Page 1

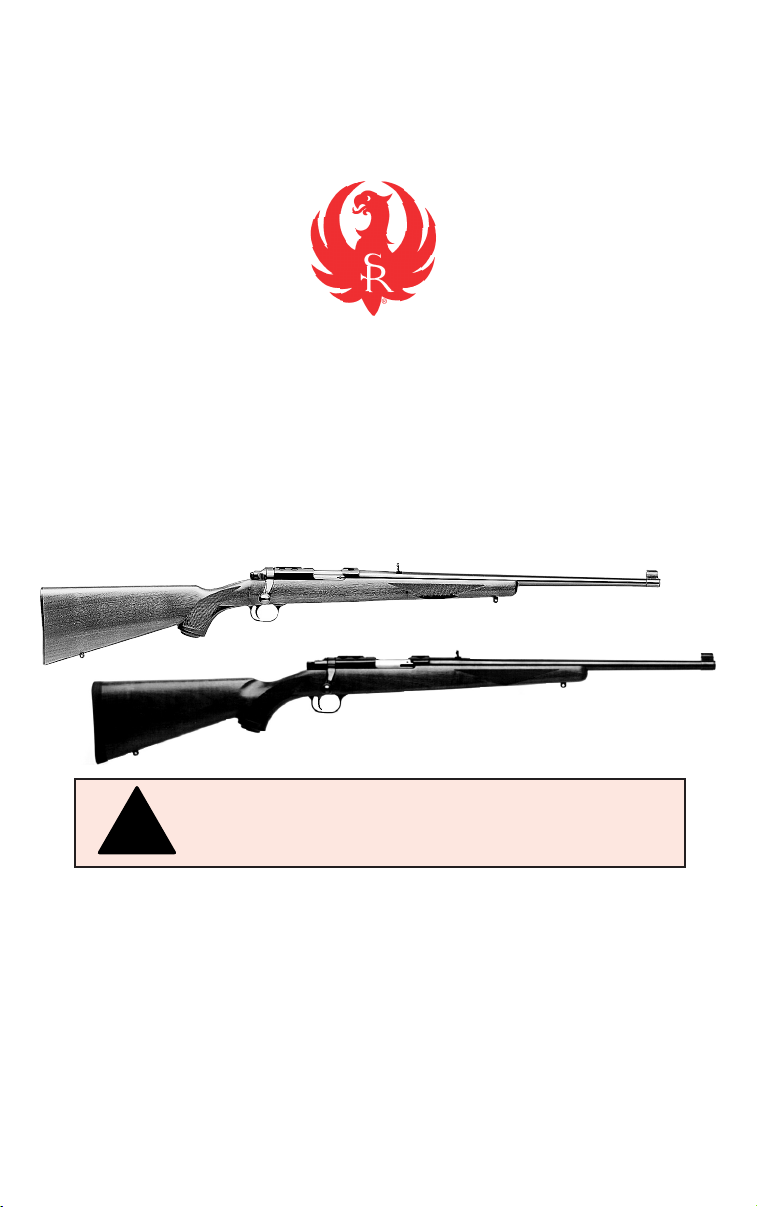

INSTRUCTION

!

MANUAL

FOR

BLUED &

STAINLESS

STEEL

®

CALIBERS

.17 HMR, .22 Long Rifle,

.22 Magnum, .22 Hornet

& .44 Magnum

RUGER

MODEL 77/22®, MODEL 77/17,

& MODEL 77/44

BOLT-ACTION RIFLES

RIMFIRE & CENTERFIRE MODELS

Model 77/22 & 77/17

TM

Model 77/44

READ THE INSTRUCTIONS AND

WARNINGS IN THIS MANUAL CAREFULLY

BEFORE USING THIS FIREARM

For Product Service on This Model Please Call:

(603) 865-2442 (See p. 30)

STURM, RUGER & Company, Inc.

Southport, Connecticut 06490 U.S.A.

THIS INSTRUCTION MANUAL SHOULD ALWAYS ACCOMPANY THIS FIREARM AND BE TRANS-

FERRED WITH IT UPON CHANGE OF OWNERSHIP, OR WHEN THE FIREARM IS LOANED OR PRE-

SENTED TO ANOTHER PERSON.

KJ/5-02

R6

Page 2

!

!

State-By-State Warnings

Certain states require by law that their own specified warning

notices in larger-than-normal type be conspicuously included by

the manufacturer, distributor, or retail dealer with firearms sold

in that state. Sturm, Ruger sells its products in compliance with

applicable laws and regulations. Because our products may be

sold in these states, we include the following:

California:

WARNING

“Children are attracted to and

can operate firearms that can

cause severe injuries or death.

Prevent child access by always

keeping guns locked away and

unloaded when not in use. If you

keep a loaded firearm where a

child obtains and improperly uses

it, you can be fined or sent to

prison.”

ADVERTENCIA

“A los niños los atraen las armas

de fuego y las pueden hacer funcionar. Ellos pueden causarses

lesions graves y la muerte. Evite

que los niños tengan accesso a las

armas de fuego guardándolas

siempre con llave y descargadas

cuando no las esté utilizando. Si

usted tiene un arma de fuego cargada en un lugar en que un niño

tiene acceso a ella y la usa indebidamente, le pueden dar una

multa o enviarlo a la carcel.”

Connecticut:

“UNLAWFUL STORAGE OF A LOADED FIREARM MAY

RESULT IN IMPRISONMENT OR FINE.”

Florida:

“IT IS UNLAWFUL, AND PUNISHABLE BY IMPRISONMENT AND FINE, FOR ANY ADULT TO STORE OR

LEAVE A FIREARM IN ANY PLACE WITHIN THE

REACH OR EASY ACCESS OF A MINOR UNDER 18

YEARS OF AGE OR TO KNOWINGLY SELL OR OTHERWISE TRANSFER OWNERSHIP OR POSSESSION OF A

FIREARM TO A MINOR OR A PERSON OF UNSOUND

MIND.”

3

Page 3

Maine:

“ENDANGERING THE WELFARE OF A CHILD IS A

CRIME. IF YOU LEAVE A FIREARM AND AMMUNITION

WITHIN EASY ACCESS OF A CHILD, YOU MAY BE

SUBJECT TO FINE, IMPRISONMENT OR BOTH. KEEP

FIREARMS AND AMMUNITION SEPARATE. KEEP

FIREARMS AND AMMUNITION LOCKED UP. USE

TRIGGER LOCKS.”

Maryland:

“WARNING: Children can operate firearms which may cause

death or serious injury. It is a crime to store or leave a loaded

firearm in any location where an individual knew or should

have known that an unsupervised minor would gain access to

the firearm. Store your firearm responsibly!”

Massachusetts:

“WARNING FROM THE MASSACHUSETTS ATTORNEY

GENERAL: This handgun is not equipped with a device that

fully blocks use by unauthorized users. More than 200,000

firearms like this one are stolen from their owners every year

in the United States. In addition, there are more than a thousand suicides each year by younger children and teenagers

who get access to firearms. Hundreds more die from accidental discharge. It is likely that many more children sustain serious wounds, or inflict such wounds accidentally on others. In

order to limit the chance of such misuse, it is imperative that

you keep this weapon locked in a secure place and take other

steps necessary to limit the possibility of theft or accident.

Failure to take reasonable preventive steps may result in innocent lives being lost, and in some circumstances may result in

your liability for these deaths.”

“IT IS UNLAWFUL TO STORE OR KEEP A FIREARM,

RIFLE, SHOTGUN OR MACHINE GUN IN ANY PLACE

UNLESS THAT WEAPON IS EQUIPPED WITH A TAMPER-RESISTANT SAFETY DEVICE OR IS STORED OR

KEPT IN A SECURELY LOCKED CONTAINER.”

4

Page 4

New Jersey:

“IT IS A CRIMINAL OFFENSE TO LEAVE A LOADED

FIREARM WITHIN EASY ACCESS OF A MINOR.”

New Y

“THE USE OF A LOCKING DEVICE OR SAFETY LOCK IS

ONLY ONE ASPECT OF RESPONSIBLE WEAPONS STORAGE. ALL WEAPONS SHOULD BE STORED UNLOADED

AND LOCKED IN A LOCATION THAT IS BOTH SEPARATE

FROM THEIR AMMUNITION AND INACCESSIBLE TO

CHILDREN AND ANY OTHER UNAUTHORIZED PERSONS.”

ork City:

North Carolina:

“IT IS UNLAWFUL TO STORE OR LEAVE A FIREARM

THAT CAN BE DISCHARGED IN A MANNER THAT A

REASONABLE PERSON SHOULD KNOW IS ACCESSIBLE

TO A MINOR.”

Texas:

“IT IS UNLAWFUL TO STORE, TRANSPORT, OR ABANDON AN UNSECURED FIREARM IN A PLACE WHERE

CHILDREN ARE LIKELY TO BE AND CAN OBTAIN

ACCESS TO THE FIREARM.”

Wisconsin:

“IF YOU LEAVE A LOADED FIREARM WITHIN THE

REACH OR EASY ACCESS OF A CHILD YOU MAY BE

FINED OR IMPRISONED OR BOTH IF THE CHILD

IMPROPERLY DISCHARGES, POSSESSES, OR EXHIBITS

THE FIREARM.”

***************** *****

Please check with your licensed retailer or state police for additional warnings which may be required by local law or regulation. Such regulations change constantly, and local authorities

are in the best position to advise you on such legal matters.

5

Page 5

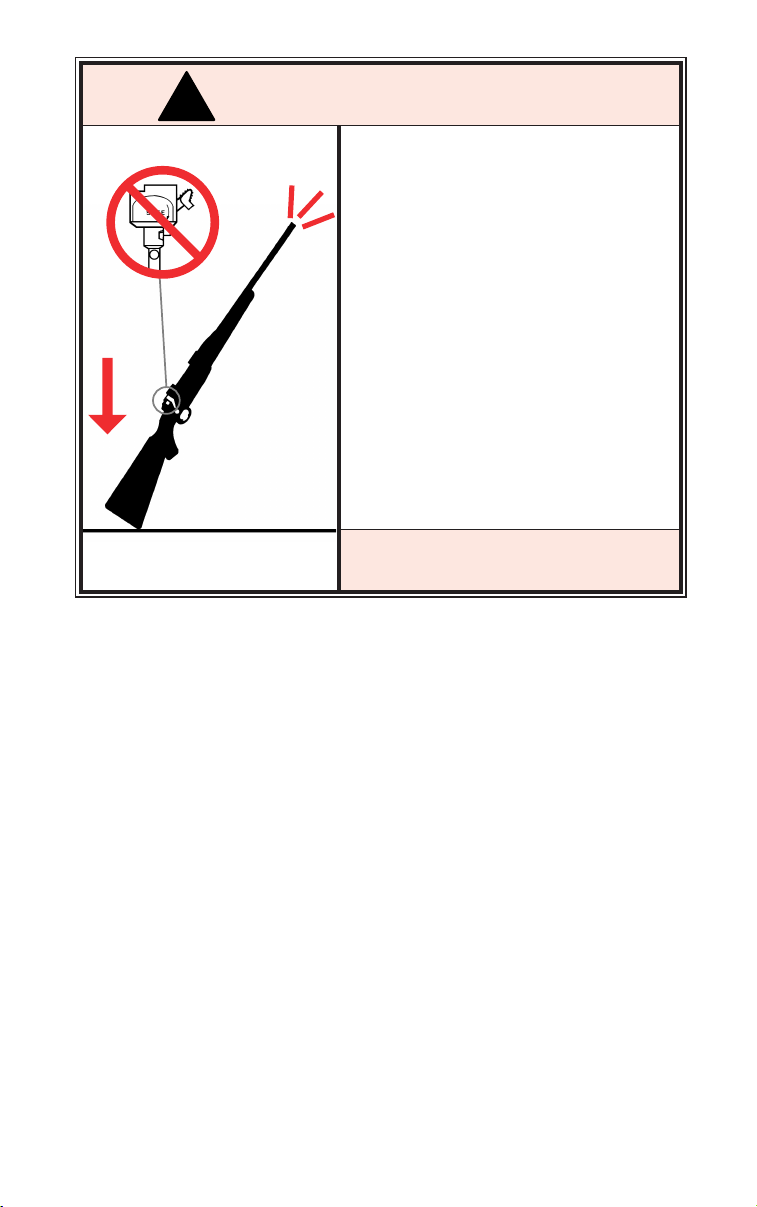

WARNING – LOCKING DEVICES

!

This firearm was originally sold

with a key-operated locking

device. While it can help provide

secure storage for your unloaded

firearm, any locking device can

fail. All guns are designed to fire if

they are loaded and the trigger is

pulled. Therefore, never install the

locking device inside the trigger

guard or in any way that it can

possibly pull the trigger! Do not

leave the keys in the lock.

DO NOT INSTALL

INSIDE TRIGGER GUARD

The ultimate responsibility for

secure storage of any firearm must

depend upon its owner and his or

her individual circumstances.

Guns should be securely stored

unloaded, in a secure location,

separate from their ammunition.

See “Storage Warning”, page 27.

