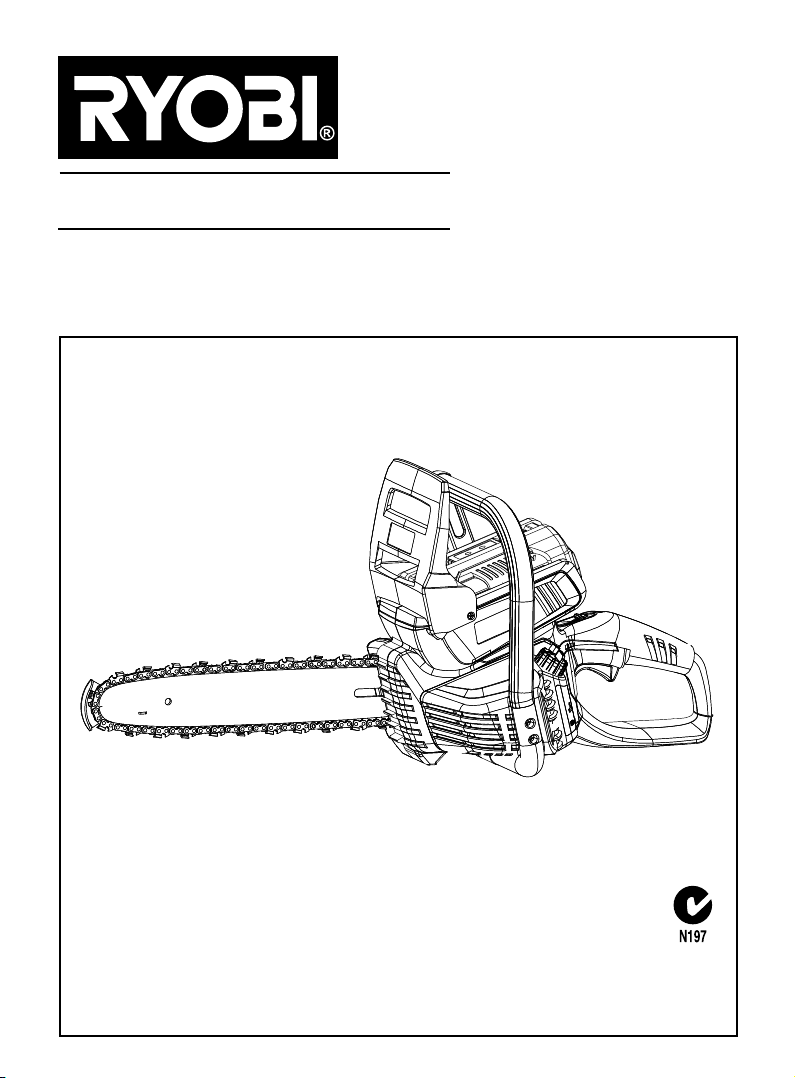

Page 1

RCS36/RCS36B

36V CORDLESS CHAIN SAW

OPERATOR’S MANUAL (Original Instructions)

Important! It is essential you read the instructions in this manual before starting and

operating this machine.

