Page 1

the Barista Express

BES875

™

EN QUICK GUIDE

Page 2

Contents

®

2 Sage

6 Components

8 Functions

14 Care & Cleaning

18 Troubleshooting

21 Guarantee

Recommends Safety First

SAGE®

RECOMMENDS

SAFETY FIRST

At Sage® we are very safety

conscious. We design and

manufacture appliances

with your safety foremost in

mind. We also ask that you

exercise a degree of care

when using any electrical

appliance and adhere to

the following precautions.

READ ALL INSTRUCTIONS

BEFORE USE AND SAVE

FOR FUTURE REFERENCE

• A downloadable version of this

document is also available at

sageappliances.com

• Before using for the rst

time, please ensure that your

electricity supply is the same

as shown on the rating label

on the underside of the

appliance. If you have any

concerns please contact your

local electricity company.

• The installation of a residual

current safety switch is

recommended to provide

additional safety when using

all electrical appliances.

Safety switches with a rated

operating current not more

than 30mA are recommended.

Consult an electrician for

professional advice.

• Remove and discard any

packaging materials safely,

before rst use.

• To eliminate a choking hazard

for young children, discard the

protective cover tted to the

power plug safely.

• Ensure the product is properly

assembled before rst use.

• This appliance is for household

use only. Do not use the

appliance for anything other

than its intended purpose.

Do not use in moving vehicles

or boats. Do not use outdoors.

Misuse may cause injury.

• Position the appliance on a

stable, heat resistant, level, dry

surface away from the counter

edge, and do not operate on

or near a heat source such as

a hot plate, oven or gas hob.

• Fully unwind the power cord

before operating.

• Do not let the power cord

hang over the edge of a

counter or table. Do not let the

power cord touch hot surfaces

or become knotted.

2

Page 3

EN

• Do not leave the appliance

unattended when in use.

• If the appliance is to be:

- left unattended

- cleaned

- moved

- assembled; or

- stored

Always switch o the espresso

machine by pressing the

POWER button to OFF.

Switch o and unplug from

the power outlet.

• Regularly inspect the power

cord, plug and actual appliance

for any damage. If found to

be damaged in any way,

immediately cease use of

the appliance and return the

entire appliance to the nearest

authorised Sage Service

Centre for examination,

replacement or repair.

• Keep the appliance and

accessories clean. Follow

the cleaning instructions

provided in this book. Any

procedure not listed in this

instruction booklet should be

performed at an authorised

Sage Service Centre.

• The appliance can be used by

children aged 8 or older and

persons with reduced physical,

sensory or mental capabilities

or a lack of experience and

knowledge, only if they have

been given supervision or

instruction concerning use

of the appliance in a safe

way and understand the

hazards involved.

• Children should not play with

the appliance.

• Cleaning of the appliance should

not be carried out by children

unless they are 8 years or older

and under adult supervision.

• The appliance and its cord should

be kept out of reach of children

aged 8 years and younger.

• Do not use attachments

other than those provided

with the appliances.

• Do not attempt to operate

the appliance by any method

other than those described

in this booklet.

• Do not move the appliance

whilst in operation.

• Do not use any other liquid

apart from cold mains/town

water. We do not recommend

the use of highly ltered,

de-mineralised or distilled water

as this may aect the taste of

the coee and how the espresso

machine is designed to function.

• Never use the appliance without

water in the water tank.

• Ensure the portalter is

rmly inserted and secured

into the brewing head before

using the machine.

• Never remove the portalter

during the brewing operation as

the machine is under pressure.

3

Page 4

• Do not place anything, other

than cups for warming, on top

of the appliance.

• Use caution when operating

machine as metal surfaces are

liable to get hot during use.

• Do not touch hot surfaces.

Allow the product to cool

down before moving or

cleaning any parts.

• Heating element surface

is subject to residual heat

after use.

• Always ensure the appliance

is turned OFF, unplugged at

the power outlet and has been

allowed to cool before cleaning,

attempting to move or storing.

• The appliance is not intended

to be operated by means of

an external timer or separate

remote-control system.

• The use of attachments not

sold or recommended by

Sage may cause re, electric

shock or injury.

• Always turn the appliance to

the o position, switch o at

the power outlet and unplug

at the power outlet when the

appliance is not in use.

• Any maintenance other

than cleaning should be

performed by an authorised

®

Sage

service centre.

• Do not use the appliance on

a sink drain board.

• Do not operate the appliance

if it is in an enclosed space,

or within a cupboard.

• Use caution when descaling

as hot steam may be released.

Before descaling, ensure drip

tray is empty and inserted.

Refer to ‘Care & Cleaning’ for

further instructions.

• Do not operate the grinder

without the hopper lid in

position. Keep ngers,

hands, hair, clothing and

utensils away from the

hopper during operation.

SPECIFIC INSTRUCTIONS

FOR WATER FILTER

• Filter cartridge should be kept

out of reach of children.

• Store lter cartridges in a dry

place in the original packaging.

• Protect cartridges from heat

and direct sunlight.

• Do not use damaged

lter cartridges.

• Do not open lter cartridges.

• If you are absent for a prolonged

period of time, empty the water

tank and replace the cartridge.

4

Page 5

EN

The symbol shown

indicates that this appliance

should not be disposed of

in normal household waste.

It should be taken to a local

authority waste collection centre

designated for this purpose or to

a dealer providing this service.

For more information, please

contact your local council oce.

To protect against electric

shock, do not immerse

the power cord, power plug

or appliance in water or any

other liquid.

