Page 1

SAGE THERMAL GAS MASS FLOW METER

Operations and

Instruction Manual

For Prime Models SIP and SRP

DOCUMENT NUMBER 100-0065

REVISION 16 - SIP/SRP (SAGE PRIME™)

Make the Wise Choice.

Choose Sage Flow Meters.

SAGE METERING, INC.

8 Harris Court, D1

Monterey, CA 93940

1-866-677-SAGE (7243)

Tel 831-242-2030

Fax 831-655-4965

www.sagemetering.com

Page 2

Page 3

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

3

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

Table of Contents

Introduction Welcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SECTION A Unpacking Your Sage Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

G

etting Started

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Locating Proper Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Insertion Flow Meter Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sage Valve Assembly Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compression Fitting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Captive Flow Conditioners . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Probe Insertion Guideline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Installation Depth Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Large Duct or Stack Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

In-line Flow Meter Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Terminal Hookup Prime Integral (Series SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

24 VDC Prime Integral Terminals Series SIP . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

AC Powered Prime and DC Powered Prime PLUS

Integral Terminals (Series SIP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Terminal Hookup Prime Remote (Series SRP). . . . . . . . . . . . . . . . . . . . . . . . . . . 21

24 VDC Prime Remote Terminals (Series SRP) . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AC Powered Prime and DC Powered Prime PLUS

Remote Series Terminals (Series SRP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Junction Box Wiring Terminals for Remote Style Meters . . . . . . . . . . . . . . . . . 24

SECTION B Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Specifications

Features and Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Sage PRIME Styles & Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sage PRIME Organic (OLED) Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SECTION C SIP Series Integral Style Flow Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Drawings

SRP Series Remote Style Flow Meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Remote Bracket Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Mounting Hardware:

SVA05 Series Isolation Valve Assembly for Insertion Meters . . . . . . . . . . . . 38

STCF Series Teflon Ferrule Compression Fitting . . . . . . . . . . . . . . . . . . . . . . 38

SVA05 Series Isolation Valve Assembly Detail . . . . . . . . . . . . . . . . . . . . . . . . 38

Mounting Plate for Thin Walled Ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

continued on next page

Page 4

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

4

REV. 16-SIP/SRP

SECTION C SVA05LP Low Pressure Isolation Valve Assembly. . . . . . . . . . . . . . . . . . . . . . . . 39

Drawings

In-Line and Insertion Flanges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SECTION D Common Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Diagnostics

In-Situ Calibration Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

SECTION E Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Warranties and Service Work

Cancellation/Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Returning Your Sage Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Return Material Authorization Form . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SECTION F Modbus Register Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Modbus

Modbus Protocol & Function Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Sage Register Output Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Sage Addresser Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Sage Addresser Typical Printout (Version 3.14) . . . . . . . . . . . . . . . . . . . . . . . . . 62

SECTION G Sage Prime™ Field Programmable “Dongle” . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix

Correction Factors For Varying Gas Mixes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Installations Where Pipe Condensation May Develop . . . . . . . . . . . . . . . . . . . 66

J-Box and Upstream Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

What Is a Thermal Mass Flow Meter? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Page 5

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

5

Welcome

We are pleased that you have purchased a Sage Metering Mass Flow Meter for your

requirement. We hope that you are satisfied with the performance, operation and

design of our highly precise, NIST traceable Thermal Gas Mass Flow Meter.

S

age Metering is your source for monitoring, measuring and controlling the gas mass

flow in your industrial process, building management system or environmental appli cation. Our high performance, NIST Traceable,Thermal Mass Flow Meters will help

increase productivity, reduce energy costs, maximize product yields, and/ or help reduce

environmental insult. Sage provides high quality In-Line and Insertion Thermal Mass

Flow Meters for a wide variety of industrial, commercial, and environmental monitoring

needs, including carbon credit verification for Greenhouse Gas reduction.

Sage Meters measure mass flow directly — there is no need for ancillary instrumentation

such as temperature or pressure transmitters. Furthermore, our instruments have exceptional signal sensitivity, have no moving parts, require little if any maintenance, have

negligible pressure drop and have a turndown up to 100 to 1, and resolve as much as

1000 to 1. Sage Flow Meters can measure the mass flow rate and consumption of air,

oxygen, natural gas, nitrogen, digester gas, biogas, flare gas, hydrogen, argon, carbon

dioxide and other gases and gas mixes.

Sage Prime is the latest addition to our family of high performance Thermal Mass Flow

Meters. It features a bright graphical display of Flow Rate,Total and Temperature, robust

industrial enclosure, and easy to access power and output terminals. Sage Prime has a

dual-compartment windowed enclosure featuring a very high contrast photo-emissive

OLED display with a new photocell activated Screen Saver. The rear compartment,

which is separated from the electronics, has large, easy to access and well marked ter minals, for ease of customer wiring. It is powered by 24 VDC (12 VDC optional, or

115/230 VAC). The power dissipation is under 2.5 watts (e.g. under 100 ma at 24 VDC

for the DC version.)

Please let us know if we can assist you in any way with your Sage Meter, or if you

have any questions about its installation, operation, or features. Simply phone us at

866-677-SAGE (7243), or visit our website at www.sagemetering.com to contact a

factory representative in your area. (To access this manual on the website, enter in

user name: sage; passcode 7243737 when prompted.)

Sincerely,

Robert Steinberg

President

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

Page 6

Page 7

Section

GETTING STARTED

A

Page 8

Page 9

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

UNPACKING YOUR SAGE METER

Your Sage flow meter is a sensitive, yet rugged,

p

recision built electronic instrument. Upon delivery,

care should be taken when opening the shipping

container and removing your meter. The meter

should be inspected for any damage that may have

occurred during transit. If damage is found, please

contact the carrier immediately to place a claim for

damaged goods. The contents of the container

should be checked against the packing list for any

discrepancies. If there are any questions as to the

contents or configuration of the equipment includ-

ing calibration ranges, or, mounting hardware,

contact Sage Metering as soon as possible. Please

save shipping container and packaging materials

(including PVC tube probe protector on Sage

Insertion Flow Meters) in case the unit needs to

be returned for any reason.

MAINTENANCE

Sage thermal mass flow meters essentially require

little or no maintenance. While the sensing element

is somewhat resistant to dirt and particulate build

up, it may become necessary to clean it from time to

time if mounted in extremely dirty environments.

NOTE: ALWAYS REMOVE THE POWER PRIOR TO

ANY CLEANING OR MAINTENANCE. A detergent or

appropriate non-corrosive solvent for removing the

buildup may be required. A soft brush can be used

to gently clean the sensing element’s surface, using

caution to avoid damaging the sensor elements

(the RTDs). If any disassembly is necessary, contact

Sage Metering, Inc. for instructions. In general, it is

recommended that your Sage Thermal Mass Flow

Meter be returned to the factory if cleaning,

repair, or recalibration is needed. This is usually

the most cost-effective and reliable alternative.

CALIBRATION

Sage Prime has continuous diag nostics. The raw

cali bration milliwats (mw) is always displayed in the

upper left hand corner of the meter's display. At any

time, you can check this reading at a “no flow” con-

dition and compare the reading to the original re -

ported “zero flow” value noted on the last few lines

of your meter’s Certificate of Conformance or the

flow meter’s data tag. This diagnostic procedure not

only checks the sensor performance and the “live

zero” calibration point, but it verifies that the sensor

is clean. It essentially provides a means to validate

the meter’s performance, verifies that there is no shift

or drift, and eliminates the need for annual factory

calibrations. This simple field diagnostic procedure

also verifies that the sensor is free from contamina-

tion, even without inspection. See “In-Situ

Calibration Check” on page 46.

Getting Started

9

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

a

CAUTION cable glands shipped with unit are for shipping purposes only.

Remove shipping cable glands before installing.

a

CAUTION If installing in a Class I hazardous location the installation

must comply with appropriate electrical codes.

a

CAUTION Installer must supply proper ground and bond wire for the

transmitter and the sensor per appropriate electrical codes

Page 10

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

10

INSTALLATION AND MOUNTING

■

Check the Certificate of Conformance included

with your Sage Thermal Mass Flow Meter for

system pressure, temperature, gas composition,

power input, and signal output.

■

It is recommended that the flow meter be inserted in

a location of maximum straight run. It is suggested

that there be a minimum of 15 pipe diameters of

straight run upstream, and 5 diameters downstream,

depending on the conditions. See chart on page 11.

Note, obstructions such as valves, blowers, expand -

ers and PVC and HDPE pipes will require addition-

al straight run (contact factory for assistance).

■

Check the orientation1: Standard calibration flow

direction is left to right when facing the flow

meter. Gas flow direction is marked with an arrow

on in-line flow meters; UPSTREAM is marked on

insertion probes.

■

Do not rotate probe1, or errors may occur. If enclo-

sure is facing incorrectly, rotate the enclosure 180˚,

but do not rotate the probe. The UPSTREAM mark

still needs to be facing Upstream.

■

Hook up the system per the wiring diagram provid-

ed with your Sage flow meter (see inside of rear

compartment cover for terminal designation).

Double check that wiring for the proper power and

signal connections are correct.

■

Check that all plumbing and electrical hook-ups

are in accordance with OSHA, NFPA, and all other

safety requirements.

■

For Remote Style Meters (SRP) be sure the Remote

Electronics is matched with the Transmitter’s

Junction Box and its attached Probe or Flow

Body. There will be Metal Serial Number Tags

on both the Transmitter as well as the Remote

Electronics enclosure. Do not mismatch the seri-

al numbers of the Remote Electronics and the

Junction Box, or calibration errors will occur.

LOCATING PROPER WIRING DIAGRAM

1) Look at the sticker on your meter. The first three

digits describe the basic model that you have.

Refer to the appropriate page numbers below for

your wiring diagram

2) SIP: see page 19

3) SRP: see page 22 for input/output terminals;

see page 24 (Junction Box Wiring Terminals

for Remote Style Meters)

WIRING

Follow the instructions below to remove the rear cap

for wiring. CAUTION: Do not open the display side!

Before removing the rear cap to access the wiring

terminals it is essential to completely remove the

screw assembly on the side of the rear enclosure to

free up the threads so the lid can be removed. Note

there is a Red Tag attached to the screw assembly

stating “Remove Screw Before Opening Lid”.

After the wiring is completed (see pages 18 to 23

for wiring details), please close the lid, and reinsert

the screw assembly in the same manner.

Note: See “Approvals” page for Hazardous Location

Approvals (DC Powered Meters Only)

REV. 16-SIP/SRP

1 The Integral Style of Sage Prime Insertion Meters have the Display oriented as shown on page 14.

If an alternate orientation of the display, or enclosure is required (ie. installation into a vertical pipe),

please furnish a sketch or drawing, and specify “ROTATE” on purchase order. However, if it is later

determined that the enclosure needs to be rotated, that procedure can be done in the field. However,

if the display needs to be rotated, then the meter must be sent back to Sage to be modified. Do not

attempt this in the field. An RMA will be required prior to returning the meter (see page 51). The

procedure for rotating the enclosure is as follows: Clamp the enclosure of the Prime in a vise with the

probe pointing up to the ceiling. Then take a 7/8 wrench and turn the probe to the proper orientation. Lock the probe into its new position with a set screw (not provided).

Page 11

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

11

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

FLOW PROFILE AND INSTALLATION

CONSIDERATIONS

Insertion Flow Meters, although generally easier to

install that In-Line Flow Meters, require proper

installation, and a well developed flow profile, in

order to perform properly. Please refer to the section

on the following pages titled PROBE INSERTION

GUIDELINE DRAWING (page 14) and INSTALLA-

TION DEPTH CHART (page 15).

