Ryobi BD4601 Owner's Manual

4 x 36

45

30

15

60

45

15

30

0

15

30

45

60

OPERATOR’S MANUAL

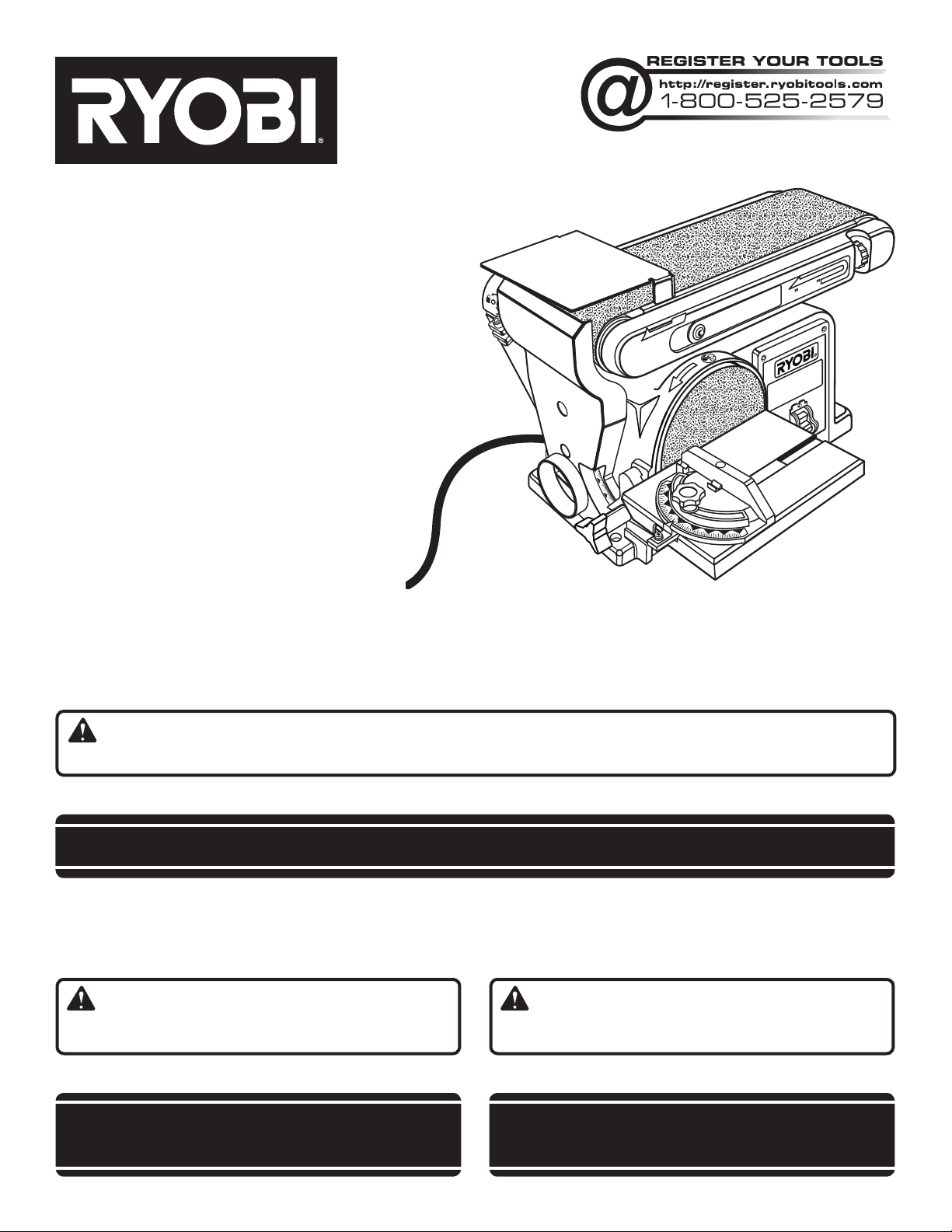

BELT/DISC SANDER

MANUEL D’UTILISATION

PONCEUSE À BANDE/DISQUE

MANUAL DEL OPERADOR

LIJADORA DE BANDA Y DISCO

BD4601

Your belt/disc sander has been engineered and manufactured to our high standard for dependability, ease of operation, and

operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING: To reduce the risk of injury, the user must read and understand the operator’s manual before using

this product.