INSTALL LOCK

AS SHOWN HERE

NEVER INSTALL

LOCKING DEVICE

INSIDE TRIGGER GUARD

6

Page 6

FIREARMS SAFETY-YOUR RESPONSIBILITY

SAFETY MUST BE THE FIRST AND CONSTANT

CONSIDERATION OF EVERY PERSON WHO

HANDLES FIREARMS AND AMMUNITION.

This Instruction Manual is designed to assist you in learning how to use and

care for your RUGER MODEL 77/22

TM

77/44

Only when you are certain you fully understand the Manual and can properly

carry out its instructions should you practice loading, etc. with live ammunition.

If you have any doubts about your ability to handle or use a particular type

of gun safely, then you should seek supervised instruction.

Such personalized instruction is often available from gun dealers, gun clubs

or police departments. If none of these sources can help you, write to the

National Rifle Association, 11250 Waples Mill Road, Fairfax, VA 22030-7406.

They will assist you.

The person with a gun in their possession has a full-time job. You cannot

guess; you cannot forget. You must know how to use your firearm safely. Do

not use any firearm without having a complete understanding of its particular characteristics and safe use.

Remember: There is no such thing as a foolproof gun.

rifles properly.

®

, MODEL 77/17 & MODEL

TABLE OF CONTENTS

Page

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation of Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Ammunition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

To Load and Fire (With Magazine) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

To Unload Rifle and Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

To Extract and Eject a Chambered Cartridge . . . . . . . . . . . . . . . . . . . . . . . .18

To Clear a Malfunction (“Jam”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

To Minimize Malfunctions (“Jams”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Basic Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Magazine Inspection and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Maintenance of Stainless Steel Rifles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Attaching Scope Rings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Sight Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service and Parts Policy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

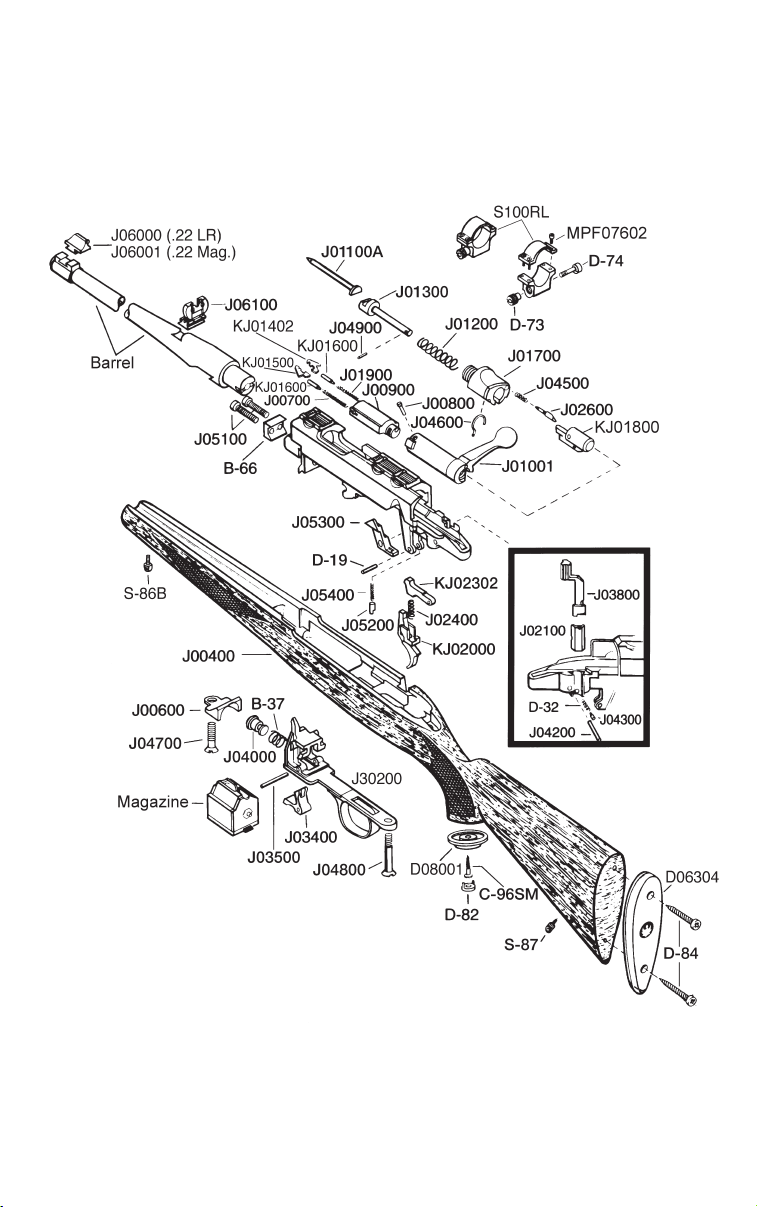

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38, 39, 44 & 45

The Basic Rules of Safe Firearms Handling . . . . . . . . . . . . . . . . . . . . . . . . . 46

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

“Ruger” and “77/22” are registered U.S. trademarks.

“77/17” & “77/44” are Sturm, Ruger trademarks.

7

Page 7

!

!

WARNINGS OF GREAT IMPORTANCE ARE

FOUND ON THE FOLLOWING PAGES:

Locking Devices 6 Handling 16

Alterations 8 Unloading 17

Manual Safety 10 Malfunctions 19

Lead Exposure 12 Disassembly 20

Ammunition 12 Lubrication 26

Loading 15 Storage 27

Firing 15 Parts Purchasers 31

OTHER CAUTIONS AND WARNINGS APPEAR

THROUGHOUT THE MANUAL.

FIREARMS ARE DANGEROUS WEAPONS–

READ THE INSTRUCTIONS AND WARNINGS IN THIS MAN-

UAL THOROUGHLY AND CAREFULLY BEFORE USING.

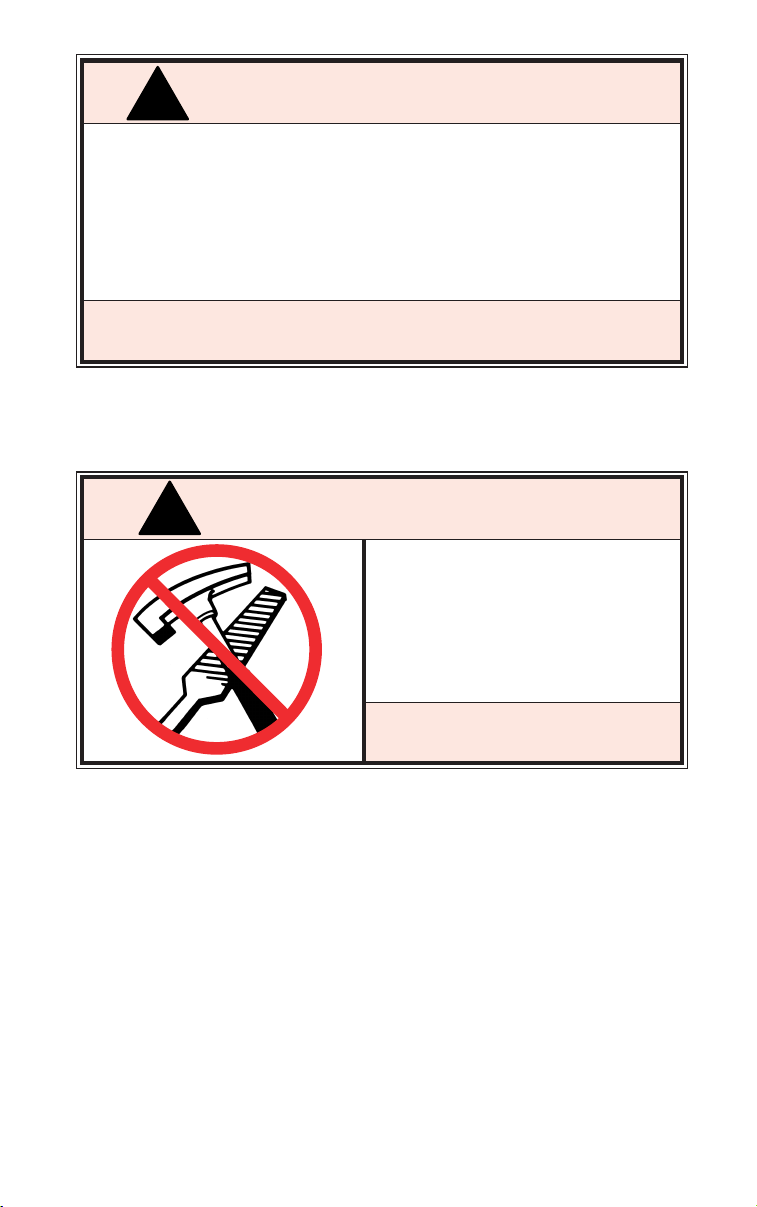

WARNING–ALTERATIONS

This product was designed to function properly in its original condition. Alterations can make it unsafe.

Do not alter any part or add or substitute parts or accessories not made

by Sturm, Ruger & Co. Inc.

DO NOT ALTER ANY GUN

GENERAL INFORMATION

AND MECHANICAL CHARACTERISTICS

The RUGER MODEL 77/22®, MODEL 77/17 & MODEL 77/44

bolt-action, magazine fed, repeating rifles. The capacity of the rotary magazine is ten

.22 Long Rifle cartridges, nine .22 WMR cartridges in the 77/22

nine .17 HMR cartridges in the 77/17, six cartridges in the 77/22

only, and four cartridges in the 77/44TMonly.

Other notable features of the RUGER MODEL 77/22

MODEL 77/44

into matching channels in the receiver, a fast lock-time trigger mechanism (nonadjustable), a flush positioned bolt stop (bolt release), an American walnut stock,

hand checkered, with a polyurethane finish, nylon butt-plate and studs to which

sling swivels can be attached.

TM

rifles include: A three-position safety, two bolt lugs locking

8

®

MAGNUM and

®

HORNET

®

, MODEL 77/17 &

TM

are

Page 8

The receiver on all versions of the Model 77/22®, Model 77/17, and the 77/44

incorporates integral scope mount bases (see illustration below). The Model 77/22®,

Model 77/17, and the 77/44

TM

rifles come with a set of two Ruger 1” steel scope

TM

rifle

rings. The R model does not have open sights. The 77/22®RS and 77/44TMRS come

with open sights - a gold bead front sight and a folding leaf rear sight which is

adjustable for elevation and windage. The corresponding 77/22® Hornet models are

the 77/22

®

RH & the 77/22®RSH. The K77/22®RP & RSP All-Weather models come

in stainless steel and have synthetic stocks with integral trigger guard assemblies.

The 77/22® Varmint Rifle in .22 Long Rifle and .22 Rimfire Magnum calibers, feature a stainless-steel heavyweight varmint barrel and a laminated American hardwood stock.

Disassembly of the rifle to its major components is readily accomplished by

removal of two screws. The bolt assembly can be quickly disassembled for cleaning.

All mechanical components are made of heat-treated chrome-molybdenum or

stainless steel, with music wire coil springs throughout the mechanism.

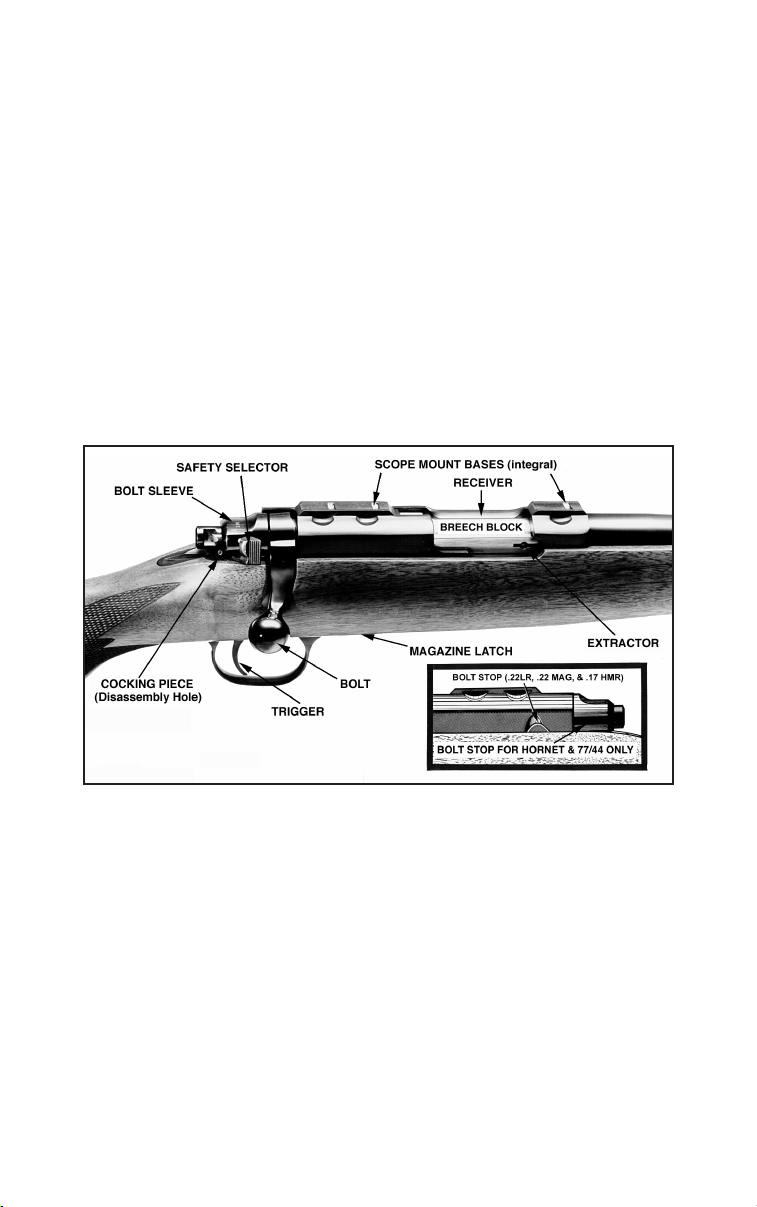

NOMENCLATURE

Figure 1. Components frequently referred to are identified. In this illustration the cocking piece is

shown cocked (protruding from the rear of the bolt sleeve) revealing the disassembly hole in the lower

portion of the cocked piece. The bolt stop (on the left side of the receiver) permits the bolt to be withdrawn simply by pressing down lightly with the thumbnail. The safety selector (show in the “Fire” posi-

tion) should be in the “Load-Unload” position when the bolt is being removed or being installed.

