Page 1

RLT26CDS

FR

COUPE-BORDURES MANUEL D’UTILISATION 1

EN

STRING TRIMMER USER’S MANUAL 10

DE

KANTENSCHNEIDER BEDIENUNGSANLEITUNG 18

ES

RECORTADORA DE HILO MANUAL DE UTILIZACIÓN 27

IT

TAGLIABORDI MANUALE D’USO 36

PT

APARADOR DE RELVA MANUAL DE UTILIZAÇÃO 45

NL

GRASTRIMMER GEBRUIKERSHANDLEIDING 54

SV

TRIMMER INSTRUKTIONSBOK 63

DA

TRÅDTRIMMER BRUGERVEJLEDNING 71

NO

TRÅDTRIMMER BRUKSANVISNING 79

FI

SIIMALEIKKURI KÄYTTÄJÄN KÄSIKIRJA 87

HU

SZEGÉLYVÁGÓ HASZNÁLATI ÚTMUTATÓ 95

CS

STRUNOVÁ SEKAČKA NÁVOD K OBSLUZE 104

RU

ЕЦзбйдйлД кмдйЗйСлнЗй ий щдлигмДнДсаа 112

RO

TRIMMER MANUAL DE UTILIZARE 121

PL

PODKASZARKA DO OBRZEŻY INSTRUKCJA OBSŁUGI 130

SL

KOSILNICA Z NITKO UPORABNIŠKI PRIROČNIK 139

HR

©I©A» KORISNI»KI PRIRU»NIK 148

ET

TRIMMER KASUTAJAJUHEND 157

LT

ŽOLIAPJOVĖ NAUDOJIMO VADOVAS 166

LV

ROKAS PĻAUJMAŠĪNA LIETOTĀJA ROKASGRĀMATA 175

SK

STRUNOVÁ KOSAČKA - VYŽÍNAČ NÁVOD NA POUŽITIE 184

BG

нкаеЦк кцдйЗйСлнЗй бД мийнкЦЕД 193

Important! It is essential that you read the instructions in this manual before mounting and operating

this machine.

Page 2

Attention ! Il est indispensable que vous lisiez les instructions contenues dans ce manuel avant

Important! It is essential that you read the instructions in this manual before mounting and operating

Achtung! Bitte lesen Sie unbedingt vor Montage und Inbetriebnahme die Hinweise dieser Bedienungsanleitung.

¡Atención! Es imprescindible que lea las instrucciones de este manual antes del montaje y de la

Attenzione! Prima di procedere al montaggio e alla messa in funzione, è indispensabile leggere

Atenção! É indispensável ler as instruções deste manual antes de montar e pôr em serviço.

Let op ! Het is absoluut noodzakelijk vóór montage en inbedrijfstelling de aanwijzingen in deze

Observera! Det är nödvändigt att läsa instruktionerna i denna bruksanvisning före montering och

OBS! Denne brugsanvisning skal læses igennem inden montering og ibrugtagning.

Advarsel! Vennligst les instruksjonene i denne bruksanvisningen før du monterer og tar i bruk

Huomio! On ehdottoman välttämätöntä lukea tässä käyttöohjeessa annetut ohjeet ennen

!

Figyelem! Feltétlenül fontos, hogy a jelen használati útmutatóban foglalt előírásokat az

Důležité upozornění! Před montáží nářadí a uvedením do provozu je nutné si přečíst následující pokyny.

ÇÌËχÌËe! иee‰ Т·УНУИ Л Б‡ФЫТНУП ЛМТЪЫПeМЪ‡ МeУ·ıУ‰ЛПУ ФУ˜eТЪ¸ ЛМТЪЫНˆЛЛ ЛБ М‡ТЪУfl˘e„У

Atenie! Este indispensabil sã citii instruciunile coninute în acest mod de utilizare înainte de montaj

Uwaga! Przed montowaniem i uruchomieniem, koniecznie musicie się Państwo zapoznać

Pomembno! Zelo pomembno je, da pred namestitvijo in prvo uporabo te naprave preberete

Upozorenje!

Dikkat! Montajdan ve aletin kullanımına başlamadan bu kılavuzda bulunan talimatları

Tähtis! Lugege enne seadme kokkupanekut ja kasutamist kindlasti läbi selles juhendis

Dėmesio! Prieš surinkdami ir paleisdami aparatą į darbą, reikia, kad jūs perskaitytumėte šiame

Uzmanību! Ir ļoti būtiski, lai jūs izlasītu norādījumus, kas sniegti šajā rokasgrāmatā, pirms ķeraties

Upzornenie! Je dôležité, aby ste si pred montážou a spustením zariadenia prečítali pokyny, ktoré sa

ÇÌËχÌËÂ! иВ‰Л Т„ОУ·fl‚‡МВ Л ФЫТН‡МВ М‡ П‡¯ЛМ‡Ъ‡ В ‚‡КМУ ‰‡ ФУ˜ВЪВЪВ ЛМТЪЫНˆЛЛЪВ ‚

Vaæno je da upute u ovom KorisniËkom priruËniku proËitate prije postavljanja i uporabe ovog alata.

le montage et la mise en service de l’appareil.

this machine.

puesta en servicio.

attentamente le istruzioni del presente manuale.

handleiding te lezen.

driftsättning.

maskinen.

asennusta ja käyttöönottoa.

összeszerelés és az üzembe helyezés ellőt elolvassa!

ÛÍÓ‚Ó‰ÒÚ‚‡.

i de punerea în funciune.

z zaleceniami zawartymi w niniejszym sposobie użycia.

navodila v tem priročniku.

okumanız gerekmektedir.

sisalduvad eeskirjad ja juhised!

vadove esančias instrukcijas.

pie ierīces montēšanas un iedarbināšanas!

nachádzajú v tomto návode.

˙ÍÓ‚Ó‰ÒÚ‚ÓÚÓ Á‡ ÛÔÓÚ·‡.