FOR HOUSEHOLD USE ONLY

SAVE THESE INSTRUCTIONS

5

Page 6

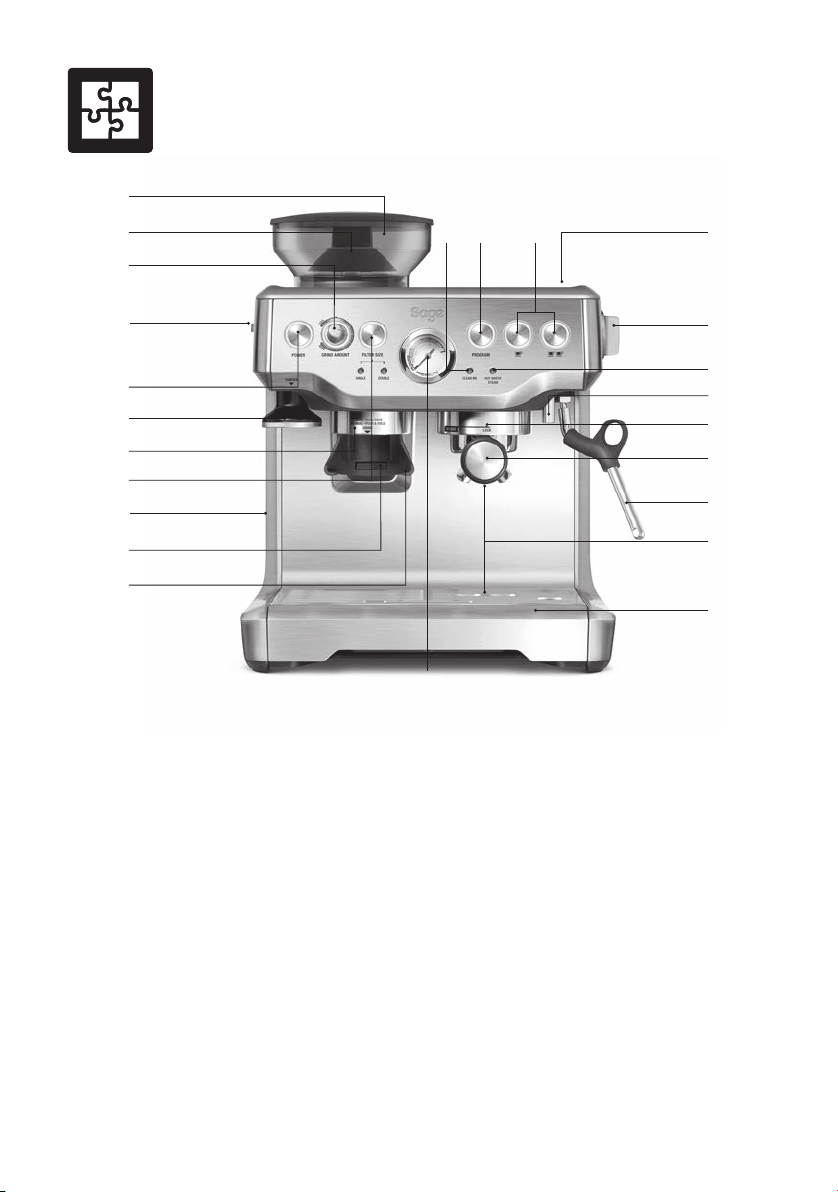

Components

A

B

G

F

```

I

J

C

H

Y

D

E

A. 250g bean hopper

B. Integrated conical burr grinder

C. Grind outlet

D. Grinding activation switch

E. Hands free grinding cradle

F. GRIND SIZE selector

G. GRIND AMOUNT dial

H. FILTER SIZE button

I. POWER button

J. Integrated removable 54mm tamper

K. Group head

L. 54mm stainless steel portalter

M. Extra-tall cup clearance for tall mugs

N. Removable wet & dry coee separator

drip tray

U

V

TW

O. Storage tray (located behind drip tray)

P. 360˚ swivel-action steam wand

Q. Dedicated hot water outlet

R. Steam/Hot Water dial

S. Steam/Hot Water light

T. 1 CUP and 2 CUP buttons

U. CLEAN ME light

V. Espresso pressure gauge

W. Programme button

Re-programs the preset 1 CUP and 2 CUP

shot volumes.

X. Cup warming tray

Y. 2L removable water tank

X

R

S

Q

K

L

P

M

N

6

Page 7

EN

1

6

2

3

10

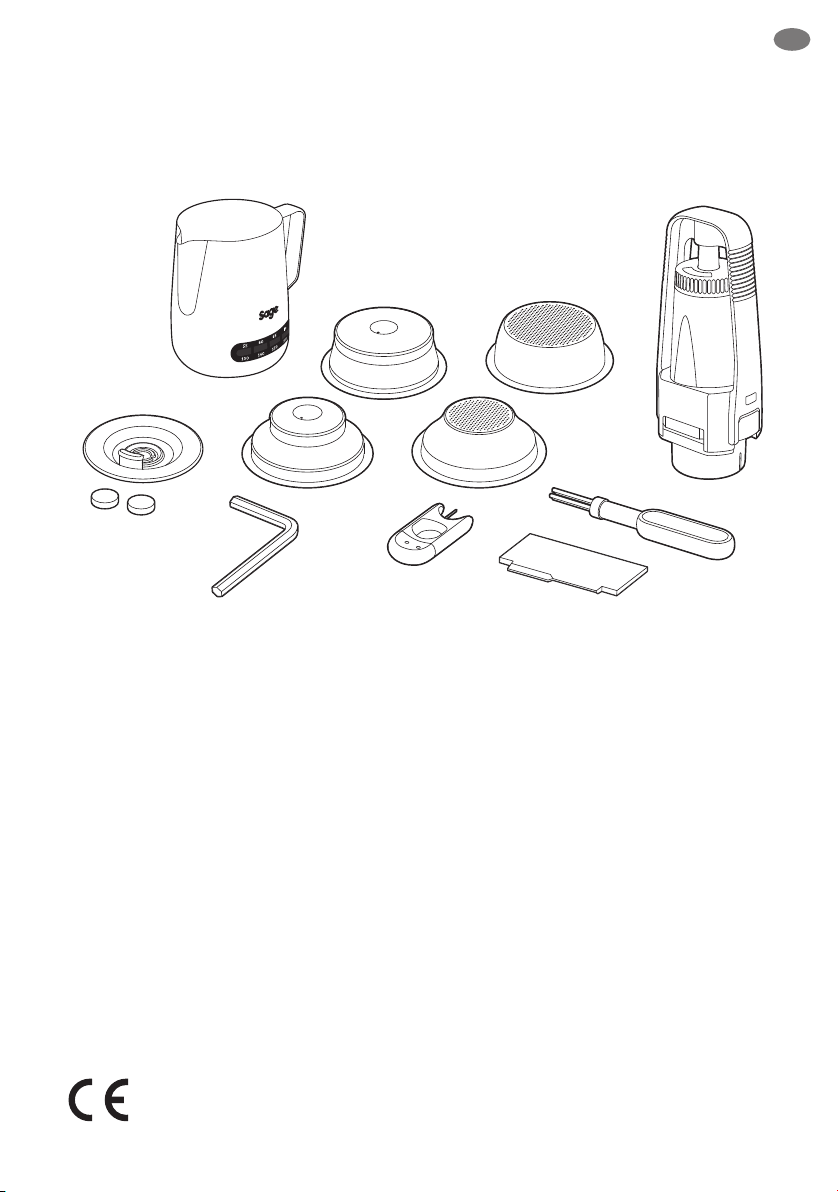

ACCESSORIES

1. Temp Control

2. Cleaning disc

3. Cleaning tablets

4. Dual Wall lter baskets

(1 cup & 2 cup) Use with pre-ground coee.

5. Single Wall lter baskets

(1 cup & 2 cup) Use when grinding fresh

whole coee beans

™

Milk Jug

4

5

7

9

6. Water lter holder and lter

7. Cleaning brush

8. The Razor

9. Cleaning tool

10. Allen key

8

™

precision dose trimming tool

Rating Information

220–240V~ 50Hz 1560–1850W

7

Page 8

Functions

INSTALLING THE WATER FILTER

• Remove the water lter and water lter holder

from the plastic bag.

• Soak the lter in cold water for 5 minutes.

• Wash the lter holder with cold water.

• Set the reminder for next month of replacement.

We recommend to replace the lter after

3 months.

• Fill the water tank with cold water before sliding

back into position at the back of the machine

and locking into place.

FIRST USE

• Ensure the water lter is securely tted inside

the water tank.

• Fill the water tank with cold, preferably ltered

water up to the MAX mark.

• Ensure the hopper is locked into position.

• Plug the power cord into a 230V power outlet.

Press the POWER button to switch the machine

on. The POWER button light will ash while the

machine is heating.

NOTE

If the hopper is not correctly locked into position,

the FILTER SIZE LED’s will ash.

1. Press 2 CUP button to run hot water through the

group head.

2. Position the steam wand tip over the drip tray.

Rotate the STEAM / HOT WATER dial to the

STEAM position and run steam through the

steam wand for 10 seconds.

• Insert the lter into the two parts of the

lter holder.

• To install the assembled lter holder into the

water tank, align the base of the lter holder

with the adapter inside the water tank.

Push down to lock into place.

8

3. Rotate the STEAM/HOT WATER dial

to the HOT WATER position and run water

through the hot water outlet for 10 seconds.

4. Repeat steps 1-3 until the water tank is empty.

Page 9

EN

GENERAL OPERATION

Setting the Grind Size

The grind size will aect the rate of water ow

through the coee in the lter basket and the

avour of the espresso.

We recommend you start at setting 8 and adjust

as required.

Setting the Grind Amount

Set the GRIND AMOUNT dial to the 3 o’clock

position as a starting point. Adjust towards LESS

or MORE as required to adjust the dose amount.

Selecting a lter basket

Use Single Wall lter baskets if grinding fresh

whole coee beans.

Selecting the Filter Size

Insert either the 1 CUP or 2 CUP lter basket into

the portalter. Press the FILTER SIZE button to

select SINGLE if using the 1 CUP lter basket,

or DOUBLE if using the 2 CUP lter basket.

Automatic Dosing

•

Push and release the portalter to engage

the grinding activation switch.

• Grinding will automatically stop, however

if you wish to stop grinding before the cycle

has nished, push and release the portalter.

Manual Dosing

•

Push and hold the portalter to engage the

grinding activation switch. Continue holding

until the desired amount of ground coee

has been dosed.

• To stop grinding, release the portalter.

Tamping the Ground Coee

•

Once grinding is complete, tamp down rmly.

• As a guide to dose, the top edge of the metal cap

on the tamper should be level with the top of the

lter basket AFTER the coee has been tamped.

Use Dual Wall lter baskets if using

pre-ground coee.

Trimming the Dose

