Page 1

RBC52FSB/RBC42FSB

COUPE-BORDURES / DÉBROUSSAILLEUSE MANUEL D’UTILISATION 1

FR

STRING TRIMMER / BRUSHCUTTER USER’S MANUAL 11

EN

KANTENSCHNEIDER / FREISCHNEIDEGERÄT BEDIENUNGSANLEITUNG 20

DE

RECORTADORA DE HILO / CORTADORA DE MALEZA MANUAL DE UTILIZACIÓN 30

ES

TAGLIABORDI / DECESPUGLIATORE MANUALE D’USO 40

IT

APARADOR DE RELVA / CORTA-SEBES MANUAL DE UTILIZAÇÃO 50

PT

GRASTRIMMER / BOSMAAIER GEBRUIKERSHANDLEIDING 60

NL

TRIMMER / RÖJSÅG INSTRUKTIONSBOK 70

SV

TRÅDTRIMMER / BUSKRYDDER BRUGERVEJLEDNING 79

DA

TRÅDTRIMMER / KRATTRYDDER BRUKSANVISNING 88

NO

SIIMALEIKKURI / RUOHORAIVURI KÄYTTÄJÄN KÄSIKIRJA 97

FI

SZEGÉLYVÁGÓ / BOZÓTVÁGÓ MOTOROS KASZA HASZNÁLATI ÚTMUTATÓ 106

HU

STRUNOVÁ SEKAČKA / KŘOVINOŘEZ NÁVOD K OBSLUZE 116

CS

БЕНЗОКОСА / ТРИММЕР РУКОВОДСТВО ОПЕРАТОРА

RU

TRIMMER / APARAT PENTRU TUNS TUFIŞURI MANUAL DE UTILIZARE 136

RO

PODKASZARKA DO OBRZEŻY / ŚCINACZ KRZEWÓW INSTRUKCJA OBSŁUGI 146

PL

KOSILNICA Z NITKO / OBREZOVALNIK GRMOVJA UPORABNIŠKI PRIROČNIK 156

SL

ŠIŠAČ / REZAČICA KORISNIČKI PRIRUČNIK 165

HR

TRIMMER-VÕSALÕIKUR KASUTAJAJUHEND 174

ET

ŽOLIAPJOVĖ / KRŪMAPJOVĖ NAUDOJIMO VADOVAS 183

LT

ROKAS PĻAUJMAŠĪNA / KRŪMGRIEZIS LIETOTĀJA ROKASGRĀMATA 192

LV

STRUNOVÁ KOSAČKA/KROVINOREZ NÁVOD NA POUŽITIE 201

SK

ТРИМЕР / ТРИМЕР ЗА РАЗЧИСТВАНЕ РЪКОВОДСТВО ЗА ОПЕРАТОРА

BG

125

Important! It is essential that you read the instructions in this manual before assembling, maintaining and

operating this machine.

Subject to technical modifications.

Page 2

ȼɚɠɧɨ

6XEMHFWWRWHFKQLFDOPRGLILFDWLRQV6RXVUpVHUYHGHPRGLILFDWLRQVWHFKQLTXHV7HFKQLVFKHbQGHUXQJHQYRUEHKDOWHQ

%DMRUHVHUYDGHPRGLILFDFLRQHVWpFQLFDV&RQULVHUYDGLHYHQWXDOLPRGLILFKHWHFQLFKH7HFKQLVFKHZLM]LJLQJHQYRRUEHKRXGHQ

&RPUHVHUYDGHPRGLILFDo}HVWpFQLFDV0HGIRUEHKROGIRUWHNQLVNHQGULQJHU0HGI|UEHKnOOI|UWHNQLVNDlQGULQJDU

7HNQLVHWPXXWRNVHWYDUDWDDQ0HGIRUEHKROGRPWHNQLVNHHQGULQJHUɦɨɝɭɬɛɵɬɶɜɧɟɫɟɧɵɬɟɯɧɢɱɟɫɤɢɟɢɡɦɟɧɟɧɢɹ

=]DVWU]HĪHQLHPPRG\ILNDFMLWHFKQLF]Q\FK=PČQ\WHFKQLFNêFK~GDMĤY\KUD]HQ\$PĦV]DNLPyGRVtWiVMRJiWIHQQWDUWMXN

3DVLOLHNDQWWHLVĊGDU\WLWHFKQLQLXVSDNHLWLPXV7HKQLOLVHGPXXGDWXVHGY}LPDOLNXG3RGORQRWHKQLsNLPSURPMHQDPD

7HKQLþQHVSUHPHPEHGRSXãþHQH3UiYRQDWHFKQLFNp]PHQ\MHY\KUDGHQpɉɨɞɥɟɠɢɧɚɬɟɯɧɢɱɟɫɤɢɦɨɞɢɮɢɤɚɰɢɢ