Page 2

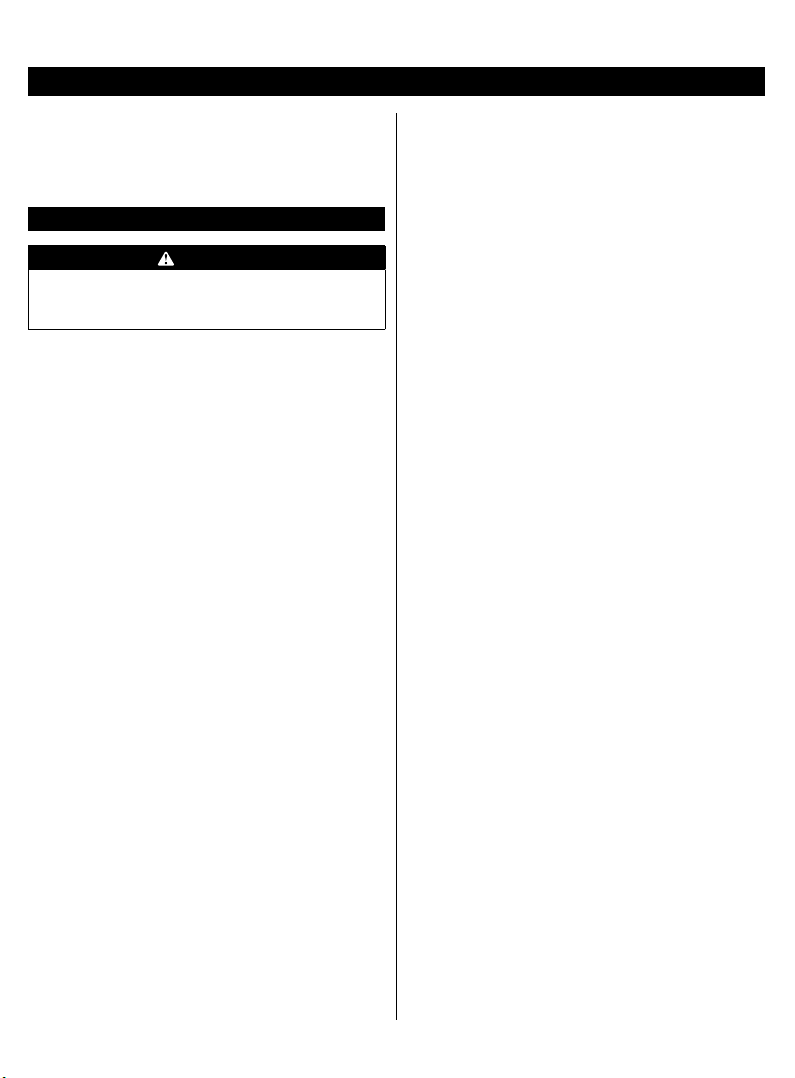

RCS36 / RCS36B

3

1

2

40

40

4

5

41

12

19

11

10

21

20

6

9

8

7

Fig. 1

13

14

15

Fig. 2 Fig. 3 Fig. 4

17 16

23

26

18

50mm

28

22

24

50mm

29

25

27

25

24

3-4mm

Fig. 5

Fig. 6 Fig. 8 Fig. 9 Fig. 10

36

Fig. 7

36

30

31

Fig. 11

32

33

39

35

34

37

35

38

Fig. 12 Fig. 13 Fig. 14 Fig. 15 Fig. 16

40

43

42

Fig. 17 Fig. 18 Fig. 19 Fig. 20 Fig. 21 Fig. 22

Page 3

English (Original Instructions)

Your product has been engineered and manufactured to

Ryobi’s high standard for dependability, ease of operation,

and operator safety. When properly cared for, it will give

you years of rugged, trouble-free performance.

Thank you for buying a Ryobi product.

GENERAL SAFETY WARNINGS

WARNING

Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in

electric shock, re and/or serious injury.

INTENDED USE

This chainsaw is designed for cutting branches, trunks,

logs and beams of a diameter determined by the cutting

length of the guide bar. It is only designed to cut wood.

It is only to be used in an outdoor, domestic application

by adults.

Do not use the chainsaw for any purpose not listed above.

This chainsaw is not to be used for professional tree

services. It is not to be used by children or by persons

not wearing adequate personal protective equipment and

clothing.

RESIDUAL RISKS:

Even with the intended use of the appliance, there are

other potential risks which cannot be prevented. According

to the type and construction of the appliance, the following

potential hazards exist:

Contact with exposed saw teeth of the saw chain

(cutting hazards).

Access to the rotating saw chain (cutting hazards).

Unforeseen, abrupt movement of the guide bar

(cutting hazards).

Flying parts from the saw chain (Cutting / injection

hazards).

Flying debris from the work piece.

Inhalation of work piece particles.

Skin contact with the fuel oil.

Loss of hearing, if no ear protection is used during

work.

Save all warnings and instructions for future

reference. The term “power tool” in the warnings

refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

WORK AREA SAFETY

Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

ELECTRICAL SAFETY

Avoid body contact with earthed or grounded

surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under the

influence of drugs, alcohol or medication. A lapse of

attention while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear

eye protection. Protective equipment such as a dust

mask, non-skid safety shoes, hard hat or hearing

protection used appropriately will reduce personal

injuries.

Prevent unintentional starting. Ensure the switch is

in the off position before connecting to power source

and/or battery pack and when picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energizing power tools that have the switch

on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

Do not over-reach. Keep proper footing and balance

at all times. This enables better control of the power

tool in unexpected situations.

