Saeco IDEA, IDEA CAP002, IDEA CAP002A, IDEA CAP002B Idea Instruction And Maintenance Manual

Page 1

Automatic espresso coffee machine

Model

IDEA

INSTRUCTION AND MAINTENANCE MANUAL

Type: CAP002/A/B

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 2

English

148

1 - MACHINE COMPOSITION. ................................... 149

2 - REFERENCE NOTES. ............................................... 150

2.1 Abbreviations ............................................. 150

2.2 Editorial symbols ......................................... 150

3 - USER. ..................................................................... 150

4 - MAINTENANCE TECHNICIAN. .............................. 150

5 - INTENDED USE OF THE MACHINE. ....................... 150

6 - WARNINGS AND CARES. ..................................... 150

7 - GENERAL PRECAUTIONARY MEASURES. ............. 151

8 - INFORMATION ABOUT THE MACHINE. ............... 151

8.1 Identification data........................................ 151

8.2 Technical characteristics ................................ 151

8.3 Overall dimensions ...................................... 151

8.4 Brew group (F. 2) ........................................ 152

8.5 Cappuccinatore Group (F. 4)......................... 152

9 - SAFETY DEVICES. .................................................. 152

9.1 Hot water and steam spouts

(except COFFEE set-up) (F. 1) ......................... 152

9.2 Residual risks .............................................. 152

10 - INSTALLATION. ..................................................... 153

10.1 Location notes ............................................. 153

10.2 Machine positioning .................................... 153

10.3 Water connection........................................ 153

10.4 Electric connection ....................................... 154

10.5 Serial port connection .................................. 154

Via Panigali, 39

40041 GAGGIO MONTANO (Bo)

Tel. 0534/770511

www.saeco.it

INTRODUCTION

• This manual is an integral part of this machine and it must be kept in a handy place, in good conditions, for as long as the machine will

be operating (including any transfer of ownership). It aims at giving the necessary information about a correct and safe use of this

machine.

• In case of lost or deterioration of this brochure, please ask a copy to the Authorized customer Service Center, specifying the model and

the year of construction of your machine.

• The Authorized Customer Service Centers, are also available for any technical explanation, information on its operation, technical

assistance and spare parts supply.

• The subjects mentioned aim, in an exclusive way, at ensuring the proper use of the machine, in the safest way for users, the very machine

and the environment. This is made through a simple diagnostics of troubles and anomalous functioning, and by carrying out some simple

checks and maintenance operations, always respecting the precautions explained in the following pages and the current Safety and

Health Regulations

• Before any intervention read very carefully and be sure to have completely understood the subject of this brochure.

• If several persons use (individually) this machine, everyone must previously and very carefully study the Instruction Manual.

• The manufacturer reserves the right to modify and improve the described models, without being bound to give any notice.

• For any particular need contact the Distributor or your Country Importer (if any) or the Constructor.

• All the rights of this brochure are reserved to SAECO Internatioal Group. Any copy or even partial divulgation, not expressively

authorized in writing, are strongly forbidden.

CONTENTS

11 - FIRST SWITCHING-ON. ......................................... 155

12 - USE OF THE MACHINE. ......................................... 155

12.1 Machine statuses ......................................... 155

12.2 Manual switching-on .................................... 155

12.3 Programmed automatic switching-on ............... 155

12.4 Stand-by temporary switching-on .................... 155

12.5 Control panel ............................................. 156

12.6 Brewing buttons programming ....................... 157

12.7 Menu programmable functions ....................... 159

12.8 Cream adjustment ....................................... 163

12.9 Temperature setting ...................................... 163

12.10 Grind adjustment ......................................... 163

12.11 Display messages ........................................ 164

12.12 Machine switching-off .................................. 164

13 - ROUTINE MAINTENANCE. .................................... 165

13.1 Machine cleaning ....................................... 165

14 - UNSCHEDULED MAINTENANCE. .......................... 167

14.1 Jamming of the coffee grinder unit ................... 167

15 - OUT OF SERVICE. .................................................. 168

16 - TROUBLES, CAUSES AND CURES. ......................... 169

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 3

English

149

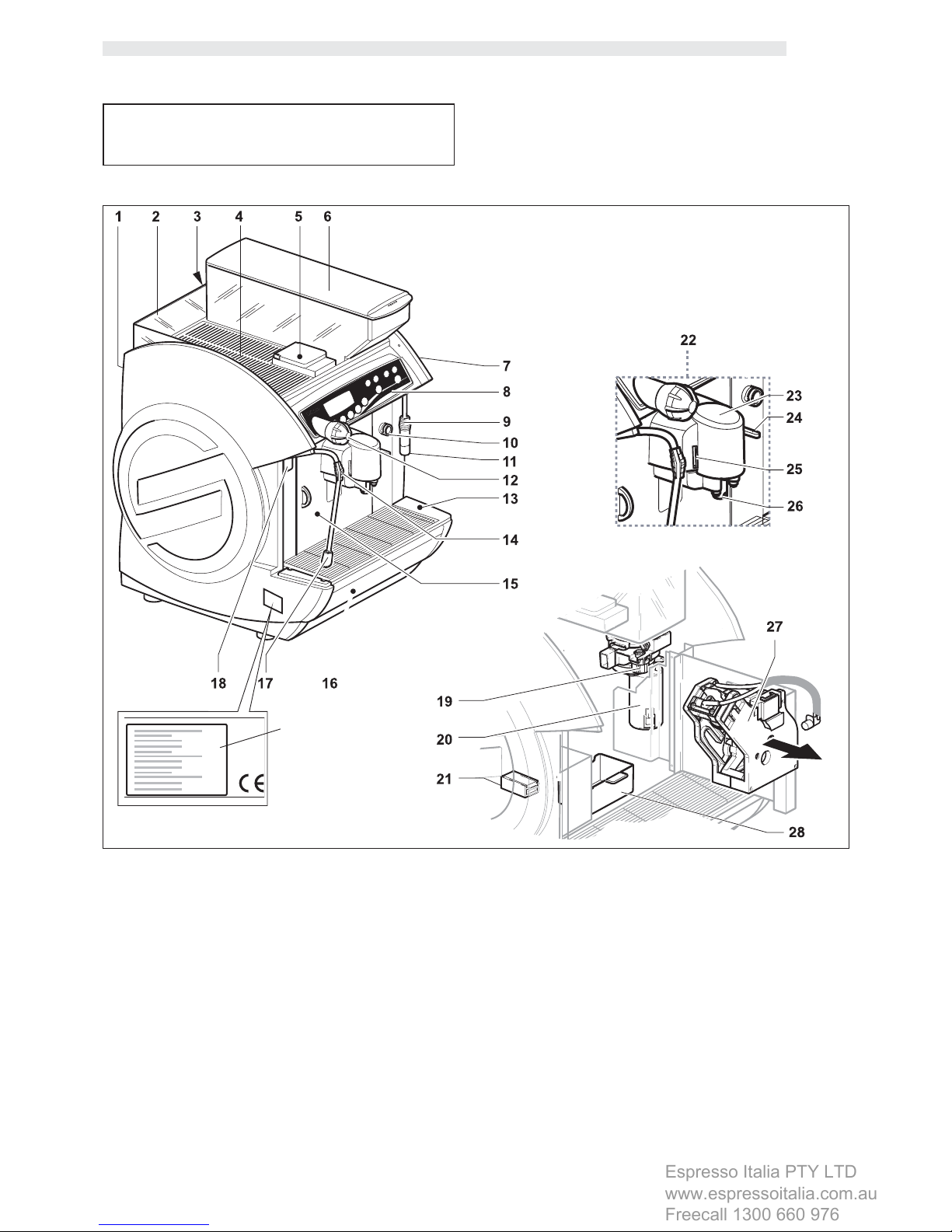

1 - MACHINE COMPOSITION

A CE label

1 Left hand side panel

2 Glass

3 Back panel

4 Cup warming plate

5 Pre-ground coffee door

6 Coffee bean hopper

7 Right hand side panel

8 Control panel

9 Rubber protector

10 Spout clamp (CAPPUCCINO set-up)

11 Hot water spout (except COFFEE set-up)

12 Steam knob (except COFFEE set-up)

Clockwise: steam jet open

Counterclockwise: steam jet closed

13 Drip tray

14 Rubber protector

15 Door

F. 1

A

NOTE - If not differently indicated by the text, the position numbers of the parts of the machine always refer to this figure.

