tools and tightening torques..........................................................................22

6 Description of nameplates ............................................................................23

6.1 DIN version .................................................................................................23

6.2 ANSI version ...............................................................................................23

7 Dimensions in mm and inches ......................................................................24

8 Customer inquiries ......................................................................................25

Page 4

4 EB 8135/8136 EN

General safety instructions

1 General safety instructions

− The control valve must be mounted, started up, or serviced by fully trained and qualied

personnel only. Make sure employees or third persons are not exposed to any danger.

All safety instructions and warnings given in these mounting and operating instructions,

particularly those concerning installation, start-up and maintenance, must be strictly observed.

− The control valves comply with the requirements of the European Pressure Equipment Di-

rective 2014/68/EU. Valves with a CE marking have a declaration of conformity which

includes information about the applied conformity assessment procedure. The declaration

of conformity can be viewed and downloaded from uhttp://www.samson.de.

− To ensure appropriate use, only use the valve in applications where the operating pres-

sure and temperatures do not exceed the specications used for sizing the valve at the ordering stage. The manufacturer does not assume any responsibility for damage caused

by external forces or any other external factors. Any hazards that could be caused in the

valve by the process medium, the operating pressure, the signal pressure or by moving

parts are to be prevented by taking appropriate precautions.

− Proper shipping and storage are assumed.

Page 5

EB 8135/8136 EN 5

General safety instructions

Note:

− For installation and maintenance, make sure the relevant section of the pipeline is depres-

surized and, depending on the process medium, drained as well. Depending on the eld

of application, allow the valve to cool down or heat up to reach ambient temperature before starting any work on it.

− When working on the valve, make sure that the pneumatic air supply or power supply as

well as the control signal are disconnected to prevent any hazards due to moving parts.

− Be particularly careful if the actuator springs of pneumatic control valves are preloaded.

Such actuators are labeled correspondingly and can also be identied by three long bolts

protruding from the bottom of the actuator. Before starting any work on the valve, relieve

the compression from the preloaded springs.

Page 6

6 EB 8135/8136 EN

Design and principle of operation

2 Design and principle of oper-

ation

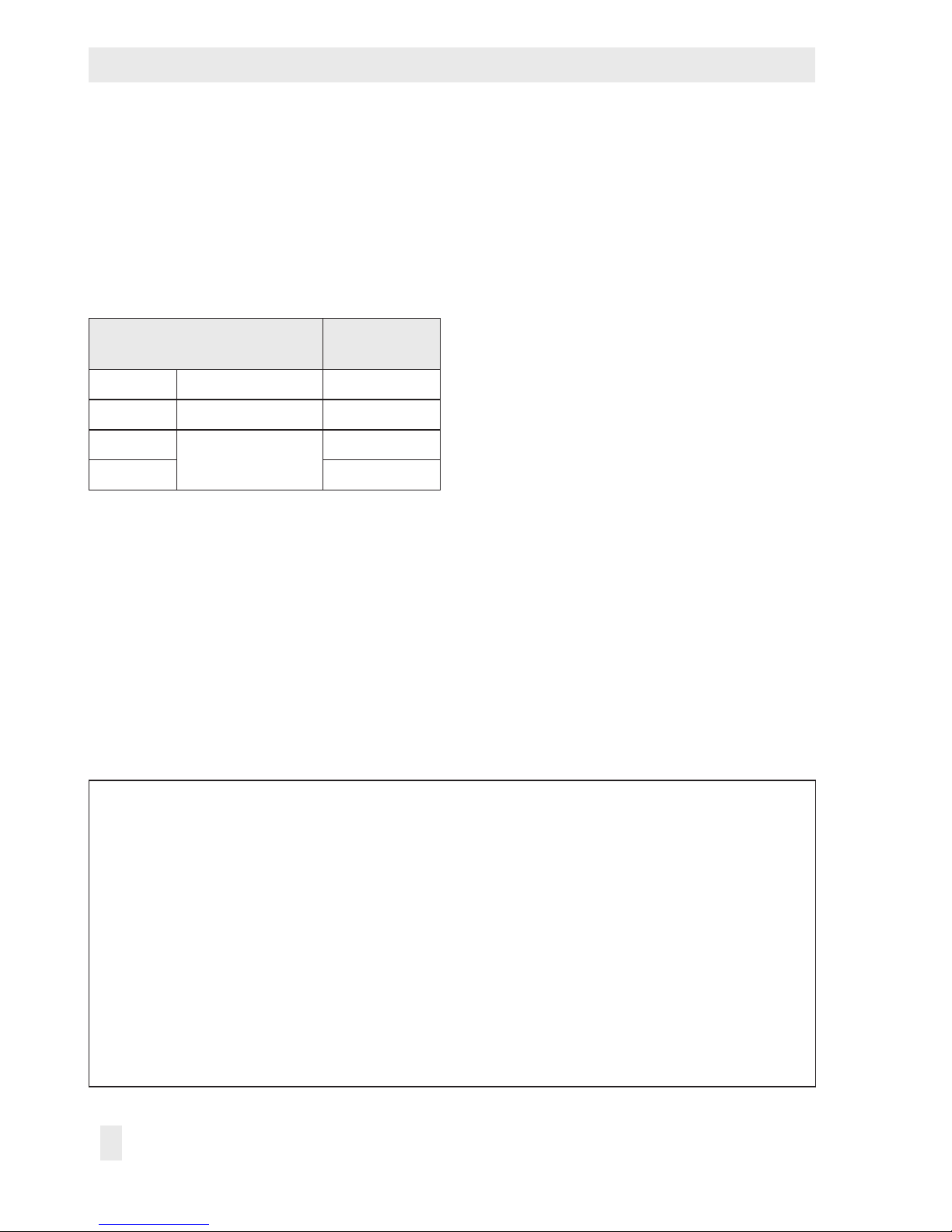

The Type3535 Three-way Valve has a modular design and can be combined with pneumatic or electric actuators (as described in

following):

Control valve

Type ...