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

POWER TOOL USE AND CARE

Do not force the power tool. Use the power tool for

the application. The correct power tool will do the job

better and safer at the rate for which it was designed.

2

Page 4

English (Original Instructions)

Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

Disconnect the battery pack from the power

tool before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting

the power tool accidentally.

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of parts and

any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

BATTERY TOOL USE AND CARE

Ensure the switch is in the off position before

inserting battery pack. Inserting the battery pack into

power tools that have the switch on invites accidents.

Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used with

another battery pack.

Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

When battery pack is not in use, keep it away from

other metal objects like paper clips, coins, keys,

nails, screws, or other small metal objects that can

make a connection from one terminal to another.

Shorting the battery terminals together may cause

burns or fire.

Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with plenty of soap and

water. If liquid contacts eyes, immediately seek

medical help. Liquid ejected from the battery may

cause irritation or burns.

SERVICE

Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

Servicing requires extreme care and knowledge and

should be performed only by a qualified service technician.

For service we suggest you return the product to your

neatest AUTHORISED SERVICE CENTRE for repair.

When servicing, use only identical replacement parts.

SPECIFIC SAFETY WARNINGS

Hold the power tool by insulated gripping surfaces

only, because the saw chain may contact hidden

wiring. Saw chains contacting a "live" wire may make

exposed metal parts of the power tool "live" and could

give the operator an electric shock.

Keep all parts of the body away from the saw chain

when the chain saw is operating. Before you start the

chain saw, make sure the saw chain is not in contact

with anything. A moment of inattention while operating

chain saws may cause entanglement of your clothing

or body with the saw chain.

Always hold the chain saw with your right hand

at the rear handle and your left hand at the front

handle. Holding the chain saw with a reversed hand

configuration increases the risk of personal injury and

should never be done.

Wear safety glasses and hearing protection. Further

protective equipment for head, hands, legs and feet

is recommended. Adequate protective clothing will

reduce personal injury from flying debris or accidental

contact with the saw chain.

Do not operate chain saw while up in a tree. Operation

of a chain saw while up in a tree may result in personal

injury.

Always keep proper footing and operate the chain saw

only when standing on fixed, secure and level surface.

Slippery or unstable surfaces such as ladders may

cause loss of balance or control of the chain saw.

When cutting a limb that is under tension, be alert

of spring back. When the tension in the wood fibres

is released, the spring loaded limb may strike the

operator and/or throw the chain saw out of control.

Use extreme caution when cutting brush and saplings.

The slender material may catch the saw chain and be

whipped toward you or pull you off balance.

Carry the chain saw by the front handle with the chain

saw switched off and away from your body. When

transporting or storing the chain saw, always fit the

guide bar cover. Proper handling of the chain saw will

reduce the likelihood of accidental contact with the

3

Page 5

English (Original Instructions)

moving saw chain.

Follow instructions for lubricating, chain tensioning

and changing accessories. Improperly tensioned

or lubricated chain may either break or increase the

chance for kickback.

Keep handles dry, clean, and free from oil and grease.

Greasy, oily handles are slippery, and may cause loss

of control.

Cut wood only. Do not use chain saw for purposes not

intended. For example: do not use chain saw for cutting

plastic, masonry or non-wood building materials. Use

of the chain saw for operations other than intended

could result in a hazardous situation.

CAUSES AND OPERATOR PREVENTION OF

KICKBACK:

Kickback may occur when the nose or tip of the guide

bar touches an object, or when the wood closes in and

pinches the saw chain in the cut.

Tip contact in some cases may cause a sudden reverse

reaction, kicking the guide bar up and back towards the

operator.

Pinching the saw chain along the top of the guide bar may

push the guide bar rapidly back towards the operator.

Either of these reactions may cause you to lose control of

the saw which could result in serious personal injury. Do

not rely exclusively upon the safety devices built into your

saw. As a chain saw user, you should take several steps

to keep your cutting jobs free from accident or injury.

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below:

Maintain a firm grip, with thumbs and fingers encircling

the chain saw handles, with both hands on the saw

and your body and arm positioned to allow you to

resist kickback forces.

Kickback forces can be controlled by the operator,

if proper precautions are taken. Do not let go of the

chain saw.

Do not overreach and do not cut above shoulder

height. This helps prevent unintended tip contact and

enables better control of the chain saw in unexpected

situations.