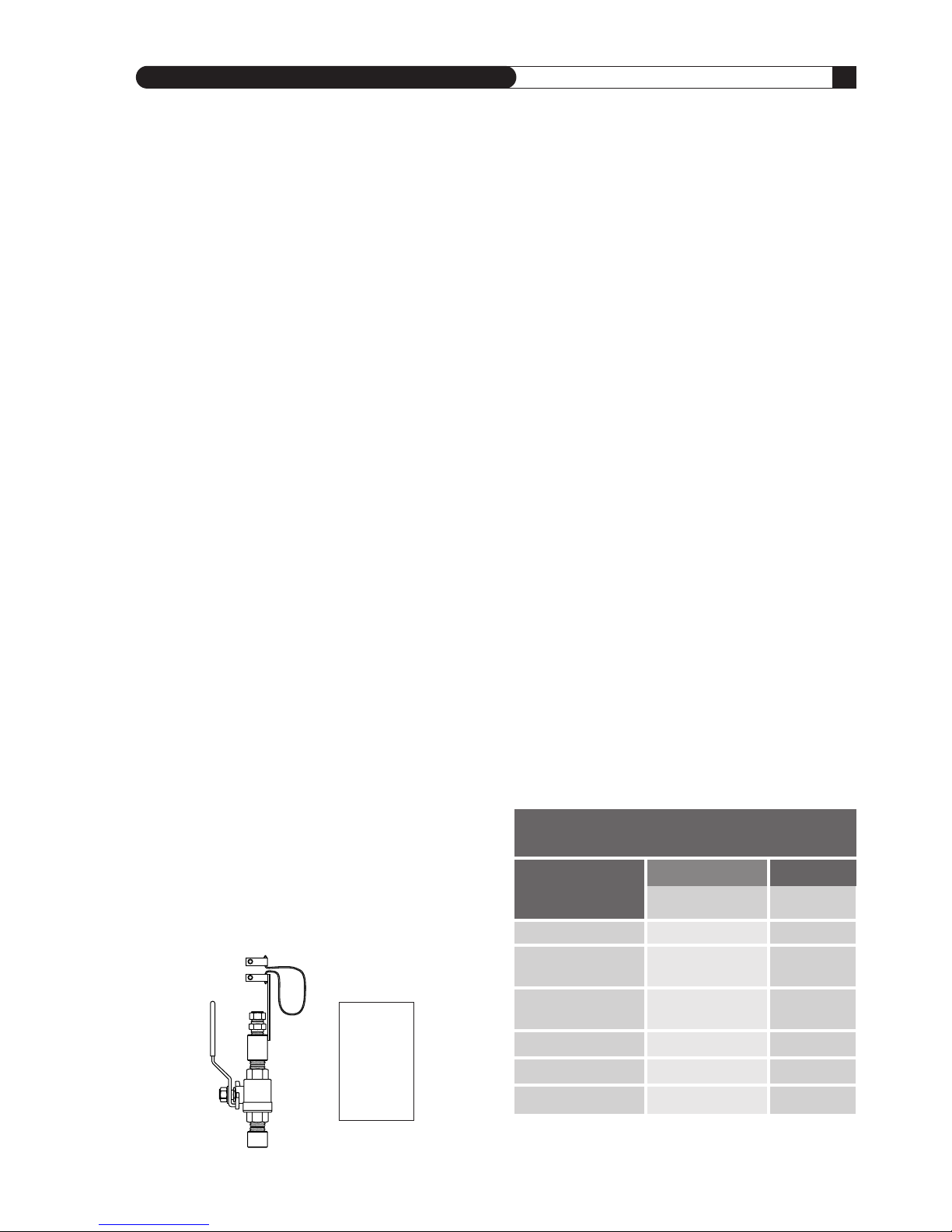

SAGE VALVE ASSEMBLY OPERATION

Valve assemblies (SVA05 and SVA05LP) are an op -

tional mounting hardware for Insertion Style Flow

Meters (see pages 38 and 39). They allow the removal

of insertion-style meters for service, cleaning, recali -

bration, relocation, etc. without the need to “shut-

down” your process. The probe insertion depth is

adjustable to permit sensor to be located at center

to optimize measurement accuracy. (Refer to PROBE

IN SERTION GUIDE LINE DRAWING and CHART, pages

14 & 15.) The ball valve will seal off leaks of the

process gas at the point of insertion after the probe

assembly has been removed. The assembly includes

a valve, threadolet, compression fitting with Teflon

ferrule, a cable restraint, and two collar clamps.

A threaded half coupling (3/4" FNPT) properly sized

to accom modate the isolation valve retractor assem-

bly must be fitted to the pipe/duct to which the

insertion probe will be inserted. Avoid T-Fittings

since they will disturb the flow profile, and effec-

tively reduce the measurement area. Direct thread-

ing together (or with necessary bushings) of the

retractor assembly may be required. In other cases,

the threadolet must be welded in place and a clear-

ance hole must be drilled through the pipe/ duct to

accept the probe assembly. If the pipe/duct is under

pressure during installation, a hot tap drill (not

available through Sage Metering) may be required.

FLOW CONDITIONING AND STRAIGHT RUN

Although a minimum of 15 pipe diameters of

upstream straight run is commonly recommended,

to absolutely assure that the flow profile is well

developed at the point of measurement, either use

Flow Conditioners (standard in Sage In-Line Flow

Meters, 1/2" and larger, and also available as assem-

blies for Insertion Flow Meters, see page 13), or

consider additional straight run. The Chart below

provides examples of the amount of straight run

that would virtually assure that there are no flow

disturbances at the point of measurement.

N O T E :

Detailed

Drawings

are shown

on pages

38 & 39.

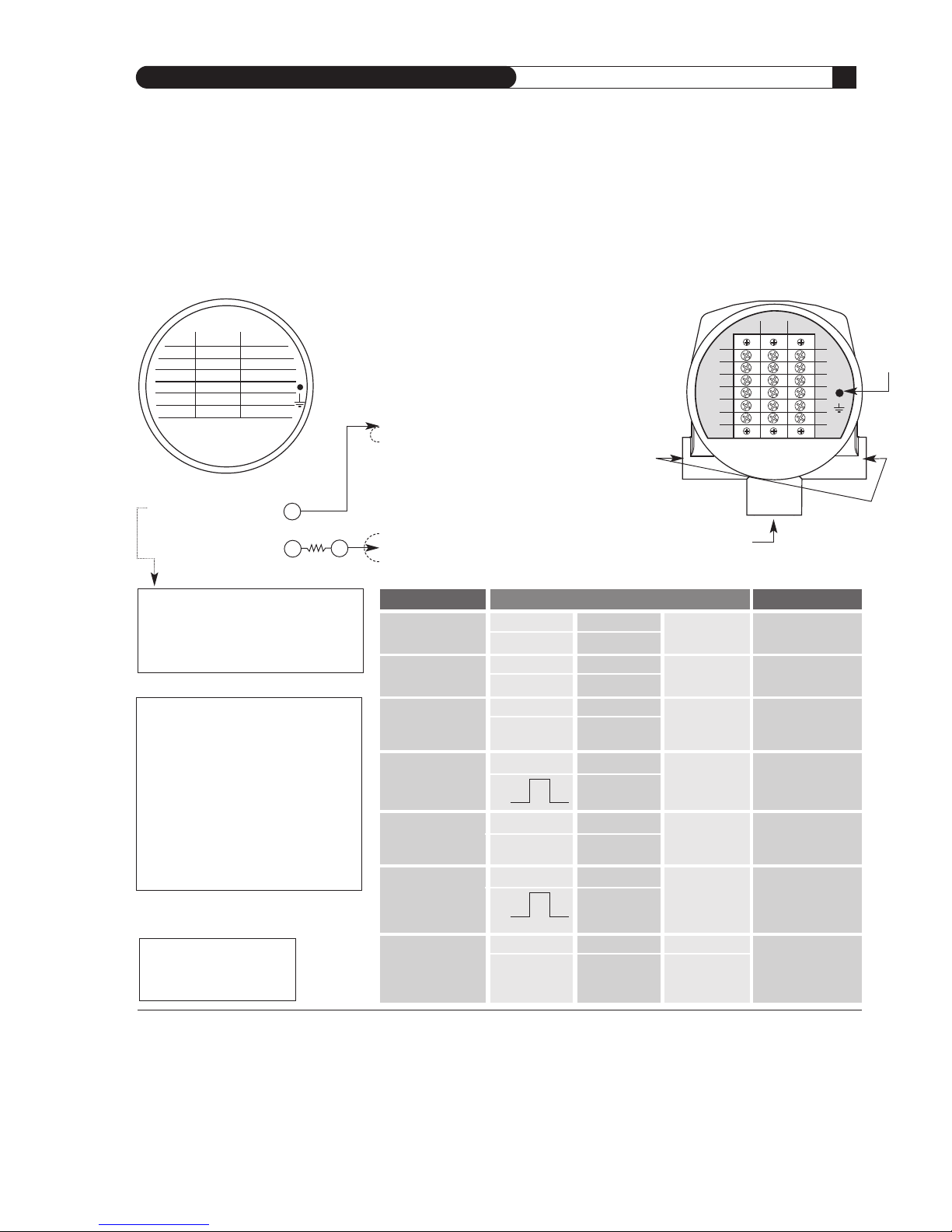

Insertion Flow Meter Application

IMPO RTANCE OF FLO W CO NDITION ING

Reco mmen ded P ipe D iameter s Ups tream

One 90˚ Elbow

Two 90˚ Elbows

in the same plane

Two 90˚ Elbows

in different planes

4:1 Area Reduction

4:1 Area Expansion

Multiple Disturbance

3

5

9

3

10

TBD

1

This column applies to In-Line Flow Meters, which come standard with built-in Flow Conditioners, as well as Insertion Meters,

when provided with upstream Captive Flow Conditioners (see page 13).

D I S T U R B A N C E

15

20

At least 40

15

At least 30

To Be Determined

WITHOUT

FLOW CONDITIONING

Minimum Industry

Recommendation

WITH FLOW

CONDITIONING

1

Sage

Recommendation

Page 12

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

12

REV. 16-SIP/SRP

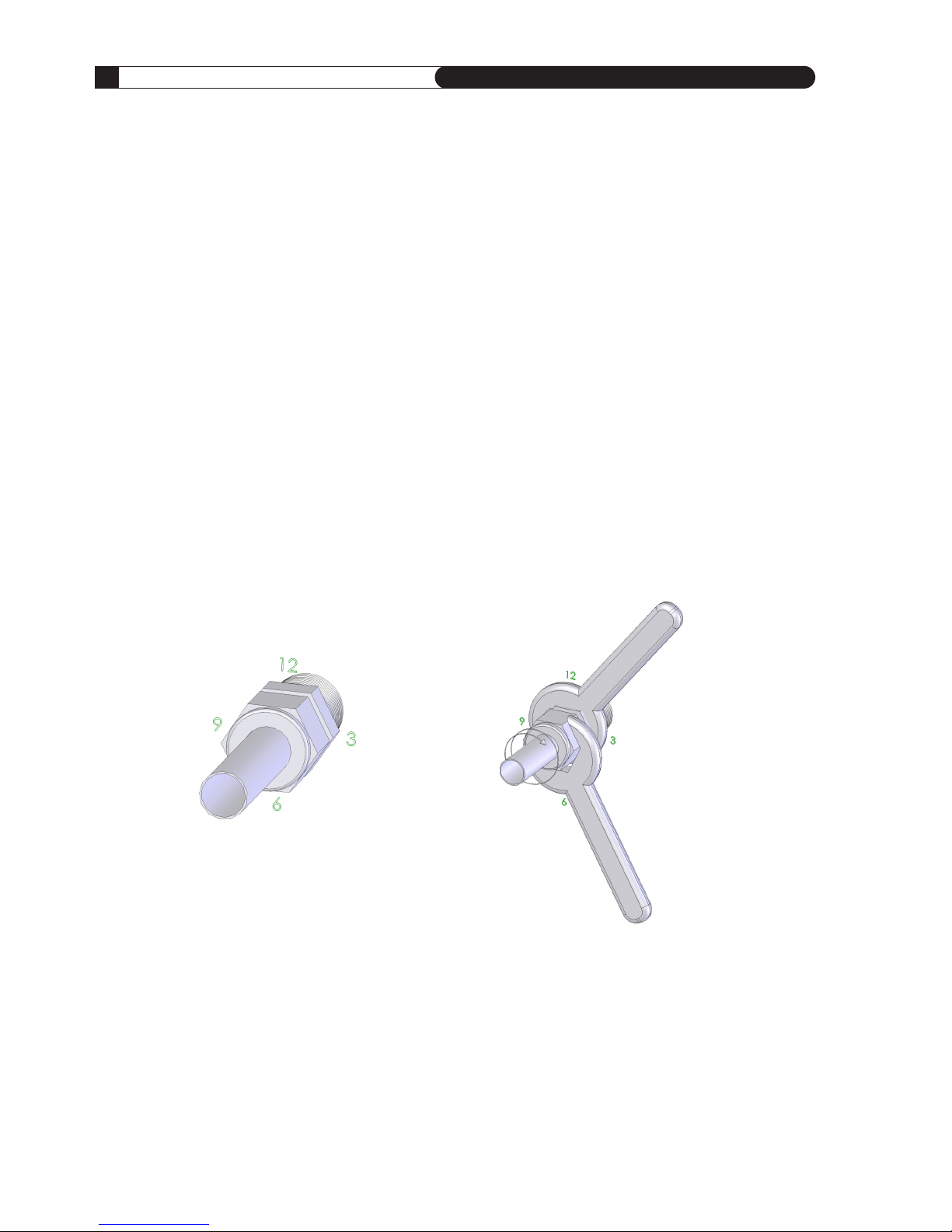

COMPRESSION FITTING OPERATION

A bored through tube fitting, properly sized to

accommodate an insertion probe’s particular OD,

can be provided by the user or purchased as an

option from Sage Metering (see page 38). Prior to

installation, a clearance hole to accommodate the

insertion probe assembly must be drilled in the

pipe/duct. A fitting (1/2" FNPT) is then welded in

place or threaded into the half-threadolet which has

been welded to the pipe/duct. The probe insertion

depth is adjustable to permit sensor to be located at

center, to optimize measurement accuracy. (Refer to

PROBE INSERTION GUIDELINE DRAWING and

CHART, pages 14 & 15.)

Insert the probe shaft tubing into the

compression fitting to the position indicated

in the Probe Insertion guidelines.

While holding the fitting body steady,

tighten the nut one and one-quar ter

turns to the 9 o’clock position.

INSTALLATION INSTRUCTIONS

1. Insert tubing into the tube fitting.

2. Make sure that the tubing is positioned properly

per the PROBE INSERTION GUIDELINE DRAW-

ING AND CHART, pages 14 & 15.