The Razor™ precision dose trimming tool allows

you to trim the puck to the right level for

a consistent extraction.

9

Page 10

• Insert the Razor™ dose trimming tool into the lter

basket until the shoulders of the tool rest on the

rim of the basket.

™

• Rotate the Razor

forth while holding the portalter on an angle over

a knock box to trim o excess coee grinds.

dose trimming tool back and

Purging the Group Head

Before placing the portalter into the group head,

run a short ow of water through the group head

by pressing the 1 CUP button.

Inserting the Portalter

Insert the portalter into the group head and

rotate the handle towards the centre until

resistance is felt.

Preset Shot Volume – 2 CUP button

Press the 2 CUP button once to extract

a double shot of espresso at the preset volume

(approx. 60ml).

Re-Programming

Shot Volume – 1 CUP or 2 Cup

1. To begin programming, press the Programme

button once.

2. Press 1 CUP or 2 CUP button to start espresso

extraction. Press 1 CUP or 2 CUP button again

once desired volume of espresso has been

extracted. The machine will beep twice to indicate

the new 1 CUP or 2 CUP volume has been set.

Resetting Default Volumes

To reset the machine to the default 1 CUP

and 2 CUP shot volumes, press and hold the

PROGRAMME button until the machine beeps

three times. Release the PROGRAMME button.

NOTE

Default settings: 1 CUP shot volume is approx.

30ml. 2 CUP shot volume is approx. 60ml.

Preset Shot Volume – 1 CUP button

Press the 1 CUP button once to extract

a single shot of espresso at the preset volume

(approx. 30ml).

NOTE

Pressing the 1 CUP or 2 CUP button during

a preset shot volume will immediately stop

the extraction.

10

Manual Shot Volume

Press and hold the 1 CUP or 2 CUP button.

The extraction will enter low pressure pre-infusion

until the button is released. When the 1 CUP

or 2 CUP button is released, extraction will

continue at full pressure. Press the 1 CUP

or 2 CUP button again once the desired volume

of espresso has been extracted.

Page 11

EN

EXTRACTION GUIDE

LOCK

INSERT

GRIND TAM PDOSE SHOT TIME

BITTER • ASTRINGENT

UNDERDEVELOPED • SOUR

CORRECT EXTRACTION UNDER EXTRACTION OVER EXTRACTION

Within

Espresso Range

• Flow starts after 4–7 secs

• Flow slow like warm honey

• Crema is golden brown with a fine

mousse texture

• Espresso is dark brown

• Extraction takes 25–35 secs

AFTER EXTRACTION

REMOVE USED

GRINDS

Used grinds will form

a coffee ‘puck’. If the

puck is wet, refer to

the ‘Under Extraction’

section.

RINSE FILTER

BASKET

Keep the filter basket

clean to prevent

blockages. Without

ground coffee in the

filter basket, lock the

portafilter into the

machine and run hot

water through.

Under

Espresso Range

• Flow starts after 1–3 secs

• Flow fast like water

• Crema is thin and pale

• Espresso is pale brown

• Tastes bitter/sharp, weak and watery

• Extraction takes up to 20 secs

SOLUTIONS SOLUTIONS

Grind Finer

Tamp using 15 kilos of

pressure. The top edge

of metal cap on the

tamper should be level

with the top of the filter

GRIND SIZE FINER

Adjust & re-test

basket AFTER tamping.

Trim the puck to the

right level using the

™

Razor

dose trimming

tool.

Always use the Razor

tool and trim off some

coffee after tamping.

Over

Espresso Range

• Flow starts after 8 secs

• Flow drips or not at all

• Crema is dark and spotty

• Espresso is very dark brown

• Tastes bitter and burnt

• Extraction takes more than 40 secs

Grind Coarser

Tamp using 15 kilos of

pressure. The top edge

of metal cap on the

tamper should be level

with the top of the filter

basket AFTER tamping.

Trim the puck to the

right level using the

Razor

tool.

Always use the Razor™

tool and trim off some

coffee after tamping.

GRIND SIZE COARSER

Adjust & re-test

™

TURNTURN

™

dose trimming

OVER EXTRACTED

TOO FINE

OPTIMUM

UNDER EXTRACTED

TOO COARS E

TOO MUCH

USE RAZOR

TO TRIM

8-10G (1 CUP)

15-18 G (2 CUP)

TOO LITTLE

INCREASE D OSE

& USE RAZOR

TO TRIM

15-2 0KG

15- 20KG

15-2 0KG

OVER 40 SEC

25-35 SE CBALANCED

UNDER 20 SEC

11

Page 12

USING THE STEAM / HOT WATER DIAL

Steam

• Position the steam wand tip over the drip tray.

• Turn the STEAM / HOT WATER dial to the

STEAM position. The STEAM / HOT WATER

light will ash to indicate the machine is heating

to create steam.

• When the STEAM/HOT WATER light stops

ashing, return the dial back to STANDBY

position.

