Page 1

Type3374 Electric Actuator

Version with positioner, revision 3

Translation of original instructions

Mounting and

Operating Instructions

EB 8331-4 EN

Firmware version 3.11

Edition August 2016

Page 2

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

(www.samson.de) > Product documentation. You can enter the document

number or type number in the [Find:] eld to look for a document.

Denition of signal words

!

DANGER

Hazardous situations which, if not avoided,

will result in death or serious injury

!

WARNING

Hazardous situations which, if not avoided,

could result in death or serious injury

2 EB 8331-4 EN

!

NOTICE

Property damage message or malfunction

Note

Additional information

Tip

Recommended action

Page 3

Contents

1 Safety instructions and measures ...................................................................6

1.1 Notes on possible severe personal injury .........................................................9

1.2 Notes on possible personal injury ...................................................................9

1.3 Notes on possible property damage ..............................................................10

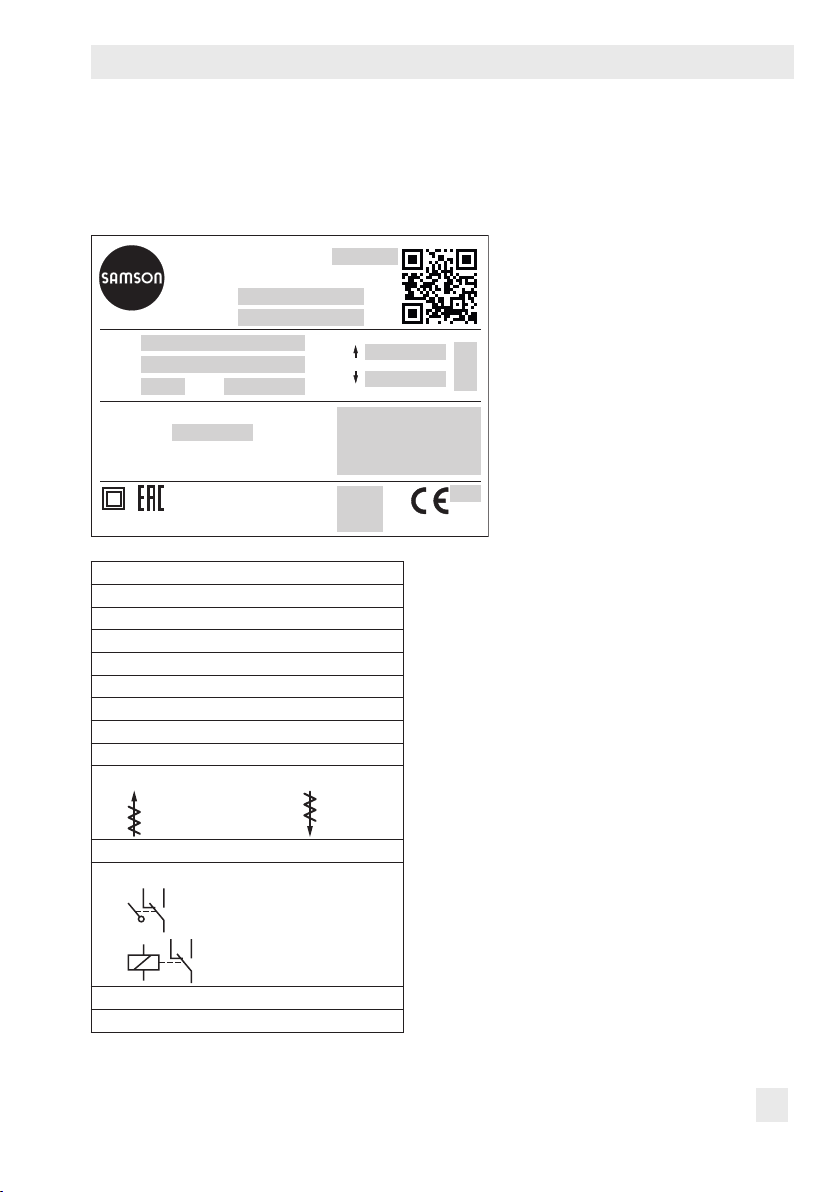

2 Markings on the device ...............................................................................11

2.1 Nameplate ..................................................................................................11

3 Design and principle of operation ................................................................12

3.1 Versions ......................................................................................................12

3.2 Limit contacts ...............................................................................................13

3.2.1 Mechanical limit contacts ..............................................................................13

3.2.2 Electronic limit contacts .................................................................................13

3.3 Manual override ..........................................................................................13

3.3.1 Mechanical override ....................................................................................13

3.3.2 Moving the actuator stem manually ...............................................................13

3.4 Communication ...........................................................................................14

3.5 Device overview and operating controls .........................................................14

3.6 Technical data .............................................................................................16

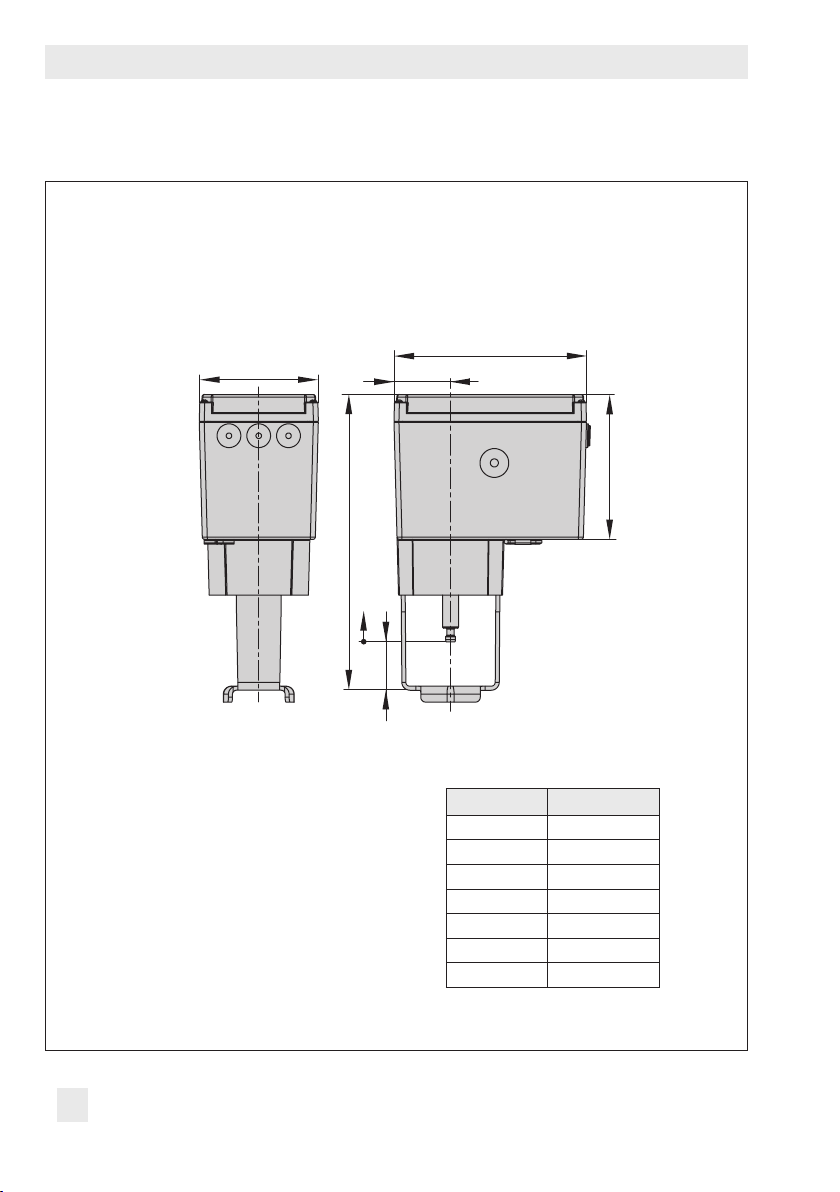

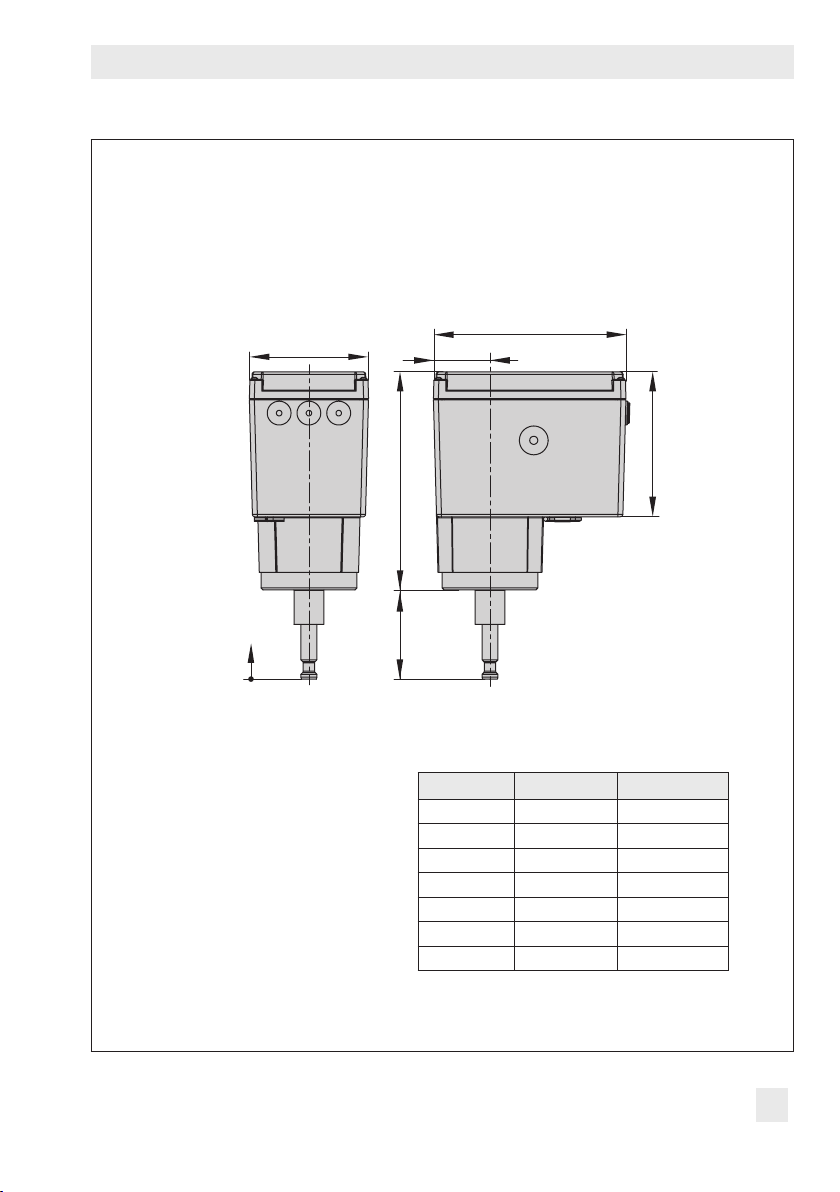

3.7 Dimensions in mm ........................................................................................20

4 Measures for preparation ............................................................................22

4.1 Unpacking ..................................................................................................22

4.2 Transporting and lifting ................................................................................22

4.2.1 Transporting ................................................................................................22

4.2.2 Lifting ..........................................................................................................22

