Rough Country 379.22 User Manual

92137900

11-12 2500/3500 Dodge 5” Long Arm Kit

Thank you for choosing Rough Country Suspension for your Off Road needs.

Rough Country recommends a certified technician installs this system. In addition to these instructions, professional

knowledge of disassemble/reassembly procedures as well as post installation checks must be known. Attempts to

install this system without this knowledge and expertise may jeopardize the integrity and/or operating safety of the vehicle. Average professional install time for this kit is 4-6 hours.

Please read all the instructions before beginning the installation. Check the kit hardware against the kit contents list on

the last page. Be sure you have all the needed parts and understand where they go.

Product Use Information

As a general rule, the taller a vehicle is the easier it will roll. We strongly recommend, because of rollover possibility,

that the vehicle be equipped with a functional roll-bar and cage system. Seat belts and should harnesses should be

worn at all times. Avoid situations where a side rollover may occur.

Also check the steering stabilizer. It is a good idea when adding larger than stock tires to go with a larger bore steering

stabilizer or a dual unit for tires 35” and above. Inspect the stabilizer and replace as necessary.

Braking performance and capability are decreased when significantly large/heavier tires and wheels are used. Take

this into consideration while driving.

Do no add, alter, or fabricate any factory or after-market parts which increase vehicle height over the intended height

of the Rough Country product purchased. Mixing component brands, lifts, and/or combining body lift with suspension

lifts voids all warranties. Rough Country makes no claims regarding lifting devices and excludes any and all implied

claims. We will not be responsible for any product that is altered.

This suspension system was developed for 37x12.50 tire on an aftermarket 17” x 9” or 20” wheels with a minimum of

5” back spacer. When larger tires are installed, speedometer recalibration is necessary. Due to ride height inconsistencies from the factory you may need to slightly trim the front plastic valance for proper tire clearance.

This kit can also be used a 3500 single rear wheel truck. Use of this kit on a dual rear wheel pickup is not rec-

ommended. Block and u-bolt combinations may vary with 3500 models.

On vehicles equipped with a two piece driveshaft & carrier bearing as on the Mega Cab, there is the potential

for take off vibration, depending on the severity this can be corrected with shimming down the carrier bearing.

Carrier bearing drop kit Part # 1110 is available from Rough Country. Also 2500/3500 trucks with factory over-

load springs the overload will have to be removed for new block and u-bolt installation.

Notice to Dealer and Vehicle Owner

Any vehicle equipped with any Rough country product must have the “Warning to Driver” decal installed on the sun

visor or dash. The decal is to act as a constant reminder for whoever is operating the vehicle of its unique handling

characteristics. INSTALLING DEALER—It is your responsibility to install the warning decal and to forward

these installation instructions to the vehicle owner for review and to be kept in the vehicle for its service life.

Tools and Supplies Needed to Install Kit

1. Torque Wrenches 8. Pitman Arm Puller

2. ½” Drive Ratchet and Sockets 9. Hammers

3. Assorted Combination Wrenches 10. 17/32” Drill Bit

4. Heavy Duty Jack Stands 11. 15/32” Drill Bit

5. Hydraulic Floor Jacks 12. Die Grinder with Cut Off Wheel

6. Center Punch 13. Safety Glasses

7. Grinder 14. WD-40

FRONT SUSPENSION INSTALLATION

1. Secure and block the rear tires of the vehicle on a level concrete or asphalt surface

2. Open the hood and remove the shock nuts, retaining washers and rubber bushings from both upper shock mounts

located inside the engine compartment. The shocks will be removed when the coils are removed.

3. Raise the front of the vehicle and support the frame with jack stands. Remove the front wheels and tires and set

aside. Position a hydraulic jack under the front axle and raise the jack until the front suspension begins to compress