Page 3

Sous réserve de modifications techniques / Subject to technical modifications / Technische Änderungen vorbehalten /

Bajo reserva de modificaciones técnicas / Con riserva di eventuali modifiche tecniche / Com reserva de modificações técnicas /

Technische wijzigingen voorbehouden / Med förbehåll för tekniska ändringar / Med forbehold for tekniske ændringer /

Med forbehold om tekniske endringer / Tekniset muutokset varataan / ! " /

A műszaki módosítás jogát fenntartjuk / Změny technických údajů vyhrazeny /

åÓ„ÛÚ ·˚Ú¸ ‚ÌeÒeÌ˚ ÚeıÌ˘eÒÍËe ËÁÏeÌeÌËfl /

Sub rezerva modificaiilor tehnice / Z zastrzeżeniem modyfikacji technicznych / Tehnične spremembe dopuščene

Podloæno tehniËkim promjenama / Teknik düzeltmeler hakkı saklıdır / Tehnilised muudatused võimalikud /

Pasiliekant teisę daryti techninius pakeitimus / Paturam tiesības mainīt tehniskos raksturlielumus / Technické zmeny vyhradené /

èÓ‰ÎÂÊË Ì‡ ÚÂıÌ˘ÂÒÍË ÏÓ‰ËÙË͇ˆËË

Page 4

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

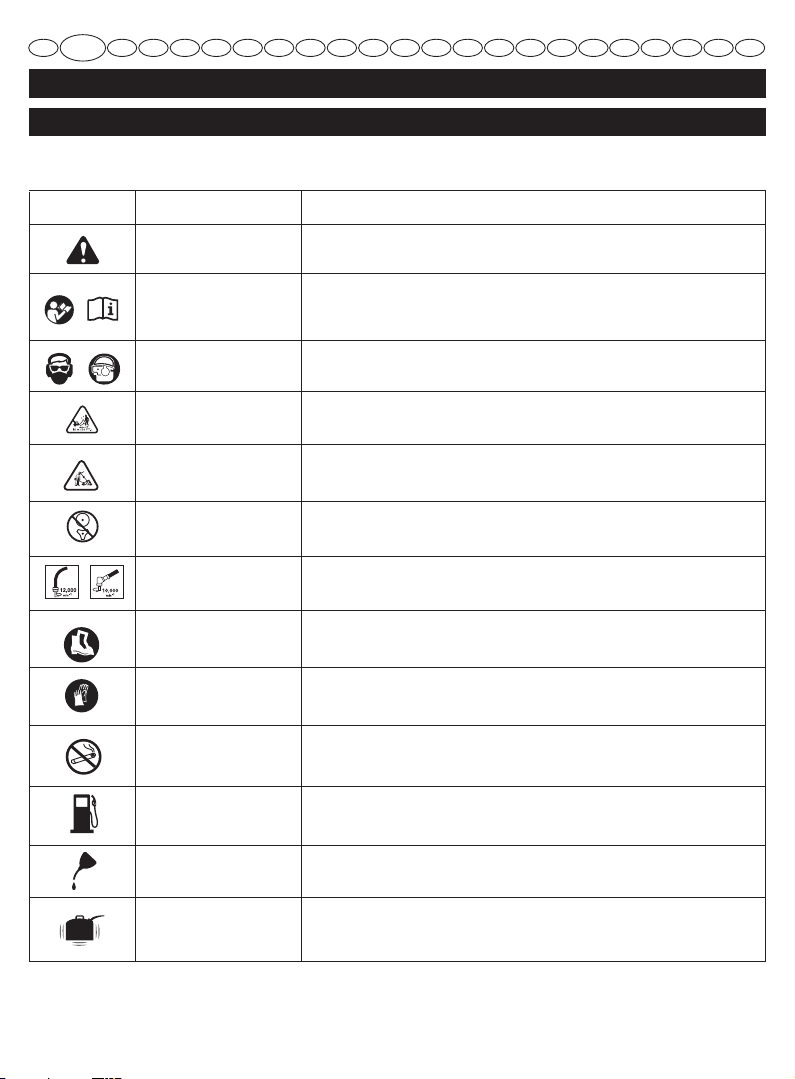

SYMBOLS

Important: Some of the following symbols may be used on your tool. Please study them and learn their meaning.

Proper interpretation of these symbols will allow you to operate the tool better and safer.

NAME EXPLANATION

Safety Alert Symbol Indicates danger, warning or caution. It means attention!!! Your safety is

involved.

Read Your Operator's Your manual contains special messages to bring attention to potential

Manual safety concerns as well as operating and servicing information. Please

read all the information carefully to ensure satisfaction and safe use.

Wear eye, hearing Wear eye, hearing and head protection when operating this equipment.

Keep bystanders away Keep all bystanders at least 15 m away.

Ricochet Danger of Ricochet.

No blade Do not install any type of blade on this unit.

RPM Decal Rotational direction and maximum speed of the shaft for the cutting

attachment.

and head protection

Boots Wear non-slip safety footwear when using this equipment.

Gloves Wear non-slip, heavy-duty gloves.

No Smoking Do not smoke when mixing fuel or filling fuel tank.

Petrol Use unleaded gasoline intended for motor vehicle use with an octane

rating of 91 ([R+M]/2) or higher.

Oil Use synthetic 2-stroke oil for air cooled engines.

Mix Petrol and Oil Mix the fuel mix thoroughly and also each time before refuelling.