Ɉɬɢɡɤɥɸɱɢɬɟɥɧɚɜɚɠɧɨɫɬɟɞɚɩɪɨɱɟɬɟɬɟɢɧɫɬɪɭɤɰɢɢɬɟɜɬɨɜɚɪɴɤɨɜɨɞɫɬɜɨɩɪɟɞɢɞɚɛɨɪɚɜɢɬɟɫ

ɬɚɡɢɦɚɲɢɧɚ

6XEUH]HUYDPRGLILFDĠLLORUWHKQLFH3DWXUDPWLHVƯEDVPDLQƯWWHKQLVNRVUDNVWXUOLHOXPXV

VL

Page 3

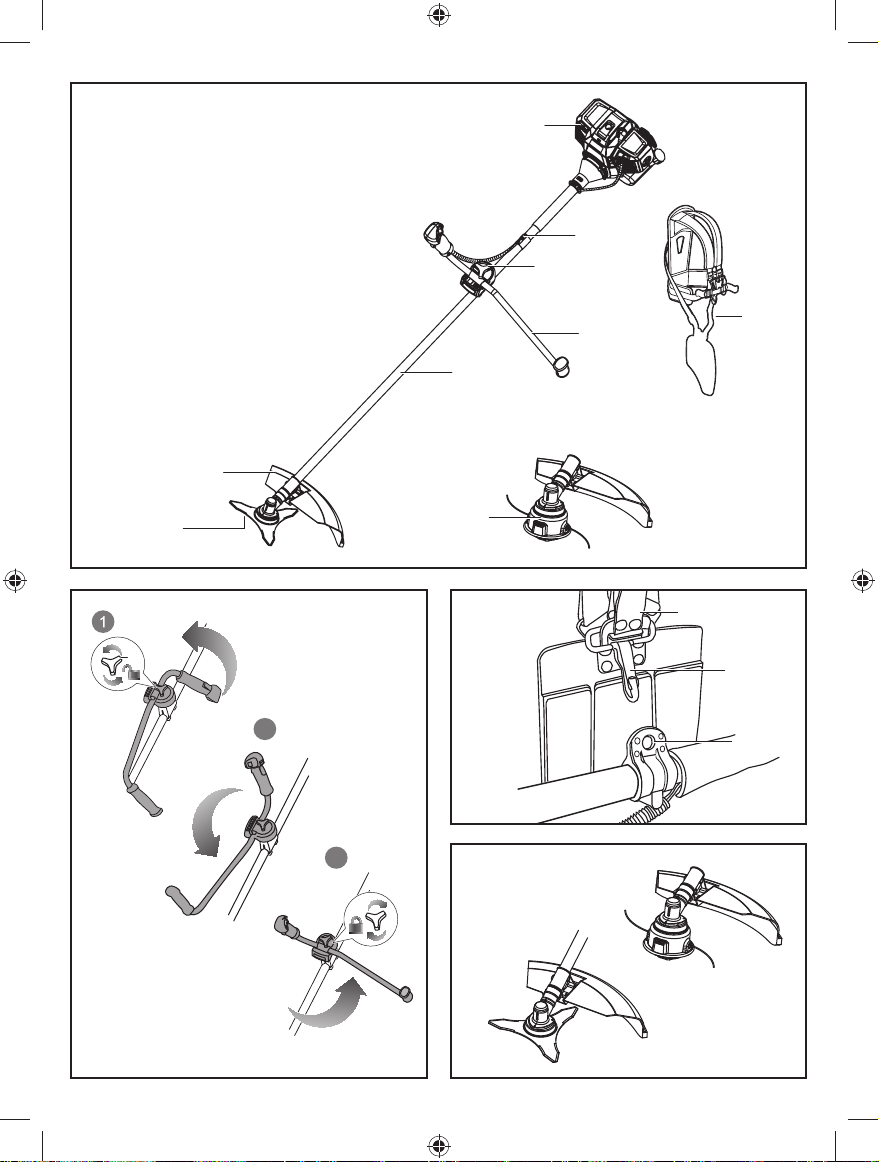

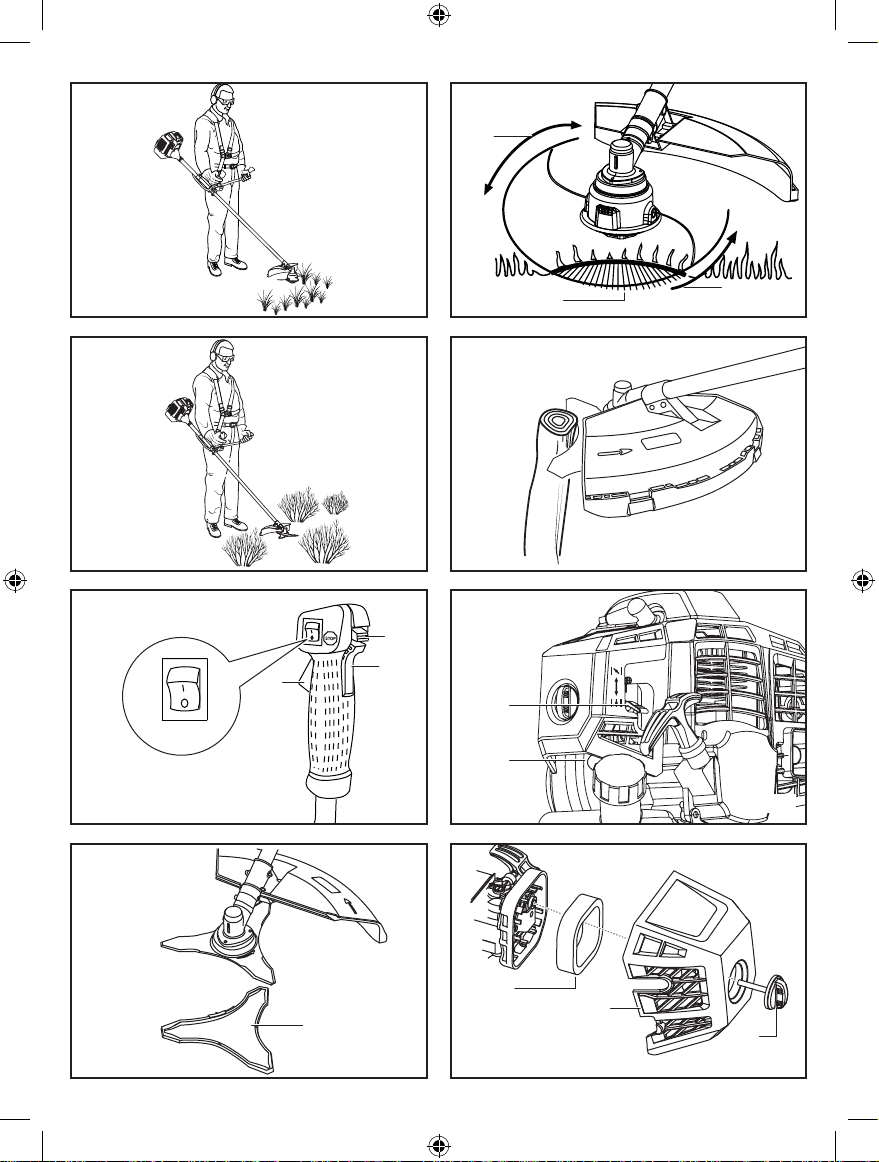

1

2

8

3

4

5

6

8

7

9

2

47

Fig 1

10

2

Fig 3

3

Fig 2

Fig 4

Page 4

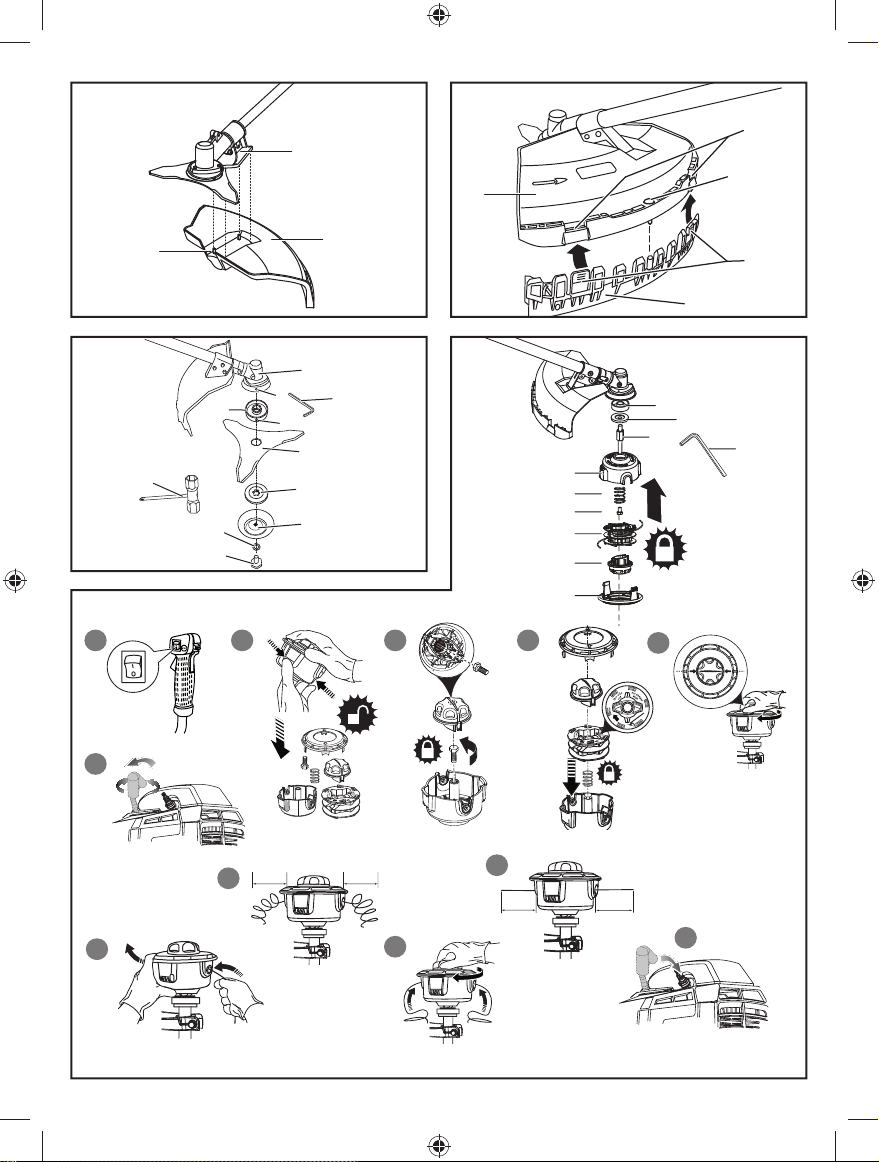

16

200mm200mm

3.0m 3.0m

31

2

54

6

7

9

8

11

10

20

22

27

17

28

29

30

31

32

33

11

14

5

12

5

15

13

Fig 6Fig 5

25

18

20

17

19

6

26

23

24

22

21

Fig 7

Fig 8

Page 5

Fig 9

35

36

34

Fig 10

Fig 11

40

39

38

42

37

41

Fig 13

46

45

43

Fig 15

Fig 12

Fig 14

44

Fig 16

Page 6

English(Original instructions)

Your product has been engineered and manufactured to

Ryobi’s high standard for dependability, ease of operation,

and operator safety. Properly cared for, it will give you

years of rugged, trouble-free performance.