OPERATION OF SAFETY

The RUGER MODEL 77/22® , MODEL 77/17 & MODEL 77/44

rifles have a three position safety. The safety selector is located at the right of the

bolt sleeve.

The safety selector can be moved from the “Fire” position to its two other positions (“Load-Unload” and “Safe”) only when the firing pin is cocked. Fully raising

the bolt handle cocks the firing pin.

The bolt handle can be raised and lowered only when the safety selector is in

either the “Fire” or the “Load-Unload” position. When the safety selector is in the

9

TM

Page 9

“Safe” position, the bolt handle is locked in the closed (full down) position in

3

2

1

SAFE

LOADUNLOAD

FIRE

order to prevent inadvertent lifting of the bolt handle and to ensure that the rifle

will be ready to fire when the safety is taken “off”.

Practice (with an unloaded rifle) moving the safety selector to the three positions

until you know the position of the safety selector for the three modes– “Fire,”

“Load-Unload,” and “Safe.” WARNING: When manipulating the safety selector,

DO NOT HAVE ANY FINGER INSIDE THE TRIGGER GUARD! When the safety

selector is in the “Fire” position and the trigger is pulled, the rifle will fire.

The safety selector should always be in the “Safe” position except when the gun

user is actually firing or unloading the rifle. The safety selector should unfailingly be moved to the “Safe” position when the gun user ceases firing.

SAFETY POSITIONS

Figure 2. Safety selector in

“FIRE” (full forward) position.

The safety selector should be

moved to this position only when

the gun user is actually firing

the rifle. When the safety is in

the fire position, it is referred to

as being “off.” (When the safety

is in the “SAFE” position, it is

referred to as being “on.”)

WARNING – MANUAL SAFETY

!

Figure 3. Safety selector in

“LOAD-UNLOAD” (middle) posi-

tion. The safety selector should be

in this position when the bolt is

being cycled to load a cartridge, or

to unload a live round. As soon as

a cartridge is chambered, the safety selector should be moved to the

“SAFE” position unless the rifle is

to be fired immediately.

Keep the safety on unless actually firing. Always

move the safety fully to its intended position and

check it. The safety has three positions –“SAFE,”

“LOAD-UNLOAD,” and “FIRE.” Never depend on a

safety mechanism or any other mechanical device

to justify careless handling or permitting the rifle

to point in an unsafe direction. The only “safe”

rifle is one in which the bolt is open and the

chamber and magazine are empty.

KNOW HOW TO USE THE SAFETY

10

Figure 4. Safety selector in

“SAFE” (full rearward) position.

The safety selector is fully nested

in the groove in the cocking piece.

When the safety selector is in this

position, the bolt handle cannot

be raised. The curved arrow on the

bolt sleeve indicates the direction

and motion of the safety selector

to bring it to the “SAFE” position.

Keep the safety in this position

except when actually loading,

unloading, or firing.

Page 10

This safety selector is held in each of its positions by a plunger that is under

!

spring tension. Therefore, the gun user should frequently check the position of

the safety selector to be certain it has not been inadvertently moved. If the safety

does not function properly, or if the selector seems to move too easily, or if the

safety selector does not seem firmly positioned in any of its three positions, the

rifle should be discontinued from use and returned to the Newport Product

Service Department for repair (see p. 30).

AMMUNITION

RUGER MODEL 77/22® rifles are chambered for many of the most popular

factory-loaded cartridges manufactured in accordance with U.S. industry practice. The particular caliber for each rifle is rollmarked on the barrel. Use car-

tridges only of the designated caliber that is marked on the barrel. Please see

AMMUNITION WARNING, p. 12 and LOADING WARNING on p. 15.

®

The RUGER MODEL 77/22

function as a repeating rifle with the .22 caliber Long Rifle rimfire cartridge,

standard, high velocity or hyper-velocity, manufactured to industry standards.

The .22 Short, .22 Long and .22 SHOT cartridges can be fired in the model

®

77/22

chamber. It should be noted that extensive use of the .22 Short cartridge can

cause a ‘ring’ to be cut in the chamber which may interfere with the extraction

of Long Rifle cartridges.

The RUGER MODEL 77/17 is chambered for the .17 HMR Hornady

Magnum Rimfire cartridge only. Do not use any other rimfire ammunition in

this rifle!

The RUGER MODEL 77/22

Winchester Magnum Rimfire cartridge only, both jacketed and hollow point. Do

not use any other .22 caliber or any other rimfire ammunition in this rifle, as

burst cases and the release of hot powder gases can result.

The RUGER MODEL 77/22

fire .22 Hornet cartridge. Do not attempt to use any .22 rimfire (short, long, long

rifle, or magnum) ammunition nor any other centerfire .22 ammunition (.222,

.223, etc.) in this model.

rifle, but such cartridges must be introduced by hand directly into the

is chambered for, and designed to properly

®

MAGNUM is chambered for the .22

®

HORNET is chambered only for the center-

WARNING: DO NOT ATTEMPT TO LOAD .22 SHORT, .22 LONG,

.22 SHOT OR ANY OTHER TYPE OF .22 CALIBER CARTRIDGE

(OTHER THAN THE .22 LONG RIFLE) INTO THE MAGAZINE

OF THE 77/22® RIFLE. THE USE OF OTHER CARTRIDGES IN THE MAGAZINE CAN CAUSE POTENTIALLY DANGEROUS JAMS AND MALFUNCTIONS

RESULTING IN DAMAGE TO THE FIREARM AND INJURY TO THE SHOOTER

AND OTHER PERSONS. TAKE CARE TO USE THE CORRECT CARTRIDGES. DO

NOT ATTEMPT TO LOAD ANY .22 RIMFIRE AMMUNITION INTO THE .22

HORNET MAGAZINE. DO NOT FIRE .17 HMR CARTRIDGES IN .22 MAGNUM RIFLES!

11

Page 11

!

The RUGER MODEL 77/44TMis chambered only for the centerfire .44

Magnum cartridge and should not be used with any other .44 caliber ammunition. Most .44 Magnum ammunition factory loaded to U.S. industry specifications

is suitable for use. However, “Medium Velocity” non-jacketed ammunition may

not give optimum accuracy and is not recommended.

WARNING: SOME TYPES OF LONG RIFLE CARTRIDGES HAVE

BLUNT-NOSE OR SHARP-SHOULDER BULLETS WHICH CAN

INTERFERE WITH SMOOTH AND RELIABLE FEEDING FROM

MAGAZINE TO CHAMBER. SUCH CARTRIDGES SHOULD NOT BE USED

BECAUSE THEY MAY DISCHARGE BEFORE BEING FULLY CHAMBERED

AND THEREBY POSSIBLY INJURE THE SHOOTER AND THOSE NEARBY.

THE SHOOTER MUST BE ALERT TO THIS POTENTIALLY DANGEROUS SITUATION AND SHOULD AT ONCE DISCONTINUE THE USE OF ANY CARTRIDGE WHICH APPEARS TO BE THE CAUSE OF FEEDING PROBLEMS OR

JAMMING.

!

WARNING – LEAD EXPOSURE

Discharging firearms in poorly ventilated

areas, cleaning firearms, or handling

ammunition may result in exposure to

lead and other substances known to the

state of California to cause birth defects,

reproductive harm, and other serious

physical injury. Have adequate ventilation

at all times. Wash hands thoroughly after

exposure.

SHOOTING OR CLEANING GUNS

MAY EXPOSE YOU TO LEAD

!

WARNING – AMMUNITION

Death, serious injury, and damage

can result from the use of wrong

ammunition, bore obstructions,

powder overloads, or incorrect cartridge components. Even the

strongest gun can be blown up by

excess pressure. Only use correct

ammunition loaded to U.S. Industry

Standards. Always wear shooting

glasses and hearing protectors.

IMPROPER AMMUNITION

DESTROYS GUNS

12

Page 12

AMMUNITION (CARTRIDGES) NOTICE

WE SPECIFICALLY DISCLAIM RESPONSIBILITY FOR ANY DAMAGE

OR INJURY WHATSOEVER OCCURRING IN CONNECTION WITH, OR

AS A RESULT OF, THE USE IN ANY RUGER FIREARMS OF FAULTY,

OR NON-STANDARD, OR “REMANUFACTURED” OR HAND-LOADED

(RELOADED) AMMUNITION, OR OF CARTRIDGES OTHER THAN THOSE FOR

WHICH THE FIREARM WAS ORIGINALLY CHAMBERED.

TO LOAD AND FIRE (WITH MAGAZINE)

Practice this important aspect of gun handling (with an unloaded rifle) until you

can perform each of the steps – described below – with skill and confidence. But

before loading the rifle, please read completely through this manual, and be certain the muzzle is pointing in a safe direction. Do not load the rifle until you are

ready to use it!

(The following procedure assumes a new rifle with the bolt out.)

1. Be certain the chamber is empty, the muzzle is pointing in a safe direction,

and keep your fingers off the trigger until you are actually ready to fire. (See

Rule 2, p. 46).

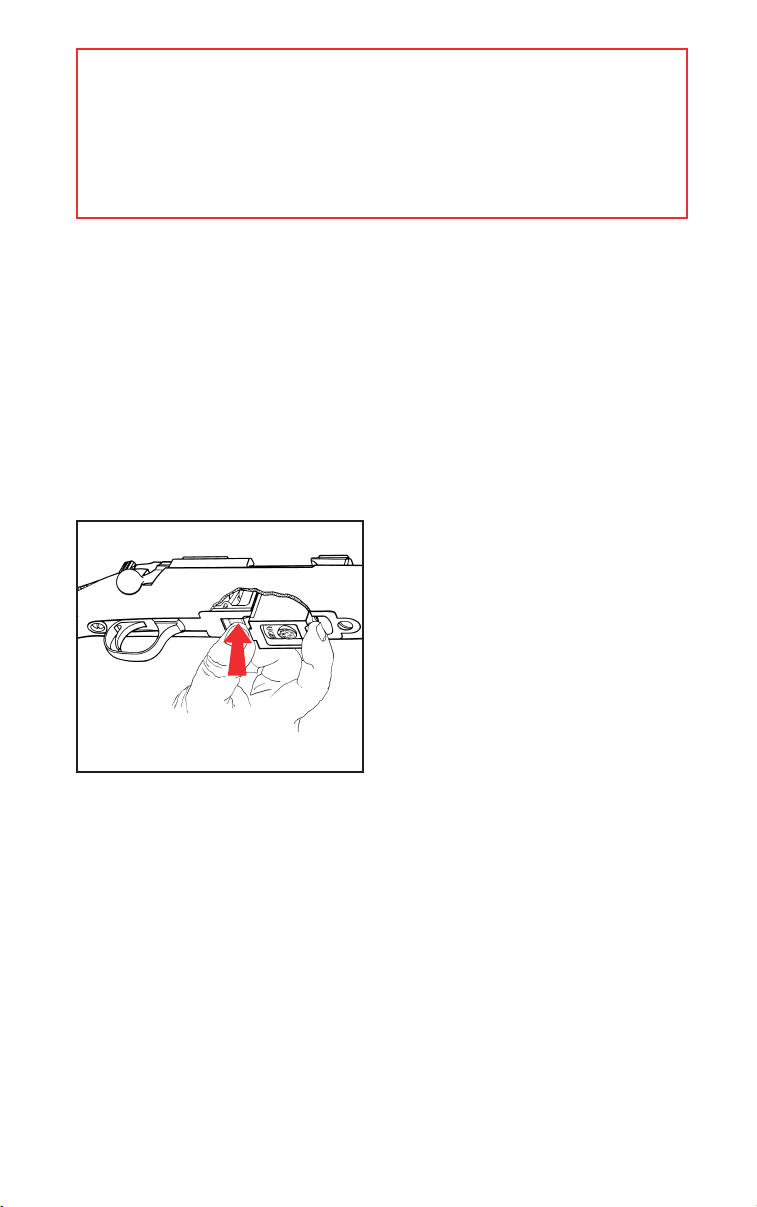

2. Remove the magazine from the rifle (See Figure 5, below).

Figure 5. The safety should be in the “LoadUnload” position or the “Safe” position when

the magazine is being removed or inserted.