4.3 Storage .......................................................................................................22

5 Mounting and start-up .................................................................................23

5.1 Mounting the actuator onto the valve .............................................................23

5.1.1 Mounting position ........................................................................................23

5.1.2 Construction with integrated yoke ..................................................................24

5.1.3 Construction with ring nut .............................................................................24

5.2 Electrical connections ...................................................................................26

5.2.1 Connecting the power supply ........................................................................26

6 Additional functions ....................................................................................28

6.1 Mechanical limit contacts ..............................................................................28

6.1.1 Installing the limit contacts ............................................................................28

6.1.2 Adjusting the limit contacts ...........................................................................32

6.2 Electronic limit contacts .................................................................................32

6.2.1 Installing the limit contacts ............................................................................32

6.2.2 Adjusting the limit contacts ...........................................................................33

EB 8331-4 EN 3

Page 4

Contents

6.3 Setting up Modbus-RTU communication .........................................................34

6.3.1 Protocol .......................................................................................................34

7 Operation ...................................................................................................36

7.1 Display .......................................................................................................36

7.2 Rotary pushbutton .......................................................................................38

7.2.1 Menu control ...............................................................................................38

7.3 Serial interface ............................................................................................39

7.4 Optional key number protection ....................................................................40

7.4.1 Customized key number ...............................................................................41

8 Operating level ...........................................................................................42

8.1 Selecting the operating mode ........................................................................42

8.2 Adapting the display ....................................................................................43

8.2.1 Reading direction .........................................................................................43

8.2.2 Backlight .....................................................................................................43

8.3 Initializing the actuator .................................................................................44

8.4 Applications ................................................................................................45

8.4.1 Selecting the application ...............................................................................45

8.4.2 Terminal assignment depending on the application selected.............................47

9 Congurationlevel ......................................................................................50

9.1 Activating and setting parameters .................................................................50

9.2 Input signal .................................................................................................51

9.3 Operating direction ......................................................................................52

9.4 End position guiding ....................................................................................53

9.4.1 Operating direction increasing/increasing .....................................................53

9.4.2 Operating direction increasing/decreasing ....................................................54

9.5 Position feedback signal ...............................................................................54

9.6 Binary input ................................................................................................55

9.7 Binary output ............................................................................................... 56

9.8 Electronic limit contacts .................................................................................57

9.9 Restart ........................................................................................................57

9.10 Blockage .....................................................................................................58

9.11 Travel ..........................................................................................................59

9.12 Characteristic ..............................................................................................60

9.13 Fast conguration level .................................................................................62

9.14 Plausibility error ...........................................................................................64

10 Information level .........................................................................................66

10.1 Activating parameters ..................................................................................66

4 EB 8331-4 EN

Page 5

Contents

11 Service level ................................................................................................67

11.1 Activating and setting parameters .................................................................67

11.2 Starting zero calibration ...............................................................................68

11.3 Starting initialization ....................................................................................68

11.4 Restarting the actuator (reset) ........................................................................68

11.5 Loading default settings ................................................................................69

11.6 Testing the display ........................................................................................69

11.7 Measuring the transit time .............................................................................70

12 Communication level ...................................................................................70

12.1 Activating and setting parameters .................................................................71

13 Memory pen ...............................................................................................72

13.1 Command pen .............................................................................................73

14 Servicing.....................................................................................................75

14.1 Preparation for return shipment .....................................................................75

15 Malfunctions ...............................................................................................76

15.1 Error messages ............................................................................................76

15.2 Troubleshooting ...........................................................................................77

15.3 Emergency action ........................................................................................78

16 Decommissioning and disassembly ..............................................................79

16.1 Decommissioning .........................................................................................79

16.2 Removing the actuator from the valve ............................................................79

16.2.1 Construction with integrated yoke ..................................................................79

16.2.2 Construction with ring nut .............................................................................79

16.3 Disposal ......................................................................................................80

17 Annex.........................................................................................................81

17.1 After-sales service ........................................................................................81

17.2 Levels and parameters ..................................................................................82

17.2.1 Operating level ............................................................................................82

17.2.2 Conguration level .......................................................................................83

17.2.3 Characteristic level .......................................................................................87

17.2.4 Information level ..........................................................................................88

17.2.5 Service level ................................................................................................89

17.2.6 Communication level ....................................................................................91

17.2.7 Further codes on the display .........................................................................92

17.2.8 Excerpt from Modbus list ..............................................................................93

Index ..........................................................................................................98

EB 8331-4 EN 5

Page 6

Safety instructions and measures

Firmware revisions

Old New

3.10 3.11 (internal revisions)

1 Safety instructions and measures

The Type3374 Electric Actuator is designed to operate a mounted globe valve used in

industrial applications as well as in heating, ventilation and air-conditioning systems. The

digital positioner ensures a predetermined assignment of the valve position to the input

signal. The actuator is designed to operate under exactly dened conditions (e.g. thrust,

travel). Therefore, operators must ensure that the actuator is only used in applications that

meet the specications used for sizing the actuator at the ordering stage. In case operators

intend to use the actuator in other applications or conditions than specied, contact

SAMSON.

SAMSON does not assume any liability for damage resulting from the failure to use the de-

vice for its intended purpose or for damage caused by external forces or any other external

factors.

Î Refer to the technical data for limits and elds of application as well as possible uses. See

section3.6.

Reasonably foreseeable misuse

The actuator is not suitable for the following applications:

− Use outside the limits dened during sizing and by the technical data

Furthermore, the following activities do not comply with the intended use:

− Use of non-original spare parts

− Performing service and repair work not described in these instructions

Qualicationsofoperatingpersonnel

The actuator must be mounted, started up, serviced and repaired by fully trained and qualied personnel only; the accepted industry codes and practices are to be observed. According to these mounting and operating instructions, trained personnel refers to individuals who

are able to judge the work they are assigned to and recognize possible hazards due to their

specialized training, their knowledge and experience as well as their knowledge of the applicable standards.

6 EB 8331-4 EN

Page 7

Safety instructions and measures

Personal protective equipment

No personal protective equipment is required for the direct handling of the electric actuator.

Work on the control valve may be necessary when mounting or removing the electric actuator.

Î Observe the requirements for personal protective equipment specied in the valve docu-

mentation.

Î Check with the plant operator for details on further protective equipment.

Revisionsandothermodications

Revisions, conversions or other modications to the product are not authorized by SAMSON.

They are performed at the user's own risk and may lead to safety hazards, for example.

Furthermore, the product may no longer meet the requirements for its intended use.

Safety features

Upon power supply failure, the Type3374 Electric Actuator causes the valve to move to a

certain fail-safe position. The fail-safe action of SAMSON actuators is specied on the

actuator nameplate.

Warning against residual hazards

To avoid personal injury or property damage, plant operators and operating personnel must

prevent hazards that could be caused in the control valve by the process medium, the operating pressure, the signal pressure or by moving parts by taking appropriate precautions. They

must observe all hazard statements, warning and caution notes in these mounting and operating instructions, especially for installation, start-up and service work.

Responsibilities of the operator

The operator is responsible for proper operation and compliance with the safety regulations.

Operators are obliged to provide these mounting and operating instructions to the operating

personnel and to instruct them in proper operation. Furthermore, the operator must ensure

that operating personnel or third persons are not exposed to any danger.

EB 8331-4 EN 7

Page 8

Safety instructions and measures

Responsibilities of operating personnel

Operating personnel must read and understand these mounting and operating instructions as

well as the specied hazard statements, warning and caution notes. Furthermore, the operating personnel must be familiar with the applicable health, safety and accident prevention

regulations and comply with them.

Referenced standards and regulations

The Type3374 Electric Actuator fullls the requirements of the Directives 2014/30/EU and

2014/35/EU. The declaration of conformity includes information about the applied conformity assessment procedure. This declaration of conformity is included in the appendix of

these instructions.

The Type3374 Electric Actuator is designed for use in low voltage installations.

Î For wiring, maintenance and repair, observe the relevant safety regulations.

Referenced documentation

The following documents apply in addition to these mounting and operating instructions:

− Mounting and operating instructions of the valve on which the electric actuator is mount-

ed, e.g. for SAMSON valves:

uEB5861 for Type3260 Three-way Valve

uEB5868 for Type3213 and Type3214 Globe Valves

uEB8113 for Type3323 Three-way Valve

uEB8131 for Type3531 Globe Valve for Heat Transfer Oil

uEB8135 for Type3535 Three-way Valve for Heat Transfer Oil

8 EB 8331-4 EN

Page 9

Safety instructions and measures

1.1 Notes on possible severe personal injury

!

DANGER

Risk of electric shock.

Î Before connecting wiring, performing any work on the device or opening the de-

vice, disconnect the power supply and protect it against unintentional reconnection.

Î Only use power interruption devices that are protected against unintentional recon-

nection of the power supply.

Î Do not remove any covers to perform adjustment work on live parts.

Risk of bursting in pressure equipment.

Valves and pipelines are pressure equipment. Improper opening can lead to valve

components bursting.

Î Before starting any work on the valve, depressurize all plant sections concerned as

well as the valve.

Î Drain the process medium from all the plant sections concerned and from the valve.

Î Wear recommended personal protective equipment. See associated valve docu-

mentation.

1.2 Notes on possible personal injury

!

WARNING

Crush hazard arising from moving parts.

The electric actuator contains moving parts (actuator and plug stems), which can injure

hands or ngers if inserted into the actuator.

Î Do not insert hands or ngers into the yoke while the valve is in operation.

Î Disconnect the power supply before performing any work on the control valve.

Î Do not impede the movement of the actuator or plug stem by inserting objects into

their path.

EB 8331-4 EN 9

Page 10

Safety instructions and measures

1.3 Notes on possible property damage

!

NOTICE

Risk of damage to the electric actuator due to the power supply exceeding the

permissible tolerances.

The Type3374 Electric Actuator is designed for use according to regulations for

low-voltage installations.

Î Observe the permissible tolerances of the power supply.

Risk of actuator damage due to excessively high tightening torques.

Observe the specied torques on tightening the mounting parts of Type3374 Electric

Actuators. Excessively tightened torques lead to parts wearing out quicker.

Î Observe the specied tightening torques.

Risk of damage to the electric actuator due to incorrect operation of the manual

override.

The actuator stem of the electric actuator can be adjusted manually.

Î Do not operate the manual override while the actuator is running and only when the

power supply is disconnected.

Risk of actuator damage due to incorrect wiring of the binary inputs.

Î Always wire the binary inputs free of voltage.

10 EB 8331-4 EN

Page 11

2 Markings on the device

2.1 Nameplate

Markings on the device

SAMSON 3374-

Electric Actuator

Var. -ID

Serial no.

U:

max

:

P

s: v:

Digital Positioner

Firmware:

0(4) ... 20 mA DC; Ri = 50 Ω

0(2) ... 10 V DC; Ri = 20 kΩ

SAMSON AG, Germany

1 Type designation

2 Conguration ID

3 Serial number

4 Power supply; power line frequency

5 Power consumption

6 Nominal transit time

7 Stroking speed

8 Thrust (stem retracts)

9 Thrust (stem extends)

10 Fail-safe action

Retracts

4

5

6

11

2

3

F

7

or

F

13

Extends

1

8

9

12

Made in Germany

10

14

0062

11 Firmware version

12 Limit contacts

Mechanical limit contacts

Electronic limit contacts

13 Testing according to DINEN14597

14 Year

EB 8331-4 EN 11

Page 12

Design and principle of operation

3 Design and principle of oper-

ation

The Type3374 Electric Actuator is used in

industrial plants as well as in heating, ventilation and air-conditioning systems.

The actuator is suitable for form-t attachment to various SAMSON valve series, depending on the version with or without fail-

safe action.

The stepper motor is switched off by

torque-dependent switches in the end positions or in case of overload. The force of the

motor is transmitted to the actuator stem via

gearing and ball screw.

The Type3374 Actuator is optionally available with either integrated yoke (Fig.1) or

using an M30x1.5 ring nut (Fig.2) including

the necessary stem connecting parts.

TestingaccordingtoDINEN14597

The Types3374 Electric Actuator with fail-

safe action "actuator stem extends" is tested

by the German technical surveillance association (TÜV) according to DINEN14597 in

combination with various SAMSON valves.

The register number is available on request.

Fig.1: Construction with integrated yoke

3.1 Versions

The Type3374 Electric Actuator is available

with or without fail-safe action.

Version with fail-safe action

Type 3374-2x and Type 3374-3x Actuators

are able to perform a fail-safe action and

contain a spring assembly and an electromag

net. The actuator moves to the fail-safe position when the electromagnet is de-energized.

12 EB 8331-4 EN

-

Fig.2: Construction for mounting with ring nut

Page 13

Design and principle of operation

3.2 Limit contacts

The actuator can be equipped with either

mechanical or electronic limit contacts to in-

uence the tasks of control equipment.

3.2.1 Mechanical limit contacts

The two mechanical limit contacts can be adjusted independently from one another. They

are operated by mechanical pins. The instal

lation and adjustment of the mechanical limit

contacts is described in section6.1.

-

3.2.2 Electronic limit contacts

The two electronic limit contacts consist of relays with changeover contacts. In contrast to

the mechanical limit contacts, the electronic

limit contacts no longer function after a power

supply failure. The relays are de-energized

and the contacts change to the idle state. The

retrotting and adjustment of the electronic

limit contacts is described in section9.8.

3.3 Manual override

There are two ways to manually move the

actuator stem:

− Manual override with 4mm hex wrench

− MAN operating mode to move the actu-

ator stem manually

3.3.1 Mechanical override

The mechanical manual override is only possible for actuators without fail-safe action. It

is performed by placing a 4mm hex wrench

on the red actuator shaft located at the side

of the housing. The hex wrench is included in

the scope of delivery. It is attached to the

bottom of the housing.

Î Do not operate the manual override

while the actuator is running and only

when the power supply is disconnected.

3.3.2 Moving the actuator stem manually

First place the actuator into MAN mode to

move the actuator stem manually. The operation and selection of the operating mode

are described in section8.1 on page42.

EB 8331-4 EN 13

Page 14

Design and principle of operation

3.4 Communication

The Type3374 Electric Actuator has two

communication interfaces:

− Internal serial RS-232 interface for SSP

protocol for conguration using TROVIS-

VIEW.

Î See section7.3

− RS-485 interface (RS-485 module re-

quired) for Modbus-RTU protocol and

SSP protocol for conguration using

TROVIS-VIEW.

Î See section6.3

3.5 Device overview and operating controls

The operating controls are located underneath the housing cover.