Only use replacement bars and chains specified by

the manufacturer. Incorrect replacement bars and

chains may cause chain breakage and/or kickback.

Follow the manufacturer’s sharpening and

maintenance instructions for the saw chain.

Decreasing the depth gauge height can lead to

increased kickback.

ADDITIONAL WARNINGS

It has been reported that vibrations from hand-held

tools may contribute to a condition called Raynaud’s

Syndrome in certain individuals. Symptoms may

include tingling, numbness and blanching of the

ngers, usually apparent upon exposure to cold.

Hereditary factors, exposure to cold and dampness,

diet, smoking and work practices are all thought to

contribute to the development of these symptoms. It

is presently unknown what, if any, vibrations or extent

of exposure may contribute to the condition. There

are measures that can be taken by the operator to

possibly reduce the effects of vibration:

y Keep your body warm in cold weather. When

operating the unit wear gloves to keep the hands

and wrists warm. It is reported that cold weather

is a major factor contributing to Raynaud’s

Syndrome.

y After each period of operation, exercise to increase

blood circulation.

y Take frequent work breaks. Limit the amount of

exposure per day.

If you experience any of the symptoms of this

condition, immediately discontinue use and see your

physician about these symptoms.

The recommended cutting capacity of this chain saw

is 153mm (6 in.) and smaller to prolong the life of the

tool and allow for safest operation. Cutting logs with

a diameter larger than this will cause excess wear on

your tool. Logs with a maximum diameter of 229mm

(9in.) can be cut, but should only be done so rarely

and with caution.

The integral spiked bumper is designed to assist

cutting. When forced against the log while cutting it

provides a more stable pivot point.

Any chainsaw is potentially lethal if used

inappropriately. It is strongly suggested that you seek

professional training in the safety and use of this tool.

SAVE THESE INSTRUCTIONS. REFER TO THEM

FREQUENTLY AND USE THEM TO INSTRUCT OTHERS

WHO MAY USE THIS UNIT. IF YOU LOAN SOMEONE

THIS UNIT, LOAN THEM THESE INSTRUCTIONS ALSO.

4

Page 6

English (Original Instructions)

SYMBOLS

Some of the following symbols may be used on this tool. Please study them and learn their meaning. Proper interpretation

of these symbols will allow you to operate the tool better and safer.

SYMBOL DESIGNATION/EXPLANATION

V Voltage

W Watt - Power

Direct current - Type or characteristic of current

Precautions that involve your safety.

Read the operation manual and follow all warnings and safety instructions.

Wear eye and hearing protection when operating this product.

Do not expose to rain or damp conditions.

97

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

Guaranteed sound power level is 97dB.

DANGER:

WARNING:

CAUTION:

CAUTION:

Indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

(Without Safety Alert Symbol) Indicates a situation that may

result in property damage.

5

Page 7

English (Original Instructions)

SPECIFICATIONS

Model RCS36 RCS36B

Rated voltage 36V DC

No Load Speed 3.6 m/s

Guide bar length 300 mm

Chain stop < 2s

Chain oil tank

capacity

Weight

Emission sound

pressure level L

Uncertainty K

Sound power level

L

WA

Uncertainty K

Guaranteed

sound power level

L

(G)

WA

Vibration total

value ah

Uncertainty K 1.5 m/s

Battery Pack 1 x BPL3626

Battery Charger 1 x BCL3620

REMARKS:

The declared vibration value has been measured with

a standard test method and may be used to compare

one tool with another.

The declared vibration value may be used in a

preliminary assessment of exposure.

(with battery)

pA

pA

WA

4.4 kg

110 ml

(without battery)

81.2 dB(A)

2 dB(A)

94.8 dB(A)

2 dB(A)

97 dB(A)

2.3 m/s

3.03 kg

2

2

WARNING

The actual vibration values during use of the tool can

be different from the above stated and depend on the

use of the tool; and the need to identify safety measures

to protect the operator are based on an estimation of

exposure in the actual conditions of use (taking account

all parts of the operating cycle such as the times when

the tool is switched off and when it is running idle in

addition to the trigger time).

CHAIN & BAR INFORMATION

Manufacture Saw chain Guide bar

Oregon 90SG045X 124MLEA041

Tri-link CL14345PB M1431245-1041HL

Oregon's chain must be tted with Oregon's bar; Trilink's chain must be tted with Tri-link's bar.

You can purchase bar and chain replacements from your

Ryobi local dealer.