Actuator

3535-P Pneumatic 3371-01xx

3535-IP Electropneumatic 3372-03xx

3535-E1

Electric

5824-30

3535-E3 3374

Depending on the plug arrangement, the

three-way valve can be used either as a mixing or diverting valve.

In mixing valves, the process media to be

mixed enter at valve ports A and B. The

combined ow exits the valve at port AB.

In diverting valves, the process medium enters at the valve port AB and the partial

ows exit at ports A and B.

The ow rate from ports A or B to AB and

vice versa depends on the cross-sectional area of ow between the seats and plugs.

The plug (3, 3.1, 3.2) is moved by changing

the control signal applied to the actuator.

The plug stem is sealed by a bellows seal

and an additional packing (4.2) and is connected to the actuator stem (8.1) by the stem

connector (7).

AB AABA

B

B

2.2

12.2

12

12.1

2.1

1

1.1

6

6.1

6.2

9

5.3

5

5.2

X

10.1

10.2

10.3

5.4

1.2

8.1

8.2

7

4

4.1

4.2

4.3

5.1

3.2

3.1

10.3

10.2

10.1

3.1

X

3.2

12

12.1

12.2

1 Valve body

1.1 Nuts

1.2 Gasket

2.1 Top seat

2.2 Bottom seat

3.1 Top plug

3.2 Bottom plug

4 Threaded bushing

4.1 Bushing

4.2 Packing (spring-loaded for DN65 and

larger)

4.3 Washer

5 Bellows seal with plug

stem

5.1 Coupling nut

5.2 Bellows housing

5.3 Gasket

5.4 Flange

6 Plug stem

6.1 Stem connector nut

6.2 Lock nut

7 Stem connector

8.1 Actuator stem

8.2 Rod-type yoke

9 Nut

10.1 Sleeve

10.2 Short sleeve

10.3 Sleeve

12 Nut

12.1 Washer

12.2 Retaining washers

X Position for open-end

wrench

Page 7

EB 8135/8136 EN 7

Design and principle of operation

AB AA

BA

B

B

2.2

12.2

12

12.1

2.1

1

1.1

6

6.1

6.2

9

5.3

5

5.2

X

10.1

10.2

10.3

5.4

1.2

8.1

8.2

7

4

4.1

4.2

4.3

5.1

3.2

3.1

10.3

10.2

10.1

3.1

X

3.2

12

12.1

12.2

Fig.1: Sectional drawing DN32 to 50, plug arrangement for mixing valve (left) and diverting valve

(right)