10

10

Page 5

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

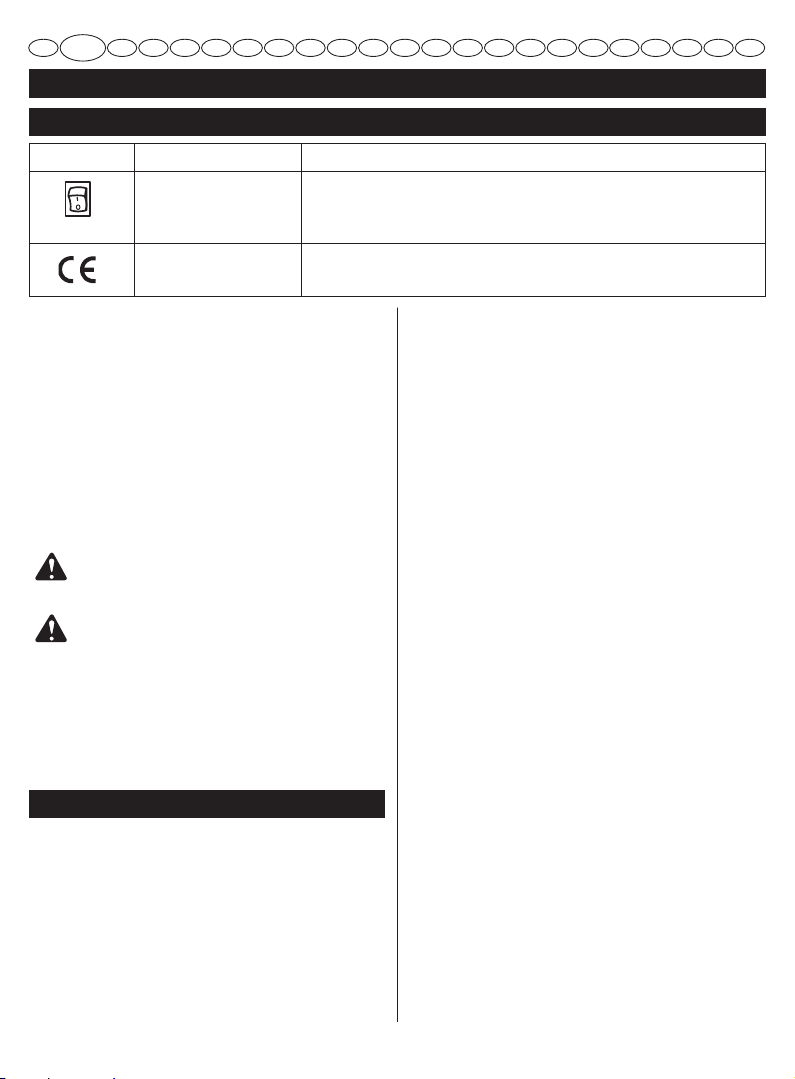

SYMBOLS

NAME EXPLANATION

Switch On/Off Switch

I = ON to Run

O = OFF to Stop

Conforms to all regulatory standards in the country in the EU where

the product is purchased.

Thank you for buying a Ryobi trimmer.

Your new trimmer has been engineered and manufactured to Ryobi’s high standard for dependability, ease

of operation, and operator safety. Properly cared for, it will

give you years of rugged, trouble-free performance.

INTENDED USE

This product should only be used outdoors.

The product is intended for cutting long grass, weed, and

similar vegetation at or about ground level. The cutting

plane should be approximately parallel to the ground

surface. The product should not be used to cut or trim

hedges, bushes or other vegetation where the cutting

plane is not parallel to the ground surface.

WARNING

To reduce the risk of injury, the user must read

and understand the operator’s manual.

WARNING

Do not attempt to operate this trimmer until you

have read thoroughly and understood completely

all instructions, safety rules etc contained in

this manual. Failure to comply may result in

accidents involving fire, electric shock or serious

personal injury. Save operator’s manual and

review frequently for continuing safe operation,

and instructing others who may use this tool.

READ ALL INSTRUCTIONS.

GENERAL SAFETY RULES

Q For safe operation, read and understand all

instructions before using the trimmer. Follow all safety

instructions. Failure to follow all safety instructions

listed below, can result in serious personal injury.

Q Do not allow children or untrained individuals to use

this unit.

Q Never start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

Q Clear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire,

or string which can be thrown or become entangled in

the bump head.

Q Wear full eye and hearing protection while operating

this unit.

Q Wear heavy long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, jewellery of

any kind, or use with bare feet.

Q Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

Q Keep all bystanders, children, and pets at least 15 m

away.

Q Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

Q Do not operate in poor lighting.

Q Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or

exposure to hot surfaces.

Q Keep all parts of your body away from any moving part.

Q Do not touch area around the muffler or cylinder of

the trimmer, these parts get hot from operation.

Q Always stop the engine and remove the spark plug

wire before making any adjustments or repairs except

for carburetor adjustments.

Q Inspect the unit before each use for loose fasteners,

fuel leaks, etc. Replace any damaged parts before use.

Q The string head will rotate during carburetor

adjustments.

Q It has been reported that vibrations from hand-held

tools may contribute to a condition called Raynaud’s

Syndrome in certain individuals. Symptoms may

include tingling, numbness and blanching of the

fingers, usually apparent upon exposure to cold.

Q Hereditary factors, exposure to cold and dampness,

diet, smoking and work practices are all thought to

contribute to the development of these symptoms.

Q It is presently unknown what, if any, vibrations or extent

of exposure may contribute to the condition. There are

measures that can be taken by the operator to possibly

reduce the effects of vibration:

a) Keep your body warm in cold weather. When

operating the unit wear gloves to keep the hands

and wrists warm. It is reported that cold weather is

a major factor contributing to Raynaud’s Syndrome.

b) After each period of operation, exercise to increase

blood circulation.

11

11

Page 6

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

c) Take frequent work breaks. Limit the amount of

exposure per day.

Q If you experience any of the symptoms of this condition,

immediately discontinue use and see your physician

about these symptoms.

Q Keep the tool well maintained, fasteners tightened

and worn parts replaced.

Q Mix and store fuel in a container approved for fuel.

Q Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

Q Stop the engine and allow to cool before refueling or

storing the unit.

Q Allow the engine to cool; empty the fuel tank and

secure the unit from moving before transporting in a

vehicle.

SPECIFIC SAFETY RULES FOR TRIMMER USE

Q Replace bump head if cracked, chipped, or damaged

in anyway. Be sure the bump head is properly

installed and securely fastened. Failure to do so can

cause serious injury.

Q Make sure all guards, straps, deflectors and handles

are properly and securely attached.