• Then within 8 seconds, insert the steam wand

tip (1–2cm) below the surface of the milk, close

to the right hand side of the jug at the 3 o’clock

position and quickly turn the dial back to the

STEAM position. Pausing the steam avoids the

milk splashing out of the jug (this pause function

lasts for 8 seconds only).

• The indicator strip on the milk jug will change

colour to highlight the exact milk temperature.

We recommend milk temperature to be between

60-65°C.

• Once the milk is at the correct temperature

(60–65°C), return the dial to the STANDBY

position BEFORE removing the jug.

• Set the jug to one side. Immediately wipe the

steam wand with a damp cloth. Then, with the

steam wand tip directed over the drip tray, briey

turn steam on to clear any remaining milk from

inside the steam wand.

• Pour milk directly into the espresso.

NOTE

Hot Water

• Turn the STEAM/HOT WATER dial to the

HOT WATER position.

• To stop the hot water, return the dial to the

STANDBY position.

ADVANCED TEMPERATURE MODE

Adjusting Water Temperature

To enter Advanced Temperature Mode:

1. Press the POWER button to switch the

machine o.

2. Press & hold the PROGRAMME button, then

press the POWER button. The machine will

beep once. The illuminated button will indicate

the current temperature selected. To adjust the

water temperature, press one of the following

buttons within 5 seconds of entering Advanced

Temperature Mode. The machine will beep twice

to conrm the change. If no buttons are pressed

within 5 seconds after entering Advanced

Temperature Mode, no change will be made

& the machine will return to STANDBY mode.

Default Temperature setting:

In Advanced Temperature Mode, press the

Programme button.

After 5 minutes of continuous steaming, the

machine will automatically disable the steam

function. The STEAM/HOT WATER light will

ash. When this occurs return the dial to the

STANDBY position.

12

Page 13

EN

Increase Water Temperature +1˚C:

In Advanced Temperature Mode, press the

1 CUP button.

Increase Water Temperature +2˚C:

In Advanced Temperature Mode, press the

2 CUP button.

Decrease Water Temperature -1˚C:

In Advanced Temperature Mode, press the

FILTER SIZE button.

AUTO OFF MODE

The machine automatically switches

to AUTO OFF mode after 30 minutes.

Decrease Water Temperature -2˚C:

In Advanced Temperature Mode, press the

POWER button.

13

Page 14

Care & Cleaning

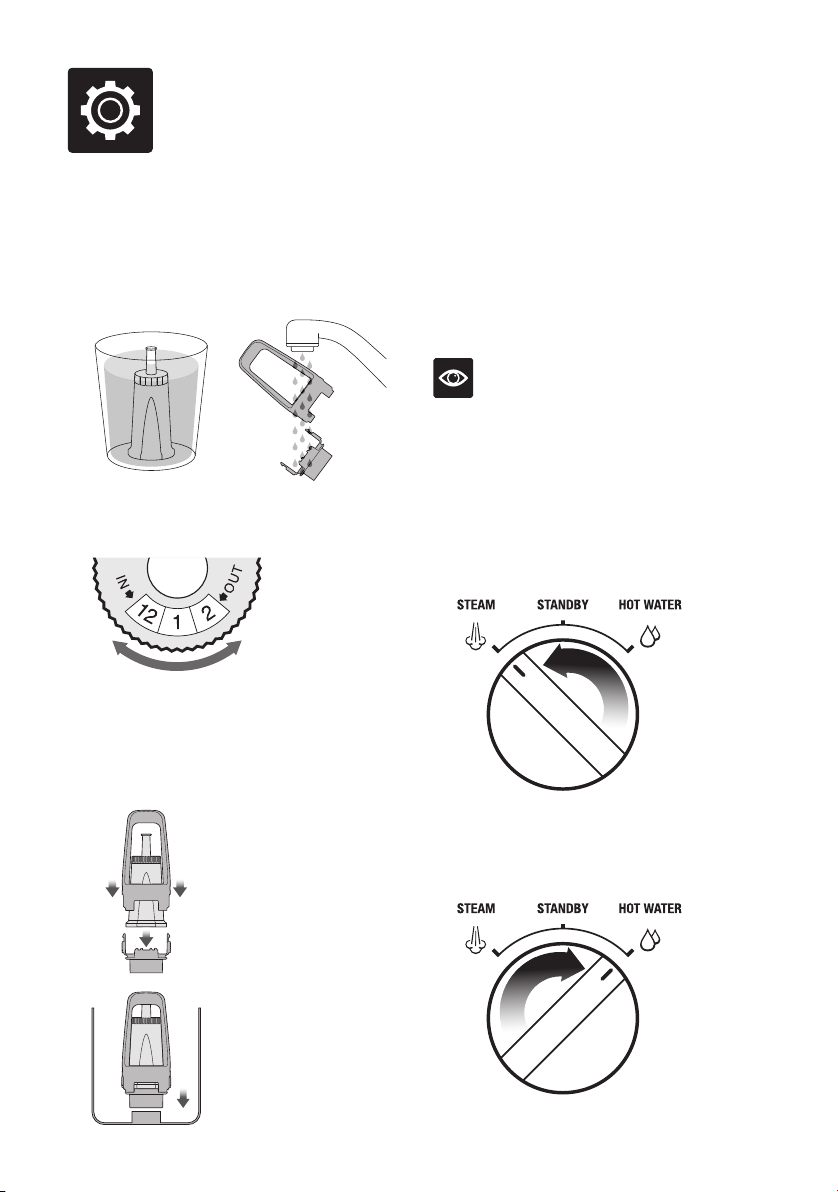

REPLACING THE WATER FILTER

1

The provided water lter helps prevent scale

build-up in and on many of the inner functioning

components. Replacing the water lter after

three months or 40L will reduce the need to

descale the machine.

The limitation of 40L is based on water hardness

level 4. If you are in level 2 area, you can increase

this to 60L.

22 3

Soak lter

for 5 min

Ensure parts are

connected

CLEANING CYCLE

The CLEAN ME light will illuminate when a

cleaning cycle is required. This is a back-

ushing cycle and is separate from descaling.

1. Insert the 1 CUP lter basket into the

portalter, followed by the supplied cleaning

disc, followed by 1 cleaning tablet.

2. Lock the portalter into the group head

and place a large container beneath the

portalter spouts.

3. Ensure the water tank is lled with cold water

and the drip tray is empty.

4. Press the POWER button to switch the

machine o.

5. Press the 1 CUP and 2 CUP buttons

simultaneously, then also press the POWER

button. Hold all 3 buttons together for

approximately 10 seconds.

6. The cleaning cycle will commence and last

for approximately 5 minutes. During this

time, water will intermittently ow from the

portalter spouts. Once complete, 3 beeps

will sound.

7. Remove the portalter and ensure the tablet

has completely dissolved. If the tablet has not

dissolved, repeat until the tablet has dissolved.

!

Replace lter after

90 days or after 40 L

Install lter in tank

54

Install water tankSet current month

DESCALING

After regular use, hard water can cause mineral

build up in and on many of the inner functioning

components, reducing the brewing ow, brewing

temperature, power of the machine, and taste

of the espresso.

1. Even if you are correctly using the water lter

provided, we recommend you to descale when

you see scale build-up in the water tank.

WARNING

Do not immerse power cord, power plug

or appliance in water or any other liquid.