When the forward section of the magazine

latch is pushed in (pivoted upward), the magazine is released. One way of removing the magazine is to cradle the rifle in the left hand with

the palm under - but not against - the magazine. Use the right forefinger to fully depress

the magazine latch and the magazine will drop

free. Another way (illustrated) is to deepress

Removing Magazine

(Keep Safety “On”)

the latch with the thumb and at the same time

grasp the magazine between the thumb and

forefinger and draw it out of the gun.

3. Position the safety selector in the “Load-Unload” position (see Figure 3, p. 10).

4. Make certain the bolt is ready to be inserted in the receiver. If there is any

doubt, see numbered paragraph 7, p. 23 (To Assemble the Bolt) in the

Reassembly section of this manual.

5. Depress the bolt-stop and insert the bolt into the receiver, closing the bolt handle fully down.

6. Move the safety selector fully rearward to the “Safe” position. This will also lock

the bolt closed (see Figure 4, p. 10).

7. Load the magazine with the cartridges (see Figure 6, p. 14).

8. Insert magazine into the magazine well of the rifle with the bullet end of the

cartridges in the direction of the barrel muzzle. (The magazine cannot be seated if it is reversed.)

9. Assuming the rifle is now to be fired, move the safety selector to the “LoadUnload” position.

13

Page 13

10. Raise the bolt handle, draw the bolt fully to the rear, then smoothly push

!

the bolt forward so that a cartridge is stripped from the magazine and

chambered. (Note: If the cartridge does not readily strip from the magazine,

or if the cartridge tends to jam while being chambered, discontinue the

loading procedure. Extract and eject the ‘problem’ cartridge and remove the

loaded magazine from the rifle. Then, read the “Ammunition” and

“Magazine Inspection and Care” sections of this manual) Now, lower the

bolt handle.

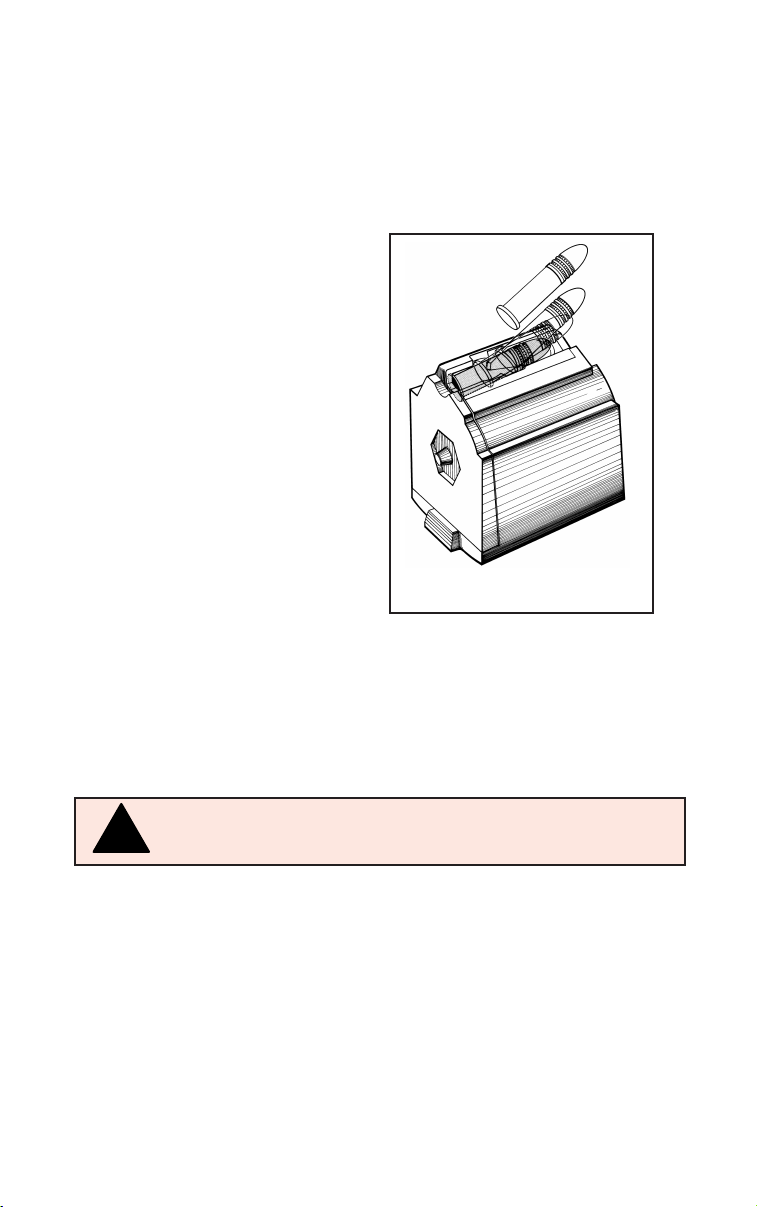

Figure 6. To load the magazine, press the

rim of the cartridge against the magazine

rotor at the widest section of the magazine

throat until the cartridge enters far enough

to be pushed to the rear end of the magazine. With the first cartridge in place, each

succeeding cartridge is pressed against the

body of the top cartridge and slid to the rear

of the magazine until a maximum of ten .22

LR cartridges (or nine .22 WMR or .17 HMR

cartridges, or six .22 Hornet cartridges, or

four .44 Magnum cartridges, depending

upon the magazine being loaded) are in the

magazine. The Ruger 77/22 & 77/44 rifles

are designed to function properly only with

the correct Ruger rotary magazine loaded

with cartridges of the correct caliber and

type.

The magazine must at all times be in good

condition or malfunctions can occur. Please

carefully read the sections in this manual on

“Magazine Inspection and Care” and the

section and warning on “Malfunctions”.

NOTE: The Ruger 10/22 magazine (BX-1) will fit in the model 77/22 rifle, but the

bottom section of the 10/22 magazine will not be flush with the trigger guard assembly of the 77/22. The 9 shot Ruger 77/22 Magnum and .17 HMR magazine is not

interchangeable with any other magazine, nor is the 6 shot 77/22 Hornet magazine.

The .44 magnum magazines for the Ruger 96/44 lever action rifle and the Deerfield

Carbine rifle will not fit into the Ruger 77/44 bolt action rifle due to dimensional differences. Do not attempt to use either of them in the Ruger 77/44.

Loading the

Magazine

.22 Long Rifle Magazine Shown

WARNING: DO NOT TOUCH THE TRIGGER UNTIL YOU ARE

ACTUALLY READY TO FIRE THE RIFLE.

11. The rifle is now fully loaded. Unless the rifle is to be immediately fired, move

the safety selector fully rearward to the “Safe” position.

12. To Fire the Rifle: Move the safety selector to the “Fire” position (see Figure

2, p. 10), and pull (squeeze) the trigger. A cartridge will be discharged.

Always be certain that you know where the bullet will strike when you fire

the rifle. (See “Handling Warning”, p. 16) Never allow the thumb to touch

the cocking piece as it can be pinched when the striker moves forward.

13. After the chambered cartridge has been fired, the bolt handle is raised and

the bolt is drawn to the rear in a firm, smooth stroke. This will extract and

eject the fired cartridge case. To chamber another cartridge, repeat the procedure detailed directly above.

14

Page 14

WARNING: REMEMBER THAT EACH TIME A CARTRIDGE IS

!

FIRED AND A NEW ONE IS CHAMBERED. THE SAFETY

SELECTOR IS IN THE “FIRE” POSITION. THEREFORE, IF

THE RIFLE IS NOT GOING TO BE DISCHARGED IMMEDIATELY AFTER THE

CARTRIDGE IS CHAMBERED, MOVE THE SAFETY SELECTOR FULLY BACK

TO THE “SAFE” POSITION.

14. To Single Load: The rifle can be used as a single shot rifle in the absence of a

magazine or for safety or training purposes. To do so, follow steps 1 - 3, p. 13.

Then load a cartridge into the chamber, and follow steps 10 - 13, p. 14. See

“Unloading Warning”, p. 17.

WARNING –LOADING

!

Know the caliber of your rifle you are loading and load

cartridges of only that caliber into it!

Before loading, be certain the primer of each cartridge

is seated flush with, or below, the surface of the cartridge case base. A cartridge discharged by the closing

of the bolt can result in possible serious injury to the

shooter and those nearby.

If a cartridge does not chamber readily, do not force it.

Check the bore and chamber to be certain that each

cartridge is the proper caliber and of correct dimensions. If you cannot determine why the cartridge will

not fit, clear the rifle of all cartridges and write or call

the factory.

The wrong ammunition can destroy your gun and

result in serious injury.

BE SURE WHAT YOU LOAD

IS CORRECT

!

WARNING – FIRING

When firing the Model 77/22®, 77/17, or 77/44

be sure that bystanders are well clear of the

shooter and standing a safe distance to the rear.

Empty cartridge cases are hot and are normally

ejected from the rifle to the right. They could

cause injury to any person who is standing too

closely alongside the shooter. Shooters who fire

right-hand rifles from their left shoulder should

be particularly cautious concerning ejected cartridge cases and the back of the bolt as it is

drawn rearward.

TM

EJECTED BRASS IS HOT

15

Page 15

WARNING –HANDLING

!

Never carry the rifle loaded with the safety selector in the “FIRE” position. If

dropped or struck with the safety off, the

rifle may fire. Such a discharge can occur

with or without the trigger being directly

struck or touched. Never rest a loaded

rifle against any object (wall, fence, vehicle, tree, etc.) because there is always the

possibility that the rifle will be jarred or

slide from its position and fall with sufficient force to discharge. Keep safety on

unless actually firing.

Never lower (uncock) the firing pin with

a loaded cartridge in the chamber. Under

such circumstances the firing pin will be

in direct contact with the primer of the

loaded cartridge and a light accidental

blow to the firing pin can readily cause

the gun to discharge.

ANY GUN MAY FIRE IF

DROPPED

TO UNLOAD RIFLE AND MAGAZINE

(Rifle Must be Pointing in a Safe Direction)

UNLOAD THE RIFLE IMMEDIATELY WHEN YOU ARE FINISHED SHOOTING.

If it has been desired to discontinue shooting before all of the cartridges in the

magazine and the chamber have been fired, proceed as follows (Keep your fingers

away from the trigger at all times during unloading):

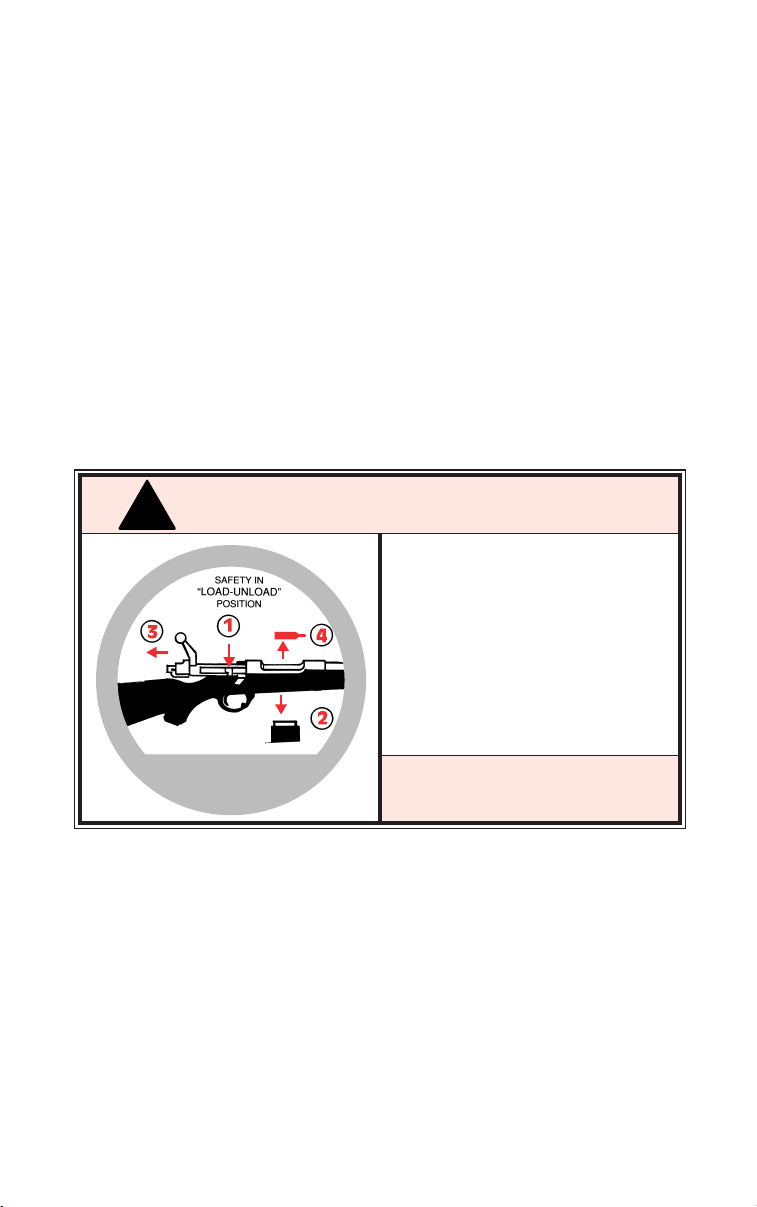

1. Move the safety selector to the “Load-Unload” position.

2. Remove the magazine.

3. Open the bolt carefully so the extracted live cartridge is not ejected forcibly.

4. Inspect the chamber to be certain the cartridge has been extracted.

5. Close the bolt fully.

6. Move the safety selector to the “Fire” position and with the rifle pointed in a

safe direction, pull the trigger.