Note

To undo the screws on the housing cover, use

a Pozidriv PZ2 screwdriver to get enough

hold on the screw heads.

14 EB 8331-4 EN

Page 15

Design and principle of operation

6

2

5

1 Rotary pushbutton

2 Display

3 Serial interface

4 Terminals

5 Actuating shaft for mechanical manual override

6 Terminal board for limit contacts

Fig.3: Operating controls (with housing cover removed)

3

1

4

EB 8331-4 EN 15

Page 16

Design and principle of operation

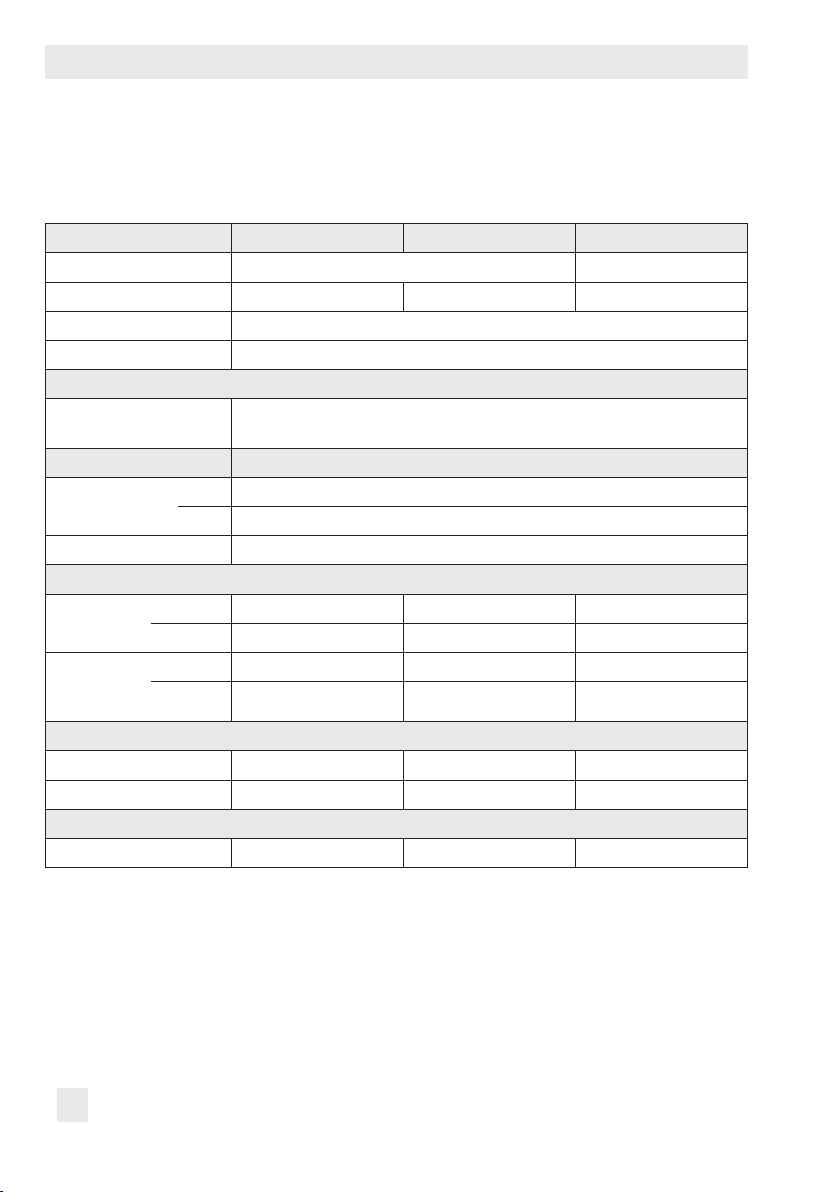

3.6 Technical data

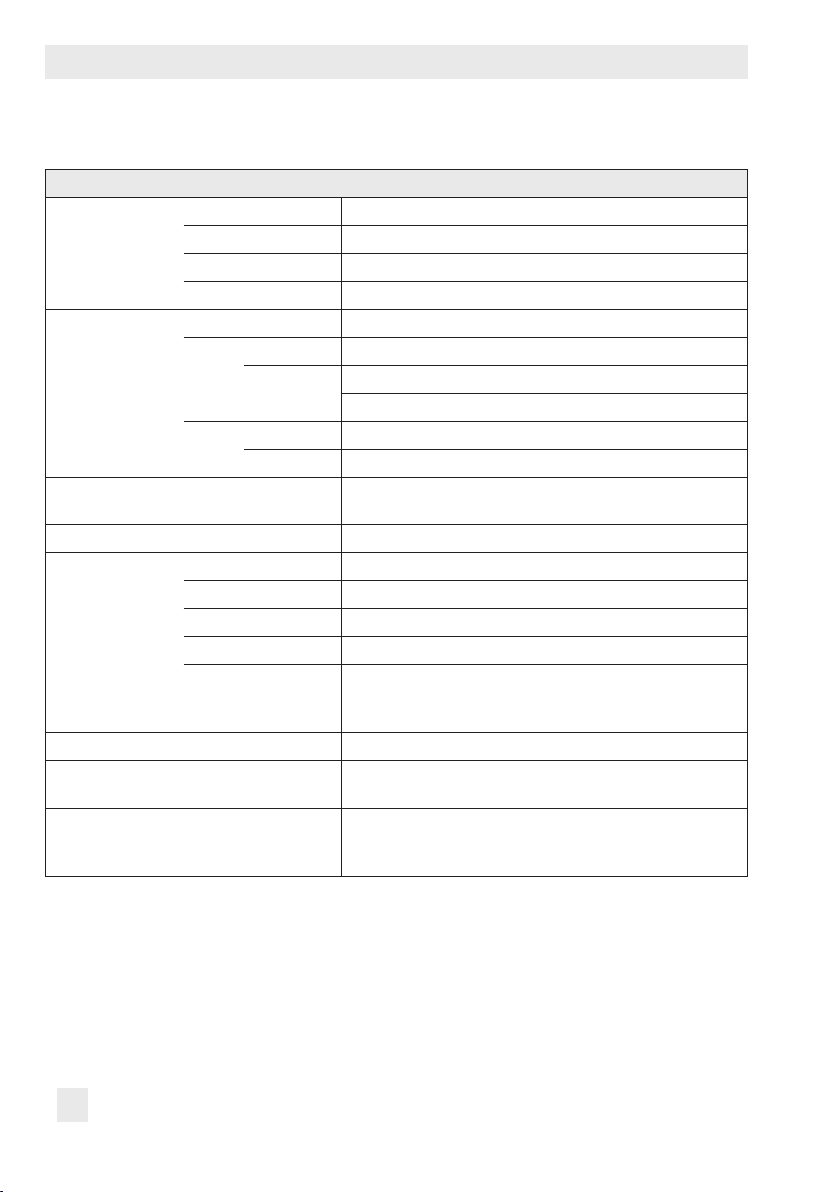

Table1: Version without fail-safe action

Type3374 -10 -11 -15

Type of connection With yoke

Travel mm 30 15 30

Travel limitation Between 10 and 100% of the rated travel

Manual override 4mm hex wrench

Electrical connection

Power supply 24V(±15%), 47 to 63 Hz and 24VDC(±15%)

Power consumption Speedlevel:Normal·Fast

24V

AC 12.5 VA · 16.5 VA

DC 7.5 W · 11 W

85 to 264 V AC 13.8 to 20VA

Transittimeins·Strokingspeedinmm/s

Standard

version

Actuator

with faster

motor

Normal

Fast

Normal

Fast

3)

4)

3)

4)

120 · 0.25 60 · 0.25 120 · 0.25

60 · 0.5 30 · 0.5 60 · 0.5

60 · 0.5 30 · 0.5 60 · 0.5

30 · 1.0 15 · 1.0

ThrustinkN(Standardversion·Versionwithfastermotor)

Extends 2.5 · 1.25 2.5 · 1.25 2.5 · 1.25

Retracts 2.5 · 1.25 2.5 · 1.25 2.5 · 1.25

Weight

kg (approx.) 3.5 3.5 3.6

1)

For attachment to SAMSON Series V2001 Valves (DN 15 to 80) and to SAMSON Type3260

(DN65 to 150) and Type3214 Valves (DN65 to 100)

2)

For attachment to SAMSON Series240 Valves and to SAMSON Type3214 Valve (DN125 to 250)

3)

Normal speed level (Code c64 = NORM)

4)

Fast speed level (Code c64 = FAST)

1)

85 to 264V, 47 to 63Hz

With ring nut

30 · 1.0

2)

16 EB 8331-4 EN

Page 17

Design and principle of operation

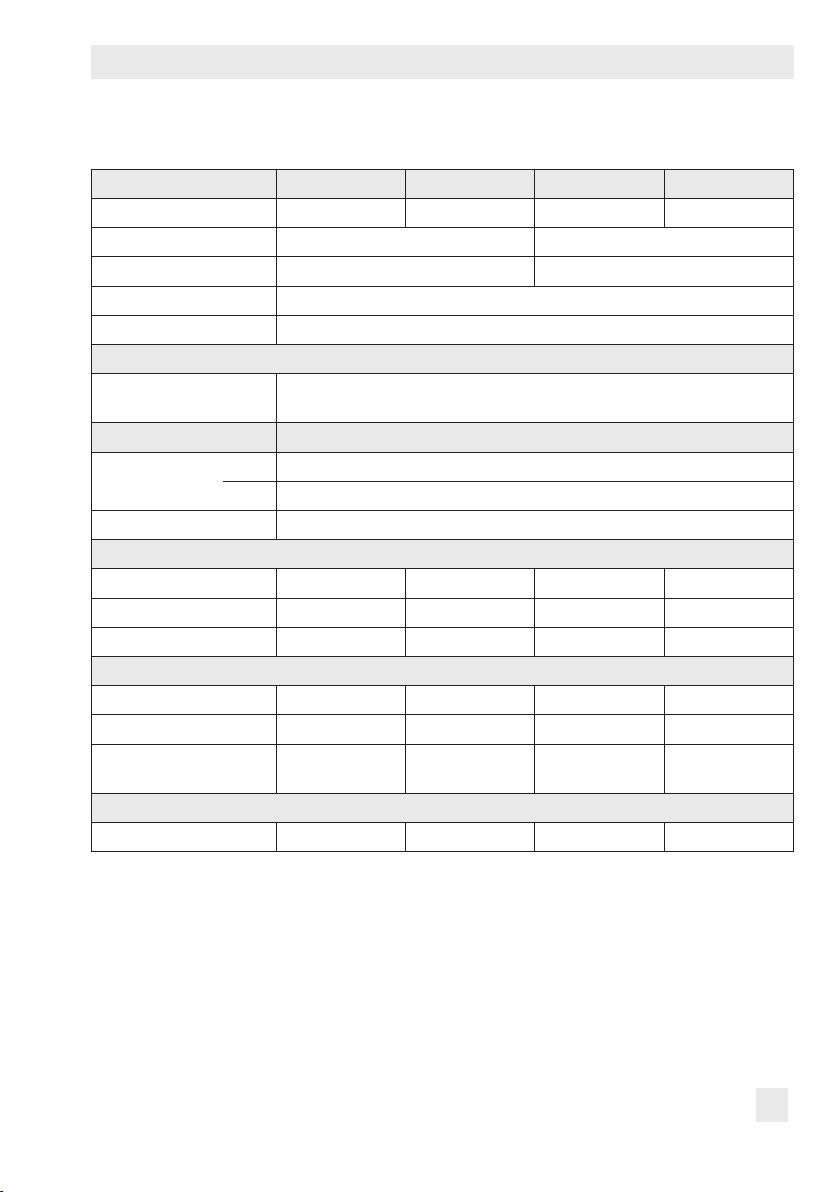

Table2: Version with fail-safe action

Type3374 -21 -26 -31 -36

Type of connection With yoke

1)

With ring nut

Fail-safe action Extends Retracts

Travel mm 15 15

Travel limitation Between 10 and 100% of the rated travel

Manual override

Electrical connection

Power supply 24V(±15%), 47 to 63 Hz and 24VDC(±15%)

85 to 264V, 47 to 63Hz

Power consumption Speedlevel:Normal·Fast

24V

AC 18 VA · 23 VA

DC 11.5 W ·15 W

85 to 264 V AC 19.8 to 26VA

Transittimeins·Strokingspeedinmm/s

Normal

4)

Fast

3)

60 · 0.25 60 · 0.25 60 · 0.25 60 · 0.25

30 · 0.5 30 · 0.5 30 · 0.5 30 · 0.5

Upon fail-safe action 12 · 1.25 12 · 1.25 12 · 1.25 12 · 1.25

Forces in kN

Thrust (stem extends) 2 2 2 2

Thrust (stem retracts) 0.5 0.5 0.5 0.5

Nominal thrust of safety

spring

2 2 0.5

Weight

kg (approx.) 4.2 4.3 3.8 3.9

1)