3. Due to the variations of tubing diameters, a

common starting point is desirable. Therefore,

tighten the nut until the tubing will not turn

by hand or move axially in the fitting.

4. Scribe the nut at the 6 o’clock position.

5. While holding fitting body steady, tighten the nut

1

1

⁄4 turns to the 9 o’clock position.

Page 13

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

13

S A G E M E T E R I N G , I N C .

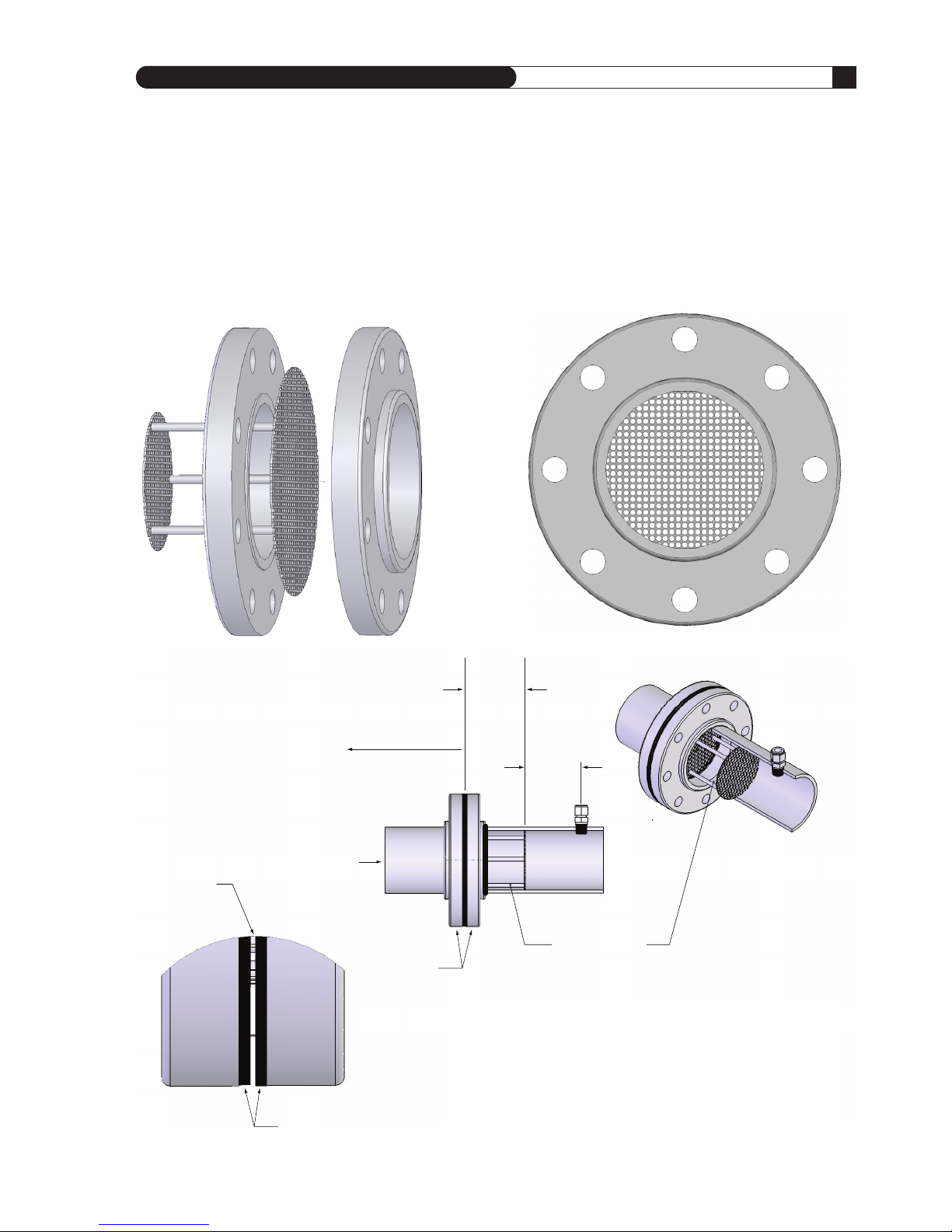

ANSI Class Flanges

(user supplied)

Largest of the

Two Perforated

Plates

Flow Conditioning

Assembly is

inserted here.

One Pipe

Diameter

FLOW

Gaskets

One Pipe

Diameter

Straight Run Requirement

from this Flange

CAPTIVE FLOW CONDITIONERS

Can Be Installed in Conjunction with Insertion Style Flow Meters

NOTE: The larger of the two perforated plates of the Sage

Flow Conditioning assembly is positioned between two flanges

and two gaskets as shown. The smaller of the two perforated

plates of the conditioner will freely slide into the application

pipe, facing downstream. The probe mounting hardware will be

placed one diameter downstream of the downstream plate.

Probe location must be one pipe ID diameter downstream of

Flow Conditioners or errors will occur.

Front View of one of the Conditioning Plates

IMPORTANT The location of the probe must be exactly one pipe ID diameter (i.e., 4” in a 4” pipe; 6” in

a 6” pipe, etc.) downstream of the Captive Flow Conditioning assembly. The Captive Flow Conditioners

are always designed to be separated by one pipe diameter. See drawing below. The probe location must

be one pipe ID diameter downstream of Flow Conditioner, or errors will occur.

Note: See table on page 11

(last Column) for Straight Run

Requirement

Page 14

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

14

REV. 16-SIP/SRP

PROBE INSERTION GUIDELINE DRAWING

1

Choose the longest straight-run section of pipe avail-

able to allow a uniform, well-developed flow profile.

A

llow for a minimum of 15 pipe diameters of straight

run upstream, and 5 diameters downstream, depend-

ing on the conditions. See chart on page 11. Note,

obstructions such as valves, blowers expanders and

PVC and HDPE pipes will require additional straight

run (contact factory for assistance). Avoid, if possible,

installations immediately downstream of bends, fans,

nozzles, heaters and especially valves, or anything

else installed in the line that may cause nonuniform

flow profiles and swirls. Otherwise signal output

errors could result, unless significantly more straight

run is provided, or in the absence of sufficient straight

run, Flow Conditioners (page 13) are in stalled (con-

tact Sage for assistance if needed). Refer to page 13 to

see the benefits of incorporating Flow Conditioners.

Insertion styles are available through Sage Metering,

Inc. with a standard 1/2" OD probe support assem-

bly; 3/4" is also available. Stan dard probe lengths

are 6", 12", 15", 18", 24", 30", 36" and 48". A common

method of mounting the probe assembly through

a pipe wall or duct (if ambient air) is with a compres-

sion fitting (STCF05). A Sage valve assembly (SVA05)

is useful and highly recommended for

pressurized applications or other gases,

such as Natural Gas. Flange mounting

is optionally available.

Sage insertion style flow meters can be assembled

and calibrated for use in virtually any size pipe or

duct (as small as 1”). Sage insertion flow meters

include a probe assembly that supports the sensing

element (a self-heated flow sensor and a tempera -

ture/reference sensor); a sensor drive circuit; micro -

pro cessor meter board, and trans mitter enclosure.

The probe assembly must be inserted into the correct

position in the pro cess gas flow conduit to allow the

gas to flow through the sensor “window” across the

sensor element. The “sensing point” or active part of

the sensor (0.5" from the end of the probe) should be

positioned as per the drawing below and the

Installation Depth Chart on page 15.

Installation Depth

The center of the pipe (assuming a well developed

turbulent flow profile) is fairly flat, and easy to

locate. See “Installation Depth Chart” on next page

to determine proper insertion depth.

Z

Y

X

4" PIPE SHOWN

LESS THAN IDEAL LOCATION

Contact Factory for Assistance

GOOD LOCATION

2,3

(See Installation Depth Chart for X and Y Dimension)

2. Probe should be inserted per Installation Depth Chart (see following page),

so sensors are in the center of the pipe.

3. The portion of the probe that remains outside of the pipe, is simply the factory

ordered probe length (i.e. “-15” = 15 inches) minus the “Y” dimension.

Center

of Pipe

PRIME

84˚F

1

3546

SCFM

4

67469670

SCF

88mW

1. SIP Industrial Meter shown in drawing. Note, probe is not bi-directional.

Page 15

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

15

S A G E M E T E R I N G , I N C .

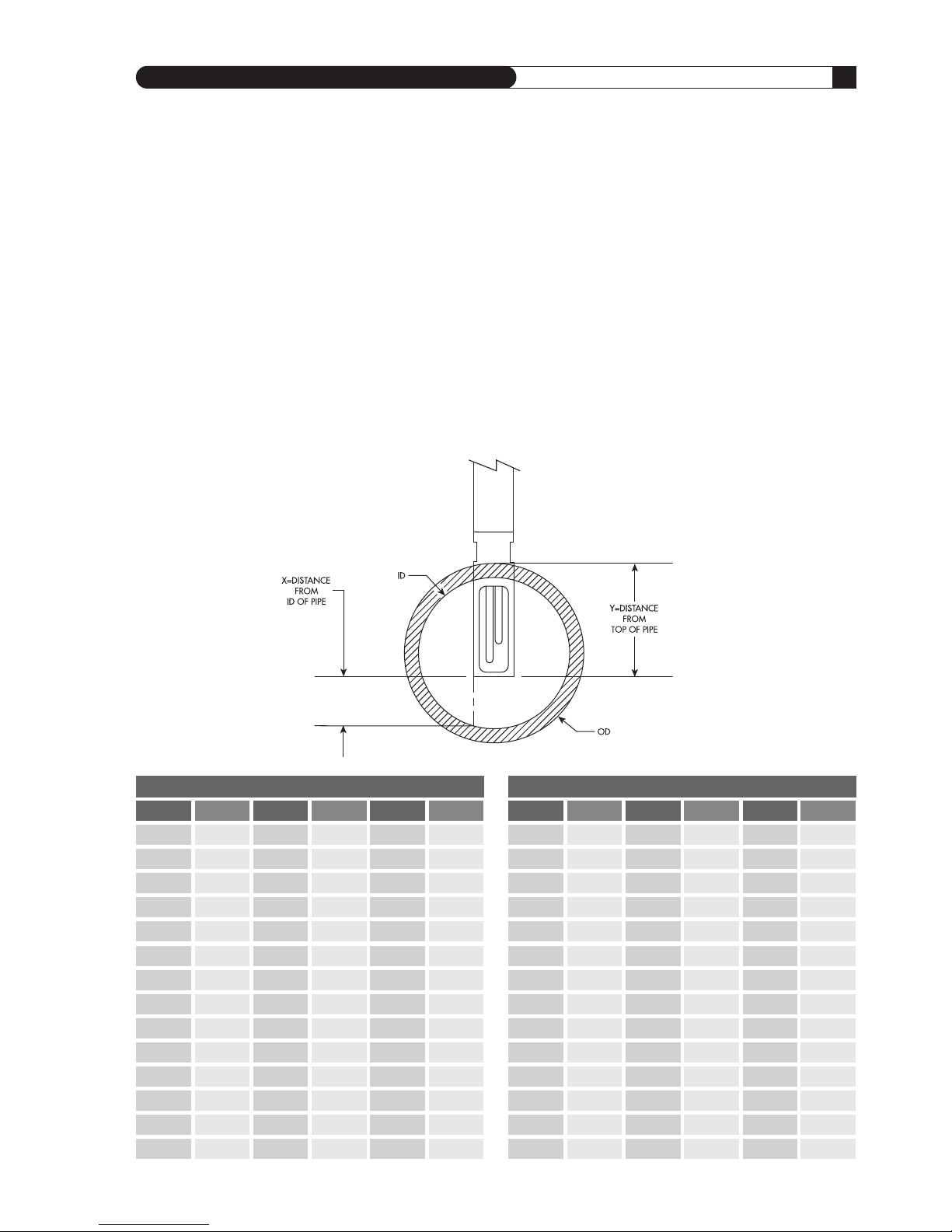

I

NSTALLATION DEPTH CHART

Methods for Probe Insertion to Pipe Center

ME TH OD 1

Using charts below, select pipe size (column 1),

determine X. Insert probe until the end touches the

bottom of the pipe (ID), mark probe as it exits top

of fitting. Lift probe distance “X” and tighten com -

pression fitting.

ME TH OD 2

Using charts below1, select pipe size (column 1),

determine Y. Subtract Y from the factory supplied

probe length. That difference Z (see drawing on page

14) should be outside of the pipe, and is measured

from the bottom of the enclosure of the probe weld

to pipe OD.