Page 8

8 EB 8135/8136 EN

Design and principle of operation

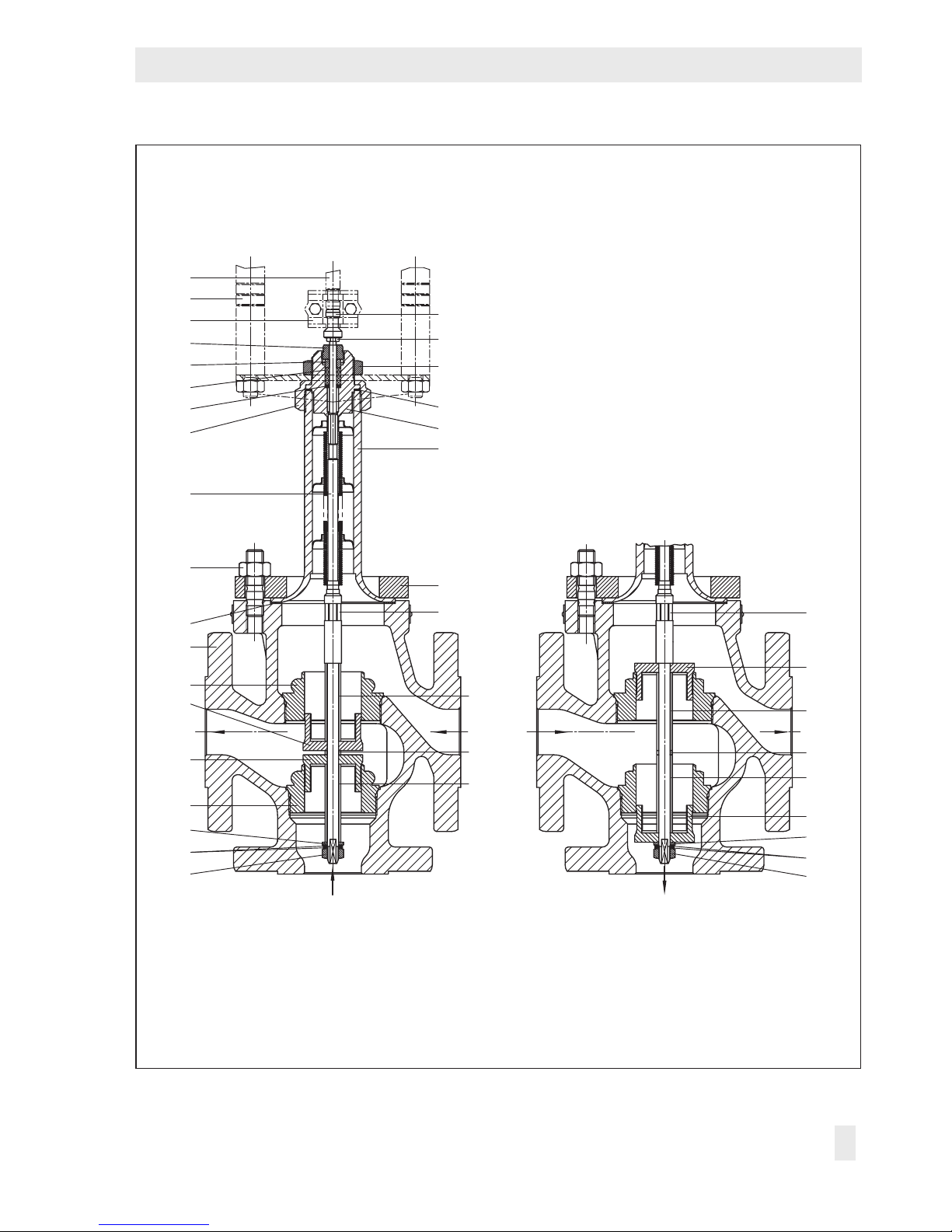

2.1 Technical data

Valve size DN 15 to 80 NPS½ to 3

Material

Spheroidal

graphite iron

EN-JS1049

Cast steel

1.0619

Stainless

steel

1.4408

Spheroidal

graphite

iron A395

Cast steel

A216 WCC

Stainless

steel A351

CF8M

Pressure rating PN16 · PN25 Class150 · Class300

Connection Flanges

EN1092-1 FormB1,

Ra3.2 to 12.5µm

EN1092-1, groove FormD

Raised face

Seat-plug seal Metal seal

Characteristic Linear

Rangeability 30:1 up to DN25 (NPS1) · 50:1 for DN32 (NPS1) and larger

Temperature range –10 to +350°C 14 to 660°F

Leakage class DINEN1349: 0.05% of K

VS

ANSI/FCI70-2: 0.05% of C

V

Compliance

·

2.2 Materials

Valve size DN 15 to 80 NPS½ to 3

Valve body

Spheroidal

graphite iron

EN-JS1049

Cast steel

1.0619

Stainless

steel

1.4408

Spheroidal

graphite

iron A395

Cast steel

A216 WCC

Stainless

steel A351

CF8M

Valve bonnet Cast steel S235JR (St 37) 1.4408 Cast steel S235JR (St 37) 1.4408

Seat ≤DN25: 1.4305 · ≥DN32: 1.4104 ≤NPS1: 1.4305 · ≥NPS1½: 1.4104

Plug 1.4305

Bellows seal 1.4541 · 1.4301

Packing PTFE

Body gasket Graphite on metal core

2.3 KVS and CV coefcients, seat diameters and travel

Valve size

DN 15 20 25 32 40 50 65 80

NPS ½ ¾ 1 – 1½ 2 2½ 3

K

VS

coefcients 4 6.3 8 16 20 32 50 80

C

V

coefcients 5 7.5 9.4 – 23 37 60 94

Seat Ø mm/in 24/0.94 40/1.57 65/2.56

Travel mm/in 15/0.59 15/0.59 15/0.59

Page 9

EB 8135/8136 EN 9

Installation

3 Installation

Valve and actuator are delivered ready

mounted.

Refer to the corresponding mounting and

operating instructions for more details on the

actuator used.

3.1 Mounting position

The valve can be mounted in any desired

position.

Î Observe the restrictions for the actuator

used.

NOTICE

Install the valve free of stress and

with the least amount of vibrations as

possible. If necessary, support the

pipelines near the connections. Do

not attach supports directly to the

valve or actuator.

Pipeline routing

To ensure that the control valve functions properly, the pipeline must be

straight and without any manifolds

or disturbances for a distance of at

least 6times the valve size (DN) upstream and downstream of the valve.

Contact SAMSON if this distance

cannot be observed.

Flush the pipeline thoroughly before

installation of the valve.

3.2 Arrangement of the valve

Install the valve as shown in Fig.2 depending on whether it is to be used for mixing or

diverting service.

The plug arrangement (i.e. either mixing or

diverting valve) is indicated on a label attached to the valve body.

Fail-safe action: the valve shuts off the ow

of the heating medium or opens the ow of

the cooling medium.

3.3 Strainer and bypass

We recommend installing a SAMSON

Type2N Strainer upstream of the valve, and

upstream of both inlet ports in mixing valves.

We recommend installing a shut-off valve

both upstream of the strainer and downstream of the valve to ensure that the plant

does not need to be shut down for maintenance. In addition, install a bypass line.

Page 10

10 EB 8135/8136 EN

Installation

Mixing service

Temperature control Q = constant

Diverting service

Temperature control Q=0 to 100%

Fail-safe action: FA = Actuator stem extends, FE = Actuator stem retracts

Heating with mixing valve (FA) or cooling with mixing valve (FE)

Installation in ow pipe Installation in return ow pipe

AAB

B

A

AB

B

Flow pipe

Return ow

pipe

Flow pipe

Return ow

pipe

A

AB

B

AAB

B

Flow pipe

Return ow

pipe

Flow pipe

Return ow

pipe

Heating with diverting valve (FA) or cooling with diverting valve (FE)

Installation in return ow pipe Installation in ow pipe

A

AB

B

A

AB

B

Flow pipe

Return ow

pipe

Flow pipe

Return ow

pipe

A

AB

B

AB

A

B

Flow pipe

Return ow

pipe

Flow pipe

Return ow

pipe

Fig.2: Typical installations

Page 11

EB 8135/8136 EN 11

Operation

4 Operation

The operating instructions only apply in conjunction with the actuator. Refer to the corresponding mounting and operating instructions.