For attachment to SAMSON Series V2001 Valves (DN 15 to 80) and to SAMSON Type3260

(DN65 to 150) and Type3214 Valves (DN65 to 100)

2)

For attachment to SAMSON Series240 Valves and to SAMSON Type3214 Valve (DN125 to 250)

3)

Normal speed level (Code c64 = NORM)

4)

Fast speed level (Code c64 = FAST)

2)

With yoke

–

1)

With ring nut

0.5

2)

EB 8331-4 EN 17

Page 18

Design and principle of operation

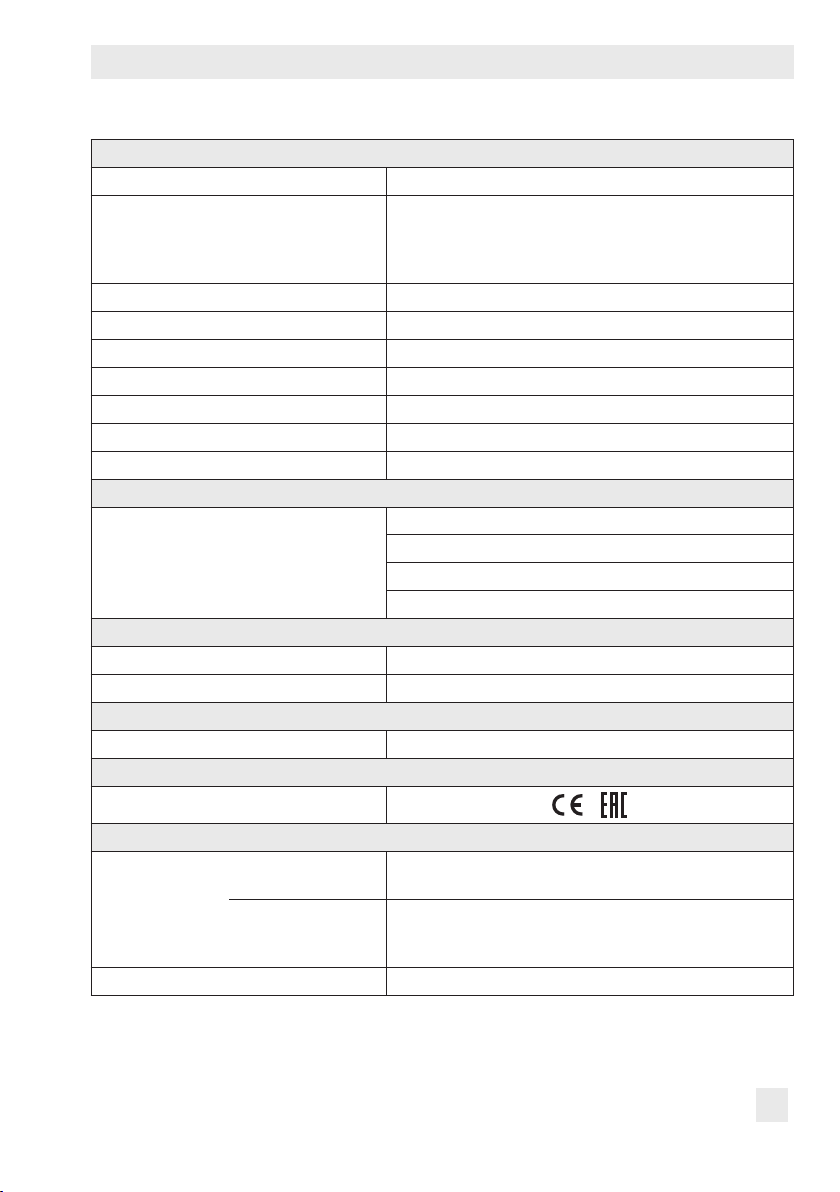

Table3: Common data

Digital positioner

Input signal

Position feedback

Binary input Open-circuit voltage: 10V; short-circuit current: 5mA

Binary output

Applications Positioner The travel follows the input signal

Display Icons for functions, codes and text eld with backlight

Rotary pushbutton Operating control for on-site operation to select and con-

Interface Standard RS-232 · For point-to-point connection to communication

Current input

Voltage input

Pt 1000 input

Binary input

0/4 to 20 mA, adjustable · Ri = 50 Ω

0/2 to 10 V, adjustable · Ri = 20 kΩ

1)

Measuring range: –50 to 150 °C, 300 µA

2)

By jumpering the terminals, not galvanically isolated

Current 0/4 to 20 mA, adjustable · Error message 24 mA

Resolution 1000 steps or 0.02mA

Load Max. 200 Ω

Voltage 0/2 to 10 V, adjustable · Error message 12 V

Resolution 1000 steps or 0.01V

Load Minimum 5 kΩ

By jumpering the terminals, not galvanically isolated

Floating, max. 230 V AC/1 A

PID controller Fixed set point control

Two-step mode Two-step behavior, control over binary input

Three-step mode Three-step behavior, control over binary input

Temperature closed-

loop control upon

The integrated PID controller uses a xed set point for

closed-loop control when the input signal is missing.

input signal failure

rm codes and values

participants or for memory pen · Permanently installed ·

Connection: RJ-12 connector socket

1)

For PID Controller (PID) and Temperature closed-loop control upon input signal failure (POSF)

applications only

2)

For two-step mode (2STP) and three-step mode (3STP) applications

18 EB 8331-4 EN

Page 19

Design and principle of operation

Safety

Motor switch-off By torque-dependent limit contacts

Degree of protection acc. to EN60529 IP54 with cable ducts

IP65 with cable glands (can be retrotted)

Suspended mounting not permitted according to

EN60664

Overvoltage category II according to EN61010

Design and testing According to EN61010

Class of protection II according to EN61140

EMC Acc. to EN61000-6-2, EN61000-6-3 and EN61326

Degree of contamination 2 according to EN61010

Noise immunity According to EN61000-6-2

Noise emission According to EN61000-6-3

Environmental conditions

Mechanical environmental conditions Class 1M2 according to EN60721-3-1:1998

Class 2M1 according to EN60721-3-2:1998

Class 3M4 according to EN60721-3-3:1998

Class 4M4 according to EN60721-3-4:1998

Permissible temperatures

2)

Ambient 5 to 60°C

Storage –25 to +70°C

Ambient conditions

Humidity 5 to 95% relative humidity, no dew formation

Compliance

·

1)

Additional electrical equipment

Limit contacts Mechanical

Two adjustable limit contacts with changeover switches;

230VAC/1A · Without contact protection

Electronic Two adjustable limit contacts with relay and changeover

switches;

230VAC/1A · Without contact protection

RS-485 module (order no. 1402-1522) Module for Modbus-RTU communication

1)

Cable glands M20x1.5 with metal nut SW 23/24 (order no. 1400-8828)

2)

The permissible medium temperature depends on the valve on which the electric actuator is

mounted. The limits in the valve documentation apply.

EB 8331-4 EN 19

Page 20

Design and principle of operation

194

120

h

1

*

)

220

h

57

193

3.7 Dimensions in mm

Type3374-10/-11/-21/-31

120

57

298

h

)

50*

*) When actuator stem is fully extended

146

Type 3374 Dimension h

-10 30

-11 15

-21 15

-31 15

-15 30

-26 15

-36 15

20 EB 8331-4 EN

Page 21

Types3374-15/-26/-36

193

Design and principle of operation

120

57

146

220

)

*

h

1

h

*) When actuator stem is fully extended

Type 3374 Dimension h Dimension h

-10 30 –

1

-11 15 –

-21 15 –

-31 15 –

-15 30 90

-26 15 75

-36 15 75

EB 8331-4 EN 21

Page 22

Measures for preparation

4 Measures for preparation

After receiving the shipment, proceed as follows:

1. Check the scope of delivery. Compare

the shipment received against the delivery note.

2. Check the shipment for transportation

damage. Report any damage to

SAMSON and the forwarding agent

(refer to delivery note).

4.1 Unpacking

Note

Do not remove the packaging until immediately before mounting and start-up.

1. Remove the packaging from the electric

actuator.

2. Dispose of the packaging in accordance

with the valid regulations.

4.2 Transporting and lifting

4.2.1 Transporting

− Protect the electric actuator against exter-

nal inuences (e.g. impact).

− Protect the electric actuator against mois-

ture and dirt.

− Observe the permissible transportation

temperature of –25 to +70°C.

4.2.2 Lifting

Due to the low service weight, lifting equipment is not required to lift the electric actuator.

4.3 Storage

!

NOTICE

Risk of electric actuator damage due to

improper storage.

− Observe storage instructions.

− Avoid long storage times.

− Contact SAMSON in case of different

storage conditions or long storage periods.

Note

We recommend regularly checking the electric actuator and the prevailing storage conditions during long storage periods.

Storage instructions

− Protect the electric actuator against exter-

nal inuences (e.g. impact).

− Protect the electric actuator against mois-

ture and dirt.

− Make sure that the ambient air is free of

acids or other corrosive media.

− Observe the permissible storage tem-

perature from –25 to +70°C.

− Do not place any objects on the electric

actuator.

22 EB 8331-4 EN

Page 23

Mounting and start-up

!

5 Mounting and start-up

!

NOTICE

Risk of malfunction due to incorrectly performed start-up.

Perform start-up following the described sequence.

1. Mount the actuator onto the valve.

Î See section5.1.

2. Connect power supply.

Î See section5.2.

3. Initialize the actuator.

Î See section8.3.

5.1 Mounting the actuator onto the valve

5.1.1 Mounting position

The control valve can be installed in the pipeline in any desired position. However, a suspended mounting position of the actuator is not permissible (see Fig.4).