Q Use only the manufacturer's replacement line in the

cutting head. Do not use any other cutting attachment.

Q Never operate unit without the safety guard in place

and in good condition.

Q Maintain a firm grip on both handles while trimming.

Keep bump head below waist level. Never cut with

the bump head located over 76 cm or more above the

ground.

SPECIFICATION

RLT26CDS

Weight (kg)

- Without fuel, without string head, without guard 3.98

- Without fuel with string head 4.35

Fuel tank volume [cm

Cutting swath (mm) 432

Engine displacement (cm

Line diameter (mm) 2.0

Maximum engine performance

(in accordance with ISO 8893) (kW) 0.65

Maximum rotational frequency

of the the spindle (minEngine speed (rotational frequency)

at recommended max. spindle

rotational frequency (minEngine speed (rotational frequency)

at idle (minFuel consumption (in accordance

with ISO 8893) at max.

engine performance [kg/h or (L/h)] 0.33 or (0.45)

Specific fuel consumption

(in accordance with ISO 8893)

at max. engine performance [g/kW.h or (L/kW.h)] 508 or (0.7)

Vibration level idling (m/s

- Front handle 7.7

- Rear handle 4.5

Vibration level racing (m/s

- Front handle 11.1

- Rear handle 12.9

Sound pressure level

(in accordance with EN ISO 22868) [LpA (dB A)] 100

Measured sound pressure level (dB A) 108

Sound power level (in accordance

with EN ISO 22868) [LwA (dB A)] 109

3

or (L)] 250 or (0.25)

3 /

cc) 26

1

) 12,000

1

) 12,000

1

) 2,800-3,800

2

)

2

)

12

12

Page 7

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

DESCRIPTION

Please refer to Fig.1

1. Primer Bulb

2. Choke Lever

3. Fuel Cap

4. Starter Grip

5. On / Off Switch

6. Throttle Trigger

7. Rear Handle

8. Front Handle

9. Shaft

10. Safety Guard

11. Bump Head

12. Cutting Line

13. Knob

14. Throttle Lock

15. Idle Speed Screw

ASSEMBLY

Please refer to Fig. 2.

WARNING

If any parts are damaged or missing, do not

operate this tool until the parts are replaced.

Failure to heed this warning could result in

serious personal injury.

WARNING

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING

To prevent accidental starting that could cause

serious personal injury, always disconnect the

engine spark plug wire from the spark plug when

assembling parts.

WARNING

Never attach or adjust any attachment while

power head is running. Failure to stop the engine

may cause serious personal injury.

WARNING

Be certain the knob is fully tightened before

operating equipment; check it periodically for

tightness during use to avoid serious injury.

OPERATION

Read the operation manual and follow all

warnings and safety instructions.

Wear eye protection and ear protection.

Keep all bystanders, especially children and

pets, at least 15 m from the operating area.

FUEL AND REFUELING

HANDLING THE FUEL SAFELY

Q Always handle fuel with care, it is highly flammable.

Q Always refuel outdoors where there are no sparks

and flames. Do not inhale fuel vapors.

Q Do not let petrol or oil come in contact with your skin.

Q Keep petrol and oil away from the eyes. If petrol

or oil comes in contact with the eyes, wash them

immediately with clean water. If irritation is still

present, see a doctor immediately.

Q Clean up spilled petrol immediately.

MIXING THE FUEL

Q This product is powered by a 2-stroke engine and

requires pre-mixing petrol and 2-stroke oil. Pre-mix

unleaded petrol and 2-stroke engine oil in a clean

container approved for petrol.

Q This engine is certified to operate on unleaded petrol

intended for automotive use with an octane rating

of 91 ([R + M] / 2) or higher.

Q Do not use any type of pre-mixed petrol / oil from fuel

service stations, this includes the pre-mixed petrol / oil

intended for use in mopeds, motorcycles, etc.

Q Use synthetic 2-stroke oil only. Do not use automotive

oil or 2-stroke outboard oil.

Q Mix 2% synthetic 2-stroke oil into the petrol. This is a

50:1 ratio.

Q Mix the fuel thoroughly and also each time before

fueling.

Q Mix in small quantities. Do not mix quantities larger

than usable in a 30 day period. Synthetic 2-stroke oil

containing a fuel stabilizer is recommended.

FILLING THE TANK

Q Clean surface around fuel cap to prevent

contamination.

Q Loosen fuel cap slowly to release pressure and to

keep fuel from escaping around the cap.

Q Carefully pour fuel mixture into the tank. Avoid spillage.

13

13

(Fig. 3)

Page 8

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

Q Prior to replacing the fuel cap, clean and inspect

the gasket.

Q Immediately replace fuel cap and hand tighten.

Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

Note: It is normal for smoke to be emitted from a new

engine during and after first use.

WARNING

Always shut off engine before fueling. Never add

fuel to a machine with a running or hot engine.

Move at least 9 m from refueling site before

starting engine. Do not smoke!

1 Litre + 20 ml =

2 Litres + 40 ml =

3 Litres + 60 ml = 50:1 (2%)

4 Litres + 80 ml =

5 Litres + 100 ml =

STARTING AND STOPPING (Fig. 4)

WARNING

Never start or run the engine inside a closed or

poorly ventilated area; breathing exhaust fumes

can kill.

NOTE: Be sure to return the stop switch to the "I" (RUN)

position before trying to start unit.

To start a cold engine:

DO NOT squeeze the throttle trigger until the engine

starts and runs.

Lay the trimmer on a flat, bare surface.

PRIME - Press the primer bulb 10 times.

SET the start lever to the START position.

PULL the rope quickly and sharply straight up until

the engine starts.

Then squeeze the trigger to run.

NOTE: Squeezing and releasing the throttle trigger

releases the start lever to the RUN position.

If the engine stalls, set the start lever to the RUN position

". Then pull starter rope until the unit starts.

"

To start a warm engine:

Make sure carburettor is set to RUN position.

PULL the rope quickly and sharply straight up until the

engine starts.