7. If necessary, cartridges can be removed from the magazine by simply pushing

them lightly downward and forward with the thumb or forefinger. But, a better

and safer procedure is to place the rubber eraser end of a pencil against the

rim of the top cartridge and press lightly downward while pushing forward.

WARNING: Do not use a loaded cartridge as a “tool” to strip cartridges from

the magazine.

16

Page 16

8. If the rifle is not cocked, as when a fired cartridge case is in the chamber or in

the event of a misfire, carefully raise the bolt handle fully upward to cock it.

(Do not

Unload” position, and repeat steps 3 - 6, p. 16.

retract the bolt at this point). Now, put the safety in the “Load-

CORRECT UNLOADING SEQUENCE

WARNING – UNLOADING

!

Removing the magazine does not prevent

the rifle from being fired! When there is a

cartridge in the chamber and the safety

selector is in the “Fire” position, the cartridge will discharge if the trigger is

pulled. It is absolutely essential for the

user to know how to completely unload it.

“Completely” means removing the maga-

then removing a chambered car-

zine and

tridge. The safety selector should always be

in the “Load-Unload” position when the

rifle is being loaded or unloaded. See the

“Operation of Safety” section of this manual.

GUN WILL FIRE WITH

MAGAZINE OUT

17

Page 17

TO EXTRACT AND EJECT

A CHAMBERED CARTRIDGE

When the bolt is operated by hand, there can be a failure to extract the cartridge

from the chamber, or a failure to eject the cartridge clear of the rifle. These failures usually are the result of the bolt not being pulled rearward vigorously, coupled with an accumulation of bullet lubricant in the chamber. From the foregoing it is clear that the gun user must:

1. Always visually check the chamber after opening the bolt to eject a chambered

cartridge. If the bolt is not vigorously retracted when being operated by hand,

the extracted cartridge can be ‘ejected’ into the magazine area, instead of outside the rifle.

oughly clean the chamber and the extractor as often as necessary to pre-

2. Thor

vent the accumulation of grease and dirt.

3. If an empty magazine is in the rifle when the bolt is being hand retracted to

extract a cartridge, the cartridge may drop on top of the magazine. Then when

the bolt goes forward, the cartridge will be chambered again! Always remove

the magazine before clearing the chamber, and visually ensure that no cartridges remain in the gun.

TO CLEAR A MALFUNCTION (“JAM”)

If a jam occurs, immediately put the safety selector in the “Load-Unload’ position

and be certain the muzzle of the rifle is at all times pointing in a safe direction.

Then study the situation to determine the nature of the jam and how best to

clear it.

–If a cartridge or fired case is caught between the bolt and the barrel, or

against a cartridge that is in the chamber, open the magazine. Then retract

the bolt fully and remove the jammed cartridge or case.

–When attempting to extract a cartridge that is “stuck” in the chamber do

not use any type of tool that is likely to act as a “firing pin” and discharge

the cartridge should the tool impact on the primer or rim of a rimfire cartridge.

–After clearing a jam, inspect the gun mechanism to determine if dirt

might be the cause of the problem. Excess lubricant or grease can cause

cartridges to feed sluggishly or fail to extract. An accumulation of grease

or dirt on the face of the bolt, under the extractor, in the chamber, or in

the magazine can contribute to cartridge feeding problems. (See sections

on “Care and Cleaning”, pp. 24 - 26).

18

Page 18

WARNING – MALFUNCTIONS

➞

!

If a cartridge hangs up, jams, or binds when

being chambered or when being fed from the

magazine into the chamber, do not attempt to

force it into the chamber by pushing or striking

the bolt handle.

Most failures of a cartridge to feed or to chamber are caused by improper loading of the magazine or ammunition that is incorrect or defective.

Whatever the cause, the gun user must, above

all, recognize that jams can result in the very

potentially dangerous situation of a cartridge

discharging before it is chambered. If this

occurs, the cartridge case will rupture and its

fragments will fly out of the gun with sufficient

force to cause injury. Always wear shooting

glasses and hearing protectors!

STRIKING RIM OR PRIMER

CAN BURST CARTRIDGE

–After clearing a jam, inspect all cartridges that have been removed from

the gun. Safely dispose of any cartridges which are in any way damaged.

–If it appears that the rifle is not at fault and that the jam was caused by

the type of cartridge being used, then try another type.

–Examine your fired cartridge cases. If they have split, blown or bulged

heads, stop using that ammunition and promptly return the rifle to the

factory for examination.

–If the above procedures do not result in a smooth and reliably functioning

firearm, don’t use the rifle. The RUGER MODEL 77/22

77/17 or MODEL 77/44

Product Service Department for inspection and repair, if required. See the

“Service and Parts Policy”, p. 30, for packing and shipping information.

TM

can be returned directly to our Newport

®

, MODEL

TO MINIMIZE MALFUNCTIONS (“JAMS”)

Firearms of all makes and types are susceptible to occasional malfunctioning

due to a cartridge not feeding from the magazine to the chamber, or due to a

cartridge or fired case not being extracted and ejected.

19

Page 19

To minimize the possibility of such occurrences the gun user should:

–Use ammunition of the correct caliber and type which is loaded to U.S.

Industry Specifications. Do not use cartridges that are deformed, or cartridges that have been reloaded.

–Clean and lubricate the gun in accordance with the instructions in this

manual.

–Learn to correctly operate the bolt and how to properly load and empty the

chamber and magazine.

–If the mechanism shows signs of not functioning correctly, or if a part is

damaged or broken – don’t use the rifle. Have it inspected and repaired.

For most repairs we recommend that Ruger guns be returned to the factory,

However, if a gun has a cartridge in it which cannot be removed, then it is a violation of Federal Regulations to ship that loaded gun whether it be by U.S. Mail

or by common carrier. Contact our Newport Product Service Department at

(603) 865-2442.

BASIC DISASSEMBLY AND REASSEMBLY

!

WARNING – DISASSEMBLY

Always unload a firearm

before cleaning, lubrication,

disassembly or assembly.

UNLOAD BEFORE CLEAN-

ING

It is preferable to carry out these procedures on a workbench or table which has

a covered top. A piece of shallow nap rug or an old, coarse blanket is an ideal covering. Such a covering not only reduces the chances of the rifle slipping and

being scratched, but it serves also to trap pins, plungers and springs that may

otherwise get lost. It is advisable to have a container – such as a shoebox – in

which each part can be placed as it is removed from the gun.

Before attempting to disassemble the rifle for the first time, study the parts

drawing and parts list so as to be familiar with the relative position, appearance

and name of each part. Carry out the disassembly slowly, and carefully note the

position of the part in the gun before starting to remove it. If a part is under

spring tension (such as, the Safety Selector, Bolt Stop, Trigger) remove it cautiously and anticipate the direction the spring and plunger are most likely to

“jump.”

20

Page 20

WARNING: If a spring or plunger become lost do not use a substitute. Springs of correct tension are vital to the safe and reliable performance of firearms. Before starting

disassembly, remove the sling, scope and rings and place the rear sight blade in its

down flat position.

(Rifle Must Be Unloaded Prior To Disassembly)

DISASSEMBLY

1. Keep the rifle pointed in a safe direction! Put the safety in the “load-unload” posi-

tion, then, remove the magazine.

2. OPEN THE BOLT AND CHECK TO BE CERTAIN THAT THE CHAMBER IS EMPTY.

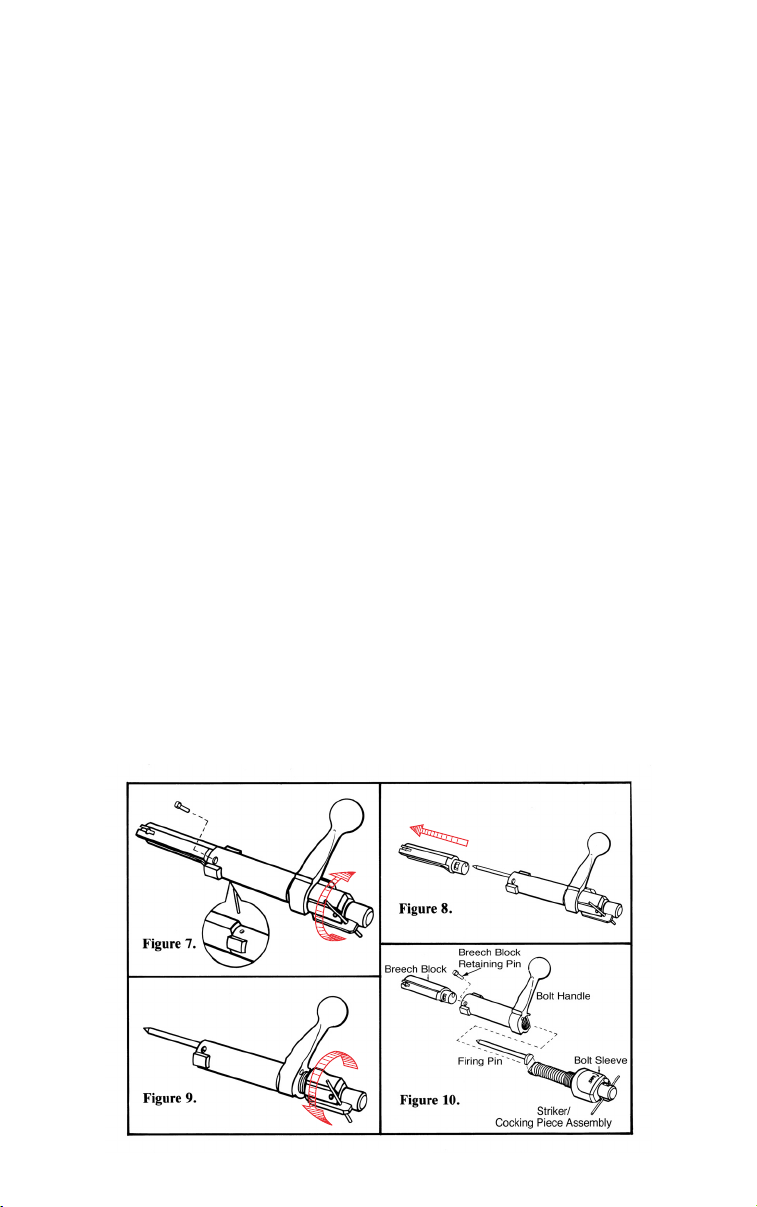

3. To remove the bolt: Before starting bolt disassembly, study Figure 10, below.

Lift the bolt handle up. Depress the bolt stop on the left side of the receiver.

Remove the bolt from the rifle.

4. To disassemble the bolt:

a. While holding the bolt handle, rotate the bolt sleeve clock-wise (as viewed

from the rear of the rifle) to position shown in Figure 7.

b. Rotate the breech block until the head of the breech block retaining pin is

aligned with the larger holes in the bolt. (Figure 7).

c. Push out the breech block retaining pin by inserting a pin through the small

hole on the side opposite from the larger hole. The alignment must be precise to

remove the retainer. (Figure 7).

d. Remove the breech block assembly by sliding it forward out of the bolt

(Figure 8).

e. Insert a small pin (or suitable nail) into the “disassembly hole” in the striker/cocking piece assembly to hold it in the rear position (Figure 8). NOTE: The

pin should be as close as possible in size to the hole diameter, and at least 2

inches long so that it can be used to ‘lever’ the cocking piece to the rear when

reassembling the bolt stop assembly into the bolt.

f. Unscrew the bolt sleeve (Figure 9). Remove the bolt sleeve assembly. Firing

pin can now be removed from the bolt sleeve assembly (Figure 10).

21

Page 21

CAUTION: The bolt sleeve assembly is intended to be a permanent

!

assembly and should not be disassembled. The parts are under great

spring pressure and if disassembled could fly apart with sufficient force to

cause serious injury. Also, special tools are required to correctly reassemble this part.

5. To remove the stock: (Be certain the bolt and magazine have been removed

from the rifle.)

NOTE: On the K77/22RP & RSP models, disregard step “b” and magazine well

liner in step “c”, below.

a. Remove the rear mounting screw in the trigger guard.

b. Swing the rear of the trigger guard out of the stock to clear trigger.

Unhook trigger guard assembly from the receiver. Remove the trigger guard

assembly.

c. Remove the front mounting screw and magazine well liner.

d. VERY CAREFULLY lift the barrel/receiver assembly from the stock.

6. To remove the barrel: (.22 LR, .22 Magnum, and .17 HMR Rifles Only

a. Remove the (2) barrel retainer screws and barrel retainer.

b. Slide the barrel forward to remove it from the receiver.

NOTE: .22 Hornet and .44 Magnum caliber barrels are threaded into the

receiver and should not

7. To remove the trigger: (Safety Selector should be in the “Fire” position).

a. While holding the trigger in place, press out the trigger pivot pin.