WARNING

To avoid serious personal injury, do not attempt to use

this product until you read thoroughly and understand

completely the operator’s manual. Failure to comply

may result in accidents involving electric shock, fi re,

and/or serious personal injury. Save this operator’s

manual and review frequently for continuing safe

operation and instructing others who may use this

product.

READ ALL INSTRUCTIONS

GENERAL SAFETY RULES

■ Do not allow children or untrained individuals to use

this product.

■ Never start or run the engine inside a closed or poorly

ventilated area; breathing exhaust fumes can kill.

■ Clear the work area before each use. Remove all

objects, such as rocks, broken glass, nails, wire

that can lead to accidents. Remove all objects such

as cords, lights, wire, or string which can become

entangled in the cutting blade.

■ Always use eye protection which is marked to comply

with EN 166.

■ Wear head and eye protection to prevent injury from

falling debris.

■ Wear heavy, long trousers, boots and gloves. Do not

wear loose fitting clothing, shorts, jewelry of any kind,

or go barefoot.

■ Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

■ Keep all bystanders, children, and pets at least 15 m

away.

■ Do not operate this unit when you are tired, ill, or under

the influence of alcohol, drugs, or medication.

■ Do not operate in poor lighting.

■ Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure

to hot surfaces.

■ Keep all parts of your body away from any moving

part.

■ Do not touch area around the exhaust, silencer or

engine of the unit; these parts get hot during operation.

■ Always stop the engine, remove the spark plug

wire and allow the product to cool before refuelling,

cleaning, maintenance or storage.

■ Inspect the unit before each use for loose fasteners,

fuel leaks, etc.

■ Replace any damaged parts before use.

■ Check for and tighten any loose parts.

■ Mix and store fuel in a container approved for fuel.

■ Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refuelling site before starting engine.

■ Stop the engine and allow to cool before refuelling or

storing the unit.

■ Debris when hit by the blade can become thrown

objects and may travel significant distances.

■ Remove all debris from the work area before operating.

■ Keep bystanders (especially children) away from the

working area by 15 m.

■ Allow the engine to cool; empty the fuel tank and

secure the unit from moving before transporting in

a vehicle. Cover the blade with the blade protector

before storing the unit, or during transportation.

SPECIFIC SAFETY RULES

STRING TRIMMER

■ Replace string head if cracked, chipped, or damaged

in any way. Make sure the trimmer head is properly

installed and securely fastened. Failure to do so can

cause serious injury.

■ Make sure all guards, deflectors and handles are

properly and securely attached.

■ Use only original manufacturer’s replacement parts.

■ Never operate the product without the safety guard in

place and in good condition.

■ Use a firm grip on the handles. Make sure you hold

the tool firmly with both handles and that you are well

balanced with your weight evenly distributed on both

feet.

■ Keep the trimmer head below waist level. Never use

the product with the cutting head positioned 76 cm or

more above ground level.

BRUSHCUTTER

■ After engine stops, keep rotating blade in heavy grass

or pulpy weeds until it stops.

■ Never operate the product without the safety guard in

place and in good condition.

■ Use heavy gloves while installing or removing blades.

■ Always stop the engine and remove the spark plug

wire before attempting to remove any obstruction

caught or jammed in the blade or before removing and

11

Page 7

English(Original instructions)

installing the blade.

■ Do not attempt to touch or stop the blade when it is

rotating.

■ A coasting blade can cause injury while it continues

to spin after the engine is stopped or throttle trigger

released. Maintain proper control until the blade has

completely stopped rotating.

■ Replace any blade that has been damaged. Always

make sure blade is installed correctly and securely

fastened before each use. Failure to do so can cause

serious injury.

■ Use only original manufacturer’s replacement parts.

■ The Tri-Arc blade is suited for cutting pulpy weeds and

vines only. Do not use for any other purpose. Never

use the Tri-Arc blade to cut woody brush.

■ Blade thrust is the reaction that may occur when the

spinning blade contacts anything it cannot cut. This

contact may cause the blade to stop for an instant, and

suddenly “thrust” the unit away from the object that

was hit. This reaction can be violent enough to cause

the operator to lose control of the unit. Blade thrust

may occur without warning if the blade snags, stalls

or binds. This is more likely to occur in areas where

it is difficult to see the material being cut. For cutting

ease and safety, approach the weeds being cut from

the right to the left. In the event an unexpected object

or woody stock is encountered, this could minimize the

blade thrust reaction.

■ Never cut any material with a diameter over 13 mm.

■ Always use the shoulder strap/harness with your unit.

Maintain a firm grip on both handles while cutting with

a blade. Keep the blade away from body and below

waist. Never use the product with the cutting head

positioned 76 cm or more above ground level.

■ Cover the blade with the blade protector before storing

the unit, or during transportation. Always remove the

blade protector before using the unit. If not removed,

the blade protector could become a thrown object as

the blade begins to turn.