RCS36 bar replacement: RAC226 (Tri-link M14312451041HL)

RCS36 chain replacement: RAC227(Tri-link CL14345PB)

DESCRIPTION

(REFER TO FIGURE SHEET)

1. Guide bar cover

2. Front handle guard

3. Front handle

4. Safety lock-out button

5. Switch trigger

6. Oil tank cover

7. Oil level gauge

8. Spike bumpers

9. Saw chain

10. Guide bar

11. Safety tip

12. Rear handle

13. Chain tensioner adjustment knob

14. Sprocket cover

15. Sprocket cover securing knob

16. Saw chain tensioning pin

17. Sprocket

18. Bar guide

19. Oil outlet

20. Bar groove

21. Chain drive links

22. Cutter

23. Felling direction

24. Danger zone

25. Escape route

26. Direction of fall

27. Notch

28. Felling back cut

29. Hinge

30. Limb cut

31. Keep work off ground leave support limbs until log is cut

32. Log supported along the entire length

33. Cut from top (over buck) avoid cutting earth

34. Log supported one end

35. Under buck

6

Page 8

English (Original Instructions)

36. Over buck

37. Log supported both ends

38. Bucking a log

39. Stand on uphill side when cutting because log may roll

40. Battery pack

41. Battery latch button

42. Charger

43. Charger cable

ASSEMBLY

This chain saw does not require assembly, but user should

know how to assemble the guide bar and saw chain.

Check the chain tensioning and add oil as described later

in this manual before each operation.

ASSEMBLING THE GUIDE BAR AND SAW CHAIN

See gure 2 - 7

Make sure remove the battery pack from the unit. Wear

protective gloves.

Unscrew the sprocket cover securing knob (item 15)

and remove the sprocket cover.

The saw chain should face in the direction of chain

rotation. If facing backwards, turn the chain loop over.

Place the chain drive links into the bar groove.

Position the chain so there is a loop at the back of

the bar.

Hold the chain in position on the bar and place the

loop around the sprocket and make sure it is correctly

mounted. Make sure the bar hole fits well with the

tensioning pin (item 16).

Replace the sprocket cover, turn the chain tension

adjust knob (item 13) clockwise until the saw chain

is properly tensioned. The guide bar must then be

pushed upwards, check chain tension again, do not

tension the chain too tight.

After the chain is well-tensioned, tighten the knob

(item 15) again.

Note: The saw chain is properly tensioned if, in the middle

of the guide bar, it can be lifted 3mm to 4mm from the

edge of the guide bar. Run the chain saw to ensure correct

movement before attempting a job. If a new saw chain is

tted, run the saw for 2-3 minutes before starting a job.

WARNING

After the run-in time, check the chain tension and retighten the chain if necessary.

charger models.

NOTE: To avoid serious personal injury, always remove

the battery pack and keep hands clear of the lock-out

button when carrying or transporting the tool.

BEFORE EACH USE CHECK THE CHAIN TENSION

See gure 2

WARNING

Remove the battery pack from the chain saw before

checking the chain tension or making adjustments to

the chain. Wear protective gloves while touching the

chain, bar or areas around the chain.

Pull the chain in the middle of the lower side of the

bar away from the bar. The gap between the cutter in

the chain and the bar should be between 3mm - 4mm.

If you need to adjust the chain tension, please refer to

the section “ADJUSTING THE CHAIN TENSION” later

in this manual.

TO INSTALL BATTERY PACK

See Figure 2.

Place the battery pack in the chain saw. Align raised

ribs on battery pack with grooves in the chain saw’s

battery port.

Make sure the latch on bottom of the battery

pack snaps in place and that battery pack is fully

seated and secure in the chain saw before beginning

operation.

TO REMOVE BATTERY PACK

See Figure 2.

Release the trigger to stop the chain saw.

Press and hold the battery latch button at the bottom

of the battery pack.

Remove battery pack from the chain saw.

CHECKING THE CHAIN LUBRICANT

See gure 1

Check the amount of oil in the chain saw by looking at

the oil level gauge (item 7). If the oil level is low, follow

the steps shown in section “ADDING CHAIN & BAR

LUBRICANT” of this manual.

WARNING

Check the chain tension before each use of the saw.