16 Dump box

17 Steam spout (except COFFEE set-up)

18 Main switch

“I” - Electrical functions enabled – Machine on –

Pilot light on.

“O” - Electrical functions disabled – Machine off -

“I” button pilot light off.

19 Grind adjustment knob

20 Grinder unit

21 Mechanical pulse counter

It displays the number of brewings.

22 Brew group

23 Brew group cover

24 Milk cream adjustment (CAPPUCCINO equipment)

25 Temperature setting (CAPPUCCINO equipment)

26 Milk dispenser (CAPPUCCINO equipment)

27 Coffee unit

28 Powder tray

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 4

English

150

2 - REFERENCE NOTES

2.1 Abbreviations

F. = Figure

P. = Page

Pr . = Paragraph

T. = Table

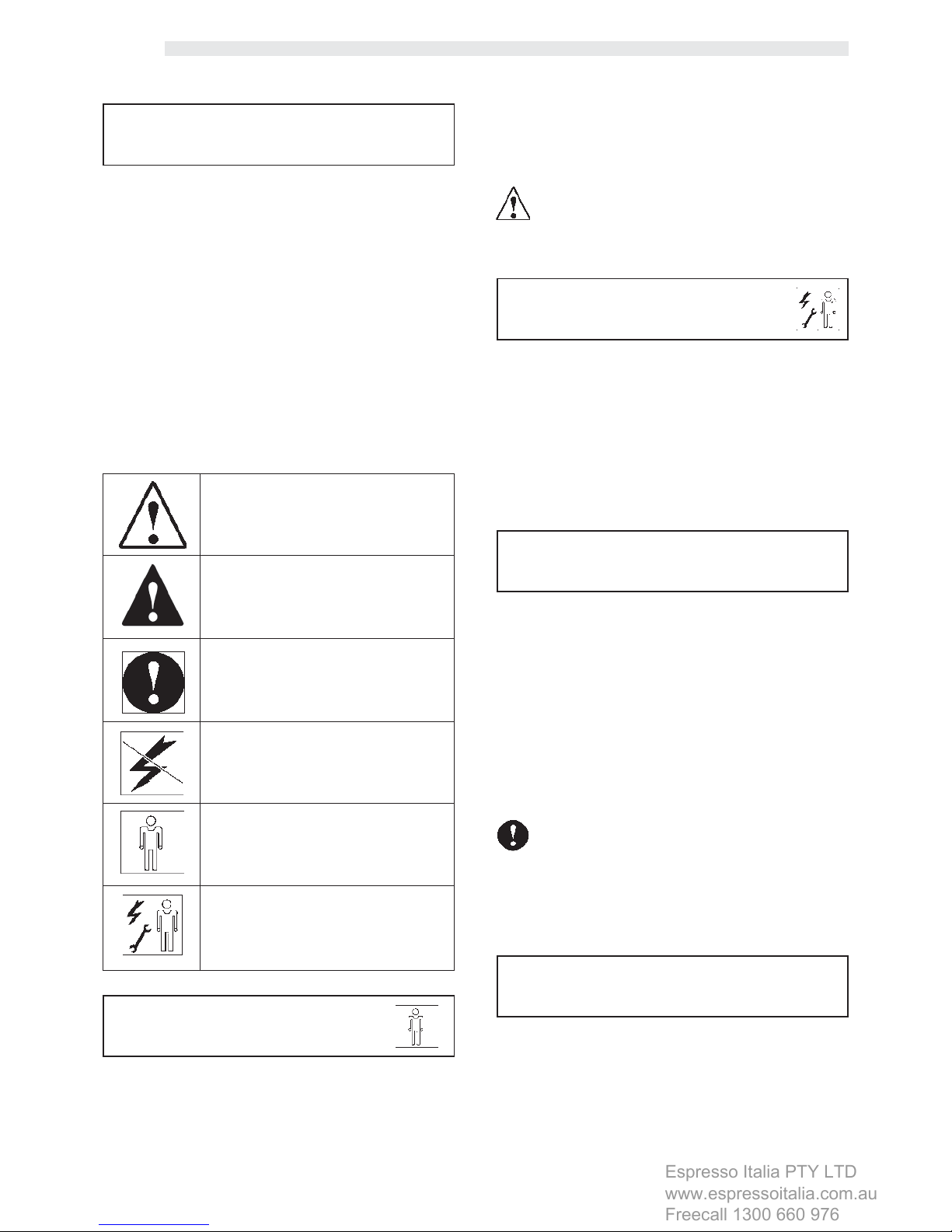

2.2 Editorial symbols

WARNING! Pay the utmost attention to the meaning of symbols.

They are aimed at drawing the attention of the reader on technical

notions or safety warnings. Therefore they have to be considered

as real “memoranda”. Refer to the list of symbols every time any

doubt about their meaning arouses.

WARNING! - Information about the user’s

safety and the machine integrity.

WARNING! - Operations that are

potentially dangerous for the maintenance

technician.

IMPORTANT! - It draws the attention on a

particularly important subject.

Maintenance technician - Operations

strictly concerning personnel in charge of

unscheduled maintenance or repairs.

Machine off - Operations to be done

without power supply .

User - Actions concerning the machine user.

- Brewing parameters adjustment.

- Grounds and liquids tray draining.

- External cleaning of the machine.

The use of this machine is strictly forbidden to

children, teenagers and non self-sufficient persons.

4 - MAINTENANCE

TECHNICIAN

• Person in charge of the following operations:

- Installation, machine starting, adjustment and setting

up.

- Unscheduled maintenance, repairs and spare parts

replacement.

5 - INTENDED USE OF THE

MACHINE

• The machines described in this manual have been designed,

manufactured and protected for the automatic programmable

brewing of the following beverages:

- instantly-ground coffee bean-based;

- pre-ground coffee-based;

- milk and instantly-ground coffee bean-based

(CAPPUCCINO set-up).

- hot water and steam (except COFFEE set-up) for beverage

preparation and heating.

- hot milk (CAPPUCCINO set-up).

The Manufacturer disclaims any responsibility for the

improper use of the machine and any damage resulting.

The improper use also implies the cancellation of any

warranty.

3 - USER

• The adult to whom the following operations are strictly

reserved:

- Operating, protecting and switching off the machine.

- Coffee beans supply.

6 - WARNINGS AND CARES

• In routine maintenance, never use detergents, diluents,

solvents, etc...

• Cleaning has to be limited at parts of the machine being

not powered and must be carried out with mild and

biodegradable products. Moreover the main switch or

the all-pole switch have to be on the “O”(OFF) position,

or the plug has to be disconnected from the power point.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 5

English

151

• The routine maintenance has to be carried out only by

competent or adequately trained personnel, having the

necessary psychophysical requirements, in the whole

respect of the instructions mentioned below and according

to the current Safety and Health Regulations.

• It is strictly forbidden to place and/or leave on the machine

tools or anything which could potentially be prejudicial to

the people safety and to the integrity of the machine.

• Changing and adjustments (even if slight) as well as the

use of non original spare parts, release the Manufacturer

from any responsibility for any type of damage and implies

the cancellation of any warranty right.

• Use only drinking water.

• The milk to be used for the CAPPUCCINATORE must be put in a

fridge at a temperature not over 4° C; do not leave it outside the

fridge for more than 30 minutes.

• If the CAPPUCCINATORE is not used for more than an hour,

carry out a cleaning cycle of the spouts before re-using.

To clean the spouts:

- immerse the milk supply tube in a container of water;

- press the milk key

;

- wait until the water has been dispensed.

PLEASE NOTE: Do not use hot water.