RESIDUAL RISKS

■ It has been reported that vibrations from hand-held

tools may contribute to a condition called Raynaud’s

Syndrome in certain individuals. Symptoms may

include tingling, numbness and blanching of the

fingers, usually apparent upon exposure to cold.

Hereditary factors, exposure to cold and dampness,

diet, smoking and work practices are all thought to

contribute to the development of these symptoms.

It is presently unknown what, if any, vibrations or

extent of exposure may contribute to the condition.

There are measures that can be taken by the operator

to possibly reduce the effects of vibration:

a. Keep your body warm in cold weather. When operating

the unit wear gloves to keep the hands and wrists

warm.

b. After each period of operation, exercise to increase

blood circulation.

c. Ensure that the machine is correctly located in a

designated working position before starting the

machine.

d. Limit the amount of exposure per day. Take frequent

work breaks.

If you experience any of the symptoms of this

condition, immediately discontinue use and see your

physician about these symptoms.

INTENDED USE

This product is only intended for use outdoors in a well

ventilated area.

The product is intended for cutting long grass, pulpy weed,

brush and similar vegetation at or about ground level.

The cutting plane should be approximately parallel to the

ground surface. The product should not be used to cut or

trim hedges, bushes or other vegetation where the cutting

plane is not parallel to the ground surface.

Some regions have regulations that restrict the use of

the product to some operations. Check with your local

authority for advice

SYMBOLS

Some of the following symbols may be used on your

tool. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate

the product better and safer.

Safety alert

To avoid serious personal injury, do not

attempt to use this product until you read

thoroughly and understand completely

the operator’s manual.

Danger of ricochet. Keep all bystanders,

especially children and pets, at least 15m

from the operating area.

This unit is not intended for use with a

toothed saw type blade.

Rotational direction and maximum speed

of the shaft for the cutting attachment.

12

Page 8

English(Original instructions)

10

Wear non-slip safety footwear when

using this equipment.

Wear non-slip, heavy duty gloves.

Use unleaded petrol intended for motor

vehicle use with an octane rating of 91

[(R + M)/2] or higher.

Use 2-stroke oil for air cooled engines.

Mix the fuel mix thoroughly and also each

time before refuelling

CE Conformity

GOST-R Conformity

Tri-Arc blade

Blade thrust may occur without warning if

the blade snags, stalls or binds.

Wear eye and hearing protection when

operating this product.

To reduce the risk of injury or damage,

avoid contact with any hot surface.

Fire hazard

Set the ignition switch to the “I” (ON)

position.

Fully press and release the primer bulb

5 times.

Pull the starter grip until the engine

attempts to start.

Starting a cold engine

Starting a warm engine

Direction of handle rotation

DESCRIPTION

1. Power head

2. Strap hanger

3. Bike handle

4. Shaft

5. Blade guard

6. Tri-Arc™ blade

7. ReelEasy™ head

8. Knob

9. Quick release tab

10. Latch

11. Mounting bracket

12. Screw

13. Grass defl ector

14. Screw

15. Locking tabs

16. Notches

17. Allen wrench (M6)

18. Hole in the gear case

19. Hole in the upper fl ange washer

20. Upper fl ange washer

21. Blade cover

22. Cupped washer

23. Washer

24. Blade nut

25. Gear head

26. Spark plug wrench

27. Drive connector

28. String head housing

29. Spring

30. Hex bolt

31. Spoo

32. Knob

33. String head cover

34. Best cutting area

35. Dangerous cutting area

36. Direction of rotation

37. Ignition switch

38. Throttle trigger

39. Throttle interlock

40. Throttle lock

41. Primer bulb

Guaranteed sound power level is 113 dB.

Choke closed

Choke open.

Pull: Quick release tab

13

Page 9

English(Original instructions)

42. Choke lever

43. Blade cover

44. Air fi lter knob

45. Air fi lter cover

46. Filter

47. Harness

ASSEMBLY

SETTING UP THE HANDLE

See fi gure 2.

1. Loosen the knob.

2. Lift and rotate the handle to the desired position.

3. Tighten the knob securely.

NOTE: The product has a built-in micro-switch that

deactivates the engine if the knob is not fully tightened.

WARNING

Check the knob for tightness periodically to avoid

serious injury.

ATTACHING THE SHOULDER STRAP

See fi gure 3.

1. Connect the latch on the shoulder strap to the strap

hanger.

2. Adjust the shoulder strap hanger to a balanced

position where the blade or cutter attachment will

suspend between 100 mm to 300 mm above the

ground surface.

3. Adjust the strap hanger to a comfortable position.

NOTE: To quickly release the product from the shoulder

strap, sharply pull the quick release tab.

ATTACHING THE BLADE GUARD AND GRASS

DEFLECTOR

See fi gure 4.

WARNING

When converting from brushcutter to string trimmer or

vice versa, make sure the correct guard/defl ector is

being used.

Blade guard

See fi gure 5.

1. Attach the blade guard to the mounting bracket and

align the screw holes on the blade guard to the screws

on the mounting bracket.

2. Tighten screws securely.

NOTE: The blade guard should remain fitted to the

product at all times.

Grass defl ector

See fi gure 6.

1. Attach the grass defl ector to the blade guard by

placing the two locking tabs into the two notches.

2. Tighten screw securely.

WARNING

To reduce the risk of serious personal injury, always

stop the engine and remove the spark plug wire before

making any adjustments such as changing cutting

heads.