OPERATION

For complete charging instructions, refer to the

Operator’s Manuals for your Ryobi battery pack and

7

Page 9

English (Original Instructions)

WARNING

Never operate the chain saw without sufcient chain

lubrication as this might damage the saw and is a threat

to safety. Check the chain lubricant level before each

use!

In order to prevent kickback, please follow these safety

instructions:

Never cut with the tip of the guide bar! Be careful when

continuing from previous cuts.

Always start cutting only when the chain saw is already

running.

Make sure that the saw chain is always properly

sharpened.

Never cut through more than one branch at a time!

When lopping off branches, be careful not to touch any

other branches.

When cross-cutting, pay attention to trunks standing

very close to each other. If possible, use a sawing trestle.

HOLDING THE CHAIN SAW

See gure 8

Always hold the chain saw with your right hand at the

rear handle and your left hand at the front handle.

Grip both handles with the thumbs and ngers encircling

the handles. Ensure that your left hand is holding the front

handle so that your thumb is underneath.

STARTING OPERATION

Before operation, ensure that the battery is charged

and correctly installed.

To start the machine: Pull the Safety lock-out button

(item 4), and then pull the switch trigger (item 5).

STOPPING OPERATION

Release the power switch trigger (item 5) to stop the

chain saw.

USING THE CHAIN SAW

Always be sure of your footing and hold the chain saw

rmly with both hands while the motor is running.

BASIC FELLING, LIMBING, AND CROSS-CUTTING

TECHNIQUES

See gure 9

FELLING A TREE

When bucking and felling operations are being performed

by two or more persons at the same time, the felling

operation should be separated from the bucking operation

by a distance of at least twice the height of the tree being

felled. Trees should not be felled in a manner that would

endanger any person, strike any utility line or cause any

property damage. If the tree does make contact with

any utility line, the utility company should be notied

immediately.

The chain saw operator should keep on the uphill side of

the terrain as the tree is likely to roll or slide downhill after

it is felled.

An escape path should be planned and cleared as

necessary before cuts are started. The escape path

should extend back and diagonally to the rear of the

expected line of fall.

Before felling is started, consider the natural lean of the

tree, the location of larger branches and the wind direction

to judge which way the tree will fall.

Remove dirt, stones, loose bark, nails, and staples from

the tree.

NOTCHING UNDERCUT (A NOTCH CUT IN A TREE TO

DIRECT THE FALL)

See Figure 10

Make the notch 1/3 in diameter of the tree, perpendicular

to the direction of falls. Make the lower horizontal notching

cut rst, this will help to avoid pinching of either the saw

chain or the guide bar when the second notch is being

made.

FELLING BACK CUT (THE FINAL CUT IN A TREE

FELLING OPERATION, MADE ON THE OPPOSITE SIDE

OF THE TREE FROM THE NOTCHING UNDERCUT)

See Figure 10

Make the felling back cut at least 50mm higher than the

horizontal notching cut. Keep the felling back cut parallel

to the horizontal notching cut. Make the felling back cut

so as to leave enough wood to act as a hinge. The hinge

wood keeps the tree from twisting and falling in the wrong

direction. Do not cut through the hinge. As the felling cut

gets close to the hinge, the tree should begin to fall. If

there is any chance that the tree may not fall in the desired

direction or it may rock back and bind the saw chain, stop

cutting before the felling back cut is complete and use

wedges of wood, plastic or aluminium to open the cut and

drop the tree along the desired line of fall. When the tree

begins to fall, remove the chain saw from the cut, release

the power trigger to stop the chain saw, put the chain saw

down, and then use the retreat path as planned. Be alert of

overhead limbs falling and watch your footing.

LIMBING A TREE

See gure 11

Limbing is removing the branches from a fallen tree. When

limbing, leave the larger lower limbs to support the log off

the ground. Remove the small limbs in one cut. Branches

under tension should be cut from the bottom up, to avoid

binding the chain saw.

BUCKING A LOG

See gure 12 - 15

8

Page 10

English (Original Instructions)

Bucking is cutting a log into lengths. It is important to

make sure your footing is rm and your weight is evenly

distributed on both feet. When possible, the log should be

raised and supported by the use of limbs, logs or chocks.

Follow the simple direction for easy cutting:

1. When the log is supported along the entire length, it is

cut from the top (over buck).

2. When the log is supported on one end, cut 1/3 of the

diameter from the underside (under buck). Then make

the nished cut by over bucking to meet the rst cut.

