RuggedCom MediaConverter, RMC-100-MM, RMC-10-MM, Rugged MediaConverter Series Installation Manual

Page 1

Rugged MediaConverter

Installation Guide

RuggedCom Inc.

300 Applewood Crescent

Concord, Ontario

Canada L4K 5C7

Web: http://www.ruggedcom.com/

Tel: +1 905 856 5288

Fax: +1 905 856 1995

Toll Free: 1 888 264 0006

Page 2

Copyright

COPYRIGHT © 2010 RuggedCom Inc. ALL RIGHTS RESERVED

Dissemination or reproduction of this document, or evaluation and communication of its contents, is

not authorized except where expressly permitted. Violations are liable for damages. All rights

reserved, particularly for the purposes of patent application or trademark registration.

This document contains proprietary information, which is protected by copyright. All rights are

reserved. No part of this document may be photocopied, reproduced or translated to another

language without the prior written consent of RuggedCom Inc.

Disclaimer of liability

We have checked the contents of this manual against the hardware and software described.

However, deviations from the description cannot be completely ruled out.

RuggedCom shall not be liable for any errors or omissions contained herein or for consequential

damages in connection with the furnishing, performance, or use of this material.

The information given in this document is reviewed regularly and any necessary corrections will be

included in subsequent editions. We appreciate any suggested improvements. We reserve the right

to make technical improvements without notice.

Registered Trademarks

Rugged MediaConverter™, ROS™ and RuggedMC™ are trademarks of RuggedCom Inc. Other

designations in this manual might be trademarks whose use by third parties for their own purposes

would infringe the rights of the owner.

Important:

The Rugged MediaConverterTM (RuggedMCTM) contains no user-serviceable parts. Attempted

service by unauthorized personnel shall render all warranties null and void.

Warning: Changes or modifications not expressly approved by RuggedCom Inc. could void the

user’s authority to operate the equipment.

TM

The RuggedMC

gained by service personnel or users who have been instructed about the reasons for the

restrictions applied to the location and about any precautions that shall be taken; and access is

through the use of a tool or lock and key, or other means of security, and is controlled by the

authority responsible for the location.

should be installed in a restricted access location where access can only be

RuggedCom

®

2

RuggedMC™ RMC Installation Guide rev105

Page 3

Contacting RuggedCom

Corporate Headquarters US Headquarters Europe Headquarters

RuggedCom Inc.

300 Applewood Crescent

Concord, Ontario

Canada, L4K 5C7

Tel: +1 905 856 5288

Fax: +1 905 856 1995

Toll-free: 1 888 264 0006

Technical Support

Toll Free (North America): 1 866 922 7975

International: +1 905 856 5288

Email: Support@RuggedCom.com

RuggedCom

1930 Harrison St., Suite 209

Hollywood, Florida

USA, 33020

Tel: +1 954 922 7938 ext. 103

Fax: +1 954 922 7984

Toll-free: 1 888 264 0006

RuggedCom

Unit 41, Aztec Centre,

Aztec West, Almondsbury, Bristol

United Kingdom BS32 4TD

Tel: +44 1454 203 404

Fax: +44 1454 203 403

Email: RuggedSales@RuggedCom.com

Web: www.RuggedCom.com

Rug

ged

Com

®

3

RuggedMC™ RMC Installation Guide rev105

Page 4

Table of Contents

Table of Contents

1 Product Overview.................................................................................................................... 5

1.1 Functional Overview....................................................................................................... 5

1.2 Feature Highlights........................................................................................................... 5

1.3 RuggedMC

1.4 RuggedMC

2 Installation............................................................................................................................... 8

2.1 DIN Rail Mounting........................................................................................................... 8

2.2 Power Supply Wiring and Grounding..............................................................................9

2.3 RJ45 Ports – Signal Description....................................................................................10

2.4 Fiber Optical Port Configuration.....................................................................................12

3 Technical Specifications.........................................................................................................14

3.1 Power Supply Specifications..........................................................................................14

3.2 Networking Standards Supported..................................................................................14

3.3 Copper Port Specifications............................................................................................15

3.4 Fiber Optical Specifications...........................................................................................15

3.5 Networking Specifications..............................................................................................15

3.6 Operating Environment..................................................................................................15

3.7 Physical Dimensions......................................................................................................16

4 Type Tests..............................................................................................................................17

4.1 IEC 61850-3 Type Tests................................................................................................17