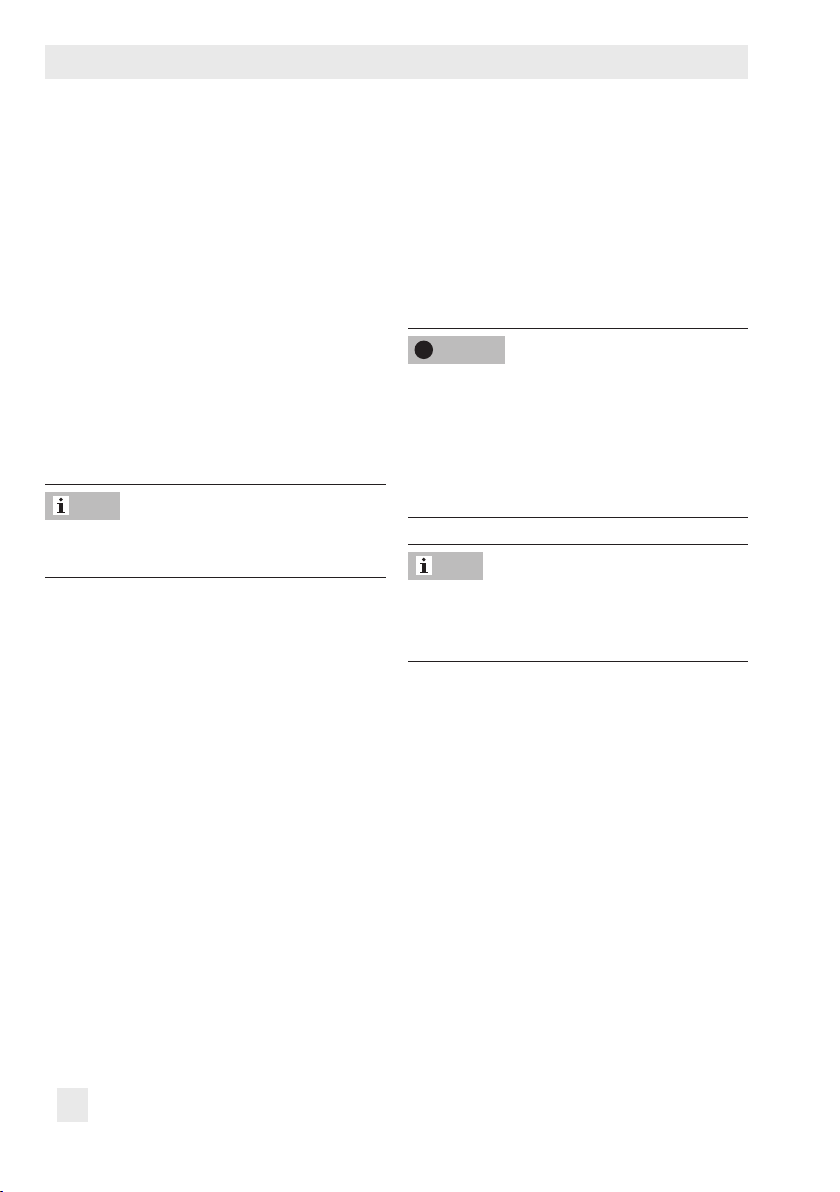

Fig.4: Mounting position

EB 8331-4 EN 23

Page 24

Measures for preparation

2.1

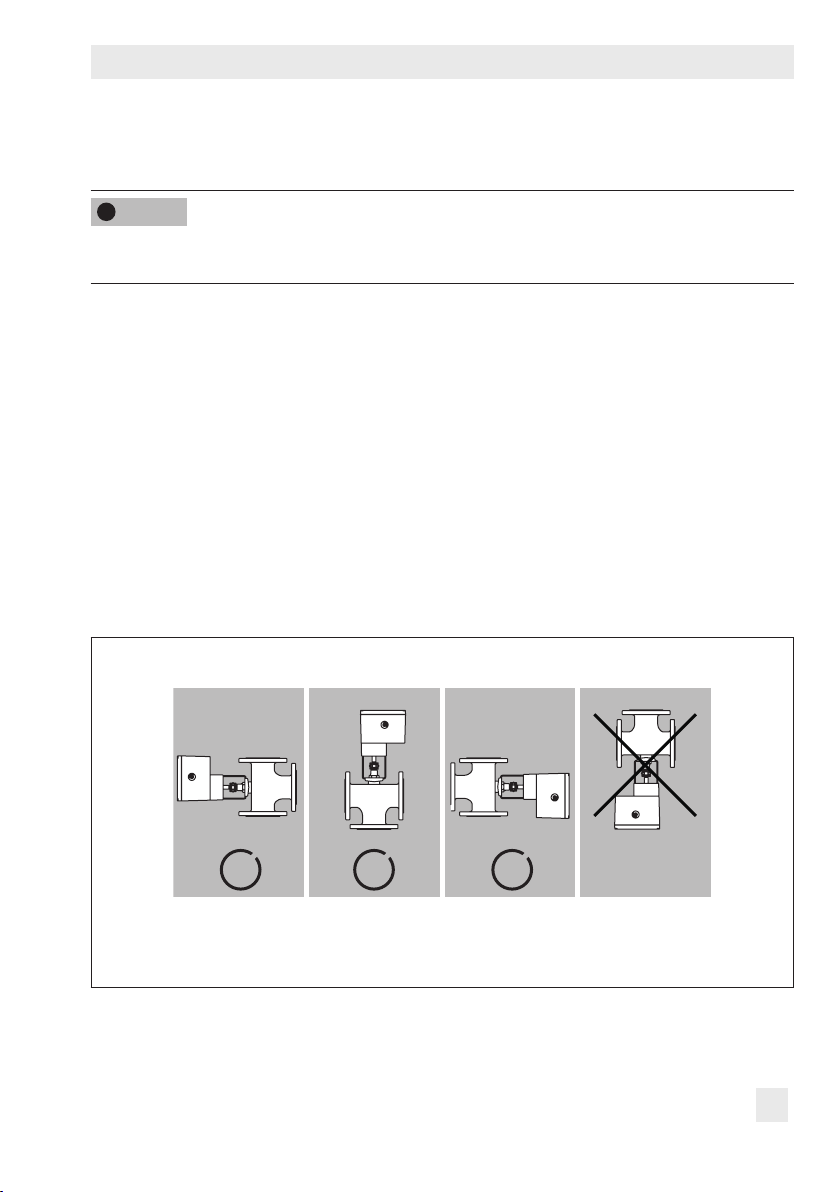

5.1.2 Construction with integrated yoke

Attachment

− Series V2001 Valves (DN15 to 80)

− Type 3260 (DN65 to 150)

− Type3214 (DN65 to 100)

Î Refer to Fig.5

4. Remove protective covers and unscrew

nut (6) from the valve.

5. Connect the power supply to the actuator

as described in section5.2.

6. Retract actuator stem (3) as described in

section3.3.

7. Place actuator with yoke onto the valve

and fasten tight using nut (6, width

across ats 36) with a minimum tightening torque of 150Nm.

8. When the plug stem (5) ts closely onto

the actuator stem (3), attach both stem

connector clamps (4) and fasten with

screws.

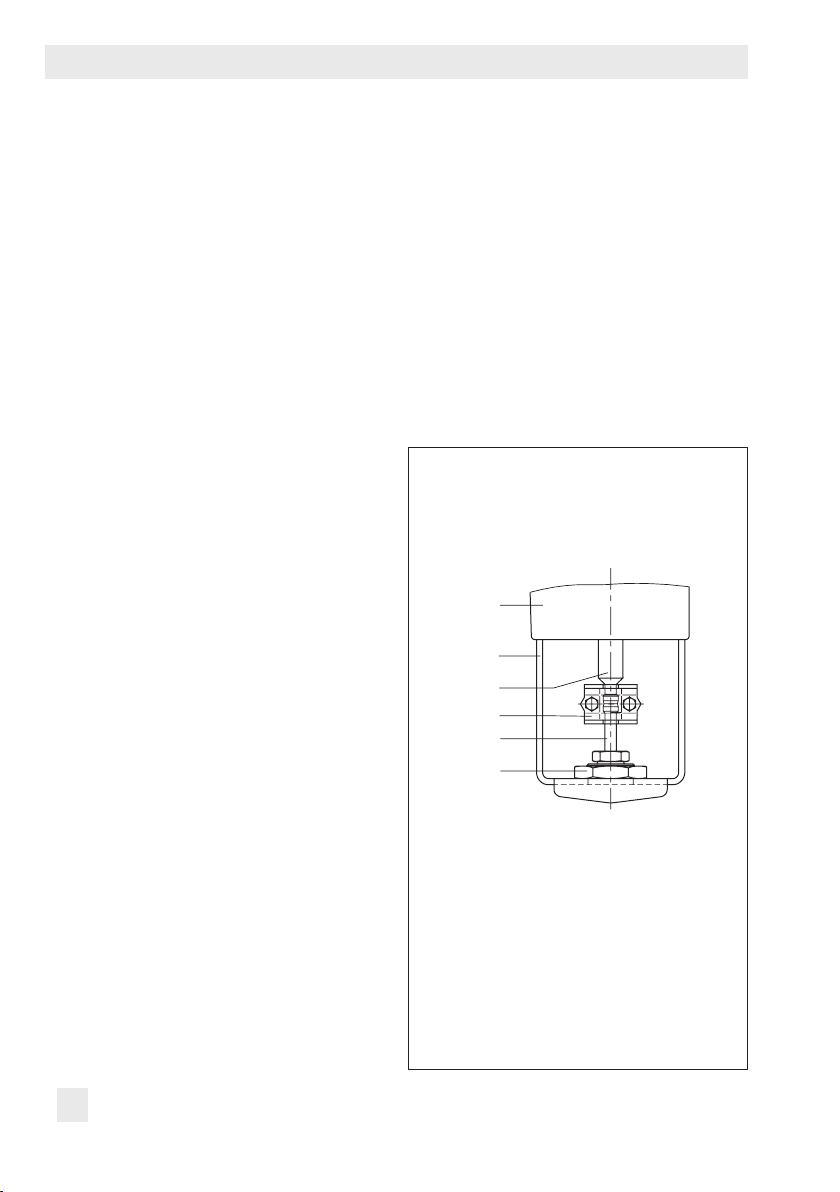

5.1.3 Construction with ring nut

AttachmenttoSeries240Valves

Î See Fig.6 on page25.

1. Slide plug stem down to close the valve.

2. Turn the stem connector nut (8) until the

measurement x = 75mm (DN100 and

larger: x = 90 mm) from the top of the

yoke to the head of the stem connector

nut (8) is achieved. Lock this position

with the lock nut (9).

Types3374-10/-11/-21/-31

Connection with yoke

Attachment to Series V2001 Valves,

Type3260 (DN65 to 150),

Type3214 (DN65 to 100)

1

3

4

5

6

1 Actuator

2.1 Actuator yoke

2.2 Valve yoke

2.3 Bonnet

3 Actuator stem

4 Stem connector

5 Plug stem

6 Nut

7 Ring nut

8 Stem connector nut

9 Lock nut

10 Travel indicator scale

Fig.5: Attachment to Series V2001 Valves

24 EB 8331-4 EN

Page 25

Measures for preparation

2.3

10

2.2

3. Connect the power supply as described

in section5.2.

4. Retract actuator stem (3) as described in

section3.3.

5. Place actuator onto the valve bonnet

(2.3) and secure using the ring nut (7).

6. When the stem connector nut (8) rests on

the actuator stem, attach both stem connector clamps (4) and fasten with screws.

Move actuator stem (3) to the end posi-

tion (valve closed) as described in sec-

tion3.3.

7. Align travel indicator scale (10) with the

middle of the stem connector (4) and

screw tight.

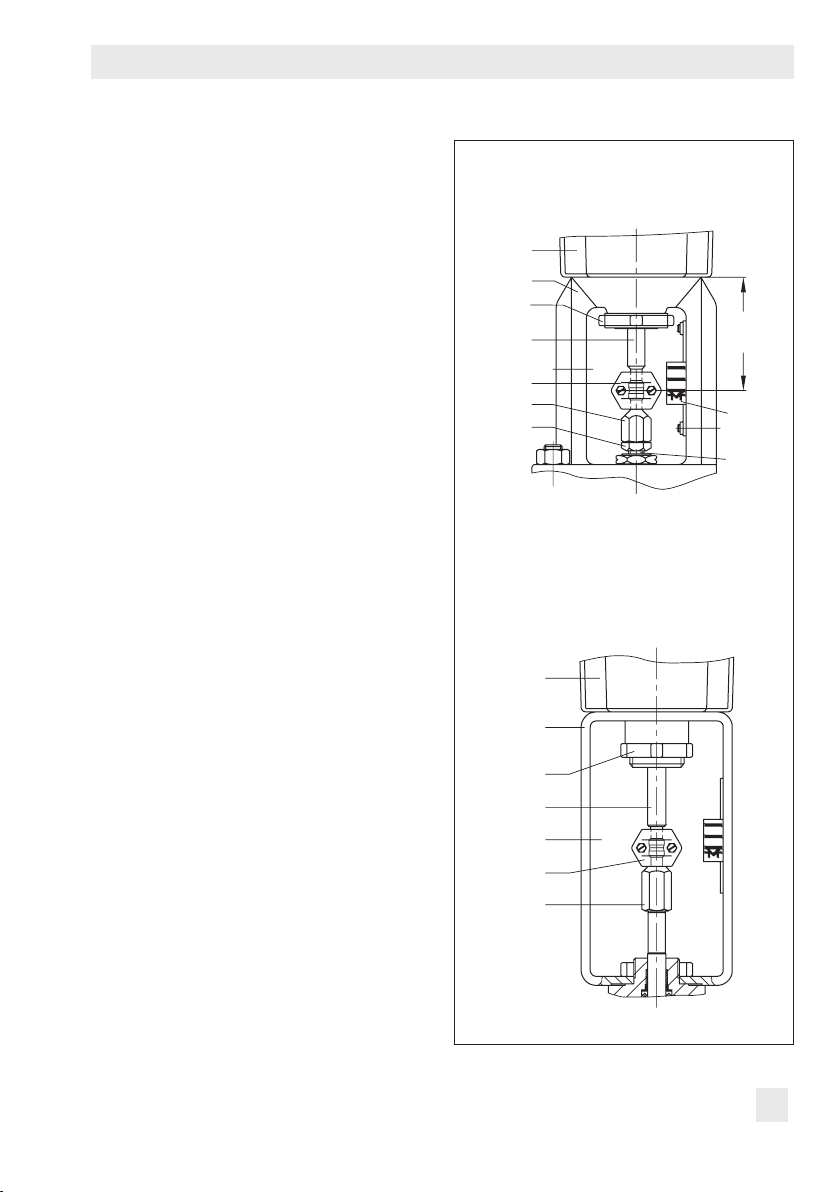

AttachmenttoType3214Valve(DN125to

250)

Î Refer to Fig.7

1. Connect the power supply as described

in section5.2.

2. Retract actuator stem (3) as described in

section3.3.

3. Place actuator onto the valve and secure

using the ring nut (7). If necessary, retract the actuator stem slightly beforehand.

4. When the plug stem ts closely onto the

actuator stem (3), attach both stem connector clamps (4) and fasten with screws.

Move actuator stem (3) to the end posi-

tion (valve closed) as described in sec-

tion3.3.

5. Align travel indicator scale (10) with the

middle of the stem connector (4) and

screw tight.

Types3374-15/-26/-36

Connection with ring nut

Attachment to Series240 Valves

1

7

3

4

8

9

5

Fig.6: Attachment to Series240 Valves

Types3374-15/-26/-36

Connection with ring nut

Attachment to Type3214 Valve (DN125 to

250)

1

7

3

10

4

5

Fig.7: Attachment to Type3214

x

EB 8331-4 EN 25

Page 26

Measures for preparation

5.2 Electrical connections

!

DANGER

Risk of electric shock.

− Upon installation of the electric cables, you

are required to observe the regulations

concerning low-voltage installations ac-

cording to DINVDE0100 as well as the

regulations of your local power supplier.

− Use a suitable power supply which guar-

antees that no dangerous voltages reach

the device in normal operation or in the

event of a fault in the system or any other

system parts.