3. When the log is supported on both ends, cut 1/3 of

that diameter from the top (over buck). Then make the

nished cut by under bucking the lower 2/3 to meet

the rst cut.

4. When bucking on a slope, always stand on the uphill

side of the log. When cutting through, to maintain

complete control, release the cutting pressure near

the end of the cut without relaxing your grip on the

chain saw handles.

Do not let the chain contact the ground. After completing

the cut, wait for the saw chain to stop before you move

the chain saw. Always stop the motor before moving from

tree to tree.

MAINTENANCE

WARNING

Always remove the battery pack from the machine

before checking the chain tension or making

adjustments to the chain. Wear protective gloves while

touching the chain, bar or areas around the chain.

ADJUSTING THE CHAIN TENSION

See gure 2

Un-tighten the sprocket cover securing knob (item 15)

slightly by turning it counterclockwise.

To increase the chain tension, turn the chain tensioner

adjustment knob (item 13) clockwise and check the

chain tension frequently. To reduce the chain tension,

turn the chain tensioner adjustment knob (item

13) counterclockwise and check the chain tension

frequently.

The chain tension is correct when the gap between the

cutter in the chain and the bar is between 3mm-4mm.

Pull the chain in the middle of the lower side of the

bar downwards (away from the bar) and measure the

distance between the bar and the chain cutters.

Tighten the sprocket cover securing knob (item 15) by

turning it clockwise.

REPLACING THE BAR AND CHAIN

See Figure 2, 3, 5, 7

Put the saw down on a flat and even surface to make

adjustments to the chain.

Make sure that you have the correct replacement

bar and chain as advised earlier in the specification

section of this manual.

Unscrew the sprocket cover securing knob (item 15)

by turning it counterclockwise until the sprocket cover

(item 14) comes loose.

Remove the sprocket cover. Remove the bar and saw

chain from unit.

To replace the bar with the new one, unscrew the nut

of the safety tip, mount the safety tip on to the new bar

and tighten the nut.

Put the new chain in the correct direction as shown in

figure 7 onto the bar and make sure that the drive links

are aligned in the bar groove (figure 5).

Attach the bar to the chain saw and loop the chain

around the drive sprocket as shown in figure 3.

Replace the sprocket cover (item 14), tighten sprocket

cover and tighten knob (item 15).

Follow the steps the section “ADJUSTING THE CHAIN

TENSION” earlier in this manual.

ADDING CHAIN & BAR LUBRICANT

Unscrew and remove the cap (item 6) from the oil tank.

Pour the oil into the oil tank and monitor the oil level

gauge (item 7). Ensure that no dirt enters the oil tank

while filling the oil in.

Put the oil cap back on and tighten it up.

One full oil tank will enable you to use the saw for 20-

40 min.

TRANSPORTING THE CHAIN SAW

Before transporting the chain saw, always remove the

battery pack from the chain saw and slide the chain cover

over the bar and chain. If several cuts are to be performed

with the chain saw, the saw must be switch off between

cuts.

GUIDE BAR COVER

See gure 1

The chain cover must be clipped onto the chain and bar

as soon as the sawing work has been completed and

whenever the machine has to be transported.

SHARPENING THE SAW CHAIN

See gure 16 - 21

When the chain penetrates into wood with difcultly, it

needs sharpening as follows:

Put the chain under tension.

Fasten the bar in a vice so that the chain can slide.

Fasten the file to the file holder and place it on cutter

at 35° angle.

9

Page 11

English (Original Instructions)

File with forward strokes only until all the worn out

parts of the cutting edge are taken away.

Count the number of strokes given to the cutter as

a reference and file away with the same number of

strokes on all other cutters.

If the depth gauge protrudes from the template after

sharpening a few times, reset its level. Use a flat file.

Finally, round off the depth gauge.

NOTE: It is recommended to have the deep or important

sharpening carried out by a service agent who is equipped

with electric sharpener.

GUIDE BAR MAINTENANCE

When you have finished working, clean out the groove

and the oil passages with a scraping hook.

Periodically trim the sides of rails using a flat file. If not

done in the long run, the feather edges might break

away and damage the bar.

If one rail is higher than the other one, it is necessary

to make it even with a flat file then smooth it with a file

or fine grain abrasive paper.

WARNING

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING

To avoid serious personal injury, always remove the

battery pack from the tool when cleaning or performing

any maintenance.