Thank you for purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette ponceuse à bande/disque a été conçue et fabriquée conformément à nos strictes normes de fiabilité, simplicité d’emploi et sécurité

d’utilisation. Correctement entretenue, elle vous donnera des

années de fonctionnement robuste et sans problème.

AVERTISSEMENT : Pour réduire les risques de

blessures, l’utilisateur doit lire et veiller à bien comprendre le

manuel d’utilisation avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su

lijadora de banda y disco

formidad con nuestras estrictas normas para brindar fiabilidad,

facilidad de uso y seguridad para el operador. Con el debido cuidado, le brindará muchos años de sólido y eficiente funcionamiento.

ha sido diseñado y fabricado de con-

ADVERTENCIA: Para reducir el riesgo de lesiones,

el usuario debe leer y comprender el manual del operador antes

de usar este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

TABLE OF CONTENTS

Introduction ..................................................................................................................................................................... 2

Warranty .......................................................................................................................................................................... 2

General Safety Rules .................................................................................................................................................... 3-4

Specific Safety Rules ....................................................................................................................................................... 4

Symbols ........................................................................................................................................................................... 5

Electrical .......................................................................................................................................................................... 6

Features ........................................................................................................................................................................... 7

Assembly ...................................................................................................................................................................... 8-9

Operation .................................................................................................................................................................... 9-11

Adjustments ................................................................................................................................................................... 11

Maintenance .................................................................................................................................................................. 12

Figure numbers (illustrations) ................................................................................................................................... 13-18

Parts Ordering / Service ................................................................................................................................... Back Page

INTRODUCTION

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability have

been given top priority in the design of this product making it easy to maintain and operate.

WARRANTY

RYOBI® POWER TOOL - LIMITED TWO YEAR WARRANTY AND 30 DAY EXCHANGE POLICY

One World Technologies, Inc., warrants its Ryobi® power tools with the following conditions:

30-DAY EXCHANGE POLICY: During the first 30 days after date of purchase, you may either request service under this

warranty or you may exchange any Ryobi® power tool which does not work properly due to defective workmanship or

materials by returning the power tool to the dealer from which it was purchased. To receive a replacement power tool

or requested warranty service, you must present proof of purchase and return all original equipment packaged with the

original product. The replacement power tool will be covered by the limited warranty for the balance of the two year period

from the date of the original purchase.

WHAT THIS WARRANTY COVERS: This warranty covers all defects in workmanship or materials in your Ryobi® power

tool for a period of two years from the date of purchase. With the exception of batteries, power tool accessories are

warranted for ninety (90) days. Batteries are warranted for two years.

HOW TO GET SERVICE: Just return the power tool, properly packaged and postage prepaid, to an Authorized Service

Center. You can obtain the location of the Service Center nearest you by contacting a service representative at One

World Technologies, Inc., P.O. Box 1207, Anderson, SC 29622-1207, by calling 1-800-525-2579 or by logging on to www.

ryobitools.com. When you request warranty service, you must also present proof of purchase documentation, which

includes the date of purchase (for example, a bill of sale). We will repair any faulty workmanship, and either repair or replace

any defective part, at our option. We will do so without any charge to you. We will complete the work in a reasonable time,

but, in any case, within ninety (90) days or less.

WHAT’S NOT COVERED: This warranty applies only to the original purchaser at retail and may not be transferred. This

warranty only covers defects arising under normal usage and does not cover any malfunction, failure or defects resulting

from misuse, abuse, neglect, alteration, modification or repairs by other than Authorized Service Centers. One World

Technologies, Inc. makes no warranties, representations or promises as to the quality or performance of its power tools

other than those specifically stated in this warranty.

ADDITIONAL LIMITATIONS: Any implied warranties granted under state law, including warranties of merchantability or

fitness for a particular purpose, are limited to two years from the date of purchase. One World Technologies, Inc. is not

responsible for direct, indirect, or incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

2 - English

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure to follow

all instructions listed below, may result in electric shock,

fire and/or serious personal injury.