4. On both sides of the vehicle, scribe alignment marks on the adjustment cam and axle bracket at the lower link to

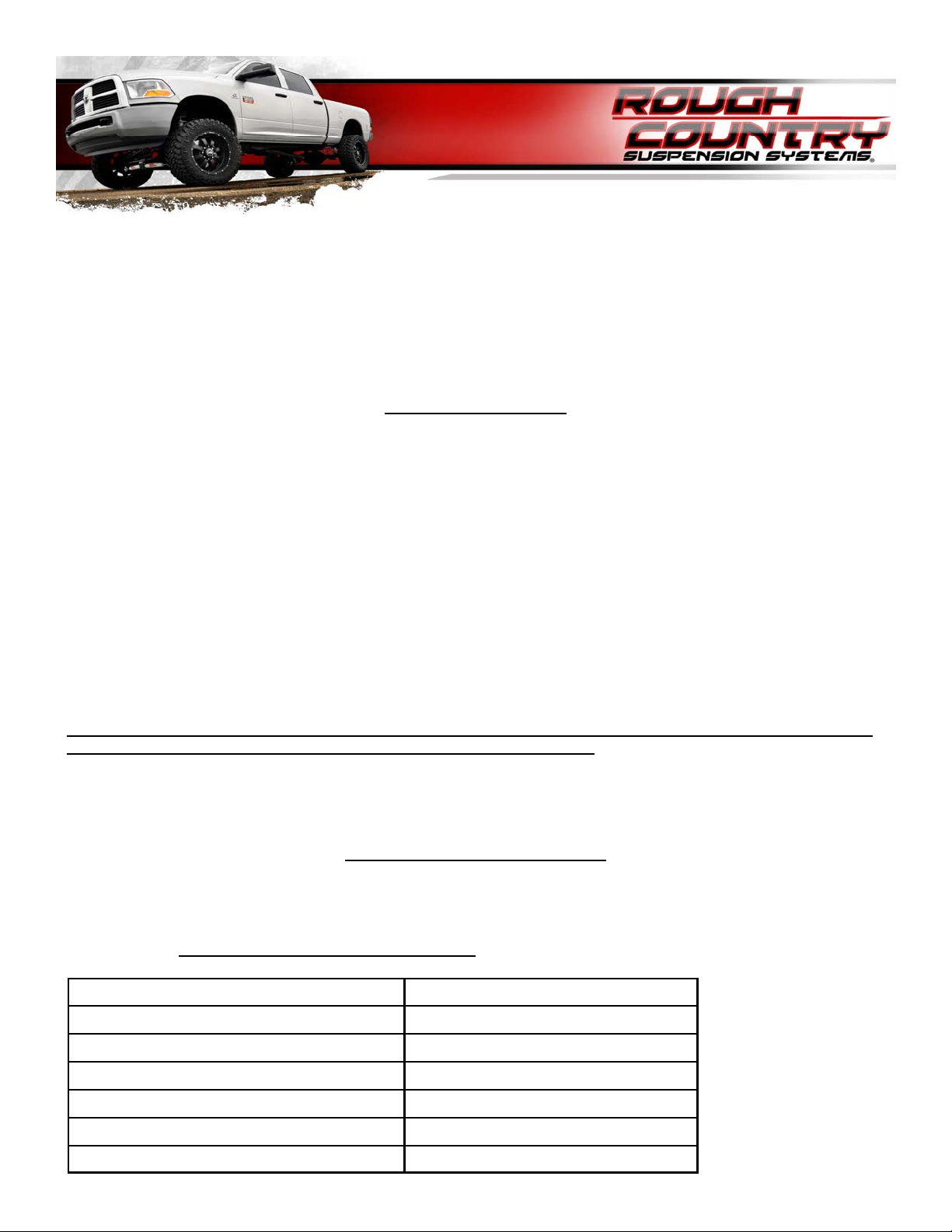

axle attachment point for later reference. See Photo 1.

5. Unbolt the brake line brackets from the control arm mount on the axle using a 13mm wrench to ensure brake line

free play during the suspension system installation.

6. Loosen the stock front upper sway bar links on the sway bar as shown in Photo 2 using a 15mm wrench.

Photo 2

Photo 1

7. Remove the track bar from its upper mounting point on the frame using a 24mm wrench and rest it on the axle. It

may be helpful to loosen the lower track bar bolt on the axle. Retain hardware for reuse.

8. Remove the cotter pin, and castle nut from the drag link where it connects to the pitman arm. A pitman arm tool

may be needed to separate the drag link from the pitman arm. Remove the stock nut, and lock washer from the

sector shaft on the steering box. Save hardware for later installation. Using a pitman arm puller carefully remove

the stock pitman arm.