(Caution: Trigger is spring loaded and under tension --- be careful!).

b. Remove the trigger and trigger/sear spring.

8. To remove the sear:

a. Press out the sear pivot pin.

b. Turn receiver upside down and slide sear forward. Sear will drop out of

the top slot in the receiver.

9. To remove safety assembly:

a. Rotate the safety selector so that the upper section is positioned fully

over the center of the receiver tang.

b. While holding the safety selector in place with thumb and forefinger,

slide the retainer up out of receiver. (Caution: Safety Selector is under

spring tension from a spring and plunger acting against the lower section of

the safety selector. The spring and plunger will jump out if not contained).

c. Lift out the safety selector.

d. Remove the safety selector detent and safety selector detent spring.

10. To remove the bolt stop:

a. Depress the bolt stop plunger (with the tip of a jewelers screwdriver

blade or similar tool) and remove the bolt stop from the pivot. (Caution:

This spring and plunger will jump out.)

b. Remove the bolt stop plunger and bolt stop plunger spring.

be removed except by the factory.

)

22

Page 22

REASSEMBLY

(Again, Be Sure Rifle Is Unloaded)

1. To replace the bolt stop:

a. Replace the bolt stop plunger and bolt stop plunger spring. (Be certain

that the step flats on the plunger match the flats on the mating surface of

the bolt stop.)

b. Depress the bolt stop plunger and replace the bolt stop on the pivot.

2. To replace the safety assembly:

a. Place the safety selector detent and safety selector detent spring into the

hole in the receiver.

b. Set the safety selector in place with its upper section positioned over the

center of the receiver tang.

c. While holding the safety selector in place with thumb and forefinger,

slide the safety selector retainer into dovetail from the top. Align the notch

in the safety selector retainer with the sear pivot pin hole.

3. To replace the sear:

a. Place the rear end (the end with the hole in it) of the sear into the slot

from the top of the receiver. Swing the rear end of the sear up and slide the

sear into position until the hole in the sear is aligned with the mating holes

in the receiver.

b. Insert the sear pivot pin.

4. To replace the trigger:

a. Place the trigger/sear spring over the dimple in the trigger.

b. Assemble the trigger while aligning the spring with the dimple on the

sear.

c. While holding the trigger in position, replace the trigger pivot pin.

5. To replace the barrel: (.22 LR, .22 Magnum, and .17 HMR Rifles Only

a. Assemble the barrel into the receiver assembly.

b. Replace the barrel retainer and barrel retainer screws.

6. To replace the barrel/receiver assembly into the stock: (Caution: Be certain

that the pivot pins are not protruding from either side of the receiver.)

NOTE: On the K77/22RP & RSP models, disregard magazine well liner installation in step “b”, and all of steps “c” & “d”, below.

a. Carefully install the barrel/receiver assembly into the stock, making sure

the barrel/receiver assembly is in the most rearward position.

b. Install the magazine well liner and front mounting screw.

c. Hook the forward end of the trigger guard assembly into the receiver.

d. Swing the rear of the trigger guard into position.

e. Install the rear mounting screw.

7. To assemble the bolt:

a. Place the firing pin into the mating slot in bolt sleeve assembly.

b. Slide the bolt sleeve assembly into the bolt from the rear.

c. Screw the bolt sleeve into the bolt to position shown.

d. Install the breech block into the front end of the bolt.

e. Align the holes in the breech block with the hole in the bolt.

)

23

Page 23

f. Replace the breech block retaining pin. Flats on the breech block retaining pin must align with the slot in the breech block when the retaining pin is

installed.

g. Rotate the bolt sleeve assembly in counter-clockwise position until the

cocking piece engages small notch in the bolt.

h. Remove the pin or nail from the cocking piece. If the breech block does

not rotate freely about 1/16” in both directions, then reinsert the pin or nail

in the cocking piece hole and check to be certain that the breech block retaining pin is fully seated. Only when the bolt is correctly assembled should it be

inserted into the receiver.

i. Insert the bolt into the receiver.

REGARDING ACCURACY: The accuracy of any rifle can vary depending upon the

make and type of cartridges used in it. Such being the case, if your RUGER

MODEL 77/22

form to expectations, it is advisable to try several brands and types of cartridges to

determine which one delivers the best accuracy, before proceeding further. If your

rifle is not as “accurate” as you believe it should be, before concluding that some

serious fault exists, run the following checks:

1. Be certain the front mounting screw and the rear mounting screw are snugly

tightened.

2. Be certain the bore is clean and free from accumulated fouling (deposited by

powder and lead bullets). See the “Care and Cleaning” section of this Manual,

pp. 25 - 26.

3. Check the sights, or scope mounting system, for tightness, setting and alignment.

4. Be certain the two barrel retainer screws are fully tightened.

If everything is tight, the bore is clean, the sights are properly aligned and secure

but the accuracy problem persists, DO NOT alter the stock bedding in any way.

Do not scrape away wood, and do not bed with “glass,” plastic, epoxy, etc. Once a

rifle stock has been altered, it cannot be reworked by our Product Service

Department. If you still have an accuracy problem, write a brief letter to our

Product Service Department, 411 Sunapee Street, Newport, New Hampshire 03773

and describe the nature of the problem based on the use of factory-loaded cartridges – not reloads. You will receive a prompt response from us and if indicated,

detailed instructions with regard to the return of the rifle.

®

, MODEL 77/17, or MODEL 77/44TMrifle does not per-

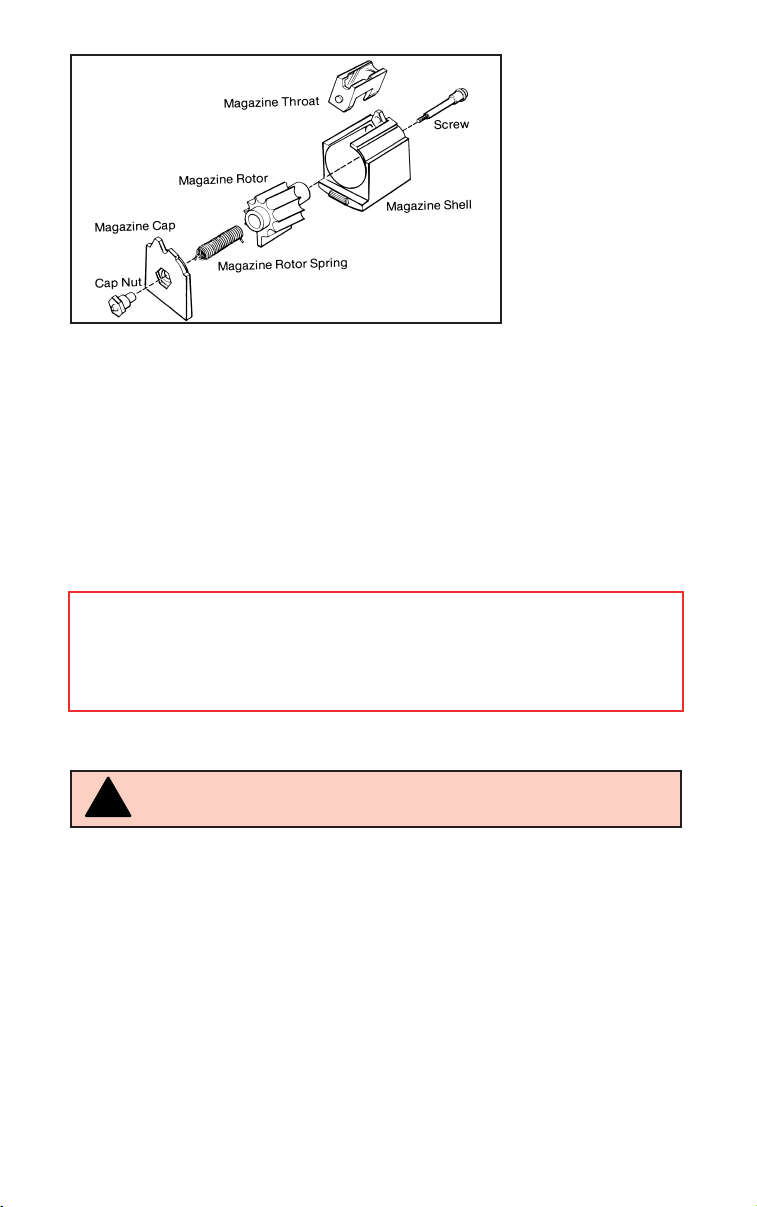

MAGAZINE INSPECTION AND CARE

Check the magazine frequently. The rotor must move freely and have adequate

tension so that each cartridge is quickly raised to the feeding position. At the time

of manufacture, proper rotor tension is set by rotating the magazine cap nut until

otor stops turning. Then the nut is turned an additional 1 1/4 turns beyond

the r

the ‘stop’ position.

To test the rotor tension, load one cartridge into the magazine and then firmly

press against the side of the cartridge case. Remove your finger quickly. The cartridge should instantly and fully move into the feeding position. If it does not, the

magazine should be cleaned. If cleaning does not restore proper rotor tension, do

not use the magazine. (NOTE: After testing, remove the test cartridge).

24

Page 24

Exploded view of the 77/22

!

Long Rifle magazine components. This illustration is

included to show the relationship and names of the

magazine components. The

®

Magnum, .17 HMR,

77/22

77/22®Hornet, and 77/44

magazines are similar. As

noted in the text above, the

magazine should not be disassembled.

Magazine Components

(.22LR Shown)

When cleaning is necessary, use a solvent that will not rust the metal components or adversely affect the plastic magazine box. After the magazine has been

soaked in solvent to loosen foreign matter, be certain to shake it vigorously (with

the loading opening away from you) to remove solvent or residue from within

the magazine.

After cleaning, always check to be certain that rotor movement and tension are

correct, and that no solvent or debris remain. Do not disassemble the magazine.

Improper reassembly or improper tensioning of the rotor spring can cause a

potentially dangerous malfunction. If you experience a problem with the magazine, don’t use it. Get a new one.

DAMAGED, NON-STANDARD, OR IMPROPERLY

ASSEMBLED MAGAZINES SHOULD NOT BE USED.

THEY CAN CAUSE THE RIFLE TO MALFUNCTION.

®

TM

CARE AND CLEANING

WARNING: BEFORE CLEANING, BE CERTAIN THE RIFLE

AND ITS MAGAZINE CONTAIN NO CARTRIDGES.

A firearm must be free of rust, dirt, grease and firing residues to function safely

and reliably. Periodic maintenance, which includes inspection of components to

determine if they are in proper working order, is absolutely essential. Firing

deposits particles of bullet lubricant and powder in the bore, chamber, bolt,

receiver, magazine and other parts of the rifle. There is no fixed rule as to how

frequently the cleaning should be carried out, but the alert gun owner soon

learns that any firearm functions most reliably and accurately when it is free of

accumulations of grease and other firing residues.

Basic cleaning equipment includes: A correct size cleaning rod equipped with

bore brushes (fiber and brass) and a tip in which a cloth patch can be inserted,

patches, powder solvent, lubricant, small lint-free cloths and a toothbrush. Use

correct size patches and brushes. Larger sizes will bind in the bore and can be

very difficult to remove!

25

Page 25

OIL

Insert rod from the chamber end of the barrel and push firmly so the patch or

brush emerges from the muzzle. Don’t reverse the rod when a brush or patch is

being used – it may bind. Don’t use patches or brushes dripping with solvent or

oil. Use rod and brushes with care so as not to damage gun.

1. Disassemble (field-strip) the rifle to the extent described on pages 21 - 22.

2. Push-pull a solvent-wetted patch through the bore several times. Next, using a

solvent-wetted brush, run it the full length of the bore as many times as is

necessary to completely remove all foreign matter from the bore and chamber. Dry the bore with clean patches and examine it. If bore remains fouled,

repeat the brushing. Complete the cleaning by dry-patch wiping of bore and

chamber.

3. Use a clean, solvent-wetted patch to remove firing residue and dirt from all

“reachable” surfaces inside the receiver. Use the solvent-wetted toothbrush to

dislodge caked dirt from all parts of the bolt assembly and from surfaces inside

the receiver that can’t be reached with a patch. Use cleaning patches or the

cloth to remove the solvent.

4. Wipe all surfaces – internal and external – with a very light coat of oil. Oil and

similar preparations “collect” dirt particles which can interfere with reliable

functioning of the rifle. Therefore, use these preparations very sparingly. A

drop of oil applied to the bolt assembly components, the pivot points of the

trigger mechanism, the safety, the bolt stop, and the magazine latch, will work

into all the parts that need lubrication.

5. Reassemble the rifle and carefully wipe all solvent, lubricating and preservative

preparations from the stock.

6. If the rifle is to be stored for an extended period, clean the rifle thoroughly.

Disassemble to the extent described elsewhere in this manual, taking care to

put pins and similar easily mislaid and “rolling” components in a tray. Rewipe

all surfaces with preservative oil. Reassemble and store properly.

WARNING – LUBRICATION

!