PIPE SIZE OD ID XYPIPE AREA

1"

1.5" 1.900 1.500 .15" 1.56" 0.0123

2" 2.375 1.939 .35" 1.82" 0.0205

2.5" 2.875 2.323 .55" 2.07" 0.0294

3" 3.500 2.900 .80" 2.38" 0.0459

4" 4.500 3.826 1.30" 2.86" 0.0798

6" 6.625 5.761 2.25" 3.95" 0.1810

8" 8.625 7.625 3.25" 4.90" 0.3171

10" 10.750 9.750 4.25" 6.00" 0.5185

12" 12.750 11.374 5.13" 7.00" 0.7056

14" 14.000 12.500 5.70" 7.50" 0.8522

16" 16.000 14.312 6.60" 8.60" 1.1172

18" 18.000 16.124 7.50" 9.60" 1.4180

24" 24.000 21.562 10.25" 12.60" 2.5357

S C H E D U L E 4 0 P I P E

2

S C H E D U L E 8 0 P I P E

2

PIPE SIZE OD ID XYPIPE AREA

1"

1.5" 1.900 1.610 .20" 1.56" 0.0141

2" 2.375 2.067 .40" 1.82" 0.0233

2.5" 2.875 2.469 .60" 2.07" 0.0332

3" 3.500 3.068 .90" 2.38" 0.0513

4" 4.500 4.026 1.40" 2.86" 0.0884

6" 6.625 6.065 2.40" 3.95" 0.2006

8" 8.625 7.981 3.40" 4.90" 0.3474

10" 10.750 10.020 4.40" 6.00" 0.5476

12" 12.750 11.938 5.50" 7.00" 0.7773

14" 14.000 13.124 6.00" 7.50" 0.9394

16" 16.000 15.000 7.00" 8.60" 1.2272

18" 18.000 16.876 8.00" 9.60" 1.5533

24" 24.000 22.625 10.75" 12.60" 2.7919

C O N S U L T F A C T O R Y

C O N S U L T F A C T O R Y

1

For other Pipe Schedules, such as Schedule 10, contact Sage, however the Y dimension will

be the same for any Schedule Pipe

2

The 1" Pipe Size needs to have the Probe “Bottomed Out” (option “BOT"); the calibration

method for the 1

1

⁄2" Pipe is either as shown below, or with option “BOT”

Page 16

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

16

REV. 16-SIP/SRP

P

RIME

84˚F

1

3546

SCFM

467469670

SCF

88mW

P

RIME

8

4

˚

F

13546 SCFM

4

67469670

SCF

88mW

PRIME

84˚F

13546 SCFM

467469670

SCF

88mW

PRIME

8

4

˚

F

1

3546

S

CFM

4

67469670

S

CF

8

8mW

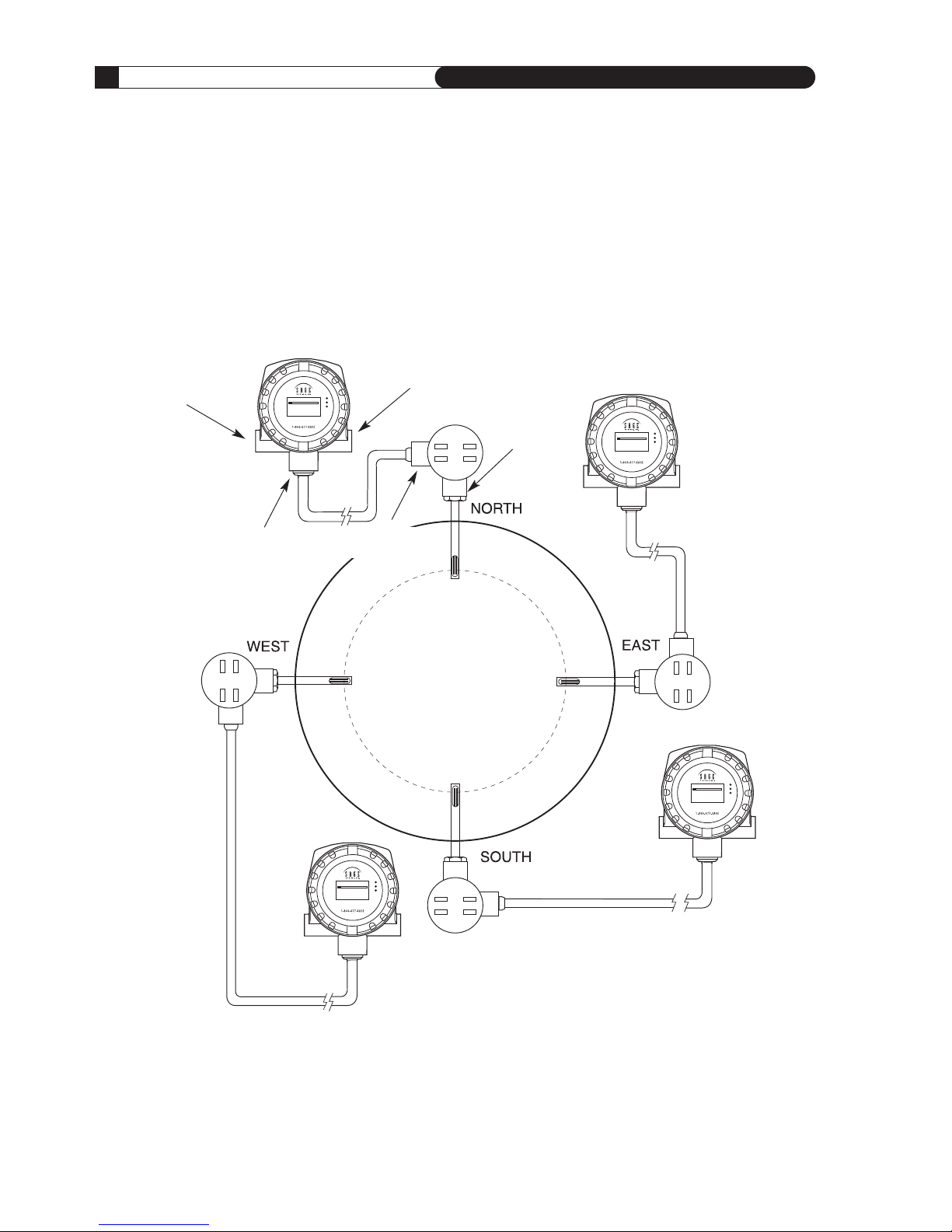

CONFIGURATION FOR UTILIZING FOUR (4) SAGE INSERTION MASS FLOW METERS FOR LARGE ROUND

PIPES OR DUCTS LARGER THAN 36" TO MINIMIZE EFFECTS OF VARYING FLOW PROFILES

(It is recommended that Factory be contacted to assist with applications of this nature)

The outputs of the four meters will be averaged

by customer’s PLC or other method to improve

overall accuracy in measuring the flow rate.

(For medium sized round pipes [18" to 36"],

two meters, on the opposite side of the same

diameter, may be sufficient [insert parallel to an

upstream 90 degree bend for optimal benefit.])

Note, in this configuration, each sensor needs

to be averaged.

1/2" NPT

User Entry

for Wiring

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Probe Support

3/4" NPT for

Remote Cable

3/4" NPT for

Remote Cable

Large Duct or Stack Applications

Page 17

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

17

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

IN-LINE FLOW METERS

In-line mounting styles are available through Sage

Metering, Inc. in sizes from 1/4" pipe through 4"

pipe. Threaded male NPT ends are standard up to

2-1/2"; ANSI 150lb flanged ends are recommended

for 3" and 4" models. Contact the factory if optional

end mounting styles are required. Pipe sizes in excess

of 4" require the insertion style mass flow meter.

The in-line style flow meter assembly flow section is

typically specified to match the user’s flow conduit

and is plumbed directly in the flow line by thread-

LENGTH “L” SAME AS NON-FLANGED METER

(See table on page 27. For example, 1"x8" flow

body has an 8" length. The length will be the same

whether an NPT flow body, or whether flanged.

If a flanged flow body, the 8" dimension will be

a Face-to-Face dimension.)

FLOW CONDITIONING SCREENS FOR IN-LINE FLOW BODIES 1/2" AND UP

1

Screens shown

with NPT fitting.

1 Note, Flow conditioning is also available for Insertion Meter applications (see page 13)

ing, flanging, welding, etc. DO NOT USE REDUCERS.

It includes the sensing element (a self-heated flow

sensor and a temperature/reference sensor) mounted

directly in the specified flow section for exposure to

the process gas; a sensor drive circuit; microprocessor

meter board, and transmitter enclosure.

All in-line Flow Meters, 1/2" and up have built-in

Flow Conditioners. See Table (page 10) for Upstream

Straight run requirements. Note, the 1/4" and 3/8"

do not have Flow Conditioners and thus require

more straight run.

In-Line Flow Meter Application

Page 18

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

18

REV. 16-SIP/SRP

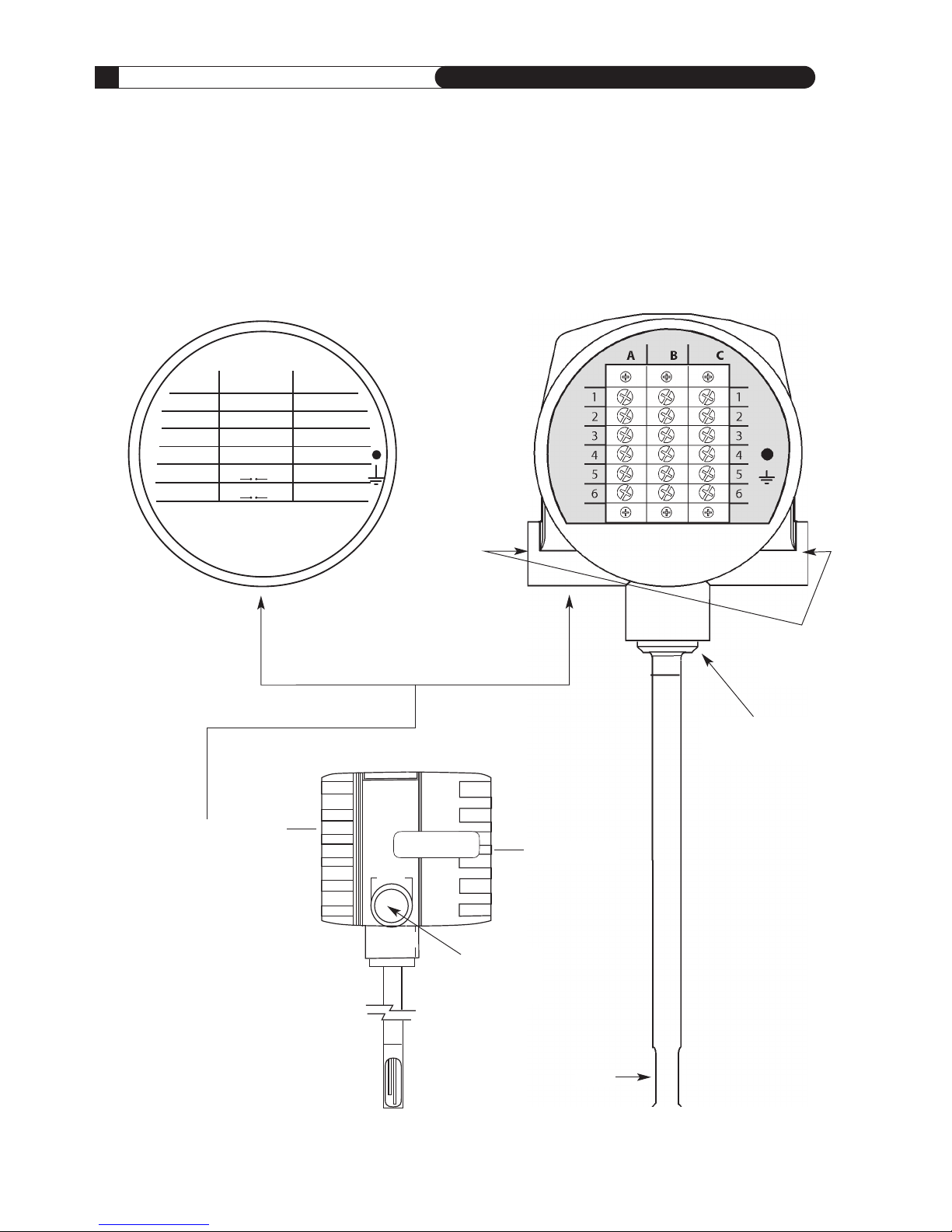

Prime Integral (Series SIP)

SEE “WIRING” ON PAGE 10 FOR INSTRUCTIONS ON HOW TO REMOVE REAR LID;

SEE FOLLOWING PAGES FOR TERMINAL HOOKUP

1 RED AC1 COM 1

2

S1 AC2 B + 2

3

RED SPARE A – 3

4

WHITE

4-20mA PWR

4

5

S2 4-20mA 5

6

WHITE VDC GND 6

A B C

24 VDC

P

ULSE

VDC IN

+

VDC GND

–

INTEGRAL

INSIDE COVER VIEW INSIDE BODY VIEW

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Probe Support

NO CUSTOMER ACCESS

DO NOT OPEN THIS SIDE

DISPLAY SIDE

1/2" NPT

View Entry

(ONE ON EACH SIDE)

FLOW

TERMINAL BLOCK SIDE

Page 19

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

19

S A G E M E T E R I N G , I N C .