READ ALL INSTRUCTIONS

WORK AREA

KNOW YOUR POWER TOOL. Read the operator’s

manual carefully. Learn the applications and limitations

as well as specific potential hazards related to this tool.

GUARD AGAINST ELECTRICAL SHOCK BY

PREVENTING BODY CONTACT WITH GROUNDED

SURFACES. For example: pipes, radiators, ranges, re-

frigerator enclosures.

KEEP GUARDS IN PLACE and in working order.

REMOVE ADJUSTING KEYS AND WRENCHES. Form

habit of checking to see keys and adjusting wrenches are

removed from tool before turning it on.

KEEP THE WORK AREA CLEAN. Cluttered work areas

and work benches invite accidents. DO NOT leave tools

or pieces of wood on the tool while it is in operation.

DO NOT USE IN DANGEROUS ENVIRONMENTS. Do

not use power tools in damp or wet locations or expose

them to rain. Keep the work area well lit.

KEEP CHILDREN AND VISITORS AWAY. All visitors

should wear safety glasses and be kept a safe distance

from work area. Do not let visitors contact tool or extension cord while operating.

MAKE WORKSHOP CHILDPROOF with padlocks,

master switches, or by removing starter keys.

DON’T FORCE THE TOOL. It will do the job better and

safer at the rate for which it was designed.

USE THE RIGHT TOOL. Do not force the tool or attach-

ment to do a job for which it was not designed.

USE THE PROPER EXTENSION CORD. Make sure your

extension cord is in good condition. Use only a cord heavy

enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gauge size

(A.W.G.) of at least 16 is recommended for an extension

cord 50 feet or less in length. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord.

DRESS PROPERLY. Do not wear loose clothing, neckties,

or jewelry that can get caught and draw you into moving

parts. Rubber gloves and nonslip footwear are recommended when working outdoors. Also wear protective

hair covering to contain long hair.

ALWAYS WEAR SAFETY GLASSES WITH SIDE

SHIELDS. Everyday eyeglasses have only impact-resis-

tant lenses, they are NOT safety glasses.

SECURE WORK. Use clamps or a vise to hold work when

practical, it is safer than using your hand and frees both

hands to operate the tool.

DO NOT OVERREACH. Keep proper footing and balance

at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and

clean for best and safest performance. Follow instructions

for lubricating and changing accessories.

DISCONNECT TOOLS. When not in use, before servic-

ing, or when changing attachments, blades, bits, cutters,

etc., all tools should be disconnected from power source.

AVOID ACCIDENTAL STARTING. Be sure switch is off

when plugging in any tool.

USE RECOMMENDED ACCESSORIES. Consult the

operator’s manual for recommended accessories. The

use of improper accessories may result in injury.

NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped.

CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of

parts, mounting and any other conditions that may affect

its operation. A guard or other part that is damaged must

be properly repaired or replaced by an authorized service

center to avoid risk of personal injury.

USE THE RIGHT DIRECTION OF FEED. Feed work into

a blade, cutter, or sanding spindle against the direction

of rotation of the blade, cutter, or sanding spindle only.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

THE POWER OFF. Don’t leave tool until it comes to a

complete stop.

PROTECT YOUR LUNGS. Wear a face or dust mask if

the cutting operation is dusty.

PROTECT YOUR HEARING. Wear hearing protection

during extended periods of operation.

DO NOT ABUSE CORD. Never carry tool by the cord or

yank it to disconnect from receptacle. Keep cord from

heat, oil, and sharp edges.

USE OUTDOOR EXTENSION CORDS. When tool

is used outdoors, use only extension cords with

approved ground connection that are intended for use

outdoors and so marked.

KEEP BLADES CLEAN, SHARP, AND WITH

SUFFICIENT SET. Sharp blades minimize stalling

and kickback.

NEVER USE IN AN EXPLOSIVE ATMOSPHERE.

Normal sparking of the motor could ignite fumes.

INSPECT TOOL CORDS PERIODICALLY. If dam-

aged, have repaired by a qualified service technician at

an authorized service facility. The conductor with insula-

tion having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug is neces-

sary, do not connect the equipment-grounding conductor

to a live terminal. Repair or replace a damaged or worn

cord immediately. Stay constantly aware of cord location

and keep it well away from the rotating blade.