− Connect the actuator to the electrical net-

work only after the power supply is rst

switched off. Make sure the power cannot

be switched on unintentionally.

!

NOTICE

Risk of actuator damage due to incorrect

wiring of the binary inputs.

Always wire the binary inputs free of voltage.

Î Connect binary signals over oating con-

tacts.

Note

After connecting the power supply

ing up the actuator for the rst time, the start

screen and the error reading E00 "RUNT"

(no initialization performed) appear in alter-

nating sequence (see Fig.13 on

page36).

on start-

5.2.1 Connecting the power supply

Î Connect the wiring as shown in Fig.8.

Additionally, the terminal assignment depends on the selected application (see

section8.4 on page45 and section8.4.2 on page47).

Î Guide the cables to the spring-cage ter-

minals from the top.

26 EB 8331-4 EN

Page 27

Measures for preparation

+OUT I

41 44 42 51 54 52

41 44 42 51 54 52

0/4 to 20mA

–OUT U/I

0/2 to 10V

+OUT U

+1 IN

–1 IN

+2IN

Inputs 1 to 4

–2IN

(see section8.4.2 for assignment)

+3IN

–3IN

+4IN

4IN

–

Position feedback

OUT B –

OUT B +

Binary output

L

Power supply

N

(depending on version 24VAC and DC; 85 to 264VAC)

Options:

Mechanical limit contacts Electronic limit contacts

41 44 42 51 54 52

Table4: Cables and stranded wires that can be used

Cable Cross section

Single-wire H05(07) V-U

Fine-wire H05(07) V-K

1)

1)

With wire ferrule acc. to DIN46228-1 0.25 to 1.5mm²

With wire ferrule and sleeve acc. to DIN46228-4 0.25 to 0.75mm²

1)

8mm stripped insulation at cable end

0.2 to 1.5mm²

0.2 to 1.5mm²

Fig.8: Electrical connection

EB 8331-4 EN 27

Page 28

Additional functions

6 Additional functions

6.1 Mechanical limit contacts

6.1.1 Installing the limit contacts

Î When ordering the limit contacts, state the conguration ID and the type designation of

the actuator. Both specications are written on the nameplate (see section2.1).

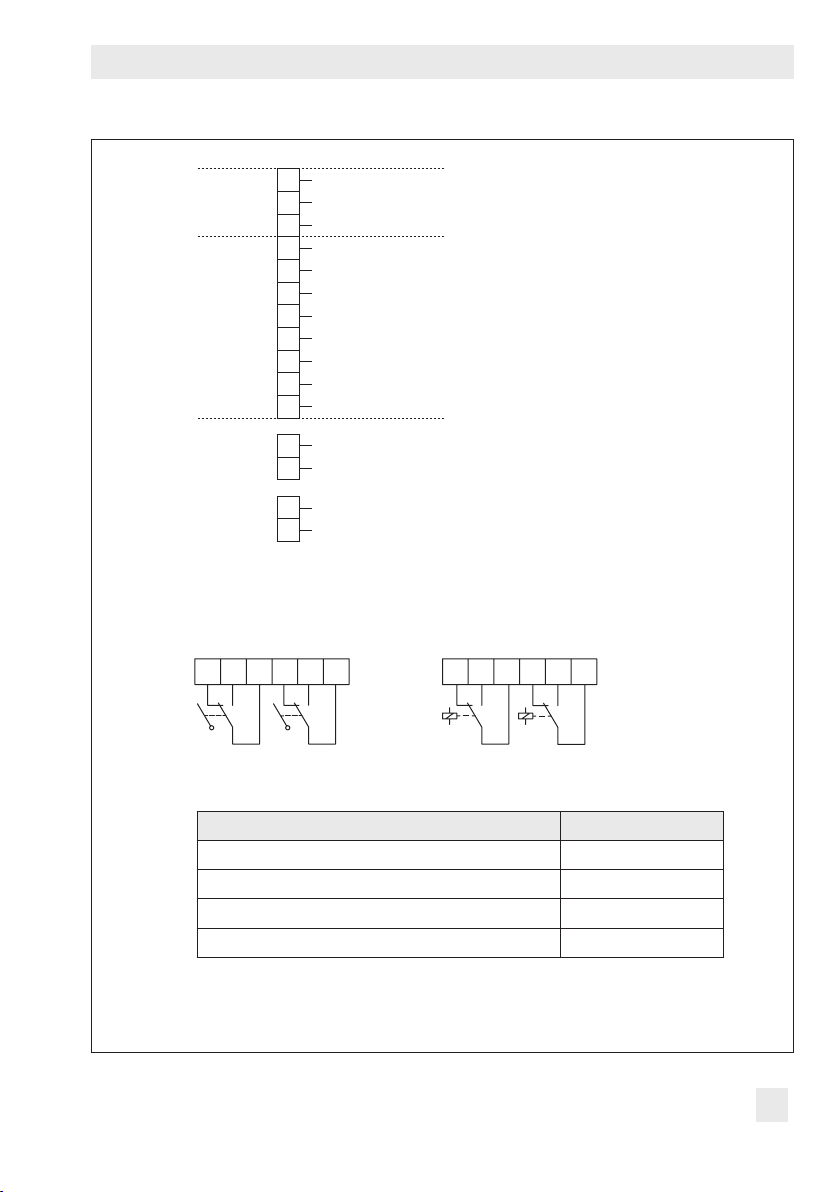

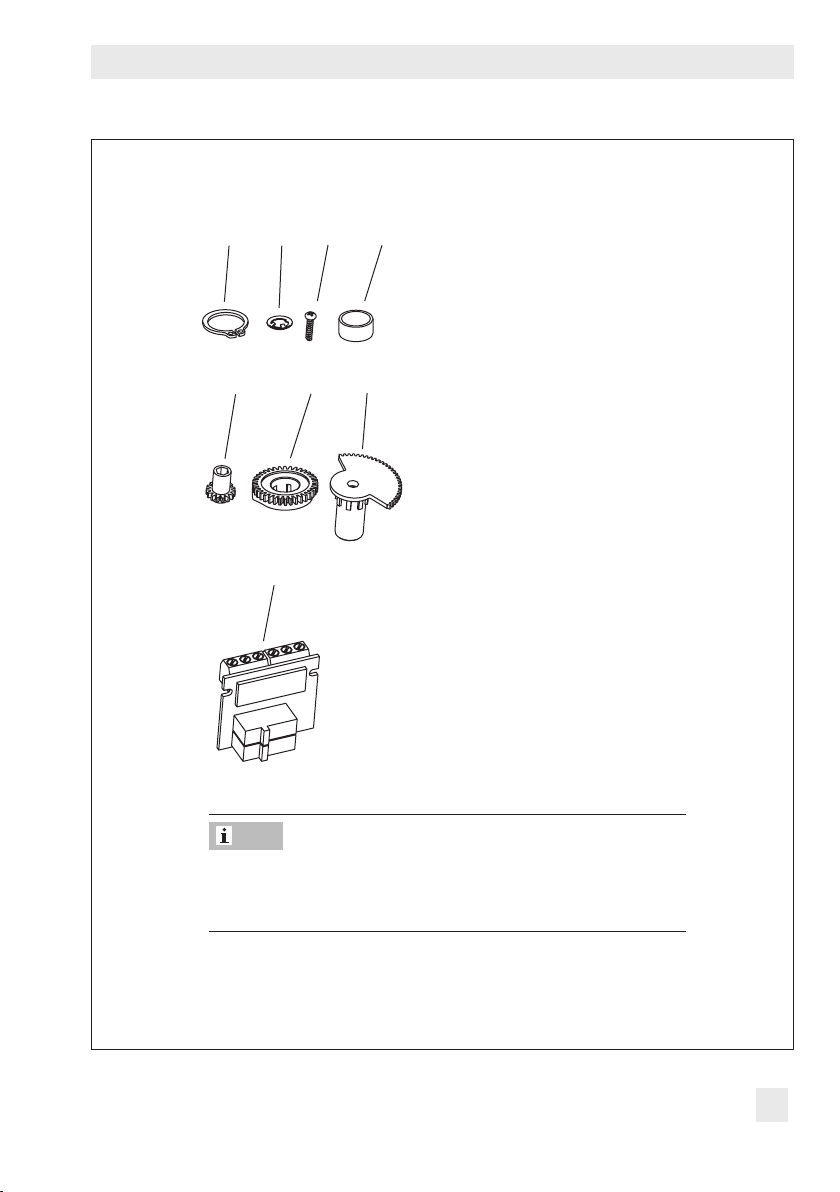

Î Required accessories (see Fig.9):

To install the electronic limit contacts, the retrot kit (order no. 1402-0898) is required.

Installinglimitcontacts(Fig.10toFig.12):

!

DANGER

Risk of electric shock.

Before installing electrical accessories, switch off the power supply and disconnect the signal

input.

Tip

We recommend applying a small amount of lubricant (e.g. Vaseline) to the spindles on the

gear faces and to the sides of the cogs.

Note

To undo the screws on the housing cover, use a Pozidriv PZ2 screwdriver to get enough hold

on the screw heads.

28 EB 8331-4 EN

Page 29

9 (2x) 16 (2x)3 8

Additional functions

18 (2x) 19 (2x)

17

20

3 Serrated ring

8 Spacer

9 Snap ring

16 Screw

17 Terminal board

18 Adjustment gear

19 Contact cam

20 Cam holder

Note

The contact cams (19) are ready-mounted to the cam holder

(20) and the retaining rings (9) to form the contact cam unit

(21, see Fig.12).

Fig.9: Accessories (order no. 1402-0898)

EB 8331-4 EN 29

Page 30

Additional functions

18 21 1

18 21 1

1. Undo screws on housing cover and take

the cover off the actuator.

2. Move the actuator stem to the end position

depending on the fail-safe action "actua

tor stem extends" or "actuator stem re-

tracts” (see section3.3).

3. Remove serrated ring and shim from spin

dle (11).

4. Slide adjustment gears (18) onto their

spindles and fasten with one screw (16)

each. Check whether the adjustment gears

can be turned easily. If not, slightly loosen

its screw again.

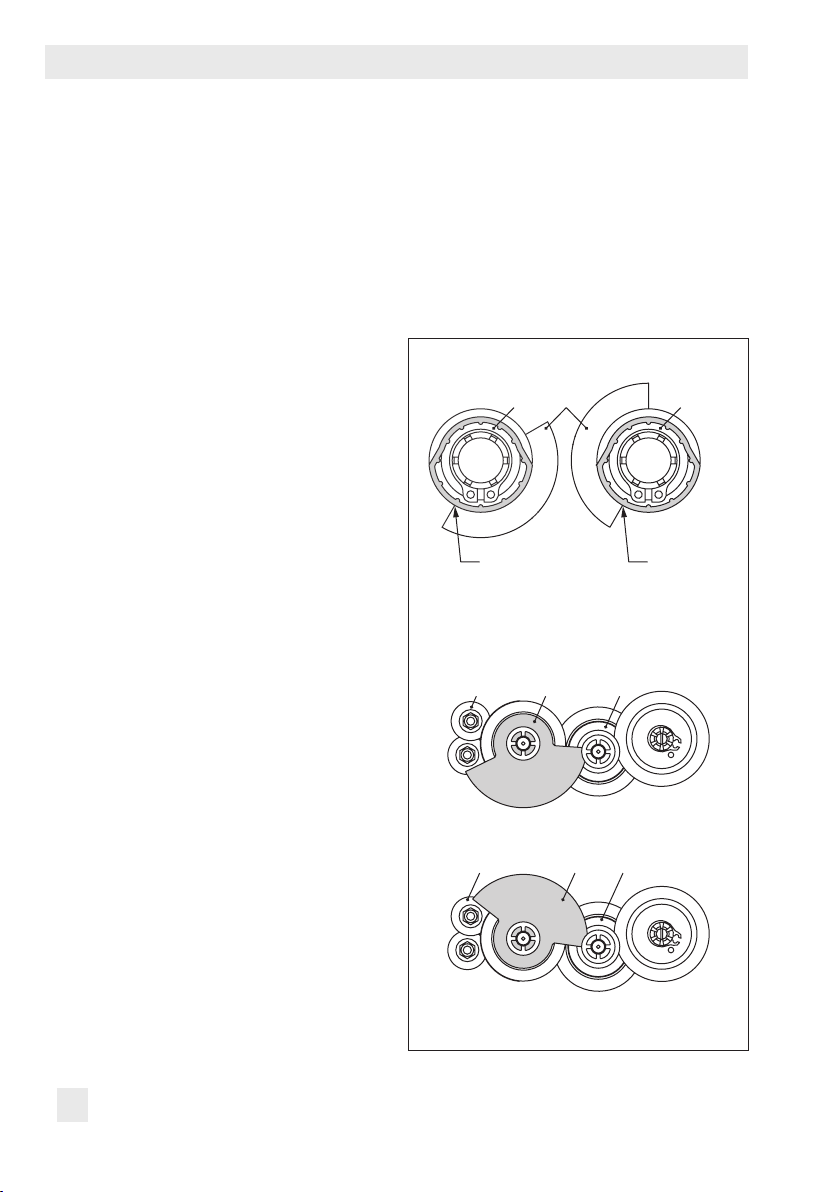

5. Turn contact cams (19) on the cam holder

(20) as illustrated in Fig.10 correspond

ing with the position of the actuator stem.