7 - GENERAL

PRECAUTIONARY

MEASURES

• Before operating the machine, be previously sure not to

have any doubt about the contents of this manual. Non

respecting the rules explained in it releases the

Manufacturer from any responsibility for any type of injury

to persons and/or damage to things.

• Keep this brochure for any further reference.

• Previously verify (in case of a new installation), the respect

of the minimal regulations of safety, positioning and

machine operating conditions, checking the environment

conditions (temperature, humidity, light) and the suitability

of the place of operation.

• Any damage to the electric power cord requires the

intervention of the Technical Authorized Customer Service

or of the maintenance technician.

• Do not use the machine on the outside.

• In case of bad functioning, always ask for the intervention

of the maintenance technician.

• Do not use water jets to clean the machine.

8 - INFORMATION ABOUT

THE MACHINE

8.1 Identification data

In the (A) plate the following identification data of the machine are

mentioned:

• Manufacturer and

marking

• model

• serial number

• manufacturing year

• mains electric voltage (V) and frequency (Hz)

• electrical power consumption (W)

• number of phases of the electric line (PH)

• pressure allowed in the water network (MPa)

NOTE-In case of any request to the Authorized Customer

Service Centers, model and serial number must be

specified.

8.2 Technical characteristics

Mains voltage ........................... 230V/400V 2N

Length of the power cord ............. 1,500 mm

Installed power

Mod. LUXE .......................... 3,250 kW

Mod. COFFEE ..................... 1,650 kW

Mod. CAPPUCCINO ............ 3,250 kW

Water pressure .......................... 0.1÷ 0.8 MPa (1÷8 bar)

Weight .................................... kg 60

Bean hopper capacity................. kg 2

NOTE-The machines can be programmed for any type of

dosing. Most electric parts are powered by 24 Vdc.