Firing a rifle with oil, grease, or any other material even partially obstructing the bore may result

in damage to the rifle and serious injury to the

shooter and those nearby. Do not spray or apply

lubricants directly on ammunition. If the powder

charge of a cartridge is affected by the lubricant,

it may not be ignited, but the energy from the

primer may be sufficient to push the bullet into

the bore where it may become lodged. Firing a

subsequent bullet onto the obstructed bore may

damage the revolver and cause serious injury or

death to the shooter and those nearby. Use lubricants properly. You are responsible for the proper

care and maintenance of your firearm.

IMPROPER LUBRICATION

DESTROYS GUNS

26

Page 26

Loaded

STORAGE

GUNS SHOULD NOT BE STORED LOADED!

USE THE LOCKING DEVICE SUPPLIED WITH THE RIFLE FOR STORAGE.

Do not store the rifle in a leather case or scabbard. Leather attracts moisture,

even though the case may appear to be perfectly dry.

TO RENDER THE RIFLE INOPERATIVE FOR SAFE STORAGE

With the muzzle pointed in a safe direction, remove the magazine (if applicable),

open the bolt, and check the chamber and the magazine to be sur

completely unloaded! Depress the bolt latch, located at the left rear of the receiver. Now pull the bolt fully to the rear. The bolt will come out the rear of the

receiver.

Store the rifle and the bolt in different locations. When disassembled in this

manner, the rifle is inoperable. It is impossible to fire the rifle until the bolt has

been correctly replaced into the rifle’s receiver.

To reassemble the rifle for firing, reinsert the bolt into the receiver from the rear.

With the muzzle pointed in a safe direction, close the bolt. Check to be sure that

the bolt can be operated fully and freely. The rifle is now reassembled and can be

loaded and fired normally.

While the rifle is less likely to be used by unauthorized persons when disassembled in the above manner, it is always safest to store any firearm with the

supplied locking device correctly installed, or to store the firearm in a gun safe

or other secure location away from children and unauthorized adults. Guns

should always be stored securely, unloaded

tion.

EE PAGE 6)

(S

e the rifle is

and separate from their ammuni-

!

LoadedLoaded

WARNING – STORAGE

Never place or store any firearm in such a

manner that it may be dislodged. Firearms

should always be stored securely and

unloaded, away from children and careless

adults. Use the locking device supplied with

the rifle for storage.

The use of a locking device or safety lock is

only one aspect of responsible firearms storage. For increased safety, firearms should be

stored unloaded in a location that is both

separate from their ammunition and inaccessible to children and any other unauthorized

person.

STORE SECURELY & UNLOADED

27

Page 27

MAINTENANCE OF

STAINLESS STEEL RIFLES

Firearms and components made of stainless steel are relatively more resistant to

corrosion than those of blued steel. However, in the interest of proper operation

and long life of a stainless steel firearm, inspect it frequently and clean, lubricate

and apply an appropriate rust preventative.

Sometimes discoloration occurs from perspiration or from contact with some

types of gun cases. Rusting may occur as a result of the firearm being exposed to

moisture, salt air or chemicals.

Minor discoloration can usually be removed by rubbing the stainless area with

an abrasive ink eraser, crocus cloth, or a “metal polishing” compound. When

using any of these abrasives, proceed with care and use light pressure to achieve

a blending of “color” with those areas that are not discolored.

External surfaces most subject to rusting from handling, or from exposure to the

elements should be cleaned and wiped dry after use or after exposure to adverse

conditions. If the rifle is to be stored, coat it with a light film of oil or preservative. Where the rifle is in continuing use, and the presence of oil or grease would

be objectionable, then the external surfaces can be coated (after cleaning and

drying) with a paste wax formulated for use on metals. Apply the wax sparingly,

allow time for it to dry hard, then buff lightly with a soft cloth. When applying

the wax, take care that it does not get into the mechanism or on the functioning

parts or in the bore.

28

Page 28

ATTACHING RUGER SCOPE RINGS

Each Ruger telescope ring is a mated assembly of a top and a base. Do not mix

the parts of the two ring assemblies as they are not interchangeable. On the

underside of each mounting ring assembly there is an integral lug, located off

center with respect to the front and back sides of the mount. The lug is nearer to

the front surface. By reference to the lug, the mounting ring can be correctly

assembled with the front of the ring toward the muzzle of the rifle.

1. Disassemble one ring and reassemble over the scope body between the turret

and the eyepiece. Remember - the lug on the base should be on the front side

of the scope.

2. Install the four top screws. Do not tighten.

3. Disassemble the other ring and install it on the forward section of the scope

tube with the lug forwardly also. Install the four top screws. Again, do not

tighten.

4. Assemble the rings to the receiver with the lugs engaging the recesses in the

top surface of the receiver. Tighten the clamp nuts so that the rings are locked

to the semicircular cuts on the sides of the receiver.

5. Rotate the scope until cross-hairs are aligned properly and slide scope to

desired eye relief. Then tighten the eight top screws each a bit at a time to grip

the scope body.

6. Sight in according to the directions with your scope.

SIGHT ADJUSTMENT

(For Rifles Equipped With Open Sights)

The folding leaf rear sight is adjustable for elevation. The slide must be moved

one graduation to change the point of impact by approximately one inch at 25

yards. Shooting to determine the slide setting for ‘zero’ at a particular distance

should be done from a bench rest and over a measured distance. Use only a small

screwdriver with a blade tip that exactly fits the screw-head. Loosen the screws

only slightly so the slide doesn’t move too freely. Move the slide in the direction

you want the point of impact of the bullet to move. When the slide is positioned

at the desired height, carefully tighten both screws.

Lateral (windage) adjustment is made by “drifting’ the sight base in its slot. Place

a short brass rod against the sight base (and only the base) and tap the sight in

the direction you wish to move the point of impact.

SUGGESTED SIGHT PICTURE

Top of front sight even with top of

rear sight slide. Front sight centered in notch of rear sight slide.

Target bull’s-eye centered on top

of front sight.

29

Page 29

SERVICE AND PARTS POLICY

!

If you have any question with regard to the performance of your RUGER

MODEL 77/22

call (603-865-2442) our Product Service Department, 411 Sunapee Street,

Newport, New Hampshire 03773, fully describing all circumstances and conditions

involved. If you should return your rifle to the factory for repair, or order parts for

it, please comply with the following suggestions for prompt service:

®

, MODEL 77/17, or MODEL 77/44TMrifle please write or

WARNING: BEFORE SHIPPING ANY FIREARM, BE

ABSOLUTELY CERTAIN THAT IT AND ITS MAGAZINE ARE UNLOADED. DO NOT SHIP CARTRIDGES WITH A FIREARM.

SHIPPING FIREARMS FOR REPAIR

RUGER MODEL 77/22®, MODEL 77/17, or MODEL 77/44TMrifles

returned to the factory for repair should be sent to: Sturm Ruger & Company,

Inc., Product Service Department, 411 Sunapee Street, Newport, New Hampshire

03773. Telephone (603) 865-2442. Guns should be sent prepaid. We will not

accept collect shipments.

The Federal Gun Control Act, as well as the laws of most States and localities, do

not prohibit an individual (who is not otherwise barred from purchasing or possessing a firearm) from shipping a firearm directly to the manufacturer for

repair. However, before you ship your rifle to us, be certain that your State or

locality does not have a law or regulation which will prohibit you from receiving

the rifle from us after it has been repaired. If such receiving is prohibited, then

please have a Federally Licensed firearms dealer ship the gun to us. If your rifle

is sent to us by a dealer, it will be returned to him after being repaired. If a handgun (pistol or revolver) is shipped by an individual who does not hold a Federal

Firearms License, it must be shipped via U.P.S. (Next Day Air) Persons who do

not hold a Federal Firearms License are prohibited by Federal law from shipping

a handgun by Mail. Handguns mailed in violation of the law are impounded by

the Post Office.

Please do not include rifle case, sling, telescopic sights or custom accessories

with a firearm being shipped to the factory for service. DO NOT SEND GUN

BOXES OR LITERATURE THAT YOU CONSIDER TO BE COLLECTOR’S

ITEMS – THESE ARE INVARIABLY DAMAGED OR DESTROYED IN

SHIPMENT. Rifles and shotguns may be shipped via Parcel Post. Always insure

your shipment.

Enclose a letter which includes your name, address, telephone number, serial

number and model of the firearm. Describe in detail the trouble you have experienced with your firearm, or the work you wish to have done. Merely stating that

the firearm “needs repair” is inadequate information.

Work performed will bear a net minimum labor charge of $20.00 plus a $12.00

shipping and handling charge. The charge for rebluing the MODEL 77/22

MODEL 77/17, or MODEL 77/44

and handling charge. Custom gunsmithing service or non-standard alterations

are NOT AVAILABLE from Ruger Product Service Departments.

TM

rifle is $50.00 plus a $12.00 shipping

30

®

,

Page 30

!

WARNING –PARTS PURCHASERS

!

It is the purchaser’s responsibility to be absolutely certain that any parts ordered from the factory

are correctly fitted and installed. Firearms are

complicated mechanisms and IMPROPER FIT-

TING OF PARTS MAY RESULT IN A DANGEROUS MALFUNCTION, DAMAGE TO THE

FIREARM, AND SERIOUS INJURY TO THE

SHOOTER AND OTHER PERSONS. The purchas-

er and installer of parts must accept full responsibility for the correct adjustment and functioning

of the firearm after such installation.

PARTS MUST FIT CORRECTLY

ORDERING PARTS

Please contact the New Hampshire Product Service Department for parts availability and current prices. All parts orders for the MODEL 77/22®, MODEL

77/17, or MODEL 77/44

Product Service Department, 411 Sunapee Street, Newport, New Hampshire,

03773, (603) 865-2442.

We cannot comply with open account or C.O.D. requests. Payment in the form of

a check, money order, Visa or Mastercard must accompany your order. Credit

Card orders must include the account number, expiration date and whether it is

a Visa or Mastercard account. Minimum parts order is $1.00 plus a $3.50 shipping and handling charge. Order parts by Part Number and Part Name and

include the entire serial number of the firearm for which the parts are being

ordered. There is a minimum net labor charge of $20.00 plus $12.00 shipping

and handling charge if the parts are factory fitted. All factory-fitted parts are fitted on an exchange basis only. We will not return the replaced parts.

Because the receiver of the MODEL 77/22

MODEL 77/44

“firearm” by Federal law and is not sold as a separate component.

*Parts designated by an asterisk must be factory fitted. These parts are fitted on

an exchange basis only. We will not return the replaced parts. We will not return

any part that is broken, malfunctioning, badly worn or has been modified. See

“Warning — Parts Purchasers”, above.

TM

rifles is a serial numbered component, it is defined as a

TM

should be sent to: Sturm, Ruger & Co., Inc.,

®

, MODEL 77/17, and

CAUTION: A gun containing modified, broken, malfunctioning,

or badly worn parts should not be fired.

31

Page 31

RUGER®MODEL 77/22®LR & MAG. & MODEL 77/17 RIFLES

PARTS LIST

Design, prices and specifications subject to change without notice.

SPECIFY MODEL AND CALIBER WHEN ORDERING

(See Exploded Views on Pages 38 & 39)