4.2 IEEE 1613 Type Tests...................................................................................................18

4.3 IEC Environmental Type Tests......................................................................................18

5 Agency Approvals ..................................................................................................................19

6 Warranty.................................................................................................................................19

TM

Front Panel Description............................................................................ 6

TM

Side and Bottom View.............................................................................. 7

Rug

ged

Com

®

4

RuggedMC™ RMC Installation Guide rev105

Page 5

Product Overview

1 Product Overview

1.1 Functional Overview

The Rugged MediaConverterTM is an industrially hardened fiber optical media converter

specifically designed to operate in harsh environments such as those found in electric utility

substations and factory floors. The RuggedMCTM family provides industrial strength Ethernet

copper-to-fiber media conversion, allowing for 10BaseT-to-10BaseFL or 100BaseTX-100BaseFX

over multi-mode or optional single-mode fiber optical media.

Specifically tested to the same standards as mission critical protective relaying equipment (i.e.

ANSI/IEEE C37.90 and IEC 60255), and the newly issued IEC 61850-3 “Communications Systems

and Networks in Substations” standard, the RuggedMCTM is ideally suited for substation or

industrial environments. The reliability of the Rugged MediaConverterTM family exceeds that of

commercial media converters by having no rotating mechanical parts (i.e. no cooling fans), utilizing

high-temperature solid state components and incorporating the necessary transient and surge

suppression circuitry required for substation and harsh industrial environments.

1.2 Feature Highlights

Utility Grade (i.e. substation hardened) per ANSI/IEEE C37.90, IEC 60255, and the new IEC

61850-3 (2002), IEC 61000-6-5 standards

Operating temperature: -40 to 85C (no fan)

Radiated RF Immunity: 35V/m per ANSI/IEEE C37.90.2

Power supply options: 24 (18-36VDC), 48 (36-72) or HI (88-300VDC / 85-264VAC)

Choice of two fiber optical modules:

1 – 100BaseFX (100Mbps) multimode or optional single-mode fiber optical port

1 - 10BaseFL (10Mbps) multimode or optional single-mode fiber optical port

1 – 10/100BaseTX Auto-Negotiating RJ45 port

Configurable Full-Duplex, Half-Duplex or Fiber-side negotiation support

Link Pass Through support

TIA/EIA-785 100BaseSX support (10FL module only)