The water tank should never be removed

or completely emptied during descaling.

Priming machine for descaling function

2. Dissolve one Sage Descaling powder

sachet into one litre of water then ll the

water tank.

3. Press and hold the 2 CUP button and

then press and hold the POWER button

simultaneously to enter the Descale mode.

The unit will heat up as part of commencing

the descaling action, during the heating

processes the POWER button should ash

continuously. The machine will indicate it

is ready for descaling when the POWER

button, 1 CUP button, CLEAN ME indicator

and HOT WATER / STEAM indicator are all

illuminated (solid on).

14

Page 15

EN

Descaling the coee component

4.

Press the 1 CUP button to start the

descaling for the coee component of the

machine. Descaling coee component

takes approximately 25 seconds. The 1 CUP

button should ash continuously and remain

constant once the descaling process has

nished. To terminate the descaling within

25 seconds, press the 1 CUP button again.

Descale the steam and hot water

components

Descaling steam and hot water takes

approximately 13 seconds and 8 seconds

respectively. Descaling can be terminated

prematurely by turning the steam dial to STANDBY.

5. Descale Steam component by turning

the steam dial LEFT towards the STEAM icon.

Repeat processes to complete descaling

After the above processes about half

(0.5 litre) of the descale solution should

be left in the water tank.

7. Repeat steps 4-6 above to complete the

descaling process to empty the solution

in the tank.

Descaling Solution Rinse

8. After descaling, remove the water tank and

rinse thoroughly then rell with fresh cold water

to the maximum capacity (2 litres) and repeat

steps 4-6 to further cleanse the machine of any

residue of the cleaning solution thoroughly.

9. Press ‘POWER’ to quit the descaling process.

This will be indicated by the LED lights

switching o.

NOTE

The machine turns o automatically if there

is no action for 5 minutes in descaling mode.

To resume descaling, please start from step 3.

6. Descale Hot water component by turning the

steam dial to the RIGHT towards the HOT

WATER icon.

15

Page 16

ADVANCED CLEANING FOR THE CONICAL BURR GRINDER

1 2 3 4 5 6

SINGLE DOUBLE

PUSH TO GRIND

7

POWER

FILTER SIZE

GRIND AMOUNT

1. GRIND FAN

2. METAL WASHER

3. FELT WASHER

3

2

1

1.

FELT WASHER

2. METAL WASHER

3.

GRIND FAN

1

2

3

This step is only required if there is a blockage between the grinding burrs and the grinder outlet.

GRIND SIZE

GRIND SIZE

LOOSEN NUT

Remove hopper

8 9

Set ‘GRIND SIZE’ to ‘1’

(finest)

Use 10mm socket. Rotate

‘Clockwise’ to loosen the

nut only

Set ‘GRIND SIZE’ to ‘16’

(coarsest)

Unlock & remove top burr Remove nut, spring & flat

10 11 12

SPRING

WASHER

FLAT

WASHER

TIGHTEN NUT

Unblock the grinds exit

chute using the brush or

a pipe cleaner

Clean chute with brush Insert washers & grind fan

using long-nose pliers

WARNING

Care should be taken as the grinder burrs are

extremely sharp.

Insert lower burr (drive pin

& cavity to align). Insert

flat washer & spring washer

If any of the holes in the lter basket become

blocked, use the pin on the end of the provided

cleaning tool to unblock the hole(s).

If the hole(s) remain blocked, dissolve a cleaning

tablet in hot water and soak lter basket and

Rotate ‘Counter-Clockwise’

to tighten nut

portalter in solution for approx. 20 minutes.

CLEANING THE STEAM WAND

The steam wand should always be cleaned after

texturing milk. Wipe the steam wand with a damp

cloth. Then with the steam wand tip directed over

the drip tray, briey set the STEAM / HOT WATER

dial to the STEAM position. This will clear any

remaining milk from inside the steam wand.

If any of the holes in the tip of the steam wand

become blocked, ensure the STEAM / HOT

WATER dial is in the STANDBY position. Press

the POWER button to switch the machine o

and allow to cool. Use the pin on the end of the

provided cleaning tool to unblock the hole(s).

If the steam wand remains blocked, remove the

tip using the integrated spanner in the cleaning

tool and soak in hot water. Use the pin on the end

of the provided cleaning tool to unblock the hole(s)

before re-attaching to the steam wand.

CLEANING THE FILTER BASKETS

AND PORTAFILTER

The lter baskets and portalter should be rinsed

under hot water immediately after use to remove