To stop the engine:

Press and hold the switch in the stop “ O ” position until

the engine stops.

OPERATING THE TRIMMER (Fig. 5)

Hold the trimmer with the right hand on the rear handle

and the left hand on the front handle. Keep a firm grip

with both hands while in operation. Trimmer should be

held at a comfortable position with the rear handle about

hip height.

Always operate trimmer at full throttle. Cut tall

grass from the top down. This will prevent grass from

wrapping around the shaft housing and bump head

which may cause damage from overheating. If grass

becomes wrapped around the bump head, stop the

engine, disconnect the spark plug wire, and remove the

grass. Prolonged cutting at partial throttle will result in oil

dripping from the silencer.

CUTTING TIPS (Fig. 6)

When cutting make sure the cutter head is at a slight angle

as shown while still approximately parallel to the ground

surface. In tall grass cut from the top down to ensure the

moving parts do not get tangled with the long grass.

Move the head in steady strokes from right to left as you

work through the grass.

ADVANCING THE LINE (Fig. 7)

If the line becomes short, tap the head on the ground

as shown to extend more line. Take care not to ‘crash’ it

against a hard surface.

MAINTENANCE

WARNING

Use only original manufacturer's replacement

parts, accessories and attachments. Failure to

do so can cause possible injury, poor performance and may void your warranty.

You may make adjustments and repairs described

here. For other repairs, have the trimmer serviced by

an authorised service agent.

Consequences of improper maintenance may

include excess carbon deposits resulting in loss of

performance and discharge of black oily residue

dripping from the silencer.

Make sure all guards, straps, deflectors and handles

are properly and securely attached to avoid the risk of

personal injury.

the cutting attachment must not rotate in idle mode. If

this requirement is not satisfied, the idle speed needs

adjustment (Fig.10) or the machine needs an urgent

maintenance by a qualified technician.

14

14

Page 9

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

SPOOL REPLACEMENT (Fig. 11)

LINE REPLACEMENT (Fig. 11)

Ensure the unit is in the off position

Remove the spark plug lead, to prevent accidental

starting.

Use 2.4mm diameter monofilament string.

Cut one piece of string approximately 6.0m in length

Rotate knob on string head until line on knob aligns

with arrows on top of string head.

Insert one end of string into eyelet located on the

side of the string head and push until string comes

out through eyelet on the other side. Continue to

push string through the string head until the middle

section of the string is inside the string head and

string outside the string head is evenly divided on

each side.

Rotate the knob on the string head counterclockwise

to wind the string

Wind the string until approximately 20cm remains

protruding from the string head.

CLEANING THE EXHAUST PORT AND

SILENCER

Depending on the type of fuel used, the type and amount

of oil used, and/or your operating conditions, the exhaust

port and silencer may become blocked with carbon

deposits. If you notice a power loss with your petrol

powered tool, a qualified service technician will need to

remove these deposits to restore performance.

SPARK ARRESTOR

The spark arrestor must be cleaned or replaced every

25 hours or yearly to ensure proper performance of

your product. Spark arrestors may be in different

locations depending on the model purchased. Please

contact your nearest service dealer for the location of the

spark arrestor for your model.

FUEL CAP

WARNING

A leaking fuel cap is a fire hazard and must be

replaced immediately.

The fuel cap contains a non-service able filter and a

check valve. A clogged fuel filter will cause poor engine

performance. If performance improves when the fuel cap

is loosened, check valve may be faulty or filter clogged.

Replace fuel cap if required.

SPARK PLUG REPLACEMENT (Fig. 9)

This engine uses a Champion RCJ-6Y or NGK BPMR7A

spark plug with .05 in. electrode gap. Use an exact

replacement and replace annually.

IDLE SPEED ADJUSTMENT (Fig. 10)

If the cutting attachment turns at idle, the idle speed

screw needs adjusting on the engine. Turn the idle speed

screw counterclockwise to reduce the idle RPM and

stop the cutting attachment movement. If the cutting

attachment still moves at idle speed, contact a service

dealer for adjustment and discontinue use until the repair

is made.

STORING THE PRODUCT

Clean all foreign material from the product. Store

idle unit indoors in a dry, well-ventilated area that is

in- accessible to children. Keep away from corrosive

agents such as garden chemicals.

Abide by all ISO and local regulations for the safe

storage and handling of petrol.

When storing 1 month or longer:

Drain all fuel from tank into a container approved for

petrol. Run engine until it stops.

CLEANING THE AIR FILTER SCREEN (Fig. 8)

For proper performance and long life, keep air filter

screen clean.

Remove the air filter cover by pushing down on the latch

with your thumb while gently pulling on the cover.

Brush the air filter screen lightly to clean.

Replace the air filter cover by inserting the tabs on the

bottom of the cover into the slots on the air filter base;

push the cover up until it latches securely in place.

15

15

Page 10

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

TROUBLESHOOTING

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM, CONTACT YOUR AUTHORISED SERVICE DEALER.

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start. 1. Power switch is off.

2. No spark.

3. No fuel.

4. Engine is flooded.

5. Starter rope now harder to

pull than when new.

Engine starts but will

not idle long enough to

engage throttle

Engine does not stop

when switch is turned

off

Engine starts but will

not ac cel er ate.

Engine starts but will

only run at high speed

at half choke.

Engine does not reach

full speed and emits

ex ces sive smoke.

Engine starts, runs,

and accelerates but will

not idle.

Temperature can effect engine

idle time and rpm.

Electrical connection is loose/

unplugged

Engine requires approximately

three minutes to warm up.

Carburetor requires

adjustment.

1. Check oil fuel mixture.

2. Air filter is dirty.

3. Spark arrestor screen is

dirty.

Idle speed screw on

carburetor requires

adjustment

1. Make sure Switch is in the ON or "I" position

2. The spark plug may be damaged, remove it and

check for dirt and cracks. Replace with a new spark

plug.

3. Push primer bulb until bulb is full of fuel. If bulb

does not fill, primary fuel delivery sys tem is blocked.