Part Name Part No. Model

* Barrel 20” - .22 LR 0J8001 Standard 77/22 - without Sights

* Barrel 20” - .22 LR K0J8001 All-Weather 77/22 - without Sights

* Barrel 20” - .22 Mag. 0J8002 Standard 77/22 - without Sights

* Barrel 20” - .22 Mag. K0J8002 All-Weather 77/22 - without Sights

* Barrel 20” - .22 LR 0J8003 Standard 77/22 - with Sights

32

* Barrel 20” - .22 LR K0J8003 All-Weather 77/22 - with Sights

* Barrel 20” - .22 Mag. 0J8004 Standard 77/22 - with Sights

* Barrel 20” - .22 Mag. K0J8004 All-Weather 77/22 - with Sights

* Barrel 24” - .22 LR K0J8010 Varmint 77/22

* Barrel 24” - .22 Mag. K0J8005 Varmint 77/22

* Barrel 22” - .17 HMR 0J8017 77/17

Barrel Retainer, V-Block B-66 All Models

Barrel Retainer Screw, 2 Req’d. J05100 All Models

* Bolt Handle J01001 Standard 77/22

* Bolt Handle KJ01001 All-Weather 77/22 or 77/17

* Bolt Handle KJ01001T Varmint 77/22

Bolt Lock Plunger J02600 Standard 77/22

Bolt Lock Plunger KJ02600 All-Weather 77/22

Page 32

Part Name Part No. Model

Bolt Lock Plunger KJ02600T Varmint 77/22

Bolt Lock Plunger Retainer J04600 All Models

Bolt Lock Plunger Spring J04500 All Models

Bolt Sleeve J01700 Standard 77/22

Bolt Sleeve KJ01700 All-Weather 77/22 or 77/17

Bolt Sleeve KJ01700T Varmint 77/22

Bolt Stop J05300 Standard 77/22

Bolt Stop KJ05300 All-Weather 77/22

Bolt Stop KJ05300T Varmint 77/22

Bolt Stop Plunger J05200 All Models

Bolt Stop Plunger Spring J05400 All Models

33

*Breech Block Assembly - .22 LR J20900 Standard 77/22

*Breech Block Assembly - .22 LR KJ20900 All-Weather 77/22

*Breech Block Assembly - .22 Mag. J20901 Standard 77/22

*Breech Block Assembly - .22 Mag. & .17 HMR KJ20901 All-Weather 77/22 or 77/17

*Breech Block Assembly - .22 LR KJ20900T Varmint 77/22

*Breech Block Assembly - .22 Mag. KJ20901T Varmint 77/22

Breech Block Retainer J00800 All Models

Butt Plate Screw, 2 Req’d. B-91 All-Weather 77/22

Cartridge Support KJ01500 All Models

Cartridge Support Plunger KJ01600 All Models

Cartridge Support Spring J00700 All Models

Cocking Piece KJ01800 Standard & All-Weather 77/22 or 77/17

Cocking Piece KJ01800T Varmint 77/22

Page 33

Part Name Part No. Model

Escutcheon, Not Illustrated, 2 Req’d. B-51 All-Weather 77/22

* Extractor KJ01402 All Models

Extractor Plunger KJ01600 All Models

Extractor Spring J01900 All Models

Ferrule, Left Side, 3 Req’d. W01015 All-Weather 77/22

Ferrule, Right Side, 3 Req’d. W01014 All-Weather 77/22

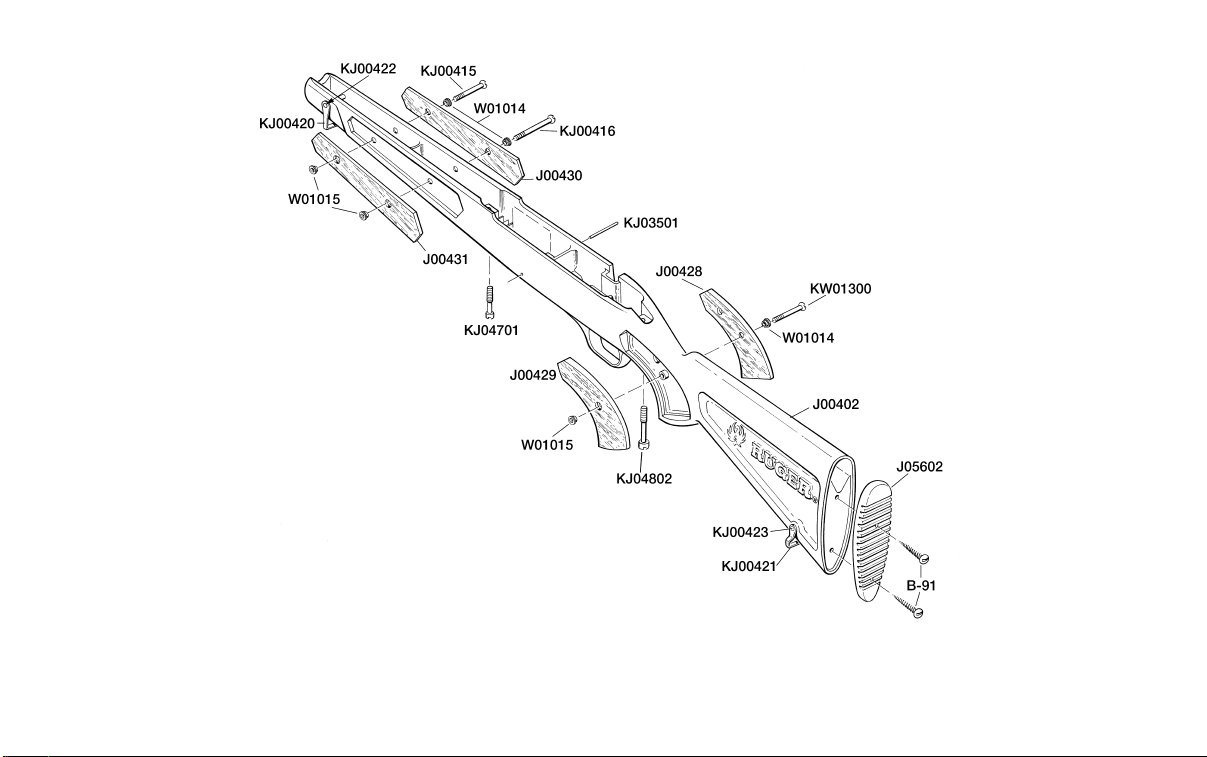

* Firing Pin J01100A All Models

Forearm Insert, Black Plastic, Left Side J00431 All-Weather 77/22

Forearm Insert, Black Plastic, Right Side J00430 All-Weather 77/22

Front Forearm Insert Screw, Front KJ00415 All-Weather 77/22

Front Forearm Insert Screw, Rear KJ00416 All-Weather 77/22

34

Front Mounting Screw J04700 Standard 77/22 or 77/17

Front Mounting Screw KJ04701 All-Weather 77/22

Front Mounting Screw KJ04700T Varmint 77/22

Front Sight - .22 LR J06000 Standard & All-Weather 77/22 - with Sights

Front Sight - .22 Mag. J06001 Standard & All-Weather 77/22 - with Sights

Front Sling Swivel KJ00420 All-Weather 77/22

Front Sling Swivel Pin KJ00422 All-Weather 77/22

Magazine Complete, 10-shot - .22 LR JX-1 All .22 LR Models

Magazine Complete, 9-shot - .22 Mag. or .17 HMR JMX-1 All .22 Mag. Models or .17 HMR

Magazine Latch Lever J03400 Standard 77/22 or 77/17

Magazine Latch Lever J03401 All-Weather 77/22

Magazine Latch Lever J03402 Varmint 77/22

Magazine Latch Block Retainer, J08800 All-Weather 77/22

Not Illustrated

Page 34

Part Name Part No. Model

Magazine Latch Pivot Pin J03500 Standard & Varmint 77/22 or 77/17

Magazine Latch Pivot Pin KJ03501 All-Weather 77/22

Magazine Latch Plunger J04000 Standard & Varmint 77/22 or 77/17

Magazine Latch Plunger B-36 All-Weather 77/22

Magazine Latch Plunger Spring B-37 All Models

Magazine Well Liner J00600 Standard 77/22 or 77/17

Magazine Well Liner KJ00600T Varmint 77/22

Pistol Grip Cap D08001 Standard 77/22 or 77/17

Pistol Grip Cap Medallion D-82 Standard 77/22 or 77/17

Pistol Grip Cap Screw C-96SM Standard 77/22 or 77/17

35

Pistol Grip Insert, Black Plastic, Left J00429 All-Weather 77/22

Pistol Grip Insert, Black Plastic, Right J00428 All-Weather 77/22

Pistol Grip Insert Screw KW01300 All-Weather 77/22

Rear Mounting Screw J04800 Standard 77/22 or 77/17

Rear Mounting Screw KJ04802 All-Weather 77/22

Rear Mounting Screw KJ04800T Varmint 77/22

Rear Sight J06100 Standard & All-Weather 77/22 - with Sights

Rear Sling Swivel KJ00421 All-Weather 77/22

Rear Sling Swivel Pin KJ00423 All-Weather 77/22

Recoil Pad J05602 All-Weather 77/22

Recoil Pad, Black, Rubber D06304 Standard & Varmint 77/22 or 77/17

Recoil Pad Screws, 2 Req’d D-84 Standard & Varmint 77/22 or 77/17

*Safety Selector J03800 Standard 77/22 or 77/17

*Safety Selector KJ03800 All-Weather & Varmint 77/22

Page 35

Part Name Part No. Model

Safety Selector Detent J04300 All Models

Safety Selector Detent Spring D-32 All Models

Safety Selector Retainer J02100 Standard 77/22

Safety Selector Retainer KJ02100 All-Weather & Varmint 77/22

Scope Ring Clamp D-74 All Models

Scope Ring Nut D-73 All Models

Scope Base Torx®Head Screw, 8 Req’d. MPF07602 Standard 77/22 or 77/17 - blued

Scope Base Torx®Head Screw, 8 Req’d. KMPF07602 Standard & All-Weather 77/22 - stainless

Scope Base Torx®Head Screw, 8 Req’d. KMPF07602M Varmint 77/22 - matte finish

Scope Rings, Low S100RL Standard 77/22

Scope Rings, Low KS100RL All-Weather 77/22

36

Scope Rings, Medium, Matte Gray KD72MTG Varmint 77/22

Scope Rings, Medium S100RM 77/17

*Sear KJ02302 Standard & All-Weather 77/22

*Sear KJ02303 Varmint 77/22 or 77/17

Sear Pivot Pin J04200 All Models

Sling Swivel Front Screw, with Nut S-86B Standard & Varmint 77/22 or 77/17

Sling Swivel Rear Mounting Stud S-87 Standard & Varmint 77/22 or 77/17

Stock, Walnut, Complete J00400 Standard 77/22 or 77/17

Stock, Laminated, Complete J00435 Varmint 77/22

Stock

, Synthetic,

With Plastic Inserts

Stock

, Synthetic,

With Plastic Inserts

Complete - .22 LR J20402A All-Weather 77/22

Complete - .22 Mag. J20403A All-Weather 77/22

Page 36

Part Name Part No. Model

Stock, Only - .22 LR J00402 All-Weather 77/22

Stock, Only - .22 Mag. J00403 All-Weather 77/22

Striker J01300 All Models

Striker/Cocking Piece Assembly J31700 Standard 77/22

Striker/Cocking Piece Assembly KJ31700 All-Weather 77/22 or 77/17

Striker/Cocking Piece Assembly KJ31700T Varmint 77/22

Striker Cross Pin J04900 All Models

Striker Spring J01200A All Models

Torx®Key Wrench, Not Illustrated MPF07601 All Models

(for scope base Torx®Head Screw)

*Trigger KJ02000 Standard & All-Weather 77/22 or 77/17

37

*Trigger KJ02000T Varmint 77/22

Trigger Guard Assembly - .22 LR J30200 Standard 77/22

Trigger Guard Assembly - .22 Mag. J30201 Standard 77/22 or 77/17

Trigger Guard Assembly - .22 LR KJ30200T Varmint 77/22

Trigger Guard Assembly - .22 Mag. KJ30201T Varmint 77/22

Trigger Pivot Pin

D-19 All Models

Trigger/Sear Spring J02400 All Models

*PARTS SO MARKED MUST BE FACTORY FITTED

Page 37

RUGER MODEL 77/22

& MODEL 77/17

EXPLODED VIEW

®

38

Page 38

39

SYNTHETIC STOCK

COMPONENT PARTS

Page 39

RUGER®MODEL 77/22®HORNET & MODEL 77/44TMRIFLES

PARTS LIST

Design, prices and specifications subject to change without notice.

SPECIFY MODEL AND CALIBER WHEN ORDERING

(See Exploded View on Page 44 & 45)

Part Name Part No. Model

* Barrel 20” 0J8008 77/22 RH, RSH

* Barrel 24” K0J8009 77/22 VHZ

* Barrel 0J8013 77/44 RS

* Barrel K0J8013 77/44 RSP

* Bolt Handle J01001 77/22 RH, RSH & 77/44 RS

* Bolt Handle KJ01001T 77/22 VHZ

40

* Bolt Handle KJ01001 77/44 RSP

Bolt Lock Plunger J02600 77/22 RH, RSH & 77/44 RS

Bolt Lock Plunger KJ02600T 77/22 VHZ

Bolt Lock Plunger KJ02600 77/44 RSP

Bolt Lock Plunger Retainer J04600 All Models

Bolt Lock Plunger Spring J04500 All Models

Bolt Sleeve J01700 77/22 RH, RSH

Bolt Sleeve KJ01700T 77/22 VHZ

Bolt Sleeve J01706 77/44 RS

Bolt Sleeve KJ01706 77/44 RSP

Bolt Stop J05302 77/22 RH, RSH & 77/44 RS

Bolt Stop KJ05302T 77/22 VHZ & 77/44 RSP

Bolt Stop Plunger Spring J05401 All Models

*Breech Block Assembly J20903 77/22 RH, RSH

*Breech Block Assembly KJ20903T 77/22 VHZ

*Breech Block Assembly J20906 77/44 RS, RSP

Page 40

Part Name Part No. Model

Breech Block Retaining Pin J00800 All Models

Butt Plate Screw, 2 Req’d B-91 77/44 RSP

Cartridge Support, Not Illustrated J01503 77/44 RS, RSP

Cartridge Support Pivot Pin, Not Illustrated J05801 77/44 RS, RSP

Cocking Piece J01800 77/22 RH, RSH & 77/44 RS

Cocking Piece KJ01800T 77/22 VHZ

Cocking Piece KJ01800 77/44 RSP

Escutcheon, Not Illustrated L05101 77/44 RS, RSP

Extractor KJ01403 77/22 RH, RSH, VHZ

Extractor L01421 77/44 RS, RSP

Extractor Pivot Pin J05800 77/44 RS, RSP

Extractor Plunger KJ01600 77/22 RH, RSH, VHZ

41

Extractor Spring J01900 77/22 RH, RSH, VHZ

Extractor Spring L05700 77/44 RS, RSP

* Firing Pin J01102A 77/22 RH, RSH, VHZ

* Firing Pin J01104A 77/44 RS, RSP

Front Mounting Screw J04702 77/22 RH, RSH

Front Mounting Screw KJ04702T 77/22 VHZ

Front Mounting Screw J04703 77/44 RS, RSP