Ryobi MMA-140 Owner's Operating Manual

OWNER’S OPERATING MANUAL

MMA INVERTER WELDER

MODEL MMA-140

KEEP THIS MANUAL FOR FUTURE REFERENCE

Your new inverter generator has been engineered and manufactured to Ryobi’s

high standard of dependability, ease of operation and operator safety. Properly

cared for, it will give you years of rugged, trouble free performance. If you use

your inverter generator properly and only for what it is intended, you will enjoy

years of safe, reliable service.

SPE CIFICATIONS

Rated input power supply......................................................AC 230V±5% 50/60Hz

Rated input capacity......................................................................................5.3KVA

Current adjustment range........................................................................... 20-140A

Rated duty cycle...................................................................

............................. 80%

Rated voltage..........................................................................................20.8-25.6

No load voltage.................................................................................................. 63V

V

Overall efficiency................................................................................................80%

Housing protection grade......

..........................................................................IP21S

Power factor..............................................................................................0.73 cosφ

Insulation grade...................................................................................................... F

Electrode diameter.........................................................................

..........1.6-3.2mm

Noise......................................................................................................... <70dB(A)

Dimensions............................................................................... 287 x 120 x 247mm

Net weight........................................................................................................ 3.8kg

THANK YOU FOR BUYING A RYOBI

MMA INVERTER WELDER

CAUTION: Carefully read through this entire owner’s

manual, paying close attention to the general

safety rules and rules for safe operation,

before using.

1

2

IMPORTANT SAFETY INSTRUCTIONS

The purpose of safety rules is to attract your

a

ttention to possible dangers. The safety symbols

and the explanations with them, require your

c

areful attention and understanding. The safety

w

arnings do not by themselves eliminate any

danger. The instruction or warnings they give are

not substitutes for proper accident prevention

measures.

SAFETY ALERT SYMBOL. Indicates

danger, caution or warning. May be used

in conjunction with other symbols or

pictures.

Failure to obey a safety warning can result in

serious injury to yourself or to others. Always follow

the safety precautions to reduce the risk of fire,

electric shock and personal injury.

Do not attempt to operate this tool until you have

read thoroughly and completely understood the

safety rules, etc. contained in this manual. Failure

to comply can result in accidents involving fire,

electric shock or serious personal injury. Save this

Owners Operating Manual and review it frequently

for continual safe operation and for instructing

others who may use this tool.

EMF INFORMATION

Considerations About Welding And The Effects Of

Low Frequency Electric And Magnetic Fields.

Welding current, as it flows through welding cables,

will cause electro- magnetic fields. There has been

and still is some concern about such fields.

However, after examining more than 500 studies

spanning 17 years of research, a special blue

ribbon committee of the National Research Council

concluded that: “The body of evidence, in the

committee’s judgment, has not demonstrated that

exposure to power- frequency electric and

magnetic fields is a human-health hazard.”

However, studies are still going forth and evidence

continues to be examined. Until the final

conclusions of the research are reached, you may

wish to minimize your exposure to electromagnetic

fields when welding or cutting.

To reduce magnetic fields in the workplace, use the

following procedures:

1. Keep cables close together by twisting or

taping them.

2. Arrange cables to one side and away from

the operator.

3. Do not coil or drape cables around your body.

4. Keep welding power source and cables as far

a

way from operator as practical.

5. Connect work clamp to work piece as close

t

o the weld as possible.

ABOUT PACEMAKERS

Pacemaker wearers consult your doctor first. If

cleared by your doctor, then following the above

procedures is recommended.

WELDING HAZARDS

The symbols shown below are used throughout this

manual to call attention to and identify possible

hazards. When you see the symbol, watch out, and

follow the related instructions to avoid the hazard.

Only qualified persons should service, test,

maintain, and repair this unit.

During servicing, keep everybody, especially

children, away.