5 Maintenance

The control valve is subject to normal wear,

especially at the seat, plug, bellows, and

packing.

Depending on the operating conditions,

check the valve at regular intervals to prevent possible failure before it can occur.

External leakage can indicate that the bellows seal or packing is defective.

If the valve does not close tightly, tight shutoff may be impaired by dirt stuck between

the seat and plug or by damaged facings.

Valves in DN15 to 25 have a one-pieced

plug, which is used for mixing and diverting

valves using the same arrangement.

In valves ≥DN32, two V-port plugs are

used. In mixing valves, the plugs are guided

in the seats from the inside. Whereas, in diverting valves, they are guided into the seats

from the outside.

To keep the exact position of the plug, spacer

sleeves are used to keep the plug on the plug

stem. The different arrangement for valves in

DN32 to 50 and for valves in DN65 and

80 as mixing and diverting valves is described in the section on assembly.

We recommend removing the parts, cleaning

them, and, if necessary, replacing them with

new ones.

WARNING!

− Before performing any work on the

control valve, make sure the relevant plant section has been depressurized and, depending on the

process medium, drained as well.

− When used at high temperatures,

allow the plant section to cool

down to ambient temperature.

− Make sure the electrical or pneu-

matic control signal for the actuator

is switched off. Remove the signal

pressure line of a pneumatic actuator.

− Valves are not free of cavities. As a

result, residual process medium

might still be contained in the

valve.

− We recommend removing the valve

from the pipeline.

NOTICE

Before performing any repair work,

remove the actuator from the valve.

Unscrew the screws on the stem con-

nector (7) and the nut (9). Lift the actuator off the valve (see Fig.1).

Note:

The required tightening torques are

specied in the following instructions.

Suitable seat wrenches are addition-

ally listed in section5.3.

Page 12

12 EB 8135/8136 EN

Maintenance

5.1 Replacing the bellows seal

If the packing leaks, this is due to a defective

bellows seal. In this case, the entire bellows

seal assembly must be replaced together

with the packing (4.2).

We recommend renewing the top gasket

(5.3) and bottom gasket (1.2) at the bellows

housing as well.

Mixing and diverting valves in DN32 to 80

differ in the arrangement of their plugs and

sleeves (see Fig.1). Valves in DN15 to 25

have the same plug and sleeve arrangement.

5.1.1 Disassembly

1. In valves ≤DN50, unscrew the lock nut

(6.2) and stem connector nut (6.1) from

the plug stem.

2. Unscrew the coupling nut (5.1) from the

bellows housing.

3. Remove nuts (1.1) and lift off the ange

(5.4).

4. Pull out the bellows housing (5.2) and

bellows seal as far as they will go. Place

an open-end wrench SW10 (≤DN50)

or SW13 (≥DN65) at the side on the

hexagon (X) or at the attened area of

the plug stem to hold the stem stationary.

Loosen the nut (12) and remove the

wrench.

5. Unscrew the nut (12). Remove the two retaining washers (12.2) and washer

(12.1).

6. DN15 to 25

Carefully pull the plug stem (6) together

with the bellows seal (5) and bellows

housing (5.2) out of the body from

above.

DN32 to 80

Keep hold of the bottom plug of diverting

valves or the bottom sleeve of mixing

valves on the plug stem. Use a long

screw (M8 for DN32 to 50 and M12 for

DN65 and 80) to keep the plugs (3.x)

and sleeves (10.x) in the right position.

Carefully pull the plug stem together with

the bellows seal (5) and bellows housing

(5.2) out of the body from above.

Guide the screw (to hold the plugs and

sleeves) into the valve body and push upwards, allowing the plugs and sleeves to

slide onto the screw.

7. Carefully clean all the parts and check

them for damage. Replace the plug stem

together with the bellows seal and packing with new parts.

Page 13

EB 8135/8136 EN 13

Maintenance

AB

A

B

12.2

12

12.1

1.1

6.1

6.2

5.3

5

5.2

X

5.4

1.2

4.2

4.3

5.1

3.2

Fig.3: Mixing valve DN32 to 50

2.2

2.1

12.1

12.2

12

3

Fig.4: Mixing valve DN15 to 25

2.2

3.2

3.1

2.1

10.2

10.3

10.1

Fig.5: Mixing valve DN32 to 50

5.1.2 Assembly

Note:

Contact your nearest SAMSON subsidiary or the SAMSON After-sales

Service department for information

on suitable lubricants.

1. Apply a suitable lubricant to the gasket

(5.3) and thread on the bellows housing.

2. Insert the gasket (5.3) on the bellows

housing (5.2).

3. Push the bellows seal (5) together with

the plug stem into the bellows housing.

Tighten the coupling nut (5.1) by hand

only at rst.

4. Insert the gasket (1.2) into the valve

body.

5. DN15 to 25

Place the ready-assembled bellows seal

assembly on the valve body, while guiding the plug stem through the holes in the

plug.