Con tact a servicing dealer. If prim er bulb fills, engine

may be flooded, proceed to next item.

4. Remove spark plug, turn unit so spark plug hole is

aimed at the ground. Set start lever to “

and pull starter cord 10 to 15 times. This will clear

excess fuel from en gine. Remove any fuel which

splashed on the product. Clean and reinstall spark

plug. Clean up any spilled fuel and move at least

9m away before restarting. Pull starter three times

with with start lever at “

set start lever to “

starting pro ce dure. If engine still fails to start, repeat

pro ce dure with a new spark plug.

5. Contact a servicing dealer.

Flip start lever to RUN “

until engine starts.

Set the start lever to CHOKE “

Immediately stop using the product. Check electrical

connection on the bottom of the trimmer and make

sure it is properly connected. Contact servicing dealer

if the problem persists.

Allow engine to completely warm up. If engine does

not accelerate after three minutes, contact a ser vic ing

dealer.

Contact a ser vic ing dealer.

1. Use fresh fuel and the correct 2-stroke oil mix.

2. Clean air filter. Refer to Clean ing the Air Filter

Screen earlier in this manual.

3. Contact a servicing dealer.

Turn idle speed screw clockwise to increase idle speed.

(Fig.10) Ensure that after adjustment the cutting head

does not rotate at idle. Contact servicing dealer if the

problem persists.

”. If en gine does not start,

” position and repeat normal

” position and pull starter

” to stop the engine.

” position

16

16

Page 11

FR DE ES IT PT NL SV DA NO FI HU CS RU RO PL SL HR ET LT LV SK BG

EN

English(Original instructions)

Line will not advance. 1. Line welded to itself.

2. Not enough line on spool.

3. Line worn too short.

4. Line tangled on spool.

5. Engine speed too slow.

Grass wraps round

shaft

housing and bump

head.

Bump knob hard to turn.

Oil drips from silencer.

NOTE: If your unit exhibits speci c performance problem(s) where the Troubleshooting section recommends a clockwise

screw adjustment on the carburetor and no adjustments have been made since original purchase, the unit should

be taken to an authorised service centre for repair. In most cases, the needed adjustment is a simple task for the

trained service representative.

1. Cutting tall grass at ground

level.

2. Operating trimmer at part

throttle.

Screws threads dirty or

damaged.

1. Operating trimmer at part

throttle.

2. Check oil/fuel mixture.

3. Air filter dirty.

1. Lubricate with silicone spray.

2. Install more line. Refer to “Line Replacement” earlier

in this manual.

3. Pull lines while alternately pressing down on and

releasing bump head.

4. Remove line from spool and rewind. Refer to “Line

Replacement” earlier in this manual.

5. Advance line at full throttle.

1. Cut tall grass from the top down.

2. Operate trimmer at full throttle.

Clean threads and lubricate with grease - if no

improvement, replace bump knob.

1. Operate trimmer at full throttle.

2. Use fresh fuel and the correct synthetic 2-stroke oil

mix.

3. Clean per instruction in Maintenance Section.

17

Page 12

(TRADUCTION À PARTIR DU MODE D'EMPLOI D'ORIGINE)

TTI garantit cet outil de jardinage contre les vices de fabrication et les

pièces défectueuses pour une durée de vingt quatre (24) mois, à compter

de la date de facture d'achat, sous réserve des limitations ci-après. Merci

de conserver votre facture originale comme preuve de date d'achat.

Cette garantie n'est valable que pour une utilisation personnelle

de l'outil, et en aucun cas pour des applications commerciales.

La présente garantie ne couvre pas les dommages et détériorations

provoqués par une mauvaise utilisation, une utilisation abusive, une

action accidentelle ou intentionnelle de l'utilisateur, une mauvaise

manipulation, une utilisation non raisonnable, une négligence, le

non-respect par l'utilisateur des consignes contenues dans le manuel

d'utilisation, une tentative de réparation par un professionnel non

qualifié, une réparation non autorisée, une modification du produit ou

l'utilisation d'accessoires et/ou de pièces non recommandés pour ce

produit.

Sont exclus de cette garantie les courroies, balais de charbon,

sacs, ampoules et toute autre pièce subissant une usure normale et

soumise à un remplacement obligatoire au cours de la période de

garantie. Sauf indication contraire stipulée dans les lois en vigueur,

cette garantie ne couvre pas non plus les frais de transport ou les

consommables tels que les fusibles.

Cette garantie limitée est nulle en cas d'effacement, modification ou

suppression des éléments d'identification de l'outil (marque, numéro

de série, etc.), si le produit n'a pas été acheté auprès d'un revendeur

agréé ou si ce produit a été vendu EN L'ÉTAT et / ou AVEC DÉFAUTS.

Dans le cadre des normes locales en vigueur, les limitations de

la présente garantie remplacent toute autre garantie, expresse ou

implicite, écrite ou orale, y compris toute garantie de QUALITÉ

MARCHANDE OU DESTINÉE À UN BUT SPÉCIFIQUE. NOUS NE

POURRONS EN AUCUN CAS ÊTRE TENUS RESPONSABLES

DE DÉGÂTS ACCIDENTELS, QU'ILS SOIENT MINEURS OU

CONSÉQUENTS. NOTRE RESPONSABILITÉ MAXIMALE NE

DÉPASSERA PAS LE COÛT D'ACHAT DU PRODUIT.

Cette garantie n'est valable que dans l'Union Européenne,

l'Australie et la Nouvelle Zélande. Pour les autres pays, merci de

contacter votre revendeur agréé Ryobi pour savoir si une autre

garantie s'applique.

LIMITED WARRANTY

EN

TTI warrants this outdoor product to be free of defects in material or

workmanship for 24 months from the date of purchase by the original

purchaser, subject to the limitations below. Please keep your invoice as

proof of date of purchase.

This warranty is only applicable where the product is used for personal

and non-commercial purposes. This warranty does not cover damage or

liability caused by / due to misuse, abuse, accidental or intentional acts by

user, improper handling, unreasonable use, negligence, failure by end user

to follow operating procedures outlined in the user’s manual, attempted

repair by non-qualified professional, unauthorized repair, modification, or

use of accessories and/or attachments not specifically recommended by

authorized party.