RuggedCom

®

5

RuggedMC™ RMC Installation Guide rev105

Page 6

Product Overview

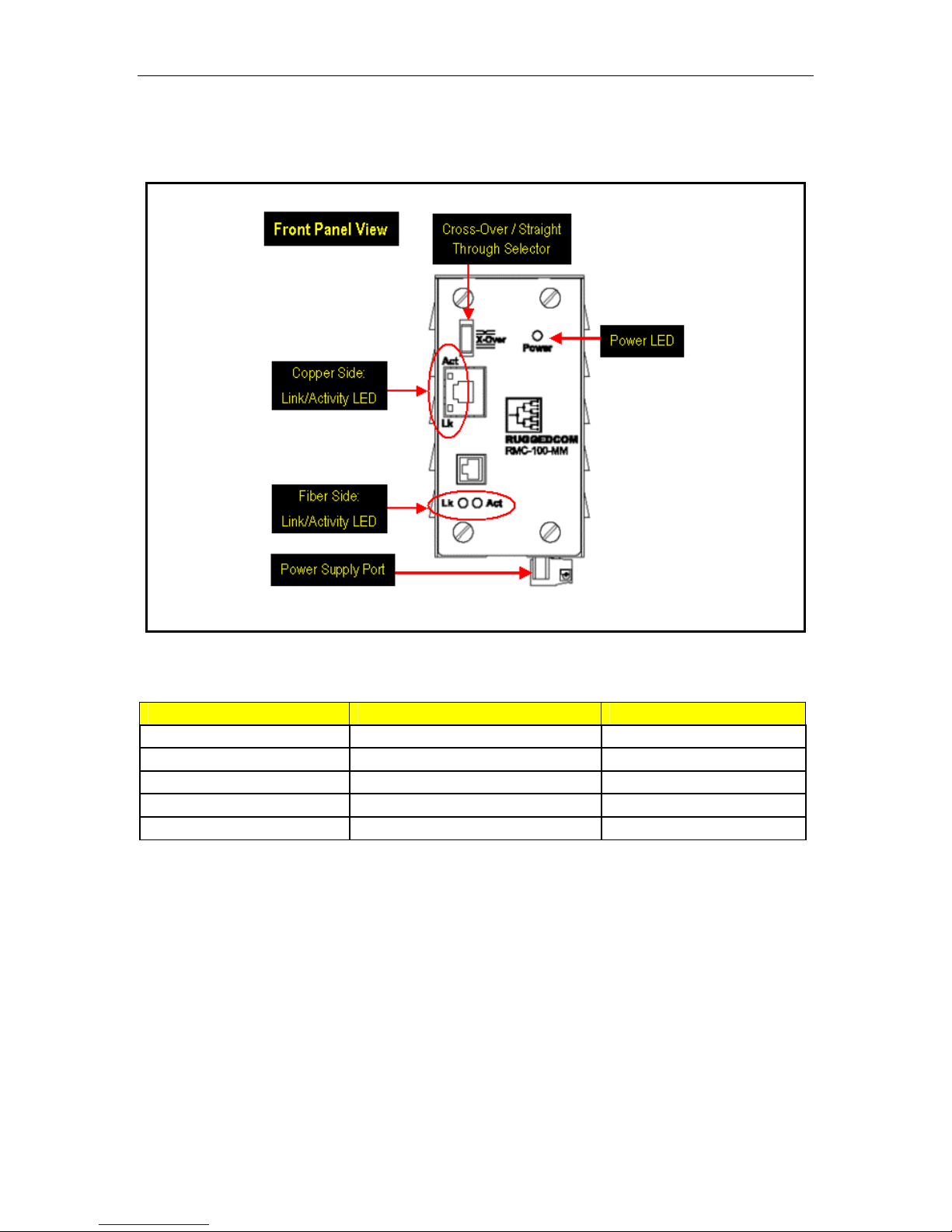

1.3 RuggedMC

TM

Front Panel Description

Figure 1: RuggedMCTM Front Panel Detail

ITEM Activity Comments

Copper Side: Link Solid (Yellow) Link Established

Copper Side: Activity Blinking (Yellow) Tx, Rx Activity

Fiber Side: Link Solid (Yellow) Link Established

Fiber Side: Activity Blinking (Yellow) Tx, Rx Activity

Power LED Solid (Green) Power On

RuggedCom

®

6

RuggedMC™ RMC Installation Guide rev105

Page 7

Product Overview

1.4 RuggedMC

TM

Side and Bottom View

Figure 2: RuggedMCTM Side and Bottom View

RuggedCom

®

7

RuggedMC™ RMC Installation Guide rev105

Page 8

Installation

2 Installation

2.1 DIN Rail Mounting

Figure 3: RuggedMCTM DIN Rail Mounting

RuggedCom

®

8

RuggedMC™ RMC Installation Guide rev105

Page 9

Installation

2.2 Power Supply Wiring and Grounding

Figure 4: RuggedMCTM Power Supply Inputs

The RuggedMCTM power supply inputs are identical and are connected as follows:

1. +/L = DC (+) / AC (Hot) is connected to the positive (+) terminal if the power source is DC

or to the (Hot) terminal if the power source is AC.

2. -/N = DC (-) / AC (Neutral) is connected to the negative (-) terminal if the power source is

DC or to the (Neutral) terminal if the power source is AC.

3. Surge Ground is connected to the Chassis Ground via a braided cable or other

appropriate grounding wire. Surge Ground is used as the ground conductor for all surge

and transient suppression circuitry internal to the RuggedMCTM.

Chassis Ground is connected to the Safety Ground terminal for AC inputs or the

equipment ground bus for DC inputs.

Note: Surge Ground must be disconnected from Chassis Ground during HIPOT

(dielectric strength) testing.

Notes:

1. For 125/250VDC rated equipment: An appropriately rated 300VDC circuit breaker

must be installed within 3 meters of unit.

2. For 110/230VAC rated equipment: An appropriately rated 250VAC circuit breaker

must be installed within 3 meters of the unit

3. A circuit breaker is not required for 48 or 24VDC rated equipment.

4. For multiple supplies, separate circuit breakers must be installed. Equipment must

be installed according to the applicable country wiring codes.

RuggedCom

®

9

RuggedMC™ RMC Installation Guide rev105

Page 10

Installation

2.3 RJ45 Ports – Signal Description

The RJ45 port accepts standard category 5 unshielded twisted pair (UTP), or screened twisted pair

(STP) cable with RJ45 male connectors. Figure 5 shows the RJ45 port pin configuration.