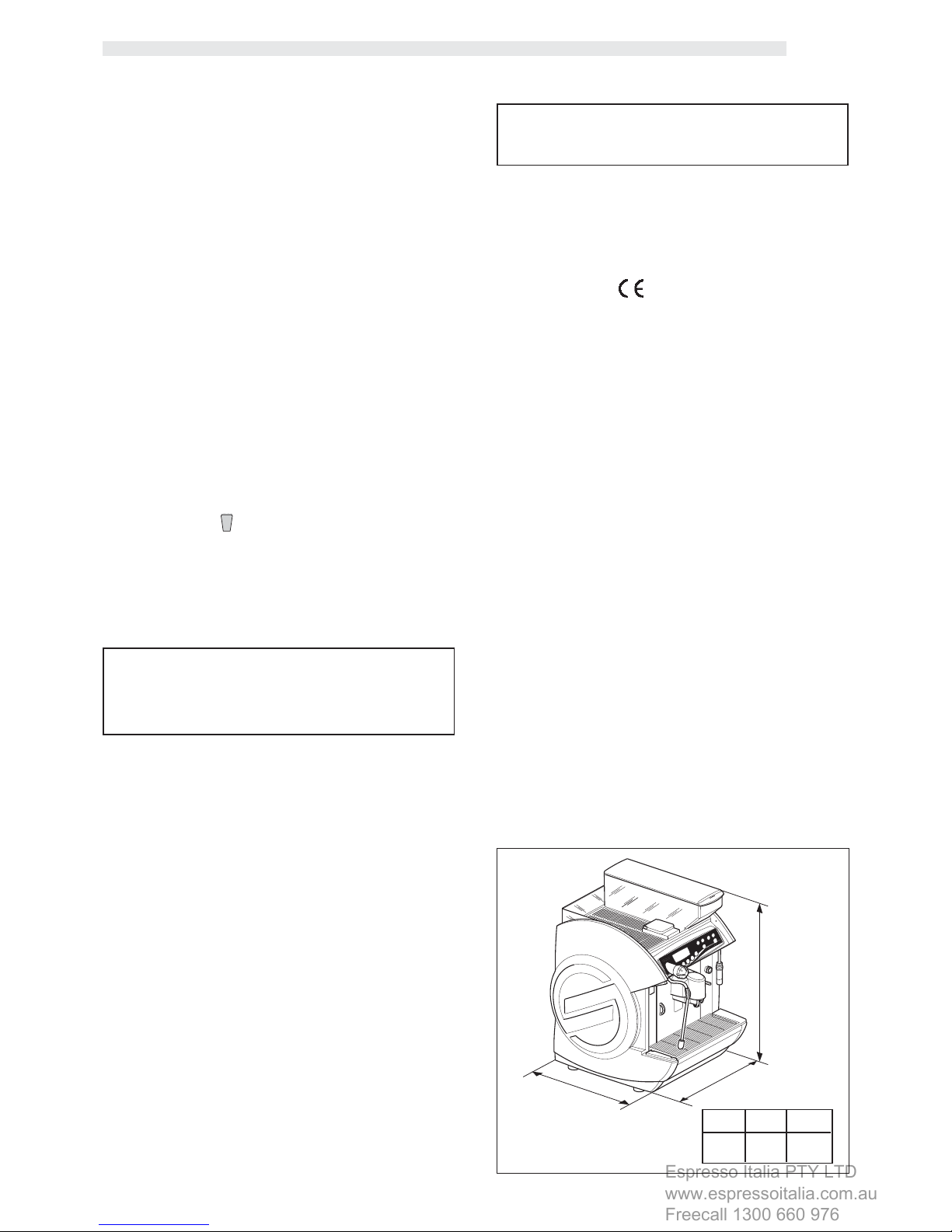

8.3 Overall dimensions

LPh

500 550 675

F. 2

L

P

h

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 6

English

152

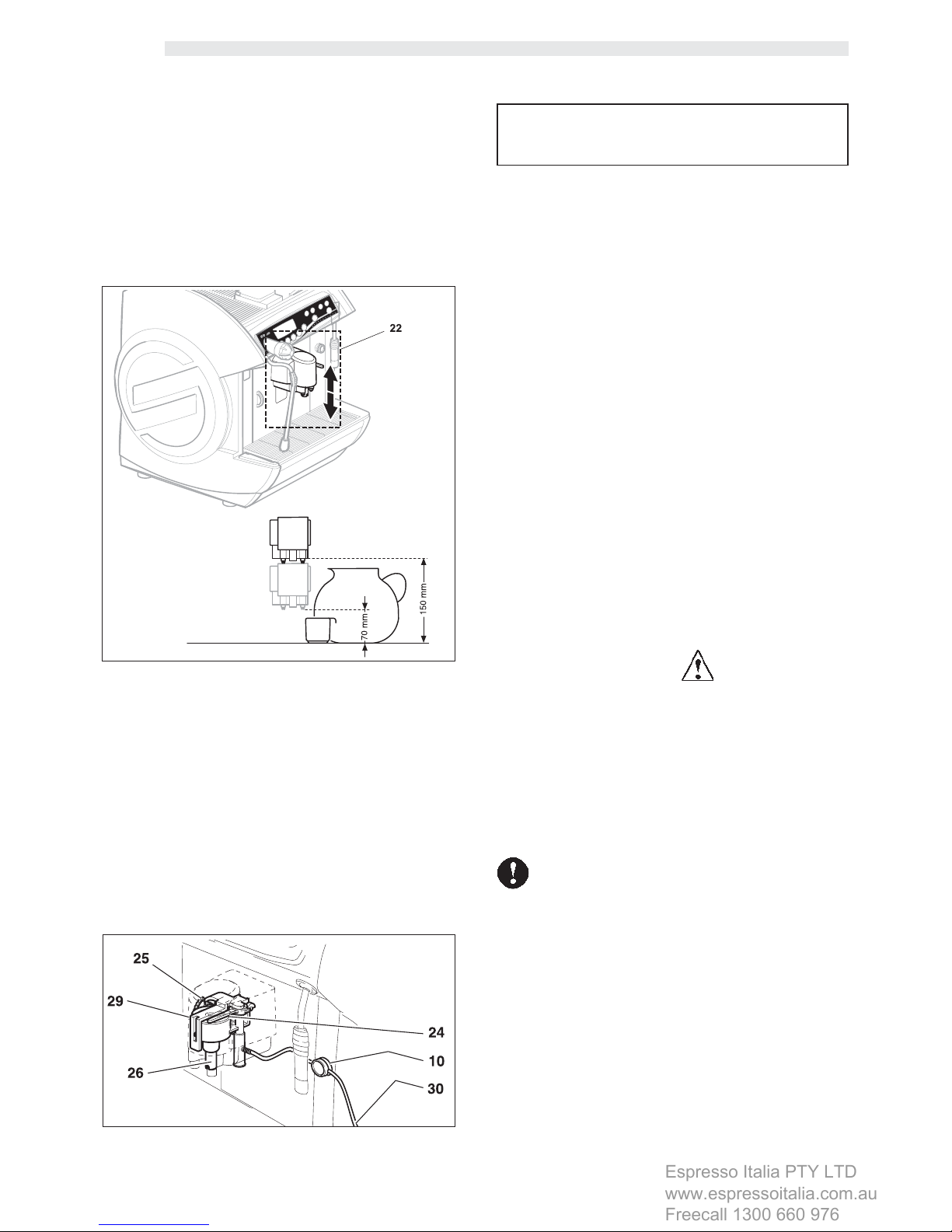

8.4 Brew group

The position of this group (22) can be adjusted according to the

height of the container used .

It is possible to position the brew group on the top or on the bottom.

Many brewing heights can be thus obtained.

8.5 Cappuccinatore Group (F. 4)

The cappuccinatore group, is composed of:

- milk suction tube (30);

- spout clamp (10);

- cappuccinatore group(29);

- cream quality adjustment (24);

- temperature setting (25);

- Milk dispenser (26).

9 - SAFETY DEVICES

NOTE - The machines described in this brochure are in conformity

with the specific current European Regulations and

therefore all their potentially dangerous parts are

protected .

• Any overpressure in the water plant that produces steam

and hot water, is detected by 3 safety valves.

• A thermostat avoids boilers overheating.

• The position of the dump box (16) and of the door (15), is

controlled by two microswitches that stop the running of the

machine if one of the two components is not properly in place;

(the display will show the component out of place).

• An electrical pulse counter and a mechanical one, record

the number or brewings and allow to schedule the routine

maintenance.

9.1 Hot water and steam spouts

(except COFFEE set-up) (F. 1)

Steam spouts (17) and hot water spouts (11) are equipped with

special rubber protectors (9 and 14) so that they can be grabbed

and adjusted even when hot.

9.2 Residual risks

• The structural characteristics of the machines described in this

brochure, do not protect the user from the direct steam or hot

water spouts (except COFFEE set-up).

• Danger of burns – During hot water and steam

brewing do not turn the spouts towards yourself or someone

else. Grab the spout only by the respective anti-burns protectors

(9 - 14).

Do not use containers that are not made of food materials.

F. 3

F. 4

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 7

English

153

10 - INSTALLATION

10.1 Location notes

• The machine has to be installed in a dry and protected place,

at the following ambient temperature : 10° C - 40° C; maximum

humidity: 90%.

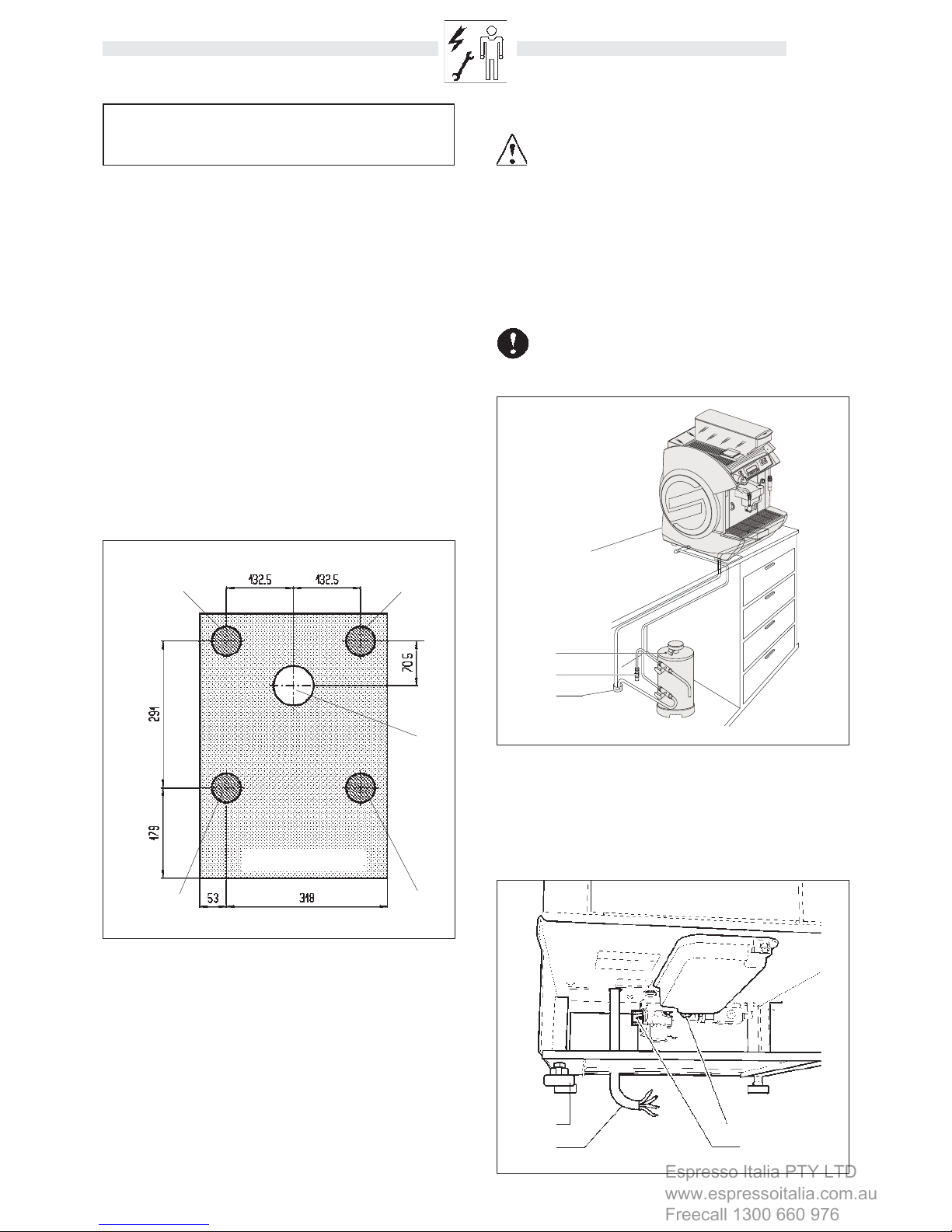

10.2 Machine positioning

NOTE - Check if the surface where the machine is installed has

the adequate dimension and solidity to support the

machine safely.

• Make a Ø 100 mm (A - F. 5) hole on the supporting surface.

• Place definitely the machine on the support (the circles B - F. 5,

indicate the suitable position of the adjustable feet).

• Level off the machine using the adjustable feet (F - F. 7).

C – WATER SOFTENER

D – WATER NETWORK

E - DRAIN CHANNEL

F. 6

C

D

E

F. 5

A

B B

B

B

F. 7

G

F

H

I

10.3 Water connection

Warning! Water hardness should not be less than 8°F.

We recommend that the machine be supplied with water treated

by a descaling device, particularly for water with high content of

calcium and magnesium (hard water). Make sure the water network

provides drinkable water, with pressure ranging between 1 and 8

bars.

- Connect the water softener (C) to the water network (D).

NB before connecting the water softener to the machine,

wash the machine until the water is clear.

• Connect a drain tube to the coupling (H - F. 7) and fix it with a

rack clamp.

• Connect (using tube and coupling made of food materials only)

the machine to the drinking water network, through the coupling

(I - F. 7).

• Insert the draining and filling pipes into hole A.

MACHINE FRONT

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 8

English

154

10.5 Serial port connection

Through the serial port the machine can be connected to the

AUTHORIZED CUSTOMER SERVICE CENTER’s equipment, for

checks or programming operations (A - F. 10).