CONVERTING FROM BRUSHCUTTER TO STRING

TRIMMER

WARNING

When using the string trimmer string head, the grass

defl ector must be attached to the blade guard.

Removing the blade

See fi gure 7.

1. Place the wrench through the slot in the upper fl ange

washer and the hole in the gear head. Turn the blade

nut clockwise to remove.

2. Remove the cupped washer and the blade.

3. Remove the upper fl ange washer from the gear shaft

and retain for later use.

4. Attach the grass defl ector to the blade guard by

placing the two locking tabs into the two notches.

5. Tighten screw securely.

NOTE: Store the disassembled parts together for later

use.

Installing the ReelEasy™ string trimmer head

See fi gure 8.

1. Stop the engine and disconnect the spark plug wire.

2. Remove currently installed string trimmer head.

3. Open the ReelEasy™ String Trimmer Head by

depressing the latches on each side. The contents

of the string trimmer head are spring loaded, so keep

your other hand over the string trimmer head cover

while depressing the latches.

4. Remove the string trimmer head cover, bump knob,

and line spool and set aside.

5. Place the cutting head housing on the drive shaft.

Make sure the housing is fully seated.

14

Page 10

English(Original instructions)

6. Install the hex bolt to secure the string trimmer head

to the drive shaft. Tighten by using the hex-shaped

opening on the inside of the bump knob.

NOTE: Only use the bump knob to tighten the bolt.

The use of other tools may allow over tightening of

the bolt, which could damage the string trimmer head.

7. Reinstall the bump head spring into the string trimmer

head and push down to seat.

8. Reinstall the line spool. For the curved shaft attachment

with the ReelEasy™ cutting head the spool should be

placed so “This side out for curved shaft" is visible on

the line spool.

9. Replace the bump knob by inserting it into the centre

of the line spool.

10. Replace the string trimmer head cover, aligning latches

with openings in the string trimmer head. Press cover

and string trimmer head together until both latches

snap into openings securely.

11. Install line as described in the next section of this

manual.

CONVERTING FROM STRING TRIMMER TO

BRUSHCUTTER

WARNING

When using the brushcutter blade, the grass defl ector

must be removed from the blade guard.

Removing the string head

See fi gure 6. See fi gure 8.

1. Open the ReelEasy™ String Trimmer Head by

depressing the latches on each side. The contents of

the bump head are spring loaded, so keep your other

hand over the string head cover while depressing the

latches.

2. Remove the string head cover, bump knob, and line

spool.

3. Remove the hex bolt from the drive shaft by using the

hex-shaped opening on the inside of the string knob.

4. Remove the string head housing from the drive shaft.

5. Place the holding pin through the upper fl ange washer

and the gear head. Using the 16 mm wrench supplied,

turn the drive connector clockwise to remove.

6. Remove the upper fl ange washer from the gear shaft

and retain for later use.

7. Use the combination wrench supplied to loosen all 3

bolts, then remove the grass defl ector from the blade

guard.

NOTE: Store the disassembled parts together for later

use.

Installing the blade

See fi gure 7.

1. Place the upper fl ange washer over the gear shaft with

the hollow side towards the blade guard.

2. Centre the blade on the upper fl ange, making sure

the blade sits fl at. Install the cupped washer with the

raised centre away from the blade.

3. Install the blade nut.

4. Place the wrench through the slot in the upper fl ange

washer and the hole in the gear head. Using the 13 mm

wrench supplied, turn the blade nut counterclockwise

and tighten securely.

OPERATION

FUEL AND REFUELLING

Handling the fuel safely

■ Always handle fuel with care. It is highly flammable.

■ Always refuel outdoors where there are no sparks and

flames. Do not inhale fuel vapour.

■ Do not let petrol or lubricant come in contact with your

skin.

■ Keep petrol and lubricant away from the eyes. If petrol

or lubricant comes in contact with the eyes, wash

them immediately with clean water. If irritation is still

present, see a doctor immediately.

■ Clean up spilled petrol immediately.

Mixing the fuel

■ This product is powered by a 2-stroke engine and

requires pre-mixing petrol and 2-stroke lubricant.

Premix unleaded petrol and 2-stroke engine lubricant

in a clean container approved for petrol.

■ This engine is certified to operate on unleaded petrol

intended for motor vehicle use with an octane rating of

91 ([R + M]/2) or higher.

■ Do not use any type of pre-mixed petrol/lubricant from

fuel service stations.

■ Use synthetic 2-stroke lubricant only. Do not use

automotive lubricant or 2-cycle outboard lubricant.

■ Mix 2% synthetic 2-stroke lubricant into the petrol. This

is a 30:1 ratio.

■ Mix the fuel thoroughly and also each time before

refuelling.

■ Mix in small quantities. Do not mix quantities larger

than usable in a 30-day period. A synthetic 2-stroke

lubricant containing a fuel stabiliser is recommended.

15

Page 11

English(Original instructions)

1 Litre + 33 ml =

2 Litres + 67 ml =

3 Litres + 100 ml = 30:1

4 Litres + 133 ml =

5 Litres + 167 ml =

Filling the tank

■ Clean surface around fuel cap to prevent

contamination.

■ Loosen the fuel cap slowly to release pressure and to

keep fuel from escaping around the cap.