9. The new control arms will be installed one side at a time on the vehicle. This is done to make it easier to remove

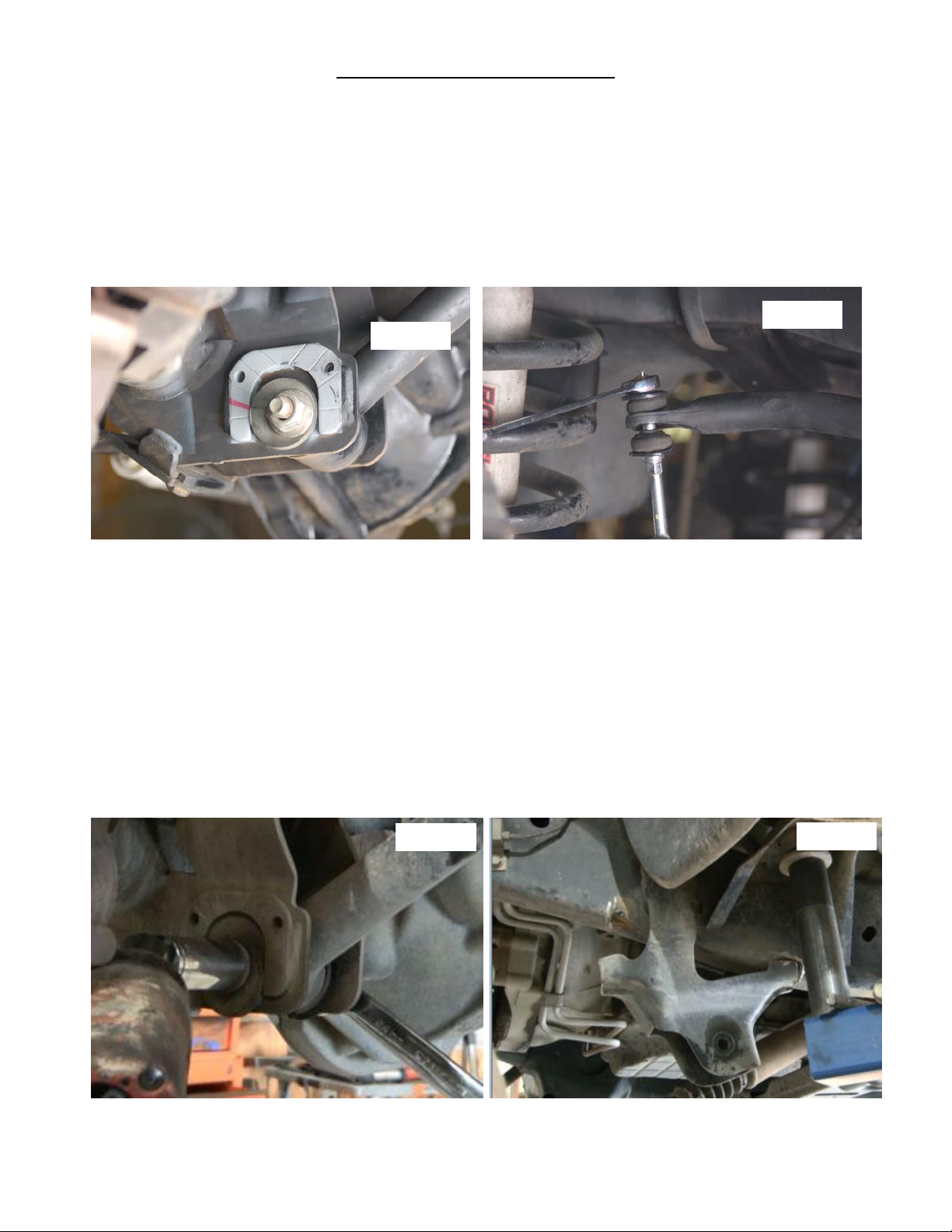

the hardware from the arms and to not cause bind in the front suspension. Remove the lower suspension arm nut,

cam, and cam bolt from the axle using a 21mm and a 24mm socket and wrench. Remove the nut and bolt from the

frame attachment point and remove the lower suspension arm from the vehicle. See Photo 3. Retain hardware for

reuse.

10. Using a 21mm socket remove the upper control arm from the axle and frame. Note—the passenger side upper

control arm frame bolt will have to be cut or remove the exhaust before the bolt can be removed.

11. Use a cut off wheel on a die grinder and cut the welds around the lower control arm frame bracket. The frame

bracket has to be removed to allow clearance for the new longer arms. See Photo 4.

Photo 3

Photo 4

12. After the factory bracket has been removed grind the frame smooth and paint to prevent rust.

13. Support the transmission cross member with a jack and remove the two bolts on end with a 18mm socket and a

21mm wrench.