• Check if the electric cables of the system are

proportioned to the machine power consumption.

The connection point (electric plug or all-pole switch) must

be located in an easily reachable place, in order to

disconnect the machine from the electric line in case of

need.

• Connect the cord (G - F. 7) to the electric network.

F. 1 0

A

10.4 Electric connection

NOTE - In case of plants with a 400 V two-phase current, use

the two phases to supply the machine with 230 V single

phase current (F. 8). As for the 230 V single-phase

connection, require the special installation kit (code

%1034.R09).

• Place the machine on the support and insert the electric power

cord (G - F. 7) in the hole (A).

F. 8

F. 9

CEI

L

1

L

2

N

L

2

L

1

Neutral (N) – Blue

Phase (L1) – Brown

Phase (L2) – Black

Ground – Yellow/green

CH

(Switzerland)

Power cord type H07RNF

section 4x2,5 mm

2

Connection of the two phase electric line plug 400 V2N~

Depending on the current regulations of the Country where

the machine operates, the cable connecting the electric

line has to be pre-set or equipped with an all-pole switch

(with a minimum contact opening of 3 mm), (or with a

plug in accordance with the same regulations).

• The all-pole switch has to be adequate to the machine

power consumption and must be able to intercept every

voltage polarity.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 9

English

155

12.1 Machine statuses

With regard to the power supply, the machine can have the

following statuses:

Off and electrically insulated

- Main switch (18) and all-pole switch on the ”0“ position

(or plug disconnected).

- Only the memory for the programmed data storing is enabled.

On

- Main switch (18) and all-pole switch on the “I“ position (or

plug connected).

- All the functions are enabled and the display (8a) is on.

In standby mode (machine switched off but not electrically

insulated):

- Main switch (18) is on “I” position.

- The following functions are enabled: “AUTOM. SWITCHING-

ON”, “ANTI-FREEZING”, if selected, and “CLOCK”, as

well as the display and the memory for the programmed data

storing.

- The display’s backlight is off.

12.2 Manual switching-on

This switching-on is necessary when the machine is in the “off

and electrically insulated” status (Pr. 12.1). Proceed as

explained is Pr. 11 excluding, in case, the beverage brewing

check.

12.3 Programmed automatic

switching-on

The machine has to be on “STANDBY” and the function “AUTOM.

SWITCHING-ON” has to be enabled.

The machine will automatically switch-on at the programmed time.

12.4 Stand-by temporary switching-on

Manual switching-on when the machine on “STANDBY”.

Press and hold the button

for 3 seconds.

The machine will automatically return on “STANDBY”, 60

minutes after the last operation.

12 - USE OF THE MACHINE

Read carefully this brochure until you get a good

understanding of the machine, before starting to operate

it.

After a long time of machine inactivity, read the previous

paragraph “First switching-on” before re-operating

the machine.

11 - FIRST SWITCHING-ON

- Fill the hopper (6) with the selected coffee beans blend.

Be sure the coffee does not contain foreign bodies which

could be dangerous for grinders.

- Check if the removable components (13 and 16) are in the

right position and if the door (15) is closed.

If they are not, when the machine is switched-on, the display

will indicate which component is in the wrong position.

- Turn the all-pole switch on “I”.

- Switch on the machine through the switch (18);

the message “WARMING UP” will be displayed.

- When the message “READY FOR USE” is displayed :

- Adjust the brew group (22) to obtain the suitable height

depending on the container used (Pr. 8.4).

- Place one or two containers under the brew group.

- Select the beverage and press the corresponding button.

Although buttons are previously programmed on a

standard base, check your beverage has the selected

features. If not, they must be reprogrammed (Pr. 12.6).

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 10

English

156

12.5 Control panel

The brewing buttons have to be pressed for less

than 1 second.

It switches the machine temporarily on (“STANDBY”)

and confirms the buttons (H - G) selection.

F

1 strong

coffee

Weak

Strong

Weak

Strong

2 strong

coffee

1 weak

coffee

2 weak

coffee

LIGHT COFFEE Brewing obtained from pre-ground coffee doses and instantly-ground coffee

COFFEE IN JUG Multiple automatic coffee brewing.

COFFEE WITH A DASH OF MILK Brewing obtained from ground coffee and a small milk dose

CAPPUCCINO Brewing obtained from hot milk and one ground coffee dose

HOT MILK Brewing obtained from milk

HOT WATER (except COFFEE set-up) Brewing obtained from water.

(*)

(*)

(*)

COFFEE Brewing obtained from instantly-ground coffee

PREGROUND COFFEE Brewing obtained from pre-ground coffee doses.

• The definitions “Strong coffee” - “Weak coffee” mean two different levels of brewing.

• When sold, the machines are programmed on a standard base.

• This brewing is programmed only for a single pre-ground coffee dose

introduced instantly in the machine.

• Press the button (once for “Pre-ground Coffee”, twice for “Coffee light”) and introduce

one coffee dose through the door (5).

• To obtain light coffee, a small quantity of ground coffee will be added.

• Up to 8 brewings can be programmed in the same container, (max 2.5 liters). To

set the number of brewings press the button repeatedly. The number of

programmed doses will be displayed. After a 2.5 liter brewing, wait 2 minutes

before programming a new brewing.

• This beverage consists in instantly ground coffee and a small dose of hot milk.

• This beverage consists in instantly ground coffee and hot milk.

• Up to 8 brewings in the same container can be programmed (max 1 liter). Push the

button several times The number of programmed doses will be displayed.

F. 1 1

esc

ent

MILK

CAPP

esc

ent

MILK

CAPP

ABC DA LI EMGF

(**) e (***)

(**) e (***)

(***)

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 11

English

157

STEAM

(Except COFFEE set-up)

• Immerse the spout (17) in the beverage to be heated.

• Turn the knob counterclockwise (12). When the required

temperature is reached, close the knob (clockwise).

After every operation, clean the steam spout with a (damp

and clean) cloth/sponge from the residues of the previously

heated beverage.

(*) Before any brewing, place the milk suction tube (30 - F. 4)

inside the milk container.

(**) Adjust the cream quantity using the pin (24 - F. 4)

(Pr. 12.8).

12.6 Brewing buttons programming

The beverage quantities linked to the respective buttons, can be

directly programmed by keypad.

To program and re-program the buttons follow these instructions:

- Switch on the machine and prepare it for the use

- Place the container under the selected spout

- Push and hold the button. The message

“

PROGRAMMING

” will be displayed

- Release the button and set the dose to be brewed

(***) N.B.: Keys

, and can be preset for brewing

beverages with any possible combination of milk and coffee. Please refer to an authorized customer service center

to change default settings.

Here is the button programming scheme.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 12

English

158

COFFEE

COFFEE WITH A DASH OF MILK

CAPPUCCINO

HOT MILK

COFFE IN JUG

HOT WATER

START

STOP

START

STOP

START

STOP

START

STOP

START

STOP

START

STOP

START

STOP

START

STOP

Brewing

Brewing

Brewing

BrewingBrewing

Brewing Brewing

Brewing

-

Hold

--

Hold

-

-

Hold

--

Hold

-

-

Hold

-

-

Hold

-

-

Hold

-

(5 sec)

(7 sec)

(7 sec)

(7 sec)

The message

“MILK PROGRAMMING”

will be displayed

M

I

L

K

M

I

L

K

C

O

F

F

E

E

C

O

F

F

E

E

to program the other coffees follow the above instructions via the following buttons:

-Hold-

2 strong coffees

1 weak coffee and 2 weak coffees

1 strong coffee

The message

“MILK PROGRAMMING”

will be displayed

The message

“MILK PROGRAMMING”

will be displayed

NOTE - This programming is only possible if the

function “PROGRAMM. HOT WATER”

is on the “ON” mode (Pr. 12.7.1).

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 13

English

159

12.7 Menu programmable functions

NOTE - The machine allows some adjustments and setting-ups

through the menu programming, in order to meet all

customer requirements.