GENERAL MAINTENANCE

Before each use, inspect the entire product for damaged,

missing, or loose parts such as screws, nuts, bolts, caps,

etc. Tighten securely all fasteners and caps and do not

operate this product until all missing or damaged parts

are replaced. Please call Ryobi Customer Service for

assistance.

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

Use clean cloths to remove dirt, dust, oil, grease, etc.

WARNING

Do not at any time let brake uids, gasoline, petroleumbased products, penetrating oils, etc., come in contact

with plastic parts. Chemicals can damage, weaken or

destroy plastic which may result in serious personal

injury.

Only the chain and bar are intended to be serviced

or replaced by the operator. All other parts should be

replaced at an Authorised Service Centre. For your

nearest Ryobi Authorised Service Centre call 1300 361

505 or visit the website www.ryobi.com.au

STORAGE

STORING THE PRODUCT

Remove the battery pack from the unit before storing.

Clean all foreign material from the unit.

Store it in a place that is inaccessible to children.

Keep away from corrosive agents such as garden

chemicals and de-icing salts.

Store and charge your batteries in a cool area.

Temperatures above or below normal room

temperature will shorten battery pack life.

Never store batteries in a discharged condition. Store

battery packs in a 30%-50% charged condition.

Store the battery pack where the temperature is below

27˚C and away from moisture.

All batteries gradually lose their charge. The higher

the temperature, the quicker they lose their charge.

If you store your unit for long periods of time without

using it, charge the pack as normal every six months

of storage. This practice will prolong battery pack life.

DISPOSAL

Power tools and accessories contain large

amount of valuable resources and plastics

that can be recycled. Waste electrical

products should not be disposed of together

with household waste. Please recycle where

facilities exist. Check with your local

authority or retailer for recycling advice.

The battery contains material which is hazardous to you

and the environment. It must be removed and disposed

of separately at a facility that accepts lithium-ion batteries.

10

Page 12

Subject to the guarantee condition below, this Ryobi

tool (hereinafter called “the product”) is guaranteed by

TECHTRONIC INDUSTRIES AUSTRALIA PTY

LIMITED (hereinafter called “the Company”) to be free

from defects in material or workmanship for a period

of 24 months from the date of original purchase

covering both parts and labour. Under the terms of

this guarantee, the repair or replacement of any part

shall be the opinion of the Company or its authorised

service centre. Should service become necessary

during the warranty period, the owner should contact

the customer service HELPLINE 1300 361 505 or

contact the retailer from whom the product was

purchased.

In order to obtain guarantee service, the owner must

present the sales docket and Guarantee Certificate to

confirm date of purchase. This product is sold by the

dealer or service centre as principal and the dealer

has no authority from the Company’s behalf except as

herein contained or herein referred to.

Guarantee Conditions

This guarantee only applies provided that the product

has been used in accordance with the manufacturer’s

recommendations under normal use and reasonable

care (in the opinion of the Company) and such

guarantee does not cover damage, malfunction or

failure resulting from misuse, neglect, abuse, or used

for a purpose for which it was not designed or is not

suited and no repairs, alterations or modifications

have been attempted by other than an authorised

service centre. This guarantee will not apply if the tool

is damaged by accident or if repairs arise from normal

wear and tear. The Company accepts no additional

liability pursuant to this guarantee for the costs of

travelling or transportation of the product or parts to

and from the service dealer or service centre - such

costs are not included in this guarantee.

Certain legislation, including the Trade Practices Act,

1974 (as amended) and other state and territorial laws

give rights to the buyer and impose liability on the

seller in certain circumstances. Nothing herein shall

have the effect of excluding, restricting or modifying

any condition, guarantee, right or liability imposed, to

the extent only that such exclusion, restriction or

modification would render any term herein void.

TECHTRONIC INDUSTRIES (AUSTRALIA) PTY. LTD.

Tel: (09) 573 0230 Free Call: 0800 279 624 Fax: (09) 573 0231

Level 1, 660 Doncaster Road,

Doncaster, Victoria 3108,

Australia

Tel: 1300 361 505 Fax: 1800 807 993

www.ryobi.com.au

TECHTRONIC INDUSTRIES N.Z. LIMITED

Auckland: 27 Clemow Drive, Mt Wellington, N.Z.

Contact during normal business hours.

www.ryobi.co.nz

Loading...

Loading...