Page 14

14 EB 8135/8136 EN

Maintenance

DN32 to 80

Gradually insert the plug stem of the

ready-assembly bellows seal assembly

(5) into the valve body, allowing the

plugs and sleeves to slide from the screw

(used to hold the plugs and sleeves) onto

the plug stem.

6. First place the washer (12.1) and then

the pair of serrated retaining washers

(12.2) onto the plug stem, making sure

the coarsely serrated surfaces of the retaining washers face each other and the

radial ribs face outwards. Thread the nut

(12) onto the plug stem by hand.

Note:

For valves in DN15 to 50, a special

tool designed to hold the washers

(12.1 and 12.2) can be ordered (see

section5.3). Especially on valves in

DN15 to 25, it is difcult to mount

the washers onto the plug stem due

to insufcient space.

7. Slightly pull out the bellows housing (5.2)

together with the bellows seal. Place an

open-end wrench at the side on the

hexagon or at the attened area (X) of

the plug stem to hold the stem stationary.

NOTICE

Do not twist the bellows.

8. Tighten the nut (12) to secure the plugs

and the sleeves:

Valve size

15 to 50 65 to 80

Nut (12) 15Nm 25Nm

9. Remove the open-end wrench.

10. Place on the ange (5.4) and align it

with the bellows housing (5.2), while

making sure the gasket (1.2) is correctly

positioned.

11. Fasten the nuts (1.1):

Valve size 15 to 25 32 to 50 65 to 80

Nuts (1.1) M10

10Nm

M12

30Nm

M16

90Nm

Tighten the coupling nut (5.1) with

80Nm tightening torque.

12. For DN15 to 50, thread the lock nut

(6.2) and stem connector nut (6.1) onto

the top end of the plug stem again. Adjust the stem connector nut (6.1) to keep

the dimension of 50mm from the top of

the bellows seal assembly (5) to the top

of the stem connector nut (6.1) after the

plug stem has been pushed completely

into the valve (see Fig.15).

13. Mount the actuator onto the valve according to the associated mounting and

operating instructions.

Page 15

EB 8135/8136 EN 15

Maintenance

5.2 Replacing the seat and

plug

When replacing the seat and/or plug, we

recommend renewing the gaskets (5.3, 1.2)

at the top and bottom of the bellows housing

as well.

5.2.1 Mixing valve

Disassembly

AB

A

B

12.2

12

12.1

1.1

6.1

6.2

5.3

5

5.2

X

5.4

1.2

4.2

4.3

5.1

3.2

Fig.6: Mixing valve DN32 to 50

2.2

2.1

12.1

12.2

12

3

Fig.7: Mixing valve DN15 to 25

12.1

12.2

12

11.1

11.2

11.3

11.4

3.1

3.2

Fig.8: Mixing valve DN65 and 80

1. In valves ≤DN50, unscrew the lock nut

(6.2) and stem connector nut (6.1) from

the plug stem.

2. Unscrew the coupling nut (5.1) from the

bellows housing. Remove nuts (1.1) and

lift off the ange (5.4).

3. Pull out the bellows housing (5.2) and

bellows seal as far as they will go. Place

an open-end wrench SW10 (≤DN50)

or SW13 (≥DN65) at the side on the

hexagon (X) or at the attened area of

the plug stem to hold the stem stationary.

Loosen the nut (12) and remove the

wrench.

Page 16

16 EB 8135/8136 EN

Maintenance

4. Unscrew the nut (12). Remove the two retaining washers (12.2) and washer

(12.1).

In mixing valves DN32 to 80, pull bottom sleeve (10.3 or 11.4) off the plug

stem.

5. Lift the bellows housing (5.2) together

with the bellows seal (5) and carefully

pull the plug stem (6) out of the valve

body.

Pull the bellows seal (5) out of the bellows housing and remove the body gasket (1.2).

6. Carefully clean all the parts and check

them for damage. Renew defective parts.

7. In valves ≥DN32, remove sleeve (10.1

or 11.1).

Unscrew the top seat (2.1) using a suitable seat wrench (see section5.3).

8. DN15 to 25

Remove the plug (3) from the valve body.

DN32 to 50

Remove the top plug (3.1), sleeve (10.2),

and bottom plug (3.2) from the valve

body.

DN65/80

Remove the top plug (3.1), sleeves (11.2

and 11.3), and bottom plug (3.2) from

the valve body.

9. Unscrew the bottom seat (2.2) from the

valve body.

10. Carefully clean all the parts and check

them. If necessary, renew or machine

them.

Assembly

AB

A

B

12.2

12

12.1

1.1

6.1

6.2

5.3

5

5.2

X

5.4

1.2

4.2

4.3

5.1

3.2

Fig.9: Mixing valve DN32 to 50

2.2

2.1

12.1

12.2

12

3

Fig.10: Mixing valve DN15 to 25

Page 17

EB 8135/8136 EN 17

Maintenance

12.1

12.2

12

11.1

11.2

11.3

11.4

3.1

3.2

Fig.11: Mixing valve DN65 and 80

1. Apply a suitable lubricant to the gasket

(5.3) and thread on the bellows housing.

2. Insert the gasket (5.3) on the bellows

housing (5.2).

3. Push the bellows seal (5) together with

the plug stem into the bellows housing.

Tighten the coupling nut (5.1) by hand

only at rst.

4. Apply a suitable lubricant to the thread

and the sealing cone of the new or machined seats.