all residual coee oils.

Rinse thoroughly.

CLEANING THE SHOWER SCREEN

The group head interior and shower screen

should be wiped with a damp cloth to remove any

ground coee particles.

Periodically purge the machine. Place an empty

lter basket and portlter into the group head.

Press and hold the 1 CUP button and run a short

ow of water to rinse out any residual coee.

CLEANING THE DRIP &

STORAGE TRAY

The drip tray should be removed, emptied and

cleaned at regular intervals, particularly when the

drip tray full indicator is showing EMPTY ME!

Remove the grid from the drip tray. Lift the coee

grind separator and dispose of any coee

grounds. The EMPTY ME! indicator can also be

removed from the drip tray by pulling upwards

to release the side latches. Wash all parts in

warm soapy water with a soft cloth. Rinse and

dry thoroughly.

SPRING

WASHER

washer. Carefully remove

lower burr

FLAT

WASHER

Remove grind fan & washers

using long-nose pliers

14

GRIND SIZE

Insert & lock top burr13Set ‘GRIND SIZE’ to ‘5’.

Replace & lock hopper

16

Page 17

EN

The storage tray (located behind the drip tray)

can be removed and cleaned with a soft, damp

cloth. Do not use abrasive cleansers, pads

or cloths which can scratch the surface.

NOTE

All parts should be cleaned by hand using warm

water and a gentle dish washing liquid. Do not

use abrasive cleansers, pads or cloths which

can scratch the surface. Do not clean any of the

parts or accessories in the dishwasher.

Clean centre of screw

before inserting Allen Key

CLEANING THE OUTER HOUSING

& CUP WARMING TRAY

The outer housing and cup warming tray can

be cleaned with a soft, damp cloth. Polish with

a soft, dry cloth. Do not use abrasive cleansers,

pads or cloths which can scratch the surface.

STORING YOUR MACHINE

Before storing, ensure the STEAM / HOT

WATER dial is in the STANDBY position, press

the POWER button to switch the machine o

and remove the plug from the power outlet.

Remove unused beans from the hopper, clean

the grinder (see page 16), empty the water

tank and the drip tray.

WARNING

Do not immerse power cord, power plug

or appliance in water or any other liquid.

USING THE ALLEN KEY

Over time, the silicone seal surrounding

the shower screen will need to be replaced

to ensure optimum brewing performance.

1. Press the POWER button to switch the

machine o and unplug the cord from the

power outlet.

2. Carefully remove the water tank and drip tray,

taking particular care if they are full.

3. Using a skewer or similar, clean the centre

of the screw of any residual coee.

4. Insert the shorter end of the Allen Key into

the centre of the screw. Turn counter-clockwise

to loosen the screw.

5. Once loosened, carefully remove and retain the

screw, stainless steel shower screen and black

dispersion plate. Make note of the side of the

shower screen and dispersion plate that are

facing downwards. This will make re-assembly

easier. Wash the shower screen and dispersion

plate in warm soapy water, then dry thoroughly.

6. Remove the silicone seal with your ngers

or a pair of long-nose pliers. Insert the new seal,

at side rst, so the ribbed side is facing you.

7. Re-insert the dispersion plate, then the shower

screen, then the screw. With your ngers, turn

the screw clockwise for 2-3 revolutions then

insert the Allen Key to tighten until the screw

is ush with the shower screen.

8. Re-insert the drip tray and water tank.

Contact Sage Customer Service or visit

www.sageappliances.com for replacement

silicone seals or for advice.

17

Page 18

Troubleshooting

PROBLEM POSSIBLE CAUSE WHAT TO DO

Machine does

not heat up.

STEAM/HOT

WATER light

ashes when

the machine

is turned on.

Water does

not ow

from the

group head.

No hot water.

• STEAM / HOT WATER dial is not in

the STANDBY position.

• Machine has not reached operating

temperature.

• Water tank is empty. • Fill tank.

• Water tank is not fully inserted

and locked into position.

• Machine needs to be descaled. • Refer to ‘Descaling’, page 14.

• Turn the STEAM / HOT WATER dial to the STANDBY

position. Machine will commence heating.

• Allow time for the machine to reach operating

temperature. The POWER button light will stop ashing

and all button lights on the control panel

will illuminate when ready.

• Push water tank down completely to lock into place.

Espresso only

drips from

the portalter

spouts or