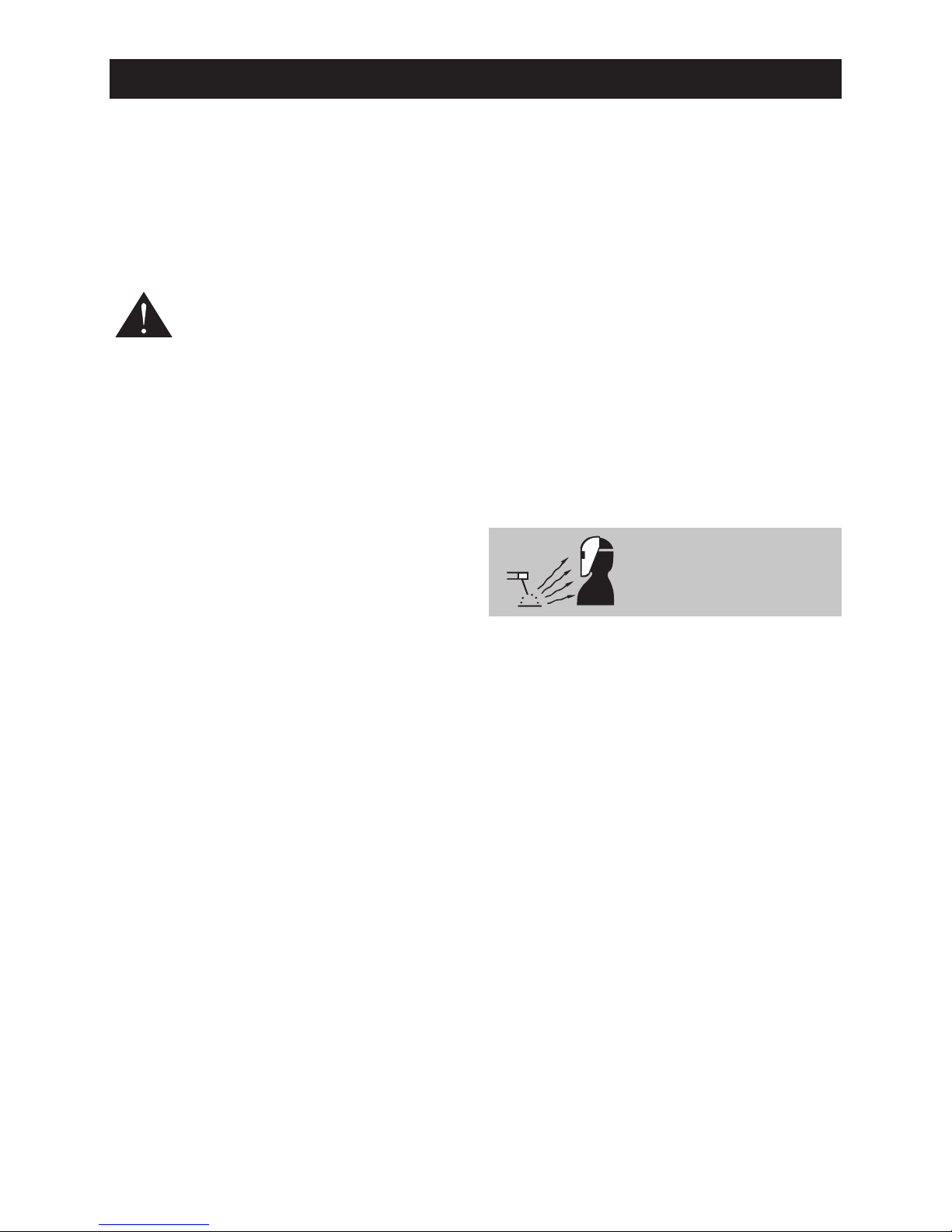

ARC RAYS can burn eyes and skin; NOISE can

damage hearing. Arc rays from the welding

process produce intense heat and strong

ultraviolet rays that can burn eyes and skin.

Noise from some processes can damage

hearing.

1. Wear a welding helmet fitted with a proper

shade of filter (ANSI Z49.1) to protect your

face and eyes when welding or watching.

2. Wear approved safety glasses. Side shields

recommended. Never wear contact lenses

while welding.

3. Use protective screens or barriers to protect

others from flash and glare; warn others not

to watch the arc.

4. Wear protective clothing made from durable,

flame-resistant material (wool and leather)

and foot protection.

5. Use approved ear plugs or ear muffs if noise

level is high.

ARC RAYS

Can Burn

3

IMPORTANT SAFETY INSTRUCTIONS

4

IMPORTANT SAFETY INSTRUCTIONS

Touching live electrical parts can cause fatal

shocks or severe burns. The electrode and

work circuit is electrically live whenever the

output is on. The input power circuit and

machine internal circuits are also live when

power is on. In semiautomatic or automatic

wire welding, the wire, wire reel, drive roll

housing, and all metal parts touching the

welding wire are electrically live. Incorrectly

installed or improperly grounded equipment is

a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body

protection.

3. Insulate yourself from work and ground using

dry insulating mats or covers.

4. Disconnect input power or stop engine before

installing or servicing this equipment. Lock input

power disconnect switch open, or remove line

fuses so power cannot be turned on

accidentally.

5. Properly install and ground this equipment

according to its Owner’s Manual and national,

state, and local codes.

6. Turn off all equipment when not in use.

Disconnect power to equipment if it will be left

unattended or out of service.