5. Use the seat wrench to screw in the bottom seat (2.2), observing the correct

tightening torques:

Valve size 15 to 25 32 to 50 65 to 80

Seat thread M32x1.5 M58x1.5 M90x1.5

Tightening

torque

120Nm 500Nm 1050Nm

6. DN15 to 25

Insert the plug (3) into the bottom seat

(2.2).

DN32 to 50

Insert the bottom plug (3.2) into the bottom seat (2.2).

Place the short sleeve (10.2) and top

plug (3.1) one after the other onto the

bottom plug. To x them into position, insert a long M8 screw through the bottom

plug.

DN65/80

Insert the bottom plug (3.2) into the bottom seat (2.2).

Place the two short sleeves (11.3 and

11.2) and top plug (3.1) one after the

other onto the bottom plug. To x them

into position, insert a long M12 screw

through the bottom plug.

7. Screw the top seat (2.1) into the body,

ensuring that the top plug can easily

slide into the seat. Refer to table in step 5

for the correct tightening torque.

8. Insert the gasket (1.2) into the top valve

ange.

9. DN15 to 25

Carefully place the bonnet onto the

valve, while guiding the plug stem into

the plug (3).

DN32 to 50

Slide the sleeve (10.1) over the plug

stem. Carefully place on the bonnet,

while guiding the plug stem through the

top plug (3.1), sleeve (10.2), and bottom

plug (3.2) and, at the same time, remove

the M8 screw.

Page 18

18 EB 8135/8136 EN

Maintenance

Slide the sleeve (10.3) onto the plug stem

from underneath.

DN65 and 80

Slide the sleeve (11.1) over the plug

stem. Carefully place on the bonnet,

while guiding the plug stem through the

top plug (3.1), two sleeves (11.2 and

10.3), and bottom plug (3.2) into the

body and, at the same time, remove the

M12 screw.

Slide the sleeve (11.4) onto the plug stem

from underneath.

10. First place the washer (12.1) and then

the pair of serrated retaining washers

(12.2) onto the plug stem, making sure

the coarsely serrated surfaces of the retaining washers face each other and the

radial ribs face outwards. Thread the nut

(12) onto the plug stem by hand.

Note:

For valves in DN15 to 50, a special

tool designed to hold the washers

(12.1 and 12.2) can be ordered (see

section5.3). Especially on valves in

DN15 to 25, it is difcult to mount

the washers onto the plug stem due

to insufcient space.

11. Slightly pull out the bellows housing (5.2)

together with the bellows seal. Place an

open-end wrench at the side on the

hexagon or at the attened area (X) of

the plug stem to hold the stem stationary.

NOTICE

Do not twist the bellows.

12. Tighten the nut (12) to secure the plugs

and the sleeves:

Valve size

15 to 50 65 to 80

Nut (12) 15Nm 25Nm

13. Remove the open-end wrench.

14. Place on the ange (5.4) and align it

with the bellows housing (5.2), while

making sure the gasket (1.2) is correctly

positioned.

15. Fasten the nuts (1.1):

Valve size 15 to 25 32 to 50 65 to 80

Nuts (1.1) M10

10Nm

M12

30Nm

M16

90Nm

Tighten the coupling nut (5.1) with

80Nm tightening torque.

16. For DN15 to 50, thread the lock nut

(6.2) and stem connector nut (6.1) onto

the top end of the plug stem again. Adjust the stem connector nut (6.1) to keep

the dimension of 50mm from the top of

the bellows seal assembly (5) to the top

of the stem connector nut (6.1) after the

plug stem has been pushed completely

into the valve (see Fig.15).

17. Mount the actuator onto the valve according to the associated mounting and

operating instructions.

Page 19

EB 8135/8136 EN 19

Maintenance

5.2.2 Diverting valve

Disassembly

1. In valves ≤DN50, unscrew the lock nut

(6.2) and stem connector nut (6.1) from

the plug stem.

2. Unscrew the coupling nut (5.1) from the

bellows housing. Remove nuts (1.1) and

lift off the ange (5.4).

3. Pull out the bellows housing (5.2) and

bellows seal as far as they will go. Place

an open-end wrench SW10 (≤DN50)

or SW13 (≥DN65) at the side on the

hexagon (X) or at the attened area of

the plug stem to hold the stem stationary.

Loosen the nut (12) and remove the

wrench.

4. Unscrew the nut (12). Remove the two retaining washers (12.2) and washer

(12.1).

5. Pull the bellows seal (5) out of the bellows housing and remove the body gasket (1.2).

6. Carefully clean all the parts and check

them for damage. Renew defective parts.

7. DN15 to 25

Unscrew the top seat (2.1). Remove the

plug (3) from the valve body. Take out

the bottom seat (2.2).

DN32 to 50

Remove the top plug (3.1) and the three

sleeves (10.1, 10.2, 10.3) from the valve

body.

DN65/80

Remove the top plug (3.1) and the four

sleeves (11.1, 11.2, 11.3, 11.4) from

the valve body.

8. DN32 to 80

Unscrew the top and bottom seat (2.1,

2.2) using a suitable seat wrench (see

section5.3) from the valve body.

Remove the bottom plug (3.2) from the

valve body.

9. Carefully clean all the parts and check

them. If necessary, renew or machine

them.

1.1

6.1

6.2

5.3

5

5.2

X

5.4

1.2

4.2

4.3

5.1

Fig.12: Valve bonnet with bellows seal

Page 20

20 EB 8135/8136 EN

Maintenance

Assembly

1. Apply a suitable lubricant to the gasket

(5.3) and thread on the bellows housing.