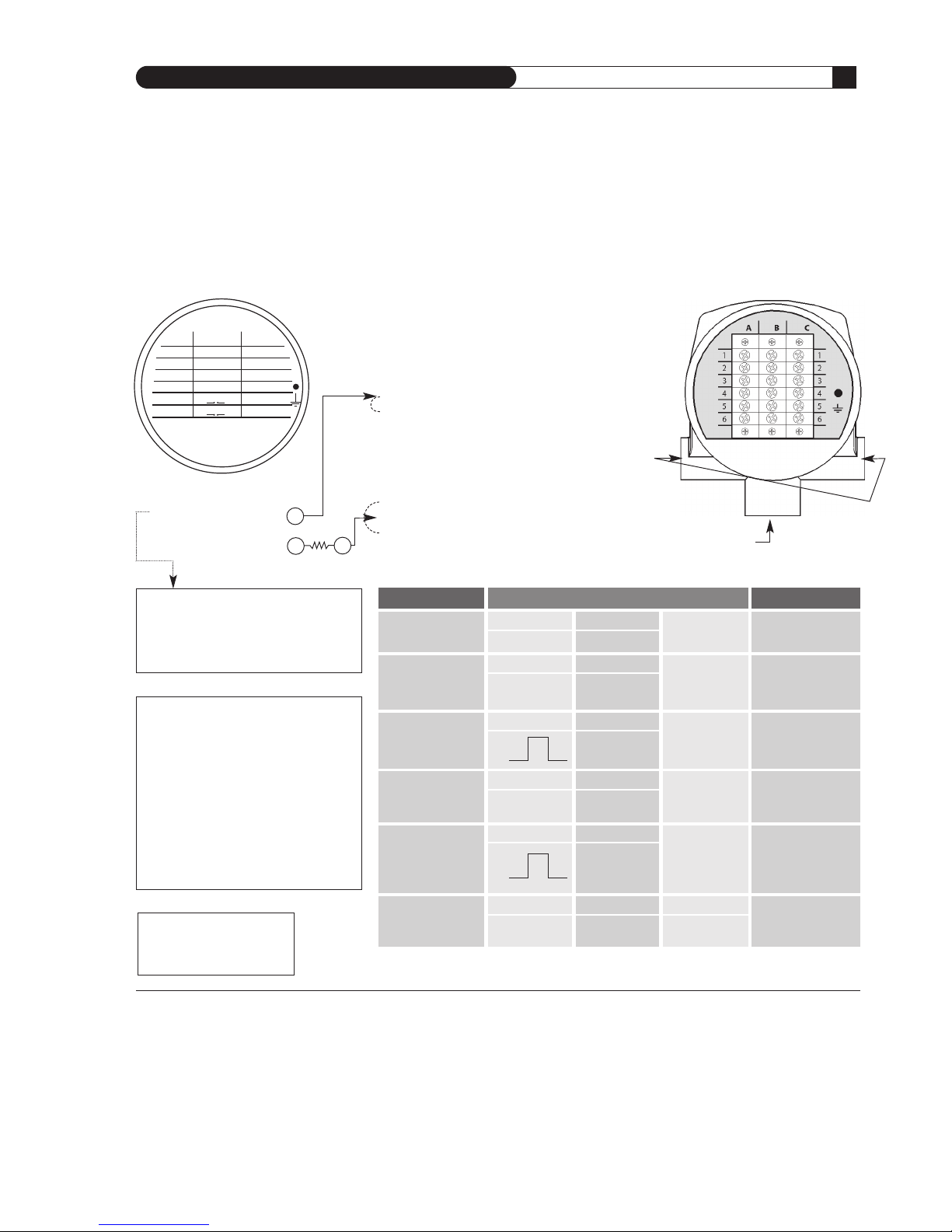

24 VDC Prime Integral Terminals (Series SIP)

(APPROVED FOR HAZARDOUS SERVICE6)

1 RED AC1 COM 1

2

S1 AC2 B +

2

3

RED SPARE A –

3

4 WHITE

4-20mA PWR

4

5

S2 4-20mA 5

6

WHITE VDC GND

6

A B C

2

4 VDC

PULSE

VDC IN

+

VDC GND

–

I

NTEGRAL

INSIDE COVER VIEW

NOTE: The Sage Prime

draws 2.4 watts maximum

(i.e. ≅ 100ma @24VDC)

–

+

C

U STO ME R

R ET UR N

E

X TE RN AL LY P OW ER ED

4 –2 0 mA BY C US TO ME R

+

*

DESCRIPTION TERMINALS NOTES

DC Input Power: B5 B6

24 VDC

7,8

+ VDC – VDC GND

Internally Powered: C5 C6 Do not remove

4-20 mA

4-20 mA Return

any Jumpers

SIGNAL DRIVE

Internally Powered: C4 C6 Do not remove

Pulsed Output

GND

any Jumpers

Externally Powered: C5 B4 Remove B4 & B5

4-20 mA

4-20 mA 4-20 mA

Jumper

SIGNAL DRIVE EX TERNAL SOURCE

Externally Powered9: C4 B3 Remove B4 & B5

Pulsed Output

JUNCTION FOR

Jumper and Connect

PULSE RETURN C4 Resistive Jumper

to B3

MODBUS C2 C3 C1 Modbus Ground

10

RS485(+) RS485(–) MODBUS GROUND

(REQ’D)

*B4 and B5 JUMPER

Remove jumper for Externally Sourced 4-20

mA. In this mode, user supplies 9-27 Volts to

externally power the 4-20 mA loop, and the

4-20 mA loop becomes optically isolated.

1 Specify the Sage Prime PLUS option in order to have the Modbus Ground (Terminal C1, COM) isolated

from the 24 VDC Sage Power Supply Ground (Terminal B6). All other features of Prime PLUS are

identical to the standard Sage Prime, except other voltage available. (See footnote 8)

2 It is important to connect the Ground when using Modbus communications, or ground loop problems

may develop. Improper wiring can also damage internal circuitry

3 Note, if customer externally powers the 4-20 mA by removing the jumper, the Pulse voltage output

is also effected: The voltage output of the Pulse will follow the customer power (i.e. 24 VDC external

power will result in a 24 VDC Pulse [maximum of 50 mA]; 12 VDC external power will result in a

12 VDC Pulse)

4 Pulse width 250 msec default (adjustable with Addresser software)

5 Using Sage Addresser, a Low Flow Cutoff (LFC), commonly referred to as Min Cutoff or Zero Cutoff

can be entered into the FLOW MIN Functions. In Versions 1.82 or higher, the Low Flow Cutoff and

the 4-20 mA Scaling are independent of each other. For example: A Low Flow Cutoff (LFC) of

10 SCFM on a Meter with a Full Scale of 100 SCFM will report 0 on the Display and 4 mA on the

output. The output will remain at 4 mA until the LFC is exceeded: (ie: 25 SCFM=8 mA). Thus the

4 mA will always be zero based

6 Class I, Div 2, Groups B,C,D,T4 and ATEX Ex na IIC T4

7 24 VDC ±10%

8 Other DC voltages (5 VDC, 12 VDC, 48 VDC) available on Prime PLUS. Contact Sage

9 Assumes the 4-20 mA is Externally Powered

10 Modbus Ground becomes isolated from the B6 Power Supply Ground only on Prime PLUS version

(specify “PLUS”)

INSIDE BODY VIEW

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Remote Cable

(on Remote Style SRP)

**

**Note, Flow Meter is supplied with a 10K

(1/2 watt) metal film resistor (Resistive

Jumper) connected across Terminals C4 and

C6. For externally powered operation, in

addition to removing B4 & B5 Jumpers, it

is necessary to connect C4 Resistive Jumper

to Terminal B3 instead of C6. Note, B3 must

be connected to the External Sources common in order to enable the optically isolated

pulse output. In this mode, Pulse Output is

optically isolated. Pulsed Output voltage will

depend on customer source voltage. Use

Sage Resistive Jumper only!

**

A1 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A2 – NO WIRE

A3 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A4 – WHITE – TEMPERATURE SENSOR WIRE

A5 – NO WIRE

A6 – WHITE – TEMPERATURE SENSOR WIRE

B3 – JUNCTION FOR ISOLATED PULSE

B4 – 4-20 mA RETURN (–) AND PULSE SOURCE

B5 – VDC IN – VOLTAGE DC – POSITIVE (+)

B6 – VDC GND – VOLTAGE DC – GROUND (–)

1

C1 – COM – RS485 MODBUS GROUND

1,2

C2 – B(+)–RS485_D1

C3 – A(–)–RS485_D0

C4 – 24 VDC PULSE – 0 TO 24 VDC PULSE OUTPUT

3,4

C5 – 4-20 mA – 4 TO 20 mA SIGNAL DRIVE

5

C6 – VDC GND – VOLTAGE DC – GROUND (–)

24

O

24

O

Page 20

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

20

AC Powered Prime Integral Terminals (Series SIP)

6

1 RED AC1 COM 1

2

S1 AC2 B +

2

3

RED SPARE A –

3

4 WHITE

4-20mA PWR

4

5

S2 4-20mA 5

6

WHITE VDC GND

6

A B C

2

4 VDC

PULSE

VDC IN

+

VDC GND

–

I

NTEGRAL

INSIDE COVER VIEW

NOTE: The Sage Prime

draws 2.4 watts maximum

(i.e. ≅ 100ma @24VDC)

–

+

C US TO ME R

R ET UR N

E

X TE RN AL LY P OW ER ED

4

– 20 m A B Y CU ST OM ER

+

*B4 and B5 JUMPER

Remove jumper for Externally Sourced 4-20

mA. In this mode, user supplies 9-27 Volts to

externally power the 4-20 mA loop, and the

4-20 mA loop becomes optically isolated.

1 Specify the Sage Prime PLUS option in order to have the Modbus Ground (Terminal C1, COM) isolated

from the 24 VDC Sage Power Supply Ground (Terminal B6). All other features of Prime PLUS are

identical to the standard Sage Prime, except other voltage available. (See footnote 8)

2 It is important to connect the Ground when using Modbus communications, or ground loop problems

may develop. Improper wiring can also damage internal circuitry

3 Note, if customer externally powers the 4-20 mA by removing the jumper, the Pulse voltage output

is also effected: The voltage output of the Pulse will follow the customer power (i.e. 24 VDC external

power will result in a 24 VDC Pulse [maximum of 50 mA]; 12 VDC external power will result in a

12 VDC Pulse)

4 Pulse width 250 msec default (adjustable with Addresser software)

5 Using Sage Addresser, a Low Flow Cutoff (LFC), commonly referred to as Min Cutoff or Zero Cutoff

can be entered into the FLOW MIN Functions. In Versions 1.82 or higher, the Low Flow Cutoff and

the 4-20 mA Scaling are independent of each other. For example: A Low Flow Cutoff (LFC) of

10 SCFM on a Meter with a Full Scale of 100 SCFM will report 0 on the Display and 4 mA on the

output. The output will remain at 4 mA until the LFC is exceeded: (ie: 25 SCFM=8 mA). Thus the

4 mA will always be zero based

6 This version does not have Hazard Approvals

7 24 VDC ±10%

8 Other DC voltages (5 VDC, 12 VDC, 48 VDC) available on Prime PLUS. Contact Sage

9 Assumes the 4-20 mA is Externally Powered

10 Modbus Ground becomes isolated from the B6 Power Supply Ground only on Prime PLUS version

(specify “PLUS”)

INSIDE BODY VIEW

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Remote Cable

(ON REMOTE STYLE SRP)

Grounding

Lug

**

**

A1 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A2 – NO WIRE

A3 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A4 – WHITE – TEMPERATURE SENSOR WIRE

A5 – NO WIRE

A6 – WHITE – TEMPERATURE SENSOR WIRE

B1 – AC1 – AC VOLTAGE

B2 – AC2 – AC VOLTAGE

B3 – JUNCTION FOR ISOLATED PULSE

B4 – 4-20 mA RETURN (–) AND PULSE SOURCE

B5 – VDC IN – VOLTAGE DC – POSITIVE (+)

B6 – VDC GND – VOLTAGE DC – GROUND (–)

1

C1 – COM – RS485 MODBUS GROUND

1,2

C2 – B(+)–RS485_D1

C3 – A(–)–RS485_D0

C4 – 24 VDC PULSE – 0 TO 24 VDC PULSE OUTPUT

3,4

C5 – 4-20 mA – 4 TO 20 mA SIGNAL DRIVE

5

C6 – VDC GND – VOLTAGE DC – GROUND (–)

24

O

24

O

DESCRIPTION TERMINALS NOTES

AC Input Power: B1 B2 Connect Ground Wire

115 VAC/230 VAC

AC1 AC2

to Grounding Lug

DC Input Power: B5 B6

24 VDC

7,8

+ VDC – VDC GND

Internally Powered: C5 C6 Do not remove

4-20 mA

4-20 mA Return

any Jumpers

SIGNAL DRIVE

Internally Powered: C4 C6 Do not remove

Pulsed Output

GND

any Jumpers

Externally Powered: C5 B4 Remove B4 & B5

4-20 mA

4-20 mA 4-20 mA

Jumper

SIGNAL DRIVE EX TERNAL SOURCE

Externally Powered9: C4 B3 Remove B4 & B5

Pulsed Output

JUNCTION FOR

Jumper and Connect

PULSE RETURN C4 Resistive Jumper

to B3

MODBUS C2 C3 C1 Modbus Ground

10

RS485(+) RS485(–) MODBUS GROUND

(REQ’D)

*

**Note, Flow Meter is supplied with a 10K

(1/2 watt) metal film resistor (Resistive

Jumper) connected across Terminals C4 and

C6. For externally powered operation, in

addition to removing B4 & B5 Jumpers, it

is necessary to connect C4 Resistive Jumper

to Terminal B3 instead of C6. Note, B3 must

be connected to the External Sources common in order to enable the optically isolated

pulse output. In this mode, Pulse Output is

optically isolated. Pulsed Output voltage will

depend on customer source voltage. Use

Sage Resistive Jumper only!