■ Carefully pour fuel mixture into the tank. Avoid spillage.

■ Prior to replacing the fuel cap, clean and inspect the

gasket.

■ Immediately replace fuel cap and hand tighten. Wipe

up any fuel spillage. Move 9 m away from refuelling

site before starting engine.

NOTE: It is normal for smoke to be emitted from a new

engine during and after first use.

■ Use the tip of the string to do the cutting; do not force

the string head into the uncut grass.

■ Wire and picket fences cause extra string wear, even

breakage. Stone and brick walls, kerbs and wood may

wear string rapidly.

■ Avoid trees and shrubs. Tree bark, wood mouldings,

cladding and fence posts can be easily damaged by

the string.

STARTING AND STOPPING

See fi gure 13 - 14.

Choke position A

Choke position B

WARNING

Never start or run the engine inside a closed or poorly

ventilated area; breathing exhaust fumes can kill.

WARNING

Always shut off engine before fuelling. Never add fuel to

a machine with a running or hot engine. Move at least 9

m (30 ft) from refuelling site before starting the engine.

Do not smoke.

OPERATING THE STRING TRIMMER

See fi gure 9.

■ Hold the product with the right hand on the trigger

handle and the left hand on the left handle. Keep a

firm grip with both hands while in operation.

■ The product should be held at a comfortable position

with the trigger handle about hip height.

■ Always operate the product at full throttle. Prolonged

cutting at partial throttle will result in lubricant dripping

from the silencer.

■ Cut tall grass from the top down to prevent grass from

wrapping around the shaft housing and string head

which may cause damage from overheating.

■ If grass becomes wrapped around the string head,

stop the engine, disconnect the spark plug wire, and

remove the grass.

CUTTING TIPS

See fi gure 10.

■ Keep the product tilted towards the area being cut.

■ Do not use in dangerous environments.

To start a cold engine:

1. Lay the product on a fl at, bare surface.

2. Set the ignition switch to the “I” (ON) position.

3. Push the primer bulb approximately 5 times.

4. Set the choke lever to position A (choke closed).

5. Pull the starter grip with a quick fi rm and consistent

upward motion until the engine starts.

6. Set the choke lever to position B (choke open).

7. Allow engine to warm up for 30 seconds prior to

operation.

To start a warm engine:

1. Lay the product on a fl at, bare surface.

2. Set the ignition switch to the “I” (ON) position.

3. Set the choke lever to position B (choke open).

4. Pull the starter grip with a quick fi rm and consistent

upward motion until the engine starts.

To stop the engine:

Set the ignition switch to the “O” (OFF) position.

OPERATING THE BRUSHCUTTER

See fi gure 11 - 12.

■ Hold the product with the right hand on the trigger

handle and the left hand on the left handle. Keep a

firm grip with both hands while in operation.

■ The product should be held at a comfortable position

with the trigger handle about hip height.

■ Maintain your grip and balance on both feet. Position

yourself so that you will not be drawn off balance by

16

Page 12

English(Original instructions)

the kick-back reaction of the cutting blade.

■ Adjust the strap hanger to a comfortable position.

Exercise extreme caution when using the blade with the

product. Blade thrust is the reaction that may occur when

the spinning blade contacts anything it cannot cut. This

contact may cause the blade to stop for an instant, and

suddenly “thrust” the unit away from the object that was

hit. This reaction can be violent enough to cause the

operator to lose control of the unit. Blade thrust may occur

without warning if the blade snags, stalls or binds. This is

more likely to occur in areas where it is diffi cult to see the

material being cut. For cutting ease and safety, approach

the weeds being cut from the right to the left. In the event

an unexpected object or woody stock is encountered, this

could minimize the blade thrust reaction.

BLADE

The blade is suited for cutting pulpy weeds and vines only.

When the blade becomes dull, it can be turned over to

extend its life. Do not sharpen the blade.

CUTTING TECHNIQUE

WARNING

The blades are very sharp and can injure even if they

are not moving. Exercise extreme caution when using

the blade with the product. Safe operation of this tool

requires that you read and understand this operator’s

manual and all labels affi xed to the tool.

■ Both hands must be used at all times to control this

product. Keep a firm grip with both hands while in

operation.

■ Maintain your grip and balance on both feet. Position

yourself so that you will not be drawn off balance by

the kick-back reaction of the cutting blade.

■ Inspect and clear the area of any hidden objects such

as glass, stones, concrete, fencing, wire, wood, metal,

etc.

■ Never use blades near footpaths, fencing, posts,

buildings or other immovable objects.

■ Never use a blade after hitting a hard object without

first inspecting it for damage. Do not use if any

damage is detected.

■ For cutting ease and safety, approach the weeds

being cut from the right to the left.

MAINTENANCE

WARNING

Use only genuine replacement parts and accessories.

Failure to do so may cause poor performance, possible

injury, and will void your warranty.

■ The cutting attachment must not work in idle mode. If

this requirement is not satisfied, the clutch has to be

adjusted or the machine needs an urgent maintenance

by a qualified technician.

■ You may make adjustments and repairs described

in this user manual. For other repairs, have the unit

serviced by an authorized service agent.

■ Consequences of improper maintenance may

include excess carbon deposits resulting in loss of

performance and discharge of black oily residue

dripping from the silencer.

■ Make sure all guards, straps, deflectors and handles

are properly and securely attached to avoid the risk of

personal injury.