2. Place on the gasket (5.3) and push the

bellows seal (5) together with the plug

stem into the bellows housing (5.2).

Tighten the coupling nut (5.1) by hand at

rst.

3. Apply a suitable lubricant to the thread

and the sealing cone of the new or machined seat.

4. DN15 to 25

Screw in the bottom seat (2.2) and tighten:

Valve size 15 to 25

Seat thread M32x1.5

Tightening torque 120Nm

Place the plug (3) in the bottom seat.

Screw in the top seat (2.1), ensuring that

the plug can slide into the seat from underneath. Tighten the top seat with the

same tightening torque.

DN32 to 50

Insert the bottom seat (3.2) into the valve

body. Use the seat wrench to screw in

the bottom seat (2.2) and top seat (2.1)

one after the other.

Valve size 32 to 50

Seat thread M58x1.5

Tightening torque 500Nm

Place the top plug (3.1) and three sleeves

(10.1, 10.2, 10.3) onto the plug stem

one after the other.

DN65 and 80

Insert the bottom seat (3.2) into the valve

body. Use the seat wrench to screw in

the bottom seat (2.2) and top seat (2.1)

one after the other:

2.2

2.1

10.1

10.2

10.3

3.2

3.1

12.1

12.2

12

11.1

11.2

11.3

11.4

2.1

3.1

3.2

2.2

Fig.13: Diverting valve DN32 to 50 Fig.14: Diverting valve DN65 and 80

Page 21

EB 8135/8136 EN 21

Maintenance

Valve size 65 to 80

Seat thread M90x1.5

Tightening torque 1050Nm

Place the top plug (3.1) and four sleeves

(11.1, 11.2, 11.3, 11.4) onto the plug

stem one after the other.

5. For diverting valves in DN32 and larger,

insert the bottom plug into the bottom

seat.

Insert the gasket (1.2) into the body

ange. Carefully guide the plug stem (6)

into the bellows housing (5.2).

Hold the bottom plug in the seat to push

the plug stem in the middle through the

plug bore.

6. First place the washer (12.1) and then

the pair of serrated retaining washers

(12.2) onto the plug stem, making sure

the coarsely serrated surfaces of the retaining washers face each other and the

radial ribs face outwards. Thread the nut

(12) onto the plug stem by hand.

Note:

For valves in DN15 to 50, a special

tool designed to hold the washers

(12.1 and 12.2) can be ordered (see

section5.3). Especially on valves in

DN15 to 25, it is difcult to mount

the washers onto the plug stem due

to insufcient space.

7. Slightly pull out the bellows housing (5.2)

together with the bellows seal. Place an

open-end wrench at the side on the

hexagon (X) or at the attened area of

the plug stem to hold the stem stationary.

NOTICE

Do not twist the bellows.

8. Tighten the nut (12) to secure the plugs

and the sleeves:

Valve size

15 to 50 65 to 80

Nut (12) 15Nm 25Nm

9. Remove the open-end wrench.

10. Place on the ange (5.4) and align it

with the bellows housing (5.2), while

making sure the gasket (1.2) is correctly

positioned.

11. Fasten the nuts (1.1):

Valve size 15 to 25 32 to 50 65 to 80

Nuts (1.1) M10

10Nm

M12

30Nm

M16

90Nm

Tighten the coupling nut (5.1) with

80Nm tightening torque.

12. For DN15 to 50, thread the lock nut

(6.2) and stem connector nut (6.1) onto

the top end of the plug stem again. Adjust the stem connector nut (6.1) to keep

the dimension of 50mm from the top of

the bellows seal assembly (5) to the top

of the stem connector nut (6.1) after the

plug stem has been pushed completely

into the valve (see Fig.15).

13. Mount the actuator onto the valve according to the associated mounting and

operating instructions.

Page 22

22 EB 8135/8136 EN

Maintenance

5.3 Tools and tightening torques

Valve size

DN 15 to 25

NPS½ to 1

DN32 to 50

NPS1½ to 2

DN65 to 80

NPS2½ to 3

Seat wrench with order

number

1280-3010 1280-3011 1280-0305

Holding tool 1280-3059 for washer (12.1) and anti-rotation xture (12.2)

Tightening torques (±10%)

Valve seat 120Nm (M32x1.5) 500Nm (M58x1.5) 1050Nm (M90x1.5)

Nut (12) 15Nm 25Nm

Body nut (1.1) 10Nm (M10) 30Nm (M12) 90Nm (M16)