7. Use fully insulated electrode holders. Never dip

holder in water to cool it or lay it down on the

ground or the work surface. Do not touch

holders connected to two welding machines at

the same time or touch other people with the

holder or electrode.

8. Do not use worn, damaged, undersized, or

poorly spliced cables.

9. Do not wrap cables around your body.

10. Ground the workpiece to a good electrical

(earth) ground.

11. Do not touch electrode while in contact with

the work (ground) circuit.

12. Use only well-maintained equipment. Repair

or replace damaged parts at once.

13. In confined spaces or damp locations, do not

u

se a welder with AC output unless it is

equipped with a voltage reducer. Use

e

quipment with DC output.

14. Wear a safety harness to prevent falling if

w

orking above floor level.

15. Keep all panels and covers securely in place.

FUMES AND GASES can be hazardous to your

health. Welding produces fumes and gases.

Breathing these fumes and gases can be hazardous to your health.

1. Keep your head out of the fumes. Do not

breath the fumes.

2. If inside, ventilate the area and/or use

exhaust at the arc to remove welding fumes

and gases.

3. If ventilation is poor, use an approved air-

supplied respirator.

4. Read the Material Safety Data Sheets

(MSDSs) and the manufacturer’s instruction

for metals, consumables, coatings, and

cleaners.

5. Work in a confined space only if it is well

ventilated, or while wearing an air-supplied

respirator.

Shielding gases used for welding can displace

air causing injury or death. Be sure the

breathing air is safe.

6. Do not weld in locations near degreasing,

cleaning, or spraying operations. The heat

and rays of the arc can react with vapors to

form highly toxic and irritating gases.

7. Do not weld on coated metals, such as

galvanized, lead, or cadmium plated steel,

unless the coating is removed from the weld

area, the area is well ventilated, and if

necessary, while wearing an airsupplied

respirator. The coatings and any metals

containing these elements can give off toxic

fumes if welded.

ELECTRIC SHOCK

Can Kill

FUMES & GASES

Can Be Dangerous

FLYING SPARKS AND HOT METAL can cause

injury.

Chipping and grinding cause flying metal.

As welds cool, they can throw off slag.

1. Wear approved face shield or safety goggles.

Side shields recommended.

2. Wear proper body protection to protect skin.

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode.

Since gas cylinders are normally part of the

welding process, be sure to treat them

carefully.

1. Protect compressed gas cylinders from

excessive heat, mechanical shocks, and arcs.

2. Install and secure cylinders in an upright

position by chaining them to a stationary

support or equipment cylinder rack to

prevent falling or tipping.

3. Keep cylinders away from any welding or other

electrical circuits.

4. Never allow a welding electrode to touch any

cylinder.

5. Use only correct shielding gas cylinders,

regulators, hoses, and fittings designed for the

specific application; maintain them and

associated parts in good condition.

6. Turn face away from valve outlet when opening

cylinder valve.

7. Keep protective cap in place over valve except

when cylinder is in use or connected for use.

W

ELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc.

The flying sparks and hot metal, weld spatter,

hot workpiece, and hot equipment can cause

fires and burns. Accidental contact of electrode

or welding wire to metal objects can cause

sparks, overheating, or fire.

1. Protect yourself and others from flying sparks

and hot metal.

2. Do not weld where flying sparks can strike

flammable material.

3. Remove all flammables within 35 ft (10.7 m) of

the welding arc. If this is not possible, tightly

cover them with approved covers.

4. Be alert that welding sparks and hot materials

from welding can easily go through small

cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher

nearby.

6. Be aware that welding on a ceiling, floor,

bulkhead, or partition can cause fire on the

hidden side.

7. Do not weld on closed containers such as

tanks or drums.

8. Connect work cable to the work as close to

the welding area as practical to prevent

welding current from traveling long, possibly

unknown paths and causing electric shock and

fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off

welding wire at contact tip when not in use.

11. When not welding, make certain no part of the

electrode circuit is touching the work or

ground. Accidental contact can cause

overheating and create a fire hazard.

5

IMPORTANT SAFETY INSTRUCTIONS

FLYING SPARKS

Can Cause Injury

CYLINDERS Can

Explode If Damaged

WELDING Can

Cause Fire or Injury

6

IMPORTANT SAFETY INSTRUCTIONS

M

oving parts, such as fans, rotors, and belts

can cut fingers and hands and catch loose

clothing.

1. Keep all doors, panels, covers, and guards

closed and securely in place.

2. Stop engine before installing or connecting

unit.

3. Have only qualified people remove guards or

covers for maintenance and troubleshooting as

necessary.