PIN 1

PIN 8

PIN 8

PIN SIGNAL

PIN SIGNAL

1 RX+

1 RX+

2 RX-

2 RX3 TX+

3 TX+

4 n.c.

4 n.c.

5 n.c.

5 n.c.

6 TX-

6 TX7 n.c.

7 n.c.

8 n.c.

8 n.c.

PIN 1

Figure 5: RJ45 Port Pins

To accommodate signals from end devices as well as network switching equipment, the

RuggedMC

TM

is equipped with a crossover selection switch.

Category 5 network cabling can be constructed in two configurations: Straight through, and

crossover (X-over). Straight through cabling involves a pin-to-pin connection, while crossover

cabling matches the transmitting differential pair to the receiving differential pair. Table 1

summarizes the two possible configurations.

TIA 568B Straight Through Pinout TIA 568B Crossover Wiring Pinout

Device 1 Device 2 Device 1 Device 2

Pin Colour Pin Colour Pin Colour Pin Colour

1 White/Orange 1 White/Orange 1 White/Orange 1 White/Green

2 Orange 2 Orange 2 Orange 2 Green

3 White/Green 3 White/Green 3 White/Green 3 White/Orange

6 Green 6 Green 6 Green 6 Orange

Table 1 - Category 5 network cabling configurations: Straight through and Crossover

RuggedCom

®

10

RuggedMC™ RMC Installation Guide rev105

Page 11

Installation

To accommodate both types of cabling, the RuggedMC

TM

contains a crossover selection switch

visible on the front panel as shown in Table 2. This switch will allow for the proper connection

regardless of the cable type configuration.

When connecting to end devices, the X-over switch should be selected to reflect the type of cabling

used. (i.e. Straight through is selected when using straight through cabling, X-over is selected

when using crossover cabling)

X-Over Position Description

UP Crossover cabling is used to connect to end devices.

DOWN Straight-through cabling is used to connect to end devices.

Table 2 - X-over switch positioning for Straight through and Crossover cabling

The presence of an active LINK LED indicates that the X-over selection switch is in the proper

position.

Figure 6: Location of X-over Switch on RuggedMCTM

NOTE: For substation applications it is not recommended to use these ports to interface to

field devices across distances which could produce high levels of ground potential rise

(GPR), (i.e. greater than 2500V) during line-to-ground fault conditions.

RuggedCom

®

11

RuggedMC™ RMC Installation Guide rev105

Page 12

Installation

2.4 Fiber Optical Port Configuration

To accommodate a wide array of fiber optical devices, the RuggedMCTM is equipped with a mode

selector switch located on the bottom panel as shown in Figure 7.

Figure 7: Mode Selector Switch located on the bottom of the RuggedMCTM

The mode selector switch configures the RuggedMCTM to accommodate different fiber partners that

operate at various duplex modes and speeds. Choose the appropriate operating mode according

to the fiber link partner.

Mode Selector

Configuration

Mode

Positioning

Description

SW1 SW2

Transparent Mode* OFF OFF 10/100 Auto-negotiating transparent mode

HDX Mode OFF ON Half-Duplex fiber partner

FDX Mode ON OFF Full-Duplex fiber partner (default)

Reserved ON ON

* Should ONLY be used on 10FL series RuggedMCTM products.

The transparent mode can be utilized when BOTH the copper side and fiber side devices are

capable of auto-negotiating duplex mode and speed as per TIA/EIA-785. When both partners are

capable of negotiation, the RuggedMCTM can support 100BaseTx to 100BaseSX, full duplex,

copper-to-fiber media conversion on 10FL standard electronics and fiber media. The TIA/EIA-785

standard allows for 10FL communication lines that are less than 300m in length to be upgraded to

100Mb/s communication links.

RuggedCom

®

12

RuggedMC™ RMC Installation Guide rev105

Page 13

Installation

The HDX and FDX modes exist to accommodate fiber link partners that are operating in the forced

mode. Due to the high number of forced full duplex fiber optical devices available, the factory

default is the FDX, full duplex, mode.

RuggedCom

®

13

RuggedMC™ RMC Installation Guide rev105

Page 14

Technical Specifications

3 Technical Specifications

3.1 Power Supply Specifications

Power Supply Type Minimum

Input

24 VDC 18 VDC 36 VDC 3.15A(T) 2

48 VDC 36 VDC 72 VDC 3.15A(T) 2

HI (88/300 VDC) 1

HI (120/240 VAC)

Notes: 1 – This is the same power supply for both AC and DC.