Coupling nut (5.1) 80Nm

Page 23

EB 8135/8136 EN 23

Description of nameplates

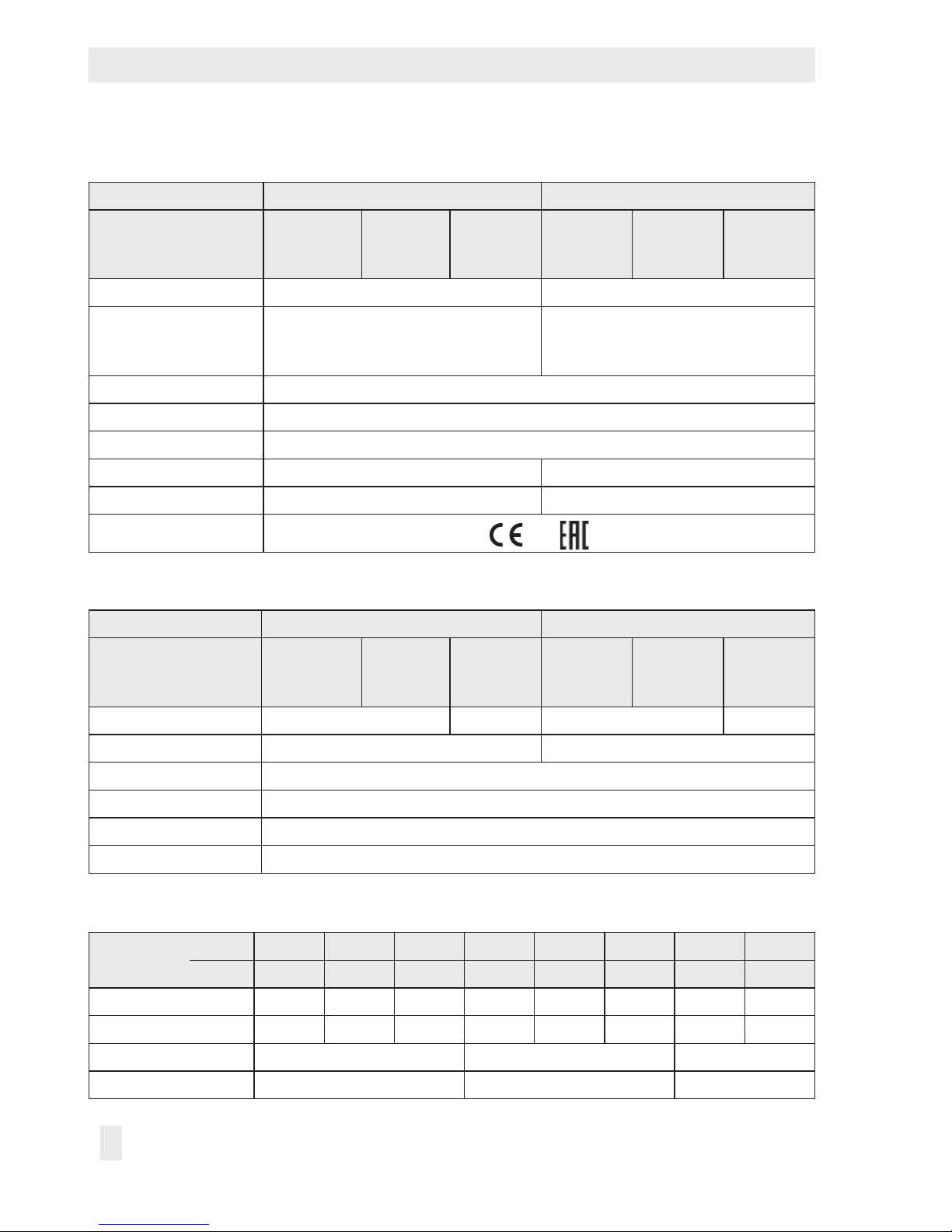

6 Description of nameplates

The DIN or ANSI versions have different specications on the nameplates.

6.1 DIN version

SAMSON

DN

bar

Made in Germany

˚C

T

bar

∆p

PN

K

vs

No

12

11

9

8

5

4

1

3

2

1 Valve type

2 Model number

3 Model number index

4 Order number or date

5 K

VS

coefcient

8 Nominal size

9 Nominal pressure

11 Permissible temperature [°C]

12 Body material

6.2 ANSI version

SAMSON

DN

bar

Made in Germany

˚C

T

bar

∆p

PN

K

vs

No

No

∆p

Made in Germany

Size

SAMSON

psi

N

psi

T

˚F

Cv

Cl

12

11

9

8

5

4

1

3

2

9

10

11

12

5

4

1

3

2

1 Valve type

2 Model number

3 Model number index

4 Order number or date

5 Valve size

9 Permissible temperature [°F]

10 Body material

11 C

V

coefcient

12 Pressure rating (Class)

Page 24

24 EB 8135/8136 EN

Dimensions in mm and inches

7 Dimensions in mm and inches

DIN version

DN L (mm) H (mm) H2 (mm)

15 130

235

70

20 150 80

25 160 85

32 180

245

100

40 200 105

50 230 120

65 290

350

130

80 310 140

ANSI version

NPS

L (in)

H (in)

H2 (in)

Class 150 Class 300 Class 150 Class 300

½

7.25

7.50

9.25

3.62

3.76

¾ 7.62 3.82

2 7.75

9.65

3.88

1½ 8.75 9.25 4.37 4.63

2 10.00 10.50 5.00 5.26

2½ 10.78 11.50

13.78

5.43 5.75

3 11.75 12.50 5.87 6.26

Page 25

EB 8135/8136 EN 25

Customer inquiries

50(1.96)

H

H2

L

Dimension applies to

plug stem pushed into

the valve body

Fig.15: Dimensional drawing of Type3535

8 Customer inquiries

Please submit the following details:

− Type designation (see nameplate)

− Order number (see nameplate)

− Serial number

− Version and nominal size of the valve

− Pressure and temperature of the process

medium

− Flow rate in m³/h

− Bench range (signal pressure range)

(e.g. 1.4 to 2.3bar with a pneumatic actuator)

− Installation drawing

Page 26

26 EB 8135/8136 EN

Page 27

EB 8135/8136 EN 27

Page 28

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

EB 8135/8136 EN

2016-10-14 · English

Loading...

Loading...