Page 21

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

21

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

Prime Remote (Series SRP)

SEE “WIRING” ON PAGE 10 FOR INSTRUCTIONS ON HOW TO REMOVE REAR LID;

SEE FOLLOWING PAGES FOR TERMINAL HOOKUP

REMOTE

1

RED AC1 COM

1

2

GREEN AC2 B +

2

3

BLUE SPARE A –

3

4

WHITE

4-20mA PWR 24 VDC PULSE

4

5

BLACK VDC IN 4-20mA

5

6

ORANGE VDC GND VDC GND

6

A B C

1

2

3

4

5

6

1

2

3

4

5

6

A B C

INSIDE COVER VIEW INSIDE BODY VIEW

DISPLAY SIDE

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Remote Cable

(ON REMOTE STYLE SRP)

3/4" NPT for

Remote Cable

3/4" NPT for

Probe Support

Junction Box

contains no

electronics,

just terminals

1/2" NPT

User Entry for Wiring

(ONE ON EACH SIDE)

FLOW

TERMINAL

BLOCK SIDE

3/4" NPT for

Remote Cable

Page 22

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

22

24 VDC Prime Remote Terminals (Series SRP)

(APPROVED FOR HAZARDOUS SERVICE6)

R

EMOTE

1

RED AC1 COM

1

2

GREEN AC2 B +

2

3

B

LUE SPARE A –

3

4

W

HITE 4-20mA PWR

2

4 VDC PULSE

4

5

B

LACK VDC IN 4-20mA

5

6

O

RANGE VDC GND VDC GND

6

A B C

A1 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A2 – GREEN – SENSE WIRE

A3 – BLUE – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A4 – WHITE – TEMPERATURE SENSOR WIRE

A5 – BLACK – SENSE WIRE

A6 – ORANGE – TEMPERATURE SENSOR WIRE

B3 – JUNCTION FOR ISOLATED PULSE

B4 – 4-20 mA RETURN (–) AND PULSE SOURCE

B5 – VDC IN – VOLTAGE DC – POSITIVE (+)

B6 – VDC GND – VOLTAGE DC – GROUND (–)

1

C1 – COM – RS485 MODBUS GROUND

1,2

C2 – B(+)–RS485_D1

C3 – A(–)–RS485_D0

C4 – 24 VDC PULSE – 0 TO 24 VDC PULSE OUTPUT

3,4

C5 – 4-20 mA – 4 TO 20 mA SIGNAL DRIVE

5

C6 – VDC GND – VOLTAGE DC – GROUND (–)

INSIDE COVER VIEW

NOTE: The Sage Prime

draws 2.4 watts maximum

(i.e. ≅ 100ma @24VDC)

–

+

C US TO ME R

R ET UR N

E

X TE RN AL LY P OW ER ED

4

– 20 m A B Y CU ST OM ER

+

*

DESCRIPTION TERMINALS NOTES

DC Input Power: B5 B6

24 VDC

7,8

+ VDC – VDC GND

Internally Powered: C5 C6 Do not remove

4-20 mA

4-20 mA Return

any Jumpers

SIGNAL DRIVE

Internally Powered: C4 C6 Do not remove

Pulsed Output

GND

any Jumpers

Externally Powered: C5 B4 Remove B4 & B5

4-20 mA

4-20 mA 4-20 mA

Jumper

SIGNAL DRIVE EX TERNAL SOURCE

Externally Powered9: C4 B3 Remove B4 & B5

Pulsed Output

JUNCTION FOR

Jumpers and Connect

PULSE RETURN C4 Resistive Jumper

to B3

MODBUS C2 C3 C1 Modbus Ground

10

RS485(+) RS485(–) MODBUS GROUND

REQ’D)

*B4 and B5 JUMPER

Remove jumper for Externally Sourced 4-20

mA. In this mode, user supplies 9-27 Volts to

externally power the 4-20 mA loop, and the

4-20 mA loop becomes optically isolated.

1 Specify the Sage Prime PLUS option in order to have the Modbus Ground (Terminal C1, COM) isolated

from the 24 VDC Sage Power Supply Ground (Terminal B6). All other features of Prime PLUS are

identical to the standard Sage Prime, except other voltage available. (See footnote 8)

2 It is important to connect the Ground when using Modbus communications, or ground loop problems

may develop. Improper wiring can also damage internal circuitry

3 Note, if customer externally powers the 4-20 mA by removing the jumper, the Pulse voltage output

is also effected: The voltage output of the Pulse will follow the customer power (i.e. 24 VDC external

power will result in a 24 VDC Pulse [maximum of 50 mA]; 12 VDC external power will result in a

12 VDC Pulse)

4 Pulse width 250 msec default (adjustable with Addresser software)

5 Using Sage Addresser, a Low Flow Cutoff (LFC), commonly referred to as Min Cutoff or Zero Cutoff

can be entered into the FLOW MIN Functions. In Versions 1.82 or higher, the Low Flow Cutoff and the

4-20 mA Scaling are independent of each other. For example: A Low Flow Cutoff (LFC) of

10 SCFM on a Meter with a Full Scale of 100 SCFM will report 0 on the Display and 4 mA on the

output. The output will remain at 4 mA until the LFC is exceeded: (ie: 25 SCFM=8 mA). Thus the

4 mA will always be zero based

6 Class I, Div 2, Groups B,C,D,T4 and ATEX Ex na IIC T4

7 24 VDC ±10%

8 Other DC voltages (5 VDC, 12 VDC, 48 VDC) available on Prime PLUS. Contact Sage

9 Assumes the 4-20 mA is Externally Powered

10 Modbus Ground becomes isolated from the B6 Power Supply Ground only on Prime PLUS version

(specify “PLUS”)

INSIDE BODY VIEW

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Remote Cable

(ON REMOTE STYLE SRP)

**

**

24

O

24

O

**Note, Flow Meter is supplied with a 10K

(1/2 watt) metal film resistor (Resistive

Jumper) connected across Terminals C4 and

C6. For externally powered operation, in

addition to removing B4 & B5 Jumpers, it

is necessary to connect C4 Resistive Jumper

to Terminal B3 instead of C6. Note, B3 must

be connected to the External Sources common in order to enable the optically isolated

pulse output. In this mode, Pulse Output is

optically isolated. Pulsed Output voltage will

depend on customer source voltage. Use

Sage Resistive Jumper only!

Page 23

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

23

S A G E M E T E R I N G , I N C .

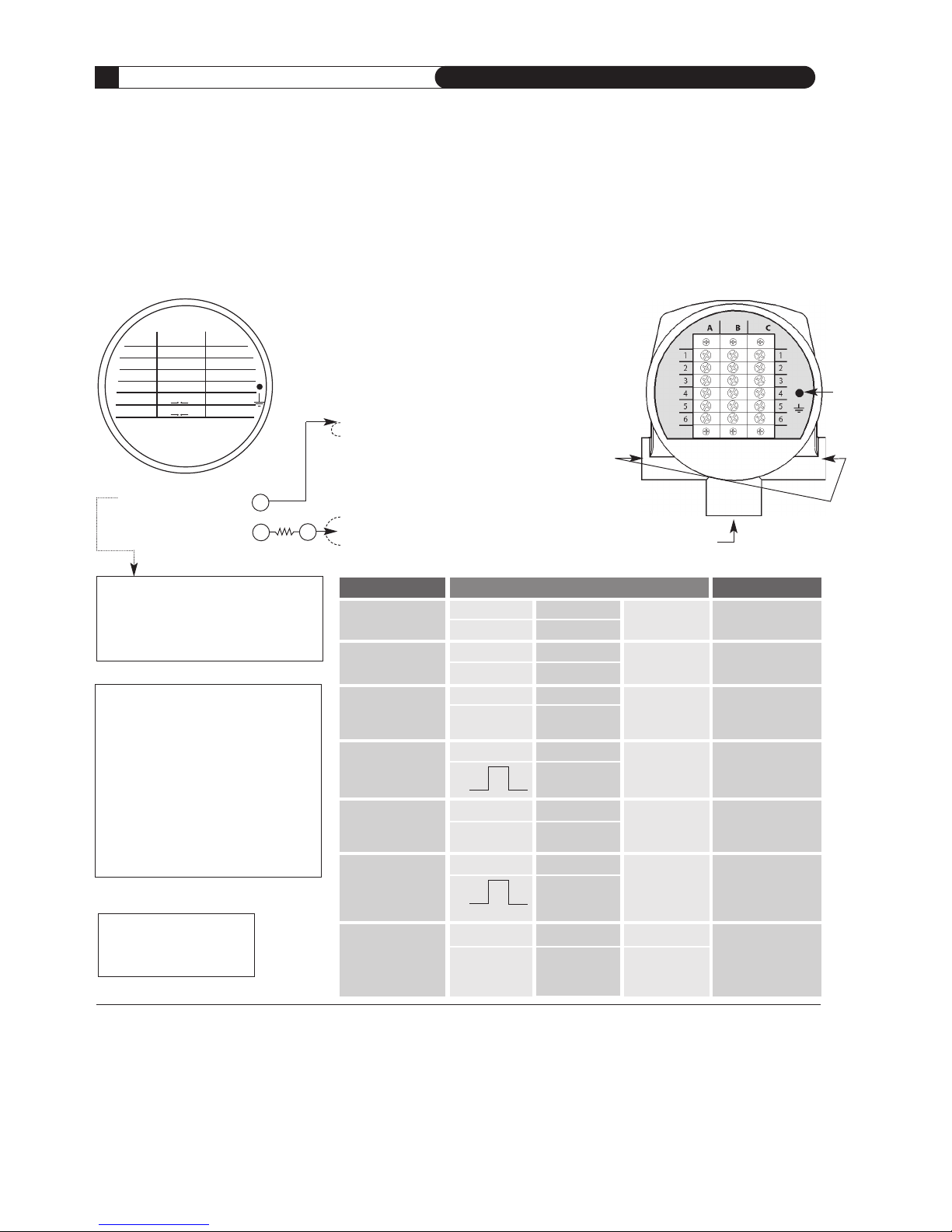

AC Powered Prime Remote Terminals (Series SRP)

6

R

EMOTE

1

RED AC1 COM

1

2

GREEN AC2 B +

2

3

B

LUE SPARE A –

3

4

W

HITE 4-20mA PWR

2

4 VDC PULSE

4

5

B

LACK VDC IN 4-20mA

5

6

O

RANGE VDC GND VDC GND

6

A B C

INSIDE COVER VIEW

NOTE: The Sage Prime

draws 2.4 watts maximum

(i.e. ≅ 100ma @24VDC)

–

+

C US TO ME R

R ET UR N

E

X TE RN AL LY P OW ER ED

4 –2 0 mA BY C US TO ME R

+

*

DESCRIPTION TERMINALS NOTES

AC Input Power: B1 B2 Connect Ground Wire

115 VAC/230 VAC

AC1 AC2

to Grounding Lug

DC Input Power: B5 B6

24 VDC

7

,8

+ VDC – VDC GND

Internally Powered: C5 C6 Do not remove

4-20 mA

4-20 mA Return

any Jumpers

SIGNAL DRIVE

Internally Powered: C4 C6 Do not remove

Pulsed Output

GND

any Jumpers

Externally Powered: C5 B4 Remove B4 & B5

4-20 mA

4-20 mA 4-20 mA

Jumper

SIGNAL DRIVE EX TERNAL SOURCE

Externally Powered9: C4 B3 Remove B4 & B5

Pulsed Output

JUNCTION FOR

Jumpers and Connect

PULSE RETURN C4 Resistive Jumper

to B3

MODBUS C2 C3 C1 Modbus Ground

10

RS485(+) RS485(–) MODBUS GROUND

(REQ’D)

*B4 and B5 JUMPER

Remove jumper for Externally Sourced 4-20

mA. In this mode, user supplies 9-27 Volts to

externally power the 4-20 mA loop, and the

4-20 mA loop becomes optically isolated.