This warranty does not cover belts, brushes, bags, bulbs or any part which

ordinary wear and tear results in required replacement during warranty

period. Unless specifically provided under applicable law, this warranty

does not cover transportation cost or consumable items such as fuses.

This limited warranty is void if the product’s original identification (trade

mark, serial number, etc.) markings have been defaced, altered or removed

or if product is not purchased from an authorized reseller or if product is

sold AS IS and / or WITH ALL FAULTS.

Subject to all applicable local regulations, the provisions of this limited

warranty are in lieu of any other written warranty, whether express or

implied, written or oral, including any warranty of MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL

WE BE LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL OR

INCIDENTAL DAMAGES. OUR MAXIMUM LIABILITY SHALL NOT

EXCEED THE ACTUAL PURCHASE PRICE PAID BY YOU FOR THE

PRODUCT.

This warranty is valid only in the European Union, Australia and New

Zealand. Outside these areas, please contact your authorized Ryobi

dealer to determine if another warranty applies.

GARANTIE

FR

(ORIGINAL INSTRUCTIONS)

EINGESCHRÄNKTE GARANTIE

DE

(ÜBERSETZUNG DER ORIGINALEN ANLEITUNGEN)

TTI garantiert, dass dieses Produkt für den Außengebrauch im Hinblick

auf Material und Verarbeitungsgüte frei ist von allen Defekten, gültig für

einen Zeitraum von 24 Monaten ab Datum des Kaufs durch den originalen

Käufer, jedoch abhängig von den unten stehen-den Beschränkungen. Bitte

bewahren Sie Ihre Rechnung als Beweis des Kaufdatums auf.

Diese Garantie ist nur dann anwendbar, wenn das Produkt für

persönliche und nicht-kommerzielle Zwecke verwendet wird. Diese

Garantie erstreckt sich nicht auf einen Schaden oder Haftung, die

durch/aufgrund von falscher Anwendung, Missbrauch, zufälligen oder

absichtlichen Handlungen des Nutzers verursacht wurden, oder durch

ei-ne unsachgemäße Handhabung, Nachlässigkeit oder das Versäumnis

des Endnutzers, die im Benutzerhandbuch angegebenen Anweisungen

zu befolgen, oder die versuchte Repa-ratur durch nicht-qualifiziertes

Personal, die Modifikation oder Nutzung von Zubehörtei-len und/oder

Zusatzgeräten, die von der autorisierten Partei nicht ausdrücklich

empfohlen werden.

Diese Garantie erstreckt sich nicht auf Riemen, Bürsten, Taschen, Birnen

oder jedes sonstige Teil, das einer gewöhnlichen Abnutzung unterliegt

und einen Ersatz im Rahmen des Garantiezeitraums erforderlich macht.

Außer für den Fall einer ausdrücklichen ge-setzlichen Vorschrift erstreckt

sich diese Garantie nicht auf Transportkosten oder Verbrauchsgüter wie

Sicherungen.

Diese eingeschränkte Garantie ist nichtig, falls die originalen Kennzeichen

(Handelsmar-ke, Seriennummer etc.) beschädigt, geändert oder entfernt

wurden, oder falls das Produkt nicht bei einem autorisierten Einzelhändler

gekauft, oder falls das Produkt in seinem IST-Zustand und / oder MIT

ALLEN VORHANDENEN MÄNGELN verkauft wurde.

Abhängig von den anwendbaren lokalen Vorschriften gelten die

Bestimmungen dieser Garantie anstelle jeder anderen schriftlichen

Garantie, sie sei schriftlich oder mündlich, einschließlich jeder

VERTRIEBSGARANTIE ODER GARANTIE IM HINBLICK AUF DIE

GEEIGNETHEIT FÜR EINEN BESTIMMTEN ZWECK. UNTER KEINEN

UM-STÄNDEN HAFTEN WIR FÜR SPEZIAL-, ZUFALLS-, FOLGEODER UNFALL-SCHÄDEN. UNSERE GESAMTHAFTUNG SOLL DEN

TATSÄCHLICHEN KAUF-PREIS, DER FÜR DAS PRODUKT GEZAHLT

WURDE, NICHT ÜBERSCHREITEN.

Diese Garantie ist nur gültig in der Europäischen Union, Australien

und Neuseeland. Bitte kontaktieren Sie Ihren autorisierten RyobiHändler außerhalb dieser Regio-nen, um festzulegen, ob eine andere

Garantieleistung anzuwenden ist.

Page 13

DÉCLARATION DE CONFORMITÉ EC (Traduction à partir du mode d'emploi d'origine)

FR

Fabricant: Homelite Far East Co.,Ltd

Adresse: 24/F, CDW building, 388 Castle Peak Road, Tsuan Wan, HongKong.

Nom et adresse de la personne habilitée à établir le dossier technique:

Nom: Simon Del-Nevo (Directeur de l'Outillage Extérieur à Moteur)

Adresse: Techtronic Industries Europe, Middle East and Africa, Medina House, Field House Lane, Marlow, Bucks.

SL7 1TB - United Kingdom

Déclarons par la présente que le produit

Catégorie .................................................................................................

Modèle .................................................................................................................. RLT26CDS

Numéro de série ............................................................................... Voir plaque signalétique

Année de fabrication.........................................................................Voir plaque signalétique

• est conforme aux réserves applicables de la Directive Machinerie(2006/42/EC)

• est conforme aux réserves applicables des autres Directives EC- suivantes

Directive EMC(2004/108/EC),

Directive Emissions Sonores (2000/14/EC modi ée 2005/88/EC), et

Directive Emissions Gazeuses (97/68/EC modi ée 2004/26/EC).