During the programming the following buttons take on a

different function from the one they usually have during

the use of the machine

(programming to enter the programming menu

access) hold it for 5 sec.

(the message:

““

““

“

PROGRAMMINGPROGRAMMING

PROGRAMMINGPROGRAMMING

PROGRAMMING

””

””

”

will be displayed);

(Enter) to switch from one menu level to the

following; to prepare a datum for the

adjustment; to confirm a datum or a

function;

(Escape) to cancel the non-confirmed adjustments;

to go back to the previous level, up to

the menu exit.

(Down) go to the following item in the same

programming level; increase the value

of the datum to be adjusted.

(Up) go to the previous item in the same

programming level; decrease the value

of the datum to be adjusted.

Some functions also enable the programming of one or more

data (already programmed on standard figures).

To adjust the figures to be re-programmed:

- Select the function.

- Confirm the function through the button

(Enter).

- The cursor will blink under the figure to be adjusted.

- Press the buttons

(Up) or (Down) to adjust its value.

- Confirm the adjustment through the button (Enter).

PROGRAMMING

5 sec.

LANGUAGE

CUP WARMING PLATE

GROUND DOSE

TEMPERATURES

PREBREWING

PROGR. HOT WATER

MILK PROGRAMMING

HOT WATER MIXING

PROGRAMMED CLEANING

BREW GROUP CLEANING

CLOCK

AUTOM. SWITCHING-ON

TIMES ON/OFF

COUNTERS

ANTI-FREEZING

UNBLOCK

CODE: 0000

OFF

ON

OFF4: mtwtfss 00:00

OFF3: mtwtfss 00:00

ON 4: mtwtfss 00:00

ON 3: mtwtfss 00:00

OFF1: mtwtfss 00:00

ON 1: mtwtfss 00:00

OFF2: mtwtfss 00:00

ON 2: mtwtfss 00:00

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

SHORT

LONG

MIN. XXX

FOLLOW INSTRUCTIONS

16:34 THU 8 NOV 2001

FIRST COFFEE

COFFEE

LOW

HIGH

STANDARD

LOW

HIGH

STANDARD

COFFEE WITH A

DASH OF MILK

CAPPUCCINO

JUG

2 WEAK COFFEES

1 WEAK COFFEE

1 STRONG COFFEE

2 STRONG COFFEES

OFF

ON

ECC.

FRANCAIS

DEUTSCH

ITALIANO

WATER TOTAL 000000

COFFEE TOTAL 000000

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 14

English

160

12.7.1 Description of functions

LANGUAGE

- Language can be selected through the “LANGUAGE” menu

.

CUP WARMING PLATE

- By selecting “ON”, the cup warming plate is switched on

together with the machine.

- By selecting “OFF”, the cup warming plate remains off.

GROUND DOSE

The quantity of ground coffee, programmed during the installation,

can be adjusted at every brewing.

- By selecting “LOW” or “HIGH”, the dose is decreased or

increased by 1 g.

- By selecting “STANDARD”, the machine will brew the dose

initially programmed by the Maintenance Technician.

TEMPERATURES

The brewing temperature of water, programmed during the

installation, can be adjusted at every brewing.

- By selecting “LOW” the temperature decreases by 3°C.

- By selecting “HIGH” the temperature increases by 3 °C.

- By selecting “STANDARD” the temperature will the one

programmed by the Maintenance Technician.

NOTE - The temperature “first coffee” is selected at the first

brewing, when the machine is switched on.

PREBREWING

This function allows a short dwell time during the first brewing

phase. This can improve the quality of the coffee which, during the

dwell, has the time to “infuse” into the first part of water received.

Selecting:

- “OFF”, no pre-brewing is performed.

- “SHORT”, the “pre-brewing” programmed by the Maintenance

Technician is performed.

- “LONG”, the “pre-brewing” is extended by 1 sec.

PROGR. HOT WATER

This function enables to set the quantity of brewed hot water. By

selecting:

- “ON”, the button

, (Pr. 12.6) can be programmed.

- “OFF”, the button

cannot be programmed, therefore the

quantity of hot water has to be manually adjusted.

functions explanation

follows in the next page

PROGRAMMING

LANGUAGE

CUP WARMING PLATE

GROUND DOSE

TEMPERATURES

PREBREWING

ITALIANO

DEUTSCH

FRANCAIS

ECC.

ON

OFF

1 STRONG COFFEE

1 WEAK COFFEE

2 WEAK COFFEES

CAPPUCCINO

JUG

COFFEE

FIRST COFFEE

LOW

LOW

STANDARD

HIGH

STANDARD

HIGH

OFF

SHORT

PROGR. HOT WATER

ON

OFF

LONG

MILK PROGRAMMING

2 STRONG COFFEES

COFFEE WITH A

DASH OF MILK

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 15

English

161

MILK PROGRAMMING

The milk quantity programming can be enabled by selecting:

- “

ON

”, the button (Pr. 12.6) is programmed .

- “

OFF

”, the button cannot be programmed, and the dose

has to be manually adjusted.

HOT WATER MIXING

While the different types of beverages are brewed, the machine

adds a certain amount of hot water, according to the programming.

By selecting:

- “

ON

”, the mixing is performed

- “

OFF

”, NO hot water will be added to the beverage.

NOTE - If the function is disabled the programmed figures remain

unchanged and ready to be used when the function is

re-activated.

PROGRAMMED CLEANING

This function enables the brewing of a small hot water quantity

(abt 5 cc), in order to avoid any deposits in the brew group. This

cleaning starts automatically after the programmed time (20÷ 240

minutes), from the last coffee brewing. By selecting:

- “

ON

”, the adjustment cursor blinks under the last right figure,

and the value can be increased or decreased by 10 min;

every adjustment must always be confirmed.

- “

OFF

”, no cleaning is performed.

NOTE - During the cleaning, the message

“PROGRAMMED“PROGRAMMED

“PROGRAMMED“PROGRAMMED

“PROGRAMMED

CLEANING”CLEANING”

CLEANING”CLEANING”

CLEANING”

will be displayed

;

cleaning can also be activated manually by holding the

button

for 3 seconds.

BREW GROUP CLEANING

This function enables the cleaning of the brew group (27) using

the provided tablets (for any information about tablets ask to an

Authorized Customer Service Center).

Procedures:

- The process begins from: “BREW GROUP CLEANING”.

- Press

; on display: “INSERT TABLET IN THE GROUP”.

- Remove the brew group; on display: “INSERT THE GROUP”;

- Put the tablet inside the brew group and refit the group; on

display: “CLOSE DOOR”.

- Close the door; on display: “CLEANING IN PROGRESS”.

The cleaning cycle begins; at the end of the cycle the message

on display will be “REMOVE THE GROUP AND WASH IN

WATER”.

- Remove the brew group; on display: “INSERT THE GROUP”.

- Wash the brew group in running water.

- Refit the brew group; on display: “CLOSE DOOR”

- Close the door; on display: “CLEANING COMPLETED.

PRESS STAR BUTTON” ;

Press

to exit the menu definitely and make the machine ready

to be used.

CLOCK

This function enables the clock and calendar set-up.

- By selecting “CLOCK”, the cursor blinks on the hours, that can

thus be adjusted.

- After confirming the hour setting, the cursor moves on the next

figure to be adjusted (the minutes, then the day, the month

and finally the year).

PROGR. HOT WATER

MILK PROGRAMMING

HOT WATER MIXING

PROGRAMMED CLEANING

BREW GRO UP CLEANING

CLOCK

AUTOM. SWITCHING-ON

ON

OFF

ON MIN. 240

OFF

INSERT TABLET

IN THE GROUP

INSERT THE GROUP

CLOSE DOOR

CLEANING IN PROGRESS

REMOVE THE GROUP AND

WASH IN WATER

INSERT THE GROUP

CLOSE DOOR

CLEANING COMPLETED

PRESS STAR BUTTON

16:34 GI 8 NOV 2001

ON

OFF

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 16

English

162

TIMES ON/OFF

This function enables to program the automatic switching-on and

off times over a whole week.

- By selecting “TIMES ON/OFF”, the cursor blinks on the day

to be modified.