6. Slide the spacer (8) onto the spindle (11).

Make sure that the long wire of the tension

spring rests on the spacer and on the in

termediate gear.

7. Slide the contact cam unit (21) onto the

spindle corresponding with the position of

the actuator stem as illustrated in Fig.11.

Make sure that the outermost cog of the

contact cam unit engages in the gear

wheel of the intermediate gear (1). In addition, the adjustment gears (18) must engage properly in the corresponding gears

of the contact cam unit (21).

8. Secure the contact cam unit (21) and in-

termediate gear (1) with the serrated ring

(3); push down the serrated ring as far as

it will go.

9. Position the terminal board (17) at the

base of the support at a 45° angle (ap

prox.) with the switches pointing towards

the gears. Swivel the upper end of the terminal board towards the gears until the

board is in a vertical position and proper

-

ly engaged in the support.

10. Adjust limit contacts as described in sec

-

-

tion6.1.2.

-

19 1920

-

Actuator stem

retracted

-

Fig.10:

Alignment of contact cam and cam holder

Actuator stem

extended

B

-

When actuator stem retracted

B

-

Fig.11:Alignment of the contact cam unit

When actuator stem extended

30 EB 8331-4 EN

Page 31

Additional functions

11

18

8

4

1 Intermediate gear

2 Spindle gear

3 Serrated ring

4 Tension spring

8 Spacer

11 Spindle

12 Actuator board

13 Bearing sleeve

17 Terminal board

18 Adjustment gear

21 Contact cam unit

17 21

Stateondelivery:

Spindle (11) with serrated

ring and shim

1 23

12

13

Fig.12:Installing the limit contacts

EB 8331-4 EN 31

Page 32

Additional functions

11. Replace cover. Briey turn the fastening

screws counterclockwise with a screwdriver to center them. Then fasten down

the cover by tightening the screws.

6.1.2 Adjusting the limit contacts

Note

To undo the screws on the housing cover, use

a Pozidriv PZ2 screwdriver to get enough

hold on the screw heads.

1. Undo screws on housing cover and take

the cover off the actuator.

2. Switch on power supply.

3. Move the valve, using manual override

or the "manual level" operating mode, to

the point at which the contact should react.

4. Use a 4mm hex wrench to turn the spin-

dle of the adjustment gears (18) for the

upper limit contact or for the lower limit

contact until the associated contact cam

(19) of the contact cam unit (21) triggers

the switch contact of the upper or lower

microswitch on the terminal board (17).

5. Replace cover. Briey turn the fastening

screws counterclockwise with a screwdriver to center them. Then fasten down

the cover by tightening the screws.

6.2 Electronic limit contacts

6.2.1 Installing the limit contacts

Required accessories

To install the electronic limit contacts, the retrot kit (order no. 1402-0591) is required.

Installinglimitcontacts:

!

DANGER

Risk of electric shock.

Before installing electrical accessories, switch

off the power supply and disconnect the signal input.

Note

To undo the screws on the housing cover, use

a Pozidriv PZ2 screwdriver to get enough

hold on the screw heads.

1. Undo screws on housing cover and take

the cover off the actuator.

2. Connect connecting cable to the plug-in

location intended for it on the board.

3. Position the terminal board (17, see

Fig.12) at the base of the support at a

45° angle (approx.) with the relay pointing towards the edge of the intermediate

board. Swivel the upper end of the terminal board until the board is properly engaged.

4. Replace cover. Briey turn the fastening

screws counterclockwise with a screw-

32 EB 8331-4 EN

Page 33

driver to center them. Then fasten down

the cover by tightening the screws.

6.2.2 Adjusting the limit contacts

The electronic limit contacts are adjusted at

the operating controls of the actuator (see

section 3.5). See section 9.8 on how to adjust them.

Additional functions

EB 8331-4 EN 33

Page 34

Additional functions

6.3 Setting up Modbus-RTU communication

The electric actuator can be connected to a

control station over Modbus and can be con-

gured using TROVIS-VIEW. For this purpose, the actuator with rmware version

3.10 and higher can be tted with an RS-

485 module. Various communications protocol (SSP or Modbus-RTU slave) are used for

various functions.

For Modbus-RTU communication, the RS-485

module (order no. 1402-1522) must be inserted into the actuator.

Î Excerpt from Modbus list: see sec-

tion17.2.8.

6.3.1 Protocol

− Setting:automatic

The SSP and Modbus-RTU protocols are

automatically detected: the interface pa-

rameters are xed internally to Baud rate

9600bit/s, 8data bits, no parity, 1stop

bit. The electric actuator can exchange

data with TROVIS-VIEW or the control

station without switching over. The station

address and bus failure monitoring are

adjustable.

− Setting:Modbus-RTU

Communication is based on the Modbus-RTU protocol. All interface parameters listed in 6.3 are adjustable.

Note

General information on operating the elec-

tric actuator: see section7.

Station address (Code A64)

The station number is used to identify the

electric actuator for the Modbus-RTU protocol.

Baud rate (Code A65)

It is the transmission rate between the electric

actuator and control station/computer. The

Baud rate adjusted at the electric actuator

must be the same as that in the control station. Otherwise, no communication is established.

Stop bit and parity (Code A66)

The number of stop bits and the parity are

set in Code A66. The parity is used to detect

data transmission errors. The parity bit is

added to the end of the string of data bits

and the total value is made up from the data

and parity bit.

Bus failure monitoring (Code A67)

The external manual level of the communication is monitored by the bus failure monitoring (timeout). After a bus failure is detected,

automatic operation is reestablished. The

time for the bus failure monitoring is adjustable. Set the value to 0 to deactivate bus

failure monitoring.

34 EB 8331-4 EN

Page 35

Additional functions

Table5: Modbus-RTU parameter (setting in the communication level, see section12)

Code Parameters Display/select (select ESC to cancel)

Serial interface

A51 Communication ENAB (enabled)

DISA (disabled)

Interface module

A61 Communication ENAB (enabled)

DISA (disabled)

A62 Interface module 485 (RS-485)

USB (USB)

ETH (Ethernet)

NONE (none)

A63 Protocol AUTO (automatic: SSP, Modbus)

MODX (Modbus, adjustable)

Modbus interface module

A64 Station address 1 to 247

A65 Baud rate (in Baud) 1200

2400

4800

9600

192 (19200)

384 (38400)

A66 Stop bits and parity 1SNP (1 stop bit, no parity)

1SEP (1 stop bit, even parity)

1SOP (1 stop bit, odd parity)

2SNP (2 stop bits, no parity)

A67 Bus failure monitoring in min (timeout) 0 to 99

A00 Exit level > ESC

EB 8331-4 EN 35

Page 36

Operation

7 Operation

7.1 Display

After switching on the power supply, the current rmware is displayed for two seconds. Afterwards, the start screen appears.

%

On starting up the actuator for the rst time, the start screen and the error reading E00 (no

initialization performed) appear in alternating sequence.

Fig.13:Start screen after starting up the actuator for the rst time

Start screen

The start screen (Fig.14) depends on the selected application (see section8.4 on

page45). On starting up the actuator for the rst time and after loading default settings,

the positioner application (POSI) is automatically selected.

Start screen with positioner

application(POSI/POSF)

Displayed reading: travel

%

Start screen with two-step

mode application (2STP)

Displayed reading: state

Fig.14:Start screen depending on application

Start screen with PID controller (PID) application

Displayed reading: process

%

variable

Start screen with threestep mode application

(3STP)

Displayed reading: state

36 EB 8331-4 EN

Page 37

Table6: Display icons

Operating modes

Operation

Automatic mode

Manual mode

Bar graph

The bars indicate the set point

deviation that depends on the

sign (+/–) and the value.

Status messages

These icons indicate that an

error has occurred.

Binaryinput/outputactive

Code in bottom left-hand

corner of the display

Enableconguration

Limit contacts

Default setting

mA unit

One bar element appears per 1%

set point

Example:

Bar graph indicates a +3% set point deviation. A maximum of ve

bar elements can appear on each side. Five bar elements indicate a

set point deviation ≥ 5%.

Failure

Maintenance demanded

Code 0 on the display, binary input active

Code 0 on the display, binary output active

Code 0 on the display, binary input/output active

Indicates that the parameters in the conguration and

service levels have been enabled for conguration.

Display

reading 1

Display

reading 2

When the scale of the bar graph is not visible and only one

bar element either side of the center is visible, this means

the indicated parameter is the same as the default setting.

The icon indicates the mA unit in conjunction with a

reading.

Indicates that the actuator stem position has

fallen below or exceeded the switching point of

the electronic limit contact.

deviation

.

Note

The display can be adapted to the mounting situation of the actuator (see section8.2).

EB 8331-4 EN 37

Page 38

Operation

7.2 Rotary pushbutton

The rotary pushbutton is used for on-site operation of the actuator.

: select/change codes and values

Turn

Press

!

Changed parameters are immediately effective!

The process is directly affected by these changes.

First check any changes made to parameters before conrming them by pressing the rotary

pushbutton.

: conrm setting/change

NOTICE

7.2.1 Menu control

Activatingthelevel/parameters

icon indicates a jump to another level with further options.

Î

1. Turn

2. Press to conrm. The code is selected.

Example shown: Conguration level Code 10 selected

Setting parameters

1. Press

2. Turn until the required setting is reached.

3. Press

Example shown: source Code c01 set to mA.

Exit level

Î Press

Example shown: Information level exited.

to select the required code.

. The reading blinks on the display.

to conrm the setting.

to exit the level.

38 EB 8331-4 EN

Page 39

7.3 Serial interface

RS232 RJ12

RS232 USB

The actuator can be congured with the

TROVIS-VIEW software. In this case, the serial interface on the actuator is used to connect the actuator to the computer.

The TROVIS-VIEW software enables the user

to easily congure the positioner as well as

view process parameters online.

Note

TROVIS-VIEW can be downloaded free of

charge from our website at www.samson.de

> SERVICE & SUPPORT > Downloads >

TROVIS-VIEW.

Further information on TROVIS-VIEW (e.g.

system requirements) is available on our

website and in the Data Sheet uT6661 as

well as the Operating Instructions

uEB6661.

Operation

Adapter: order no. 8812-2001

Connecting cable: order no. 1400-7699

Modular adapter: order no. 1400-7698

Required accessories for connecting the actuator to a computer

− Connecting cable RJ-12/D-Sub, 9 pin

(order no. 1400-7699)

− USB/RS-232 adapter

(order no. 8812-2001)

− Hardware package consisting of con-

necting cable, modular adapter and

memory pen: order no. 1400-9998

EB 8331-4 EN 39

Memory pen-64: order no. 1400-9753

Hardware package: order no. 1400-9998,

consisting of:

− Memory pen-64

− Connecting cable

− Modular adapter

Fig.15:Accessories for data transmission

Page 40

Operation

7.4 Optional key number protection

To change parameters in the conguration level, a key number can be activated in the actuator over Codec94. When the key number function is activated, the key number must be en-

tered before the parameter setting can be changed. If a code is selected without entering a

key number beforehand when the key number function is activated, LOCK is displayed and

the parameter settings cannot be changed.

Code Description WE Adjustment range

c94 Key number active NO NO (deactivated)

YES (activated)

Whenthekeynumberisactive,proceedasfollows:

1. Turn (when the start screen appears) to select Code 9.

2. Press to conrm.

Î Display: Input eld for key number

3. Press to activate the input eld.

4. Turn

Î The service key number can be found at the end of these

mounting and operating instructions.

5. Press to conrm.

Î

change the parameter.

40 EB 8331-4 EN

to enter the service key number.

icon indicates that the conguration level is enabled to

Page 41

Operation

After entering the key number, the corresponding levels are enabled for ve minutes (indicated by

icon). The levels are automatically locked again after ve minutes.

Levels can also be locked again: Select Code 9 again. OFF is displayed. After conrming it

by pressing , the icon disappears.

7.4.1 Customized key number

In addition to the xed service key number, a customized key number can be used. It is entered in the same way as the service key number in Code9 and is set by default to "0000".

You can change the customized key number in Code c92. If the customized key number is

deactivated in Code c91, only the xed service key number is effective.

Code Description WE Adjustment range

c91 Customized key number active YES NO (deactivated)

YES (activated)

c92 Customized key number 0000 0000 to 1999

Tip

An additional write protection function can be achieved by deactivating the communication

in Code A51 or Code A61 (see sections12 and 17.2.6).

EB 8331-4 EN 41

Page 42

Operating level

8 Operating level

The operating level is active while the actuator is in the automatic mode. In this level, important information on the operation is shown, the operating mode is selected and the initialization started. The other levels are accessible from the operating level.