1 Specify the Sage Prime PLUS option in order to have the Modbus Ground (Terminal C1, COM) isolated

from the 24 VDC Sage Power Supply Ground (Terminal B6). All other features of Prime PLUS are

identical to the standard Sage Prime, except other voltage available. (See footnote 8)

2 It is important to connect the Ground when using Modbus communications, or ground loop problems

may develop. Improper wiring can also damage internal circuitry

3 Note, if customer externally powers the 4-20 mA by removing the jumper, the Pulse voltage output

is also effected: The voltage output of the Pulse will follow the customer power (i.e. 24 VDC external

power will result in a 24 VDC Pulse [maximum of 50 mA]; 12 VDC external power will result in a

12 VDC Pulse)

4 Pulse width 250 msec default (adjustable with Addresser software)

5 Using Sage Addresser, a Low Flow Cutoff (LFC), commonly referred to as Min Cutoff or Zero Cutoff

can be entered into the FLOW MIN Functions. In Versions 1.82 or higher, the Low Flow Cutoff and

the 4-20 mA Scaling are independent of each other. For example: A Low Flow Cutoff (LFC) of

10 SCFM on a Meter with a Full Scale of 100 SCFM will report 0 on the Display and 4 mA on the

output. The output will remain at 4 mA until the LFC is exceeded: (ie: 25 SCFM=8 mA). Thus the

4 mA will always be zero based

6 This version does not have Hazard Approvals

7 24 VDC ±10%

8 Other DC voltages (5 VDC, 12 VDC, 48 VDC) available on Prime PLUS. Contact Sage

9 Assumes the 4-20 mA is Externally Powered

10 Modbus Ground becomes isolated from the B6 Power Supply Ground only on Prime PLUS version

(specify “PLUS”)

1

2

3

4

5

6

1

2

3

4

5

6

A B C

INSIDE BODY VIEW

1/2" NPT

User Entry

for Wiring

3/4" NPT for

Remote Cable

(ON REMOTE STYLE SRP)

Grounding

Lug

**

**

A1 – RED – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A2 – GREEN – SENSE WIRE

A3 – BLUE – VELOCITY SENSOR WIRE (HEATED ELEMENT)

A4 – WHITE – TEMPERATURE SENSOR WIRE

A5 – BLACK – SENSE WIRE

A6 – ORANGE – TEMPERATURE SENSOR WIRE

B1 – AC1 – AC VOLTAGE

B2 – AC2 – AC VOLTAGE

B3 – JUNCTION FOR ISOLATED PULSE

B4 – 4-20 mA RETURN (–) AND PULSE SOURCE

B5 – VDC IN – VOLTAGE DC – POSITIVE (+)

B6 – VDC GND – VOLTAGE DC – GROUND (–)

1

C1 – COM – RS485 MODBUS GROUND

1,2

C2 – B(+)–RS485_D1

C3 – A(–)–RS485_D0

C4 – 24 VDC PULSE – 0 TO 24 VDC PULSE OUTPUT

3,4

C5 – 4-20 mA – 4 TO 20 mA SIGNAL DRIVE

5

C6 – VDC GND – VOLTAGE DC – GROUND (–)

24

O

24

O

**Note, Flow Meter is supplied with a 10K

(1/2 watt) metal film resistor (Resistive

Jumper) connected across Terminals C4 and

C6. For externally powered operation, in

addition to removing B4 & B5 Jumpers, it

is necessary to connect C4 Resistive Jumper

to Terminal B3 instead of C6. Note, B3 must

be connected to the External Sources common in order to enable the optically isolated

pulse output. In this mode, Pulse Output is

optically isolated. Pulsed Output voltage will

depend on customer source voltage. Use

Sage Resistive Jumper only!

Page 24

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

24

REV. 16-SIP/SRP

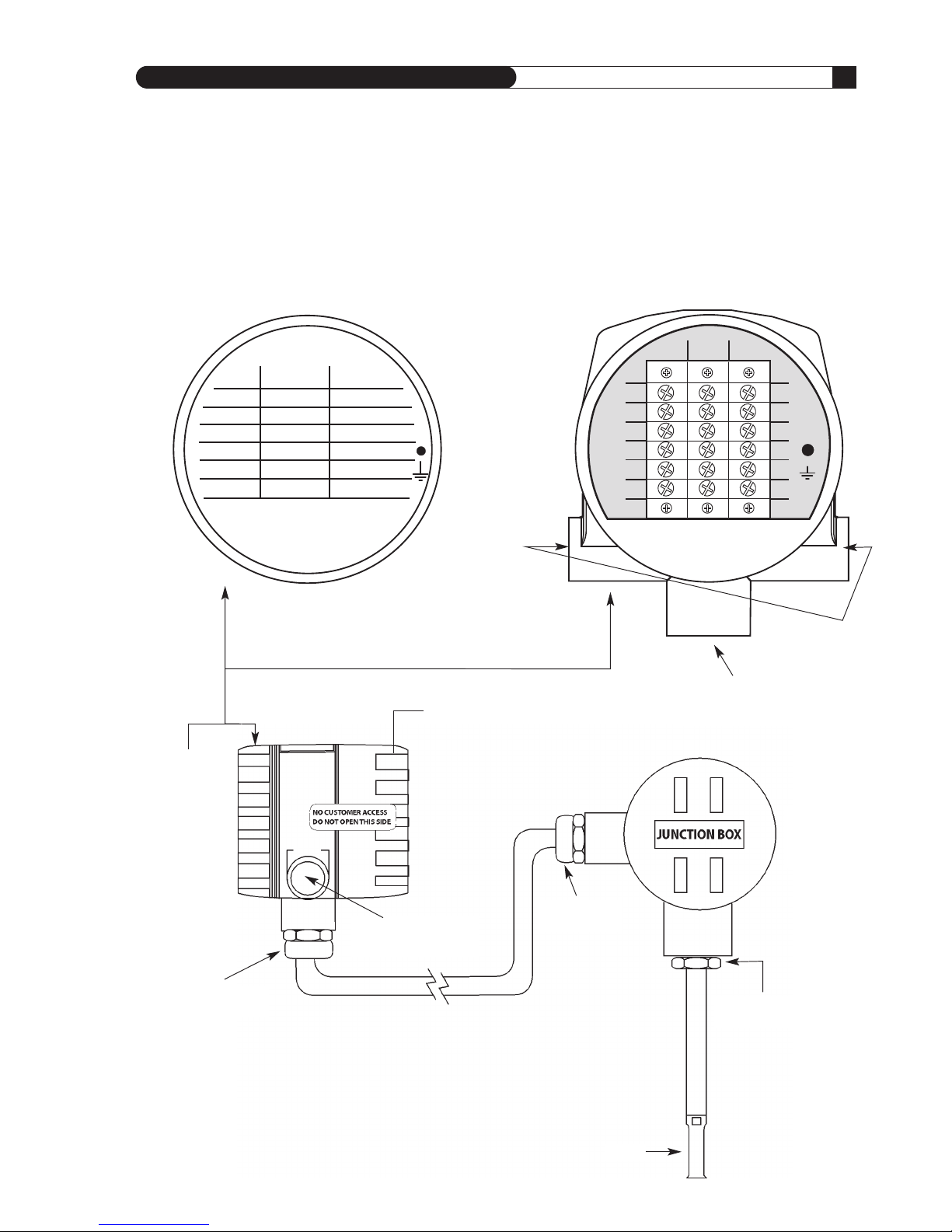

Junction Box Wiring Terminals for Remote Style Meters (Series SRP)

(THERE ARE NO ELECTRONICS INSIDE JUNCTION BOX)

CUSTOMER SIDE

1

(Wired at Installation Site)

FACTORY SIDE

(Wired at Factory)

Red

Red

White

W

hite

Blue

Green

Red

Orange

Black

White

CAUTION: Strip wires 3/8" and

d

o not crimp insulation.

4.37

3/4” FNPT

Conduit Receptacle

Grounding Screw

GROUNDING SCREW NOT USED

(The shield [drain wire] is only connected

on the other end [the electronics end]).

Metal Conduit

is recommended

with appropriate

grounding to

minimize effects

from external

noise sources.

Interconnect Cable

2

To Terminal A1 to A6

(see page 21–23)

SEE THE PREVIOUS PAGE FOR THE OTHER END OF THE REMOTE WIRING HOOKUP (the electronics side).

NOTE: The Sensor Junction Box

will have a serial number tag.

It is important to match this serial

number with the serial number

of the Remote electronics. Mixing

components from different meters

can result in significant errors.

a

CAUTION: Cable and cable glands are not for use in hazardous area

environments. Power, ground, outputs, shielded cable, seal fittings

and conduits are to be supplied by customer.

1 NOTE: There are hidden jumpers (underneath the terminal strip) that short together the Blue

and Green wires, and also short together the Black and Orange wires. These extra wires are part

of the meter's Lead Length Compensation circuitry, allowing the user to change the length of the

interconnect cable (from 0 to 1000 feet) without effecting the accuracy. 25 feet of cable are initially supplied (for cabling longer than 1000 feet, contact Sage).

2 Sage supplies 25 feet of cable for the interconnect wires between the Junction Box and the Remote

Enclosures: Carroll (manufacturer), Part #C0783, 20 gauge, 6 conductor, foil shielded, grey PVC jacket.

Page 25

Section

STYLES AND FEATURES

B

Page 26

Page 27

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

27

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

Sage Thermal Mass Flow Meters have two sensors

constructed of reference grade platinum windings

(RTDs). The two RTDs are clad in a protective 316SS

sheath and are driven by a proprietary sensor drive

circuit. One of the sensors is self-heated (flow sen-

sor), and the other sensor (temperature/reference

sensor) measures the gas temperature. The pair is

referred to as the sensing element, and is either

installed in a probe as an Insertion style, or inserted

into a pipe section as an In-Line style flow meter.

As gas flows by the flow sensor, the gas molecules

carry heat away from the surface, and the sensor

cools down as it loses energy. The sensor drive

circuit replenishes the lost energy by heating the

flow sensor until it is a constant temperature differ-

ential above the reference sensor. The electrical

power required to maintain a constant temperature

differential is directly proportional to the gas mass

flow rate and is linearized to be the output signal

of the meter.

Principle of Operation of the Thermal Mass Flow Meter

It is essential that this constant temperature differ -

ential be maintained, even if there are wide fluctua-

tions in gas temperature. It is the function of the

Sage hybrid-digital proprietary sensor drive circuit to

maintain the differential, whether or not the gas

temperature changes, or however quickly molecules

cool off the flow sensor. It is also necessary to proper-

ly calibrate the device with the actual gas (or close

equivalent with certain gases), in the Sage National

Institute of Standards certified (NIST) calibration

facility. By accomplishing these two critical objec-

tives, the Sage meters provide an extremely repeat-

able (0.2% of Full Scale) and accurate output directly

proportional to the mass flow rate of the gas being

measured.

FLOW SENSOR

(Self Heated)

TEMPERATURE SENSOR

(Reference Sensor)

Page 28

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

28

REV. 16-SIP/SRP

Features and Benefits

MAJOR BENEFITS OF THERMAL MASS FLOW METERS

■

Direct Mass Flow – No need for separate temperature or pressure

transmitters

■

High Accuracy and Repeatability – Precision measurement and

extraordinary repeatability

■

Turndown of 100 to 1 and resolution as much as 1000 to 1

■

Low-End Sensitivity – Measures as low as 5 SFPM (e.g., 1 SCFM

in a 6" pipe)

■

Negligible Pressure Drop – Will not impede the flow or waste energy

■

No Moving Parts – Eliminates costly bearing replacements, and

prevents undetected accuracy shifts

■

Dirt Insensitive – Provides sustained performance

■

Low cost-of-ownership

■

Ease of installation and convenient mounting hardware

SPECIFIC BENEFITS OF THE SAGE PRIME

■

High contrast photo-emissive OLED display with numerical Flow

Rate, Total and Temperature, as well as Graphical Flow Indicator

■

Photocell activated Screen Saver to extend display life

■

Calibration milliwatts (mw) is continuously displayed, providing for

ongoing diagnostics, and in-situ calibration check

■

Modbus® compliant RS485 RTU communications

■

Isolated 4-20 ma output

■

Rugged, user-friendly packaging with easy terminal access

■

Option for Solar Energy use (12VDC models)

■

Low power dissipation, under 2.5 Watts (e.g. under 100 ma at 24 VDC)

■

Powerful state-of-the-art microprocessor technology for high performance mass flow measurement and low cost-of-ownership

■

Proprietary digital sensor drive circuit provides enhanced signal

stability and unaffected by process temperature & pressure changes

■

Remote Style has Lead-Length Compensation. Allows remote electronics up to 1000 feet from probe; Explosion Proof Junction Box has

no circuitry, just terminals

■

Field reconfigurability via Sage ADDRESSER or Sage DONGLE

■

Flow conditioning built into In-Line flow meters (1/2" and up)

■

Captive Flow Conditioners for Insertion Meter applications, if required

SAGE PRIME™ THERMAL MASS FLOW METER

FOR GASES

Sage Prime is the top selling meter in our Product Line. The Sage

Prime Thermal Mass Flow Meter features a bright, high contrast,

photo-emissive OLED display of Flow Rate, Total and Temper ature

in a robust, yet lightweight, dual-compartment industrial enclosure.

The flow rate is also displayed graphically in a horizontal bar graph

format. The rear compartment is completely separated from the

electronics, and has large, easy-to-access, well marked terminals, for

ease of customer wiring (see photo below). It is powered by 24 VDC

(12 VDC optional, or 115/230 VAC). The power dissipation is under

2.5 watts (e.g. under 100 ma at 24 VDC).

The Sage Prime Flow Meter is offered in Integral or Remote Style

(which has lead-length compensation up to 1000 feet as well as an

Explosion Proof Junction Box). Specify any standard probe length

or flow body size. It has a 4-20 ma output as well as a Pulsed Output

of Totalized Flow (solid state transistor drive). In addition, Sage Prime

supports full Modbus® compliant RS485 RTU communi cations (IEEE

32 Bit Floating Point).

Sage Prime is CE approved, and CSA and UL approved for

Hazardous Service2(see Approvals tab on the website).