- Enter the day, using the button

(down), turning the small

letter into a capital one.

- Remove the day from the setting, using the button

(up), turning

the capital letter into a small one.

- Confirm the adjustment.

To set the time use the same procedure followed to set the clock.

Example:

the function explanation scheme shows a machine

programming which schedules the machine switching-on at 08:00

and the switching-off at 18:00 from Monday to Friday. The

switching-on at 09:00 and off at 12:30 on Saturday, and a stop

over the whole Sunday.

COUNTERS

One of these two functions indicates the total number of coffee

brewing cycles; the other indicates the number of hot water brewing

cycles.

If the automatic dosing of hot water is disabled (see “HOT WATER

PROG.” function), one cycle will be counted every time the

electrovalve is switched-on.

NOTE - Both functions cannot be reset and are just reference

functions.

ANTI-FREEZING

When the machine on “STANDBY” is exposed to low

temperatures, the anti-freezing function is important to prevent the

damages caused by icing-up in boilers. This function keeps the

boilers temperature at the minimum value to prevent freezing.

- By selecting “ON”, the function is enabled.

- By selecting “OFF”, the function is disabled.

NOTE - This function can only be enabled if also function

“AUTOM. SWITCHING-ON”

is on and if the machine

is on

“STANDBY”

. When the function is enabled the

message

“ANTI-FREEZING”

will be displayed.

UNBLOCK

This function enables to temporarily unblock the machine when the

number of cycles programmed for maintenance and descaling

has been reached. To get the unblock code refer to the firm that

has installed the machine or that supplies maintenance. Then enter

the code into the function:

- Select “UNBLOCK”; the cursor will blink under the first figure to

be modified;

- enter the datum and confirm;

- after every confirmation, the cursor blinks under the following

figure and goes on until the code is completed.

AUTOM. SWITCHING-ON

This function enables the programming of automatic switching-on

and off of the machine, in two different time ranges, every day of

the week. By selecting:

- “ON”, the function can be programmed .

- “OFF”, the machine can only be switched on and off manually,

through the main switch (18).

Any automatic switching-on and off times previously set, remain

stored anyway.

- To program the time ranges and the days see the following

function “TIMES ON/OFF”.

NOTE - The automatic switching-on of the machine is possible

only if the main switch (18) is on the “I” position.

CLOCK

AUTOM. SWITCHING-ON

TIMES ON/OFF

COUNTERS

ANTI-FREEZING

UNBLOCK

CODE: 0000

OFF

ON

OFF4: mtwtfss 00:00

OFF3: mtwtfss 00:00

ON 4: mtwtfss 00:00

ON 3: mtwtfss 00:00

OFF1: mtwtfss 00:00

ON 1: mtwtfss 00:00

OFF2: mtwtfss 00:00

ON 2: mtwtfss 00:00

OFF

ON

COFFEE TOTALE 000000

WATER TOTALE 000000

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 17

English

163

12.10 Grind adjustment

Whatever the coffee blend is, a very fine grinding (notch

on low values) increases the density, the cream quantity

and the brewing time of the beverage. On the contrary a

coarse grinding (notch on high values) decreases the

density, the cream, as well as the brewing time.

Do not turn the knob counterclockwise to the limit stop

(19 - F. 14); this action causes the grinders tightening

and the consequent machine block.

If any foreign body in the coffee blend should cause the

block of grinders and the subsequent block of the

machine(on display:

“GRINDER ERROR”

), refer to an

Authorized Customer Service Center.

NOTE - The grinding is preset by the Manufacturer on standard

values, but it can be adjusted in the following way:

• Open the door (15 - F. 14), turn the knob (19 - F. 14)

anticlockwise to obtain a finer grinding (the notch moves onto

lower values), and clockwise to obtain a coarser grinding (the

notch moves onto higher values).

F. 1 2

19

F. 1 4

15

12.8 Cream adjustment

The quality of the cream in the beverages depends on the use of

the adjustment lever (24).

• By turning the lever clockwise, there will be a greater quantity

of cream.

• By turning the lever anti-clockwise, there will be a smaller quantity

of cream.

F. 1 3

C°-

C°+

12.9 Temperature setting

Milk temperature is adjusted through lever (25).

• By turning the lever upward, the temperature will grow.

• By turning the lever downward, the temperature will lower.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 18

English

164

12.11 Display messages

NOTE - Here follows a list of alarm messages (in addition to

those explained before) that can be displayed and the

relative machine conditions.

STANDBY: the machine is switched off (the main switch is on “I”)

and the automatic switching-on/off functions enabled (Pr. 12.7.1).

ANTI-FREEZING: the machine is switched off (the main switch

is on “I”) and the function protecting boilers from icing-up is enabled

(Pr.12.7.1).

PROGRAMMED CLEANING: it is displayed when the machine is

performing the automatic cleaning of the brew group (Pr. 12.7.1).

COFFEE EMPTY, GUILLOTINE CLOSED: the machine, during the grinding, detects the lack of coffee beans in the relative

container (6), or that the guillotine is closed.

FILL CIRCUIT: this message is displayed if the machine detects

the lack of water in the boilers during a beverage brewing.

After checking if there is actually water in the supply network,

press the button

( ^ in the COFFEE version), until water comes

out properly from the spout (11) and from the brew group (22). In

the “COFFEE” version the water comes out only from the brew

group

PROGRAMMING: it is displayed during the machine programming

(Pr. 12.6).

REMOVE GROUNDS: it is displayed if the dump box (16) is almost

full (the machine performed the programmed number of brewings).

More brewings can anyway be performed.

OUT OF SERVICE – REMOVE GROUNDS: the dump box (16)

is completely full (the machine performed the programmed number

of brewings).

The machine is blocked and no more brewings can be performed

until the dump box is emptied.

CLOSE DOOR: the door (15) is not properly closed.

INSERT BOX: the dump box (16) is not properly inserted.

INSERT DRIP TRAY: the powder tray (12) is not properly in

place.

INSERT GROUP: the brew group (27) is not properly inserted.

GROUP ERROR: the brew group (27) is not properly performing

his working cycle; switch the machine off and call the AUTHORIZED

CUSTOMER SERVICE CENTER.

PUMP ERROR: one of the pumps is damaged. Switch the machine

off and call the AUTHORIZED CUSTOMER SERVICE CENTER.

SENSOR ERROR 01: is displayed when a temperature sensor

fails. Switch the machine off and call the AUTHORIZED CUSTOMER

SERVICE CENTER.

TEMPER. ERROR 01: is displayed when one of the boilers

resistance is damaged. Switch the machine off and call the

AUTHORIZED CUSTOMER SERVICE CENTER.

DESCALING: it is displayed when the machine needs a descaling

intervention, and after performing the programmed number of

brewings. Switch the machine off and call the AUTHORIZED

CUSTOMER SERVICE CENTER.

The descaling interventions are set on working cycles of the

machine, and can be programmed by the maintenance

technician.

MAINTENANCE: it is displayed when the machine needs

maintenance and after performing the programmed number of

brewings. Switch the machine off and refer to the AUTHORIZED

CUSTOMER SERVICE CENTER.

The maintenance interventions are set on working cycles of the

machine, and can be programmed by the maintenance

technician.

12.12 Machine switching-off

Programmed automatic switching-off

This is possible when the function “AUTOM.SWITCHING-ON”

(Pr. 12.7.1) is enabled and the function “TIMES ON/OFF”

(Pr. 12.7.1) has been programmed .

At the programmed time the machine goes on “STANDBY”.

Manual switching-off

This switching-off is necessary if the function “AUTOM.

SWITCHING-ON” (Pr. 12.7.1) is not enabled.

It can be obtained by switching both the main switch (18) and the

all-pole switch on the “0” position or by disconnecting the plug.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 19

English

165

13 - ROUTINE

MAINTENANCE

Warning

• In case of troubles, usually indicated on display, switch

the machine immediately off, disconnect the power supply

through the all-pole switch or by disconnecting the plug, and

call the nearest CUSTOMER SERVICE.