not at all.

Espresso

runs out too

quickly.

18

• Coee is ground too nely and/or

too much coee in lter basket and/

or over tamping and/or lter basket

is blocked.

• Coee is ground too nely. • Use slightly coarser grind. Refer to ‘Setting the

• Too much coee in the lter basket. • Lower dose of coee. Refer to ‘Setting the Grind

• Coee tamped too rmly. • Tamp between 15–20kg of pressure.

• Water tank is empty. • Fill tank.

• Water tank is not fully inserted and

locked into position.

• The lter basket may be blocked. • Use the pin on the end of the provided cleaning tool

• Machine needs to be descaled. • Refer to ‘Descaling’, page 14.

• Coee is ground too coarsely. • Use slightly ner grind. Refer to ‘Setting the Grind Size’,

• Not enough coee in the lter

basket.

• Coee tamped too lightly. • Tamp between 15–20kg of pressure.

• See below, ‘Espresso only drips from the portalter

spouts or not at all’.

Grind Size’, page 9 and ‘Over Extraction’, page 11.

Amount’, page 9 and ‘Over Extraction’, page 11.

• Push water tank down completely to lock into place.

to unblock the hole(s). If the hole(s) remain blocked,

dissolve a cleaning tablet in hot water and soak lter

basket and portalter in solution for approx.

20 minutes. Rinse thoroughly.

page 9 and ‘Under Extraction’, page 11.

• Increase dose of coee. Refer to ‘Setting the Grind

Amount’, page 9 and ‘Under Extraction’, page 11.

Page 19

EN

PROBLEM POSSIBLE CAUSE WHAT TO DO

Espresso runs

out around the

edge of the

portalter.

• Portalter not inserted

in the group head correctly.

• There are coee

grounds around the

lter basket rim.

• Coee tamped too lightly. • Tamp between 15–20kg of pressure.

• Ensure portalter is completely inserted and rotated

until resistance is felt.

• Clean excess coee from the rim of the lter basket

to ensure a proper seal in group head.

No steam.

Coee not

hot enough.

• Too much coee in the lter basket. • Lower dose of coee. Refer to ‘Setting the Grind

• The silicone seal surrounding the

shower screen needs to be replaced

to ensure the portaler is properly

secured into the group head.

• Machine has not reached operating

temperature.

• Water tank is empty. • Fill tank.

• Water tank is not fully inserted

and locked into position.

• Machine needs to be descaled. • Refer to ‘Descaling’, page 14.

• Steam wand is blocked. • Refer to ‘Cleaning the Steam Wand’, page 16.

• STEAM/HOT WATER dial is not

in the STEAM position.

• Cups not pre-heated. • Rinse cups under hot water outlet and place

• Portalter not pre-heated. • Rinse portalter under hot water outlet.

Amount’, page 9.

• Refer to ‘Using the Allen Key’, page 17.

• Allow time for the machine to reach operating

temperature. The STEAM / HOT WATER light will

ash to indicate the machine is heating to create

steam. During this time, condensed water may purge

from the steam wand. This is normal. When the

STEAM / HOT WATER light stops ashing the steam

wand is ready for use.

• Push water tank down completely to lock into place.

• Ensure the STEAM / HOT WATER dial is completely

rotated to the STEAM position.

on cup warming tray.

Dry thoroughly.

• Milk not hot enough

(if making a cappuccino or latté etc).

• Machine needs to be descaled. • Refer to ‘Descaling’, page 14.

• Heat milk until side of the jug becomes hot to touch.

19

Page 20

PROBLEM POSSIBLE CAUSE WHAT TO DO

No crema.

• Coee tamped too lightly. • Tamp between 15-20kg of pressure.

Drip tray lls

too quickly.

Pulsing/

pumping

sound while

extracting

espresso

or steaming

milk.

Water leaking.

Machine is on

but ceases

to operate.

• Coee is ground too coarsely. • Use slightly ner grind. Refer to ‘Setting the Grind

• Coee beans or pre-ground coee

are not fresh.

• The lter basket may be blocked. • Use the pin on the end of the provided cleaning tool

• Single Wall lter baskets are being

used with pre-ground coee.

• Auto purge feature. Water is

automatically released into the drip

tray after the steam and hot water

functions to ensure the thermocoil

is at the optimal temperature

for extracting espresso.

• The machine is carrying out the

normal operation of the 15 bar

Italian pump.

• Water tank is empty. • Fill tank.

• Water tank is not fully inserted

and locked into position.

• Auto purge feature. Water is

automatically released into the drip

tray after the steam and hot water

functions to ensure the thermocoil