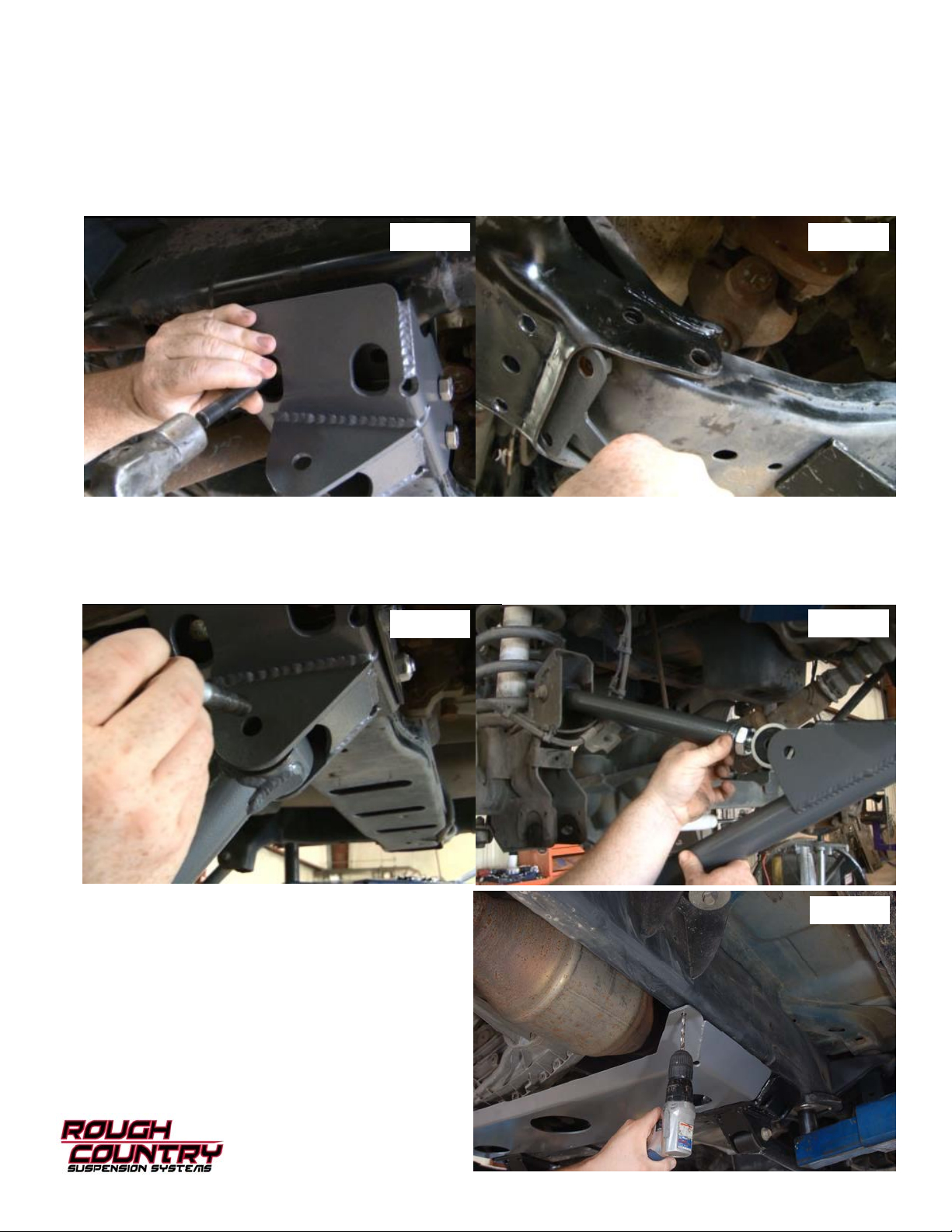

14. Install the new lower control arm mount with the supplied 14mm x 200mm long bolts. Do not tighten at this time.

Hold the bracket up close to the frame and use a transfer punch to mark the frame. See Photo 5. Drill the frame with

a 17/32” drill bit (clearance for the new 1/2” bolts). Remove the two bolts and the new control arm bracket from the

cross member.

15. Place flag nut in-between trans cross-member See Photo 6 and frame mount where you have just drill holes and

reinstall lower control arm bracket with the 14mm x 200mm bolts, washers, and nuts. Insert the supplied 1/2” x 1”

bolts into the drilled holes to secure bracket. Tighten all bolts using a 22mm for 14mm bolts (Do not tighten inside

bolt it will be used to hold the skid plate later) and a 19mm for the 1/2” bolts.

Photo 5 Photo 6

16. Install lower control arm into new bracket using stock hardware. See Photo 7. NOTE new lower control arm will be

install with the pocket facing outward. Assemble the upper control arm and adjust the length to 17.25” for the 5inch

lift.

17. Install upper control arm into pocket on axle using stock hardware then attach it to lower control arm using supplied

9/16” x 3.75” bolts. See Photo 8. Then install lower control arm to axle using stock cam bolts. Hand tighten only.

Photo 7

18. Repeat steps 9-17 on the passenger side.

19. Remove the nuts on the two center bolts of the cross

member that was installed earlier. This will be the

mounting point of the new skid plate.

20. Hang the new skid plate on the 2 bolts and reinstall the

nuts. Tighten with a 22mm socket and wrench.

21. Make sure the skid plate is center before drilling the

holes for the self taping bolts

22. Drill the 4 holes using a 15/32” drill and install the 4

self taping bolts with a 9/16 socket. See Photo 9.

Photo 8

Photo 9

Loading...

Loading...