2 – (T) Denotes time-delay fuse

1

88 VDC

85 VAC

3.2 Networking Standards Supported

Maximum

Input

300 VDC

264 VAC

Internal

Fuse

Rating

3.15A(T)

Maximum Power

Consumption

2

3 W

Parameter 10FL

Module

IEEE 802.3

IEEE 802.3u

IEEE 802.3x

TIA/EIA 785

100FX

Notes

Module

10BaseT

100BaseTX / 100BaseFX

Full Duplex Operation

10/100BaseSX Capable

All RuggedMCTM products feature Link Pass Through support. When loss of link is detected on

either the fiber side or the copper side, link pulses are no longer transmitted on any of the

RuggedMCTM ports. This feature allows for prompt loss of link detection and user correction. The

faulty link partner can be identified by loss of link on the RuggedMCTM front panel indicators.

RuggedCom

®

14

RuggedMC™ RMC Installation Guide rev105

Page 15

Technical Specifications

3.3 Copper Port Specifications

Data Port Media Distance Connector Type

10/100 Mbps Auto-negotiating Cat 5 UTP/STP 100m RJ45

3.4 Fiber Optical Specifications

Parameter 10Mbps Ports 100Mps Ports

Multi-Mode Single-Mode* Multi-Mode Single-Mode*

Speed Standard 10BaseFL 100BaseFX

Connector Type ST MTRJ LC

Segment Length 2 km 15 km 2 km 15 km

Optical Wavelength 820nm 1310nm 1300nm 1310nm

Cable Size

Core/Cladding

Optical Tx Power

Min/Max (dBm Peak)

Optical Rx Sensitivity

(dBm Average)

Max Optical Rx Power

(dBm Peak)

Typical Optical

Power Budget (dB)

* Available as an option

62.5/125m 9/125m 62.5/125m 9/125m

-13.5/-7.6 -23/-15 -16/-11 -15/-8

-34.4 -38 -33.5 -31

-8.2 -3.0 -11 -5

22 18 17 16.5

3.5 Networking Specifications

Parameter 10FL Module 100FX Module Notes

Latency

1 S 1 S

Cut-through conversion

3.6 Operating Environment

Parameter Range Comments

Ambient Operating

Temperature

-40 to 85C

Ambient Relative Humidity 5% to 95% Non-condensing

Ambient Storage

Temperature

-40 to 85C

15

RuggedCom

®

Ambient Temperature as measured

from a 30cm radius surrounding the

center of the RuggedMCTM enclosure.

RuggedMC™ RMC Installation Guide rev105

Page 16

Technical Specifications

3.7 Physical Dimensions

Parameter Value Comments

Dimensions

3.55 x 2.07 x 3.86 inches

(90,35) x (52,59) x (98,04) mm

(Length x Width x Height)

Weight 1.5 lb (0,68 Kg)

Enclosure 21 gauge Galvanized Steel

RuggedCom

®

16

RuggedMC™ RMC Installation Guide rev105

Page 17

Type Tests

4 Type Tests

4.1 IEC 61850-3 Type Tests

Test Description Test Levels

IEC 61000-4-2 ESD

IEC 61000-4-3 Radiated RFI Enclosure ports 20 V/m x

IEC 61000-4-4

IEC 61000-4-5 Surge

IEC 61000-4-6

IEC 61000-4-8 Magnetic Field Enclosure ports

IEC 61000-4-29

IEC 61000-4-11

IEC 61000-4-12

IEC 61000-4-16

IEC 61000-4-17

IEC 60255-5

IEC 60255-5 H.V. Impulse

Burst (Fast

Transient)

Induced

(Conducted) RFI

Voltage Dips &

Interrupts

Damped

Oscillatory

Mains

Frequency

Voltage

Ripple on D.C.