is at the optimal temperature for

extracting espresso.

• Water tank is not fully inserted

and locked into position.

• The silicone seal surrounding the

shower screen needs to be replaced

to ensure the portaler is properly

secured into the group head.

• The safety thermal-cut out may have

activated due to the pump or grinder

overheating.

Size’, page 9 and ‘Under Extraction’, page 11.

• If grinding fresh whole coee beans, buy freshly

roasted coee with a “roasted on” date and use

within 2 weeks of this date.

• If using pre-ground coee, use within a week

of grinding.

to unblock the hole(s). If the hole(s) remain blocked,

dissolve a cleaning tablet in hot water and soak lter

basket and portalter in solution for approx.

20 minutes. Rinse thoroughly.

• Ensure you use Dual Wall lter baskets with

pre-ground coee.

• No action required as this is the normal operation

of the machine.

• No action required as this is the normal operation

of the machine.

• Push water tank down completely to lock into place.

• Ensure the drip tray is rmly pushed in place after

using the steam and hot water functions.

• Empty the drip tray regularly.

• Push water tank down completely to lock into place.

• Refer to ‘Using the Allen Key’, page 17.

• Press the POWER button to switch the machine o

and unplug from the power outlet. Allow to cool for

about 30–60 minutes.

• If problem persists, call Sage Customer Service on:

0808 178 1650.

20

Page 21

EN

PROBLEM POSSIBLE CAUSE WHAT TO DO

No ground

coee coming

from grinder.

FILTER SIZE

LED’s are

ashing.

Too much/

too little

ground coee

is being

delivered

to the lter

basket.

Too much/too

little espresso

is being

delivered to

the cup.

Grinder

is making

a loud noise.

• No coee beans in hopper. • Filler hopper with fresh coee beans.

• Blocked grinder chamber or chute. • Clean and clear grinder chamber and chute.

• Water / moisture in grinder chamber

and chute.

• Bean hopper is not attached correctly. • Remove hopper, check for debris and then re-lock

• Grind amount settings are incorrect

for particular grind size.

• Grind amount and/or grind size

settings and/or shot volumes

require adjustment.

• Blockage or foreign object in grinder. • Remove hopper, check for debris or blockage.

Refer to ‘Advanced Cleaning for the Conical Burr

Grinder’, page 16.

• Clean and clear grinder chamber and chute. Refer

to ‘Advanced Cleaning for the Conical Burr Grinder’,

page16. Ensure burrs are thoroughly dry before

re-assembling. It is possible to use a hair

dryer to blow air into the grinder chamber.

hopper into position.

• Use the GRIND AMOUNT dial to increase or

decrease the grind amount. Refer to ‘Setting the

Grind Amount’, page 9 and ‘Extraction Guide’,

page 11.

• Try the following, one at a time:

• Reset the machine to its original default settings.

Refer to ‘Resetting Default Volumes’, page 10.

• Re-programme the shot volumes. Refer to

‘Re-Programming Shot Volume’, page 10.

• Adjust the grind amount and/or grind size settings.

Refer to ‘Setting the Grind Size’, page 9, ‘Setting

the Grind Amount’, page 9 and ‘Extraction Guide’,

page 11.

If necessary, clean and clear grinder chamber and

chute. Refer to ‘Cleaning the Conical Burr Grinder’,

page 16.

Guarantee

2 YEAR LIMITED GUARANTEE

Sage Appliances guarantees this product for

domestic use in specied territories for 2 years

from the date of purchase against defects caused

by faulty workmanship and materials. During this

guarantee period Sage Appliances will repair,

replace, or refund any defective product (at the

sole discretion of Sage Appliances).

All legal warranty rights under applicable

national legislation will be respected and will

not be impaired by our guarantee. For full terms

and conditions on the guarantee, as well as

instructions on how to make a claim, please visit

www.sageappliances.com.

21

Page 22

Notes

22

Page 23

EN

Notes

23

Page 24

GBR IRE

BRG Appliances Limited

Unit 3.2, Power Road Studios, 114 Power Road, London, W4 5PY

Freephone (UK Landline): +44 (0)808 178 1650

Mobile Calls (National Rate): 0333 0142 970

www.sageappliances.com

• Due to continued product improvement, the products illustrated or photographed in this document may vary slightly from the actual product.

Registered in England & Wales No. 8223512.

Copyright BRG Appliances 2019.

BES875 UG1 E19

Loading...

Loading...