Nous déclarons par ailleurs que

• les parties suivantes (parties/clauses des) standards Européens harmonisés ont été utilisées

EN ISO 11806 :2008

EN ISO 22867 :2008

EN ISO 22868 :2008

EN ISO 14982:1998

EN ISO 3744:1995

Niveau de puissance sonore mesuré 108 dB(A)

Niveau de puissance sonore garanti 109 dB(A)

Méthode d’évaluation de conformité de l’Annexe V/ Directive 2000/14/EC

Fait à, le: Hong Kong, 29/10/2009 Signature: Andrew John Eyre (BEng, CEng, MIET)

Vice président de l'Ingénierie

EC DECLARATION OF CONFORMITY (Original Instructions)

EN

Manufacturer: Homelite Far East Co.,Ltd

Address: 24/F, CDW building, 388 Castle Peak Road, Tsuan Wan, HongKong.

Name and address of the person authorised to compile the technical le:

Name: Simon Del-Nevo (Director of Outdoor Power Equipment)

Address: Techtronic Industries Europe, Middle East and Africa, Medina House, Field House Lane, Marlow, Bucks.

SL7 1TB - United Kingdom

Herewith we declare that the products

Category ...................................................................................STRING TRIMMER

Model ..................................................................................................... RLT26CDS

Serial number ....................................................................See product rating label

Year of Construction .......................................................... See product rating label

• is in conformity with the relevant provisions of the Machinery Directive (2006/42/EC)

• is in conformity with the provisions of the following other EC-Directives

EMC Directive (2004/108/EC),

Noise Emission Directive (2000/14/EC amended by 2005/88/EC), and

Gas Emission Directive (97/68/EC amended by 2004/26/EC).

And furthermore, we declare that

• the following (parts/clauses of) European harmonised standards have been used

EN ISO 11806 :2008

EN ISO 22867 :2008

EN ISO 22868 :2008

EN ISO 14982:1998

EN ISO 3744:1995

COUPE-BORDURES

Measured sound power level 108 dB(A)

Guaranteed sound power level 109 dB(A)

Conformity assessment method to Annex V/ Directive 2000/14/EC

Place, date: HongKong, 29/10/2009 Signature: Andrew John Eyre (BEng, CEng, MIET)

Vice president of Engineering

Page 14

TECHTRONIC INDUSTRIES EMEA

Medina House, Field house Lane,

Marlow, Bucks

SL7 1TB-UNITED KINGDOM

RYOBI TECHNOLOGIES (UK) LIMITED.

Medina House, Field house Lane,

Marlow, Bucks

SL7 1TB-UNITED KINGDOM

Tel: + 44 (0) 1628 894400

Fax: + 44 (0) 1628 894401

Technical Helpline : + 44 (0) 800 389 0305

TECHTRONIC INDUSTRIES FRANCE SAS

Immeuble Le Grand Roissy

Z.A. du Gué - 35 rue de Guivry

77990 LE MESNIL AMELOT FRANCE

Phone: + 33(0)1 60 94 69 70

Fax: + 33(0)1 60 94 69 79

RYOBI BELGIUM

Avenue des Pâquerettes, 55

Zoning artisanal - bâtiment 5

B - 1410 Waterloo

BELGIQUE

Tel : + 32(0) 2357 8140

Fax : + 32(0) 2357 8149

TTI ITALIA SRL

Via Fratelli Gracchi, 39

20092 Cinisello Balsamo (MI)

Italia

Tel : + 39(0) 5923 8408

Fax : + 39(0) 5924 6960

TECHTONIC INDUSTRIES IBERIA S.L

Av. De la Industria,52

Coslada – Madrid – España

Tel: 91 485 12 10

TECHTRONIC INDUSTRIES SOUTH AFRICA

CO. (PTY) LTD

P.O Box 83888, South Hills, Johannesburg, 2136

South Africa

TECHTRONIC INDUSTRIES (ASIA) CO., LTD.

24/F, CDW Building,

388 Castle Peak Road,

Tsuen Wan, Hong Kong.

Tel : + 852 2402 6888

RYOBI TECHNOLOGIES GMBH

Itterpark 4

D-40724 Hilden

DEUTSCHLAND

Tel: + 49 (0) 2103 2958-0

Fax: + 49 (0) 2103 2958-29

RYOBI TECHNOLOGIES GMBH

Vertriebsbüro Österreich

Schinitzgasse 13

A-8605 Kapfenberg

Tel.: + 43 (0) 3862 23590-0

Fax: + 43 (0) 3862 23590-25

TECHTRONIC INDUSTRIES AUSTRALIA PTY LIMITED.

Building B, Rosehill Industrial Estate,

3 Shirley Street,

Rosehill NSW 2142

AUSTRALIA

Tel: (02) 8892 1800 or 1300 361 505

Fax: 1800 807 993

TECHTRONIC INDUSTRIES (NZ) LIMITED.

27 Clemow Drive, Mt Wellington

PO Box 12-806, Penrose, Auckland

NEW ZEALAND

Tel: + 64 (0) 9 573 0230

Free Call: +64 0800 279 624

Fax: + 64 (0) 9 573 0231

A&M MIDDLE EAST FZCO

P.O.Box 61254

Jedel Ali, Dubai,

UNITED ARAB EMIRATES

Tel.: + 9714 8861399

Fax: + 9714 8861400

TECHTRONIC INDUSTRIES DENMARK APS

Stamholmen 147, 4.

DK-2650 Hvidovre

Denmark

Tlf 43 56 55 55, Fax 43 56 55 56

E-mail: kundeservice@tti-emea.com

TECHTRONIC INDUSTRIES NORWAY AS

Tlf.: 800 12 493, Faks: 800 12 492

E-mail: kundetjeneste@tti-emea.com

TECHTRONIC INDUSTRIES SWEDEN AB

Tel (+46) 08 24 60 30. fax (+46) 08 24 60 31.

E-mail: kundtjanst@tti-emea.com

TECHTRONIC INDUSTRIES FINLAND OY

Tel. 0800 1 09000, Fax 0800 1 09001

Email: asiakaspalvelu@tti-emea.com

960401009-03

Loading...

Loading...