STRING REPLACEMENT

See fi gure 8.

■ Ensure the unit is in the off position

■ Remove the spark plug lead to prevent accidental

starting.

■ Use a 2.4 mm diameter monofilament string.

■ Cut one piece of string approximately 6 m in length.

■ Rotate the knob on the string head until the line on

knob aligns with the arrows on the top of string head.

■ Insert one end of the string into the eyelet located on

the side of the string head and push until string comes

out through eyelet on the other side. Continue to push

string through the string head until the middle section

of the string is inside the string head and string outside

the string head is evenly divided on each side.

■ Rotate the knob on the string head clockwise to wind

the string.

■ Wind the string until approximately 20cm remains

protruding from the string head.

BLADE GUARD

See fi gure 15.

Always place the blade protector on the blade when the

unit is not in use. The blade protector has clips round the

edges to snap over the blade and keep it in place. Wear

gloves and be cautious when handling the blade.

NOTE: Always remove the blade protector before using

the unit. If not removed, the blade protector could become

17

Page 13

English(Original instructions)

a thrown object as the blade begins to turn.

CLEANING THE EXHAUST PORT AND SILENCER

Depending on the type of fuel used, the type and amount

of lubricant used, and/or your operating conditions, the

exhaust port and silencer may become blocked with

carbon deposits. If you notice a power loss with your gas

powered tool, a qualifi ed service technician will need to

remove these deposits to restore performance.

CLEANING THE AIR FILTER

See fi gure 16.

■ Ensure the unit is in the off position.

■ Remove the screw and air filter cover.

■ Remove the air filter and clean it with warm soapy

water.

■ Rinse, and let the air filter dry completely.

■ Replace the air filter.

■ Replace the holding plate and air filter cover.

■ Tighten the screw.

CHECKING THE FUEL CAP

WARNING

A leaking fuel cap is a fi re hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable fi lter and a

check valve. A clogged fuel fi lter will cause poor engine

performance. If performance improves when the fuel cap

is loosened, check valve may be faulty or fi lter clogged.

Replace fuel cap if required.

REPLACING THE SPARK PLUG

This engine uses a TORCH L7RTC with 0.6 mm - 0.7 mm

electrode gap. Use an exact replacement.

■ Drain all of the fuel from the tank into a container

approved for gasoline.

■ Run the engine until it stops.

■ Clean all foreign material from the product.

■ Store the product in a well-ventilated place that is

inaccessible to children. Keep away from corrosive

agents such as garden chemicals and de-icing salts.

■ Cover the blade with the blade protector before storing

the unit, or during transportation.

■ Abide by all government and local regulations for the

safe storage and handling of petrol.

INSPECTION AFTER DROPPING OR OTHER IMPACTS

Thoroughly inspect the product and identify any affections

or damage with it. Any part that is damaged should be

properly repaired or replaced by an authorized service

centre.

CAUTION

Be careful not to cross-thread the spark plug. Crossthreading will seriously damage the engine.

STORING THE PRODUCT

Short term storage

■ Clean all foreign material from the product.

■ Store the product in a well-ventilated place that is

inaccessible to children.

Long term storage (1 month or longer)

18

Page 14

English(Original instructions)

TROUBLESHOOTING

Problem Possible cause Solution

The spark plug may be damaged, remove it and check for

dirt and cracks. Replace with a new spark plug.

Push primer bulb until bulb is full of fuel. If bulb does not

fi ll, primary fuel delivery system is blocked. Contact a

service dealer. If primer bulb fi lls, engine may be fl ooded

(see next item).

Remove spark plug, turn trimmer so spark plug hole is

aimed at the ground. Make sure lever is in the open choke

position and pull starter cord 10 to 14 times. This will clear

excess fuel from engine. Clean and reinstall spark plug.

With the throttle trigger fully depressed, pull starter cord

three times with lever at open choke position. If engine

does not start, move choke lever to close choke position

and follow normal starting instructions in “STARTING

AND STOPPING” section. If engine still fails to start,

repeat procedure with a new spark plug.

Contact a service dealer.

Clean air fi lter. Refer to “Replacing and Cleaning Air

Filter” earlier in this manual.

Engine will not start.

Engine starts but will not

accelerate.

Engine does not reach full speed

and emits excessive smoke.

Engine starts, runs, and

accelerates but will not idle.

Blade continues to rotate at idle

speed.

Grass wraps round shaft housing

and string head.

Oil drips from silencer.

No spark

No fuel.

Flooded engine.

Starter rope pulls harder now than when

new.

Carburetor requires adjustment. Contact a service dealer.

Check oil fuel mixture. Use fresh fuel and the correct synthetic 2-stroke oil mix.

Air fi lter dirty.

Carburetor requires adjustment. Contact a servicing dealer.

Carburettor requires adjustment. Contact a servicing dealer.

Carburetor requires adjustment. Contact a servicing dealer.

Cutting tall grass at ground level. Cut tall grass from the top down.

Operating trimmer at part throttle. Operate trimmer at full throttle.

Operating trimmer at part throttle. Operate trimmer at full throttle.

Check oil/fuel mixture. Use fresh fuel and the correct synthetic 2-stroke oil mix.

Air fi lter is dirty. Clean per instruction in Maintenance Section.

Carburetor requires adjustment. Contact a servicing dealer.

19

Loading...

Loading...