Power Supply

Dielectric

Strength

Enclosure Contact +/- 8kV 4

Enclosure Air +/- 15kV 4

Signal ports +/- 4kV @ 2.5kHz x

D.C. Power ports +/- 4kV 4

A.C. Power ports +/- 4kV 4

Earth ground ports +/- 4kV 4

Signal ports +/- 4kV line-to-earth, +/- 2kV line-to-line 4

D.C. Power ports +/- 2kV line-to-earth, +/- 1kV line-to-line 3

A.C. Power ports +/- 4kV line-to-earth, +/- 2kV line-to-line 4

Signal ports 10V 3

D.C Power ports 10V 3

A.C. Power ports 10V 3

Earth ground ports 10V 3

40 A/m continuous Note 1

1000 A/m for 1 s 5

D.C. Power ports 30% for 0.1s, 60% for 0.1s, 100% for 0.05s N/A

A.C. Power ports

Signal ports

D.C. Power ports

A.C. Power ports

Signal ports 30V Continuous, 300V for 1s 4

D.C. Power ports 30V Continuous, 300V for 1s 4

D.C. Power ports 10% 3

Signal ports 2kV AC (Fail-Safe Relay output) N/A

D.C. Power ports 1.5kVDC N/A

A.C. Power ports 2kVAC N/A

Signal ports 5kV (Fail-Safe Relay output) N/A

D.C. Power ports 5kV N/A

A.C. Power ports 5kV N/A

30% for 1 period, 60% for 50 periods N/A

100% for 5 periods, 100% for 50 periods

2.5kV common, 1kV differential mode @

1MHz

2.5kV common, 1kV differential mode @

1MHz

2.5kV common, 1kV differential mode @

1MHz

Severity

Levels

2

N/A

3

3

3

Table 3 - IEC 61850-3 Type Tests

Note:

1. Ruggedcom specified severity levels

RuggedCom

®

17

RuggedMC™ RMC Installation Guide rev105

Page 18

Type Tests

4.2 IEEE 1613 Type Tests

IEEE

IEEE Test

C37.90.3 9 ESD

C37.90.2 8 Radiated RFI Enclosure ports 35 V/m

C37.90.1 7 Fast Transient

C37.90.1 7 Oscillatory

C37.90 6 H.V. Impulse

C37.90 6 Dielectric Strength

1613

Clause

Description Test Levels

Enclosure Contact +/- 8kV

Enclosure Air +/- 15kV

Signal ports +/- 4kV @ 2.5kHz

D.C. Power ports +/- 4kV

A.C. Power ports +/- 4kV

Earth ground ports +/- 4kV

Signal ports 2.5kV common mode @ 1MHz

D.C. Power ports 2.5kV common & differential mode @ 1MHz

A.C. Power ports 2.5kV common & differential mode @ 1MHz

Signal ports 5 kV (Failsafe Relay)

D.C. Power ports 5 kV

A.C. Power ports 5 kV

Signal ports 2kVAC

D.C. Power ports 1.5kVDC

A.C. Power ports 2kVAC

Table 4 - IEEE 1613 Type Tests

Notes:

If the unit contains copper ports, the IEEE 1613 conformance is Class 1 (During

disturbance, errors may occur but recovery is automatic).

If the unit contains all fiber ports, the IEEE 1613 conformance is Class 2 (During

disturbance, no errors will occur).

4.3 IEC Environmental Type Tests

Test Description Test Levels

IEC 60068-2-1 Cold Temperature Test Ad -40 deg. C, 16 Hours N/A

IEC 60068-2-2 Dry Heat Test Bd +85 deg. C, 16 Hours N/A

IEC 60068-2-30

IEC 60255-21-1 Vibration 2g @ (10-150) Hz Class 2

IEC 60255-21-2 Shock 30g @ 11 ms Class 2

Table 5 - Environmental Type Tests

Note:

Cla ss 2 refers to “Measuring relays and protection equipment for which a very high

security margin is required or where the vibration levels are very high, (e.g. shipboard

application and for severe transportation conditions).”

Humidity (Damp

Heat, Cyclic)

Test Db 95% (non-condensing), 55°C, 6 cycles N/A

Severity

Levels

RuggedCom

®

18

RuggedMC™ RMC Installation Guide rev105

Page 19

Agency Approvals

5 Agency Approvals

Agency Standards Comments

cCSAus, CE

CSA C22.2 No. 60950, UL 60950,

EN 60950, EN 61000-6-2

PENDING

6 Warranty

Five (5) years from date of purchase, return to factory. For warranty details, visit

www.ruggedcom.com or contact your customer service representative.

Should this product require warranty or service, contact the factory at:

RuggedCom Inc.

300 Applewood Crescent

Concord, Ontario

Canada L4K 5C7

Phone: +1 905 856 5288

Fax: +1 905 856 1995

RuggedCom

®

19

RuggedMC™ RMC Installation Guide rev105

Loading...

Loading...