4. To prevent accidental starting during servicing,

disconnect negative (-) battery cable from

battery.

5. Keep hands, hair, loose clothing, and tools

away from moving parts.

6. Reinstall panels or guards and close doors

when servicing is finished and before starting

engine.

SPARKS can cause BATTERY GASES TO EXPLODE; BATTERY ACID can burn eyes and

skin. Batteries contain acid and generate explosive gases.

1. Always wear a face shield when working on

a battery.

2. Stop engine before disconnecting or

connecting battery cables.

3. Do not allow tools to cause sparks when

working on a battery.

4. Do not use welder to charge batteries or jump

start vehicles.

5. Observe correct polarity (+ and –) on

STEAM AND PRESSURIZED HOT COOLANT

can burn face, eyes, and skin.

The coolant in the radiator can be very hot and

under pressure.

1. Do not remove radiator cap when engine is

hot. Allow engine to cool.

2. Wear gloves and put a rag over cap area when

removing cap.

3. Allow pressure to escape before completely

removing cap.

1. High-frequency (H.F.) can interfere with radio

navigation, safety services, computers, and

communications equipment.

2. Have only qualified persons familiar with

electronic equipment install, test, and service

H.F. producing units.

3. The user is responsible for having a qualified

electrician promptly correct any interference

problem resulting from the installation.

4. If notified by the FCC about interference, stop

using the equipment at once.

5. Have the installation regularly checked and

maintained.

6. Keep high-frequency source doors and panels

tightly shut, keep spark gaps at correct setting,

and use grounding and shielding to minimize

the possibility of interference.

MOVING PARTS

Can Cause Injury

SPARKS Can Cause

BATTERY GASES

TO EXPLODE

SPARKS Can Cause

BATTERY GASES

TO EXPLODE

H.F. RADIATION Can

Cause Interference

1. Electric current flowing through any conductor

causes localized Electric and Magnetic Fields

(EMF). Welding current creates EMF fields

around welding cables and welding machines.

2. EMF fields may interfere with some

pacemakers, and welders having a pacemaker

should consult their physician before welding.

3. Exposure to EMF fields in welding may have

other health effects which are now not known.

4. All welders should use the following

procedures in order to minimize exposure to

EMF fields from the welding circuit:

5. Route the electrode and work cables together Secure them with tape when possible.

6. Never coil the electrode lead around your

body.

7. Do not place your body between the electrode

and work cables. If the electrode cable is on

your right side, the work cable should also be

on your right side.

8. Connect the work cable to the workpiece as

close as possible to the area being welded.

9. Do not work next to welding power source.

1. Lift unit with handle on top of case.

2. Use handcart or similar device of adequate

capacity.

3. If using a fork lift vehicle, place and secure

unit on a proper skid before transporting.

1

. Turn off input power using the disconnect

switch at the fuse box before working on the

equipment.

2. Install equipment in accordance with the

countries National Electrical Code, all local

codes and the manufacturer’s

recommendations.

3. Ground the equipment in accordance with the

countries National Electrical Code and the

manufacturer’s recommendations.

1. Do not touch hot parts bare handed.

2. Allow cooling period before working on

welding gun or torch.

1. Do not place unit on, over, or near

combustible surfaces.

2. Do not service unit near flammables.

1. Put on grounded wrist strap BEFORE handling

boards or parts.

2. Use proper static-proof bags and boxes to

store, move, or ship PC boards.

7

IMPORTANT SAFETY INSTRUCTIONS

ELECTRIC AND

MAGNETIC FIELDS

May Be Dangerous

FALLING UNIT Can

Cause Injury

FOR ELECTRICALLY

Powered Equipment

HOT PARTS Can

Cause Severe Burns

FIRE or EXPLOSION

Hazard

STATIC Can Damage

PC Boards

8

IMPORTANT SAFETY INSTRUCTIONS

1

. Allow cooling period; follow rated duty cycle.

2. Reduce current or reduce duty cycle before

starting to weld again.

3. Do not block or filter airflow to unit.

1

. Consult the Owner’s Manual for welding

safety precautions. Do not install, operate or

repair this equipment without reading this

manual and the safety precautions throughout.

2. Use only genuine replacement parts

OVERUSE Causes

OVERHEATING

READ THE

INSTRUCTIONS

ADDITIONAL SAFETY INSTRUCTIONS

1. ALWAYS ensure that there is full free air

circulating around the outer casing of the

machine, and that the louvres are

unobstructed.

2. ALWAYS use a proper welding face shield or

helmet, with suitable filter lenses. Proper

gloves and working clothes should be worn at

all times.