All the parameters of the operating level as well as fatal and EEPROM errors are listed in

section17.2.1.

8.1 Selecting the operating mode

The actuator is normally in automatic mode indicated by the icon (displayed in Code 0 to

3). In automatic mode, the actuator stem follows the input signal according to the functions

set in the conguration level.

In manual mode, the actuator stem moves to the adjusted manual positioning value. An active manual mode is indicated in Code 0 by the

Code Description WE Adjustment range

2 Operating mode AUTO AUTO (automatic mode)

3 Positioning value (manual mode) – 0.0 to 100.0%

icon.

MAN(manual mode)

Note

The positioning value (manual mode) selected in Code 3 must be adjusted by the amount

corresponding to at least half the dead band (adjustable in c67, page59). Otherwise, the

actuator stem will not move.

Example: Dead band adjusted to 2.0 % (default setting)

The positioning value (manual mode) must be adjusted by at least 1.0% (for example,

à

moving the actuator stem from 2.2% to 3.2%).

42 EB 8331-4 EN

Page 43

Operating level

8.2 Adapting the display

8.2.1 Reading direction

To adapt the reading on the display to the mounting situation of the actuator, the display con-

tents can be turned by 180° in Code4.

Code Description WE Adjustment range

4 Reading direction DISP DISP,

On changing the reading direction, the position of the icons and bar graph reading remains

unchanged, while the segments for numbers, text as well as binary input and output are

turned by 180°:

DISP

S

%

mm

Default reading direction

mm

%

S

%

mm

Reading direction turned by 180°

mm

%

8.2.2 Backlight

The display backlight can be changed to be always switched on in Codec93.

Code Description WE Adjustment range

c93 Backlight always on NO

Note

− Regardless of the setting in Code c93, the backlight starts to blink whenever an error oc-

curs (section 15).

− The display backlight can also be switched on and off by the binary input (section 9.6).

NO

YES

EB 8331-4 EN 43

Page 44

Operating level

8.3 Initializing the actuator

!

WARNING

Risk of injury due to the actuator stem extending or retracting.

Do not touch or block the actuator stem.

!

NOTICE

The process is disturbed by the movement of the actuator stem.

Do not perform the initialization while the process is running. First isolate the plant by closing

the shut-off valves.

The initialization is performed in Code5. During initialization, the actuator stem moves from

its current position to the 100% end position. Starting from the 100% end position, the actuator stem moves to the 0% end position.

Note

The 0% and 100% end positions depend on the operating direction used (section9.3).

Î Before initialization, mount the actuator on the valve as described in section5.1.

Code Description WE Adjustment range

5 Start initialization INI

Howtoproceed:

1. Turn (when the start screen appears) to select Code 5.

2. Press . INI blinks on the display.

3. Press

starts.

Î Initialization can be canceled at all times by selecting ESC.

Î After the initialization has been successfully completed, OK is

indicated.

4. Press

Î The actuator is ready for use.

44 EB 8331-4 EN

again. INI and the icon appear. Initialization

to conrm.

Page 45

Operating level

8.4 Applications

The actuator's application can be selected from one of the following applications:

− Positioner (POSI)

− PID controller (PID)

− Two-step mode (2STP)

− Three-step mode (3STP)

− Temperature closed-loop control upon input signal failure (POSF)

Note

− Depending on the selected application, wire the terminals of the actuator as specied (see

section8.4.2).

− Not all parameters and settings are shown when a certain application is selected.

Selectingtheapplication:

Code Description WE Adjustment range

6 Application POSI POSI (positioner)

PID (PID controller)

2STP (two-step mode)

3STP (three-step mode)

POSF (temperature closed-loop

control upon input signal failure)

8.4.1 Selecting the application

Positioner application

The actuator stem's position directly follows the input signal.

Î Set Code 6 to POSI.

Î Use terminal assignment according to Fig.16.

EB 8331-4 EN 45

Page 46

Operating level

PID controller application

The set point adjustable at the actuator is used to position the valve using a PID algorithm.

The input signal is used as the process variable. The PID controller is adjusted using the parameters: Proportional-action coefcient Kp, Reset time Tn, Derivative-action time Tv and Op-

erating point Y

:

0

The proportional-action coefcient Kp acts as gain.

The reset time Tn is the time it takes for the integral component during a step response in a PI

controller to produce a change in the manipulated variable identical to the change produced

by the P component. Increasing the reset time Tn reduces the rate of change in the output

when the set point deviation is constant.

The derivative-action time Tv is the time it takes the rise response of a PD controller to reach a

certain manipulated variable value earlier than it would take the response with the P component only. Increasing the derivative-action time Tv causes an increase in the manipulated

variable amplitude when the rate of change is constant. After ramped changes of the set

point deviation, a longer derivative-action time Tv causes the D component to have a longer

effect.

The operating point Y

determines the positioning value, which is fed to the controlled system

0

when the process variable is the same as the set point. The operating point is normally only

important for P and PD controllers, but it can also be set for control strategies PI, PID and I

due to the possible limitation of the integral-action component. For control strategies with integral-action component, the operating point can also be used as the initial value for a restart.

Î Set Code 6 to PID.

Î Use terminal assignment according to Fig.17.

Two-step mode application

The binary input IN2 is used for this function. When the binary input is in the active switching state, the actuator stem retracts to 100% of the adjusted travel range. When the binary

input is in the inactive switching state, the actuator stem moves to the closed position (0%).

Î Set Code 6 to 2STP.

Î Use terminal assignment according to Fig.18.

Three-step mode application

The binary input IN2 is used for this function to retract the actuator stem and binary input

IN3 to extend the actuator stem.

Î Set Code 6 to 3STP.

Î Use terminal assignment according to Fig.19.

46 EB 8331-4 EN

Page 47

Operating level

+1 IN

IN

IN

IN

IN

IN

IN

IN

Temperature closed-loop control upon input signal failure application

The travel follows the input signal. Upon failure of the input signal, the set point determined

in the actuator by the integrated PID controller is used to position the stem.

Î Set Code 6 to POSF.

Î Use terminal assignment according to Fig.20.

Note

The 0 to 10V or 0 to 20mA setting for the input signal is not possible in combination with

this function. The lower value must be at least 0.5V or 1mA.

8.4.2 Terminal assignment depending on the application selected

Î Wire the terminals of the actuator according to Fig.16 to Fig.20.

!

NOTICE

Risk of actuator damage due to incorrect wiring of the binary inputs.

Always wire the binary inputs free of voltage.

Note

The function of the inputs depend on how the actuator is congured: inputs that have not

been congured do not have any effect.

Application:Positioner(POSI)

–1

+2

–2

+3

–3

+4

4

–

Fig.16:Terminal assignment when positioner selected as the application

0(4) ... 20 mA

0(2) ... 10 V

Binary signal

Î Wire the input free of voltage.

EB 8331-4 EN 47

Page 48

Operating level

+1 IN

IN

IN

IN

IN

IN

IN

IN

+1 IN

IN

IN

IN

IN

IN

IN

IN

Application:PIDcontroller(PID)

–1

+2

–2

+3

–3

+4

4

–

Fig.17:Terminal assignment when PID controller selected as the application

0(4) ... 20 mA

0(2) ... 10 V

Pt 1000

Binary signal

Î Wire the input free of voltage.

Application:Two-stepmode(2STP)

–1

+2

–2

+3

–3

+4

4

–

Binary signal

Wire all the inputs free of voltage.

Fig.18:Terminal assignment when two-step mode selected as the application

48 EB 8331-4 EN

Page 49

Application:Three-stepmode(3STP)

+1 IN

IN

IN

IN

IN

IN

IN

IN

+1 IN

IN

IN

IN

IN

IN

IN

IN

:

:

+1 IN

IN

IN

IN

IN

IN

IN

IN

Three-wire connection: Four-wire connection:

Operating level

–1

+2

–2

+3

–3

+4

4

–

Fig.19:Terminal assignment when three-step mode selected as the application

+

–

Binary signal

Wire all the inputs free of voltage.

–1

+2

–2

+3

–3

+4

4

–

Binary signal

Application:Temperatureclosed-loopcontrolupon

input signal failure (POSF)

–1

+2

–2

+3

–3

+4

4

–

0(4) ... 20 mA

0(2) ... 10 V

Pt 1000

Binary signal

Î Wire the input free of voltage.

Retracts

Extends

Fig.20:Terminal assignment when temperature closed-loop control upon input signal failure selected

as the application

EB 8331-4 EN 49

Page 50

Congurationlevel

9 Congurationlevel

The actuator is adapted to its control task in the conguration level. The codes in this level

have a 'c' prex to identify them.

All the parameters of the conguration level are listed in section17.2.2 on page83.

9.1 Activating and setting parameters

Changingsettingsinthecongurationlevel

Activatethecongurationlevel

1. Turn (when the start screen appears) to select Code 10.

2. Press to activate the conguration level.

Change parameter setting (example shown: source Code c01)

1. Press

2. Turn until the required setting is reached.

3. Press

Exitcongurationlevel

1. Turn

. The reading blinks on the display.

to conrm the setting.

to select the code c00.

2. Press to conrm the setting.

50 EB 8331-4 EN

Page 51

Congurationlevel

9.2 Input signal

The input signal determines the actuator stem position. Either a current or voltage signal can

be applied to the input depending on the conguration in Codec01. The default lower and

upper range values of the input signal are 2 to 10V or 4 to 20mA. The input signal range

can be adapted, e.g. to achieve a plant operation characteristic by connecting two or more

actuators in parallel (split-range operation).

Note

The input signal must be ≥0.5V or ≥1mA.

Example: Two valves regulate the process medium in one common pipeline to achieve a

large rangeability. One valve opens with a 0 to 5V input signal, while the second valve also

opens when the input signal increases further (5 to 10V) and the rst valve remains open.

The two valves close in the reverse order.

Note

At least 2.5V or 5mA (depending on the input signal used) must separate the upper and

lower range values.

Code Description WE Adjustment range

c01 Source (depending on the selected

application)

c02 Lower range value 2.0V or

c03 Upper range value 10.0V or

mA mA (current signal)

V (voltage signal)

C (Pt-1000)

VIA (via interface)

0.0 to 7.5V or 0.0 to

4.0mA

20.0mA

15.0mA

2.5 to 10.0V or

5.0 to 20.0mA

Detect input signal failure

The actuator detects a congured failure of the input signal and the error reading E01 starts

to blink on the display as soon as the input signal falls below the lower range value by 0.3V

or 0.6mA. If the input signal failure function is active (c31 = YES), the reaction of the actuator upon failure of the input signal is determined by Codec32:

EB 8331-4 EN 51

Page 52

Congurationlevel

− Internalpositioningvalue(c32=INT): The actuator stem moves to the position specied

in Code c33 upon failure of the input signal.

− Lastposition(c32=LAST): The actuator stem remains in the last position that the valve

moved to before failure of the input signal.

The error message is reset and the actuator returns to closed-loop operation if the input sig-

nal moves within 0.2V or 0.4mA of the lower range value.

Code Description WE Adjustment range

c31 Detect input signal failure NO NO (function inactive)

YES (function active)

c32 Positioning value upon input signal fail-

ure

c33 Internal positioning value 0.0 % 0.0 to 100.0%

INT INT (internal positioning value)

LAST (last position)

9.3 Operating direction

Î See Fig.21 on page53.

− Increasing/increasing(c42=>>):

The actuator stem retracts as the input signal increases.

− Increasing/decreasing(c42=<>):

The actuator stem extends as the input signal increases.

Actuator stem extended

− With globe valves: Valve closed

− With three-way mixing valves: Port A à AB open, B à AB closed

− With three-way diverting valves: Port AB à A closed, AB à B open

Actuator stem retracted

− With globe valves: Valve open

− With three-way mixing valves: Port A à AB closed, B à AB open

− With three-way diverting valves: Port AB à A open, AB à B closed

52 EB 8331-4 EN

Page 53

Congurationlevel

A

AB

Mixing valve for mixing service

Flow pipe

B

Return ow pipe

Diverting valve for mixing service

Flow pipe

A

Return ow pipe

B

AB

Return ow pipe

For diverting service

Flow pipe

Return ow pipe

For diverting service

Flow pipe

AB

A

AB

B

A

B

Fig.21:Operating principle of three-way mixing and diverting valves

Code Description WE Adjustment range

c42 Direction of action >> >> (increasing/increasing)

<> (increasing/decreasing)

9.4 End position guiding

The actuator stem moves to the end positions earlier if the end position guiding function is

active.

9.4.1 Operatingdirectionincreasing/increasing

− Endpositionguiding(stemretracts)(c35): The actuator stem moves the valve to the top

end position if the input signal reaches the value entered in this code. Setting c35 =

100.0% causes this function with a retracting actuator stem to be deactivated.

− Endpositionguiding(stemextends)(c36): The actuator stem moves the valve to the