•

Before intervening with any type of maintenance or

cleaning, disconnect the power supply through the main switch

(18) and the all-pole switch(or disconnecting the plug).

•

Any operation must be done when the machine is cool.

•

Never perform any cleaning operation when the machine

is on

“STANDBY”

.

•

Never wash any part of the machine in the dishwasher.

•

Do not use direct water jets.

13.1 Machine cleaning

If you need to open the machine door, position the brew

group at the bottom. Any different position of the brew

group would make the door opening impossible.

• The cleaning must be done every day and before an extended

out-of-service times, in order to avoid the solidification of residues

in containers, trays and brew groups.

• The removable parts of the machine which have to be cleaned,

must be washed and rinsed in running water.

• To clean coatings, panels and the machine controls, use soft

cloths moderately soaked in warm water.

• To clean the fixed parts and the very machine, use only cold

or warm water, non-abrasive sponges and damp cloths.

• All the parts to be cleaned are easily reachable and do not

require the use of any tool.

Routine maintenance and cleaning preserve and extend

the machine efficiency and durability, as well as granting

the respect of the hygienic standard regulations.

The machine automatically indicates when maintenance

and descaling operations are required. The exact number

of brewings is indicated by the mechanical counter or by

the machine display. If the Maintenance Technician fails

to intervene, the machine could block.

13.1.1 Brew group (F. 15)

The following can be removed:

- the upper protection cover (A), of the dispenser by pulling it

outwards;

- the lower protection cover (D) of the dispenser, by unscrewing

the bottom knob;

- the brew group (C-E) by pulling it outwards;

- the coffee fitting (B) by turning it approx. 90 degrees.

F. 1 5

A

B

C

D

E

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 20

English

166

13.1.2 Brew group (F. 16)

Cleaning must be carried out with the group empty.

• Periodically clean the brew group using the special tablets

(Pr. “12.7.1 Explanation of functions – CLEANING GROUP”).

- Remove the brew group (28) pulling the appropriate handle

(A) and pressing the button marked by “PRESS”.

- Wash abundantly with warm water.

Do not use detergents.

- Delicately scrape the upper filter (B) with a plastic coffee spoon.

13.1.3 Drip tray and relative grill

Remove the drip tray (13) from the machine and wash it with

running water, paying particular attention to the grill.

13.1.4 Dump box

Remove the drip tray (13), remove the dump box (16) from its

place and then wash it with running water .

13.1.5 Steam and hot water spouts

(except COFFEE set-up)

Clean the spouts (11-17) with a non-abrasive damp cloth.

If the nozzles are clogged the final section of the spouts can be

unscrewed, and the nozzles can be cleared with a pin.

13.1.6 Cup warming plate

Use a non abrasive damp cloth to clean the cup warming plate

(4).

13.1.7 Coffee bean hopper

Use a non abrasive damp cloth to clean the coffee bean hopper

(6).

13.1.8 Cappuccinatore cleaning

Never clean the cappuccinatore when the machine is on

“standby”.

Every time the CAPPUCCINATORE is used, it must be

cleaned in order to avoid the solidification of residues.

All the removable parts must be washed and rinsed in

running water.

13.1.9 Cappuccino brew group (F. 17)

To clean each part of the cappuccinatore group separately, remove:

- the top protection cover (23), by pulling it outwards;

- remove the cappuccinatore (29) by pulling it outwards;

- the fork (32);

- the cream adjustment lever (24);

- la temperature setting lever (25);

- the cappuccinatore body cap (33);

- the fitting (31) connecting the suction pipe to the body of the

cappuccinatore;

- the milk dispenser (26);

- milk suction tube (30)

F. 1 7

F. 1 6

B

27

A

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 21

English

167

14 - UNSCHEDULED

MAINTENANCE

NOTE- Unscheduled maintenance includes every repairing or

part replacing. The Maintenance Technician is the

only person authorized to perform these operations.

14.1 Jamming of the coffee grinder

unit

• A foreign body among the coffee beans can cause the grinders

jamming and the subsequent machine block; the message

“GRINDER ERROR” will be displayed.

• In this case open the coffee grinder unit (20) and remove the

foreign body.

14.1.1 Grinder unit assembly/disassembly

• Close the bean hopper (H) bulkhead (A)

• Remove the screws (B) from the container using the appropriate

tool (C). Remove the container from the machine pulling

upwards.

• Remove the coffee beans on the grinder’s top with a vacuum

cleaner.

• Remove the screws (D).

• Remove the gearwheel (E).

• Unscrew and remove the adjustment ring nut (F) and clean

both grinders with a vacuum cleaner and a brush.

Check the grinder’s degree of wear. In case of manifest

damages, they must be replaced.

F. 1 8

H

B

H

A

C

F. 1 9

F. 2 0

D

E

D

F. 2 1

F

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 22

English

168

To re-assemble the coffee grinder unit, do as follows:

• Screw fully the adjustment ring nut (F), then unscrew it

by 1/2 turn.

This 1/2 turn untightening of ring nut is necessary to

avoid grinders jamming and damage.

• Replace the gearwheel (E) and fix it tightening the screws (D).

• Replace the coffee bean hopper (H).

Be careful to place the gasket properly (G). It has to

correctly engage with the gearwheel (E) and the ring nut

(F).

• Fix the container (H) tightening the screws (B) with the

appropriate tool (C).

• Open the bulkhead (A).

Before re-operating the machine, a new grind

adjustment is required.

15 - OUT OF SERVICE

In case you will put the machine out of service, disconnect the

power and the water supply, empty the drip trays, boilers and

piping and clean the machine (Pr. “13.1 Machine cleaning”).

If the machine is scrapped, the different materials composing

the machine have to be separated and disposed of according to

their composition and to the current State regulations.

F. 2 3

F. 2 2

F

G

E

F

B

H

C

F. 2 4

A

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Page 23

English

169

16 - TROUBLES, CAUSES

AND CURES

TROUBLE CAUSE

CURE

The machine does not start

Display message:

““

““

“

DUMPDUMP

DUMPDUMP

DUMP

BOXBOX

BOXBOX

BOX

FULLFULL

FULLFULL

FULL

””

””

”

Grinder error

Instead of coffee only water is

brewed

No water or steam supply

Coffee flows too rapidly

Coffee flows too slowly

Coffee is not hot enough

Coffee has not enough cream

The machine requires too much time

to warm up, the water quantity is

reduced

The brew group cannot be removed

The brew group cannot be refit

The cappuccinatore does not dispense

milk

No voltage

Dump box full

Coffee grinder unit blocked

The button selecting pre-ground coffee has

been pressed but the relative container has

not been filled with instant coffee.

The steam/hot water spout’s hole is

clogged

Grinding is too coarse

Grinding is too fine

The cup has not been preheated

The machine has not yet reached the

suitable temperature

The coffee blend is not appropriate, coffee

is not fresh off the roasting, the coffee powder

has been ground too finely or too coarsely.

The machine circuit is clogged by scale

The brew group is not in the right position

(N)

The brew group is not in the right position

(N)

The milk used is not cold enough (see warnings)

No more milk in the container

Check:

- if the plug is connected

- if the all-pole switch (if any) is on

- the system fuses

- the electric connections

Empty the dump box and reintroduce it

properly

Clean the coffee grinder (Pr. “14.1

Jamming of the coffee grinder unit”)

Place the coffee dose in the relative hopper

and restart the cycle

Clean it with a thin needle

Set a finer grinding

Set a coarser grinding

Preheat the cup on the cup warming plate

Wait for the machine to reach the suitable

temperature

Change the coffee blend or check its

grinding (if pre-ground)

Descale the machine

Switch the machine on and off through the

main switch

Manually turn the group onto the standard

position (N), matching the reference mark

placed on the structure with the arrow N (F. 16)

Move the temperature adjusting lever

downward

Fill milk container

Here is a list of the possible machine troubles.

The symbol

in the “cure” box means that the operation must be carried out by the Maintenance Technician only.

Espresso Italia PTY LTD

www.espressoitalia.com.au

Freecall 1300 660 976

Loading...

Loading...