3. ALWAYS check that the pressure regulator and

gauges are working correctly. DO NOT

lubricate the regulator.

4. ALWAYS use the correct regulator. Each

regulator is designed to be used with a specific

gas.

5. ALWAYS inspect the hose before use to

ensure it is in good condition.

6. ALWAYS keep the free length of gas hose

outside the work area.

7. ALWAYS remove all flammable materials from

the welding area.

8. NEVER remove any of the panels unless the

machine is disconnected from the supply, AND

never use the machine with any of the panels

removed.

9. NEVER attempt any electrical or mechanical

repair unless your are a qualified technician.

If you have a problem with the machine contact

your local RYOBI dealer.

10. NEVER use or store in a wet/damp

environment. DO NOT EXPOSE TO RAIN.

11. NEVER use gas from a cylinder, the content

of which is unknown. It is important to ensure

the appropriate gas is being used.

12. NEVER use a damaged cylinder.

13. NEVER lift the cylinder by the valve.

14. NEVER expose the cylinder to a heat source

or sparks.

15. NEVER continue to weld, if, at any time, you

feel even the smallest electric shock. Stop

welding IMMEDIATELY, and DO NOT attempt

to use the machine until the fault is diagnosed

and corrected.

16. NEVER use the welder with input connections

greater than 10M in length.

17. NEVER point the torch at any person or

animal.

18. NEVER touch the torch nozzle until the welder

is switched OFF and the nozzle has been

allowed to cool off.

19. NEVER connect, disconnect, or attempt to

service the torch, until the machine is switched

OFF and disconnected from the mains supply.

20. NEVER allow the cables to become wrapped

around the operator or any person in the

vicinity.

21. Safety devices such as interlocks and circuit

breakers should not be disconnected or

shunted out.

22. Before installation, inspection, or service of

equipment, shut OFF all power and remove

line fuses to prevent accidental turning ON

of power.

23. Do not open power circuit or change polarity

while welding.

9

ADDITIONAL SAFETY INSTRUCTIONS

24. If, in an emergency, it must be disconnected,

g

uard against shock burns, or flash from switch

arcing. Always shut OFF and disconnect all

p

ower to equipment. Power disconnect switch

m

ust be available near the welding power

source.

25. Fully insulated electrode holders should be

used. Do NOT use holders with protruding

screws or with any form of damage.

26. Fully insulated lock-type connectors should be

u

sed to join welding cable.

27. Frequently inspect cables for wear, cracks and

d

amage. IMMEDIATELY REPLACE those with

excessively worn or damaged insulation to

a

void possibly lethal shock from bared cable.

Cables with damaged areas may be taped to

give resistance equivalent to original cable.

Keep cable dry, free of oil and grease, and

protected from hot metal and sparks.

INSTALLATION

ENVIRONMENT

These units are designed for use in environments

with increased hazard of electric shock.

A. Examples of environments with increased

hazard of electric shock are:

1. In locations in which freedom of movement is

restricted, so that the operator is forced to

perform the work in a cramped (kneeling,

sitting or lying) position with physical contact

with conductive parts.

2. In locations which are fully or partially limited

by conductive elements, and in which there is

a high risk of unavoidable or accidental contact

by the operator.

3. In wet or damp hot locations where humidity

or perspiration considerable reduces the skin

resistance of the human body and the

insulation properties of accessories.

B. Environments with increased hazard of electric

shock do not include places where electrically

conductive parts in the near vicinity of the

operator, which can cause increased hazard,

have been insulated.

LOCATION

This machine can operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable operation:

• This machine must be located where there is

free circulation of clean air without restrictions

for air movement to and from the air vents. Do

not cover the machine with paper, cloth or rags

when switched on.

• Dirt and dust that can be drawn into the

machine should be kept to a minimum.

• This machine has a protection rating of IP21S.

Keep it dry and do not place it on wet ground

or in puddles. Do not use in wet or damp

locations. Store indoors.

• Locate the machine away from radio controlled

machinery. Normal operation may adversely

affect the operation of nearby radio controlled

machinery, which may result in injury or

equipment damage.

Read the section on electromagnetic compatibility

in this manual.

• Do not operate in areas with an ambient

temperature greater than 40°C.

TILTING

Place the machine directly on a secure, level

surface.

Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

The machine may topple over if this procedure is

not followed.

VENTILATION

This cutting machine can create powerful cutting

current and has strict cooling requirements that

cannot be met with natural ventilation. Therefore

the built-in fan is very important in enabling the

machine to work stable with effective cooling. The

operator should make sure that the louvers be

uncovered and unblocked. The minimum distance

between the machine and nearby objects should

be 25cm.

Loading...

Loading...