CONTINUOUS DIAGNOSTICS & FIELD

CONFIGURABILITY

Sage Prime has continuous diagnostics. The raw calibration milliwatts (mw) is always displayed in the upper left hand corner of the

meter’s display. At any time, you can check this reading at a “no flow”

condition, and compare the reading to the original re ported “zero

flow” value noted on the last few lines of your meter’s Certificate of

Con formance or the flow meter’s data tag. This in-situ diagnostic pro cedure not only checks the sensor performance and the “live zero”

calibration point, but it also verifies that the sensor is clean. It essentially provides a means to validate that the meter is oper ating prop-

erly, verifies that there is no shift or drift, and eliminates the need for

annual fac tory calibrations. This simple field diagnostic procedure,

in addition, verifies that the sensor is free from

contamination, even without inspection.

Although Sage Prime is fully configured

upon shipment, for the pipe and process

con ditions requested, there are three

strategies if changes are needed: Sage

DONGLE; the Sage ADDRESSER software

program; or the Sage ADDRESSER advanced pro-

gram. Contact Sage for details.

1 Note, a built-in photocell continuously monitors the ambient light, and adjusts the display brightness for

optimum long-term life, and also senses motion which automatically switches display from Screen Saver

mode to Normal mode

2 Only available with 24VDC powered meters

Page 29

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

29

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

Sage PRIME™ Styles and Specifications

S I P S E R I E S – I N T E G R A L

Mou ntin g

H

ardw are

(in clud ed)

Flow Element is In-Line Style consisting of a choice of 316

Stainless Steel Schedule 40 Flow Bodies sized from 1/4” x

6” long to 4” x 12” long

Flow Element is Insertion Style, consisting of a 1/2” OD

probe (3/4” optional) with lengths up to 36” long

(typically 15” long) suitable for insertion into the center

of a process pipe

Electronics is Remote Style, with rugged windowed dual compartment NEMA 4 enclosure with display. The display is a high contrast photoemissive OLED display with Screen Saver, and it displays Mass Flow Rate, Totalized Flow and Temperature as well as a graphical representation of

Flow Rate in a horizontal bar graph format. In addition, the calibration milliwatts (mw) is continuously displayed, providing ongoing diagnostics. Includes Remote Mounting Hardware.

The Flow Element’s Junction Box is Explosion Proof (Class 1, Div 1, Groups B, C, D), and does not have any electronics – only a wiring terminal

block. The Junction Box is connected to the Remote Electronics by 25 feet of lead-length compensated cable. The cable (6-conductor) can be

lengthened or shortened without affec ting accuracy (max loop resistance 10 ohms, over 1000 feet), if grounded properly.

REMOTE STYLE ELECTRONICS

X

SRP In-Line

1,3,5

SRP Insertion

2

ENGINEERING SPECIFICATIONS OF OPTIONAL SAGE PRIME PLUS

T

his is an optional version of Sage Prime offering a separate ground for the 24VDC

Power Supply (optional 5 VDC or 12 VDC Power Supplies) which isolates the Modbus

ground from the power supply ground. All other features of Prime PLUS are identical

to the standard Sage Prime, except Approvals do not apply at this time.

Flow Element is In-Line Style consisting of a choice of 316

Stainless Steel Schedule 40 Flow Bodies sized from 1/4" x

6” long to 4" x 12" long

Flow Element is Insertion Style, consisting of a 1/2" OD

probe (3/4" optional) with lengths up to 36" lo ng

(typically 15" long) suitable for inser tion into the center

of a process pipe

INTEGRA L STYLE EL ECTRO NICS

Electronics is Integral Style, with rugged windowed dual compartment NEMA 4 enclosure with local display. The display is a high contrast photo-emissive OLED display with Screen Saver, and it displays

Mass Flow Rate, Totalized Flow and Temperature as well as a graphical representation of Flow Rate in a horizontal bar graph format. In

addition, the calibration milliwatts (mw) is continuously displayed,

providing ongoing diagnostics.

X

SIP In-Line

1,3,5

SIP Insertion

2

1 Male NPT ends are standard, with flanged ends, tube, or butt weld optionally available

2 Mounting hardware such as Isolation Valve Assemblies, Compression Fittings, and Flanges, are optional

3 Chart of Flow Body length “X” is on Application Data Sheet on website as well as in the Prime O&M

4 Enhanced accuracy available upon request, especially if turndown limited. Contact Sage

5 Flow Conditioners are built into In-Line Style Flow Bodies from 1⁄2" to 4"

Sage Metering is your source for monitoring, measuring and controlling the gas mass

flow in your industrial process, building management system or environmental application. Our high performance, NIST Traceable, Thermal Mass Flow Meters will help in c

rease productivity, reduce energy costs, maximize product yields, and/or help reduce

environmental insult. Sage provides high quality In-Line and Insertion Thermal Mass

Flow Meters for a wide variety of industrial, commercial, and environmental monitoring needs, including carbon credit verification for Greenhouse Gas reduction.

Our experienced application engineers, many of whom have worked in the

Thermal Mass Flow marketplace since its inception, will assist you in choosing

the proper gas Flow Meter for your application – and they will be pleased to offer

i

nstallation guidance to assure that the meter(s) selected will perform as accurately

as possible. Additionally, our Service Staff stand ready to support you with any

after-sale assistance that you may require.

S R P S E R I E S – R E M O T E

PRIME SIP/SRP

Standard accuracy is +/– 0.5% of Full Scale +/– 1% of reading with a turndown of 100 to 1 and resolution as much as 1000 to 1. Repeatability is 0.2%.

NOTE: Enhanced accuracy optionally available with limited turn-down4.

The electronics has an isolated 4 to 20 mA output proportional to Mass Flow Rate

as well as pulsed outputs of Totalized Flow (24 VDC solid state transistor drive). In

addition, Modbus RS485 RTU communications is standard (IEEE 32 Bit Floating Pt).

O

pti onal SVA 05 Iso lati on V alve As semb ly

®

®

Page 30

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

30

REV. 16-SIP/SRP

1 Upon start-up, the Revision No., Serial No., and Modbus ID will display for a few seconds.

Also the output configurations symbol is momentarily displayed

2 Note, a built-in photocell continuously monitors the ambient light, and adjusts the display

brightness for optimum long-term life, and also senses motion which automatically switches

display from Screen Saver mode to Normal mode

3 To view display, wave hand over display or use a flashlight. The Flow Meter displays for one

minute, then the Screen Saver resumes

1

Raw Calibration milliwatts (mw) for Diagnostics

and Periodic “Zero Flow” Calibration Check

2 Graphical Indication of Percentage of Full Scale

Flow Rate

3 Flow Rate

4 Totalized Flow (Consumption)

(Value is Retained during Power Outage

or Power Cycling)

5 Flashes with each pulsed output of consumption

6 Engineering Units of Flow Rate (the last digit

can be S(seconds), M(minute), H(hour), D(day)

7 Engineering Units of Consumption

8 Photocell activated Screen Saver extends display life

M E T E R I N G , I N C .

1 - 8 6 6 - 6 7 7 - S A G E

PRIME

COM M

PWR

.

.

.

N8˚'

4$'.

4$'

1

2

3

4

5

6

7

Sage PRIME Organic (OLED) Display

1,2,3

8

Page 31

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

31

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

HAZARDOUS LOCATION APPROVALS

All 24 VDC Powered Sage Prime Meters (SIP Integral

I

nsertion, SIP In-Line, SRP Remote Insertion, SRP

Remote In-Line) are approved for Class 1, Div 2,

Groups B, C, D, T4 and ATEX: Ex nA IIC T4.

AC Powered Meters are not approved.

Testing is in accordance with the following Safety

Standards:

• UL1604, Third Edition, Electrical Equipment for

Use in Class I and II, Division 2, and Class III

Hazardous (Classified) Locations

• CSA C22.2 No. 213-M1987 (R1999), First Edition,

Non-incendive Electrical Equipment for Use in

Class I, Division 2 Hazardous Locations

• UL/CSA 61010-1, Second Edition, Safety Require -

ments for Electrical Equipment for Measurement,

Control, and Laboratory Use – Part 1: General

Requirements

The following is required to comply with the above

mentioned Approvals

1) Repair of the product (or replacement of compo-

nents) is not possible by the user

2) As noted on the following label (see below) it will

contain the following markings: Ex symbol, nA

symbol IIC, temperature class

3) All Prime DC meters will be marked with “X”

which means that these Special Conditions of

Use will apply:

a) The completed meter must be installed with a

rigid or flexible metal conduit in order to satis-

fy approval conditions.

b) The meter has been approved for use with the

electronics enclosure in an ambient tempera-

ture from –20˚C < Ta < 65˚C.

4) Sage Metering considers a linear correction suit-

able for temperatures exceeding the temp code

rating of 40C (104F) thus no customer correction

is needed.

CONFORMANCE

All AC & DC Powered Sage Metering, Inc. Series

SIP (Sage Prime-Integral) and Series SRP (Sage Prime-

Remote) are CE Compliant for the following CE

directives:

• EN61000-6-4 for Electromagnetic compatibility;

• EN61000-3-2 for Harmonics;

• EN61000-3-3 for Flicker;

• EN61000-6-2 for Electromagnetic Compatibility

(Immunity for Industrial Environments), which

includes EN61000-4-2 for ESD;

• EN61000-4-3 for Radiated Immunity;

• EN61000-4-4 for EFT/B; EN61000-4-5 for Surge;

• EN61000 for Conducted Immunity;

• EN61000-4-8 for Magnetic Immunity;

• EN61000-4-11 for Voltage Interruptions

MEDICAL CONFORMANCE

Contact Sage Metering if Medical CE Conformance

is required. (AC Powered Sage Prime Meters only.)

The Standard is to IEC 60601-1-2:2007 Edition 3

Approvals

S

AGE METERING, INC.-MTRY, CA 93940/ PRIME THERMAL MFM

Class I, Div 2, Groups B,C,D T4 ATEX: Ex nA IIC T4 X

MODEL #

SERIAL # mW0 =

FOR USE IN HAZARDOUS LOCATIONS–CAUTION–DISCONNECT FROM POWER

S

UPPLY BEFORE OPERATING. KEEP COVER TIGHT WHILE CIRCUITS ARE ALIVE.

CONDUIT SEALS MUST BE INSTALLED WITHIN 18˚ OF THE ENCLOSURE.

ATTENTION–OUVRIR LE CIRCUIT AVANT

D’ENLEVER LE COUVERCLE GARDER

L

E COUVERCLE BIEN FERME TANT QUE LES CIRCUITS SONT SOUS TENSION.

UN SCELLEMENT DOIT ETR INSTALLE A MOINS DE 45CM DU BOITER.

Page 32

Page 33

Section

DRAWINGS

C

Page 34

Page 35

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

35

S A G E M E T E R I N G , I N C .

REV. 16-SIP/SRP

INSERTION STYLE

2

150#, 300#, or 600# flanged mounting is optionally available. Available probe lengths are 6", 12", 15", 18", 24", 30",

36" or 48". Standard probe is 1/2" diameter (3/4" optional –

recommended for 36" or 48")

4.50

4.60

Probe Length

FLOW

SIP Series Integral Style Mass Flow Meters

IN-LINE STYLE

1,3

150#, 300#, or 600# flanged ends are optionally available.

(150# flanges recommended on 3" and 4" Flow Bodies)

5.38

2-3/4” Nominal

See Chart

FLOW

4.61

1 NPT Fittings standard

2 Flanged Mounting available for high pressure operation

3 Flow Conditioning built in to Flow Meter Pipe Sizes 1/2" and up. Contact Sage for optional

1/4" tube flow body.

Depth: DC Enclosure depth is 4.35"

AC Enclosure depth is 5.35"

1/2" NPT

User Entry

for Wiring

1/2" NPT

User Entry

for Wiring

CAUTION:

Do not rotate the

Enclosure of In-Line

Style Meters relative

to the Flow Tube, or

the calibration may

be effected since the

sensors may become

misaligned.

Page 36

S A G E M E T E R I N G , I N C .

O p e r a t i o n s a n d I n s t r u c t i o n M a n u a l

36

REV. 16-SIP/SRP

SRP Series Remote Style Mass Flow Meters

INSERTION STYLE

2

150#, 300#, or 600# flanged mounting is optionally available. Available probe lengths (C) are 6", 12", 15", 18", 24",

30", 36" or 48".

See Chart

on Page 35

IN-LINE STYLE

1,3,4

150#, 300#, or 600# flanged ends are optionally available.

(150# flange recommended on 3" and 4" Flow Bodies)

1 NPT Fittings standard

2 Flanged Mounting available for high pressure operation

3 Flow Conditioning built in to Flow Meter Pipe Sizes 1/2" and up. Contact Sage for optional

1/4" tube flow body.

4 See Chart on page 35.

5 Junction Box has the following certifications: Class I, Groups B,C,D; Class II, Groups E,F,G; Class III;

4X, 7BCD, 9EFG; FM Standard 3615; UL Standard 1203; CSA Standard C22.2 No. 30; and NEMA

Compliance

4.60

4.50

3.50

Junction Box is Explosion

Proof, Class 1, Div. 1 & 2,