3 - English

GENERAL SAFETY RULES

INSPECT EXTENSION CORDS PERIODICALLY and

replace if damaged.

KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND

GREASE. Always use a clean cloth when cleaning. Never

use brake fluids, gasoline, petroleum-based products, or

any solvents to clean tool.

STAY ALERT AND EXERCISE CONTROL. Watch what

you are doing and use common sense. Do not operate

tool when you are tired. Do not rush.

DO NOT USE TOOL IF SWITCH DOES NOT TURN IT

ON AND OFF. Have defective switches replaced by an

authorized service center.

INSPECT FOR AND REMOVE ALL NAILS FROM LUM-

BER BEFORE USING THIS TOOL. Following this rule

will reduce the risk of serious personal injury.

SPECIFIC SAFETY RULES

FIRMLY CLAMP OR BOLT your tool to a workbench or

table at approximately hip height.

NEVER stand or have any part of your body in line with

the path of the workpiece.

PLAN YOUR WORK TO REDUCE THE RISK OF

THROWBACKS (when the workpiece catches the sand-

ing drum and is torn from your hands).

MAKE SURE THERE’S NO DEBRIS between the

workpiece and its supports.

WHEN SANDING IRREGULARLY SHAPED WORK-

PIECES, plan your work support so it will not slip and be

pulled from your hands.

USE EXTRA CAUTION WITH LARGE, very small or

awkward workpieces.

NEVER USE THIS TOOL to finish pieces too small to

hold by hand.

USE EXTRA SUPPORTS (TABLES, SAW HORSES,

BLOCKS, ETC.) for any workpieces large enough to tip

when not secured to the work surface.

NEVER sand more than one piece at a time. DO NOT

STACK more than one workpiece on the sander table at

a time.

ALWAYS FEED WORKPIECE FROM LEFT TO RIGHT

against the direction the drum sleeve is rotating.

DO NOT USE DRUMS, sanding sleeves or belts which

show visual signs of wear such as grooves, tears or rips.

ALWAYS STAY ALERT! Do not allow familiarity (gained

from frequent use of your sander) to cause a careless

mistake. ALWAYS REMEMBER that a careless fraction

of a second is sufficient to inflict severe injury.

NEVER START A TOOL WHEN ANY ROTATING COM-

PONENT IS IN CONTACT WITH THE WORKPIECE.

DO NOT OPERATE A TOOL WHILE UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR ANY

MEDICATION.

WHEN SERVICING use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

USE ONLY RECOMMENDED ACCESSORIES listed

in this manual or addendums. Use of accessories that

are not listed may cause the risk of personal injury.

Instructions for safe use of accessories are included

with the accessory.

DOUBLE CHECK ALL SETUPS. Make sure the spindle

or sanding belt assembly is tight and not making con-

tact with sander or workpiece before connecting to

power supply.

MAKE SURE THE WORK AREA HAS AMPLE LIGHTING

to see the work and that no obstructions will interfere with

safe operation BEFORE performing any work using your

tool.

ALWAYS TURN OFF THE SANDER before disconnect-

ing it to avoid accidental starting when reconnecting to

power supply. NEVER leave the tool unattended while

connected to a power source.

SUPPORT WORKPIECE with miter gauge, work rest, or

worktable.

MAINTAIN 1/16 in. clearance between worktable and

sanding belt or disc.

AVOID KICKBACK by sanding in accordance with

directional arrows.

IF THE POWER SUPPLY CORD IS DAMAGED, it must

be replaced only by the manufacturer or by an authorized

service center to avoid risk.

THIS TOOL should have the following markings:

a) Wear eye protection.

b) Support workpiece with miter gauge, backstop (work

support), or worktable.

c) Maintain 1/16 in. maximum clearance between work

table and sanding belt or disc.

d) Do not perform any operation freehand.

e) Avoid kickback by sanding in accordance with

directional arrows.

SAVE THESE INSTRUCTIONS. Refer to them frequently

and use them to instruct others who may use this tool. If you

loan someone this tool, loan them these instructions also.

4 - English

Loading...

Loading...